Page 1

316 Load Frame

Product Information

l

100-105-843 B

Page 2

Copyright information © 2008 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation.

Contact information MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255 (within the U.S. or Canada)

Phone: 952-937-4000 (outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

http://www.mts.com

Publication information

Manual Part Number Publication Date

100-105-843 A

100-105-843 B

January 2003

April 2008

Page 3

Contents

Introduction 5

Functional Description 6

Specification 9

Direct Shear Capability 11

Operation 13

Hydraulic Configurations 13

Specimen Mounting Considerations 14

Uniaxial Configuration 15

Installation of Hardware 15

Installation of spacers as required 16

Specimen installation 17

Specimen removal 18

Tri-axial Configuration 19

Installation of Hardware 19

Tri-axial Cell Initial Installation 22

Installation of the specimen into the triaxial cell 24

Specimen removal in the triaxial cell configuration 27

Direct Shear Configuration 28

Installation of Hardware 28

Installation of the Direct Shear hardware 29

Direct Shear Specimen Preparation 30

Direct Shear Specimen Insertion into the Test Space 31

Direct Shear Specimen Removal from Test Space 32

Test specimen removal from specimen box 33

Maintenance 35

Making Daily Inspections 35

Preventing Rust 36

Checking the Accumulators’ Precharge Pressures 37

Servicing the Actuator 38

Installation 39

Series 316 Load Frame Product Information

3

Page 4

Unpacking and Inspection 39

Lifting and Moving Instructions 40

Installation of Load Frame 41

4

Series 316 Load Frame Product Information

Page 5

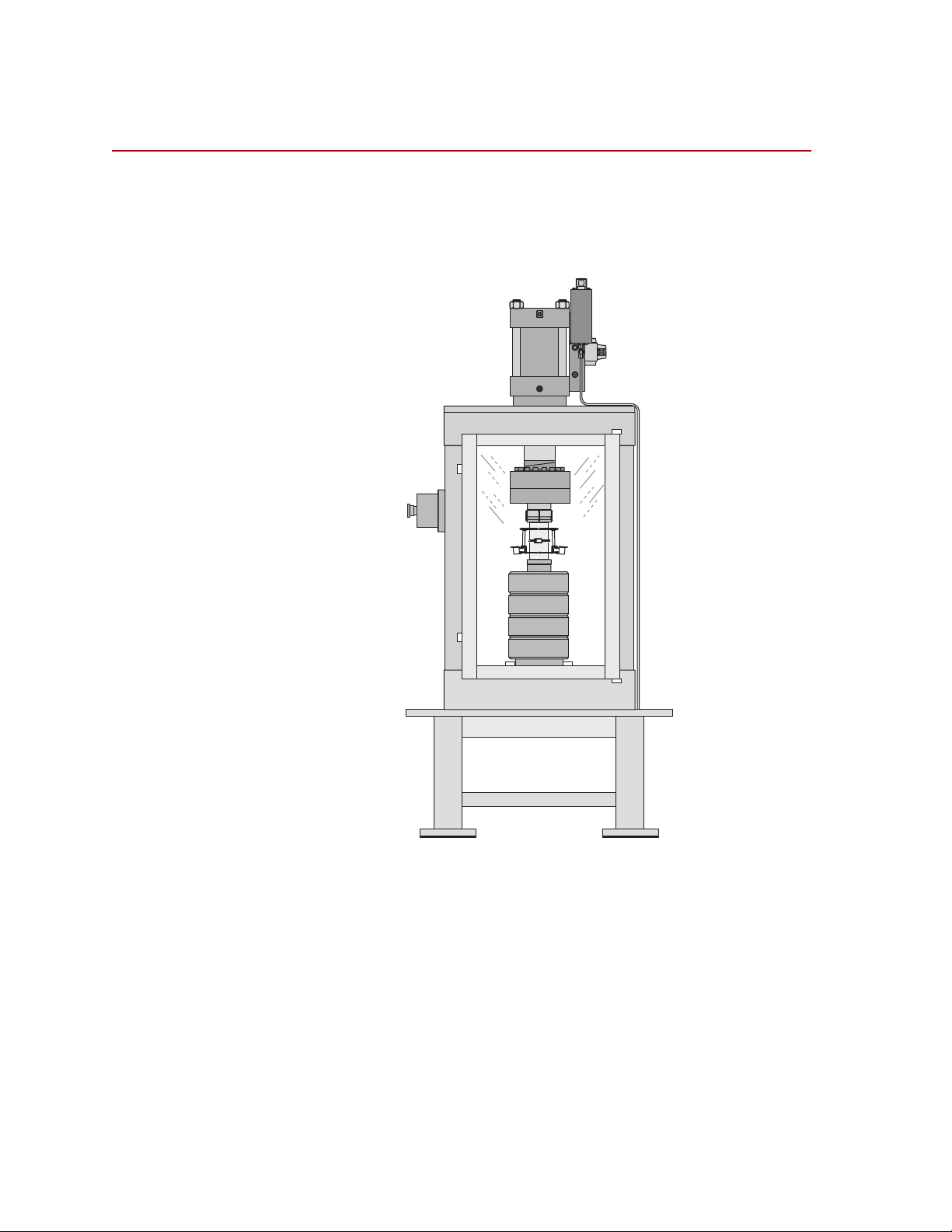

Introduction

The MTS Series 316 Load Frame Assembly is used to apply axial loads to rock

or concrete specimens for unaxial compression, tension, and fracture mechanics

tests. The assembly consists of a fixed crosshead mounted on four columns,

which are bolted to the base plate, resulting in a rigid, yet freestanding frame.

The four-column design allows access to the test area from all four sides for easy

insertion and removal of a wide range of specimen sizes and fixtures. Plastic

curtains on three sides and a front door enclose the test area. The test area height

is adjusted by using spacer plates for uniaxial testing. The load frame itself rests

on a rigid table to provide a convenient working height.

When a triaxial cell is inserted into the test space, the Series 316 Load Frame

actuator applies axial stress to the specimen inside the triaxial cell. Alternatively,

a horizontal loading assembly that includes a horizontal actuator can be attached

to the axial load frame to provide a shearing load for direct shear tests. In this

configuration, the Series 316 Load Frame actuator applies the normal load.

The load frame assembly is available in four standard sizes based on load

capacity. Choosing a load frame depends on the strength and size of the material

being tested and the testing requirements.

Series 316 Load Frame Product Information Introduction

5

Page 6

Functional Description

r

Model

632.94

r

Model

632.94

815-316-01_A

Functional Description

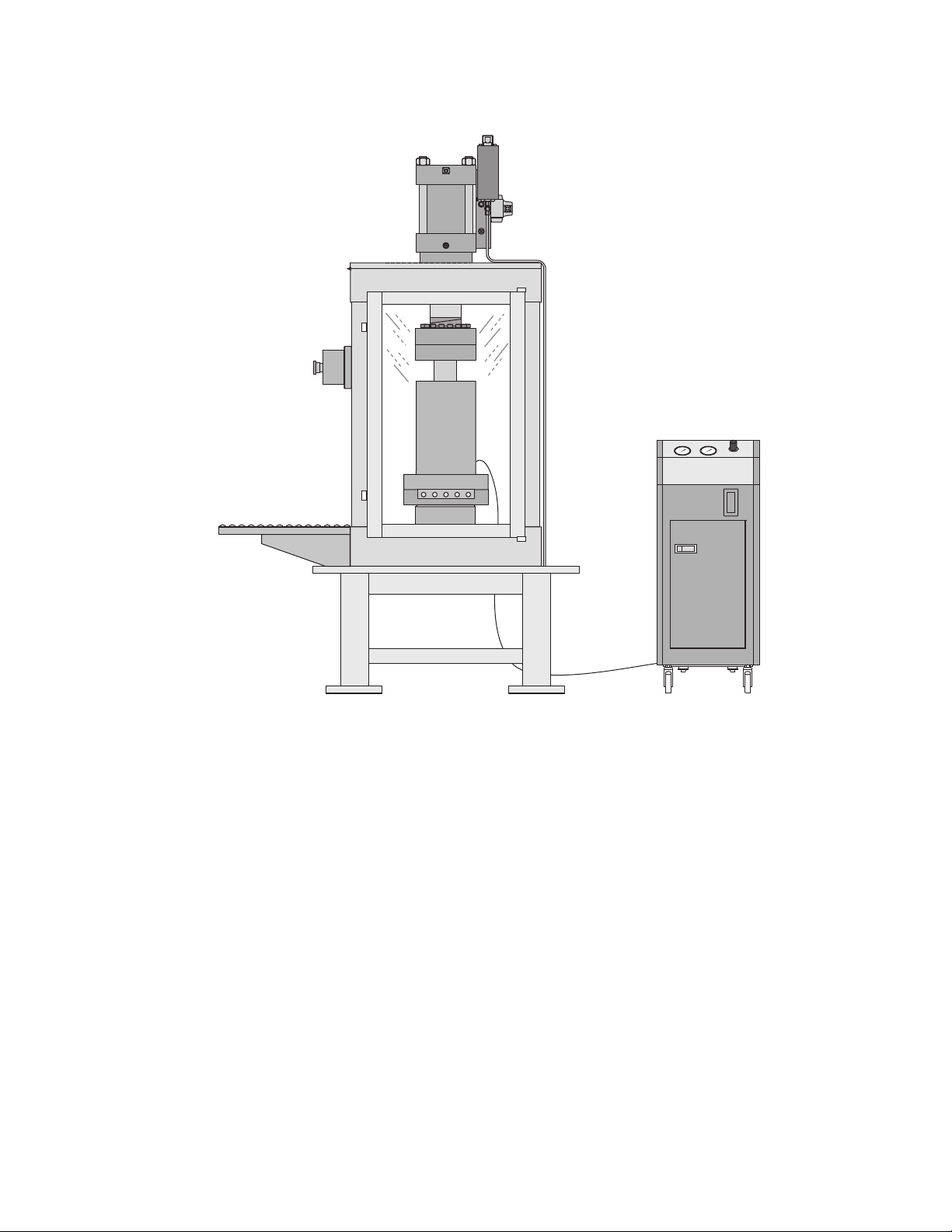

Series 316 Load Frames consist of four vertical columns that support a fixed

crosshead and fixed platen. A combination of the number of spacers and the

actuator stroke is used for adjusting the test space height.

6

Introduction

Series316 Load Frame configured for uniaxial compression testing

Series 316 Load Frames have the capability of testing specimens using a triaxial

cell as shown in the following illustration.

Series 316 Load Frame Product Information

Page 7

Functional Description

815-316-09

m

Series 316 Load Frame configured for triaxial testing

Series 316 Load Frame Product Information Introduction

7

Page 8

Functional Description

815-316-05

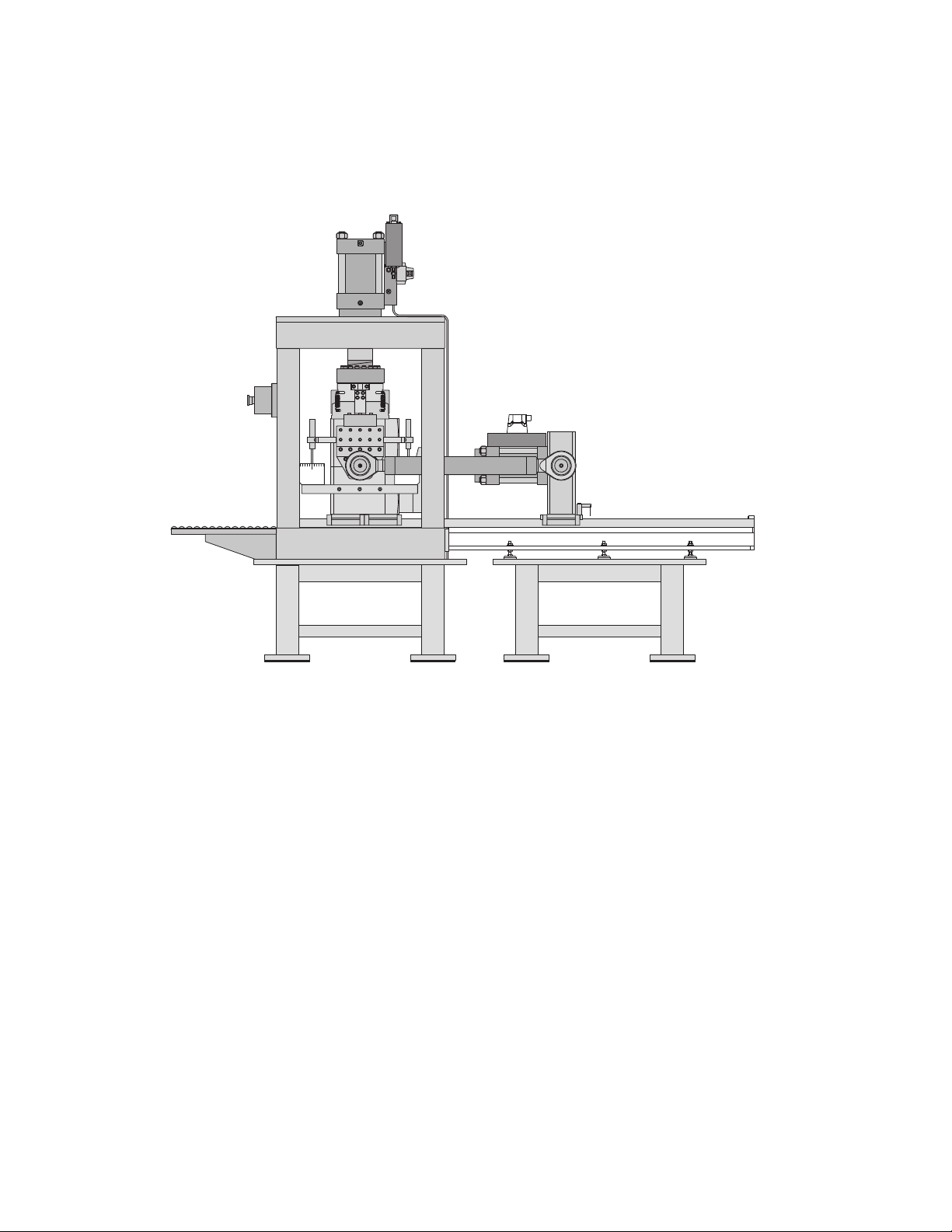

Series 316 Load Frames, when combined with a shear testing assembly, have the

capability of testing specimens in a direct shear mode, as shown in the following

illustration.

Series 316 Load Frame configured for direct shear testing

8

Introduction

Series 316 Load Frame Product Information

Page 9

Specification

Specification

The Series 316 load frames are freestanding and the weight of the frames are

distributed adequately to prevent overload of most laboratory floors. Isolation

pads are provided with the load frames.

This table lists dimensions and weights of the standard 316 Load Frames.

316 Load Frame Specifications (part 1 of 2)

ERIES 316.01 SERIES 316.02 SERIES 316.03 SERIES 316.04

S

Actuator 243.40S 243.60S 243.70S 243.80S

Compression kN(kip) 496(111) 1013(227) 1459(328) 1984(446)

Tension kN(kip) 291(65) 648(145) 961(216) 1334(300)

Actuator Displacement

mm(in)s

Load Frame Spring Rate:

N/m 1.1x10^9 2.6x10^9 2.6x10^9 3.0x10^9

Lb/in 6.2x10^6 1.5x10^7 1.5x10^7 1.7x10^7

Parallel alignment Between

platens

100(4) 100(4) 100(4) 100(4)

0.051(0.002) 0.051(0.002) 0.051(0.002) 0.051(0.002)

Series 316 Load Frame Product Information Introduction

9

Page 10

Specification

316 Load Frame Specifications (Continued) (part 2 of 2)

SERIES 316.01 SERIES 316.02 SERIES 316.03 SERIES 316.04

Force Measurement Load Cell Load Cell ΔP transducer ΔP transducer

Load Frame Height:

(Standard) mm(in) 1523(60) 1653(65) 1733(68) 1765(69)

(Table) mm(in) 609(24) 617(34) 617(34) 617(34)

Test Space mm(in) 736+/-50 (29+/-2) 735+/-50 (29+/-2) 735+/-50 (29+/-2) 730+/-50 (28.75+/-2)

Floor Loading Length mm

(in)

Floor Loading Depth mm (in) 686(27) 762(30) 762(30) 762(30)

Approx. Load Frame Weight

Kg (lbs)

Floor Loading

kg/m2 (psi)

940(37) 1118(44) 1118(44) 1118(44)

2512 (5540) 3266 (7200) 3400 (7500) 3855 (8500)

3895 (5.6) 3834 (5.5) 3991 (5.7) 4525 (6.5)

10

Introduction

Series 316 Load Frame Product Information

Page 11

Direct Shear Capability

Refer to the assembly drawings typically found on teh system reference manual

CD for additional information.

P

ARAMETER SPECIFICATION

Specification

Actuator

Tension kN (lbs) 162 (36.4)

Compression kN (lbs) 254 (57.0)

Actuator Displacement mm (in) 100(4.0)

Force Measurement Load Cell

Specimen Dimension

Diameter mm (in) 150 (5.90)

Length mm (in) 300 (11.82)

Gap mm (in) 20 (0.79)

Floor Loading Length mm (in) 1365(54)

Floor Loading Width mm (in) 760 (30)

Approximate Frame Weight

Kg (lbs) 2425 (1100)

* For additional information, refer to the Series 243 Hydraulic

Actuator Product Information Manual; part number 011774800

243.20

*

Series 316 Load Frame Product Information Introduction

11

Page 12

Specification

12

Introduction

Series 316 Load Frame Product Information

Page 13

Operation

Procedures in this section assume the operator is familiar with all operating

aspects of the system electrical controller and interlock restrictions that apply to

starting the hydraulic power supply.

The operation instructions for the Series 316 Load Frame include specimen

mounting for Uni-axial and Direct Shear configurations. The instructions also

describe insertion of MTS Model 656 Tri-axial cells. Please see the appropriate

Tri-axial instruction manual for specimen preparation and insertion inside the triaxial cell.

Hydraulic Configurations

Series 316 Load Frames are provided with hydraulic service manifolds for

control of hydraulic pressure. Systems configured for direct shear applications

are provided with a Model 293 hydraulic service manifold for control of

hydraulic pressure to the axial and direct shear actuators; refer the the 293.1x

Hydraulic Service Manifold Product Information, part number 015081000, for

additional information.

Hydraulic Configurations

Attached to the return pressure lines is a dump solenoid that will direct returnline hydraulic pressure to the drain line following shutdown. Shutdown without

a dump solenoid would cause the actuators to slowly drift because the actuators

have unequal area pistons.

Series 316 Load Frame Product Information Operation

13

Page 14

Specimen Mounting Considerations

Specimen Mounting Considerations

Specimen mounting is the most critical and potentially hazardous step in system

operation. Improper operation of the load frame during specimen installation or

testing can cause damage to equipment or specimens. Observe the following

precautions when installing a specimen.

• Configure the test program to reduce the possibility of specimen buckling

both during the test and at specimen failure. Buckling can cause damaging

side loads to be applied to the load cell.

• If the specimen will be tested in both tension and compression, reduce

backlash to a minimum. This will reduce the possibility of data being

invalidated by fixture or specimen shifting.

14

Operation

Series 316 Load Frame Product Information

Page 15

Uniaxial Configuration

Shown with crosshead removed

Installation of Hardware

If not already installed, attach the square loading block to the base of the frame.

Uniaxial Configuration

Note Torque the bolts per the specifications on the load frame assembly

drawing for full tension capability of the system. Compression testing

conditions do not require this torque setting. The bolts should however

be tightened to a level to prevent mechanical backlash when conducting

through-zero tests (tension/compression/tension).

Series 316 Load Frame Product Information Operation

15

Page 16

Uniaxial Configuration

Compression Indirect Tension

Installation of spacers as required

Install the appropriate number of spacers for the test to be conducted. When

determining the number of spacers needed, it is best to extend the actuator to a

position that leaves just enough stroke for the expected testing needs. This

actuator position helps reduce the risk of damage to the specimen or fixtures due

to actuator over-travel.

Typical steps for determining load train components:

1. After ensuring that there is adequate clearance, fully extend the actuator.

2. Retract the actuator the estimated distance required for the test.

3. Compare the opening with the sum of the displacement required for the test,

the height of the specimen, and the height of any fixturing required for the

test such as compression platens and adapter plates.

4. Determine the number of spacers required to fill the remaining test space.

By adjusting the actuator position and adding or removing spacers, it will be

possible to obtain the correct test space.

5. Install all components and ensure that all bolts are tightened appropriately.

Operation

16

Series 316 Load Frame Product Information

Page 17

Specimen installation

1. Turn the hydraulic service manifold (HSM) off.

2. Insert the specimen into the test space. Attach extensometers to the

3. Attach any electrical cabling for the load cell and extensometers.

4. Remove the zero pins from the extensometers and zero offset the transducer

5. Close the front door of the load frame. The front door interlock will engage

6. If not already in stroke control, change the actuator control mode to stroke

7. Turn the hydraulic service manifold (HSM) on.

8. Zero the load signal and change the control mode to load control, and apply

Uniaxial Configuration

specimen, with the zero pins in place.

signals. For additional information see the TestStar Operations Manual.

when the door is closed.

control.

a seating load to the specimen.

Note Opening the door will generate a program interlock but will not turn off

the hydraulic service manifold (HSM).

Series 316 Load Frame Product Information Operation

17

Page 18

Uniaxial Configuration

Specimen removal

1. When the test is complete or the specimen is to be removed from the test

space, change the servo control mode to stroke control and retract the

actuator.

2. Turn the hydraulic service manifold (HSM) off.

3. Open the front door of the frame.

4. Remove the extensometers from the specimen, and insert the zero pins. The

zero pins help protect the extensometers from inadvertent over-travel.

5. Remove the specimen.

18

Operation

Series 316 Load Frame Product Information

Page 19

Tri-axial Configuration

Shown with

optional lift

Tri-axial Configuration

316 Load Frame with Closed Triaxial Cell

Installation of Hardware

1. Remove any spacer plates that may have been used in the uniaxial or direct

shear test configurations

2. Remove the uniaxial load cell.

3. Install the square loading plate on the base of the frame if it is not already

installed.

Series 316 Load Frame Product Information Operation

19

Page 20

Tri-axial Configuration

Note Torque the bolts per the specifications on the drawing for full tension

capability of the system. Compression testing conditions do not require

this torque setting. The bolts should however be tightened to a level to

prevent mechanical backlash when conducting through-zero tests

(tension/compression/tension).

4. Install positive stops, quantity 2.

20

Operation

Series 316 Load Frame Product Information

Page 21

5. Install locating block for the triaxial cell.

Tri-axial Configuration

Series 316 Load Frame Product Information Operation

21

Page 22

Tri-axial Configuration

Tri-axial Cell Initial Installation

1. Position the vessel-mounting table on the slides that extend out from the

front of the load frame test space.

22

Operation

Series 316 Load Frame Product Information

Page 23

Tri-axial Configuration

2. The loading bolts should be tightened to hold the bell of the tri-axial cell to

the tri-axial cell base.

3. Using the crane, lift and place the triaxial cell onto the vessel-mounting

table.

4. Disconnect the crane from the tri-axial cell.

Series 316 Load Frame Product Information Operation

23

Page 24

Tri-axial Configuration

Shown with

optional lift

Installation of the specimen into the triaxial cell

Note It is assumed that the actuator has been retracted to allow adequate

room to insert the triaxial cell into the test space.

24

Operation

316 Load Frame with Open Triaxial Cell

1. Use spring loaded retention pins to hold the triaxial cell locating plate to

horizontal slides.

2. Attach the lifting crane to the triaxial cell.

3. Apply a lifting load to the bell of the triaxial cell and lift the bell high

enough to allow for specimen installation.

Note Due to seal pressure, it may be necessary to tap the lower base plate

with a softheaded hammer as the bell is being removed from the base

plate.

4. Install the specimen and any additional hardware such as endcaps,

extensometers, and pore pressure lines. Connect transducers cables to the

mounted connectors inside the triaxial cell.

5. For Ultrasonic testing, specific platens containing the ultrasonic P, S1 and

S2 crystals must be installed. These platens are operated with external

electronics.

Series 316 Load Frame Product Information

Page 25

Tri-axial Configuration

6. After the specimen has been installed and all internal electrical connections

have been made, turn the crane handle counter-clockwise to lower the bell

of the tri-axial cell onto the base plate using the locating pins as guides.

7. Disconnect the crane from the triaxial cell.

8. Connect the tri-axial cell bell to the base plate.

9. Slide the triaxial cell into the test space until it comes to rest against the

positive stops.

10. Attach the locating stop to the base of the frame.

11. Attach confining and pore lines to the triaxial cell as required for the test.

12. Connect all transducer ID and system cables.

Series 316 Load Frame Product Information Operation

25

Page 26

Tri-axial Configuration

13. Close the front door of the load frame.

14. Turn the hydraulic service manifold (HSM) on with the actuator in stroke

control.

15. Switch to load control and extend the actuator so that the actuator touches

the upper pushrod of the triaxial cell.

16. Turn the HSM off.

17. Open the door and attach the pushrod to the actuator rod with bolts.

18. Close the front door and proceed with the test program, which would

include such items as filling the vessel with fluid, bringing pressure system

to desired test parameters and electrically zero all transducers.

Note The door interlock does not turn off the HSM. The switch does provide a

program interlock. See the TestStar manuals for more information about

testing programs that use control hardware interlock.

26

Operation

Series 316 Load Frame Product Information

Page 27

Specimen removal in the triaxial cell configuration

1. When the test is complete, turn the HSM off.

2. Open the door and remove the bolts attaching the triaxial cell pushrod to the

actuator rod.

3. Close the door, turn the HSM on and retract the actuator.

4. Turn the HSM off.

5. Drain the confining fluid out of the triaxial cell.

6. Disconnect the confining and pore pressure lines.

7. Disconnect the transducer ID and system transducer cabling.

8. Remove the locating stop from in front of the triaxial cell.

9. Slide the triaxial cell out along the rails.

10. Use the spring-loaded retention pins to hold the locating plate to the rails.

Tri-axial Configuration

11. Attach the lifting crane to the triaxial cell.

Note To release the lifting cable, it may be necessary to pull on the end while

turning the crank counterclockwise.

12. Apply a lifting load to the bell of the triaxial cell.

Note Seal pressure may require using three jacking screws in the base of the

cell to help the triaxial cell bell separate from the baseplate.

13. Move the bell of the tri-axial cell off to the side and lower it to a safe

position.

14. Remove the specimen.

15. Remove the extensometers from the specimen, and insert the zero pins. The

zero pins help protect the extensometers from inadvertent over-travel.

Series 316 Load Frame Product Information Operation

27

Page 28

Direct Shear Configuration

Direct Shear Configuration

Installation of Hardware

1. Remove any spacer plates that may have been used in the uniaxial and

triaxial configurations.

2. Remove the uniaxial load cell.

3. Install the axial load cell used with the direct shear testing configuration.

Note Use spanner wrenches to preload the mechanical joint.

4. Optional: Remove restraint blocks on the axial spherical seat

5. Remove square loading plate on the base of the frame.

6. Remove the positive blocks, quantity 2, used to for the triaxial test

configuration.

7. Remove locating block for the triaxial cell.

Note It assumed that the actuator has been retracted to a safe position.

28

Operation

Series 316 Load Frame Product Information

Page 29

Installation of the Direct Shear hardware

Note The upper and lower portions of the direct shear specimen box may be

attached with handles. Do not remove the handles until the direct shear

system is installed in the test space and the upper portion of the fixture is

attached to the actuator rod.

1. Remove the locating pin on the direct shear hardware and push the assembly

into test space.

2. Insert the locating pin into the forward locating hole.

3. Close the load frame front door.

4. With the axial actuator in stroke control, turn the HSM on.

5. Position the axial actuator to allow connection of the axial load cell used

with the direct shear configuration.

6. If attached, remove handles supporting the upper portion of the direct shear

assembly.

Direct Shear Configuration

Series 316 Load Frame Product Information Operation

29

Page 30

Direct Shear Configuration

Direct Shear Specimen Preparation

1. Locate the two specimen shear boxes.

2. Place the lower shear box on a clean, flat surface. Use a sealant such as

modeling clay to seal around the inside edges of the box to prevent leakage

of the filler. Typical filler material is Hydro-stone plaster. Hydro-stone uses

a weight mix ratio of 32/100 (water/plaster), or a mixture of 0.326 liters of

water per kilogram of Hydro-stone.

Note Water weighs approximately 0.98 kg/liter (8 lbs/gallon).

3. Place the specimen in the box such that the desired specimen shear plane is

horizontal, and located vertically in the center of the gap between the two

halves of the box. If necessary, support the specimen with a block of wood.

Fill the cavity of the box with the appropriate filler.

Note Large spaces around the specimen may be filled with pieces of filler from

previous tests.

4. Place the specimen box spacers on the corners of the lower shear box.

5. Place the spacer material on top of the lower shear box. For reference, wood

is often used for this material with a nominal thickness of about 25 mm.

This material will have to be cut to accommodate the specimen and

specimen box spacers.

6. Using a sealant such as modeling clay seal the edges of the upper inside

specimen box.

7. Place the upper shear box on top of the box spacers. Attach the front handle

to the upper and lower shear boxes. Once the handle is bolted in place, the

upper and lower shear boxes will be correctly positioned with respect to

each other.

8. Fill the upper shear box with the filler material.

9. Let the filler set. A typical set time is 12 hours.

30

Operation

Series 316 Load Frame Product Information

Page 31

Direct Shear Configuration

Direct Shear Specimen Insertion into the Test Space

Note It is assume that system is in a safe operating condition.

1. Attach the crane to lifting eyes on the upper direct shear box with a lifting

strap.

2. Open the front door of the load frame. Place the nylon spacer on top of the

triaxial cell vessel-mounting table.

3. Using the crane place the direct shear box assembly on the nylon spacer of

the loading plate. Disconnect the crane from the direct shear boxes.

4. Push the direct shear box assembly into the test space.

5. Attach the shear box assembly to the direct shear system with 16 bolts and

torque each bolt to 7.8 N-m (69 in-lbs), alternating between top and bottom

shear box assembly.

6. Remove the front handles.

7. Remove the two bolts from the spherical seat assembly that were used to lift

the upper specimen box.

8. Attach all transducer ID and system cables.

9. Adjust the six displacement transducers into positions that are close to the

electrical null of the transducer output.

10. Remove any remaining electrical offsets with the controller.

11. Close the front door of the load frame.

12. Change the control mode so that the direct shear actuator is in stroke control

and the axial actuator is in load control.

13. Remove any servo error in the system and turn the system axial and direct

shear HSM on.

14. Proceed with testing.

Note Opening the door will generate a program interlock but not turn off the

HSM.

Series 316 Load Frame Product Information Operation

31

Page 32

Direct Shear Configuration

Direct Shear Specimen Removal from Test Space

1. Change control modes so that the axial and direct shear actuators are in

stroke control.

2. Attach the upper specimen box to the spherical seat using two lifting bolts.

3. Using the axial actuator, position the specimen boxes appropriately to attach

the front handles to the specimen boxes, and attach the front handles.

4. Turn the axial and direct shear HSM off.

5. Open the front door of the load frame.

6. Disconnect the shear box from the direct shear assembly by loosening and

removing the 16 bolts that hold the specimen to the shear assembly.

7. Slide the assembly onto the carriage and remove it from the test space. Use

the crane assembly with lifting eyes and a strap to move the specimen box

assembly.

32

Operation

Series 316 Load Frame Product Information

Page 33

Test specimen removal from specimen box

Removing grout (filler) material from the specimen boxes using a mallet to break

up the grout. Some disassembly of the specimen box may be required to remove

all the grout.

Direct Shear Configuration

Series 316 Load Frame Product Information Operation

33

Page 34

Direct Shear Configuration

34

Operation

Series 316 Load Frame Product Information

Page 35

Maintenance

Making Daily Inspections

Before the start of each day’s testing, do a quick inspection of your load frame.

Following are typical items that should be checked daily:

• Ensure that there are no leaks from the hydraulic lifts or locks.

• Ensure that there are no leaks from the actuator, hydraulic service manifold,

servovalve, or accumulators.

• Ensure that electrical connections are tight, with no frayed or poorly routed

cables.

• Ensure that hoses are routed properly and that fittings are not leaking.

Making Daily Inspections

Series 316 Load Frame Product Information Maintenance

35

Page 36

Preventing Rust

Preventing Rust

The operating environment determines how often you take rust prevention

measures. Humid and corrosive environments require more prevention.

Recommended supplies:

• #1 grade kerosene

• Silicone spray

• 000 emery cloth

• Touchup paint; MTS part numbers 011-059-854 (beige), 011-059-856

• Metal primer paint

• Lint-free cloths

Unpainted surfaces: Spray with silicone, and then wipe with a clean, lint-free

cloth. Or, wipe with a clean, lint-free cloth dampened with clean hydraulic fluid.

(gray), 044-587-501 (brown)

The direct shear specimen boxes should be protected with a rust inhibitor when

not in use.

Chrome plated surfaces: For microscratches, wipe with a clean, lint-free cloth

dampened with #1 kerosene. For rust discoloration, polish with 000 emery cloth,

and then wipe down. Black oxide surfaces: Spray with silicone, and then wipe

with a clean, lint-free cloth. Or, wipe with a clean, lint-free cloth dampened with

clean hydraulic fluid. Painted surfaces: For small scratches, use touchup paint.

For large scratches, sand, prime, and use touchup paint.

36

Maintenance

Series 316 Load Frame Product Information

Page 37

Checking the Accumulators’ Precharge Pressures

Checking the Accumulators’ Precharge Pressures

Check pressure at least once a month; more often as required by operating

conditions. An accumulators’ correct precharge pressure is written on its label.

See the Series 111 Accumulator Product Information manual (part number

011553304) for the complete details on checking the precharge intervals and

servicing the accumulators. Record both the pressures and the room temperature

in a logbook. Use these readings as a basis for increasing or decreasing the

interval between pressure checks. Generally, recharging is required when there is

a change of ±1.4 MPa (200 psi) in the pressure line accumulator or ±50% in the

return line accumulator.

Series 316 Load Frame Product Information Maintenance

37

Page 38

Servicing the Actuator

WARNING

Servicing the Actuator

If the actuator begins leaking hydraulic fluid or its performance becomes poor, it

should be serviced by a qualified service technician.

The hydraulic blocking valves will cause system pressure to be trapped in

actuator that can cause unexpected actuator rod movement.

Unexpected actuator rod movement can result in personal injury and

equipment damage.

There is a pressure relief control on the actuator manifold that allows this pressure

to be dissipated.

38

Maintenance

Series 316 Load Frame Product Information

Page 39

Installation

This section provides installation instructions for Series 316 Load Frame. MTS

System Corporation recommends that the procedures in the following

subsections be performed in the order given or referenced to minimize the chance

of damage to equipment or injury to personnel.

Unpacking and Inspection

Unpacking and Inspection

Unpacking Load

Frame

Unpacking Direct

Shear

Inspection Inspect the load frame for evidence of structural damage. Inspect any electrical

If the load frame is shipped in the horizontal position strapped to a wooden skid,

it should be uncrated and tipped to its upright position before it is moved. Use

the following procedure:

1. Carefully cut and remove the strap form around the load frame using an

appropriate tool. Some load frames are bolted to the skid. Remove these

bolts if applicable.

2. Series 316 load Frames are shipped with eye bolts installed in the holes in

the top of the crosshead.

A. Attach lifting chain hooks (or equivalent) to all lift point eyebolts or

hoist rings. Ensure chain hooks are secure and of sufficient capacity

for the task (see “Specification” on page 9 for the weight of frame.)

B. Block the bottom of the load frame to prevent slipping as the load

frame is raised.

C. Slowly lift load frame to vertical position.

1. Remove direct shear assembly with guide rails from crate.

2. Carefully cut and remove holding straps to direct shear assembly.

connectors mounted on the load frame base for damage and cleanliness. If

shipped with hydraulic hoses attached, inspect the hose for evidence of damage

and leakage. Inspect the hose connections fitting for damage.

Series 316 Load Frame Product Information Installation

39

Page 40

Lifting and Moving Instructions

WARNING

Lifting and Moving Instructions

This subsection provides a procedure for lifting and moving the load frame.

Improper lifting or transportation of the device can result in damage to

equipment or injury to personnel.

Read and comply with the following instructions and refer to the Lifting and

Moving Instructions booklet attached to the load frame.

1. Ensure all devices involved in lifting and moving the load frame are in good

working order. Inspect eyebolts or hoist rings, chains, overhead crane, etc,

for cracks and damage. Replace as necessary.

2. Ensure all devices involved in lifting and moving the load frame can support

the weight of the load frame. (This weigh includes the load frame, load cell,

actuator, servo valve(s), manifold(s) grips, etc.)

3. The load frame must be lifted at the designated lift points only. The lift

points are locate on top of the crosshead.

4. If chains will be used to lift and move the load frame, the lifting chains must

not exceed a 30-degree angle from vertical to prevent undesired stress/strain

on the eyebolts or hoist rings.

5. Do not apply shock loads when lifting or moving the load frame. Shock

loads can cause momentary forces exceeding the actual load frame weight,

which can result in exceeding the recommended force rating of the lifting

devices.

6. Before lifting or moving the load frame, ensure all lifting chain hooks (or

equivalent are securely placed in all lift point eyebolts or hoist rings.

7. Lift load frame only has high as necessary. It is recommended to lift the

load frame only a few inches off the ground.

8. Move load frame to desire location and carefully lower into position

40

Installation

Series 316 Load Frame Product Information

Page 41

Installation of Load Frame

1. Move the load frame to the desired location.

Location requirements of the load frame are based primarily upon size,

weight, and hydraulic requirements. Floor structure should be checked to

ensure that the weigh of the load frame could be supported. Ensure safe

and adequate access space in all directions around the load frame. Ensure

safe and adequate lighting. Adequate and appropriate routing of control

cables and hoses should be located, playing special attention to conditions,

which can cause cable or hose damage.

2. Level the load frame.

If it is necessary to level the load frame, one or more pieces of shim stock

can be placed under one or more of the feet. This operation should be done

in conjunction with the vibration pad installation( see atep 3).

3. Install vibration isolation pads.

Most load frames are supplied with rubber vibration isolation pads that

absorb some of the vibration of the load frame, protecting the support floor.

These pads must be stacked, separated by metal dividers, and installed under

the four corners of the load frame.

Installation of Load Frame

4. Install direct shear fixture.

A. Position the direct shear fixture base at the rear of the 316-load frame.

B. Place isolation pads under direct shear base. If necessary metal shims

may be used.

C. Attach bolts that attach direct shear base to rear of load frame base.

Note Direct Shear fixture can slide without proper support. Do not allow direct

shear fixture to slide off guide rails.

D. Align guide rails to mounting hole pattern on base of load frame.

E. Adjust feet of direct shear fixture.

F. Attach guide rails to load frame base.

5. Install 293.11 Service Manifold.

The service manifold does not require isolation pad. It may be located in a

convenient spot within reach of system hoses.

6. Install hydraulic hoses and electrical connections.

A. Connect all applicable hydraulic hoes and all electric cables.

B. Typical hose connections to load frame consist of –6 pressure, -6 return

and –6 drain. Care should be observed that appropriate hose

connections are made.

C. Typical hose connections to direct shear assembly consist of –4

pressure, -4 return and –4 drain.

Series 316 Load Frame Product Information Installation

41

Page 42

Installation of Load Frame

42

Installation

Series 316 Load Frame Product Information

Page 43

Page 44

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

http://www.mts.com

ISO 9001:2000 Certified QMS

Loading...

Loading...