Page 1

Series 315 Load Frame

Product Information Manual

Model 315.01

Model 315.02

Model 315.03

Model 315.04

l

100-104-403 A

Page 2

Copyright information © 2002 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation.

Contact information MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255 (within the U.S. or Canada)

Phone: 952-937-4000 (outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

http://www.mts.com

Publication information

Manual Part Number Publication Date

100-104-403 A

November 2002

Page 3

Contents

Introduction 5

Component Identification 7

Functional Description 8

Specifications 10

Load Frame Dimensions 11

Floor Loading Footprint Dimensions 13

Load Frame Stiffness Calculation 14

Installation 17

Lifting and Moving Instructions 18

Connecting Cables 23

Connecting Hydraulics 24

Operation 25

Emergency Stop 25

Crush Point Hazards 26

Maintenance 27

Maintenance Intervals 28

Making Daily Inspections 29

Minimizing Rust 30

Methods for Various Surfaces 30

Checking the Accumulators’ Precharge 31

Series 315 Load Frame Contents

3

Page 4

4

Contents

Series 315 Load Frame

Page 5

Introduction

Contents Component Identification 7

The Series 315 Load Frames are designed to perform high-velocity tension

or compression testing, high-frequency fatigue testing, as well as other

tests. The load frame must be configured with optional actuators,

servovalves, force transducers, grips, and other components from MTS

Systems Corporation.

Functional Description 8

Specifications 10

“Load Frame Stiffness Calculation” on page 14

815

Rock Mechanics

r

Test System

Series 315 Load Frame Introduction

5

Page 6

What you

need to know

This manual assumes that you know how to use your system controller.

See the appropriate manual for information about performing any

controller-related step in this manual’s procedures. You are expected to

know how to do the following:

• Turn system electrical power on and off

• Turn hydraulic pressure on and off

• Manually adjust the actuator position

• Use your grips and fixtures

Related products The load frame includes other products. See the following product manuals

for product-specific information and maintenance procedures.

• The Series 111 Accumulator Product Information manual.

(part number 011-553-300)

• The Series 252 Servovalve Product Information manual

(part number 011-182-900)

• The Series 298 Actuator Manifold Product Information manual

(part number 011-563-103)

6

Introduction

Series 315 Load Frame

Page 7

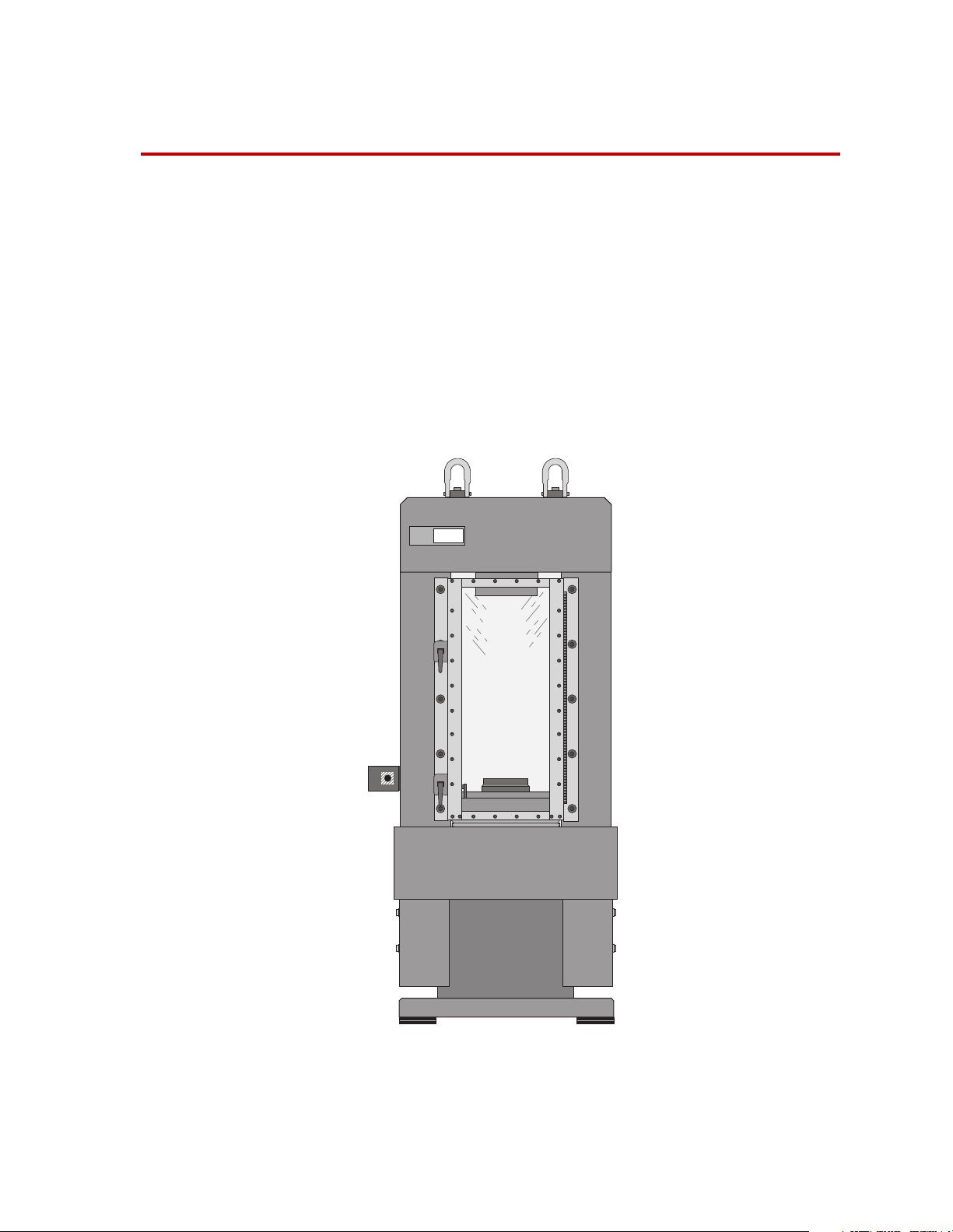

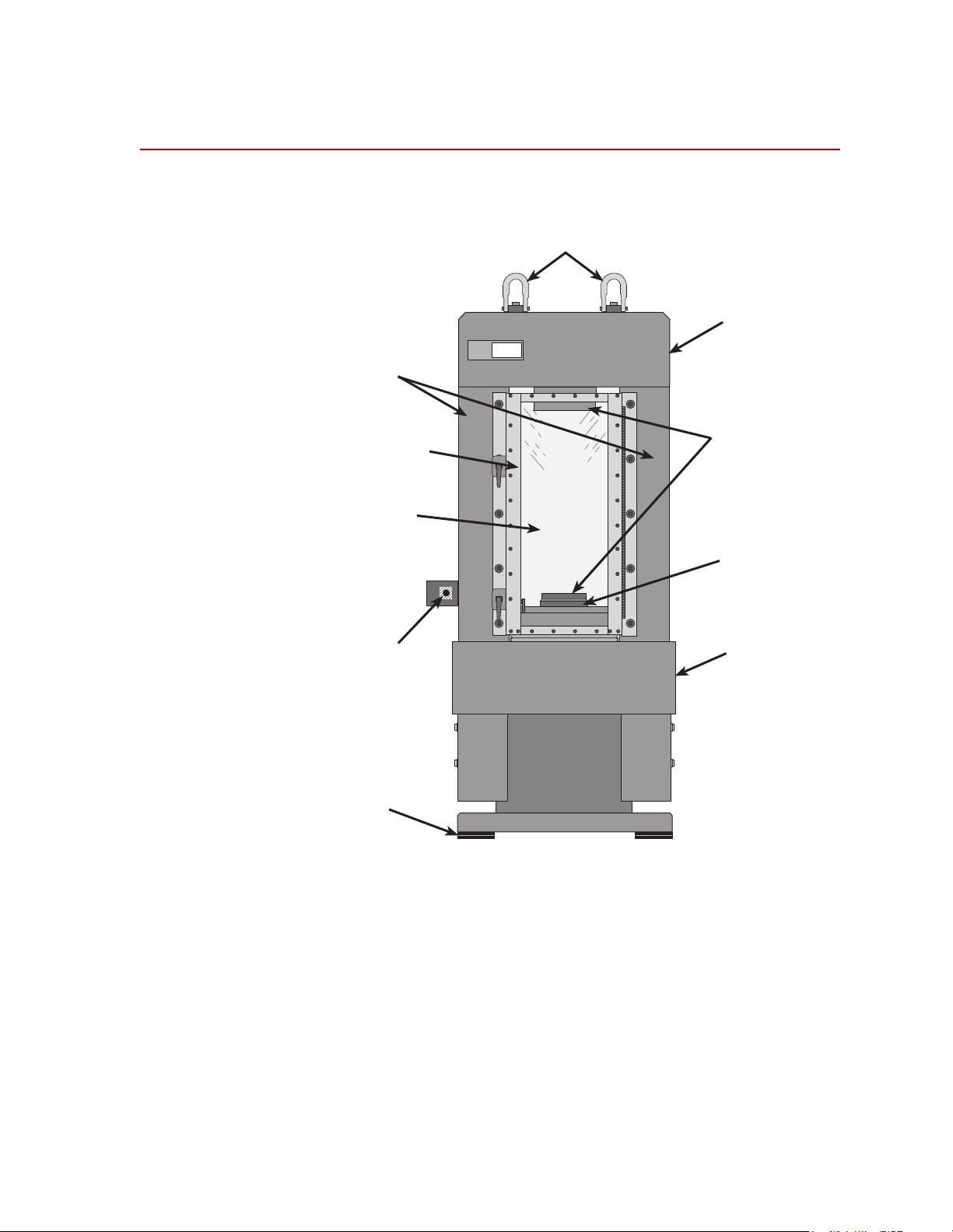

Component Identification

Retangular

Columns

Security

Door

Impact Resistant

Lexan Panel

r

Rock Mechanics

Test System

815

Hoist Rings

Rigid Fixed

Crosshead

Accessory

Attachment

Plates

Fatigue Rated,

Single-ended,

Double-acting

Actuator

Emergency Stop

Button

Vibration

Isolation Pads

Stiff Base

Plate

Series 315 Load Frame Introduction

7

Page 8

Functional Description

The load frame is a stand alone testing structure. The following paragraphs

describe the components shown on the illustration in the “Component

Identification” on page 7.

Load Frame The load frame has an integrated construction that provides high stiffness,

reducing deflection energy stored in the frame — ideal for testing brittle

materials. The actuator is integrated into the base plate which decreases

frame height and increases stiffness.

The integrated construction also provides a precision, parallel alignment

between crosshead and actuator surface for proper specimen loading.

The load frame provides a large test area for uniaxial and triaxial testing.

The front security door allows easy access to test space. The impact

resistant Lexan panels in front and back allow observation of tests in

progress and helps contain specimen fragments.

Actuator The actuator is a single ended, double acting design allows testing in

compression and tension. The actuator provides a 100 mm (4 in) actuator

stroke for tests requiring large displacements.

Proprietary seal and bearing designs, which have set an industry standard

for durability, ensure long life and performance. Direct-bonded polymer

bearings reduce friction and maximize heat dissipation.

Transducers The load frame usually includes a force transducer and an LVDT (or other

Differential Pressure

∆P) Transducer

(

Internal Linear Variable

Differential Transformer

(LVDT)

displacement measurement device.

The ∆P transducer provides force readout without affecting load frame

stiffness. The ∆P transducer is accurate to within ±1% of the calibrated

range at loads above 1000kN. It provides useful measure of external loads

applied to specimens inside a triaxial cell, when conducting multiple

failure state tests per ISRM. The output signal is conditioned at the Digital

Controller for closed-loop control and data acquisition.

The LVDT is calibrated to full scale actuator travel to provide complete

positioning control. The LVDT is used for specimen positioning and

preloading, and measuring actuator displacement during the test. The

output signal is conditioned at the Digital Controller for closed-loop control

and data acquisition.

8

Introduction

Series 315 Load Frame

Page 9

Servovalves Servovalves regulate the direction and flow of the hydraulic fluid to and from a

hydraulic actuator. The servovalve responds to the polarity and magnitude of the

command signal generated by the controller.

Hydraulic distribution Hydraulic distribution includes a hydraulic manifold (also called an actuator

manifold or hydraulic service manifold) which controls the hydraulic pressure to the

load frame. The manifold includes solenoid valves that control the hydraulic

pressure (off, low, or high). An actuator manifold is mounted directly to the actuator

on the load frame. A hydraulic service manifold (HSM) is located near the load

frame and connects to the actuator with hydraulic hoses.

Most hydraulic distribution systems will also include a check valve in the return line.

The purpose of this check valve is to minimize actuator drift where pressure is

present on the return line without servo control of the 315 frame.

Series 315 Load Frame Introduction

9

Page 10

Specifications

Compression rating

kN 1600 2700 4600 4600

kip 350 600 1000 1000

Model 315.01 Model 315.02 Model 315.03 Model 315.04

Tension rating

*

kN 1050 1350 2300 2300

kip 240 300 500 500

Actuator displacement

mm 100 100 100 100

in 4444

Load frame spring rate

†

N/m

lb/in

Parallel alignment between

platens

mm 0.051 0.051 0.051 0.051

in 0.002 0.002 0.002 0.002

Weight

kg 2359 3855 6350 7590

lb 5200 8500 14,000 16,700

7. 0 x 10

4.0 x 10

9

7

9.0 x 10

5.0 x 10

9

7

11.0 x 10

6.3 x 10

9

7

10.5 x 10

6.0 x 10

9

7

Floor Load (using four102 x

152 mm (4 x 6 in.) vibration

isolation pads)

‡

kPa 380 614 1007 1200

psi 55 89 146 174

* Although the Load Frame assembly is capable of producing the indicated force in tension, the actual

tensile force limit is dependent on the attachment hardware (e.g., threaded connectors) that attach

the gripping fixtures to the crosshead and actuator.

† See “Load Frame Stiffness Calculation” on page 14 for the method used to determine load frame

spring rate.

‡ See the figure and table below for the floor loading footprint dimensions.

10

Introduction

Series 315 Load Frame

Page 11

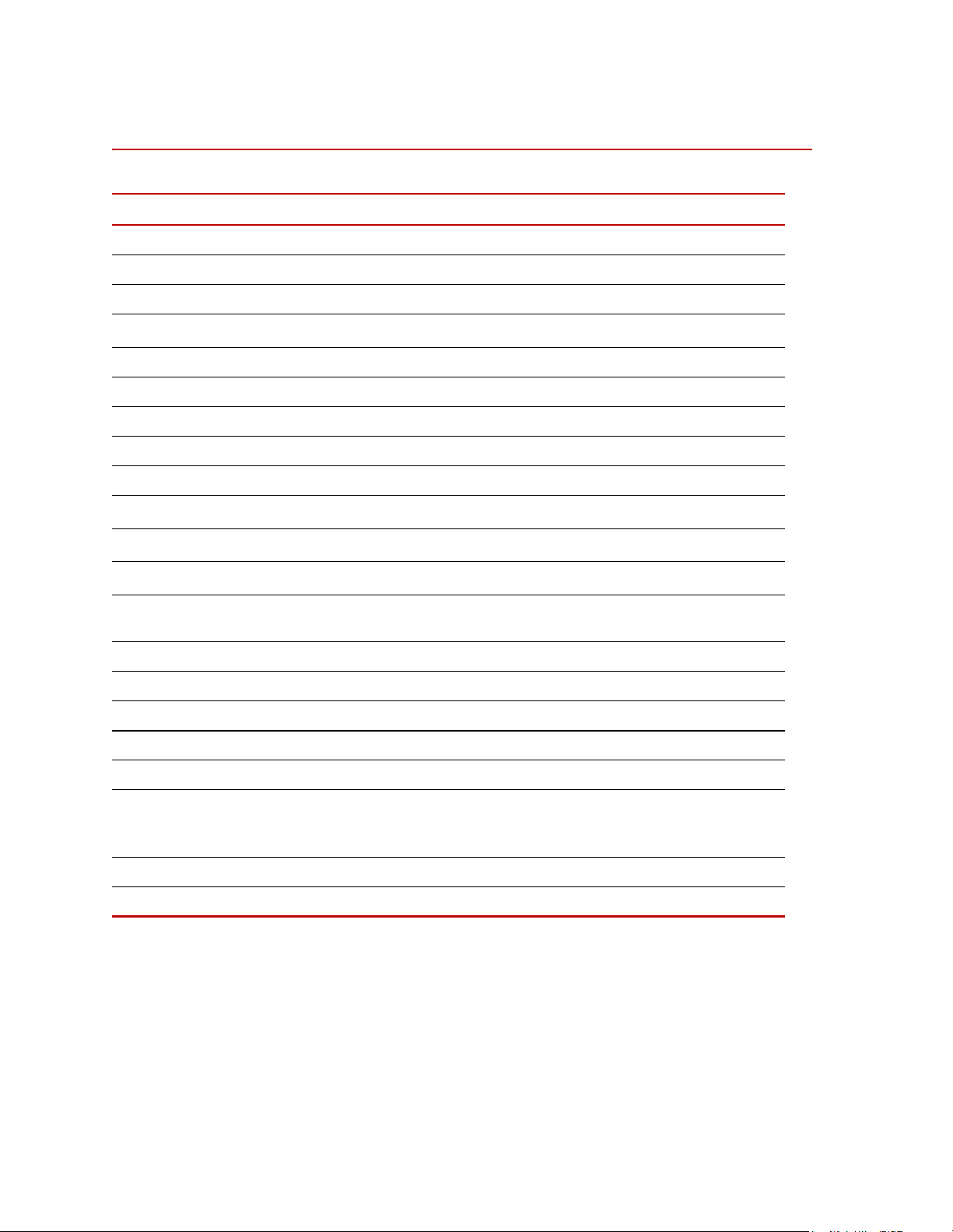

Load Frame Dimensions

D

E

H

J

L

G

A

L

J

B

C

F

M

Model 315 Load Frame Dimensions

N

K

815-315-02

Series 315 Load Frame Introduction

11

Page 12

Model 315.01 Model 315.02 Model 315.03 Model 315.04

*

Dimensions

A 2184 86 2337 92 2692 106 2972 117

B 711 28 914 36 1016 40 1143 45

C 483 19 610 24 737 29 737 29

D 686 27 864 34 953 37.5 1143 45

E 305 12 305 12 356 14 356 14

F 635 25 787 31 965 38 1041 41

mm in mm in mm in mm in

†

G

868 min

970 max

34.2 min

38.2 max

868 min

970 max

34.2 min

38.2 max

868 min

970 max

34.2 min

38.2 max

1160 min

1262 max

45.7 min

49.7 max

H 457 18 457 18 546 21.5 686 27

‡

J

191 7.5 305 12 381 15 381 15

K 640 25.2 805 31.7 927 36.5 927 36.5

L 74 2.94 74 2.94 74 2.94 74 2.94

M 432 17 483 19 584 23 584 23

N 229 9 312 12.3 406 16 406 16

Weight of each

18 kg 40 lb 43 kg 95 lb 68 kg 150 lb 68 kg 150 lb

accessory

attachment

plate (L)

§

* Refer to the figure below for dimension locations.

† The minimum dimension is with the actuator rod fully extended; the maximum dimension is with the

actuator rod fully retracted.

‡ This dimension applies to the piston rod and the accessory attachment plates for the piston rod and

crosshead.

§ Both accessory attachment plates must be removed to use a Model 656 Triaxial Cell in the load frame.

12

Introduction

Series 315 Load Frame

Page 13

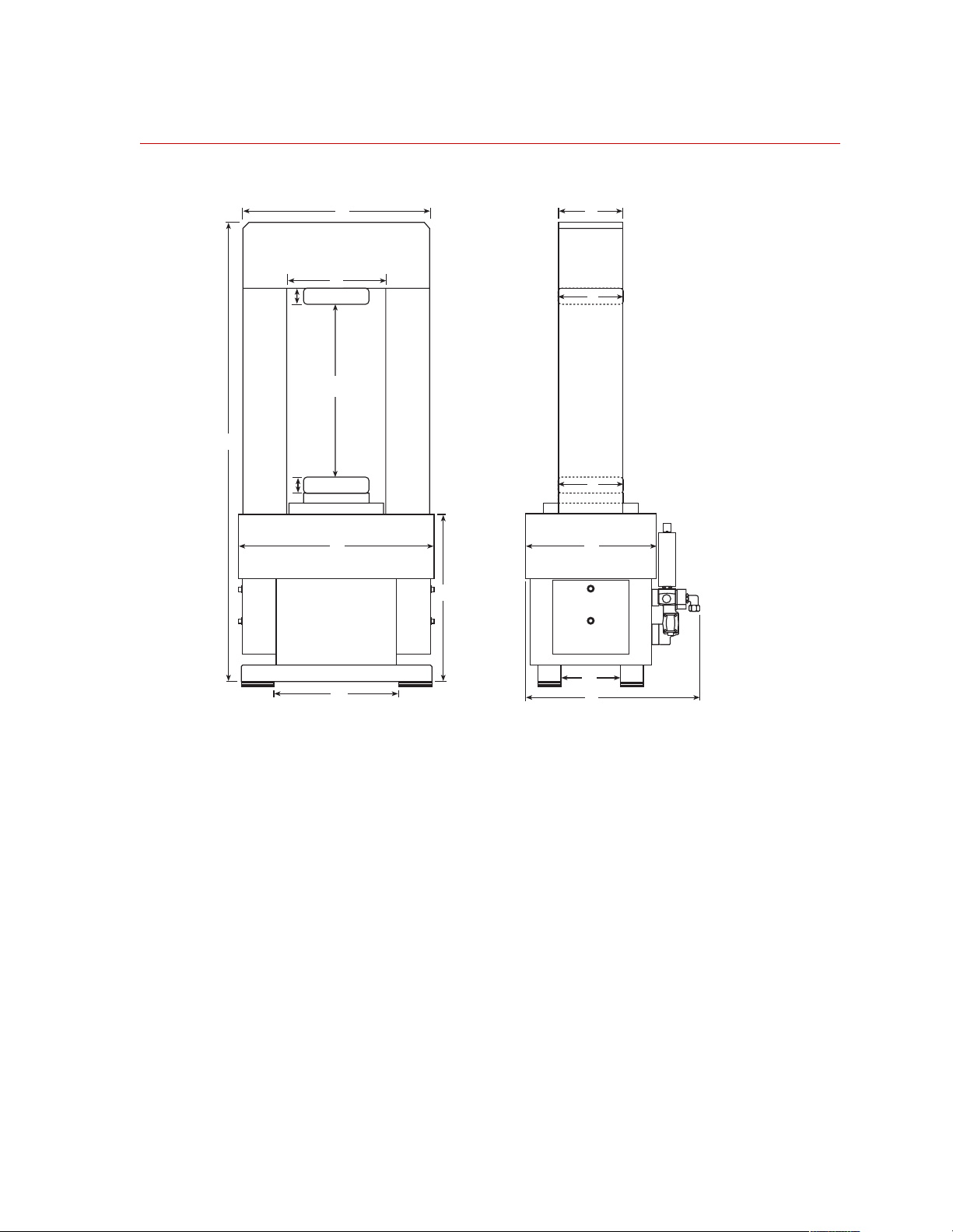

Floor Loading Footprint Dimensions

Model

315.01

Length 737 mm

29 in

Depth 432 mm

17 in

Model

315.02

889 mm

35 in

521 mm

20.5 in.

Vibration Isolation

Pads

Length

Model

315.03

991 mm

39 in

610 mm

24 in

102 mm

(4 in)

Model

315.04

991 mm

39 in

610 mm

24 in

152 mm

(6 in)

Depth

815-315-08

Series 315 Load Frame Introduction

13

Page 14

Load Frame Stiffness Calculation

The Load Frame Spring Rate (stiffness) value reported by MTS is a combination of

the theoretical stiffness of the top plate (crosshead), columns and baseplate. The

equations that are used to calculate these numbers are presented below.

Top Plate

Columns

Base Plate

Spring Model

(T)

(C)

(B)

W

H

T

T

D

T

Top Plate

Columns

W

C

H

C

W

H

B

B

D

C

D

B

Base Plate

815-315-09

Definition of Terms A = Area

Introduction

14

D = Depth

E = Modulus of Elasticity

G = Modulus of Rigidity

H = Height

I = Moment of Inertia

K = Spring Rate

L = Length

W = Width

Series 315 Load Frame

Page 15

Top Plate

-

--

ACE

I

T

DTHT)3(

----------------------

=

12

Columns

Base Plate

Spring rate

LTWT2W

ATDTH

ACWCD

–=

=

T

=

C

LCHC=

DBHB)3(

----------------------

I

=

B

LBWT2W

ABHBD

K

K

C

12

–=

=

B

48EI

---------------

=

T

L

T

-----------

=

L

C

C

C

1–

20ATG

T

------------------

+

3

(for each column)

6L

1– 1–

T

K

B

K

System

48EI

--------------- -

=

1–

20ABG

B

------------------ -

+

3

L

B

K

1–

++[=

T

6L

2KC()1–K

1– 1–

B

1–

1–

]

B

Series 315 Load Frame Introduction

15

Page 16

Note to spring rate

equations

Although the baseplate is modeled as a solid rectangular beam, it actually has a large

hole through it where the actuator is mounted. It is assumed, however, that since the

actuator is attached to the baseplate with fully preloaded fasteners, the stiffness of

the baseplate/actuator assembly is approximately comparable to a solid baseplate

(i.e. with no hole through it). The calculated spring rate values have been found to

be in good agreement with actual measurements on load frame assemblies.

The intent in reporting a spring rate value is to allow comparison between load

frames. For this reason, other, more variable elements in the load train, such as

compression platens, force transducers (load cells) and spacers, are not taken into

consideration. (Typically, different components are used for each application

configuration. Including these elements in the calculation would make direct

comparison between frames difficult.)

Since a servo-hydraulic actuator assembly is a dynamically controlled device that

displays a complex effective “spring rate” (based on oil pressure, oil volume,

cylinder deflection, etc.), it is also not included in the calculation. In general, a high

response servo-hydraulic, closed-loop control system in conjunction with a load

frame properly designed for high stiffness, is sufficient to actively control the

actuator, absorb elastic energy stored in the load frame, and prevent loading system

induced specimen failure. Appendix B discusses in more detail the influence of load

frame stiffness on specimen failure behavior.

16

Introduction

Series 315 Load Frame

Page 17

Installation

Contents Lifting and Moving Instructions 18

Prerequisite You will need a fork lift or overhead crane capable of lifting the load

This section describes how to install the Series 315 Load Frame.

Connecting Cables 23

Connecting Hydraulics 24

frame. Ensure the lifting equipment can accommodate the weight of the

load frame, see the following table.

315 Load Frame Weights

Model Weight

315.01 2359 kg (5200 lb)

315.02 3855 kg (8500 lb)

315.03 6350 kg (14,000 lb)

315.04 7590 kg (16,700 lb)

Procedure Perform the following to install the load frame.

1. Unpack the load frame. Go to “Lifting and moving” on page 19 to unpack and

move the load frame.

2. Connect the cables between the load frame and controller. Go to “Connecting

Cables” on page 23 to make the various controller connections. Return to this

procedure when done.

3. Connect the hydraulic hoses between the load frame and hydraulic

service manifold. Go to “Connecting Hydraulics” on page 24 to connect the

load frame to your hydraulic supply system. Return to this procedure when

done.

Series 315 Load Frame Installation

17

Page 18

Lifting and Moving Instructions

Required equipment The load frame is shipped horizontally on a wooden pallet. You will need

the following equipment to unpack the load frame:

• Lifting slings—not chains—to lift the load frame from its pallet

• Lifting chains to tip the load frame upright

• Rubber mats for the load frame’s feet to rest on

• Wooden blocks for the load frame’s columns to rest on

• A knife to cut the packing straps

WARNING

The load frame is extremely heavy.

The weight of the load frame can seriously hurt you and damage your load

frame.

• Do not allow the load frame to drop or topple.

• Ensure that your chains, slings, and crane have a working capacity greater

than the load frame’s weight (see “315 Load Frame Weights” on page 17).

• Ensure that the lifting eyebolts are tight.

• Ensure that the crosshead locking bolts are fully tightened.

• Lift the load frame only high enough to clear its pallet.

• Operate the crane smoothly to prevent sudden shocks to the sling.

Precautions Read and observe the following precautions when moving this load frame.

1. The loaf frame must be lifted at designated lift points. Lift points are

located at the top of the load frame and are noted by placards similar to the

one shown here:

18

Installation

LIFT POINT

2. Ensure all devices involved in lifting and moving the load frame are in

good repair and working order. Repair or replace any hoist rings,

chains, hooks, lifting device, etc., that might be cracked or damaged.

Ensure the hoist rings are properly mounted in the load frame and

properly secured.

Series 315 Load Frame

Page 19

3. Ensure that the device(s) use for lifting and moving the load frame can

support the entire weight shown on the Lifting and Moving Caution placard on

the back of the load frame. This weight includes the load frame, load cell (if

applicable), actuator, servovalve(s), hydraulic service manifold, grips, and any

other devices attached to the load frame as delivered.

4. Do not apply shock loads to the lifting device(s) when lifting or

moving the load frame. Shock loads can cause momentary forces that

exceed the actual load frame weight. Such shock loads can exceed the

recommended lift capacity of the lifting device(s).

5. Before lifting the load frame, ensure that lifting chain hooks (or equivalent

devices) are securely placed in both hoist rings.

6. Lift the load frame only as high as necessary to clear fixed

obstructions.

7. If chains are used to lift the load frame, the lifting chains should not exceed a

30

° angle from vertical. Angles exceeding 30° can cause undesirable stress/

strain on the hoist rings. This restriction applies only when the total weight of

the load frame is to be supported.

Lifting and moving 1. Unpack the load frame from its shipping container.

Remove all devices (straps, bolts, etc.) that secure the load frame to

the shipping skid or crate. If the load frame was shipped in the

horizontal position, remove all crating material down to the base skid.

2. Inspect the load frame for shipping damage.

Look for the following:

• Scratches in the load frame or columns

• Damaged electrical connections

• Damaged hydraulic connections

• Dents and other structural damage

• Torn, kinked, or breaking hoses

Report any damage found to both the carrier and MTS. In the U.S. and

Canada, call the MTS HELPLine at 1-800-328-2255. Elsewhere, contact

your local MTS office.

Note Steps 3 through 5 of this procedure apply only to load frames shipped in

the horizontal position. If the load frame was shipped in a vertical

position, skip to Step 6.

Series 315 Load Frame Installation

19

Page 20

3. Attach lifting device(s).

A. Attach lifting chain hooks (or equivalent devices) to the hoist

rings on top of the load frame. When attaching both hoist rings to

the same point, do not exceed a 30° chain angle as shown in the

following figure. Exceeding a 30° chain angle causes undesired

stress or strain on the eye bolts or hoist rings.

30° Maximum

B. Remove the side covers from the actuator.

C. Attach lift straps around the ends of the upper leg as shown in the

following illustration.

Hoist Ring

D. Connect the slings to a second, separate lifting device.

E. Ensure the attachment devices are secure.

Side Cover

Load Frame Upper Leg

Lift Strap

Side Cover

Supports

Actuator

Lower Leg

20

Installation

Series 315 Load Frame

Page 21

4. Lift the load frame and prepare for vertical positioning.

A. Lift the load frame, keeping it horizontal, until it is completely

clear of the skid and supports.

B. Remove the skid and supports.

C. Place wood beams beneath the bottom (actuator) end of the load

frame, with the length of the beams running parallel to the length

of the load frame.

5. Raise the load frame to its vertical (upright) position.

A. Lower the bottom end of the load frame until it contacts the wood

beams.

B. Block the beams so they do not slide.

C. Slowly raise the load frame to a vertical position. As the unit rises,

keep moving the crane to keep the chains as straight as possible.

D. Disconnect the lift straps from the bottom end of the load frame.

6. Move the load frame to its final location.

Before you move the load frame review the following:

• The floor where the load frame will sit can bear its weight (see “315 Load

Frame Weights” on page 17).

• The path to the load frame’s destination is clear and uncluttered.

• The area where the load frame will sit is clean and well lit, with

all hoses and cables moved out of harm’s way.

A. When the load frame is upright, raise it slightly to clear the wood

beams. Lift the load frame only as high as necessary.

B. Move the load frame slowly to its installation site.

Series 315 Load Frame Installation

21

Page 22

7. Place the load frame onto the isolation pads.

Install stock metal shims between the pads and the floor.

Load Frame

Install

Shims

to Level

Floor

Isolation Pads

C. Lower the load frame gently into place.

D. Replace the actuator side covers.

8. Remove the chains.

22

Installation

Series 315 Load Frame

Page 23

Connecting Cables

Your controller manual should have cabling information about the

connections described in this section. Most controller manuals provide the

signal pinouts of the connector and assembly numbers for standard MTS

cables.

Note Many of the cables are connected to optional equipment. The following

Prerequisite You must have either a cable assembly drawing of your test system, or you must

know the system controller well enough to determine each type of cable connection.

paragraphs list the most common connections. The exact connector

locations vary quite a bit among the various models of the load frame.

Typical cable

connections

• The force transducer is connected to a DC conditioner in the controller.

• The ground connection is located on the back of the control panel. This is

usually connected to a chassis ground on a console or the controller chassis.

• The load frame control panel is connected to the controller chassis. It contains

the emergency stop signal.

• The servovalve is connected to a valve driver in the controller.

• The displacement sensor (also called an linear variable displacement transducer

or LVDT) is connected to an AC conditioner in the controller.

Series 315 Load Frame Installation

23

Page 24

Connecting Hydraulics

The procedure describes how to connect the load frame to the hydraulic

power source. The load frame can be connected directly to the hydraulic

power unit (also called HPU), to hydraulic plumbing in the workplace, or

through a hydraulic service manifold (HSM).

Note The internal hydraulic connections from the actuator manifold and

accessories such as the hydraulic lifts and locks should already be made.

The load frame actuator usually has a manifold mounted to it. The

manifold connects the ports on each end cap to the ports for a servovalve.

The hydraulic connection are made at this manifold.

1. Connect the return line from the hydraulic power source to the

hydraulic port on the manifold labeled “R”.

2. Connect the pressure line from the hydraulic power source to the

hydraulic port on the manifold labeled “P”.

3. Connect the drain line from the hydraulic power source to the

hydraulic port on the manifold labeled “D”.

4. Turn on the HPU and check for any hydraulic pressure leaks.

5. Select low pressure for the load frame and check for hydraulic leaks in

the load frame.

6. Select high pressure for the load frame and check for hydraulic leaks

in the load frame.

7. Return to the installation procedure.

24

Installation

Series 315 Load Frame

Page 25

Operation

This section describes how to use the Series 315 Load Frame.

Contents Emergency Stop 25

Crush Point Hazards 26

Emergency Stop

Emergency Stop The Emergency Stop button shuts down the hydraulic pressure and stops

the test program. Press this button to shut down hydraulic power, and twist

the switch clockwise to release it. Use the Emergency Stop button to shut

down your test if something unexpected should happen.

815

Rock Mechanics

r

Test System

Emergency Stop

Button

Series 315 Load Frame Operation

25

Page 26

Crush Point Hazards

It is important to stay clear of any potential crush points when the system is

operating. You should know where the crush points are in your system

and protect yourself and others from those crush points with appropriate

safety devices. The following paragraphs describe crush points and

precautions to take while working around crush points.

Crush point

Crush points

Locations A crush point exists between the platen and crosshead on load frames

where the actuator piston rod and specimen move (both areas are shown).

Another potential crush point exists where the lower end of the actuator

piston rod extends below the platen and the bottom of the load frame/load

frame.

Precautions Keep clear of any mechanical linkage that moves within a closed area. If

the linkage should move (when the system starts or due to mechanical

failure), very high forces can be present that could pinch, cut, or crush

anything in the path of linkage movement.

26

Operation

Never allow any part of your body to enter the path of machine movement

or to touch moving machinery, linkages, hoses, cables, specimens, etc.

These present serious crush points or pinch points.

Series 315 Load Frame

Page 27

Maintenance

This section describes the procedures which must be periodically performed to

ensure the continued safe and effective operation of your load frame. The

maintenance interval table on page 28 shows a schedule to maintain your load

frame.

Contents Maintenance Intervals 28

Making Daily Inspections 29

Minimizing Rust 30

Checking the Accumulators’ Precharge 31

Series 315 Load Frame Maintenance

27

Page 28

Maintenance Intervals

The following table lists the recommended interval for each of these procedures.

What to Do When to Do It

Making daily inspections

Minimizing rust

Checking the

accumulators’ precharge

pressures

For maintenance items listed that do not have a corresponding procedure in this manual, call the MTS

*

HELPLine.

Before the start of each day’s testing. See “Making Daily Inspections” on

Depends on the operating

environment; more often in humid

environments.

At least once a month; more often as

required by operating conditions.

How to Do It

page 29.

See “Minimizing Rust” on page 30.

See “Checking the Accumulators’

Precharge” on page 31.

*

28

Maintenance

Series 315 Load Frame

Page 29

Making Daily Inspections

Before the start of each day’s testing, do a quick inspection of your load frame.

Following are typical things that should be checked daily:

• Ensure that there are no leaks from the actuator, hydraulic service manifold,

servovalve, or accumulators.

• Ensure that electrical connections are tight, with no frayed or poorly routed

cables.

• Ensure that hoses are routed properly and fittings are not leaking.

Series 315 Load Frame Maintenance

29

Page 30

Minimizing Rust

Where you operate the load frame determines how often you take rust prevention

measures. Humid and corrosive environments require more prevention.

Recommended

supplies:

• 1 grade kerosene

• Silicone spray

• 000 emery cloth

• Touchup paint; MTS part numbers 011-059-854 (beige),

011-059-856 (grey), 044-587-501 (brown)

• Metal primer paint

• Lint-free cloths

Methods for Various Surfaces

The method and supplies needed to minimize rust, depends on the surface type.

These surface types and methods are described in the follow paragraphs.

Black oxide surfaces Spray with silicone, and then wipe with a clean, lint-free cloth. Or, wipe with a clean,

lint-free cloth dampened with clean hydraulic fluid.

Painted surfaces For small scratches, use touchup paint. For large scratches, sand, prime, and use

touchup paint.

Chrome plated

surfaces

For microscratches, wipe with a clean, lint-free cloth dampened with #1 kerosene.

For rust discoloration, polish with a very fine emery cloth, and then wipe down.

Unpainted surfaces Spray with silicone, and then wipe with a clean, lint-free cloth. Or, wipe with a clean,

lint-free cloth dampened with clean hydraulic fluid.

30

Maintenance

Series 315 Load Frame

Page 31

Checking the Accumulators’ Precharge

An accumulators’ correct precharge pressure is written on its label. Begin by

checking precharge pressures at least once a month.

See the Series 111 Accumulator Product Information manual for the complete details on

checking the precharge intervals and servicing the accumulators.

Record both the pressures and the room temperature in a log book. Use these

readings as a basis for increasing or decreasing the interval between pressure checks.

Generally, recharging is required when there is a change of ±1.4 MPa

(200 psi) in the pressure line accumulator or ±50% in the return line accumulator.

Series 315 Load Frame Maintenance

31

Page 32

32

Maintenance

Series 315 Load Frame

Page 33

Page 34

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

http://www.mts.com

ISO 9001:2000 Certified QMS

Loading...

Loading...