Miele G 7883 User Manual

Operating Instructions

Laboratory Glassware

Washer

G 7883

To prevent accidents and machine damage read these instructions before

UV

installation or use. |

M.-Nr. 05 893 860 |

Contents

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description of the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

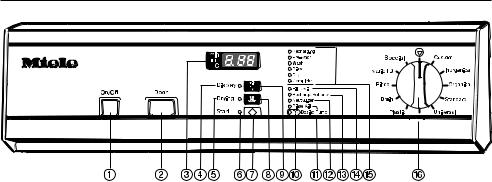

Guide to the lab washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Opening and closing the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

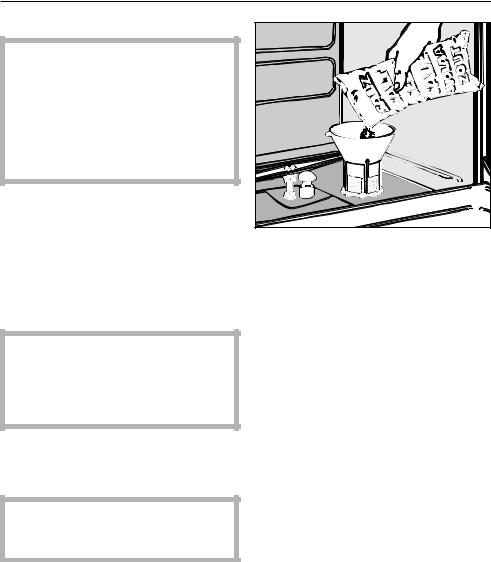

Water softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Setting the water softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Filling the salt reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Salt indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

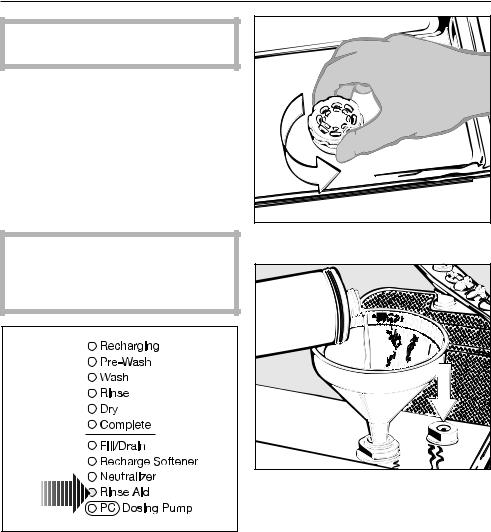

Adding rinse aid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Setting the rinse aid dosage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adding neutralizing agent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Adding detergent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Adjusting the upper basket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Program guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Turning on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Starting a program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Changing a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 At the end of a program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Turning off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Canceling a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Programming special functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Machine care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Trouble shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

After Sales Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Plumbing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Water inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2

IMPORTANT SAFETY INSTRUCTIONS

This appliance is only intended for specialized applications. Only use the appliance for its intended purpose. Any other use, conversion or modification is dangerous. The manufacturer cannot be held responsible for damages caused by improper use of this machine.

This appliance complies with current safety requirements. Improper use of the appliance can lead to personal injury and material damage.

Read all instructions before installing or using this appliance.

Keep these operating instructions in a safe place and pass them on to any future user.

Installation and Service

The machine should only be installed, maintained and repaired

by a Miele authorized service technician. Repairs by unqualified persons could be dangerous.

Do not install the machine in an area where a danger of explosion

or freezing may be present.

Be certain this appliance is properly installed and grounded by

an authorized technician. To guarantee the electrical safety of this appliance, continuity must exist between the appliance and an effective grounding system. It is imperative that this basic safety requirement be met. If there is any doubt, have the electrical system of the building checked by a qualified technician. The manufacturer cannot be held responsible for damage or injury caused by the lack of or inadequacy of an effective grounding system.

A damaged machine is dangerous; turn off the machine at the main

power supply immediately and call the Miele Technical Service Department.

Before servicing, disconnect the power supply by either removing

the fuse or "tripping" the circuit breaker.

3

IMPORTANT SAFETY INSTRUCTIONS

Use

Personnel operating the machine should be trained regularly.

Children and untrained personnel must not be allowed access to the machine or its controls.

BURN AND SCALD HAZARD This washer reaches very high

temperatures. Take care when unloading the unit. Let baskets and inserts cool before touching them. Any water which may remain in containers will be very hot and must be emptied into the wash cabinet.

BURN HAZARD

The heating elements become extremely hot during use. Do not touch the heating elements during or directly after the end of a program.

Take care when handling liquids such as detergents, wetting agents

or neutralizing agents. These may contain irritating or corrosive ingredients. Do not use an organic solvent in this washer, as an explosion may occur. Wear protective gloves and goggles. The manufacturer’s safety conditions must be observed for all chemical agents.

Avoid inhaling powdered detergent. If swallowed, it can

cause burning in the mouth and throat or inhibit breathing.

Be careful when sorting items with sharp pointed ends. If possible,

place the pointed end downwards.

The water in the machine must not be used as drinking water.

Do not sit or lean on the open door. Injury or machine damage could

result.

Never use a water hose or a high pressure hose to clean the

machine or the areas surrounding it.

Only use cleaning agents formulated for special processes

and approved by Miele for use with this machine. Use of unsuitable cleaning agents could adversely affect the components of the machine.

4

IMPORTANT SAFETY INSTRUCTIONS

Pre-treatments with cleaning or disinfecting agents can create

suds, as can certain rinsing agents. For pre-treatment and / or cleaning, only use low-sudsing detergents and disinfecting agents which have been approved by Miele. Suds can have an adverse effect on the cleaning process.

When a chemical additive is recommended on technical application grounds (for example, with a cleaning agent), this does not imply that the manufacturer of the machine takes responsibility for the effect of the chemical on the material of the items being cleaned. Please be aware that

changes in formulation, storage conditions, etc, which may not be published by the chemical producer, can have a negative effect on the cleaning result.

When using cleaning agents and specialized products, it is essential

that the manufacturer’s instructions are followed. Only use the product for the application described by the manufacturer to avoid any material damage or the occurrence of strong chemical reactions.

The machine is designed only for operation with water and additive

cleaning agents. Organic solvents must not be used in the machine. An explosion or machine corrosion could occur with the use of organic solvents.

In critical applications where very exact requirements must be met, it

is highly recommended that all the relevant factors for the process, such as cleaning agent, quality of water, etc., are discussed with Miele’s Application Specialist.

The mobile units and special inserts should only be used for

their specific applications.

Empty any containers or utensils before arranging them in the

machine.

Do not allow any remains of acids or solvents, particularly

hydrochloric acid or chloride solutions, to get into the wash cabinet. The presence of any solvents should be minimized.

To prevent corrosion damage, ensure that solutions or steam containing hydrochloric acid do not

come into contact with the steel outer casing of the machine.

5

IMPORTANT SAFETY INSTRUCTIONS

Accessories

Only genuine Miele parts or accessories should be used with

the Laboratory Glassware washer. The performance and safety of non-genuine parts or accessories cannot be guaranteed, and use of such parts or items may void the machine warranty. If you have specific questions about machine options or accessories, please call Miele.

Disposal of an appliance

When discarding a lab washer, disconnect it from the power

supply, remove the door to the wash cabinet and cut off the power cord.

For environmental and safety reasons, ensure the machine is

completely drained of any residual water and cleaning agent. (Observe safety regulations and wear safety goggles and gloves). Make appropriate arrangements for the safe disposal of the machine.

SAVE THESE

INSTRUCTIONS

6

Description of the machine

The G 7883 is the "industry standard" undercounter washer designed to handle the vast majority of glassware cleaning applications.

7

Guide to the lab washer

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a "On/Off" button |

|

j "Add liquid detergent" indicator * |

|

||||||||

b "Door" button |

|

k "Add rinse aid" indicator |

|

||||||||

c Display |

|

l "Add neutralizing agent" indicator |

|

||||||||

d "Display" indicator |

|

m "Recharge Softener" indicator |

|

||||||||

e "Drying" indicator |

|

n "Check fill/drain" indicator |

|

||||||||

f "Start" indicator |

|

o Program sequence display |

|

||||||||

g "Start" button |

|

p Program selector |

|

||||||||

h "Drying" button |

|

* (only with optional DOS-Module) |

|

||||||||

i "Display" button |

|

|

|

|

|

|

|||||

|

|

(toggles between the elapsed |

|

|

|

|

|

|

|||

|

|

time, active wash blocks and actual |

|

|

|

|

|

|

|||

|

|

temperature displays) |

|

|

|

|

|

|

|||

8

Guide to the lab washer

a Connection for optional DOS-Module |

d Powdered detergent dispenser |

b Filter combination |

e Rinse aid reservoir |

c Salt reservoir |

(with dosage selector) |

|

|

(water softener) |

f Rinse aid level indicators |

9

Opening and closing the door

Electric door lock

The machine is equipped with an electric door lock. The door can only be opened when the electrical supply to the machine is turned on, and the "On/Off" button is pressed.

To open the door

^Press the "Door" button in as far as it will go. At the same time, grip the handle and open the door.

After the first intake of water, the door remains locked and cannot be opened until the end of the program (except during the "Rinse" and "Drain" programs). The machine can be programmed to open during the "Drying" program, if desired.

Do not touch the heating elements. They remain hot for some time after the end of the program and can cause burns.

To cancel a program

If a program has to be canceled in an emergency, e.g. the program has been interrupted due to a fault, the door will have to be opened manually.

^Turn the program selector to the "Stop" f position. The program is canceled after approximately

2 seconds.

To close the door

^Lift the door upwards and push it until it clicks shut. Do not press the release catch while shutting the door.

10

Opening and closing the door

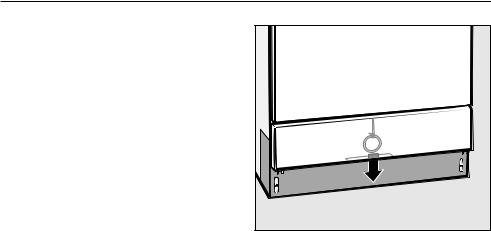

To open the door with the emergency release

The emergency release should only be used when the door cannot be opened normally, e.g. in the event of a power failure.

^Turn the program selector to "Stop" f.

^Press the "On/Off" button to turn the machine off.

^Take precaution against pressure wave release (rapid opening of the door).

^Pull the emergency release cable (located at the bottom of the machine behind the service panel) downwards to open the door.

The door latch will reset after the emergency cable has been activated.

11

Water softener

Before using the machine for the first time, the water softener should be programmed. The water needs to be softened to avoid calcium deposit buildup on the items being cleaned and in the machine itself.

To ensure a steady supply of soft water:

1.Make sure the water softener is programmed correctly.

The softener contains settings from

1- 60 gr/gal or 20 - 1080 ppm.

2.The salt reservoir must be filled with reactivation salt.

(If the water hardness level is below

4gr/gal [70 ppm]), the reservoir does not need to be filled.)

The machine is set at the factory for a water hardness level of 19 gr/gal (340 ppm).

Your local water authority will advise you on the water hardness in your area. If the water supply is harder or softer than the factory setting (including below 4 gr/gal or

70 ppm), the setting will need to be changed. See "Setting the water softener".

12

Water softener

Settings

Settings |

gr/gal |

ppm |

1 - 30 |

1 - 30 |

CaCO3 |

1 |

1 |

20 |

2 |

2 |

40 |

3 |

3 |

50 |

4 |

4 |

70 |

5 |

5 |

90 |

6 |

6 |

110 |

7 |

7 |

130 |

8 |

8 |

140 |

9 |

9 |

160 |

10 |

10 |

180 |

11 |

11 |

200 |

12 |

12 |

220 |

13 |

13 |

230 |

14 |

14 |

250 |

15 |

15 |

270 |

16 |

16 |

290 |

17 |

17 |

310 |

18 |

18 |

320 |

19 |

19 *) |

340 |

20 |

20 |

360 |

21 |

21 |

380 |

22 |

22 |

400 |

23 |

23 |

410 |

24 |

24 |

430 |

25 |

25 |

450 |

26 |

26 |

470 |

27 |

27 |

490 |

28 |

28 |

500 |

29 |

29 |

520 |

30 |

30 |

540 |

|

|

|

*) factory setting

Settings |

gr/gal |

ppm |

31 - 60 |

31 - 60 |

CaCO3 |

31 |

31 |

560 |

32 |

32 |

580 |

33 |

33 |

590 |

34 |

34 |

610 |

35 |

35 |

630 |

36 |

36 |

650 |

37 |

37 |

670 |

38 |

38 |

680 |

39 |

39 |

700 |

40 |

40 |

720 |

41 |

41 |

740 |

42 |

42 |

760 |

43 |

43 |

770 |

44 |

44 |

790 |

45 |

45 |

810 |

46 |

46 |

830 |

47 |

47 |

850 |

48 |

48 |

860 |

49 |

49 |

880 |

50 |

50 |

900 |

51 |

51 |

920 |

52 |

52 |

940 |

53 |

53 |

950 |

54 |

54 |

970 |

55 |

55 |

990 |

56 |

56 |

1010 |

57 |

57 |

1030 |

58 |

58 |

1040 |

59 |

59 |

1060 |

60 |

60 |

1080 |

|

|

|

13

Water softener

Setting the water softener

^Turn off the machine with the "On/Off" button.

^Turn the program selector to the "Stop" f position.

^Press and hold the "Start" 6 and "Display" ß buttons at the same time. Turn the machine on with the "On/Off" button.

The current program status "P..." will appear in the display.

The "Fill/Drain" indicator will illuminate.

The first time the water softener is set the "Recharge Softener" light will illuminate. This light will also illuminate after restoring the factory settings, see "Programming special functions".

^Press the "Drying" 0 button once. "E01" (programming level 1) will appear in the display.

^Turn the program selector one switch position clockwise (1 o’clock position).

The number "19" will appear in the display (this indicates the factory water hardness setting in gr/gal, equivalent to 340 ppm).

^Press the "Display" ß button as many times as necessary, or hold it in until the required value (hardness level in gr/gal) appears in the display. Once the number "60" has been reached, the counter will begin again at "0".

^Press the "Start" 6 button. "SP" will appear in the display.

^Press the "Start" 6 button again.

The setting will now be stored in memory. The display will go out.

For future servicing, it is useful to make a note of your water hardness level.

^ Enter your water hardness level here:

gr/gal

or

ppm

^If your water is already soft and you would like to deactivate the water softener, set the hardness setting to "0".

14

Water softener

Filling the salt reservoir

Only special, coarse-grained reactivation salt* should be used in this machine.

*Available from Miele’s Professional Customer Service Department. Please see back page for more information.

Do not use other types of salt, e.g. table salt, agricultural or gritting salt. These could contain components which are insoluble in water and could damage the water softener. If in doubt, consult Miele’s Professional Department.

The salt reservoir holds approx. 2.5 kg of salt.

,Inadvertently filling the salt reservoir with detergent will damage the water softener.

Before filling, make sure that you are using reactivation salt.

^Remove the bottom basket from the machine.

^Unscrew the salt reservoir cap.

Before filling the salt reservoir with reactivation salt for the first time fill it with approx. 2.5 liters of water.

^Place the funnel provided in place.

^Carefully fill the reservoir with salt. Displaced water will run out as it is being filled.

^Wipe any residual salt off the screw threads on the socket.

^Screw the cap on firmly.

^Immediately after this step: Run the "Rinse" program to remove any traces of salt from the cabinet.

Note: There may be a delay before the "Rinse" program starts due to the reactivation of the water softener.

15

Water softener

Salt indicator

When the salt reservoir is empty the "Recharge Softener" indicator, b, illuminates to remind you to fill the reservoir.

Reactivation takes place automatically during a program. The "Recharging" indicator, a, illuminates while this is occurring.

16

Adding rinse aid

Rinse aid is not used in laboratory glassware cleaning applications.

If rinse aid is required, the rinse aid dosage must be activated with assistance from Miele Technical Service.

Rinse aid (e.g. Mielclear) is filled in the storage container and dispensed automatically. The storage reservoir holds about 180 ml.

,Inadvertently filling the storage reservoir with detergent will damage the reservoir. Be sure only to use rinse aid in the reservoir.

^ Unscrew the cap. |

^If the "Add Rinse aid" indicator illuminates, the rinse aid storage container needs to be refilled. The storage container has a level

indicator on the interior of the door.

^Open the door.

^Pour rinse aid into the storage container until the level indicator is dark (see arrow in the illustration). Use a funnel if necessary.

^Replace and tighten the cap. Clean up any spilled rinse aid to prevent oversudsing in the next wash.

^Wait until the "Rinse" indicator on the control panel illuminates before adding any more rinse aid.

17

Adding rinse aid

Setting the rinse aid dosage

The dosage adjuster (see arrow in the illustration) in the opening has settings adjustable from 1 to 6 (1 - 6 ml).

It is preset to "3" (3 ml).

^Use a flat headed screwdriver to turn the dial to the correct setting.

If spots remain on the items, use a higher setting.

If smearing or cloudy streaks appear, use a lower setting.

18

Adding neutralizing agent

Neutralizer (pH-level: acidic) neutralizes detergent residue on the surface of glassware and other items being cleaned. It is automatically dispensed in the rinse following the wash step of a program.

The relevant program (see "Program Guide" - DOS 3) cannot be started until the dispensing system has been primed. (This function can only be canceled by a Miele Service Engineer.)

^Place the container of neutralizer (red) next to the machine.

When the "Add neutralizer" indicator illuminates:

^Insert the siphon tube into the container (observe the color code).

Setting the dosage and priming the dispensing system

^ See "Programming special functions".

Important

The container should not be allowed to empty completely.

19

Adding neutralizing agent

Setting the neutralizer dosage and priming the neutralizer dispensing system

First you need to access the programming mode:

To access the programming mode

^Turn the program selector to "Stop" f.

^Turn the machine off.

^Press and hold the "Display" ß and "Start" 6 button. At the same time turn the lab washer on by the main switch I-0.

The display shows the current program status "P...".

The Fill/Drain indicator lights.

^Press the "Drying" 0 button twice. "E02" (programming level 2) appears in the display.

The dosage is factory set to 0.10, you may or may not be required to adjust it.

Set the dosage concentration according to the detergent manufacturer’s recommendations.

Example:

The manufacturer recommends a neutralizer concentration of 0.3 %. The value to be set is 0.30.

^First access the programming level to "E02".

^Turn the program selector clockwise to "Intensive".

The display shows the set dosage concentration in % from 0.05 % - 0.5 %.

^Press and hold the "Display" ß button until the desired value appears.

The dosage time / dosage concentration is saved.

^Please note the dosage setting:

To store the settings

^Press the "Start" 6 button. "SP" appears in the display.

^Press the "Start" 6 button again. The change has been saved.

NOTE: This change will set the neutralizer dispensing amount for all wash programs that use neutralizer.

20

Loading...

Loading...