Page 1

100-233-111 A

MTS FundamentalTM Video Extensometer

Product Information

Page 2

Copyright information © 2011 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark and MTS Fundamental is a trademark of MTS

Systems Corporation within the United States. These trademarks may be

protected in other countries.

VidéoTraction is a trademark of Iris Technologies. All other trademarks or

service marks are the property of their respective owners.

Publication information

Manual Part Number Publication Date

100-233-111 A April 2011

2

Fundamental Video Extensometer

Page 3

Contents

Technical Support 5

How to Get Technical Support 5

Before You Contact MTS 5

If You Contact MTS by Phone 7

Problem Submittal Form in MTS Manuals 8

Preface 9

Before You Begin 9

Conventions 10

Documentation Conventions 10

Video Extensometer 13

Introduction 13

Specifications 14

Version LC X 14

Version LC XY 15

Additional Specifications 16

Other lens are available: 20, 40, 50, 100, 500, 1000 mm 16

Principle of Markers Tracking 17

Two Markers 17

Four Markers 18

Seven Markers 19

Starting the Video Extensometer 21

Test Parameters 21

Test Window 26

The Main Window 26

The Test Procedure 26

Strain Visualization 30

VideoStrain Test Window 31

Software Registration 32

Installation 33

System Components 33

Fundamental Video Extensometer

3

Page 4

Connections 34

Equipment Installation 34

Camera Mounting 34

Specimen Installation 34

Lighting 34

Software Installation 35

4

Fundamental Video Extensometer

Page 5

Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes software, look for

online help and README files that contain additional product inform ation.

If you cannot find answers to your technical questions from these sources, you

can use the Internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact Technical Support in

one of the following ways.

www.mts.com The web site provides access to our technical support staff by means of an online

form:

www.mts.com > Contact MTS > Service & Technical Support button

E-mail tech.support@mts.com

Telephone MTS Call Center 800-328-2255

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Fax 952-937-4515

Please include “Technical Support” in the subject line.

Outside the U.S. For technical support outside the United States, contact your local sales and

service office. For a list of worldwide sales and service locations and contact

information, use the Global MTS link at the MTS web site:

www.mts.com > Global MTS > (choose your region in the right-hand

column) > (choose the location closest to you)

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

Fundamental Video Extensometer Technical Support

The site number contains your company number and identifies your equipment

type (such as material testing or simulation). The number is typically written on a

label on your equipment before the system leaves MTS. If you do not know your

MTS site number, contact your sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies

your system. You can find your job number in your order paperwork.

Example system number: US1.42460

5

Page 6

Know information from

prior technical

If you have contacted MTS about this problem before, we can recall your file

based on the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem and know the answers to the following questions:

• How long and how often has the problem occurred?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the equipment model numbers?

• What is the controller model (if applicable)?

• What is the system configuration?

Know relevant

computer information

Know relevant

software information

For a computer problem, have the following information available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive where the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

For software application problems, have the following information available:

• The software application’s name, version number, build number, and (if

available) software patch number. This information can typically be found

in the About selection in the Help menu.

• The names of other applications on your computer, such as:

– Anti-virus software

– Screen savers

– Keyboard enhancers

– Print spoolers

Technical Support

6

– Messaging applications

Fundamental Video Extensometer

Page 7

If You Contact MTS by Phone

A Call Center agent registers your call before connecting you with a technical

support specialist. The agent asks you for your:

• Site number

• Name

• Company name

• Company address

• Phone number where you can be reached

If your issue has a notification number, please provide that number. A new issue

will be assigned a unique notification number.

Identify system type To enable the Call Center agent to connect you with the most qualified technical

support specialist available, identify your system as one of the following types:

• Electromechanical material test system

• Hydromechanical material test system

• Vehicle test system

• Vehicle component test system

Be prepared to

troubleshoot

Write down relevant

information

After you call MTS logs and tracks all calls to ensure that you receive assistance for your

• Aero test system

Prepare to perform troubleshooting while on the phone:

• Call from a telephone close to the system so that you can implement

suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

In case Technical Support must call you:

• Verify the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions.

problem or request. If you have questions about the status of your problem or

have additional information to report, please contact Technical Support again and

provide your original notification number.

Fundamental Video Extensometer Technical Support

7

Page 8

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems with your software,

hardware, manuals, or service that are not resolved to your satisfaction through

the technical support process. The form includes check boxes that allow you to

indicate the urgency of your problem and your expectation of an acceptable

response time. We guarantee a timely response—your feedback is important to

us.

Access the Problem Submittal Form:

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form button (electronic

form to be e-mailed to MTS)

Technical Support

8

Fundamental Video Extensometer

Page 9

Preface

Before You Begin

Safety first! Before you use your MTS product or system, read and understand the Safety

manual and any other safety information provided with your system. Improper

installation, operation, or maintenance can result in hazardous conditions that can

cause severe personal injury or death, or damage to your equipment and

specimen. Again, read and understand the safety information provided with your

system before you continue. It is very important that you remain aware of

hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional manuals in paper or

electronic form.

You may also receive an MTS System Documentation CD. It contains an

electronic copy of the manuals that pertain to your test system, such as:

• Hydraulic and mechanical component manuals

• Assembly drawings

• Parts lists

• Operation manual

• Preventive maintenance manual

Controller and application software manuals are typically included on the

software CD distribution disks).

Fundamental Video Extensometer Preface

9

Page 10

Conventions

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions Hazard notices may be embedded in this manual. These notices contain safety

information that is specific to the activity to be performed. Hazard notices

immediately precede the step or procedure that may lead to an associated hazard.

Read all hazard notices carefully and follow all directions and recommendations.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury or equipment damage,

or could endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. They are examples only and do

not necessarily represent your actual system configuration, test application, or

software.

Electronic manual

conventions

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

10

Preface

Fundamental Video Extensometer

Page 11

Conventions

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

Fundamental Video Extensometer Preface

11

Page 12

Conventions

12

Preface

Fundamental Video Extensometer

Page 13

Video Extensometer

Introduction

The video extensometer is available in models for the simple longitudinal strain

to the advanced PRO and DEV models that integrate a machine control system.

This no-contact system of mechanical tests use video for the analysis of

polymers, elastomers, metals strains, and so forth.

Introduction

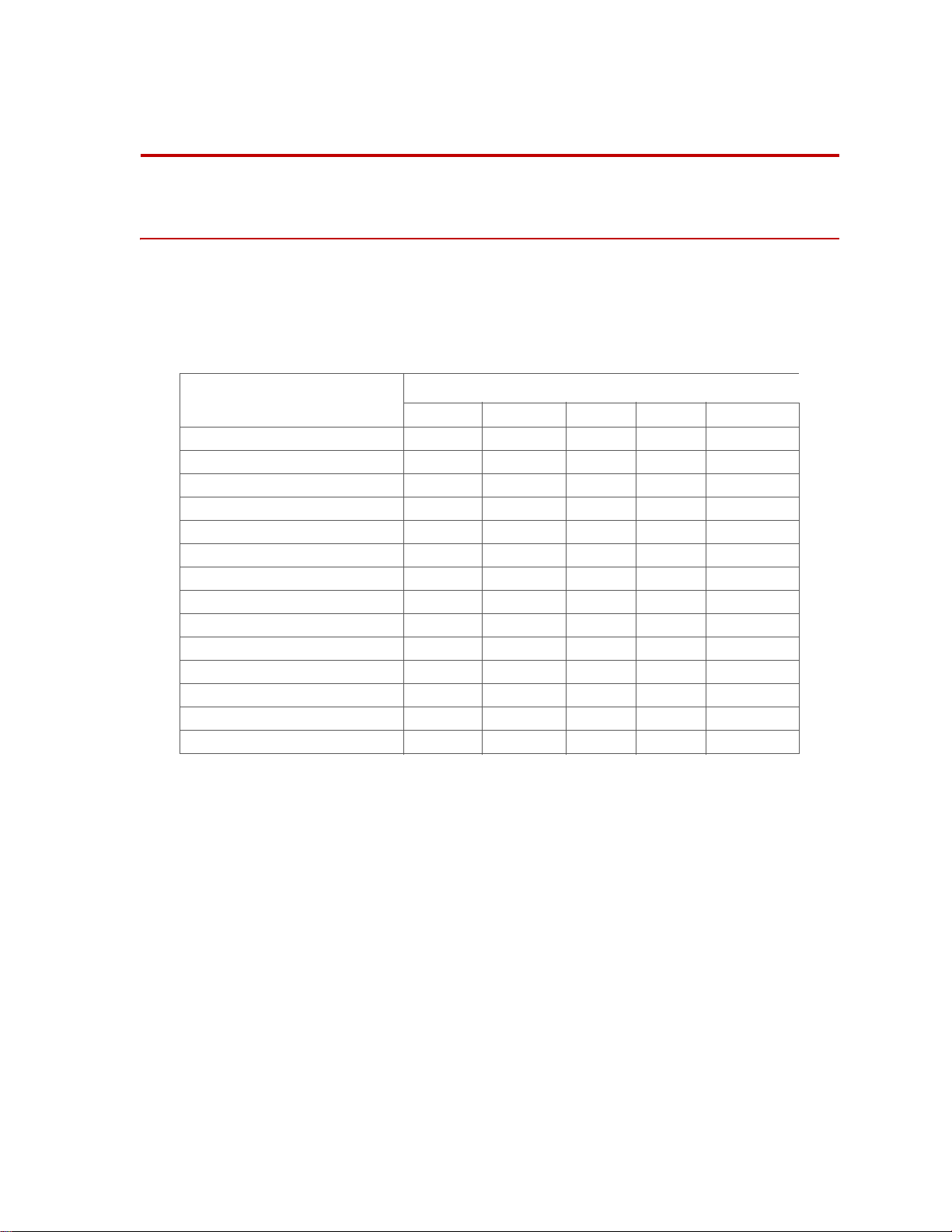

Components

DEV PRO LC X LC XY LC XY-b

Video acquisition board X X X X X

Video camera X X X X X

Standard lens X X X X X

Extension bellow X X O O O

Zoom lens X X O O O

Telescopic column X X O O O

Photo foot U U X X X

Control board X X U U U

Analog output board 0-10V U U X X X

Fluorescent Lamp X X O O O

2 markers control X X X X X

4 markers control X X U X X

5 markers control X X U U U

7 markers control X U O U X

* X = Standard; O = Optional; U= Unavailable

Version LC X allow you to measure longitudinal strain. Version LC XY allows

you to measure transverse strain. Version LC XY-b allows you to determine the

volumetric strain.

Models

*

These versions are installed on the computer provided with your tensile testing

machine and are well adapted for large strains and tests at high or low

temperature.

The principle of measurement is the following-up in real time of the barycenter

position of the markers laid out on the tensile specimen.

The system deduces the strains from the markers (

information to the control machine software either by a RS232 connection or by

transmitting +/- 10 V signal.

Fundamental Video Extensometer

ε1 and/or ε2) and sends

13

Page 14

Specifications

Specifications

Version LC X

VidéoTraction Processing Software

Measures the deformation field of a sample or plastic part during an external mechanical loading

through the displacement of marks printed (2 marks) onto the surface.

Measures axial strain.

Collects and processes video pictures of the targeted area.

Displays information through a user-friendly interface.

Sends the deformations by external signals in 0-10 V or RS232.

Mechanical tests Tensile and compression

Principle Follow-up center of gravity of marks

Operating System Windows 2000, XP, Vista

Number of marks 2

Processing frequency Until 15 Hz

Sample geometry Iso 527-specimens, cylindrical specimens, films

High Resolution Video Camera with Mounting Set

Collects monochrome pictures of the targeted area of the specimen.

Description CCD B/W video camera module

Effective picture elements 1380*1035

Lens mount C mount

Weight 110 g

Power / Consumption requirements DC12 V / 1.5 W

Tripod

Power supplied to the camera

14

Fundamental Video Extensometer

Page 15

Version LC XY

VidéoTraction Processing Software

Measures the deformation field of a sample or plastic part during an external mechanical loading

through the displacement of marks printed (2 or 4 marks) onto the surface.

Simultaneous measurement of both axial and transversal strain.

Collects and processes video pictures of the targeted area.

Displays information through an user-friendly interface including calibration routine, calibration of

both strain (%) and elongation (mm).

Sends the deformations by external signals in 0-10 V or RS232.

Mechanical tests Tensile, compression and creeping tests

Principle Follow-up center of gravity of marks

Operating System Windows 2000, XP, Vista

Number of marks 2, 4

Specifications

Processing frequency Until 15 Hz

Sample geometry Iso 527-specimens, cylindrical specimens, films

High Resolution Video Camera with Mounting Set

Collects monochrome pictures of the targeted area of the specimen.

Description CCD B/W video camera module

Effective picture elements 1380*1035

Lens mount C mount

Weight 110 g

Power / Consumption requirements DC12 V / 1.5 W

Tripod

Power supplied to the camera

Fundamental Video Extensometer

15

Page 16

Specifications

Additional Specifications

Additional Specifications

Field of View (FOV) 50 mm (2 in) 100 mm (4 in)

AXIAL MEASUREMENT

Resolution

Minimum axial gauge length 5 mm (0.2 in) 10 mm (0.4 in)

Data rates 50 Hz 50 Hz

Recommended marking 2 mm (0.08 in) diameter dots 4 mm (0.16 in) diameter dots

Alternate marking 1 mm (0.04 in) thick lines 1 mm (0.04 in) thick lines

Maximum following test speed 125 mm/min (5 in/min) 250 mm/min (10 in/min)

Resolution with chamber (axial

at 23°C)

Accuracy with chamber

Classification to ASTM E 83 Class C Class C

μm (0.12 μin) 4 μm (0.16 μin)

3

3

μm + 1 μm/25°C 4pm + 1 μm/25°C

μm or twice resolution

±6

(whichever is greater)

Other lens are available: 20, 40, 50, 100, 500, 1000 mm

±8 μm or twice resolution

(whichever is greater)

FOV 20 mm 40 mm 50 mm 100 mm 500 mm 1000 mm

Classification to IS0 9513, EN10002-4 Class 0.5 Class 1 Class 1 Class 1 Class 1 Class 1

Net Measurement Accuracy

16

0.2 μm0.5 μm0.5 μm1 μm5 μm 10 μm

Fundamental Video Extensometer

Page 17

Principle of Markers Tracking

Two Markers

Place the gage such that it is centered on the specimen (Figure 1).

Trace the two markers, by using the sites corresponding to the test chosen, using

a felt pen. The markers must be similar and have distinct edges (Figure 2). Let

dry for a few seconds.

Principle of Markers Tracking

Note If the specimens are of dark color, use a white felt pen and if the

It is also possible to have self-adhesive reflective stickers on the specimen.

Fundamental Video Extensometer

specimens are of clear color, use a black felt pen, because the software

needs a strong contrast to identify the markers correctly.

17

Page 18

Principle of Markers Tracking

Four Markers

Place the gage such that it is centered on the specimen (Figure 3).

Trace the four markers, by using the sites corresponding to the test chosen, using

a felt pen. The markers must be similar and have distinct edges. The markers

must be similar and have distinct edges (Figure 4). Let dry for a few seconds.

18

Note If the specimens are of dark color, use a white felt pen and if the

specimens are of clear color, use a black felt pen, because the software

needs a strong contrast to identify the markers correctly.

It is also possible to have self-adhesive reflective stickers on the specimen.

Fundamental Video Extensometer

Page 19

Seven Markers

Width 1

Principle of Markers Tracking

A seven-markers test makes it possible to perform a tensile test on sample with a

banded structure. The configuration allows you to measure the longitudinal strain

(by interpolation of the partial strains) in a material section where the transverse

strain is measured. Volume variation during the test is deduced with the

assumption of transverse isotropy.

The markers must be placed as indicated on the figure below:

Starting with the central marker, add two other markers on both sides at equal

distance from the central marker and the border of specimen, and then add the

last four markers along the specimen.

The four extreme markers positioned horizontally and vertically must form a

square.

If the four markers do not form a square it can cause a problem of

repeatability between specimens of the same materials and less accuracy

on the measurement.

It is very important that the four markers form a square because they define the

representative volume element which correctly defines the material behavior.

Fundamental Video Extensometer

19

Page 20

Principle of Markers Tracking

Here is the calculation of the partial strains:

The calculation of the transverse strain:

The calculation of the longitudinal deflection by interpolation of the partia l

strains:

20

Fundamental Video Extensometer

Page 21

Starting the Video Extensometer

Test Parameters

This window allows you to change test settings or to load previous tests.

Starting the Video Extensometer

Fundamental Video Extensometer

1. The Load INI button allows you to recover the characteristics of a previous

test.

2. Color of the markers allows you to choose the color of the markers used on

the specimen.

21

Page 22

Starting the Video Extensometer

OR

3. Numbers of markers: According to the version, it is possible to choose

different types of tests (see “Principle of Markers Tracking” on page 17):

• A 2-markers test allows you to track the distance between the 2

markers onto a sample, and to calculate the longitudinal strain.

• A 4-markers test is the same procedure of that for the 2 markers, with

the addition of 2 horizontal markers for calculating the transverse

strain.

• A 7-markers testis a special test for the determination of volumetric

strain.

• A sand-glass test allows you to prepare a tensile test on a cylindrical

sample with a follow-up of the strain starting from the minimum

diameter of the sample.

• A N-markers test allows you to record the coordinates of the barycenter

of each markers in a file. You must specify the number of markers

present on the specimen, not to exceed 200 markers. By default the

software records the first image with the classification of the markers

in order to link each marker with the data file. You can change the

default name of the file image by checking the Start box.

4. The strains are:

• The true strain which is calculated as Ln(L/L0).

• The nominal strain which is calculated as (L – L0)/L0.

• The relative strain which is calculated as L- L0.

• The length corresponding to the new length.

Relative strain and length are available only after a calibration procedure.

5. Average provides averaging the image number before sending it to the

testing machine. To activate this choice, check the Activating box and

indicate the number of measures to be taken into account.

6. The channel of communication is the method the testing machine uses to

receive the strain(s). If the choice of the channel is the RS232 or the 10

Volts, the values can be entered by clicking Parameters.

22

Fundamental Video Extensometer

Page 23

Starting the Video Extensometer

7. If a T elescopic column (motorized column) is available, it can be controlled

by the software to follow the marks on the specimen to measure the strain in

the longitudinal direction, until the space between the markers is too large

for the image field of the camera.

8. To record the images at various intervals during the test:

A. At the start and the end of the test by checking the corresponding

checkbox. The suffix _beginning is added to the name of the first

image, and the suffix _end is added for the last image.

B. During the test, it is possible to save the image with an interval of

strain. The interval being defined in the Seconds field, after checking

the Automatic checkbox. For filenames, the software adds the image

number and the suffix _longitudinal-strain-value.

C. These images will be saved in the Directory

<My Documents\ApollorImg> of the logged in user.

To further define the image filename, you must ent er a de sired name in the

Name for the images field; for example the specimen batch number or

operator name.

Fundamental Video Extensometer

23

Page 24

Starting the Video Extensometer

9. The buttons:

• Press the Save INI… button to record the test configuration inside a file

in the selected directory.

• Press the OK button to accept the parameters and proceed to the Test

window. Or in the case of bi-camera configuration, proceed to the

Settings window for the second camera.

• Press the Cancel to quit the application without saving changes.

• Press the Files DCF… button to select the configuration file of the

camera (Full resolution, Partial Scan ½, 1/3, bi-camera).

Available DCF files are:

– METAL_FULL_SAP.dcf or METAL_FULL_BC_SAP.dcf

Allows you to carry out tests with the full resolution of the

camera; The number of images which can be processed is 16

images/second with a resolution of 1380 * 1035.

– METAL_PAR2_SAP.dcf or METAL_PAR2_BC_SAP.dcf

Allows you to carry out tests by reducing the width of the image

by ¼ on each sides; The number of images which can be

processed is 30 images/second with a resolution of 1380 * 513.

– METAL_PAR3_SAP.dcf or METAL_PAR3_BC_SAP.dcf

Allows you to carry out tests by reducing the width of the image

by ⅓ on each sides; The number of images which can be

processed is 43 images/second with a resolution of 1380 * 341.

24

Fundamental Video Extensometer

Page 25

Starting the Video Extensometer

10. Recording of the data allows you to record the strains in a data file. Other

information is present like the number of points and the time (in seconds)

since the beginning of the test.

You need to define:

• The number of cycles between each recording. One cycle corresponds

to each received image or when the average is active, each averaged

strain, and

• The file name of the recording.

Keep in mind the data file is available only after a test has stopped; that is

when you have clicked on Return, New test, New specimen, or OK. New

specimen is the recommended action.

When you click Stop then Reinitialize, the existing data file is overwritten if it

has not been renamed and saved. A message will warn you of this fact each

time you click Reinitialize.

11. Communication:

See Calibration manual.

Fundamental Video Extensometer

25

Page 26

Starting the Video Extensometer

Test Window

The Main Window

T o select a region of interest of the image, click and hold the left mouse button on

the image then drag to define the rectangle of interest then let go of the mouse

button. When the left mouse button is released, the image is increased according

to the selected area.

The Test Procedure

26

Four combinations are offered to the user:

• Automatic optimization of the image and automatic search of the markers'

area.

• Manual optimization of the image and automatic search of the markers' area.

• The automatic optimization of the image and manual search of the markers'

area.

• Completely manual optimization o f the image and the search of the markers'

area.

Before beginning the initialization of the test, it is highly recommended to check

the setting in the window “Condition of tensile test”. The information to verify is

the color and the number of markers and the type of strain selected. It is strongly

recommended to press Initialize before starting a test to determine the maximum

strain possible.

Fundamental Video Extensometer

Page 27

Starting the Video Extensometer

To carry out a test, three essential stages must be followed:

Note In the procedure is automatic, the first two operations are carried out

consecutively, if the manual search of the markers is not checked.

• The first step is the image optimization, which can be carried out in an

automatic manner (using the Optimize the image button) or manual manner.

In the case of the manual adjustment, contrast and brightness are the two

main factors of a good optimization. The adjustment allows you to obtain a

good contrast between the markers and the background.

• The second step is the search of the markers; As for the optimization, this

step can be carried out automatically or manually. In the case of a manual

adjustment, the objective is to determine the approximate area of the

markers.

• The last step is the initialization of the test. Click on the Initialize button to

start the measurement(s) of L0 on 100 images, then check if the strains

calculated in the window Information of strain are correct. Finally, click on

Reduce; a small window appears displaying the images and the distances

between markers currently noted which are represented by lines of different

colors depending on the strain.

Fundamental Video Extensometer

27

Page 28

Starting the Video Extensometer

Refer to the following table for a description of the callouts in the above figure.

Callout Description

1

Confirmation of the localization of the markers:

• the green circle represents the minimal area.

• the red circle represents the maximum area.

The markers must be positioned approximately between these two circles. If it is not the case,

continue its progression until meeting new markers or until reaching the end of the progression

bar.

2

Display of the image captured by the video acquisition board. It also makes it possible to

visualize the area of the markers as well as the noted strains.

3

4

Recall of the test conditions.

Posting of information related to the strain, like L0 of each strain and the current strain. In

addition, it allows to know the number of processed images per second during the test.

5

Manual optimization of the image. If the box is checked, it is possible to reach the sliders, which

make it possible to adjust the image. Brightness varies the level of white and contrast varies the

level of black.

Recall: The image can be adjusted manually and the automatic search of the markers is still

possible.

6

Manual adjustment of the area of the markers. It is necessary to determine the size of the area in

which the markers are. In this case the circles appear automatically.

28

Fundamental Video Extensometer

Page 29

Callout Description

Starting the Video Extensometer

7

If you previously checked the option of the telescopic column, click the Motorized Column...

button.

It is possible to move the motorized column up and down, in order to be able to correctly

visualize the markers, before the beginning of the test or at the end of the test to return to the

initial position.

The reactivity value makes it possible to determine on which proportion of the image, the signal

10V will be cut out. On this example, value 4 indicates that the 0 – 10V will be expressed on a ¼

of the image. Higher the value is, more reactive the column will be. The value indicated will be

the value retained for all the tests carried out with the column.

Note This window is not available during the test because the program automatically controls

the column, which follows the progression of the strain.

8

The Reduce button reduces the window and displays the small window.

The New test... button launches a new test, the window of the settings reappears with the default

settings.

The New specimen button restarts a test, by preserving the same settings that the previous test,

all that is necessary is to seek the markers and to initialize again.

The Return button carries out modifications in the window of the test settings, if the information

in the window “Condition of tensile test” is not the one desired.

Fundamental Video Extensometer

29

Page 30

Starting the Video Extensometer

Strain Visualization

When all the information is correct, click the Reduce button; the following small

window appears.

This window shows the strain(s) or a warning message if the markers are lost.

30

Fundamental Video Extensometer

Page 31

VideoStrain Test Window

In contrast with the VIDEOTRACTION LC XY, the VIDEOSTRAIN software

(N markers) does not calculate the possible strain and does not post the strains.

Each marker is numbered, and the barycentric coordinates are saved in the test

file.

Starting the Video Extensometer

Fundamental Video Extensometer

31

Page 32

Software Registration

Software Registration

This software must be registered to be used for an unlimited amount of time. To

register your software, click About, then click Resister.

A key is generated and sent by email. Fill in the Key received field after you

receive the key.

32

Fundamental Video Extensometer

Page 33

Installation

System Components

1. Digitizer (optional)

2. Camera

3. Cable video and power supply

4. Lens

5. Analog board (+/-10 V or serial port RS232)

6. Cable for data transfer

System Components

Fundamental Video Extensometer

33

Page 34

Connections

Connections

There is a network cable which goes from the acquisition card to the camera

using the Ethernet port of the PC to transfer the images. The other cable is for the

power supply of the camera; it uses a Hirose 12-pin connector.

Equipment Installation

Camera Mounting

In order to carry out tests of good quality, level the camera perfectly in the axis of

the specimen.

Specimen Installation

It is essential that the grips be perfectly aligned to avoid a rotation of the

specimen at the beginning of the test which would distort the measurements

(especially transverse strain).

Lighting

The specimen can be illuminated by either a natural light, or by an artificial light

to improve contrast.

If you use an artificial light, it is recommended to use it without focusing directly

on the specimen. Focusing directly on the specimen can create shadow areas

which could affect the sharpness of the image; but it depends on the specimen

With a UV spotlight, use direct lighting close to the specimen, and use anti-UV

safety glasses.

34

Fundamental Video Extensometer

Page 35

Software Installation

Installation is done in several steps that install the software and external devices,

set up the network, and register the software. The following provides guidelines

for the installation.

1. Software Setup

Remove the old software version before launching the new installation of

the software, in the order indicated below:

• For all versions, remove the software in Add/remove programs located

in the control panel.

• For the first installation you must install all the software and devices

following the recommendations described in this manual. The

following window appears:

Software Installation

Fundamental Video Extensometer

The choices for your installation are already configured with the default

parameters. Click OK to continue.

2. Install Video Extensometer software.

Installation of the Video Extensometer is straight forward. Read the dialogs

on the screens and follow the prompts.

During this part of installation, you will need to select the type of camera.

For the Metal mode, choose between Full Frame which allows the

maximum resolution of the picture, or Partial scan which represents the

truncated picture of a quarter of picture on the left and on the right. In all the

other cases, choose Standard. The default mode is Metal (Full frame).

3. Install USB-RS232 cable.

A. Install the driver. This driver is necessary to use the serial port

connected via the USB port. Read the dialogs on the screens and follow

the prompts.

35

Page 36

Software Installation

B. When the driver installation is finished, plug in the USB-serial cable on

the PC. The hardware installation wizard assistant will detect and

install the four new serial ports, a dialog will appear for each new port

(repeat this operation four times). Do not stop the installation until all

ports are configured.

4. Install Sapera LT.

Read the dialogs on the screens and follow the prompts.

On the last window, choose No. I will restart my computer later. It is

recommended to install all the software before shutdown. Then click Finish.

5. Install Sapera Processing.

Read the dialogs on the screens and follow the prompts.

6. Install Genie Framework.

Read the dialogs on the screens and follow the prompts.

7. TCPIP Configuration for systems running Windows XP.

It is recommended to have a network administrator present to help with this

part of the installation.

A. Click on Start menu bar. Click on Control Panel menu item

36

Fundamental Video Extensometer

Page 37

Software Installation

B. Double click on “Network Connections” icon

C. Right click on Local Area Connection icon. Click on Properties menu

item.

D. Check Internet Protocol (TCP/IP) box. Click Properties button.

Fundamental Video Extensometer

37

Page 38

Software Installation

E. Check and choose Obtain an IP address automatically and obtain a

DNS server address automatically.

When you connect the camera to the Ethernet port of the PC or when you

start the PC you must wait a certain moment for recognition of this one.

This icon shows you that the camera is not connected.

Wait this icon before starting the video extensometer.

38

Fundamental Video Extensometer

Page 39

Software Installation

8. Register Software

To register the software, click About, the following window opens. Then

click Register.

The window below appears, You must communicate to us the “Number”

registered in the greyed box at this email address

EM.TechSupport@mts.com and then we will return the software key. Enter

the key number in the key received field and click OK to complete

registration.

Fundamental Video Extensometer

39

Page 40

Software Installation

40

Fundamental Video Extensometer

Page 41

Page 42

m

MTS Systems Corporation

http://www.mts.com/en/Global/index.asp

ISO 9001 Certified QMS

Loading...

Loading...