Solution for Liquid Level Detect error of BS200

Solution for Liquid Level Detect error of BS200

I. General

When aspirating samples/reagents and dispensing sample in reaction disc, the

BS-200 chemistry analyzer requires the probe to dip into the liquid for a specific depth

(3mm below the liquid level), so as to avoid carryover that has impacts on test results, and

to avoid air aspiration when the reagent/sample is insufficient. Also when washing the

probe in washing pool, probe also need to stay at a special depth to wash the inner part

and outer part.

II. Composition of Level Detection System

The Level Detection System consists of:

1) Sample/reagent probe,

2) Liquid level detection board,

3) Electric wire from liquid level detection board to probe connection board,

4) Electric wire from liquid level detection board to main board,

5) Main board.

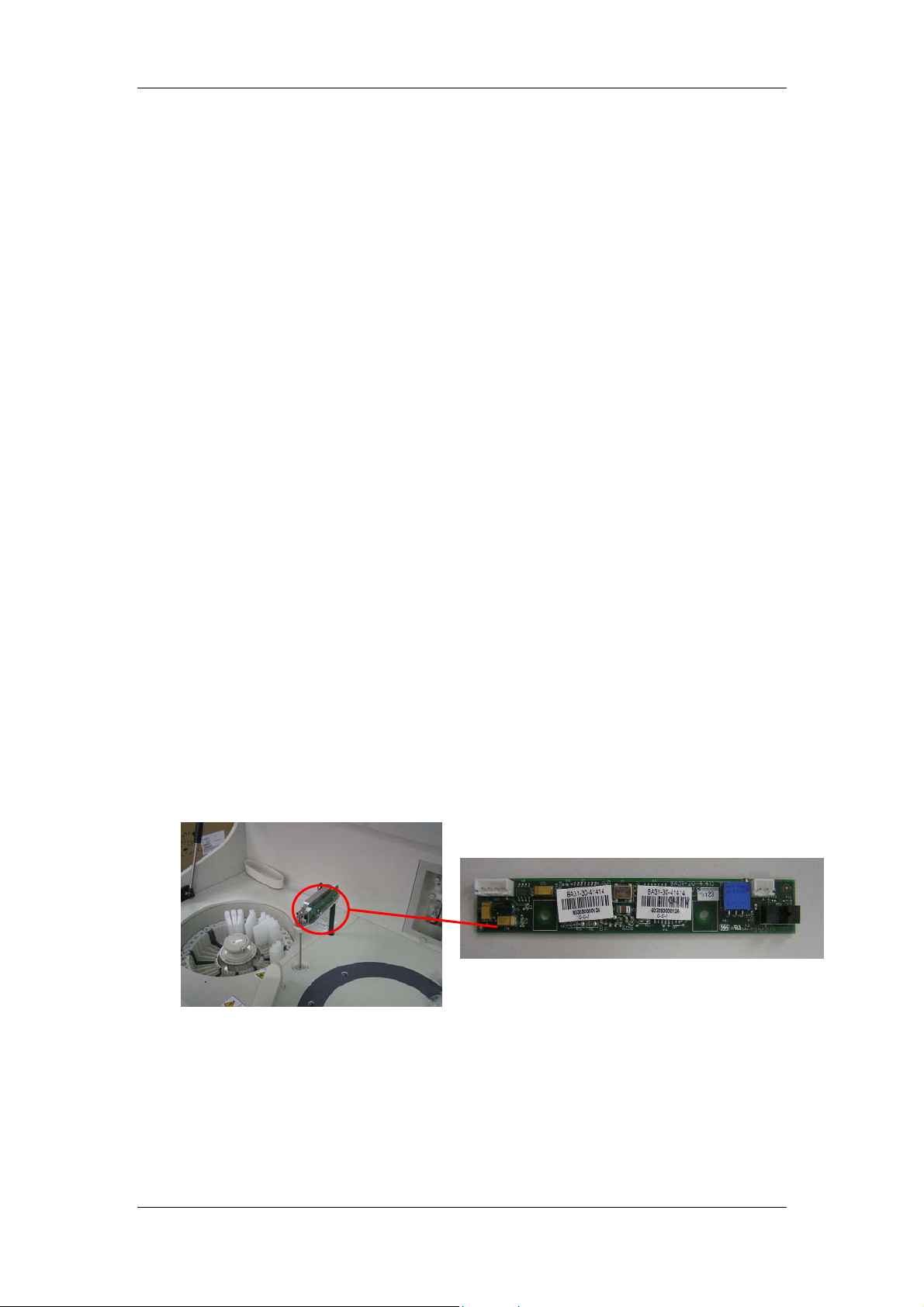

Liquid Level Detect board

The level detection board requires the 5V and 9V voltages. The 9V voltage is the

working voltage of the phase-locked loop, and 5V is the working voltage of other

components on this board. The main control board supplies this board with a 12V voltage,

which is converted into the 5V and 9V voltages as required.

:

Main board

Solution for Liquid Level Detect error of BS200

r

Sample/reagent Probe (Dual-tube)

Inner probe tube

内针管

Inner insulation layer

内绝缘层

Outer probe tube

外针管

Outer insulation laye

外绝缘层

III. Level Detection process

When the sample/reagent probe touches the sample/reagent level, there will be a

change in the capacitance between the two tubes inside the probe. As the capacitance

Solution for Liquid Level Detect error of BS200

changes, the phase changes. The phase discriminator then outputs a voltage variation,

which will be filtered by a low-pass filter. After that, a band-pass filter takes the variation

and reshapes it to pulse signals, which are finally transmitted to the MCU of the main

control board.

Solution for Liquid Level Detect error of BS200

A

r

t

IV. Check procedure (please enlarger the font to see clearly)

LLD error

1) Can’t detect

liquid level in

reaction disc

When aspirate reagent, probe detect reagent level by mistake, so probe aspirates air which leads

to no reagent in reaction disc, when add sample, probe can’t detect liquid level at special height.

Cause: see 3) Detect liquid level by mistake

When aspirate reagent, probe aspirates insufficient reagent and add to reaction disc, when add

sample, probe can’t detect liquid level at special height in reaction disc.

Cause: syringe not fixed, bubble in reagent disc, reagent leakage

s 2) LLD function paralysis

No reagent in reaction disc

Insufficient reagent in reaction disc

LLD function paralysis

When probe touches liquid level, the LLD voltage changes normally, and LED1 is on for about 2

seconds, but still there is an error message said: can’t detect liquid level

Cause: wire disconnect or bro ken, c onnec tor f aulty. In this cas e, u sually w e can’ t detec t th e v olt ag e

change in main board.

Solution: reconnect wire on LLD board and on main board,

LLD signal transmit failure

When probe touches liquid level, the conversion of LLD voltage changes normally, and LED1 is on fo

about 2 seconds, also we can measure the v olt age change i n J35, but still ther e is a LLD e rror message

Shown in the screen.

LLD signal tackle error (by main board)

2) LLD function

paralysis

3) Detect liquid

level by mistake

Probe is ok, but LED on LLD board is always on, or even

probe touches the liquid level, LED still off, that may be

Produce LLD

signal

Failure

In this condition, there is no error message at all, but we can know from reaction curve that no

sample/reagent be added

Possible problem: Probe broken, connection wire not good, signal influence (main board or LLD

board not work normally).

Solution: reference check procedure and change relation parts

This condition only occurs when add sample, (when add reagent, the probe doesn’t detec

liquid level) although there is no error message at all, but we can get some information from

reaction curve, also, there will be some leakage from the needlepoint when probe moves from

reaction disc to washing pool.

Possible problem: probe isn’t in the center of cuvette, bubble in reaction cuvette

something wrong with LLD board, also we can check the

voltage on LLD board to confirm.

Solution: change the LLD board, adjust LLD voltage

Inner part and outer part depart, distort, and so on

Solution: change probe

Detect liquid level by mistake in sample/reagent disc

Detect liquid level by mistake in reaction disc

LLD board problem

Probe problem

Solution for Liquid Level Detect error of BS200

V. Convert defective parts

(a) LLD voltage adjustment

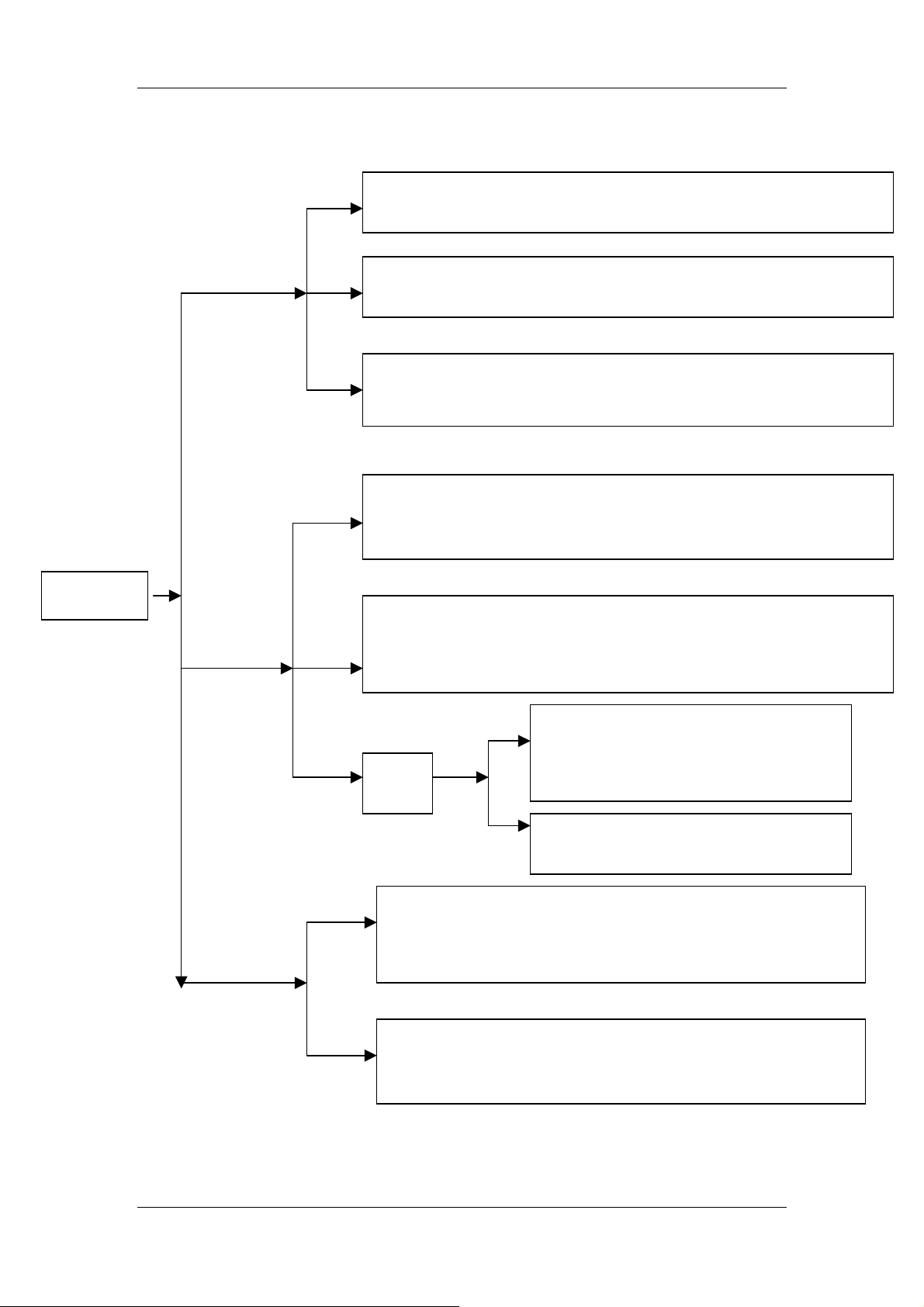

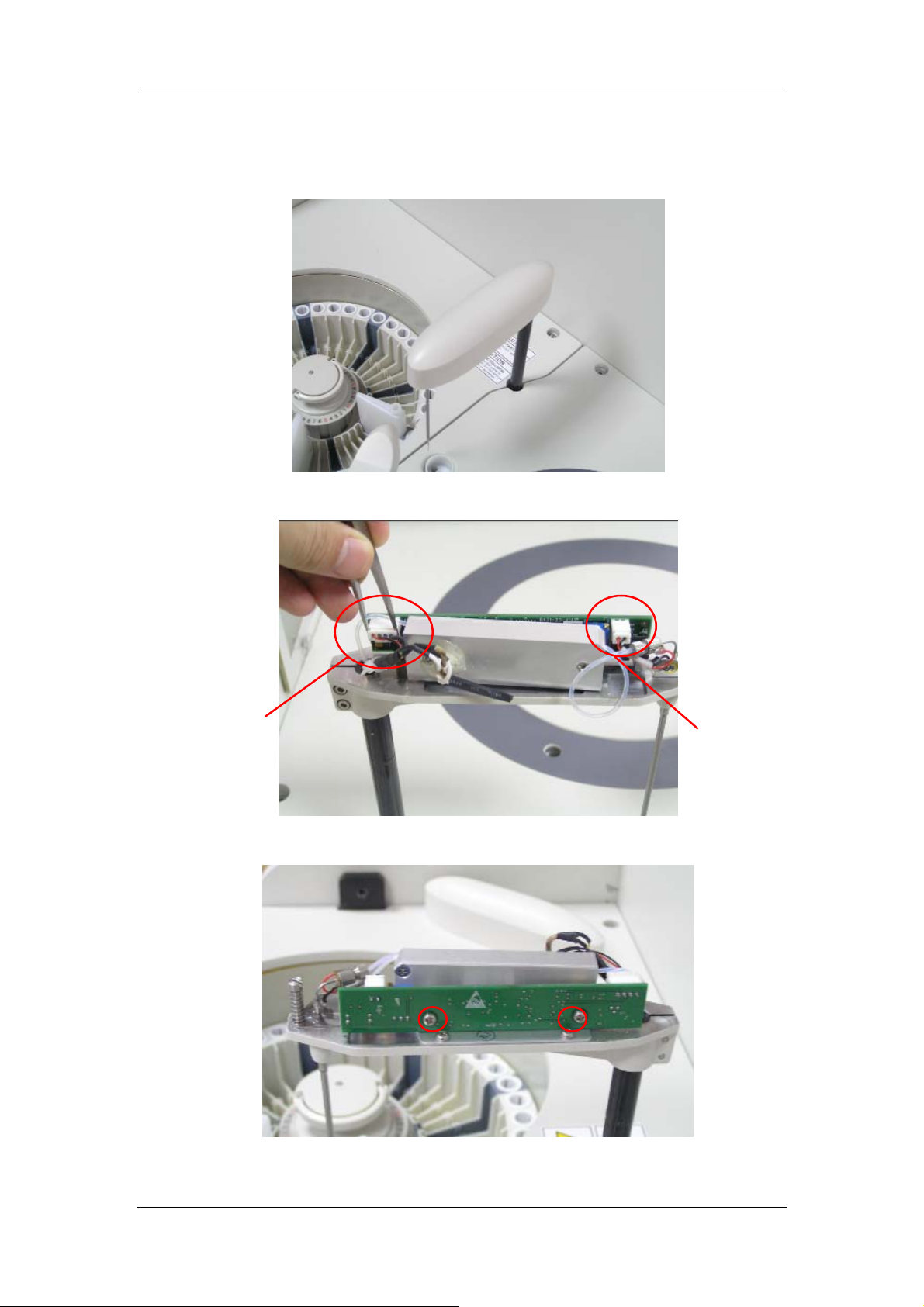

Location of the liquid level detect board:

LED1

Liquid Level Detect board:

FRONT VIEW 1

TP2

What we need to do is like below:

1) Detach the cover of probe arm.

J66

VR1

TP4(ground)

Solution for Liquid Level Detect error of BS200

2) Find TP2, TP4, and the VR1 (marked above)

BACK VIEW 1

TP4(ground)

TP2

3) Adjust VR1, to make voltage between TP2 and TP4 are 4.5 volt.

Remember: every time after we convert a new probe or LLD board, we need to

adjust LLD voltage to 4.5V.Also,this adjustment is the foundation of solution for

LLD error.

(b) Replace probe

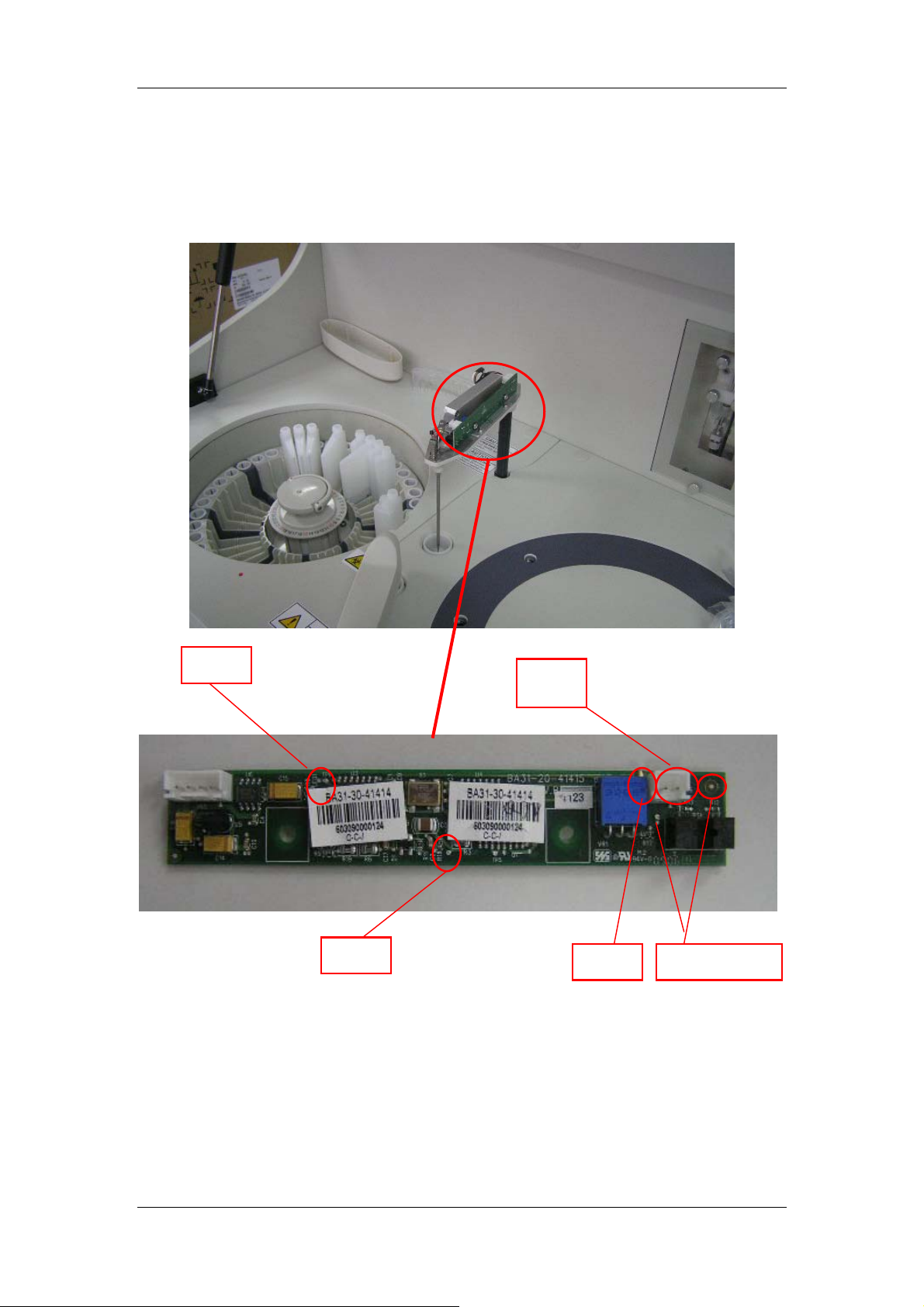

(i) Removing the old Probe

Before replacing or unclogging the probe, remove it first in the following procedures:

1. Place the Power of the analyzing unit to OFF.

2. Pull the probe arm to the highest point by hand. Rotate the probe arm to a

position above the sample/reagent disk for convenient operation.

3. Grab the lower part of the arm covers with two hands and pull them slightly

outwards and remove the cover upward from the arm base.

Solution for Liquid Level Detect error of BS200

Removing the arm cover

4. Disconnecting the probe from the tubing.

Hold the probe’s fluid connector with one hand and the tubing connector with the other.

Rotate the tubing connector counter-clockwise until it is loosened. Unplug the tube from

the probe.

Disconnecting the probe from the tubing

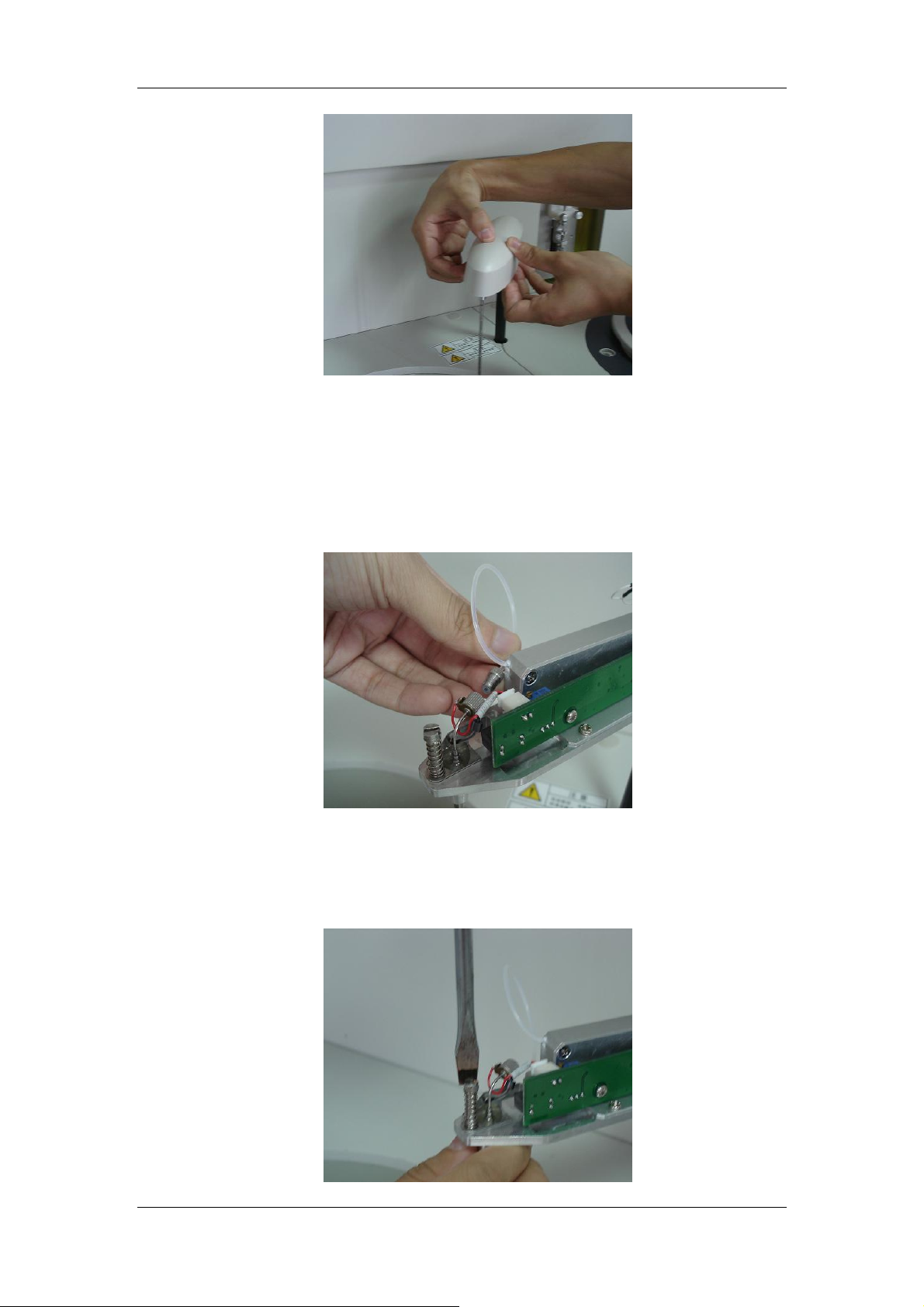

5. Removing the retaining screw of the probe

Remove the retaining screw with a screwdriver and take away the spring.

Solution for Liquid Level Detect error of BS200

1 Removing the retaining screw

6. Unplugging the lead of the level detector

The probe arm is delicate. Exercise caution when disconnecting the connector. Excessive

force may damage the connector and/or the level detection board.

图 2 Unplugging the connector

7. Removing the probe

Slowly pull the probe away from the probe arm.

(ii) Install new probe

1. Add the small washer in to the probe.

2. Insert the probe into the probe arm.

Put the washer in the root

hole of probe (prevent

leakage)

Solution for Liquid Level Detect error of BS200

3. Sleeve the spring over the pole in the probe arm, and screw the retaining screw

back onto the pole.

4. Insert the connector of the probe lead into corresponding jack on the level

detection board. The probe arm is delicate. Exercise caution when inserting the

connector. Excessive force may damage the connector and/or the level detection

board.

5. Screw the probe’s fluid connector back to the tubing connector. Note that

excessive force may bend the probe.

6. Then push the probe upward and then release the probe to check if it can move

Solution for Liquid Level Detect error of BS200

freely. If not, find the reason and solve the problem.

7. Adjust the liquid level detect voltage to 4.5V as (a).

8. Installing the arm cover.

9. Pinch the probe by the part near the probe arm. Gently push the probe upward

and then release the probe to see if it can move freely. If not, remove the arm

cover and re-install it.

10. Do some tests to check whether every thing is ok.

Solution for Liquid Level Detect error of BS200

(c) Replace LLD board

1. Detach the arm cover.

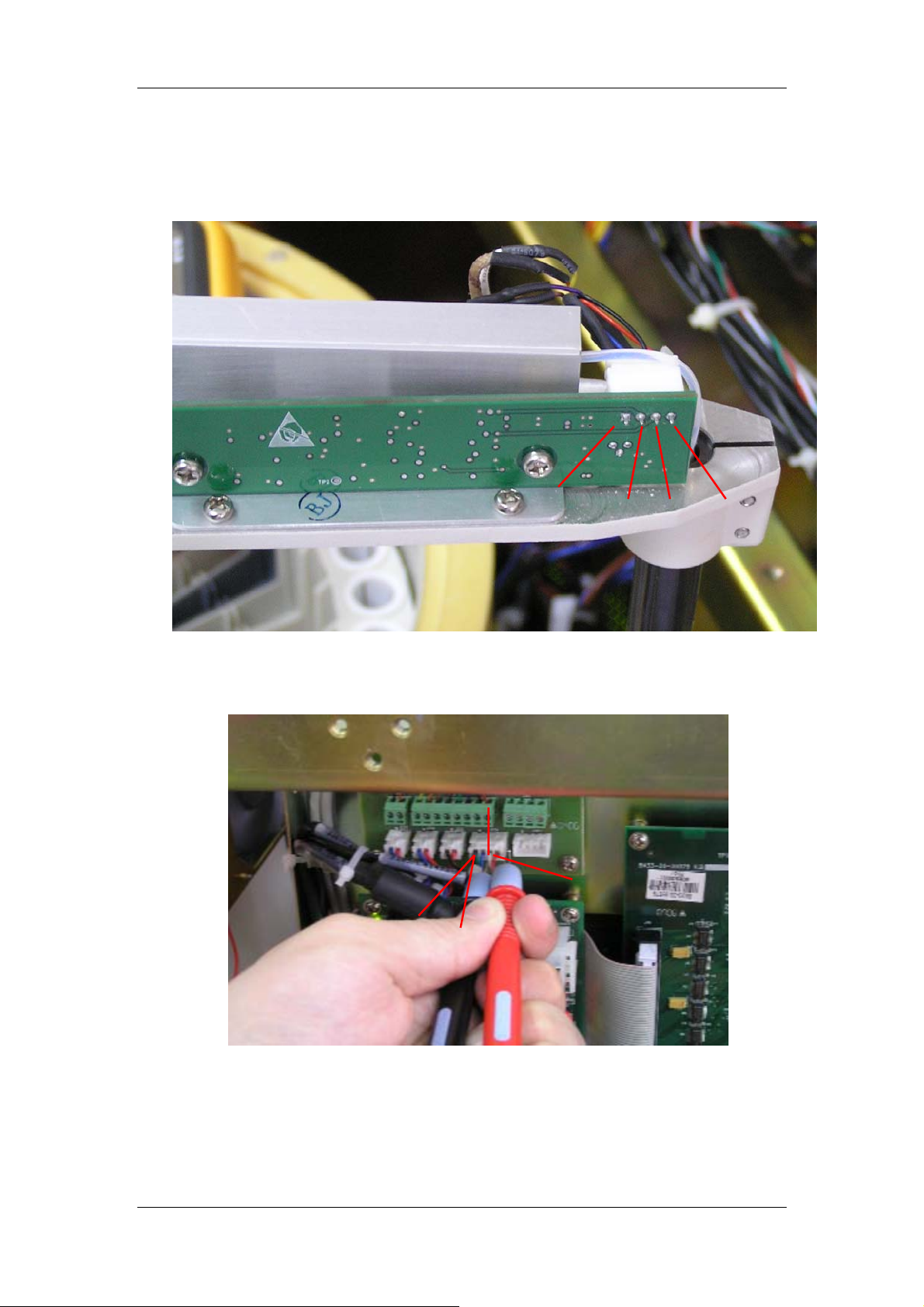

2. Unplug J65 and J66

J65

3. Disconnect the 2 screws and we can detach the LLD board.

4. Change the board.

J66

Solution for Liquid Level Detect error of BS200

5. Set everything back and remember to adjust LLD voltage to 4.5V as procedure

(a), and pinch the probe by the part near the probe arm. Gently push the probe

upward and then release the probe to see if it can move freely.

We should make sure the

block board of probe in

the sensor

(d) Replace Main board

1. Detach the screws, and we can detach the protective cover.

There are totally 3

screws each side

2. After that, detach the 10 screws and we can remove the desk cover.

Solution for Liquid Level Detect error of BS200

3. Remove the 8 screws below, and detach the cover of board and syringe.

4. We can see the main board

5. Just disconnect the four screws and all of the connectors; we can change the

main board.

Probe connection

Board

Main board

Solution for Liquid Level Detect error of BS200

6. Set everything back.

VI. Check procedure of LLD signal

1. First, we need to know how to simulate LLD and collision function. Two picture

below indicates the method.

Simulate collision function

Lift

Simulate LLD function

Det ach relation p arts until we can see the main board and LLD board. (See procedure

d)

Not touch liquid level Touch liquid level

2. Turn on the main power and analysis power.

3. Adjust LLD voltage on LLD board to 4.5V(TP2 and TP4). When detect liquid level,

voltage between TP2 and TP4 should rise more than 4.5v(4.8v, 5v,and so on), if

we can’t do this, or we can do this but there is LLD error, please turn to step 5.

Solution for Liquid Level Detect error of BS200

4. Check the LLD signal in LLD board (in this condition, you’d better ask a people to

help you simulate LLD and collision function):

Signal in LLD board:

AD BC

Signal in probe connection board:

Signal in probe connection board

A

Signal in LLD board

C

D

B

Signal in main board:

Solution for Liquid Level Detect error of BS200

Signal in main board

DACB

Pin Function Description

A Ground

Collision

B

signal

C LLD signal

D Power supply

LLD: normally point A and C is 0V,when the probe touches

the liquid, voltage will suddenly change to 5v,and after

about 1 second, back to 0V again.

Collision: normally point A and B is 5V,when collision

occurs, voltage will suddenly change to 0v.

Power supply is always 12V without change.

VII. Summary (not finished)

Because BS200 only have one probe, one LLD board, and one syringe, so we can

image that sometimes when LLD error occurs, always this error will happen in both

sample disc and reagent disc. If only occurs in one disc, we should pay more attention to

ample and reagent itself.

Loading...

Loading...