Page 1

881 Compact IC pro

881 Compact IC pro – Anion – MCS

Manual

8.881.8014EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

881 Compact IC pro

881 Compact IC pro – Anion – MCS

2.881.0030

8.881.8014EN

Manual

05.2011 zst

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.2 Intended use ......................................................................... 3

1.3 About the documentation ................................................... 3

1.3.1 Symbols and conventions ........................................................ 3

1.4 Safety instructions ................................................................ 4

1.4.1 General notes on safety ........................................................... 4

1.4.2 Electrical safety ........................................................................ 4

1.4.3 Tubing and capillary connections ............................................. 5

1.4.4 Flammable solvents and chemicals ........................................... 5

1.4.5 Recycling and disposal ............................................................. 6

2 Overview of the instrument 7

2.1 Front ...................................................................................... 7

Table of contents

2.2 Rear ........................................................................................ 8

3 Installation 10

3.1 About this chapter .............................................................. 10

3.2 Initial installation ................................................................ 10

3.3 Installation diagram ........................................................... 14

3.4 Setting up the instrument .................................................. 17

3.4.1 Packaging .............................................................................. 17

3.4.2 Checks .................................................................................. 17

3.4.3 Location ................................................................................ 17

3.5 Capillary connections in the IC system ............................. 17

3.6 Rear of the instrument ....................................................... 20

3.6.1 Transport locking screws ....................................................... 20

3.6.2 Leak sensor ........................................................................... 20

3.6.3 Drainage tubings ................................................................... 21

3.7 Capillary and cable feed-throughs .................................... 23

3.8 Eluent ................................................................................... 25

3.8.1 Connecting eluent bottle ....................................................... 25

3.9 Eluent degasser ................................................................. 29

881 Compact IC pro – Anion – MCS

3.10 High pressure pump ........................................................... 31

3.10.1 Capillary connections high pressure pump/purge valve ........... 31

3.10.2 Deaerating the high pressure pump ....................................... 33

3.11 Inline filter ........................................................................... 35

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

3.12 Pulsation absorber ............................................................. 36

3.13 Sample degasser ................................................................. 37

3.14 Injection valve ..................................................................... 39

3.14.1 Connecting the injection valve ............................................... 39

3.14.2 Mode of operation of the injection valve ............................... 40

3.14.3 Selecting the sample loop ...................................................... 41

3.15 Column heater .................................................................... 41

3.16 Peristaltic pump .................................................................. 45

3.16.1 Principle of the peristaltic pump ............................................. 45

3.16.2 Installing the peristaltic pump ................................................ 47

3.17 Metrohm Suppressor Module (MSM) ............................... 51

3.17.1 Connecting the suppressor .................................................... 51

3.18 Metrohm CO2 Suppressor (MCS) ....................................... 54

3.18.1 General information on the MCS ........................................... 54

3.18.2 Connecting MCS ................................................................... 54

3.18.3 Installing the adsorption cartridges ........................................ 56

3.19 Connecting the instrument ................................................ 58

3.19.1 Connecting the instrument to the PC ..................................... 58

3.19.2 Connecting the instrument to mains supply ........................... 58

3.20 Guard column ..................................................................... 59

3.21 Separation column ............................................................. 60

4 Start-up 63

4.1 Initial start-up ..................................................................... 63

4.2 Conditioning ........................................................................ 64

5 Operation and maintenance 66

5.1 General notes ...................................................................... 66

5.1.1 Care ...................................................................................... 66

5.1.2 Maintenance by Metrohm Service .......................................... 66

5.1.3 Operation .............................................................................. 67

5.1.4 Shutting down ...................................................................... 67

5.2 Capillary connections ......................................................... 67

5.2.1 Operation .............................................................................. 67

5.3 Door ..................................................................................... 68

5.4 Eluent ................................................................................... 68

5.4.1 Production ............................................................................. 68

5.4.2 Operation .............................................................................. 69

■■■■■■■■

IV

5.5 High pressure pump ........................................................... 69

5.5.1 Protection .............................................................................. 69

5.5.2 Maintenance ......................................................................... 70

881 Compact IC pro – Anion – MCS

Page 7

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

5.6 Inline filter ........................................................................... 80

5.6.1 Maintenance ......................................................................... 80

5.7 Sample degasser ................................................................. 82

5.7.1 Operation .............................................................................. 82

5.8 Inline sample preparation .................................................. 82

5.9 Rinsing the sample path .................................................... 83

5.10 Injection valve .................................................................... 84

5.10.1 Protection .............................................................................. 84

5.11 Peristaltic pump .................................................................. 84

5.11.1 Operation .............................................................................. 84

5.11.2 Maintenance ......................................................................... 85

5.12 Metrohm Suppressor Module (MSM) ............................... 87

5.12.1 Protection .............................................................................. 87

5.12.2 Operation Suppressor ........................................................... 87

5.12.3 Maintenance ......................................................................... 88

5.13 Metrohm CO2 Suppressor (MCS) ....................................... 93

5.13.1 Replacing the CO2 adsorption cartridge ................................. 93

5.13.2 Regenerating the H2O adsorption cartridge ............................ 93

5.14 Separation column ............................................................. 94

5.14.1 Separating efficiency .............................................................. 94

5.14.2 Protection .............................................................................. 94

5.14.3 Storage ................................................................................. 95

5.14.4 Regeneration ......................................................................... 95

5.15 Quality Management and validation with Metrohm ....... 95

6 Troubleshooting 97

6.1 Problems and their solutions ............................................. 97

7 Technical specifications 101

7.1 Reference conditions ........................................................ 101

7.2 Instrument ......................................................................... 101

7.3 Leak sensor ....................................................................... 101

7.4 Ambient conditions .......................................................... 101

7.5 Housing ............................................................................. 102

7.6 Eluent degasser ................................................................ 102

7.7 High pressure pump ......................................................... 102

881 Compact IC pro – Anion – MCS

7.8 Sample degasser ............................................................... 103

7.9 Injection valve ................................................................... 103

7.10 Column heater .................................................................. 104

7.11 Peristaltic pump ................................................................ 104

■■■■■■■■

V

Page 8

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

7.12 Metrohm Suppressor Module (MSM) ............................. 104

7.13 Metrohm CO2 Suppressor (MCS) ..................................... 105

7.14 Mains connection ............................................................. 105

7.15 Interfaces .......................................................................... 105

7.16 Safety specification .......................................................... 106

7.17 Electromagnetic compatibility (EMC) ............................. 106

7.18 Weight ............................................................................... 107

8 Conformity and warranty 108

8.1 Declaration of Conformity ............................................... 108

8.2 Quality Management Principles ...................................... 109

8.3 Warranty (guarantee) ....................................................... 110

9 Accessories 112

9.1 Scope of delivery .............................................................. 112

9.2 Optional accessories ........................................................ 122

Index 125

■■■■■■■■

VI

881 Compact IC pro – Anion – MCS

Page 9

■■■■■■■■■■■■■■■■■■■■■■

Table of figures

Figure 1 Front 881 Compact IC pro – Anion – MCS ......................................... 7

Figure 2 Rear 881 Compact IC pro – Anion – MCS .......................................... 8

Figure 3 Installation diagram 881 Compact IC pro – Anion – MCS ................. 15

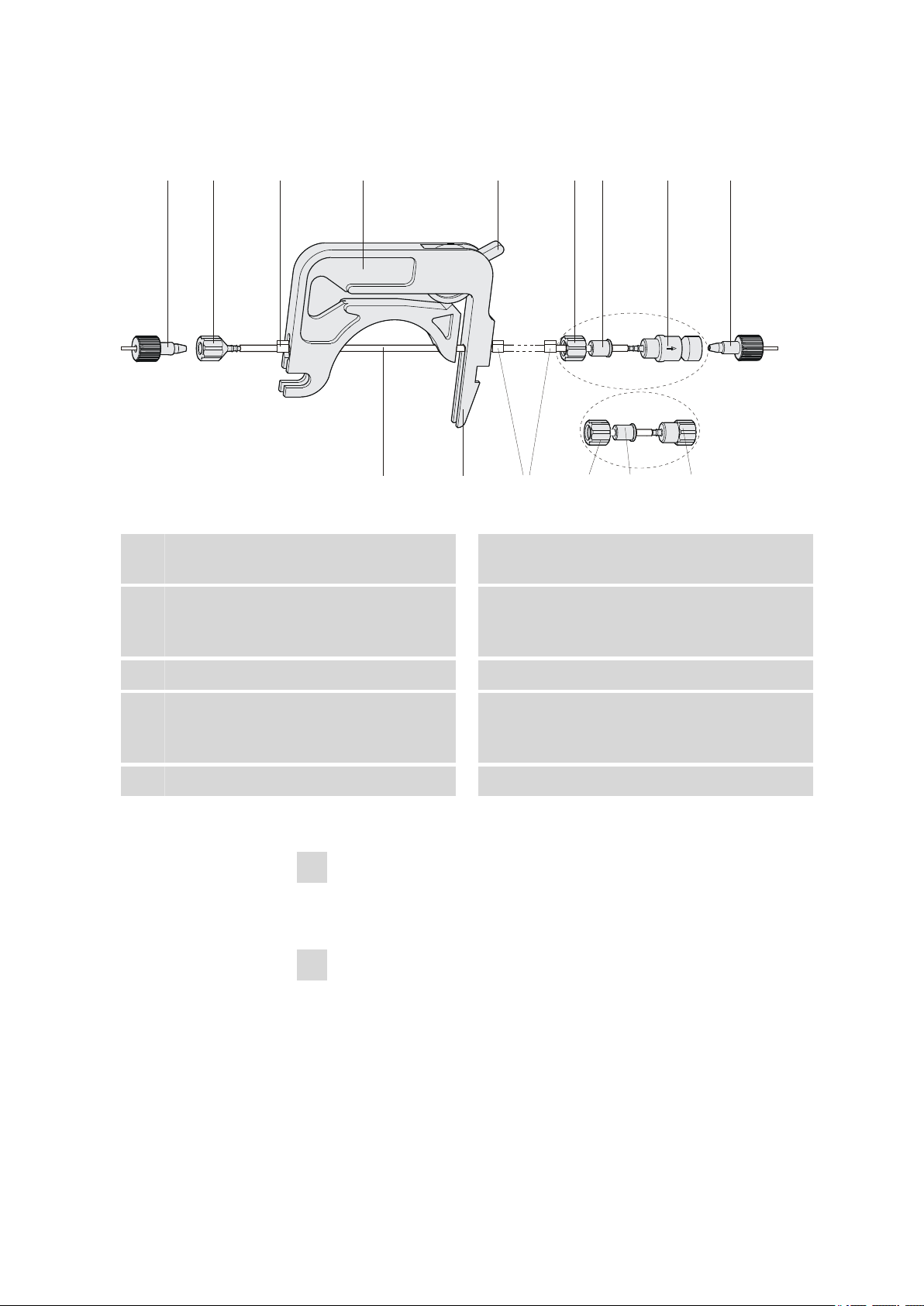

Figure 4 Connection of capillaries with pressure screws ................................ 18

Figure 5 Connection for the leak sensor on the rear of the instrument .......... 21

Figure 6 Drainage tubings ............................................................................. 22

Figure 7 Capillary and cable feed-throughs ................................................... 24

Figure 8 Installing eluent bottle attachment .................................................. 26

Figure 9 Mounting aspiration filter ................................................................ 26

Figure 10 Install tubing weighting and aspiration filter .................................... 27

Figure 11 Eluent aspiration tubing fully equipped. ........................................... 27

Figure 12 Eluent bottle – connected ............................................................... 28

Figure 13 Eluent degasser ............................................................................... 30

Figure 14 Capillary connections high pressure pump/purge valve .................... 31

Figure 15 High pressure pump – Connect inlet ................................................ 32

Figure 16 Deaerate the high pressure pump .................................................... 34

Figure 17 Connecting the inline filter .............................................................. 36

Figure 18 Pulsation absorber – Connection ..................................................... 37

Figure 19 Sample degasser ............................................................................. 38

Figure 20 Injection valve – connected ............................................................. 39

Figure 21 Injection valve – Positions ................................................................ 40

Figure 22 Column heater ................................................................................ 42

Figure 23 Column heater – Installing capillaries ............................................... 44

Figure 24 Peristaltic pump ............................................................................... 46

Figure 25 Installing the pump tubing .............................................................. 47

Figure 26 Install pump tubing connection with filter ....................................... 48

Figure 27 Install pump tubing connection without filter .................................. 49

Figure 28 Suppressor – connection capillaries ................................................. 52

Figure 29 MCS – connection ........................................................................... 55

Figure 30 Adsorption cartridge holder ............................................................. 56

Figure 31 Pump head – removing the piston ................................................... 71

Figure 32 Components of the piston cartridge ................................................ 72

Figure 33 Tool for piston seal .......................................................................... 73

Figure 34 Removing the piston seal ................................................................. 74

Figure 35 Inserting the piston seal into the tool ............................................... 74

Figure 36 Inserting the piston seal into the pump head ................................... 75

Figure 37 Removing valves .............................................................................. 76

Figure 38 Dismantling valve ............................................................................ 77

Figure 39 Components of the inlet valve and outlet valve ................................ 78

Figure 40 Change filters (of the inline filter) ..................................................... 80

Figure 41 Pump tubing connection – Changing the filter ................................. 86

Figure 42 Parts of the suppressor .................................................................... 88

Table of figures

881 Compact IC pro – Anion – MCS

■■■■■■■■

VII

Page 10

Page 11

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The instrument 881 Compact IC pro – Anion – MCS is one of the

model versions of the 881 Compact IC pro line of instruments manufactured by the Metrohm Company. The 881 Compact IC pro line of instruments is distinguished by:

■ the intelligence of its components, which are able to monitor and

optimize all functions and to provide documentation according to FDA

requirements.

■ its compact style of construction.

■ its transparency. All components are easily accessible and arranged in

a clear manner.

■ its safety. Chemicals and electronics are separated and a leak sensor is

integrated in the wet end.

■ its environmental compatibility.

■ its low noise emission.

1 Introduction

The instrument is operated with MagIC Net™ software. It is connected

via a USB connection to a PC on which MagIC Net™ is installed. The software automatically recognizes the instrument and checks its functional

readiness. MagIC Net™ controls and monitors the instrument, evaluates

the measured data and administers it in a database. The operation of

MagIC Net is described in the online help or in the tutorial for

MagIC Net™.

The instrument contains the following components:

Eluent degasser

The eluent degasser removes gas bubbles and dissolved gases from the

eluent. For degassing, the eluent flows into a vacuum chamber through a

special fluoropolymer capillary.

High pressure pump

The intelligent and low pulsation high pressure pump pumps the eluent

through the system. It is equipped with a chip on which its technical specifications and "life history" (operating hours, service data, … ) are saved.

Inline filter

Inline filters protect the separation column securely against possible contamination from the eluent. Inline filters can however also just as well be

used for the purpose of protecting other sensitive components against

contaminations in the solutions used. The filter platelets with a pore size

881 Compact IC pro – Anion – MCS

■■■■■■■■

1

Page 12

1.1 Instrument description

■■■■■■■■■■■■■■■■■■■■■■

of 2 µm can be replaced quickly and easily. They remove particles like e. g.

bacteria and algae from the solutions.

Pulsation absorber

The pulsation absorber protects the separation column from damage

caused by pressure fluctuations when switching the injection valve, and

reduces interfering pulsations during highly sensitive measurements.

Sample degasser

The sample degasser removes gas bubbles and dissolved gases from the

sample. For degassing, the sample flows into a vacuum chamber through

a special fluoropolymer capillary.

Injection valve

The injection valve connects the eluent and sample path through rapid

and precise valve switchover. A precisely measured amount of sample

solution is injected and rinsed with eluent onto the separation column.

Column heater

The perfect isolation of the column chamber ensures thermally stable conditions for the separation column. The temperature of the column heater

can be set in the software.

Peristaltic pump

The Peristaltic pump is used for pumping sample and auxiliary solutions. It

can rotate in both directions.

Metrohm Suppressor Module (MSM)

The MSM is used for chemical suppression in anion analysis with conductivity detection or UV detection.It is pressure-stable, robust and resistant

to solvents.

Metrohm CO2 Suppressor (MCS)

The Metrohm CO2 Suppressor (MCS) removes the CO2 from the eluent

flow. This reduces the background conductivity, improves the detection

sensitivity and minimizes the injection and carbonate peaks.

Separation column

The intelligent separation column is the heart of the ion chromatographic

analysis. It separates the different components corresponding to their

interactions with the column. Metrohm separation columns are equipped

with a chip on which their technical specifications and their history (first

use / setting up, operating hours, injections, …) are saved.

■■■■■■■■

2

881 Compact IC pro – Anion – MCS

Page 13

■■■■■■■■■■■■■■■■■■■■■■

1.2 Intended use

The instrument 881 Compact IC pro – Anion – MCS is used for ion

chromatographic determination of anions or polar substances with

sequential suppression:

■ Chemical suppression with the Metrohm Suppressor Module (MSM)

and subsequent

■ CO

2

The use of sequential suppression reduces background conductivity to a

minimum.

If required, the instrument can also be used for the determination of cations or anions without suppression.

This instrument is suitable for processing chemicals and flammable samples. The usage of the 881 Compact IC pro – Anion – MCS therefore

requires that the user has basic knowledge and experience in the handling

of toxic and caustic substances. Knowledge with respect to the application of the fire prevention measures prescribed for laboratories is also

mandatory.

1 Introduction

suppression with the Metrohm CO2 Suppressor (MCS).

1.3 About the documentation

1.3.1 Symbols and conventions

The following symbols and styles are used in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the

second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

Warning

This symbol draws attention to a possible life hazard

or risk of injury.

Warning

This symbol draws attention to a possible hazard due

to electrical current.

Warning

881 Compact IC pro – Anion – MCS

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

■■■■■■■■

3

Page 14

1.4 Safety instructions

1.4 Safety instructions

1.4.1 General notes on safety

Warning

This instrument may only be operated in accordance with the specifications in this documentation.

■■■■■■■■■■■■■■■■■■■■■■

Warning

This symbol draws attention to a possible biological

hazard.

Caution

This symbol draws attention to a possible damage of

instruments or instrument parts.

Note

This symbol marks additional information and tips.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

1.4.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Warning

Warning

■■■■■■■■

4

881 Compact IC pro – Anion – MCS

Page 15

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

Mains voltage

Warning

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

Protection against electrostatic charges

Warning

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Always pull the mains cable out of the mains connection socket before

connecting or disconnecting electrical appliances on the rear panel of

the instrument.

1.4.3 Tubing and capillary connections

Caution

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are mandatory.

1.4.4 Flammable solvents and chemicals

Warning

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location (e.g. laboratory

flue).

■ Keep all sources of flame far from the workplace.

■ Clean up spilled fluids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

881 Compact IC pro – Anion – MCS

■■■■■■■■

5

Page 16

1.4 Safety instructions

1.4.5 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

6

881 Compact IC pro – Anion – MCS

Page 17

■■■■■■■■■■■■■■■■■■■■■■

1

12

10

2

3

4

7

5 6

8

13

11

9

2 Overview of the instrument

2.1 Front

2 Overview of the instrument

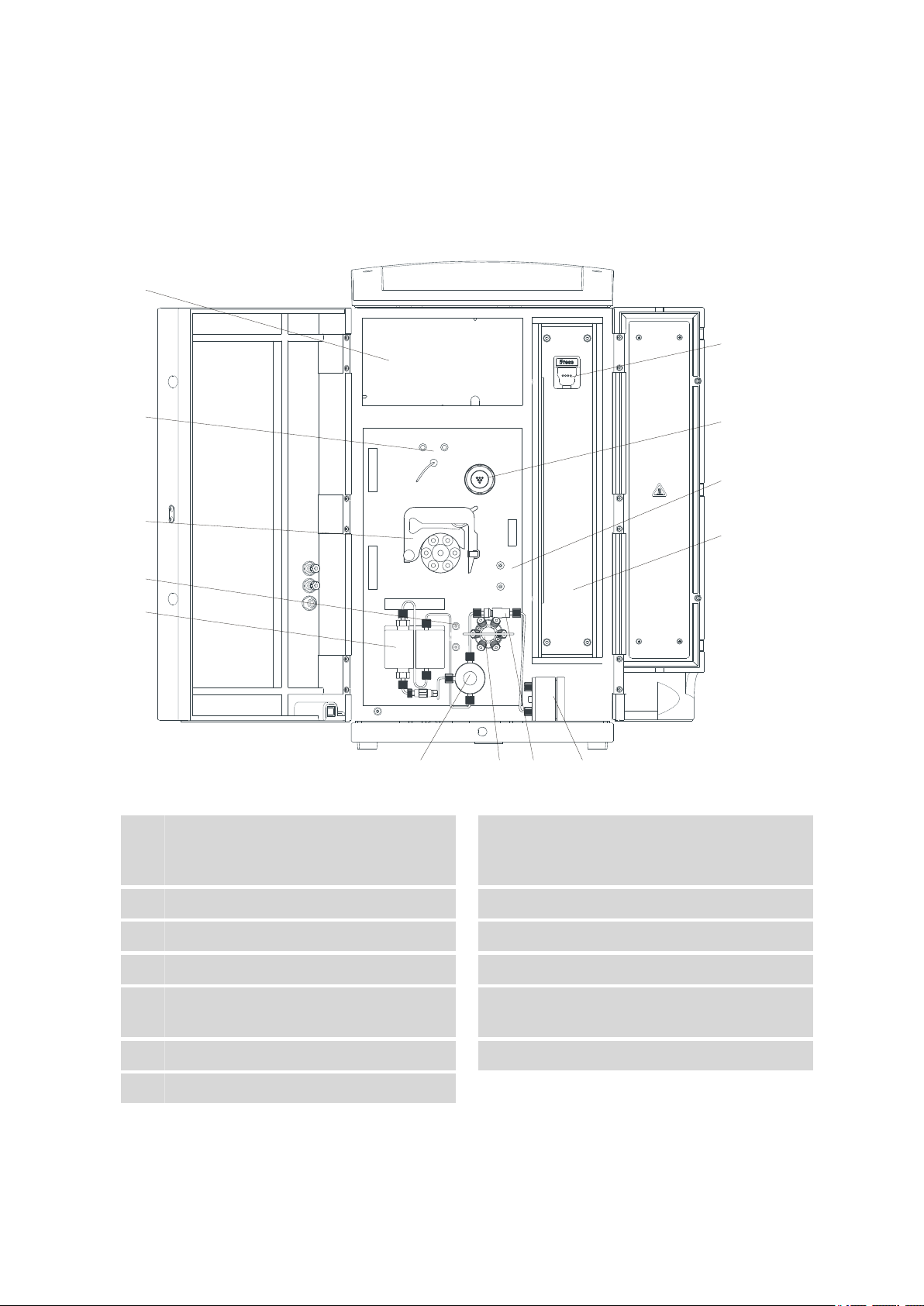

Figure 1 Front 881 Compact IC pro – Anion – MCS

Detector chamber

1

Room for the detector and the adsorption

cartridges for the MCS.

High pressure pump

3

Inline filter

5

Injection valve

7

Column holder

9

With column recognition.

Metrohm Suppressor Module (MSM)

11

Sample degasser

13

881 Compact IC pro – Anion – MCS

Eluent degasser

2

Purge valve

4

Pulsation absorber

6

Column heater

8

Peristaltic pump

10

Metrohm CO2 Suppressor (MCS)

12

■■■■■■■■

7

Page 18

2.2 Rear

14

15

16

17

18

20

21

19

22

11

1213

1

2

4

5

3

7

8

10

9

6

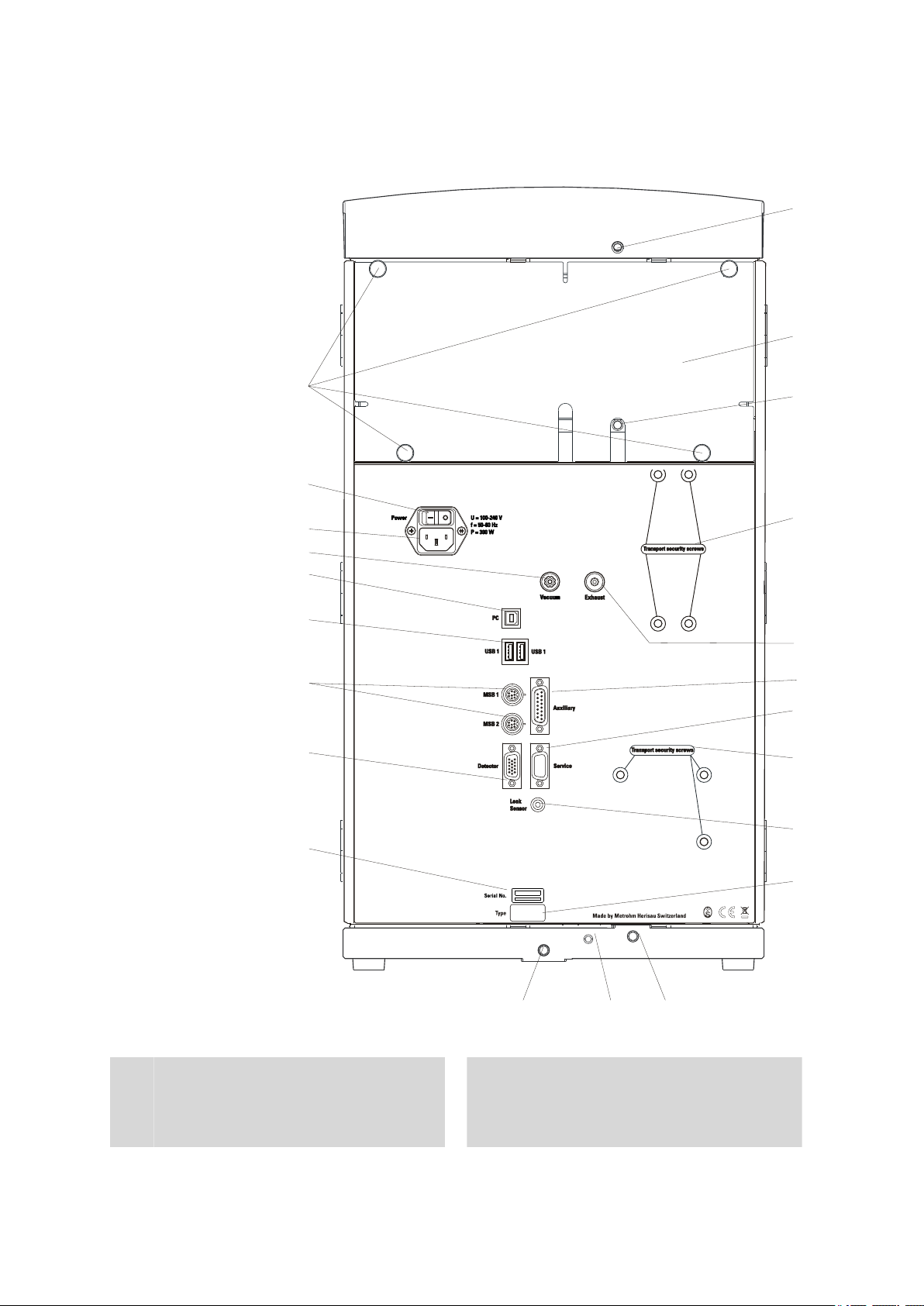

2.2 Rear

■■■■■■■■■■■■■■■■■■■■■■

Figure 2 Rear 881 Compact IC pro – Anion – MCS

1

■■■■■■■■

8

Drainage tubing connector

For connecting the drainage tubing which

leads away escaped fluids from the flask

holder.

Rear panel

2

Removable. Access to the detector chamber.

881 Compact IC pro – Anion – MCS

Page 19

■■■■■■■■■■■■■■■■■■■■■■

2 Overview of the instrument

Drainage tubing connector

3

For connecting the drainage tubing which

leads away escaped fluids from the detector

chamber.

Exhaust air opening

5

For extracting the air from the vacuum

chamber. Labeled with Exhaust.

Service connection socket

7

For Metrohm service only.

Leak sensor connection socket

9

For connecting the leak sensor connection

cable.

Drainage tubing connector

11

For connecting the drainage tubing which

leads escaped fluids to the leak sensor.

Drainage tubing connector

13

For connecting the drainage tubing which

leads escaped fluids to the waste vessel.

Transport locking screws

4

For securing the vacuum pump when transporting the instrument.

Auxiliary connection socket

6

For connecting a 891 Professional Analog

out (2.891.0010).

Transport locking screws

8

For securing the high pressure pump when

transporting the instrument.

Type plate

10

Leak sensor connection cable

12

Extractable. For connecting the leak sensor.

Serial number

14

Detector connection socket

15

For connecting Metrohm detectors. Labeled

with Detector.

USB connectors

17

2 USB connectors labeled with USB 1 and

USB 2.

Vacuum connection

19

Plugged with a stopper. Not Used.

Mains switch

21

For switching the instrument on and off.

I = On

O = Off

MSB connectors

16

2 MSB connectors for connecting MSB devices. Labeled with MSB 1 and MSB 2.

MSB = Metrohm Serial Bus

PC connection socket

18

For connecting the instrument to the computer with the USB cable (6.2151.020).

Mains connection socket

20

For connecting the mains cable.

Knurled screws

22

For fastening the removable rear panel.

881 Compact IC pro – Anion – MCS

■■■■■■■■

9

Page 20

3.1 About this chapter

3 Installation

3.1 About this chapter

The Installation chapter contains

■ this overview.

■ a brief set of instructions for the initial installation of the 881 Compact

IC pro – Anion – MCS. At each step you will find cross-references to

more detailed installation instructions for individual components,

should you require such aids.

■ an installation diagram (see Chapter 3.3, page 14), showing a com-

pletely installed 881 Compact IC pro – Anion – MCS.

■ several chapters with detailed installation instructions for all compo-

nents, including those that are already installed at the time the instrument is delivered.

■■■■■■■■■■■■■■■■■■■■■■

3.2 Initial installation

Note

A number of the capillaries is already connected at the time the instrument is delivered.

The following work steps must still be carried out:

881 Compact IC proInstalling – Anion – MCS

1

Setting up the instrument

(see Chapter 3.4, page 17).

2

Installations on the rear of the instrument

■ Place the detector in the instrument and connect it (see manual

of the detector).

■ Remove all of the transport locking screws with the 4 mm hexa-

gon key (6.2621.030) and keep them in a safe place.

■ Connect the leak sensor (see Chapter 3.6.2, page 20).

■ Connect the drainage tubings (see Chapter 3.6.3, page 21).

■■■■■■■■

10

881 Compact IC pro – Anion – MCS

Page 21

■■■■■■■■■■■■■■■■■■■■■■

3

Connecting the eluent path

■ Lead the eluent aspiration tubing (6.1834.080) out of the instru-

ment through a capillary feed-through and connect it with the

eluent bottle (see Chapter 3.8.1, page 25).

■ Connect the column inlet capillary (6.1831.100) and the capillary

of the MSM labeled with in to one another with a coupling

(6.2744.040) and two short pressure screws (6.2744.070).

■ Use a long pressure screw (6.2744.090) to connect the capillary

of the MSM labeled with out to the input of the of the MCS (see

"Connecting the MCS", page 55).

■ Connect the detector inlet capillary with a long pressure screw

(6.2744.090) to the output of the MCS (see "Connecting the

MCS", page 55).

4

Connecting the sample path

Note

3 Installation

The sample degasser does not have to be connected. We recommend the usage of the sample degasser only if the sample matrix

requires it (see Chapter 3.13, page 37).

■ Guide the sample aspiration capillary connected to the sample

input of the injection valve out of the instrument through a capillary feed-through and connect it with the Sample Processor, if

applicable (see Sample Processor manual)..

■ Guide the sample outlet capillary connected to the sample output

of the injection valve out of the instrument through a capillary

feed-through and onward to the waste container and then fasten

it there.

5

Installing the peristaltic pump

(see Chapter 3.16.2, page 47)

Prepare the pump tubing for the regeneration solution:

■ Plug a tubing olive (6.2744.034) onto one end of the pump tub-

ing (6.1826.320).

Plug a pump tubing connection (6.2744.180) onto the other end

of the pump tubing.

881 Compact IC pro – Anion – MCS

■■■■■■■■

11

Page 22

3.2 Initial installation

■■■■■■■■■■■■■■■■■■■■■■

■ Connect one end of the aspirating capillary (6.1803.020) for the

regeneration solution to the tubing olive on the pump tubing

using a short pressure screw (6.2744.070).

Guide the other end of the aspirating capillary out of the instrument through a capillary feed-through, slide it through a bottle

attachment (6.1602.150) and screw the bottle attachment onto

the bottle (6.1608.020) containing the regeneration solution.

Ensure that the end of the aspirating capillary reaches down to

the bottom of the bottle.

■ Place the pump tubing into a tubing cartridge.

Prepare a second pump tubing for the rinsing solution:

■ Plug a tubing olive (6.2744.034) onto one end of the pump tub-

ing (6.1826.320).

Plug a pump tubing connection (6.2744.180) onto the other end

of the pump tubing.

■ Connect one end of the aspirating capillary (6.1803.020) for the

rinsing solution to the tubing olive on the pump tubing using a

short pressure screw (6.2744.070).

Guide the other end of the aspirating capillary out of the instrument through a capillary feed-through, slide it through a bottle

attachment (6.1602.150) and screw the bottle attachment onto

the bottle (6.1608.020) containing the rinsing solution. Ensure

that the end of the aspirating capillary reaches down to the bottom of the bottle.

■ Place the pump tubing into a tubing cartridge.

Place both tubing cartridges into the peristaltic pump.

6

Connecting the MSM

(see Chapter 3.17, page 51)

■ Connect the capillary of the MSM labeled with regenerant to the

pump tubing connection of the pump tubing for the regeneration

solution using a short pressure screw (6.2744.070).

■ Connect the capillary of the MSM labeled with rinsing solution

to the pump tubing connection of the pump tubing for the rinsing

solution using a short pressure screw (6.2744.070).

■ Guide the two capillaries of the MSM labeled with waste reg.

and waste rins. out of the instrument through a capillary feed

through to a waste container and fasten them there.

7

Connecting the MCS

(see Chapter 3.18, page 54)

■■■■■■■■

12

881 Compact IC pro – Anion – MCS

Page 23

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

■ Attach the CO

adsorption cartridge (6.2837.000) to the adsorp-

2

tion cartridge holder (6.2057.080) (see "Installing the adsorption

cartridges", page 57).

■ Prepare the H

O adsorption cartridge (6.2837.010) (see leaflet to

2

the H2O adsorption cartridge) and attach it to the adsorption cartridge holder as well (see Figure 30, page 56).

■ Plug the adapter (6.1808.190) onto the PVC tubing and connect

the two adsorption cartridges with one another (see Figure 30,

page 56).

■ Place the adsorption cartridge (6.2057.080) holder in the detector

chamber.

■ Connect the MCS air aspirating capillary (3-15) to the tip of the

CO2 adsorption cartridge (6.2837.000).

8

Connecting the instrument

■ Connect the instrument to a computer (see Chapter 3.19.1, page

58) on which the software MagIC Net™ is installed using the

USB cable (6.2151.020).

■ Connect the instrument to the mains supply (see Chapter 3.19.2,

page 58).

9

Initial start-up

(see Chapter 4.1, page 63)

■ Switch on the PC and start MagIC Net™.

■ Switch on the instrument.

■ Deaerate the high pressure pump (see Chapter 3.10.2, page

33).

■ Set contact pressure of the peristaltic pump (see "Set flow rate",

page 50).

■ Rinse the instrument without column with eluent for 5 minutes.

10

Installing guard and separation column

■ Remove the coupling (6.2744.040) between the column inlet

capillary and the capillary of the MSM labeled with in.

■ (Optional) Connect guard column (see Chapter 3.20, page 59)

– Fasten the guard column to the end of the column inlet

capillary (see leaflet to the guard column).

– Rinse the guard column with eluent for approx. 5 minutes.

881 Compact IC pro – Anion – MCS

■■■■■■■■

13

Page 24

3.3 Installation diagram

■■■■■■■■■■■■■■■■■■■■■■

■ Connect the separation column (see Chapter 3.21, page 60)

– Connect the inlet oft the separation column either with the

end of the column input capillary using a PEEK pressures

screw (6.2744.070).

or

Connect the inlet of the separation column with the guard

column (if used) (see leaflet to the separation column)

– Connect the MSM capillary labeled with in with the output

of the separation column using a PEEK pressure screw

(6.2744.070).

■ Hang separation column with chip in the column holder of the

instrument.

11

Conditioning the instrument

(see Chapter 4.2, page 64)

The instrument is now ready for measuring samples.

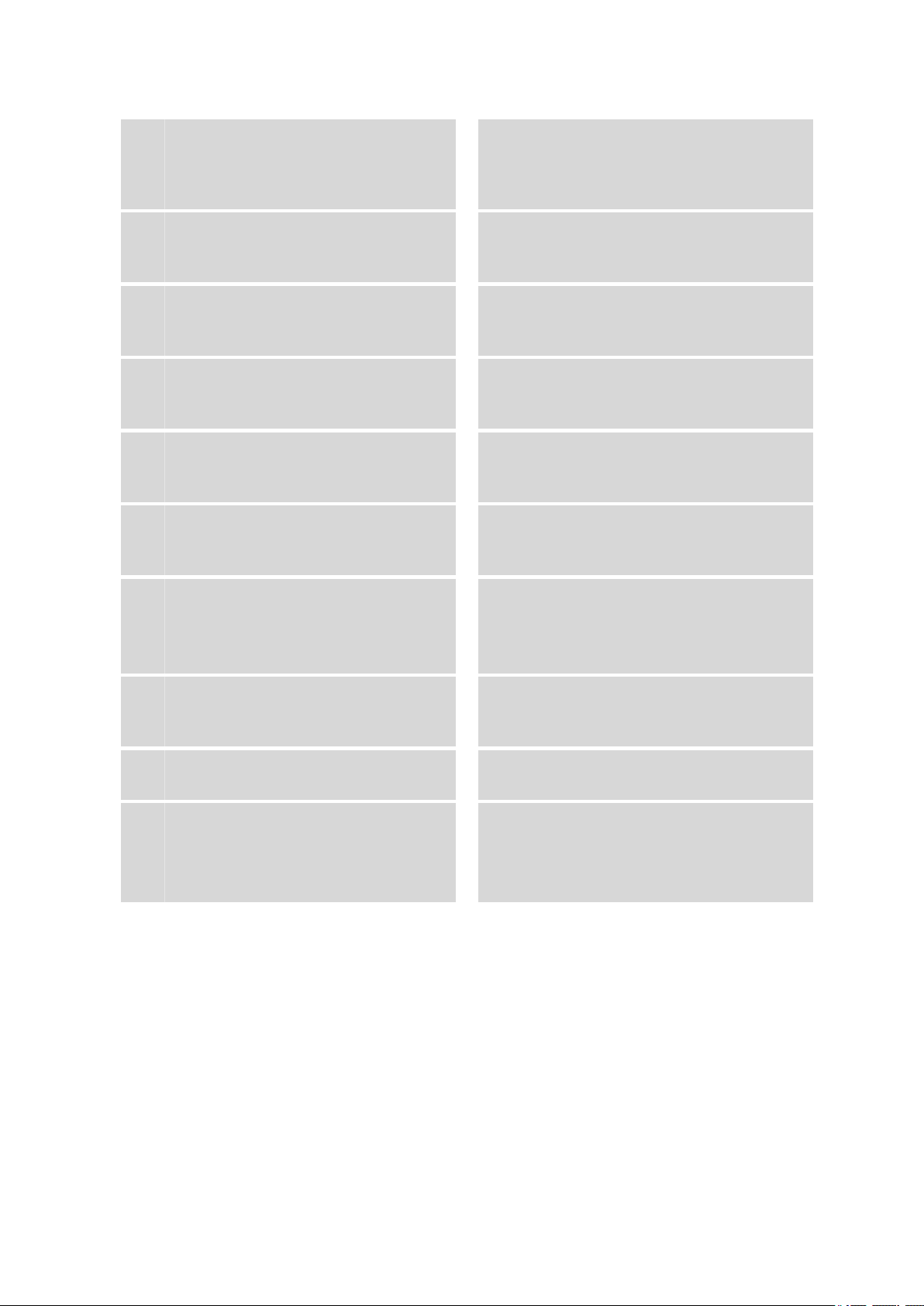

3.3 Installation diagram

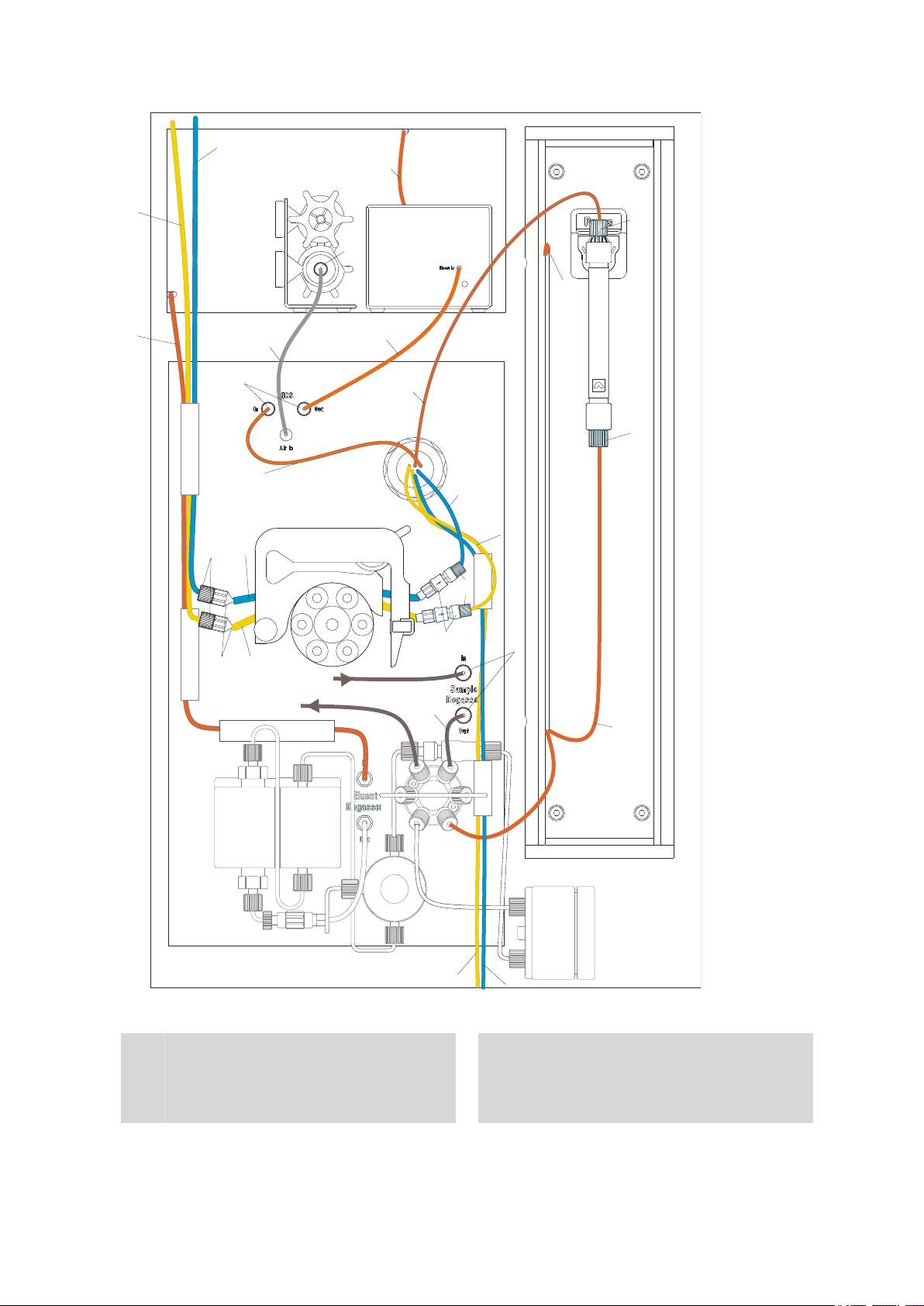

The following installation diagram shows the schematics of the front of

the instrument after installation has been completed with the connected

sample degasser. Many capillaries are already installed at the time the

instrument is delivered; these capillaries are not numbered in the diagram.

Numbered capillaries must be connected at the time of installation.

■■■■■■■■

14

881 Compact IC pro – Anion – MCS

Page 25

■■■■■■■■■■■■■■■■■■■■■■

1

2

6

19

19

16

18

7

8

9

10

11

12

13

14

3

4

19

20

21

19

17

5

15

22

22

23

2

3 Installation

Figure 3 Installation diagram 881 Compact IC pro – Anion – MCS

1

Eluent aspirating capillary (6.1834.080)

Connected to the eluent degasser.

Column input capillary (6.1831.150)

2

Connected to the injection valve and threaded into the capillary recesses of the column

heater.

881 Compact IC pro – Anion – MCS

■■■■■■■■

15

Page 26

3.3 Installation diagram

■■■■■■■■■■■■■■■■■■■■■■

MSM eluent inlet capillary

3

Labeled with in.

Detector inlet capillary

5

Regeneration solution aspirating capil-

7

lary (6.1803.020)

MSM regeneration solution inlet capil-

9

lary

Labeled with regenerant.

Rinsing solution aspirating capillary

11

(6.1803.020)

MSM rinsing solution inlet capillary

13

Labeled with rinsing solution.

MCS aspirating capillary

15

For aspirating air low in CO2 out of the CO

cartridge.

MSM eluent outlet capillary

4

Labeled with out.

Detector outlet capillary

6

Pump tubing (6.1826.320)

8

With orange/yellow stoppers, for the regeneration solution.

MSM regeneration solution outlet

10

capillary

Labeled with waste reg..

Pump tubing (6.1826.320)

12

With orange/yellow stoppers, for the rinsing

solution.

MSM rinsing solution outlet capillary

14

Labeled with waste rins..

Sample aspirating capillary

16

2

(6.1803.040)

Connection Sample Degasser – Sample Processor.

Sample aspirating capillary

17

(6.1803.040)

Connected to the injection valve. Can be

connected to the sample degasser if the

sample matrix requires it.

PEEK pressure screws, short

19

(6.2744.070)

Pump tubing connection (6.2744.180)

21

With safety device and filter, for connecting

capillaries to the outlet side of the peristaltic

pump.

Luer coupling (6.2744.120)

23

Mounted on the MCS aspirating capillary

with a short pressure screw (6.2744.070).

For connecting the CO2 adsorption cartridge.

Sample outlet capillary (6.1803.040)

18

Tubing olive (6.2744.034)

20

For connecting capillaries to the aspiration

side of the peristaltic pump.

PEEK pressure screws, long

22

(6.2744.090)

■■■■■■■■

16

881 Compact IC pro – Anion – MCS

Page 27

■■■■■■■■■■■■■■■■■■■■■■

3.4 Setting up the instrument

3.4.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

3.4.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

3.4.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

Place the instrument in a location of the laboratory which is suitable for

operation, free of vibrations, protected from corrosive atmosphere, and

contamination by chemicals.

3 Installation

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

3.5 Capillary connections in the IC system

This chapter contains general information concerning the capillary connections in the IC instruments and systems.

Generally speaking, capillary connections between two components of an

IC system are made up of one connection capillary and two pressure

screws with which the capillary is connected to the respective components.

881 Compact IC pro – Anion – MCS

■■■■■■■■

17

Page 28

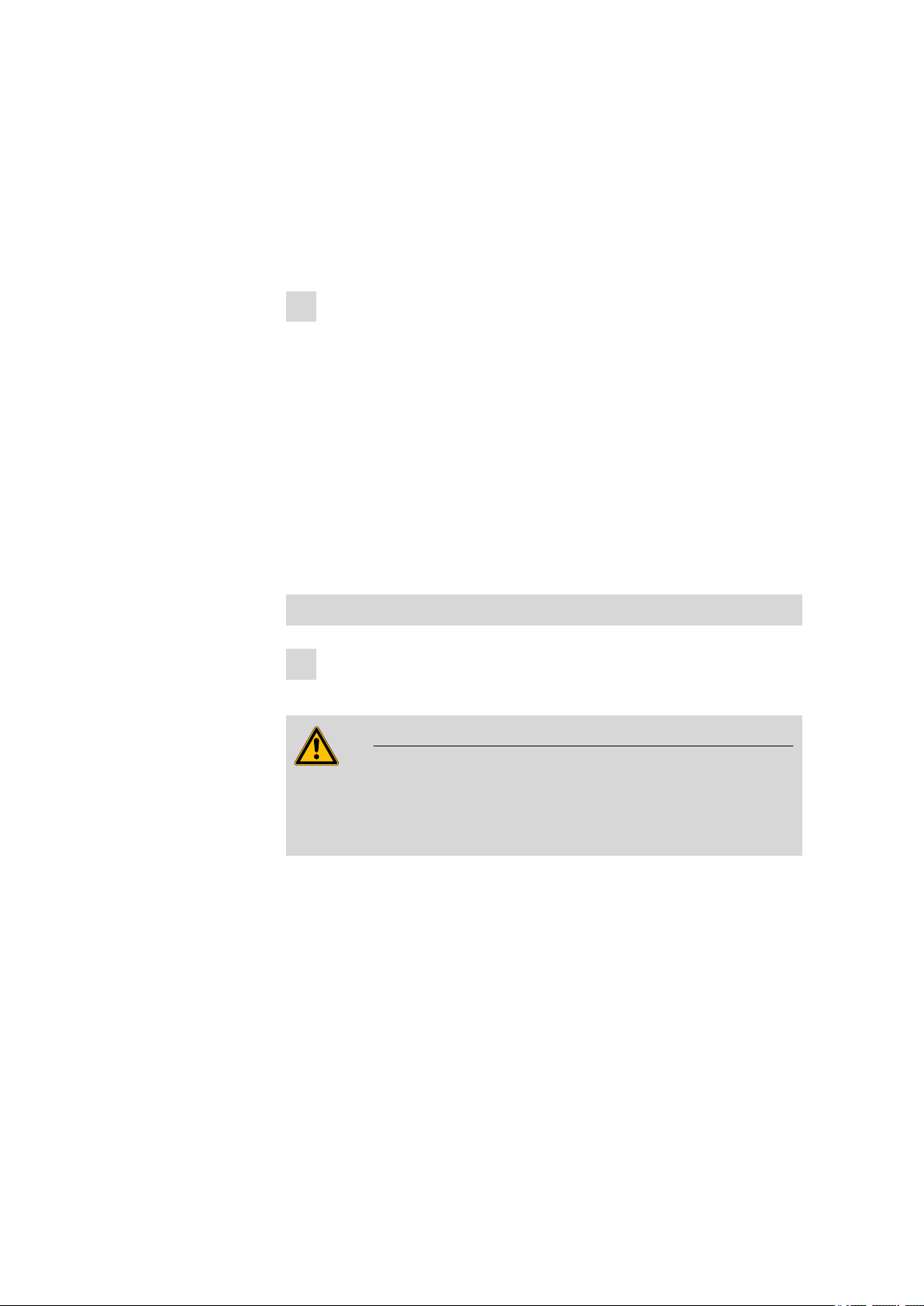

3.5 Capillary connections in the IC system

4

1

2 3

Pressure screws

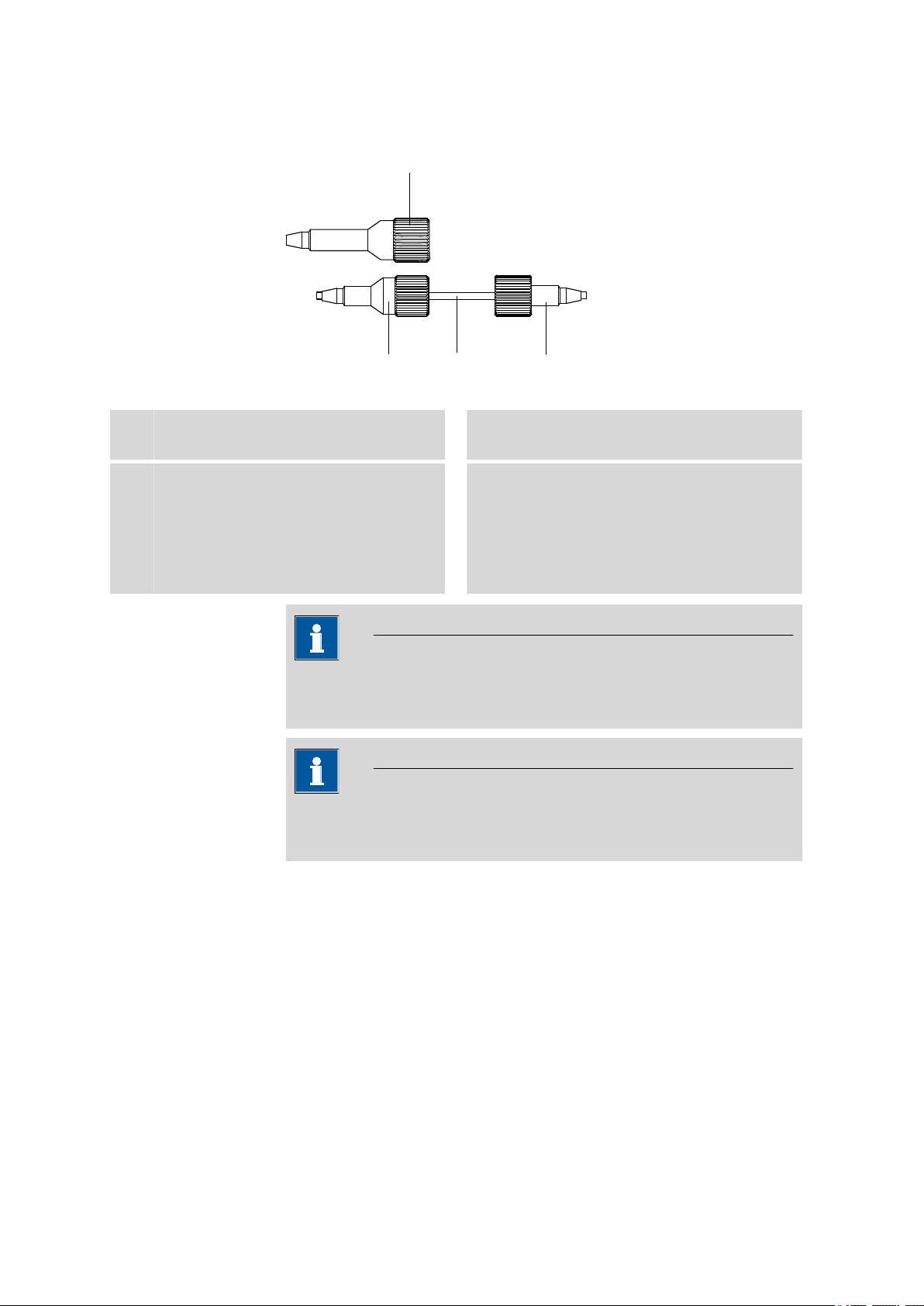

Figure 4 Connection of capillaries with pressure screws

■■■■■■■■■■■■■■■■■■■■■■

PEEK pressure screw (6.2744.014)

1

Use on the injection valve.

PEEK pressure screw, short

3

(6.2744.070)

For use on the high pressure pump, the

purge valve, the inline filter, the pulsation

absorber, the guard column and the separation column.

In order to keep the dead volume as low as possible, capillary connections should generally be as short as possible.

For an improved overview, capillary and tubing connections can be

bundled with the 6.1815.010 spiral band.

Note

Note

Connection capillary

2

PEEK pressure screw, long

4

(6.2744.090)

Use on special components. Is not used on

all instruments.

PEEK capillaries (polyetheretherketone)

■■■■■■■■

18

Connection capillaries

PEEK capillaries and PTFE capillaries are used in the IC system.

PEEK capillaries are temperature-resistant up to 100°C, stable under pressure up to 400 bar, flexible, chemically inert and exhibit an extremely

smooth surface. They can be readily cut down to the desired length with

the 6.2621.080 capillary cutter.

Usage:

■ PEEK capillaries (6.1831.010) with an internal diameter of 0.25 mm for

the entire high pressure range.

881 Compact IC pro – Anion – MCS

Page 29

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

■ PEEK capillaries (6.1831.030) with an internal diameter of 0.75 mm for

sample handling in the ultra trace range.

Caution

For the capillary connections between the injection valve and detector ,

PEEK capillaries with an internal diameter of 0.25 mm must be used.

These are already connected to a newly delivered instrument.

PTFE capillaries (polytetrafluoroethylene)

PTFE capillaries are transparent and enable visual tracing of the liquids to

be pumped. They are chemically inert, flexible and temperature-resistant

up to 80°C.

Usage:

PTFE capillaries (6.1803.0x0) are used for the low pressure range.

■ PTFE capillaries with internal diameter of 0.5 mm for sample handling.

■ PTFE capillaries with internal diameter of 0.97 mm for sample handling

as well as for rinsing solutions (they do not have to be in the scope of

delivery of the instrument).

Capillary connections

In order to achieve optimum analysis results, capillary connections in an IC

system must be absolutely tight and free of dead volume. Dead volume

occurs if two capillary ends connected to each other do not fit exactly,

thus allowing liquid to escape. There are two possible reasons for this:

■ The capillaries do not have exactly cut edges.

■ The two capillary ends do not completely meet.

One prerequisite for dead volume free capillary connection is, that both

capillary ends are cut exactly plane. Therefore we recommend only to cut

PEEK capillaries with the capillary cutter (6.2621.080).

881 Compact IC pro – Anion – MCS

Creating dead volume free capillary connections

To create dead volume free capillary connections, proceed as follows:

Slide the pressure screw over the capillary. Ensure that the capillary

1

protrudes 1–2 mm from the tip of the pressure screw.

Plug the capillary all the way into the connection or coupling until

2

the stop.

Only then start turning the pressure screw, while keeping the capil-

3

lary pressed in space.

■■■■■■■■

19

Page 30

3.6 Rear of the instrument

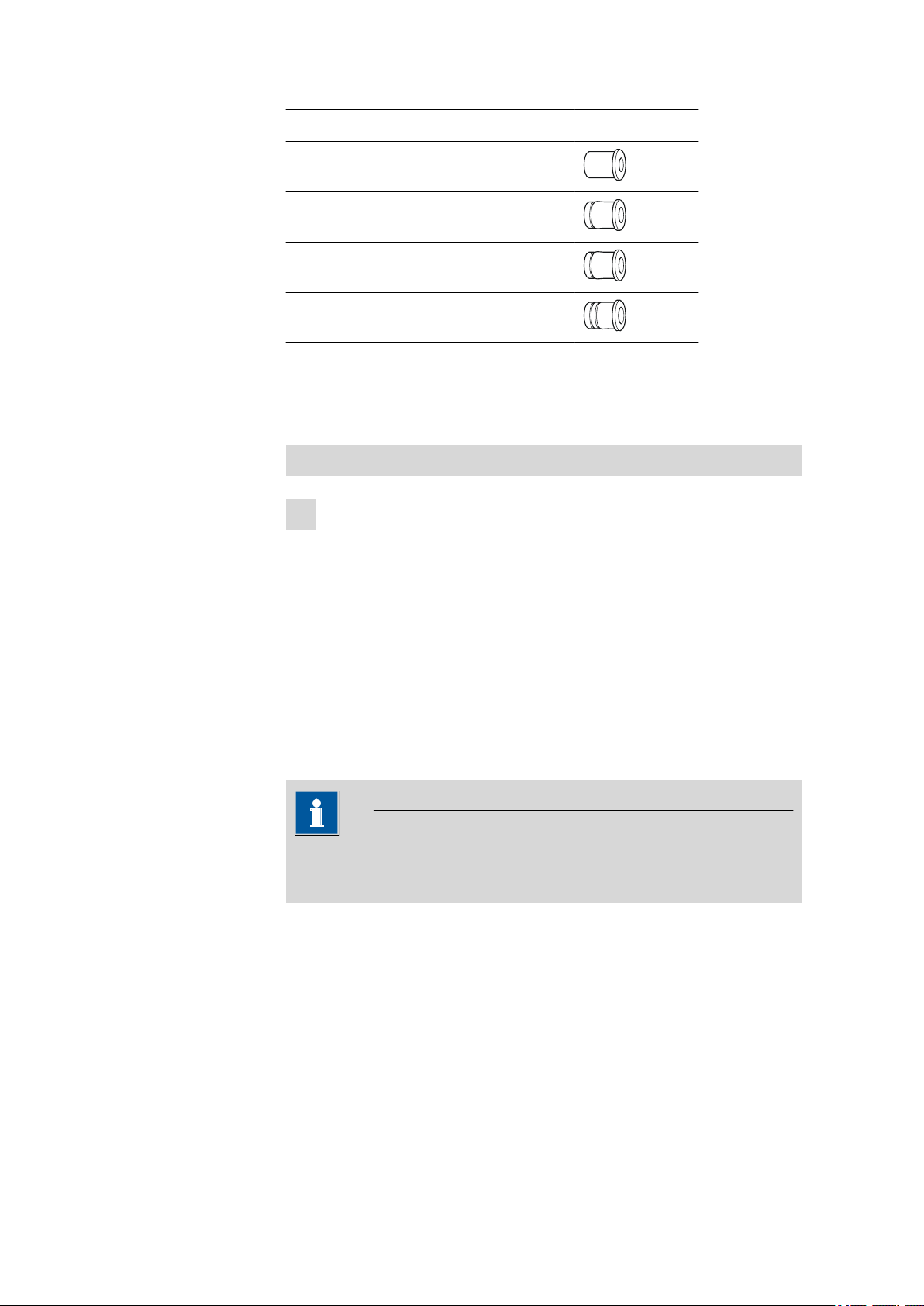

Colored sleeves for PEEK capillaries

The enclosed set of varicolored sleeves for PEEK capillaries (6.2251.000)

serves to easily differentiate the various flows of liquid in the system

through color coding. Each capillary leading a given liquid (e. g. eluent)

can be highlighted with sleeves of the same color.

To highlight a capillary, proceed as follows:

Slide a sleeve of a selected color over a capillary an move it to an

1

easily visible position.

If the capillary heats up, the sleeve shrinks and adapts to the form of

the capillary.

3.6 Rear of the instrument

3.6.1 Transport locking screws

To avoid damage to the high pressure pump and vacuum pump during

transport, the pumps are secured with transport locking screws .

■■■■■■■■■■■■■■■■■■■■■■

Remove these transport locking screws before the initial start-up.

Removing transport locking screws

In order to avoid damage to the pump, the transport locking screws

must be remounted each time the instrument undergoes major transport.

3.6.2 Leak sensor

The leak sensor detects escaping liquid which collects in the base tray of

the instrument.

To activate the leak sensor, the leak sensor connector plug (5-2) must be

connected, the instrument switched on and the leak sensor switched to

active in MagIC Net.

Remove all of the transport locking screws with the 6.2621.030 4

1

mm hexagon key and keep them in a safe place.

Warning

■■■■■■■■

20

881 Compact IC pro – Anion – MCS

Page 31

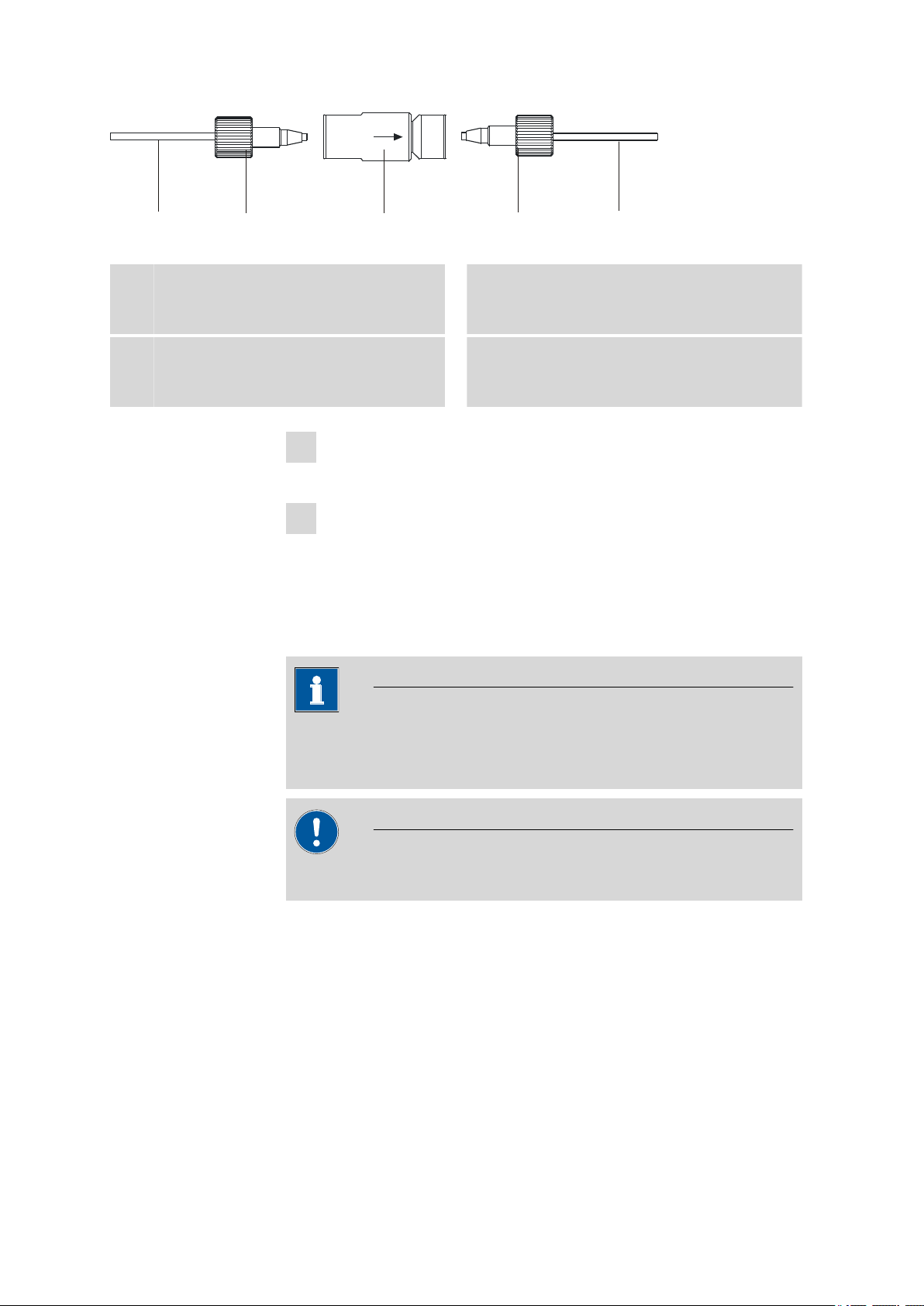

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

Connecting the leak sensor

Plug the leak sensor connector plug (5-2) into the leak sensor con-

1

nection socket (5-1) on the rear of the instrument .

3 Installation

Figure 5 Connection for the leak sensor on the rear of the instrument

Leak sensor connection socket

1

Is labeled with Leak Sensor.

Leak sensor connection cable

3

Is firmly mounted on the rear of the instrument.

Leak sensor connector plug

2

3.6.3 Drainage tubings

Fluid that escapes in the covering plate or in the detector chamber flows

through the drainage tubings into the base tray and past the leak sensor

into the waste container. This ensures that any leaks in the system will be

detected by the leak sensor.

881 Compact IC pro – Anion – MCS

■■■■■■■■

21

Page 32

3.6 Rear of the instrument

2

4

5

6

1

3

7

9

8

■■■■■■■■■■■■■■■■■■■■■■

Figure 6 Drainage tubings

Drainage tubing connection

1

For draining escaped liquid from the cover.

Drainage tubing connection

3

For draining escaped fluid from the detector

chamber.

Y connector (6.1807.010)

5

For connecting the two drainage tubings

(6-2) and (6-4).

Drainage tubing

7

Section of the 6.1816.020 silicon tubing.

Guides escaped fluid into a waste container.

Drainage tubing connection

9

Leads to the leak sensor.

Drainage tubing

2

Section of the 6.1816.020 silicon tubing. For

draining escaped liquid from the cover.

Drainage tubing

4

Section of the 6.1816.020 silicon tubing. For

draining escaped fluid from the detector

chamber.

Drainage tubing

6

Section of the 6.1816.020 silicon tubing.

Guides escaped fluid to the leak sensor.

Drainage tubing connection

8

For draining escaped fluid.

■■■■■■■■

22

881 Compact IC pro – Anion – MCS

Page 33

■■■■■■■■■■■■■■■■■■■■■■

Installing drainage tubings

Proceed as follows to install the drainage tubings:

Connect drainage tubing (6-2) to the drainage tubing connection

1

(6-1) and shorten to the required length.

Connect drainage tubing (6-4) to the drainage tubing connection

2

(6-3) and shorten to the required length.

Connect drainage tubing (6-2) and drainage tubing (6-4) to the Y

3

connector (6-5).

Connect drainage tubing (6-6) to the Y connector (6-5), shorten to

4

the required length and connect the other end of the drainage tubing to the drainage tubing connection (6-9).

Connect drainage tubing (6-7) to the drainage tubing connection

5

(6-8) and guide the other end into a waste container.

3 Installation

3.7 Capillary and cable feed-throughs

Several openings have been integrated for feeding through capillaries and

cables. These can be found at the door, at the rear panel, and below the

bottle holder and above the base tray (see Figure 7, page 24).

881 Compact IC pro – Anion – MCS

■■■■■■■■

23

Page 34

3.7 Capillary and cable feed-throughs

1

2

3

1

2

3

6

7

4

5

■■■■■■■■■■■■■■■■■■■■■■

Figure 7 Capillary and cable feed-throughs

Capillary feed-through

1

For feeding capillaries from the front to the

rear of the instrument.

Capillary feed-through

3

For feeding capillaries from the front to the

left side of the instrument.

Capillary feed-through

5

At the door of the instrument. For feeding

capillaries out of the instrument.

Cable feed-through

7

At the rear of the instrument. For feeding

the detector cable out of the detector chamber.

Do not feed capillaries through the Luer connectors (7-4). The capillaries

are fastened with PEEK pressure screws (6.2744.070) from inside to the

Luer connector. From outside, liquid can be aspirated or injected with a

syringe.

Capillary feed-through

2

Fro feeding capillaries from the front to the

right side of the instrument.

Luer connector

4

For connecting a (6.2816.020) syringe. For

manual sample feeding.

Capillary feed-through

6

At the rear of the instrument. For feeding

capillaries out of the detector chamber.

■■■■■■■■

24

881 Compact IC pro – Anion – MCS

Page 35

■■■■■■■■■■■■■■■■■■■■■■

3.8 Eluent

3.8.1 Connecting eluent bottle

The eluent is aspirated out of the eluent bottle via the eluent aspiration

tubing (8-1).

The eluent aspiration tubing is connected to the eluent degasser (see

Chapter 3.9, page 29). The tubing must be threaded through a suitable

capillary feed-through of the instrument before the other end can be

equipped.

You will require the parts from the following accessories for equipping the

eluent aspiration tubing:

■ 6.1602.160 Eluent bottle attachment GL 45

■ 6.2744.210 tubing adapter for aspiration filter

■ 6.2821.090 aspiration filter

To equip the eluent aspiration tubing proceed as follows:

3 Installation

Assembling eluent aspiration tubing

Guide the free end of the eluent aspiration tubing (8-1) out of the

1

instrument through a suitable capillary feed-through.

2

Installing eluent bottle attachment 6.1602.160

■ Slide tubing nipple (8-2) and O-ring (8-3) onto the eluent aspira-

tion tubing (8-1).

■ Push eluent aspiration tubing (8-1) through the bottle attachment

(8-4) and screw tight.

881 Compact IC pro – Anion – MCS

■■■■■■■■

25

Page 36

3.8 Eluent

1 2

3

4

■■■■■■■■■■■■■■■■■■■■■■

Figure 8 Installing eluent bottle attachment

Eluent aspiration tubing 6.1834.080

1

O-ring

3

From accessories set 6.1602.160.

3

Filter holder

1

From accessories set 6.2744.210.

Tubing nipple

2

From accessories set 6.1602.160.

Bottle attachment

4

From accessories set 6.1602.160.

Mounting aspiration filter

■ Insert filter holder (9-1) into the aspiration filter (9-2) and screw

tight.

Figure 9 Mounting aspiration filter

Aspiration filter 6.2821.090

2

■■■■■■■■

26

881 Compact IC pro – Anion – MCS

Page 37

■■■■■■■■■■■■■■■■■■■■■■

3

4

5

4

Install tubing weighting and aspiration filter

Figure 10 Install tubing weighting and aspiration filter

3 Installation

Eluent aspiration tubing 6.1834.080

1

Tubing weighting

3

From accessories set 6.2744.210.

Aspiration filter 6.2821.090

5

With filter holder from accessories set

6.2744.210.

■ Slide the tubing weighting (10-3) onto the eluent aspiration tub-

■ Slide the clamping screw (10-4) onto the eluent aspiration tubing

■ Insert the eluent aspiration tubing (10-1) into the aspiration filter

■ Screw together clamping screw (10-4) and filter holder (9-1).

Eluent bottle attachment 6.1602.160

2

Clamping screw

4

From accessories set 6.2744.210.

ing (10-1).

(10-1).

(10-5). The end of the tubing should approximately reach to the

center of the aspiration filter.

Figure 11

881 Compact IC pro – Anion – MCS

Eluent aspiration tubing fully equipped.

5

Mounting eluent aspiration tubing to the eluent bottle

■ Insert the eluent aspiration tubing into the eluent bottle (12-10).

■■■■■■■■

27

Page 38

3.8 Eluent

1

1

2

3

4

5

6

7

89

10

11

12

13

14

■■■■■■■■■■■■■■■■■■■■■■

■ Fasten the completely equipped bottle attachment (12-10) on the

eluent bottle. The aspiration filter (12-6) must rest on the base of

the eluent bottle.

■ Close the remaining small opening on the bottle attachment with

a threaded stopper from the accessories set.

6

Mounting the adsorber tube

Note

In the case of alkaline eluents and eluents with lower buffer

capacity, the eluent bottle must be equipped with a CO2 adsorber

(12-4).

■ First, place a piece of cotton (12-3), then the CO

adsorber (12-4)

2

in the large opening of the adsorber tube (12-2) and close with

the plastic cover.

■ Fasten the adsorber tube (12-2) using the SGJ clip (12-12) onto

the bottle attachment (12-11).

28

Eluent aspiration tubing 6.1834.080

1

For aspirating the eluent. Pre-installed.

■■■■■■■■

Figure 12

Eluent bottle – connected

Adsorber tube 6.1609.000

2

881 Compact IC pro – Anion – MCS

Page 39

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

Wadding

3

Eluent

5

Filter holder

7

From accessories set 6.2744.210.

Tubing weighting

9

From accessories set 6.2744.210.

Bottle attachment 6.1602.160

11

Tubing nipple

13

3.9 Eluent degasser

Gas bubbles in the eluent lead to an unstable baseline, as high pressure

pumps can transport liquids, but not gases. The eluent therefore has to be

degassed, before it reaches the high pressure pump.

The eluent degasser removes gas bubbles and dissolved gases from the

eluent. For degassing, the eluent flows into a vacuum chamber through a

special fluoropolymer capillary.

CO2 adsorber

4

Adsorbs CO2 from the air (e.g. Merck soda

lime with indicator, no. 6839.10).

Aspiration filter 6.2821.090

6

Clamping screw

8

From accessories set 6.2744.210.

Eluent bottle 6.1608.070

10

SGJ clip 6.2023.020

12

Threaded stopper

14

Note

The eluent degasser is already installed in the newly delivered instrument. The following installation instructions must only be followed, if

the connections to the degasser had to be disconnected for maintenance.

881 Compact IC pro – Anion – MCS

■■■■■■■■

29

Page 40

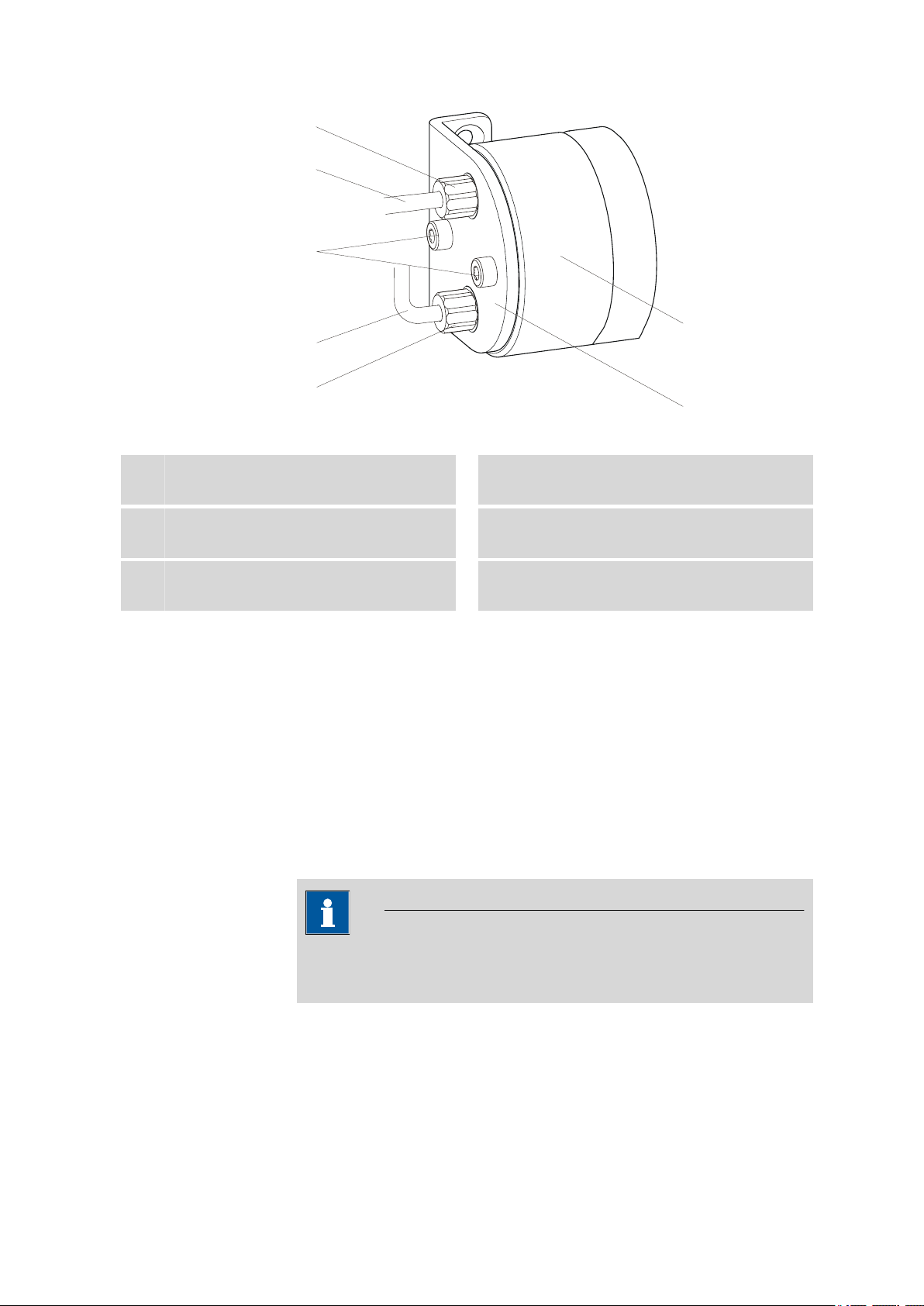

3.9 Eluent degasser

5

6

1

3

4

■■■■■■■■■■■■■■■■■■■■■■

Connecting the eluent degasser

Figure 13 Eluent degasser

Eluent degasser input

1

Tubing flare

3

With tubing nipple.

Eluent aspiration tubing (6.1834.080)

5

For aspirating the eluent. The clamping

screw (13-4) is firmly mounted.

1

■ Insert the eluent aspiration tubing (13-5) into the eluent degasser

■ Carefully tighten the clamping screw (13-4).

■ Insert connection capillary (13-6) (the end with the longer clamp-

2

■ Carefully tighten the clamping screw (13-4).

■ Connect the other end of the connection capillary (13-6) (with

Eluent degasser output

2

Clamping screw

4

Connection tubing (6.1834.090)

6

Connection from the eluent degasser to the

high pressure pump (see Chapter 3.10, page

31). The clamping screw (13-4) is firmly

mounted.

Caution

The clamping screws (13-4) must be tightened carefully. Use the

wrench (6.2621.050) to do this.

input (13-1).

ing screw (13-4)) into the eluent degasser output (13-2).

the shorter clamping screw ) to the high pressure pump (14-9)

(see "Connecting inlet to the high pressure pump", page 32).

■■■■■■■■

30

881 Compact IC pro – Anion – MCS

Page 41

■■■■■■■■■■■■■■■■■■■■■■

10

8

9

1

2

3

4

5

6

2

7

2

2

2

11

2

12

2

13

3.10 High pressure pump

The intelligent and low pulsation high pressure pump pumps the eluent

through the system. It is equipped with a chip on which its technical specifications and "life history" (operating hours, service data, … ) are saved.

The purge valve is used for deaerating (see Chapter 3.10.2, page 33)

the high pressure pump.

3.10.1 Capillary connections high pressure pump/purge valve

Note

All of the capillary connections of the high pressure pump and the

purge valve are already installed in the newly delivered instrument.

3 Installation

Connection capillary

1

PEEK capillary, connects main piston and

auxiliary piston.

Outlet valve holder

3

881 Compact IC pro – Anion – MCS

Figure 14

Capillary connections high pressure pump/purge valve

PEEK pressure screw, short

2

(6.2744.070)

Pump head (6.2824.110)

4

■■■■■■■■

31

Page 42

3.10 High pressure pump

5

1

2

3

4

■■■■■■■■■■■■■■■■■■■■■■

Fastening screws

5

For fastening the pump head.

Pump head inlet capillary

7

PEEK capillary at the input of the pump

head.

Coupling

9

For the connection of the eluent path at the

input of the high pressure pump. Can be

ordered together with the pressure screw

(14-8) under the number (6.2744.230).

Purge valve

11

For deaerating the high pressure pump.

With rotary knob in the center and pressure

sensor.

Connection capillary

13

Connects the output of the pump head with

the purge valve.

Note

Inlet valve holder

6

Pressure screw

8

For connecting a PEEK capillary to the coupling (14-9).

Deaerating capillary

10

For aspirating the eluent when deaerating

the high pressure pump (see Chapter

3.10.2, page 33).

Connection capillary

12

For connecting the inline filter (see Chapter

3.11, page 35).

The eluent aspiration capillary is already installed in the newly delivered

instrument. The following installation instructions need not be carried

out at the time of initial installation.

Connecting inlet to the high pressure pump

Figure 15

Pressure screw

1

For connecting the coupling (15-2) to the

pump head inlet capillary (14-7).

Can be ordered together with the coupling

under the number (6.2744.230).

High pressure pump – Connect inlet

Coupling (6.2744.230)

2

For connecting the eluent connection capillary (15-4) to the input of the high pressure

pump.

■■■■■■■■

32

881 Compact IC pro – Anion – MCS

Page 43

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

Clamping screw

3

Backup ring

5

Eluent aspiration tubing

4

Eluent aspiration tubing (6.1834.080) or

(6.1834.090).

1

Connecting coupling

Fasten the coupling (15-2) with a pressure screw (15-1) on the pump

head inlet capillary (14-7).

2

Connecting eluent aspiration tubing

Caution

The clamping screws must be tightened carefully. To tighten, grip

the coupling (15-2) with the key (6.2739.000) and grip the clamping screw (15-3) with the wrench (6.2621.050).

■ Plug the eluent aspiration tubing (15-4) into the coupling (15-2).

■ Tighten the clamping screw (15-3).

3.10.2 Deaerating the high pressure pump

The high pressure pump will only operate perfectly if the pump head contains no more air bubbles. Therefore it must be deaerated during initial

start-up and after every change of eluent.

Caution

The high pressure pump must not be deaerated before the initial startup (see Chapter 4.1, page 63).

Deaerate the high pressure pump as follows (see Figure 16, page 34):

Deaerate the high pressure pump

The instrument must be connected to the PC and switched on to deaerate

the high pressure pump.

881 Compact IC pro – Anion – MCS

■■■■■■■■

33

Page 44

3.10 High pressure pump

5

1

2

6

7

5

3

4

5

■■■■■■■■■■■■■■■■■■■■■■

Figure 16 Deaerate the high pressure pump

Syringe 10 mL (6.2816.020)

1

For aspirating the eluent.

Purging needle (6.2816.040)

3

PEEK pressure screws, short

5

(6.2744.070)

Purge valve rotary knob

7

Luer connector

2

Part of the purging needle (6.2816.040)

Deaerating capillary

4

Purge valve

6

1

Connecting the purging needle

■ Push the end of the purging needle (16-3) over the end of the

deaerating capillary (16-4) on the purge valve.

2

Connecting the syringe

■ Insert syringe (16-1) in the Luer connector (16-2) of the purging

needle (see Figure 16, page 34).

3

Opening purge valve

■ Open the rotary knob (16-7) by approx. ½ rotation counterclock-

wise.

4

Setting the flow rate

■ Start MagIC Net™ (if not yet started).

■ Ensure that the eluent aspiration tubing is immersed sufficiently in

the eluent.

■ Let the high pressure pump run.

■■■■■■■■

34

881 Compact IC pro – Anion – MCS

Page 45

■■■■■■■■■■■■■■■■■■■■■■

5

6

3.11 Inline filter

Between the purge valve and the pulsation absorber the inline filter

(6.2821.120) is installed as protection against particles.

Inline filters protect the separation column securely against possible contamination from the eluent. Inline filters can however also just as well be

used for the purpose of protecting the suppressor against contaminations

in the regeneration or rinsing solutions. The filter platelets with a pore size

of 2 µm can be replaced quickly and easily. They remove particles like e. g.

bacteria and algae from the solutions.

3 Installation

Aspirating eluent

■ Aspirate with the syringe (16-1) until bubble-free eluent flows into

the syringe.

Completing deaerating

■ Switch off high pressure pump.

■ Close rotary knob (16-7).

■ Remove syringe (16-1) from the Luer connector (16-2).

■ Pull the purging needle (16-3) out of the deaerating capillary

(16-4).

Note

The inline filter is already installed in the newly delivered instrument.

The following installation instructions need not be carried out at the

time of initial installation.

Installing the inline filter

Caution

Observe the flow direction marked on the filter housing for the connection of the inline filter.

881 Compact IC pro – Anion – MCS

■■■■■■■■

35

Page 46

3.12 Pulsation absorber

2 3

2 4

1

Figure 17 Connecting the inline filter

■■■■■■■■■■■■■■■■■■■■■■

Connection capillary

1

Connects the purge valve with the inline filter

Inline filter (6.2821.120)

3

Protects against particles.

Screw on the connection capillary running from the purge valve to

1

the input side of the inline filter using a pressure screw (6.2744.070).

Screw on the connection capillary running to the pulsation absorber

2

to the output side of the inline filter using a pressure screw

(6.2744.070).

3.12 Pulsation absorber

Note

PEEK pressure screws, short

2

(6.2744.070)

Connection capillary

4

Connects the inline filter with the pulsation

absorber.

■■■■■■■■

36

The pulsation absorber is already installed in the newly delivered instrument.

Caution

The pulsation absorber is maintenance-free and may not be opened.

The pulsation absorber protects the separation column from damage

caused by pressure fluctuations when switching the injection valve, and

reduces interfering pulsations during highly sensitive measurements. In

order to ensure these functionalities, it must be connected between the

high pressure pump (see Chapter 3.10, page 31) and injection valve (see

Chapter 3.14, page 39).

The pulsation absorber can be operated in both directions.

881 Compact IC pro – Anion – MCS

Page 47

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

3

4

5

6

3 Installation

Figure 18 Pulsation absorber – Connection

Connection capillary

1

Connection to the inline filter.

PEEK pressure screws, short

3

(6.2744.070)

Pulsation absorber (6.2620.150)

5

3.13 Sample degasser

The sample degasser removes gas bubbles and dissolved gases from the

sample. For degassing, the sample flows into a vacuum chamber through

a special fluoropolymer capillary.

Gas bubbles in the sample lead to poor reproducibility, as the quantity of

sample in the sample loop would not always be the same. Samples (containing gas) should therefore be degassed before injection. For this the

sample is sucked through a degasser chamber before injection, whereby

any gas bubbles are automatically removed.

Note

Fastening screws

2

Holder for pulsation absorber

4

Connection capillary

6

Connection to the injection valve.

When using the sample degasser, the rinsing time extends by at least 2

minutes.

881 Compact IC pro – Anion – MCS

■■■■■■■■

37

Page 48

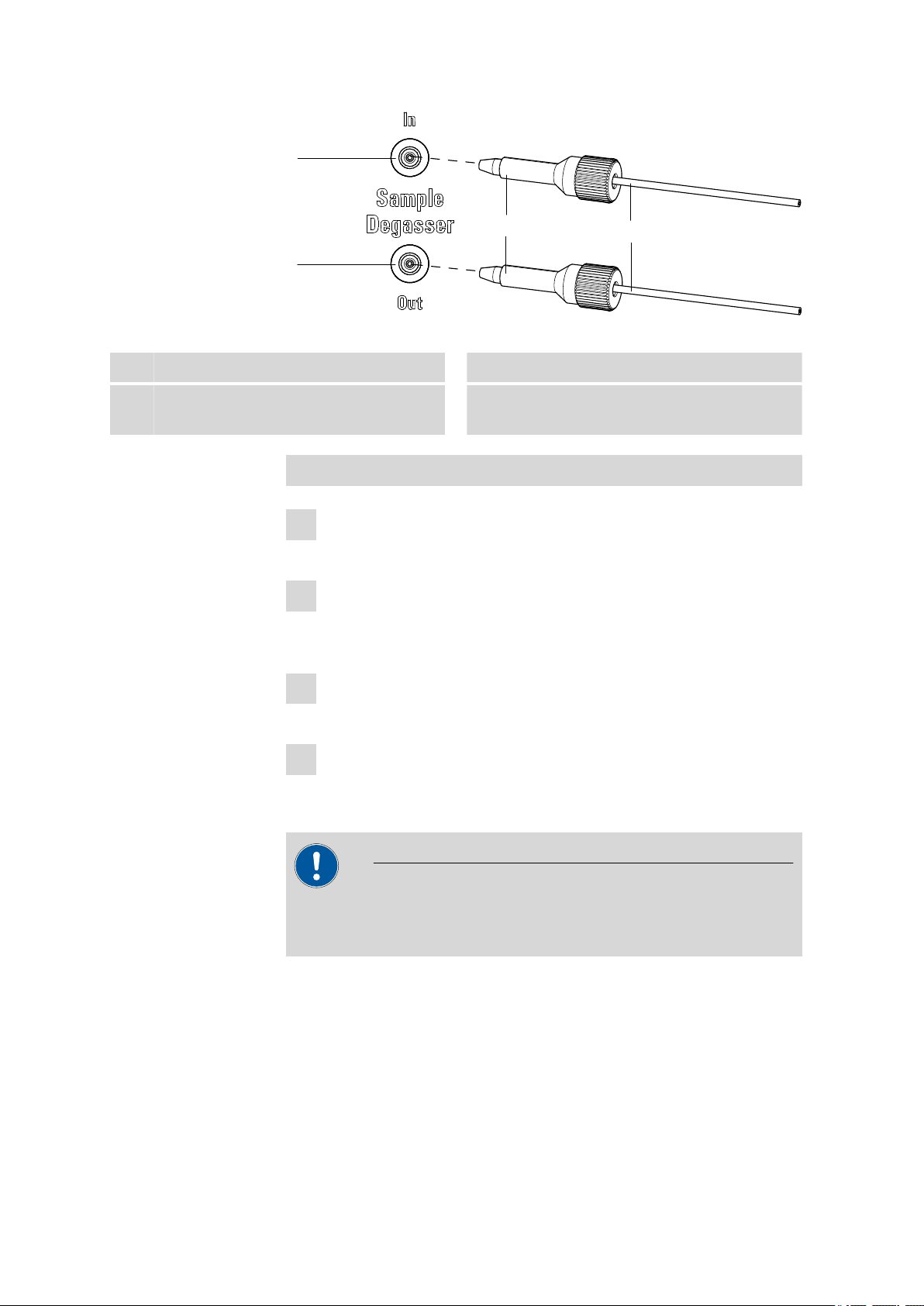

3.13 Sample degasser

1

2

3

4

■■■■■■■■■■■■■■■■■■■■■■

Figure 19 Sample degasser

Sample degasser input

1

PEEK pressure screw, long

3

(6.2744.090)

Sample degasser output

2

Connection capillaries (6.1803.040)

4

Connecting the sample degasser

Remove and keep the threaded stoppers (6.2744.220) from the input

1

and output of the sample degasser.

Connect the end of the sample aspirating capillary (6.1803.040) con-

2

nected to the injection valve to the output of the sample degasser

(19-2), using a long PEEK pressure screw (19-3).

Connect the connection capillary (6.1803.040) to the input of the

3

sample degasser (19-1), using a long PEEK pressure screw (19-3).

Guide the other end of the connection capillary out of the instrument

4

through a capillary feed-through and connect it with the Sample Processor, if applicable.

Caution

If the sample degasser is not used, the input and output must be

sealed with the threaded stoppers (6.2744.220).

■■■■■■■■

38

881 Compact IC pro – Anion – MCS

Page 49

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

5

6

2

4

5

7

7

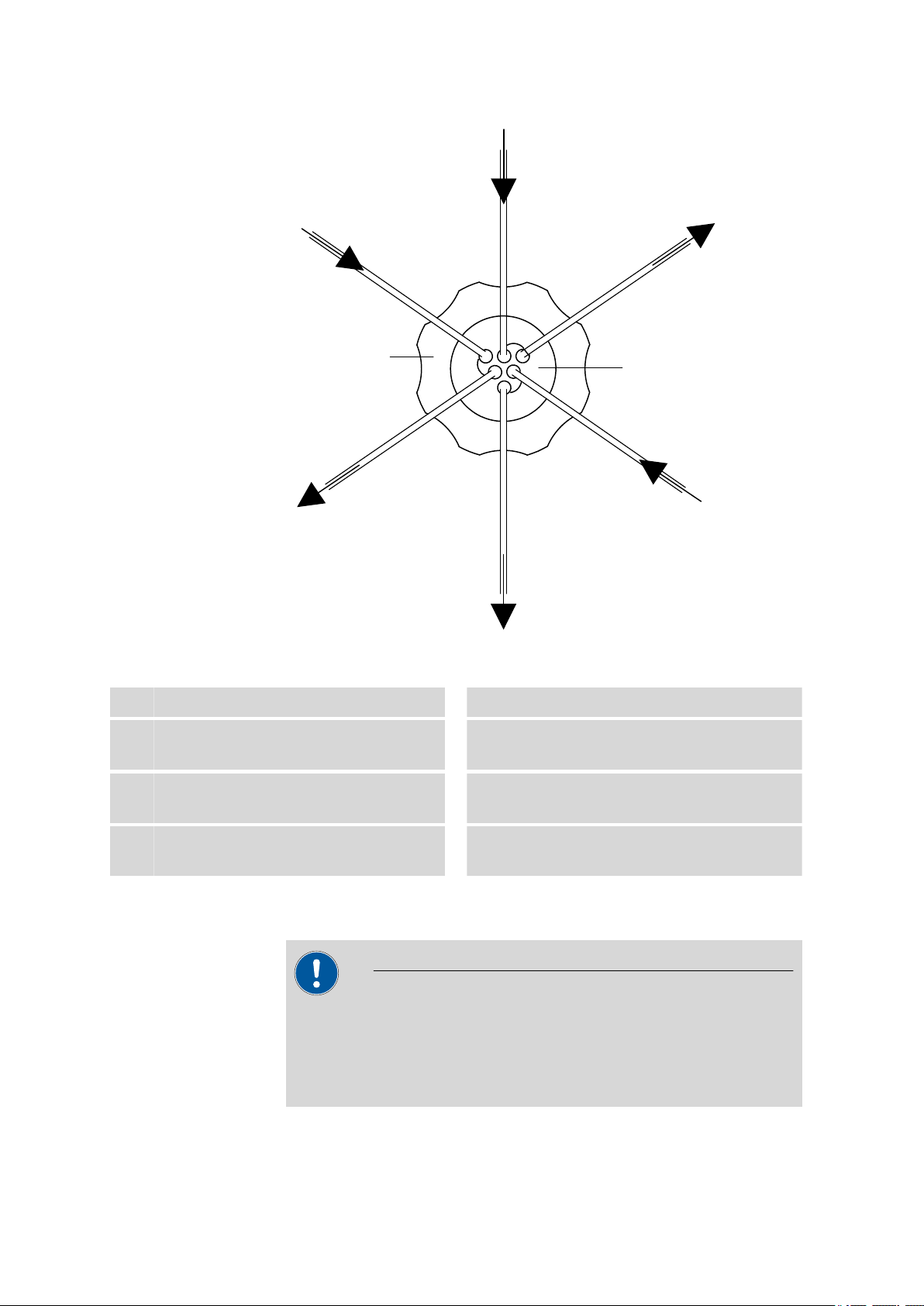

3.14 Injection valve

The injection valve connects the eluent and sample path. Through rapid

and precise valve switchover a precise amount of sample solution defined

by the size of the sample loop is injected and rinsed with eluent onto the

separation column.

3.14.1 Connecting the injection valve

The injection valve has six connectors: two for the sample path (connectors 1 and 2), two for the eluent path (connectors 4 and 5) and two for

the sample loop (connectors 3 and 6).

Note

The capillaries of the eluent path and the sample path and the sample

loop are already installed in the newly delivered instrument.

3 Installation

Figure 20

Injection valve

1

Connection capillary

3

Connected to connector 4. Carries eluent to

the injection valve.

Connection capillary

5

Connected to connector 1. Carries sample to

the injection valve.

PEEK pressure screw 6.2744.010

7

881 Compact IC pro – Anion – MCS

Injection valve – connected

Sample loop

2

Connected to connectors 3 and 6.

Connection capillary (column inlet

4

capillary)

Connected to connector 5. Carries eluent to

the separation column.

Connection capillary

6

Connected to connector 2. Carries sample to

the waste container.

■■■■■■■■

39

Page 50

3.14 Injection valve

1

2

4 5

3 6

12

4 5

3 6

1

2

4

3

5

4

3

1

2

A B

■■■■■■■■■■■■■■■■■■■■■■

Replacing the sample loop

The sample loop can be replaced, depending on requirements. For additional information concerning selection of the appropriate sample loop,

see Chapter 3.14.3, page 41.

Note

Use only 6.2744.010 PEEK pressure screws for connecting capillaries

and sample loop to the injection valve.

1

Removing existing sample loop

■ Loosen 6.2744.010 pressure screws at connector 3 and connec-

tor 6.

■ Remove sample loop.

2

Mounting new sample loop

■ Fasten one end of the sample loop (20-2) with a 6.2744.010

PEEK pressure screw (20-7) to connector 3.

■ Fasten the other end of the sample loop (20-2) with a second

6.2744.010 PEEK pressure screw (20-7) to connector 6.

3.14.2 Mode of operation of the injection valve

The injection valve (see Figure 21, page 40) can adopt two valve positions - FILL and INJECT. Switching back and forth between the two valve

positions determines whether the sample path or the eluent path is guided through the sample loop. The following figure provides a schematic

display of the flow paths of the two valve positions.

Figure 21

Injection valve – Positions

Position FILL

A

■■■■■■■■

40

Position INJECT

B

881 Compact IC pro – Anion – MCS

Page 51

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

Eluent input

1

Capillary coming from the high pressure

pump.

Sample input

3

Sample aspirating capillary.

Sample loop

5

Position A In the position FILL, the sample solution flows

Position B In the position INJECT, the eluent flows through

Eluent output

2

Capillary to the column.

Sample output

4

Capillary to waste container.

through the sample loop to the waste container.

The eluent flows directly to the separation column at the same time.

the sample loop to the separation column. If

sample solution is to be found in the sample

loop at the time of the valve switchover, then

this will be conveyed along with the eluent, thus

making its way to the separation column. The

flow in the sample path is either stopped or the

sample flows directly to the waste container.

3.14.3 Selecting the sample loop

The amount of sample solution injected depends on the volume of the

sample loop. The choice is made on the basis of the application. The following sample loops are normally used:

Cation determination

Anion determination with suppression 20 µL

Anion determination without suppression 100 µL

3.15 Column heater

The perfect isolation of the column chamber ensures thermally stable conditions for the separation column. The temperature of the column heater

can be set in the software.

10 µL

881 Compact IC pro – Anion – MCS

■■■■■■■■

41

Page 52

3.15 Column heater

1

2

2

3

4

■■■■■■■■■■■■■■■■■■■■■■

Figure 22 Column heater

Column holder

1

For engaging the column. With column

detection.

Holder plate

3

For fixing the capillaries that have been

threaded in.

Capillary recesses

2

For threading in the capillaries to be tempered

Capillary feed-throughs

4

For guiding the capillaries in and/or out of

the column chamber.

The column heater contains a column holder (22-1) equipped with chip

recognition. The separation column (see Chapter 3.21, page 60) is

clicked into the column holder with the chip.

The capillaries must be guided into and out of the column heater via suitable capillary feed-throughs (22-4).

■■■■■■■■

42

881 Compact IC pro – Anion – MCS

Page 53

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

In order to bring the eluent to the required temperature, the capillaries

must be guided through the capillary recesses (22-2) before connection to

the separation column.

Note