Page 1

be certain.

m

318 Load Unit

Product Information

Model 318.10

Model 318.25

Model 318.50

100-183-837 B

Page 2

Copyright information © 2007, 2009 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation within the United

States. This trademark may be protected in other countries.

Molykote is a registered trademark of Dow Chemical Corporation. All other

trademarks or service marks are property of their respective owners.

Publication information

MANUAL PART NUMBER PUBLICATION DATE

100-183-837 A June 2007

100-183-837 B April 2009

Page 3

Contents

Technical Support 7

How to Get Technical Support 7

Before You Contact MTS 7

If You Contact MTS by Phone 9

Problem Submittal Form in MTS Manuals 10

Preface 11

Before You Begin 11

Conventions 12

Documentation Conventions 12

Introduction 15

Load Unit: Overview 15

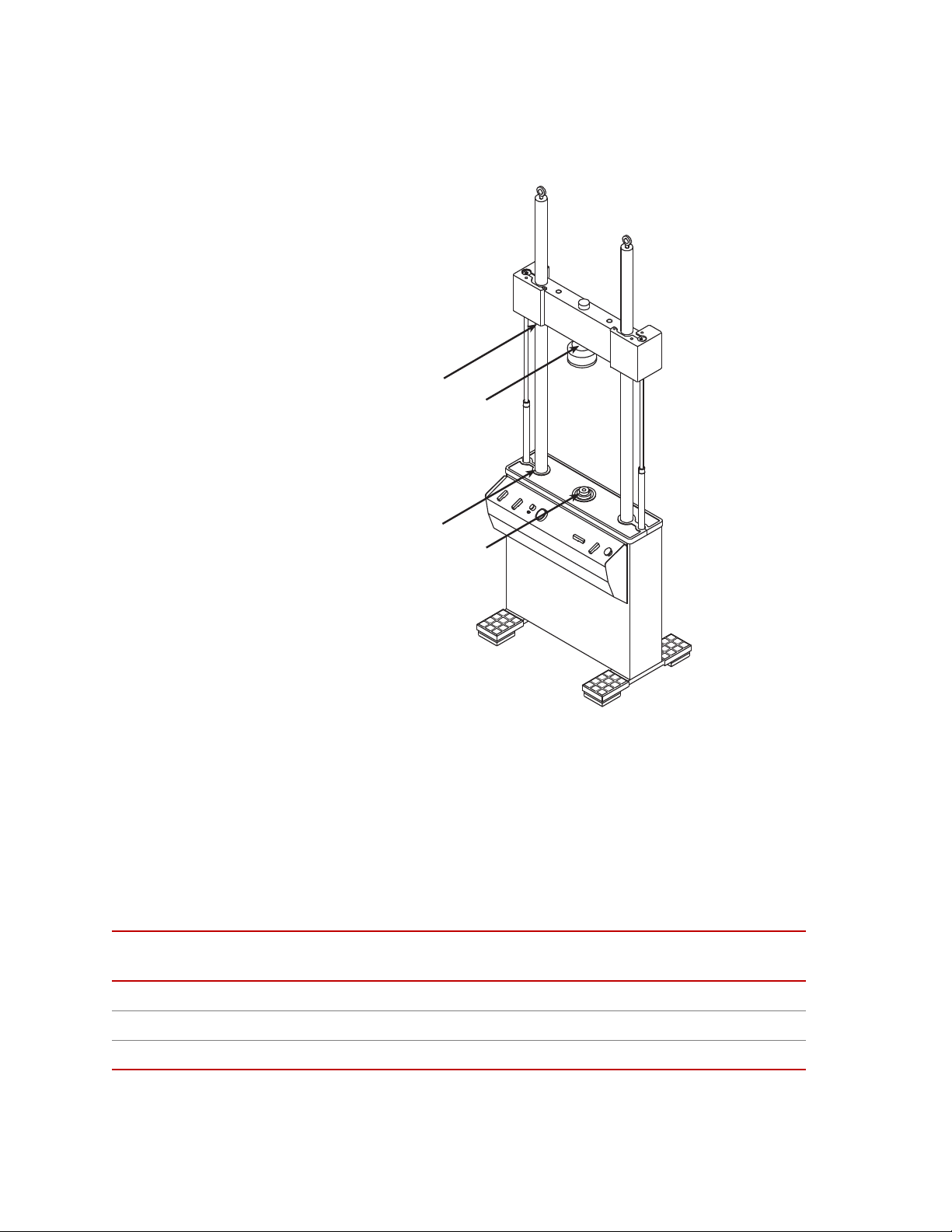

318 Load Unit: Component Identification 17

318 Load Unit: Component Description 18

318 Load Unit: Specifications 20

Series 661 Force Transducer: Specifications 24

318 Load Unit: Dimensions 26

Safety 33

General Safety Practices 33

Safety Practices Before System Operation 34

Safety Practices While the System Is in Operation 39

Hazard Icons 41

318 Load Unit: Hazard Labels 42

45

318 Load Unit: Crush Point Hazards 45

318 Load Unit Contents

3

Page 4

Installation 47

318 Load Unit: Unpack Upright Configuration 47

318 Load Unit: Unpack Horizontal Configuration 49

318 Load Unit: Connect Cables 54

318 Load Unit: Connect Hydraulics 56

318 Load Unit: Unlock the Crosshead 56

Operation 59

Load Unit: Operation Preface 59

318 Load Unit: Control Module 60

318 Load Unit: Crush Point Hazards 62

318 Load Unit: Specimen Installation 62

318 Load Unit: Position the Crosshead Hydraulically 65

318 Load Unit: Position the Crosshead Manually 66

318 Load Unit: Adjust the Grips’ Clamp Rate 69

318 Load Unit: Adjust the Grips’ Clamp Force 70

Maintenance 73

Routine Maintenance Overview Checklist 74

318 Load Unit: Maintenance Intervals 77

318 Load Unit: Daily Inspections 78

318 Load Unit: Clean the Columns 78

318 Load Unit: Prevent Rust 79

318 Load Unit: Maintain Airmount Pressures 80

318 Load Unit: Bleed the Hydraulic Lift Cylinders 81

318 Load Unit: Adjust the Hydraulic Locks 83

318 Load Unit: Lubricate the Crosshead Locking Bolts 86

318 Load Unit: Align the Force Transducer 87

111 Accumulator: Maintenance Overview 93

111 Accumulator: Check and Change Precharge Pressure 94

244 Actuator: Maintenance 98

298 HSM: Maintenance 98

252 Servovalve: Maintenance Overview 100

252 Servovalve: Replace the Filter Element 100

252 Servovalve: Adjust the Mechanical Null 102

Servohydraulic Load Frame Maintenance and Service Logs 107

4

Contents

318 Load Unit

Page 5

8 Hours/Daily 108

40 Hours/Weekly 109

80 Hours/Biweekly 110

500 Hours: Crosshead and Frame 111

500 Hours: Actuator 112

500 Hours: HSM 113

500 Hours: Hoses and Cables 114

500 Hours: Overall Complete System 115

500 Hours: Grips 116

1000 Hours 117

2000 Hours: Annual Maintenance 118

318 Load Unit Contents

5

Page 6

6

Contents

318 Load Unit

Page 7

Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

MTS web site

www.mts.com

E-mail techsupport@mts.com

Telephone MTS Call Center 800-328-2255

Fax 952-937-4515

Technical support

outside the U.S.

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes MTS software, look

for online help and README files that contain additional product information.

If you cannot find answers to your technical questions from these sources, you

can use the internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact MTS in one of the

following ways.

The MTS web site gives you access to our technical support staff by means of a

Technical Support link:

www.mts.com > Contact MTS > Service & Technical Support

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Please include “Technical Support” in the subject line.

For technical support outside the United States, contact your local sales and

service office. For a list of worldwide sales and service locations and contact

information, use the Global MTS link at the MTS web site:

www.mts.com > Global MTS > (choose your region in the right-hand

column) > (choose the location closest to you)

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

318 Load Unit Technical Support

The site number contains your company number and identifies your equipment

type (material testing, simulation, and so forth). The number is usually written on

a label on your MTS equipment before the system leaves MTS. If you do not

have or do not know your MTS site number, contact your MTS sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies

which system you are calling about. You can find your job number in the papers

sent to you when you ordered your system.

Example system number: US1.42460

7

Page 8

Know information from

prior technical

If you have contacted MTS about this problem before, we can recall your file.

You will need to tell us the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem you are experiencing and know the answers to the

following questions:

• How long and how often has the problem been occurring?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the model numbers of the suspect equipment?

• What model controller are you using (if applicable)?

• What test configuration are you using?

Know relevant

computer information

Know relevant

software information

If you are experiencing a computer problem, have the following information

available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive in which the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

For software application problems, have the following information available:

• The software application’s name, version number, build number, and if

available, software patch number. This information is displayed briefly

when you launch the application, and can typically be found in the “About”

selection in the “Help” menu.

• It is also helpful if the names of other non-MTS applications that are

running on your computer, such as anti-virus software, screen savers,

keyboard enhancers, print spoolers, and so forth are known and available.

Technical Support

8

318 Load Unit

Page 9

If You Contact MTS by Phone

Your call will be registered by a Call Center agent if you are calling within the

United States or Canada. Before connecting you with a technical support

specialist, the agent will ask you for your site number, name, company, company

address, and the phone number where you can normally be reached.

If you are calling about an issue that has already been assigned a notification

number, please provide that number. You will be assigned a unique notification

number about any new issue.

Identify system type To assist the Call Center agent with connecting you to the most qualified

technical support specialist available, identify your system as one of the

following types:

• Electromechanical materials test system

• Hydromechanical materials test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

troubleshoot

Write down relevant

information

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action

Prepare yourself for troubleshooting while on the phone:

• Call from a telephone when you are close to the system so that you can try

implementing suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

Prepare yourself in case we need to call you back:

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording

or performance monitoring.

is taken regarding your problem or request. If you have questions about the status

of your problem or have additional information to report, please contact MTS

again and provide your original notification number.

318 Load Unit Technical Support

9

Page 10

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems you are experiencing

with your MTS software, hardware, manuals, or service which have not been

resolved to your satisfaction through the technical support process. This form

includes check boxes that allow you to indicate the urgency of your problem and

your expectation of an acceptable response time. We guarantee a timely

response—your feedback is important to us.

The Problem Submittal Form can be accessed:

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form (electronic form to

be e-mailed to MTS)

Technical Support

10

318 Load Unit

Page 11

Preface

Before You Begin

Safety first! Before you attempt to use your MTS product or system, read and understand the

Safety manual and any other safety information provided with your system.

Improper installation, operation, or maintenance of MTS equipment in your test

facility can result in hazardous conditions that can cause severe personal injury or

death and damage to your equipment and specimen. Again, read and understand

the safety information provided with your system before you continue. It is very

important that you remain aware of hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional MTS manuals in paper or

electronic form.

If you have purchased a test system, it may include an MTS System

Documentation CD. This CD contains an electronic copy of the MTS manuals

that pertain to your test system, including hydraulic and mechanical component

manuals, assembly drawings and parts lists, and operation and preventive

maintenance manuals. Controller and application software manuals are typically

included on the software CD distribution disc(s).

318 Load Unit Preface

11

Page 12

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions As necessary, hazard notices may be embedded in this manual. These notices

contain safety information that is specific to the task to be performed. Hazard

notices immediately precede the step or procedure that may lead to an associated

hazard. Read all hazard notices carefully and follow the directions that are given.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury, equipment damage, or

endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. It is important for you to be

aware that these illustrations are examples only and do not necessarily represent

your actual system configuration, test application, or software.

Electronic manual

conventions

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

12

Preface

318 Load Unit

Page 13

Conventions

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

318 Load Unit Preface

13

Page 14

Conventions

14

Preface

318 Load Unit

Page 15

Introduction

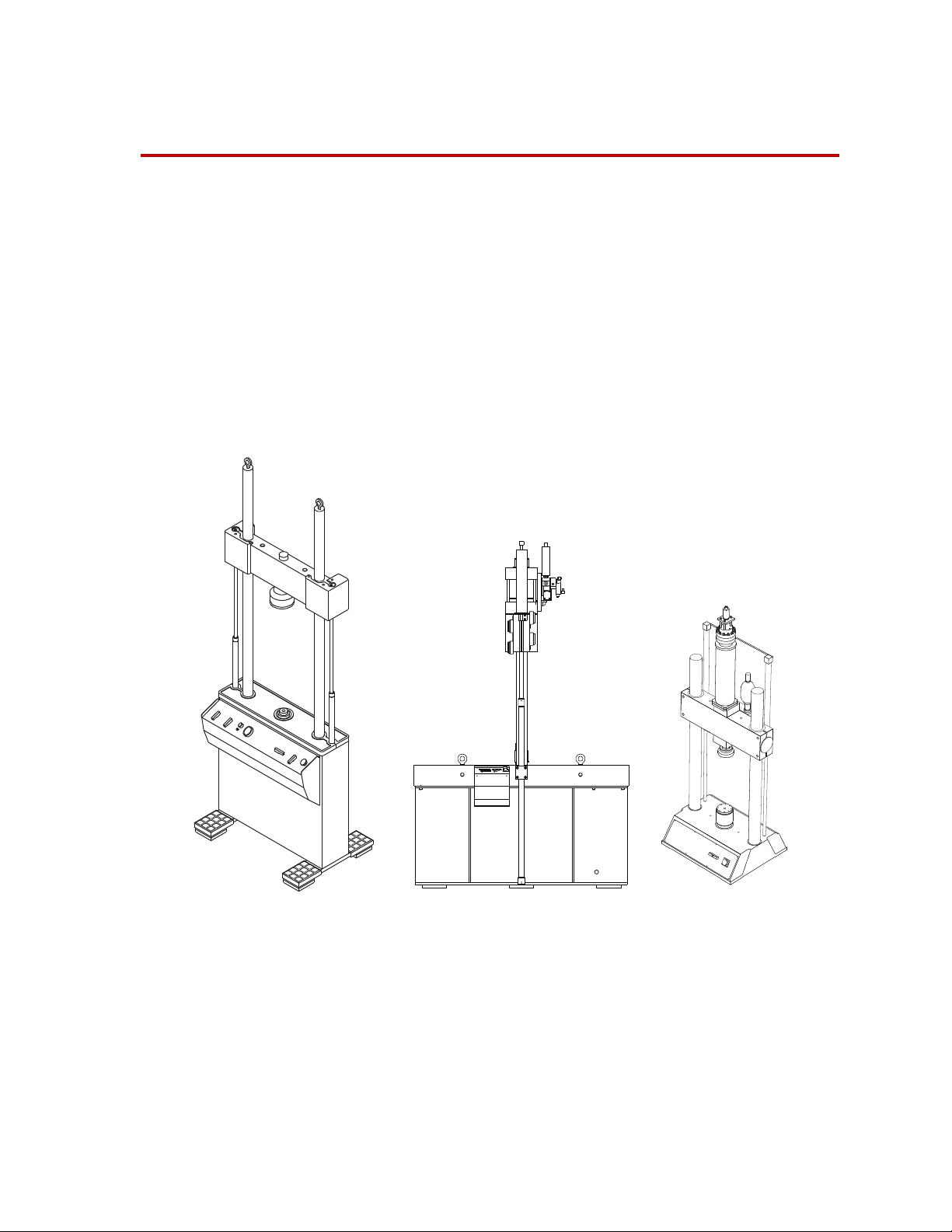

Model 318

Model 322

Model 359

Typical Load Units

Load Unit: Overview

The Load Unit is the primary structure for most materials testing. It is a standalone testing unit. The load unit consists of the load frame plus additional parts,

such as hydraulic crosshead lifts and control modules. Load units come in

different sizes and shapes. The following illustration shows typical load units

with common accessories.

The Load Units are designed for testing materials. They can perform tension and

compression tests, fatigue and fracture mechanics tests, as well as other tests.

MTS manufactures a variety of grips, mounting fixtures, test area guards, and

environmental chambers that can be used with the load unit.

318 Load Unit Introduction

15

Page 16

What you

need to know

MTS Systems Corporation assumes that you know how to use your controller.

See the appropriate manual for information about performing any controllerrelated step in this manual’s procedures. You are expected to know how to

perform the following procedures:

• Turn hydraulic pressure on and off

• Select a control mode

• Adjust the actuator position

• Zero a sensor signal

• Zero a sensor output

• Use your grips and fixtures

• Define a simple test

• Run a test

16

Introduction

318 Load Unit

Page 17

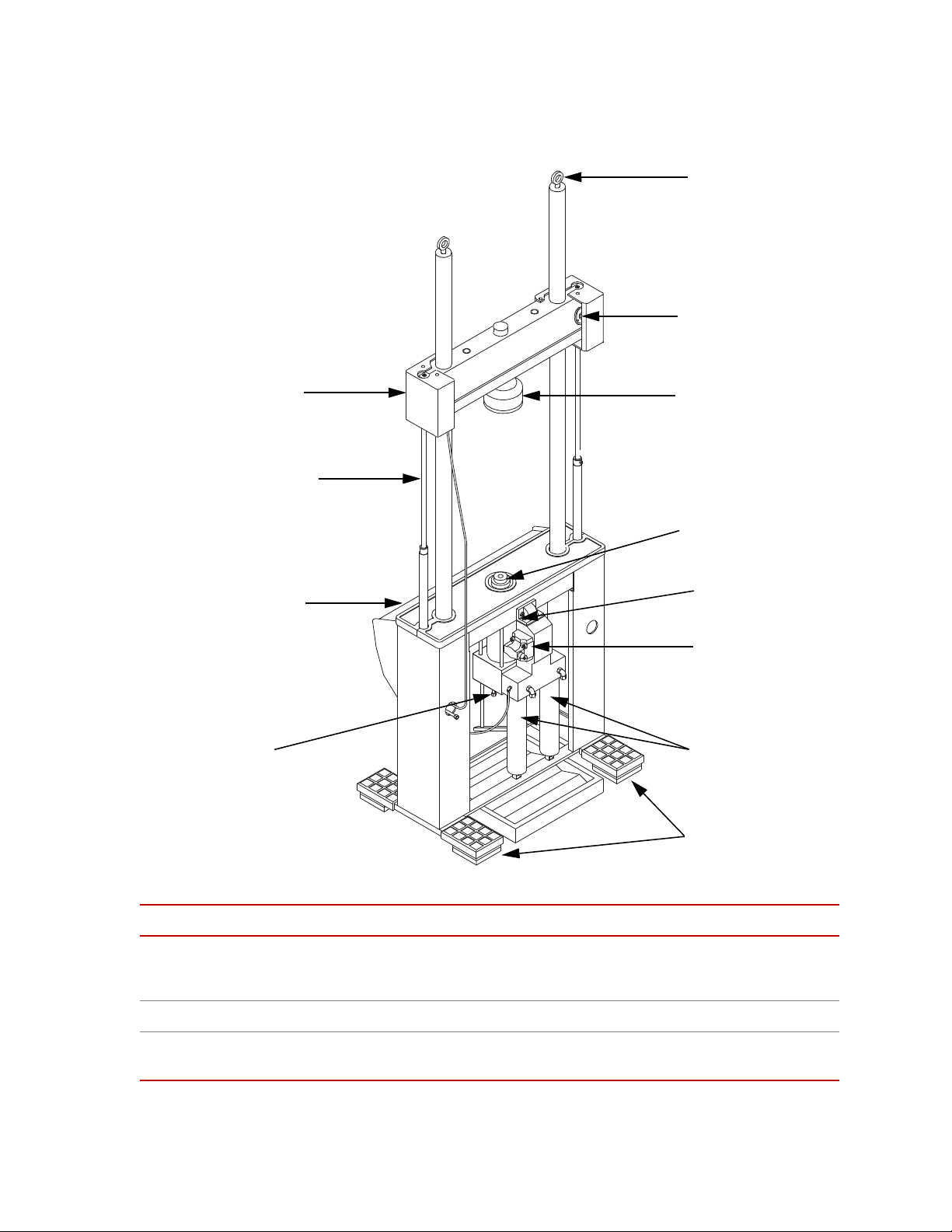

318 Load Unit: Component Identification

11

1

12

2

8

5

7

9

10

3

6

4

Component Descriptions

I

TEM COMPONENT DESCRIPTION

1 Crosshead

Moves the up and down the column to accommodate different sized

specimens and fixtures. The crosshead is stiff and light weight; it is one end of

the force train.

2 Crosshead locks

3 Crosshead lifts

Clamps the crosshead to the columns. The locks are hydraulically powered.

Raises and lowers the crosshead hydraulically to accommodate different

specimen sizes. The lifts are small hydraulic actuators.

318 Load Unit Introduction

17

Page 18

Component Descriptions

TEM COMPONENT DESCRIPTION

I

4 Control panel

Grip

controls

Crosshea

d lift

control

Emergenc

y Stop

5 Servovalve

6Isolation pads

7 Accumulators

8LVDT

9Manifold

The Emergency Stop button is standard; the other controls are optional.

Clamps and unclamps the hydraulically controlled grips during specimen

installation and removal.

Controls the crosshead lifts to raise and lower the crosshead hydraulically.

Removes hydraulic pressure from the load unit and issues an interlock signal

to the controller to stop the test program.

Controls both the flow rate and the direction of fluid entering the actuators. It

determines how fast the actuator extends or retracts.

Dampens the natural frequency to about 20 Hz. Optional air inflated isolators

dampen the frequency to about 2 Hz.

Stores hydraulic fluid under pressure to increase the actuator’s response time.

One accumulator connects to the pressure line; the other to the return line.

Measures the displacement of the actuator’s travel. The linear variable

displacement transducer (LVDT) is located inside the actuator.

Serves as the junction point between the hydraulic power unit (HPU),

accumulators, servovalve, and actuator. The actuator manifold controls the

hydraulic circuit that connects the hydraulic components.

10 Linear actuator

Applies axial forces to specimens. The actuator is a hydraulically powered

device that provides linear displacement of (or forces into) a specimen. Grips

and fixtures can be mounted to the actuator.

11 Force transducer

12 Lifting rings

Measures the axial forces applied to specimen.

Allows the load unit to be moved by lifting the entire load unit.

318 Load Unit: Component Description

The load unit is a stand alone testing structure. It consists of the following

components:

• Load frame

• Crosshead lifts and locks

• Manifold

–Actuators

– Servovalves

– Accumulators

• Transducers

18

Introduction

• Grip controls

318 Load Unit

Page 19

Load frame The load frame is the basic structure which provides the reaction mass for the

force train. The base of the load frame is one end of the reaction mass and the

crosshead is the other end of the reaction mass. Installing a specimen and other

fixtures or components between the load unit base and the crosshead create a

force train.

The load frame and the other hydraulic components mounted to it collectively

create the load unit. The base houses the actuators, servovalves, and hydraulic

manifold. The crosshead is mounted above the base by two columns. A control

panel lets you operate the crosshead lifts, locks, and grips to assist in specimen

installation procedures.

Crosshead lifts

and locks

The crosshead can be positioned anywhere along the load frame columns. It is

moved along the column with hydraulic lifts. When the crosshead is in an

appropriate test position, it is hydraulically clamped to that position. This lets

you change the load unit to test specimens of different lengths.

Actuator manifold The Series 298 Actuator Manifold (also called a hydraulic service manifold or

HSM) acts as the hydraulic interface between the HPU and the components

mounted to the manifold (actuator, servovalves, and accumulators) of the load

unit. It contains the required hydraulic porting and plumbing to accommodate the

hydraulic components. The manifold can also control the hydraulic pressure to

the load unit.

Actuators The Series 244 Actuators can be located in the middle of the load unit base or

crosshead. It is a hydraulically powered piston that applies displacement of (or

force into) a specimen. It can apply equal power in tension and compression. One

end of the test specimen is installed into a fixture which is mounted to the end of

the actuator rod.

Servovalves The Series 252 Servovalves regulates the direction and flow of the hydraulic

fluid to and from a hydraulic actuator. The servovalve responds to the polarity

and magnitude of the command signal generated by the controller.

Accumulators The Series 111 Accumulators suppress line-pressure fluctuations. The load unit

includes a pressure-line accumulator to provide fluid storage so a constant line

pressure can be maintained at the servovalves for maximum performance. The

return-line accumulator minimizes return-line pressure fluctuations.

Pressure control The load unit can be configured for several pressure configurations. The free low

configuration passes the hydraulic pressure from the HPU (or hydraulic service

manifold) through the manifold to the hydraulic components. The hydraulic

pressure options include on/off control, high/low/off control, and high/low/off

control with a proportional valve to ramp the pressure transitions.

Transducers The load unit includes a force transducer and an LVDT.

Force The force transducer (also called load cell or force sensor) measures the amount

of tension or compression and rotational torque applied to it. It has four strain

gages that form a balanced Wheatstone bridge. When forces are applied to the

bridge, it becomes unbalanced and produces an electrical signal that is

proportional to the force applied to it. The force transducer is a resistive device

and requires a DC conditioner to process the axial signal from the Wheatstone

bridge.

318 Load Unit Introduction

19

Page 20

LVDT The LVDT measures the linear actuator’s travel. The LVDT consists of a

transformer with one primary and two secondary coils wound on a common

cylinder. The coil is stationary inside the actuator. A core is attached to the piston

rod of the actuator. As it moves inside the coil, it produces an electrical signal

that represents the position of the piston rod. The phase of the signal indicates the

direction the actuator rod is moving. An LVDT requires an AC conditioner to

process the signal.

Grip Controls The grip controls provide independent clamping control of the upper and lower

grips. The maximum pressure for the grip controls can be set up to 69 MPa

(10,000 psi). The pressure is factory set to 20 MPa (3000 psi); 45 MPa (6500

psi); or 69 MPa (10,000 psi) to accommodate a variety of grips manufactured by

MTS Systems Corporation. A front panel control allows the grip pressure to be

adjusted within the factory setting. A rate control sets how fast the grips open and

close.

318 Load Unit: Specifications

This section provides the specifications of the Series 318 Load Unit.

General specifications The following table lists general specifications for the Series 318 Load Unit:

P

ARAMETER SPECIFICATION

Load frame

Lifts

Locks

Grip control

Service manifold

Maximum flow

Axial actuator

Displacements

Accumulator Series 111 Accumulator

Hydraulic (optional)

Hydraulic (optional)

Hydraulic (optional)

Series 298 Actuator Manifold

114 L/min (30 gpm)

Series 244 Actuator

100 mm (4 in)

150 mm (6 in)

250 mm (10 in)

20

Introduction

318 Load Unit

Page 21

PARAMETER SPECIFICATION

Force Ratings The Series 318 Load Units include other products. The following table lists

MODEL FRAME

FATIGUE RATING

Weight*

Base mount

318.10

318.25

318.50

Crosshead mount

318.10

318.25

318.50

* The weight specification is for lifting and moving purposes. The weight of

accessories and special fixtures must be added. The actual shipping

weight must be determined by a scale.

approximate minimum weight

500 kg (1100 lb)

960 kg (2120 lb)

1900 kg (4200 lb)

555 kg (1225 lb)

1065 kg (2345 lb)

2100 kg (4625 lb)

specifications from several product information manuals. Specifications listed in

the respective product information manual supersede the following

specifications.

ACTUATOR

*

R

ATING

TRANSDUCER

R

ATING

MOUNTING

T

HREADS

318.10 100 kN

(22 kip)

318.25 250 kN

(55 kip)

318.50 500 kN

(110 kip)

* At 21 MPa (3000 psi)

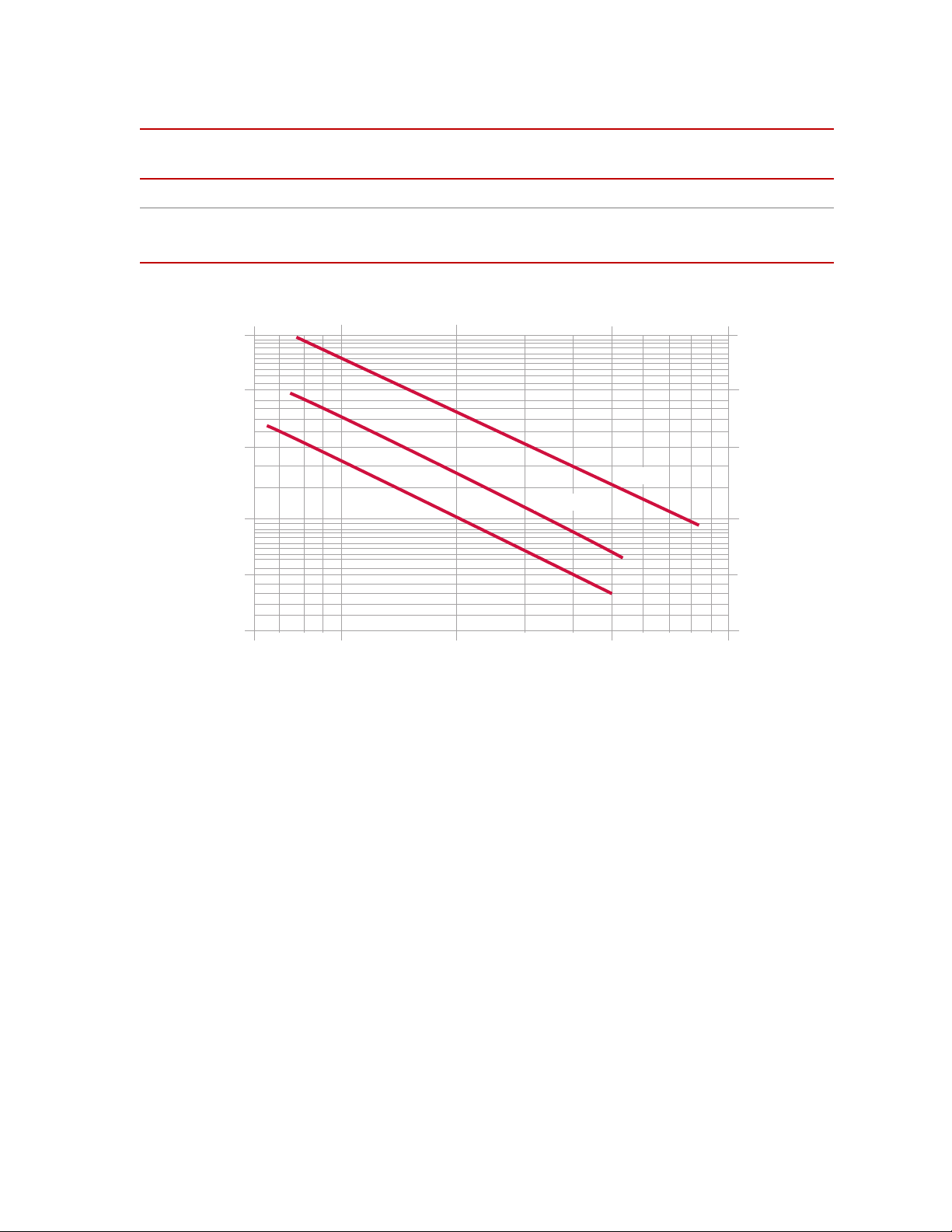

Stiffness Data Stiffness is a way to measure the deflection of the force train. Deflection rates can

25 kN

(5.5 kip)

50 kN

(11 kip)

100 kN

(22 kip)

100 kN

(22 kip)

250 kN

(55 kip)

250 kN

(55 kip)

500 kN

(110 kip)

25 kN

(5.5 kip)

50 kN

(11 kip)

100 kN

(22 kip)

100 kN

(22 kip)

250 kN

(55 kip)

250 kN

(55 kip)

500 kN

(110 kip)

M27 x 2

(1 - 14 UNS)

M27 x 2

(1 - 14 UNS)

M27 x 2

(1 - 14 UNS)

M27 x 2

(1 - 14 UNS)

M36 x 2

(1 1/2 - 12 UNF)

M36 x 2

(1 1/2 - 12 UNF)

M52 x 2

(2 -12 UNF)

vary 20%, depending on the actuator and force transducer you use.

318 Load Unit Introduction

21

Page 22

For the most accurate high frequency test results, use a load unit with a fatigue

A

B

D

C

rating that is larger than its actuator’s force rating.

For example, a Model 318.25 Load Unit with a 55 kip fatigue rating and a 22 kip

actuator will have smaller deflections than a Model 318.10 Load Unit with a 22

kip fatigue rating and a 22 kip actuator.

Spring rates are determined at each load unit’s full fatigue rating with its

crosshead raised 1270 mm (50 in.) above the baseplate.

The Stiffness Graph shows how stiffness is affected when the height of the

crosshead is changed.

DEFLECTIONS MODEL 318.10

100

KN/22 KIP

A - B base 0.15 mm 0.006 in 0.18 mm 0.007 in 0.20 mm 0.008 in

B - C columns 0.10 mm 0.004 in 0.15 mm 0.006 in 0.18 mm 0.007 in

C - D crosshead 0.13 mm 0.005 in 0.25 mm 0.010 in 0.28 mm 0.011 in

Introduction

22

MODEL 318.25

250

KN/55 KIP

MODEL 318.50

500

KN/110 KIP

318 Load Unit

Page 23

DEFLECTIONS MODEL 318.10

Free Column Length (cm)

Free Column Length (in)

Maximum Side Load Limits (kips)

Maximum Side Load Limits (kN)

10 25 50 125 250

5 10 20 50 100

20

10

5

2

1

0.5

80

45

22

9

4.5

2

318.10

318.25

318.50

100

KN/22 KIP

A - D overall frame 0.38 mm 0.015 in 0.58 mm 0.023 in 0.66 mm 0.026 in

MODEL 318.25

250

KN/55 KIP

MODEL 318.50

500

KN/110 KIP

Spring rates

2.6 x 10

(1.5 x 10

8

N/m

6

lb/in)

4.3 x 10

(2.4 x 10

8

N/m

6

lb/in)

7.5 x 10

(4.3 x 10

8

N/m

6

ib/in)

Stiffness Graph

318 Load Unit Introduction

23

Page 24

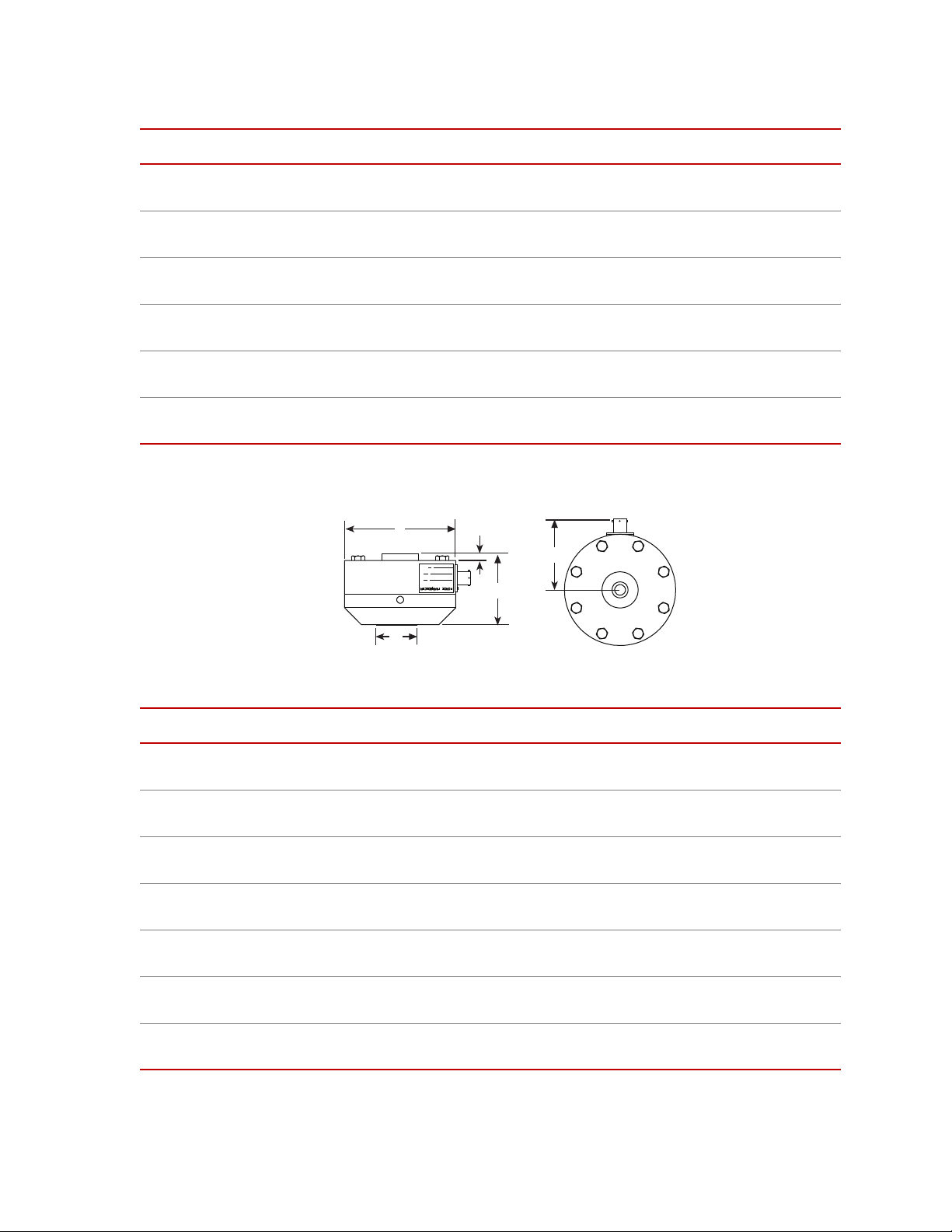

Series 661 Force Transducer: Specifications

The force transducer used with this system is a Series 661 Force Transducer. The

following are the specifications for the force transducers.

ARAMETER SPECIFICATION

P

Maximum excitation voltage 15 V DC

Bridge resistance 350 ¾

Maximum crosstalk 1.0% of full scale torsional to load

Hysteresis 0.08% of full scale (250 N–2.5 kN)

Nonlinearity 0.08% of full scale

0.05% of full scale (5 kN–50 kN)

0.15% of full scale (100 kN–500 kN)

0.20% of full scale (1000 kN)

0.15% of full scale for Models 661.22/.23/.31

Temperature

Output 2 mV/V at full-scale load

Connector PT02ER-10-6P

MODEL LOAD CAPACITY

661.11-01 250 N

(50 lbf)

661.11-02 500 N

(100 lbf)

661.18-01 1 kN

(220 lbf)

661.18-02 2.5 kN

(550 lbf)

661.19-01 5 kN

(550 lbf)

Usable range

Compensated range

Sensitivity

THREAD SIZE

M6 x 1.0 mm x 6.3 mm

(1/4 - 28 UNF x 0.25 in

M6 x 1.0 mm x 6.3 mm

(1/4 - 28 UNF x 0.5 in

M12 x 1.25 mm x 25.4 mm

(1/2 - 20 UNF x 1.0 in)

M12 x 1.25 mm x 25.4 mm

(1/2 - 20 UNF x 1.0 in)

M12 x 1.25 mm x 25.4 mm

(1/2 - 20 UNF x 1.0 in)

*

0.004% of reading/°C (0.002%/°F)

-54°C (-65°F) to +121°C (+250°F)

+21°C (+70°F) to +77°C (+170°F)

0.0036% of full scale/°C

(0.0020% of full scale/°F)

WEIGHT

0.45 kg

(1 lb)

0.45 kg

(1 lb)

2.27 kg

(5 lb)

2.27 kg

(5 lb)

3.07 kg

(6.75 lb)

661.19-02 10 kN

(2.2 kip)

661.19-03 15 kN

(3.3 kip)

661.19-04 25 kN

(5.5 kip)

Introduction

24

M12 x 1.25 mm x 25.4 mm

(1/2 - 20 UNF x 1.0 in)

M12 x 1.25 mm x 25.4 mm

(1/2 - 20 UNF x 1.0 in)

M12 x 1.25 mm x 25.4 mm

(1/2 - 20 UNF x 1.0 in)

3.07 kg

(6.75 lb)

3.07 kg

(6.75 lb)

3.07 kg

(6.75 lb)

318 Load Unit

Page 25

MODEL LOAD CAPACITY

A

B

C

D

E

THREAD SIZE

*

WEIGHT

661.20-01 25 kN

(5.5 kip)

661.20-02 50 kN

(11 kip)

661.20-03 100 kN

(2.2 kip)

661.22-01 250 kN

(3.3 kip)

661.23-01 500 kN

(5.5 kip)

661.31-01 1000 kN

(220 kip)

* The thread sizes are available with either coarse or fine threads.

M27 x 2.0 mm x 31.7 mm

(1 - 14 UNS-3B x 1.25 in)

M27 x 2.0 mm x 31.7 mm

(1 - 14 UNS-3B x 1.25 in)

M27 x 2.0 mm x 31.7 mm

(1 - 14 UNS-3B x 1.25 in)

M36 x 2.0 mm

(1 1/2 - 12 UNC-2B)

M52 x 2.0 mm x 48.3 mm

(2.0 - 12 UN-2B x 1.9 in)

M76 x 1.75 mm x 28.4 mm

(2.0 - 12 UN-2B x 1.35 in)

Dimensions The following dimensions are rounded off to the nearest millimeter or eight-inch.

9.75 kg

(21.5 lb)

9.75 kg

(21.5 lb)

9.75 kg

(21.5 lb)

13.2 kg

(29 lb)

16 kg

(35.3 lb)

49.9 kg

(110 lb)

MODEL A

661.11-01 70 mm

(2–3/4 in)

661.18-01 105 mm

(4–1/4 in)

661.19-01 105 mm

(4–1/4 in)

661.20-01 154 mm

(6 in)

661.22-01 114 mm

(4–1/2 in)

661.23-01 152 mm

(6 in)

661.31-01 222 mm

(8–3/4 in)

* This dimension applies to both ends

318 Load Unit Introduction

*

B

18 mm

(3/4 in)

32 mm

(1–1/4 in)

32 mm

(1–1/4 in)

57 mm

(2–1/4 in)

92 mm

(3–5/8 in)

140 mm

(5–1/5 in)

203 mm

(8 in)

CD*E

7 mm

(1/4 in)

7 mm

(1/4 in)

7 mm

(1/4 in)

10 mm

(3/8 in)

1 mm

(>1/4 in)

N/A 203 mm

N/A 305 mm

38 mm

(1–1/5 in)

67 mm

(2–5/8 in)

67 mm

(2-5/8 in)

95 mm

(3–3/4n)

203 mm

(8 in)

(8 in)

(12 in)

61 mm

(2–3/8 in

64 mm

(2–1/5 in)

64 mm

(2–1/5 in)

89 mm

(3–1/2 in)

74 mm

(2–7/8 in)

86 mm

(3–3/8 in)

124 mm

(4–7/8 in)

25

Page 26

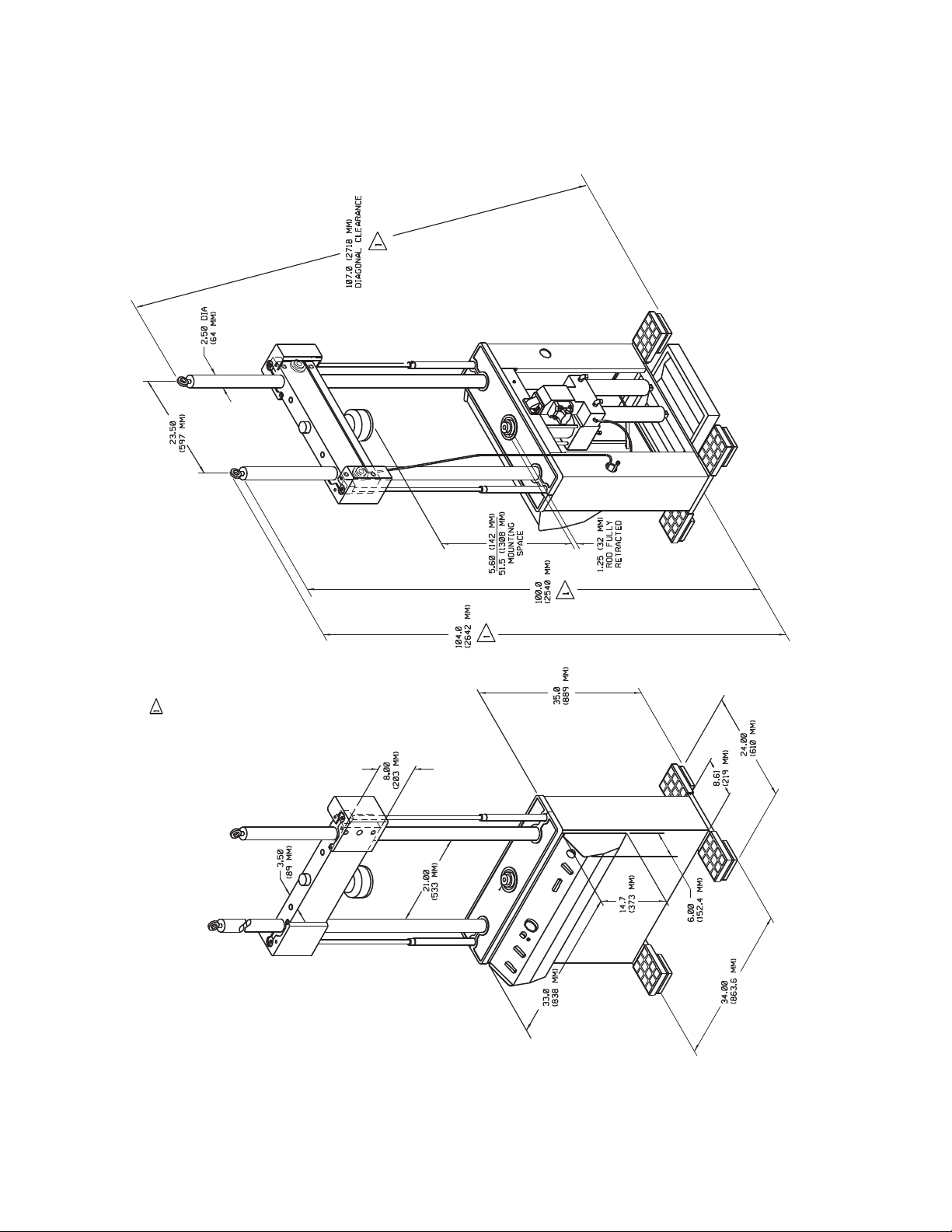

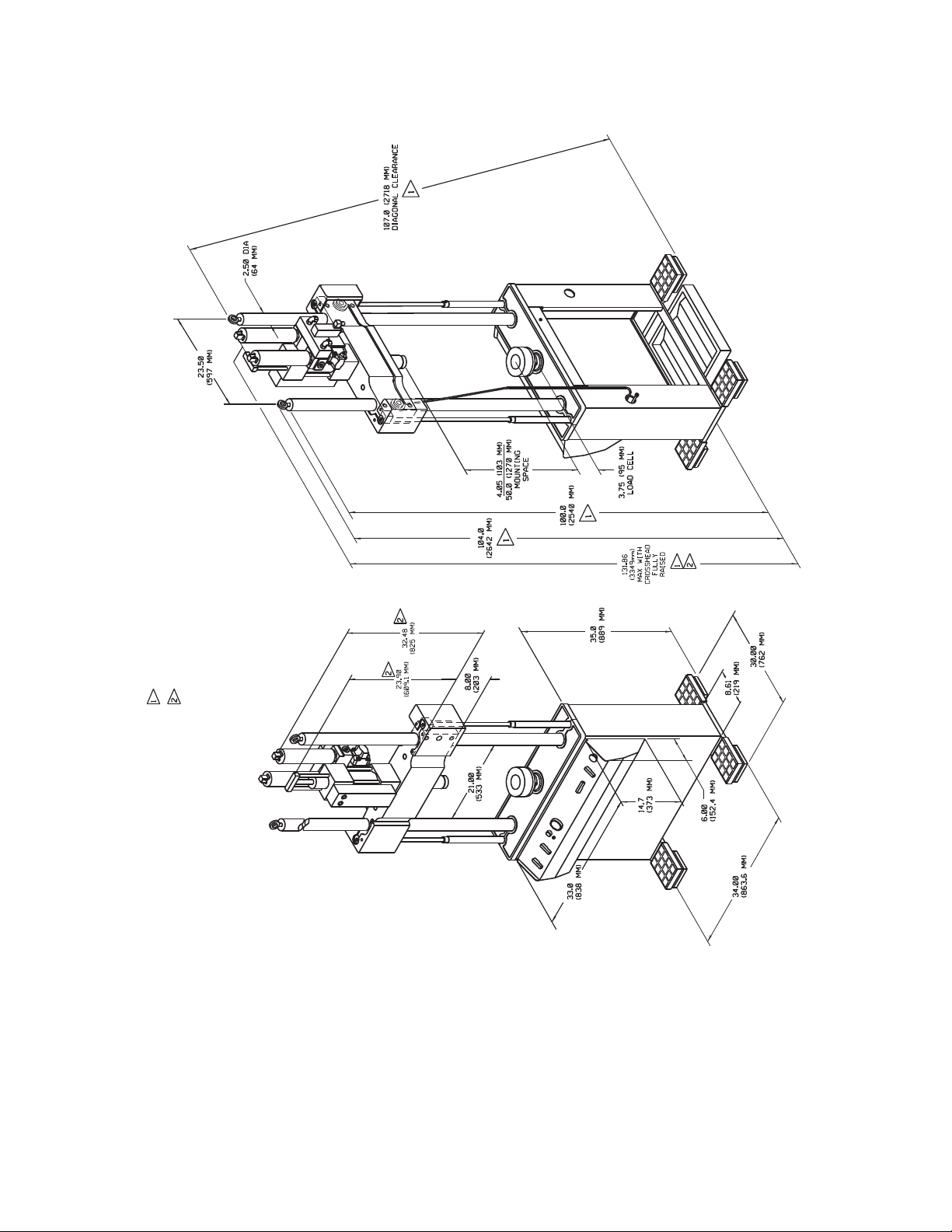

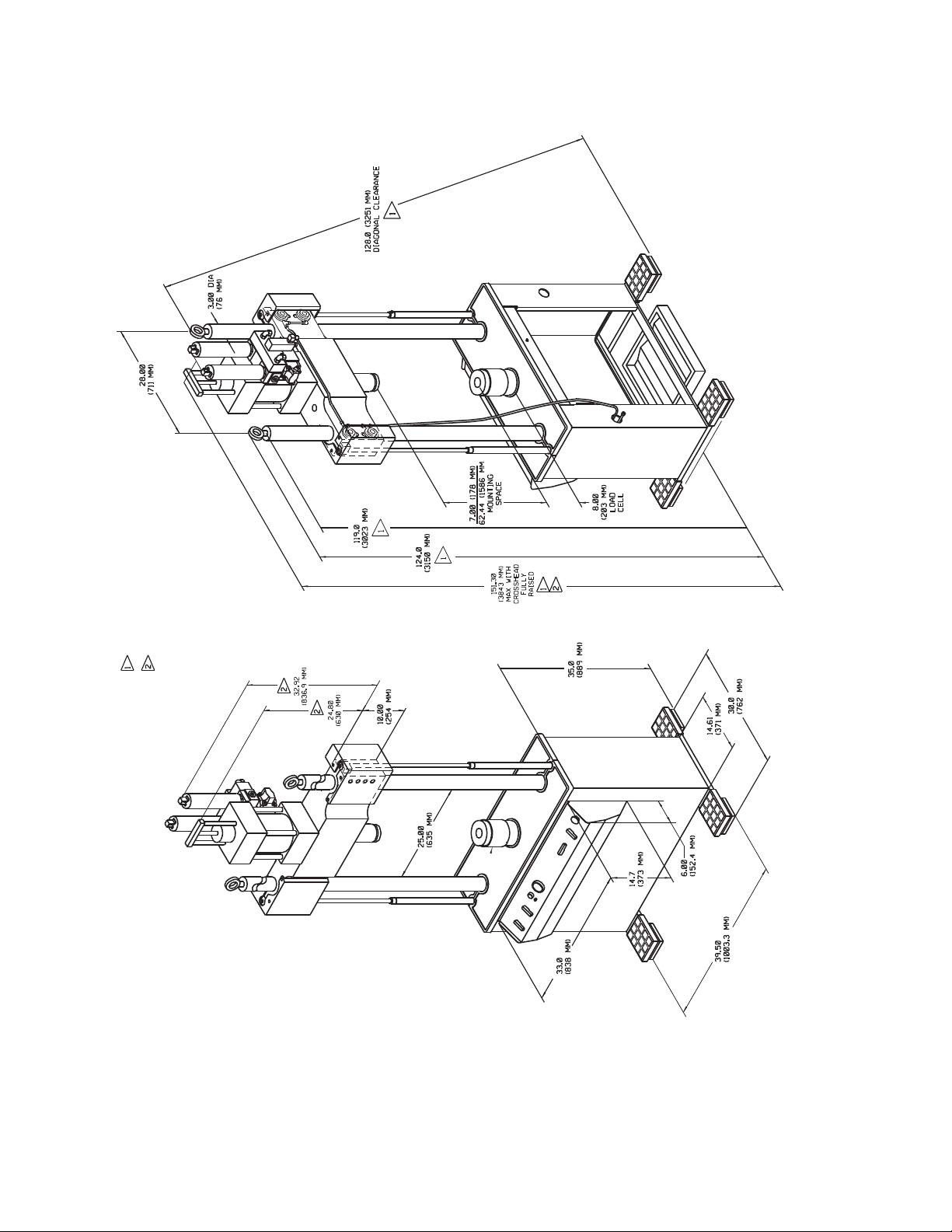

318 Load Unit: Dimensions

Standard column lengths indicated

Note: Dimensions are inches

(mm)

Weight: 1100 lbs (500 kg) is normal maximum

weight. Accessories and special fixtures

must be added. This weight specification

is for lifting and moving purposes.

Actual shipping weight must be

determined by scale.

Introduction

26

318.10B Load Unit Dimensions

318 Load Unit

Page 27

Standard column lengths indicated

Note: Dimensions are inches

(mm)

Standard column lengths indicated

Note: Dimensions are inches

(mm)

318.25B Load Unit Dimensions

318 Load Unit Introduction

27

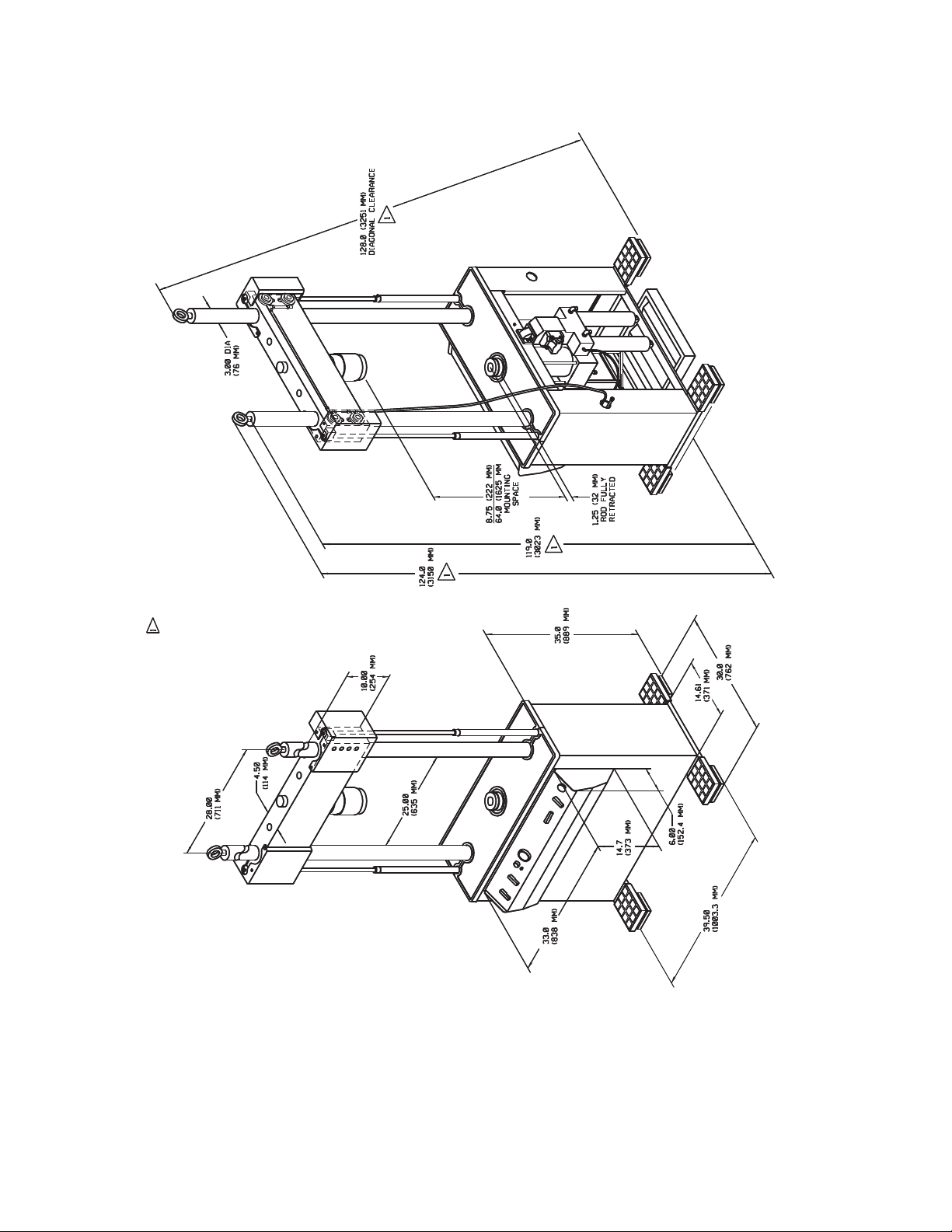

Page 28

Standard column lengths

Note: Dimensions are

(mm

Weight: 4200 lbs (1900 kg) is normal

maximum weight. Accessories and

special

fixtures must be added. This weight

specification is for lifting and moving

purposes. Actual shipping weight

318.50B Load Unit Dimensions

28

Introduction

318 Load Unit

Page 29

Standard column lengths

Standard 6" (152.5 mm) actuator stroke indicated

Note: Dimensions are

(mm

Weight: 1100 lbs (500 kg) is normal

maximum

weight. Accessories and special fixtures

must be added. This weight specification

is for lifting and moving purposes.

Actual shipping weight must be

318.10B Load Unit with Crosshead Actuator Dimensions

318 Load Unit Introduction

29

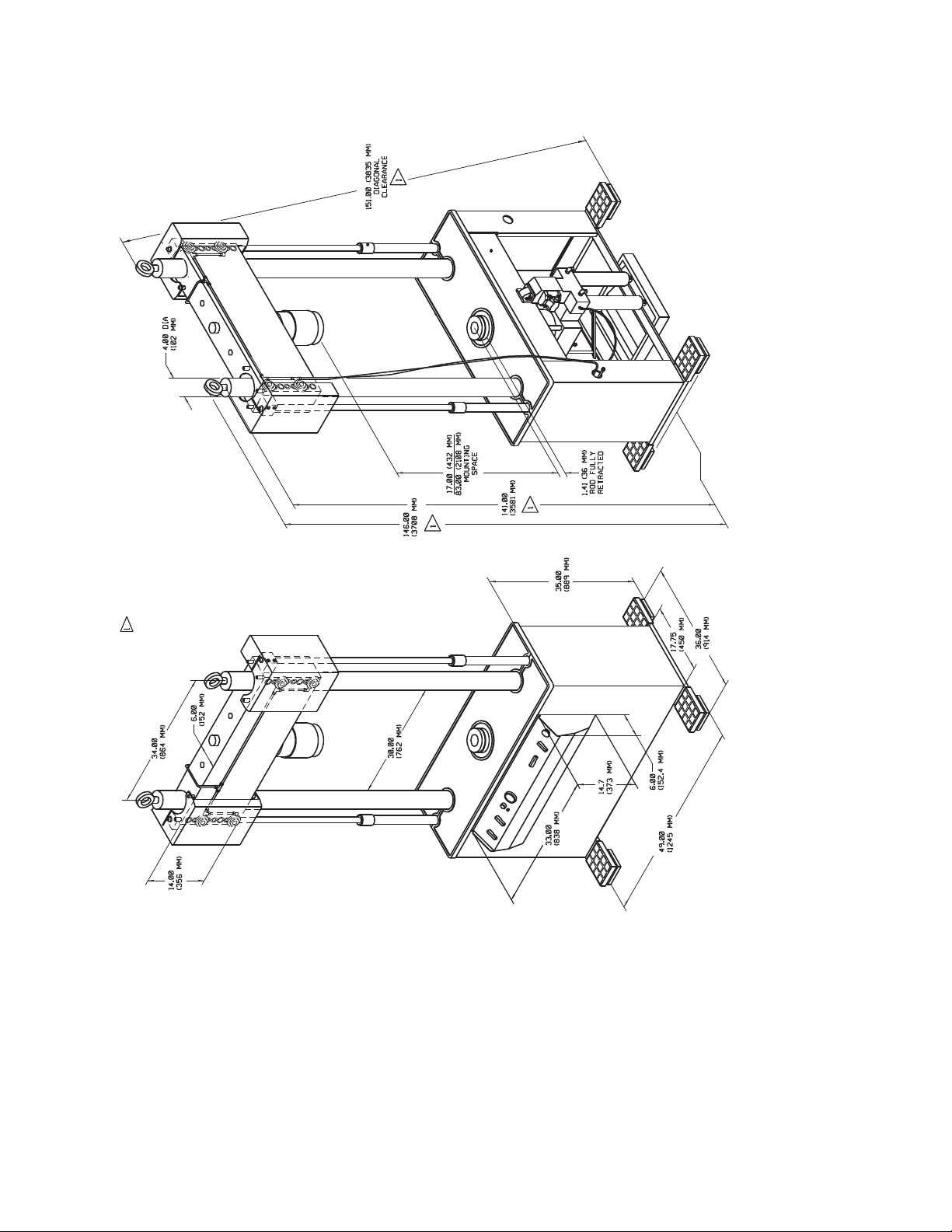

Page 30

Standard column lengths indicated

Standard 6" (152.5 mm) actuator stroke indicated

Note: Dimensions are inches

(mm)

Weight: 2120 lbs (960 kg) is normal maximum

weight. Accessories and special fixtures

must be added. This weight specification

is for lifting and moving purposes.

Actual shipping weight must be

determined by scale.

318.25B Load Unit with Crosshead Actuator Dimensions

30

Introduction

318 Load Unit

Page 31

Standard column lengths

Standard 6" (152.5 mm) actuator stroke indicated

Note: Dimensions are

(mm

Weight: 4200 lbs (1900 kg) is normal

maximum weight. Accessories and

special

fixtures must be added. This weight

specification is for lifting and moving

purposes. Actual shipping weight

318.50B Load Unit with Crosshead Actuator Dimensions

318 Load Unit Introduction

31

Page 32

32

Introduction

318 Load Unit

Page 33

Safety

General Safety Practices

This section provides information about safety issues that pertain to

servohydraulic systems in general. These issues include statements to the

intended use and foreseeable misuse of the system, the hazard zone, definition for

the graphical hazard labeling that is affixed to your product, and other (more

general) safety information that relates to the high-pressure and highperformance characteristics of MTS servohydraulic systems.

MTS test systems are designed to generate motions and forces and impart these

motions and forces into a test specimen.

When you prepare to operate the system and during system operation, ensure the

following:

• Do not use or allow personnel to operate the system who are not

• Do not disable safety components or features (including limit detectors,

experienced, trained, or educated in the inherent dangers associated with

high-performance servo hydraulics and who are not experienced, trained, or

educated with regard to the intended operation as it applies to this test

system.

light curtains, or proximity switches/detectors).

• Do not attempt to operate the system without appropriate personal safety

gear (for example, hearing, hand, and eye protection).

• Do not apply energy levels that exceed the maximum energies and velocities

for the system design. Refer to the system specifications.

• Do not test a specimen that exceeds the minimum (if applicable) or

maximum allowable mass. Refer to the system specifications.

• Do not use specimens that are combustible, flammable, pressurized, or

explosive.

• Do not use humans as specimens or allow humans to ride in or on the test

specimen or the test system for any purpose unless the system is man-rated

and all associated safety conditions are strictly enforced.

• Do not modify the system or replace system components using parts that are

not MTS component parts or effect repairs using parts or components that

are not manufactured to MTS specifications.

• Do not operate the system in an explosive atmosphere.

• Do not use the system in a test area where uncontrolled access to the test

system is allowed when the system is in operation

• Do not operate the system unless an interlock is installed to monitor supply

pressure into the HSM and initiate a system interlock if a low or no pressure

event occurs.

318 Load Unit Safety

33

Page 34

If you have system related responsibilities (that is, if you are an operator, service

engineer, or maintenance person), you should study safety information carefully

before you attempt to perform any test system procedure.

You should receive training on this system or a similar system to ensure a

thorough knowledge of your equipment and the safety issues that are associated

with its use. In addition, you should gain an understanding of system functions

by studying the other manuals supplied with your test system. Contact MTS for

information about the content and dates of training classes that are offered.

It is very important that you study the following safety information to ensure that

your facility procedures and the system’s operating environment do not

contribute to or result in a hazardous situation. Remember, you cannot eliminate

all the hazards associated with this system, so you must learn and remain aware

of the hazards that apply to your system at all times. Use these safety guidelines

to help learn and identify hazards so that you can establish appropriate training

and operating procedures and acquire appropriate safety equipment (such as

gloves, goggles, and hearing protection).

Each test system operates within a unique environment which includes the

following known variables:

• Facility variables (facility variables include the structure, atmosphere, and

utilities)

• Unauthorized customer modifications to the equipment

• Operator experience and specialization

• Test specimens

Because of these variables (and the possibility of others), your system can

operate under unforeseen circumstances that can result in an operating

environment with unknown hazards.

Improper installation, operation, or maintenance of your system can result in

hazardous conditions that can cause death, personal injury, or damage to the

equipment or to the specimen. Common sense and a thorough knowledge of the

system’s operating capabilities can help to determine an appropriate and safe

approach to its operation.

Safety Practices Before System Operation

Before you apply hydraulic power to the test system, review and complete all of

the safety practices that are applicable to your system. The goal, by doing this, is

to improve the safety awareness of all personnel involved with the system and to

maintain, through visual inspections, the integrity of specific system

components.

Read all manuals Study the contents of this manual and the other manuals provided with your

system before attempting to perform any system function for the first time.

Procedures that seem relatively simple or intuitively obvious can require a

complete understanding of system operation to avoid unsafe or dangerous

situations.

34

Safety

318 Load Unit

Page 35

Locate and read

hazard placards/labels

Find, read, and follow the hazard placard instructions located on the equipment.

These placards are placed strategically on the equipment to call attention to areas

such as known crush points and electrical voltage hazards.

Locate Lockout/tagout

points

Know facility safe

procedures

Locate Emergency

Stop buttons

Know where the lockout/tagout point is for all of the supply energies associated

with your system. This includes the hydraulic, pneumatic, electric, and water

supplies (as appropriate) for your system to ensure that the system is isolated

from these energies when required.

Most facilities have internal procedures and rules regarding safe practices within

the facility. Be aware of these safe practices and incorporate them into your daily

operation of the system.

Know the location of all the system Emergency Stop buttons so that you can

stop the system quickly in an emergency. Ensure that an Emergency Stop button

is located within 2 meters (6 feet) of the operator at all times.

Know controls Before you operate the system for the first time, make a trial run through the

operating procedures with the power off. Locate all hardware and software

controls and know what their functions are and what adjustments they require. If

any control function or operating adjustment is not clear, review the applicable

information until you understand it thoroughly.

Have first aid available Accidents can happen even when you are careful. Arrange your operator

schedules so that a properly trained person is always close by to render first aid.

In addition, ensure that local emergency contact information is posted clearly and

in sight of the system operator.

Know potential crush

and pinch points

Be aware of potential crush and pinch points on your system and keep personnel

and equipment clear of these areas.

Be aware of

component movement

with hydraulics off

Know electrical

hazards

Remember, when hydraulic power is interrupted on a servohydraulic system, it is

likely that stored accumulator pressure will persist for some time within the

system. In addition, it is likely that as stored energy dissipates, gravity will cause

portions of the system to move.

The crosshead can slowly drift down the columns if the locks are turned off and

when hydraulic pressure is turned off. The crosshead can damage any test

fixtures, grips, and specimen in its path. Unlock the crosshead only to reposition

it. Always lock the crosshead after you have repositioned it and never leave the

crosshead unlocked.

The actuator rod can also drift down when hydraulics are turned off hitting

anything in its path. This uncommanded movement is because of oil movement

between the pressure/return ports and oil blow by across the piston hub. Be aware

that this can happen and clear the area around the actuator rod when hydraulics

are turned off.

When the system electrical power is turned on, minimize the potential for

electrical shock hazards. Wear clothing and use tools that are properly insulated

for electrical work. Avoid contact with exposed wiring or switch contacts.

Whenever possible, turn off electrical power when you work on or in proximity

to any electrical system component. Observe the same precautions as those given

for any other high-voltage machinery.

318 Load Unit Safety

35

Page 36

Keep bystanders

safely away

Keep bystanders at a safe distance from all equipment. Never allow bystanders to

touch specimens or equipment while the test is running.

Wear proper clothing Do not wear neckties, shop aprons, loose clothing or jewelry, or long hair that

could get caught in equipment and result in an injury. Remove loose clothing or

jewelry and restrain long hair.

Remove flammable

fluids

Know compressed gas

hazards

Remove flammable fluids from their containers or from components before you

install the container or component. If desired, you can replace the flammable

fluid with a non-flammable fluid to maintain the proper proportion of weight and

balance.

Most servohydraulic systems contain accumulators that require a high-pressure

gas precharge (pressures that exceed 138 bar [2000 psi]). In addition, some

systems can contain devices, such as static supports, that are pneumatically

operated. High-pressure devices are potentially dangerous because a great

amount of energy is available in the event of an uncontrolled expansion or

rupture.

36

Safety

318 Load Unit

Page 37

Observe the following safety practices when you work with high-pressure air or

gases:

• When you charge an accumulator, follow all the charging instructions

provided in the appropriate product information manuals. When precharging

accumulators, properly identify the type of gas to be used and the type of

accumulator to be precharged.

Use only dry-pumped nitrogen to precharge nitrogen-charged accumulators.

(Dry-pumped nitrogen can also be labeled “oil pumped” or “dry water

pumped.”) Do not use compressed air or oxygen for precharging: the

temperature increase caused by rapid gas compression can result in highly

explosive conditions when hydraulic fluid is in the presence of oxygen or

compressed air.

• Always follow the recommended bleeding procedures before you remove or

disassemble components that contain pressurized gas. When you bleed a gas

or remove a fitting, hose, or component that contains a gas, remember that

many gases cannot support life. Therefore, as the ratio of released gas to

oxygen increases, so does the potential for suffocation.

• Wear appropriate safety devices to protect your hearing. Escaping air or gas

can create a noise level that can damage your hearing.

• Ensure that all pressurized air or gas is bled out of a pneumatic or gas-

charged device before you start to disassemble it. A thorough understanding

of the assembly and its pressurized areas is necessary before you undertake

any maintenance. Refer to the appropriate product information for the

correct bleeding procedure.

Check bolt ratings and

torques

It might not be obvious or intuitive which bolts or fittings are used to

restrain a pressurized area. On some assemblies, you must remove a cover

plate to gain access to the structural bolts. Sometimes, to protect you from a

rapid release of trapped gases, a small port is exposed when you remove this

cover plate. Exposing this port ensures that the gas precharge is fully bled

before disassembly. However, this is not the recommended procedure for

bleeding a pneumatic or gas-charged device, because it can expose you to

the dangers of escaping compressed gas and particulates that are expelled

from the chamber or around the seals. Do not assume that cover plates and

ports are installed in all the critical locations.

Consult MTS when in doubt about the safety or reliability of any system-related

procedure or modification that involves devices that contain any type of

compressed gas.

To ensure a reliable product, fasteners (such as bolts and tie rods) used in MTSmanufactured systems are torqued to specific requirements. If a fastener is

loosened or the configuration of a component within the system is modified, refer

to the system and component assembly drawings (located on the System

Documentation CD) to determine the correct fastener, fastener rating, and torque.

Overtorquing or undertorquing a fastener can create a hazardous situation due to

the high forces and pressures present in MTS test systems.

318 Load Unit Safety

37

Page 38

On rare occasions, a fastener can fail even when it is correctly installed. Failure

usually occurs during torquing, but it can occur several days later. Failure of a

fastener can result in a high velocity projectile. Therefore, it is a good practice to

avoid stationing personnel in line with or below assemblies that contain large or

long fasteners.

Practice good

housekeeping

Protect hoses and

cables

Provide proper

hydraulic fluid

filtration.

Protect accumulators

from moving objects.

Keep the floors in the work area clean. Hydraulic fluid that is spilled on any type

of floor can result in a dangerous, slippery surface. Do not leave tools, fixtures,

or other items not specific to the test, lying about on the floor, system, or decking.

Protect electrical cables from spilled hydraulic fluid and from excessive

temperatures that can cause the cables to harden and eventually fail. Ensure that

all cables have appropriate strain relief devices installed at the cable and near the

connector plug. Do not use the connector plug as a strain relief.

Protect all system hoses and cables from sharp or abrasive objects that can cause

the hose or cable to fail. Never walk on hoses or cables or move heavy objects

over them. Consider hydraulic distribution system layout and route hoses and

cables away from areas that expose them to possible damage.

When removing hydraulic hoses for equipment repair or changing testing

components (for example, hydraulic grips), make sure to cap the hose ends to

avoid spilling hydraulic fluid.

If the system is equipped with a non-MTS hydraulic power unit, ensure proper

filtration to the hydraulic distribution system and testing components. Particles

present in hydraulic fluid and cause erratic or poor system response.

Protect accumulators with supports or guards. Do not strike accumulators with

moving objects. This could cause the accumulator(s) to separate from the

manifold resulting in equipment damage and personal injury.

Record changes If you change any operating procedure, write the change and the date of the

change in the appropriate manual.

Provide test area

guards

Do not exceed the

Maximum Supply

Pressure

Do not disable safety

devices

Use appropriately

sized fuses

Use protective guards such as cages, enclosures, and special laboratory layouts

when you work with hazardous test specimens (for example, brittle or

fragmenting materials or materials that are internally pressurized).

For standard MTS systems, ensure that hydraulic supply pressure is limited to a

maximum 21 MPa (3000 psi). If you system has a custom application that

requires higher pressure, make sure you limit supply pressure to that rated for the

custom components.

Your system might have active or passive safety devices installed to prevent

system operation if the device indicates an unsafe condition. Do not disable such

devices as it can result in unexpected system motion.

Whenever you replace fuses for the system or supply, ensure that you use a fuse

that is appropriately sized and correctly installed. Undersized or oversized fuses

can result in cables that overheat and fuses that explode. Either instance creates a

fire hazard.

38

Safety

318 Load Unit

Page 39

Provide adequate

lighting

Ensure adequate lighting to minimize the chance of operation errors, equipment

damage, and personal injury. You need to see what you are doing.

Provide means to

access out-of-reach

components

Ensure equipment is

secure

Make sure you can access system components that might be out of reach while

standing on the floor. For example ladders or scaffolding might be required to

reach load cell connectors on tall load units.

Make sure the equipment is secure or provide vibration isolation. Some testing

can be performed at resonant frequencies that might cause the equipment to

vibrate and move during testing.

Safety Practices While the System Is in Operation

Wear appropriate

personal protection

Provide test area

guards

Wear eye protection when you work with high-pressure hydraulic fluid,

breakable specimens, or when anything characteristic to the specimen could

break apart.

Wear ear protection when you work near electric motors, pumps, or other devices

that generate high noise levels. Some systems can create sound pressure levels

that exceed 70 dbA during operation.

Wear appropriate personal protection equipment (gloves, boots, suits, respirators)

whenever you work with fluids, chemicals, or powders that can irritate or harm

the skin, respiratory system, or eyes.

Use protective guards such as cages, enclosures, and special laboratory layouts

when you work with hazardous test specimens (for example, brittle or

fragmenting materials or materials that are internally pressurized).

Specimen temperature

changes

Handle chemicals

safely

Know servohydraulic

system interlocks

During cyclic testing, the specimen temperature can become hot enough to cause

burns. Wear personal protection equipment (gloves) when handling specimens.

Whenever you use or handle chemicals (for example, hydraulic fluid, batteries,

contaminated parts, electrical fluids, and maintenance waste), refer to the

appropriate MSDS documentation for that material and determine the appropriate

measures and equipment required to handle and use the chemical safely. Ensure

that the chemical is disposed of appropriately.

Interlock devices should always be used and properly adjusted. Interlock devices

are designed to minimize the chance of accidental damage to the test specimen or

the equipment. Test all interlock devices for proper operation immediately before

a test. Do not disable or bypass any interlock devices as doing so could allow

hydraulic pressure to be applied regardless of the true interlock condition. The

Reset/Override button is a software function that can be used to temporarily

override an interlock while attempting to start the hydraulic power unit and gain

control of the system.

Know system limits Never rely on system limits such as mechanical limits or software limits to

protect you or any personnel. System limits are designed to minimize the chance

of accidental damage to test specimens or to equipment. Test all limits for proper

operation immediately before a test. Always use these limits and adjust them

properly.

318 Load Unit Safety

39

Page 40

Do not disturb sensors Do not bump, wiggle, adjust, disconnect, or otherwise disturb a sensor (such as

an accelerometer or extensometer) or its connecting cable when hydraulic

pressure is applied.

Ensure secure cables Do not change any cable connections when electrical power or hydraulic pressure

is applied. If you attempt to change a cable connection while the system is in

operation, an open control loop condition can result. An open control loop

condition can cause a rapid, unexpected system response which can result in

severe personal injury, death, or damage to equipment. Also, ensure that all

cables are connected after you make any changes in the system configuration.

Stay alert Avoid long periods of work without adequate rest. In addition, avoid long periods

of repetitious, unvarying, or monotonous work because these conditions can

contribute to accidents and hazardous situations. If you are too familiar with the

work environment, it is easy to overlook potential hazards that exist in that

environment.

Contain small leaks Do not use your fingers or hands to stop small leaks in hydraulic or pneumatic

hoses. Substantial pressures can build up, especially if the hole is small. These

high pressures can cause the oil or gas to penetrate your skin, causing painful and

dangerously infected wounds. Turn off the hydraulic supply and allow the

hydraulic pressure to dissipate before you remove and replace the hose or any

pressurized component.

Stay clear of moving

equipment/avoid crush

points

Know the causes of

unexpected actuator

motions

Do not use RF

transmitters

Stay clear of mechanical linkages, connecting cables, and hoses that move

because you can get pinched, crushed, tangled, or dragged along with the

equipment. High forces generated by the system can pinch, cut, or crush anything

in the path of the equipment and cause serious injury. Stay clear of any potential

crush points. Most test systems can produce sudden, high-force motion. Never

assume that your reactions are fast enough to allow you to escape injury when a

system fails.

The high force and velocity capabilities of MTS actuators can be destructive and

dangerous (especially if actuator motion is unexpected). The most likely causes

of unexpected actuator response are operator error and equipment failure due to

damage or abuse (such as broken, cut, or crushed cables and hoses; shorted wires;

overstressed feedback devices; and damaged components within the servocontrol

loop). Eliminate any condition that could cause unexpected actuator motion.

Keep radio frequency (RF) transmitters away from the workstation computers,

remote terminals, and electronics consoles. Intense RF fields can cause erratic

operation of the more sensitive circuits in the system.

40

Safety

318 Load Unit

Page 41

Hazard Icons

CON DESCRIPTION

I

Moving parts; pinch points. Keep clear of areas

noted with this label

High pressure fluid or gasses. Do not tamper with

fittings or hoses.

Possible explosive or flying debris. Wear

appropriate protection such as safety goggles and

hearing protection.

Following are the hazard icons used on the MTS products.

Possible tipping hazard. The machine should only

be moved by qualified riggers familiar with moving

heavy, delicate equipment. Once in final operation

position, the frame should be bolted to a suitable

reaction mass.

Alternate possible tipping hazard. The machine

should only be moved by qualified riggers familiar

with moving heavy, delicate equipment. Once in

final operation position, the frame should be bolted

to a suitable reaction mass.

Read the manuals or instructions. Become familiar

with safety information. Also become familiar with

operating and maintenance information.

318 Load Unit Safety

41

Page 42

I

CON DESCRIPTION

Alternate read the manuals or instructions. Become

familiar with safety information. Also become

familiar with operating and maintenance

information.

Hot surfaces. Possible burn hazard. Wear personal

protective equipment such as gloves when working

near hot surfaces.

Object is heavy. Requires more that one person to

lift and move.

318 Load Unit: Hazard Labels

This section provides information on hazard labeling. Part numbers are provided

should replacement labels be necessary due to damage.

42

Safety

318 Load Unit

Page 43

Base Assembly

View A-A

1

1

2

3

4

5

ITEM PART NUMBER DESCRIPTION

1

2

3

4

5

045-384-101 Warning. High force moving parts. Can cause severe injury or

equipment damage.

Stay clear and use eye protection while test is in progress.

Read instructions before operating or servicing.

037-588-901 Identification label. Includes model number, part number, serial

number, force capacity, and manufacture date.

050-275-301 Information label. No step.

050-275-201 Caution. Heavy control panel (up to 15 kg/30 lbs). Can cause

personal injury or equipment damage.

Support control panel until bolts are out. Let down slowly.

005-905-101 Warning. If lift cylinder line is opened, air may enter causing

crosshead to drop when unlocked. Bleed both cylinders before

unlocking crosshead.

318 Load Unit Safety

43

Page 44

Cylinder Assembly

1

2

ITEM PART NUMBER DESCRIPTION

1

2

037-588-801 Identification label. Includes model number, serial number,

assembly number, force, effective date, static stroke, dyn stroke,

and hydrostatic bearing.

038-202-801 Warning. Subjecting this equipment to working pressure above

3000 psi (21 MPa) can result in component rupture and injury to

personnel. See the product manual for safety precautions before

operating.

44

Safety

318 Load Unit

Page 45

318 Load Unit: Crush Point Hazards

6

4

7

H

ydraulicWedgeGri

p

6

4

7

H

ydraulicWedgeGri

p

Crush

point

areas

It is important to stay clear of any potential crush points when the system is

operating. Know where the crush points are in your system and protect yourself

and others from those crush points with appropriate safety devices. The

following paragraphs describe crush points and precautions to take while

working around crush points.

Locations A crush point exists between the platen and crosshead on load units where the

actuator piston rod and specimen move (both areas are shown). Another potential

crush point exists where the lower end of the actuator piston rod extends below

the platen and the bottom of the load unit/load frame.

Precautions Keep clear of any mechanical linkage that moves within a closed area. If the

linkage should move (when the system starts or due to mechanical failure), very

318 Load Unit Safety

high forces can be present that could pinch, cut, or crush anything in the path of

linkage movement.

Never allow any part of your body to enter the path of machine movement or to

touch moving machinery, linkages, hoses, cables, specimens, etc. These present

serious crush points or pinch points.

45

Page 46

46

Safety

318 Load Unit

Page 47

Installation

318 Load Unit: Unpack Upright Configuration

1. Unpack the load unit.

A. Remove the shipping container (if used).

B. Remove the protective wrapping around the columns.

C. Use a clean cloth to wipe the columns clean.

Note The load unit can be moved by a fork lift as long as the load unit is

attached to its pallet.

D. Remove the bolts from the wooden beams clamping the load unit to the

pallet.

If you plan on moving the load unit with a fork lift, do not remove the

bolts holding the load unit on the pallet until the load unit has been

moved.

E. Cut the pallet straps.

318 Load Unit Installation

47

Page 48

2. Inspect the load unit for shipping damage.

Look for the following:

• Scratches in the load unit or lift cylinder columns

• Damaged electrical connections

• Damaged hydraulic connections

• Dents and other structural damage

• Torn, kinked, or breaking hoses

Report any damage found to both the carrier and MTS. In the U.S. and

Canada, call the MTS HELPLine at 1-800-328-2255. Elsewhere, contact

your local MTS office.

3. Move the load unit to its final location.

Before you move the load unit, check that:

• The floor where the load unit will sit can bear its weight.

• The path to where the load unit will sit is clear and uncluttered.

• The area where the load unit will sit is clean and well lit, with all hoses and

cables moved out of harm’s way.

• The eyebolts are tight.

• The crosshead is manually locked.

Lift the load unit only as high as necessary. Move it slowly to its installation

site.

4. Place the load unit onto the isolation pads or airmounts.

• If your load unit has isolation pads, and the load unit does not sit level,

install stock metal shims between the pads and the floor.

• If your load unit has airmounts, inflate each air mount in 5 mm (0.20 in)

increments to level the load unit.

– Check the airmounts’ pressures often to ensure they do not exceed 0.55

MPa (80 psi).

– Check the airmounts’ inflated heights to make sure that they are all

between 83 and 88 mm (3.25 and 3.5 in).

– Adjust the air pressure to level the load unit.

48

Installation

318 Load Unit

Page 49

Airmounts can be overinflated and then explode.

WARNING

You can be seriously hurt if an airmount explodes, sending fragments flying.

Do not overinflate the airmounts.

318 Load Unit: Unpack Horizontal Configuration

Prerequisites The load unit is shipped horizontally on a wooden pallet. You will need the

following equipment to unpack the load unit:

• Lifting slings—not chains—to lift the load unit from its pallet

• Rubber mats for the load unit’s feet to rest on

• Wooden blocks for the load unit’s columns to rest on

• A knife to cut the packing straps

318 Load Unit Installation

49

Page 50

The load unit is extremely heavy.

WARNING

The weight of the load unit can seriously hurt you and damage your load

unit.

Do not allow the load unit to drop or topple. Observe the following precautions:

• Ensure that your chains, slings, and crane have a working capacity greater

than the load unit’s weight.

• Ensure that the lifting eyebolts are tight.

• Ensure that the crosshead locking bolts are fully tightened.

• Lift the load unit only high enough to clear its pallet.

• Operate the crane smoothly to prevent sudden shocks to the sling.

50

Installation

Unpacking the Load Unit

1. Cut the packing straps and remove any bolts as needed. Make sure the

lifting eyebolts are tight.

318 Load Unit

Page 51

Scratches in the load unit columns can affect how the crosshead performs.

CAUTION

Keep the base steady

Slings at center of gravity

Slide

Rubber mat

Wooden blocks

Chains will scratch the columns.

Use slings to lift the load unit from its pallet.

318 Load Unit Installation

Removing the Load Unit from Its Pallet

51

Page 52

2. Inspect the load unit for shipping damage.

Look for the following:

• Scratches in the load unit or lift cylinder columns

• Damaged electrical connections

• Damaged hydraulic connections

• Dents and other structural damage

• Torn, kinked, or breaking hoses

Report any damage found to both the carrier and MTS. In the U.S. and

Canada, call the MTS HELPLine at 1-800-328-2255. Elsewhere, contact

your local MTS office.

3. Wrap slings around the columns at the load unit’s balance point.

A. With someone else steadying the load unit, slightly lift the load unit to

ensure that you have found its balance point. Keep adjusting the slings

and slightly lifting the load unit until you find its balance point.

B. Lift the load unit just enough to clear its pallet. Slide the pallet out of

the way. Then lower the load unit so that its feet rest on rubber mats

and its columns on the wooden blocks.

4. Lift the load unit upright.

A. Attach the chains to the lifting eyebolts. Move the crane/forklift to keep

the chains as straight as possible.

B. Slowly raise the load unit to its upright position. As the unit rises, keep

moving the crane to keep the chains as straight as possible. Do not

exceed a 30° chain angle.

52

Installation

318 Load Unit

Page 53

C. Once the load unit is upright, raise it slightly so that the pallet can be

Crane travel

30° maximum

removed.

Bringing the Load Unit Upright

Before you move the load unit, that:

• The floor where the load unit will sit can bear its weight.

• The path to where the load unit will sit is clear and uncluttered.

• The area where the load unit will sit is clean and well lit, with all hoses

and cables moved out of harm’s way.

• The eyebolts are tight.

• The crosshead is manually locked.

Lift the load unit only as high as necessary. Move it slowly to its installation

site.

5. Place the load unit onto the isolation pads or airmounts.

• If your load unit has isolation pads, and the load unit does not sit level,

install stock metal shims between the pads and the floor.

318 Load Unit Installation

53

Page 54

• If your load unit has airmounts, inflate each air mount in 5 mm (0.20 in)

WARNING

Load Unit

Load Unit

0.55 MPa (80 psi)

maximum pressure

83-86 mm

(3.25-3.5 in)

Install

shims

to level

Airmount Foot Support Isolation Pads

increments to level the load unit.

– Check the airmounts’ pressures often to ensure that they do not exceed

0.55 MPa (80 psi).

– Check the airmounts’ inflated heights to ensure that they are all

between 83 and 88 mm (3.25 and 3.5 in).

– Adjust the air pressure to level the load unit.

Airmounts can be overinflated and then explode.

You can be seriously hurt if an airmount explodes, sending fragments flying.

Do not overinflate the airmounts.

6. Remove the chains.

318 Load Unit: Connect Cables

Your controller manual should have cabling information about the connections

described in this section. Most controller manuals provide the signal pinouts of

the connector, assembly numbers for standard MTS cables, and cable

specifications for cables you may build.

54

Installation

318 Load Unit

Page 55

Prerequisite You must have either a cable assembly drawing of your test system, or you must

Ê

Ë

Ì

Í

Î

Ï

know the system controller well enough to determine each type of cable

connection.

1. The force transducer is connected to a DC conditioner in the controller.

2. The ground connection is located on the back of the control panel. This is

usually connected to a chassis ground on a console or the controller chassis.

3. The load unit control panel is connected to the controller. It contains the

emergency stop and crosshead lock signals.

4. The servovalve is connected to a valve driver in the controller.

5. The actuator manifold is connected to the hydraulic service manifold (HSM)

connector on the controller. The actuator manifold may include a

proportional valve or solenoid valves. Controllers can have two connectors

(one for each HSM type) or one connection that may be configured. See

your controller documentation.

6. The displacement sensor (also called an linear variable displacement

transducer or LVDT) is connected to an AC conditioner in the controller.

318 Load Unit Installation

55

Page 56

7. Return to the installation procedure.

CAUTION

318 Load Unit: Connect Hydraulics

The procedure describes how to connect the load unit to the hydraulic power

source. The load unit may be connected directly to the hydraulic power unit (also

called HPU), to hydraulic plumbing in the workplace, or through a hydraulic

service manifold.

Note The internal hydraulic connections from the actuator manifold and

accessories such as the hydraulic lifts and locks should already be

made.

1. Connect the return line from the hydraulic power unit to the hydraulic port

on the manifold labeled “R”.

2. Connect the pressure line from the hydraulic power unit to the hydraulic

port on the manifold labeled “P”.

3. Connect the drain line from the hydraulic power unit to the hydraulic port on

the manifold labeled “D”.

4. Turn on the HPU and check for any hydraulic pressure leaks.

5. Turn on the actuator manifold (also called a hydraulic service manifold or

HSM) and check for hydraulic leaks in the load unit.

6. If you have hydraulic lifts, bleed the air out of the hydraulic lift cylinders.

7. Return to the installation procedure.

318 Load Unit: Unlock the Crosshead

When the load unit is shipped, the crosshead is clamped to the columns with the

manual clamping bolts in the crosshead.

Note This procedure only applies to load units equipped with hydraulic lifts and

locks.

The crosshead can slowly drift down the columns if the locks are turned off

and when hydraulic pressure is turned off.

The crosshead can damage any test fixtures, grips, and specimen in its

path.

Unlock the crosshead only to reposition it. Always lock the crosshead after you

have repositioned it and never leave the crosshead unlocked.

1. Turn on hydraulic pressure.

56

Installation

318 Load Unit

Page 57

2. Fully loosen the manual crosshead locking bolts in the order shown in the

318.10

136 N·m (100 lbf·ft)

318.25

271 N·m (200 lbf·ft)

318.50

271 N·m (200 lbf·ft)

1

3

2

4

1

3

2

4

1

2

following figure.

Loosening the Manual Lock Bolts

3. Cycle the lock control to unclamp, and then reclamp, the crosshead.

4. Use the lock control to unclamp the crosshead. The unclamped symbol is

shown at the right. Wait 30 seconds for the pressure in the crosshead locks to

drop to zero.

5. Use the lift control to position the crosshead where you want it.

6. Use the lock control to clamp the crosshead to its current position. The

318 Load Unit Installation

clamped symbol is shown at the right. Wait 30 seconds for the locks to fully

clamp the columns.

57

Page 58

58

Installation

318 Load Unit

Page 59

Operation

CAUTION

Load Unit: Operation Preface

This section describes the load unit controls, crush point hazards, and procedures

performed during the normal, day-to-day operation of the load unit.

Application note Special considerations must be followed when using low force transducers in a

high force systems. Small force transducers are commonly used in larger

systems. You need to be aware that the load unit can produce forces that exceed

the rating of the low force transducer.

Low force transducers in high force systems can be exposed to excessive

forces.

Applying forces that exceed the rated capacity of the force transducer can

damage the transducer.

Ensure that all test commands are within the force transducer’s rating when it is

installed. Your warranty does not cover damage caused by a high force actuator.

MTS recommends the following:

• Position the crosshead so that fixtures cannot touch each other when the

actuator is fully extended. This may not always be feasible at all times, but it

should be practiced whenever possible.

• Use force limits. Force limits can help in some instances but might not stop

the actuator fast enough in all situations.

• Ensure that you have selected the correct calibration for the transducer being

used. Also ensure that the system tuning has been optimized for the

transducer being used.

318 Load Unit Operation

59

Page 60

318 Load Unit: Control Module

Emergency Stop

Crosshead Lift / Lock Control

Hydraulic Grip Control

Rate

Pressure

1

2

3

Unclamp Clamp

Upper

Lower

Grip

Grip

Pressure

1

2

3

Rate

The controls for the 318 Load Unit are located on a module mounted to the front

of the load unit.

Series 318 Load Unit Controls

C

ONTROL DESCRIPTION

Hydraulic Grip Controls

Pressure

Rate

Controls the optional hydraulic grips. Hydraulic grips let you quickly and

easily install and remove specimens. The left handle controls the lower grip

and the right handle controls the upper grip.

Adjusts the amount of hydraulic pressure to the grips. The adjustment range is

1–21 MPa (100–3000 psi) or 1–69 MPa (100–10,000 psi). The highest

pressure setting depends on the maximum pressure setting. Adjust the control

clockwise to increase the hydraulic pressure. Use the pressure gage to measure

the clamping force.