Page 1

872 Extension Module

IC Module – 2.872.0030

Manual

8.872.8004EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

872 Extension Module

IC Module – 2.872.0030

8.872.8004EN

Manual

01.2010 zst

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.2 Intended use ......................................................................... 2

1.3 About the documentation ................................................... 2

1.3.1 Content and scope .................................................................. 2

1.3.2 Symbols and conventions ........................................................ 3

1.4 Safety instructions ................................................................ 4

1.4.1 General notes on safety ........................................................... 4

1.4.2 Electrical safety ........................................................................ 4

1.4.3 Tubing and capillary connections ............................................. 5

1.4.4 Flammable solvents and chemicals ........................................... 5

1.4.5 Recycling and disposal ............................................................. 5

2 Overview of the instrument 7

Table of contents

2.1 Front ...................................................................................... 7

2.2 Rear ........................................................................................ 8

3 Assembly 9

3.1 General .................................................................................. 9

3.2 Mounting the extension module onto the IC instru-

ment ..................................................................................... 10

3.3 Mounting the extension module below the IC instru-

ment ..................................................................................... 13

3.4 Setting up the extension module next to the IC instru-

ment ..................................................................................... 16

3.5 Transport locking screws ................................................... 20

4 Installation 21

4.1 About this chapter .............................................................. 21

4.2 Installation overview .......................................................... 21

4.3 Installation diagram ........................................................... 22

4.4 Eluent ................................................................................... 23

4.4.1 Connecting eluent bottle ....................................................... 23

872 Extension Module IC Module

4.5 Eluent degasser ................................................................. 27

4.6 High pressure pump ........................................................... 29

4.6.1 Capillary connections high pressure pump/purge valve ........... 29

4.6.2 Deaerating the high pressure pump ....................................... 31

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

4.7 Inline filter ........................................................................... 33

4.8 Pulsation damper ............................................................... 34

4.9 Injection valve ..................................................................... 35

4.9.1 Connecting the injection valve ............................................... 35

4.9.2 Mode of operation of the injection valve ............................... 37

4.9.3 Selecting the sample loop ...................................................... 38

5 Set to work 39

6 Operation and maintenance 40

6.1 General information ........................................................... 40

6.1.1 Care ...................................................................................... 40

6.1.2 Maintenance by Metrohm Service .......................................... 40

6.1.3 Operation .............................................................................. 40

6.1.4 Shutting down ...................................................................... 41

6.2 Door ..................................................................................... 41

6.3 Eluent ................................................................................... 41

6.3.1 Production ............................................................................. 41

6.3.2 Operation .............................................................................. 42

6.4 High pressure pump ........................................................... 42

6.4.1 Protection .............................................................................. 42

6.4.2 Maintenance ......................................................................... 43

6.5 Inline filter ........................................................................... 53

6.5.1 Maintenance ......................................................................... 53

6.6 Inline sample preparation .................................................. 55

6.7 Rinsing the sample path .................................................... 55

6.8 Injection valve .................................................................... 57

6.8.1 Protection .............................................................................. 57

6.9 Quality Management and validation with Metrohm ....... 57

7 Troubleshooting 58

7.1 Problems and their solutions ............................................. 58

8 Technical specifications 60

8.1 Reference conditions .......................................................... 60

8.2 Instrument ........................................................................... 60

8.3 Ambient conditions ............................................................ 60

■■■■■■■■

IV

8.4 Housing ............................................................................... 61

8.5 Eluent degasser .................................................................. 61

8.6 High pressure pump ........................................................... 61

8.7 Injection valve ..................................................................... 62

872 Extension Module IC Module

Page 7

■■■■■■■■■■■■■■■■■■■■■■

9 Conformity and warranty 64

10 Accessories 68

Index 75

Table of contents

8.8 Interfaces ............................................................................. 62

8.9 Safety specification ............................................................ 62

8.10 Electromagnetic compatibility (EMC) ................................ 63

8.11 Weight ................................................................................. 63

9.1 Declaration of Conformity ................................................ 64

9.2 Quality Management Principles ........................................ 65

9.3 Warranty (Guarantee) ........................................................ 66

10.1 Scope of delivery ................................................................ 68

872 Extension Module IC Module

■■■■■■■■

V

Page 8

Table of figures

Table of figures

Figure 1 Front 872 Extension Module IC Module ............................................. 7

Figure 2 Rear 872 Extension Module IC Module .............................................. 8

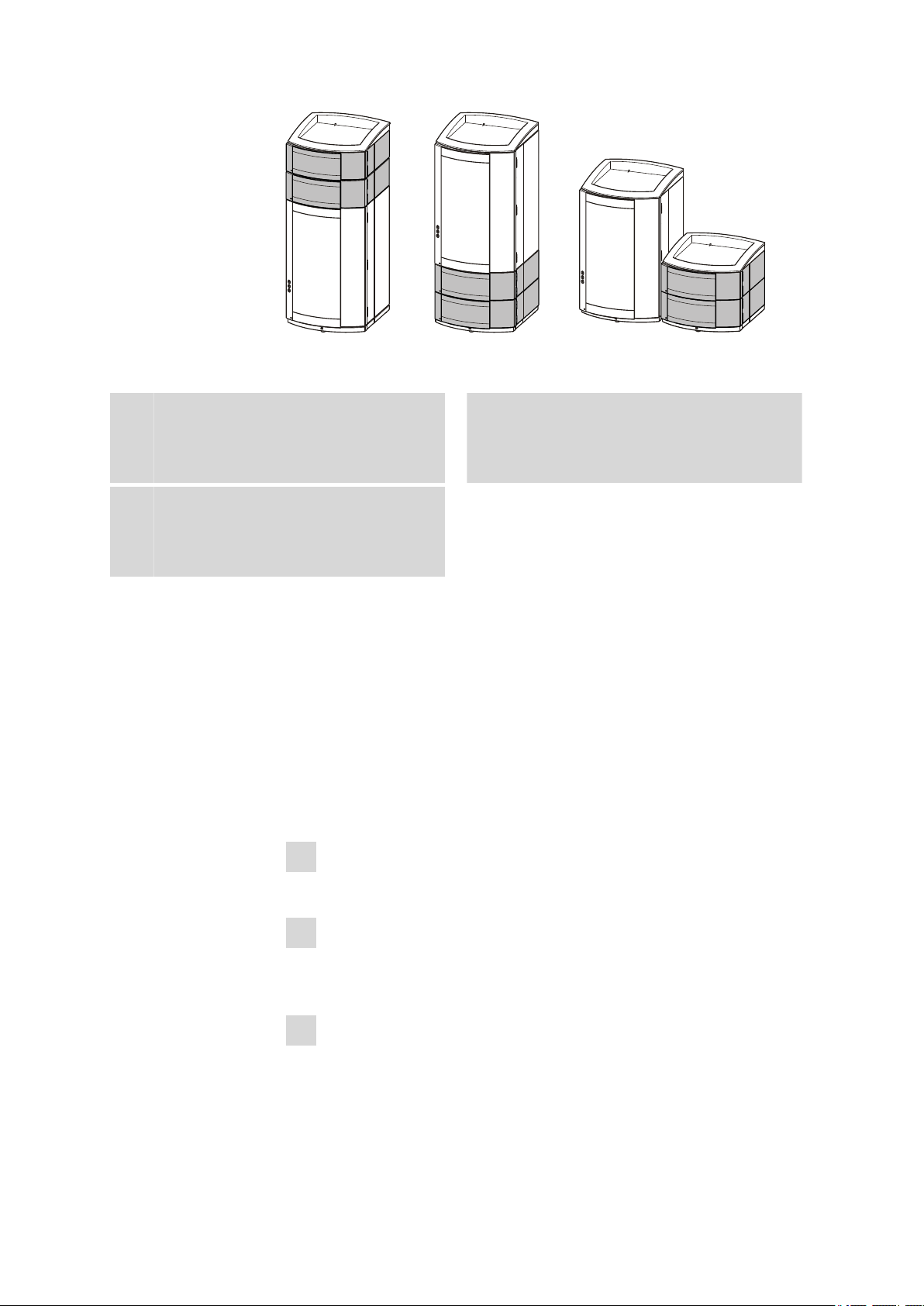

Figure 3 Setup versions ................................................................................. 10

Figure 4 Dismounting the bottle holder ......................................................... 11

Figure 5 Mounting the bottle holder ............................................................. 12

Figure 6 Removing the base tray ................................................................... 14

Figure 7 Mounting the base tray ................................................................... 15

Figure 8 Mounting the base tray ................................................................... 17

Figure 9 Mounting the bottle holder ............................................................. 18

Figure 10 Connecting the drainage tubings ..................................................... 19

Figure 11 Installation diagram ......................................................................... 23

Figure 12 Installing eluent bottle attachment .................................................. 24

Figure 13 Mounting aspiration filter ................................................................ 24

Figure 14 Install tubing weighting and aspiration filter .................................... 25

Figure 15 Eluent aspiration tubing fully equipped. ........................................... 25

Figure 16 Eluent bottle – connected ............................................................... 26

Figure 17 Eluent degasser ............................................................................... 28

Figure 18 Capillary connections high pressure pump/purge valve .................... 29

Figure 19 High pressure pump – Connect inlet ................................................ 30

Figure 20 Deaerating the high pressure pump ................................................. 32

Figure 21 Connecting inline filter .................................................................... 34

Figure 22 Pulsation damper – Connection ....................................................... 35

Figure 23 Injection valve – connected ............................................................. 36

Figure 24 Injection valve – Positions ................................................................ 37

Figure 25 Removing piston ............................................................................. 44

Figure 26 Components of the piston cartridge ................................................ 45

Figure 27 Tool for piston seal 6.2617.010 ....................................................... 46

Figure 28 Removing the piston seal ................................................................. 47

Figure 29 Insert the piston seal into the tool ................................................... 47

Figure 30 Inserting the piston seal into the pump head ................................... 48

Figure 31 Removing valves .............................................................................. 49

Figure 32 Dismantling valve ............................................................................ 50

Figure 33 Components of the inlet valve and outlet valve ................................ 51

Figure 34 Changing the filter .......................................................................... 53

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

VI

872 Extension Module IC Module

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

Existing 850 Professional IC instruments can be expanded to include additional functions by means of 872 Extension Modules. Every 850 Professional IC instrument can be supplemented with up to 3 extension modules.

The 872 Extension Module IC Module allows to extend an 850 Professional IC instrument by another IC Module complete with high pressure

pump, purge valve, inline filter, pulsation damper and injection valve.

The 872 Extension Module IC Module can be used wherever an additional IC Module is necessary.

With the 872 Extension Module IC Module, a one-channel low pressure

gradient instrument can this way be extended to a two-channel AnCat

instrument with low pressure gradient. All instruments with sample preparation can be extended to two-channel systems as well.

1 Introduction

In a system with photometric detection with a 886 Professional Thermostat/Reactor as column holder and thermostat and an 887 Professional

UV/VIS Detector, it is also possible to use the 872 Extension Module IC

Module for conveying reagents.

The extension module is operated with MagIC Net software, just like the

IC instrument. When it is connected to an 850 Professional IC instrument,

MagIC Net recognizes the extension module automatically and checks its

functional capability. It controls and monitors the unit IC instrument –

extension module, evaluates the measured data and administers it in a

database.

The 872 Extension Module – IC Module comprises the following components:

Eluent degasser

The eluent degasser removes gas bubbles and dissolved gases from the

eluent. For degassing, the eluent flows into a vacuum chamber through a

special fluoropolymer capillary.

High pressure pump

The intelligent and low pulsation high pressure pump pumps the eluent

through the system. It is equipped with a chip on which its technical specifications and "life history" (operating hours, service data, ... ) are saved.

872 Extension Module IC Module

■■■■■■■■

1

Page 10

1.2 Intended use

■■■■■■■■■■■■■■■■■■■■■■

Inline filter

Inline filters protect the separation column securely against possible contamination from the eluent. Inline filters can however also just as well be

used for the purpose of protecting other sensitive components against

contaminations in the solutions used. The fine 2 µm material of the readily

and easily replaceable filter platelets removes particles such as bacteria

and algae from the solutions.

Pulsation damper

The pulsation damper protects the separation column from damage

caused by pressure fluctuations when switching the injection valve, and

reduces interfering pulsations during highly sensitive measurements.

Injection valve

The injection valve connects the eluent and sample path through rapid

and precise valve switchover. A precisely measured amount of sample

solution is injected and rinsed with eluent onto the separation column.

1.2 Intended use

The present instrument is suitable for processing chemicals and flammable

samples. The usage of the 872 Extension Module therefore requires that

the user has basic knowledge and experience in the handling of toxic and

caustic substances. Knowledge with respect to the application of the fire

prevention measures prescribed for laboratories is also mandatory.

1.3 About the documentation

1.3.1 Content and scope

This document describes the 872 Extension Module – IC Module, its

assembly and connection to the IC instrument, as well as the installation,

operation and maintenance of the individual components. Technical specifications, troubleshooting and information concerning scope of delivery

and optional accessories makes up the rest of the manual.

This document does not on the other hand describe the functions of the

IC instrument - IC extension module unit, nor does it describe the capillary

connections that proceed from the extension module. For this purpose,

please refer to the manual for the IC instrument and that for the sample

processor.

■■■■■■■■

2

Additional information concerning the configuration of MagIC Net can be

found on the online help for MagIC Net.

872 Extension Module IC Module

Page 11

■■■■■■■■■■■■■■■■■■■■■■

1.3.2 Symbols and conventions

The following symbols and styles are used in this documentation:

1 Introduction

Cross-reference to figure legend

The first number refers to the figure number, the

second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

Warning

This symbol draws attention to a possible life hazard

or risk of injury.

Warning

This symbol draws attention to a possible hazard due

to electrical current.

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

Warning

This symbol draws attention to a possible biological

hazard.

Caution

This symbol draws attention to a possible damage of

instruments or instrument parts.

Note

This symbol marks additional information and tips.

872 Extension Module IC Module

■■■■■■■■

3

Page 12

1.4 Safety instructions

1.4 Safety instructions

1.4.1 General notes on safety

Warning

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

1.4.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

Warning

■■■■■■■■■■■■■■■■■■■■■■

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

Warning

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Mains voltage

Warning

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

■■■■■■■■

4

872 Extension Module IC Module

Page 13

■■■■■■■■■■■■■■■■■■■■■■

Protection against electrostatic charges

Warning

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Always pull the mains cable out of the mains connection socket before

connecting or disconnecting electrical appliances on the rear panel of

the instrument.

1.4.3 Tubing and capillary connections

Caution

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

1 Introduction

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are mandatory.

1.4.4 Flammable solvents and chemicals

Warning

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location (e.g. laboratory

flue).

■ Keep all sources of flame far from the workplace.

■ Clean up spilled fluids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

1.4.5 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

872 Extension Module IC Module

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

■■■■■■■■

5

Page 14

1.4 Safety instructions

■■■■■■■■■■■■■■■■■■■■■■

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

■■■■■■■■

6

872 Extension Module IC Module

Page 15

■■■■■■■■■■■■■■■■■■■■■■

Eluent

Degasser

In

Out

Sample

Eluent

Standard

1

2

3

4

5

6

1

2 3

4

5

6

7

8

2 Overview of the instrument

2.1 Front

2 Overview of the instrument

Figure 1 Front 872 Extension Module IC Module

Standby indicator

1

Coupling 6.2744.230

3

For connecting the eluent aspiration tubing.

Pulsation damper

5

See Chapter 4.8

Inline filter

7

See Chapter 4.7

High pressure pump

2

See Chapter 4.6

Purge valve

4

See Chapter 4.6

Injection valve

6

See Chapter 4.9

Eluent degasser

8

See Chapter 4.5

872 Extension Module IC Module

■■■■■■■■

7

Page 16

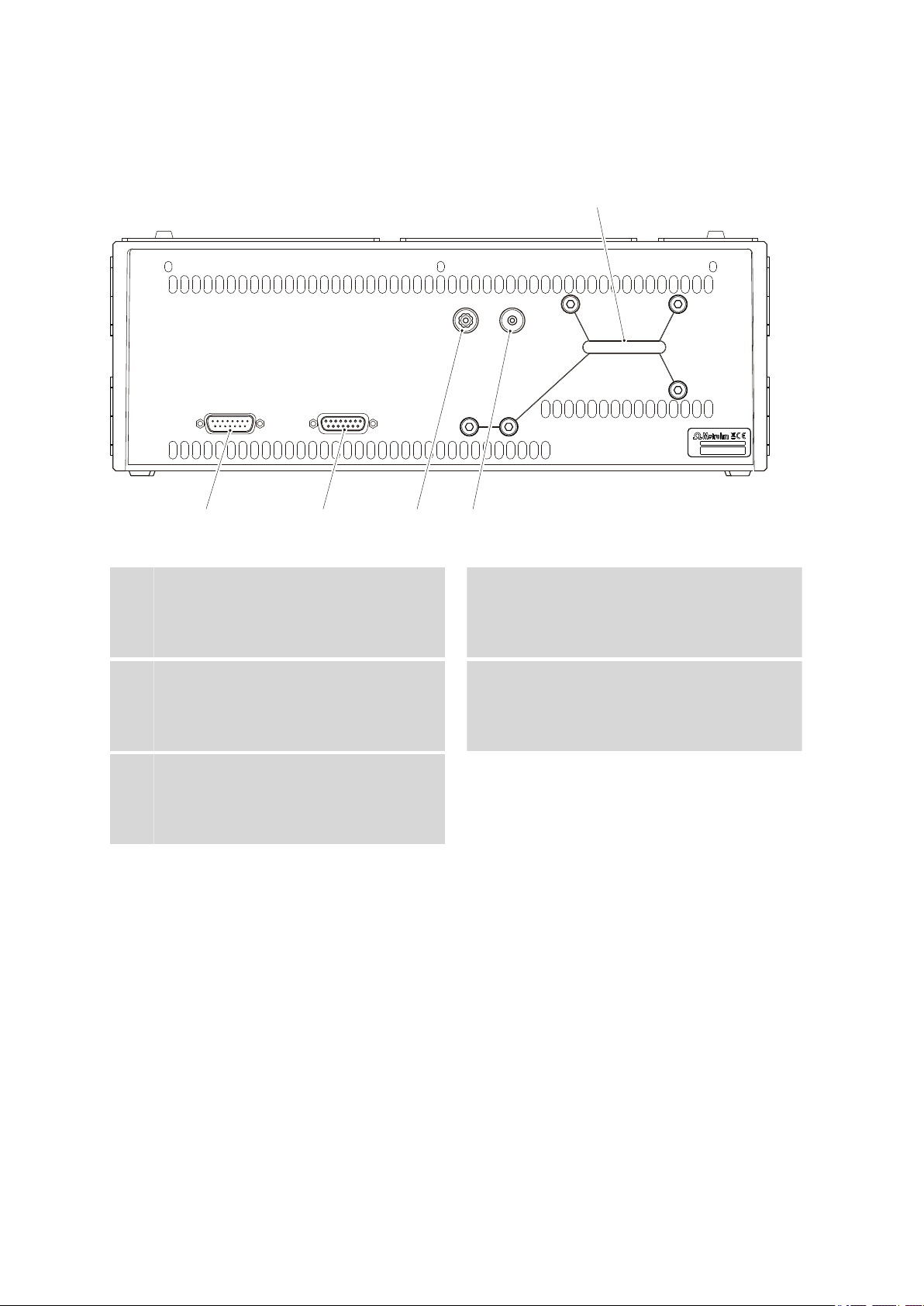

2.2 Rear

Vacuum

Exhaust

Made by Metrohm Herisau Switzerland

Out

In

Transport locking screws

1

2

3

4

5

2.2 Rear

■■■■■■■■■■■■■■■■■■■■■■

Figure 2 Rear 872 Extension Module IC Module

Connector In

1

To connect the extension module to the IC

instrument or to a previous extension module.

Connector Vacuum

3

For connecting further degassing chambers

in extension modules (labeled with Vac-

uum).

Transport locking screws

5

For securing the high pressure pump and

the vacuum pump when transporting the

instrument.

Connector Out

2

To connect an additional extension module.

Waste air opening

4

For extracting the air from the vacuum

chamber (labeled with Exhaust).

■■■■■■■■

8

872 Extension Module IC Module

Page 17

■■■■■■■■■■■■■■■■■■■■■■

3 Assembly

3.1 General

3 Assembly

The extension modules are fitted directly to the 850 Professional IC instrument and connected with it via 6.2156.060 connection cable. Extension

modules have no power supply of their own, but rather draw the electricity they require from the instrument with which they are connected.

Up to three extension modules can be connected to an 850 Professional

IC instrument. The following restrictions are to be taken into account:

Restrictions

The 850 Professional IC instruments and their extension modules must not

have more than 4 identical components in common, i.e.:

■ a maximum of 4 high pressure pumps,

■ a maximum of 4 peristaltic pumps,

■ a maximum of 4 injection valves,

■ a maximum of 4 suppressors (MSM, SPM incl.),

BUT

■ only a maximum of 3 degassers

■ and a maximum of 3 CO

suppressors (MCS)

2

Note

If all 4 high pressure pumps are being used at once, then not all of

them are permitted to run at maximum flow for longer periods of time.

Extension modules can be mounted in the following setup versions:

■ above, between instrument and bottle holder (3-A), or

■ below, between instrument and base tray (3-B), or

■ next to the instrument (3-C) with a separate 6.2061.110 base tray and

a 6.2061.100 bottle holder (to be ordered additionally). For this, the

longer 6.2156.070 connection cable (to be ordered additionally), is

necessary, too.

872 Extension Module IC Module

■■■■■■■■

9

Page 18

3.2 Mounting the extension module onto the IC instrument

A B

C

Figure 3 Setup versions

■■■■■■■■■■■■■■■■■■■■■■

Extension module above the IC instru-

A

ment

Between the 850 Professional IC and the

bottle holder.

Extension module next to the IC instru-

C

ment

With its own base plate and its own bottle

holder next to the 850 bottle holder.

Extension module on the below the IC

B

instrument

Between the base plate and the 850 Profession IC.

Position the extension module in such a way that the capillary connections

can be kept as short as possible. If several extension modules are used,

then they should all be installed in the same location if possible – either

above, below or next to the IC instrument. If this is not possible, then the

extension modules that are located at greater distances from one another

must be connected with one another by means of the longer 6.2156.070

connection cable (available as optional accessory).

3.2 Mounting the extension module onto the IC instrument

■■■■■■■■

10

1

Switching off the IC instrument

Switch the IC instrument off and disconnect the mains cable.

2

Clearing the bottle holder

If there are bottles and other items on the bottle holder, remove

them.

3

Removing drainage tubings

Loosen the drainage tubing from the drainage tubing connector on

the bottle holder.

872 Extension Module IC Module

Page 19

■■■■■■■■■■■■■■■■■■■■■■

1

2

1

2

4

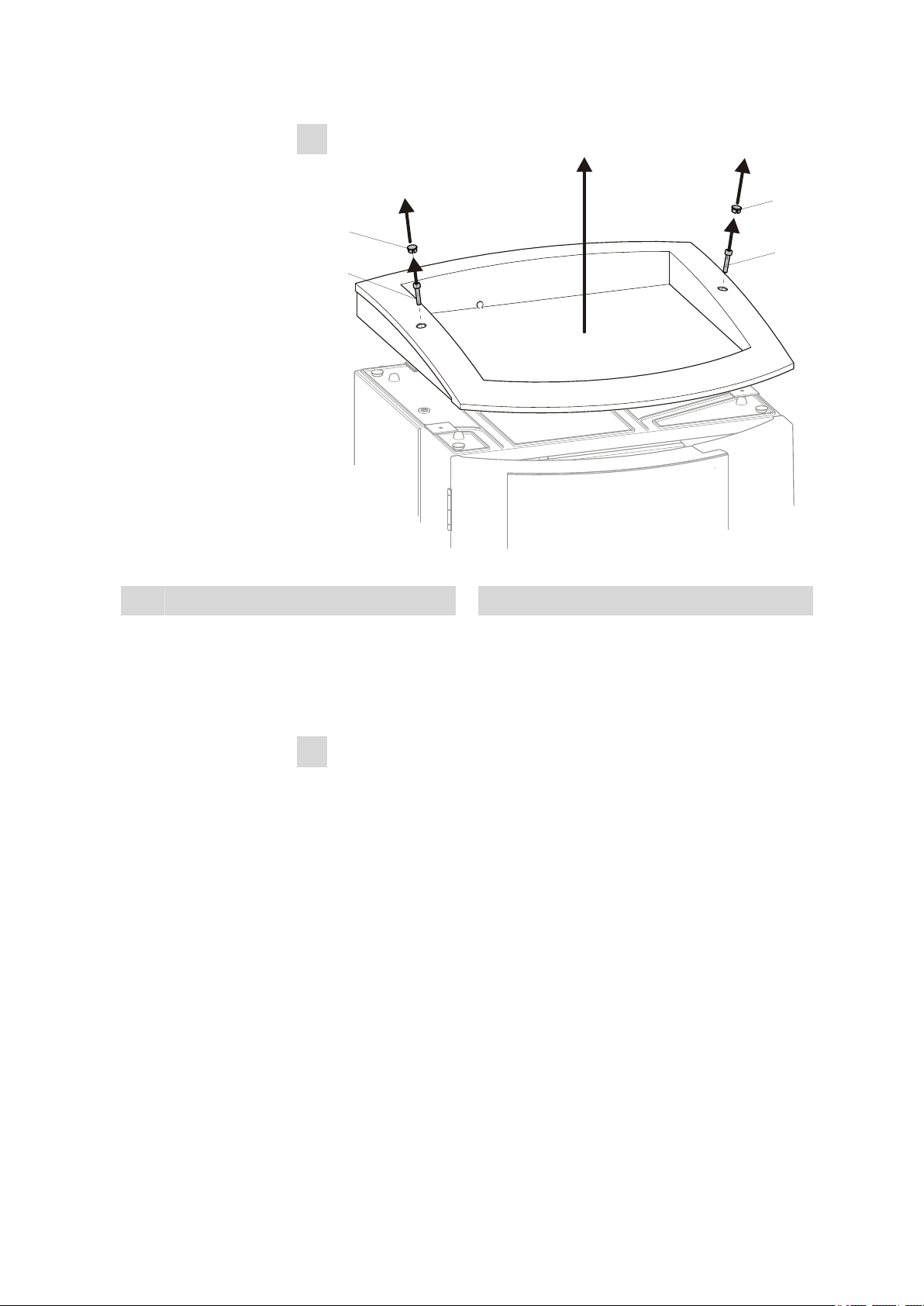

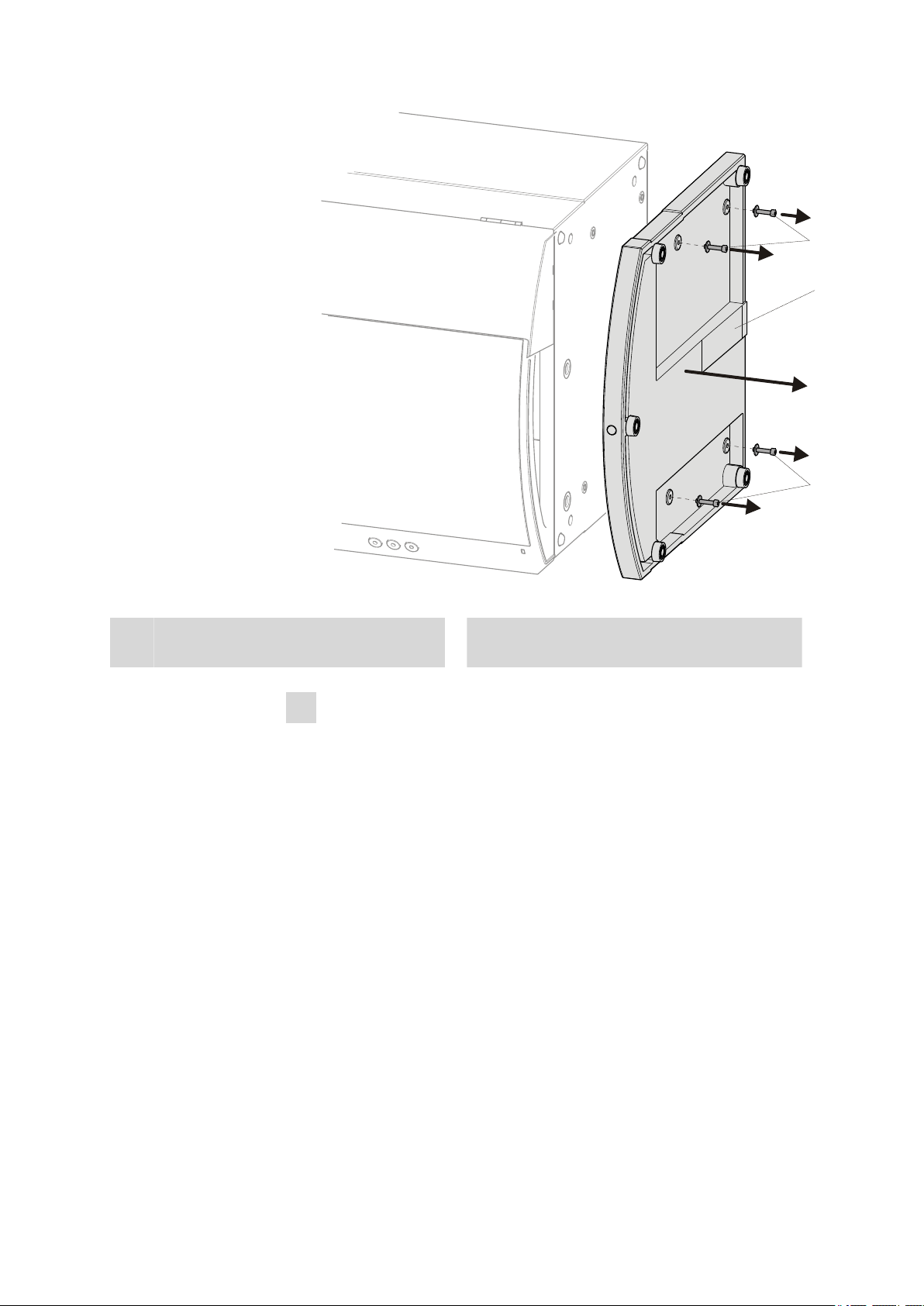

Dismounting the bottle holder

3 Assembly

Figure 4 Dismounting the bottle holder

Cover stoppers

1

■ Remove covering stoppers (4-1).

■ Loosen the cylinder screws with a 6.2621.100 3 mm hexagon

Cylinder screws

2

key.

■ Remove the bottle holder

5

Attaching the extension module(s)

Place the extension module(s) on the IC instrument.

872 Extension Module IC Module

■■■■■■■■

11

Page 20

3.2 Mounting the extension module onto the IC instrument

1

2

1

2

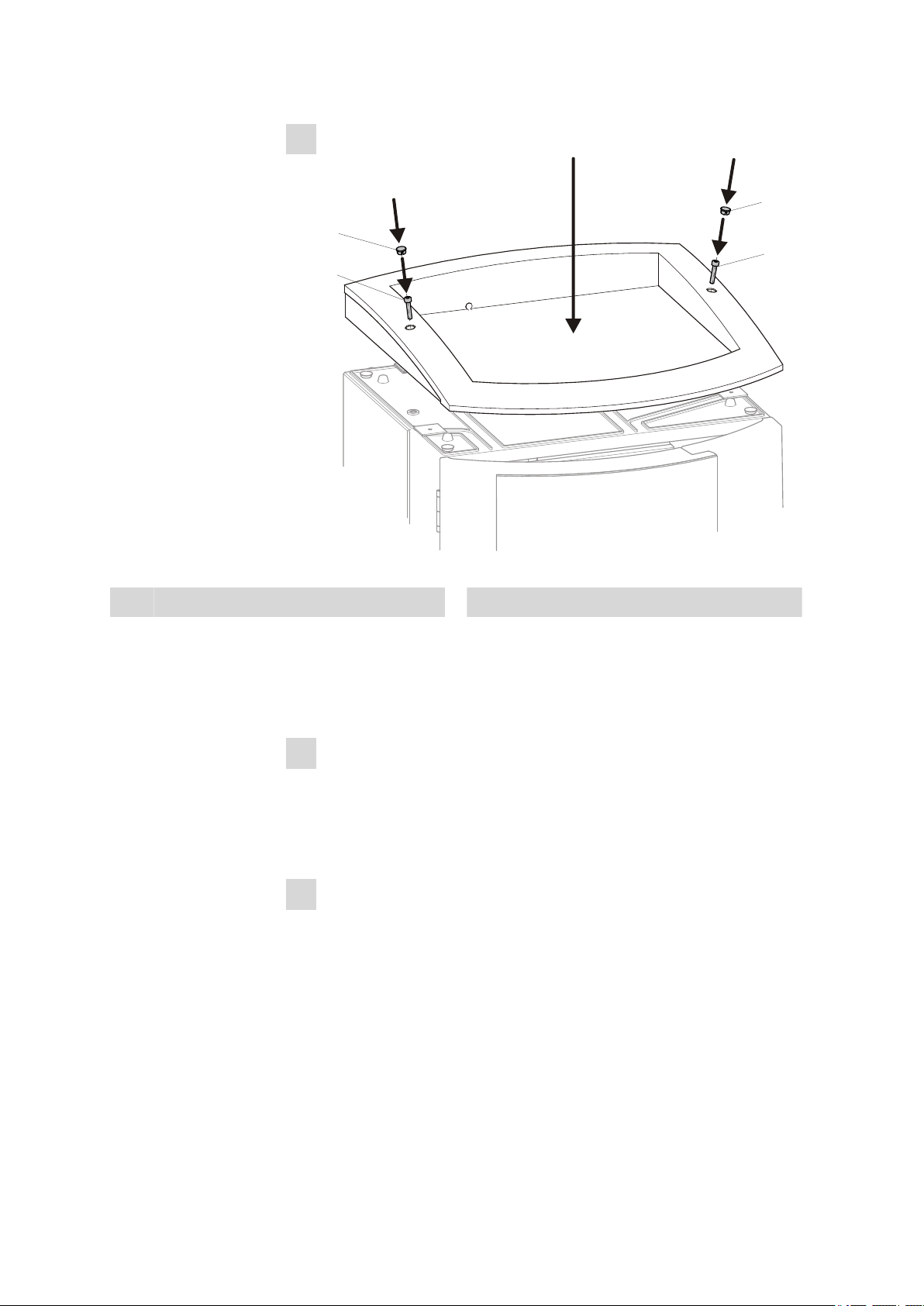

6

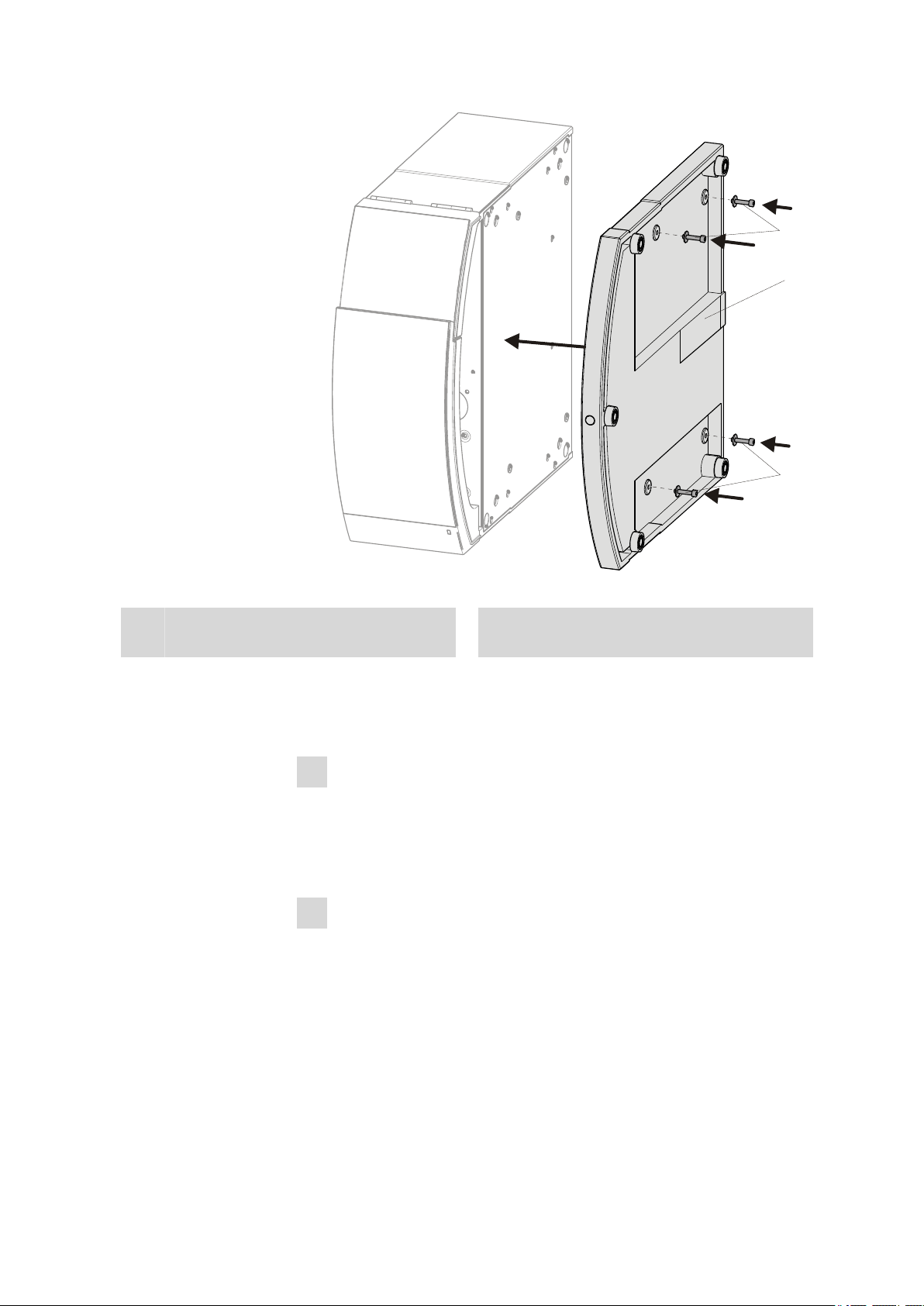

Mounting the bottle holder

■■■■■■■■■■■■■■■■■■■■■■

Figure 5 Mounting the bottle holder

Cover stoppers

1

■ Attach the bottle holder on the extension module.

■ Tighten the cylinder screws (4-2) with an 6.2621.100 3 mm hexa-

Cylinder screws

2

gon key

■ Insert covering stoppers (4-1).

7

Connecting the extension module

■ Plug a 6.2156.060 cable into the connector In of the extension

module and screw it tight.

■ Plug the other end of the cable into the Extension module con-

nector of the IC instrument and screw it tight.

8

Optional: Connecting a further extension module

■ Plug the cable 6.2156.060 or a longer 6.2156.070 cable (optional

accessory) into the connector In of the second extension module

and screw it tight.

■ Plug the other end of the cable into the Out connector of the first

extension module and screw it tight.

■■■■■■■■

12

872 Extension Module IC Module

Page 21

■■■■■■■■■■■■■■■■■■■■■■

9

Mounting the drainage tubing

3 Assembly

Reconnect the drainage tubing to the drainage tubing connector of

the bottle holder.

Possibly, a longer section of silicone tubing 6.186.020 must be cut to

fit and mounted (see also the manual for the IC instrument).

3.3 Mounting the extension module below the IC instrument

1

Switching off the IC instrument

Switch the IC instrument off and disconnect the mains cable.

2

Clearing the bottle holder

If there are bottles and other things on the bottle holder, remove

them.

3

Disconnecting all connections on the rear of the instrument

■ Disconnect the mains cable,

■ Disconnect the MSB cable,

■ Disconnect the USB cable,

■ Disconnect the leak sensor,

■ Remove the drainage tubings.

4

Removing the detector(s)

Disconnect the detector cable(s) and remove the detector(s) from the

IC instrument (see manual for the IC instrument).

5

Removing the base tray

■ Tilt the IC instrument sideways and lay it down flat.

■ Loosen the cylinder screws with a 6.2621.100 3 mm hexagon

key.

■ Remove base tray.

872 Extension Module IC Module

■■■■■■■■

13

Page 22

3.3 Mounting the extension module below the IC instrument

1

2

2

■■■■■■■■■■■■■■■■■■■■■■

1

Base tray

Figure 6 Removing the base tray

Cylinder screws

2

With washer.

6

Mounting the base tray

■ Tilt the extension module sideways and lay it down flat.

■ Attach base tray.

■ Slide the washers onto the cylinder screws (7-2) and tighten these

with a 3 mm hexagon key (6.2621.100).

■■■■■■■■

14

872 Extension Module IC Module

Page 23

■■■■■■■■■■■■■■■■■■■■■■

1

2

2

3 Assembly

1

Base tray

Figure 7 Mounting the base tray

Cylinder screws

2

With washer.

■ Set up the extension module.

■ Optional: Set up further extension modules.

■ Set up the IC instrument.

7

Connecting the extension module

■ Plug a 6.2156.060 cable into the connector In of the extension

module and screw it tight.

■ Plug the other end of the cable into the Extension module con-

nector of the IC instrument and screw it tight.

8

Optional: Connecting a further extension module

■ Plug the cable 6.2156.060 or a longer 6.2156.070 cable (optional

accessory) into the connector In of the second extension module

and screw it tight.

■ Plug the other end of the cable into the Out connector of the first

extension module and screw it tight.

872 Extension Module IC Module

■■■■■■■■

15

Page 24

3.4 Setting up the extension module next to the IC instrument

9

Inserting the detector(s) again and connecting it (them)

■■■■■■■■■■■■■■■■■■■■■■

See manual for the IC instrument.

10

Restoring the loosened connections

■ Reconnect the drainage tubings,

Possibly, a longer section of silicone tubing 6.186.020 must be

cut to fit and mounted (see also the manual for the IC instru-

ment).

■ Connect the leak sensor (see manual for the IC instrument),

■ Connect the USB cable,

■ Connect the MSB cable,

■ Plug in the mains cable.

3.4 Setting up the extension module next to the IC

instrument

1

Switching off the IC instrument

Switch the IC instrument off and disconnect the mains cable.

2

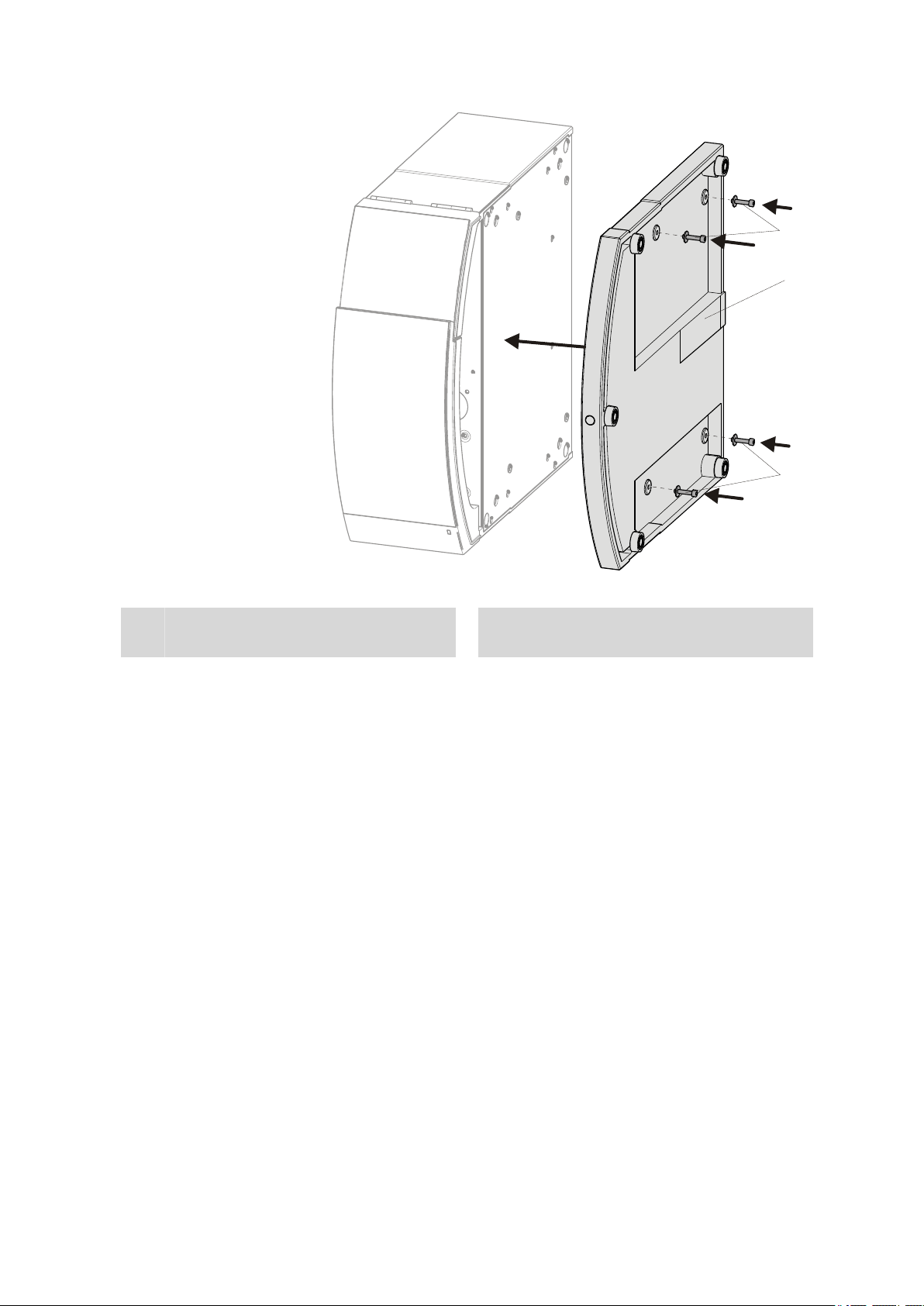

Mounting the base tray

■ Tilt the extension module sideways and lay it down flat.

■ Attach base tray.

■ Tighten the washers and the cylinder screws (8-2) with a 3 mm

hexagon key (6.2621.100).

■■■■■■■■

16

872 Extension Module IC Module

Page 25

■■■■■■■■■■■■■■■■■■■■■■

1

2

2

3 Assembly

1

Base tray

Figure 8 Mounting the base tray

Cylinder screws

2

With washer.

■ Set up the extension module.

■ Optional: Set up further extension modules.

872 Extension Module IC Module

■■■■■■■■

17

Page 26

3.4 Setting up the extension module next to the IC instrument

1

2

1

2

3

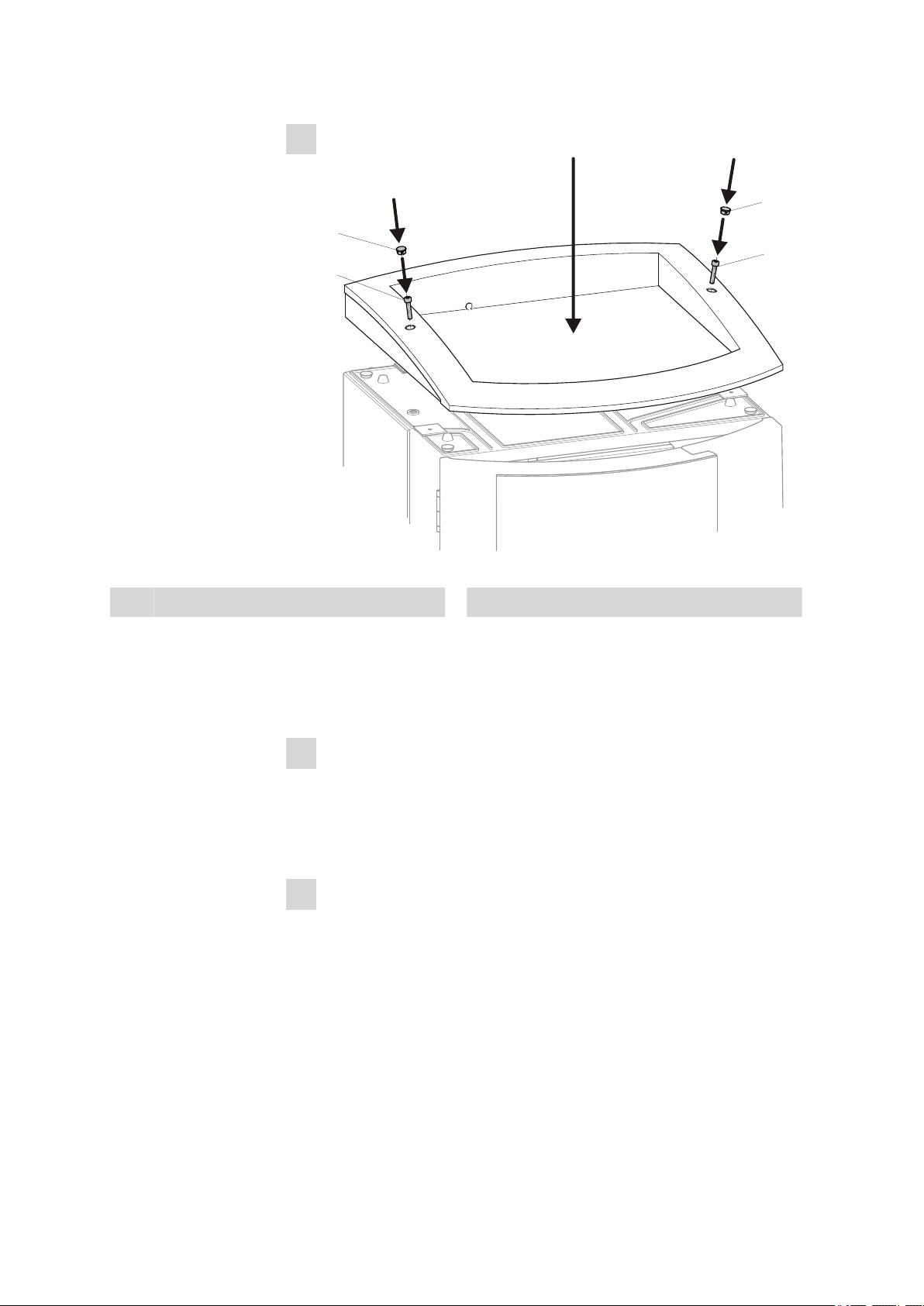

Mounting the bottle holder

■■■■■■■■■■■■■■■■■■■■■■

Figure 9 Mounting the bottle holder

Cover stoppers

1

■ Place the bottle holder on the extension module.

■ Tighten the cylinder screws (9-2) with an 6.2621.100 3 mm hexa-

Cylinder screws

2

gon key.

■ Insert covering stoppers (9-1).

4

Connecting the extension module

■ Plug a 6.2156.060 cable into the connector In of the extension

module and screw it tight.

■ Plug the other end of the cable into the Extension module con-

nector of the IC instrument and screw it tight.

5

Optional: Connecting a further extension module

■ Plug the cable 6.2156.060 or a longer 6.2156.070 cable (optional

accessory) into the connector In of the second extension module

and screw it tight.

■ Plug the other end of the cable into the Out connector of the first

extension module and screw it tight.

■■■■■■■■

18

872 Extension Module IC Module

Page 27

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

5

6

Connecting the leak sensor

■ Plug the 6.2103.170 adapter into the leak sensor connector of

the IC instrument.

■ Connect the leak sensor cable of the IC instrument to the adapter.

■ Connect the leak sensor cable of the extension module to the

adapter.

7

Connecting the drainage tubings

3 Assembly

Figure 10 Connecting the drainage tubings

Drainage tubing connector

1

For draining escaped liquid from the bottle

holder.

872 Extension Module IC Module

Drainage tubing

2

Section of the 6.1816.020 silicon tubing. For

draining escaped liquid from the bottle

holder.

■■■■■■■■

19

Page 28

3.5 Transport locking screws

■■■■■■■■■■■■■■■■■■■■■■

Drainage tubing connection

3

For supplying escaped liquid through the

connected drainage tubing to the leak sensor.

Drainage tubing

5

Section of the 6.1816.020 silicon tubing.

Guides escaped liquid into a waste container.

■ Plug the drainage tubing (10-2) onto the drainage tubing connec-

tor (10-1) of the bottle holder and shorten to required length.

■ Plug the other end of the drainage tubing (10-2) onto the drain-

age tubing connector (10-3) of the base tray.

■ Plug the drainage tubing (10-5) onto the drainage tubing connec-

tor (10-4) and guide the other end into a waste container.

3.5 Transport locking screws

To avoid damage to the high pressure pump and vacuum pump during

transport, the pumps are secured with transport locking screws .

Drainage tubing connector

4

For draining escaped liquid from the base

tray through the connected drainage tubing.

Remove these transport locking screws before the initial start-up.

Removing transport locking screws

Remove all of the transport locking screws with the 6.2621.030 4

1

mm hexagon key and keep them in a safe place.

Warning

In order to avoid damage to the pump, the transport locking screws

must be remounted each time the instrument undergoes major transport.

■■■■■■■■

20

872 Extension Module IC Module

Page 29

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

4.1 About this chapter

The Installation chapter contains

■ this overview

■ a brief set of instructions for the installation of the 872 Extension Mod-

ule IC Module (see Chapter 4.2, page 21). At each step you will find

cross-references to more detailed installation instructions for individual

components, should you require such aids.

■ an installation diagram (see Chapter 4.3, page 22), showing a com-

pletely installed instrument.

■ several chapters with detailed installation instructions for all compo-

nents, including those that are already installed at the time the instrument is delivered.

4 Installation

4.2 Installation overview

Note

A number of the capillary connections are already connected at the

time the instrument is delivered.

The following work steps must still be carried out:

Installing 872 Extension Module IC Module

1

Installing the eluent path

■ Tighten the clamping screw of the 6.1834.080 eluent aspiration

tubing to the eluent degasser input.

Equip the free end of the eluent aspiration tubing (11-1) and connect it to the eluent bottle (see Chapter 4.4, page 23).

■ Tighten one end of the 6.1831.010 PEEK capillary with a

6.2744.014 PEEK pressure screw to the connector 4 of the injection valve (see Chapter 4.9.1, page 35).

Shorten to required length with the capillary cutter and with the

aid of a 6.2744.040 coupling and two 6.2744.010 pressure

screws connect to the column outlet capillary in the IC instrument.

872 Extension Module IC Module

■■■■■■■■

21

Page 30

4.3 Installation diagram

■■■■■■■■■■■■■■■■■■■■■■

Note

The separation column must not be connected to the system

before having it started up for the first time (see manual for the IC

instrument).

2

Installing the sample path

■ Connect one end of the 6.1803.040 PTFE capillary (11-3) with a

6.2744.014 PEEK pressure screw to connector 1 of the injection

valve (see Chapter 4.9.1, page 35).

Guide the other end through a suitable capillary feed-through out

of the extension module to the Sample Processor and connect it

there (see Sample Processor manual).

■ Connect one end of the second 6.1803.040 PTFE capillary (11-4)

with a 6.2744.014 PEEK pressure screw to connector 2 of the

injection valve.

Guide the other end through a capillary feed-through out of the

extension module to a waste container and fasten it there.

3

Putting the extension module into operation

See Chapter 5, Page 39

■ Putting the extension module into operation together with the IC

instrument (see chapter Start-up in the manual for the IC instrument).

■ Deaerate the high pressure pump at the same time (see Chapter

4.6.2, page 31).

4.3 Installation diagram

Figure 11 Installation diagram shows the capillary connections of the 872

Extension Module IC Module as an additional IC Module which can be

integrated into any existing system.

The arrangement of the modules in the diagram corresponds to the front

view of the extension module.

A few of the capillaries are already pre-installed at the time the instrument

is delivered. Capillaries on which nothing needs to be done at the time of

initial installation are not numbered in the diagram.

■■■■■■■■

22

872 Extension Module IC Module

Page 31

■■■■■■■■■■■■■■■■■■■■■■

Eluent

Degasser

In

Out

Sample

Eluent

Standard

1

2

3

4

5

6

1 2

3

4

Figure 11 Installation diagram

4 Installation

Eluent aspiration tubing 6.1834.080

1

Connected to the eluent degasser. Connect

the other end to the eluent bottle.

Sample aspirating capillary 6.1803.040

3

The following chapters describe the individual installation steps in detail.

4.4 Eluent

4.4.1 Connecting eluent bottle

The eluent is aspirated out of the eluent bottle via the eluent aspiration

tubing (12-1).

The eluent aspiration tubing is connected to the eluent degasser (see

Chapter 4.5, page 27). The tubing must be threaded through a suitable

capillary feed-through of the instrument before the other end can be

equipped.

You will require the parts from the following accessories for equipping the

eluent aspiration tubing:

■ 6.1602.160 Eluent bottle attachment GL 45

■ 6.2744.210 tubing adapter for aspiration filter

■ 6.2821.090 aspiration filter

Eluent connection capillary 6.1831.010

2

Sample outlet capillary 6.1803.040

4

872 Extension Module IC Module

To equip the eluent aspiration tubing proceed as follows:

Assembling eluent aspiration tubing

Guide the free end of the eluent aspiration tubing (12-1) out of the

1

instrument through a suitable capillary feed-through.

■■■■■■■■

23

Page 32

4.4 Eluent

1 2

3

4

■■■■■■■■■■■■■■■■■■■■■■

2

Installing eluent bottle attachment 6.1602.160

■ Slide tubing nipple (12-2) and O-ring (12-3) onto the eluent aspi-

ration tubing (12-1).

■ Push eluent aspiration tubing (12-1) through the bottle attach-

ment (12-4) and screw tight.

Figure 12 Installing eluent bottle attachment

Eluent aspiration tubing 6.1834.080

1

O-ring

3

From accessories set 6.1602.160.

3

Filter holder

1

From accessories set 6.2744.210.

Tubing nipple

2

From accessories set 6.1602.160.

Bottle attachment

4

From accessories set 6.1602.160.

Mounting aspiration filter

■ Insert filter holder (13-1) into the aspiration filter (13-2) and screw

tight.

Figure 13 Mounting aspiration filter

Aspiration filter 6.2821.090

2

■■■■■■■■

24

872 Extension Module IC Module

Page 33

■■■■■■■■■■■■■■■■■■■■■■

3

4

5

4

Install tubing weighting and aspiration filter

Figure 14 Install tubing weighting and aspiration filter

4 Installation

Eluent aspiration tubing 6.1834.080

1

Tubing weighting

3

From accessories set 6.2744.210.

Aspiration filter 6.2821.090

5

With filter holder from accessories set

6.2744.210.

■ Slide the tubing weighting (14-3) onto the eluent aspiration tub-

■ Slide the clamping screw (14-4) onto the eluent aspiration tubing

■ Insert the eluent aspiration tubing (14-1) into the aspiration filter

■ Screw together clamping screw (14-4) and filter holder (13-1).

Eluent bottle attachment 6.1602.160

2

Clamping screw

4

From accessories set 6.2744.210.

ing (14-1).

(14-1).

(14-5). The end of the tubing should approximately reach to the

center of the aspiration filter.

Figure 15

872 Extension Module IC Module

Eluent aspiration tubing fully equipped.

5

Mounting eluent aspiration tubing to the eluent bottle

■ Insert the eluent aspiration tubing into the eluent bottle (16-10).

■■■■■■■■

25

Page 34

4.4 Eluent

1

1

2

3

4

5

6

7

89

10

11

12

13

14

■■■■■■■■■■■■■■■■■■■■■■

■ Fasten the completely equipped bottle attachment (16-10) on the

eluent bottle. The aspiration filter (16-6) must rest on the base of

the eluent bottle.

■ Close the remaining small opening on the bottle attachment with

a threaded stopper from the accessories set.

6

Mounting the adsorber tube

Note

In the case of alkaline eluents and eluents with lower buffer

capacity, the eluent bottle must be equipped with a CO2 adsorber

(16-4).

■ First, place a piece of cotton (16-3), then the CO

adsorber (16-4)

2

in the large opening of the adsorber tube (16-2) and close with

the plastic cover.

■ Fasten the adsorber tube (16-2) using the SGJ clip (16-12) onto

the bottle attachment (16-11).

26

Eluent aspiration tubing 6.1834.080

1

For aspirating the eluent. Pre-installed.

■■■■■■■■

Figure 16

Eluent bottle – connected

Adsorber tube 6.1609.000

2

872 Extension Module IC Module

Page 35

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

Wadding

3

Eluent

5

Filter holder

7

From accessories set 6.2744.210.

Tubing weighting

9

From accessories set 6.2744.210.

Bottle attachment 6.1602.160

11

Tubing nipple

13

4.5 Eluent degasser

Gas bubbles in the eluent lead to an unstable baseline, as high pressure

pumps can transport liquids, but not gases. The eluent therefore has to be

degassed, before it reaches the high pressure pump.

The eluent degasser removes gas bubbles and dissolved gases from the

eluent. For degassing, the eluent flows into a vacuum chamber through a

special fluoropolymer capillary.

CO2 adsorber

4

Adsorbs CO2 from the air (e.g. Merck soda

lime with indicator, no. 6839.10).

Aspiration filter 6.2821.090

6

Clamping screw

8

From accessories set 6.2744.210.

Eluent bottle 6.1608.070

10

SGJ clip 6.2023.020

12

Threaded stopper

14

Note

The eluent degasser is already installed in the newly delivered instrument. The following installation instructions must only be followed, if

the connections to the degasser had to be disconnected for maintenance.

872 Extension Module IC Module

■■■■■■■■

27

Page 36

4.5 Eluent degasser

5

6

1

3

4

■■■■■■■■■■■■■■■■■■■■■■

Connecting the eluent degasser

Figure 17 Eluent degasser

Eluent degasser input

1

Tubing flare

3

With tubing nipple.

Eluent aspiration tubing (6.1834.080)

5

For aspirating the eluent. The clamping

screw (17-4) is firmly mounted.

1

■ Insert the eluent aspiration tubing (17-5) into the eluent degasser

■ Carefully tighten the clamping screw (17-4).

■ Insert connection capillary (17-6) (the end with the longer clamp-

2

■ Carefully tighten the clamping screw (17-4).

■ Connect the other end of the connection capillary (17-6) (with

Eluent degasser output

2

Clamping screw

4

Connection tubing (6.1834.090)

6

Connection from the eluent degasser to the

high pressure pump (see Chapter 4.6, page

29). The clamping screw (17-4) is firmly

mounted.

Caution

The clamping screws (17-4) must be tightened carefully. Use the

wrench (6.2621.050) to do this.

input (17-1).

ing screw (17-4)) into the eluent degasser output (17-2).

the shorter clamping screw ) to the high pressure pump (18-9)

(see "Connecting inlet to the high pressure pump", page 30).

■■■■■■■■

28

872 Extension Module IC Module

Page 37

■■■■■■■■■■■■■■■■■■■■■■

10

8

9

1

2

3

4

5

6

2

7

2

2

2

11

2

12

2

13

4.6 High pressure pump

The intelligent and low pulsation high pressure pump pumps the eluent

through the system. It is equipped with a chip on which its technical specifications and "life history" (operating hours, service data, ... ) are saved.

The purge valve is used for deaerating (see Chapter 4.6.2, page 31) the

high pressure pump.

4.6.1 Capillary connections high pressure pump/purge valve

Note

All of the capillary connections of the high pressure pump and the

purge valve are already installed in the newly delivered instrument.

4 Installation

Connection capillary

1

PEEK capillary, connects main piston and

auxiliary piston.

Outlet valve holder

3

872 Extension Module IC Module

Figure 18

Capillary connections high pressure pump/purge valve

PEEK pressure screw, short 6.2744.070

2

Pump head 6.2824.110

4

■■■■■■■■

29

Page 38

4.6 High pressure pump

5

1

2

3

4

■■■■■■■■■■■■■■■■■■■■■■

Fastening screws

5

For fastening the pump head.

Pump head input capillary

7

PEEK capillary at the input of the pump

head.

Coupling

9

For the connection of the eluent path at the

input of the high pressure pump. Can be

ordered together with the pressure screw

(18-8) under the number 6.2744.230.

Purge valve

11

For deaerating the high pressure pump.

With rotary knob in the center and pressure

sensor.

Connection capillary

13

Connects the output of the pump head with

the purge valve.

Note

Inlet valve holder

6

Pressure screw

8

For connecting a PEEK capillary to the coupling (18-9).

Deaerating capillary

10

For aspirating the eluent when deaerating

the high pressure pump (see Chapter 4.6.2,

page 31).

Connection capillary

12

For connecting the inline filter (see Chapter

4.7, page 33)

The eluent aspiration tubing is already installed in the newly delivered

instrument. The following installation instructions need not be carried

out at the time of initial installation.

Connecting inlet to the high pressure pump

Figure 19

Pressure screw

1

For connecting the coupling (19-2) to the

pump head input capillary (18-7).

Can be ordered together with the coupling

under the number 6.2744.230.

High pressure pump – Connect inlet

Coupling 6.2744.230

2

For connecting the eluent aspiration tubing

(19-4) to the input of the high pressure

pump.

■■■■■■■■

30

872 Extension Module IC Module

Page 39

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

Clamping screw

3

Backup ring

5

Eluent aspiration tubing

4

Eluent aspiration tubing 6.1834.080 or

6.1834.090.

1

Connecting coupling

Fasten the coupling (19-2) with a pressure screw (19-1) on the pump

head input capillary (18-7).

2

Connecting eluent aspiration tubing

Caution

The clamping screws must be tightened carefully. To tighten, grip

the coupling (19-2) with the 6.2739.000 key and grip the clamping screw (19-3) with the 6.2621.050 wrench.

■ Plug the eluent aspiration tubing (19-4) into the coupling (19-2).

■ Tighten clamping screw (19-3).

4.6.2 Deaerating the high pressure pump

The high pressure pump will only operate perfectly if the pump head contains no more air bubbles. Therefore it must be deaerated during initial

start-up and after every change of eluent.

Caution

The high pressure pump must not be deaerated before the initial startup .

Deaerate the high pressure pump as follows (see Figure 20, page 32):

Deaerating the high pressure pump

The instrument must be connected to the PC and switched on to deaerate

the high pressure pump.

872 Extension Module IC Module

■■■■■■■■

31

Page 40

4.6 High pressure pump

5

1

2

6

7

5

3

4

5

■■■■■■■■■■■■■■■■■■■■■■

Figure 20 Deaerating the high pressure pump

Syringe 10 mL 6.2816.020

1

For aspirating the eluent.

Purging needle 6.2816.040

3

PEEK pressure screws, short

5

6.2744.070

Purge valve rotary knob

7

Luer connector

2

On purging needle.

Deaerating capillary

4

Purge valve

6

1

Connecting the purging needle

■ Push the end of the purging needle (20-3) over the end of the

deaerating capillary (20-4) on the purge valve.

2

Connecting the syringe

■ Insert syringe (20-1) in the Luer connector (20-2) of the purging

needle (see Figure 20, page 32).

3

Opening purge valve

■ Open the rotary knob (20-7) by approx. ½ rotation counterclock-

wise.

4

Setting the flow rate

■ Start MagIC Net (if not yet started).

■ Ensure that the eluent aspiration tubing is immersed sufficiently in

the eluent.

■ Let the high pressure pump run.

■■■■■■■■

32

872 Extension Module IC Module

Page 41

■■■■■■■■■■■■■■■■■■■■■■

5

6

4.7 Inline filter

Between the purge valve and the pulsation damper the 6.2821.120 inline

filter is installed as protection against particles.

Inline filters protect the separation column securely against possible contamination from the eluent. Inline filters can however also just as well be

used for the purpose of protecting the suppressor against contaminations

in the regeneration or rinsing solutions. The fine 2 µm material of the

readily and easily replaceable filter platelets removes particles such as bacteria and algae from the solutions.

4 Installation

Aspirating eluent

■ Aspirate with the syringe (20-1) until bubble-free eluent flows into

the syringe.

Completing deaerating

■ Turn off high pressure pump.

■ Close rotary knob (20-7).

■ Remove syringe (20-1) from the Luer connector (20-2).

■ Pull the purging needle (20-3) out of the deaerating capillary

(20-4).

Note

The inline filter is already installed in the newly delivered instrument.

The following installation instructions need not be carried out at the

time of initial installation.

Installing the inline filter

Caution

Observe the flow direction marked on the filter housing for the connection of the inline filter.

872 Extension Module IC Module

■■■■■■■■

33

Page 42

4.8 Pulsation damper

2 3

2 4

1

Figure 21 Connecting inline filter

■■■■■■■■■■■■■■■■■■■■■■

Connection capillary

1

Connects the purge valve with the inline filter

Inline filter 6.2821.120

3

Protects against particles.

Screw on the connection capillary running from the purge valve with

1

a 6.2744.070 pressure screw to the input side of the inline filters.

Screw on the connection capillary running to the pulsation damper

2

with a 6.2744.070 pressure screw to the output side of the inline filter.

4.8 Pulsation damper

Note

PEEK pressure screws, short

2

6.2744.070

Connection capillary

4

Connects the inline filter with the pulsation

damper.

■■■■■■■■

34

The pulsation damper is already installed in the newly delivered instrument.

Caution

The pulsation damper is maintenance-free and may not be opened.

The pulsation damper protects the separation column from damage

caused by pressure fluctuations when switching the injection valve, and

reduces interfering pulsations during highly sensitive measurements. In

order to ensure these functionalities, it must be connected between the

high pressure pump (see Chapter 4.6, page 29) and injection valve (see

Chapter 4.9, page 35).

The pulsation damper can be operated in both directions.

872 Extension Module IC Module

Page 43

■■■■■■■■■■■■■■■■■■■■■■

3

4

5

2

3

6

1

2

4 Installation

Figure 22 Pulsation damper – Connection

Connection capillary

1

Connection to the inline filter.

PEEK pressure screws, short

3

6.2744.070

Pulsation damper 6.2620.150

5

Fastening screws

2

Holder for pulsation damper

4

Connection capillary

6

Connection to the injection valve.

4.9 Injection valve

The injection valve connects the eluent and sample path. Through rapid

and precise valve switchover a precise amount of sample solution defined

by the size of the sample loop is injected and rinsed with eluent onto the

separation column.

4.9.1 Connecting the injection valve

The injection valve has six connectors: two for the sample path (connectors 1 and 2), two for the eluent path (connectors 4 and 5) and two for

the sample loop (connectors 3 and 6).

Note

The capillaries of the eluent path and the sample path and the sample

loop are already installed in the newly delivered instrument.

872 Extension Module IC Module

■■■■■■■■

35

Page 44

4.9 Injection valve

1

2

3

4

5

6

2

4

5

7

7

■■■■■■■■■■■■■■■■■■■■■■

Figure 23 Injection valve – connected

Injection valve

1

Connection capillary

3

Connected to connector 4. Carries eluent to

the injection valve.

Connection capillary

5

Connected to connector 1. Carries sample to

the injection valve.

PEEK pressure screw 6.2744.010

7

Replacing the sample loop

The sample loop can be replaced, depending on requirements. For additional information concerning selection of the appropriate sample loop,

see Chapter 4.9.3, page 38.

Use only 6.2744.010 PEEK pressure screws for connecting capillaries

and sample loop to the injection valve.

Note

Sample loop

2

Connected to connectors 3 and 6.

Connection capillary (column inlet

4

capillary)

Connected to connector 5. Carries eluent to

the separation column.

Connection capillary

6

Connected to connector 2. Carries sample to

the waste container.

■■■■■■■■

36

1

Removing existing sample loop

■ Loosen 6.2744.010 pressure screws at connector 3 and connec-

tor 6.

■ Remove sample loop.

2

Mounting new sample loop

■ Fasten one end of the sample loop (23-2) with a 6.2744.010

PEEK pressure screw (23-7) to connector 3.

■ Fasten the other end of the sample loop (23-2) with a second

6.2744.010 PEEK pressure screw (23-7) to connector 6.

872 Extension Module IC Module

Page 45

■■■■■■■■■■■■■■■■■■■■■■

12

4 5

3 6

12

4 5

3 6

1

2

4

3

5

4

3

1

2

A B

4.9.2 Mode of operation of the injection valve

The injection valve (see Figure 24, page 37) can adopt two valve positions - FILL and INJECT. Switching back and forth between the two valve

positions determines whether the sample path or the eluent path is guided through the sample loop. The following figure provides a schematic

display of the flow paths of the two valve positions.

4 Installation

Figure 24 Injection valve – Positions

Position FILL

A

Eluent input

1

Capillary coming from the high pressure

pump.

Sample input

3

Sample aspirating capillary.

Sample loop

5

Position INJECT

B

Eluent output

2

Capillary to the column.

Sample output

4

Capillary to waste container.

Position A In the position FILL, the sample solution flows

through the sample loop to the waste container.

The eluent flows directly to the separation column at the same time.

Position B In the position INJECT, the eluent flows through

the sample loop to the separation column. If

sample solution is to be found in the sample

loop at the time of the valve switchover, then

this will be conveyed along with the eluent, thus

making its way to the separation column. The

flow in the sample path is either stopped or the

sample flows directly to the waste container.

872 Extension Module IC Module

■■■■■■■■

37

Page 46

4.9 Injection valve

4.9.3 Selecting the sample loop

The amount of sample solution injected depends on the volume of the

sample loop. The choice is made on the basis of the application. The following sample loops are normally used:

Cation determination 10 µL

Anion determination with suppression 20 µL

Anion determination without suppression 100 µL

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

38

872 Extension Module IC Module

Page 47

■■■■■■■■■■■■■■■■■■■■■■

5 Set to work

The extension module is put into operation together with the IC instrument.

Putting IC instrument into operation with extension modules

1

2

3

4

5

5 Set to work

Start MagIC Net.

Connect the 872 Extension Module to the 850 Professional IC.

Connect the 850 Professional IC instrument to the PC and switch on.

The extension module is recognized automatically by MagIC Net.

Follow the other instructions in the chapter Initial start-up of the

manual for the 850 Professional IC.

Deaerate the high pressure pump at the same time (see Chapter

4.6.2, page 31).

872 Extension Module IC Module

■■■■■■■■

39

Page 48

6.1 General information

6 Operation and maintenance

6.1 General information

6.1.1 Care

Warning

The instrument housing must not be opened by untrained personnel.

The instrument requires appropriate care. Excess contamination of the

instrument may result in functional disruptions and a reduction in the service life of the sturdy mechanics and electronics.

Caution

■■■■■■■■■■■■■■■■■■■■■■

Although this is prevented to a great extent by design measures, the

mains plug should be unplugged immediately if aggressive media has

penetrated the inside of the instrument, so as to avoid serious damage

to the instrument electronics. In such cases, the Metrohm Service must

be informed.

Spillages of chemicals and solvents should be cleaned up immediately. In

particular, the plug connections on the rear panel of the instrument (especially the mains plug) should be protected from contamination.

6.1.2 Maintenance by Metrohm Service

Maintenance of the instrument is best carried out as part of an annual

service, which is performed by specialist personnel from Metrohm. If

working frequently with caustic and corrosive chemicals, a shorter maintenance interval is recommended. The Metrohm service department offers

every form of technical advice for maintenance and service of all Metrohm

instruments.

6.1.3 Operation

Caution

■■■■■■■■

40

In order to avoid disturbing temperature influences, the entire system

must be protected against direct sunlight.

872 Extension Module IC Module

Page 49

■■■■■■■■■■■■■■■■■■■■■■

6.1.4 Shutting down

If the instrument is shut down for a longer period of time, the entire IC

system must be rinsed as follows to rid it of salts in order to prevent eluent salts from forming crystals which may cause subsequent damage.

■ rinse all capillaries and the Dosino with methanol/ultra pure water

(1:4),

■ rinse all pump tubings of the peristaltic pump with ultra pure water.

6.2 Door

The door is made of PMMA (polymethylmetacrylate). It must never be

cleaned with abrasive media or solvents.

6 Operation and maintenance

Caution

Caution

6.3 Eluent

6.3.1 Production

The chemicals used for the production of eluents should have a degree of

purity of at least "p.a.". Only ultra pure water (resistance > 18.2 MΩ *cm)

may be used for dilution (this generally applies for reagents which are

used in ion chromatography).

Newly produced eluents should always be microfiltered (filter 0.45 µm).

The composition of the eluent has a crucial effect on the chromatographic

analysis:

Concentration An increase in the concentration generally leads

Never use the door as a handle.

Caution

Only microfiltered (filter 0.45 µm) eluents may be used.

to shorter retention times and faster separation,

but also to higher background conductivity.

872 Extension Module IC Module

■■■■■■■■

41

Page 50

6.4 High pressure pump

pH pH changes result in shifts in the dissociation

Organic solvents The addition of an organic solvent (e.g. metha-

6.3.2 Operation

6.3.2.1 Supply bottle

The supply bottle with the eluent must be connected as indicated in

ter 4.4.1, page 23. This is above all important for eluents with volatile solvents (e.g. acetone).

Moreover, condensation must also be prevented in the eluent bottle. Drop

formation can change the concentration ratio in the eluent.

■■■■■■■■■■■■■■■■■■■■■■

equilibria and hence changes in the retention

times.

nol, acetone, acetonitrile) to aqueous eluents

generally accelerates lipophilic ions.

chap-

6.3.2.2

6.3.2.3

Aspiration filter

To protect the IC system against foreign particles, we recommend aspirating the eluents via a 6.2821.090 aspiration filter (13-2). This aspiration filter must be replaced should it show signs of yellow discoloration (but no

later than every 3 months).

In the case of very sensitive measurements, the eluent should be stirred

constantly with a magnetic stirrer.

Changing the eluent

When changing the eluent, it must be ensured that no precipitates can

occur. Solutions following one another in direct succession must therefore

be miscible. If the system has to be rinsed organically, several solvents

with rising or falling lipophilia must be used.

6.4 High pressure pump

6.4.1 Protection

Caution

■■■■■■■■

42

The pump head is filled ex works with methanol/ultra pure water. It

must be ensured that the eluent used is freely miscible with the solvent

remaining in the pump head.

To protect the high pressure pump against foreign particles, we recommend that the eluent undergoes a microfiltration (filter 0.45 µm) before

being aspirated via a 6.2821.090 aspiration filter (see "Assembling eluent

aspiration tubing", page 23).

872 Extension Module IC Module

Page 51

■■■■■■■■■■■■■■■■■■■■■■

Salt crystals between the piston and seal cause abrasion particles which

can find their way into the eluent. These lead to contaminated valves, a

rise in pressure and in extreme cases scratched pistons. It is therefore

essential to ensure that no precipitates can occur (see Chapter 6.3.2.3,

page 42).

In order to spare the pump seals, the pump should not be operated dry.

Therefore ensure that the eluent supply is correctly connected and that

there is enough eluent in the eluent bottle each time before turning on

the pump.

6.4.2 Maintenance

6 Operation and maintenance

Caution

Caution

Maintenance work on the high pressure pump may not be carried out

unless the instrument is switched off.

Pump head maintenance

An unstable baseline (pulsation, flow fluctuations) is in many cases the

result of contaminated valves (31-2), (31-3) or defective, leaking piston

seals on the high pressure pump. Proceed as follows for cleaning contaminated valves and/or replacing worn parts such as pistons, piston seal and

valves:

This maintenance work should be carried out at least once a year.

Removing the pump head

Turn off high pressure pump and wait until pressure is released.

1

Loosen the pressure screw on the inlet valve holder (18-2) and

2

unscrew the coupling (18-9), the pump head input capillary (18-7)

and the eluent aspiration tubing from the pump head.

Unscrew the pump head output capillary (18-13) from the pump

3

head.

Remove pump head from the pump housing by loosening the 4 fas-

4

tening screws (18-5) using the 6.2621.030 hexagon key. The main

872 Extension Module IC Module

■■■■■■■■

43

Page 52

6.4 High pressure pump

2

1

■■■■■■■■■■■■■■■■■■■■■■

piston is on the left (viewed from the front), and the auxiliary piston

is on the right.

Cleaning/replacing the zirconium oxide piston

Clean one piston after the other as follows:

1

Removing the piston cartridge from the pump head

Loosen the piston cartridge with a wrench and unscrew from the

pump head by hand.

1

Pump head

Figure 25 Removing piston

Piston

2

2

Dismantle the piston

Caution

On the inside of the piston cartridge there is a taut spring than can

jump out of the piston cartridge if suddenly loosing tension.

When opening the piston cartridge, hold pressure towards the

spring and unscrew carefully.

■ Loosen the screw of the piston cartridge with a wrench and

unscrew carefully by hand and by holding pressure towards the

taut spring.

■ Remove the zirconium oxide piston and lay on a tissue.

■■■■■■■■

44

872 Extension Module IC Module

Page 53

■■■■■■■■■■■■■■■■■■■■■■

1 2

3

4

5 6

7

8

■ Remove the spring retainer, spring and the inner plastic sleeve

from the piston cartridge and lay by.

■ Remove the backup ring from the pump head and lay to the other

parts.

Figure 26 Components of the piston cartridge

6 Operation and maintenance

Piston cartridge screw

1

Zirconium oxide piston with piston

3

shaft

Order number: 6.2824.070.

Spring

5

Order number: 6.2824.060.

Piston cartridge

7

3

4

Retaining washer

2

Spring retainer

4

Inner plastic sleeve

6

Protects from metallic abrasion.

Backup ring

8

Cleaning the components of the piston

■ Clean zirconium oxide pistons contaminated by abrasion or

deposits with pure abrasive cleaning powder, rinse particle free

with ultra pure water and dry.

Replace highly contaminated or scratched zirconium oxide pistons

(spare part: 6.2824.070 zirconium oxide piston).

■ Rinse the other parts of the piston and dry with a lint-free cloth.

Assembling the piston

■ Insert the inner plastic sleeve, spring and spring retainer into the

piston cartridge.

■ Slide the zirconium oxide piston carefully into the piston cartridge

until its tip emerges from the small opening of the piston cartridge.

■ Attach screw and tighten by hand.

872 Extension Module IC Module

■■■■■■■■

45

Page 54

6.4 High pressure pump

2

1

■■■■■■■■■■■■■■■■■■■■■■

Replacing the piston seal

The 6.2617.010 special tool (see Figure 27, page 46) is necessary in

order to remove the piston seal from the pump head. It consists of two

parts: a tip for removing the old piston seal and a sleeve for inserting the

new piston seal.

Figure 27 Tool for piston seal 6.2617.010

Pin

1

Pin for removing the old piston seal.

Sleeve

2

Sleeve for inserting the new piston seal.

Caution

Screwing the 6.2617.010 special tool for the piston seal into the piston

seal destroys this completely!

1

Removing the piston seal

Caution

Avoid touching the sealing surface in the pump head (18-4) with

the tool.

Screw the special tool for the piston seal (27-1) with the narrow side

just as far into the piston seal as the same can be removed.

■■■■■■■■

46

872 Extension Module IC Module

Page 55

■■■■■■■■■■■■■■■■■■■■■■

1

2

1

2

6 Operation and maintenance

Figure 28 Removing the piston seal

Piston seal

1

2

Tool for piston seal 6.2617.010

1

Sleeve for inserting the new piston seal.

Tool for piston seal

2

Pin of the tool.

Inserting the new piston seal into the tool

Insert the new piston seal tightly by hand into the recess of the

sleeve of the tool for the piston seal (27-2). The sealing springs must

be visible from the outside.

Figure 29 Insert the piston seal into the tool

Piston seal

2

Order number: 6.2741.020

872 Extension Module IC Module

3

Inserting the new piston seal into the pump head

Guide the sleeve of the tool for the piston seal (27-2) with inserted

piston seal into the pump head and press the seal with the wide end

of the tool for the piston seal (27-1) into the pump head recess.

■■■■■■■■

47

Page 56

6.4 High pressure pump

1

2

■■■■■■■■■■■■■■■■■■■■■■

Figure 30 Inserting the piston seal into the pump head

4

Replacing the piston cartridge

Screw the assembled piston cartridge back into the pump head and

tighten, first by hand, then additionally by approx. 15° with a

wrench.

Cleaning the inlet valve and outlet valve

1

Removing valves

■ Unscrew the connection capillary for the auxiliary piston (18-1)

from the outlet valve holder.

■ Unscrew the holders for the inlet and outlet valves and remove

valves.

■■■■■■■■

48

872 Extension Module IC Module

Page 57

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

6 Operation and maintenance

Figure 31 Removing valves

Outlet valve holder

1

Inlet valve

3

Order number: 6.2824.170

Outlet valve

2

Order number: 6.2824.160

Inlet valve holder

4

2

Cleaning undissected valve

Clean contaminated or blocked valves initially without dismantling

them completely.

■ Rinse the valve in eluent flow and counterflow direction using a

spray bottle filled with ultra pure water, RBS solution or acetone.

■ The rinsing effect is further increased through a short treatment

(lasting for a maximum of 20 s) in an ultrasonic bath.

Note

Longer lasting ultrasonic baths can damage the ruby ball of the

valve.

Only if this cleaning is useless, dismantle the valves separately and

clean the components.

3

Dismantling valve

Dismantle every valve separately.

872 Extension Module IC Module

Note

For dismantling the valve the 6.2617.020 tool for valve cartridges

is required.

■■■■■■■■

49

Page 58

6.4 High pressure pump

1

3

4

2

■■■■■■■■■■■■■■■■■■■■■■

■ Place the valve with the seal faced downwards above the recess

in the holder.

■ Push the valve components out of the valve housing using the

needle of the tool.

Figure 32 Dismantling valve

Needle

1

For pushing the valve components out of

the valve housing.

Holder

3

The components of the valve are collected in the recess of the

holder.

■ The inlet valve and the outlet valve consist of the same, just differ-

Valve

2

Recess

4

For collecting the valve components.

Note

The components of the valve are very small. In order not to lose

them, put the components into a dish.

ently arranged components (see Figure 33, page 51).

■■■■■■■■

50

872 Extension Module IC Module

Page 59

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

5

6

7

8

9

10

9

8

7

10

5

4

6

6 Operation and maintenance

Figure 33 Components of the inlet valve and outlet valve

Inlet valve 6.2824.170

1

Inlet valve housing

3

Sealing ring (black)

5

Sapphire sleeve

7

The shiny side must point to ruby ball.

Ceramic holder for ruby ball

9

4

Clean the components of the valve

Outlet valve 6.2824.160

2

Outlet valve housing

4

Sleeve

6

Ruby ball

8

Seal

10

The larger opening must point outwards.

Rinse the valve components with ultra pure water and/or acetone

and dry with a lint-free cloth.

5

Reassemble the valve

Reassemble valve components according to figure 33, page 51.

■ Insert the seal with the larger opening faced downwards into the

recess of the tool.

■ Lay the other valve components above another in the correct

sequence (see Figure 33, page 51).

872 Extension Module IC Module

■■■■■■■■

51

Page 60

6.4 High pressure pump

■■■■■■■■■■■■■■■■■■■■■■

■ Place the valve housing over the stacked components and hold it

tightly.

■ By tilting the tool, the valve components slide into the valve hous-

ing.

■ Press the seal by hand well on the valve housing.

6

Checking the flow direction

Rinse the valve in the direction of the arrow on the valve housing and

check wether liquid is escaping on the other end.

If this is not the case, the valve has to be dismantled again and be

assembled correctly (see Figure 33, page 51).

7

Inserting the valves back into the pump head

Caution

If by mistake, the inlet valve is mounted instead of the outlet valve,

an extreme pressure builds up within the working cylinder, which

can destroy the piston seal!

When inserting the valves, please take into account that the liquid

is being pumped through the pump head from bottom to top.

■ Insert the inlet valve into the inlet valve holder the way the seal is

visible.

■ Screw the inlet valve holder into the bottom of the pump head

and tighten with a wrench (31-4).

■ Insert the outlet valve into the outlet valve holder the way the seal

is visible.

■ Screw the outlet valve holder into the top of the pump head and

tighten with a wrench (31-1).

■■■■■■■■

52

872 Extension Module IC Module

Page 61