Vital Signs Monitor

Service Manual

Intellectual Property Statement

SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called Mindray) owns the

intellectual property rights to this product and this manual. This manual may refer to information

protected by copyrights or patents and does not convey any license under the patent rights of

Mindray, nor the rights of others. Mindray does not assume any liability arising out of any

infringements of patents or other rights of third parties.

Mindray intends to maintain the contents of this manual as confidential information. Disclosure

of the information in this manual in any manner whatsoever without the written permission of

Mindray is strictly forbidden. Release, amendment, reproduction, distribution, rent, adaption and

translation of this manual in any manner whatsoever without the written permission of Mindray

is strictly forbidden.

Mindray in China and other countries. All other trademarks that appear in this manual are used

only for editorial purposes without the intention of improperly using them. They are the property

of their respective owners.

Contents of this manual are subject to changes without prior notice.

For this manual, the issued Date is January 2015 (Version 2.0).

© Copyright 2013-2015 Shenzhen Mindray Bio-Medical Electronics Co., Ltd. All rights reserved.

, , and are the registered trademarks or trademarks owned by

WARNING

Federal Law (USA) restricts this device to sale by or on the order of a physician.

NOTE

This manual describes all features and options. The equipment may not have all of

them. Contact Mindray service department for any questions.

I

Manufacturer’s Responsibility

Contents of this manual are subject to changes without prior notice.

All information contained in this manual is believed to be correct. Mindray shall not be liable for

errors contained herein nor for incidental or consequential damages in connection with the

furnishing, performance, or use of this manual.

Mindray is responsible for safety, reliability and performance of this product only in the condition

that:

All installation operations, expansions, changes, modifications and repairs of this

product are conducted by Mindray authorized personnel; and

The electrical installation of the relevant room complies with the applicable national

and local requirements; and

This product is operated under strict observance of this manual.

Warranty

Mindray warrants that components within its products will be free from defects in

workmanship and materials for a period of three years from the date of purchase except that

disposable or one-time use products are warranted to be free from defects in workmanship

and materials up to a date one year from the date of purchase or the date of first use,

whichever is sooner.

This warranty does not cover consumable items such as, but not limited to, batteries,

external cables, and sensors.

Mindray shall not be liable for any incidental, special, or consequential loss, damage, or

expense directly or indirectly arising from the use of its products. Liability under this

warranty and the buyer’s exclusive remedy under this warranty is limited to servicing or

replacing the affected products, at Mindray’s option, at the factory or at an authorized

distributor, for any product which shall under normal use and service appear to Mindray to

have been defective in material or workmanship. Recommended preventative maintenance,

as prescribed in the service manual, is the responsibility of the user and is not covered by

this warranty.

No agent, employee, or representative of Mindray has any authority to bind Mindray to any

affirmation, representation, or warranty concerning its products, and any affirmation,

representation or warranty made by any agent, employee, or representative shall not be

enforceable by buyer or user.

THIS WARRANTY IS EXPRESSLY IN LIEU OF, AND MINDRAY EXPRESSLY DISCLAIMS, ANY

OTHER EXPRESS OR IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY, NON-INFRINGEMENT, OR FITNESS FOR A PARTICULAR PURPOSE, AND OF

ANY OTHER OBLIGATION ON THE PART OF MINDRAY.

Damage to any product or parts through misuse, neglect, accident, or by affixing any

II

non-standard accessory attachments, or by any customer modification voids this warranty.

Mindray makes no warranty whatsoever in regard to trade accessories, such being subject to

the warranty of their respective manufacturers.

A condition of this warranty is that the equipment or accessories which are claimed to be

defective be returned when authorized, freight prepaid to Mindray DS USA, Inc., Mahwah,

New Jersey 07430 or its authorized representative. Mindray shall not have any responsibility

in the event of loss or damage in transit.

Exemptions

Mindray's obligation or liability under this warranty does not include any transportation or

other charges or liability for direct, indirect or consequential damages or delay resulting

from the improper use or application of the product or the use of parts or accessories not

approved by Mindray or repairs by people other than Mindray authorized personnel.

This warranty does not extend to:

Malfunction or damage caused by improper use or man-made failure.

Malfunction or damage caused by unstable or out-of-range power input.

Malfunction or damage caused by force majeure events, such as (i) flood, fire and

earthquake or other similar elements of nature or acts of God; (ii) riots, war, civil

disorders, rebellions, or revolutions in any country; or (iii) any other cause beyond the

reasonable control of Mindray.

Malfunction or damage caused by improper operation or repair by unqualified or

unauthorized service people.

Malfunction of the instrument or part whose serial number is not legible.

Others not caused by instrument or part itself.

III

Return Policy

In the event that it becomes necessary to return a unit to Mindray, follow the instructions below.

1. Obtain a return authorization.

Contact the Mindray Service Department and obtain a Mindray Customer Service

Authorization Number. The Mindray Customer Service Authorization Number must

appear on the outside of the shipping container. Return shipments will not be accepted

if the Mindray Customer Service Authorization Number is not clearly visible. Please

provide the model number, serial number, and a brief description of the reason for

return.

2. Freight policy

The customer is responsible for freight charges when this product is shipped to

Mindray for service (including any relevant customs fees or other freight related

charges).

3. Return address

Please send the part(s) or equipment to the address offered by Customer Service

Department.

Contact Information

Manufacturer:

Address:

Tel :

Fax:

Website:

Distributor:

Address:

Tel :

Website:

Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Mindray Building, Keji 12th Road South, Hi-tech Industrial Park, Nanshan,

Shenzhen 518057 P.R. China

+86 755 81888998

+86 755 26582680

www.mindray.com

Mindray DS USA, Inc.

800 MacArthur Boulevard Mahwah, New Jersey 07430 USA

1.800.288.2121, 1.201.995.8000

www.mindray.com

IV

Preface

Manual Purpose

This manual provides detailed information about the assembling, dissembling, testing and

troubleshooting of the equipment to support effective troubleshooting and repair. It is not

intended to be a comprehensive, in-depth explanation of the product architecture or technical

implementation.

Observance of the manual is a prerequisite for proper equipment maintenance and prevents

equipment damage and personnel injury.

Intended Audience

This manual is for biomedical engineers, authorized technicians or service representatives

responsible for troubleshooting, repairing and maintaining the equipment.

Passwords

A password may be required to access different modes of the following equipment. The

passwords are listed below:

User maintenance: 888888

Configuration mode: 315666

It is recommended that the user should change the passwords for user maintenance and

configuration mode once they take ownership of the equipment.

V

FOR YOUR NOTES

VI

Contents

1 Introduction ........................................................................................................................... 1-1

1.1 Manual Information .................................................................................................................................... 1-1

1.2 Safety Information ....................................................................................................................................... 1-1

1.2.1 Warnings ............................................................................................................................................ 1-2

1.2.2 Cautions ............................................................................................................................................. 1-2

1.2.3 Notes ................................................................................................................................................... 1-2

1.3 Equipment Symbols ................................................................................................................................... 1-3

2 Theory of Operation .............................................................................................................. 2-1

2.1 Overview ......................................................................................................................................................... 2-1

2.2 Connectors for Peripheral Devices ........................................................................................................ 2-2

2.3 Main Unit ........................................................................................................................................................ 2-2

2.4 Front Housing Assembly ........................................................................................................................... 2-4

2.5 Main Board ..................................................................................................................................................... 2-4

2.6 Rear Housing Assembly ............................................................................................................................ 2-5

2.7 External Module ........................................................................................................................................... 2-6

3 Equipment Installation ......................................................................................................... 3-1

3.1 Unpacking the Equipment ....................................................................................................................... 3-1

3.2 Preparation for Installation ...................................................................................................................... 3-1

3.2.1 Preparation for Installation Site ................................................................................................ 3-1

3.2.2 Environmental Requirements .................................................................................................... 3-1

3.2.3 Electrical Requirements ............................................................................................................... 3-2

3.3 Equipment Installation .............................................................................................................................. 3-2

3.3.1 Preparation for Power on ............................................................................................................ 3-3

4 Testing and Maintenance ...................................................................................................... 4-1

4.1 Introduction ................................................................................................................................................... 4-1

4.2 Performance Tests ....................................................................................................................................... 4-1

4.2.1 Performance Test Frequencies .................................................................................................. 4-1

4.2.2 Visual Inspection ............................................................................................................................. 4-2

4.2.3 SpO2 test ............................................................................................................................................ 4-2

4.2.4 NIBP Test ............................................................................................................................................ 4-4

4.2.5 Temperature Test ............................................................................................................................ 4-6

4.2.6 Nurse Call Reply Performance Test .......................................................................................... 4-7

4.3 Electrical Safety and Other Tests ............................................................................................................ 4-8

4.3.1 Electrical Safety and Other Test Frequencies ....................................................................... 4-8

4.3.2 Electric Safety Tests ........................................................................................................................ 4- 8

4.3.3 Power-on Test .................................................................................................................................. 4-8

4.3.4 Touchscreen Calibration .............................................................................................................. 4-9

4.3.5 Recorder check ................................................................................................................................ 4-9

1

4.3.6 Bar Code Scanner Test .................................................................................................................. 4-9

4.3.7 Battery Check ................................................................................................................................. 4-10

4.4 Factory Maintenance ............................................................................................................................... 4-10

4.4.1 Accessing Factory Maintenance Menu ................................................................................ 4-10

4.4.2 Drawing Waves .............................................................................................................................. 4-11

4.4.3 Software Version ........................................................................................................................... 4-11

4.4.4 Monitor Information ................................................................................................................... 4-12

5 Troubleshooting .................................................................................................................... 5-1

5.1 Overview ......................................................................................................................................................... 5-1

5.2 Part Replacement ........................................................................................................................................ 5-1

5.3 Checking Equipment Status .................................................................................................................... 5-1

5.4 Checking Software Version ...................................................................................................................... 5-1

5.5 Checking Technical Alarms ...................................................................................................................... 5-2

5.6 Troubleshooting Guide ............................................................................................................................. 5-2

5.6.1 Power On/Off Failure..................................................................................................................... 5-2

5.6.2 Display Failures ............................................................................................................................... 5-2

5.6.3 Alarm Lamp Failures ...................................................................................................................... 5-3

5.6.4 Button and Knob Failures ............................................................................................................ 5-3

5.6.5 Sound Failures ................................................................................................................................. 5-4

5.6.6 Battery Failures ................................................................................................................................ 5-5

5.6.7 Recorder Failures ............................................................................................................................ 5-5

5.6.8 Output Interface Failure .............................................................................................................. 5-6

5.6.9 Data Storage Failure ...................................................................................................................... 5-6

5.6.10 Wired Network Related Problems ......................................................................................... 5-7

5.6.11 Wi-Fi Related Problems .............................................................................................................. 5-7

5.6.12 Module defective ......................................................................................................................... 5-8

5.6.13 Technical Alarm Messages ........................................................................................................ 5-8

6 Disassembly and Repair ........................................................................................................ 6-1

6.1 Tools Required .............................................................................................................................................. 6-1

6.2 Preparations for Disassembly ................................................................................................................. 6-1

6.3 Disassembling the Main Unit .................................................................................................................. 6-2

6.3.1 Disassembling the Temperature Module (Optional) ........................................................ 6-2

6.3.2 Removing the Recorder ............................................................................................................... 6-3

6.3.3 Separating the Front and Rear Half of the Monitor ........................................................... 6-3

6.3.4 Removing the Parameter Connector Panel Assembly ..................................................... 6-5

6.3.5 Disassembling the Main Bracket Assembly ......................................................................... 6-6

6.3.6 Removing the Parameter Board (SpO2 Optional) and Power Management Board6-8

6.3.7 Disassembling Pumps and Valves ............................................................................................ 6-9

6.3.8 Disassembling AC/DC Power Board and Battery Converter Board ........................... 6-10

6.4 Disassembling the Front Housing Assembly .................................................................................. 6-10

6.4.1 Removing the Touchscreen Control Board ......................................................................... 6-11

6.4.2 Removing the Wi-Fi Module (Optional) ............................................................................... 6-11

2

6.4.3 Removing the Main Control Board ........................................................................................6-12

6.4.4 Removing SD Card .......................................................................................................................6-13

6.4.5 Removing the Touchscreen ......................................................................................................6-13

6.4.6 Disassembling the Display ........................................................................................................6-14

6.4.7 Removing the Keypad ................................................................................................................6-14

6.4.8 Removing the Encoder ...............................................................................................................6-14

6.4.9 Removing the Alarm Lamp .......................................................................................................6-15

6.5 Disassembling the Temperature Module (Optional) ....................................................................6-15

6.5.1 Removing the Temperature Module PCBA and Module Power Board PCBA ........6-15

6.5.2 Disassembling the Temperature On-Position Detection Board PCBA .....................6-16

7 Parts ........................................................................................................................................ 7-1

7.1 Introduction ................................................................................................................................................... 7-1

7.2 Main Unit ........................................................................................................................................................ 7-1

7.2.1 Exploded View ................................................................................................................................. 7-1

7.2.2 Parts List ............................................................................................................................................. 7-1

7.3 Front Housing Subassembly (Touchscreen) ...................................................................................... 7-2

7.3.1 Exploded View ................................................................................................................................. 7-2

7.3.2 Parts List ............................................................................................................................................. 7-3

7.4 Rear Housing Assembly ............................................................................................................................ 7-4

7.4.1 Exploded View ................................................................................................................................. 7-4

7.4.2 Parts List ............................................................................................................................................. 7-4

7.5 Main Bracket Assembly ............................................................................................................................. 7-6

7.5.1 Exploded View ................................................................................................................................. 7-6

7.5.2 Parts List ............................................................................................................................................. 7-6

7.6 Power Management Board Assembly ................................................................................................. 7-7

7.6.1 Exploded View ................................................................................................................................. 7-7

7.6.2 Parts List ............................................................................................................................................. 7-7

7.7 Parameter Connector Panel Assembly ................................................................................................ 7-8

7.7.1 Exploded View ................................................................................................................................. 7-8

7.7.2 Parts List ............................................................................................................................................. 7-8

7.8 Predictive Temperature Assembly ......................................................................................................... 7-9

7.8.1 Exploded View ................................................................................................................................. 7-9

7.8.2 Parts List ............................................................................................................................................. 7-9

8 Hardware and Software Upgrade ......................................................................................... 8-1

8.1 Hardware Upgrade ...................................................................................................................................... 8-1

8.1.1 Upgrade Package ........................................................................................................................... 8-1

8.1.2 Upgrading Parameter Modules ................................................................................................ 8-1

8.1.3 Upgrading Temperature .............................................................................................................. 8-2

8.1.4 Enabling Parameter Functions .................................................................................................. 8-2

8.2 Software Upgrade ....................................................................................................................................... 8-2

A Electrical Safety Inspection .................................................................................................. A-1

3

A.1 Power Cord Plug ......................................................................................................................................... A-1

A.2 Device Enclosure and Accessories ....................................................................................................... A-2

A.3 Device Labeling .......................................................................................................................................... A-2

4

1 Introduction

1.1 Manual Information

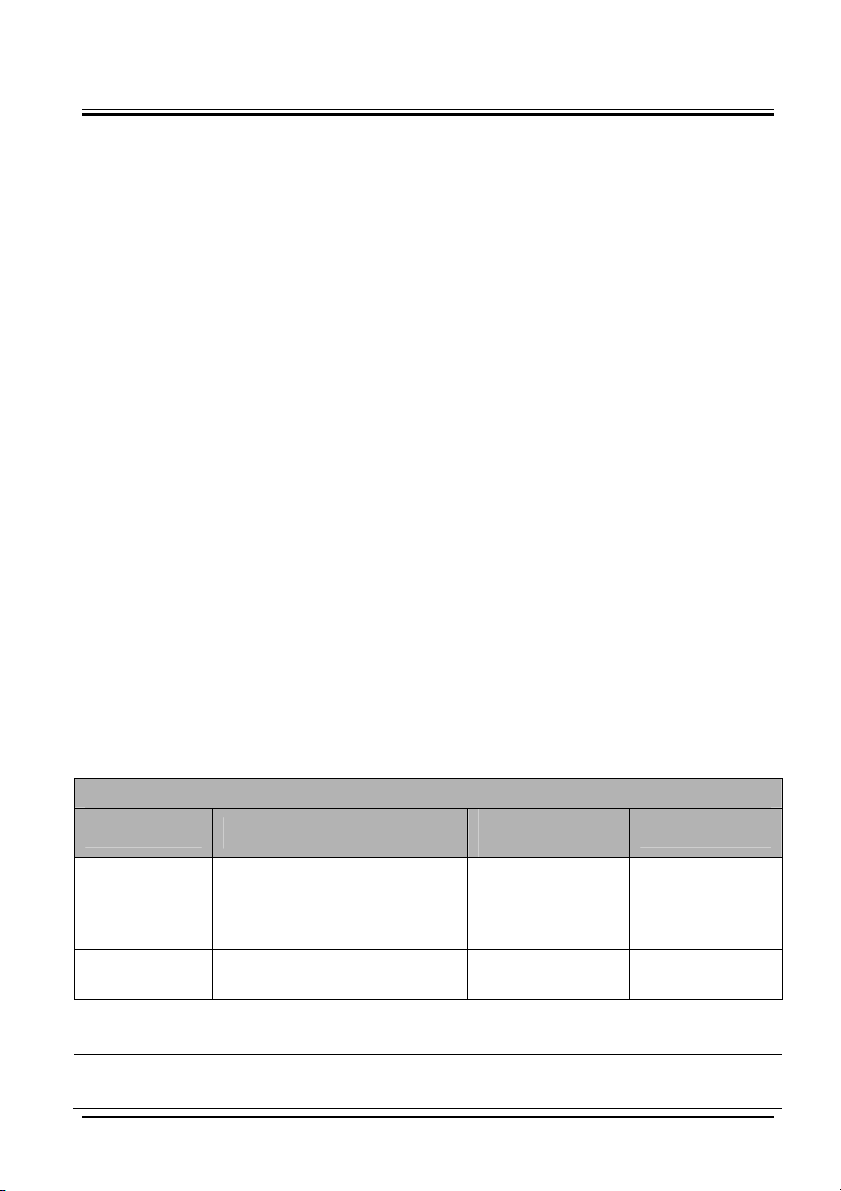

Version Revision History

1.0 New

2.0 Modify temperature module test method, update parts list

1.2 Safety Information

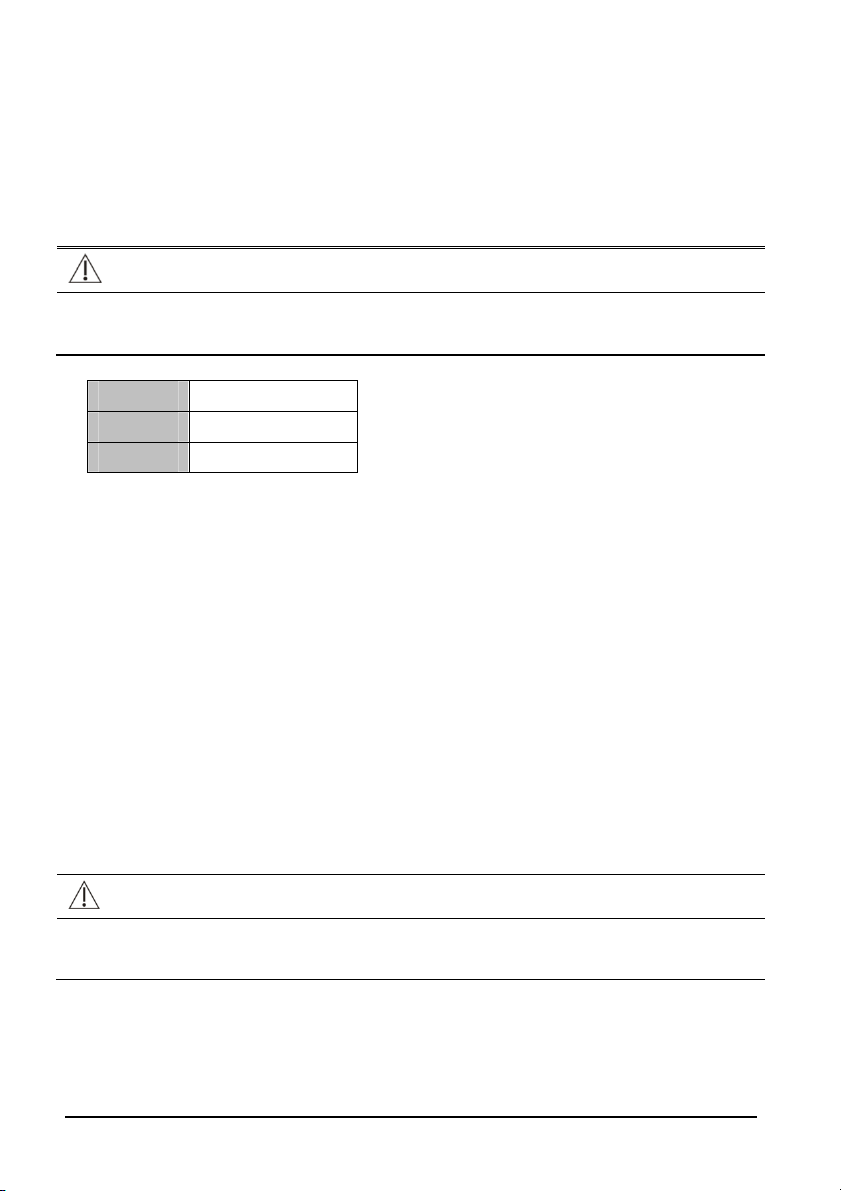

WAR NIN G

Indicates a potential hazard or unsafe practice that, if not avoided, will result in

death or serious injury.

CAUTION

Indicates a potential hazard or unsafe practice that, if not avoided, could result in

minor personal injury or product/property damage.

NOTE

Provides application tips or other useful information to ensure that you get the

most from your product.

1-1

1.2.1 Warnings

WAR NIN G

All installation operations, expansions, changes, modifications and repairs of this

product are conducted by Mindray authorized personnel.

There is high voltage inside the equipment. Never disassemble the equipment

before it is disconnected from the AC power source or the battery.

When you disassemble/reassemble a parameter module, a patient leakage current

test must be performed before it is used again for monitoring.

The equipment must be connected to a properly installed power outlet with

protective earth contacts only. If the installation does not provide for a protective

earth conductor, disconnect it from the power line and operate it on battery power,

if possible.

Disposal of the packaging material should observe the applicable waste control

regulations and keeping it out of children’s reach.

1.2.2 Cautions

CAUTION

Make sure that no electromagnetic radiation interferes with the performance of the

equipment when preparing to carry out performance tests. Mobile phone, X-ray

equipment or MRI devices are a possible source of interference as they may emit

higher levels of electromagnetic radiation.

Before connecting the receiver to the power line, check that the voltage and

frequency ratings of the power line are the same as those indicated on the unit’s

label or in this manual.

Protect the equipment from damage caused by drop, impact, strong vibration or

other mechanical force during servicing.

1.2.3 Notes

NOTE

Refer to operator’s manual for detailed operation and other information.

1-2

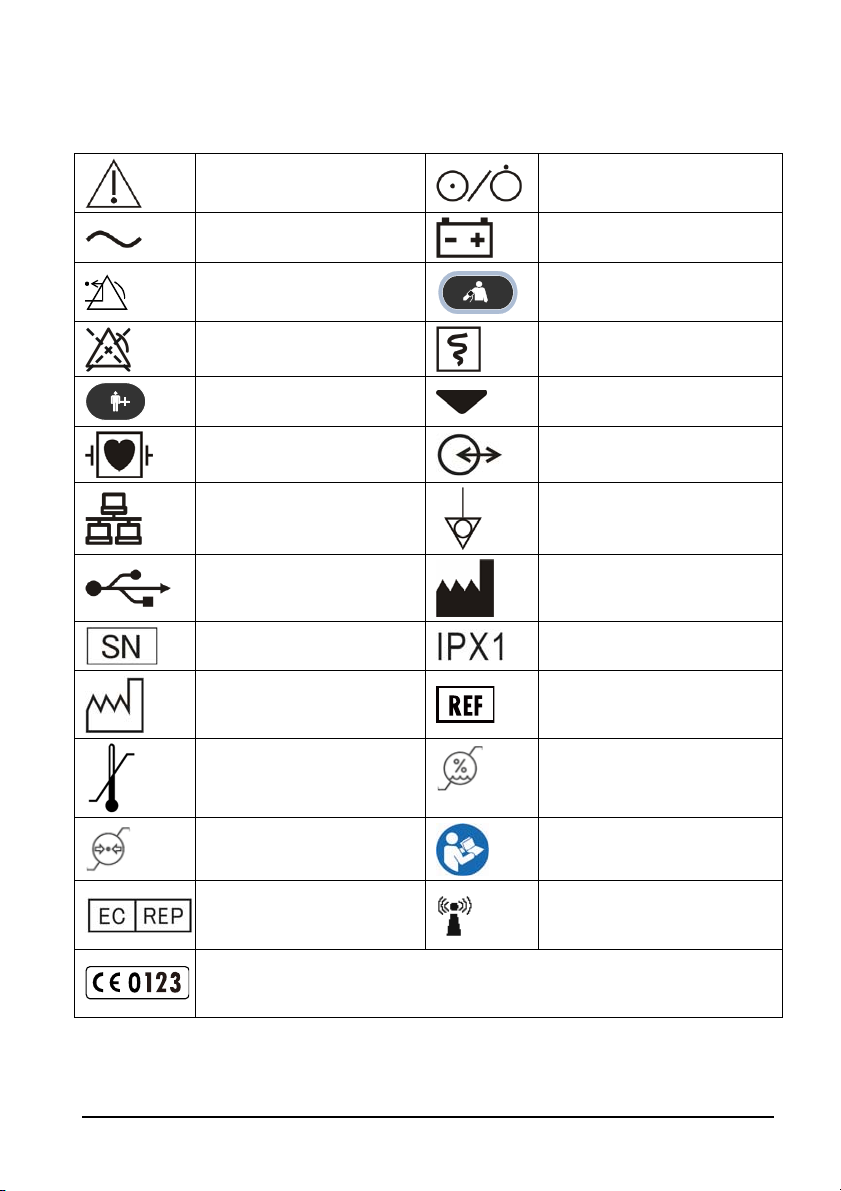

1.3 Equipment Symbols

Some symbols may not appear on your equipment.

Caution

Alternating current (AC)

Alarm Reset

Alarm Paused

Admit a new patient

DEFIBRILLATION –PROOF

TYPE CF APPLIED PART

Network connector

USB connectors

Serial number

DATE OF MANUAFACTURE

Power ON/OFF

Battery indicator

NIBP Start/Stop key

Record

Insertion Direction

Input/Output

Equipotentiality

Manufacturer

Protection against fluid ingress

CATALOGUE NUMBER

Temperature limit

Atmospheric pressure

limitation

AUTHORISED

REPRESENTATIVE IN THE

EUROPEAN COMMUNITY

The product bears CE mark indicating its conformity with the provisions of the

Council Directive 93/42/EEC concerning medical devices and fulfills the

essential requirements of Annex I of this directive.

1-3

Humidity limitation

Refer to instruction manual/

booklet

Interference may occur in the

vicinity of equipment marked

with this symbol

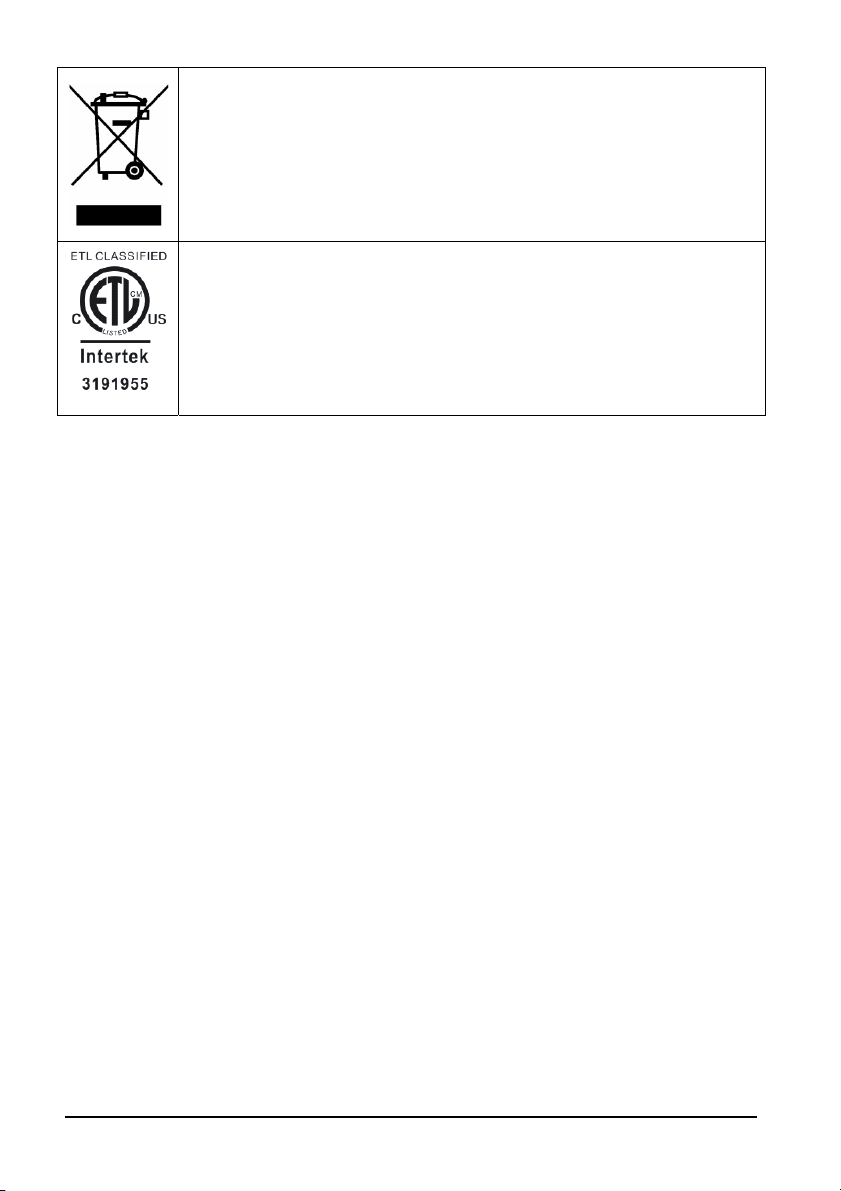

The following definition of the WEEE label applies to EU member states only.

This symbol indicates that this product should not be treated as household

waste. By ensuring that this product is disposed of correctly, you will help

prevent bringing potential negative consequences to the environment and

human health. For more detailed information with regard to returning and

recycling this product, please consult the distributor from whom you purchased

it.

* For system products, this label may be attached to the main unit only.

The presence of this label indicates the machine was certified by ETL with the

statement:

Conforms to AAMI Std ES 60601-1, IEC Std 60601-1-6, IEC Std 60601-1-8, IEC Std

60601-2-49, IEC Std 80601-2-30, ISO Std 80601-2-56, ISO Std 80601-2-61.

Certified to CSA Std C22.2 NO. 60601-1, NO. 60601-1-6, NO. 60601-1-8, NO.

60601-2-49, NO. 80601-2-30, NO. 80601-2-56, NO. 80601-2-61.

1-4

y

r

2 Theory of Operation

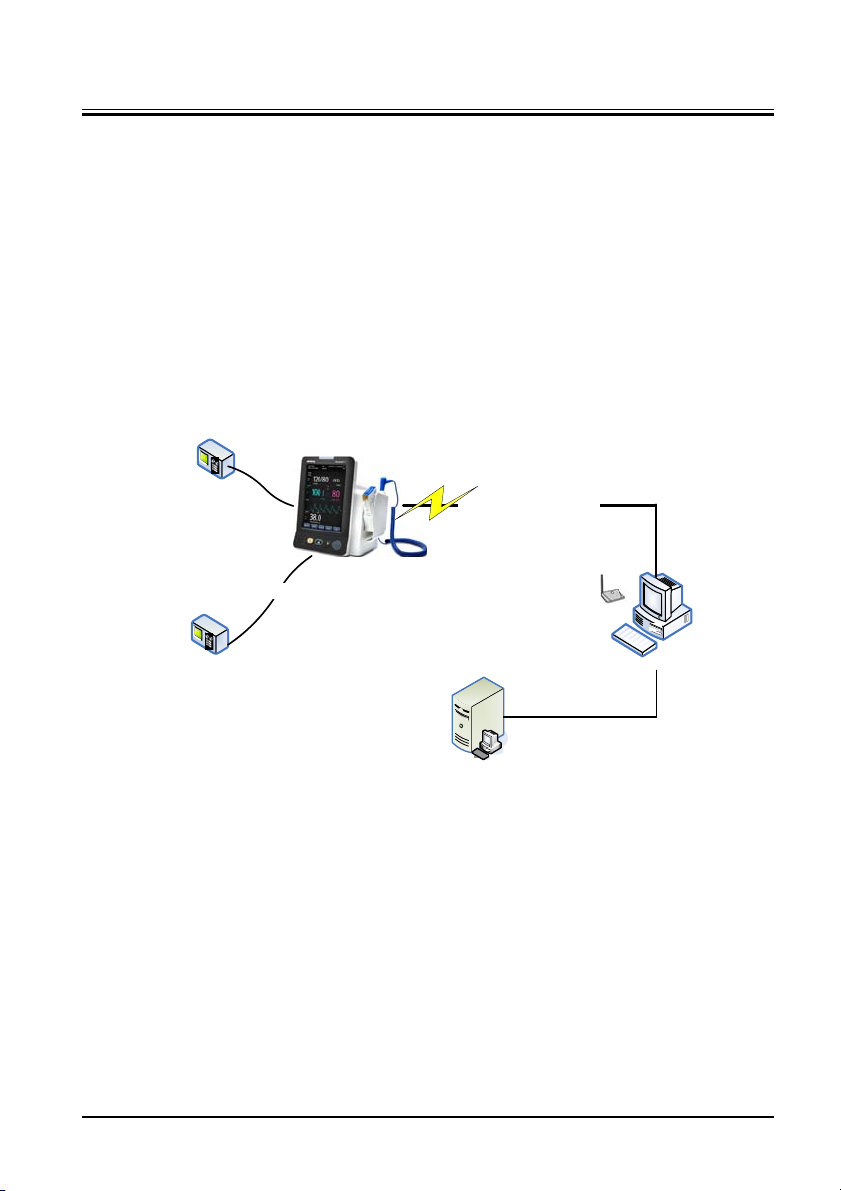

2.1 Overview

The Monitor is intended for monitoring physiologic parameters, including SpO2, Pulse Rate, NIBP

and Temperature, on adult, pediatric, and neonatal patients in healthcare facilities by clinical

physicians or appropriate medical staff under the direction of physicians.

The equipment also:

Provides audible and visual alarm indications in case of patient or equipment problems;

Provides display, review, storage and printing of monitored information;

Incorporates multiple input devices such as buttons, knob, and touchscreen; and,

Enables program upgrade over the network.

Monito

Nurse Call

Reserved port

Other device

Mindray Proprietary LAN

i

F

-

i

W

EMR Server

AP

CMS/Gatewa

The above figure shows a system consisting of the vital signs monitor and its peripheral devices.

The vital signs monitor:

Can be used for monitoring the physiological parameters, giving alarms and reviewing

patient data, etc.

Supports recorder.

Supports nurse call function.

Supports Wi-Fi module, wired network, remote view, and communication with the

Hypervisor Central Monitoring System (hereinafter called CMS).

Supports external AC power source and an internal battery.

Supports clinical data acquisition: by SD card or by USB drive.

2-1

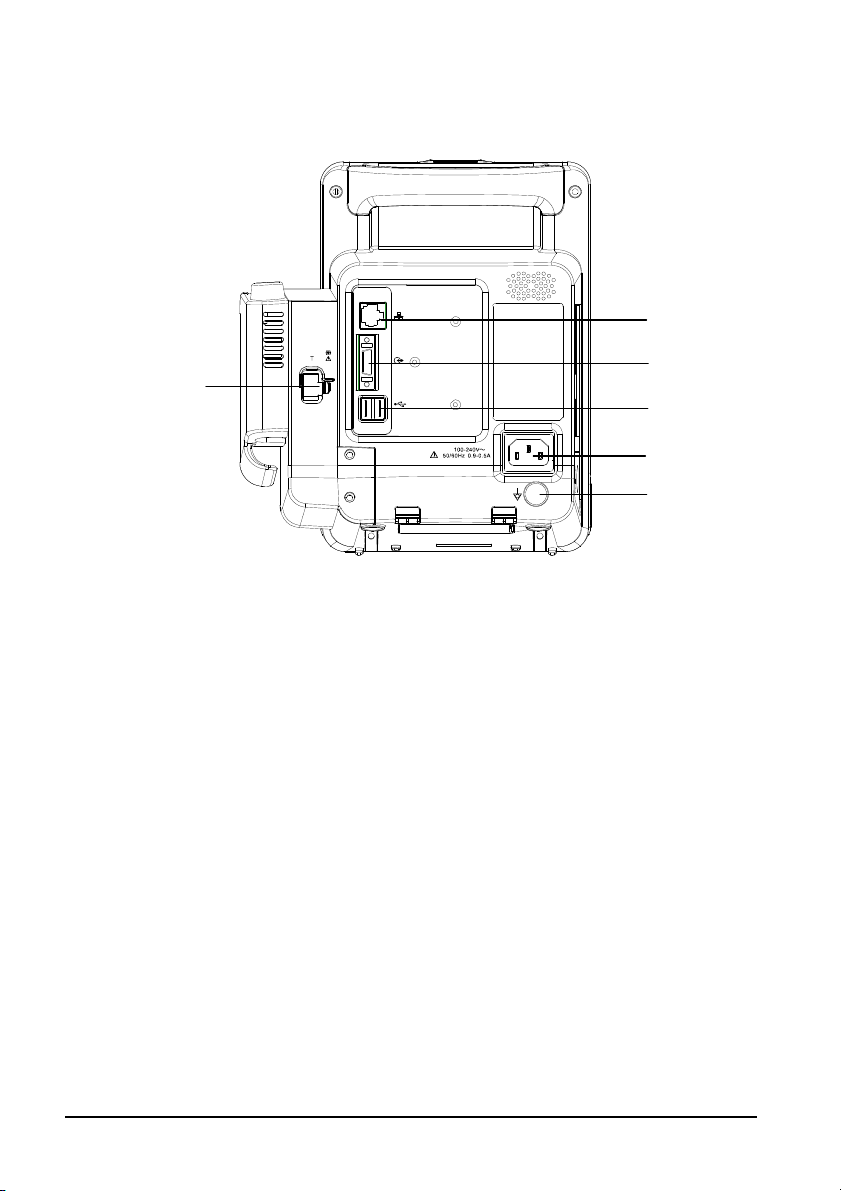

2.2 Connectors for Peripheral Devices

1

2

3

4

5

6

1. Connector for Temperature probe

2. Network connector: It is a standard RJ45 connector used to communicate with external

devices, such as central monitoring system, e-Gateway, or used to export data or

upgrade the system.

3. Multi-function connector: connects to the hospital's nurse call system, or connects

external devices through DIAP protocol.

4. USB connector: connects to barcode scanner or USB disk.

5. AC Power Input

6. Equipotential grounding terminal: When the equipment and other devices are to be

used together, their equipotential grounding terminals should be connected together

to eliminate the potential difference between them.

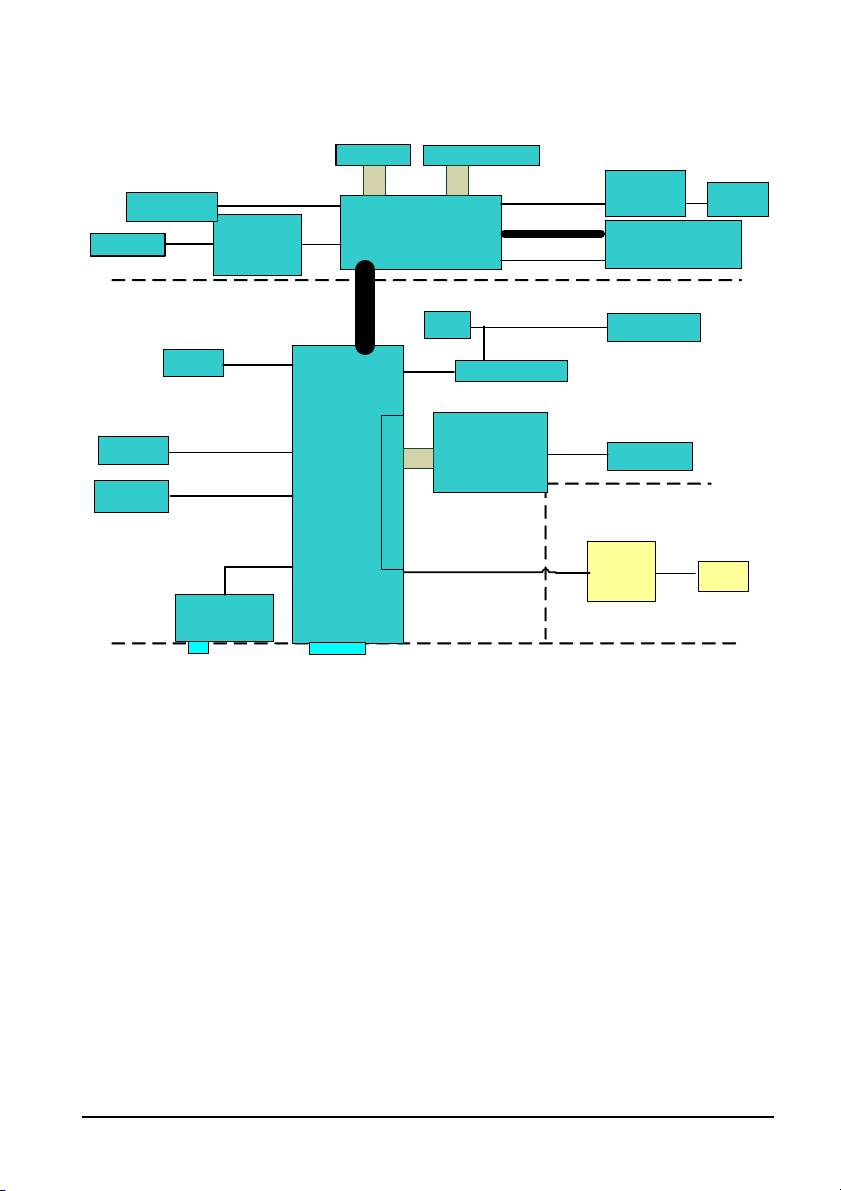

2.3 Main Unit

The main unit of the vital signs monitor consists of three parts:

Front housing assembly: main board, Wi-Fi module, keypad board assembly (knob),

display, touchscreen, and alarm lamp board.

Rear housing assembly: power module (AC/DC), power management and interface

board (including SpO

board.

SpO

2

External module:Temperature module.

isolation power), recorder, speaker, battery, NIBP module, and

2

2-2

The following figure shows the main unit architecture of the vital signs monitor.

Front Housing Assembly

Alarm lamp

board

Knob

Power

On/Off

keypad

(Indicator)

SD card

Main board

Wi-Fi module

I2C

LVD

S

Backlight

Touchscree

n control

board

LCD display

Touch

screen

Rear Housing Assembly

Speaker

Recorder

2600mAh

battery

15V

AC-DC power

module

AC-IN

Power

management

and interface

board

SpO

2

isolation power

External interface

RJ45/USB/Multifunctional

(nurse call, extended ports)

Pump

NIBP module

SpO2 board

(Standard

Mindray, OEM

optional)

NIBP socket

SpO2socket

External Module

Predictive

Temp

module

Temp

probe

2-3

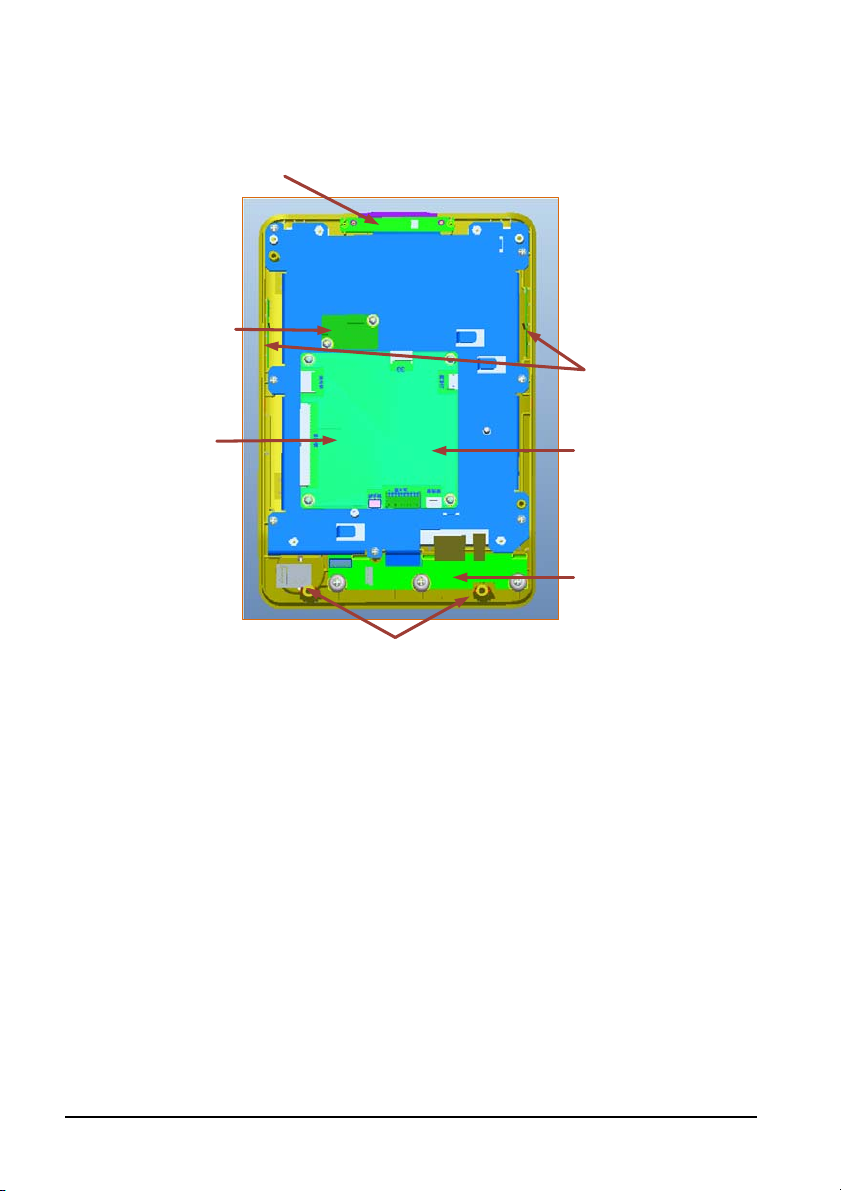

2.4 Front Housing Assembly

Alarm lamp board

Touchscreen

control board

Wi-Fi

antenna

Main board

Screws securing the front and rear housing

Wi-Fi

module

Keypad

2.5 Main Board

The main board is the control center of the equipment. It provides communication, display, and

data storage functions, including:

Communication with SpO

connector;

Communication with power management board, keypad board, and recorder through

connectors;

Providing drive for display and backlight;

Providing 2 USB connectors, a network connector, and a multifunctional connector;

Communication with touchscreen control board through I2C;

Providing drive for SD card; and,

Providing drive for Wi-Fi module.

board, NIBP module, and Temperature module through

2

2-4

Keypad

The keypad scans and detects the input of keys and encoder, integrates the power on/off key,

and connects AC and battery indicators.

Alarm Lamp Board

The alarm lamp board is located at the top of front housing. It has two-color indicators, red and

yellow. The alarm lamp board directly connects the main board through a cable. It is controlled

directly by the main board.

Touchscreen and Touchscreen Control Board

The touchscreen control board drives the touchscreen and implements communication with the

vital signs monitor.

Wi-Fi Module (Optional)

The Wi-Fi Module enables the equipment to connect to an 802.11 b/g/n Mindray proprietary

network.

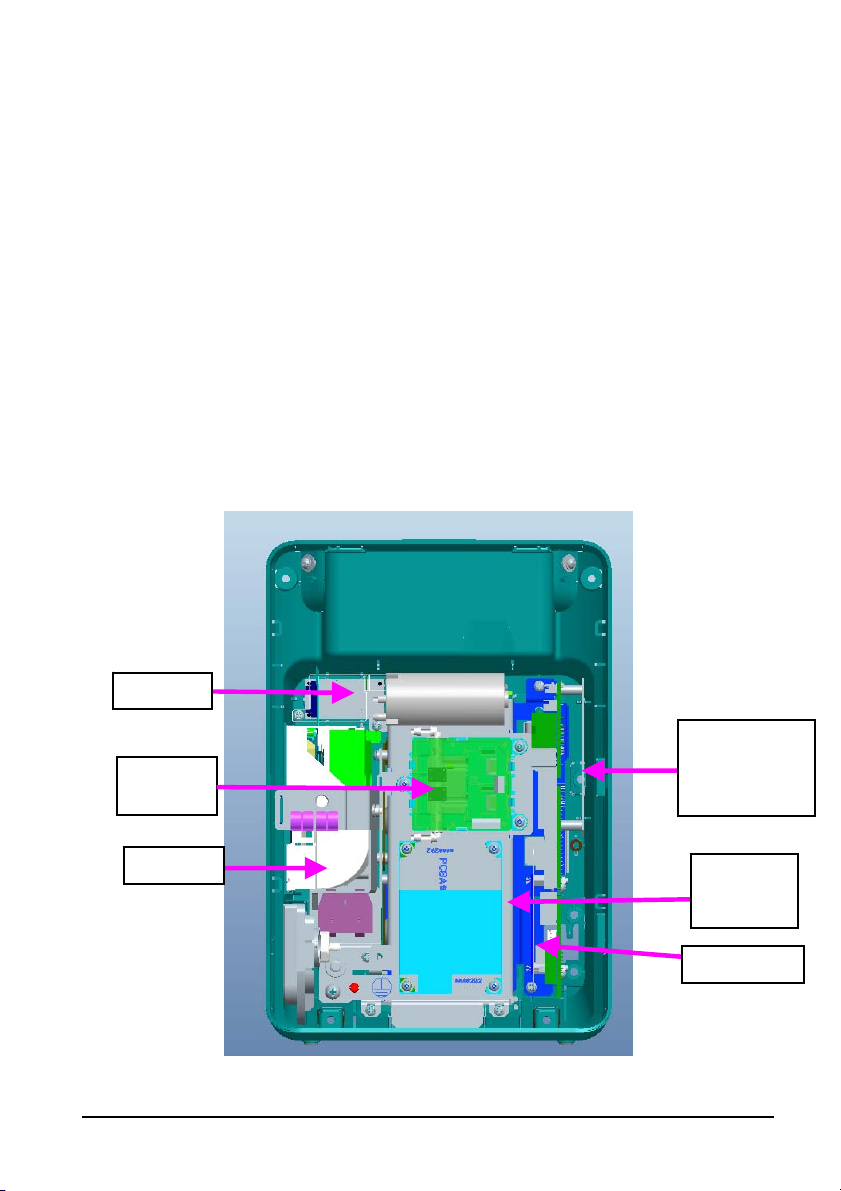

2.6 Rear Housing Assembly

Speaker

Power

NIBP

module

Recorder

Rear housing assembly consists of power module (AC/DC), power management and interface

board (including SpO

isolation power), recorder, speaker, battery, NIBP module, and SpO2 board.

2

2-5

management

and interface

board

AC/DC

power

module

SpO2board

AC/DC Power Module

The AC/DC power board transforms the input AC into DC power, which is the power source for all

voltages in the equipment.

Power Management and Interface Board

The power management and interface board provides the following functions:

Charge and discharge of battery and charge detection;

DC/DC conversion: outputs 12V and 5V DC power;

Control over power on/off key and AC, BAT indicator;

Communication transmission among parameter modules;

Providing isolation power for SpO

Providing external connectors, filter and protection for these connectors.

module; and,

2

Recorder

The recorder receives data from the main board and sends them to the thermal printhead for

printing.

NIBP Module

The NIBP module consists of blood pressure measurement board and pump and valve assembly,

providing measurement acquisition of blood pressure data. The main functions of the NIBP

module are:

NIBP measurement; and,

Data exchange with the main board.

SpO2 Board

The SpO

to the main board. The power management interface board provides isolation power for it.

board collects SpO2 signals, processes SpO2 algorithm and sends measurement results

2

2.7 External Module

An external Temp module can be attached to the monitor.

The independently developed Mindray Temperature module consists of an isolation power board,

Temperature measurement board, and probes. The Temperature measurement board collects

Temperature signals, processes algorithm and sends measurement results to the main board.

2-6

3 Equipment Installation

3.1 Unpacking the Equipment

Open the package and take out the packing list. Check that all the articles included in the

packing list are available and the quantity and specification are correct. Make sure that:

All the optional parts purchased by the customer have been received.

Notify Mindray North America if your order is incorrect or is incomplete.

In case of damage during transportation, keep the packing material and notify Mindray

North America immediately.

Keep the packing material until all equipment is checked and accepted.

3.2 Preparation for Installation

3.2.1 Preparation for Installation Site

1. Ensure that the site meets all safety, environmental and power requirements.

2. Ensure that a network connector is available if the equipment needs to be connected to

network.

3.2.2 Environmental Requirements

To avoid explosion hazard, do not use the equipment in the presence of flammable anesthetics,

vapors or liquids. The environment where the equipment will be used should be reasonably free

from vibration, dust and corrosive substances. If these conditions are not met, the system may

not function normally.

The environmental specification is as follows:

Main Unit

Item

Operating

environment

Storage

environment

Temperature (℃)

0 to 40 (without Temperature

module)

5 to 40 (with Temperature

module)

-30 to 70 10% to 95% 120.0 to 805.5

NOTE

The environmental specifications of unspecified accessories are the same as those of

the main unit.

Relative humidity

(noncondensing)

15% to 95% 427.5 to 805.5

Altitude (mmHg)

3-1

3.2.3 Electrical Requirements

Check cables and power cords. Make sure that:

1. System cables, power cords, and power plugs are not damaged, and that the pins are

not loose. If damage is noted, discontinue use and replace.

2. Patient cables and connections are secure.

WARNING

Use only properly grounded power outlets.

Use the supplied power cord only!

Vol tage

Current

Frequency

100 to 240V AC

0.9 to 0.5A

50/60 Hz

3.3 Equipment Installation

Follow the procedure below to install the equipment:

1. Ensure the unit and accessories are not damaged.

2. Install the battery (optional). For detailed operations, please refer to the operator’s

manual of the vital signs monitor.

3. Connect AC power.

4. Connect the accessories.

Installation Support

The vital signs monitor can be mounted on a wall bracket or on a trolley support. The wall

bracket or trolley support can be ordered optionally. Each type of mounting bracket is delivered

with a complete set of mounting hardware and instructions. For detailed installation information,

please refer to Wall-mount Bracket Instructions for Use (PN: 0010-20-42933) and Rollstand

Instructions for Use (PN: 0010-20-42934).

CAUTION

Use only Mindray supplied or approved mounting solutions.

The mounting bracket should be installed by qualified service personnel.

3-2

3.3.1 Preparation for Power on

1. Before using the equipment, check for any mechanical damage and make sure that all

external cables, plug-ins and accessories are properly connected.

2. Plug the power cord into the AC power source. If you run the equipment on battery

power, ensure that the battery is sufficiently charged.

3. Press the Power ON/OFF button (

) on the front panel to turn on the equipment.

3-3

FOR YOUR NOTES

3-4

4 Testing and Maintenance

4.1 Introduction

The expected service life of the equipment is five years. To ensure the equipment always

functions normally, qualified service personnel should perform regular inspection, maintenance

and test. This chapter provides a checklist of the testing procedures for the equipment with

recommended test equipment and frequency. The service personnel should perform the testing

and maintenance procedures as required and use appropriate test equipment.

The testing procedures provided in this chapter are intended to verify that the equipment meets

the performance specifications. If the equipment or a module fails to perform as specified in any

test, repairs or replacements must be done to correct the problem. If you have any question,

contact our Technical Support Department.

CAUTION

All tests should be performed by qualified service personnel only.

Care should be taken to avoid changing the settings in [User Settings >>] and

[Factory Maintenance >>] menus to avoid loss of data.

Service personnel should acquaint themselves with the test tools and make sure

that test tools and cables are available.

4.2 Performance Tests

Performance test are designed to ensure that measurement results are accurate. The following

sections provide a list of performance and accuracy tests and their recommended frequencies.

4.2.1 Performance Test Frequencies

Check/Maintenance Item Frequency

Visual inspection 1. When first installed or reinstalled.

SpO2test

Leakage test

NIBP test

TEMP test

Nurse call function test

Accuracy test

NIBP cuff

overpressure test

1. If the user suspects that the measurement is

incorrect.

2. Following any repairs or replacement of relevant

module.

3. Every two years.

Note: Per year is recommended for NIBP leakage

and accuracy tests.

If the user suspects that the nurse call function does

not work well.

4-1

4.2.2 Visual Inspection

Perform an overall inspection on the appearance of the equipment. The test is passed if the

equipment has no obvious signs of damage. Follow these guidelines when inspecting the

equipment:

Carefully inspect the case, display screen, buttons, and knob for obvious signs of

damage.

Inspect all external connections for loose connectors, bent pins or frayed cables.

Inspect all connectors on the equipment for loose connectors or bent pins.

Make sure that safety labels and data plates on the equipment are clearly legible.

4.2.3 SpO

Test Meth od 1

Too l requir ed:

None

Test procedure:

1. Connect SpO

2. Place the SpO

3. Verify the Pleth Wave and Pulse Rate are displayed on the screen.

4. Remove the SpO

Measurement validation

The SpO

measured with a CO-oximeter. Pulse oximeter measurements are statistically distributed, and

only about two-thirds of the measurements can be expected to fall within the specified accuracy

compared to CO-oximeter measurements.

NOTE

The SpO

test

2

sensor for adult to the SpO2 connector of the monitor. Set [Patient

2

Category] to [Adult].

sensor on your finger.

2

sensor from your finger and make sure that the SpO2 Sensor Off alarm

2

is triggered.

accuracy has been validated in human studies against arterial blood sample reference

2

simulator can only be used to verify that the pulse oximeter operates

2

properly. It cannot be used to verify the accuracy of the pulse oximeter or the SpO

sensor. To verify the accuracy, clinical tests are required.

2

4-2

Test Meth od 2

Too l requir ed:

SpO

simulator, Index-2 recommended

2

Test procedure:

1. Connect the SpO

2. Selected the model and manufacturer of the SpO

and set the simulator as follows: SpO

sensor to the SpO2 simulator.

2

to 96% and Pulse Rate to 80 bmp.

2

module to be tested on the simulator,

2

3. Set the patient type to [Adult], [Pediatric], and [Neonatal] respectively. Observe the

monitor and make sure the displayed SpO

and Pulse Rate value fall in the following

2

range.

Manufacturer SpO

Nellcor

Masimo

Pulse Rate

2

96% ± 2% (Adult, pediatric)

96% ± 3% (Neonate)

96% ± 2% (Adult, pediatric)

96% ± 3% (Neonate)

80 ± 3 bpm

80 ± 3 bpm

4-3

4.2.4 NIBP Test

Leakage Test

NOTE

Perform NIBP leakage test before any other NIBP test and calibration.

Tools required:

Adult NIBP Cuff

NIBP Hose

Cylinder

Follow this procedure to perform the leakage test:

1. In the [Patient Demographics] menu, set [Patient Category] to [Adult].

2. Connect the NIBP cuff to the NIBP connector on the monitor.

3. Apply the cuff to the cylinder as shown below.

Monitor

Connector for NIBP cuff

NIBP Hose

Cylinder

Cuff

4. Select [Main]→[Maintenance >>]→[NIBP Leakage Test]. The message [Leakage

Tes t in g… ] is displayed in the NIBP parameter area.

After about 20 seconds, the monitor will automatically deflate. This means the test is complete. If

no message is displayed in the NIBP parameter area, it indicates that the system has no leakage. If

the message [NIBP Pneumatic Leak] is displayed, it indicates that the system may have a leak.

Check the tubing and connections for leakages. Ensure that the tubing and connections are all

correct, perform a leakage test again. If the problem persists, contact our Technical Support

Department.

You may also perform a manual leakage test:

1. Perform steps 1 to 4 in the NIBP Accuracy Test section.

2. Raise the pressure in the rigid vessel to 250 mmHg with the manometer bulb. Then,

wait for 5 seconds to allow the pressure to stabilize.

3. Record the current pressure value, wait 60 seconds and record the pressure again.

4. Compare the two pressure values and verify the difference is 6mmHg or less.

4-4

NIBP Accuracy Test

Too l requir ed:

T-shape connector

Appropriate tubing

Manometer bulb

Rigid Vessel with volume 500 ± 25 ml

Reference manometer (calibrated with accuracy equal to or better than 0.75 mmHg)

Follow this procedure to perform the accuracy test:

1. Connect the equipment as shown below.

Monitor

Connector for NIBP cuff

Manometer bulb

Appropriate tubing

Standard

sphygmomanometer

Rigid Vessel

2. Before inflation, check that the reading of the manometer is 0. If not, turn off the

manometer bulb to let the whole airway open to the atmosphere. Turn on the

manometer bulb after the reading is 0.

3. Select [Main]→[Maintenance >>]→enter the required password→[Module

Maintenance >>]→[NIBP Accuracy Test].

4. Check the manometer values and the monitor values. Both should be 0 mmHg.

5. Raise the pressure in the rigid vessel to 50 mmHg with the manometer bulb. Then, wait

for 10 seconds to let the measured values become stable.

6. Compare the manometer values with the monitor values. The difference between the

manometer and displayed values should be ± 3 mmHg. If it is greater than ± 3 mmHg,

contact Mindray Technical Support.

7. Raise the pressure in the rigid vessel to 200 mmHg with the manometer bulb. Then,

wait for 10 seconds to let the measured values become stable. Repeat step 6.

NOTE

You can use an NIBP simulator to replace the manometer bulb and the reference

manometer to perform the test.

4-5

NIBP Cuff Overpressure Test

Tools required:

T-shape connector

Appropriate tubing

Manometer bulb

Metal Vessel with volume 500 ± 25 ml

Reference manometer (calibrated, with accuracy equal to or better than 0.75 mmHg)

Follow this procedure to perform the calibration:

1. Perform steps 1 to 4 in the NIBP Accuracy Test section.

2. Select [Main]→[Maintenance >>]→[Factory Maintenance >>]→enter the required

password→[Calibrate NIBP >>]→[Overpressure Protection Circuit].

3. In [Overpressure Protection Circuit] menu, set [Patient Category] to [Adu/Ped].

Raise the pressure to 330 mmHg. After the pressure value is stabilized, select [Calibrate]

to start calibration.

4. In the [Overpressure Protection Circuit] menu, set [Patient Category] to [Neonatal].

Raise the pressure to 165 mmHg. When the pressure value is stabilized, select

[Calibrate] to start calibration.

5. All calibration results are displayed in the [Calibrate NIBP] menu. If the calibration fails,

check the test system for leakage and perform another calibration.

4.2.5 Temperature Test

Required Tool:

Thermostatic oil tank (HART 7102 recommended) or Water Bath and Precision

Thermometer for reference

Test procedure:

1. Set the temperature of the oil tank or water bath to 37°C and conduct the test after the

temperature stabilizes.

2. Set temperature unit to °C.

3. Select temperature parameter area to access [Te mp Se tup ] menu, and then set

temperature type to [Monitor].

4. In Monitor Mode, remove the Temperature probe from the probe sheath, insert a probe

cover, and place the probe into the oil tank or water bath.

5. Wait till the Temp value displayed on the monitor stabilizes. Verify that the displayed

value is ±0.1°C of the oil bath thermostat setting or reference thermometer.

Contact our Technical Support Department if the Temperature test fails.

4-6

NOTE

Due to the different application environment and the test object in vivo and vitro

conditions, there are deviations in the measurement result. The maximum deviation

of 2.5℃ may exist in predictive Temperature measurement by liquid bath

techniques.

4.2.6 Nurse Call Reply Performance Test

Too l requir ed:

Oscilloscope

Test procedure:

1. Connect the nurse call cable to the Multi-function connector on the rear panel.

2. Select [Main]→[Maintenance >>]→[User Settings >>]→enter the required password

→[Ok]→[Nurse Call >>].

3. In the [Nurse Call Setup] menu, select the [Alarm Level] and [Alarm Category], and set

[Conta ct Type] to [Normally Open, and [Signal Type] to [Continuous].

4. Click

5. Select [Main]→[Maintenance >>]→[Demo >>]→enter the required password→[Ok]

to enter demo mode.

6. Make the monitor to generate an alarm and check that the oscilloscope outputs

continuous high level when there is an alarm.

7. Quit the demo mode, and repeat step 2.

8. In the [Nurse Call Setup] menu, select the [Alarm Level] and [Alarm Category], and

set [Conta ct Type] to [Normally Open, and [Signal Type] to [Pulse].

9. Repeat steps 4 and 5.

10. Create an alarm condition and verify that the oscilloscope displays positive pulses of 1

second width when there is an alarm.

to save the changes and quit the menu.

4-7

4.3 Electrical Safety and Other Tests

4.3.1 Electrical Safety and Other Test Frequencies

Check/Maintenance Item Frequency

1. Following any repair or replacement of any

module

Electric Safety Tests

Power- on test

Touchscreen calibration

Recorder check Following any repair or replacement of the recorder.

Bar code scanner test

Functional test

Battery check

Performance test

4.3.2 Electric Safety Tests

See Appendix A Electrical Safety Inspection for electrical safety tests.

4.3.3 Power-on Test

This test is to verify that the equipment can power up correctly. This test is passed if the

equipment starts up by following this procedure:

1. Insert the battery in the battery compartment, and connect the equipment to the AC

mains. The AC mains indicator and battery indicator light up.

2. If monitor is physically damaged.

3. Every two years.

For details, refer to A Electrical Safety Inspection.

1. When first installed or reinstalled.

2. Following any repairs or replacement of any main

unit parts.

1. When the touchscreen appears abnormal.

2. After the touchscreen is replaced.

Following any repair or replacement of the bar code

scanner.

1. When first installed.

2. Whenever a battery is replaced.

Once per year or if the battery run time reduced

significantly.

2. Press the Power ON/OFF button (

The work status indicator lights up inside the Power ON/OFF button.

3. The equipment gives a beep, which indicates that the selftest for alarm audio is passed,

and the alarm lamp turns yellow, then red, and then off, which indicates that the

selftest for alarm lamp has passed.

4. The welcome screen clears and the normal operation screen is displayed.

) on the front panel to turn on the equipment.

4-8

4.3.4 Touchscreen Calibration

Too l requir ed:

None

Test procedure:

1. Select [Main]→[Maintenance >>]→[Calibrate Touchscreen].

2. The

3. Select, in turn, the central point of the

4. After the calibration is completed, the message [Screen Calibration Completed!].

Select [Ok] to confirm the completion of calibration.

symbol will appear at different positions of the screen.

symbol.

4.3.5 Recorder check

Too l requir ed:

None

Test procedure:

1. Print SpO

be clear.

2. Remove the paper from the recorder then try to print and verify that an error message

(recorder out of paper) appears. Reinstall the paper and verify the recorder functions

properly.

3. Set the recorder to print trend data. Verify the recorder prints trends correctly.

Contact our Technical Support Department if the recorder test fails.

Pleth waveform. The recorder should print correctly and the printout should

2

4.3.6 Bar Code Scanner Test

Too l requir ed:

None

Test procedure:

1. Aim the bar code scanner at the target bar code. Adjust the field of view to capture the

bar code.

2. Hold the trigger until the bar code scanner gives a beep, indicating the bar code is

successfully decoded. Meanwhile, the indicator turns green and scanned characters are

displayed on the monitor.

Please contact our service personnel if the bar code scanner fails to work normally.

4-9

4.3.7 Battery Check

Too l requir ed:

None

Func tional Test

1. Remove the battery (if equipped), then connect the equipment to AC power.

2. Verify that the equipment works correctly when powered form an AC source.

3. Disconnect AC power and reinstall the battery.

4. Verify the equipment functions properly on battery power.

Performance Test

Run the equipment on battery power and verify it performs in accordance to the specifications

stated in the Battery chapter in the operator’s manual (P/N: 046-004882-00).

4.4 Factory Maintenance

4.4.1 Accessing Factory Maintenance Menu

Select [Main]→[Maintenance >>]→[Factory Maintenance >>]→enter the required password→

[Ok] to access the Factory Maintenance menu.

4-10

4.4.2 Drawing Waves

There are two methods for drawing waves: [Color] and [Mono].

Color: selecting Color will have smoother waveforms.

Mono: selecting Mono will have a wider viewing angle.

4.4.3 Software Version

Selecting the [Software Version >>] will show software version information, as shown below:

1

2

1. System software version

2. Power software version

3. Module software version

4-11

3

4.4.4 Monitor Information

Selecting [Monitor Information >>] will show the status of the monitor as shown below:

NOTE

If the main board is replaced, the serial number of the monitor must be entered on

the new main board in the Electronic SN Setup menu.

4-12

5 Troubleshooting

5.1 Overview

In this chapter, equipment problems are listed along with possible causes and

recommended corrective actions. Refer to the tables to check the monitor, identify and

correct problems.

The tables provided are meant as a general guide. For more detailed troubleshooting

assistance, contact our Technical Support Department.

5.2 Part Replacement

Printed circuit boards (PCBs), major parts and components in the monitor are replaceable.

Once you isolate a PCB you suspect defective, follow the instructions in chapter 6

Disassembly and Repair to replace the PCB with a known good one and check that the

trouble disappears or the equipment passes all performance tests.

To obtain information on replacement parts or order them, refer to chapter 7 Parts.

5.3 Checking Equipment Status

Some troubleshooting tasks may require you to identify the hardware version and status of

your monitor. To check equipment status:

1. Select [Main]→[Maintenance >>]→[Monitor Information >>]. Then you can

view the information on system start time, selfcheck, etc.

2. Select [Main]→[Maintenance >>]→[Factory Maintenance >>]→enter the

required password→[Ok]→[Monitor Information >>]. You can also view the

information on the monitor’s current status.

5.4 Checking Software Version

Some troubleshooting may involve software compatibility. Thus it requires you to know

your monitor configuration and software version. For detailed information on version

compatibility, please contact our Customer Service Department. To view information on

the system configuration and system software version,

Select [Main]→[Maintenance >>]→[Factory Maintenance >>]→Enter the required

password→[Ok]→[Software Version >>]. You can also view the information on system

software version and module software version.

5-1

5.5 Checking Technical Alarms

Before troubleshooting the monitor, check for technical alarm messages. Correct all

Technical Alarms before continuing.

For detailed information on technical alarm message, possible cause and corrective action,

refer to the monitor’s operation manual.

5.6 Troubleshooting Guide

5.6.1 Power On/Off Failure

Symptoms Possible Cause Troubleshooting

AC mains not

connected or battery

too low

The monitor

fails to start.

Cable defective

Power board defective Replace the power board.

Power management

board defective

The main board failed. Replace the main board.

5.6.2 Display Failures

Check that AC mains is properly connected or

battery capacity is sufficient.

1. Check that the cable between the keypad

board and main board is correctly connected.

2. Check that the cable between the power

board and power management board is

correctly connected.

3. Check that the cable between the main

board and power management board is

correctly connected.

Replace the power management board.

Symptoms Possible Cause Troubleshooting

1. Check if the cable between the display and

main board and the backlight cable are

The display is

blank or

black.

Images

overlapped or

Cable defective

Main board defective Replace the main board.

Display defective Replace the display.

Main board error

correctly connected.

2. Check that the cables and connectors are

not damaged.

Replace the main board, or upgrade the main

board with the upgrade software.

5-2

distorted

Touchscreen

does not

respond.

Tou ch

position

invalid

Cable defective

Touchscreen disabled

Cable defective

Touchscreen control

board defective

Touchscreen defective Replace the touchscreen.

The main board failed. Replace the main board.

Touchscreen not

calibrated

Check if the cable between the display and

main board and the backlight cable are

correctly connected.

Check if there is a

above the [Main] quickkey. If yes, press and

hold the [Main Menu] quickkey for more than

3 seconds to enable the touchscreen.

1. Check that the cable between the

touchscreen and touchscreen control board is

correctly connected.

2. Check that the cable between the

touchscreen control board and main board is

correctly connected.

Replace the touchscreen control board.

Calibrate the touchscreen.

5.6.3 Alarm Lamp Failures

Symptoms Possible Cause Troubleshooting

1. Check that the cable between the alarm

lamp board and main board is correctly

The Alarm

Lamp does not

illuminate

properly or not

at all.

Cable defective

Alarm lamp board

defective

The main board

failed.

connected.

2. Check that the cables and connectors are

not damaged.

Replace the alarm lamp board

Replace the main board.

5.6.4 Button and Knob Failures

symbol displayed

Symptoms Possible Cause Troubleshooting

Buttons do not

work

Cable defective

Keypad board failure Replace the keypad board.

Check that the cable between the keypad

board and main board is correctly connected.

5-3

1. Check that the cable between the knob and

Cable defective

Knob does not

work

Knob failure Replace the knob encoder.

Keypad board failure Replace the keypad board.

keypad board is correctly connected.

2. Check that the cable between the keypad

board and main board is correctly connected.

5.6.5 Sound Failures

Symptoms Possible Cause Troubleshooting

No hardkey or

knob sound,

or hardkey or

knob sound

abnormal

No alarm

sound or

alarm sound

abnormal

The key volume is set

to 0.

Cable defective

Speaker defective Replace the speaker.

The main board failed. Replace the main board.

Power management

board defective

The alarm volume is

set to 0.

Cable defective

Speaker defective Replace the speaker.

The main board failed. Replace the main board.

Power management

board defective

Select [Main]→[General Setup >>] to adjust

the key volume.

Check that the cable between the speaker and

interface board is properly connected.

Replace the power management board.

Select [Main]→[Maintenance >>]→]User

Settings >>]→enter the required password→

[Ok]→[Alarm Setup >>] and set the

[Minimum Alarm Volume] to a proper level in

the prompt menu. Select [Main]→[General

Setup >>] to adjust the key volume.

1. Check that the cable between the speaker

and interface board is properly connected.

Replace the power management board.

5-4

5.6.6 Battery Failures

Symptoms Possible Cause Troubleshooting

Battery defective Replace the battery.

Check that the cable between the battery

interface board and power management board

is correctly connected.

Replace the power management board.

Replace the battery interface board.

Battery

cannot be

charged

Cable defective

Power management

board defective

Battery interface

board defective

NOTE

If the Battery Module fails, it may affect other modules or boards in the main

unit.

Components of the main unit are powered by the power module. In the event

that a component malfunctions, check if the operating voltage is correct.

5.6.7 Recorder Failures

Symptoms Possible Cause Troubleshooting

1. Check if the recorder status indicator lights.

2. If yes, select [Main]→[Maintenance >>]→

[Factory Maintenance >>]→enter the required

password→[Ok]→[Device Config. >>] and

check the recorder box in the prompt menu to

enable the recorder. Otherwise, check for other

possible causes.

Check that the cable between the recorder and

main board is correctly connected.

Stop the recorder and re-install the paper roll.

1. Check the thermal print head and the paper

roller for foreign matter.

2. Clean the thermal print head with an

appropriate cleaning solution such as contact

cleaner or isopropal alcohol.

5-5

No printout

Poor print

quality or

paper not

feeding

properly

Recorder module

disabled

Paper reversed Re-install the paper roll.

Cable defective

Recorder defective Replace the recorder.

Paper roll not

properly installed

Print head dirty

Recorder defective Replace the recorder.

5.6.8 Output Interface Failure

Symptoms Possible Cause Troubleshooting

1. Check that the cable between the power

management board and main board is

correctly connected.

2. Check that the cable between power

management board and interface board is

correctly connected.

Replace the connector board.

Replace the power management board.

Select [Main]→ [Transfer Data to USB]

Unable to use

the USB devices;

USB drive data

transfer failure

Cable defective

The connector board

failed.

Power management

board defective

The main board failed. Replace the main board.

Improper setup

5.6.9 Data Storage Failure

Symptoms Possible Cause Troubleshooting

Fails to review

archived patient

data

SD card failure

Abnormal patient

admitting

SD card full; unavailable

for more patient data

The main board failed. Replace the main board.

SD card not formatted Format the SD card.

SD card failure Replace the SD card.

SD card is locked Unlock the SD card.

Main board defective Replace the main board.

Admit the patient properly.

Delete uneeded patient data, clear the

related alarm, and readmit the patient.

5-6

5.6.10 Wired Network Related Problems

Symptoms Possible Cause Troubleshooting

Check LAN cable connection. LAN

cable shall not be longer than 50

meters.

Check for IP address conflict. If yes,

reconfigure the IP address.

1. Check that the cable between the

power management board and main

board is correctly connected.

2. Check that the cable between power

management board and interface

board is correctly connected.

Replace the connector board.

Replace the power management

board.

Check LAN cable connection. LAN

cable shall not be longer than 50

meters.

Check LAN cable connection. LAN

cable shall not be longer than 50

meters.

A monitor can only be viewed by four

other monitors at the same time under

the View Others mode. The excessive

view requests system will be ignored.

Check for IP address conflict. If yes,

reconfigure the IP address.

Unable to connect the

wired network

The monitor is

frequently off line or

disconnects from the

network.

The monitor is

connected to a LAN

but cannot view other

patients under the

View Others mode

Incorrect LAN cable

connection

Incorrect IP address

configuration

Cable defective

The connector board

failed.

Power management

board defective

The main board failed. Replace the main board.

Incorrect LAN cable

connection

Incorrect LAN cable

connection

Excessive requests for

viewing the monitor at

the same time

Incorrect IP address

configuration

5.6.11 Wi-Fi Related Problems

Symptoms Possible Cause Troubleshooting

The monitor is

frequently off line or

disconnects from the

Wi-Fi network.

The Wi-Fi signal is unstable in

the operating area.

The monitor's Wi-Fi antenna is

detached or not properly

connects the Wi-Fi module.

Antenna damaged Replace the Wi-Fi antenna.

5-7

Check the signal quality of the

Mindray Wi-Fi network.

Disassemble the monitor and

fix the Wi-Fi antenna.

Symptoms Possible Cause Troubleshooting

Wi-Fi module defective Replace the Wi-Fi module.

Check for IP address conflict. If

yes, reconfigure the IP

address.

Check the signal quality of the

Mindray Wi-Fi network.

Fix the Wi-Fi antenna.

Unable to connect the

Wi-Fi network.

Incorrect IP address

configuration

The Wi-Fi signal is unstable in

the operating area.

The monitor's Wi-Fi antenna is

detached or not connects the

Wi-Fi module.

Antenna damaged Replace the Wi-Fi antenna.

Wi-Fi module defective Replace the Wi-Fi module.

Main board defective Replace the main board.

5.6.12 Module defective

Symptoms Possible Cause Troubleshooting

1. Check that the cable between the

external converter board inside the

Module defective

Failed to connect the

external parameter

modules

Main unit defective

Cable defective

Module can be

loaded, but "XX

communication

stopped" is reported

or some parameters

cannot be used

"XX" indicates the configured modules, such as NIBP, SpO2 and Temperature.

inside the module

Parameter module

defective

Converter board

defective inside the

module

module and the converter board is

correctly connected.

2. Replace the converter board.

1. Check that the cable between the

main board and power management

board is correctly connected.

2. Replace the power management

board.

3. Replace the main board.

Check the cables connecting the

converter board and corresponding

parameter module.

Replace the corresponding module.

Replace corresponding converter board.

5.6.13 Technical Alarm Messages

Please refer to the operator’s manual.

5-8

6 Disassembly and Repair

6.1 Tools Required

To disassemble and replace the parts and components, the following tools may be required:

Philips screwdrivers

Tweezers

Sharp nose pliers

Clamp

Slot-type screwdriver

6.2 Preparations for Disassembly

Before disassembling the equipment, finish the following preparations:

Stop monitoring, turn off the equipment, and disconnect all the accessories and

peripheral devices.

Disconnect the AC power source and remove the battery.

WARNING

Before disassembling the equipment, be sure to eliminate the static charges first.

When disassembling the parts labeled with static-sensitive symbols, make sure you

are wearing electrostatic discharge protection such as antistatic wristband or gloves

to avoid damaging the equipment.

Properly connect and route the cables and wires when reassembling the equipment

to avoid short circuit.

Follow correct sequence to disassembly the equipment. Otherwise, the equipment

may be damaged permanently.

Be sure to disconnect all the cables before disassembling any parts. Be sure not to

damage any cables or connectors.

Place the screws and parts from the same module together to facilitate

reassembling.

Use care during reassembly to ensure cables are properly routed and all gaskets are

intact and correctly positioned.

6-1

T

6.3 Disassembling the Main Unit

NOTE

The recorder can be disassembled separately.

To disassemble the equipment, place the equipment on a work surface free from

foreign material, avoiding damaging the antiglare screen, touchscreen and the

knob. Be careful not to break the two cotters on the front ends of rear housing.

All repairs should be performed in an anti-static environment by qualified service

personnel.

6.3.1 Disassembling the Temperature Module (Optional)

1. Lay the monitor on a table as shown below. Unscrew the three M3×6 screws, pull the

Temperature module up, and disconnect the Temperature cable.

emperature

cable

6-2

6.3.2 Removing the Recorder

Unscrew the two M3×6 screws and pull the clamps as indicated to remove the recorder. Then

disconnect the cable.

Clamps

NOTE

The recorder can be disassembled separately.

6.3.3 Separating the Front and Rear Half of the Monitor

1. Lay the monitor on a table as shown below. Unscrew the four M3 screws.

6-3

2. Remove the recorder or recorder cover, and pull the rear housing out as indicated

below to separate the front and rear housing.

3. Stand the monitor and separate the front housing assembly and rear housing assembly

with caution. Disconnect the cable between the main board and power management

board and then take off the front panel.

Cable

NOTE

When reassembling the equipment, be sure to check if the front housing waterproof

strip is correctly placed.

6-4

6.3.4 Removing the Parameter Connector Panel Assembly

Lay the rear housing assembly of the equipment on a table. Disconnect the cable for AC

receptacle and SpO

Parameter connector panel assembly

cable, and then the silicon tube.

2

Silicon tube

Cable for AC

input

receptacle

SpO2signal

cable

6-5

6.3.5 Disassembling the Main Bracket Assembly

1. For monitors without a multi-function connector, use a flat blade screwdriver to gently

lift the cover release on the inside of the unit, and then remove the cover.

Cover

6-6

2. Disconnect the speaker cable, recorder cable, power cord and battery interface board

cable.

3. Unscrew the five self-tapping screws and one grounding screw. Then remove the main

bracket assembly.

Battery interface

board cable

Speaker cable

Recorder

cable

Grounding screw

Power cord

6-7

5 self-tapping

screws

6.3.6 Removing the Parameter Board (SpO

Optional) and Power

2

Management Board

1. Unscrew the three screws and remove the power management board assembly from

the main bracket assembly.

2. Unscrew the two M3 screws and remove the parameter board from the power

management board assembly.

Parameter Board

6-8

2 M3 screws

3. Unscrew the two M3 screws and remove the power management board assembly.

2 M3 screws

Power

management

board