.

,

..-'"

OI<UMA

TECHNICAL

SINGAPORE

..

CENTR-E

--

-PROGRAMMING

-.'

"FO.R

CNC,~LATHE

..';H;1i\1;~:2~,~11~..

MANUIAL

,-

-

...

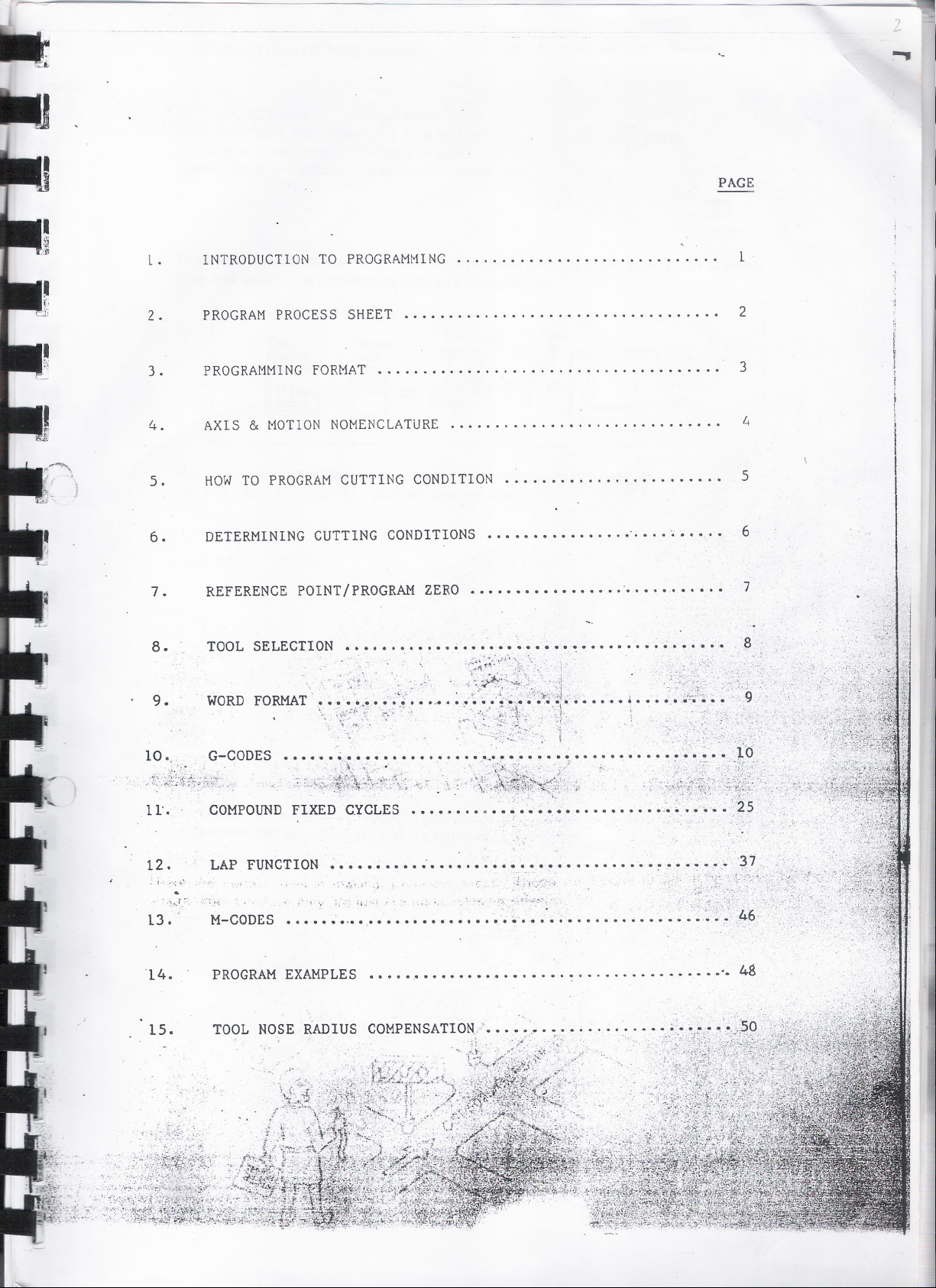

PAGE

1.

2.

3. PROGRAMMING FORMAT

4.

5. HOW TO PROGRAM CUTTING CONDITION

6.

7.

8.

INTRODUCTION TO PROGRAMMING

PROGRAM PROCESS SHEET

.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

AXIS & MOTION NOMENCLATURE

DETERMINING CUTTING CONDITIONS

REFERENCE POINT/PROGRAM ZERO

TOOL SELECTION

......................

...............

9. WORD FORMAT

..

.. .. .. .. .. .. ..

... ................

.. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

..........

..............

1

2

3

4..........

5

6

7

10

. . ::,::,~~;:t.~,~;:':;;~.~;.~.,:". . :: ~ .; ;~.;l,~;~~~.~~i,~~ .

11' .

12.

" i.'

13.

'14.

COMPOUND FIXED CYCLES

LAP FUNCTION

.'..'

, ~.~

M-CODES 8 ;.,... .. .. .. .. .. .. .. .. ..

. .

PROGRAM EXAMPLES

15. TOOL NOSE RADIUS COMPENSATION.,j".......

. .

.. .. .. .. .. .. .. .. .. .. .. . .. .. .. -. . .. .. .. .. .. .. .. ..

... ..............

.. .. .. .. .. .. .. .. .. .. .. .. .. .. -. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .-.

48

f

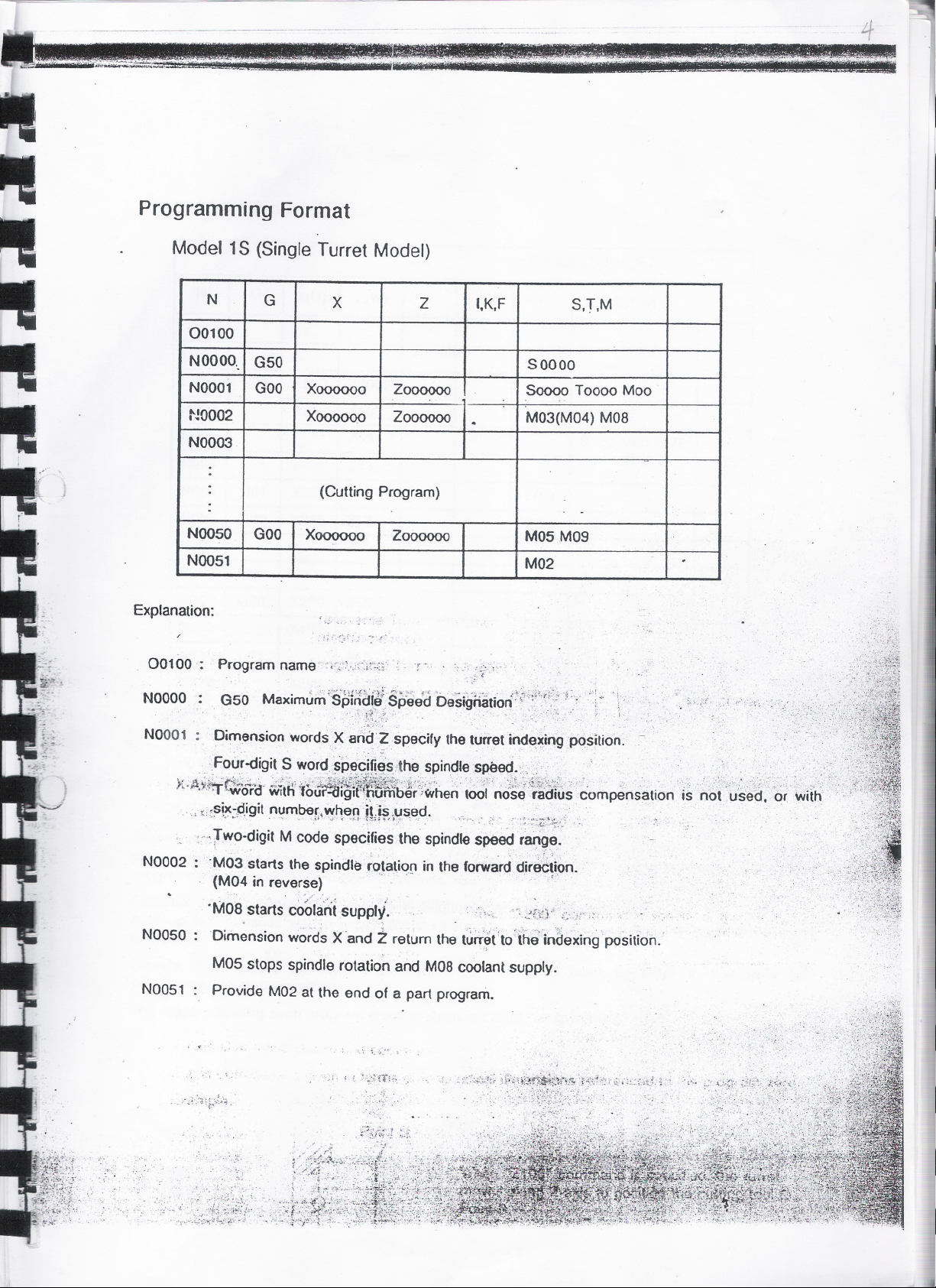

ProgrammingFormat

Model 1S (Single Turret Model)

00100

NOOOO.

NOO01

NOO02

NOO03

N0050 GOO

NOO51

Explanation:

NOOOO

NOO01

N

.

.

.

.

.

.

G

G50

GOO

X

2

Xoooooo 2000000

X()()()()()O

2000000

(Cutting Program)

Xoooooo

200000o

',K,F

S.r,M

S 00 00

Soooo T0000 Moo

. M03(M04) MOB

-

M05M09

M02

~:.'

Dim43nsionwords. X ari~'?specify the turret inde)Cingposition,

.

0

'..

'.,

FOUr-digitSwordspecifi~s;thesPindlespee<fo,>,. . "'." .,' '. ..' '," ,.., :

X~)\.~i,=~6rc3'iiIit~;~fb~f~1~~i;~;~i~heri' ~~I;no~~'~~1h~;~ompensationi~ . no. '~-~t:J: '6r 'wit'h '

, psix-:digit number, when iLis..used. _ , .'.,'

'.~ . '" J~'; 1" .q. ~~i~'.::':' ~". ' . ,:~ '- ... ';':~$..~:~~.

::'-;Two-digitM code speci~ies the spindle Speed r~~o

N0002 : 'M03 starts the spindle r~tatiq~ in the forward dir8c~ipn.

(M~4in rever~;). . ' .

'

O

M

08 t

s a s cooan suppz., . '. ,_.,.,) __., ,. . , "

~

"'

".'

.

rt

t

.; ,,',., ~~,\1'.' .;..'," .

I

N0050 : Dim~nsionword~X'and ~return th~ t~iT~t'to'fhE{inae~ing position.'

M05 stops spindle rotation and MOBcoolant supply.

','

...;

: ",

N0051

'.

Provide M02 at the end of a part program.

: '..

'.'.

,.

.

Program Process Sheet

PROCESS SHEET

.,-.

N

0104

-

N001

-

N002

-

N003

N004

-

NOOS

-

N006

-

N007

-

N008

-

N009

-

,01O

-

..-

, ,(,}0.11

N012

,.NO13 '- ~:;, :':; ,W~;~:1':; .~Z40 $, '

N01l '-;;GOO'( ')(2~o5 t~4~'"

N01S'

G

X(U) Z(W)

GOO

G01

GOO

G01

GOO

.~192

:9°l:!,.t;;~~".:, .1"if~,8:,:,."

'>

X800

X250

X20S

X250

X205

X230 1258

X200,

Z2000

Z100

Z53

-

Z43

I

I Z50

Z40

I

K F

:~~K.~;<i~:"."

.:" r

'!~'~0:', .~-.-.

, r

.,,', ',1 ./J ~I ':i,

S,T,M

M41

S120 M03 M08

FO.3,

FO.25

ro.4

"';;:'.

. ,

. t'~G~.'~:~,-. ,'_'.~-.;". :,..,;. ¥J."i"" t'~P"T""..d':'; ~ - t:~..:. '::,,: "~~~ . };_;." i. __.: _', ~~, ..-,!~~.\~_'-"'~o..~~~';~:;~~"_

, Shown' a~ov~i:,.i1>:~~?,.:~el~-,WPleO! .a program"~'':ocess shee~. It is ~~ti~Wlgwhiph:~e~~!J~~;i~~~:~~\Bf ....

programml~g, InstrUCtions,'compnslng alphabetic and numenc char.ac~~~,,,@~raE9ep,,1.0,;;a'~:~_9.f!.QI~!!.Hft\

':)IF:;~~~f:L

programmin~fscheme:iWith'1hese"instructions,operationsofthe machin~;jirtr'exptess~d:.' y~ >t"'''::~:' :; ':~i;;:"

Ecicn'line of the~

Agr'oup of commaf\ds .wJi~tef!in o.ne,line,is referred to.as a -block- and it-describes one machine,.'.' .

operation. . , ., ;

T.' '., . " ---"" .. _' ~ ~. .~:r ~.~. '. ~ . I. :; :

Usually, '(he machine executes, the programmed commands block by block in the order as

programmed to produce a part.

The steps preparing such program process sheet is called .programming~.

p

. . . _ ,',' .' , _,_'. :,.-:,;~, ,- .-. ," ~:_::,.,:..:():::-~~~ .-:.'\:~_-~~~~:':::.r~~:i'rj~

rocess'~t1eet ~tarts with'

, . _: '.. ',,"..~: ~.t~.- ..".' " . . : \.', " '. . "\.' . - ~

.'

. .' . :",.,;..,,,\

S

'.' uencatNumber :{N''Wora)

eq

:,~t;KIn"

,--', -:?;,;,;~.:, """;}~~?;;f~~

I~'

II

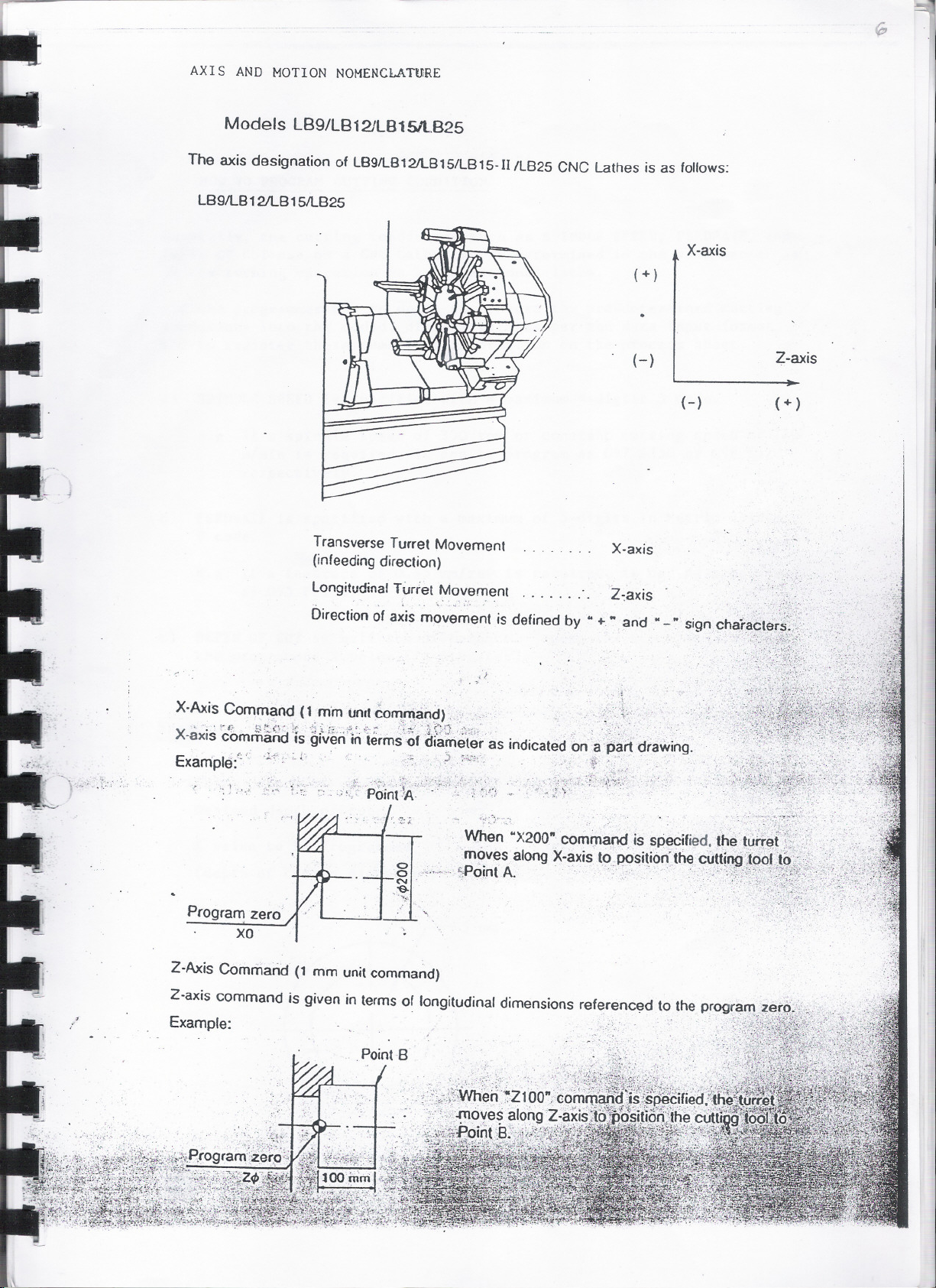

AXIS AND MOTION NOMENCLATURE

.

Models LB9/LB121LB1S1lB25

The axis designation of LB91l812/LB151lB 15-IIIL825 CNC Lathes is as follows:

LB91l812/LB 151lB25

X-axis

(+ )

(-)

(-)

Transverse Turret Movement

(infeeding direction)

. . . . . . . .

X-axis

Z-axis

(+ )

Z~axis

,'.

.'

-.t-:.;.

LongitudinalTurret ~ovement

". . .

Direction of axis movement is defined by .. +" and ..-" sign

;1

. >

X-Axis Command (1 mm unit ~OfT!rr~an~).; :' ;, i;. . "

. ~ f;: t1 '" '{'p,. ~ '}1 i";- _ ':;, or C~"'. :';';,;' 'i~/D...:._~i-':-t;~... . ..:_.:':/:." '_"",. ',_. ;._:

X-axis command'is given'iriierms'Ofdiameter as indicatedon apart drawing.

.

E

. t. '. '1+..:, 1', . . '..0; :> :..::,.:' ".

I

xamp e:' . ,

Program zero

----

xo

Z-Axis Command (1 mm unit command)

/

Z-axis command is given in terms of longitudinal dimensions referenc~d to the progra"rt~,'3.t9;}_c;;:i'-';'-i;;-:

Example:

. ." '-;;J;~:~(~..{i~~:::~~~:~~:..~""'~',;[o"j..:_\.-~.~..

~=.~ ,..,-~~

11II'

_~.r..,~'~~",~, ~ ..

1

III

--

.'

181

HOWTO PROGRAM CUTTING CONDITION

Basically, the cutting conditions such as SPINDLE SPEED, FEEDRATE, and

DEPTH OF CUT use on a CNC Lathe can be determined in the same manner as

in the turning operation on a co~ventionallathe.

All the programmer has to do is to convert the

conditions into the coded, digital form as -per

and to register thes~ numerical information on

a) SPINDLE SPEED is specified wit~ a maximum 4-d~gits S code.

e.g If a spindle speed

m/min is required,

respectively.

b) FEEDRATE is specified with a maximum of 5-digits in Metric system

of 350 rpm or constant cutting speed of 120

it can be program as G97 S350 or G96 5120

pre-determined cutting

the data input format

the process sheet.

F code.

e.g If a feedrate of 0.35 mm/rev is required, it can be programmed

as G95 FO.35.

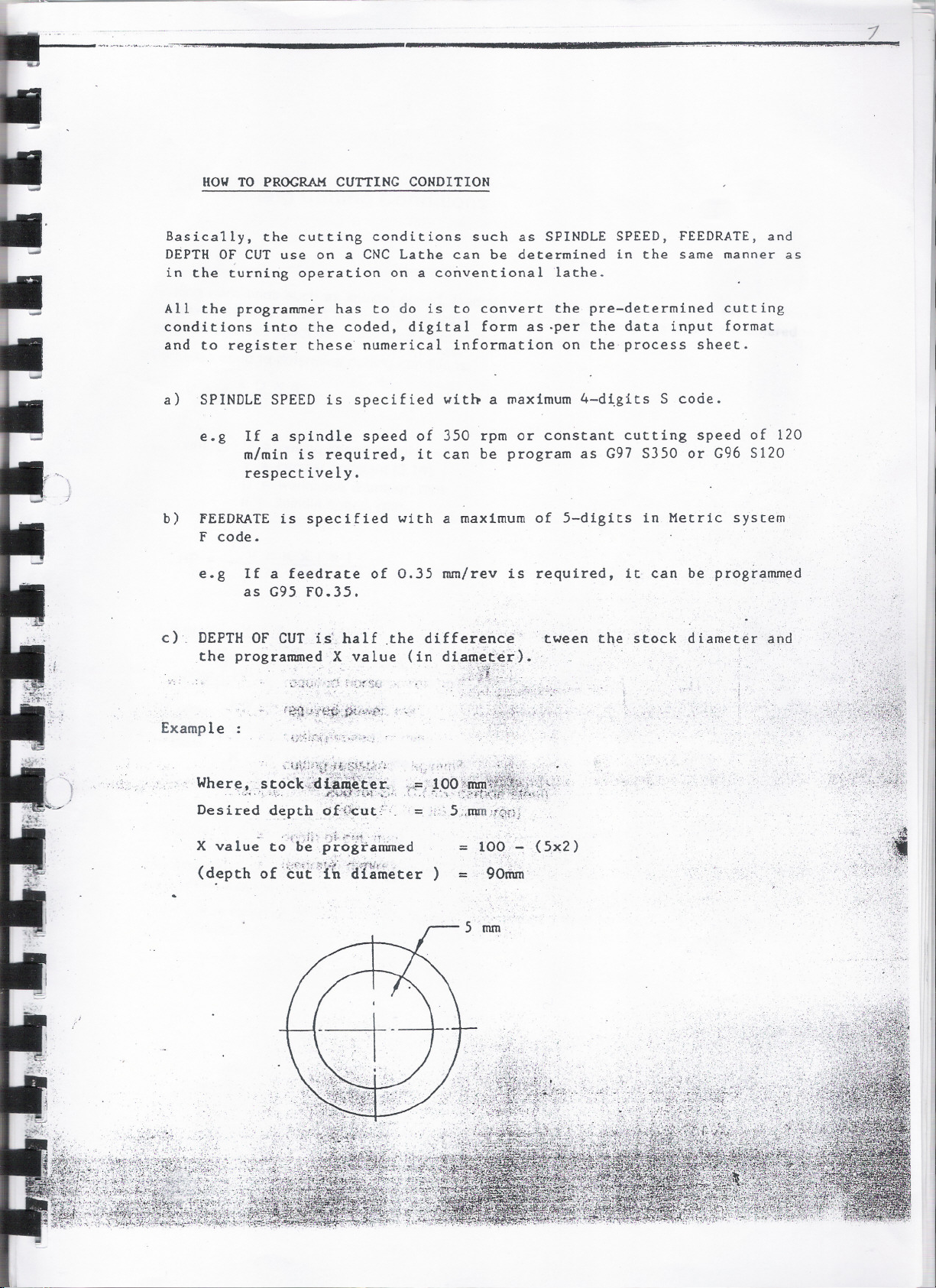

C),

Example

Where, 'st6ck-4;ditnt~t~ei..

Des iredd~pth ()t(~ut,~i. ='i~5 ;,mm 't.~nj

X value to oePEogrammed

(depth of ;~m:~{~ '~a7~ri;eter)

. ,,~uV.r~~{~'Jt..~f~~~f?~.~'~;:;~-:. r~p:;:J:

. ",~:"~;". ;--\~~. ,... ~~J:~;).r:.;;:.!.',

.:.:.. .',.f'''-,r. ;-..;i,;~',--~.."r . .

= 100 ~ (5x2)

=

90tfun'

,.....

Determining Cutting Conditions

Cutting conditions such as spindle speed, feedrate and depth of cut are selected more or less in

the same manner as witha conventional lathe. WithCNC lathes, these conditionsare entered in a

program process sheet using alphanumerics in the predetermined format. '

Formulas used to determine cutting conditions:

V=1rXDxn

where, V = cuttingspeed, m/min

I

1000

rr =circular constant (3.14)

o =workpiece diameter, mm

n =spindle speed, rpin

HP =

kW

. . j -"'!"-~" ~... . r ". _\ .

~here, ~ HP, ~ required hor:sepo~er, ~p e/i'.:" ~'.<,.

VXKxtXf

7S x 60

, .

V xJs ~_!'-x

6000'

, , ,

'-'-":'~~i;.;t:'ieq~~~~?, ~O~!~'.~~\ 1'co' "'" ' ',Q'I~J,

.:~Y:.:~~:'~>._~~mrig'.s~ed,' m/min

~."I< =, cutting :r~sis~~nce~ ~.g/t1Jm2, ,

". ...: :1.:',,,.~ 1',0i-: .' ...

,,~~;;.1iEXartiple:' "26d'fO'r~45C :'CJJS,carbon steel)'

"

,', 120 for FC20 (JIS,

,~:dt ZL;' depth of cut, i'nm

cast iron)

';.,

. .,'

..

"

,'~

......

,~,

- -,'

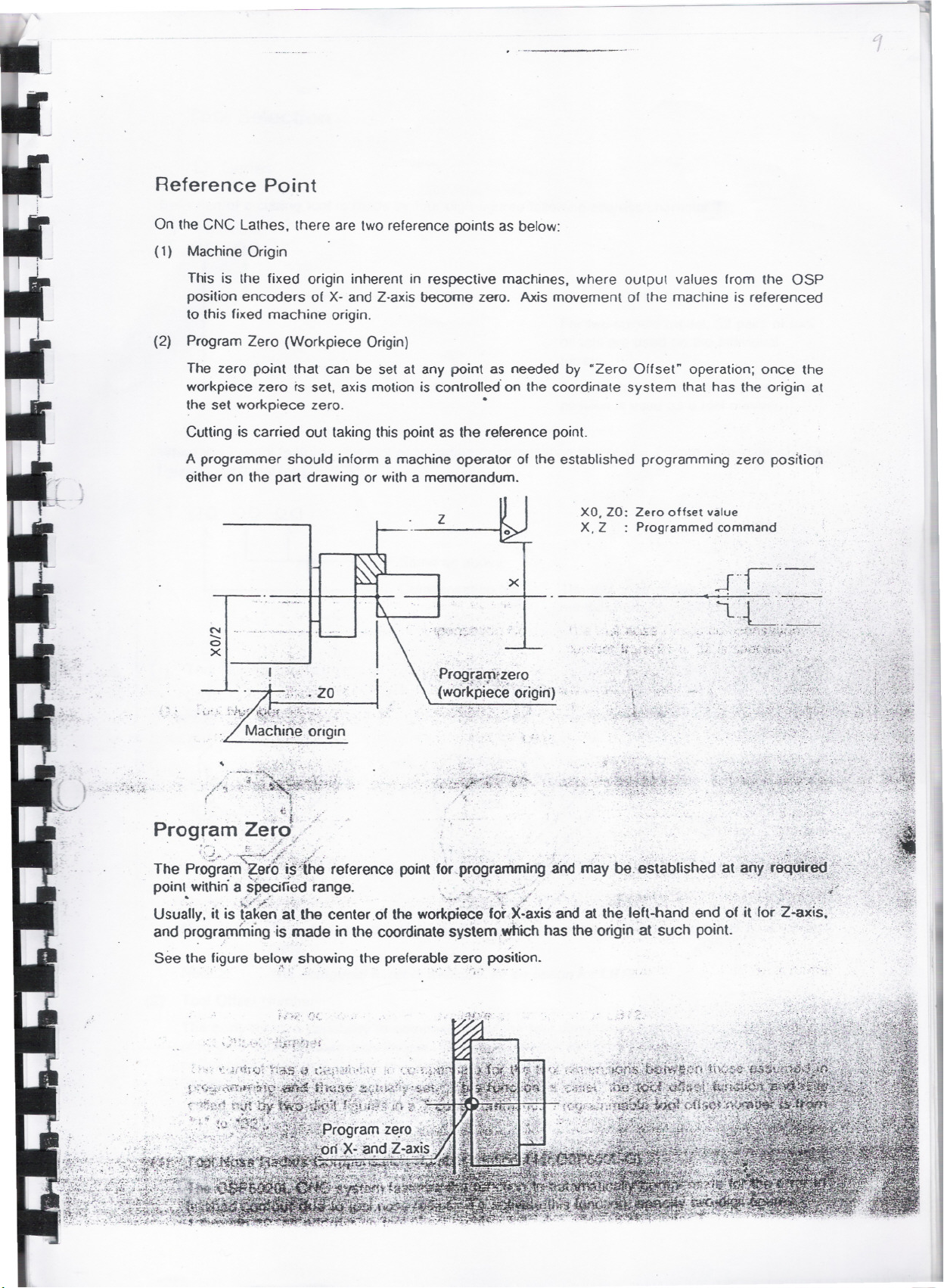

Reference Point

On the CNC Lathes. there are two reference points as below:

(1) Machine Origin

This is the fixed origin inherent in respective machines. where output values from the ~SP

position encoders of X- and Z-axis become zero. Axis movement of the machine is referenced

to this fixed machine origin. .

(2) Program Zero (Workpiece Origin)

The zero point that can be set at any point as needed by "Zero Offset" operation; once the

workpiece zero rs set. axis motion is controlled' on the coordinate system that has the origin at

the set workpiece zero.

Cutting is carried out taking this point as the reference point.

.

A programmer should inform a machine operator of the established programming zero position

either on the part drawing or with a memorandum.

Z

x

.~.. ~..

N

.......

a

X

. .

.\J".

XO.Zo: Zero offset value

X.Z : Programmedcommand

'~."~.

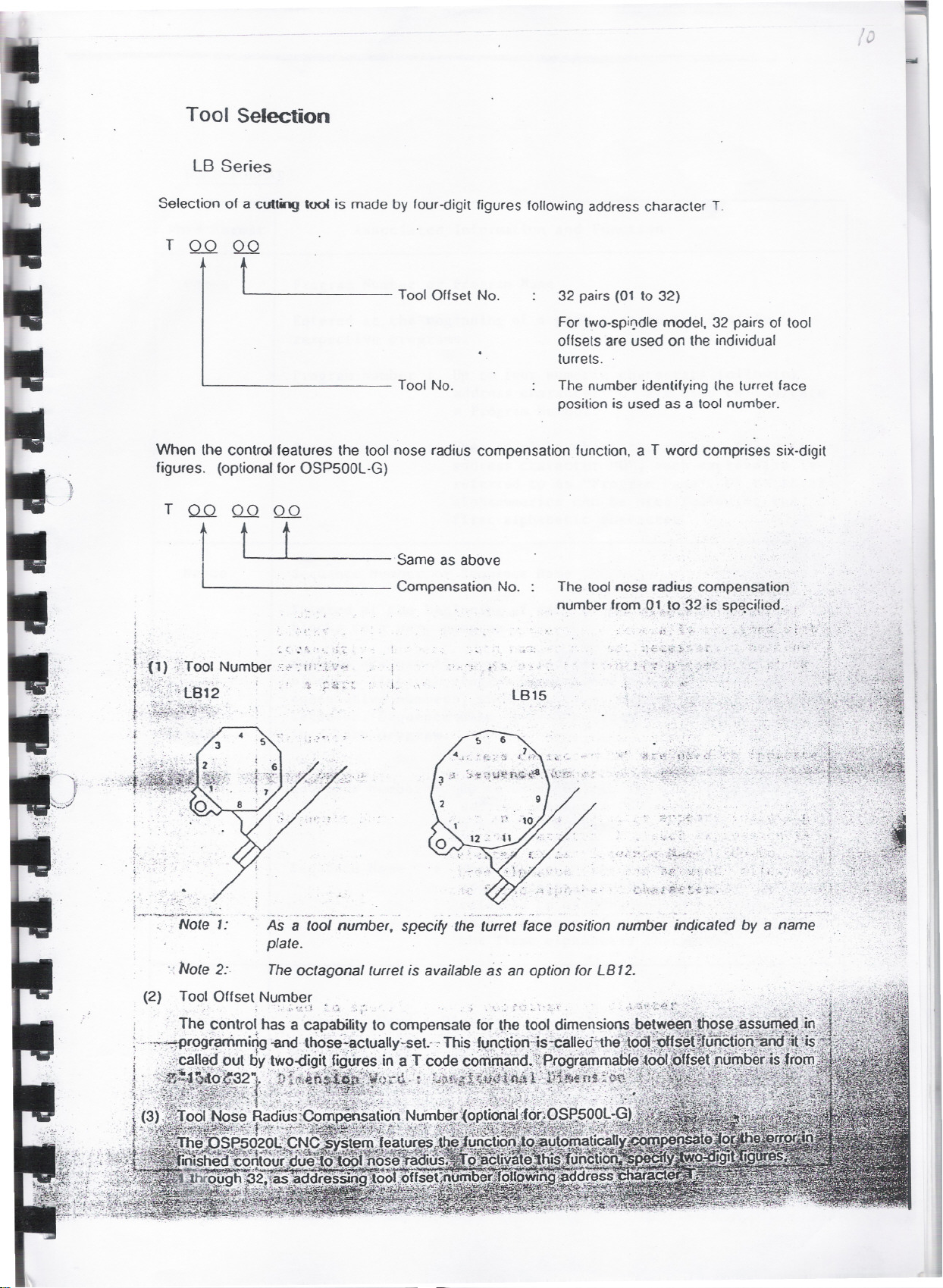

Tool Selection

LB Series

Selection of a cutting 1001is made by four-digit figures followingaddress character T,

T 00 QQ

,

v

t

Tool Offset No.

32 pairs (01 to 32)

For two-spil)dle model, 32 pairs of tool

offsets are used on the individual

turrets.

ToolNo.

The number identifying ihe turret face

position is used as a tool number.

When the control features the toolnose radius compensation function,a T word comprises she-digit

figures. (optionalfor OSP500L-G)

T Q.Q 00 00

tU

(

i

.t .

FC;) :"ToolNumber

, '

r:~.::,;:;~~:;~~~}~. '

. . >~.. . ",,~,., .

.

!

. '~t!.::~."~~~~._t"7j. - -~..'

I

"..~. .. I!.~. . t.. )....

..-~ ~

. Same as above

Compensation No.

lB15

The toolnose radius compensation .

number fI:o.mo."-,o 32 is sp~cified. ;

.: <:.-~..;-;..~'

~ , .; '~j. ,":.">'~'S.<~.'

';::.". ~~.'

\;' 3~\~".:t'\~.f~",~ ''''~''

,tf~~$.~~:~_i._'-,:", .

-~''::-

;

t,

o ~<-.- .

,

"

(2)

- -.. -. .,--, ~--'. - ~ -. .'.,.~ ..." . -.' 'p .-

As a tool number, sp'ecifythe turret (ace position number inc!icatedby a name

plate.

, Note 2:, The octagonal turret is available as an option (or LB 12.

Tool Offset Number

. ~. ..~ ~1. ~ .....

, .

. '.' -. .::"". .-'{

-::to":~." ,to

. ~",'~. .

..~

.

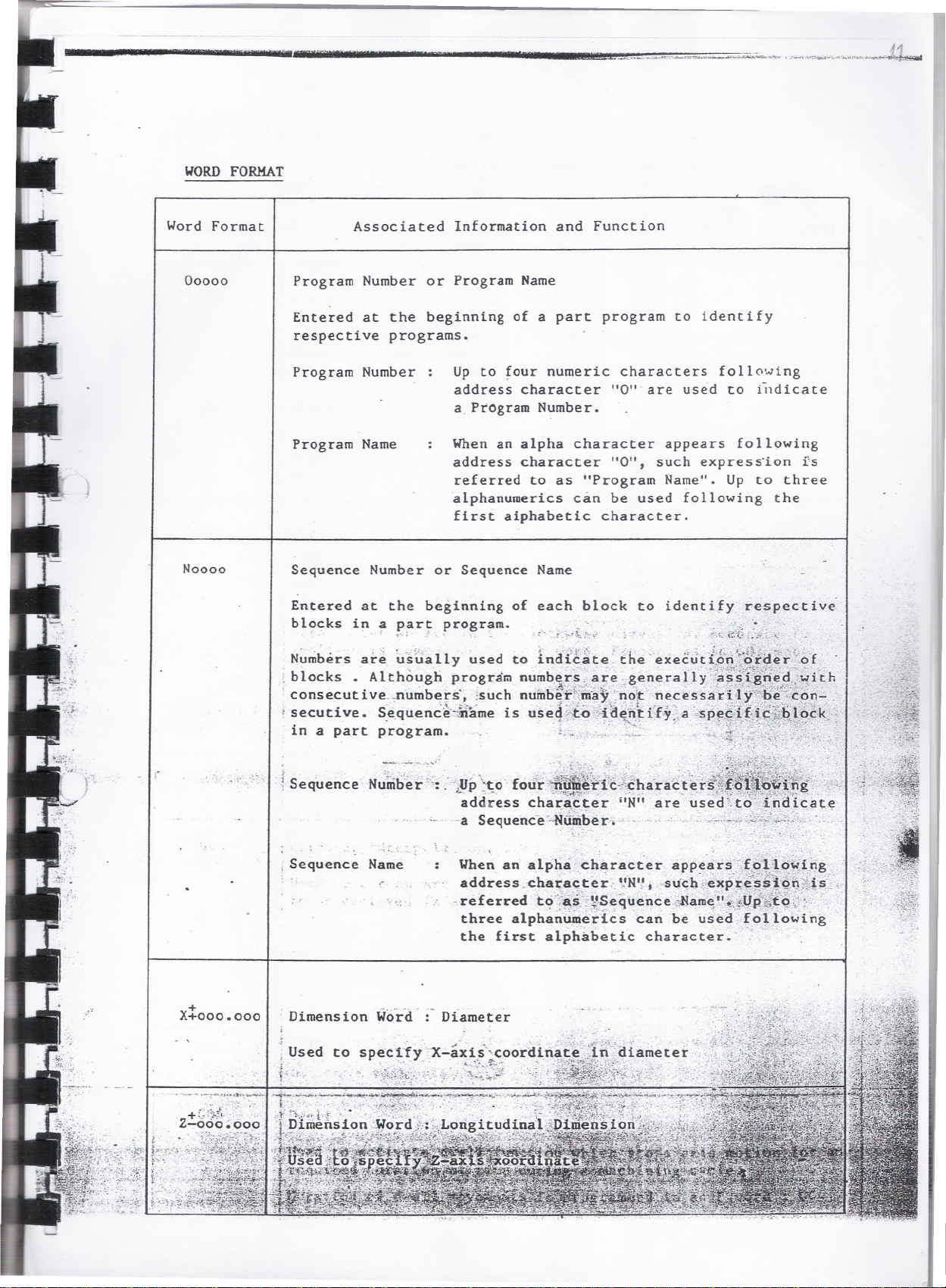

WORD FORMAT

Word Format

00000

Noooo

Associated Information and Function

Program Number or Program Name

Entered at the beginning of a part program to identify

respective programs.

Program Number Up to four numeric characters following

address character "0'" are used to illdicate

a.Program Number.

Program Name

When an alpha character appears following

address character "0", such express'ion is

referred to as "Program Name". Up to three

alphanumerics can be used following the

first aiphabetic character.

Sequence Number or Sequence Name

Entered at the beginning of each block to identify respective

blocksin a p~r~ program. d...; -: ';.'.;,:~,. '.

~"" ". ~ :-".'1:,

~"" ~ '.' /'"..1..C'1...~ ~~;'\-.1..:"

X:::ooo.ooo

N~mbers .ar~ \£~ta lly used to Indg~te ;'tbe'exe~Jd::g~:;::gt~~?~:~.~ .

; blocks. Although program numb.e~~..a~fi!~.general.1Y"a.;>.§,{.gI1.e~,t~lth

. consecut i ve. .,numbers'~ ;such numbe.i;'!::.m~y, :1J9\t"necessarlJ.y-"r!>,;~'~,C~ri-': .

. '_'~." ,.",';~ _ ," " '., '. . .'.., .,:', '...,'~..~rv7.t, ..

-.-;. ~ _ .:1 ",' _,,~ :..,.'(. :"~'''-..:Z, ,"_ '. , ' ''''''":j .' ~...'t '~.-J: ~.,." ',:;. :

'secutive. S.e.quence'-iiame is use~;'.~~s:1-}t.~~~i:fy.;.a.'sPf~~;\}~~~J,ec.k>,

in a part program. !.~..",' '''---~~':~;,<:~'f;~';;':':~';:;'

!Sequence N.;!;iil~~:;:.'i!Jp~~" fou'hiitl~'<i.,1a...{t~~_i',

address chaE:~F,ter"N" a:reused?tO:c;:~Nlicat~

.a Sequence"-N~m!:>er'," . _.,..;:.~.:J:/':./~,~'_

. . -,.~'..

,Sequence Name

When an alpha ch~r~cter appears'.~i£,~i.~l.~~1.#g..

,..:::::::t~:1#~~~;~~ij:~~c':;~~~:;~;1:il.~~t.~~!.$.:-

three alphan~.erics can be used.fol,lowing

the first alph~betic character. "

Dimension Word' :- Diameter

. .

,

,.

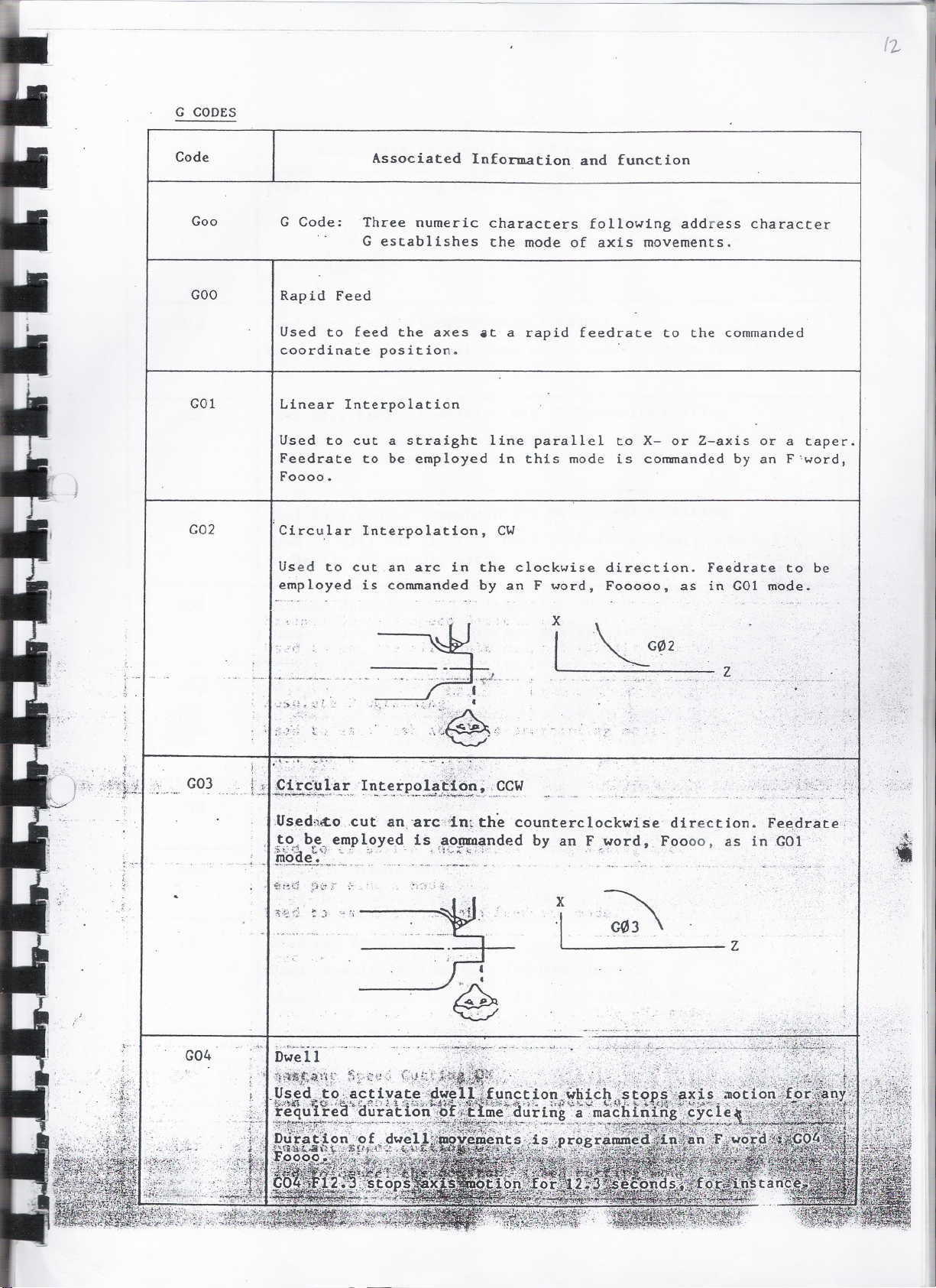

G CODES

{2-

Code

Goo

G Code: Three numeric characters following address character

Associated Information and function

G establishes the mode of axis movements.

GOO

Rapid Feed

Used to feed the axes .t a rapid feedrate to the commanded

coordinate position.

GOI

Linear Interpolation

Used to cut

Feedrate to

a straight line parallel to X- or Z-axis or a taper.

be employed in this mode is commanded by an F'word,

Foooo.

G02 rCircular Interpolation, CW

Used to cut an arc in the clockwise direction. Feearate to be

employed is commanded by an F word, Fooooo, as in GOI mode.

'x

.~'f~

t,

i

,

G03

-or,....~_._._._..

""-.

,,~.-~.-\"'" '-'''-..~:':,:~~

~L~li0:11_r.. 'I~~_~':,e.~!l~~l_'_~~,~

.Used;l~O"cut,an,'arcc-;i!.mthecounterclockwise direction. Fe~drate,

_t?.-ibe~empl,oye,d_

.........-

~OQe~.'1~..~.:.' .._ .. ,.'''':~_:=,,:''_" ,"

,.

G04

is ,~_0!J!4~nded by an F}~ord, F()ooo. as inGOI

. t

1 :0

.-.- .. ".

z

z

'..

'"

/3

1

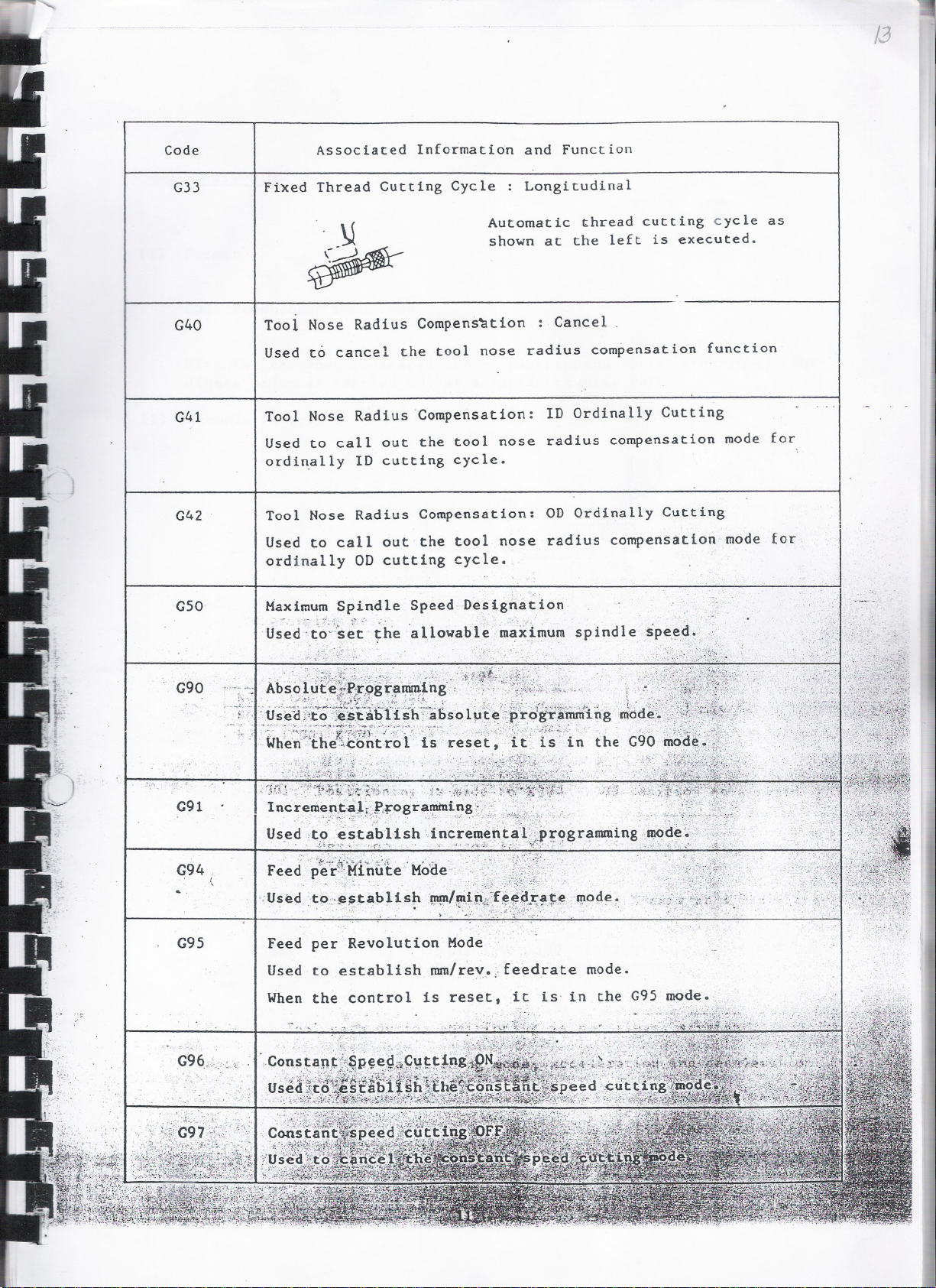

Code

G33

G40

G41

G42

Associated Information and Function

Fi~ed Thread Cutting Cycle : Longitudinal

Automatic thread cutting cycle as

shown at the left is executed.

Tool Nose Radius Compens~tion : Cancel.

Used to cancel the tool nose radius compensation function

Tool Nose Radius Compensation: ID Ordinally Cutting

Used to callout the tool nose radius compensation mode for

ordi~ally 10 cutting cycle.

Tool Nose Radius Compensation: 00 Ordinally Cutting

Used to callout the tool nose radius compensation mode for

ordinally 00 cutting cycle.

G50 I Maximum Spindle Speed.Designation

:Us-ed'::t'~::;'~:t'~he 'allowable maximum spindle spe,~d.

G90 ~.

\

G91

G94

. l

G95

~':'5({J,.~:-;?~.~~:~~"~~:~k~~~. 5~-~;5 ~{~::-:.7?1~:?-~3:~~:':}r~7i\,*:~~~~f1,

IncreriieJl.i:aJ.d't~QgramiUing ..:',' ..

_ ..-'.'.:'~>~:'_;'t-\..~..:;.. ;;". ,~,; ,.~..:<-'.~:.~.~J~::...:t::.};. . ":..~",.

Us.ed ,t~es tabUsh increm~t\.t~l~Gpr<?gr~umil~ngD.1<>d~{

. . oJ.'~p'~.~'~""=...f'(-, .. ,"?~,,_,'l~,--~~.;~..1f~L.~-:i.~',.' . "-- ""~'(-:":~"'1::.1:~'-

Feed p~~~~:;¥n~~e- M~~e" ':;,; ;,~l:ii~r:

;Usedto:~

~~ ~ab 11 sp~~~ita~~;!!i~~~:~fJ~l!Iode ~

Feed per Revolution Mode

Used to establish mm/reY~lfeedrate mode.

When the control is reset, it is' in the G95 mode.

."..'.;...,".~" . . .'.

.-

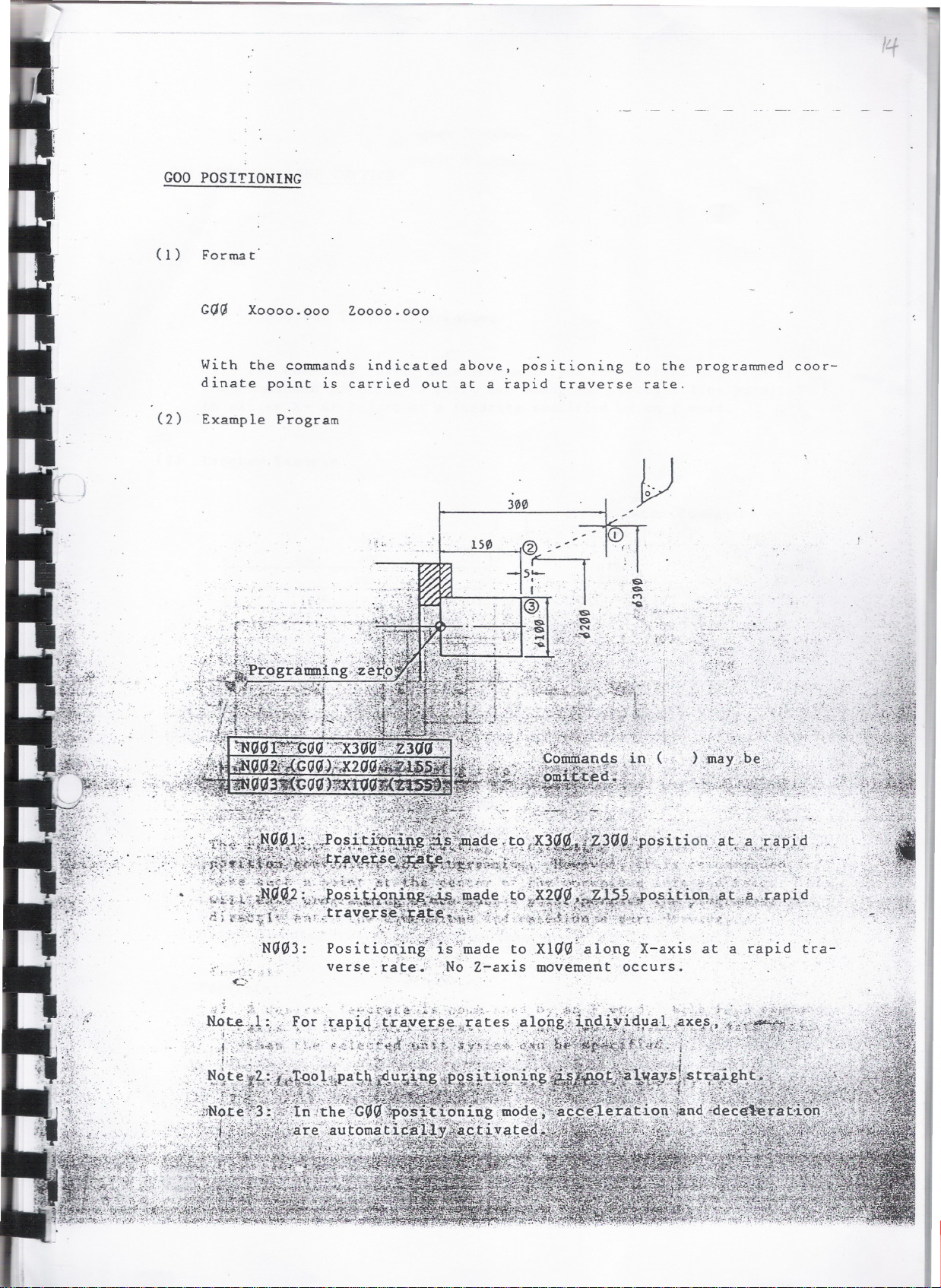

GOO POSITIONING

( 1 ) Forma t'

Xoooo.ooo Zoooo.ooo

I .

....

With the commands indicated

dinate point is carried out

(2) .Example Program

above. positioning

at a rapid traverse

300

to the programmed

rate.

coor-

.-.

;;)'. r

Position:ing'i"s\made to .Xl(N-along X-axis ata rapid tra-

verse: rate.:. . ,No Z-axis mov.ement occurs.

. ._r...,,...),;..,.,'~'' : , .. . ~"" .'

, ...;, ,:.". . ,'-.

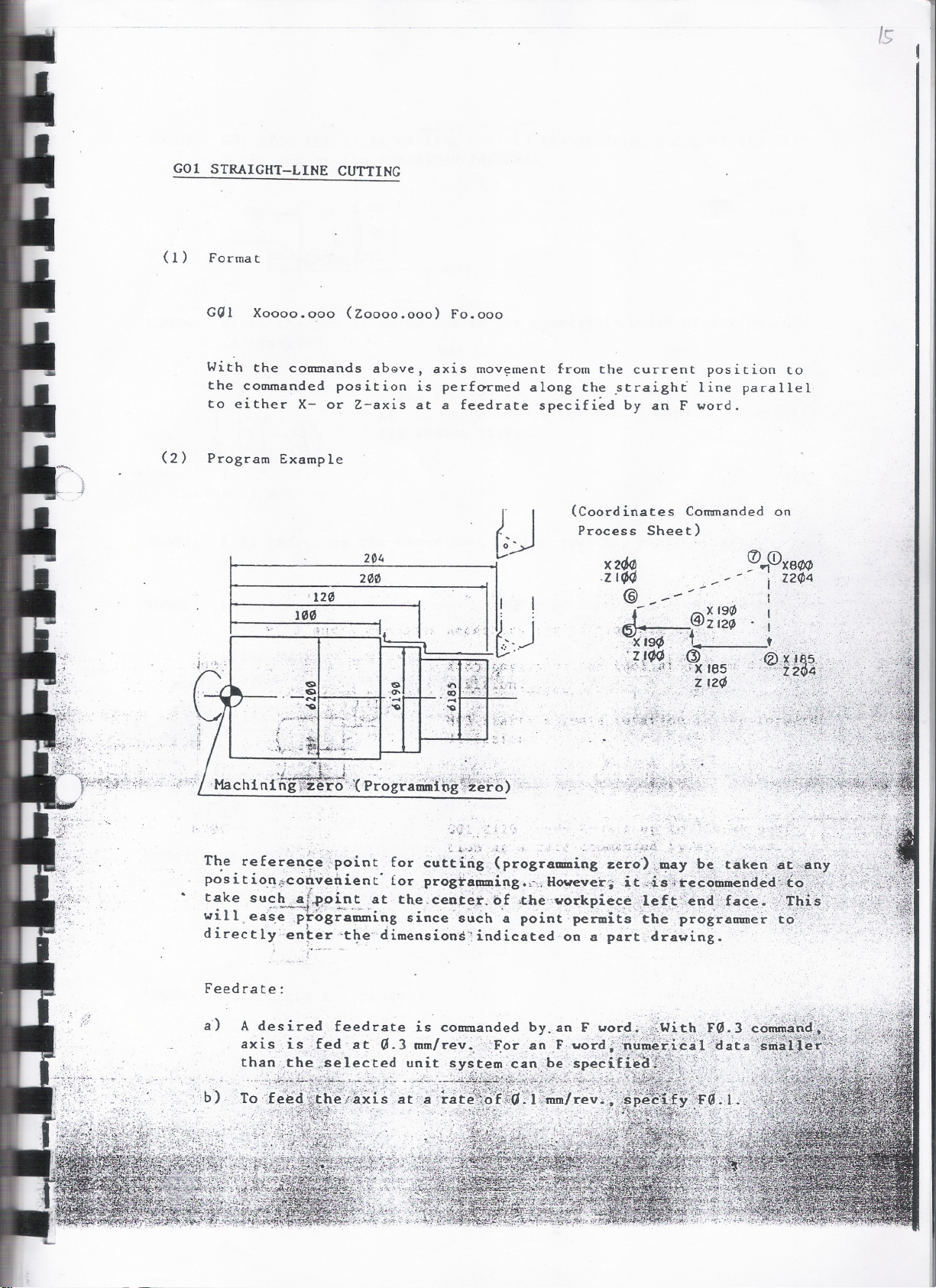

GOl STRAIGHT-LINE CUTTING

(1) Format

GQl Xoooo.ooo (Zoooo.ooo) Fo.ooo

With the commands abGve, axis mov~ment from the current position to

the commanded position is perf~rmed along the ~traight line parallel

to either X- or Z-axis at a feedrate specified by an F wordo

(2) Program Example

/s

; ._,

(Coordinates Commanded on

Process Sheet)

100

.' '$

-....

': "0

...-6:-f':~;'

! ; . .

, 120

....

..

$

i;~;d~r;)1;';

204

200

~.~t" ;",.,:>.l~.:.j

<5>

'0-

. I

X2~ ([) (!)X8/f4

ItA -~

.zIOff ;._ - - i Z24>4

@_-- - . I

:.;' '

~- . X194> I

..

,.,.,.. .?z 12~ 0,

-)(j9~" , t.

..:!/~.;'.<:fi. .(zt~)

,.:!, ';'

, '~:,,"Z !2~' >:',.~;.;

X!e5

" ...,

Z2

"5..'>

"'.-

a

..\..-:,.~,

'"

Feedrate:

;':b) ,

NOOO): G01 2200 feeds the cutting tool to the starting point of the arc

to be cut at the specified feedrate.

N0004: Since the arc is to be cut in the counterclockwise direction, GO)

is provided.

X and 2 words are used to ~pecify the coordinates

of the end point of the arc. L word is to specify

the radius she.

. ~.

Center of arc

N0005: 2185 in~icates the coordinate of the starting point of arc.

N0006: Since the. ~r~ .is to be cut in the clockwise direction, G02 code is

. provided."'~ J.~

center,:'of'~~f~~;-:-~1~~.~.."': :.-,:."i,.' .

,.,u:~ :~~~,;;;:t~;~~~:~~::~:t;1r;r~~~1~e t:~:~~~l~~t~h~. C~:t:~;~:~;

.~~; ., ,'\(':tf1'",' , '

-

- -. ., , , '-..

; .__~-..~~ ~,.,\..::;';~~~.._._~._no','.'

-."' -.: f~~"~-"~'~'--; ~~;;:'::;:f~'\ ~~...' .", . -

N0007:

.~

.X80~.<~2q~~ retu'rns the cutting :to~l to the starting point.

.~'/~:';:'~~:;!'..\; ~~':.. _..' _ '. . --:-..:~--<~t~.

M05 'stops'::1,th~-;;spinalerotation~ >.:';~ .

~'. '.; :'j:_~~?~"-:-

M09 stops.~.th.~ _~9pl~nt ~upply .;.

.;--L

N0008: M02 resets the control.

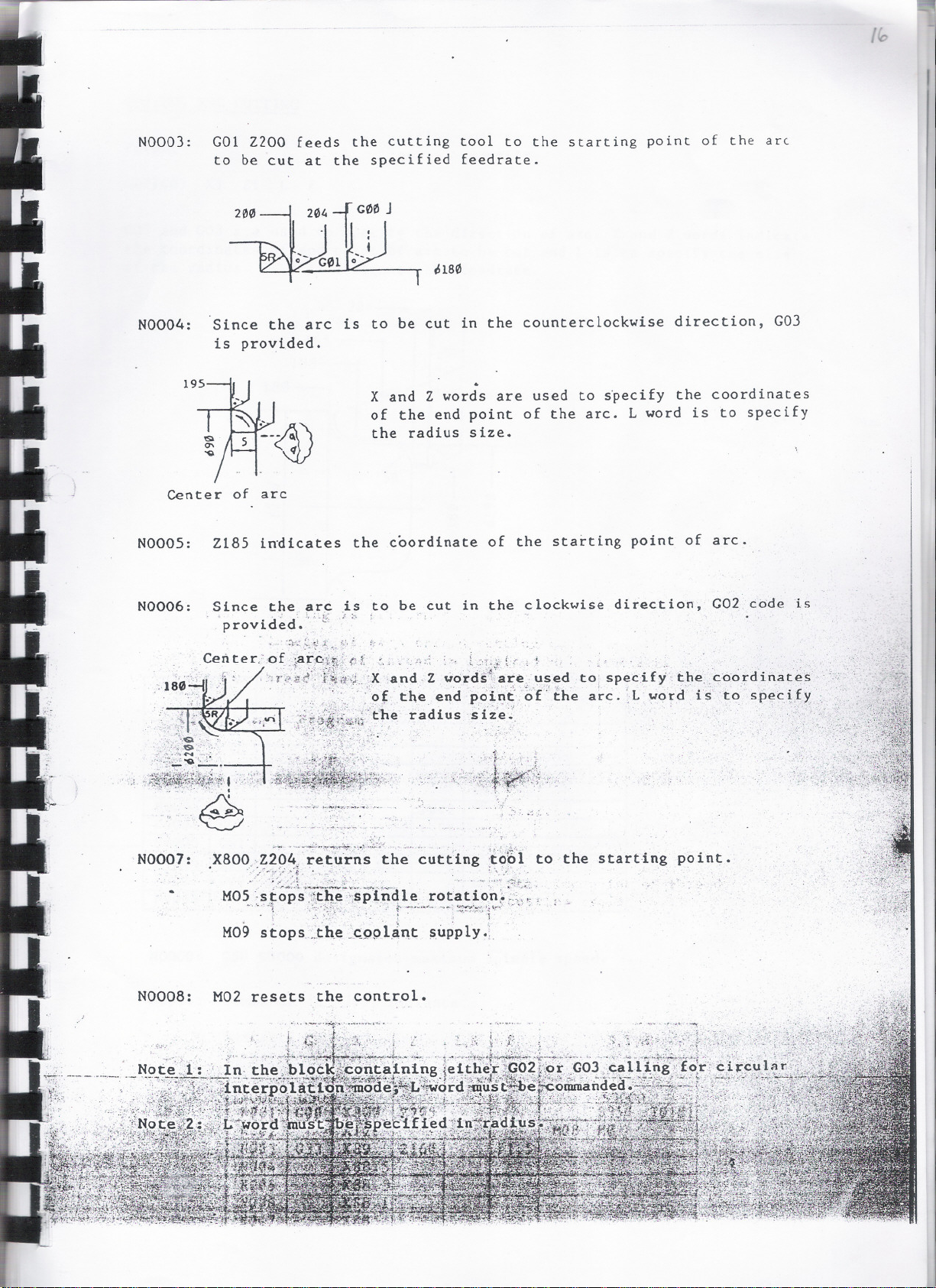

G02/G03 ARC CUTTING

Format

G02!G03

Xl 21

L F

G02 and G03 are used to specify the directi:'n of arc. X and Z words indicate

the coordinates of .end point of arc to be cut and L is to specify the size

of the radius. F is to designate the feedrate.

point

5R

N

'G -.

. ....$

..-.-..-

NOOOO G50

NOGGLeo .c,,

N(,)G(,)2-

NIJG/J3G1J1'

NOGIJ4 GO)) X19/J

, .N1J1J1J5 GIJI. . ..--,.:.... '.. Zl-85

1/J1J1J6

NOGIJ7

N(,J008

Vl.'

GQ2S

GIJG XSO/)

,',.... ..

--X Z

\,.

+

'., ....

'XIS/J'

:2(J1J:>

J9

8GG

"

t.-c ::.

Z204.

Z20/J FO .' 2

'195

Z18/J

Z204

..< .: . )ii1

. L5\

'L5:U

.L

. .

:': -:r;':'

,..",.:.I..

F:

..... ."...".

.;\;.;it:,

.';':;1r£.i::'

c,;t'i

. ..,'-

-!' t:"t1t">

'..&\iPJ

NOIJ/)I: Commands in NO/)lJl indicate:

.0;. ..

-

-. .

S,T,M .

53000 )-" .,;.:,):.

ij;'.'..::

,s2QIJi.$fkTQ 1<1 14

M08 MG3

..

-:i . .:.'.::

.----------.----..::- _...:...

.'('..

...'

M09 .M1J5

..

!:-;-

MIJ2

,_:,- '..-'

-OJ."

.~j

-,

-- ". .

'.

I

N I

NOOOO

N<lGI11 GI1I1

N

NI1<lG3

NGGG4 X2<lG

NI111G5 GI1G x811G .Z2114

N

G I x I z

I [,K

F

G50 S300

X8GG Z2<l4 S211G

2

6

GGI

Xl85

Z211G

ZIGG

FI1.5

. .

NOOOO:

N<1<1<l1 : Commands in NG<1<11 inrlirate:

N<1<1<12:

G50 S3000 designates maximum spindle speed.

starting point

spindle speed

tool number

Xl85 positions the tool at 18S.mm

diameter position.

S,T,M

MQ8

MI19 MGS

MI12

MG3

TI11111

HG3 ,starts, spi~dle ,rotation in. the'.for-

wa~ci'direcCio'o~,

~~~ffI; ..;;~~~.;t;;!;~~L~3~i~~i,~~.~?5~~f~~\~

"'-~. j

, " " .....

~J. " . .'"

~~. S :3'.~

':f;;~42:~K:. =!'~.,-:.~~~:~:~~'; J~'., ~:;:~.~

...1N<l<1Gt.:~.("""";" j ft., {; ',;i'1;" . ·

,'N Y!.C'i".!? ;;Q~:e.:-r~;~~

£eedrate 'iri:PI1l.-mode'

'.

'-0';"."

.

G04 DWELL TIME

With G04, the tool is stopped for a designated period. The numerals are

after F word indicate the unit in seconds.

Format: G04 F... .

A dwell for 2.5.seconds.

NIOOO G04 F2.5

Note:

GQ4 function is effective only for the block commanded.

G33 THREAD CUTTING (STRAIGHT 1. CONSTANT LEAD THREAD

(1) Format.

GOO

G33

Thread cutting is performed in G33 mode.

Xoooo.ooo

Xoooo.ooo

Xoooo.ooo

Xoooo.ooo

X: Diarneter,;.ofeach thread cuttiI!g:cycle;

Z: :End'point of thread in longitudinal direction.

F: 'Thr~ad";lJad ;;'cj. j,.. ,

'" ;": ~:::::;;. . ",. "~'" .

Zoooo.ooo

Zoooo.ooo

Foo.ooo

> .:...:;. .:~~.~.- .i:._'~...

.( -

.- ...

d:.t'e8..d

.; !~\,:.-- " \ .:.,:

.. ~ I'.~.~ .~t..

..~ ... i. ...,.

N G

t.. .

,'/... 0

lStardng~"~o1nt 'of

c~tt1n~;;c;ycle

0-

x

z

I,K

F

S,T,M

-- --------.

GO! TAPER CUTTING

Format

(1)

.

GtJl Xoooo.ooo

The same commands as straight-line cutting. are used for cutting a

taper.

(2) Example Program

Zoooo.ooo

100

Fo.ooo

<Coord inates

N I

G

X Z

[,K

F

S,T,H

GSO 53000

GGG X8GG Z2G4

Xl8S

Zl2G FCI.s

HG3

HG8

52C1 TGIGI

ZlClG

[ )

z2C14 I I I HG5 HQ9

HG2

Commands in ( ), where the same command as provided in the

previous block is to be entered, can be omitted.

NOOOO:

NClG01

..

.)+t; ,..,~. :.:

~t ::'~/',t~.;:.~.'~~~~~~~~.'ri.~~r..

NaaG3:

G50 53000 designates maximum spindle speed.

Dimension words X and Z indicate the turret indexing position.

Sand T commands

M,

. .

necessary for cutting ate ente~ed~

. .

n. . .

'v ."._~. .'

Has starts.coolant supply.

..

NCHHJ4 : GOI X190 feeds X-axis up to 19~ mm

diameter position at 0.5 mm/rev. which is

120-I

specified in the preceding block to finish

the shoulder.

NIJ"Q5:

GQQ X8QQ Z21J4 returns

M"5 stops spindle

MIJ9 ~tops coola~i supply.

NG01J8: MIJ2

.' ~~~ ~$'~~-~~-l: .'.

100 -j

resets the control.

. ---". ._-~~ ~'- -'"

GQI ZIGQ feeds Z-axis up to IQQ mm POSi-

tion at Q.5 mm/rev.

Gal X2GG feeds, X-axis up

diameter positio;; at Q.5

to 2GQ mm

mm/rev. to

the shoulder.

the

s ta r ~,i,~8;;!"~j~it~

- '

ro'tat ion.

-

the cu t.t ing,.to?,l to

£ ~...~':;;;.;'!-~:..-l-.~.

t

.'

finish

:~. .~:-;.~

",.

"

......

"

GSO SETTING OF MAXIMUM SPINDLE SPEED

If the maximum spindle speed is specified with a ~ digit 5 value preceded

by G50 code (G50 5 ), the actual spindle speed will not exceed the

maximum RPM, .specified even when the programmed S value calls for the speed

exceeding the maximum rpm of that range.

Format

N0002: .G50 53000

The actual spindle speed will not exceed 30QO rpm if the speed is specified

as $4000 by mistake.

G50 command should be written in an individual block by itself.

G41 & G42 TOOL NOSE RADIUS COMPENSATION

G4.1

G4.2

Z2 Z1

. ~

,

,

ZI4 Z;3 :

I I I ~

I , I I

i _L

:

V

-1 , I

I I I

I

I I I

l) I

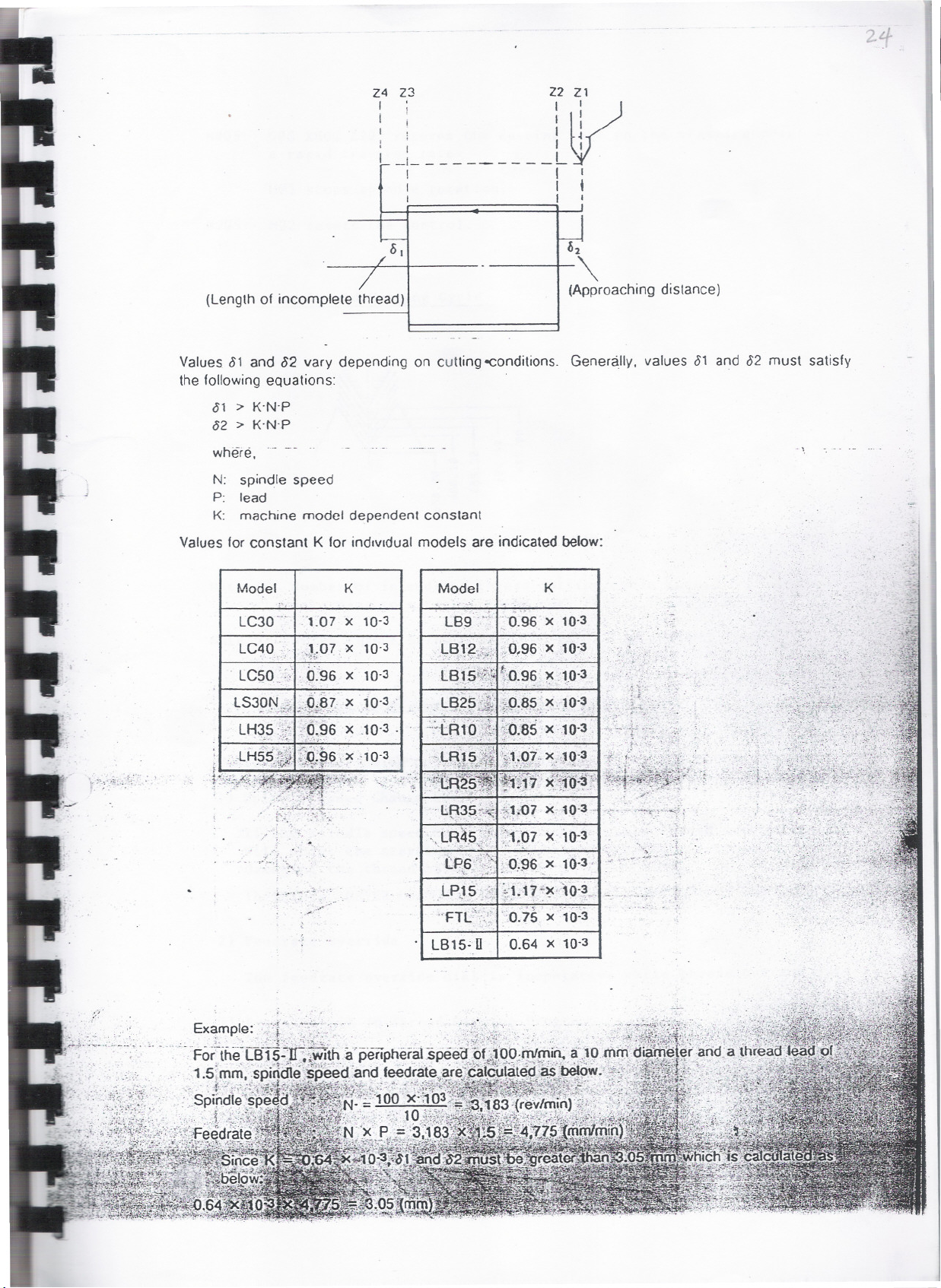

62

'\

(Lengthof incomplete thread)

Values. 81 and 82 vary depending on cutting-conditions. Generally, values 81 and 82 must satisfy

the followingequations: .

81 > K-N'P

82 > K'N'P

where. .- --

N: spindle speed

P: lead

K: machine model dependent constant

Values for constant K for individual models are indicated below:

(Approaching distance)

".

Model 1

K

-

LC30 _. '1.07 x 10-3

LC40

. LC50.:: . 9.'96 x 10-3

LS30N)~ j),87. x j 0'3.'

LH35 ,'0,96 x .10.3.

.LH55~~ ~::O;96 x; 10.3

.., ',¥"""..,.. .

_J.;;07x 10.3

~ '., .. 'Y"~""'~' .

;. '"';0

.,", . -' :.,: ./: ..~. ....

'.

. ,..,-, -"

..

Model

. lB9 ~"L "D.96 x 10-3

.lB12.;.;.",,;,0,96 x 10.3

",:" -; .., , .' .

LBJ~";;)

'l.A3St~ ,~l;{)7 x 10.3 -I,',

. . LA4S'): ":-1"07 x 10-3

'-. '.-:~...:.',~:,'.;,'- '''.;..!.~ , .

tp6'i<~ 'O~96x 10.3-

lPJ5 .': ~

"FTl~';'.': "0.75 x ',023

':~'O.96 x .'1.0'3

,

. . . .

". . - .

. . ..., -. -,

'

'\. :,...:'..;- '.. ...

. .

K

.;1~17~~"0-3...

.

0.64 X 10-3

.}L-;

..

N(.J(J8: GGG x8/J'/J' Z2(1S returns the cutting tool to the startIng !"'lllt <II

a rapid traverse rate.

MGS stops spindle rotation.

Naa9: M02 resets the control.

X Words in Thread Cuttin~cle

Note I: Number of infe~ds ~n thread cutting cycle should

bp Sp.(p.clt'd

a~~o~ding to"material to be cut, t~read l~ad, etc.

Note

~ _. ...' ~ . -.~.""._- '" '. ',. ,.- ,~._~...;.,..,:... .' ." " :

. . .. - .

CUTTING CYCLE.

PRECAUTIONSi~FoR-; PRoGRAHKINC;1tHR.EAi>,jCUTTING CYCLES

..",,'.~:',~~~~'r-:.§~~~.>o:.. ~:~~j~!~~J;L~'~':"~~~_?'T-:1S.t.:!,~j.,:~.;L:'...

Observe.-:~he;(opowing p~h1fs~$h~rit progr8'mritJng'jf;4r~a4~utt: ing.

.,u;\,;.;;~*!~"i+it~;;, .f"i~i1~ft'r~'1':'~\ '~.;;:'\??;y(~~~'f;~~;~J;.~,~.;..

1) Spindle :Spe'ed ChangeL.Di.a"dri'g,,":,Thread Cutting Cycle

~ f.::~"4'&,~, j'i~) ," :. .~, t. - .~. . : ,

. If the spindle .speedtdl~g~~-',,{s. iptended'''r~ile t.hread cutting_~~~te,

will shift the start~ng ..:poinLof thethr~ad c'\.itting cycle, thll~'

damaging' the t~read ~e!.~~~~~~:.' ':~'~~j "'i':".:'. "I,-~'2,

Therefore ,NEVER CHlfGE"SPINDLE SPEED. WH~~E'THREAD'CUTTING CYCL~~~'/

2) Feedrate Override

The feedrate override dial is inoperative while thread

j, . -' ' ~._;.;. . . ... . .~ , . <' ,'.,

":,. L

..:;".,

it

NOOO: G50 83000 designates maximum spindle speed.

NGG1: Commands in NGGlindicate:

starting point

spindle ~peed

tool number

u

NQQ2:

KQ3 starts spindle rotation in the

normal direction.

XI2G indicates the X coordinate of thread

cutting cycle starting point.

NQG3: - G33 calls for threiia-cuttlng-cycIe-"""iow1iicn' th'e cutting'

tool performs a cycle (I) through (4).

. (I)

The cutting tool moves to the first

thread cutting diameter position at a

rapid traverse rate.

Upset ~/

0)

(4)."y,

-- I

(3)f -(-2) <.':(1)

..

1:>>'!6.~tt~*'t:'~~:'-i'thread cudihg}~ycJ.e,';stah loge, point

. (4) The cutting'~~¥~9'rret'u't.ns.to"~he "

The cutting tool is then fed aiong Z-

axis at a. f.e.e<iJat.~speci fiedby .the F

'word (1. 5.'fo'r"'thre~d lead o'.r-:1.S m'm>.

.; . ."- . . '.' .' ~

, The;i,c;utti~g,~~~iA.:.~~b~ct.s ,f~dm.;.t:he

. . ". I .'~r.., ':...0\"f-!,,:>:~-~- :~\'~"';~.-,,-.,t~.:-' "_,.i. :~,:'''~.;-'" ~ '.,:--;;..->" ._

workplece at.',the'd~s Lgnated.feedra te.

. - >.'~,:: .1.: :'r.. . ...'.' ." .

:..; .; ," 'T' ~.

. -"',:-- .". " at:.~.~~~,.~t.:.~~~~{{~£.K~~~;i,:..:!.J~tE.%;~

"i.p~mens ion word {X~~:i.q,~~~,a~e.s .the .d ~a~~i~EF-,!i.b~hic.h.,~tte . fJc.s t.,

t.hread cutting cycle isperformed,'and.'Z:::the

.'..\.thr.ead~' Thr.e.ad (_le~4,~i s)ic.olDl11~nded ;bY1.lf~:,fi,?,!ord'. .

NlJG4:' .:,.X.words, in cthese ,b.locks;indicate

: ~,;,. . .pa~$esof ;t,~rfea~~utt'~ng. cycle.

NClfJ1 . '(j,~!'1','" '," .:.~",. r, ~~n~ " d ;. ," ..

, .

'f~ .

. . . .

r:,~~::!f;:f:f:?~:~;;>~;~,.~(t:J4~?'"

.

.,:t~~~

. ~~~,...',

~:~~ ~~~ ::~.~..

endpoint of the

," . - '~"'<'''. .

'. .

the, id.i,aine ter.o' t.; r.eSPE!

'.:.-:"i"

.""'... ~.'

Start.ing

In G11 mode <hread rutting cycle a' ,ho~n belo~ " performed'

,,~u'--1 . ' .." ' \

, .. ' ,'-

, .

\: : ' . ,.' ,n

. , ,j{ \

1

.-., -:---,:-; " ,......

1

\

~ ,'. '. " '

.i > ' -, ~

.~. -' ~~.."

7.

. ---"", ," ' .'

, _ _, B

. ---' ---"" ." '..' ' ' '

'---"~~'

'V"~ ;.'on'.f:.X ~.

----------

\

.- - - - ....

~ _ _ 0:.."-'- _.- - - -

, .

'--

<.

point of

i'"

th'cead cutting

cycle

" 1

'

' 2

/

1U

' . ~-"

.

./?

,

- - .J

Format.:'

D

z

G71

D6scription of each word:

X: Final diameter of thread

z, Z coordinate of end point of <hread

A: Taper angle

I' Difference in radiu' be<~een ,<>r<i~g ;P9.io(""od'e.d",p~tj{~'

x

<hre~d (expre"ed

B

i~. #;,1,~1~/",~i>~II.:f;4:;jF\F

For' <ape r <hread. usete~ <Me. A or;J ~td"",,(,!;l. ,..;; ·

'.' ":J~"f:~;ikt:ic~;;;i1,: ',~If~§;g"-:'\'i\!:.

u

L

R

fJ

M Q

." . '." ,.",

.";.~

COKPOUND FIXED CYCLE (SPECIAL FIXED CYCLE)

GENERAL DESCRIPTION

This feature allows a series of cyclic operation, which usually requires

commands over several to more than ten blocks, to be specified by the Com-

mands in one block making the most of one of the features inherent in '

OSPSQQL-G/OSPSQQQL-G, high processtng speed.

There are three types of compound fixed cycle as:

(1) Thread cutting compound fixed cycle (G71, G72)

(2) Grooving/drilling compound fixed cycle (G73, G74)

(3) Tapping compound fixed cycle (G77, G78)

Outline of individual fixed cyclE'

(I) Thread cutting compound fixed cycle

Two modes of thread cutting cycles as Gil longitudinal thrf'"d e,lt t il!l:

cycle and G72 transverse (end face) thread cutting cycle are

available. 'In.addition, combination of M cod.e.designating ciJttilig

mode and the' one selecting infeed patte,-n permits the pr.ograllunt,:(i\I

select the ~ost desir~ble mode'of thr~ad cutting fromav~,i~ilhl.' ';1,.

typ~s of threadcutt i~g cycles:, . . c.,

.'

. - . .~ .

Two modes of'capping cycles as G77 right-hand

",.it;~::;;:,'aeft~hand.:it4P,plt)i~cycles are avai lable. This

.,. progra~ing~or,l>oth right-hand and Ieft-hand

. ;:~.: .~ ":~._~~.} tj }.:~,~:.(.e:.!':~r. (if~ _~.th 1 '. '.:

"

. .

-. ',-

~ ..J ~

..

tapping ~ycle ~nd G78

cyc1esimplifies the

tapping operat ions.,

Format:

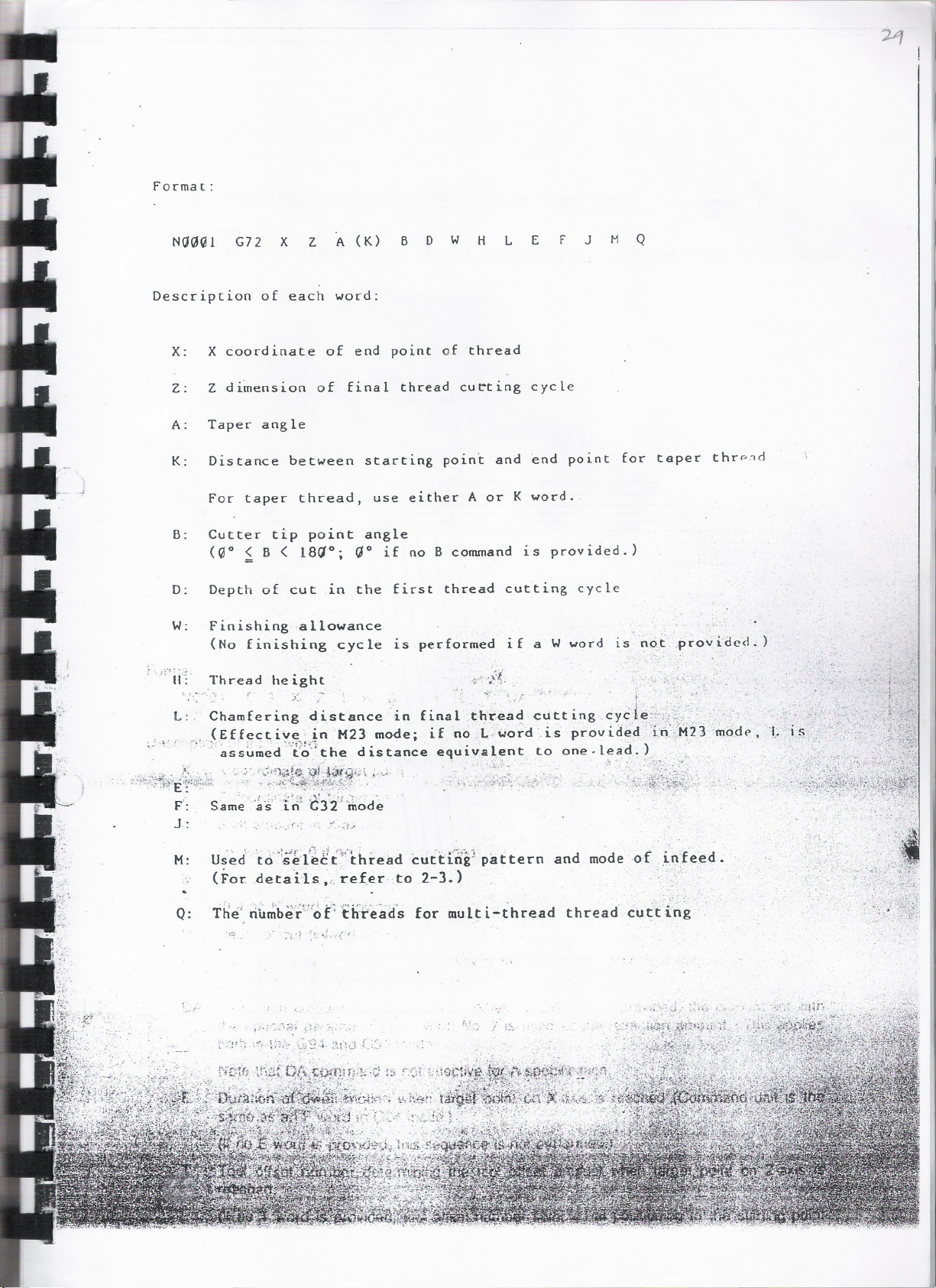

Na(.J(.Jl G72 X Z A (K) B D W H L E F J M Q

Description of each word:

X:

X coordinate of end point of thread

Z:

Z dimension of final thread cu~ting cycle

A:

Taper angle

K:

Distance between starting point and end point for teper thrp~d

For taper thread, use either A or K word.

B:

Cutter tip point angle

(Go ~ B < 18ao; ao if no B command is provided.)

D:

Depth of cut in the first thread cutting cycle

w.

Finishing allowance

(No finishing cycle is performed if a W word

. .

1S nQt .pro" idecl.)

" 'Ir~

. ,', _.,J~ff~<;tiy,~_..Jn

~.~ , . ., ., '4 '1" . I'.. . - .

Thread height

,:'.~ , Y. .,- . ": ',r. ." . f. ".'

L:. Chamfering distance in final.threaci cutting cyCle::;:.;::;;L.'.

M23 mode; if no L.,word.ispiovid~d Iq:\:)123'm(jM,

.. assumed to the dlstance equlval.~nt to one.l~ad.

. ~ .~

F':

J.:

M:

Used' 'to":S'~'l~E{'(thread cud:i'rif pattern and mode of itffe~d.

,,"~.

(For:deta'ils .(,re.(er .to 2-3.)

T~e; ri1i~beF:'of th:t'e~(fs for mult i-thread thread cutting

Q:

.~.". ~. :

~ "

." ..;';."'

..

-- -- -

----.-

..

..

G72

~

t' I

I

I

TRANSVERSE THREAD CUTTING COMPOUND FIXED CYCLE

In this fixed cycle, thread cutting cycle as shown below is performed.

A

(2-

w

H

Starting

point of-

thread cutting

,.........

..

I

I

II

"

'-'" I.~I ,.,p.., ~

.

w:.. ~'4~.' ..,

...

-~.. ~....-. '1' 7'... ~

.. "

.' c::.:,". ,.

.

. '

---1:

-- -~-- .

X

I

--~---:.-~.,

' ... ~...""-:,.:Y

L

: ~ ..'

l

Z ; i-:---

.

-,. :

.,.

.:.:-

Longitudinal Grooving Fixed Cycle (G1'3)}

In G73 mode. grooving cycle as shown below ISpetbmed.

'rrnrrnrrnrn'

'r////",,////, ~

T when poS.tlOn"'!jIO _<'<JJ".n"".JL~..

the coordinate 01 End pO.nl

largel point is made 0

I"", /' /'/' ',~ ~

I

z _. .-.

_ iJJ

l-C)

x

- .-.----.

Format:

NOOOt

"'f:_~l.::i:; :..

G 73 X Z

K 0 L F E l' OA

OescriptRfOJOf~ach word:'

x ).,><. coordinate of target point

_j".s";ffpti(.R~::J: 0<1::;; Wi). Ii. .

.~4~' ;"6 :~OQrcfinate.0; target

. """-;&}!'~

~-~..~,..,..n.'" ."'

"

. ,."' ~'''''~, .irt..\R \. ,tarU~ '. "'1

I .~ :~:.Shift ainotint~in' X-axis.' irec'tion

.. : 2. (;'Qr;.~.rc')~r: : '; .J! i'.,:f.':.!.t"!.~r;:.f

(in,diameter; 0 if nol word is provided)

~. J~l'~J' ~;'''''\;1' ." ~ ",", ~. .~.'t'g'rl"f(" .

K :::~PJf~~.ci9.~r:tt' .in~4:~~i~. ~rrn~tig~

, ~. - .", : .,.,. .

_ ~ ~(O.Jif,,'1q,KY!'0rcfis:Pf~Y!P~<;f). ,

t.

:i''''~'

. oint

''~

.

!

'H''''-C'

.

. :~

o . :'O~plt{6ft:ut(infeed.~iWc5\1ht)

L"l: ~TbtaHnft;edJamouht"ioiliiooi withdrawal motion (in diameter; tool sequence is not per-

.forfO~d when L worp is)not .specified.)

.

"

.,.

. (,~.

.- .~

~ . ".

..~,

OA: R'etradion amount

oia" 'is"specified. When no OA word is provided. the amou[Jt set with

;,the :9PtioQal.para,!T\ete~ (1Q.~g.word) No.7 is used .asJhe. retra~tipni~u:noW}i.~..~i-'tbJ~",~ppli~~.~t

bo.\t! i.qJh~, G~4. ~rJcf~~5~rn9jes. '. i;';<"'~,:$ .~,,' '::'.f,o.c:;'~'>:),~rJi},!;;;~',';;~~!;'~f~*'2'.;,.,

.tl8t~'tf1Mtb.tfd{mm5n~~S\not1!ifective forA speahciiiidf!.' ":;..::r~;',:£r.9~'

'. . .::E~ :i~~iridn;Pt'd~eltlb~lt8Ri:l*an~\';rg'et:p6Int:".b6!:~~~~~~~~~~#*i

~. . "

. "",.f!!:£.'T!P_'-:Jo5:;~"', ''''''.5~ !n-t"

"; -'.«; <sa'!le,'<!S on rc'worU'1n:~ :moue: (:-" . .", :: '~;~lJ't;.:;:::;',.,',""V';

.,.,..1"""~~t.-.

~

. !. ".-.,i;~;~...'\~"'~JV:1:~Xf-t.:H: ':. ,. '.. . .- ~M~,"'~~~Jf:!~f;.G('1 .j.:;..-€ :!t~'M1;di.1u J...,~~..;:.i:::

'...,.

.

. :no~E: \Yo'rd'!S~.provid.e~a;.Jbis$e.quence isnoi".c:~'~ ;:,~"-'-,'..I.,,'\r~',,..'

.~1~ki.~.(J:( di'ti'(D~f~1 .i!~~~,.i.if-~j

...:na...., :.o.I"

.

'

~

.

~

fs'e(:numDeh:ij~mihi~cJ'~:ihe,toolJ

. ",-, ...

'

~"~"'f' . ".' .";, ,?"""'"",;;:".,.,!\,.~ :."'-

O

~

"r..: )" "

.

.. \ij,t~

. ,. -i~""¥""

~

.

.

.""'\;>'1,';

Transverse Grooving Fixed Cycle (G74)

'In G74 mode. grooving cycle as shown below is performed,

T when posilionlng 10

lhe coordinale 01

largel poinl is made

z

r - - - - - - - - - - - -- - -- - - - - - - - - -- - - - - ~ - - - - - - - - - - - - --0~~ ,.,.-

C

I

J End pouIl I.: ~~

r

. L.:~':-.J

X

-....---.

Format: ' ,.,_ '.

'.~:. ,"

.~,..

NOOq1..~G!4 X Z I K 0 l F E T DA

. ~~~~~

.'

-." _/

, ,

...~~~"

r::: "C

t~~~~

t:,-,-~L_

Description of each word:. .'

X '~:9<~C9brdi!,ale'Of1~:r9~1~~itn~},~~~!'Jri,~.:

~l':_~cka~(7. ,:! ~;~:~.;;.».::'(:~~'?t,.r.\1.-~(ryc:t,,~.n

Z : ~~,;e8s?(d.j~.a,te.pf,.~<:trg~~ e?~t~~j(!i~' W .'

. '. -.' "'. ~ ','"

..t':.i. ~~~~~1~"J~YC'~

. .:'0,

,,-...-.

:"Shift~mountin X'axis'dii~cti(jn ~..'\" .

.. :(i.n~~.i~m~teG:.~.:if}1~:L~p!.~~~,pr.,?vid.~9)

K ::'Shiit;amount in Z-axi$:d!iectiorf~;" .

(O,jf!l9,.l~)'~9~e~,prj>,!~?~)~,\_.;;;". ..'

- ;::'

,~r

-

o :. Dep'th1ofeut (infeed' amoui1t)" !'.';'.''.

L

Totalinfeed amount fo(tOoI'withdrawalmotion

(The sequence is notperfo.rmed when l wordis not spec:;ified.)

:-:_ . ,J' .,,-".-.. . . ..,;."' ~ _ -~".. '.

DA: Retraction amount "a" is specified. When no DAword is provided. the am()ilot~et with

.t~e,>!?pti()nal~pa,ra~et!3r JI9.,n9.,Y"0r~), No.. 7 is P~~.rP.~€!~;;:fl:~,~~S~i~W.~~~~~\.:1~tt!!§.it)P.(ies/ -..'

~._i.;~9%1?!.~~.~~~ and G.95~~~.S.. -,,'. . .'

E :. Duration. of .dwell. molion.iwhen..laroet oolnt.. on i.z~;.ireache:d';(C9m'

'~~&~~~~1li~Ti;;.~\f;~:j:,~.:,j.~~r

.~-~~~.~"."31~.:~~

..J ." .."~

--.~ ,,~. I:.

"'/:J>"..-;".

_. ..

--.--

-- -- ---

----

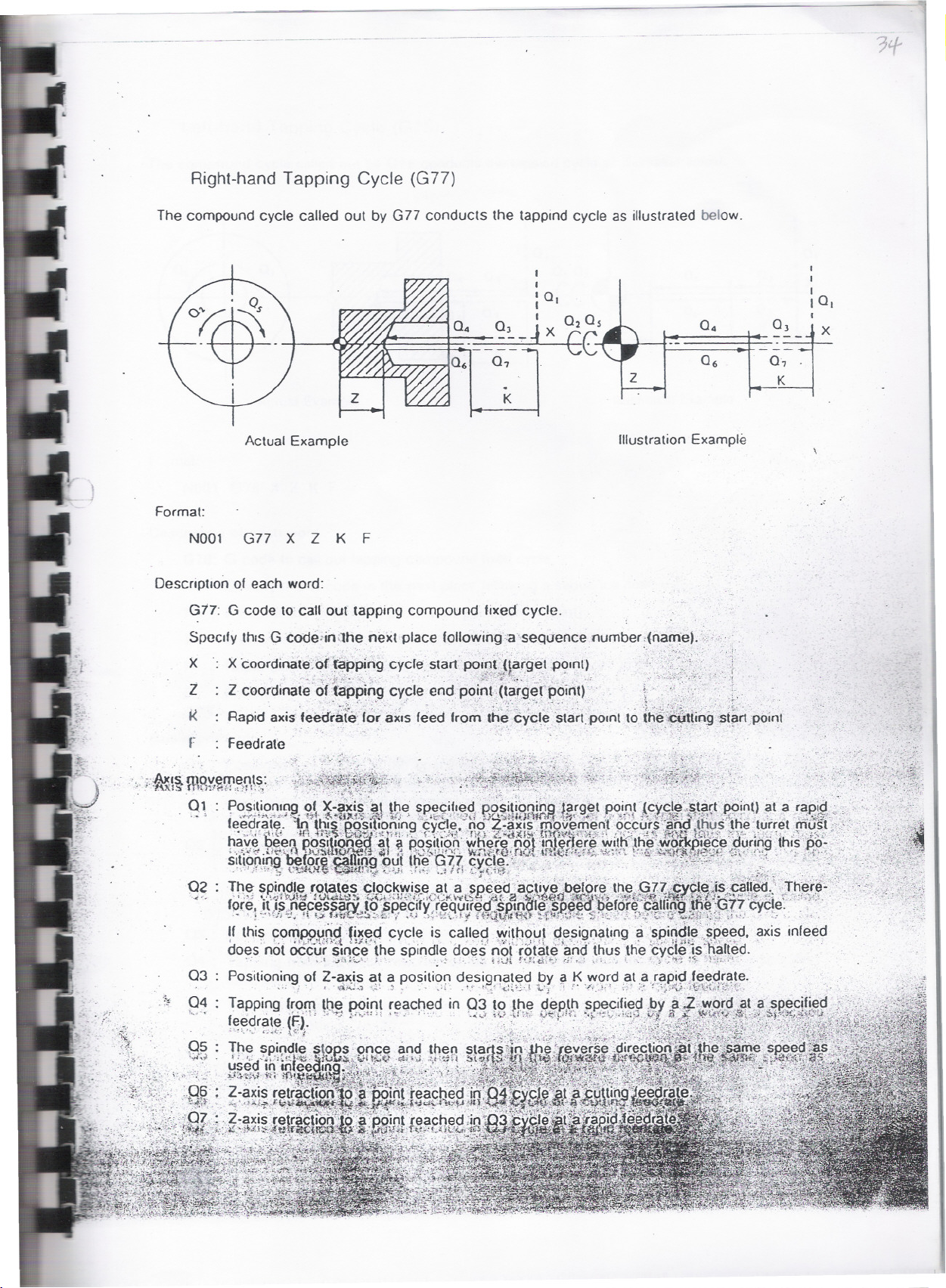

Right-hand Tapping Cycle (G77)

The compound cycle called out by G77 conducts the tapplnd cycle as illustrated below.

I

I

I

la,

o~.

.

z

K

Actual Example

Illustration Example

Format:

N001 G77 X Z K F

Description 0.1each word:

G:17: G code to call out tapping compound lixed cycle.

Speedy this G code;in;lh~ next plaee following:a'.sequenee number:.(na"-Je).",,;, :

X X coordin~lte:o(~pping cyelestart PO!g!'Jlafg~t PC?,nt>, .;, }

~_ '" t '.. '.. . .. ,;-;,; '..', ,.~. .. . .;. . "

Z Z coordinate offapPlngcy~le cnd pointJtar.gefpoint) '. ~" .".'.,: " ..i-. '.

K : Rapid axis feedra(~' 'or aXIsfeed 'rom the Cycl~ 'starq>Olnt to the~tting'5t.~rt .point

. _ ~' '~:.~.."~;.'::-: / h '". :-:';:,~"t.;: (~' ' .'~ ". " ..~.;-:.:~j":~i#:.,'~,:;-: -; _';~- '. .'

. -

- .. .

r : Feedrate . . .

."

--- --- ---

G75 AUTOMATIC CHAMFERING

When cutting a workpiece, it is often necessary to chamfer the sharp edge

(either 45 deg. chamfering or rounding). Such chamfering can be

accomplished using conventional taper and circular interpolation G codes

such as GQ1, GQ2 and GU3. However, this Automatic Chamfering Function per-

mits chamfering t6 be done in a simple programming.

Commands used in this feature are:

G75:

G76:

L

Chamfering at 45 deg.

Rounding

Size of chamfering

4S DEG. CHAMFERING (G75)

+X

(Xl20.00 250.(,10)

E

-;

(Xl20.00 2115.00)

D

,C(X120. 00 Z120. 00)

I

I

B(X110.00 Z120.00)

A(X50.00 Z120JQ(,1)

,

+z

.-

. ,

Wit-h the,c~ands above., the .cutting tool moves Jrom:Point A to~~~~4'.'.then ,'"

"."<0'D "thus au tomatica lly ,chamferioO' th,,'curn'r."tE~ 5.de.. w.i.H'1>!I~iJ"" f."

5 ;!~~~~i1,.,

'.Sp~cifies chamferi.ng at 45deg.

. ;:~.-i S~5. fr~c~~' ~ -. '. '.:_I: ~,":::":'

X12~: X.~Q~rdiQate of Point C

" _.t_..,.., J .. .

L-:5 :

S.~,;_e"oJ, chamfered face

'...

-;.,i

:~.

G76 ROUNDING

( XI ZII.P8 B II.P8 ,

E

(XIZc1.pll lll~~gl

o -'~CCX I Z,.P8 EI ZU')

BCXII'.~~ lIZ,.'"

ACX511.U l IU." I

+l

To cut the above shown contour along the Points A, B, D and E, program as:

G76 G~l X12Q

L-S Faa CR

after positioning the cutting tool to Point A.

With the commands above, the cutting to~i moves from Point A to B and then

to D, thus automatically rounding the corner .at 5 mm radius.

G76: Specifies rounding of corner

X12Q: X coordinate of Point C

L-5 :

Radius of r~o'~d'i~g:-~'ircle

Its sign is 'd~~~f~i~ed by

"+" ... ..when i-axis (X-axis) moves in

( ; ..

./~ '\'" f~""'- ~ "..

. J'::t_.:.c..::._~... '.. .': ."'

the direction of a)cismovement;'

,<",

. . . ~')

,~.~fter ~:X~axis'{ Z-axi s ) moved.

"_" ;;?-f~i~~e~~(i~i~f~::~"(~~~xis );aioves .in

. . after X-axis (Z-axis) moved.

By. c~mma~4h~g .the coordinates of Point E. .,thedcutting tool moves from:Point

o .to<PoiWt:':~E.~~'~: -' v . . . -..'> -'....

'--::0,-:(;0..

"'NOTES'

/. i :~~

Z ~~t~~~.. ,. .

.t-,'~

. .

.':...;

,..,."

1. (;75/G76 is effectiveonly in GOI mode. If it is speCified in otheithan GOI

.mode, it causes an alarm. . -.

"~

.....

-- - -~-

G90/G91 INGREHENTAL PROGRAMKING

---~. - -

With OSP S020L/OSP SOOL-G, programming is usually prepared in absolute

dimensioning system; however, it can accept the commands expressed in

incremental dimensioning system. Combined use of absolute and incremental

dimension words .i~ also acceptable.

G codes" used to select dimensioning system

.G90 Absolute programming

(cancel of incremental programming)

when the control is reset, it is in the G90 mode.

G91

.............

Incremental prog/"amming

Example(positioning from point (1) to point (2»:

~;.

" (2)Xl00 ZS0

,"(J, "'". ";.~~ it'.." l"~.~

;..

X

Incremental

.~>&~~~~ .

* Des ignate ciimens ional d i ffere''nc~s be-

tween points (2) and (1).

. . . . ., ~,:...,.,.i.;:':::*~f~~~ff~t,i,.:_:.:.

N.ote:

;

_Absolute

In 1ncremental programm1.ng. X word shoul~ be express~d ."l.,n""d " """

-

::::,,;

))

'

"\i~'

I

~l~;~~:.

,,:.'~-',,,

,.

--- --

LAP

LATHE AU'1'O-PII.OG8AI FUNCTION

GENERAL DESCRIPTION

LAP (Lathe Auto-Programming) is the function to make use of high speed

processing capability which characterizes the OSP500L-G/OSP5000L-G series.

With this function, the control automatically generates tool path to

produce the requ~red part contour.

In this function. the program comprising, dimension data of the final

contour to be finished including rough cut conditions is prepared as the

Contour Definition Program; when it is called out with the cutting

conditions specified, the:control automatically generates tool- path for

respective rough cut. cycles, and then finish the workpiece to the

programmed dimensions.

... '1,.';0.".':

,...".' :.'" :

This feature permits the programmer to complete the part program simply

picking up the dimensions specified in an engineering drawing and, there-

fore, it simplifies programming JS well as it reduces programming time; .

this furthermore facilitates tape check procedure and also tape punch\

procedure.

Various cutting modes available with the LAP can cope with any type of

cutting intended.

Features of LAP are:

1) No

2) 'Tape'p're'~:ar~t~on time. can be,. gr~atly reduced. .'.: ..'

:;j) '.prog'~a~F~~::;rf~1t~U'gh'

. manua~ calCjl.ation~hUeprogramming.' . . ,. ,', . : :./: ."

:.n:.'~ ,".' u. ~3S:"7'.:T;,~:<:".t1~~~., ;.:~:~H~'11.:~,~:'~tl{':',:.)''''<::~ ",,;."~.;~;::t'~.;~:L:=,:'~:~;':;'~',';:':/;,:'~~~::'"'

4)

' ange .:0 ifU'ttY'g-'conu ons!;uCn' as ep~n 0 . cu,an .' e,e ra e': 5:;">/:"1""

sp~c.i>a( p.r;ogramming languag~ is neede4.. The. :same":;progr.a~i'.1g .iIi~riner

as

ili" 'c'onven.t'16na f' p'rograninilai~Cteduiiqu4!:":can 'ha-ridle':'the t..(p fulic hon.

- " ~ '-:;.1 t ~ .;..1'. =: I .f" . ' f'j ._=.!.,",q -:..- ;.,f.'.. ~ ,~,,!-~,:,,!:.':~t:;:.~,' ..:. ." ~., : .c : J.§ ~,

~ r ." ~ ~ . .

hit" 'ti~~:~#~a-:rt'fb~>ifiirtlii~ t~ti';~':f~ri<f\~this 5ini~~j1fi e s

'

.i

' "

t

1

'.:1.,.", "'

...Ht.:~ ". ""'

.

ij

J~~;, '"'

':: 't

f

,t

d olt

t

d

.

'

...'

'

.,r

d

f..

t

.

.

Ch

.' . - . . , '. . '.

i.:1:t~

"p'Gm::na.n~".,., <~

f

M

.'b

.

..,:

..1:J,;.:t;

i

.

.

.

.

POSS~_~:;~~Y~~~i!,~:"'~E:~;~~~~~'. .~~~~Jil;~.

FORMAT (Ct}tOpE~,:,~Q'" . ( ".!,J':,-: <..",: , ~,<-'", ,"~. -:~-\ ~ '. .. .,. '

.,.g,8~

,... -,

C81

G82

G85

\or~>\"'t... - t ~ 't'~~p'f. f~~...: ~." ./". i.~r 1.,;': ~ C.!~) ;>-:> i" ~-i: '1t--

E~,dJW~!r~~~~~.~l(:-~e,~i~~!:~lc~~i! :t!~':".~<'""'ie.!;>

.";.. -:.' ..;' ~..:.Oc t:.. .;'::;,. _ :) ~,.. t'., -J)" - ~ .-t.. -..,:.-". .

St'ait :ot"f"'c'tiiltoiii' definitioh~,"~lon'--:ltu(U:na'f

~,il':..,;~,1i{U;~;~,.,t,..,.(';.. (;,. ;.- .'~'.''.i,'f~'t;.~, ~r'~],:,.*~~.. ':

Starf'of. 'C'ont9ur defini tipn,T.ransverse

~i no .;.".~.t:'I.t:..- :-. ~.'.''!l .:'P{; '~'n ~u -~..

'. ,~r~''''.{~';''(i~l''' ,-

Bar .t'\£rniri'~f rough cut cycle

~'i;"{ ~i~.;;~\'

~'" >.

by

.

'

.,,4i

-"'~~

G87 Finish cJi 'cycle

"

'..

. .

,

~

-.

180

TOOL NO,

35

TOI T03

T05

(17

V"I

V"I

Q.

-----

11"I

..:1

Q.

\

.'

,;.

11"I

oj

Q

.',

'-

N

-

\..

LR 60

ClJIT1~ SPEED

SELECTION

-

....

T:HJi. BIT

CUTTI NG

&J &J W

150 H/MlN

00 ROUGH

120 M/MlN200 M/MlN

__~ ~____ _ _ _ __ _ 4_____ _ _ _ ____+

------------------------------------------------------------------------------

'N G

-----------------------------------------------------------------------------

: GOO

: G50

NLAP1: G8t

GOO G42 : X25

G01

x

: X5.00

I

I

: X30

Z

,

Z250

I

, I

I

I I I I

: Z201

,

Z198.5

,

L F

I I I

I I I

I I

I

.

I I

.- -.-

FO.15I

S T M

S3500

I

Z175

X33.38

G03

G01

G02

GOt

: X35.337 : Z174.208: l1

: X45

: X53

: X55

I

,

Z151.477,

Z144

.

Z140

.

: Z139

L4

,

I

\.

Z110.979

I G02

: G01

I

I

,

I

.,

"

: X55 : Z63.021

,

,

,

.

Z35

: X62

,

.I

X62

.

,

.

L60

. ""-., "_.0 >...

41

I

I

.

I

I

"" .-

G87 FINISH CUT CYCLE

Format

NQ203 G87 NLAPI

L--J L-..J ' J ~

NQ2~3: Sequenc~ number

G87 : G code calling out finish cut cycle

To be provided right after sequence number (name)

NLAPl: Sequence name in the first block of contour defining bl0.cKs

Blank: Enter either tab or space code

u

w

Stock removal in finish cut cycle, X component

Stock removal in finish cut cycle, Z component

u W

l..J l..J

.,..:,..

--~--- --"-- - -- -- ~--- ---" -- --

EXPLANATION OF LAP FUNCTIONS AND PROGRAM

Tool Path and Program

Contour Definitiun

- Longitudinal Turning

Tool chance po.! t tC)1\

(ZLXtl X

Ct.rtOtnc pOCI t Ion

I' I

..-

1&11,11 'r.

,XA Z

4' II:' - u;

,

1/

"

'(12..'0'.)

%

.-

IM/Z

i ,;; '.~~ f~ ~:, ~.~ _.. ,.. . ~ . .. f'

,:~LAP ICSI -- ~ "'---- ~-- ---:'

:~<J(Jal ;CI1(J';"X.:'~:Za"'" .

:tI<J(J(J2, Cl1l Xb Zb

:~(J(J(J3 Xc Zc

!N(J(J(J4CI13 Xci' Zel 1a l<d Fd" sa

: ',:t.[M<JQS. Cl1l . Xe . Ze Fe;';'.$~

,':,~st~iiOO,;::::~o~s'~5~h.~:; Fii:1o

,::;,NO(JI1S '.:.'~S<J'>"E';:;-.~..;. - ..;.- - - - .,.,:::':"

,.

..

" .

NI1HH CQ(J

NI1102

'NOlG3

{$ ~"";,

$

. ". Rough Cut Cycle

.~ l.f? ,~-..;:: :'":

Xc Zt

Xs' Zs

spind Ie speed for tIn Ish

. " .'

Feedrate (or ~ough 'cut cycle. fough

/.:cu ~.',,.~l~~g£~~'~v~t ':,

.~~~~:J~t:.f~!.'c~~i?~l~:~~:?i.l\i t ion

" '"" . . "

.'

- '. ." " "

. .:.~"-'7'~}':~X: :~'-'-ft,_;/<,"

" ," ;<,,#~~j~i.\X~~,~~~fi,7'"

.~

''"'End.of contourde~~nition

anclfeeclrate up to

sco~kreDOv~l ~unt in finish cut

cyc Ie' .

___"_._, -__ _u.._

..---- - _. <-

Bar turning cycIe(G85)

GOO X800 Z800

G50 S3500

NAPI G82

GOO G4l X82 242

Gal Z45 Al35 FO.l8

X60

Z50 Al20

Longitudinal/ID(G81~ and End face(G82)

45

X37

Z52

G40

G80

NAP2 G8l

GOO G4l X43.5 Z5l

GOI X38~5 A45 FO.15

Z33

G03 X32.5 Z30 L3

Gal X30

Z25

X25 Z20

X18

G40

G80

GOO X800 Z800 M41 M03 S600 M63

NTAI X9~ Z51 TOI0101 M08

'

G96 S150.. '. ,',t:. .'_"

G85

N

_

_

_

API '02' iiri. 4 wo.~i f,O. 3

..,'" .

,

~

- "30

~

"'- :

I Q '&

--~

_. .

~

o

D

SO I

---"

',;.'

.:~Dj;tJ<90'2:51' .. .

.~,g9'7":-X800. Z800 $600 M05.,M63..

. :~NTA2 X90 Z52 S800 M42 M03 T020202 MG3

);:/;:9~6' S200 '. . .

, 'o:;'G.'87,:: NAP 1

'-:.:.' " '.0 '0

!CO~G97X800cZ800 S800 M63

~..~ ,

NTA3 X18 Z55 T030303 S2300 M63

,G.9 6:.$ 15 0

'G85 NAP204 UO.3 WO.l FO.25

GOO:':.G97:Xl~ :;.Z'S5 52300 M63..:':"

X800 Z800.' "', :-,'., .,'

NTA4 ..xIs' Z55 '1'040404 S2800'M63

G9G S180"

G87 NAP2,

GOO G97 X18 Z55S2800 M63

X800 2800 S1500 M63

~TA5 X34 Z56~T0505

G71X40 Z40 B60 00.4 VO.05 Hl.5 Fl.S.Ll M33 M7j~M23

X800 2800 MOS M22 M63

M02 .

~ .--- ___Ujj

'

60

,· /

-,.. -~ . . Ira...;,

1

;

/ "()

1

.:'J;,s

~

I

-'::'-

"~ t ~

1

~

I

~~i

,

JIll

"--"--'

(G96/G97) PROGRAMMING CONSTANT SPEED CUTTING OPERATION

--

When the constant speed cutting function is selected, cutting at

cutting speed can be performed. This feature can reduce cutting

also assure stable'finish in end face cutting operation.

Format:

G96 50000

G96 Entry of constant cutting speed mode

50000 Numerical value in the'5 word-expresses the desired".

cut~ing speed.

SIGG means IQG m/min.

G97

50000

G97 Cancel of G96

'J

j Soooo

" ,1

,:i~,~~~..; ,-,,'.

',' " When

.........

the control

Numerica

spindie"speed~' ,~: ';Jf"':"!'," i" ' .

I value:,'of;:'the Sword e'icpres5'es the ,'desi'ree,\

is reset, it is in the'G97 mode~

-:' ,.:.

a constant

time and

;,.~j&xamp 1 c

,t

,~,,~, __

"

.t ,. .

,i . , ~':~','

,

,

,

I Noaa G96 SlQG

.:

Nooo G97 SSGG

.,

G96 calls for 'c'onst~mt speed "cOtt iog modeand:":the

commands following this block are ;;!I exec\lt,ed in

this mode.

..:;........

SlQG lUG m/min.

G97 cancels G96 mode, and' cutt ing after this block

is carried out at ,8 spindle speed of SGG rpin.'

..

"

r

- - - -.---

5. H CODES

Code

MOO

MOO

MOl

Associated Information and function

M Code

Up to three numeric characters following address

character M are used for specifying various miscellan

eous machine functions such as spindle CW/CCW,

collant ON/OFF, etc.

~rogram Stop

When MOO is executed, machine operation goe~ into cycle stop

state; spindle rotation and collant supply are also brought

to a stop.

To continue ex~c~ii~~ ot-the part program, press the

START button.

This program stop function is effectively used for measuring

finished dimensions and also for removing chips during cycle.

Optional Stop

CYC~E

':-"M02

"','

',' "'-4 . .", ",.-. ' "

M03

MOl performs the same function a.s MOO Program

that the control ignores progra~ed MOl codes

OPTIONAL STOP 'switch is ,turned""qN.

,':'t . . . .: :.-;..:

. ~. ,'c .;. 'f

End o';i.,P,rogram-

M02 provided. at the end of a p.it..,t,:"pr~gram ".r.esets ti1e

"

~,~"=-",,,,,__'''''.~M_''''''_-'''''''_'''''' ,.,... ___" ., ~ ~...~.",:",~~~ , .- ~ ~"_'''.''''~''''''''

. -'i:

. .~: '.f~~:;~~~-'.', -~.- .

StoPi.except

unless the

CW Rotation'

"

~M03~s~arts.the:~pindle ~otation,'to advanc~ a right handed

screw into the workpiece. ,-

..,.~_....

... ..:.

MG3 rotation /"

.(3---~

Viewing spindle

c:;ootro 1.

l: ,... _

'-' ;>:~

"

Code

Associated Information and function

M04 CCW Rotation

M04 starts spindle rotation to.retract a right-handed screw

from the workpiece.

rotation

M05

M08

Spindle Stop

MOS stops spindle rotation

Coolant ON

Coolant OFF

Cancel of M23

J~~ ~- J ;' .

.Chamfering ON

.' "..." j ~

';;;H1j4~~ectjtes chamfering 1u's'fng

G33.thread cutting cycle.]

..~ 0"

.';f.at.tern of thread cutt4;?g

Patt~rn of threadcutting

,-". ~ :.

'\. :... '.

.'

..

Pattern of thread cutting

..

"..:

..

.-- ---- - - - --- - -- - -

I'ROGRI\HHINGEXAMPLE

-

~..

~'-

L

>

.., \.,

...,.-

~~ t~

X'~.;,

: - 'I

.'

NO

< 3

.- 6

.; : r

1

2

4

5

"

0.0. ROUGH CUT

0.0. FINIBH CUT

CENTRING (CENTRE DRILL)

-GROOVING:

DRILLING (UIA. 6.8)

('Wl DTII 3Jj\m).._

..

..-.~

THREADING (M30xl.5P)

7

TAPPING (M8xl.25P)

I

I

I

I

I

I

I

t1

"

- .

-"

~

;"..

~.

~XAMPLE :

~OO X800 2800 , TURRET RETURN Tv ~iMiT

G50 53500 ( MAXIMUM SPINDLE SPEED CONTROL

GOO X800 2800 M42 M03 51000

NLAPl G8l ( Start of contour defInitIon

GOO G42 X24 Zl01.

GOl X30 A135 FO.15

260

X40

X50 AlSO

Z40

G02

Gal

X82

G40

G80 ( End of contour -defIn!t.ion

NT1 GOO X82 Z105 TOI0101 M08

G.9 6- S 22 a

G85 NLAPl D6 UO.4 WO.1 FO.30 (-- Call for rough cuttIng cycle

.

$G84 XA=50 DA=8 FA=0.35 <~ Change cuutinq condition

GOO X82 Z105

G97 X800 Z800. S1200

NT2 X82 Z105 T020202

. ..G~6,~S25

, ~'.'.

'''

' .

.: ):G~?;L~~Ap,J"f.S~ ~_:-_;__:--- Call for fini5hcutt!nq cyclei"">

":!-,'". .f!":_ " ,._ ;-;<;~'~"" ",._,;.:..>~. .

'-':"J .,',",-..'d-.,''';-:. "'~'-:',:."'""h ~":O:f~;'"__'~..

",

O

0

G

. ?"'~.]::~:~~~H) O.}j,~'8. QO S 1 0 0 0 " ... ..' ,;.

..,,,.-(-_-,,.4f~~..,,;,;.. ~t,~~:f,~~<~.~fEij.::f":. ,'.". .:. #.' ~"- .' .' _;.ri..":,,;.,.~,, ".:\.';.,;..;"t.,

~:N.~)~Jt'j,;z.1:~n.~,ro) 03 (":.-- -,- - - - ...- :-.- Ce n t red rIll.;.

'~'~~~"_~;~~~~~~;.:.t'.~:.~ ,~~,~.~,.:" ,.~: ~! . ,- ;'..,.,;.!"",' ',,;'; t'- ~

X70 Z)O

X78

A135

0 .

.

""':

'.'~:

..Y' 6."'

X

2

Z

l10 KO

~ "

' ~'

' '. '. .

l

O

5

".~;, '-.. ; '~':"'_' -. :1;. ,-__~"~_ .~~','

.....

,

,.

~. -.

03 ~'L6El

-. ~.

,

EO.S T14 ( Grooving ~ycle

. __ n _ _ __

- - ---,---.-.

< :.: :-- Dr i 11i09 cycle.

TOOL NOSE RADIUS COMPENSATION

FUNCTION (Standard

The data processingperformance of the OSPS020UOSP500L-G series is all the more enhanced by

diSllnctive feature: The Tool Radius Compensatiol) Function.

one

The tool tip point radius of most cutting tools used in turning operation is the cause of inconsisten-

cies between the designated tool paths and the actually finished workpiece contour. With the tool

radius

gramming. .'

In die Sinking or milling operation. cutting is performed by a large diameter milling cutter. There,

control systems are equipped with the Cutter Offset function where the actual tool path generated is

ollset from the designated path by the amount equivalent to the radius of the cutter used. This is a

stan(r.~t(1function with OSPSOOOseries controllers: However. in comparison with the cutter offsel

funcllon. the tool nose

compensation function. such geometiic error is automatically compensated by simple. pro-

compensation function offers specialle~tures that are requIsites for lathes. \

for OSP5020L only)

.~.~......

.. ~.

ii~.

k. .

~1i.

Tool Offset and Nose Radius Compen$ation .

. : I~'.~ttmllng operation. va~ious tYP.es and d"fere!:'t.s~apes 01 tools are us~..to' hni,$f:\:og~:worki>:;E!.cet.:",",i.l>

':.~")£t;~~,~.t};n~ tools. 00 c~ibng'toP~S. rough cut to,o.'S. (~~!$tI.;C~tt90ls. driU";~~f;,{1~~()~q!ngIY;.:~h,~':}~~t1.~:~tit:~~~..";,,

:);.~.~.~~~::r~dlus compensation function has to be actlVated.slmultaneously Yf~t~,.;.tlj7Jqo~;~f{~e~~YPS!}g3;:.;:{;:{~i~~;riit'

.. ~'::::;;'~~~:~r\: . ..' '. ~.;:.'~"~.,..": '.

..,."",:ii ":; <., -t. .., II. ~,..,.. .. " " ...,,~...'-- -. H . -.' ."..'\."" o. ."" ,.,, ...~.~~.~.~:;.A..~:~;;. ~ - . ...: - '. - ~- r;.,".~~~~<~. .~_--~..~,..~:-~f~:T\..>;_"

Nose radius "

'compensation I

Position offset ~

..

'.

.<. . ..u~:',~. .,:- '" .~:.,...~<,.~;~~~.:~~'::.".~v'r;G~.: '!l~'.t3f:~:!"'::P

+

" .' '. '.. ',.' .:. ,...

1he t~~I'noseradiLJs,f~p~tionis~ctlvatedby a ~ix~(;'igiY'''Tcommand:

. T 00 00 00

(01 to 32)

-II Tooloffsel numb..

Tool number

(01 to 12)

Geometrical Cutting Error Due to Too Nose Radius

If culling along paths A-B-C-D-E in Fig. 16-3 is intended without activating the tool nose radius

compensation function, the portions indicated by hatching lines will remain uncut and cause a

geometrical errors. This is because the 1001setting is made to locale the imaginary cutting

point P in Fig. 16-2 al Ihe datum poinl and Irace programmed path as controlled by NC

commands. However, the actual cutting tip point is not precisely located on that datum point

because of the tool nos~ radius and this produces geometrical errors.

POlnlP

F,g, 16.2 Tool SellIng POliti

FIg. 16.3 1001 Palh and ResultIng Erf:Ur

. WithoUt 1001 Nosa RadIus CompensatiOr1

.- !

The tool nose radius compensation function automatically'c9mpensates the inconsislen~y

between the designated and actual tool paths caused by the too' nose radius. .

..., . ."

. :~~~~ ': -,','

Comp~n~ation Movement

With ,th~0''90' ,nose radius compensation function activate'!, o.!I}E3,.Jool.path is compensated. as

iIIustiafecnn ,~ig~'16-4 to eliminate )he portions left uncut; sHown in Fig. 16-2. This assur'es

accucate'finish as programmed: I. ,.d - . .', '.' .' ,

. .~ ~ ,; .~. ;~'~~.-.~":'~) . - .

..

Programming

Programming commands, G. M and T codes. used to activate the tool nose radius compensation

function, are detailed in this section.

G Codes

G40: Used to cancel the tool nose radius compensation mode.

G41: Tool nose radius compensation

-Left

Used when the tool moves on the left side of the workpiece.

G42: Tool nose radius compensation -Right

Used when the tool moves on the right side of the workpiece.

Note 1: The term indicatingthe side of the workpiece, rightor left, is determmed accordmg to

the direction in which the tool is advancing.

)<. .

A lurrcl

- lwo,saddic

st)uc,hCillonn

ZB-

x.

G42' Righi 10

j

./

workplcce

lell It) _

workJlI(,ct!

. ,

f.g. 16.5

"

I .~

".

, J.". ;..~

T Codes

"

Six numerical, characters 101l0Wll1gaddress character -r specifies the nose radius compensation

number~ tool number, and tool offset number.", ...'<,'

To sef 011set data through the keyboard, 3'2 pairs 01 compensation data for the tool nose radius' and

tool offset function can be entered (01 through 32). For the tool number, 01 through 12 are

available.

T 00 00 00

-II Tool ollsel numbe'

Tool number

Tool Nose Radius Compensation Data

As seen. in the previous section, programming procedure to activate the tool nose radius

compensation function has been simplified. However, to finish workpieces accurately using this

function,the toolnose radius of the tool to be used must be measured precisely and the measured

value entered correctlyinthe NC memory.

Measuring .Nose Radius

Measure the center of the tool nose circle with respect to the tool tip reference point which is taken

as the imaginary tool tip point for tool.presetting. See Fig. 16-6..below.

The imaginary tool tip point indicates the ideal tool tip point which can be expressed only by the tool

ollset amounts withouttoolnose R. Ac!iJally,such tools are not present. \

When the control has no tool nose radius compensation function, it controls the coordinated <j:(,!S

mohon so that the tool tip reference pOintfollows the programmed path.

Ideal 1001Wlthoul nose R

(hatching lines area)

-,;-

~-.

i '

Imaginary toolb~

".- . ... . . '.';" ~

.r .-~'.' ';";~".'~" .:'" .'_ ',' ':;"',-';'" <, ...-

'.f~'~"~''':>'::.

.~~

.~.

.;: :{~~'~;ik;:>~:!- .-::.

-.f~:.lnt~e_.medsurement of nose R compensation data, b~itiiti:~:i,oseR compensa~i~h'1irnouniand the

:>.d.l.rectlonof nose R center inreference to the imaginarytQQftip.

. " . : .

~;j;{pir~~tionof nose R center in reference to the imagi~&~t~OI'~t~P isexpres~~ in the.'.fOIiOWingtwo

~¥i~~,s':..:. " . . '.;'~f~: i.' . . '

!:~a.Lt~ypos.itive a('!dneg~tive signs of X, Z compensation a.mounts

.-.":" 'Y . . . .

~~~;t~) '. .~By a P number ,.

< ;.t.:~ -". - ::." .

~~:h";Umethod' a) is used, positive and negative signs are determined from the position of the nose R

" ) center in reference to the originas in Fig. 16-7.

x+

x~

Cenler of nose R

z-

z+

. .

O

rlgln (Imaginary too lip) /

I

.. /

Fig. 16-7 Signs of Compensation Amount by Nose R Center Position

With method b). coded numbers are assIgned in advance for In9ivldual nose R center pOSition

orientation to distrngulSh the dlrectrons

P=3

P=7

P=2

..

..

P=9

..

. -.

:: ".:!::~

:i.'. "'....

:~.". ~~~_!.,

P=6

. -.

...

When P =

Setting Compensation Amounts

Set the toolcompensation amounl at lhe NOSER COMPcolumns al the TOOL DATASET screen.

The compensalion amounls can be set in the same manner as selting tool offset amounls.

Orientation of nose R cenler in reference to the imaginary tool tip may be set either by positive or

negative sign preceding the compensation amount or P number. If P numbers are used. set the

number al P column.

Tool Offset and Nose R Compensation Data Setting Screen

a) Monochrome specificalion

J. .

oJ

-:''J 0 L [> t-.T.to SET

F-a 1 .6. t.Uf"r'!'t

£1.:°19

r<'. T

1

-

;;

.

E.

-

E:

1(\

11 C.00C' e.0OO O.EeJ 0.000

1

L>:::;T [..:oTI=<

. TOOL OFT ,. ,. rf.:IS[-P. Corf" ..

,:.

.:0

H

,:,

,:,

..

:.

:.

:..

:-: I-.

O.eoo

('. ooe- a.000

0.000

0.000 e.eoo a.eoo

('\.000

".eeo

c,oeo

6. eoc,

C.OOl'

". eoc.

Q.el'C O.eoc' O.e0C'

.

0.000

:1. XI. :A

6.000

e.eeo e.eoo 0.000

0.000 0.000'

a.BOO 0.000 C.OO0

o.eoo a.BOO 0.000

0.000 0.0OC' C.000

a.BOO O.l'CO 0.000

'0.000 O.OOC 0.000

e.eoo

..

.roo.0I:.'(, :::. .!OO.OOO T("'J_

('. 00CI

'JlM5rG8

LJiIT 1......

I . .~..

N

e

0.000

0.000

C.OOO

C.0l¥'

.,.;',:'."

'-

/1conditl~Cf:pfl'J+Radiusyc)+e"~tion F~~~,~i"~:f"...' ..~~''!,;1i''

J The OSP5020UOSP5000l-G series u~uaUy operates it) .t~e ~-.buffe( mode. See fig~',~1ti;,,9..

While the positioning commarid from'Point:"a:to'j>Oin18:i$ being<'~xecute(f;.the positi~~s;{~int

dataofpointsC, Dand E arereadarnistoredinbuffer\This iscaUedthe 3-buffer.fu~tion>:'. .

~hon th~. tool nose. radius function.is ;activated, the targei1>fi~t:.E.is::cal~u~at~..fi'o.~\~J.~~~ht

hnes DE and EF. This means that the data '.in'the block four >blocks ahead the currefl~:target.

'.~.point are reaq ifthe toolnose radiusfu~ctionsis actW~. i,} . c':_<>;/

Reading point

~, .' : ~ '-."":.>' .. . '. .- " ,;.,f,-..:::.::-\.:d;;_:~:.;;....

The fourth positioning point

F

E

Loading...

Loading...