Page 1

863 Compact Autosampler

Manual

8.863.8003EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

863 Compact Autosampler

Manual

8.863.8003EN 06.2011 dm

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.1.1 Instrument versions ................................................................. 1

1.1.2 Instrument components .......................................................... 1

1.1.3 PC-controlled operation ........................................................... 1

1.1.4 Stand-alone operation ............................................................. 2

1.1.5 Intended use ........................................................................... 2

1.2 About the documentation ................................................... 2

1.2.1 Symbols and conventions ........................................................ 2

1.3 Safety instructions ................................................................ 3

1.3.1 General notes on safety ........................................................... 3

1.3.2 Electrical safety ........................................................................ 3

1.3.3 Tubing and capillary connections ............................................. 4

1.3.4 Personnel safety ...................................................................... 5

1.3.5 Flammable solvents and chemicals ........................................... 6

1.3.6 Recycling and disposal ............................................................. 6

Table of contents

2 Overview of the instrument 7

3 Installation 10

3.1 Setting up the instrument .................................................. 10

3.1.1 Packaging .............................................................................. 10

3.1.2 Checks .................................................................................. 10

3.1.3 Location ................................................................................ 10

3.2 Connecting the mains cable .............................................. 10

3.3 Connecting a computer ...................................................... 11

3.4 Setting up the needle holder ............................................. 13

3.5 Installing the peristaltic pump .......................................... 15

3.6 Tubing and capillary connections ..................................... 18

3.7 Connecting a keyboard, printer and other USB devi-

ces ........................................................................................ 18

3.8 Remote connections ........................................................... 21

3.8.1 Connecting IC instruments ..................................................... 21

3.8.2 Connecting a 797 VA Computrace ........................................ 21

4 Automation sequences 23

863 Compact Autosampler

4.1 Sample with air gap ........................................................... 23

4.2 Sample no air gap .............................................................. 24

4.3 Double injection .................................................................. 25

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

4.4 Triple injection .................................................................... 26

4.5 VA 797 Remote start .......................................................... 27

4.6 VA 797 Manual start .......................................................... 28

5 Operation 29

5.1 Switching the instrument on and off ............................... 29

5.2 Fundamentals of operation ............................................... 30

5.2.1 The keypad ............................................................................ 30

5.2.2 Structure of the dialog windows ............................................ 30

5.2.3 Navigating in the dialog ......................................................... 31

5.2.4 Entering text and numbers ..................................................... 31

5.3 Methods .............................................................................. 32

5.3.1 Method templates ................................................................. 32

5.3.2 Creating a new method ......................................................... 33

5.3.3 Saving a method ................................................................... 33

5.3.4 Loading a method ................................................................. 35

5.3.5 Exporting a method ............................................................... 35

5.4 Performing a sample series ............................................... 36

5.4.1 Starting the sample series ...................................................... 36

5.4.2 Pausing a sample series and continuing ................................. 38

5.5 Printing a report manually ................................................. 40

5.6 Manual control ................................................................... 41

5.6.1 Rotating the sample rack ....................................................... 41

5.6.2 Moving the lift ....................................................................... 42

5.6.3 Controlling the peristaltic pump ............................................. 42

6 System settings 44

6.1 Basic settings ...................................................................... 44

6.2 File management ................................................................ 47

6.3 Lift settings (Lift) ................................................................ 48

6.4 Configuring external devices ............................................. 49

6.5 Instrument diagnosis .......................................................... 50

6.5.1 Loading program versions and language files ......................... 50

6.5.2 Diagnosis functions ............................................................... 51

7 Parameters 52

■■■■■■■■

IV

7.1 Automation: Sample with air gap ..................................... 52

7.2 Automation: Sample no air gap ........................................ 52

7.3 Automation: Double injection ........................................... 53

7.4 Automation: Triple injection .............................................. 53

7.5 Automation: VA 797 Remote start ................................... 54

863 Compact Autosampler

Page 7

■■■■■■■■■■■■■■■■■■■■■■

8 Handling and maintenance 56

9 Troubleshooting 59

10 Appendix 60

Table of contents

7.6 Automation: VA 797 Manual start ................................... 54

8.1 Peristaltic pump .................................................................. 56

8.1.1 Operation .............................................................................. 56

8.1.2 Pump tubing ......................................................................... 56

8.1.3 Quality Management and validation with Metrohm ............... 57

9.1 Problems and their solutions ............................................. 59

10.1 Remote interface ................................................................ 60

10.1.1 Pin assignment of the remote interface .................................. 60

10.1.2 Status diagram of the remote interface .................................. 61

10.2 USB devices ......................................................................... 61

10.2.1 Numerical USB keypad 6.2147.000 ........................................ 62

10.2.2 Printer ................................................................................... 62

10.3 System initialization ........................................................... 63

11 Technical data 65

11.1 Lift ........................................................................................ 65

11.2 Turntable ............................................................................. 65

11.3 Peristaltic pump .................................................................. 65

11.4 Interfaces and connectors ................................................. 66

11.5 Mains connection ............................................................... 66

11.6 Safety specifications ........................................................... 66

11.7 Electromagnetic compatibility (EMC) ................................ 66

11.8 Ambient temperature ......................................................... 67

11.9 Reference conditions .......................................................... 67

11.10 Dimensions .......................................................................... 67

12 Conformity and warranty 68

12.1 Declaration of Conformity ................................................. 68

12.2 Warranty (guarantee) ......................................................... 69

13 Accessories 72

863 Compact Autosampler

12.3 Quality Management Principles ........................................ 70

13.1 Scope of delivery 2.863.0010 for IC applications ............ 72

13.2 Scope of delivery 2.863.0020 for VA applications .......... 77

■■■■■■■■

V

Page 8

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

13.3 Optional accessories for 2.863.0010 ................................ 82

13.4 Optional accessories for 2.863.0020 ................................ 87

Index 88

■■■■■■■■

VI

863 Compact Autosampler

Page 9

■■■■■■■■■■■■■■■■■■■■■■

Table of figures

Figure 1 Front 863 Compact Autosampler ....................................................... 7

Figure 2 Rear 863 Compact Autosampler ........................................................ 8

Figure 3 Peristaltic pump ................................................................................. 9

Figure 4 Connecting the mains cable ............................................................ 10

Figure 5 Connecting the computer ............................................................... 12

Figure 6 Installing the needle ........................................................................ 13

Figure 7 Installing the pump tubing .............................................................. 15

Figure 8 Inserting the tubing cartridge .......................................................... 16

Figure 9 Tubing guide ................................................................................... 18

Figure 10 Connecting USB devices .................................................................. 19

Figure 11 Connecting the USB stick ................................................................ 20

Figure 12 Connecting the 6.2147.000 USB keyboard with USB stick and

printer ............................................................................................. 20

Figure 13 Remote connection 863 Compact Autosampler - 861 Compact

IC .................................................................................................... 21

Figure 14 Remote connection 863 Compact Autosampler - 843 Pump Station -

797 VA Computrace ........................................................................ 22

Figure 15 Keypad 863 Compact Autosampler ................................................. 30

Figure 16 Adjusting the needle ....................................................................... 49

Figure 17 Pin assignment of remote socket and plug ...................................... 60

Figure 18 Remote status diagram .................................................................... 61

Table of figures

863 Compact Autosampler

■■■■■■■■

VII

Page 10

Page 11

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The 863 Compact Autosampler is an autosampler for ion chromatography

or voltammetry with a wide variety of applications. It can be used both as

a central control instrument in a stand-alone automation system or as an

integrated sample changer in a PC-controlled automation system.

1.1.1 Instrument versions

The 863 Compact Autosampler is available in two versions with different

accessories.

863 Compact IC Autosampler (2.863.0010)

With accessories for ion chromatography.

863 Compact VA Autosampler (2.863.0020)

With accessories for voltammetry.

1 Introduction

1.1.2 Instrument components

The 863 Compact Autosampler has the following components:

■ Turntable

Permanently mounted sample rack with 36 positions for sample tubes.

■ Lift with lift head

With needle holder for PEEK needles.

■ 1-channel peristaltic pump

For the transport of sample solutions.

■ USB (OTG) connector

For connection to a computer, to a printer or to a USB stick (for system

backup or method export).

■ Remote connector

For connecting instruments with a remote connector.

1.1.3 PC-controlled operation

If the 863 Compact Autosampler is controlled by means of a USB connection using the PC software MagIC Net, then arbitrary automation

sequences can be programmed. This allows optimal utilization of the

instrument components. The software can trigger the instrument components directly and use them more flexibly.

863 Compact Autosampler

■■■■■■■■

1

Page 12

1.2 About the documentation

1.1.4 Stand-alone operation

The 863 Compact Autosampler can be used as the central control instrument in an automation system which can include various ion chromatography instruments or the 797 VA Computrace. The 863 Compact Autosampler thereby plays the part of the reliable sample changer.

The given method sequences can be parameterized individually and saved

as sample-specific methods. Methods can be exported on an USB memory

stick and then copied onto another instrument quickly and easily.

1.1.5 Intended use

The 863 Compact Autosampler is designed for usage as an automation

system in analytical laboratories. It is not suitable for usage in biochemical, biological or medical environments in its basic equipment version.

1.2 About the documentation

Caution

■■■■■■■■■■■■■■■■■■■■■■

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which have to be followed by the user in order to ensure

safe operation of the instrument.

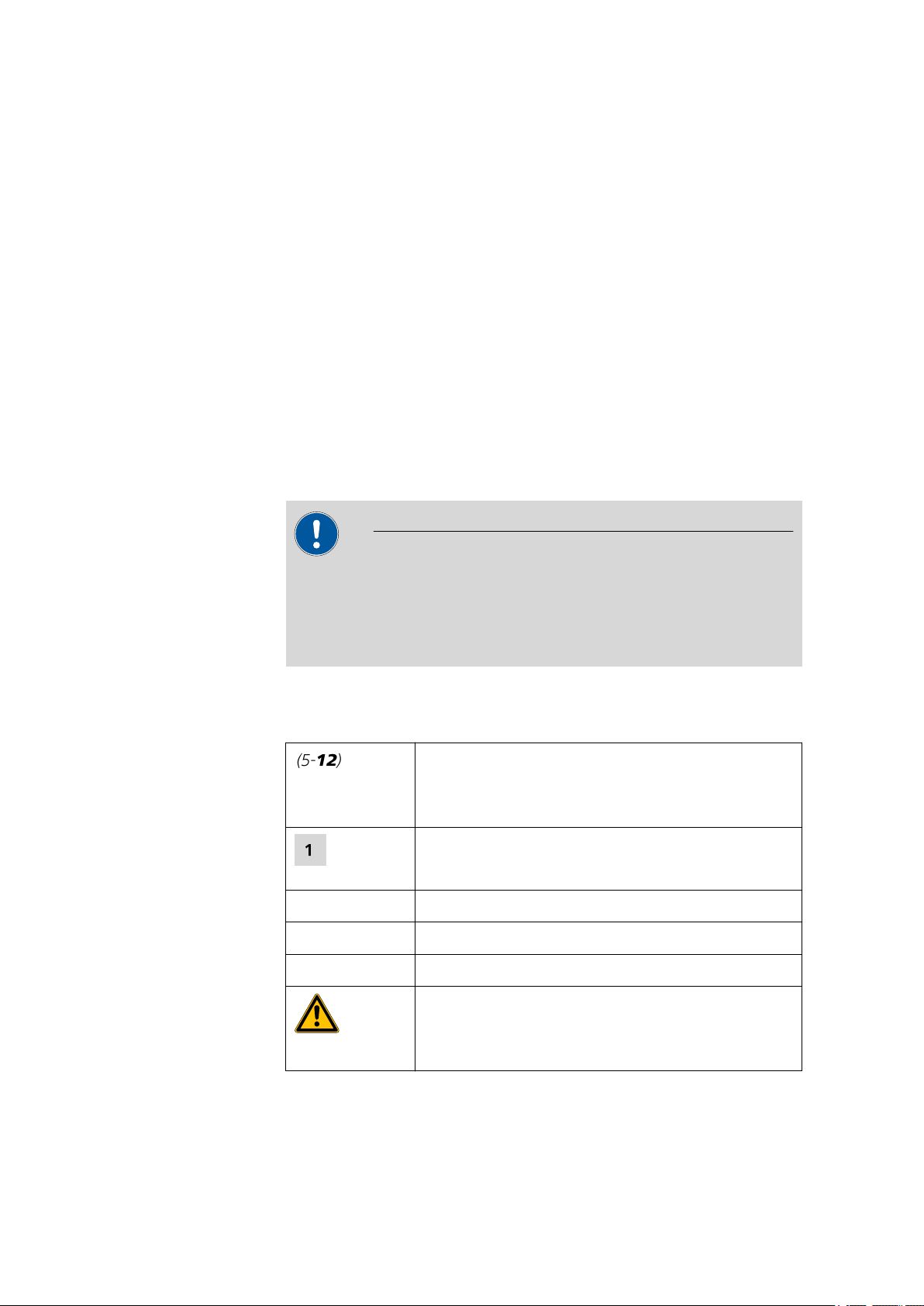

1.2.1 Symbols and conventions

The following symbols and styles are used in this documentation:

Method Dialog text, parameter in the software

File ▶ New

[Next] Button or key

Cross-reference to figure legend

The first number refers to the figure number, the

second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

Menu or menu item

Warning

■■■■■■■■

2

This symbol draws attention to a possible life hazard

or risk of injury.

863 Compact Autosampler

Page 13

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

Warning

This symbol draws attention to a possible hazard due

to electrical current.

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

Warning

This symbol draws attention to a possible biological

hazard.

Caution

This symbol draws attention to a possible damage of

instruments or instrument parts.

Note

This symbol marks additional information and tips.

1.3 Safety instructions

1.3.1 General notes on safety

Warning

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

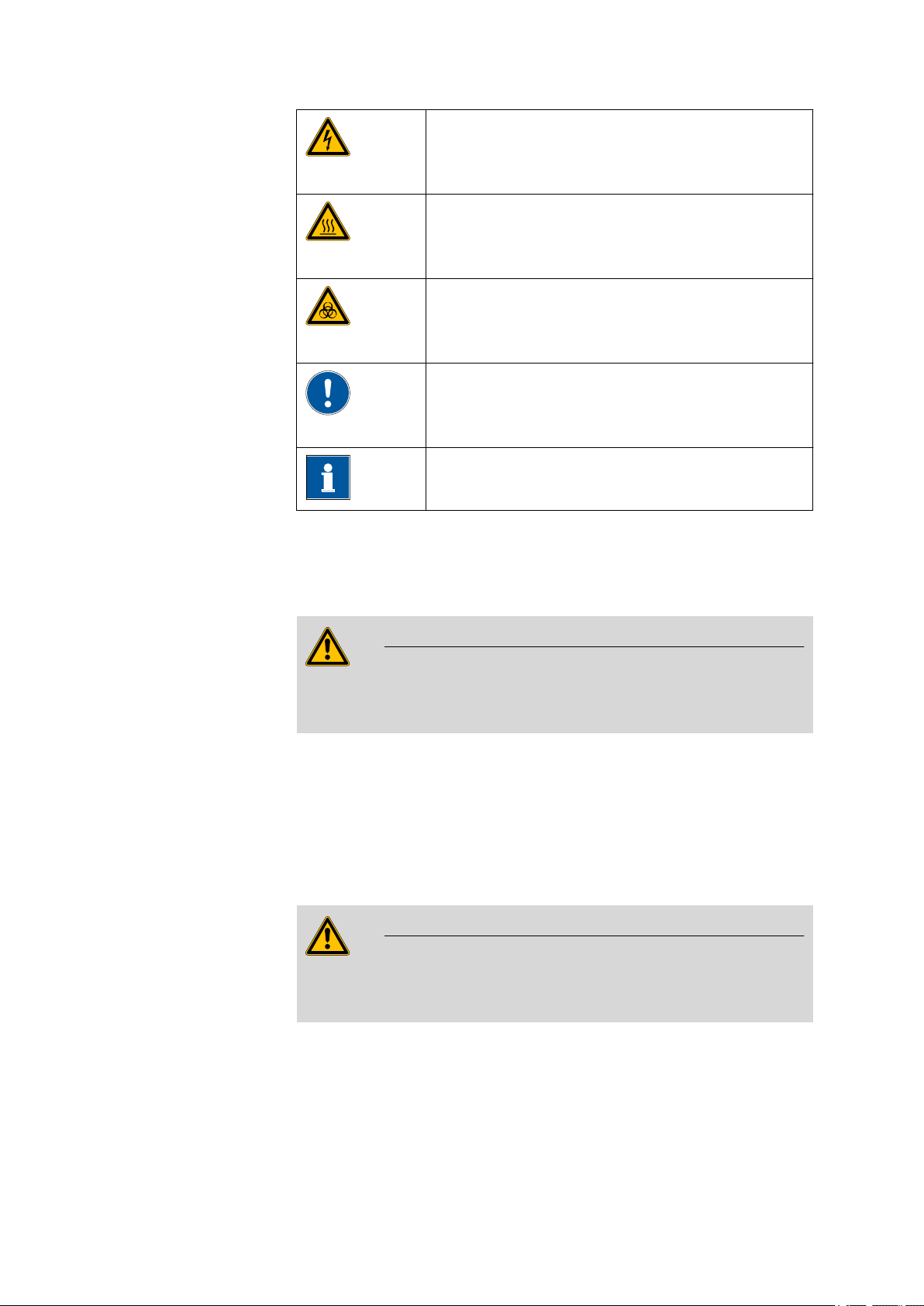

1.3.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

Warning

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

863 Compact Autosampler

■■■■■■■■

3

Page 14

1.3 Safety instructions

■■■■■■■■■■■■■■■■■■■■■■

Warning

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Mains voltage

Warning

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

Protection against electrostatic charges

Warning

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Always pull the mains cable out of the mains connection socket before

connecting or disconnecting electrical appliances on the rear panel of

the instrument.

1.3.3 Tubing and capillary connections

Caution

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are mandatory.

■■■■■■■■

4

863 Compact Autosampler

Page 15

■■■■■■■■■■■■■■■■■■■■■■

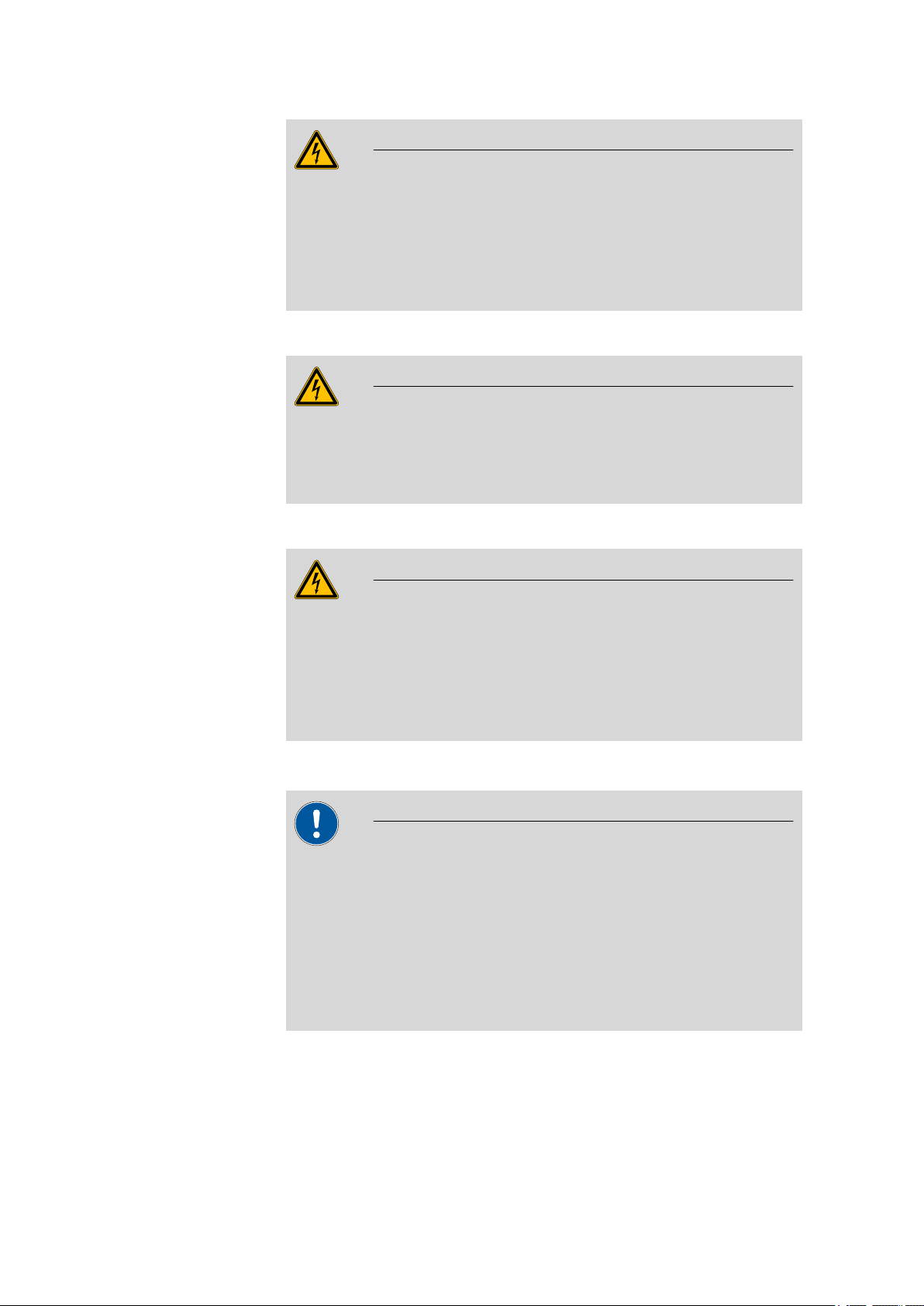

1.3.4 Personnel safety

Wear protective goggles and working clothes suitable for laboratory

work while operating the 863 Compact Autosampler. It is also advisable

to wear gloves when caustic liquids are used or in situations where

glass vessels could break.

Always install the safety shield supplied with the equipment before

using the instrument for the first time. Pre-installed safety shields are

not allowed to be removed.

The 863 Compact Autosampler may not be operated without a safety

shield!

1 Introduction

Warning

Warning

Warning

Personnel are not permitted to reach into the working area of the

instrument while operations are running!

A considerable risk of injury exists for the user.

Warning

In the event of a possible blockage of a drive, the mains plug must be

pulled out of the socket immediately. Do not attempt to free jammed

sample vessels or other parts while the device is switched on. Blockages

can only be cleared when the instrument is in a voltage-free status; this

action generally involves a considerable risk of injury.

Warning

The 863 Compact Autosampler is not suitable for utilization in biochemical, biological or medical environments in its basic equipment version.

863 Compact Autosampler

Appropriate protective measures must be implemented in the event

that potentially infectious samples or reagents are being processed.

■■■■■■■■

5

Page 16

1.3 Safety instructions

1.3.5 Flammable solvents and chemicals

Warning

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location.

■ Keep all sources of flame far from the workplace.

■ Clean up spilled fluids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

1.3.6 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

■■■■■■■■■■■■■■■■■■■■■■

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

■■■■■■■■

6

863 Compact Autosampler

Page 17

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

5

6

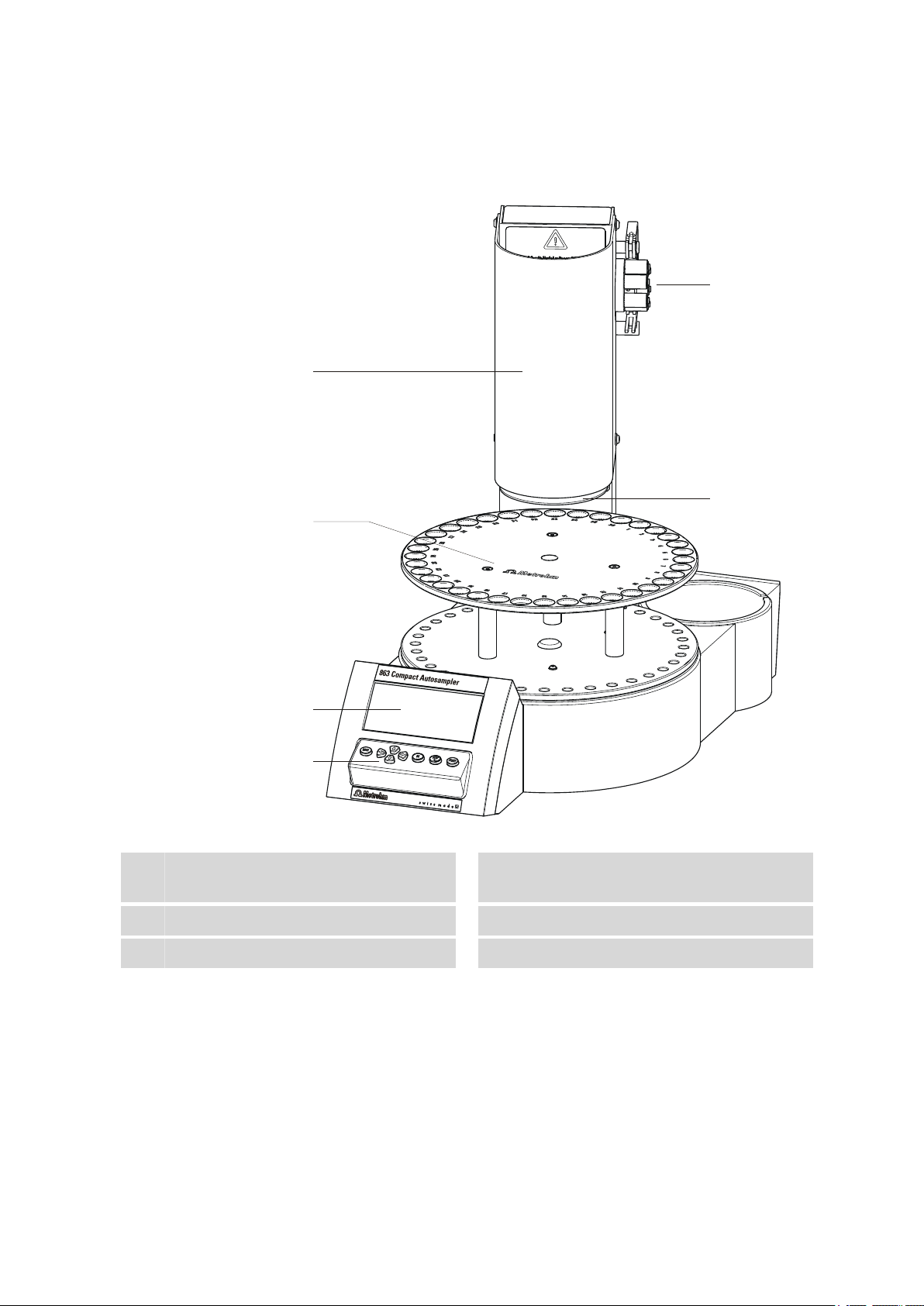

2 Overview of the instrument

2 Overview of the instrument

Figure 1 Front 863 Compact Autosampler

Safety shield

1

Display

3

Peristaltic pump

5

863 Compact Autosampler

Sample rack

2

For 36 sample tubes

Keypad

4

Retaining plate

6

■■■■■■■■

7

Page 18

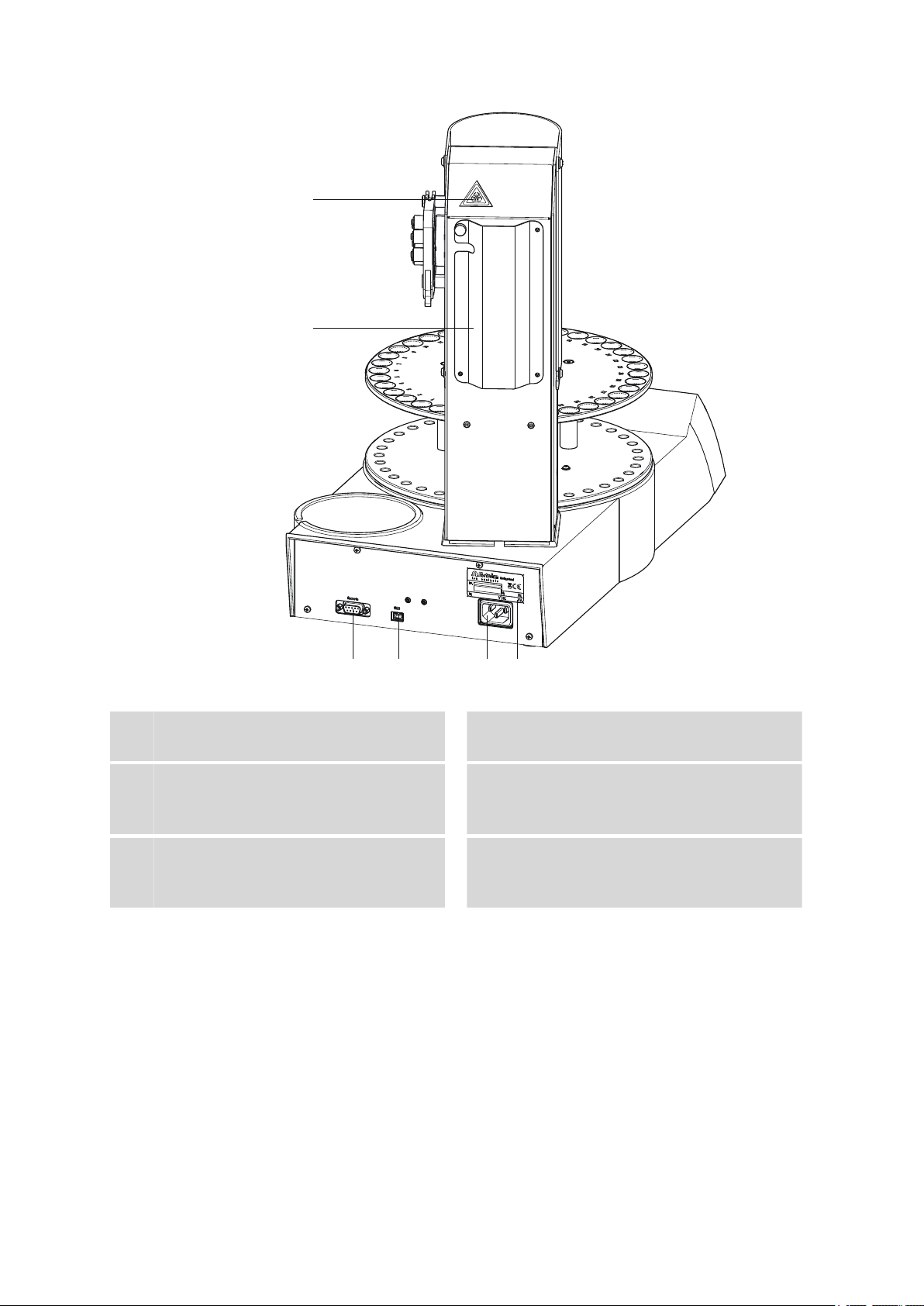

■■■■■■■■■■■■■■■■■■■■■■

1

2

3 4 5 6

Figure 2 Rear 863 Compact Autosampler

Warning symbol

1

(see Chapter 1.3.4, page 5)

Remote connector

3

For connecting instruments with a remote

interface. D-Sub, 9-pin.

Mains connection socket

5

Tubing and cable cover

2

USB (OTG) connector

4

For connecting computers, printers, USB

sticks, USB hubs, etc.

Type plate

6

Contains specifications concerning mains

voltage and serial number.

■■■■■■■■

8

863 Compact Autosampler

Page 19

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

5

2 Overview of the instrument

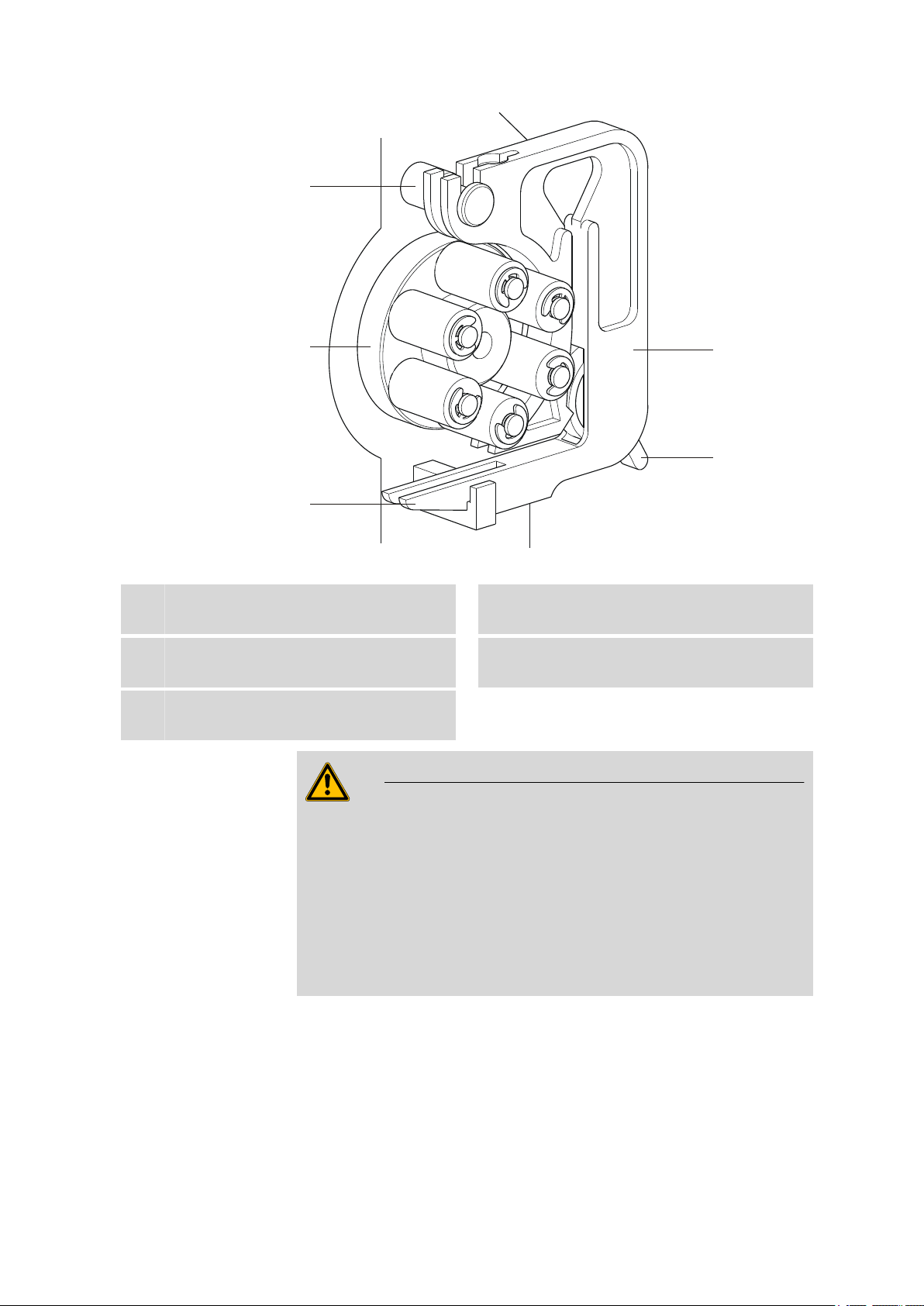

Figure 3 Peristaltic pump

Mounting pin

1

For engaging the tubing cartridge

Snap-action lever

3

For releasing the tubing cartridge

Contact pressure lever

5

For regulating contact pressure

Pump drive

2

Roller head with contact pressure rollers

Tubing cartridge 6.2755.000

4

For 6.1826.xx0 pump tubings

Warning

Never attempt to carry out manipulations on the tubing cartridge or on

the pump drive while the instrument is running. There is a considera-

ble risk of injury.

The pump tubing may not be replaced unless the instrument is

switched off.

Switch off the instrument immediately if the roller drive becomes

blocked. Only then should you attempt to eliminate the problem.

863 Compact Autosampler

■■■■■■■■

9

Page 20

3.1 Setting up the instrument

3 Installation

3.1 Setting up the instrument

3.1.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

3.1.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

3.1.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

■■■■■■■■■■■■■■■■■■■■■■

Place the instrument in a location of the laboratory which is suitable for

operation, free of vibrations, protected from corrosive atmosphere, and

contamination by chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

3.2 Connecting the mains cable

Warning

This instrument may only be used with the mains voltage specified (see

rear of the instrument).

Protect the connection sockets against moisture.

■■■■■■■■

10

Figure 4 Connecting the mains cable

863 Compact Autosampler

Page 21

■■■■■■■■■■■■■■■■■■■■■■

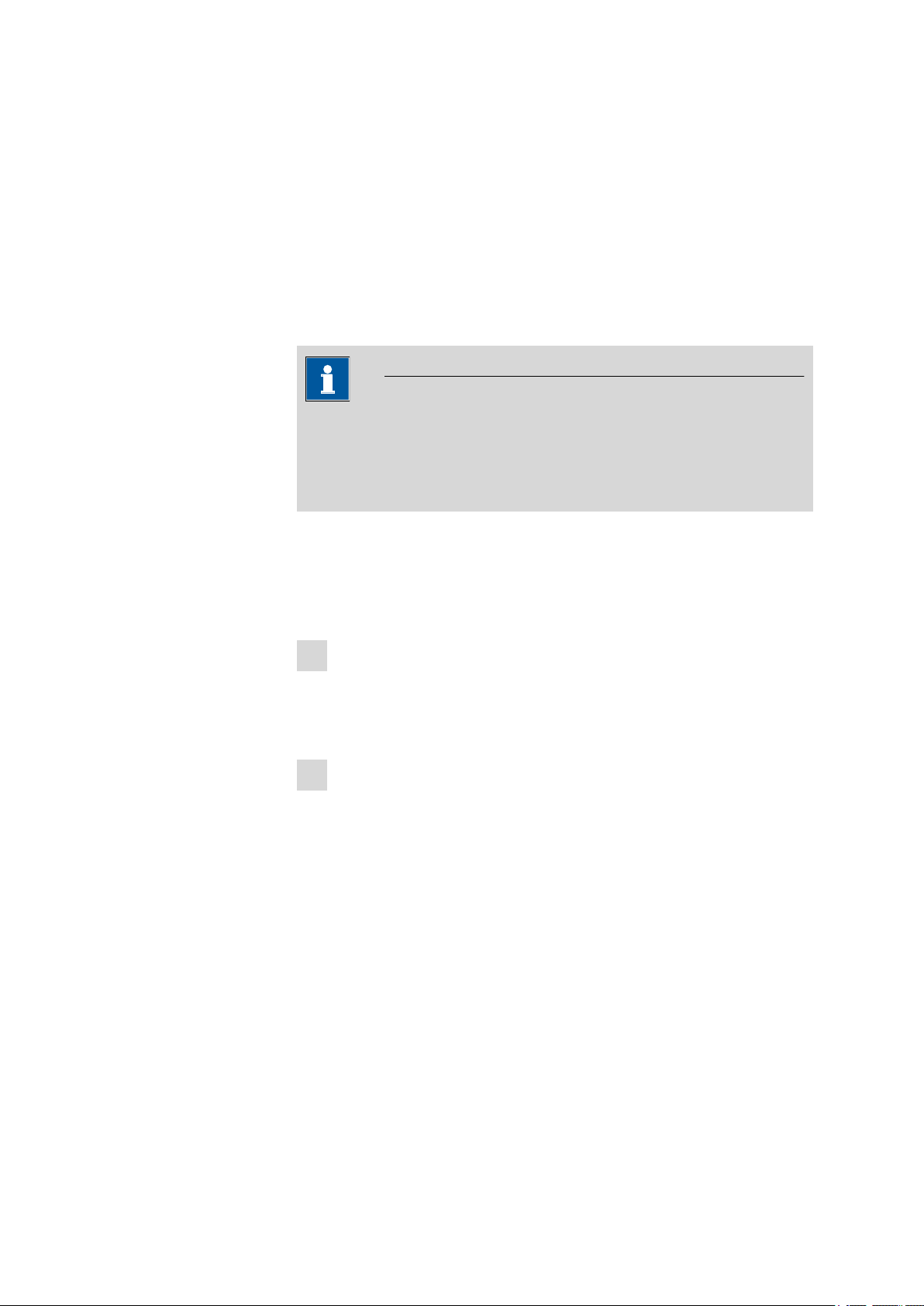

3.3 Connecting a computer

The 863 Compact Autosampler requires a USB connection to a computer

in order to be able to be controlled by the PC software MagIC Net (version 1.1 or newer). With a 6.2151.110 USB connection cable (Mini-USB

OTG/USB A), the instrument can be connected either directly to a USB

socket on a computer, to an attached USB hub or to another suitable

Metrohm instrument (e.g. 850 Professional IC, 881 Compact IC pro, 882

Compact IC plus or 883 Basic IC plus).

Note

If the 863 Compact Autosampler is not to be controlled by MagIC Net,

then no direct connection to a PC is required. In such cases, the instrument is used in so-called stand-alone mode and is connected via

remote cable to a corresponding control instrument.

3 Installation

Cable connection and driver installation

A driver installation is required in order to ensure that the 863 Compact

Autosampler is recognized by MagIC Net. To accomplish this, you must

comply with the procedures specified. The following steps are necessary:

1

Install the software

■ Insert the MagIC Net installation CD and carry out the installation

program directions.

■ Exit the program if you have started it after the installation.

2

Establish the cable connections

■ Connect the instrument to the mains supply if you have not

already done this.

■ Connect the instrument to a USB connector (Type A) of your com-

puter (see manual of your computer). The 6.2151.110 cable is

used for this purpose.

863 Compact Autosampler

■■■■■■■■

11

Page 22

3.3 Connecting a computer

6.2151.110

■■■■■■■■■■■■■■■■■■■■■■

Figure 5 Connecting the computer

The instrument is recognized. The now following driver installation

varies, depending on the version of the Windows operating system

used.

■ Either the required driver is installed automatically, or an installa-

tion assistant is started.

Follow the instructions of the installation assistant.

3

If problems should occur during installation, contact your company's IT

supporter.

Registering and configuring the instrument in MagIC Net

The instrument must be registered in the configuration of MagIC Net.

Once that has been done, you can then configure it according to your

requirements. Proceed as follows:

1

Set up the instrument

■ Start MagIC Net.

The instrument is automatically recognized. The configuration dialog for the instrument is displayed.

■ Make configuration settings for the instrument and its connec-

tors.

More detailed information concerning the configuration of the

instrument can be found in the documentation for the respective PC

software.

■■■■■■■■

12

863 Compact Autosampler

Page 23

■■■■■■■■■■■■■■■■■■■■■■

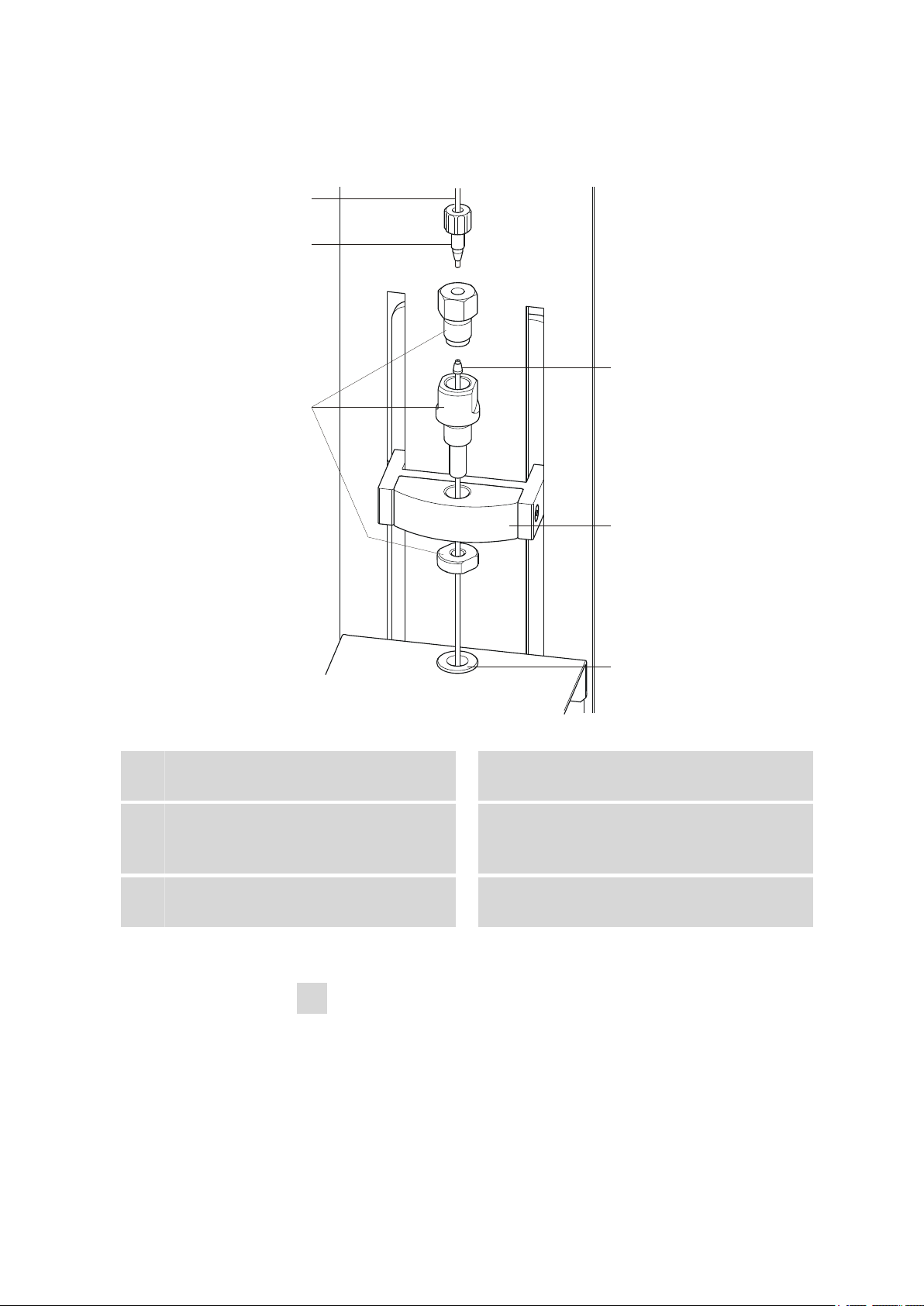

1

2

3

4

5

6

3.4 Setting up the needle holder

3 Installation

Figure 6 Installing the needle

PEEK capillary

1

6.1831.050 (40 cm) or 6.1831.060 (100 cm)

Needle holder (6.2833.030)

3

Comprising pressure screw, needle guide

and nut

Lift

5

With lift head

This is how you mount needle and capillary:

1

Open the safety shield

PEEK pressure screw (6.2744.070)

2

Sample aspiration needle (6.2846.000)

4

With PEEK ring wedge, outer diameter 1/8"

Centering aid

6

Loosen the lower two fastening screws of the safety shield using the

hexagon key provided, and tip up the safety shield.

863 Compact Autosampler

■■■■■■■■

13

Page 24

3.4 Setting up the needle holder

■■■■■■■■■■■■■■■■■■■■■■

2

Remove the nut

Loosen and remove the nut screwed onto the needle holder.

3

Insert the needle holder

Insert the needle holder in the lift head and screw it tight with the

nut from below.

4

Insert the needle

■ Loosen the pressure screw from the needle holder and remove it.

■ Insert the needle part way from above into the opening of the

needle holder.

■ Slide the PEEK ring wedge down over the needle from above. The

narrow side of the seal must face upwards.

5

Fasten the needle

■ Screw the pressure screw into the needle holder from above. At

the same time push the needle slightly upward from below to

apply a little pressure.

■ Tighten the pressure screw firmly.

6

Connect the capillary

■ Slide a 6.2744.010 PEEK pressure screw over the end of the capil-

lary.

■ Manually screw tight the PEEK pressure screw with the capillary in

the pressure screw resting on the needle holder. The capillary

must be pressed tight while doing so.

7

Close the safety shield

Tip down the safety shield and fix it with the fastening screws.

■■■■■■■■

14

Warning

The safety shield must always be closed for safety reasons during operation of the 863 Compact Autosampler.

863 Compact Autosampler

Page 25

■■■■■■■■■■■■■■■■■■■■■■

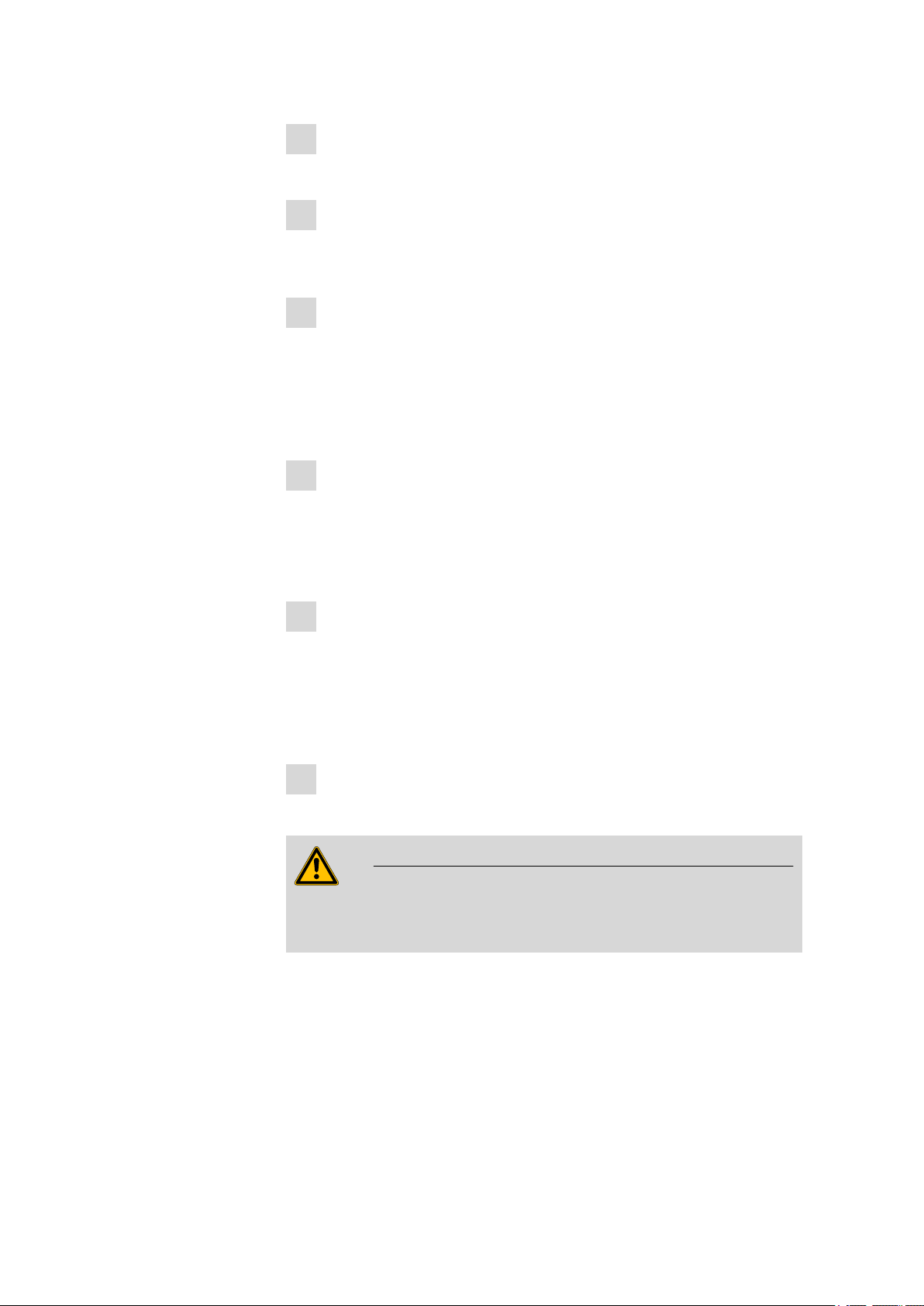

1 2 3 4 5 6 7 8 1

9 10 3

6.2744.160

3.5 Installing the peristaltic pump

3 Installation

Figure 7 Installing the pump tubing

PEEK pressure screws, short

1

(6.2744.070)

Stopper

3

The colors of the stopper indicate the inner

diameter of the pump tubing.

Contact pressure lever

5

Adapter

7

Pump tubing (6.1826.xx0)

9

Tubing olive (6.2744.034)

2

Tubing cartridge (6.2755.000)

4

Union nut

6

Tubing olive

8

Snap-action lever

10

Mount the pump tubing as follows:

1

Removing the tubing cartridge

Release the tubing cartridge from the cartridge holder by pressing

the snap-action lever and unhooking from the mounting pins (see

Figure 3, page 9).

2

Connecting the aspiration side

863 Compact Autosampler

Place a 6.2744.034 tubing olive (7-2) on the aspiration side of the

pump tubing.

■■■■■■■■

15

Page 26

3.5 Installing the peristaltic pump

■■■■■■■■■■■■■■■■■■■■■■

Note

For the voltammetry, we recommend connecting the aspiration

side the same way as the pressure side, see following section. The

necessary second set of the 6.2744.160 pump tubing connection

is enclosed.

3

Connecting the pressure side

■ Slide the union nut (7-6) of the 6.2744.160 pump tubing connec-

tion (without filter) onto the pump tubing.

■ Select a suitable adapter (7-7) and slide it onto the pump tubing.

The type of adapter depends on the pump tubing (see Table 1,

page 17).

■ Place the tubing olive (7-8) onto the pump tubing.

■ Screw the union nut (7-6) tight on the tubing olive (7-8).

4

Inserting the pump tubing

■ Press the contact pressure lever all the way down.

■ Place the pump tubing in the tubing cartridge. The stoppers (7-3)

must snap into the corresponding holders of the tubing cartridge.

5

Inserting the tubing cartridge

■ Hang the tubing cartridge in the mounting pin and press in the

cartridge holder until the snap-action lever snaps in.

■■■■■■■■

16

Figure 8 Inserting the tubing cartridge

863 Compact Autosampler

Page 27

■■■■■■■■■■■■■■■■■■■■■■

6

Connecting the capillaries

■ Screw the respective capillaries tightly to the two tubing olives

with PEEK pressure screws (7-1).

Table 1 Pump tubings and suitable adapters

Pump tubing Adapter

6.1826.020 (blue/blue)

6.1826.310 (orange/green)

6.1826.320 (orange/yellow)

6.1826.330 (orange/white)

6.1826.340 (black/black)

3 Installation

6.1826.360 (white/white)

6.1826.380 (gray/gray)

6.1826.390 (yellow/yellow)

Set flow rate

The contact pressure of the tubing cartridge must be adjusted in order to

regulate the flow rate. Proceed as follows:

Set the contact pressure

■ Fully loosen the contact pressure lever (7-5), i.e. press it all the

1

way down.

■ Switch on the peristaltic pump.

■ Raise the contact pressure lever one step at a time until liquid

flows.

■ When liquid starts flowing, raise the contact pressure lever by an

additional 2 ratchet increments.

863 Compact Autosampler

The contact pressure is now set optimally.

The delivery rate depends not only on the correct contact pressure

but also on the interior diameter of the pump tubing and the rotational speed of the drive.

■■■■■■■■

17

Page 28

3.6 Tubing and capillary connections

Inject

Note

Pump tubings are consumable material. The service life of the pump

tubings depends on the contact pressure amongst other factors.

3.6 Tubing and capillary connections

■■■■■■■■■■■■■■■■■■■■■■

Figure 9 Tubing guide

In order to lay the tubing and capillaries neatly, you can insert them into

the tubing cover on the rear side of the tower. The above illustration

shows one of the possible variants. The tubing cover can be removed by

loosening the four red knurled screws.

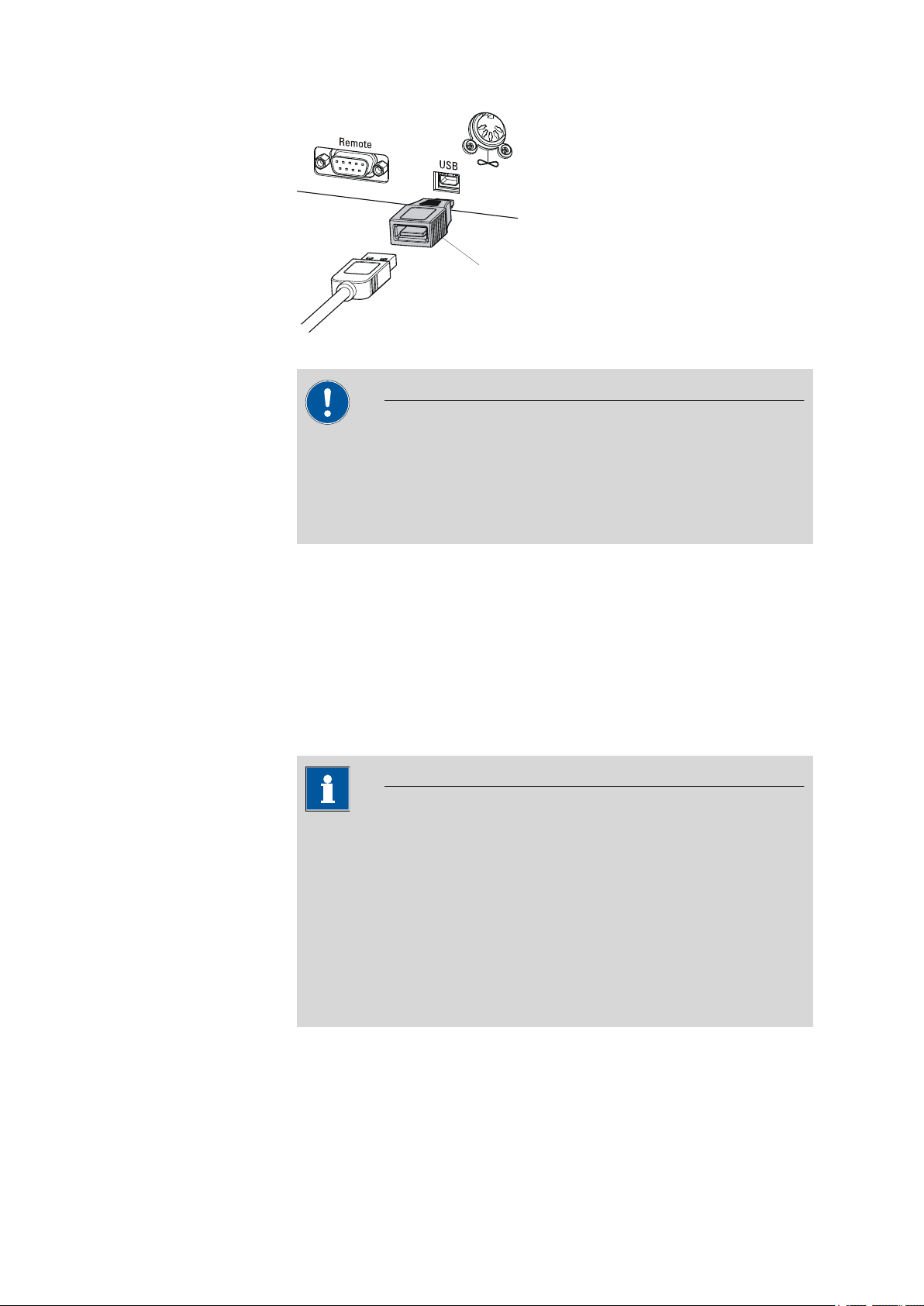

3.7 Connecting a keyboard, printer and other USB devices

The 863 Compact Autosampler has a USB (OTG) connector. Use the provided 6.2151.100 adapter USB MINI (OTG) - USB A for connecting USB

devices as e.g. printers, keyboards or USB sticks, see the following figure.

■■■■■■■■

18

863 Compact Autosampler

Page 29

■■■■■■■■■■■■■■■■■■■■■■

6.2151.100

3 Installation

Figure 10 Connecting USB devices

Caution

Switch the instrument off before connecting or disconnecting a USB

device or a USB stick.

The 863 Compact Autosampler can only recognize the device immediately after switching on.

The following devices can be operated directly on the USB connector

with the 6.2151.100 adapter:

■ USB sticks (for the backup or storing of methods)

■ 6.2147.000 numerical USB keypad

■ USB hub (with or without an own power supply)

The 6.2147.000 numerical USB keypad serves for comfortable numerical input and for navigating in the dialog. In addition, it provides two USB

connectors. Connect additional USB devices to the keypad.

Note

Most of the USB devices need a so-called hub in order to work correctly.

A USB hub is a distributor to which several USB devices can be connected. USB hubs are available in specialty stores in a number of different

models.

The USB (OTG) connector of the 863 Compact Autosampler has no

such hub. The 6.2147.000 numerical USB keypad has a USB hub and

two USB connectors.

863 Compact Autosampler

The following devices can only be connected to a 6.2147.000

numerical keypad or to a USB hub:

■ Printer (with USB connector, use the 6.2151.020 connecting cable)

■■■■■■■■

19

Page 30

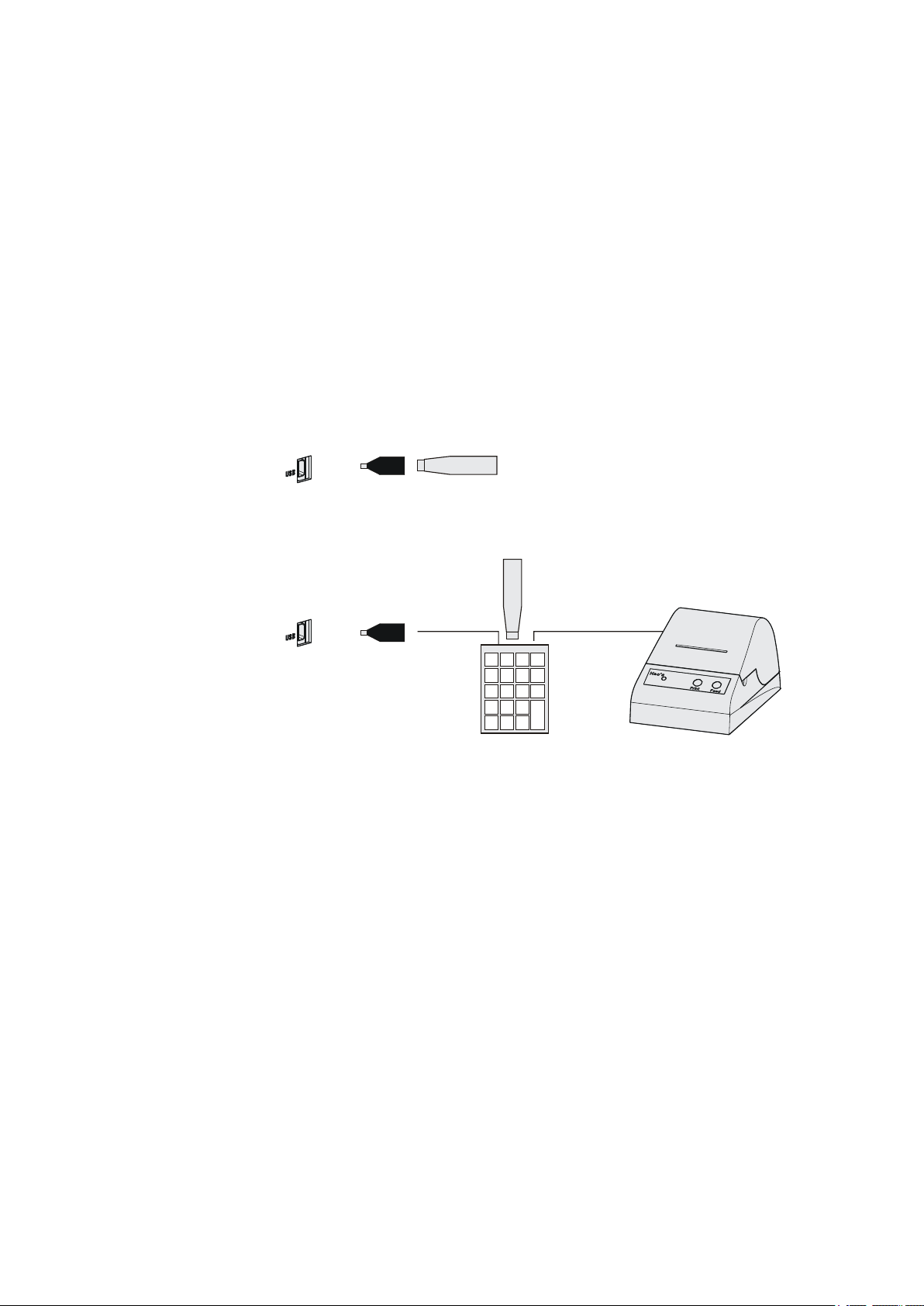

3.7 Connecting a keyboard, printer and other USB devices

USB MINI (OTG)-USB

USB stick

6.2151.100

USB MINI (OTG)-USB

USB stick

Keypad

6.2147.000

6.2151.100

Printer

■ Barcode reader (with USB cable)

■ Mouse (PC mouse with USB cable, for navigating in the dialog)

The following devices can only be connected to a USB hub:

■ PC keyboard (with USB cable, for the comfortable input of letters and

numbers)

■ Keypad with numerical keypad (with USB cable)

If you wish to connect several different instruments without own

power supply, then you must possibly use a USB hub with own power

supply (self powered). The USB (OTG) connector of the 863 Compact

Autosampler is not designed for supplying power to several devices with

elevated electricity requirements.

Examples:

Figure 11 Connecting the USB stick

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

20

Figure 12 Connecting the 6.2147.000 USB keyboard with USB stick and

printer

863 Compact Autosampler

Page 31

■■■■■■■■■■■■■■■■■■■■■■

6.2141.270

S

WARNING - Fire Hazard -

with the same type and rating of fuse

For continued protection replace only

Type 1.761.

Fuse

100-120V:

220-240V:

1,0A(T)

0,5A(T)

Made by Metrohm Herisau Switzerland

RS 232

Detector Block

Remote

Waste B

Waste A

Transport security screws

861 Compact IC

863 Compact Autosampler

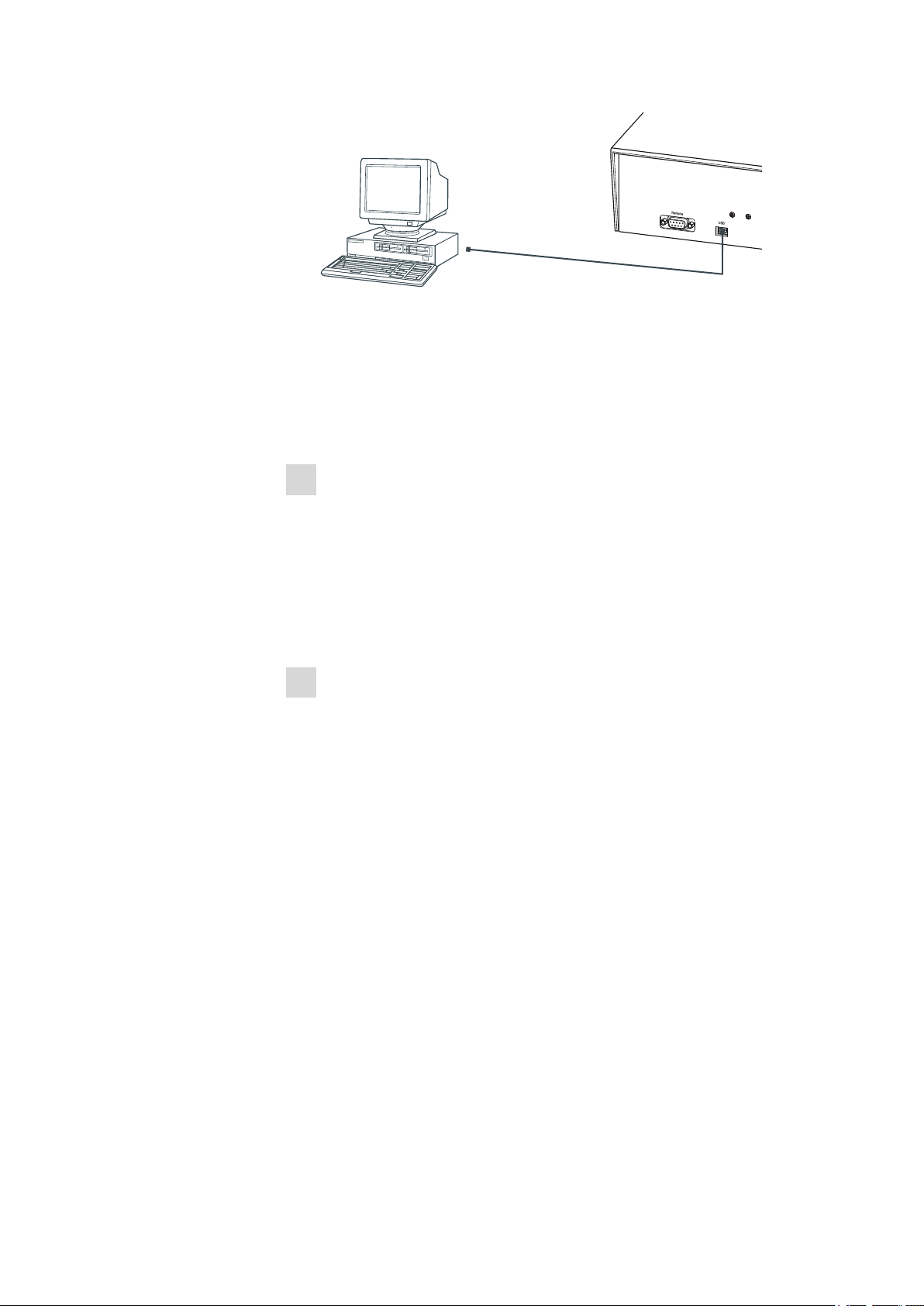

3.8 Remote connections

The 863 Compact Autosampler can be used as a control device for a simple automation system with a large variety of different instruments. Even

older Metrohm instruments can thus be integrated into an automated

analysis system.

3.8.1 Connecting IC instruments

The following illustration shows, as an example, the connection of an 861

Compact IC. In addition, the following IC instruments can be connected

with the 6.2141.270 remote cable: 732 IC Detector, 761 Compact IC, 790

Personal IC, 819 IC Detector und 844 UV/VIS Compact IC.

3 Installation

3.8.2 Connecting a 797 VA Computrace

Figure 13 Remote connection 863 Compact Autosampler - 861 Com-

An 843 Pump Station is also required for operation with a 797 VA Computrace.

pact IC

863 Compact Autosampler

■■■■■■■■

21

Page 32

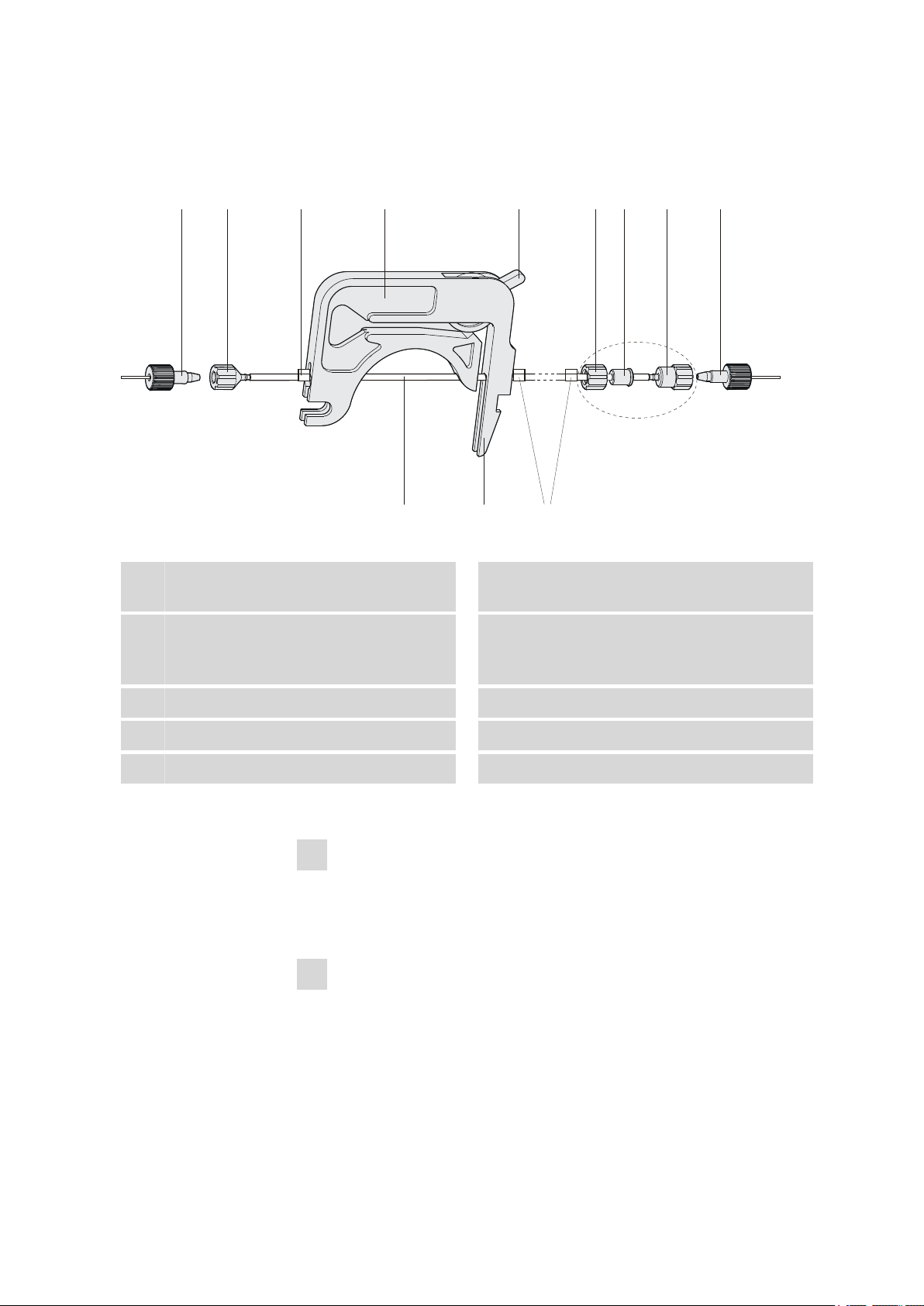

3.8 Remote connections

6.2141.230

6.2141.280

843 Pump Station

863 Compact Autosampler

797 VA Computrace

■■■■■■■■■■■■■■■■■■■■■■

Figure 14 Remote connection 863 Compact Autosampler - 843 Pump

Station - 797 VA Computrace

The 863 Compact Autosampler is connected with a 6.2141.230 cable to

the Remote 2 connector of the 843 Pump Station. Remote 1 is connected to the 797 VA Computrace with the aid of a 6.2141.280 cable.

The pumps of the 843 Pump Station are activated by the 797 VA Computrace.

■■■■■■■■

22

863 Compact Autosampler

Page 33

■■■■■■■■■■■■■■■■■■■■■■

4 Automation sequences

Note

The following method sequences and parameters can only be used if

the 863 Compact Autosampler is not controlled by a PC software (e.g.

MagIC Net) via USB connection.

4.1 Sample with air gap

This method template is suitable for simple determinations.

An air gap is formed in the transfer tubing between the individual samples.

4 Automation sequences

Preparing and starting the sample series

Press [START].

1

Under Number of samples, enter the number of samples or the

2

maximum value of 99.

Under Next sample pos., enter the rack position of the first sample

3

to be processed.

Press [BACK].

4

Start the sample series in the IC Net software.

5

Note

The method run will be automatically restarted for every sample via

remote connection (Autostart). A stepping pulse of the connected

instrument is expected at the end of the method run. The 863 Compact

Autosampler must be stopped manually by means of the button

[STOP] after the processing of the last sample.

863 Compact Autosampler

The individual steps of the method:

■ Move to the sample

■■■■■■■■

23

Page 34

4.2 Sample no air gap

■ Lower the lift to the work position

■ Switch on the peristaltic pump for the sample transfer

■ Wait for the pump time to be completed

■ Switch off the peristaltic pump

■ Move the lift upward

■ Switch on the peristaltic pump

■ Wait for the waiting time for air gap to be completed

■ Switch off the peristaltic pump

■ Wait for the stepping pulse

4.2 Sample no air gap

This method template is suitable for simple determinations.

No air gap is formed in the transfer tubing between the individual samples.

Preparing and starting the sample series

Press [START].

1

Under Number of samples, enter the number of samples or the

2

maximum value of 99.

Under Next sample pos., enter the rack position of the first sample

3

to be processed.

Press [BACK].

4

Start the sample series in the IC Net software.

5

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

24

Note

The method run will be automatically restarted for every sample via

remote connection (Autostart). A stepping pulse of the connected

instrument is expected at the end of the method run. The 863 Compact

Autosampler must be stopped manually by means of the button

[STOP] after the processing of the last sample.

The individual steps of the method:

■ Move to the sample

■ Lower the lift to the work position

■ Switch on the peristaltic pump for the sample transfer

863 Compact Autosampler

Page 35

■■■■■■■■■■■■■■■■■■■■■■

■ Wait for the pump time to be completed

■ Switch off the peristaltic pump

■ Wait for the stepping pulse

4.3 Double injection

This method template enables two sample transfers of the same sample.

No air gap is formed in the transfer tubing between the individual samples.

Preparing and starting the sample series

Press [START].

1

Under Number of samples, enter the number of samples or the

2

maximum value of 99.

Under Next sample pos., enter the rack position of the first sample

3

to be processed.

Press [BACK].

4

Start the sample series in the IC Net software.

5

4 Automation sequences

Note

The method run will be automatically restarted for every sample via

remote connection (Autostart). A stepping pulse of the connected

instrument is expected at the end of the method run. The 863 Compact

Autosampler must be stopped manually by means of the button

[STOP] after the processing of the last sample.

The individual steps of the method:

■ Move to the sample

■ Lower the lift to the work position

■ Switch on the peristaltic pump for the first sample transfer

■ Wait for the pump time to be completed

■ Switch off the peristaltic pump

■ Wait for the stepping pulse

■ Switch on the peristaltic pump for the second sample transfer

■ Wait for the pump time to be completed

■ Switch off the peristaltic pump

863 Compact Autosampler

■■■■■■■■

25

Page 36

4.4 Triple injection

■ Wait for the stepping pulse

4.4 Triple injection

This method template enables three sample transfers of the same sample.

No air gap is formed in the transfer tubing between the individual samples.

Preparing and starting the sample series

Press [START].

1

Under Number of samples, enter the number of samples or the

2

maximum value of 99.

Under Next sample pos., enter the rack position of the first sample

3

to be processed.

Press [BACK].

4

Start the sample series in the IC Net software.

5

■■■■■■■■■■■■■■■■■■■■■■

Note

The method run will be automatically restarted for every sample via

remote connection (Autostart). A stepping pulse of the connected

instrument is expected at the end of the method run. The 863 Compact

Autosampler must be stopped manually by means of the button

[STOP] after the processing of the last sample.

The individual steps of the method:

■ Move to the sample

■ Lower the lift to the work position

■ Switch on the peristaltic pump for the first sample transfer

■ Wait for the pump time to be completed

■ Switch off the peristaltic pump

■ Wait for the stepping pulse

■ Switch on the peristaltic pump for the second sample transfer

■ Wait for the pump time to be completed

■ Switch off the peristaltic pump

■ Wait for the stepping pulse

■ Switch on the peristaltic pump for the third sample transfer

■■■■■■■■

26

863 Compact Autosampler

Page 37

■■■■■■■■■■■■■■■■■■■■■■

■ Wait for the pump time to be completed

■ Switch off the peristaltic pump

■ Wait for the stepping pulse

4.5 VA 797 Remote start

This method template is suitable for sample transfer to a 797 VA Computrace. The actual pump time is determined by the control software.

The sample series is started on the 797 VA Computrace (Remote Start).

Preparing and starting the sample series

Press [START].

1

Under Number of samples, enter the number of samples or the

2

maximum value of 99.

Under Next sample pos., enter the rack position of the first sample

3

to be processed.

Press [BACK].

4

Start the sample series in the VA Computrace software.

5

4 Automation sequences

Note

The method run will be automatically restarted for every sample via

remote connection (Autostart). A stepping pulse of the connected

instrument is expected at the end of the method run. The 863 Compact

Autosampler must be stopped manually by means of the button

[STOP] after the processing of the last sample.

The individual steps of the method:

■ Move to the sample

■ Lower the lift to the work position

■ Wait for the stepping pulse

■ Switch on the peristaltic pump for the sample transfer

■ Wait for the minimum pump time to be completed

■ Wait for the stepping pulse

■ Switch off the peristaltic pump

■ 2 seconds waiting time

■ Wait for the stepping pulse

863 Compact Autosampler

■■■■■■■■

27

Page 38

4.6 VA 797 Manual start

4.6 VA 797 Manual start

This method template is suitable for sample transfer to a 797 VA Computrace. The actual pump time is determined by the control software.

Preparing and starting the sample series

Press [START].

1

Under Number of samples, enter the number of samples or the

2

maximum value of 99.

Under Next sample pos., enter the rack position of the first sample

3

to be processed.

Press [START].

4

■■■■■■■■■■■■■■■■■■■■■■

Note

The method run will be automatically restarted for every sample via

remote connection (Autostart). A stepping pulse of the connected

instrument is expected at the beginning of the method run. The 863

Compact Autosampler may need to be stopped manually by means of

the button [STOP] after the processing of the last sample.

The individual steps of the method:

■ Wait for the stepping pulse

■ Move to the sample

■ Lower the lift to the work position

■ Wait for the stepping pulse

■ Switch on the peristaltic pump for the sample transfer

■ Wait for the minimum pump time to be completed

■ Wait for the stepping pulse

■ Switch off the peristaltic pump

■■■■■■■■

28

863 Compact Autosampler

Page 39

■■■■■■■■■■■■■■■■■■■■■■

5 Operation

5.1 Switching the instrument on and off

Switching on the instrument

Proceed as follows:

■ Press the red [STOP] key.

1

The instrument is initialized and a system test performed. This

process takes some time.

The main dialog is displayed:

5 Operation

Switching off the instrument

The instrument is switched off with the [STOP] key. The fact that the key

needs to be pressed down for an extended time prevents accidental

switch off.

Proceed as follows:

■ Keep the red [STOP] key pressed down for at least 3 s.

1

A progress bar is displayed. If the key is released during this time,

then the instrument will not be switched off.

863 Compact Autosampler

■■■■■■■■

29

Page 40

5.2 Fundamentals of operation

5.2 Fundamentals of operation

5.2.1 The keypad

Figure 15 Keypad 863 Compact Autosampler

BACK Apply the input and exit the dialog.

⇧ ⇩ Move the selection bar either up or down by one

line at a time. Select the character to be entered

in the text editor.

⇦ ⇨ Select the character to be entered in the text and

number editor. Select the individual functions in

the function bar.

■■■■■■■■■■■■■■■■■■■■■■

OK Confirm the selection.

STOP Stop an ongoing method run or a manual func-

tion. Switch the instrument on/off.

START Start a method run.

5.2.2 Structure of the dialog windows

The current dialog title is displayed on the left-hand side of the title line.

The current status of the system is displayed in the upper right-hand corner:

ready The instrument is in normal status.

busy A method has been started.

hold A method has been paused.

■■■■■■■■

30

Some dialogs have a so-called function bar on the bottom line. The functions contained therein can be selected with the arrow keys [⇦] or [⇨]

and executed with [OK].

863 Compact Autosampler

Page 41

■■■■■■■■■■■■■■■■■■■■■■

5.2.3 Navigating in the dialog

The selection bar is displayed in inverted style. Use the arrow keys [⇧] and

[⇩] to move the selection bar upward or downward one line at a time. If

a dialog text is marked with ">", then additional settings are available in

a subordinate dialog. Use [OK] to access this dialog.

Example: System settings

5 Operation

Use the [BACK] key to return to the next higher level.

5.2.4 Entering text and numbers

In the editing dialog for text or numerical input you can select the individual characters with the arrow keys. Use [OK] to apply the character in the

input field. The following functions are available:

Editing function Description

Accept

Cancel

Clear

The modification is applied and the editing dialog

is exited.

The editing dialog is exited without applying the

modification.

The content of the input field is deleted completely.

863 Compact Autosampler

■■■■■■■■

31

Page 42

5.3 Methods

■■■■■■■■■■■■■■■■■■■■■■

Editing function Description

The character left of the cursor is deleted (backspace).

Text editor only

The cursor within the input field is shifted to the

left by one character each time that [OK] is

pressed.

Text editor only

The cursor within the input field is shifted to the

right by one character each time that [OK] is

pressed.

[BACK]

The [BACK] key has the same function as Accept.

5.3 Methods

The 863 Compact Autosampler works with process methods that are

based on specified method templates. Individual working steps of a

method run can be individually parameterized, depending on the application. An optimized method run can be saved as a reusable method.

5.3.1 Method templates

The 863 Compact Autosampler contains method templates which are

already configured except for a few parameters.

The following method templates can be selected:

Sample with air

gap

Sample no air gap Sample transfer for IC without air gap between

The modification is applied and the editing dialog

is exited.

Sample transfer for IC with air gap between the

samples.

the samples.

■■■■■■■■

32

Double injection Two-time sample transfer for IC without air gap

between the transfers.

Triple injection Three-time sample transfer for IC without air gap

between the transfers.

VA 797 Remote

start

VA 797 Manual

start

Sample transfer for VA applications with remote

start of the 863 Compact Autosampler by the

797 Computrace.

Sample transfer for VA applications with manual

start of the 863 Compact Autosampler.

863 Compact Autosampler

Page 43

■■■■■■■■■■■■■■■■■■■■■■

You will find a detailed description of the methods in chapter 4 Automation sequences, page 23ff.

5.3.2 Creating a new method

Proceed as follows to create a new method:

1

Open the method table

■ In the main dialog, select Method and press [OK].

The method table opens:

2

Select the method template

■ In the function bar, select New and press [OK].

5 Operation

The list of method templates opens:

3

Load the method template

■ Select the desired template and press [OK].

The method template is now loaded and is displayed in the main dialog under Method.

If a new method has been created, then the individual parameters can be

modified under Menu ▶ Parameters.

5.3.3 Saving a method

If you modify method parameters, then you can save these as your own

method. A maximum of 100 methods can be saved.

863 Compact Autosampler

■■■■■■■■

33

Page 44

5.3 Methods

To save a method, proceed as follows:

1

Open the method table

■ In the main dialog, select Method and press [OK].

The method table opens:

2

Modify/apply the method name

■ In the function bar, select Store and press [OK].

A method name will be suggested for new methods. If the

method has already been saved once, then the method name will

be displayed:

■■■■■■■■■■■■■■■■■■■■■■

Apply the name:

■ Press [BACK].

The method will be saved and the method table is displayed.

Enter a new name:

■ Press [OK].

The text editor opens.

■ Enter a method name (max. 12 characters) and apply with

Accept or [BACK].

■ Press [BACK].

The method will be saved and the method table is displayed.

■■■■■■■■

34

863 Compact Autosampler

Page 45

■■■■■■■■■■■■■■■■■■■■■■

5.3.4 Loading a method

To load a method, proceed as follows:

1

Open the method table

■ In the main dialog, select Method and press [OK].

The method table with the stored methods opens:

2

Select a method

■ Select the desired method.

3

Load the method

■ In the function bar, select Load and press [OK].

5 Operation

The method is now loaded and is displayed in the main dialog under

Method.

5.3.5 Exporting a method

The methods can be exported on a connected USB stick.

This function is possible only if a USB stick is connected as an external

storage medium.

To export a method, proceed as follows:

1

Open the method table

■ In the main dialog, select Method and press [OK].

The method table with the stored methods opens:

Note

863 Compact Autosampler

■■■■■■■■

35

Page 46

5.4 Performing a sample series

2

Select a method

■ Select the desired method.

3

Export the method

■ In the function bar, select Export and press [OK].

The method is being exported. The directory structure on the USB

stick is listed in chapter 6.2, page 47.

5.4 Performing a sample series

■■■■■■■■■■■■■■■■■■■■■■

Samples can be placed anywhere on the rack. They are processed according to ascending rack position.

If the 863 Compact Autosampler is used together with the 797 Computrace, each vessel with sample has to be followed by one with ultrapure

water.

Note

The following descriptions are only of significance if the 863 Compact

Autosampler is operated in stand-alone operation, i.e. not controlled by

a PC via a USB connection.

5.4.1 Starting the sample series

Starting a sample series

A suitable method must be loaded before a sample series is started (see

Chapter 5.3.4, page 35). The necessary parameters ) can then be modi-

fied.

1

Define the sample series

Press the [START] key.

■■■■■■■■

36

863 Compact Autosampler

Page 47

■■■■■■■■■■■■■■■■■■■■■■

You can now enter the quantity and the first rack position of the

samples to be processed.

2

Enter the number of samples

■ Select Number of samples and press [OK].

■ Enter the number of samples. If the methods to be started via

remote connection are used, the maximum value for the number

of samples (99) can be entered here.

■ Close the input dialog with [BACK] or Accept.

3

Enter the rack position of the first sample

■ Select Next sample pos. and press [OK].

■ Enter the starting position of the sample series.

■ Close the input dialog with [BACK] or Accept.

5 Operation

The value for the number of samples remains saved for the next sample series. The position of the first sample is increased with each

method run.

You can still cancel the start of the sample series at this time with

[BACK] or [STOP].

4

Close the sample series dialog

Close the dialog with the [BACK] key.

5

Start the sample series

Start the sample series in the PC software (IC-Net or VA Computrace).

The sample changer is started automatically by the remote connection.

863 Compact Autosampler

■■■■■■■■

37

Page 48

5.4 Performing a sample series

Note

When using the method template VA 797 Manual start, the

method has to be started first at the sample changer in the sample

series dialog with the [START] key. The sample changer then

waits for a stepping pulse of the 797 VA Computrace.

Stopping a sample series

A sample series can be canceled at any time.

Press the [STOP] key.

1

The method run is stopped. The sample series cannot be resumed.

5.4.2 Pausing a sample series and continuing

■■■■■■■■■■■■■■■■■■■■■■

Pausing a sample series

A method run of the 863 Compact Autosampler can be paused and then

continued again. The connected instruments are however not paused.

Note

Interruption of the method run is not possible during the execution of

commands during which the 863 Compact Autosampler waits for a signal from the connected titrator. This is the case during the conditioning

of the titration cell and the execution of the KF titration.

No interruption is possible while the 863 Compact Autosampler waits for

a remote signal.

■■■■■■■■

38

A function bar with the entry "Hold" is displayed during the run of a sample series in the so-called "Live" dialog.

Press the [OK] key.

1

863 Compact Autosampler

Page 49

■■■■■■■■■■■■■■■■■■■■■■

5 Operation

The method run is paused. However, currently running movements

of the sample rack or the lift will be finished.

Instead of the "Hold" function, "Continue" is displayed in the function bar.

Continuing sample series

If a method run is paused, then the "Hold" status is displayed in the title

bar, see previous figure. The sequence can be continued with the "Con-

tinue" function.

In the "Hold" status, a method run can be stopped completely, and with

it the entire sample series, by pressing the [STOP] key.

Press the [OK] key.

1

As is also the case at the start of a sample series, a request dialog

appears here in which the number of samples to be processed can

still be changed. It is thus possible to shorten a sample series or to

extend it, without stopping it.

Press the [OK] key and enter the number of samples that still need to

2

be processed. The current sample must be taken into account.

Press the [START] key.

3

The sample series continues.

863 Compact Autosampler

■■■■■■■■

39

Page 50

5.5 Printing a report manually

5.5 Printing a report manually

Menu ▶ Print reports

To print a report manually, proceed as follows:

1

Open the main menu

■ In the main dialog, select Menu and press [OK].

2

Open the print dialog

■ Select the menu item Print reports and press [OK].

■■■■■■■■■■■■■■■■■■■■■■

The dialog window with the available reports opens:

3

Select a report

■ Select the desired report and press [OK].

The report is being printed out.

The following reports can be printed out manually:

Parameters Report with all method parameters of the loaded

method.

System System report with system settings, solution list,

external devices, etc.

■■■■■■■■

40

863 Compact Autosampler

Page 51

■■■■■■■■■■■■■■■■■■■■■■

5.6 Manual control

The manual control of sample rack, lift and peristaltic pump is accomplished directly in the main dialog. If one of the lines Rack position, Lift

position or Pump is selected, then a function bar will appear at the lowest line with the selection of available functions.

5.6.1 Rotating the sample rack

If the Rack position line is selected, then the arrow keys [⇨] and [⇦] can

be used to select one of the following functions, which can then be run

by pressing [OK]:

5 Operation

Next The lift is moved upward and the next-higher

rack position is placed in front of the lift.

If the [OK] key remains pressed, the rack automatically moves to the next position.

Previous The lift is moved upward and the next-lower

rack position is placed in front of the lift.

If the [OK] key remains pressed, the rack automatically moves to the next position.

Reset The rack is initialized. The lift is moved upward

and the sample rack is rotated to the starting

position. At the same time, the starting position

(Next sample pos.) is reset to 1 for the start of

the next sample series.

The rack position display is always updated as soon as the rack is in the

new position.

863 Compact Autosampler

■■■■■■■■

41

Page 52

5.6 Manual control

5.6.2 Moving the lift

If the Lift position line is selected, then the lift can be moved to the position suggested in the function bar by pressing [OK]. Only two positions

are possible:

Work pos. The working height. It can be set under

Shift pos. The rotating height. The lift moves all the way to

The current lift position is displayed. The respective other possible position

is offered in the function bar.

■■■■■■■■■■■■■■■■■■■■■■

Menu ▶ System ▶ Lift .

the top.

5.6.3 Controlling the peristaltic pump

If the Pump line is selected, then the arrow keys [⇨] and [⇦] can be used

to select one of the following functions, which can then be run by pressing [OK]:

On Switches on the peristaltic pump if it is switched

off.

Off Switches off the peristaltic pump if it is switched

on.

Pump+ Increases the rotational speed by one step.

Pump- Reduces the rotational speed by one step.

The status and the rotational speed that has been set are displayed in the

main dialog.

■■■■■■■■

42

863 Compact Autosampler

Page 53

■■■■■■■■■■■■■■■■■■■■■■

Pump+ / Pump-

5 Operation

Rotational speed and shift direction

Setting the rotational speed. It can be set in steps of –7 to +7. The default

setting 3 corresponds to approx. 18 U/min.

The shift direction of the roller drive changes as the algebraic sign of the

rotational speed changes.

■ "'+": clockwise rotation

■ "–": counterclockwise rotation

Range

Default value

–7 ... 7

3

The rotational speed can also be changed when the pump is switched off.

863 Compact Autosampler

■■■■■■■■

43

Page 54

6.1 Basic settings

6 System settings

6.1 Basic settings

Menu ▶ System ▶ Settings

This chapter contains a description of general instrument settings.

User name

A user name can be entered here for the report. This parameter will only

be printed if a user has been defined.

■■■■■■■■■■■■■■■■■■■■■■

Instrument name

Serial number

Program version

Time

Input

Default value

An instrument name can be entered here for the report. This parameter

will only be printed if a designation has been defined.

Input

Default value

Serial number of the instrument. This is printed as a component of the

instrument identification in the report header.

Version number of the instrument software. This is printed as a component of the instrument identification in the report header.

Current time. Only valid numbers can be entered.

Format: hh:mm:ss

max. 12 characters

empty

max. 10 characters

empty

Date

Language

■■■■■■■■

44

Current date. Only valid numbers can be entered.

Format: YYYY:MM:DD

Setting the dialog language. In addition to English one further language

can be selected.

863 Compact Autosampler

Page 55

■■■■■■■■■■■■■■■■■■■■■■

Dialog type

6 System settings

Note

A second language must be installed in advance in order to be able to

select it here. The installation may only be carried out by competent

personnel.

The user dialog can be limited for routine operations. One can operate

normally with methods in the limited dialog. However, no settings can be

made or methods deleted.

The resetting of the dialog does not take effect until the main menu is exited.

The limitation of the dialog has the following effects:

■ The menu items System and Parameters are not shown in the main

menu.

■ Methods can only be loaded, but not deleted, exported or created.

Note

If the limited dialog is activated for routine operations, then the expert

dialog cannot be switched on during running operations. To change

the dialog type, the 863 Compact Autosampler must be switched off

and then back on again. The expert dialog can be forced at the time

the instrument is started. Then it is possible to enter whatever settings

one wishes, e.g. the changing of the dialog type. If the instrument is

switched off again without changing the dialog type, then the routine

dialog will remain activated.

Forcing the expert dialog:

■ Switch on the instrument.

■ Wait for the display of the instrument logo with the lettering easy,

safe, precise.

■ Press the [STOP] key once again and hold it down while also briefly

pressing the [BACK] key.

■ Release both keys once again.

Selection

Default value

Expert | Routine

Expert

863 Compact Autosampler

Expert

Complete dialog.

Routine

Limited dialog for routine operations.

■■■■■■■■

45

Page 56

6.1 Basic settings

Contrast

■■■■■■■■■■■■■■■■■■■■■■

The contrast of the display can be adjusted with the arrow keys [⇦] and

[⇨].

■ [⇦]: the contrast will be decreased by one step each time the key is

pressed.

■ [⇨]: the contrast will be increased by one step each time the key is

pressed.

Beep

Range

Default value

150 ... 240

212

Note

Alternatively, the contrast can also be modified in the following manner:

Keep the red [STOP] key pressed down. As soon as the progress bar

appears, also press the arrow key [⇩] or [⇧] repeatedly.

This method will however cause the contrast to be modified by several

steps.

If this parameter is activated, then a short beep will be heard in the following cases:

■ When a key is pressed.

■ At the end of the determination.

Selection

Default value

on | off

on

■■■■■■■■

46

863 Compact Autosampler

Page 57

■■■■■■■■■■■■■■■■■■■■■■

6.2 File management

Menu ▶ System ▶ File management

Note

This menu item is visible only when a USB stick has been connected as

an external storage medium.

Methods can be imported and deleted from a USB stick in this dialog.

Only methods located in the Files directory are displayed in the list (see

"Directory structure on the USB stick", page 47).

A backup can be made of the system (all data and settings). Similarly, an

existing backup can be reloaded.

Import

Import the selected method.

6 System settings

Delete

Backup

Restore

Delete the selected method.

Create a backup of all data and settings on the USB stick.

Note

Only one backup can be created on the same USB stick.

If a backup has already been stored on the stick, then it will be overwritten when this function is carried out again.

Load the backup from a connected USB stick.

Directory structure on the USB stick

A directory with the instrument number is generated on the USB stick. The

structure within the directory appears as follows:

Backup All of the files of the backup are stored in this

directory. The directory will be created the first

time a backup is created.

863 Compact Autosampler

■■■■■■■■

47

Page 58

6.3 Lift settings (Lift)

Files Exported methods will be stored in this directory.

6.3 Lift settings (Lift)

Menu ▶ System ▶ Lift

Work position

The working height of the lift can be set to the desired value. This is

accomplished by means of the direct operation of the lift.

■■■■■■■■■■■■■■■■■■■■■■

The directory will be created the first time a

method is exported.

Only methods being located in this directory can

be imported.

Three functions can be selected from the function bar with [⇦] and [⇨]

and then executed by pressing [OK]:

■ Work pos. moves the lift to the current working height.

■ Up moves the lift 6 mm upward.

■ Down moves the lift 6 mm downward.

When this dialog page is exited, the respective current lift position will be

applied as Work position.

Range

Default value

0 ... 126 mm (Increment: 6)

60 mm

The lift can only be moved by steps of 6 mm. If more a accurate setting is

required, the needle position can be fine aligned.

Adjusting the needle position

First move the lift to working height.

1

Open the safety shield

Loosen the two lower fastening screws of the safety shield using the

hexagon key provided, and tip up the safety shield.

2

Loosen the nut

Slightly loosen the nut below the lift head using a wrench.

■■■■■■■■

48

863 Compact Autosampler

Page 59

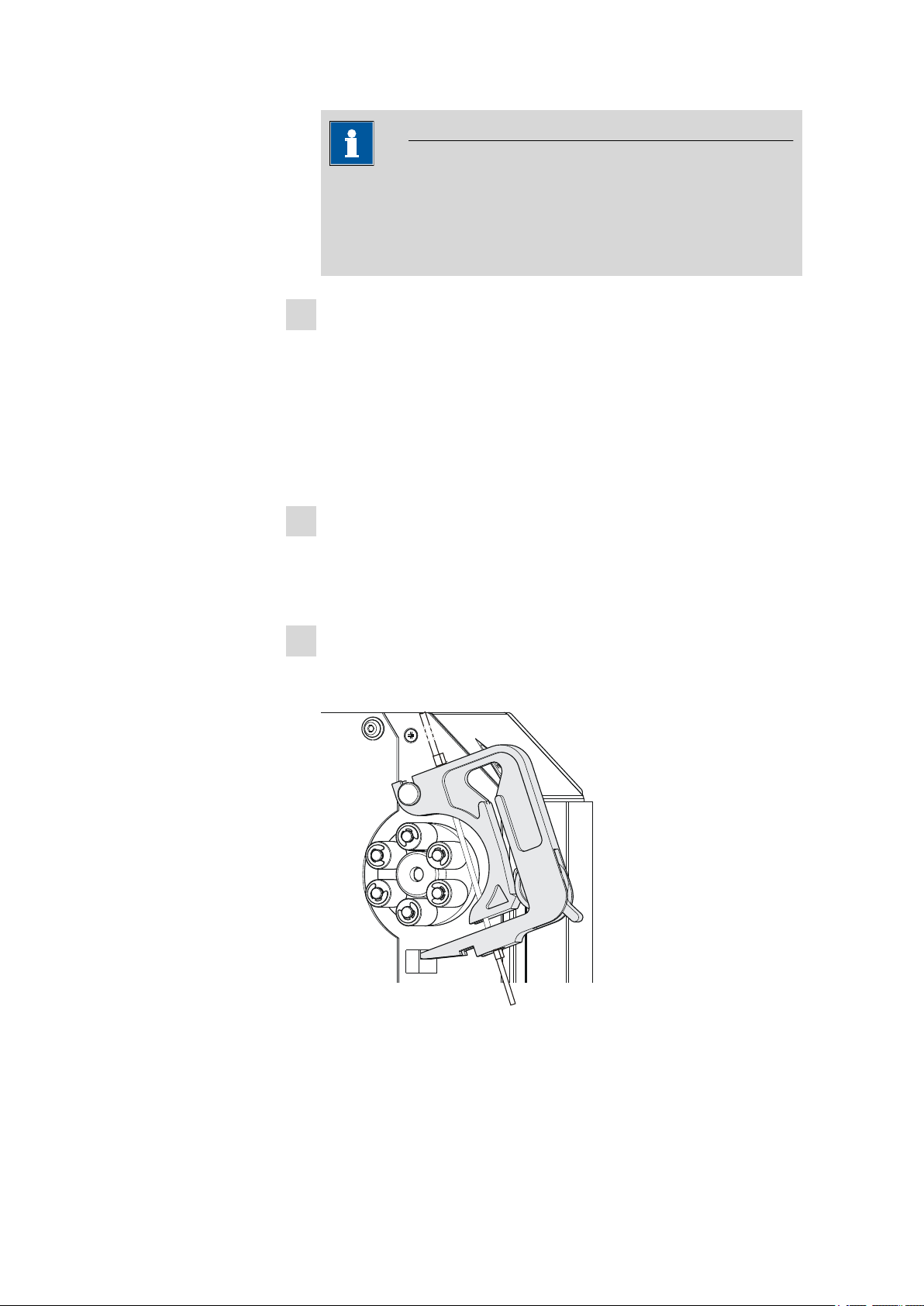

■■■■■■■■■■■■■■■■■■■■■■

3

2

6 System settings

Figure 16 Adjusting the needle

3

Adjust the needle holder

Turn the needle holder a few millimeters out of the lift head (turn

counterclockwise).

Now you can redefine the working height of the lift (see previous

section), and precisely set the needle position by turning the needle

holder.

4

Tighten the nut

Using the wrench, fasten the nut again.

5

Close the safety shield

Tip down the safety shield and fix it with the fastening screws.

6.4 Configuring external devices

Menu ▶ System ▶ External devices

Printer

If a printer is connected, then the printer type needs to be defined here in

order for the reports to be printed out correctly.

The printers that have the designation ESC-POS are so-called POS printers

(point-of-sale printers), i.e. they print on continuous paper.

Selection

Default value

Keyboard layout

A commercially available USB keyboard can be connected to make it easier to enter text and numbers. Specify the country-specific keyboard layout

here.

Citizen (ESC-POS) | Custom (ESC-POS) | Epson |

Epson (ESC-POS) | HP DeskJet | HP LaserJet |

Seiko (ESC-POS)

HP DeskJet

863 Compact Autosampler

■■■■■■■■

49

Page 60

6.5 Instrument diagnosis

■■■■■■■■■■■■■■■■■■■■■■

Selection

English US | French FR | German CH | German

DE | Spanish ES

Default value

English US

Editing the COM2 settings

Menu ▶ System ▶ External devices ▶ COM2 settings

6.5 Instrument diagnosis

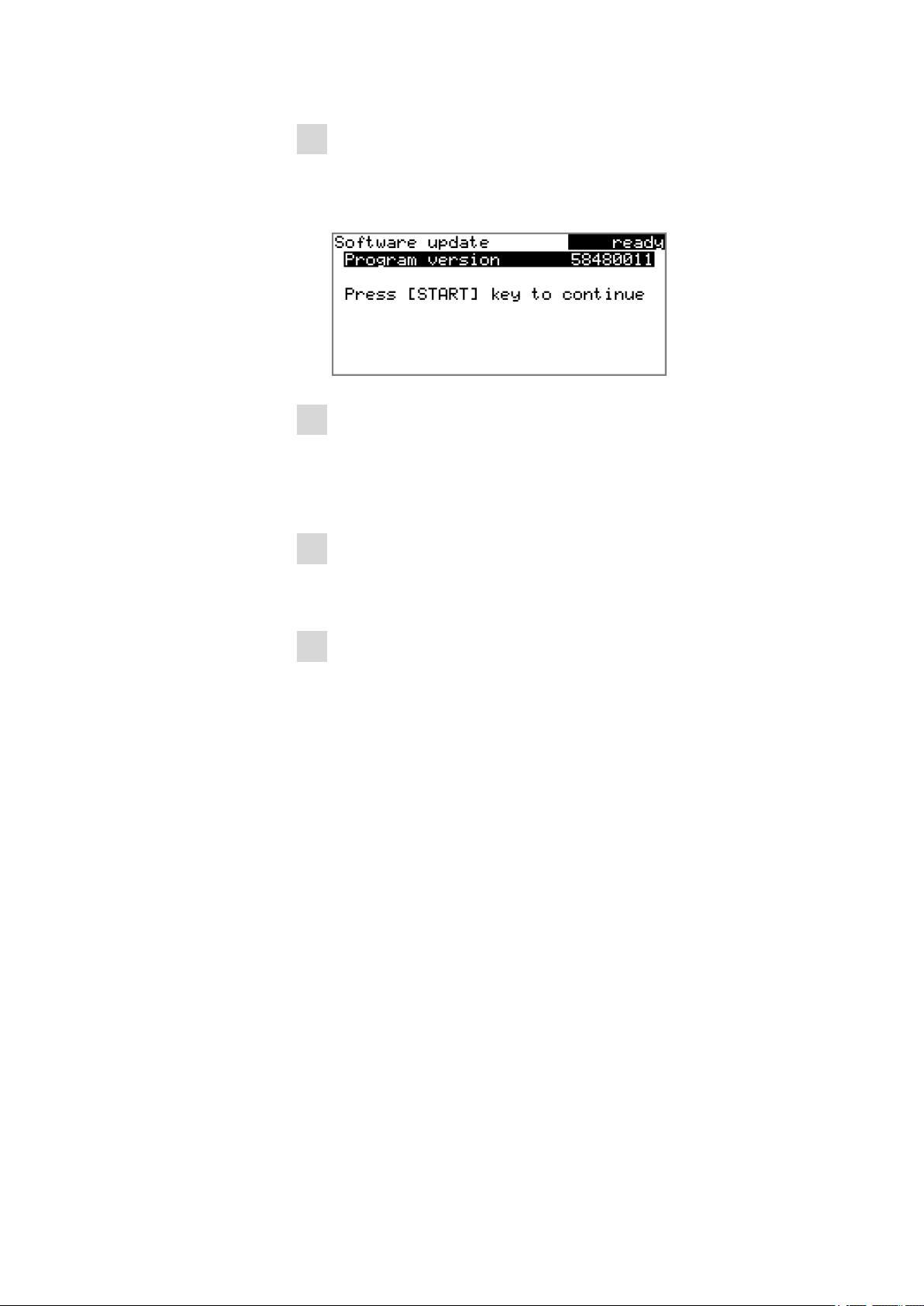

6.5.1 Loading program versions and language files

Menu ▶ System ▶ Diagnosis

New program versions or language files can be loaded from a USB stick.

The corresponding file must be saved on the USB stick in a directory with

the instrument number (e.g. 848 or 863).

You can distinguish between language files and program files by noting

how the file name is constructed.

Program files

They are instrument-specific. The file name has the following structure:

5XXXyyyy.bin where

XXX =

yyyy =

Instrument type (e.g. 848 for the 848 Titrino plus)

Program version

Language files

They can be recognized by means of the two-digit language code in the

file name. A language file contains the dialog texts for various instrument

types. It is not instrument-specific. The file name has the following structure:

5848xxxxYY.bin where

xxxx =

YY =

Version number

Language, e.g. DE (German), FR (French), ES (Spanish)

Loading a file

Proceed as follows:

1

Connect the USB stick

■ Plug in the USB stick with the 6.2151.100 adapter (USB MINI

(OTG) - USB A) at the USB connector on the instrument.

■ Switch on the instrument.

■■■■■■■■

50

863 Compact Autosampler

Page 61

■■■■■■■■■■■■■■■■■■■■■■

6 System settings

2

Open the update dialog

■ Under Menu ▶ System ▶ Diagnosis, select the menu item

Software update.

■ Press [OK].

3

Open the file selection

■ Press [OK].

The selection list with the program and language files available on

the USB stick is opened.

4

Select the file

■ Select the required file with the arrow keys.

■ Press [OK].

5

Start the update

■ Press [START].

The update process is started, it runs automatically. At the end of the

process, the instrument is automatically switched off and then back

on again. No user intervention is required.

6.5.2 Diagnosis functions

Electronic and mechanical functional groups in Metrohm instruments can

and should be checked as part of regular maintenance by specialist personnel from Metrohm. Please ask your local Metrohm agent regarding the

precise terms and conditions involved in concluding a corresponding

maintenance agreement.

863 Compact Autosampler

■■■■■■■■

51

Page 62

7.1 Automation: Sample with air gap

7 Parameters

7.1 Automation: Sample with air gap

Menu ▶ Parameters

Automation

Display of the template used for the automation sequence.

Sample pump time

The time during which the peristaltic pump aspirates sample solution.

■■■■■■■■■■■■■■■■■■■■■■

Range

Default value

Air gap pump time

The time during which the peristaltic pump aspirates air for an air gap.

Range

Default value

Pump rate

Rate of the peristaltic pump. One step corresponds to 6 rpm. Positive values = shift direction is clockwise, negative values = shift direction is counterclockwise.

Range

Default value

0 ... 999 s

120 s

0 ... 999 s

6 s

-7 ... 7

3

7.2 Automation: Sample no air gap

Menu ▶ Parameters

Automation

Sample pump time

■■■■■■■■

52

Display of the template used for the automation sequence.

The time during which the peristaltic pump aspirates sample solution.

Range

Default value

0 ... 999 s

120 s

863 Compact Autosampler

Page 63

■■■■■■■■■■■■■■■■■■■■■■

Pump rate

7 Parameters

Rate of the peristaltic pump. One step corresponds to 6 rpm. Positive values = shift direction is clockwise, negative values = shift direction is counterclockwise.

Range

Default value

-7 ... 7

3

7.3 Automation: Double injection

Menu ▶ Parameters

Automation

Display of the template used for the automation sequence.

Sample pump time

The time during which the peristaltic pump aspirates sample solution.

Range

Default value

Pump rate