Program construction

Program:

The most controller are using as a job control

language the symbols from the DIN66025.

After this the partprogram are contains a

sequence of lines.

A line contains several words.

A word contains a letter and a number.

Part program:

N10 G50 S2500

N20 G0 X500 Z500

N30 G0 X50 Z2 T0101 G97 S2500 M3 M8

24

OKUMA

Line:

N20 G0 X500 Z500

Word:

X 500

Address Number

The separate line contains:

• Program technical information.

• Geometrical information.

• Technical information.

24

OKUMA

Program technical information:

For the execution of the program are necessary.

For example : + Plus

— Minus

. decimal point

Geometrical information.

Means motion of some axis in the machine, the

word for the motion is from that address G

( Engl. Word for Go ) and some numbers behind.

The most important G commands are:

G00 positioning

G01 linear interpolation

24

OKUMA

Technical information.

F = Feedrate

T = Tool

S = Spindlespeed

M = additional function

For example:

F – command = F0.25 ( mm/rpm )

T – command = T0101 ( Tool no. 1 )

S – command = S1000 ( 1000 rpm )

M – command = M03 ( spindle direction CW )

25

OKUMA

Main Address Characters

Main Address Characters

•N Block Number

• G Preparatory Function (See List)

• X Diameter Value

• Z Length Value

• F Feedrate (mm/min or mm/rev)

• (or Dwell time in seconds)

• S Spindle Speed (m/min or rev/min)

• T Turret Station/Offset Number

• M Miscellaneous Function (See List)

M––

M

M – function are help function, just to

switch on some additional function, e.g.

coolant on or off, C –axis on or off.

Function

Function

25

OKUMA

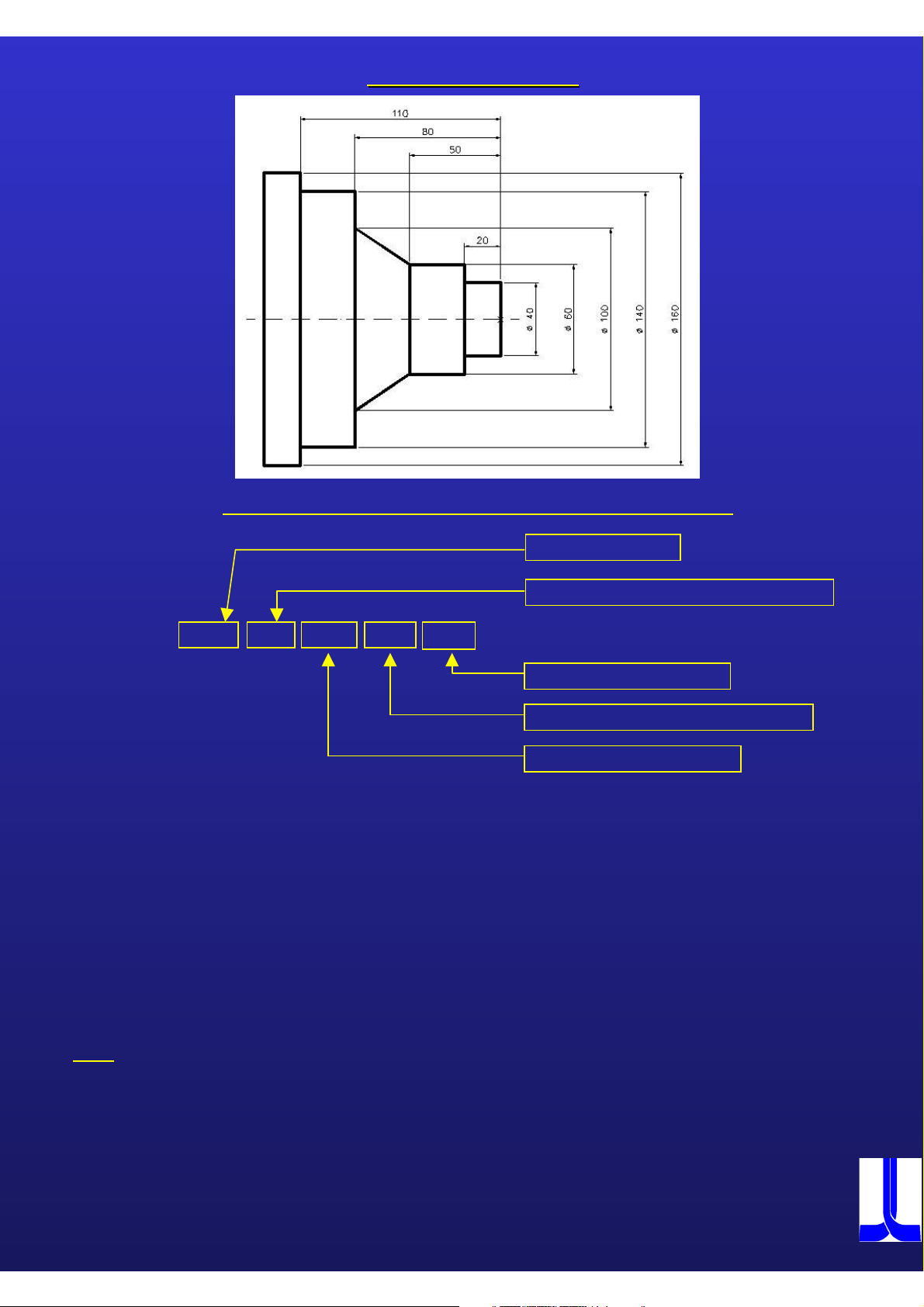

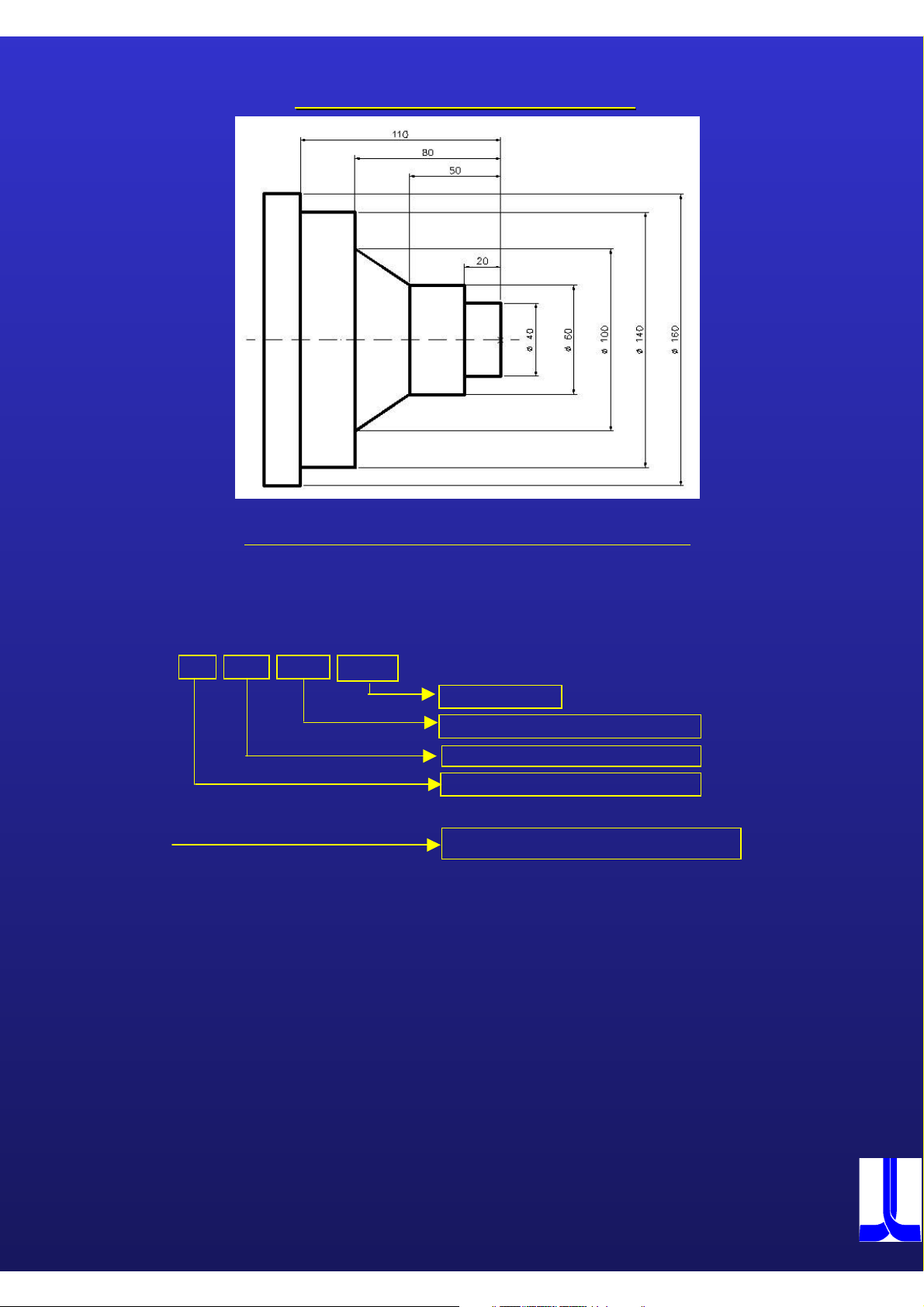

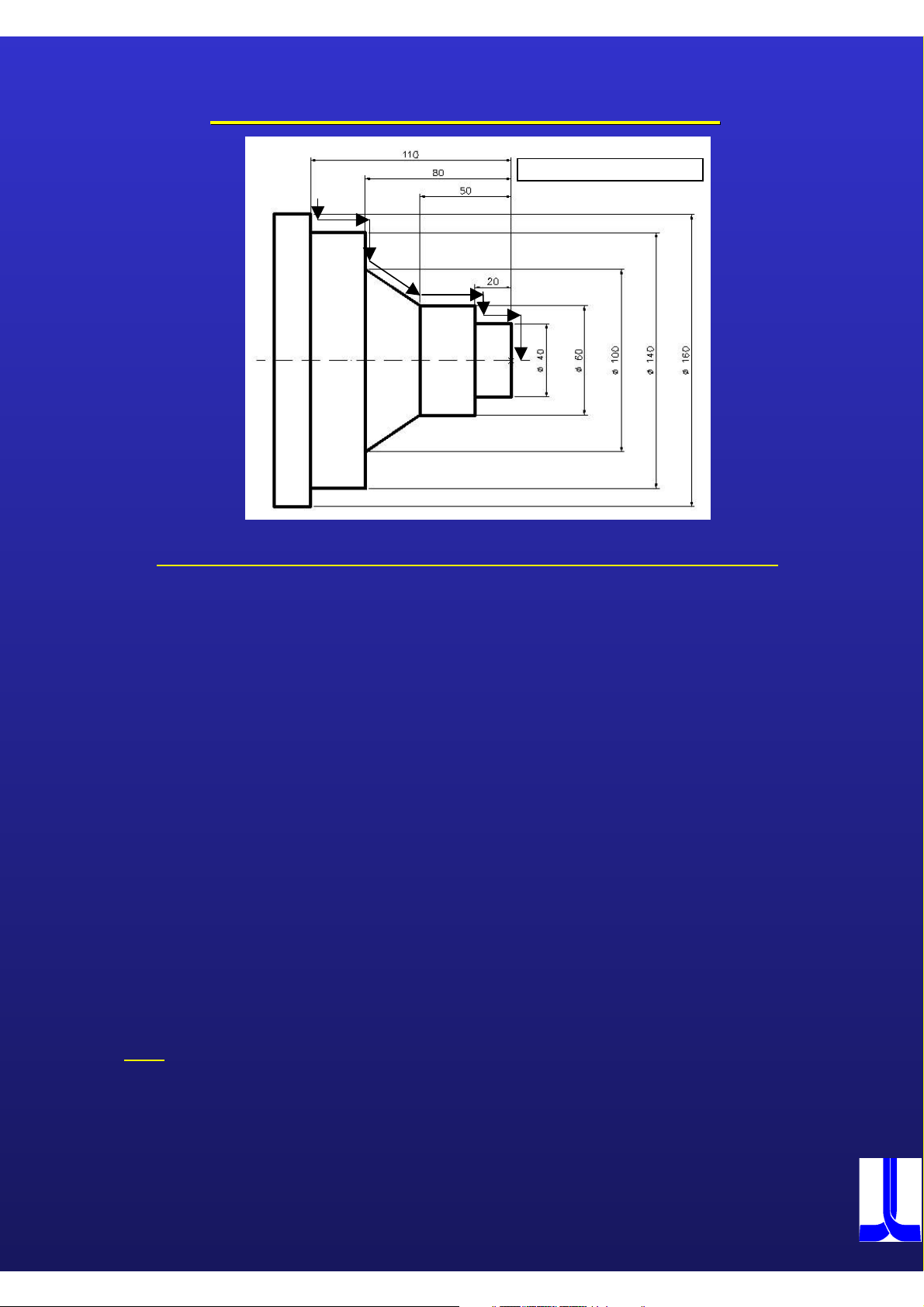

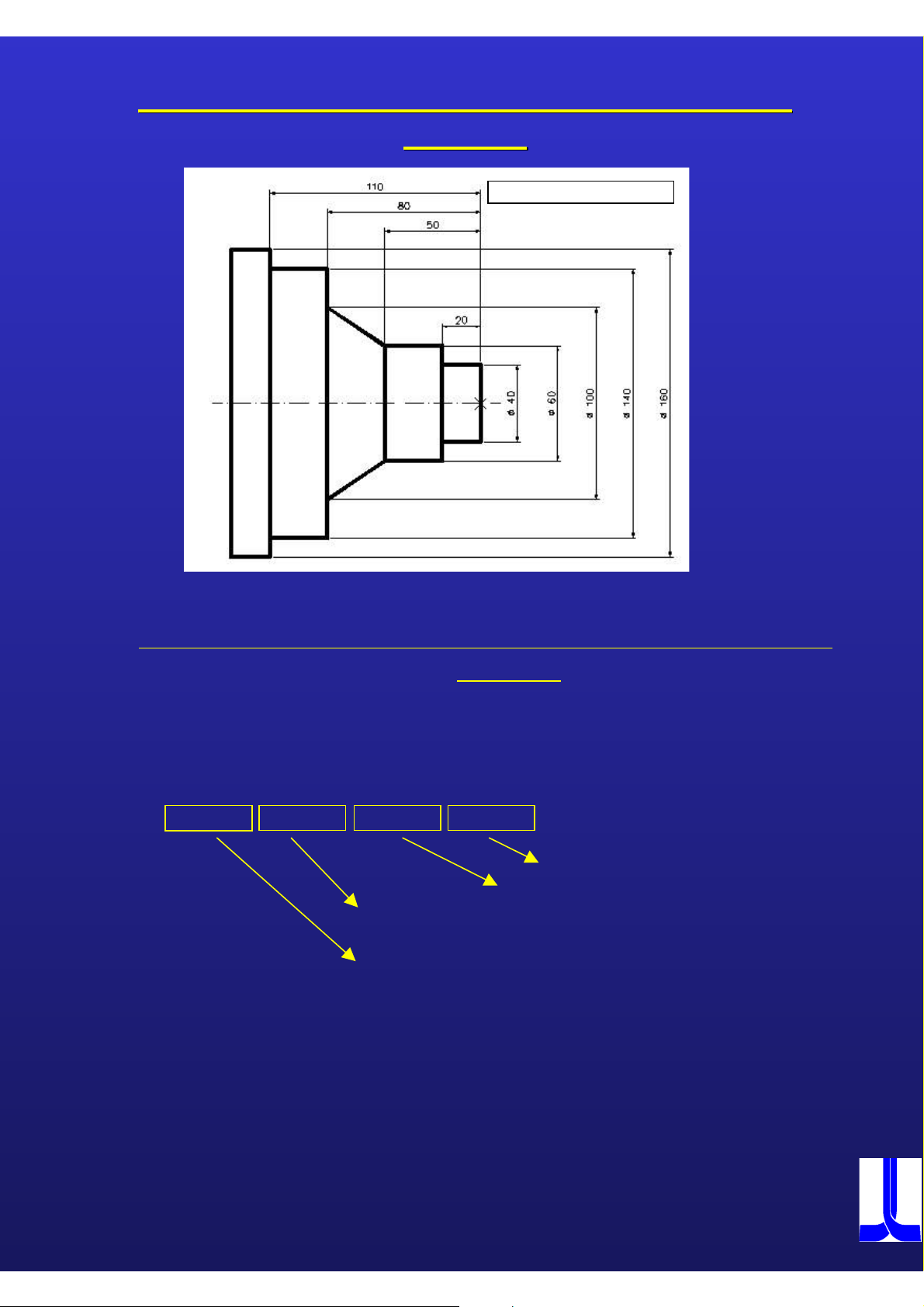

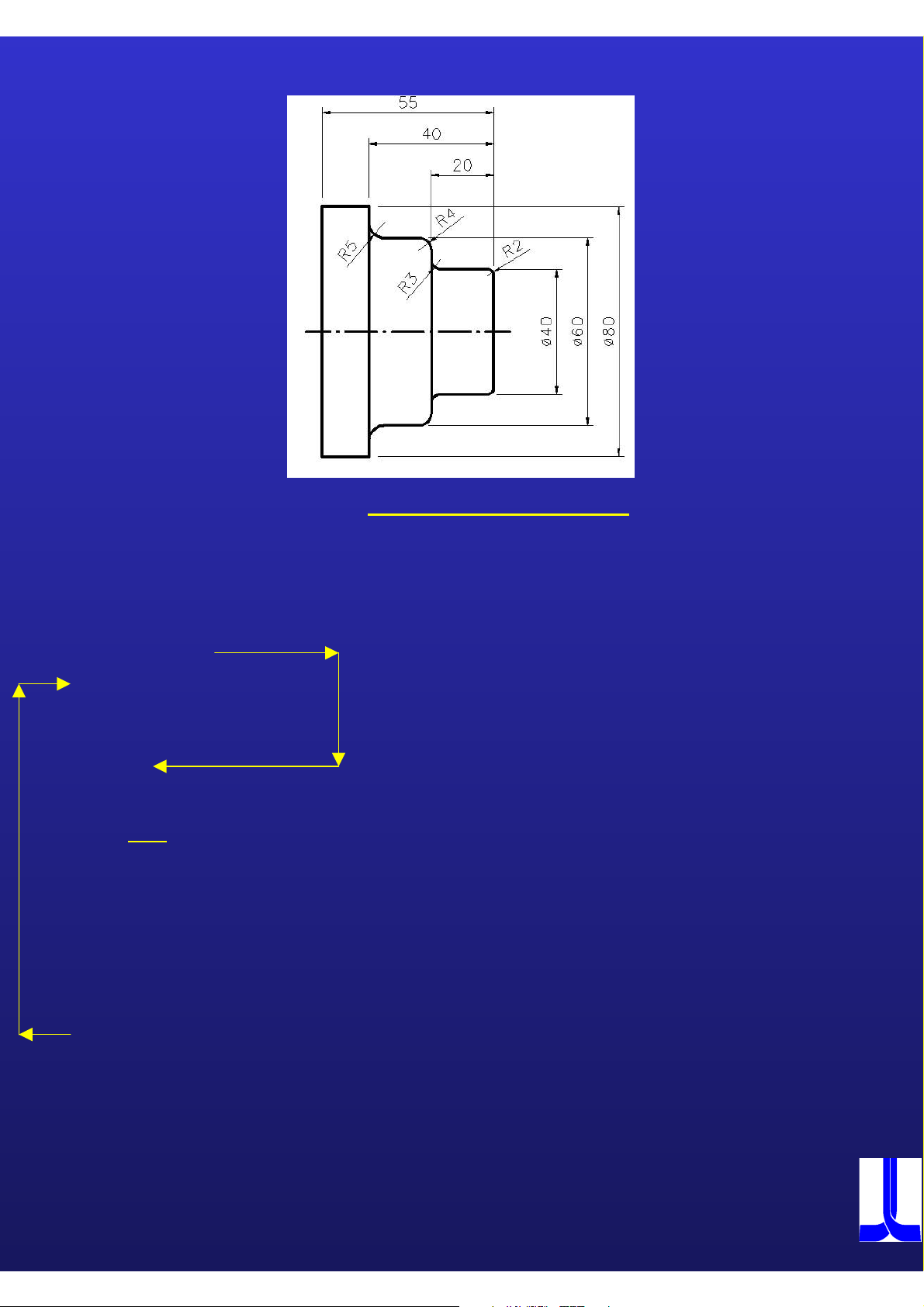

Lesson with G01

Lesson with G01

Program construction for 2 axis lathe machine

G50 S4500

G00 X500 Z500

G00 X0 Z2 T0101 G96 S250 M03 M08

G01 Z0 F0.15

G01 X40

G01 Z-20

G01 X60

G01 Z-50

G01 X100 Z-80

G01 X140

G01 Z-110

G01 X160

G01 Z-130

G00 X500 Z500 M09

M02

Tool command

G Code for constant cutting speed

M- code coolant on

M-code for spindle direction

Cutting speed in m/min

Note

The G00 command means that the machine will move with rapid feedrate , the rapid feedrate

is dependent on the machine. The unit for rapid feedrate is m/min.

The G01 command means that the machine will move with feedrate, therefore it is necessary

to program in the first line with G01 a feedrate command.

The address for feedrate is ”F ” for example F0.25 = 0.25mm by one rotation of the spindle

OKUMA

Lesson with G85 Lap cycle

Lesson with G85 Lap cycle

Program construction for G85 Lap cycle

G50 S4500

G00 X500 Z500

G00 X160 Z2 T0101 G96 S250 M03 M08

G85 NAP1 D5 U0.5 W0.1 F0.35

F = Feedrate

W = Stock removal in Z

U = Stock removal in X

D = Cuttingdepth in diameter

NAP1 G81 G81 = Cutting direction in Z - axis

G01 X0 Z0

X40

Z-20

X60

Z-50

X100 Z-80

X140

Z-110

X160

G80

G00 X500 Z500 M09

M02

27

OKUMA

Exercise G85 /G81

Exercise G85 /G81

28 ( 29 )

OKUMA

Lesson G85 Lap Cycle in X --

Lesson G85 Lap Cycle in X

Blank material D= 162

Direction

Direction

Program construction for G85 Lap cycle in X -Direction

G50 S4500

G00 X500 Z500

G00 X162 Z2 T0101 G96 S250 M03 M08

G85 NAP1 D4 U0.5 W0.1 F0.35

NAP1 G82

G0 Z-110

G1 X140

G1 Z-80

G1 X100

G1 X60 Z-50

G1 Z-20

G1 X40

G1 Z0

G80

G00 X500 Z500

M02

Note

Please consider, the G82 contour description start from the spindle and will go in

direction of the tailstock.

30

OKUMA

Exercise G85 / G82

Exercise G85 / G82

31 ( 32 )

OKUMA

Lesson G85 Lap Cycle in Z ––

Lesson G85 Lap Cycle in Z

contour definition

contour definition

Blank material D= 162

direction with blank

direction with blank

G50 S4500

G00 X500 Z500

G00 X165 Z2 T0101 G96 S250 M03 M08

G85 NAP1 D4 U0.5 W0.1 F0.35

NAP1 G83 G – Code for blank material

G0 X0 Z5

G1 X45

G1 Z-15

G1 X65 Z-45

G1 X105 Z-75 Blank material definition

G1 X145

G1 Z-105

G1 X170

G81 G – Code for longitudinal shape designation

G0 X0 Z2

G1 Z0

G1 X40

G1 Z-20

G1 X60 Z-50 Finish shape

G1 X100 Z-80

G1 X140

G1 Z-110

G1 X160

G1 Z-130

G1 X162

G80

G00 X500 Z500

M02 33

OKUMA

Exercise G85 / G83

)

Exercise G85 / G83

34 ( 35

OKUMA

Lesson G85 Lap Cycle with G84 changing cutting

Lesson G85 Lap Cycle with G84 changing cutting

condition

condition

Blank material D= 162

Program construction for G85 Lap cycle with changing cutting

condition

G50 S4500

G00 X500 Z500

G00 X165 Z2 T0101 G96 S250 M03 M08

G85 NAP1 D4 U0.5 W0.1 F0.35

$ G84

NAP1 G81

G00 X0 Z2

G01 Z0 F0.1

G01 X40

G01 Z-20

G01 X60

G01 Z-50

G01 X100 Z-80

G01 X140

XA=100 ZA=2 DA=1 FA=0.1

Feedrate

Cutting depth

Start point in Z for reduction of

the cutting condition

Start point in X for reduction of

the cutting condition

G01 Z-110

G01 X160

G80

G00 X500 Z500

M02

OKUMA

Lesson G87 Lap Cycle finish cutting cycle

Lesson G87 Lap Cycle finish cutting cycle

Blank material D= 162

Program construction for G87 finish cutting cycle

Program construction for G87 finish cutting cycle

G50 S4500

G00 X500 Z500

( OD Rough )

G00 X162 Z2 T0101 G96 S250 M03 M08

G85 NAP1 D4 U0.5 W0.1 F0.35 G84 XA=100 ZA=2 DA=1 FA=0.1

NAP1 G81

G00 X0 Z2

G01 Z0 F0.1

G01 X40

G01 Z-20

G01 X60 Z-50

G01 X100 Z-80

G01 X140

G01 Z-110

G01 X160

G01 Z-130

G80

G00 X500 Z500

( OD Finish )

G00 X165 Z2 T0202 G96 S250 M03 M08

G87 NAP1

G00 X500 Z500

M02

37

OKUMA

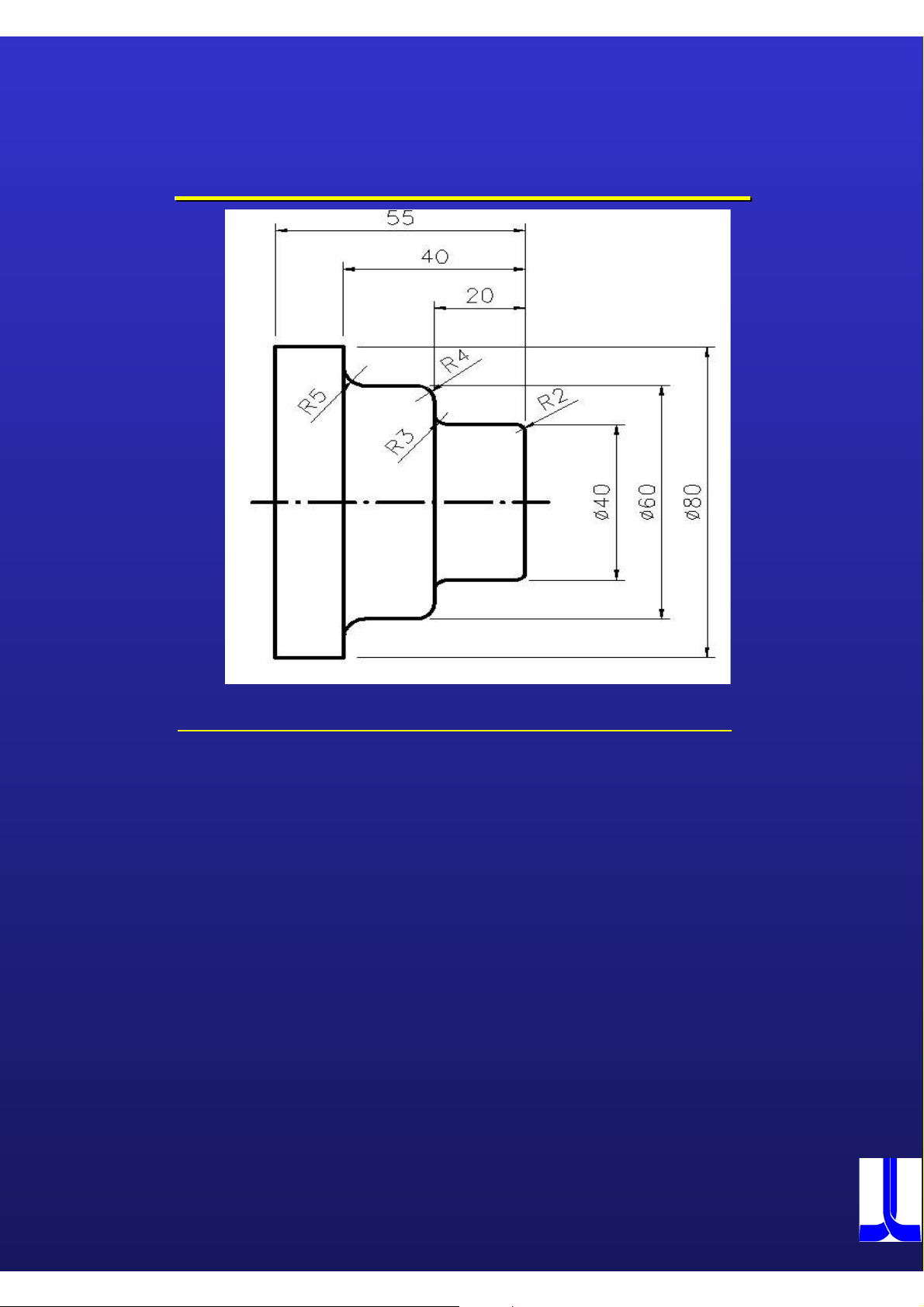

Lesson G76 automatic rounding

Lesson G76 automatic rounding

Program construction for G76 automatic rounding

G50 S4500

G00 X500 Z500

G00 X165 Z2 T0101 G96 S250 M03 M08

G00 X0

G01 Z0 F0.1

G01 G76 X40 L2

G01 G76 Z-20 L3

G01 G76 X60 L4

G01 G76 Z-40 L5

G01 X85

G00 X500 Z500 M09

M02

38

OKUMA

Lesson G75 automatic chamfering

Lesson G75 automatic chamfering

Program construction for G75 automatic chamfering

G50 S4500

G00 X500 Z500

G00 X165 Z2 T0101 G96 S250 M03 M08

G00 X0

G01 Z0 F0.1

G01 G75 X40 L2

G01 G75 Z-20 L3

G01 G75 X60 L4

G01 G75 Z-40 L5

G01 X85

G00 X500 Z500 M09

M02

39

OKUMA

Lesson Taper cutting by angle designation and G76

Lesson Taper cutting by angle designation and G76

function

function

Program construction for Taper cutting by angle designation and

G76 function

G50 S4500

G00 X500 Z500

G00 X165 Z2 T0101 G96 S250 M03 M08

G00 X0

G01 Z0 F0.1

G01 X40

G01 G76 Z-17.5 A170 L30

G01 G76 Z-37.5 A150 L5

G01 X85

G01 X105 A120

G01 Z-55

G01 X110

G00 X500 Z500 M09

M02

40

OKUMA

A VALUE

DIRECT ANGLE COMMAND

135°

-225°

180°

-180°

90°

-270°

START POINT

OF ANGLE

0°

41

270°

-90°

OKUMA

Lesson Taper cutting

Lesson Taper cutting

by

angle designation and G76

by

angle designation and G76

function

function

Program construction for Taper cutting by angle designation

and G76 function

G50 S4500

G00 X500 Z500

G00 X165 Z2 T0101 G96 S250 M03 M08

G00 X0

G01 Z0 F0.1

G01 X40

G01 G76 Z-17.5 A170 L30

G01 G76 Z-37.5 A150 L5

G01 X85

G01 X105 A120

G01 Z-55

G01 X110

G00 X500 Z500 M09

M02

42

OKUMA

43 ( 44 )

OKUMA

Lesson G71 thread cutting

Lesson G71 thread cutting

Program construction for G71 thread cutting cycle

G71 X 47.4 Z-40 H2.6 D0.25 U0.04 B60 F2 M73 M33

G50 S2500

G00 X500 Z500

G0 X54 Z4 T0101 G97 S510 M3 M8

Thread cutting mode

Infeed pattern

Pitch

Infeed angle

Stock removal

First cutting depth

Thread height

Z - coordinate for end point

Final diameter of thread

G71 X47.4 Z-40 H2.6 D0.25 U0.04 B60 M73 M33

G00 X500 Z500

M2

Note:

In case of G71 cycle it is not possible to use G96 command.

45

OKUMA

Lesson G71 thread cutting cycle

Lesson G71 thread cutting cycle

B60 M32

Straight Infeed along thread

Face ( left Face )

Cuttingdepth calculation:

B60 M33

Zig zag Infeed

B60 M34

Straight Infeed along thread

Face ( right Face

)

M73 Infeed is made by D ( in diameter ) in each thread cutting cycle up

to the point D mm away from ” H –U (W) position. After that point is

reached, Infeed amount change to D/2 D/4 D/8, leaving stock

removal U (W) if specified. And in the finishing cycle, Infeed is made as

much as the specified amount U (W). ( until 800 Kg / mm² )

M74 Infeed is made by D ( in diameter ) until the point is away from ” H –U

(W) position . ( Aluminium, Brass, plastic )

M75 Infeed is made always by the same chip section . ( from 800 Kg / mm² )

46

OKUMA

Lesson G73 Grooving cycle

Lesson G73 Grooving cycle

Program construction for G73 grooving cycle

G73 X20 Z-70 K4 D2 L10 E0.2

Dwell time

Total Infeed amount to the cutting start point

Depth of cut per peck feed

Shift amount to the startpoint

Endpoint in Z

Final diameter in X

G50 S2500

G00 X500 Z500

G00 X62 Z-24 T0404 G96 S150 M3 M42 M08

G73 X20 Z-70 K4 D2 L10 E0.2 F0.15

G00 X500 Z500

M02

47

OKUMA

Lesson G74 Drill cycle

Lesson G74 Drill cycle

Program construction for G74 drill cycle

G74 X0 Z-70 D20 L40 E0.2

Dwell time

Total Infeed amount to the cutting start point

Depth of cut per peck feed

Final point in Z

End point in X

G50 S2500

G00 X500 Z500

G00 X0 Z4 T0404 G97 S1500 M3 M42 M08

G74 X0 Z-70 D20 L40 E0.2 F0.15

G00 X500 Z500

M02

48

OKUMA

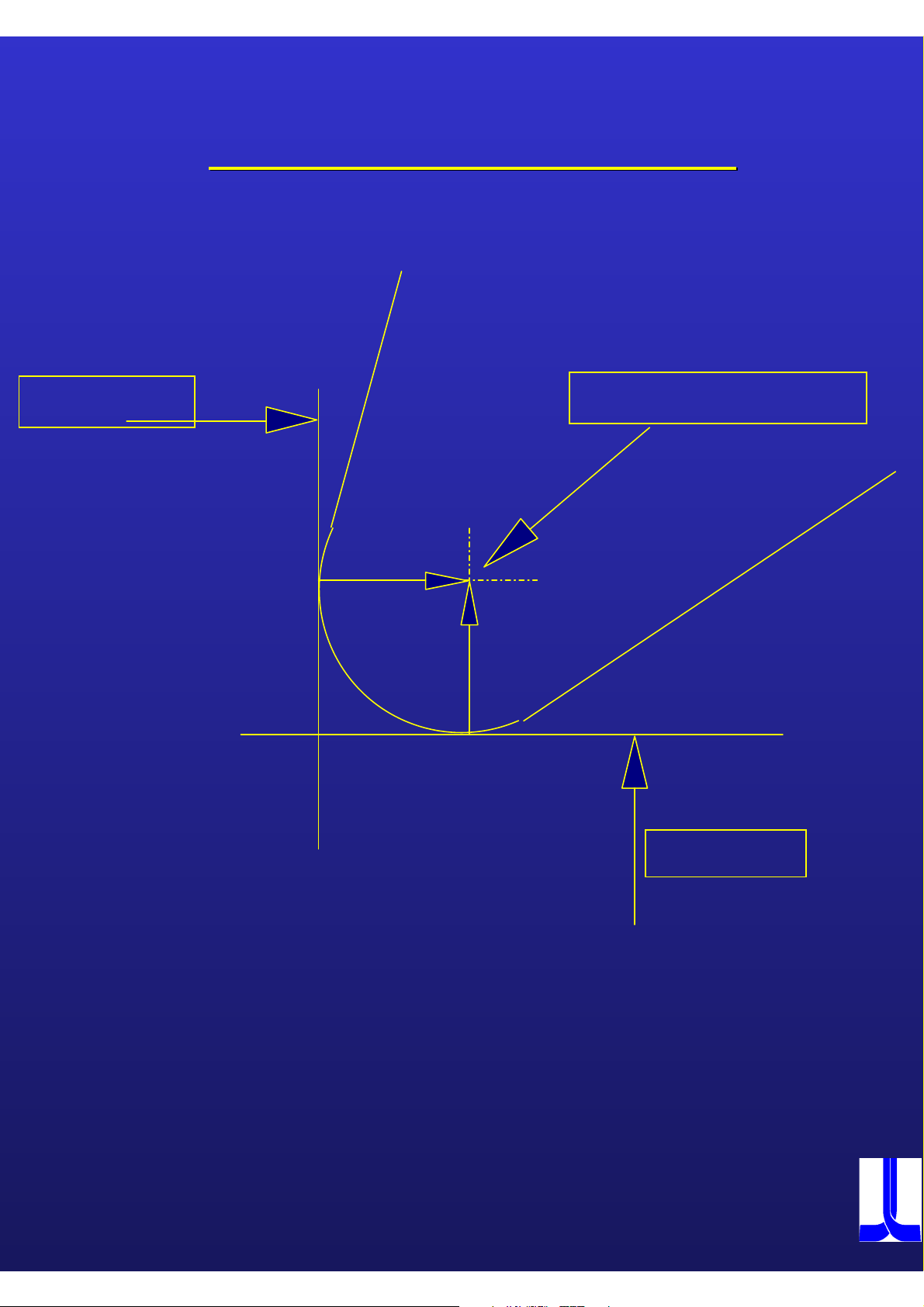

Lesson

Lesson

Recognition aid for different cutting direction during

works with automatic cutting radius compensation.

Cutterradius

Cutterradius

compensation

compensation

One sees in the direction of feedrate (arrows) and the tool is to

the right of the outline, than it is necessary to program G42.

If is to the left there of the cutting direction then, the command

must be G41.

49

OKUMA

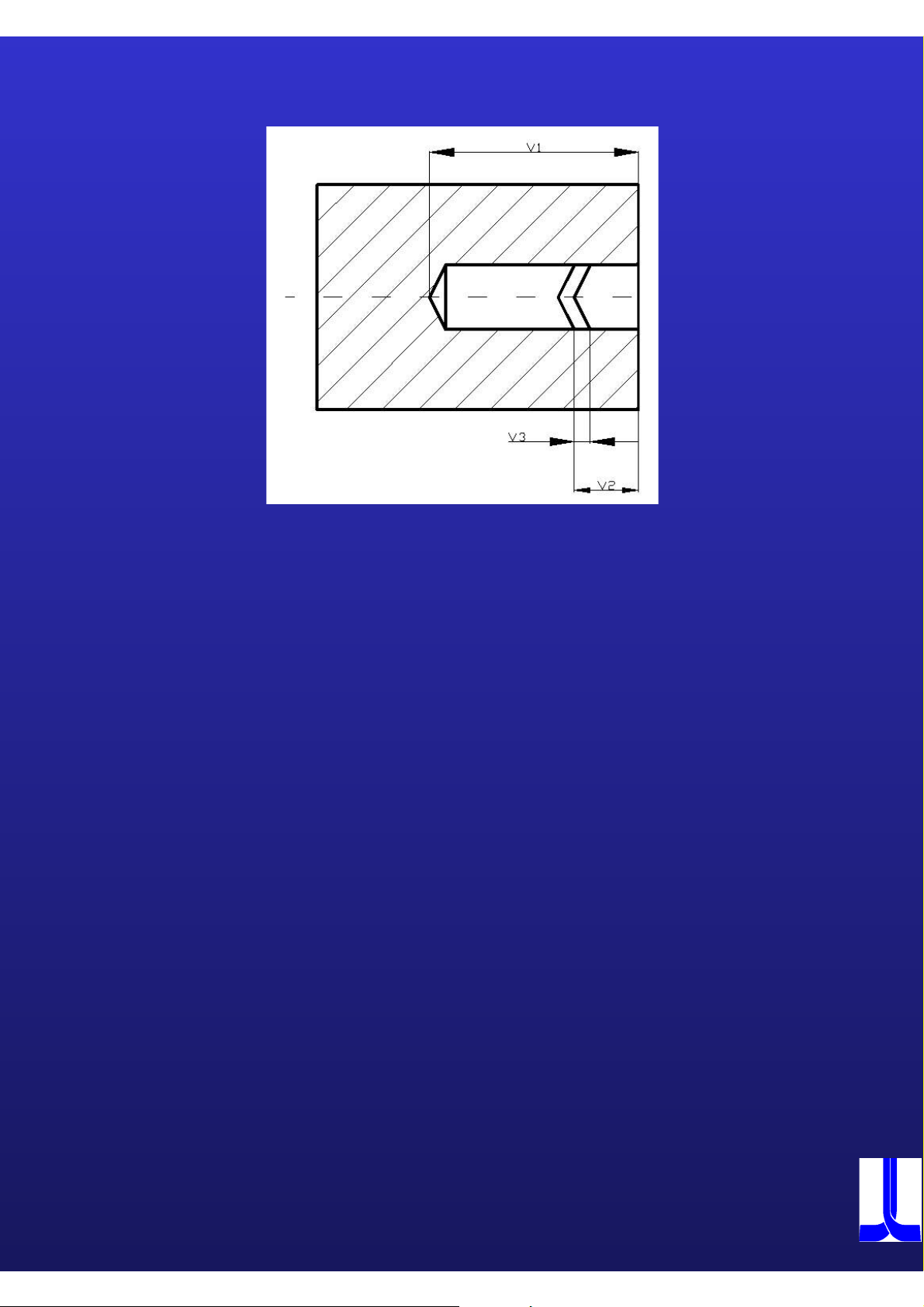

Lesson

Lesson

Cutterradius

Cutterradius

compensation

compensation

Z OFFSET

RADIUS CENTRE

50

X OFFSET

OKUMA

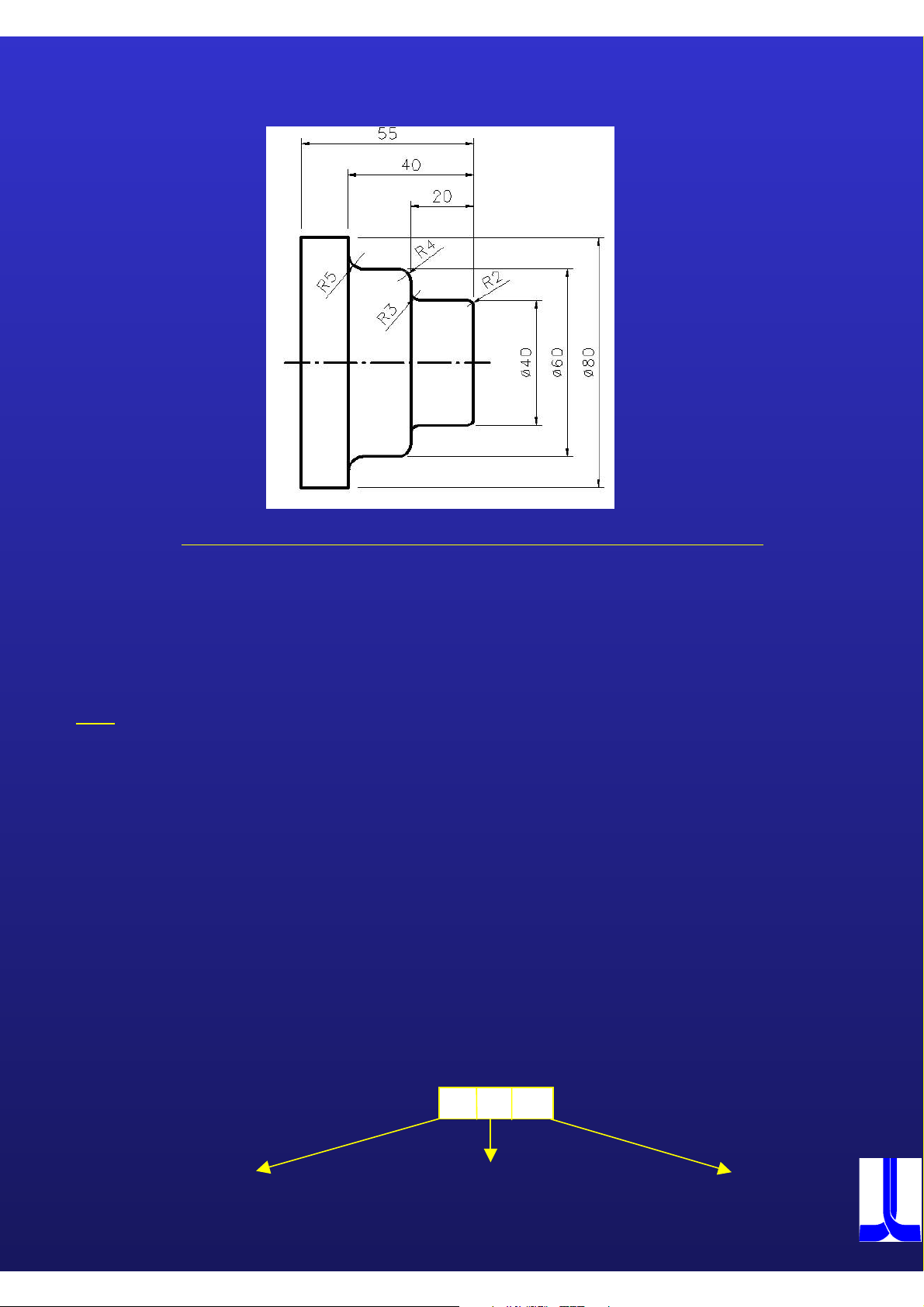

Lesson G41/G42 Cutter radius compensation

Lesson G41/G42 Cutter radius compensation

Program construction for cutter radius compensation

G50 S4500

G00 X500 Z500

G00 X165 Z2 T010101 G96 S250 M03 M08

G00 X0

G01 G42

G01 G76 X40 L2

G01 G76 Z-20 L3

G01 G76 X60 L4

G01 G76 Z-40 L5

G01 X85

G40

G00 X500 Z500 M09

M02

Note:

Z0 F0.1

If it is necessary to use G41 / G42 than the tool command must change to T010101.

01 01 01

T 01 01 01

Radius-offset Position on Turretdisk Tool-offset

51

OKUMA

Lesson Sub program calling

Lesson Sub program calling

Program construction

G50 S4500

G00 X500 Z500

G00 X165 Z2 T010101 G96 S250 M03 M08

CALL OSUB

G00 X500 Z500 M09

M02

OSUB

G00 X0

G01 G42

G01 G76 X40 L2

G01 G76 Z-20 L3

G01 G76 X60 L4

G01 G76 Z-40 L5

G01 X85

G40

Z0 F0.1

RTS

Note:

To call an Subprogram in a main program it is necessary the use the command ” CALL ”

The subprogram name must begin with an " O " and may have not more than 4 signs.

The subprogram must end with command ” RTS ” .

52

OKUMA

Macro’s

Macro’s

What is a Macro?

A group of instructions, which are

possible to store and called as an

unit, this make it possible the reduce

the time of programming for

repeatable jobs or family parts.

53

OKUMA

Variables Function:

In OSP controller it is possible to use 5 kind of Variable.

1.)Common variables

2.)Local variables

Common Variables

The term ”common” in ”common variables” can be literally understood as common; they can be used in

common for main and subprograms. When the same variable is used in two or more programs, the

variable number used in those programs must be identical. Therefore, a common variable, the result of

calculation in one program, can be referred to in other programs.

[Format]

V numerals = numerical data or expression

Common variable designations consist of up to three digits following ”V”. The usable common variables

are V1 through 200.

Examples:

N101 V5 = 10

N101 V5 = V5 + 1

[Details]

- Common variables are effective both in main programs and subprograms.

- Common variables are not affected by resetting the control or turning power off. That is, the

data are retained unless they are re-set or a control software is installed.

- Besides setting or changing them in a program, common variables can be set or changed by

setting a parameter. For detailed information on parameter setting, refer to SECTION

PARAMETER SETTING, DATA OPERATION in OPERATION MANUAL.

Local Variables

As is apparent from the term ”local”, local variables are the variables that a user can set as desired with

meaningful names assigned to them. Up to 127 local variables each can be used for the A and B saddles.

[Format]

Letter Letter two alphanumeric = Numerical data or expression

O, N and V cannot be used.

Example: ‘DlA1’ ‘ITH5’

54

OKUMA

[Details]

A local variable cannot be assigned the same name as already used for a

function name, comparison operator, Boolean operator, or extended address

character.

Extended address characters are provided to realise LAP, pattern processing,

and user-specific fixed cycles. They are necessary because there are not

enough letters in the alphabet to cover the required number of extension

names. The following extended address characters are currently used.

<AA> <AB> <DA> <DB> <FA> <FB> <IA> <IB> <KA> <KB>

<LA> <LB> <RA> <RB> <SA> <SB> <TA> <TB> <UA> <UB>

<WA> <WB> <XA> <XB> <ZA> <ZB> <BC> <BR>

Characteristics of Local Variables

- Local variables are cleared when the control is reset.

- When a new local variable is set in a main program, that is, when data is

assigned to a new local variable name, that local variable name and

corresponding data are registered in the memory.

NOTICE

If a local variable name is used without

- When new data is assigned to a local variable already registered with other

data, that old data is updated.

N0010 DIA1 = 160

In N0010, numerical data "160" is assigned to local variable

:

name "DIA1", and this data remains effective up to sequence

:

:

N0049. In N0050, the new numerical data "200" is assigned

to the same local variable name "DlA1". This clears the old

setting any data for it, an alarm results.

N0049

data "160" and replaces it with the new data "200"

N0050 DIA1 = 20

:

:

:

- Up to 127 local variables can be used.

55

OKUMA

Lesson with common variable

Lesson with common variable

Program construction with common variable

V1=40

V2=20

V3=60

V4=50

V5=100

V6=80

V7=140

V8=110

V9=160

G50 S4500

G00 X500 Z500

G00 X=V9 Z2 T0101 G96 S250 M03 M08

G01 X0 Z0

X=V1

Z=-V2

X=V3

Z=-V4

X=V5 Z=-V6

X=V7

Z=-V8

X=V9

G00 X500 Z500 M09

M02

56

OKUMA

DIA1=40

LEN2=20

DIA3=60

Lesson with local variable

Lesson with local variable

Program construction with local variable

LEN4=50

DIA5=100

LEN6=80

DIA7=140

LEN8=110

DIA9=160

G50 S4500

G00 X500 Z500

G00 X=DIA9 Z2 T0101 G96 S250 M03 M08

G01 X0 Z0

X=DIA1

Z=-LEN2

X=DIA3

Z=-LEN4

X=DIA5 Z=-LEN6

X=DIA7

Z=-LEN8

X=DIA9

G00 X500 Z500 M09

M02

67

OKUMA

Arithmetic Operation Function

This function allows arithmetic operation using variables. The programming can be

done in the same way as for general arithmetic expressions.

Address character, Extended address character, Variable = Expression

The expression on the right-hand side, requesting an arithmetic operation, is made

up of constants, variables, comparison expressions, and operators.

The arithmetic and comparison expressions are described below.

1. )Arithmetic Expression

2.) Comparison Expression

58

OKUMA

3. ) Function

V1= V1 * SIN [V3]

V1= V1 * COS [V3]

V1= V1 * TAN [V3]

V1 = ATAN [V2]

V1 = ATAN2 [2]

V1 = SQRT [V2]

V1 = ABS [V2]

V1 = BIN [V2]

V1 = BCD [V2]

V1 = ROUND [V2]

V1 = FIX [V2]

V1 = FUP [V2]

V1 = DROUND [V2]

V1 = DFIX [V2]

V1 = DFUP [V2]

V1 = MOD [V2/V3]

59

OKUMA

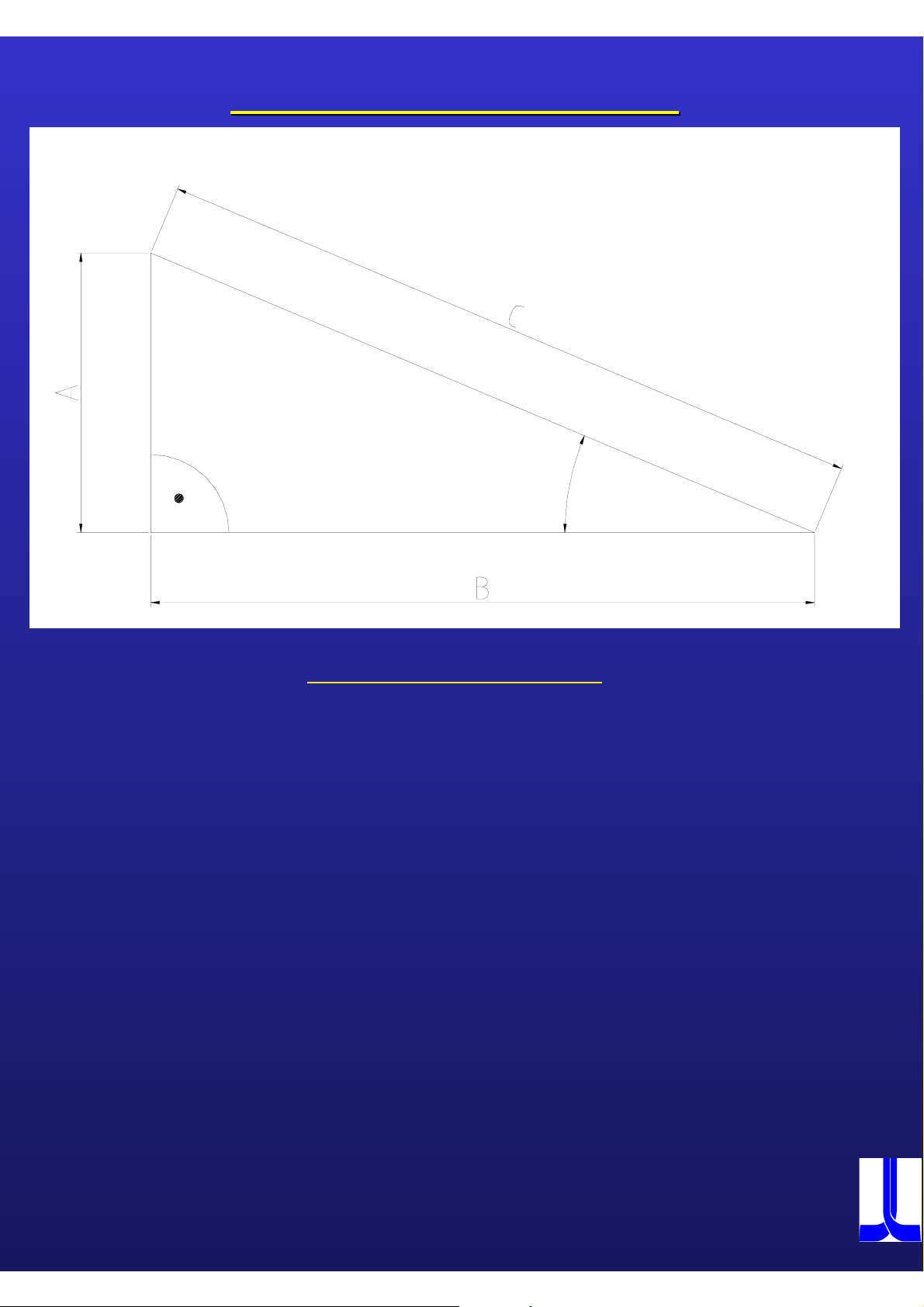

Lesson for triangle calculation

Lesson for triangle calculation

Formula for calculate the sides of a triangle: A² + B²=C² ( Pythagorean )

A = 25

B = 55

C = ?

One possibility for calculation.

V1=25

V2=55

V10=V1*V1 (625)

V11=V2*V2 (3025)

V12=V10+V11 (3650)

V13=SQRT[V12] (60.415)

M2

Another possibility for calculation

V1=25

V2=55

V3=SQRT[[V1*V1]+[ V2*V2]]

M2

A maximum of seven pairs of [ ] can used.

60

OKUMA

Lesson for triangle calculation

Lesson for triangle calculation

D

Tan D = ----- Sin D = ----- Cos D = -----

A = 25

B = 55

C = 60.415

D = ?

V1=25

V2=55

V3=60.415

Formula for angle calculation:

AAB

BCC

V10=V1/V2 ( 0.454545)

V11=ATAN[V10] (24.444°)

M2

61

OKUMA

Exercise for triangle calculation

Exercise for triangle calculation

E

D

Exercise:

Please calculate

Side A and B and angle E

We have:

C = 75.716

D = 32.335

Solution:

62

OKUMA

Practical Exercise

Practical Exercise

Please make a macro for the workpiece shape above.

63

OKUMA

Example for make an counter program with alarm

Example for make an counter program with alarm

message

message

V1=0

V2=20

N10

N20

.

.

.

.

.

.

N90

N100

V1=V1+1

IF[V1 GE V2] NALM

GOTO N10

NALM VUACM[1]='COUNTER OVER'

VDOUT[992]=4711

M2

Alarm message programming

VUACM[1] = 'COUNTER OVER'

System Variable Alarm message max. 16 characters

VDOUT [ 992 ] =

System Variable

4711

Alarm A,B or C

Alarm number designing by operator

64

OKUMA

Test

Test

Please make a macro for the deep hole drilling, after every step, drill should retract

at the Z - position where the macro starts.

V1=50 ( Z – endpoint of hole )

V2=5 ( Depth of cut per peck feed )

V3=0.5 ( Approaching distance )

OKUMA

Loading...

Loading...