Page 1

be certain.

m

Model 409.83 Temperature Controller

Product Information

015-058-901 F

Page 2

Copyright information © 1997, 2000, 2001, 2004, 2008 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation within the United

States. This trademark may be protected in other countries.

Eurotherm is a registered trademark of Eurotherm Controls Ltd.

Publication information

Manual Part Number Publication Date

015-058-901 A August 1997

015-058-901 B March 2000

015-058-901 C October 2001

015-058-901 D March 2004

015-058-901 E June 2004

015-058-901 F March 2008

2

Manual Template 4.3

Page 3

Contents

EC Declaration of Conformity 5

Manufacturer/Importer: 6

Technical Support 7

How to Get Technical Support 7

Before You Contact MTS 7

If You Contact MTS by Phone 8

Problem Submittal Form in MTS Manuals 9

Preface 11

Before You Begin 11

Conventions 12

Documentation Conventions 12

Introduction 15

Model 409.83 Temperature Controller Functional Description 15

Model 409.83 Temperature Controller Specifications 16

Safety Information 19

Hazard Placard Placement 19

Installation 21

Model 409 High Temperature Controller Connections 22

Model 409.83 Temperature Controller Configuration 24

Model 409.83 Temperature Controller Calibration 25

Model 409.83 Temperature Controller

3

Page 4

Operation 27

Model 409.83 Temperature Controller Powerup 27

Model 409.83 Temperature Controller Controls and Indicators 28

Temperature Setpoints 29

Parameter Settings 30

About Alarms 31

Process Alarms 31

Diagnostic Alarms 32

Access Levels 32

Selecting an Access Level 33

Maintenance 35

Controller Settings 37

4

Model 409.83 Temperature Controller

Page 5

EC Declaration of Conformity

Description of Model MTS Model 409.83 Multizone Temperature Controller and 653.01, 02, 03, 04

Furnaces.

Manufacturer MTS Systems Corporation

14000 Technology Drive

Eden Prairie, MN, USA 55344

phone: 952-937-4000

European agent MTS Systems GmbH

Hohentwielsteig 3

14163 Berlin, Germany

phone: +49-30-810020

Test Standards Tests were performed to verify that this product met the Essential Requirements

of the Low Voltage directive 73/23/EEC and the EMC directive 89/336/EEC by

conforming to the following product specifications:

EN 61010-1:2001 and EN 61010-2-010:1994 Safety requirements for electrical

equipment for measurement, control and laboratory use, Part 1: General

requirements.

EN 61000-6-2 Electromagnetic compatibility, Generic immunity standard, Part

2: industrial environment (March 1999).

D

ESCRIPTION BASIC STANDARD TEST SPECIFICATION

Limits for harmonic current emissions EN 61000-3-2 / 2000 per EN 61000-6-2:1999

Limits for voltage fluctuations and flicker EN 61000-3-3 / 2001 per EN 61000-6-2:1999

Electrostatic discharge EN 61000-4-2 / 1995 4 kV contact discharge

8 kV air discharge

Radio frequency electromagnetic field,

amplitude modulated

Electrical fast transient EN 61000-4-4 / 1995 2 kV control, signal, and mains

Surge immunity test EN 61000-4-5 / 1995 2 kV mains

Radio frequency common mode, amplitude

modulated

Power frequency magnetic field EN 61000-4-8 / 1993 30 A/m

Voltage dips, short interruptions and

voltage variations

EN 61000-4-3 / 1993 10 V/m

EN 61000-4-6 / 1993 10 Vrms

EN 61000-4-11 / 1994 per EN 61000-6-2:1999

Model 409.83 Temperature Controller EC Declaration of Conformity

5

Page 6

Manufacturer/Importer:

Manufacturer/Importer:

Signed:

Name: Leo Kühhass

Title: European Operations Manager

EN 55011 Specification for limits and methods of measurement of radio

disturbance characteristics of industrial, scientific and medical (ISM) radio

frequency equipment (1991). Group 1, class A (non-domestic where RF is NOT

used in the treatment of material).

ASIC STANDARD DESCRIPTION

B

Radiated emissions EN 55011

Conducted emissions EN 55011

Date: May 12, 2004

EC Declaration of Conformity

6

Model 409.83 Temperature Controller

Page 7

Technical Support

How to Get Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

MTS web site

www.mts.com

E-mail techsupport@mts.com

Telephone MTS Call Center 800-328-2255

Fax 952-937-4515

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes MTS software, look

for online help and README files that contain additional product information.

If you cannot find answers to your technical questions from these sources, you

can use the internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact MTS in one of the

following ways.

The MTS web site gives you access to our technical support staff by means of a

Technical Support link:

www.mts.com > Contact Us > Service & Technical Support

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Please include “Technical Support” in the subject line.

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

Model 409.83 Temperature Controller Technical Support

The site number contains your company number and identifies your equipment

type (material testing, simulation, and so forth). The number is usually written on

a label on your MTS equipment before the system leaves MTS. If you do not

have or do not know your MTS site number, contact your MTS sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies

which system you are calling about. You can find your job number in the papers

sent to you when you ordered your system.

Example system number: US1.42460

7

Page 8

If You Contact MTS by Phone

Know information from

prior technical

If you have contacted MTS about this problem before, we can recall your file.

You will need to tell us the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem you are experiencing and know the answers to the

following questions:

• How long and how often has the problem been occurring?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the model numbers of the suspect equipment?

• What model controller are you using (if applicable)?

• What test configuration are you using?

Know relevant

computer information

If you are experiencing a computer problem, have the following information

available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive in which the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

Know relevant

For software application problems, have the following information available:

software information

• The software application’s name, version number, build number, and if

available, software patch number. This information is displayed briefly

when you launch the application, and can typically be found in the “About”

selection in the “Help” menu.

• It is also helpful if the names of other non-MTS applications that are

running on your computer, such as anti-virus software, screen savers,

keyboard enhancers, print spoolers, and so forth are known and available.

If You Contact MTS by Phone

Your call will be registered by a Call Center agent if you are calling within the

United States or Canada. Before connecting you with a technical support

specialist, the agent will ask you for your site number, name, company, company

address, and the phone number where you can normally be reached.

Technical Support

8

Model 409.83 Temperature Controller

Page 9

Problem Submittal Form in MTS Manuals

If you are calling about an issue that has already been assigned a notification

number, please provide that number. You will be assigned a unique notification

number about any new issue.

Identify system type To assist the Call Center agent with connecting you to the most qualified

technical support specialist available, identify your system as one of the

following types:

• Electromechanical materials test system

• Hydromechanical materials test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

Prepare yourself for troubleshooting while on the phone:

troubleshoot

• Call from a telephone when you are close to the system so that you can try

implementing suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

Write down relevant

Prepare yourself in case we need to call you back:

information

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording

or performance monitoring.

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action

is taken regarding your problem or request. If you have questions about the status

of your problem or have additional information to report, please contact MTS

again and provide your original notification number.

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems you are experiencing

with your MTS software, hardware, manuals, or service which have not been

resolved to your satisfaction through the technical support process. This form

includes check boxes that allow you to indicate the urgency of your problem and

your expectation of an acceptable response time. We guarantee a timely

response—your feedback is important to us.

The Problem Submittal Form can be accessed:

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form (electronic form to

be e-mailed to MTS)

Model 409.83 Temperature Controller Technical Support

9

Page 10

Problem Submittal Form in MTS Manuals

Technical Support

10

Model 409.83 Temperature Controller

Page 11

Before You Begin

Preface

Before You Begin

Safety first! Before you attempt to use your MTS product or system, read and understand the

Safety manual and any other safety information provided with your system.

Improper installation, operation, or maintenance of MTS equipment in your test

facility can result in hazardous conditions that can cause severe personal injury or

death and damage to your equipment and specimen. Again, read and understand

the safety information provided with your system before you continue. It is very

important that you remain aware of hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional MTS manuals in paper or

electronic form.

If you have purchased a test system, it may include an MTS System

Documentation CD. This CD contains an electronic copy of the MTS manuals

that pertain to your test system, including hydraulic and mechanical component

manuals, assembly drawings and parts lists, and operation and preventive

maintenance manuals. Controller and application software manuals are typically

included on the software CD distribution disc(s).

Model 409.83 Temperature Controller Preface

11

Page 12

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions As necessary, hazard notices may be embedded in this manual. These notices

contain safety information that is specific to the task to be performed. Hazard

notices immediately precede the step or procedure that may lead to an associated

hazard. Read all hazard notices carefully and follow the directions that are given.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury, equipment damage, or

endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. It is important for you to be

Electronic manual

conventions

Preface

12

aware that these illustrations are examples only and do not necessarily represent

your actual system configuration, test application, or software.

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

Model 409.83 Temperature Controller

Page 13

Documentation Conventions

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

Model 409.83 Temperature Controller Preface

13

Page 14

Documentation Conventions

14

Preface

Model 409.83 Temperature Controller

Page 15

Introduction

Eurotherm Model 2216

Temperature Control

Modules

Model 409.83 Temperature Controller Functional

The MTS Model 409.83 Temperature Controller is a microprocessor-based

controller for use with MTS Model 652 and 653 High-Temperature Furnaces. It

may be mounted on a table top or on a load unit.

Model 409.83 Temperature Controller

Inappropriate use Before you attempt to use the Model 409.83 High Temperature Controller, read

and understand this manual. Improper installation or operation of this product

can result in hazardous conditions that can cause severe personal injury or death,

and damage your equipment and specimen.

WEEE The Waste Electrical and Electronic Equipment (WEEE) symbol ( ) means

that the controller and its electronic parts must not be disposed of as unsorted

municipal waste. Proper disposal is required by approved electronic waste

collection agencies. Customers in the EC region who desire to return an end-oflife controller and its electronic parts are encouraged to contact your local MTS

Systems Sales/Service Offices for instructions.

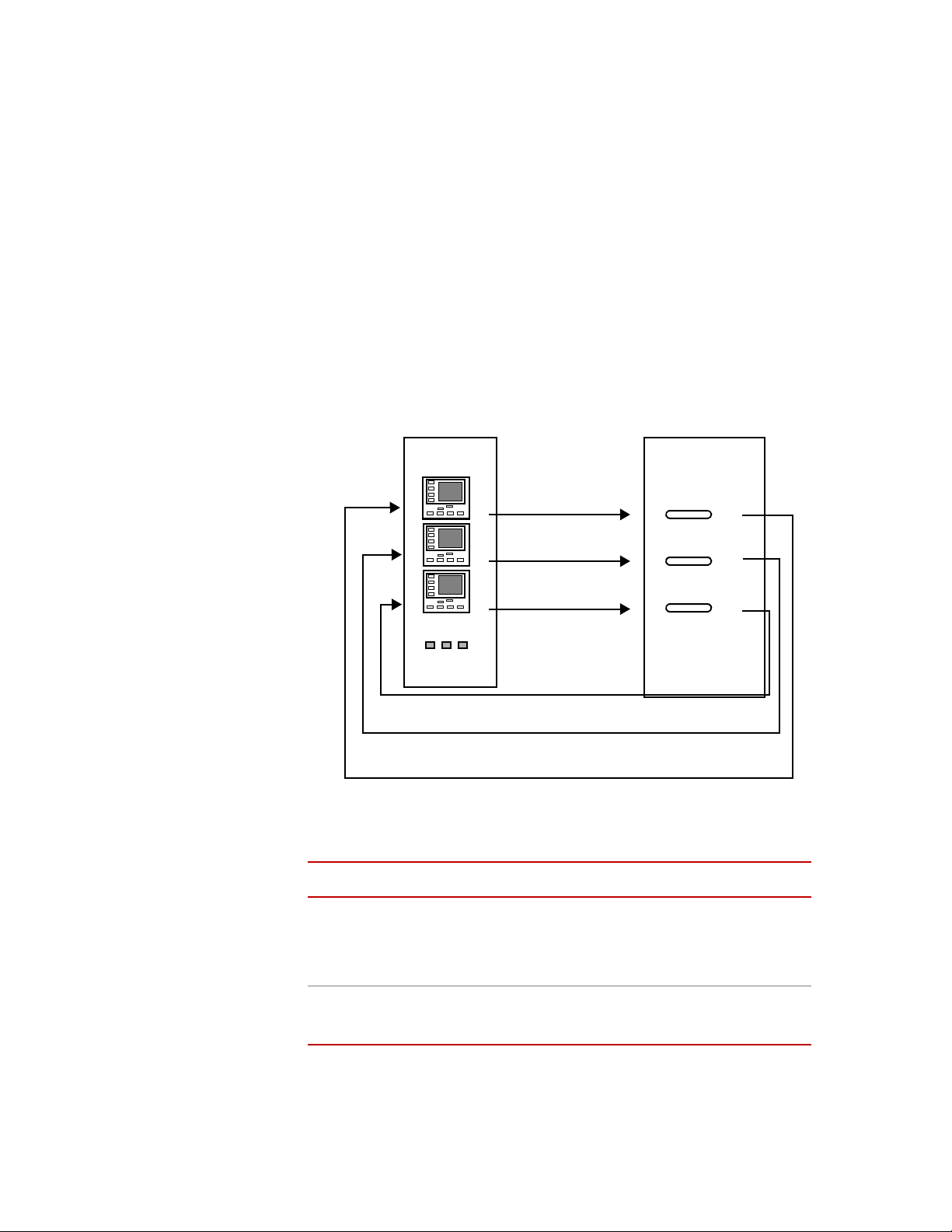

Model 409.83 Temperature Controller Functional Description

Closed-loop control is maintained in each zone by a single Eurotherm Model

2216 Temperature Controller (control module). The Model 409.83 Temperature

Controller includes up to three Eurotherm control modules which correspond to

up to three heat zones in the furnace. Each module accepts a thermocouple input

and outputs proportional power to control the respective furnace heating element.

The control modules are programmed at MTS for use with Series 652 or 653

High-Temperature Furnaces. Tuning parameters establish the temperature

setpoint, control accuracy, and operating limits. Alarm circuits function as an

Model 409.83 Temperature Controller Introduction

15

Page 16

Model 409.83 Temperature Controller Specifications

High

Temperature

Furnace

Upper Control

Signal

Middle Control

Signal

Lower Control

Signal

Lower Thermocouple

Signal

Middle Thermocouple Signal

Upper Thermocouple Signal

element

element

element

Temperature

Controller

interlock when the heater elements are enabled. If undesirable conditions arise,

power to the heater elements is cut off automatically.

The following figure illustrates a block diagram of the Model 409.83

Temperature Controller and a high-temperature furnace.

A temperature setpoint is selected for each furnace heat zone. The setpoint is

compared to the temperature measurement provided by a thermocouple inside in

the furnace. Any difference (between the setpoint and the actual temperature)

causes an error signal.

The error signal produces a time proportional signal. This time proportional

signal is sent to a corresponding solid state relay. The time proportional output

pulses the solid state relay on and off at a rate determined by the amplitude and

polarity of the error signal. The solid state relay applies the AC power to the

corresponding heating element in the furnace.

Model 409.83 Temperature Controller Specifications

Introduction

16

Environmental:

Line Voltage

Parameter

Tem per atu re

Relative Humidity

†

Specification

0°C to 50°C (32°F to 122°F)

10 to 90%, noncondensing

100–120 V AC± 10%, 50/60 Hz

220–240 V AC± 10%, 50/60 Hz

Model 409.83 Temperature Controller

*

Page 17

Model 409.83 Temperature Controller Specifications

Parameter

Line Current

1 zone

2 zone

3 zone

Cable length, AC line cord Approximately 2.4 m (8 ft.)

Cable length, Control to Furnace Maximum 3.96 m (13 ft.)

Operating Temperature, Furnace 100°C to 1400°C (212°F–2552°F)

Number of Zones 1, 2, or 3

Thermocouple Type R

* Specifications are subject to change without notice. Contact MTS for

verification of specifications critical to you needs.

† The Model 409.83 Temperature Controller line voltage must be specified

at time of order (it is not field selectable). The AC line voltage

specification listed conforms to the CE low-voltage directive. The

specification allows for ±10% of the values listed.

100–120 V 220–240 V

8 A 4 A

16 A 8 A

N/A 12 A

Specification

*

Model 409.83 Temperature Controller Introduction

17

Page 18

Model 409.83 Temperature Controller Specifications

18

Introduction

Model 409.83 Temperature Controller

Page 19

Safety Information

This unit

wired for

100-120 V~

50/60 Hz

16 amp

This unit

wired for

220-240 V~

50/60 Hz

12 amp

This unit

wired for

220-240 V~

50/60 Hz

8 amp

Left

Furnace

Right

Furnace

J5

J4

This unit

wired for

100-120 V~

50/60 Hz

8 amp

This unit

wired for

220-240 V~

50/60 Hz

4 amp

J6

Upper Lower

J6

Lower

Upper Mid

Hazard Placard Placement

Hazard placards contain specific safety information and are affixed directly to the

system so they are plainly visible.

Each placard describes a system-related hazard. When possible, international

symbols (icons) are used to graphically indicate the type of hazard and the

placard label indicates its severity. In some instances, the placard may contain

text that describes the hazard, the potential result if the hazard is ignored, and

general instructions about how to avoid the hazard.

The following labels are typically located on the controller.

L

ABEL DESCRIPTION

Identification label.

Hazard Placard Placement

Part # 002-680-701

Contains the following information:

• MTS contact information

• Year manufactured

• Final assembly number

• Model

• Serial number

A combination of these information

labels may appear somewhere on the

controller.

Label Set Part # 052-546-801

Model 409.83 Temperature Controller Safety Information

19

Page 20

Hazard Placard Placement

Safety Information

20

Model 409.83 Temperature Controller

Page 21

Installation

CAUTION

This chapter provides installation information for the Model 409.83 Temperature

Controller.

Do not use this controller with incompatible furnaces.

The temperature controller is programmed for use with the Model 652 or 653 High

Temperature Furnaces. The heating elements of older furnaces could be

damaged if used with this temperature controller.

Note The 409.83 is a class 1 LED product as defined by the CE low voltage

directive.

Mounting

considerations

The Model 409.83 Temperature Controller can be mounted on a table top (with

an optional table top bracket) or floor stand. The temperature controller must be

mounted such that the lamps on the controller are visible from the furnace.

1. Ensure that the temperature controller has arrived with no shipping damage.

If damaged, contact the Customer Service division of MTS Systems

Corporation.

2. Locate the table-top or floor stand that accompanied the controller. Mount

the temperature controller to it using the nuts and bolts provided.

3. Connect cables and wires per the cable assembly drawing.

AC power disconnect Turn off the AC power switch. Remove the AC power cord from the unit. This

will remove all AC power from the chassis.

Note Be sure to locate the chassis so that you have adequate access to

disconnect the power cord form the chassis.

Model 409.83 Temperature Controller Installation

21

Page 22

Model 409 High Temperature Controller Connections

WARNING

Platinum/Rhodium (Black)

Platinum (Red)

From

Thermocouple

+

–

Model 409 High Temperature Controller Connections

All input/output signals that interface the temperature controller and other system

components are available on the bottom panel. This section provides information

on all input/output signals of the temperature controller.

Model 409.83 Temperature Controller Bottom Panel

The furnace/controller must be connected to a supply source which

incorporates a residual current operated circuit-breaker which interrupts the

supply at a differential current of 30mA or less.

Due to the fact that the heaters are hazardous live and are accessible, the

equipment must be connected to a supply source that incorporates such a circuit

breaker.

Chassis voltage The temperature controller receives power from a detachable, three-wire power

cord. The power cord plugs into an input power connector block located on the

bottom panel. The chassis power switch is located on the rear panel; on is labeled

|, and off is labeled 0. The line voltage is selected at time of order (120 or 240 V)

and is not field selectable.

J1, J2, J3

thermocouple inputs

Temperature feedback is provided through a single Type ‘R’ thermocouple lead

(for each zone). The furnace thermocouples should be connected to the input

connectors. The connections are polarized; the longer slot is negative (–) and the

shorter slot is positive (+).

22

Installation

J1, J2, and J3 Thermocouple Input Connections

Model 409.83 Temperature Controller

Page 23

Model 409 High Temperature Controller Connections

Left

Furnace

Right

Furnace

J4, J5 heating element

outputs

J6 serial

communication

Socket-style connectors J4 and J5 transfer the heater control signal (line voltage)

from the temperature controller to the furnace heater elements. The cables

connected to J4 and J5 are interchangeable.

J4 and J5 Heating Element Output Connections

The J6 serial communication port has three functions:

• Interlock input

The interlock input can be connected to an external (normally-closed)

switch or contact. If the external switch or contact opens, the temperature

controller alarm is triggered, and power is cut off to the heating elements.

• Interlock contact output

The interlock output (relay output) can be connected to an external

monitoring device to follow the enable/alarm state of the temperature

controller. This contact is closed when the Model 409.83 Controller heating

elements are enabled. If an alarm is triggered or the Disable button is

pressed (interlock is open), a signal is sent to the external monitoring device.

• RS–485 communication port to temperature control module

All functions and readout values in each Eurotherm 2216 Controller can be

monitored and adjusted by a single RS-485 serial port located at J6.

If nothing is connected to the J6 port, a jumper plug must be installed (MTS part

number 525099-01).

J6 Serial Communication Connection

Model 409.83 Temperature Controller Installation

23

Page 24

Model 409.83 Temperature Controller Configuration

CAUTION

Model 409.83 Temperature Controller Configuration

Through the configuration level you can set up the fundamental characteristics of

the controller. These include:

• The type of control

• The input type and range

• The alarm functions

• The output functions

• The communications configuration

• Calibration

• Passwords

Selecting an access

level

1. Access the configuration level.

• If the controller is powered up, select the appropriate configuration

level.

• If the controller is not powered up, press and hold the up and down

arrows simultaneously while powering up the controller. This takes you

directly to the ConF password entry display.

2. At the PASS prompt, enter the configuration password.

The password is initially factory-set to 2.

Note Refer to the Eurotherm Model 2216 Temperature Controller manual for

information on changing passwords.

3. Press the scroll button.

The first display of the configuration will be shown.

A. To return to the operator access level from the ConF access level, press

the page and scroll buttons simultaneously. At the Exit prompt, use the

up or down arrows to select Ye s . This will return you to the Home

display in the operator access level.

24

Installation

Configuration is protected by password and should only be carried out by

qualified persons.

Incorrect configuration could result in damage to the process being controlled or

personal injury.

Note For complete information on parameter availability (including navigation

diagrams), refer to the Eurotherm Model 2216 Temperature Controller

manual.

Model 409.83 Temperature Controller

Page 25

Model 409.83 Temperature Controller Calibration

Model 409.83 Temperature Controller Calibration

The basic calibration of the controller is highly stable and set for life. User

calibration allows you to offset the permanent factory calibration to either:

• Calibrate the controller to your reference standards.

• Match the calibration of the controller to that of a particular transducer or

sensor input.

• Calibrate the controller to suit the characteristics of a particular installation

• Remove long term drift in the factory-set calibration.

User calibration works by introducing zero and span offsets onto the factory-set

calibration.

Note For complete information on enabling and performing user calibration,

refer to the Eurotherm Model 2216 Temperature Controller manual.

Model 409.83 Temperature Controller Installation

25

Page 26

Model 409.83 Temperature Controller Calibration

26

Installation

Model 409.83 Temperature Controller

Page 27

Operation

WARNING

2216

OP1

OP2

SP2

REM

26.0

20.0

Measured

temperature

Setpoint

EUROTHERM

This chapter provides operational procedures and a functional description of the

Model 409.83 Temperature Controller front panel and indicators.

The protection provided by this equipment can be impaired if this furnace is

not used in its intended manner.

Do not operate the furnace in a manner contrary to its intended use.

Model 409.83 Temperature Controller Powerup

When the temperature controller is turned on, each control module goes through

a self-test sequence that takes approximately three seconds. When the test

sequence is completed, the control module defaults to the “Home” display. The

Home display indicates the actual temperature (or process value) in the upper

readout and the temperature setpoint in the lower readout (see the following

figure).

Model 409.83 Temperature Controller Powerup

Home Display

If the controller detects an alarm condition, the yellow alarm indicator

illuminates, and the control module flashes an alarm message in either the upper

or lower readout of the Home display.

Model 409.83 Temperature Controller Operation

27

Page 28

Model 409.83 Temperature Controller Controls and

Disable Enable Alarm

2216

EUROTHERM

MAN

OP1

SP2

REM

OP2

RUN

1

2

3

4

5

6

7

14

13

12

9

10

8

Top of controller

11

Model 409.83 Temperature Controller Controls and Indicators

The following figure illustrates the lower part of the Model 409.83 Temperature

Controller front panel.

.

C

ALLOUT CONTROL OR

I

NDICATOR

Note There are two control modules on a two-zone and three control modules

1 OP1 Output 1

2 OP2 Output 2

28

Operation

Front Panel Layout

on a three-zone temperature controller.

Controls and Indicators

NAME DESCRIPTION

When lit, it indicates that output 1 is on. This is normally

the heating output.

When lit, it indicates that output 2 is on. This is normally

the cooling output, and it is not connected on typical

systems.

Model 409.83 Temperature Controller

Page 29

Controls and Indicators (Continued)

Temperature Setpoints

ALLOUT CONTROL OR

C

I

NDICATOR

3 SP2 Setpoint 2

4REM Remote

5MAN Manual

6 Page Button

7Scroll Button

8 Down Button

NAME DESCRIPTION

When lit, this indicates that setpoint 2 has been selected.

When lit, this indicates that the PDSIO remote setpoint

Setpoint

input has been selected.

When lit, it indicates that manual mode has been

Mode

selected.

Press to select a new list of parameters.

Press to select a new parameter in a list.

Press to decrease a value in the lower readout.

To speed up the rate of change, press and hold the button.

9 Up Button

Press to increase a value in the lower readout.

To speed up the rate of change, press and hold the button.

10 RUN Run Indicator

When lit, it indicates that setpoint rate limit is active.

11 LCD Display Readout

12 Switch/Indicator

(red)

13 Switch/Indicator

(green)

14 Indicator (yellow) Alarm

Not

Shown

Power Switch I / O

Disable

Enable

Temperature Setpoints

Normal operation of the temperature controller requires the desired temperature

setpoints to be entered into each control module. After the setpoints have been

entered, the heater elements can be enabled.

To enter the temperature setpoints:

1. From the Home display, press the up or down arrow (to increase or decrease

the current value).

Displays temperature controller data (temp readout,

setpoint, parameter value, and so forth.)

Disables the heating elements of the high-temperature

furnace.

Enables the heating elements of the high-temperature

furnace.

Functions in conjunction with the alarm indicators of

each temperature controller. When the interlock is

broken, the Alarm indicator lights, and power to the

elements is cut off.

Chassis power switch (on back panel). On is labeled I,

Off is labeled O.

Model 409.83 Temperature Controller Operation

29

Page 30

Parameter Settings

2216

OP1

OP2

SP2

REM

AL

LiSt

List header

Always displays

‘LiSt’

Parameter Settings

Two seconds after releasing either button, the display blinks to show the

control module has accepted the new value.

2. Repeat step 1 for each control module.

You can return to the Home display by pressing the scroll and page buttons

simultaneously. Alternatively, you will always be returned to the Home

display if no button is pressed for 45 seconds.

3. Press the Enable Heater Elements switch.

This will bring the furnace up to temperature.

Note Parameters are set at MTS Systems according to the configuration

drawing at the end of the manual. If a control module is replaced, set the

parameters according to the MTS-factory settings and then run the

Eurotherm Automatic Tuning. Once the MTS factory settings have been

entered, you may deviate from them (in small steps).

Parameters are settings within the control module that determine how the control

module will operate. For example, alarm setpoints are parameters that determine

when alarms will occur. Parameters are arranged in lists. The names of these lists

are found in the list headers. The available lists are:

Home List Set Point List On/Off List

Alarm List Input List Communications List

PID List Output List Access List

Typical List Header Display

Note Refer to the Eurotherm Model 2216 product manual shipped with this

manual for a listing of the parameters available under each list header.

To change the value of a parameter:

30

Operation

1. From the Home display, press the page button to select the appropriate list

header.

Model 409.83 Temperature Controller

Page 31

About Alarms

About Alarms

Lists always show LiSt in the lower readout.

2. From the list header display, press the scroll button to select the required

parameter.

The parameter name displays in the upper readout and its value in the lower.

3. From the parameter display, press the up or down arrow (to increase or

decrease the current value).

Two seconds after releasing either button, the display blinks to show the

control module has accepted the new value.

4. Repeat Steps 1–3 for each parameter in each control module.

You can return to the Home display by pressing the scroll and page buttons

simultaneously. Alternatively, you will always be returned to the Home

display if no button is pressed for 45 seconds.

If any of the temperature controllers detect an alarm condition, two indicators

notify the operator.

Process Alarms

The alarm indicator on the lower panel lights, and an alarm message flashes in

either the upper or lower readout of the Home display. Alarms can be

acknowledged by pressing the page or scroll buttons on the display on the

affected control module.

On the control modules, new alarms are displayed as a double flash, followed by

a pause. If there is more than one alarm, the display cycles through the relevant

alarm conditions.

There are two types of alarms: Process and Diagnostic.

Process alarms warn of a problem with the process being monitored by the

controller.

Process Alarms

ALARM DISPLAY

-FSH Full Scale High Alarm

–FSL Full Scale Low Alarm

–dHi Deviation High Alarm

†

DESCRIPTION

*

–dLo Deviation Low Alarm

–dEV Deviation Band Alarm

Model 409.83 Temperature Controller Operation

31

Page 32

Diagnostic Alarms

Diagnostic Alarms

* Refer to the Eurotherm Model 2216 Temperature Controller manual

shipped with this manual for information on how to correct alarm

conditions.

† In place of the dash, the first character will indicate the alarm number.

Diagnostic alarms indicate that a fault exists in either the controller or other

connected devices.

Diagnostic Alarms

ALARM DISPLAY DESCRIPTION

EE.Er

S.br

L.br

Ld.F

SSr.F

Htr.F

HW.Er

rmt.F

LLLL

HHHH

Err1

Err2

Err3

Electrically Erasable Memory Error

Sensor Break

Loop Break

Load Failure

Solid State Relay Failure

Heater failure

Hardware error

Remote input failure

Out of range low reading

Out of range high reading

Error 1: ROM self-test failure

Error 2: RAM self-test failure

Error 3: Watchdog fail

*

Access Levels

Operation

32

Err4

Err5

Pwr.F

* Refer to the Eurotherm Model 2216 Temperature Controller manual

shipped with this manual for information on how to correct alarm

conditions.

Error 4: Keyboard failure

Error 5: Input circuit failure

Power failure (low line voltage)

Access levels provide the ability to restrict parameter changes. There are four

levels of access in the temperature controller:

• Operator Level

Model 409.83 Temperature Controller

Page 33

• Full Level

• Edit Level

• Configuration Level

Full, Edit, and Configuration levels are password-protected to prevent

unauthorized access.

Selecting an Access Level

To select an access level:

1. From the Home display, press the page button until you see the ACCS list

Selecting an Access Level

• Allows viewing and editing of parameters defined in the Edit level.

• Allows viewing and editing of all parameters.

• Allows you to set which parameters are accessible in the Operator

level.

• Allows you to set up the fundamental characteristics of the controller.

header.

Editing the

operator access

2. Press the scroll button.

The display will read CODE. Enter the password using the up and down

keys (the password is set to 1 when the unit is shipped from the factory).

Once the correct password is entered, the lower display will read PASS,

indicating that the access level is unlocked.

Note Refer to the Eurotherm Model 2216 Temperature Controller manual for

information on changing passwords.

3. Press the scroll button to proceed to the GOTO display.

4. From the GOTO display, press the up or down arrows to select the desired

access level.

There are four access levels available:

• OPER Operator level

• FULL Full level

• EDIT Edit level

• CONF Configuration level

In the edit access level, you can set which parameters are accessible in the

Operator access level and/or accessible from the Home display. To set operator

access to a parameter:

1. Select the Edit level.

2. Select the parameter to be set by toggling through the list headers (page

button) and selecting the parameter (scroll button).

Model 409.83 Temperature Controller Operation

33

Page 34

Selecting an Access Level

3. Once the parameter has been selected, use the up and down arrows to set the

parameter availability in Operator level.

There are four codes available:

• ALTR Makes a parameter alterable in Operator level

• PRO Promotes a parameter to the Home list display

• READ Makes a parameter or list header read-only

• HIDE Hides a parameter or list header

Returning to

operator level

To return to operator level from either FULL or EDIT level, repeat entry of

password and select OPER on the GOTO display. In Edit level, the control

module will automatically return to operator level if no button is pressed for 45

seconds.

34

Operation

Model 409.83 Temperature Controller

Page 35

Maintenance

CAUTION

Cleaning Keep the exterior of the temperature controller free from dust and other debris.

Should the controller require cleaning, keep the following points in mind:

Do not clean the controller exterior with harsh detergents.

Use only a soft cloth to clean the exterior of the controller. If a cleaning agent is

needed, use only mild detergent with water. Harsh detergents can damage the

temperature controller finish and electronics.

• Power should be disconnected (by unplugging the AC line cord at the wall

outlet) before cleaning.

• Use a soft cloth to remove dust and other debris from the exterior of the

temperature controller. If a cleaning agent is required, use only a mild

detergent and water.

• Allow for sufficient dry time before reconnecting power to the temperature

controller.

Replacing a Eurotherm

2216

Parameters are set at MTS Systems Corporation according to the configuration

drawing (MTS part number 531124-xx). If a control module is replaced, set the

parameters according to the MTS-factory settings and then run the Eurotherm

Automatic Tuning. Once the MTS factory settings have been entered, you may

deviate from them (in small steps).

Model 409.83 Temperature Controller Maintenance

35

Page 36

36

Maintenance

Model 409.83 Temperature Controller

Page 37

Controller Settings

Model 409.83 Temperature Controller Controller Settings

37

Page 38

Controller Settings

38

Model 409.83 Temperature Controller

Page 39

Page 40

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

Internet: www.mts.com

ISO 9001 Certified QMS

Loading...

Loading...