Miele G 7804 Operating instructions

Operating and Installation

Instructions

Laboratory Glassware

Washer

G 7804

To prevent accidents

and machine damage

read these instructions

before

installation or use.

en-US

M.-Nr. 09 234 570

2

Contents

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Function of the glassware washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Guide to the glassware washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Opening and closing the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Water softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting the water softener ...........................................13

Filling the salt reservoir .............................................15

Salt indicator .....................................................16

Areas of application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Spring adapter for the water connection ................................19

Adjusting the upper basket ..........................................19

Effects of Processing Chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Dispensing chemical agents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Turning on the lab washer ...........................................31

Starting a program.................................................31

Select the Drying 3 function if desired ................................31

Changing a program ...............................................31

Starting the program ...............................................32

Program sequence display ..........................................32

End of a program..................................................32

Turning off .......................................................32

Canceling a program...............................................33

Program guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Programming functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

The following instructions apply to all programming functions:...............36

To access the programming mode .................................36

Saving to memory and exiting the programming mode ..................36

Exiting the programming mode without saving ........................36

Buzzer ..........................................................37

Changing program parameters .......................................38

Changing the temperature ........................................38

Changing the holding time ........................................38

Activating Rinse 2 .................................................39

Delay start .......................................................40

Restoring the factory settings ........................................41

3

Contents

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Routine checks ...................................................42

Cleaning and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Frequently asked questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Thermo switch ....................................................58

After Sales Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

INSTALLATION INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Plumbing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Water inlet .......................................................64

Drainage ........................................................66

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Caring for the environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4

IMPORTANT SAFETY INSTRUCTIONS

This machine conforms to current

safety requirements. However,

inappropriate use can lead to

personal injury and property

damage.

To avoid the risk of accidents and

machine damage read the operating

instructions carefully before using

this machine.

Keep these instructions in a safe

place and pass them on to any

future user.

Please pay attention to the following

notes to maintain safe procedures.

Installation and repair work should

~

be performed by a Miele authorized

service technician. Work by unqualified

persons could be dangerous and may

void the warranty.

Do not use the labwasher until

~

properly installed.

Do not install the machine in an area

~

where a danger of explosion or of

freezing temperatures may be present.

WARNING - To reduce the risk of fire,

electric shock or injury:

Use

This lab washer is not intended for

~

any purpose that is not indicated in the

operating instructions. Conversions,

modifications, and other unintended

uses are considered to be dangerous.

The cleaning processes described here

apply only to those medical products

that are specifically designed by the

manufacturer to be re-used. Follow the

product manufacturer's instructions.

This lab washer in intended for

~

indoor stationary use only.

Before installation, make sure that

~

the voltage and frequency listed on the

data plate correspond with the

household electrical supply. This data

must correspond to prevent injury and

machine damage. Consult a qualified

electrician if in doubt.

Be certain this machine is properly

~

installed and grounded by an

authorized technician. To guarantee

the electrical safety of this machine,

continuity must exist between the

machine and an effective grounding

system. It is imperative that this basic

safety requirement be met. If there is

any doubt, have the electrical system

checked by a qualified technician.

Do not install or use a damaged

~

machine. A damaged machine is

dangerous. Unplug the machine and

call your Miele dealer or the Miele

Technical Service Department.

If the power cord is damaged it

~

must only be replaced by a Miele Ser

vice technician with a genuine Miele

power cord.

-

5

IMPORTANT SAFETY INSTRUCTIONS

Do not use an extension cord to

~

connect this machine to electricity.

Extension cords do not guarantee the

required safety of the machine (e.g.

danger of overheating).

Defective components should be

~

replaced by Miele original parts only.

Before installation or service,

~

disconnect the power supply to the

work area by unplugging the unit,

"tripping" the circuit breaker or

removing the fuse.

When work has been performed on

~

the supply plumbing, air must be bled

from the supply line to the labwasher.

Otherwise, the water softening system

may be damaged.

Use

Please follow the advice on

~

installation in this manual and in the

separate Installation Instructions.

Personnel operating the lab washer

~

should be trained regularly. Children

and untrained personnel must not be

allowed access to the machine or its

controls.

Persons who lack physical, sensory

~

or mental abilities, or experience with

the machine should not use it without

supervision or instruction by a

responsible person.

Do not allow children to play in or

~

around the machine, or to operate it.

BURN AND SCALD HAZARD

~

This machine reaches very high

temperatures. Take care when

unloading the unit. Let baskets and

inserts cool before touching them. Any

water which may remain in containers

will be very hot and should be emptied

into the wash cabinet.

BURN HAZARD

~

The heating elements become

extremely hot during use. Do not touch

the heating elements during or directly

after the end of a program.

Take care when handling

~

processing chemicals (detergents,

softeners, neutralizers, etc.). These may

contain irritant or corrosive ingredients.

Wear protective gloves and goggles.

With all chemical agents the

manufacturer’s safety conditions must

be observed.

6

IMPORTANT SAFETY INSTRUCTIONS

The lab washer is only designed to

~

operate with water and the

recommended processing chemicals.

The machine must NOT be operated

with organic solvents or flammable

liquids. This may cause an explosion or

damage to rubber and plastic

components, which in turn allows liquid

substances to leak out.

Avoid inhaling detergent. If

~

swallowed, it can cause burning in the

mouth and throat or inhibit breathing.

Be careful when sorting and loading

~

items to be washed: locate sharp items

so that they are not likely to damage the

door seal; and load sharp knives with

the handles up to reduce the risk of

injuries.

The water in the machine must not

~

be used as drinking water.

Do not sit or lean on the open door.

~

This could cause the machine to tip or

be damaged.

Never clean the machine or near its

~

vicinity with a water or high pressure

hose.

Only use cleaning agents

~

formulated for special processes and

approved by Miele for use with this

labwasher. Use of unsuitable cleaning

agents could adversely affect the

components of the machine.

Pre-treatments with detergents can

~

create suds, as can certain rinsing

agents. For pre-treatment and / or

cleaning only, use low-sudsing

detergents which have been approved

by Miele. Suds can have an adverse

effect on the cleaning process.

When a chemical additive is

~

recommended on technical application

grounds (e.g. with a detergent), this

does not imply that the manufacturer of

the labwasher takes responsibility for

the affect of the chemical on the

material of the items being cleaned.

Please be aware that changes in

formulation, storage conditions, etc.,

which may not be publicized by the

chemical producer, can have a

negative effect on the cleaning result.

Always follow the instructions of the

~

chemical manufacturer when using

detergents and special application

chemicals. Only use such chemicals for

the purpose and in the situation

specified to avoid such dangers as

chemical reactions and material

damage.

The labwasher is designed only for

~

operation with water and additive

cleaning agents. Organic solvents must

not be used in the machine. An

explosion or machine corrosion could

occur with the use of organic solvents.

In critical applications where very

~

stringent requirements must be met, it

is highly recommended that all relevant

factors for the process, such as

cleaning agent, quality of water, etc.,

be discussed with a Miele Application

Specialist.

For applications that demand

~

especially stringent cleaning and

rinsing results, the operator must

ensure that quality control occurs on a

regular basis.

7

IMPORTANT SAFETY INSTRUCTIONS

The mobile units and special inserts

~

should only be used for their specific

application.

Empty any containers or utensils

~

before arranging them in the machine.

Do not allow any remains of acids or

~

solvents, particularly hydrochloric acid

or chloride solutions, to get into the

wash cabinet. The presence of any

solvents should be minimized

(especially those in hazard class A1).

To avoid corrosion damage ensure

~

that solutions or steam containing

hydrochloric acid do not come into

contact with the steel outer casing of

the labwasher.

Please note the following symbols on

the machine:

Caution : See Operating

Instructions!

Caution : Danger of electric

shock!

Accessories

Only genuine, Miele parts and

~

accessories should be used with this

lab washer, including Miele mobile

units, baskets and inserts.

Adequate cleaning results cannot

~

be guaranteed when non-Miele

accessories are used, or when Miele

accessories are altered. Damages

resulting from the use of unsuitable

accessories are not covered by the

warranty.

Disposal of an old appliance

Obsolete appliances should be made

unusable. To do this, first disconnect

the appliance from the power supply,

then cut off the power cord. It is

important to note that the old appliance

may be contaminated from exposure to

pathogens, genetically modified

material, blood, etc., and therefore

must be decontaminated before

disposal.

For safety and environmental

protection, be sure to remove all

chemical residue, in compliance with

safety regulations (wear protective

eyewear and gloves!).

Remove or destroy the door latch, to

prevent children from locking

themselves inside. The appliance can

now be sent for disposal through the

proper resource recovery facilities.

SAVE THESE

INSTRUCTIONS

8

Function of the glassware washer

This Miele dishwasher is designed for

cleaning and rinsing laboratory

glassware which is suitable for machine

reprocessing. Always follow the

labware manufacturer's instructions.

Examples of application areas:

laboratory glassware used in

–

research and development,

laboratory glassware used in areas

–

of analysis and specimen taking,

laboratory glassware used in

–

micro-biology and biotechnology.

The type of laboratory glassware which

can be reprocessed ranges from Petri

dishes to centrifugal test tubes.

Reprocessing glassware by machine

achieves reproducible results and

should be used in preference to

processing them by hand.

The cleaning program as well as the

agents used must be chosen according

to the type of soiling and load being

processed.

The agents used in the machine for

reprocessing should be selected

according to the level of cleaning

required as well as the method the

product will be used.

The use of a suitable carrier (mobile

unit, module, insert etc.) is important to

ensure adequate cleaning. Examples

are given in the section "Areas of

application".

The dishwasher is programmed to carry

out the final rinse with mains water or

with processed water of a quality to suit

the application (e.g. distilled, purified,

de-ionized or demineralized water). The

water quality is important for

applications requiring analytically clean

laboratory glassware.

9

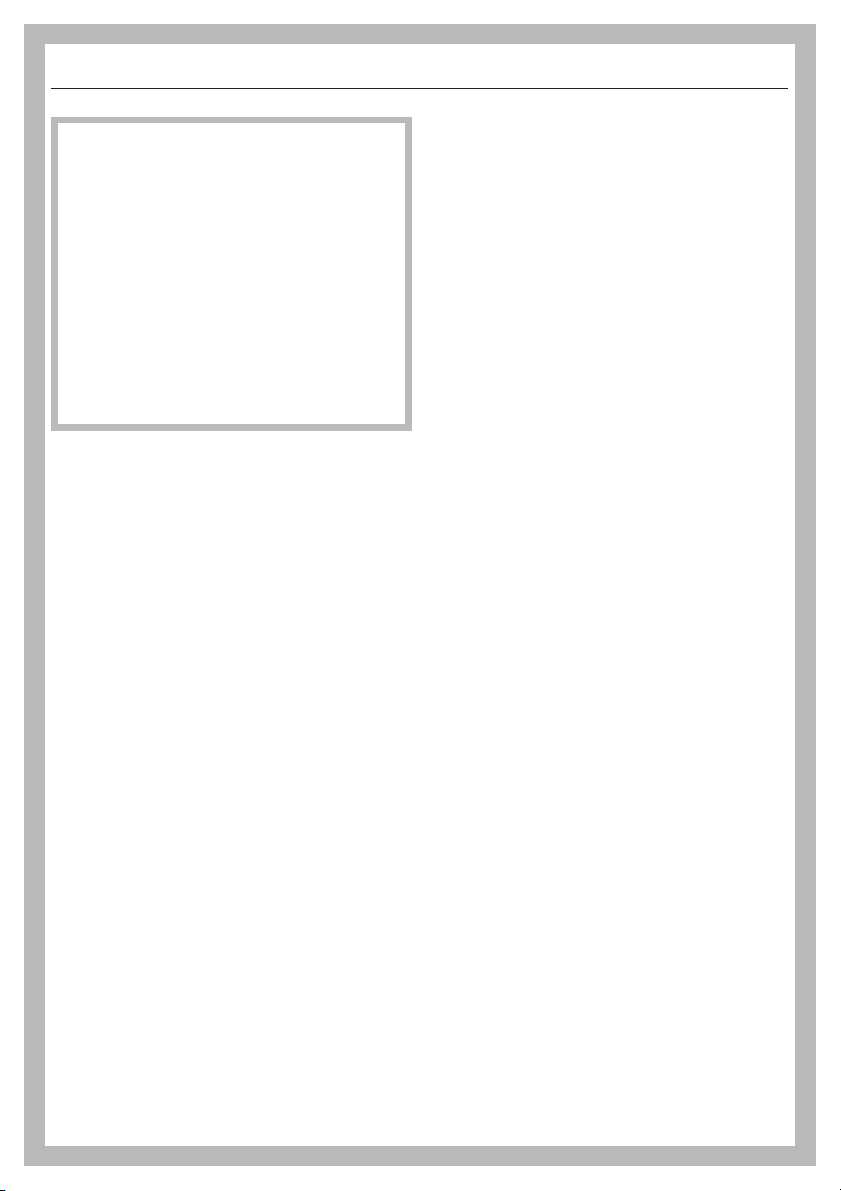

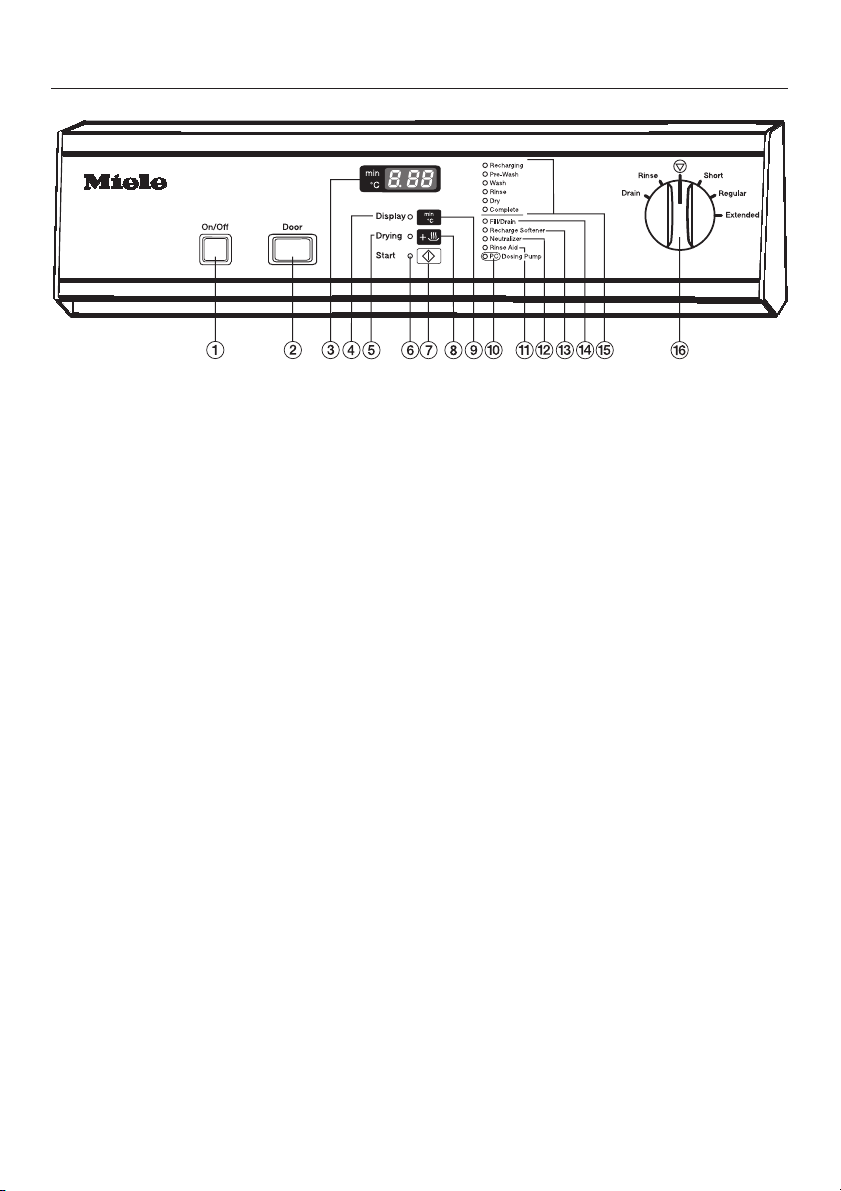

Guide to the glassware washer

a On/Off button

b Door button

c Display

d Display indicator

e Drying indicator

f Start indicator

g Start button 6

h Drying button 3

i Button 4 to switch between the

actual temperature and the elapsed

time.

Check / Refill indicators:

j 8 Optical interface for service

technician

k Rinse Aid

l Neutralizer

m Recharge softener

n Fill/Drain

o Program sequence indicators

p Program selector

10

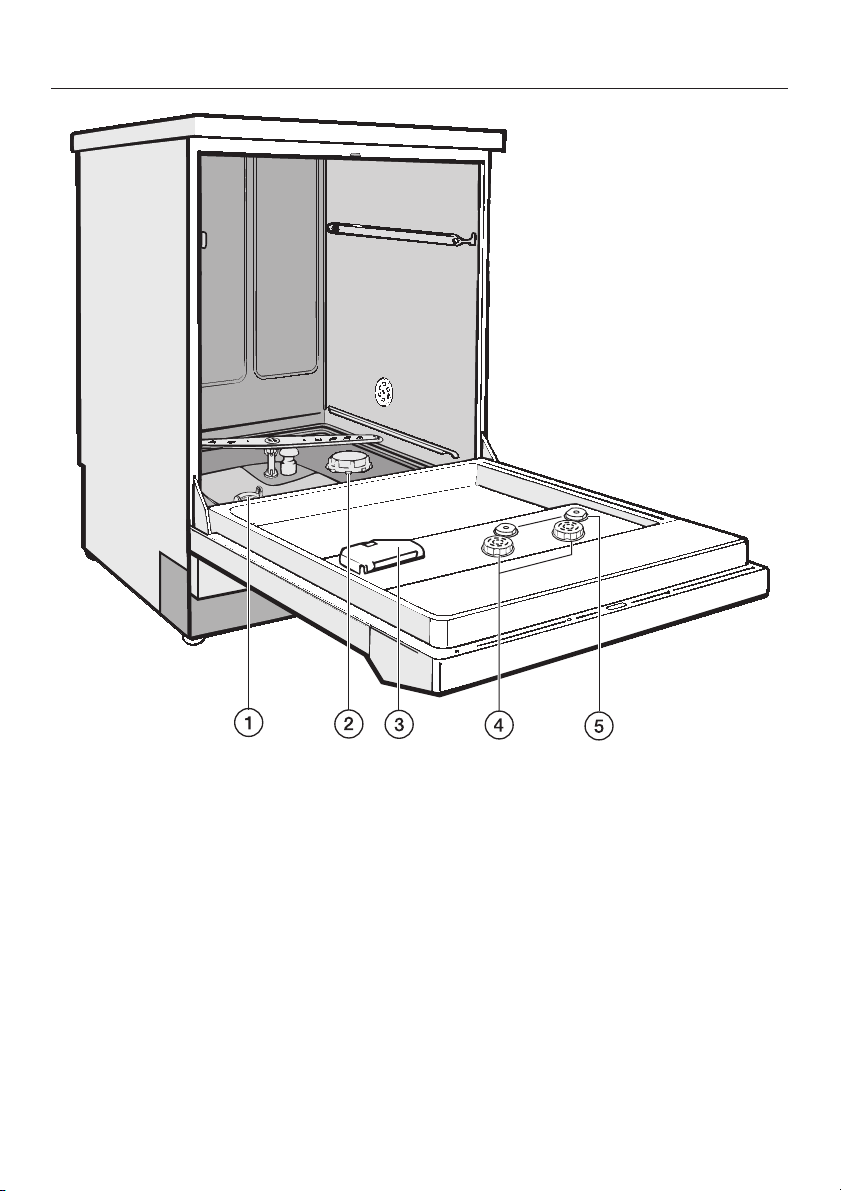

Guide to the glassware washer

a Filter combination

b Salt reservoir (water softener)

c Dispenser for powdered detergent

d Dispenser for rise aid or netralizing

agent (with dosage selector)

e Level indicator for rinse aid or

neutralizing agent

11

Opening and closing the door

Electric door lock

The machine is equipped with an

electric door lock. The door can only be

opened when the electrical supply to

the machine is turned on, and the

"On/Off" button is pressed.

To open the door

Press the "Door" button in as far as it

^

will go. At the same time, grip the

handle and open the door.

After the first intake of water, the door

remains locked and cannot be opened

until the end of the program (except

during the "Rinse" and "Drain"

programs). The machine can be

programmed to open during the

"Drying" program, if desired.

Do not touch the heating elements.

They remain hot for some time after

the end of the program and can

cause burns.

To open the door with the

emergency release

The emergency release should only be

used when the door cannot be opened

normally, e.g. in the event of a power

failure.

Turn the program selector to "Stop"

^

f.

Press the "On/Off" button to turn the

^

machine off.

Take precaution against pressure

wave release (rapid opening of the

door).

To close the door

^

Lift the door upwards and push it

until it clicks shut. Do not press the

release catch while shutting the door.

To cancel a program

If a program has to be canceled in an

emergency, e.g. the program has been

interrupted due to a fault, the door will

have to be opened manually.

^

Turn the program selector to the

"Stop" f position. The program is

canceled after approximately

2 seconds.

12

^

Pull the emergency release cable

(located at the bottom of the machine

behind the service panel) downwards

to open the door.

The door latch will reset after the

emergency cable has been activated.

Water softener

Before using the lab washer for the first

time, the water softener should be

programmed. The water needs to be

softened to avoid calcium deposits on

the items being cleaned and in the

machine itself.

If the water supply is harder or softer

than the factory setting (including

below 4 gr/gal or 70 ppm), the setting

will need to be changed. See "Setting

the water softener".

In order to function properly, the

–

water softener requires a supply of

reactivation salt.

– The cleaner must be correctly

programmed to match the hardness

of the tap water supply.

– Your local water authority can

provide information about the

hardness of the tap water in your

area.

If the water hardness is known to

fluctuate, always program for the

highest value.

The built-in water softener can be

programmed at settings from

1 - 60 gr/gal or 20 - 1080 ppm.

It is useful to make a note of your water

hardness so that you can provide the

service technician with this information

in the event of any service calls.

Please note the water hardness in the

space provided here:

gr/gal or ppm

Setting the water softener

Use the On/Off button to switch off

^

the machine.

Turn the program selector to f.

^

Simultaneously press and hold the

^

"Display" ß and "Start" 6 buttons,

while turning the machine on with the

On/Off button.

The current program status P....

will appear in the display, and the

"Fill/Drain" indicator will come on.

Press the "Drying" 0 button once.

^

E01 will appear in the display.

^ Turn the program selector one switch

position clockwise (to 1 o'clock).

The number 19 will appear in the

display (this indicates the factory

setting in gr/gal).

^ Press and hold the "Display" ß

button until the required value

appears in the display.

Please refer to the "Settings" table for

detailed water hardness tables (water

hardness in gr/gal and ppm).

Once the 60 setting has been reached,

the counter begins again from 0.

^

Press "Start" 6.

SP will appear in the display.

^

Press "Start" 6 again.

The setting you selected will now be

stored in memory. The display light(s)

will turn off.

The machine is now ready for use.

13

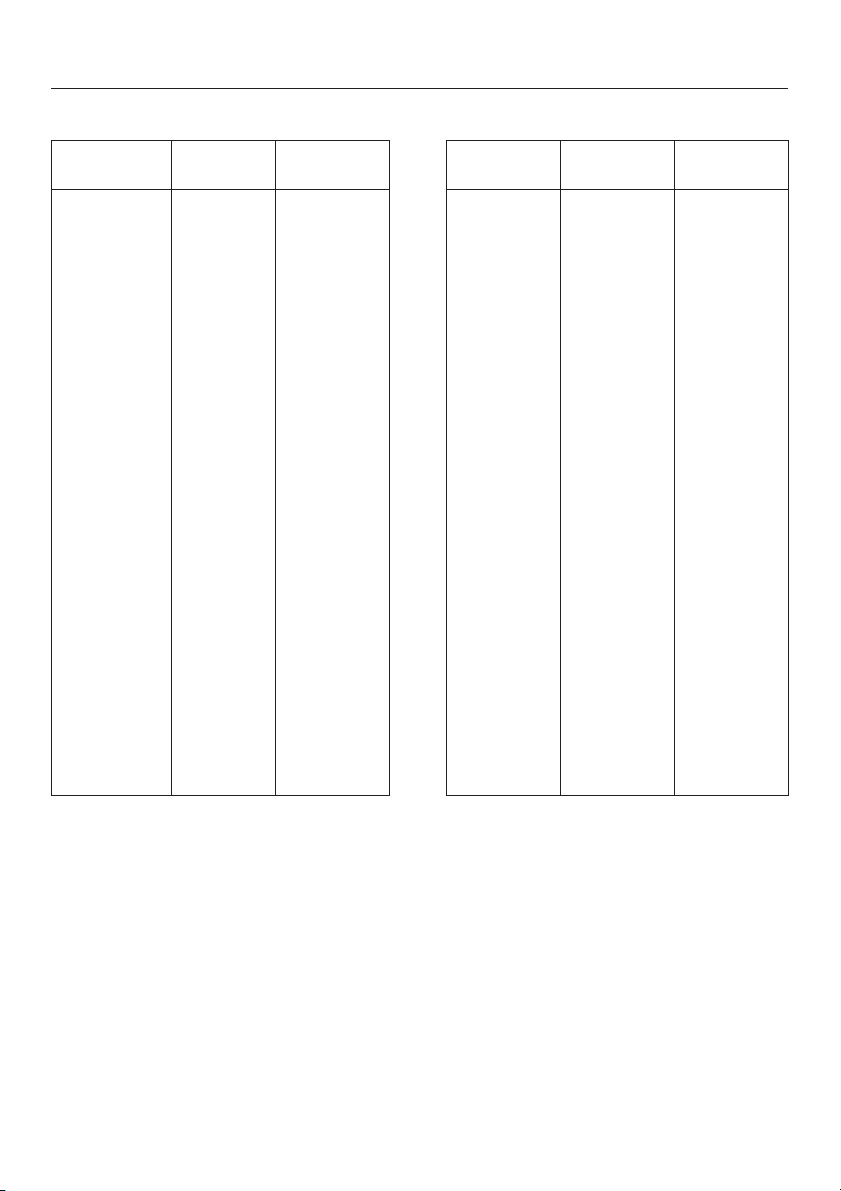

Water softener

Settings

Settings

1-30

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

gr/gal

1-30

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19 **)

20

21

22

23

24

25

26

27

28

29

30

ppm

CaCO

0*)

20

40

50

70

90

110

130

140

160

180

200

220

230

250

270

290

310

320

340

360

380

400

410

430

450

470

490

500

520

540

Settings

3

31-60

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

gr/gal

31-60

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

ppm

CaCO

560

580

590

610

630

650

670

680

700

720

740

760

770

790

810

830

850

860

880

900

920

940

950

970

990

1010

1030

1040

1060

1080

3

**) The "0" setting is only for machines that do not have a water softener

*) Factory setting

14

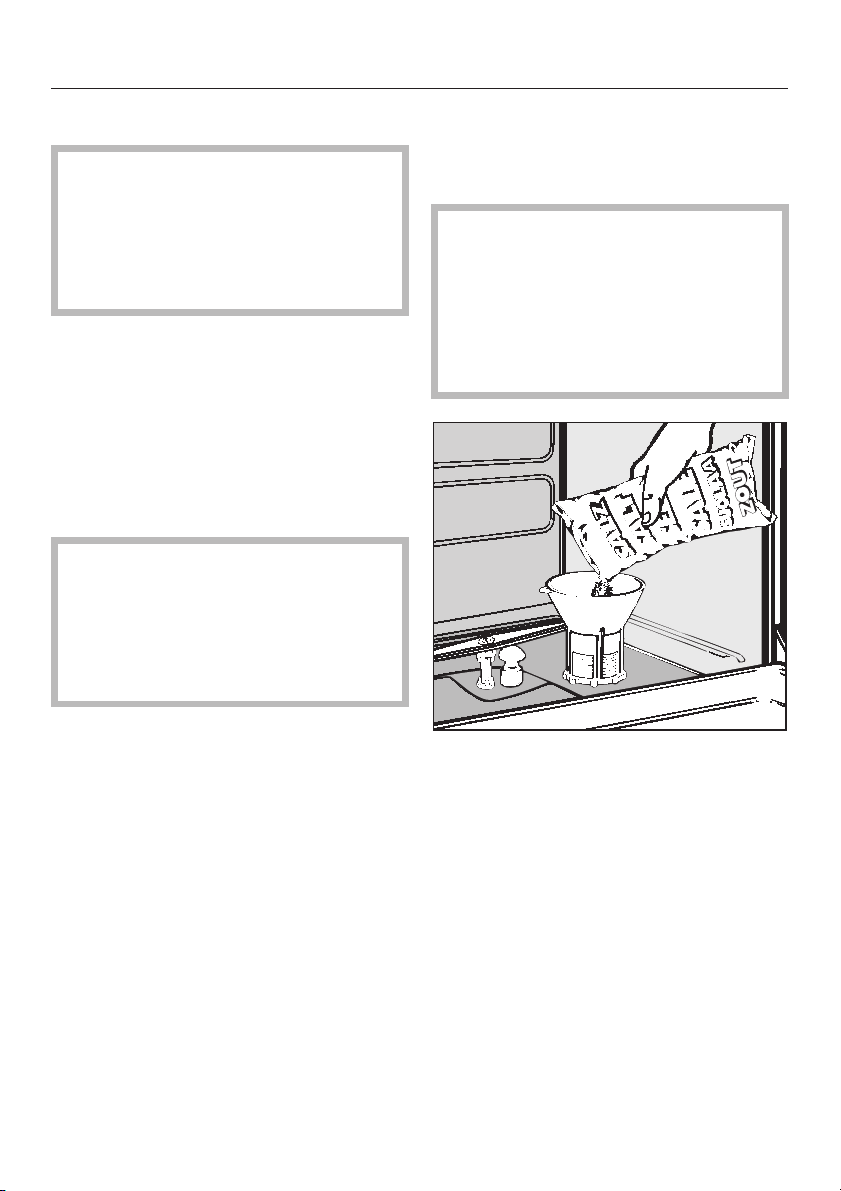

Water softener

Filling the salt reservoir

Only special, coarse-grained

reactivation salt* should be used in

this lab washer.

*Available from Miele. Please see

back page for more information.

Do not use other types of salt, e.g. table

salt, agricultural or gritting salt. These

could contain components which are

insoluble in water and could damage

the water softener. If in doubt, consult

Miele Technical Service.

The salt reservoir holds approximately

2.5 kg salt.

Inadvertently filling the salt

,

reservoir with detergent will damage

the water softener.

Before filling the reservoir, make

sure that you are using reactivation

salt.

Remove the bottom basket from the

^

machine.

Unscrew the salt reservoir cap.

^

Before filling the salt reservoir for the

first time fill the reservoir with

approximately 2.5 liters of water, so

that the salt can dissolve properly.

Once the lab washer has been

operated, there will always be

enough water in the reservoir.

^

Place the funnel provided in place.

^

Carefully fill the reservoir with the

reactivation salt.

15

Water softener

Wipe any residual salt off the screw

^

threads and seal of the reservoir.

^ Screw the cap on securely.

^ Immediately after this step, start the

"Rinse" program, to remove any

traces of salt from the inside of the

lab washer.

Note: There may be a delay of a few

minutes before the "Rinse" program

starts due to the reactivation of the

water softener.

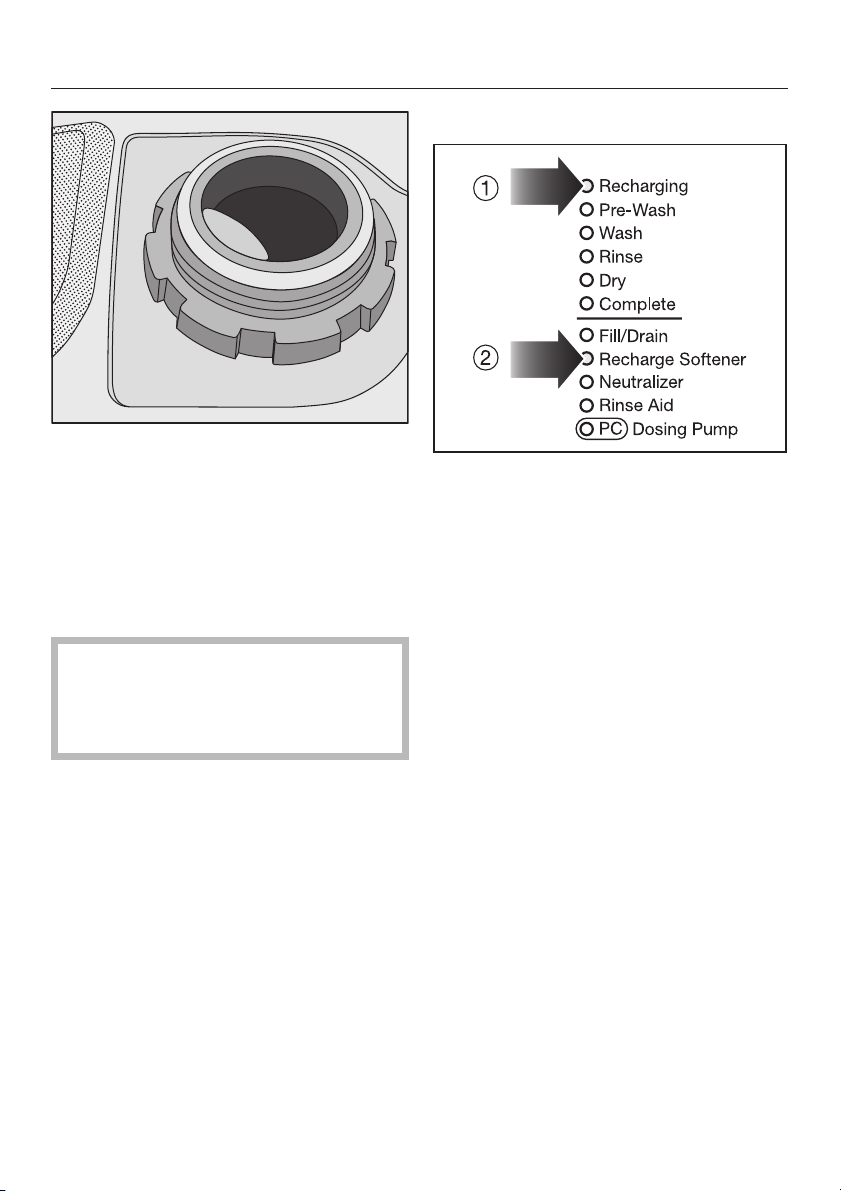

Salt indicator

When the salt reservoir is empty, the

"Recharge Softener" indicator b lights

to remind you to fill the reservoir.

Reactivation takes place automatically

as needed during a program. The

"Recharging" indicator a lights while

this is occurring.

16

Areas of application

Depending on the type of labware you

wish to clean, the lab washer can be

used with an upper basket, lower

basket, or injector wagon, as well as an

assortment of inserts and special

baskets to suit your needs.

Baskets and inserts should be

properly selected to match the

application desired.

Before every program start, conduct

the following visual inspection:

– Is the labware properly loaded and

secured in the lab washer?

– Are the hollow vessels properly

loaded so that all cavities and

channels will be flushed clean?

– Are the spray arms clean, and can

they rotate freely?

– Is the filter combination free of

coarse debris (clean if necessary)?

After every program completion,

conduct the following visual

inspection:

Inspect the labware for cleanliness.

–

Has any hollowware been dislodged

–

from its proper position on the

nozzles?

Any items that were dislodged

,

from the adapters during a program

cycle must be washed again.

Are the cavities and channels in any

–

hollow vessels cleaned through?

– Are the nozzles and connections

firmly attached to the

baskets/inserts?

–

Is the basket adapter properly

connected to the water supply for the

spray arms and nozzles?

–

Are the chemical dispensers filled?

17

Areas of application

Loading the machine

Disposable items must not be

processed in the machine.

Always load items in a way that all

–

surfaces are exposed. This ensures

that the items will be properly

cleaned.

Do not nest any items inside other

–

items. Keep each item separate.

Hollow vessels must be arranged for

–

complete inside exposure to the

cleaning water.

– Prior to loading the machine or

connecting to the machine ensure

that vessels with long, narrow

cavities they can be completely

flushed.

– Hollow vessels should be inverted

and placed in suitable baskets and

inserts so that water will have

unrestricted access and exit.

–

Deep-based items should be

arranged at an angle, so that water

can run off easily.

–

Tall, narrow pieces should be placed

in the center of the basket for best

water coverage.

–

Secure light loads with netting and

place small items in a mesh

tray/basket so that they do not

obstruct the spray arms.

–

Baskets and inserts with an adapter

must be properly connected.

–

The spray arms must not be blocked

by items that are too tall or hang

through the baskets.

To avoid corrosion, only load

–

stainless steel instruments in good

condition.

Do not use this machine to wash

–

nickel-plated items or discolored

(oxidized) aluminum items.

Do not load plastics unless they are

–

heat-resistant.

Prepare items before loading

Empty all glassware before loading

^

into the machine. Comply with all

applicable infection-control

regulations.

^ Remove all agar residue from petri

dishes.

^ Remove all stoppers, corks, labels,

sealing wax residue, etc.

,

Ensure that no acid or solvent

residues, especially hydrochloric

acid or chlorides, get inside the

machine.

Special preparations before

operating the machine

Items effected by heavy contamination

that resists removal, such as vacuum

grease, paper labels, etc., can affect

the cleaning and rinsing of the whole

load. Pre-treat these items before

loading.

Lab equipment that is contaminated by

microbiological material, pathogens,

propathogens, genetically altered

material, etc., should be sterilized

before being washed in the lab washer

18

Areas of application

Spring adapter for the water

connection

The spring adapter for the water

connection must be properly engaged

when a basket or the injector wagon is

inserted into the machine. It must be

4-5mmhigher than the water inlet in

the machine.

If this is not the case, the adapter

needs to be adjusted as follows:

Adjusting the upper basket

The upper basket can be adjusted

above and below the middle position,

by 2 cm.

Depending on the height selected and

which inserts are used, labware of

various heights can be arranged in the

baskets.

To adjust the upper basket:

Pull the upper basket out as far as it

^

will go, lift it up off the runners and

remove.

Use a wrench to unscrew the roller

bearings on either side of the basket,

then reposition as required.

^

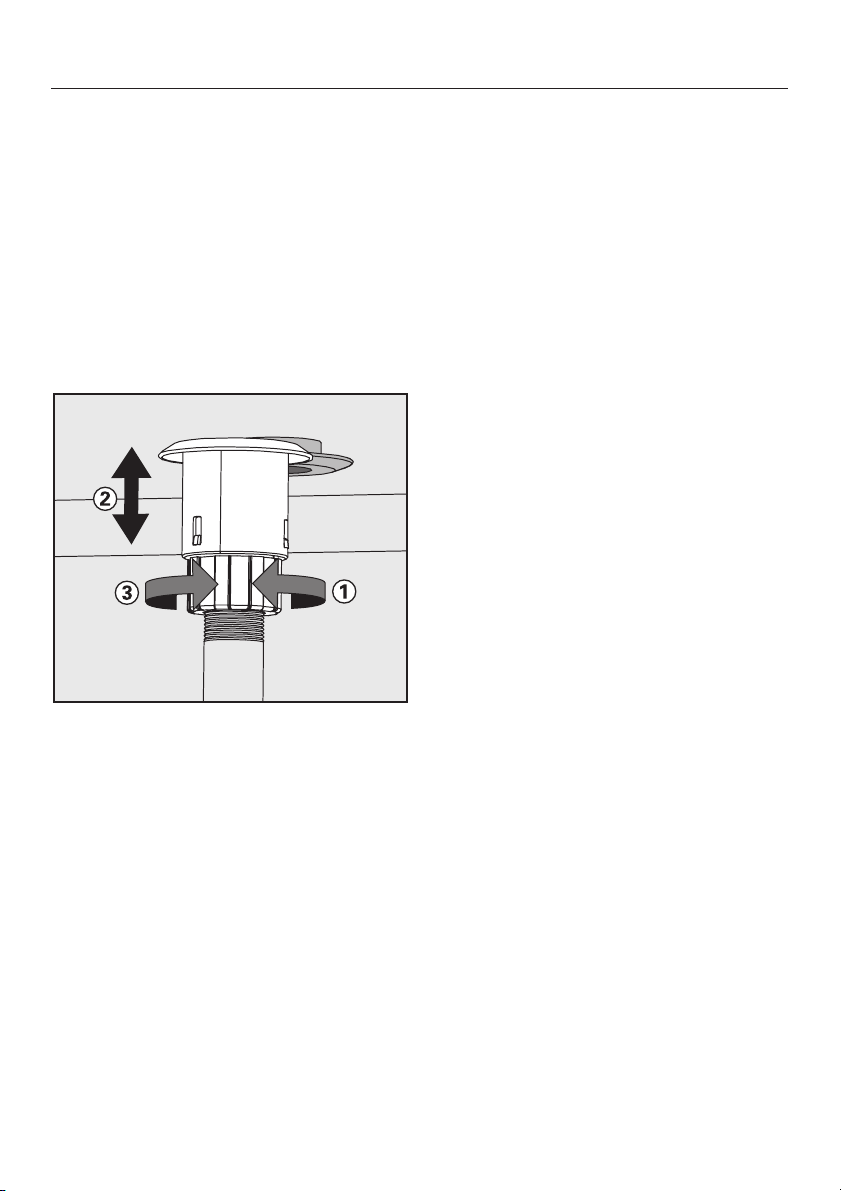

Loosen the locking ring a.

^

Move the adapter up to the proper

height b.

^

Tighten the locking ring c.

19

Areas of application

Laboratory equipment

Wide-necked labware, e.g., beakers,

wide-necked Erlenmeyer flasks and

Petri dishes, or cylindrical items,

e.g., test tubes, can be cleaned inside

and out by the rotating spray arms.

For proper cleaning, load these items in

whole, half or quarter inserts, and place

them in an empty lower basket or upper

basket with spray arm.

Narrow-necked items, e.g., narrow

necked Erlenmeyer flasks, round flasks,

volumetric flasks and pipettes, require

the use of injector wagons or injector

baskets.

Separate instructions are included

for the use of injector baskets and

inserts for narrow-necked labware.

This section only covers basic

information on how to prepare and load

labware.

Petri dishes and similar items should

–

be loaded in a suitable insert with the

soiled side facing center.

Pipettes should be placed with the

–

narrow end facing down.

Protective netting can be used to

–

avoid glass breakage.

Quarter baskets should be loaded at

–

least 3 cm away from the edge of the

wagon.

20

Areas of application

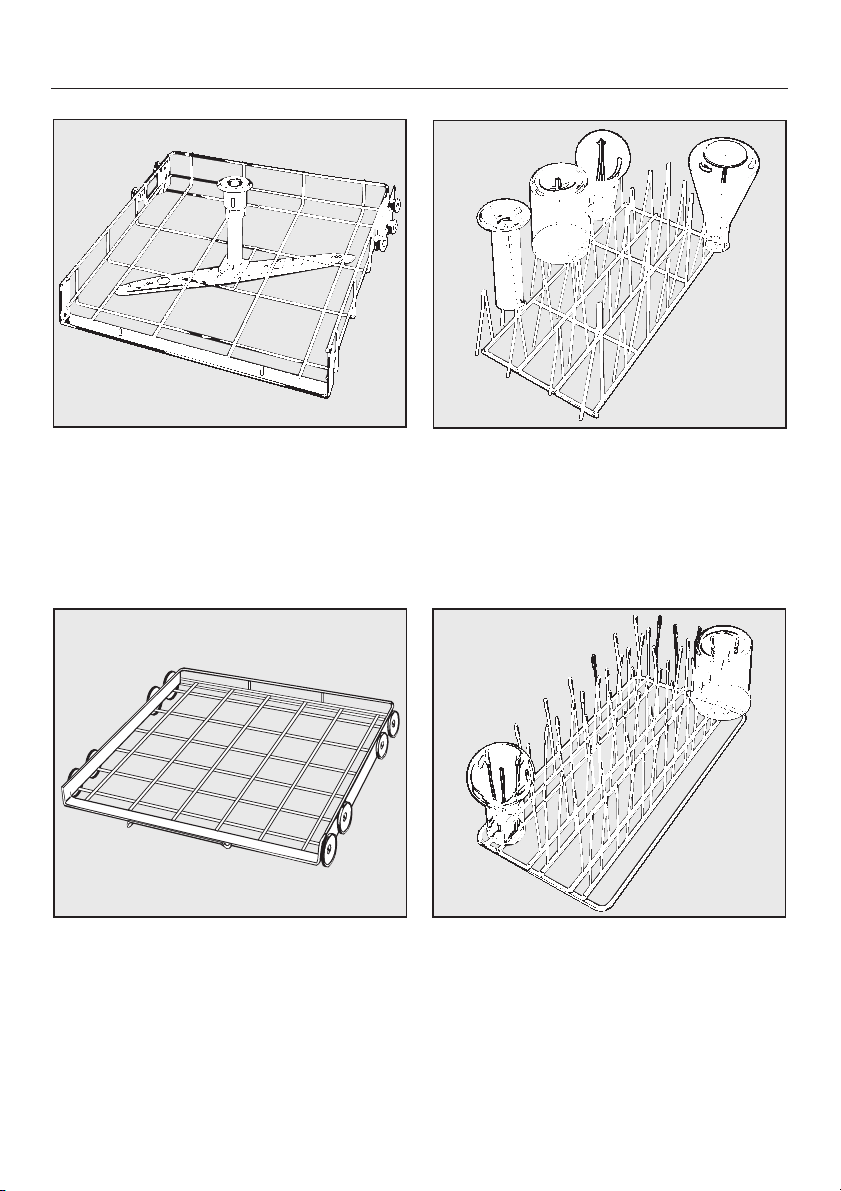

Upper basket O 188/1

For various inserts.

Lower basket U 874/1

For various inserts.

E 106/2

Stainless steel half insert with 26 spring

hooks in 2 different heights for various

glassware, e.g. narrow necked flasks,

graduated cylinders, medicine bottles,

etc.

E 109

Stainless steel half insert to

accommodate 21 beakers up to 250 ml,

Erlenmeyer flasks, round flasks, etc.

21

Effects of Processing Chemicals

General information

Effects Action

Damage to elastomer (seals and hoses)

or plastic components of the lab

washer may cause the materials to

swell, shrink, harden or become brittle,

possibly causing cracks to form in the

materials. This will impair their function,

which will generally lead to leaks.

Strong foaming during the program

prevents proper cleaning and rinsing of

the load. Foam escaping from the wash

compartment can result in damage to

the lab washer.

If foaming occurs, the cleaning process

is not standardized and not validated.

Stainless steel corrosion in the wash

compartment and/or accessories may

appear in various ways:

– rust formation (red spots / stains),

–

black spots / stains,

–

white spots / stains (smooth surface

is slightly corroded).

Corrosion that forms holes can result in

leaks in the lab washer. Depending on

the application, the corrosion may

impair the cleaning and rinsing results

(laboratory analysis) or cause corrosion

of the load (stainless steel).

Find and correct the causes of the

–

damage.

See "Connected processing

chemicals", "Soiling" and "Reactions

between processing chemicals and

soils" for more information.

Find and correct the cause of the

–

foaming.

The process must be checked

–

regularly in order to detect any

foaming.

See "Connected processing

chemicals", "Soiling" and "Reactions

between processing chemicals and

soils" for more information.

– Find and correct the cause of the

corrosion.

See "Connected processing

chemicals", "Soiling" and "Reactions

between processing chemicals and

soils" for more information.

22

Loading...

Loading...