okuma OSP E100 Instruction Manual

GAUGING SYSTEMS

OSP-E100M / OSP-E10M

INSTRUCTION MANUAL

(8th Edition)

Pub No. 4297-E-R6 (ME51-221-R8) Aug. 2004

4297-E P-(i)

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The machine is equipped with safety devices which serve to protect personnel and the machine itself from hazards arising from unforeseen accidents. However, operators must not rely exclusively on these safety devices: they must also become fully familiar with the safety guidelines presented below to ensure accident-free operation.

This instruction manual and the warning signs attached to the machine cover only those hazards which Okuma can predict. Be aware that they do not cover all possible hazards.

1.Precautions Relating to Machine Installation

(1)Install the machine at a site where the following conditions (the conditions for achievement of the guaranteed accuracy) apply.

•Ambient temperature: 17 to 25°C

•Ambient humidity: 40% to 75% at 20°C (no condensation)

•Site not subject to direct sunlight or excessive vibration; environment as free of dust, acid, corrosive gases, and salt spray as possible.

(2)Prepare a primary power supply that complies with the following requirements.

•Voltage: 200 V

•Voltage fluctuation: ±10% max.

•Power supply frequency: 50/60 Hz

•Do not draw the primary power supply from a distribution panel that also supplies a major noise source (for example, an electric welder or electric discharge machine) since this could cause malfunction of the CNC unit.

•If possible, connect the machine to a ground not used by any other equipment. If there is no choice but to use a common ground, the other equipment must not generate a large amount of noise (such as an electric welder or electric discharge machine).

(3)Installation Environment

Observe the following points when installing the control enclosure.

•Make sure that the CNC unit will not be subject to direct sunlight.

•Make sure that the control enclosure will not be splashed with chips, water, or oil.

•Make sure that the control enclosure and operation panel are not subject to excessive vibrations or shock.

•The permissible ambient temperature range for the control enclosure is 0 to 40°C.

•The permissible ambient humidity range for the control enclosure is 30 to 95% (no condensation).

•The maximum altitude at which the control enclosure can be used is 1000 m (3281ft.).

2.Points to Check before Turning on the Power

(1)Close all the doors of the control enclosure and operation panel to prevent the entry of water, chips, and dust.

(2)Make absolutely sure that there is nobody near the moving parts of the machine, and that there are no obstacles around the machine, before starting machine operation.

(3)When turning on the power, turn on the main power disconnect switch first, then the CONTROL ON switch on the operation panel.

4297-E P-(ii)

SAFETY PRECAUTIONS

3.Precautions Relating to Operation

(1)After turning on the power, carry out inspection and adjustment in accordance with the daily inspection procedure described in this instruction manual.

(2)Use tools whose dimensions and type are appropriate for the work undertaken and the machine specifications. Do not use badly worn tools since they can cause accidents.

(3)Do not, for any reason, touch the spindle or tool while spindle indexing is in progress since the spindle could rotate: this is dangerous.

(4)Check that the workpiece and tool are properly secured.

(5)Never touch a workpiece or tool while it is rotating: this is extremely dangerous.

(6)Do not remove chips by hand while machining is in progress since this is dangerous. Always stop the machine first, then remove the chips with a brush or broom.

(7)Do not operate the machine with any of the safety devices removed. Do not operate the machine with any of the covers removed unless it is necessary to do so.

(8)Always stop the machine before mounting or removing a tool.

(9)Do not approach or touch any moving part of the machine while it is operating.

(10)Do not touch any switch or button with wet hands. This is extremely dangerous.

(11)Before using any switch or button on the operation panel, check that it is the one intended.

4.Precautions Relating to the ATC

(1)The tool clamps of the magazine, spindle, etc., are designed for reliability, but it is possible that a tool could be released and fall in the event of an unforeseen accident, exposing you to danger: do not touch or approach the ATC mechanism during ATC operation.

(2)Always inspect and change tools in the magazine in the manual magazine interrupt mode.

(3)Remove chips adhering to the magazine at appropriate intervals since they can cause misoperation. Do not use compressed air to remove these chips since it will only push the chips further in.

(4)If the ATC stops during operation for some reason and it has to be inspected without turning the power off, do not touch the ATC since it may start moving suddenly.

5.On Finishing Work

(1)On finishing work, clean the vicinity of the machine.

(2)Return the ATC, APC and other equipment to the predetermined retraction position.

(3)Always turn off the power to the machine before leaving it.

(4)To turn off the power, turn off the CONTROL ON switch on the operation panel first, then the main power disconnect switch.

4297-E P-(iii)

SAFETY PRECAUTIONS

6.Precautions during Maintenance Inspection and When Trouble Occurs

In order to prevent unforeseen accidents, damage to the machine, etc., it is essential to observe the following points when performing maintenance inspections or during checking when trouble has occurred.

(1)When trouble occurs, press the emergency stop button on the operation panel to stop the machine.

(2)Consult the person responsible for maintenance to determine what corrective measures need to be taken.

(3)If two or more persons must work together, establish signals so that they can communicate to confirm safety before proceeding to each new step.

(4)Use only the specified replacement parts and fuses.

(5)Always turn the power off before starting inspection or changing parts.

(6)When parts are removed during inspection or repair work, always replace them as they were and secure them properly with their screws, etc.

(7)When carrying out inspections in which measuring instruments are used - for example voltage checks - make sure the instrument is properly calibrated.

(8)Do not keep combustible materials or metals inside the control enclosure or terminal box.

(9)Check that cables and wires are free of damage: damaged cables and wires will cause current leakage and electric shocks.

(10)Maintenance inside the Control Enclosure

a)Switch the main power disconnect switch OFF before opening the control enclosure door.

b)Even when the main power disconnect switch is OFF, there may some residual charge in the MCS drive unit (servo/spindle), and for this reason only service personnel are permitted to perform any work on this unit. Even then, they must observe the following precautions.

•MCS drive unit (servo/spindle)

The residual voltage discharges two minutes after the main switch is turned OFF.

c)The control enclosure contains the NC unit, and the NC unit has a printed circuit board whose memory stores the machining programs, parameters, etc. In order to ensure that the contents of this memory will be retained even when the power is switched off, the memory is supplied with power by a battery. Depending on how the printed circuit boards are handled, the contents of the memory may be destroyed and for this reason only service personnel should handle these boards.

(11)Periodic Inspection of the Control Enclosure

a)Cleaning the cooling unit

The cooling unit in the door of the control enclosure serves to prevent excessive temperature rise inside the control enclosure and increase the reliability of the NC unit. Inspect the following points every three months.

•Is the fan motor inside the cooling unit working?

The motor is normal if there is a strong draft from the unit.

•Is the external air inlet blocked?

If it is blocked, clean it with compressed air.

4297-E P-(iv)

SAFETY PRECAUTIONS

7.General Precautions

(1)Keep the vicinity of the machine clean and tidy.

(2)Wear appropriate clothing while working, and follow the instructions of someone with sufficient training.

(3)Make sure that your clothes and hair cannot become entangled in the machine. Machine operators must wear safety equipment such as safety shoes and goggles.

(4)Machine operators must read the instruction manual carefully and make sure of the correct procedure before operating the machine.

(5)Memorize the position of the emergency stop button so that you can press it immediately at any time and from any position.

(6)Do not access the inside of the control panel, transformer, motor, etc., since they contain highvoltage terminals and other components which are extremely dangerous.

(7)If two or more persons must work together, establish signals so that they can communicate to confirm safety before proceeding to each new step.

8.Symbols Used in This Manual

The following warning indications are used in this manual to draw attention to information of particular importance. Read the instructions marked with these symbols carefully and follow them.

DANGER

DANGER

WARNING

WARNING

CAUTION

CAUTION

NOTICE

Indicates an imminent hazard which, if not avoided, will result in death or serious injury.

Indicates hazards which, if not avoided, could result in death or serious injury.

Indicates hazards which, if not avoided, could result in minor injuries or damage to devices or equipment.

Indicates precautions relating to operation or use.

4297-E P-(i)

INTRODUCTION

INTRODUCTION

Thank you very much for choosing our CNC system. This numerical control system is a expandable CNC with various features including a multi-main CPU system. Major features of the CNC system are described below.

(1)Expandable CNC with a multi-main CPU system

A multi-main CPU system on which up to seven engines (main CPUs) can be mounted is used. An excellent performance and cost effectiveness have been realized as a leader of increasingly rapid and accurate machine tools. The CNC system can be adapted to any models and variations by changing the construction of the main CPUs. The machine is controlled by a built-in PLC.

(2)Compact and highly reliable

The CNC system has become compact and highly reliable because of advanced hardware technology, including UCMB (Universal Compact Main Board), I/O link, and servo link. The ‘variable software’ as a technical philosophy of the OSPs supported by a flash memory. Functions may be added to the CNC system as required after delivery.

(3)NC operation panels

The following types of NC operation panels are offered to improve the user-friendliness.

•Color CRT operation panels

•Thin color operation panels (horizontal)

•Thin color operation panels (vertical)

One or more of the above types may not be used for some models.

(4)Machining management functions

These functions contribute to the efficient operation of the CNC system and improve the profitability from small quantity production of multiple items and variable quantity production of variations. Major control functions are described below.

a) Reduction of setup time

With increase in small-volume production, machining data setting is more frequently needed. The simplified file operation facilitates such troublesome operation. The documents necessary for setup, such as work instructions, are displayed on the CNC system to eliminate the necessity of controlling drawings and further reduce the setup time.

b) Production Status Monitor

The progress and operation status can be checked on a real-time basis on the screen of the CNC system.

c) Reduction of troubleshooting time

Correct information is quickly available for troubleshooting.

(5)Help functions

When an alarm is raised, press the help key to view the content of the alarm. This helps take quick action against the alarm.

To operate the CNC system to its maximum performance, thoroughly read and understand this instruction manual before use.

Keep this instruction manual at hand so that it will be available when you need a help.

Screens

Different screens are used for different models. Therefore, the screens used on your CNC system may differ from those shown in this manual.

4297-E P-(i)

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL |

|

|

|

BREAKAGE DETECTION FUNCTION ........................................................ |

1 |

1. |

Overview....................................................................................................................................... |

1 |

|

1-1. Displaying the Result of Gauging .......................................................................................... |

2 |

|

1-2. Function Menu....................................................................................................................... |

3 |

2. |

Automatic Tool Length Offset/Automatic Tool Breakage Detection Operation............................. |

9 |

|

2-1. Setting the Touch Sensor Zero Point .................................................................................. |

10 |

|

2-2. Setting the Tool Pot No./Tool No. Table.............................................................................. |

15 |

|

2-3. Operation Mode Designation............................................................................................... |

16 |

|

2-4. Automatic Tool Length Offset Function ............................................................................... |

18 |

|

2-5. Setting the Tool Change Position (Other Than MC-H) ........................................................ |

22 |

|

2-6. Automatic Tool Breakage Detection .................................................................................... |

23 |

|

2-7. Cycle Time Reduction for Automatic Tool Length Offset/Automatic Tool Breakage |

|

|

Detection Cycle ................................................................................................................... |

28 |

|

2-8. New Cycle Time Reduction Function for Automatic Tool Length Offset/Automatic Tool |

|

|

Breakage Detection Cycle ................................................................................................... |

30 |

3. Automatic Tool Length Offset/Automatic Tool Breakage Detection Function for |

|

|

|

Special Tools and Attachments .................................................................................................. |

34 |

|

3-1. Automatic Tool Length Offset/Automatic Tool Breakage Detection Function for |

|

|

Horizontal Tools of MCM ..................................................................................................... |

34 |

|

3-2. Operation for Automatic Tool Length Offset/Automatic Tool Breakage Detection on |

|

|

B/C-axis Attachments, 90° Angular Attachments and Extension Attachments (Option) ..... |

41 |

|

3-3. Operation of Automatic Tool Length Offset/Automatic Tool Breakage Detection with |

|

|

30° Angular Attachments (Option)....................................................................................... |

50 |

4. |

Y-axis Escape Position (MCM-B/MCR-B II/MCR-A/VH-40)........................................................ |

62 |

|

4-1. Setting the Y-axis Escape Position...................................................................................... |

62 |

|

4-2. Tool Movements during Automatic Tool Length Offset (Cutter Radius Compensation)/ |

|

|

Automatic Tool Breakage Detection Cycle .......................................................................... |

63 |

5. Interference Prevention Measures for MCV-A/MCV-A II During Execution of the |

|

|

|

Automatic Tool Length Offset/Automatic Tool Breakage Detection Cycle.................................. |

64 |

|

5-1. Touch Sensor Operation Interlock....................................................................................... |

64 |

|

5-2. Measures against Interference during Execution of the Automatic Tool Length Offset/ |

|

|

Tool Breakage Detection Cycle ........................................................................................... |

64 |

6. |

Variables Used in Subprograms ................................................................................................. |

66 |

|

6-1. Table of Subprograms and Variables .................................................................................. |

66 |

|

6-2. Table of Subprograms and Variables (MCM Horizontal Tools) ........................................... |

69 |

|

6-3. How to Use Variables .......................................................................................................... |

72 |

7. |

Cautions on Operation................................................................................................................ |

80 |

8. Program Examples ..................................................................................................................... |

82 |

|

|

8-1. Automatic Tool Length Offset .............................................................................................. |

82 |

|

4297-E P-(ii) |

|

|

TABLE OF CONTENTS |

|

|

8-2. Automatic Tool Breakage Detection .................................................................................... |

84 |

9. |

Alarm List.................................................................................................................................... |

87 |

SECTION 2 AUTOMATIC GAUGING FUNCTION ........................................................ |

94 |

|

1. |

Overview..................................................................................................................................... |

94 |

|

1-1. Dimension Check Function.................................................................................................. |

94 |

|

1-2. Automatic Zero Offset Function........................................................................................... |

94 |

2. |

Operation of the Automatic Gauging Function............................................................................ |

95 |

|

2-1. Setting the Datum Hole Zero Point...................................................................................... |

96 |

|

2-2. Touch Probe Radius Compensation.................................................................................... |

98 |

|

2-3. Touch Probe Length Offset ............................................................................................... |

103 |

|

2-4. Inner Diameter (ID) Gauging Function .............................................................................. |

105 |

|

2-5. Outer Diameter (OD) Gauging Function............................................................................ |

107 |

|

2-6. End Face Gauging Cycle................................................................................................... |

110 |

|

2-7. Saving of Gauging Cycle Results ...................................................................................... |

115 |

|

2-8. Calculating the Center and Distance between Two Points................................................ |

116 |

|

2-9. Calculating the Center and Distance between Two End Faces ........................................ |

118 |

|

2-10.Automatic Zero Offset Function........................................................................................ |

121 |

|

2-11.Copying the Touch Probe Offset Data.............................................................................. |

122 |

3. |

Automatic Gauging Function for B-/C-axis, 90° Angular and |

|

|

Extension Attachments (Option) ............................................................................................... |

123 |

|

3-1. Automatic Gauging for 90° Angular Attachment and B-/C-axis Attachment (PAB=90°)... |

125 |

|

3-2. Automatic Gauging for Extension Attachment and B-/C-axis Attachment (PAB=0°)......... |

126 |

4. |

Power ON/OFF Cycle of Renishaw's Optical Touch Probe (MP7/MP9/MP10) ....................... |

127 |

|

4-1. Power ON/OFF Cycle Commands .................................................................................... |

127 |

|

4-2. Power ON/OFF Cycle Operation ....................................................................................... |

128 |

5. |

Details....................................................................................................................................... |

130 |

|

5-1. Touch Probe Movements .................................................................................................. |

130 |

|

5-2. Approach Speed to the Workpiece.................................................................................... |

133 |

|

5-3. Variables Used in Subprograms........................................................................................ |

135 |

6. |

Touch Probe Safety Measures ................................................................................................. |

147 |

|

6-1. Checking Proximity Switch Operation ............................................................................... |

147 |

|

6-2. Replacing the Touch Probe Battery................................................................................... |

148 |

7. |

Supplementary Information....................................................................................................... |

149 |

8. |

Program Examples ................................................................................................................... |

151 |

|

8-1. ID Gauging ........................................................................................................................ |

151 |

|

8-2. OD Gauging....................................................................................................................... |

152 |

|

8-3. End Face Gauging on Z-axis............................................................................................. |

153 |

|

8-4. Distance between End Faces (X-axis direction)................................................................ |

154 |

|

8-5. Automatic Zero Offset........................................................................................................ |

155 |

|

|

4297-E P-(iii) |

|

|

TABLE OF CONTENTS |

|

8-6. Example Program for MCM Horizontal Spindle ................................................................. |

156 |

9. |

Examples of Gauging Result Display ....................................................................................... |

159 |

10.Alarm List.................................................................................................................................. |

162 |

|

|

10-1.Alarm List.......................................................................................................................... |

162 |

|

10-2.Gauging Impossible Cause Code Chart (Alarm B 2305)................................................. |

164 |

SECTION 3 GAUGING DATA OUTPUT FUNCTION .................................................. |

170 |

|

1. |

Overview................................................................................................................................... |

170 |

|

1-1. Parameters ........................................................................................................................ |

170 |

|

1-2. Output Operation ............................................................................................................... |

171 |

|

1-3. Example Program.............................................................................................................. |

172 |

|

1-4. Example of Outputs ........................................................................................................... |

173 |

|

1-5. Output Items ...................................................................................................................... |

174 |

2. |

Interface Specifications for Connecting VP-600 ....................................................................... |

175 |

|

2-1. Connection Diagram.......................................................................................................... |

175 |

|

2-2. Parameters ........................................................................................................................ |

176 |

SECTION 4 GAUGING DATA OUTPUT TO FILE ....................................................... |

177 |

|

1. |

Outline ...................................................................................................................................... |

177 |

2. |

Parameters ............................................................................................................................... |

177 |

|

2-1. NC Optional Parameter Bit ................................................................................................ |

177 |

3. |

Designation of Displaying Device ............................................................................................. |

178 |

4. |

Print Command......................................................................................................................... |

178 |

|

4-1. System Variables for Printing ............................................................................................ |

179 |

SECTION 5 MANUAL GAUGING ................................................................................ |

181 |

|

1. |

Overview................................................................................................................................... |

181 |

|

1-1. Specifications .................................................................................................................... |

181 |

|

1-2. Overview of Manual Gauging Functions............................................................................ |

182 |

|

1-3. List of Display Screens ...................................................................................................... |

186 |

2. |

Basic Operation ........................................................................................................................ |

187 |

3. |

Preparation for Gauging ........................................................................................................... |

188 |

|

3-1. Preparation for Work Gauging/Tool Length Gauging Cycles ............................................ |

188 |

|

3-2. Preparation for Cutter Radius Compensation Cycle.......................................................... |

195 |

4. |

Work Gauging........................................................................................................................... |

197 |

|

4-1. End Face Gauging (X, Y, Z) .............................................................................................. |

197 |

|

4-2. I.D. Center Gauging........................................................................................................... |

202 |

|

4-3. O.D. Center Gauging......................................................................................................... |

207 |

|

4-4. Internal Faces Center Gauging ......................................................................................... |

213 |

|

4-5. External Faces Center Gauging ........................................................................................ |

225 |

|

|

4297-E P-(iv) |

|

|

TABLE OF CONTENTS |

|

4-6. Inclination and Corner Gauging......................................................................................... |

237 |

5. |

Tool Length Gauging ................................................................................................................ |

244 |

6. |

Cutter Radius Gauging ............................................................................................................. |

247 |

7. |

Comparison and Calculation of Gauging Results ..................................................................... |

250 |

|

7-1. Transferring Gauging Results............................................................................................ |

250 |

|

7-2. Comparison with Gauging Data......................................................................................... |

252 |

|

7-3. Example of Calculation Results Display ............................................................................ |

252 |

8. |

Error List ................................................................................................................................... |

255 |

SECTION 6 INTERACTIVE GAUGING FUNCTION.................................................... |

257 |

|

1. |

Specifications............................................................................................................................ |

257 |

2. |

List of Display Screen ............................................................................................................... |

258 |

3. |

Switches ................................................................................................................................... |

259 |

|

3-1. Main Operation Panel........................................................................................................ |

259 |

|

3-2. Interactive Gauging Operation Panel ................................................................................ |

261 |

4. |

Terminology .............................................................................................................................. |

262 |

5. |

Basic Operation ........................................................................................................................ |

264 |

6. |

Outline of Interactive Gauging Function ................................................................................... |

265 |

7. |

Work Gauging Function ............................................................................................................ |

271 |

|

7-1. PARAMETER (WORK) Screen ......................................................................................... |

271 |

|

7-2. PREPARATION (WORK) Screen...................................................................................... |

272 |

|

7-3. X, Y, Z END FACE ............................................................................................................ |

278 |

|

7-4. I.D. CENTER ..................................................................................................................... |

282 |

|

7-5. O.D. CENTER ................................................................................................................... |

285 |

|

7-6. INT END CENTER ............................................................................................................ |

287 |

|

7-7. EXT END CENTER ........................................................................................................... |

290 |

|

7-8. INCLINE, CORNER........................................................................................................... |

293 |

8. |

Tool Length Gauging ................................................................................................................ |

296 |

|

8-1. Parameter (Tool Length) ................................................................................................... |

296 |

|

8-2. Preparation (Tool Length).................................................................................................. |

297 |

|

8-3. Tool Length Gauging ......................................................................................................... |

300 |

9. |

Other Supplementary Explanations .......................................................................................... |

303 |

10.Operation Flow ......................................................................................................................... |

305 |

|

11.Error List ................................................................................................................................... |

306 |

|

SECTION 7 NON-CONTACT SENSOR CALCULATION FUNCTION......................... |

308 |

|

1. |

What is Non-contact Sensor? ................................................................................................... |

308 |

2. |

Outline ...................................................................................................................................... |

309 |

3. |

Maker's Subprogram in the Movable Sensor Mode.................................................................. |

310 |

4. |

Maker's Subprogram in the Fixed Sensor Mode....................................................................... |

330 |

|

4297-E P-(v) |

|

|

TABLE OF CONTENTS |

|

5. |

Maker's Subprogram for Gauging a Vertical Spindle Tool in the Fixed Sensor Mode.............. |

331 |

6. |

Maker's Subprogram for Gauging a Horizontal Spindle Tool in the Fixed Sensor Mode.......... |

345 |

7. |

List of Alarms ............................................................................................................................ |

359 |

SECTION 8 NON-CONTACT SENSOR GAUGING FUNCTION FOR |

|

|

|

HORIZONTAL MC ................................................................................... |

360 |

1. |

What is Non-contact Sensor? ................................................................................................... |

360 |

2. |

Outline ...................................................................................................................................... |

361 |

3. |

Gauging with the Fixed Sensor................................................................................................. |

361 |

4. |

Each Manufacturer's Subprogram for the Fixed Sensor........................................................... |

362 |

5. |

List of Alarms ............................................................................................................................ |

380 |

SECTION 9 SPECIAL BARRIER FUNCTION FOR HORIZONTAL MC ...................... |

381 |

|

1. |

Outline ...................................................................................................................................... |

381 |

2. |

Detailed Specifications ............................................................................................................. |

381 |

|

2-1. Parameter Setting.............................................................................................................. |

381 |

|

2-2. Setting Items...................................................................................................................... |

382 |

|

2-3. Barrier Range Setting Example ......................................................................................... |

383 |

|

2-4. Barrier Alarm and Resetting Method ................................................................................. |

383 |

3. |

Alarms....................................................................................................................................... |

384 |

|

3-1. Alarm A.............................................................................................................................. |

384 |

SECTION 10NON-CONTACT SENSOR GAUGING FUNCTION FOR MCR-AF......... |

385 |

|

1. |

What is Non-contact Sensor? ................................................................................................... |

385 |

2. |

Outline ...................................................................................................................................... |

386 |

3. |

Manufacturer's Subprogram for the Fixed Sensor .................................................................... |

387 |

4. |

Manufacturer's Subprogram for Gauging Vertical Spindle Tools with the Fixed Sensor .......... |

387 |

5. |

List of Alarms ............................................................................................................................ |

406 |

SECTION 11NON-CONTACT SENSOR GAUGING FUNCTION FOR 30°/45° AT |

|

|

|

(103 VERSIONS) ..................................................................................... |

407 |

1. |

What is Non-contact Sensor? ................................................................................................... |

407 |

2. |

Outline ...................................................................................................................................... |

408 |

3. |

Manufacturer's Subprogram for the Fixed Sensor .................................................................... |

409 |

4. |

Manufacturer's Subprogram for 30°/45° AT Tool Gauging by the Fixed Sensor ...................... |

410 |

5. |

List of Alarms ............................................................................................................................ |

428 |

4297-E P-1

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/ AUTOMATIC TOOL BREAKAGE DETECTION FUNCTION

1.Overview

The automatic tool length offset/automatic tool breakage detection function automatically calculates the tool offset data and detects breakage (chipping) of tools such as drills, taps, reamers and boring bars.

The specifications of this function are classified into the following two types.

•Specifications for automatic tool length offset only, and

•Specifications for automatic tool length offset and automatic tool breakage detection

A touch sensor is mounted in the machine: a tool mounted in the spindle is brought into contact with this touch sensor to determine the tool offset data and to detect if the tool has been broken.

For tools which are mounted and removed without using the ATC, refer to the section Tool Management Function in the special specifications of the Operation Manual.

(1)Automatic Tool Length Offset

With the tool length offset function, the tool mounted in the spindle is brought into contact with the touch sensor to calculate the tool length. A subprogram prepared for this purpose is used for this operation.

(2)Automatic Tool Breakage Detection

With the automatic tool breakage detection function, the same contact detection cycle as used for the tool length offset function is executed to obtain the tool length.

The function compares the obtained tool length with the tool length offset data stored in the CNC memory to judge if the tool has been broken.

If the tool is found to have been broken, it is replaced with a spare tool.

4297-E P-2

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

1-1. Displaying the Result of Gauging

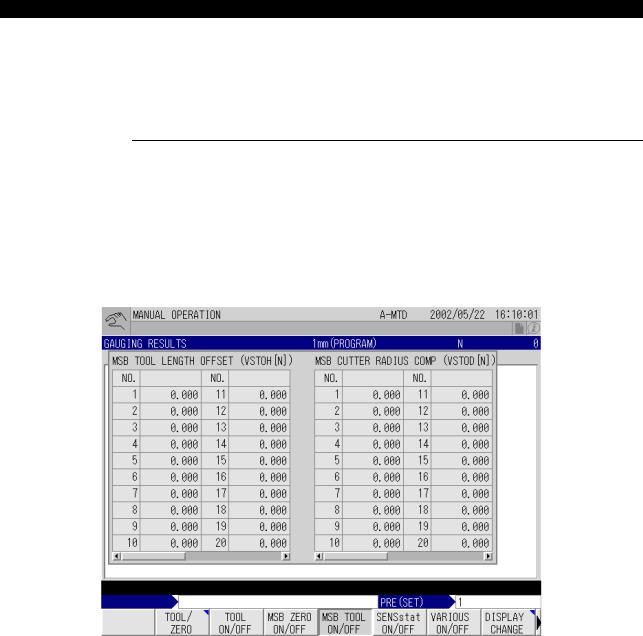

Display the screen that displays the gauging result (GAUGING RESULTS screen) by following the steps indicated below.

Procedure :

1Select an operation mode (automatic, MDI, manual).

2Press function key [F8] (DISPLAY CHANGE). The DISPLAY CHANGE window opens.

3In the DISPLAY CHANGE window, select “GAUGING RESULTS”.

4Press function key [F8] (CLOSE).

The GAUGING RESULTS screen, shown below, is displayed.

EIOEMR5S1001R01

4297-E P-3

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

1-2. Function Menu

The function menu switches as shown below to display the functions relating to the gauging result when the extend key, to the right of function key [F8] (DISPLAY CHANGE), is pressed.

EIOEMR5S1002R01

When the extend key is pressed.

|

EIOEMR5S1003R01 |

The function menu relating to gauging result processing is described below. |

|

|

|

Function Menu |

Description |

|

|

TOOL/ZERO |

Displays the presently set zero offset/tool offset number. |

|

|

MSB ZERO ON/OFF |

Displays the offset data presently set for the individual zero offset num- |

|

bers. |

|

|

MSB TOOL ON/OFF |

Displays the offset data presently set for the tool length offset number |

|

and the cutter diameter offset number. |

|

|

SENSstat ON/OFF |

Displays the value set for system variable VNCOM and the sensor con- |

|

tact status. |

|

|

VARIOUS ON/OFF |

Displays the values set for the system variables. |

|

|

For details on the function keys, refer to [1-2-1. TOOL/ZERO Function Key] to [1-2-5. VARIOUS ON/ OFF Function Key].

4297-E P-4

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

1-2-1. TOOL/ZERO Function Key

The TOOL/ZERO pop-up window displays the presently set zero offset number and tool offset numbers. To display the TOOL/ZERO pop-up window, follow the procedure indicated below.

Procedure :

1Display the GAUGING RESULTS screen.

For the procedure used to display the GAUGING RESULTS screen, refer to [1-1. Displaying the Result of Gauging].

2Press the extend key to switch the function menu.

3Press function key [F2] (TOOL/ZERO). The TOOL/ZERO pop-up window opens.

EIOEMR5S1004R01

The TOOL/ZERO pop-up window closes when function key [F2] (TOOL/ZERO) is pressed again.

4297-E P-5

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

1-2-2. MSB ZERO ON/OFF Function Key

The MSB (VSZO [N]) pop-up window displays the offset data set for the individual zero offset numbers. To display the MSB (VSZO [N]) pop-up window, follow the procedure indicated below.

Procedure :

1Display the GAUGING RESULTS screen.

For the procedure used to display the GAUGING RESULTS screen, refer to [1-1. Displaying the Result of Gauging].

2Press the extend key to switch the function menu.

3Press function key [F4] (MSB ZERO ON/OFF). The MSB (VSZO [N]) pop-up window opens.

EIOEMR5S1005R01

The MSB (VSZO [N]) pop-up window closes when function key [F4] (MSB ZERO ON/OFF) is pressed again.

4297-E P-6

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

1-2-3. MSB TOOL ON/OFF Function Key

The TOOL OFFSET/COMPENSATION pop-up window displays the offset data set for the individual tool length offset and cutter radius compensation numbers. To display the TOOL OFFSET/COMPENSATION pop-up window, follow the procedure indicated below.

Procedure :

1Display the GAUGING RESULTS screen.

For the procedure used to display the GAUGING RESULTS screen, refer to [1-1. Displaying the Result of Gauging].

2Press the extend key to switch the function menu.

3Press function key [F5] (MSB TOOL ON/OFF).

The MSB TOOL LENGTH OFFSET (VSTOH[N])/MSB CUTR RADIUS COMP (VSTOD[N]) pop-up window opens.

EIOEMR5S1006R01

The MSB TOOL LENGTH OFFSET (VSTOH[N])/MSB CUTR RADIUS COMP (VSTOD[N]) pop-up window closes when function key [F5] (MSB TOOL ON/OFF) is pressed again.

4297-E P-7

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

1-2-4. SENSstat ON/OFF Function Key

The NC COMMUNICATION (VNCOM[N]) pop-up window displays the values set for system variables VNCOM and the contact status of the sensor. To display the NC COMMUNICATION (VNCOM[N]) pop-up window, follow the procedure indicated below.

Procedure :

1Display the GAUGING RESULTS screen.

For the procedure used to display the GAUGING RESULTS screen, refer to [1-1. Displaying the Result of Gauging].

2Press the extend key to switch the function menu.

3Press function key [F6] (SENSstat ON/OFF).

The NC COMMUNICATION (VNCOM[N]) pop-up window opens.

EIOEMR5S1007R01

The NC COMMUNICATION (VNCOM[N]) pop-up window closes when function key [F6] (SENSstat ON/OFF) is pressed again.

4297-E P-8

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

1-2-5. VARIOUS ON/OFF Function Key

The VARIOUS DATA pop-up window displays the values set for the individual system variables. To display the VARIOUS DATA pop-up window, follow the procedure indicated below.

Procedure :

1Display the GAUGING RESULTS screen.

For the procedure used to display the GAUGING RESULTS screen, refer to [1-1. Displaying the Result of Gauging].

2Press the extend key to switch the function menu.

3Press function key [F7] (VARIOUS ON/OFF). The VARIOUS DATA pop-up window opens.

EIOEMR5S1010R01

The VARIOUS DATA pop-up window closes when function key [F7] (VARIOUS ON/OFF) is pressed again.

4297-E P-9

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

2.Automatic Tool Length Offset/Automatic Tool Breakage Detection Operation

A general breakdown of the operational procedure for carrying out automatic tool length and tool breakage detection functions is given below.

Setting the zero point for the touch sensor

Setting the correspondence between pot numbers/tool numbers

Executing the automatic tool length offset cycle with the tool used for setting the touch sensor zero point

Executing automatic tool length offset for other tools

Setting the tool change position data

Zero point setting is necessary only when the machine is installed.

(If higher gauging accuracy is required, however, you are recommended to set the zero point occasionally.)

When tools in the magazine are replaced, it is necessary to set the new correspondence between the tool pot numbers and the tool numbers.

Make sure that the tool length offset value is "0±0.005 mm" or "PLI setting±0.005mm".

Call the tool whose tool length offset data is to be set from the magazine and mount it in the spindle, then execute the automatic tool length offset cycle. Repeat this operation for all tools that require tool length offset data setting.

This step is not necessary for MC-H.

|

Executing automatic tool |

|

breakage detection cycle |

Tool not |

Checking for breakage |

|

|

broken |

Tool broken |

|

Pallet change, etc.

[Supplement]

Usually, the tool breakage detection cycle is executed after each cutting operation with the relevant tool is completed.

Tool length offset data must be set for tools that are checked for breakage.

The function determines whether the machining is continued as programmed or error processing is executed according to the result of the automatic tool breakage detection cycle.

This step is not necessary if the setting that specifies the machine should stop in the alarm stop state when tool breakage is detected is made.

When the setting that specifies automatic selection of a spare tool if tool breakage is detected is made, the error processing on occurrence of tool breakage should be as follows: the CNC judges that the workpiece machined using the broken tool is defective, changes the pallet to a new one and starts machining for a new workpiece.

EIOEMR5S1009R01

With a double-column machining center that has a touch sensor at a location other than the crossrail (on the table, for example), the Z-axis zero point must be set after positioning the crossrail.

4297-E P-10

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

2-1. Setting the Touch Sensor Zero Point

2-1-1. Setting the Touch Sensor Zero Point (Z-axis)

Set the Z-axis direction offset value of the touch sensor zero point using a reference tool so that the automatic tool length offset/automatic tool breakage detection function operates correctly.

NOTICE

If Y-axis has to be retracted to set the touch sensor zero point, set the Y-axis retraction position first by referring to [4. Y-axis Escape Position (MCM-B/MCR-B II/MCR-A/VH-40)].

Procedure :

1After selecting the MDI mode, input “VFST= ”, press the CYCLE START button.

Set an appropriate value for " " by referring to [2-3. Operation Mode Designation]. In this setting, either the automatic tool length offset mode or the automatic tool breakage detection cycle may be selected.

The set value can be confirmed by opening the VARIOUS DATA pop-up window on the GAUGING RESULTS screen.

EIOEMR5S1010R01

For the procedure for opening the VARIOUS DATA pop-up window, refer to [1-2-5. VARIOUS ON/OFF Function Key].

2Execute the sensor advance command M144 in the MDI mode. (In the case of a movable type sensor)

3Set the reference tool in the spindle, and manually bring the nose of the reference tool near the Z-axis touch sensor.

There will inevitably be some slight displacement between the center of the sensor and the center of the reference tool. This displacement, however, does not pose a problem for the succeeding operation.

4297-E P-11

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

[Supplement]

The “reference tool” means the tool used for setting the zero point in a work coordinate system.

4At this position, execute the following program after selecting the automatic mode. CALL OO30 PAXI=7 PLI= (VFST= )

M02

[Supplement]

The settings for PLI should be as indicated below

Offset Type |

PLl Setting |

|

|

Relative offset type |

0 |

|

|

Absolute offset type |

Length from the spindle nose |

|

face |

|

|

Usually, the tool used for zero setting of the work coordinate system is also used for the sensor zero point setting cycle. Therefore, there is no tool length difference between the tools used for the two different zero point setting cycles, and the setting for PLI should be “zero” (PLI = 0).

For the absolute offset type, set the accurate length of the tool currently set in the spindle as illustrated to the left.

If no value is set for PLI, either “PLI = 150 mm.” or “PLI = 200 mm” is assumed. Which of the values is used is determined by the machine model.

Relative offset type

PLI = 0

Absolute offset type

PLI

EIOEMR5S1011R01

[Supplement]

VFST may be set in this step instead of setting it first in the MDI mode.

As the program above is executed, the reference tool automatically comes into contact with the Z-axis touch sensor, whereupon Z-axis zero offset is executed.

Zero offset of both the X and Y axes is executed so that the present (actual) position of the reference tool becomes X = 0, Y = 0.

How the reference tool moves during the execution of the program is explained in [2-1-2. Reference Tool Movements during Z-axis Touch Sensor Zero Point Setting].

4297-E P-12

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

5Execute the sensor advance command M144 in the MDI mode. (In the case of a movable type sensor)

6Mount a small-diameter drill in the spindle.

7Bring the drill tip manually near to the touch sensor and align the spindle center (drill center) with the center of the touch sensor.

8At this position, execute the following program after selecting the automatic mode. CALL OO30 PAXI=3

M02

X- and Y-axis zero offset is executed so that the present (actual) position of the drill becomes X = 0, Y = 0. (The Z-axis does not move.)

After the execution of the X- and Y-axis zero offset, the Z-axis moves at a rapid feedrate to the travel end in the positive (+) direction and the sensor retracts, completing touch sensor zero point setting.

The result is fed back to the offset data of system work coordinate system No. 1.

The set offset data can be checked by opening the MSB ZERO OFFSET (VSZO [N]) pop-up window on the GAUGING RESULTS screen. The offset data of the X-, Y- and Z-axis is displayed at the X, Y, and Z columns of the NO. 1 line

EIOEMR5S1012R01

[Supplement]

Since system work coordinate system No. 1 is used exclusively for the automatic tool length offset and automatic tool breakage detection functions, it cannot normally be set or referenced.

For the procedure for opening the MSB ZERO OFFSET (VSZO [N]) pop-up window, refer to [1-2-2. MSB ZERO ON/OFF Function Key].

This completes the Z-axis touch sensor zero point setting.

4297-E P-13

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

2-1-2. Reference Tool Movements during Z-axis Touch Sensor Zero Point Setting

During the execution of the Z-axis touch sensor zero point setting, the reference tool moves as indicated below.

Machine operation

(1)The Z-axis moves at a rapid feedrate to the travel end in the positive (+) direction.

(2)The spindle is oriented.

(3)If the movable type sensor is used, the sensor moves back once and then moves forward.

(4)The Z-axis moves at an approach feedrate in the negative (-) direction until the reference tool comes into contact with the touch sensor.

(5)The Z-axis comes to a stop when the reference tool comes into contact with the touch sensor.

(6)The Z-axis moves at a rapid feedrate to the travel end in the positive (+) direction.

(7)If the movable type sensor is used, the sensor moves back.

2-1-3. Setting the Touch Sensor Zero Point (Y-axis)

When the specifications for automatic tool length offset and automatic breakage detection in the Y- axis direction (diameter direction) are selected, set the Y-axis touch sensor zero point retraction position first by referring to [2-4. Automatic Tool Length Offset Function].

Procedure :

1After selecting the MDI mode, input “VFST= ”, and press the CYCLE START button.

Set an appropriate value for " " by referring to [2-3. Operation Mode Designation]. In this setting, either the automatic tool length offset mode or the automatic tool breakage detection cycle may be selected.

If an appropriate value is already set for VFST, it is not necessary to set the value here.

The set value can be confirmed by opening the VARIOUS DATA pop-up window on the GAUGING RESULTS screen. For the procedure for opening the VARIOUS DATA pop-up window, refer to [1-2-5. VARIOUS ON/OFF Function Key].

2Execute the sensor advance command M144 in the MDI mode. (In the case of a movable type sensor)

3Set the reference tool in the spindle, and manually bring the nose of the reference tool near the Y-axis touch sensor.

Align the center of the reference tool with the center of the Y-axis touch sensor.

4At this position, execute the following program after selecting the automatic mode.

CALL OO30 PAXI=#17H PLI=0(or accurate length of reference tool)

PY=Accurate radius of reference tool (VFST=**)

M02

EIOEMR5S1013R01

In actual programming, the three lines of program above are expressed in one line as indicated below.

4297-E P-14

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

[Example]

CALL OO30 PAXI=#17H PLI=0 PY=10 (VFST=1)

φ or accurate length of reference tool Accurate radius of reference tool

EIOEMR5S1014R01

[Supplement]

1)When setting PLI, pay attention to the same point as explained in [2-1-1. Setting the Touch Sensor Zero Point (Z-axis)].

2)Always set PY. If it is not set, “PY = 0” is assumed.

3)VFST may be set in this step instead of setting it first in the MDI mode.

As the program above is executed, the reference tool automatically comes into contact with the Y-axis touch sensor, whereupon Y-axis zero offset is executed. Zero offset of both the Z and X axes is executed at the same time.

How the reference tool moves during the execution of the program is explained in [2-1-4. Reference Tool Movements during Y-axis Touch Sensor Zero Point Setting].

The result is fed back to the offset data of system work coordinate system No. 4.

The set offset data can be checked by opening the MSB ZERO OFFSET (VSZO [N]) pop-up window on the GAUGING RESULTS screen. The offset data of the X-, Y- and Z-axis is displayed at the X, Y, and Z columns, respectively.

[Supplement]

Since system work coordinate system No. 4 is used exclusively for the automatic tool length offset and automatic tool breakage detection functions, it cannot normally be set nor referenced.

For the procedure for opening the MSB ZERO OFFSET (VSZO [N]) pop-up window, refer to [1-2-2. MSB ZERO ON/OFF Function Key].

This completes the Y-axis touch sensor zero point setting.

2-1-4. Reference Tool Movements during Y-axis Touch Sensor Zero Point Setting

During the execution of the Y-axis touch sensor zero point setting, the reference tool moves as indicated below.

Machine operation

(1)The Z-axis moves at a rapid feedrate to the travel end in the positive (+) direction.

(2)The spindle is oriented.

(3)If the movable type sensor is used, the sensor moves back once and then moves forward.

(4)The Z-axis moves to the Y-axis touch sensor position (the position where the Z-axis was first moved manually).

(5)The Y-axis moves at an approach feedrate until the reference tool comes into contact with the touch sensor.

(6)The Y-axis comes to a stop when the reference tool comes into contact with the touch sensor.

(7)The Y-axis moves at a rapid feedrate to the approach start position.

(8)The Z-axis moves at a rapid feedrate to the travel end in the positive (+) direction.

(9)If the movable type sensor is used, the sensor moves back.

4297-E P-15

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

2-2. Setting the Tool Pot No./Tool No. Table

Set the correspondence between tool numbers and tool pot numbers in the tool pot number - tool number correspondence table.

The table setting shown below uses a machine with 10-tool capacity magazine as an example.

Assign a tool number to each tool.

Magazine capacity: 10 tools

The total number of tools user for cutting the various types of workpieces is 300.

Correspondence Table

Toolpot Number |

Tool Number |

|

|

1 |

1 |

|

|

2 |

2 |

|

|

3 |

3 |

|

|

4 |

20 |

|

|

5 |

30 |

|

|

6 |

31 |

|

|

7 |

32 |

|

|

8 |

105 |

|

|

9 |

270 |

|

|

10 |

271 |

|

|

Write the correspondence between the tool number and the pot number on the screen when tools in the magazine are to be changed for new setup.

The memory of the OSP can hold the life expectancy data of up to 300 tools.

Max. tool number:

Standard 50

Option 300

EIOEMR5S1015R01

The tool offset data obtained by the execution of an automatic tool length offset cycle is set for the same offset number as the tool number of the tool presently being used (active tool).Similarly, the tool offset number referred to and compared when the automatic tool breakage detection cycle is executed is the same offset number as the tool number of the active tool.

[Supplement]

To automatically change a tool for a spare tool, tools must be registered in a tool group.

For the procedure for registering tools in a group, refer to the Tool Management Function section of the special specifications of the Operation Manual.

4297-E P-16

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

2-3. Operation Mode Designation

The basic operation mode of automatic tool length offset and automatic tool breakage detection is designated by the system variable VFST.

Since the system variable VFST is backed up in the CNC memory, it only has to be designated once: it does not have to be set each time the MSB of the automatic tool length offset/automatic tool breakage detection cycle is called.

VFST consists of one byte (8 bits) and each bit has the following significance.

VFST |

|

Bit 7 |

|

Bit 6 |

|

Bit 5 |

Bit 4 |

|

Bit 3 |

Bit 2 |

|

Bit 1 |

Bit 0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EIOEMR5S1016R01 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit No |

|

|

Setting |

|

|

|

|

|

Description |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 0 |

|

|

0 |

Automatic tool breakage detection cycle |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

1 |

Automatic tool length offset cycle |

|

|

|

|||||||||

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Bit 1 |

|

|

1 |

Executes the automatic tool length offset/automatic tool breakage detec- |

|||||||||||

|

|

tion cycle in the Y-axis direction. |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Executes the automatic tool length offset/automatic tool breakage detec- |

|||||||||

|

|

|

|

|

|

tion cycle in the Y-axis direction after the execution of the automatic tool |

|||||||||

Bit 2 |

|

|

1 |

length offset/automatic tool breakage detection cycle in the Z-axis direc- |

|||||||||||

|

|

tion. |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

To execute automatic tool length offset/automatic tool breakage detec- |

|||||||||

|

|

|

|

|

|

tion cycle only in the Z-axis direction, set “0” for both Bit 1 and Bit 2. |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Does not move the X-axis when positioning a reference tool at the touch |

|||||||||

Bit 3 |

|

|

1 |

sensor position. |

|

|

|

|

|

|

|||||

|

|

Set “1” for Bit 3 with machine models such as MCV in which the touch |

|||||||||||||

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

sensor is installed independently of the X-axis movement. |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 4 |

|

|

0 |

Always set “0”. |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 5 |

|

|

0 |

Always set “0”. |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 6 |

|

|

0 |

Always set “0”. |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Designates the relative offset type. |

|

|

|

||||||

|

|

|

|

0 |

The tool length in reference to the reference tool used for zero point set- |

||||||||||

Bit 7 |

|

|

|

|

ting of a work coordinate system is used as the tool length offset data. |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

Designates the absolute offset type. |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

1 |

The length of the tool from the spindle nose surface is regarded as the |

||||||||||

|

|

|

|

|

|

tool length offset data. |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4297-E P-17

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

An example of VFST settings is given in the following table.

|

Relative/ |

X-axis |

|

Automatic Tool Length Off- |

VFST |

|

Model |

Absolute |

Movement |

Z-axis/Y-axis Offset |

set/Automatic Tool Break- |

||

Value |

||||||

|

Offset Type |

Yes/No |

|

age Detection |

||

|

|

|

||||

|

|

|

|

|

|

|

|

Relative |

|

|

Automatic tool length offset |

#01H |

|

|

Yes |

Only Z-axis offset |

|

|

||

|

Automatic tool breakage |

|

||||

|

offset |

#00H |

||||

MC-H |

|

|

detection |

|||

|

|

|

|

|||

MC-V |

|

|

|

|

|

|

Absolute |

|

|

Automatic tool length offset |

#81H |

||

|

Yes |

Only Z-axis offset |

|

|

||

|

Automatic tool breakage |

|

||||

|

offset |

#80H |

||||

|

|

|

detection |

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Automatic tool length offset |

#09H |

|

|

|

|

Only Z-axis offset |

|

|

|

|

|

|

Automatic tool breakage |

#08H |

||

|

|

|

|

detection |

||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Relative |

|

|

Automatic tool length offset |

#0BH |

|

|

No |

Only Y-axis offset |

|

|

||

|

Automatic tool breakage |

|

||||

|

offset |

#0AH |

||||

|

|

|

detection |

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

MCV |

|

|

Y-axis offset after Z- |

Automatic tool length offset |

#0DH |

|

|

|

|

|

|||

|

|

Automatic tool breakage |

|

|||

|

|

axis offset |

#0CH |

|||

MCR |

|

|

||||

|

|

detection |

||||

MCM |

|

|

|

|

||

|

|

|

|

|

||

|

|

|

Automatic tool length offset |

#89H |

||

(Vertical |

|

|

|

|||

|

|

Only Z-axis offset |

|

|

||

spindle) |

|

|

Automatic tool breakage |

#88H |

||

|

|

|

|

detection |

||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Absolute |

|

|

Automatic tool length offset |

#8BH |

|

|

No |

Only Y-axis offset |

|

|

||

|

Automatic tool breakage |

|

||||

|

offset |

#8AH |

||||

|

|

|

detection |

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Y-axis offset after Z- |

Automatic tool length offset |

#8DH |

|

|

|

|

|

|

||

|

|

|

Automatic tool breakage |

|

||

|

|

|

axis offset |

#8CH |

||

|

|

|

detection |

|||

|

|

|

|

|

||

|

|

|

|

|

|

[Supplement]

Refer to [3-1. Automatic Tool Length Offset/Automatic Tool Breakage Detection Function for Horizontal Tools of MCM] for details of automatic tool length offset/automatic tool breakage detection for the horizontal tools of MCM horizontal.

4297-E P-18

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

2-4. Automatic Tool Length Offset Function

The automatic tool length offset function automatically corrects the tool length according to the offset data set using the reference tool.

2-4-1. Z-axis Automatic Tool Length Offset

Automatic tool length offset in the Z-axis direction is executed in the manner indicated below.

NOTICE

Make sure that the zero point of the Z-axis touch sensor has been set before executing Z-axis automatic tool length offset. Never execute Z-axis automatic tool length offset when the Z-axis touch sensor zero point has not been set.

Procedure :

1After selecting the MDI mode, input “VFST= ”, and press the CYCLE START button. Set an appropriate value for " " by referring to [2-3. Operation Mode Designation].

The set value can be confirmed by opening the VARIOUS DATA pop-up window on the GAUGING RESULTS screen. Refer to [1-2-5. VARIOUS ON/OFF Function Key].

2Mount the tool for which automatic tool length offset is to be executed in the spindle.

When the tool is mounted in the spindle manually, make sure that the active tool number displayed on the ATC TOOL DISPLAY (MEMORY RANDOM) screen (for the ATC memory random specification) or the POT NO./TOOL NO. TABLE (FIXED ADDRESS) screen (for the ATC fixed address specification) agrees with the tool number of the tool mounted in the spindle.

This operation is not necessary when the tool is mounted in the spindle by executing the M06 command, either in automatic or MDI operation.

3Execute the following program after selecting the automatic mode. CALL OO30 (VFST= ) (PLI = Anticipated tool length)

M02

When the program is executed, the tool is automatically brought into contact with the Z-axis touch sensor and the tool length offset data is calculated and stored in the CNC memory.

The set tool length offset data can be checked by displaying the TOOL LENGTH OFFSET/ CUTTER RADIUS COMPENSATION screen of the TOOL DATA screen.

4297-E P-19

SECTION 1 AUTOMATIC TOOL LENGTH OFFSET/AUTOMATIC TOOL BREAKAGE DETECTION

The obtained results are also displayed on the GAUGING RESULTS screen

EIOEMR5S1017R01

This ends the Z-axis automatic tool length offset processing.

[Supplement]

1)VFST may be set in this step instead of setting it first in the MDI mode.

2)Set the anticipated tool length for PLI.

If no value is set for PLI, the value set for CNC optional parameter (long word) No. 43 (distance from the spindle gauge line) is automatically set as the anticipated tool length.

Machine operation

During the execution of the Z-axis automatic tool length offset, the tool moves as indicated below.

(1)The Z-axis moves at a rapid feedrate to the travel end in the positive (+) direction.

(2)The spindle is oriented.

(3)The X- and Y-axis move at a rapid feedrate to align the tool nose with the center of the touch sensor.

For tools whose nose is not at the center of the spindle, refer to items (6) PX and (7) PY in [6-3. Explanation of Variables].

(4)The Z-axis moves at a fast approach feedrate until the tool comes into contact with the touch sensor.

(5)The Z-axis comes to a stop when the reference tool comes into contact with the touch sensor.

(6)The Z-axis moves back several millimeters at a rapid feedrate.

(7)The Z-axis moves at an approach feedrate until the tool comes into contact with the touch sensor again.

(8)The Z-axis comes to a stop when the reference tool comes into contact with the touch sensor. The result of gauging is stored under the same tool length offset number as the tool number of the active tool.

(9)The Z-axis moves at a rapid feedrate to the travel end in the positive (+) direction.

Loading...

Loading...