Page 1

CH-9101 Herisau/Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

EMail info@metrohm.ch

http://www.metrohm.ch

796 Titroprocessor

Program version 5.796.0010

Instructions for use

8.796.1003 02/2000 dm

Page 2

Table of content

Table of contentTable of content

1 Introduction 1

1.1 Range of applications ________________________________1

1.2 Application possibilities ______________________________1

1.3 Instrument description _______________________________3

1.3.1 Model versions............................................................................ 3

1.3.2 Front view....................................................................................3

1.3.3 Rear view..................................................................................... 4

1.3.4 Peripheral device connections.................................................... 4

1.3.5 Measuring interfaces / Measuring inputs....................................5

1.3.6 Data cards / Key cards................................................................ 5

1.3.7 The built-in thermal printer........................................................... 6

1.4 The keyboard _________________________________________7

1.4.1 Function keys (softkeys).............................................................. 7

1.4.2 Hotkeys........................................................................................ 7

1.4.3 Action keys..................................................................................8

1.4.4 Manual printing............................................................................ 8

1.4.5 Navigation and editing keys........................................................8

1.4.6 HELP key.....................................................................................9

1.4.7 The GLP key................................................................................ 9

1.4.8 Special key abbreviations............................................................ 9

1.5 Dialog _______________________________________________ 11

1.5.1 Dialog overview......................................................................... 11

1.5.2The main page...........................................................................11

1.5.3 The status window..................................................................... 12

1.5.4 The trace window...................................................................... 13

1.5.5 How to navigate......................................................................... 13

1.5.6 Field cursor................................................................................ 14

1.6 How to edit__________________________________________ 14

1.6.1 Navigation in edit mode ............................................................ 15

2 Installation 16

2.1 Instrument setup ___________________________________ 16

2.2 Mains supply ________________________________________ 16

2.3 Mains connection ___________________________________ 17

2.3.1 Fuses......................................................................................... 17

2.3.2 Mains cable and mains connection.......................................... 18

2.3.3 Setting up the thermal printer.................................................... 18

2.4 Data / key card handling (PC cards)________________ 19

2.5 Safety information __________________________________ 21

2.6 Connections ________________________________________ 22

2.6.1 System components and peripheral devices............................22

2.6.2 Dosing devices ......................................................................... 23

2.6.3 External bus............................................................................... 24

2.6.4 Sample changers...................................................................... 25

2.6.5 Sensors / Electrodes................................................................. 26

2.6.6 Connecting a balance...............................................................27

2.6.7 Connecting an external printer..................................................29

2.6.8 Connecting a bar-code reader.................................................. 30

2.6.9 Devices on the remote interface...............................................31

2.6.10 LIMS connection ..................................................................... 33

796 Titroprocessor, Instructions for use

Page 3

Table of contentTable of content

3 Configuration 34

3.1 Basic settings _______________________________________34

3.2 Configuration of sample changers __________________ 38

3.2.1 Sample racks.............................................................................39

3.2.2 Special beakers.........................................................................42

3.2.3 Basic configuration of 717 Sample changer..............................43

3.3 Interface configuration______________________________ 44

3.3.1 Setting the RS232 interfaces......................................................45

3.3.2 Balances and printers................................................................45

3.3.3 Data communication settings....................................................45

3.3.4 Internal thermal printer ...............................................................46

3.3.5 Initializing the RS232 interfaces .................................................46

3.4 Buret units___________________________________________ 47

3.4.1 Tubing definitions.......................................................................48

3.4.2 700 Dosino, dosing units...........................................................49

3.4.3 685 Dosimat, exchange units ....................................................51

4 Manual operation 53

4.1 Overview_____________________________________________53

4.2 Dosing devices ______________________________________ 54

4.2.1 Automatic reagent check...........................................................54

4.2.2 Dosing device functions ............................................................55

4.2.3 Manual dosing ...........................................................................56

4.3 Sensors ______________________________________________57

4.3.1 Automatic sensor check............................................................57

4.3.2 Manual measurement ................................................................57

4.3.3 Calibration..................................................................................58

4.4 Sample changer _____________________________________ 63

4.4.1 Sample rack and lift functions....................................................65

4.5 Stirrer at measuring interface ______________________ 66

4.6 Remote lines (Input / Output) _______________________66

4.7 Print _________________________________________________67

4.7.1 The printer menu........................................................................67

4.7.2 General reports..........................................................................68

4.7.3 Determination reports ................................................................69

5 Methods and determinations 71

796 Titroprocessor, Instructions for use

5.1 General ______________________________________________71

5.2 Method editor________________________________________ 71

5.2.1 Load method..............................................................................72

5.2.2 Create new method ...................................................................72

5.2.3 Softkeys and their functions.......................................................74

5.2.4 Determination report..................................................................75

5.3 Determinations ______________________________________80

5.3.1 Carrying out a determination......................................................80

5.3.2 Individual determinations...........................................................81

5.3.3 System variables........................................................................85

5.3.4 Determination files .....................................................................85

5.3.5 Sample series............................................................................87

5.3.6 Course of a sample series.........................................................90

Page 4

Table of contentTable of content

6 Sample data and sample silo 92

6.1 Sample data entry __________________________________ 92

6.1.1 Direct data transfer from balances............................................ 92

6.1.2 Bar-code reader........................................................................ 93

6.2 Sample silo _________________________________________ 93

6.2.1 Sample silo configuration..........................................................96

6.2.2 Automatic data input and output...............................................97

7 Titration and measuring modes 99

7.1 General _____________________________________________ 99

7.2 DET Dynamic equivalence point titration ________ 101

7.2.1 Measuring mode.....................................................................101

7.2.2 Reagent addition and measurement acceptance .................. 101

7.2.3 Automatic equivalence point recognition................................102

7.2.4 Fixed endpoints....................................................................... 102

7.2.5 Evaluation of pK and HNP values............................................ 102

7.3 MET Monotonic equivalence point titration ______ 104

7.3.1 Measuring mode.....................................................................104

7.3.2 Reagent addition and measurement acceptance .................. 104

7.3.3 Automatic equivalence point recognition................................105

7.3.4 Fixed endpoints....................................................................... 105

7.3.5 Evaluation of pK and HNP values............................................ 106

7.4 SET Titration to a preset endpoint _______________ 107

7.4.1 Measuring mode.....................................................................107

7.4.2 Reagent addition..................................................................... 107

7.4.3 Measuring point list.................................................................108

7.4.4 Switch-off criteria at the endpoint............................................ 108

7.5 SEC Endpoint conditioning ________________________ 109

7.5.1 Control of the conditioning mode............................................ 109

7.6 KFT Karl Fischer titrations _______________________ 111

7.6.1 Measuring mode.....................................................................111

7.6.2 Reagent addition..................................................................... 112

7.6.3 Measuring point list.................................................................112

7.6.4 Switch-off criteria at the endpoint............................................ 112

7.7 KFC Karl Fischer conditioning_____________________ 114

7.7.1 Control of the conditioning mode............................................ 114

7.8 MEAS Extended measuring functions ____________ 115

7.8.1 Measuring modes...................................................................115

7.8.2 Standard measurement........................................................... 115

7.8.3 Multiple measurement.............................................................116

7.9 CAL Calibration of pH sensors ___________________ 117

7.107.10 Calculations / Formulas __________________________ 119

7.10.1 System variables ................................................................... 121

7.10.2 Mathematical functions ......................................................... 122

7.11 Reports ___________________________________________ 124

796 Titroprocessor, Instructions for use

Page 5

Table of contentTable of content

8 Command Reference 128

8.1 Titration modes ___________________________________ 128

8.2 DET ________________________________________________ 129

8.2.1 [ * Param ] Specific parameters for DET modes.....................131

8.2.2 User adjustments.....................................................................137

8.2.3 EP recognition..........................................................................139

8.2.4 Curve display ...........................................................................142

8.3 MET ________________________________________________ 144

8.3.1 [ * Param ] Specific parameters for MET modes.....................144

8.3.2 User adjustments.....................................................................145

8.3.3 EP Recognition.........................................................................146

8.3.4 Curve display ...........................................................................148

8.4 SET_________________________________________________ 149

8.4.1 Specific parameters for SET modes [* Param ].......................149

8.4.2 Custom Adjustments................................................................152

8.4.3 Curve display with SET.............................................................154

8.5 SEC ________________________________________________ 155

8.5.1 Specific parameters for SEC modes [ * Param ].....................156

8.6 KFT_________________________________________________ 159

8.6.1 Specific parameters for KFT modes [ * Param ]......................159

8.6.2 Custom adjustments................................................................165

8.6.3 Curve display with KFT.............................................................167

8.7 KFC ________________________________________________ 168

8.7.1 Specific parameters for KFC modes [ * Param ].....................169

8.8 MEAS ______________________________________________ 172

8.8.1 Standard measurement ...........................................................175

8.8.2 Multiple measurement..............................................................176

8.8.3 Curve display in MEAS modes.................................................178

8.9 CAL ________________________________________________ 179

8.9.1 Simple calibration ....................................................................179

8.9.2 Specific CAL* mode parameters [ * Param ]..........................181

8.9.3 Automatic calibration................................................................182

8.10 Sample changer commands _____________________ 184

8.10.1 Sample changer commands.................................................184

8.11 Dosing commands _______________________________ 192

8.12 CASE sequences _________________________________ 195

8.13 Communication functions _______________________ 200

8.13.1 Application mode of operation of CTRL and SCAN...............200

8.13.2 Remote connections..............................................................200

8.13.3 RS 232 interfaces...................................................................203

8.13.4 Other communication commands.........................................206

8.14 Auxiliary commands _____________________________ 207

9 Results and statistics 213

796 Titroprocessor, Instructions for use

9.1 Results page_______________________________________ 213

9.1.1 Statistics...................................................................................216

9.2 The <RESULT> key ________________________________ 218

Page 6

Table of contentTable of content

10 Curves and re-evaluation 219

10.1 Single curves _____________________________________ 219

10.2 Overlapping curves _______________________________ 222

10.3 Curve presentation _______________________________ 223

10.4 Re-evaluation _____________________________________ 225

11 File manager 226

11.1 File list____________________________________________ 226

11.2 File operations____________________________________ 227

11.3 Format data card _________________________________ 228

11.4 File backup _______________________________________ 229

12 Troubleshooting 231

12.1 Error messages___________________________________ 231

12.2 Remedying storage errors________________________ 257

12.2.1 Titroprocessor new start........................................................ 257

12.2.2 RAM initialization (original initialization) ................................. 257

12.2.3 Clearing up memory errors in the data memory.................... 257

13 Appendix 260

13.1 Diagnosis _________________________________________ 260

13.2 Common variables________________________________ 270

13.3 Key cards and access control____________________ 272

13.3.1 Configuration of the softkey bars........................................... 273

13.3.2 Status definitions...................................................................274

13.3.3 Creating a key card...............................................................276

13.3.4 Modifying an existing Access Control file.............................. 277

13.3.5 Monitoring a key card............................................................277

13.4 Remote operation / Key simulation ______________ 278

13.5 Validation / GLP __________________________________ 280

13.5.1 Maintenance intervals............................................................ 280

13.5.2 Sensor test ............................................................................ 280

13.5.3 System validation................................................................... 283

13.5.4 Preparing for a validation....................................................... 284

13.6 Technical specifications _________________________ 288

13.7 Warranty and certificates ________________________ 292

13.7.1 Warranty................................................................................. 292

13.7.2 EC Declaration of conformity................................................. 293

13.7.3 Certificate of conformity and system validation..................... 294

13.8 Scope of delivery and accessories Scope of delivery and accessories ______________ 295

13.8.1 Titroprocessors ..................................................................... 295

13.8.2 Options..................................................................................296

14 Index 299

796 Titroprocessor, Instructions for use

Page 7

1 Introduction

1.1 Range of applications

The Metrohm 796 Titroprocessor is a very versatile analytical instrument. It

has been designed exclusively for use in production plant and laboratories

where it covers a wide range of applications. Together with the Metrohm 717

Sample changer it is very useful when processing large series of samples

covering the whole field of titrations or for different measurement tasks.

1. Introduction

Designed as a stand-alone precision titrator and the central unit of a comprehensive high-performance analytical system, it is predestined for mastering even the most complex applications with its various measuring inputs

and dosing device interfaces. As a result of its extensive communications

possibilities it does not just work with the wide range of Metrohm titrators,

measuring instruments and dosing units, but can also control or be controlled by any other instruments equipped with a suitable communications

interface. These capabilities mean that it is the right instrument for all automation tasks imaginable in a modern laboratory and it also offers the possibility of transferring the measuring data and results it produces to an existing laboratory information management system (LIMS).

Thanks to its extremely adaptable dialog structure and its versatile range of

functions it is not only used by experts for working out complex methods,

but also by routine analysts who wish to make their work easier with predefined methods and as simple a user interface as possible.

1.2 Application possibilities

The 796 Titroprocessor is completely designed for communication:

• Two RS 232C interfaces provide rapid communication with a balance,

PC or LIMS. A parallel interface is available for use with an external

printer.

• GLP-conform printout on the built-in thermal printer or, for versions without printer, on almost any commercially available printer.

796 Titroprocessor, Instructions for use

11

Page 8

1.2 Instrument description

• Up to twelve Dosinos or Dosimats can be addressed for titrating or dos-

• The 796 Titroprocessor has a connection for a bar-code reader for en-

• External instruments such as conductivity meters, dosing units, ion me-

• A measuring group on the 796 Titroprocessor comprises two high-

The run sequences for processing the individual samples can be freely defined within wide limits and can be stored as methods both in the internal

memory of the Titroprocessor or separately on a separate data card and be

transferred to other instruments of the same type.

Methods can include up to 99 command steps, of which up to five can be

titration or measuring modes whose measuring data and results can be

printed out directly, transferred to a LIMS system or stored. The measuring

data produced can be reloaded at a later date and re-evaluated and recalculated.

ing tasks.

tering sample-specific data available in bar-code format.

ters or any other peripheral devices can be operated both via the two

serial RS 232C interfaces as well as via the "Remote" socket of the Titroprocessor and the "remote" socket(s) of the 717 Sample changer(s) (two

717 Sample changers can be connected at the same time). In the full

version there are 36 output lines and 24 input lines available which can

be individually set or monitored.

impedance measuring inputs for pH, redox or ISE sensors as well as an

input for a separate reference electrode. These inputs can also serve as

differential amplifier connections. A measuring input for polarized electrodes with a polarizer also forms a part of a measuring group, as does a

measuring input for Pt 1000 or Pt 100 temperature sensors.

The instrument versions with two measuring groups have twice the number of measuring connections mentioned above.

For complex automation tasks numerous functions for operating the 717

Sample changer are available. Two sample changers can be connected at

the same time; however, in an automatic method run only one of them can

be operated at once.

If series of samples are to be processed then special start and finish sequences (OMOVE and CMOVE sequences) can be defined, each of which

is processed once only at the start and finish of a series of samples. This

means that for a series of titrations the electrodes can be conditioned or

calibrated with a specific series of buffers.

The 717 Sample changer itself offers all the functions necessary for a powerful automated system. Operation of the turntable, titrating heads, pumps

and stirrers, even the 'Remote' interface of the sample changer can be carried out directly from the Titroprocessor.

Interchangeable standard sample racks are available for many sizes of

sample vessels. Freely definable "special beaker" positions can be defined

for each rack. These are used to locate the position of rinsing or conditioning beakers in the rack; these can be selected in any part-sequence.

Key cards enable every user of the 796 Titroprocessor to have his own working environment, which includes individual status settings, his own specific

methods on the card and a customized user dialog, which means, only the

dialog pages are accessible that he needs.

22

796 Titroprocessor, Instructions for use

Page 9

1. Introduction

1.3 Instrument description

1.3.1 Model versions

The 796 Titroprocessor is available in four versions.

Versions with 1 measuring group:

2.796.0010 with complete accessories, without built-in printer, but with parallel

interface for an external printer

2.796.0020 as 2.796.0010, but with built-in space-saving thermal printer

(DIN A4), without additional parallel interface for a printer

Versions with 2 measuring groups:

2.796.0110 with complete accessories, without built-in printer, but with parallel

interface for an external printer

2.796.0120 as 2.796.0110, but with built-in space-saving thermal printer

(DIN A4), without additional parallel interface for a printer

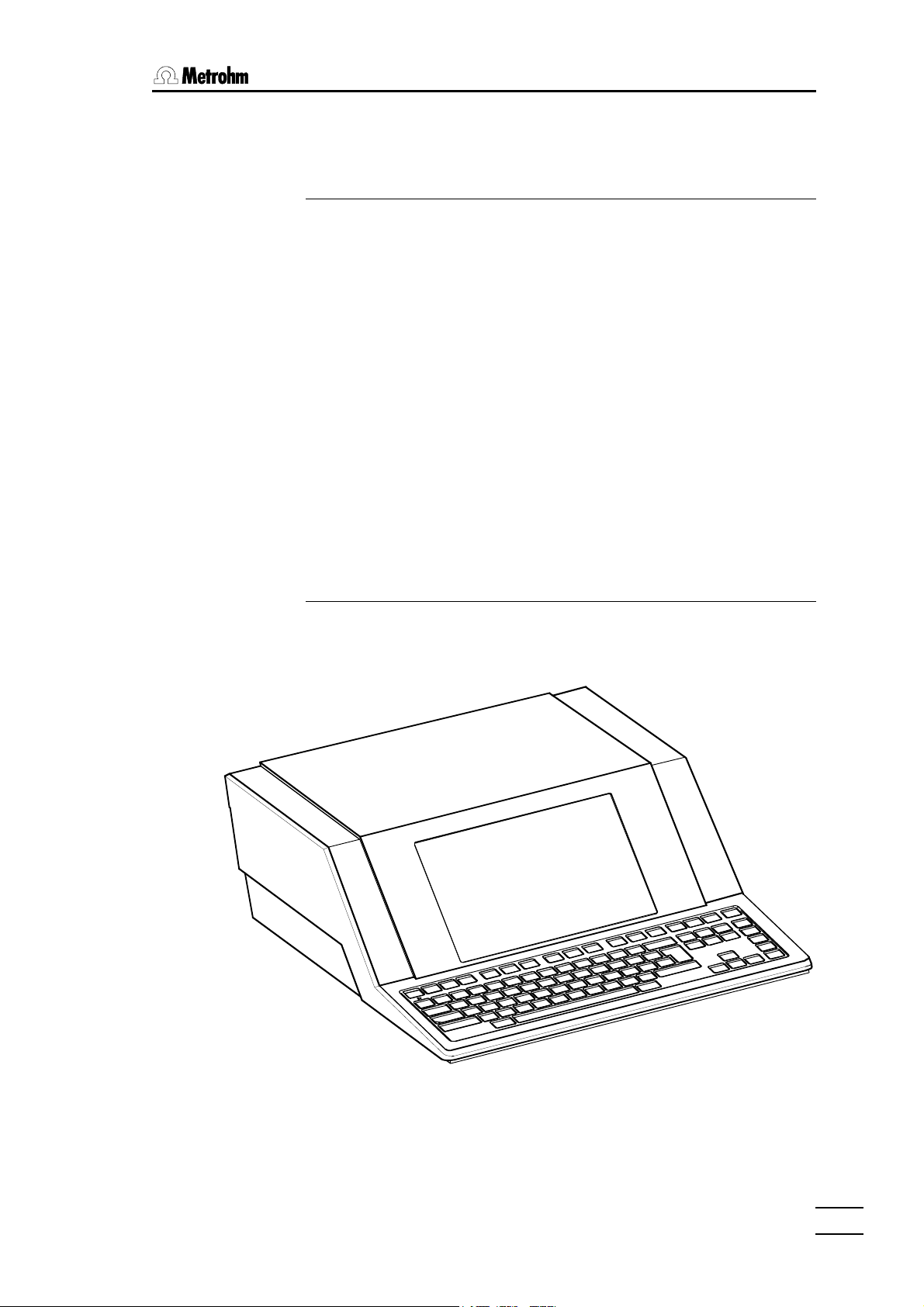

1.3.2 Front view

Model 2.796.0010 of the 796 Titroprocessor without built-in printer.

796 Titroprocessor, Instructions for use

33

Page 10

1.3 Instrument description

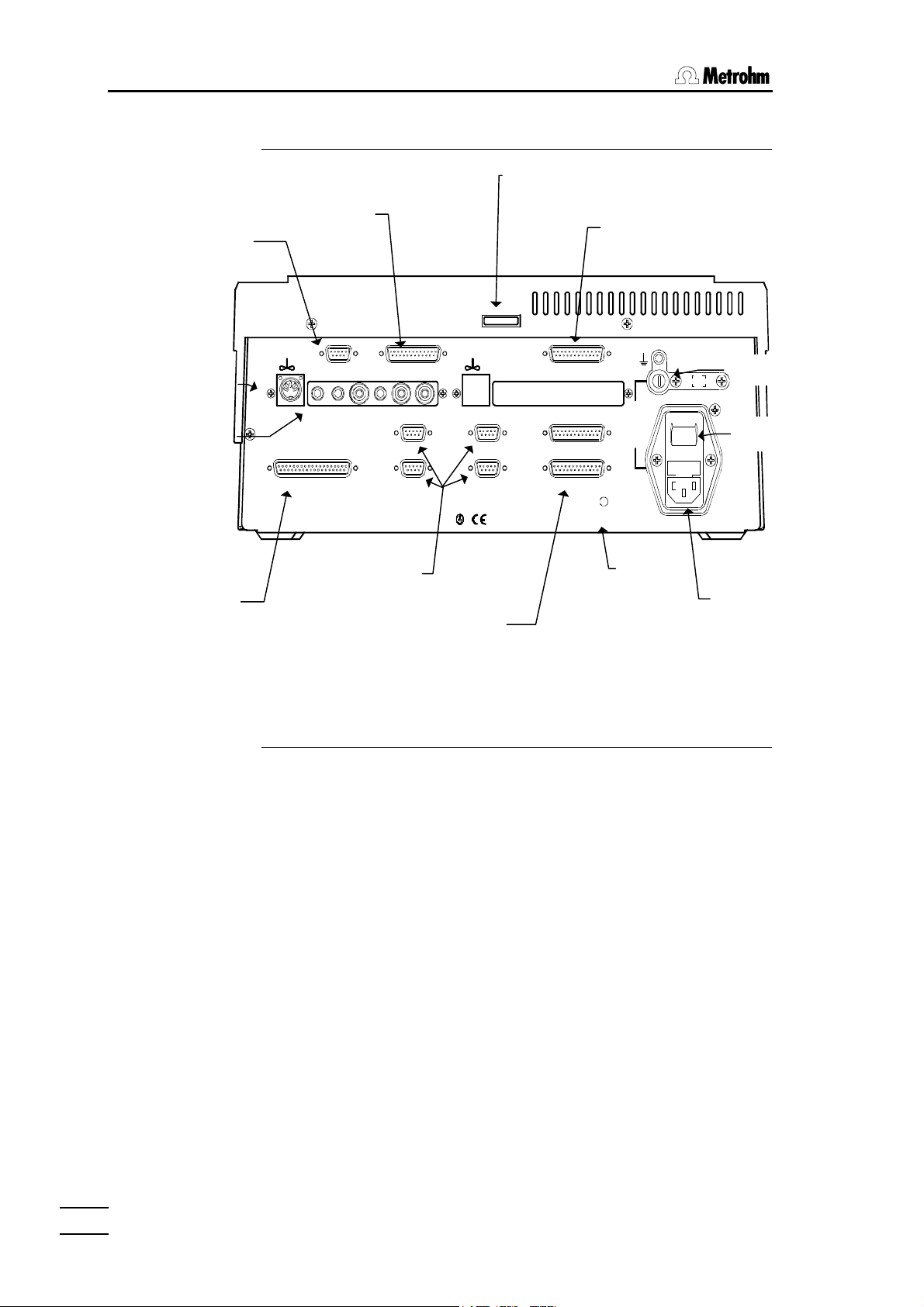

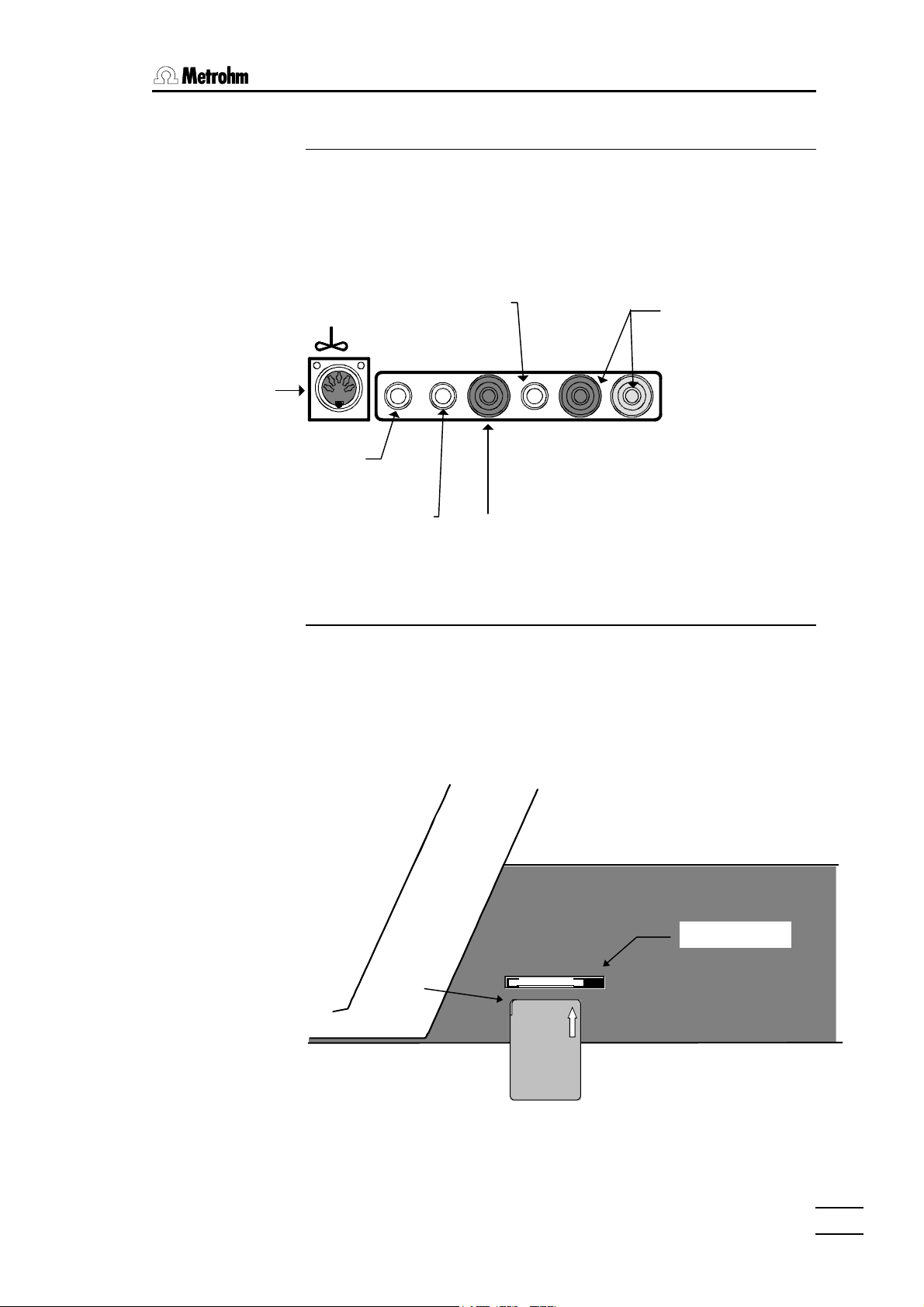

1.3.3 Rear view

Serial number

Bar-code

connector

Stirrer Int A

connector

Measuring

interface A

External bus

connector

Remote socket

Ind A2 Ind A1 Ref Pol Pt100/1000 Ind B2 Ind B1 Ref Pol Pt100/1000

External Bus

B

Dosing unit

connectors

Printer connector

(parallel interface)

Bar Remote Printer

Code

D E F

Sensors A Sensors B

Dos. A1

Dosing Units

Dos. A2

Made by Metrohm Herisau Switzerland 50-60Hz 160VA

21

CC

Dos. A3

RS 232 Interface 1

Dos. A4

A

G

RS 232 Interface 2

2A(TH)

115V230V

Reset

Type 1.796.0010

1

0

Reset

button

RS 232 communi-

cation interface

Fuse holder

Mains switch

Mains connector

1.3.4 Peripheral device connections

Instrument Interface designation Label

Balance RS 232 interface 1 or 2 G

Indicator electrodes Sensors A or B (Ind A1, Ind A2, ..) C

Indicator electrodes Sensors A or B (Ref) C

Temperature sensors Sensors A or B (Pt100/1000) C

Stirrer Sensors A or B C

Dosing devices Dosing units A

Sample changer External bus B

Dosing interface 729 External bus B

Printer (Centronics) Printer F

Printer (serial) RS 232 interface 1 or 2 G

Bar-code reader Bar-code D

Personal computer/LIMS RS 232 interface 1 or 2 G

Auxiliary instruments Remote E

44

796 Titroprocessor, Instructions for use

Page 11

1. Introduction

Notch

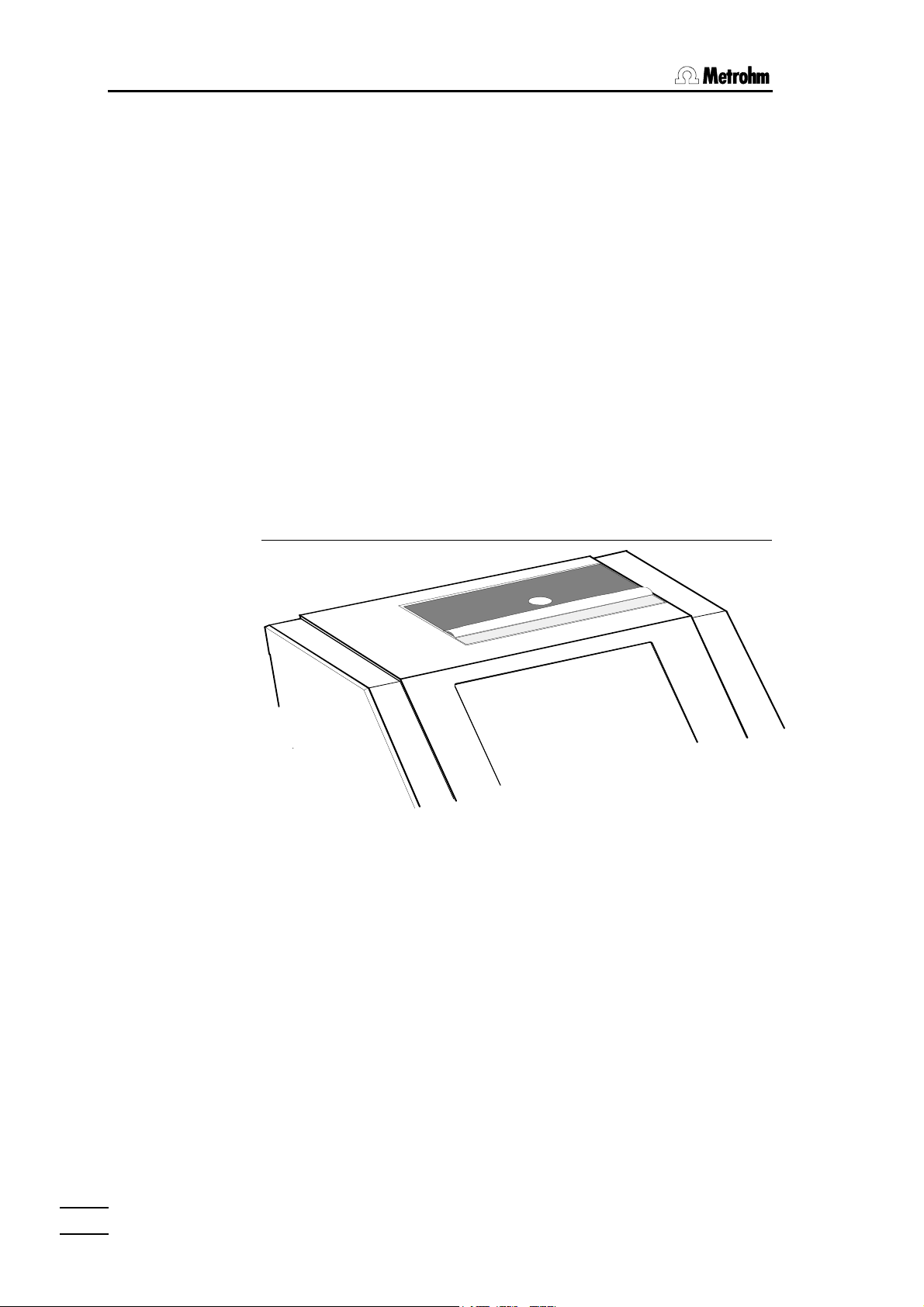

1.3.5 Measuring interfaces / Measuring inputs

The 796 Titroprocessor models 2.796.0110 and 2.796.0120 are equipped

with 2 measuring interfaces (Sensors A and Sensors B).

The diagram below shows where the sensors are to be connected to measuring interface A, which is found on all 796 Titroprocessor models.

Stirrer Int A con-

nector

Indicator electrode

Polarized

electrode

Pt100 / Pt1000

Temperature sensor

1

Ind A2 Ind A1 Ref Pol Pt100/1000

Sensors A

A2

Indicator electrode

A1

1.3.6 Data cards / Key cards

Data cards can be used to store methods or measuring data and to transfer

them from one instrument to another. They are an excellent mobile storage

medium.

Key cards enable every user to have his own specific methods and user interface settings.

Data cards or key cards are to be insertet in the memory card slot on the

right hand side of the 796 Titroprocessor.

Reference

electrode

796 Titroprocessor, Instructions for use

Right-hand side of housing

Eject button

Data

card

Attention must be paid to several points when handling data cards.

55

Page 12

1.3 Instrument description

So-called PC cards which meet the Standard PCMCIA 2.x (68 Pins) / JEIDA

4.x can be used.

Flash cards can be read but not written on, e.g. the application card

SRAM cards can be read and written on.

Card battery

Data cards are battery-buffered storage media. The battery must be

changed periodically in order to avoid data loss. Make a note of the expiry

date of the battery which is given on the leaflet accompanying the card.

Important:

The expiry date of the battery refers to a storage temperature of 25°C. At

higher storage temperatures the working life of the battery is shorter. Do not

carry the card next to your body; do not store it near a heater or expose it to

direct sunlight. The battery has to be replaced while the card is inserted in

the instrument.

1.3.7 The built-in thermal printer

(Order. no. 6.6038.000) supplied with the Titroprocessor

Capacity: 128 KB (Order no. 6.2245.010) to 2 MB (Order

no. 6.2245.030).

Titroprocessor models with built-in printer (2.796.0020 and 2.796.0120) can

additionally have a second printer (or two) connected to an RS 232 interface. However, an additionally connected printer must have a serial interface

as Titroprocessor models with built-in thermal printers do not have a parallel

printer interface.

66

796 Titroprocessor, Instructions for use

Page 13

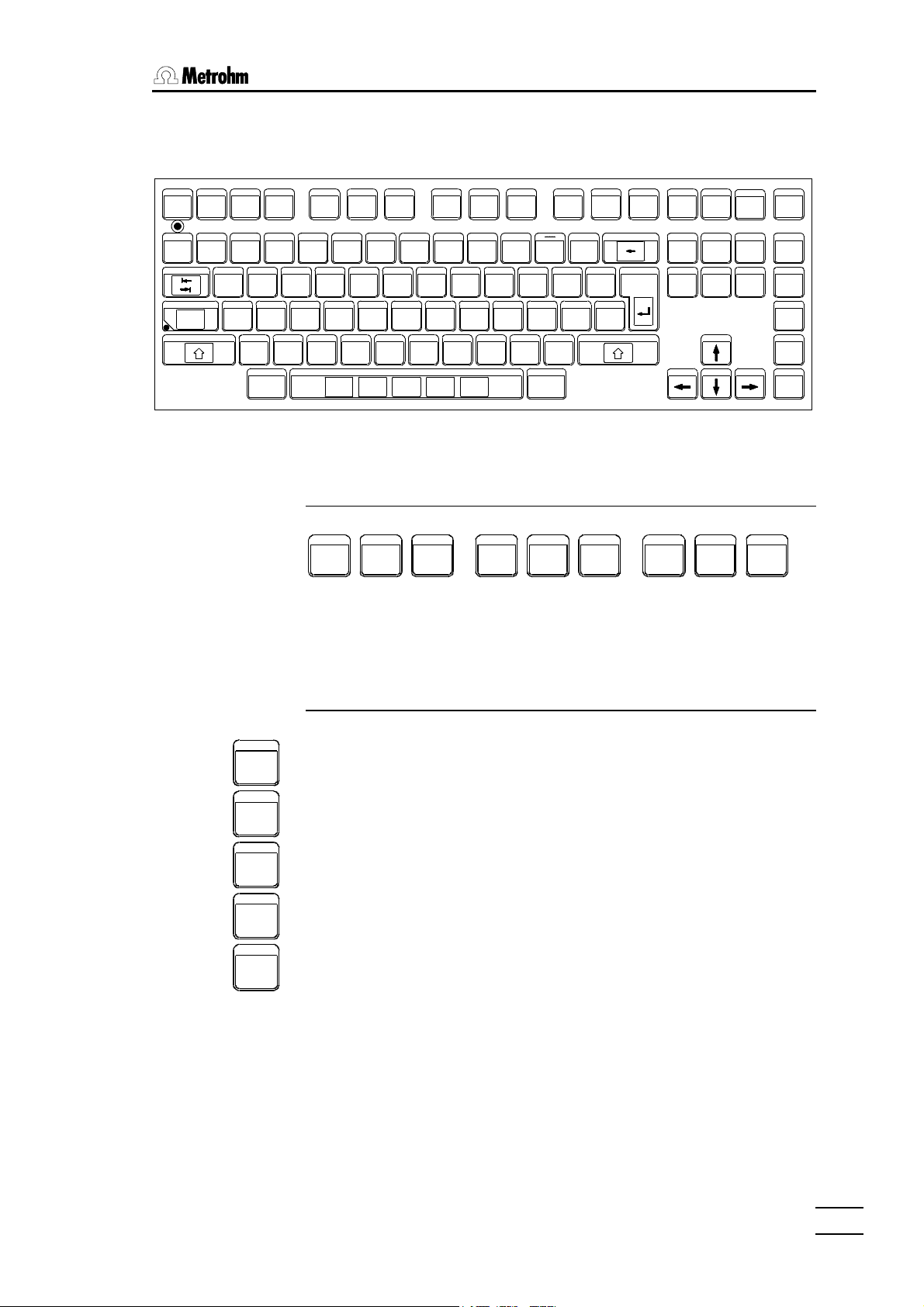

1.4 The keyboard

1. Introduction

QUIT PRINT

ON

GLP

CAPS LOCK

OFF

STOP FORM

STOP

PG UP

NEXTDELAYSKIP

START

MAN

CONTROL

STATUS

METHOD

SAMPLE

RESULT

LINE

PRINT

FEED

SCREEN

F1 F2 F3 F4 F5 F6 F7 F8 F9

#@!

&

^$

)

(*

+

=-0987654321

µ

°

ENTER

REWQ

T

LKJHGFDSA

;

><

ALTALT

][POIUY

|":

,

\

?

/.,MNBVCXZ

HOLD

HELP

CONT

HOME

INS

DEL END PG DN

The PC-like keyboard allows comfortable editing and data input in method

development and routine use.

1.4.1 Function keys (softkeys)

F1 F2 F3 F4 F5 F6 F7 F8 F9

The blue function keys are used for navigation within the window-oriented

operator dialog system. The function of these keys depends on the dialog

page and the particular window. The softkey bar at the lower edge of the

screen always shows the possible functions.

MAN

CONTROL

STATUS

METHOD

SAMPLE

RESULT

1.4.2 Hotkeys

The yellow hotkeys allow direct access to the most important functions or

dialog pages of the 796. Hotkeys can be used anywhere in dialog except

during the 'live' display of a curve while a determination is being carried out.

MAN CONTROL - opens the dialog page for manual operation

STATUS - displays the status information as shown on the main page

METHOD - opens the method selection window

SAMPLE - opens the sample input window or the sample silo

RESULT - opens a window which shows short result reports and statistics

796 Titroprocessor, Instructions for use

77

Page 14

1.4 Instrument description

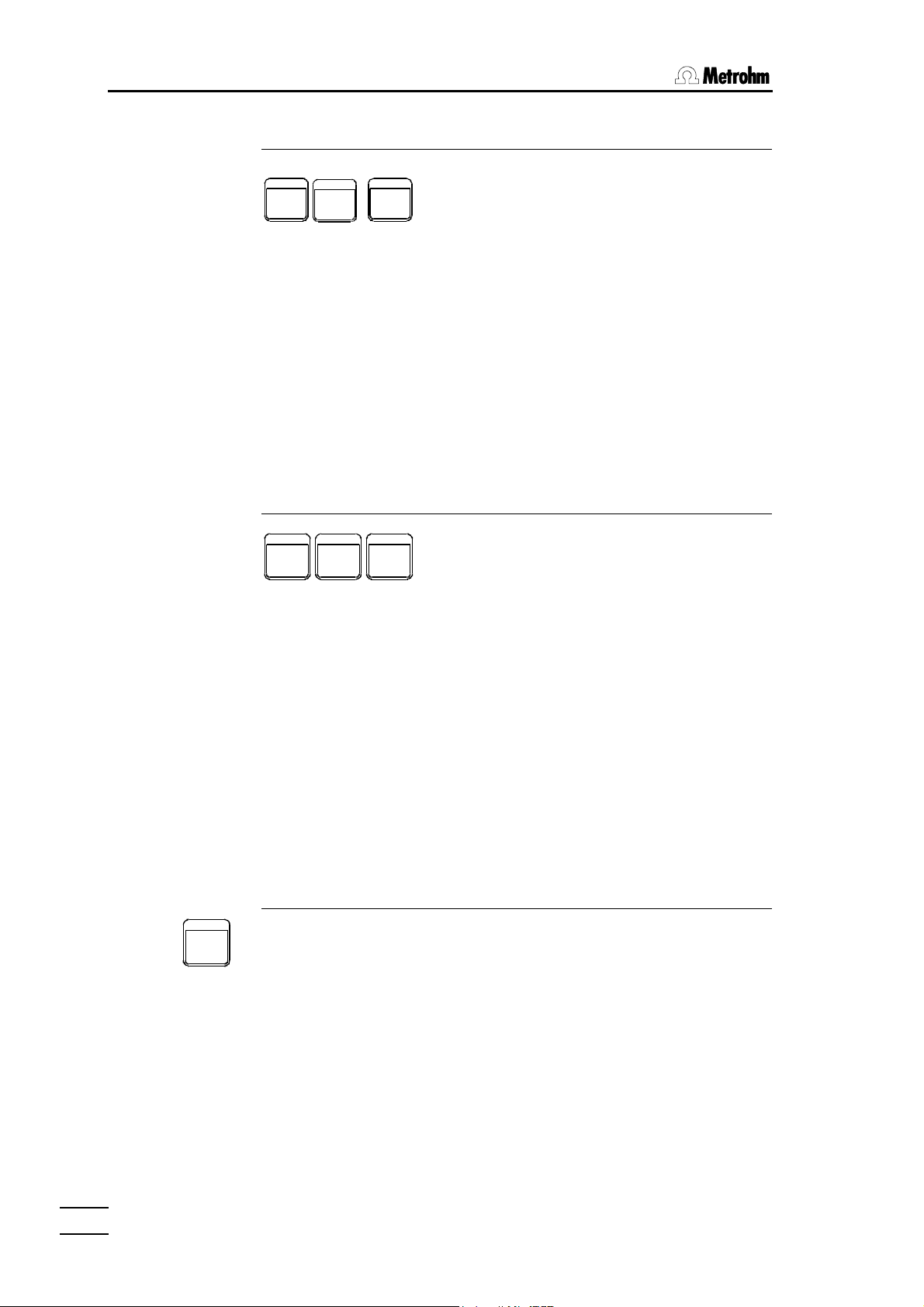

1.4.3 Action keys

The action key have an immediate effect on the course of a method. The

<START> key starts a method; the <STOP> key ends it. The <HOLD /

CONT> key can be used to interrupt a method or to resume it.

If the <Shift> key is pressed at the same time as an action key the processing of a series of samples can be controlled directly (with Autostart 'on').

<Shift><START> (=NEXT) ends the processing of the current sample and

starts processing the next sample in the series.

<Shift><STOP> (=DELAY) stops the sample series after the current sample has been processed.

<Shift><HOLD> (=SKIP) ends the execution of the current command and

jumps to the next command line of the loaded method.

1.4.4 Manual printing

HOLD

CONT

STOP

NEXTDELAYSKIP

START

QUIT

STOP FORM

PRINT

FEED

LINE

PRINT

SCREEN

The built-in A4 thermal printer or any other connected printer can be operated manually with the yellow printer keys.

The <PRINT> key opens the printer menu where the type of report can be

selected. Global reports and determination reports (if a determination report

is present in the working menu) can be selected.

<Shift><PRINT> (= STOP PRINT) interrupts a printout immediately.

<LINE FEED> executes a line feed on the connected printer.

<Shift><LINE FEED> (= FORM FEED) executes a form feed on the con-

nected printer.

<PRINT SCREEN> prints the current screen contents.

1.4.5 Navigation and editing keys

The <QUIT> key closes an editing field, a window or a dialog page and accepts previous parameter modifications. The dialog switches to the next

higher level.

<INS> (= Insert) switches the insert mode on/off for editing an entry

<DEL> (= Delete) deletes the character to the right of the cursor position

<Shift><DEL> deletes a complete editing field.

<HOME> places the cursor on the first editing field of a dialog window (in

navigation mode).

<END> places the cursor on the last sample silo line or command line (in

method editor).

88

796 Titroprocessor, Instructions for use

Page 15

1. Introduction

HOME

INS

DEL END PG DN

PG UP

<PG UP> moves the field cursor in the sample silo or method editor up by

one page.

<PG DN> moves the field cursor in the sample silo or method editor down

by one page.

<Cursor up> moves the cursor up by one line.

<Cursor down> moves the cursor down by one line.

<Cursor left> moves the cursor one field (in navigation mode) or one char-

acter (in editing mode) to the left.

<Cursor right> moves the cursor one field (in navigation mode) or one

character (in editing mode) to the right.

1.4.6 HELP key

HELP

The <HELP> key opens a page with help texts which refer to the opened

dialog page or window. In the editing mode it opens a help window for parameter input.

1.4.7 The GLP key

GLP

The GLP key opens the dialog pages in which the basics functions for validating the Titroprocessor as an analytical system and for checking sensors

(sensor test) can be carried out.

1.4.8 Special key abbreviations

For certain functions special key combinations have been provided; these

are listed below.

ALT+↑↑ increase display contrast

ALT+↓↓ reduce display contrast

ALT+A opens a dialog window to enter the access control page

ALT+T transfer screen contents via the communications interface

(printscreen to RS 232 interface)

ALT+X transfer screen contents via the communications interface

(with screen attributes line by line)

ALT+U transfer screen contents via the communications interface

(with screen attributes character by character)

796 Titroprocessor, Instructions for use

ALT+V transfer field contents of a selected editing field via the

communications interface

SHIFT+ALT

+DEL Titrator restart (mains on)

99

Page 16

1.4 Instrument description

Entry of special characters

In the editing mode any character contained in the ASCII character set can

be entered. This is carried out by first entering the character ^ and then the

3-place number of the required character. This is then displayed immediately.

Examples:

αα →→ ^224

ββ →→ ^225

≈≈ →→ ^247

≥≥ →→ ^242

≤ ≤ →→ ^243

±± →→ ^241

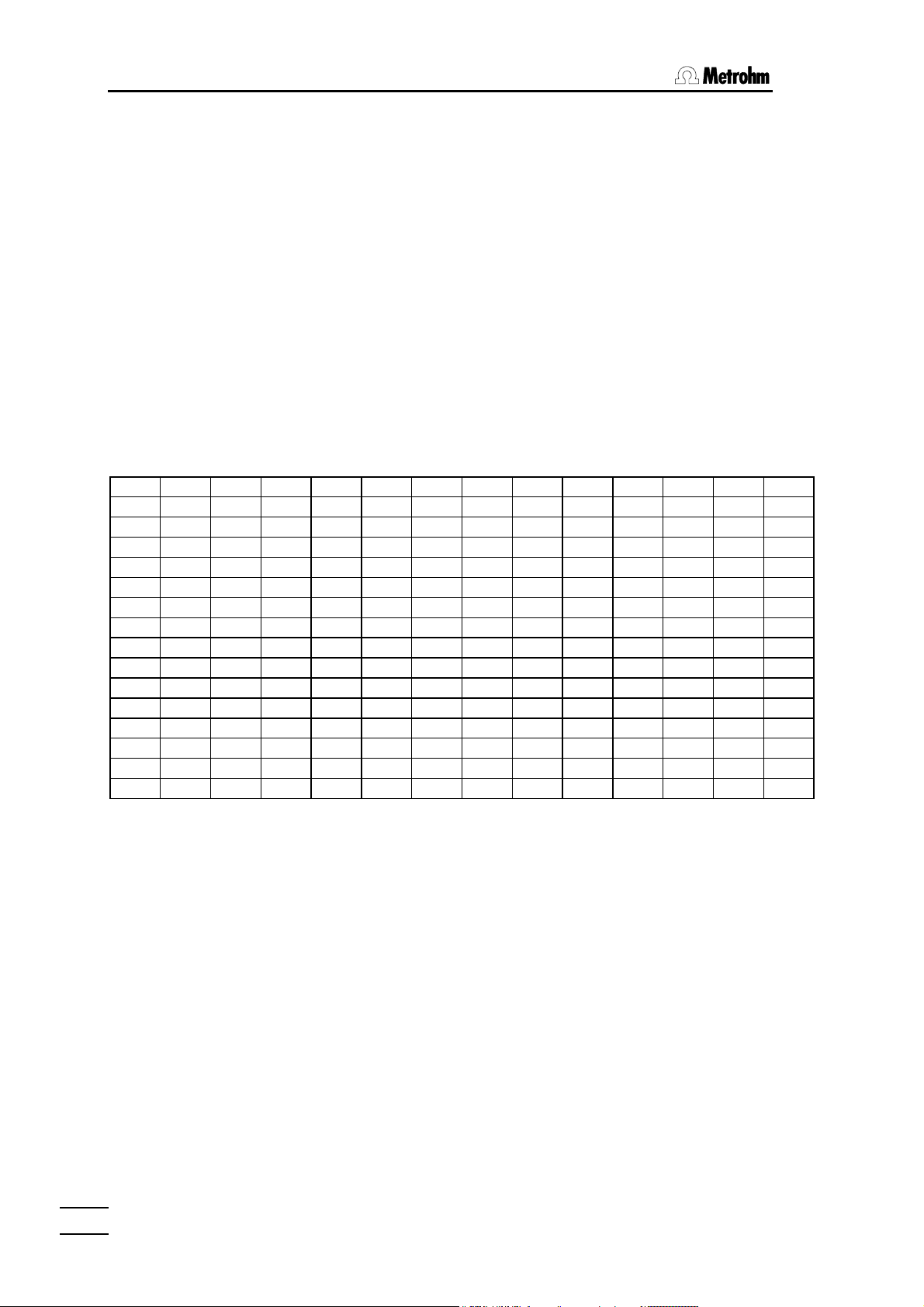

The complete table of the characters which are possible and their character numbers:

032 048 0 064 @ 080 P 096 ``112 p 128 Ç 144 É 160 á 176 °° 192 ÀÀ 208 ÐÐ 224 αα 240 ≡≡

033 ! 049 1 065 A 081 Q 097 a 113 q 129 ü 145 æ 161 í 177 ±± 193 ÁÁ 209 ÑÑ 225 ββ 241 ±±

034 "" 050 2 066 B 082 R 098 b 114 r 130 é 146 Æ 162 ó 178 ²² 194 ÂÂ 210 ÒÒ 226 ΓΓ 242 ≥≥

035 # 051 3 067 C 083 S 099 c 115 s 131 â 147 ô 163 ú 179 ³³ 195 ÃÃ 211 ÓÓ 227 ππ 243 ≤≤

036 $ 052 4 068 D 084 T 100 d 116 t 132 ä 148 ö 164 ñ 180 ´´ 196 ÄÄ 212 ÔÔ 228 ΣΣ 244 ⌠⌠

037 % 053 5 069 E 085 U 101 e 117 u 133 à 149 ò 165 Ñ 181 µµ 197 ÅÅ 213 ÕÕ 229 σσ 245 ⌡⌡

038 & 054 6 070 F 086 V 102 f 118 v 134 å 150 û 166 ª 182 ¶¶ 198 ÆÆ 214 ÖÖ 230 µµ 246 ÷

039 '' 055 7 071 G 087 W 103 g 119 w 135 ç 151 ù 167 º 183 ·· 199 ÇÇ 215 ×× 231 ττ 247 ≈≈

040 ( 056 8 072 H 088 X 104 h 120 x 136 ê 152 ÿ 168 ¿ 184 ¸¸ 200 ÈÈ 216 ØØ 232 ΦΦ 248 °°

041 ) 057 9 073 I 089 Y 105 i 121 y 137 ë 153 Ö 169 ©© 185 ¹¹ 201 ÉÉ 217 ÙÙ 233 ΘΘ 249 ••

042 * 058 : 074 J 090 Z 106 j 122 z 138 è 154 Ü 170 ªª 186 ºº 202 ÊÊ 218 ÚÚ 234 ΩΩ 250 ⋅⋅

043 + 059 ; 075 K 091 [ 107 k 123 { 139 ï 155 ¢ 171 ½ 187 »» 203 ËË 219 ÛÛ 235 δδ 251 √√

044 ,, 060 < 076 L 092 \ 108 l 124 ¦ 140 î 156 £ 172 ¼ 188 ¼¼ 204 ÌÌ 220 ÜÜ 236 ìì 252 üü

045 -- 061 = 077 M 093 ] 109 m 125 } 141 ì 157 ¥ 173 ¡ 189 ½½ 205 ÍÍ 221 ÝÝ 237 ø 253 ²

046 .. 062 > 078 N 094 ^ 110 n 126 ~~ 142 Ä 158 žž 174 « 190 ¾¾ 206 ÎÎ 222 ÞÞ 238 εε 254 þþ

047 // 063 ? 079 O 095 _ 111 o 127 -- 143 Å 159 ƒ 175 » 191 ¿¿ 207 ÏÏ 223 ßß 239 ∩∩ 255

1010

796 Titroprocessor, Instructions for use

Page 17

1.5 Dialog

1. Introduction

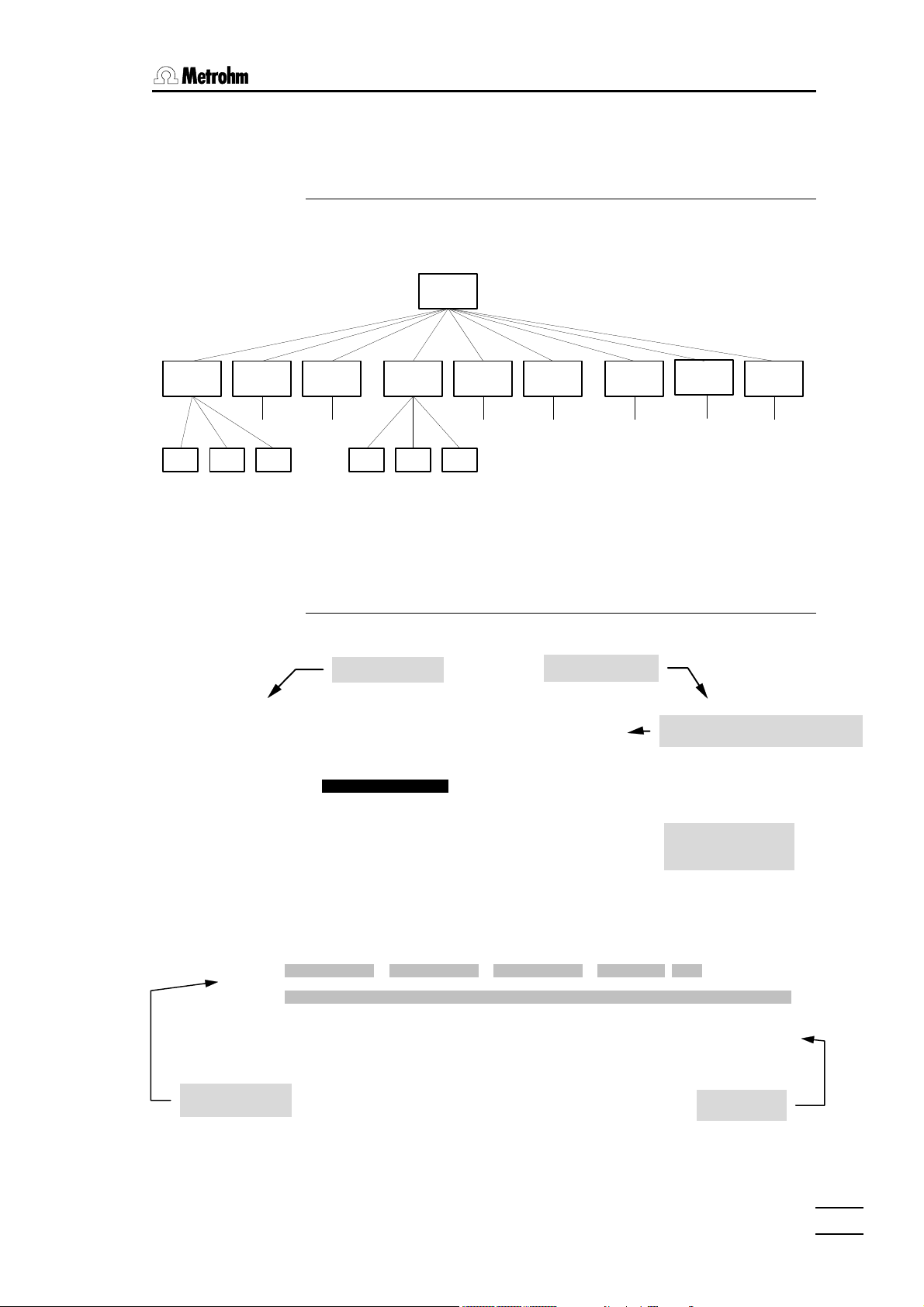

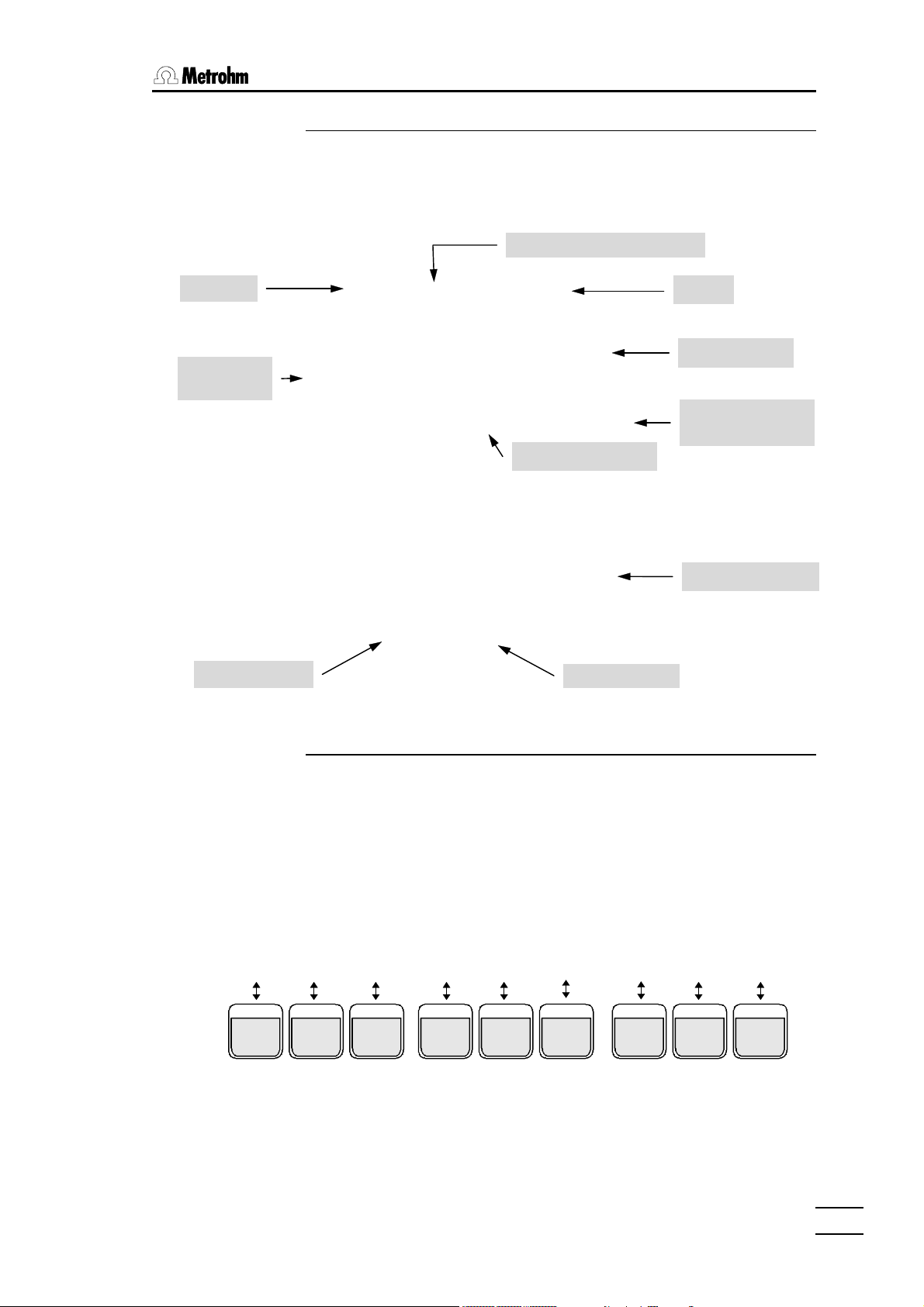

1.5.1 Dialog overview

The user dialog of the 796 Titroprocessor consists of 10 dialog pages,

which contain hierarchically structured subwindows.

Main

page

Sub-

window

Load

method

window

Sub-

Files

page

Sub-

window

Method

page

Sub-

window

sub-

window

Curves

page

Results

page

Samples

page

Card

Sign on

Configuration

page

Sub-

window

The main page of the 796 Titroprocessor is the entry to the user dialog. All

other pages can be accessed by using the corresponding softkeys (<F1>

to <F9>).

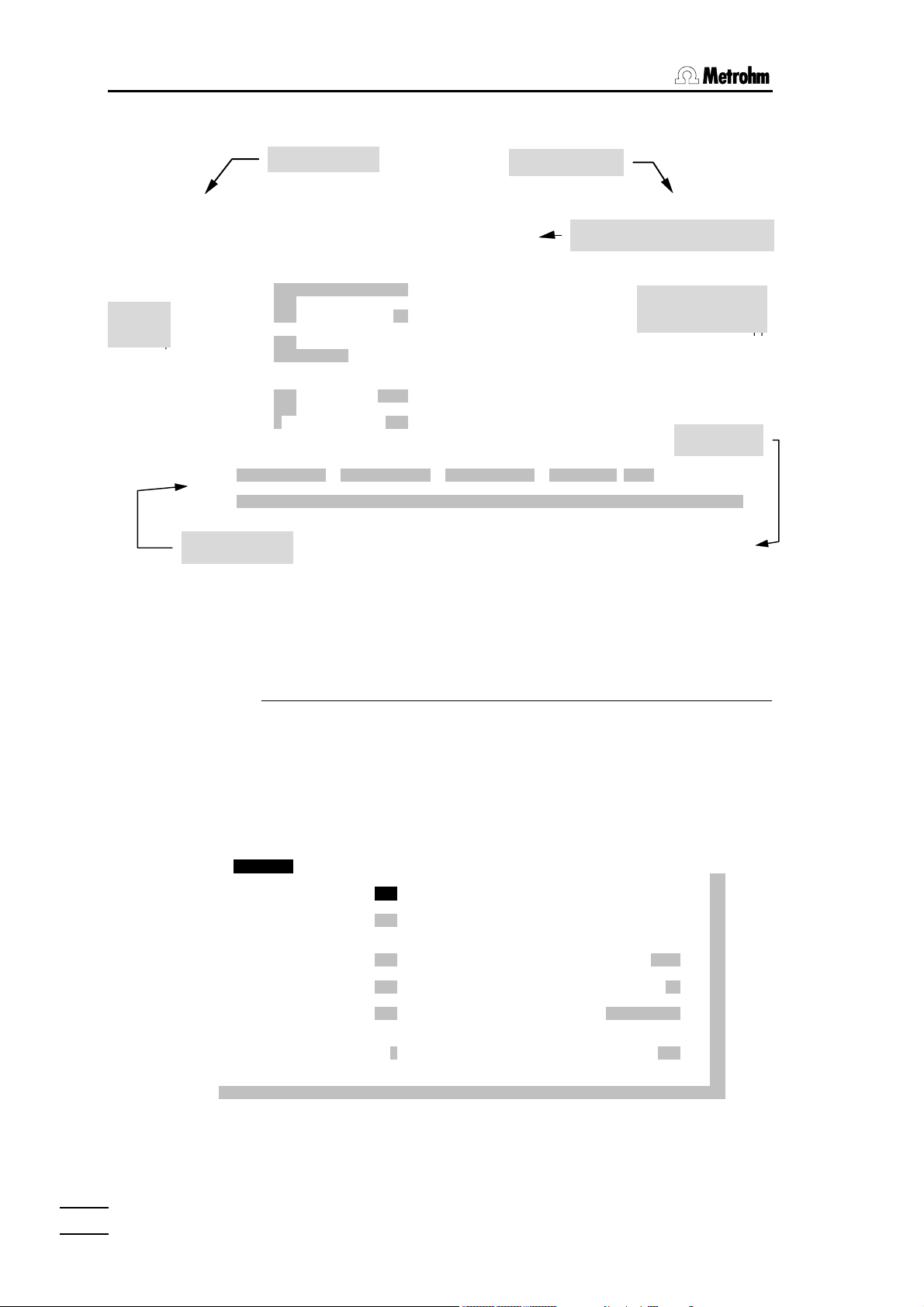

1.5.2 The main page

The main page in standard user level.

Date and time

ЪДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД¿

³ 2000-02-21 08:31:19 MAIN PAGE 796 Titroprocessor * ready * ³

³ ³

³ Method Tutorial.mth Simple acid/base titration ³

³ ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД³

³ ³

³ ЪДДДДДДДДДД Application Note ДДДДДДДДДДДДДДД¿³

³ User B. Miller ³ ³³

³ ³ This is a simple application method for ³³

³ ³ acid or base titrations. ³³

³ ³ ³³

³ ³ Example: ³³

³ ³ ------------------------------------------³³

³ ³ Weigh 150 mg TRIS in a beaker, dilute in ³³

³ ³ 70-80 mL dist. water and titrate with ³³

³ ³ c(HCl)=0.1 mol/L. ³³

³ ³ Use a comb. pH electrode as sensor. ³³

³ ³ ³³

³ АДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЩ³

³ ³

³ Ident1 Ident2 Ident3 Size Unit ³

³ Sample ³

³ ³

³ Remark ³

³ ³

³ ЪДДДДДДДВДДДДДДДВДДДДДДД¿ ЪДДДДДДДВДДДДДДДВДДДДДДД¿ ЪДДДДДДДВДДДДДДДВДДДДДДД¿ ³

³ ³Config.³Load ³File ³ ³Edit ³Show ³Results³ ³Sample ³Card ³Common ³ ³

³ ³ ³method ³manager³ ³method ³curves ³ ³ ³silo ³Sign on³vars ³ ³

³ АДДДДДДДБДДДДДДДБДДДДДДДЩ АДДДДДДДБДДДДДДДБДДДДДДДЩ АДДДДДДДБДДДДДДДБДДДДДДДЩ ³

АДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЩ

Sample data

Instrument state

Method name and comment

Application note

and trace window

Softkey bar

Variables

page

796 Titroprocessor, Instructions for use

1111

Page 18

1.5 Instrument description

The main page in expert user level.

Date and time

ЪДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД¿

³ 2000-02-02 09:24:13 MAIN PAGE Titroprocessor 796 * ready * ³

³ ³

³ Method 3455.mth Chloride in Tap Water ³

³ ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД³

³ ³

³ Auto save on 1.7 % free ³ Pipet accurately 100.00 mL of sample in a ³³

³ Destination Data card ³ 150 mL beaker. ³³

³ Determ.name ³ ³³

³ ³ Reagent: c(HNO3)=2 mol/L Dos A2 ³³

³ Auto start on 1 of 10 ³ Titrant: c(AgNO3)=0,01 mol/L Dos A1 ³³

³ Silo on in# 12 out# 1 ³ Sensor : Ag-Titrode 6.0430.100 Ind A1 ³³

³ Changer 1 Sample pos. 1 ³ ³³

³ АДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЩ³

³ ³

³ Ident1 Ident2 Ident3 Size Unit ³

³ Sample 001120/1 12 3455 100 mL ³

³ ³

³ Remark ³

³ ³

³ ЪДДДДДДДВДДДДДДДВДДДДДДД¿ ЪДДДДДДДВДДДДДДДВДДДДДДД¿ ЪДДДДДДДВДДДДДДДВДДДДДДД¿ ³

³ ³Config.³Load ³File ³ ³Edit ³Show ³Results³ ³Sample ³Devices³Common ³ ³

³ ³ ³method ³manager³ ³method ³curves ³ ³ ³silo ³ManCtrl³vars. ³ ³

³ АДДДДДДДБДДДДДДДБДДДДДДДЩ АДДДДДДДБДДДДДДДБДДДДДДДЩ АДДДДДДДБДДДДДДДБДДДДДДДЩ ³

АДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЩ

³ ЪДДДДДДДДДД Application note ДДДДДДДДДДДДДДД¿³

³ User B. Miller ³ Chloride in Tap Water ³³

³ Run number 000 ³ ------------------------------------------³³

³ Statistics on 0 of 10 ³ Sample preparation: ³³

Status

³ ³ ³³

Area

Sample data

Instrument state

Method name and comment

Application note

and trace window

Softkey bar

The settings of the status area are the same as in the status window

(<STATUS>key). See below for details.

1.5.3 The status window

In the standard user level the status settings are available only in the status

window. The <STATUS> key on the keyboard will open the status window.

ЪДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД¿

АДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЩ

³ 2000-02-10 14:04:05 MAIN PAGE 796 Titroprocessor * ready * ³

³ ³

³ Method Acid.mth Acid titration c(HCl)=0.1 mol/L ³

³ ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД³

³ ³

³ ЪДДДДДДДДДД Application Note ДДДДДДДДДДДДДДД¿³

³ UseЪДДД Status ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД¿ ³³

³ ³ ³ ³³

³ ³ Run number 000 Determination name ³------³³

³ ³ ³te in ³³

³ ³ Sample silo on Next sample in silo line 1 ³th ³³

³ ³ Sample entry in silo line 1 ³ ³³

³ ³ ³ ³³

³ ³ Auto start on Current sample 0 of 9999 ³ ³³

³ ³ ³ ³³

³ ³ Statistics on Data records 0 of 2 ³ ³³

³ ³ ³ ³³

³ ³ Save determ. data on Destination Data card ³ДДДДДДЩ³

³ ³ Free Memory 1.6 % ³ ³

³ ³ ³ ³

³ Sam³ Sample changer 1 First rack position 1 ³ ³

³ ³ ³ ³

³ RemАДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД QUIT ДЩ ³

³ ³

³ ЪДДДДДДДВДДДДДДДВДДДДДДД¿ ЪДДДДДДДВДДДДДДДВДДДДДДД¿ ЪДДДДДДДВДДДДДДДВДДДДДДД¿ ³

³ ³ ³ ³ ³ ³ ³ ³ ³ ³ ³ ³ ³ ³

³ ³ ³ ³ ³ ³ ³ ³ ³ ³ ³ ³ ³ ³

³ АДДДДДДДБДДДДДДДБДДДДДДДЩ АДДДДДДДБДДДДДДДБДДДДДДДЩ АДДДДДДДБДДДДДДДБДДДДДДДЩ ³

1212

796 Titroprocessor, Instructions for use

Page 19

1. Introduction

command with line number

quantity

Measured value

1.5.4 The trace window

During the course of a method the display window of the application note

changes to a trace window, showing the state of the currently executed

command. The display format depends on the current command or mode.

Line time

Measuring

Control indicator

ЪДДДДДДДДДДДДДДДДД Trace ДДДДДДДДДДДДДДДДДДД¿

³ 0s 1. DET_PH* Titr. ³

³ ³

³ ЬЫЫЫЬ ЬЫ ЬЫ ³

³ Ы Ы Ы Ы ЫЯЫ ЫЯЫ ³

³ Ы Ы ЯЫЫЫЫ Ы ЫЯ Ы ³

³ ЫЫЫЬ ЫЫЫЫЫ Ы Ы Ы Ы ³

³ Ы Ы Ы Ы Ь Ы Ы ЫЫЫЫЫ ³

³ ЫЫЫЯ Ы Ы ЯЫЫЫЯ Ы ЫЫЫЫ Ы ³

³ Ы ³

³ Ы ³

³ 2.991mL 1 EP's ³

АДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЩ

or

ЪДДДДДДДДДДДДДДДДД Trace ДДДДДДДДДДДДДДДДДДД¿

³ 0s 1. SET_PH* Titr. ³

³ ³

³ ЬЫ ЬЫЫЫЬ ЬЫЫЫЬ ЬЫЫЫЬ ³

³ ЫЯЫ Я Ы Ы Ы Ы Ы Ы ³

³ Ы ЫЫЯ ЯЫЫЫЫ ЯЫЫЫЫ Ы ³

³ Ы ЯЫ Ы Ы ЫЫЬЫЬ Ы ³

³ Ы Ь Ы Ь Ы Ь Ы Ы Ы Ы Ы ³

³ ЫЫЫЫ Ы ЯЫЫЫЯ ЯЫЫЫЯ ЯЫЫЫЯ Ы Ы Ы ЫЫЫЫ ³

³ ³

³ ЫЭЭЭЭЭЭ.............. ³

³ pH 9.81 ³

АДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЩ

Dispensed volume

Status

Measured value

Equivalence points

found

Dispensed volume

1.5.5 How to navigate

To navigate from page to page or from subwindow to subwindow you can

use the blue function keys <F1> to <F9> . These function keys alter their

meaning or functionality, depending on the dialog page or window that is

shown on the screen. The function of the corresponding function key is always shown at the bottom of the screen. It is called the softkey bar. The

function keys (<F1> to <F9>) are called softkeys.

ЪДДДДДДДВДДДДДДДВДДДДДДД¿ ЪДДДДДДДВДДДДДДДВДДДДДДД¿ ЪДДДДДДДВДДДДДДДВДДДДДДД¿

³Config.³Load ³File ³ ³Edit ³Show ³Results³ ³Sample ³Card ³Common ³

³ ³method ³manager³ ³method ³curves ³ ³ ³silo ³Sign on³vars ³

АДДДДДДДБДДДДДДДБДДДДДДДЩ АДДДДДДДБДДДДДДДБДДДДДДДЩ АДДДДДДДБДДДДДДДБДДДДДДДЩ

F1

F9F8F7F6F5F4F3F2

A dialog page or window can be left or closed by pressing the <QUIT> key.

Any prior modifications of parameters will be accepted.

796 Titroprocessor, Instructions for use

1313

Page 20

1.6 Instrument description

The shortcut keys of the rightmost key column on the keyboard allow direct

access to some important dialog windows or features.

The shortcut keys are: <MAN CONTROL>, <STATUS>, <METHOD>,

<SAMPLE>, <RESULT>.

1.5.6 Field cursor

To navigate on a page or in a dialog window you can use the cursor keys

<ç>, <è>, <é> or <ê>. The position of the so called field cursor is

indicated by the black field background of the edit field the cursor is pointing to. To navigate right or left within a line you can use the <TAB> key or

the <Shift><TAB> key combination, respectively. The <HOME> key sets

the field cursor to the first edit field of a page or dialog window.

1.6 How to edit

To edit an entry of an edit field just type in the new value or press the

<SPACE> key. In most cases a picklist is shown, from which you can select

a given value by using the cursor keys <êê> and <éé>. The selection must

be confirmed with <ENTER> or the picklist may be closed by pressing the

<QUIT> key. The field cursor will turn into a block cursor which indicates the

edit mode.

The PC-like keyboard allows comfortable editing of text or numeric entries.

To erase any character use the <DEL> (forward deletion) or the

<BACKSPACE> key (<[ çç ]> backward deletion). The <INS> key switches

the insert mode to the overwrite mode and vice versa.

In this mode a special softkey bar is shown.

ЪДДДДДДДВДДДДДДДВД … ДВДДДДДДД¿

³Help on³Select ³ … ³Cancel ³

³entry ³ ³ … ³ ³

АДДДДДДДБДДДДДДДБД … ДБДДДДДДДЩ

• The [Help on entry] softkey may be used to open a window with a short

explanation of the meaning or the content of the entry field to be edited.

The entry range and one or more examples for entry values will be

shown.

• The [Select] softkey opens the picklist of the selected entry field. If no

picklist is available, the [Select] softkey is displayed in gray letters to indicate that its function is not available.

• The [Cancel] softkey rejects any modifications and resets the former

field content. The edit mode will be canceled as well.

Modifications of field contents are to be confirmed with the <ENTER> or the

<QUIT> key. The latter will terminate the edit mode.

1414

796 Titroprocessor, Instructions for use

Page 21

1. Introduction

Tip:

If the edit mode (entry on the configuration page, or press the <INS>key) is

set to 'overwrite', you can simply type in the first letter or the first two letters

of an entry item and press <ENTER> to change the content of an entry field

with a selector list. If this entry can be uniquely assigned to an item of the

selector list, it will be automatically completed.

Example:

To change the destination memory of data files for use with the auto save

function, set the field cursor to the destination field on the Titroprocessor's

main page. Type 'd' then and press the <ENTER>key. The entry of the de-

stination field will be set automatically to 'Data card'.

This is the quickest way to modify entry fields .

1.6.1 Navigation in edit mode

In edit mode the cursor keys <çç> and <èè> allow the navigation within an

entry field. To access other fields in the same line use the <TAB> key or the

<Shift><TAB> key combination, respectively. The cursor keys <êê> and

<éé> allow vertical navigation.

796 Titroprocessor, Instructions for use

1515

Page 22

2.1 Safety information

2 Installation

2.1 Instrument setup

Packaging

The 796 Titroprocessor is supplied together with the specially packed accessories in packaging containing shock-absorbing foam which provides

excellent protection. Please store this special packaging as it guarantees

damage-free transport of the instrument.

Checks

Please check immediately on receipt whether the shipment is complete and

undamaged (compare with delivery note and list of accessories on page

290). If transport damage is established see section 13.7 Warranty and

certificates (p. 292).

Location

Place the 796 Titroprocessor in a convenient working position in the laboratory; this should be vibration-free and not exposed to corrosive atmospheres or contamination by chemicals.

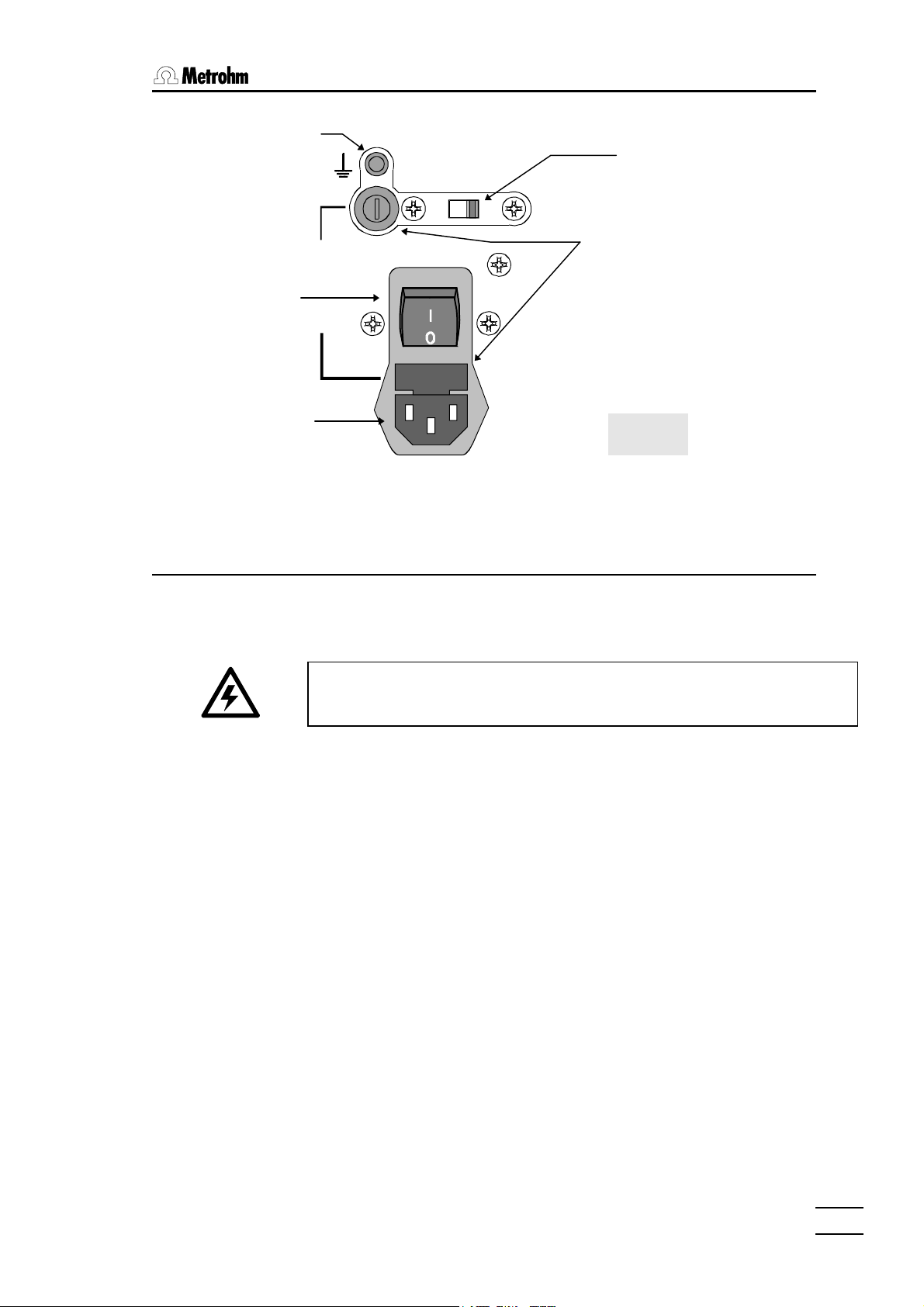

2.2 Mains supply

Follow the instructions given below for connection to the mains

supply. If the instrument is operated with the mains voltage incorrectly set and/or the wrong mains fuse there could be a danger of

fire!

Setting the mains voltage

Before switching on the 796 Titroprocessor for the first time check that the

mains voltage set on the instrument (can be seen in the mains voltage selector) corresponds to the local mains voltage. The mains voltage selector is

located on the rear panel of the instrument: please refer to following page.

If the mains voltage is incorrectly set then it must be set correctly by sliding

the mains voltage selector with the help of a screwdriver:

1616

230V

230V: 220V ... 240 V ± 10%

115V: 100V ... 120 V ± 10%

115V

796 Titroprocessor, Instructions for use

Page 23

Earth socket

115V: 100V...120V 10%

230V: 220V...240V 10%

230V

22. . InstallationInstallation

Mains voltage selector

S1

2A(TH)

Mains switch

115V

230V

Mains connection

50-60Hz 160VA

2.3 Mains connection

2.3.1 Fuses

Two fuses S1S1 and S2S2 are built into the 796 Titroprocessor as standard;

both are type 2 ATH (2 A, slow-blow, with high switching capacity, Metrohm

order no. U.600.0107).

Make sure that the instrument is never operated with any different type

of fuse as otherwise there is a fire hazard!

S2

Fuse holder

Rear view

For continued protection replace only

WARNING - Fire Hazard -

with the same type and rating of fuse

To change blown fuses proceed as follows:

Exchange fuse S1 (zero conductor, 2 ATH)

• Remove mains cable from mains connector.

• Use a screwdriver to turn fuse holder S1S1 to the left until it can be pulled

out.

• Pull out the fuse holder, remove the blown fuse and replace it with a

spare fuse (2 ATH).

• Insert the fuse holder in the instrument, press it down with a screwdriver

and then turn it to the right to fix it in position.

Exchange fuse S2 (phase, 2 ATH)

• Remove mains cable from mains connector.

• Use a screwdriver to push fuse holder S2S2 upwards until it can be pulled

out.

• Pull out the fuse holder, remove the blown fuse and replace it with a

spare fuse (2 ATH).

• Insert the fuse holder in the instrument and push until it clicks into place.

796 Titroprocessor, Instructions for use

1717

Page 24

2.3 Safety information

2.3.2 Mains cable and mains connection

The instrument is supplied with one of three types of cable:

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which has three leads and is fitted with a plug with an earthing pin. If a different plug has to be fitted then the yellow/green lead (IEC standard) must

be connected to the earth (protection class 1). If no earthed socket is available then a proper earth connection must be made via the earthing socket

of the instrument.

Any break in the earthing lead, whether inside or outside the instrument, can cause the instrument to become a hazard!

Insert the mains cable into the mains connector of the 796 Titroprocessor.

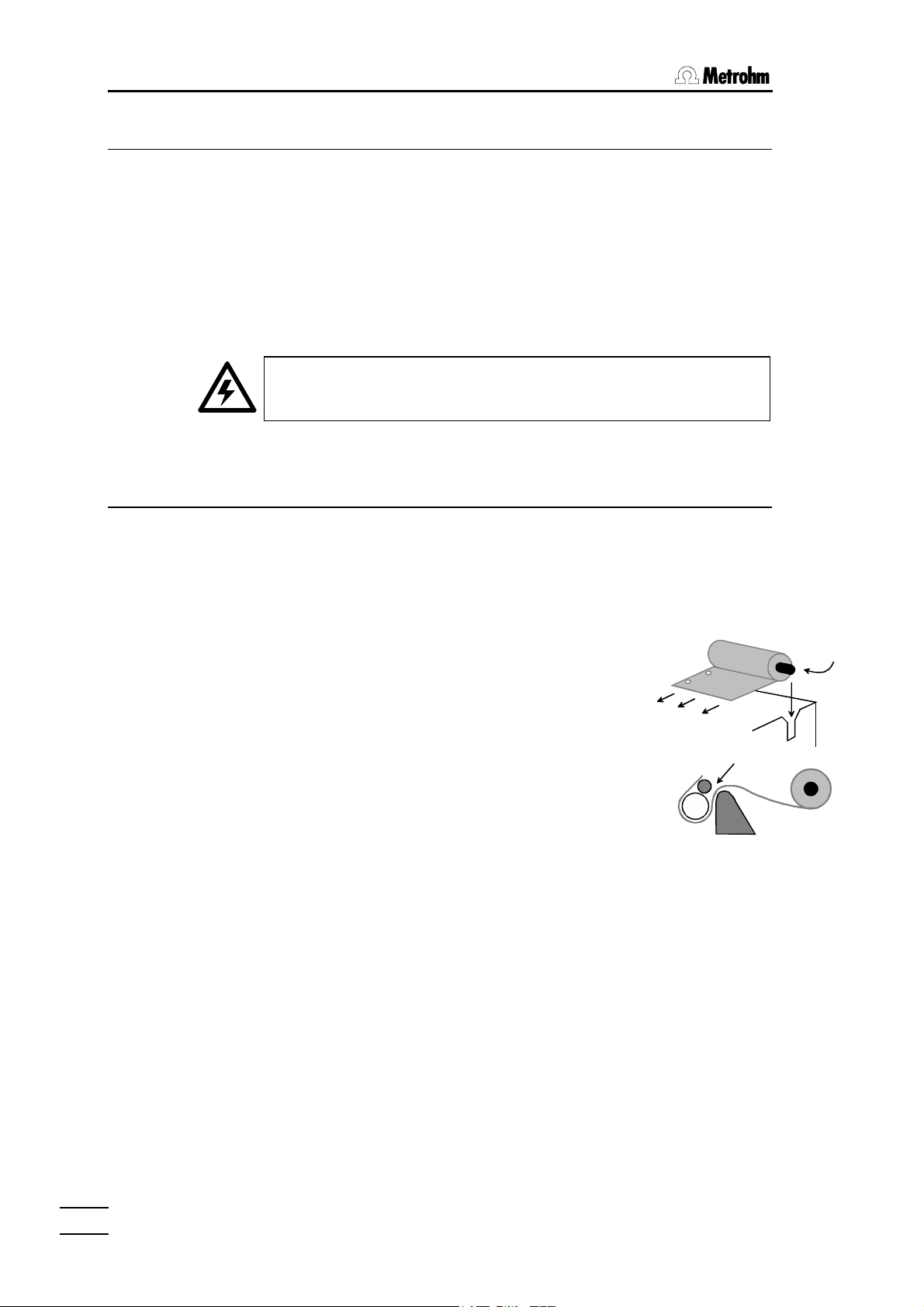

2.3.3 Setting up the thermal printer

Insert paper (only for the built-in printer)

The thermal printer of the Titroprocessors (models 2.796.0010 and

2.796.0110) is supplied without inserted paper. The thermal paper

6.2237.040 included with the accessories (roll approx. 40 m ≅ 130 A4

pages) is inserted into the printer as follows:

Preparations

• Switch on 796 Titroprocessor.

• Lift up the printer cover.

• Make sure that the roll of thermal paper 6.2237.040

has a straight edge; if necessary, carefully tear off the

paper at the first perforation.

• Remove any scraps of paper or dust from the paper

storage compartment. Check the new paper roll for

scraps, too.

Insertion

• Insert paper spool 6.2241.020 in thermal paper roll 6.2237.040.

• Place the roll of paper with the paper spool in the two recesses at the

sides of the printer so that the paper leaves the roll from the rear and the

file hole margin is on the left-hand side when seen from the front.

• Carefully insert the straight-edged paper manually into the paper guide

slot to the limit stop and hold it there.

1818

Paper transport

• Press the two keys <Shift> and <FORM/LINE FEED>. The paper will

be fed in automatically and transported to the correct position.

• Close the cover of the paper storage compartment.

796 Titroprocessor, Instructions for use

Page 25

2.4 Data / key card handling (PC cards)

The 796 Titroprocessor can write data onto SRAM storage cards and read

this data in at a later date. It is not possible to use FLASH cards others than

the one delivered with the instrument. The following SRAM cards can be

used as storage or key cards:

• 6.2245.030 Metrohm Data card (capacity 2 MB)

• 6.2245.010 Metrohm Data card (capacity 128 kB)

• Commercial SRAM cards of any capacity (up to 4 MB) with the hardware

format JEIDA 4.0 (68 pin) as well as PCMCIA cards based on them

Because of different file systems PCMCIA cards cannot be used at

the same time for the 796 Titroprocessor and PCs.

When handling data cards with the 796 Titroprocessor the following points

are important:

SRAM card preparation

The following preparations are necessary before data cards (or key cards)

are used for the first time:

22. . InstallationInstallation

• New SRAM cards are supplied with a separately included battery. This

should be inserted in the memory card according to the accompanying

description.

• Data cards can only be inserted in the instrument in the position shown

below. The included label should be attached to the top of the data card.

Label

• The SRAM card battery has a limited lifetime; this is given in the accompanying leaflet. In order to avoid accidental loss of data, the date when

the battery is due to be exchanged should be written on the data card

label.

• Before data can be stored on the SRAM card it must be formatted. Proceed as follows:

• Insert card in the 796 Titroprocessor (see above drawing).

• Select file manager with the softkey [File manager] on the main

page. Change the memory area with the softkey [Change storage],

select 'data card' with the cursor keys and press <ENTER>.

Notch

796 Titroprocessor, Instructions for use

• If an unformatted SRAM card has been inserted a system window

appears on the display. Enter <f> to format the card.

• A query about the card name is then made. A name with max. 20

characters can be entered; this will now be displayed in the file manager whenever the card is inserted. When the entry has been completed the data card is formatted with <Enter>.

1919

Page 26

2.4 Safety information

Data card insertion and removal

• The data card can only be inserted in den 796 Titroprocessor in one

particular position (see above illustration). It must be pressed firmly

into the slot provided until the eject button fully protrudes.

• A data card inserted into the Titroprocessor slot can be ejected by

pressing the eject button and then removed manually.

SRAM cards are sensitive to electrostatic charges. Make sure that

you are earthed each time you insert or remove a data card (e.g.

by previously touching the earthed green 796 Titroprocessor

housing).

Changing the battery

• The battery of the SRAM card has a limited working life which is given

in the leaflet accompanying the card. Please note that the working life

of batteries depends on the storage temperature. Data cards or

spare batteries should therefore be stored as cool as possible (in any

case below 25°C).

• The date for the next battery change should be marked on the data

card label (see above). In order to avoid accidental data loss the

battery should be replaced by this date at the latest.

• Insert the data card in the 796 Titroprocessor.

The battery must only be exchanged with the card inserted in the

instrument, as otherwise the data stored on the card will be lost.

The card is powered by the Titroprocessor while the battery is being changed.

• Change the battery according to the accompanying description.

• Mark the data card label with the new date for the next battery

change (see under ”data card preparation” above).

2020

796 Titroprocessor, Instructions for use

Page 27

2.5 Safety information

If failure or malfunctioning occurs during operation of the 796 Titroprocessor

we recommend that the diagnostic functions are first used to try and determine the cause (see page 260). If this does not help to rectify the failure or if

the cause of the malfunction cannot be remedied then please consult the

service department of your local Metrohm agency.

If opening the instrument cannot be avoided then the following safety

measures must be strictly observed:

The instrument must be disconnected from all electricity supplies before opening. Make sure the mains plug has been pulled

out.

Only in exceptional cases should the instrument be opened while it is

switched on. As this exposes current-conducting components it should only

be undertaken by an expert who is familiar with the associated dangers.

22. . InstallationInstallation

Electronic components are sensitive to static electricity and can be destroyed by discharges. Before touching any components inside the instrument both the person and his tools should be earthed by grasping an

earthed object (e.g. the instrument housing or a radiator) in order to eliminate any static electricity.

If it becomes apparent that the instrument can no longer be operated safely

then it should not be used at all.

796 Titroprocessor, Instructions for use

2121

Page 28

2.6 Safety information

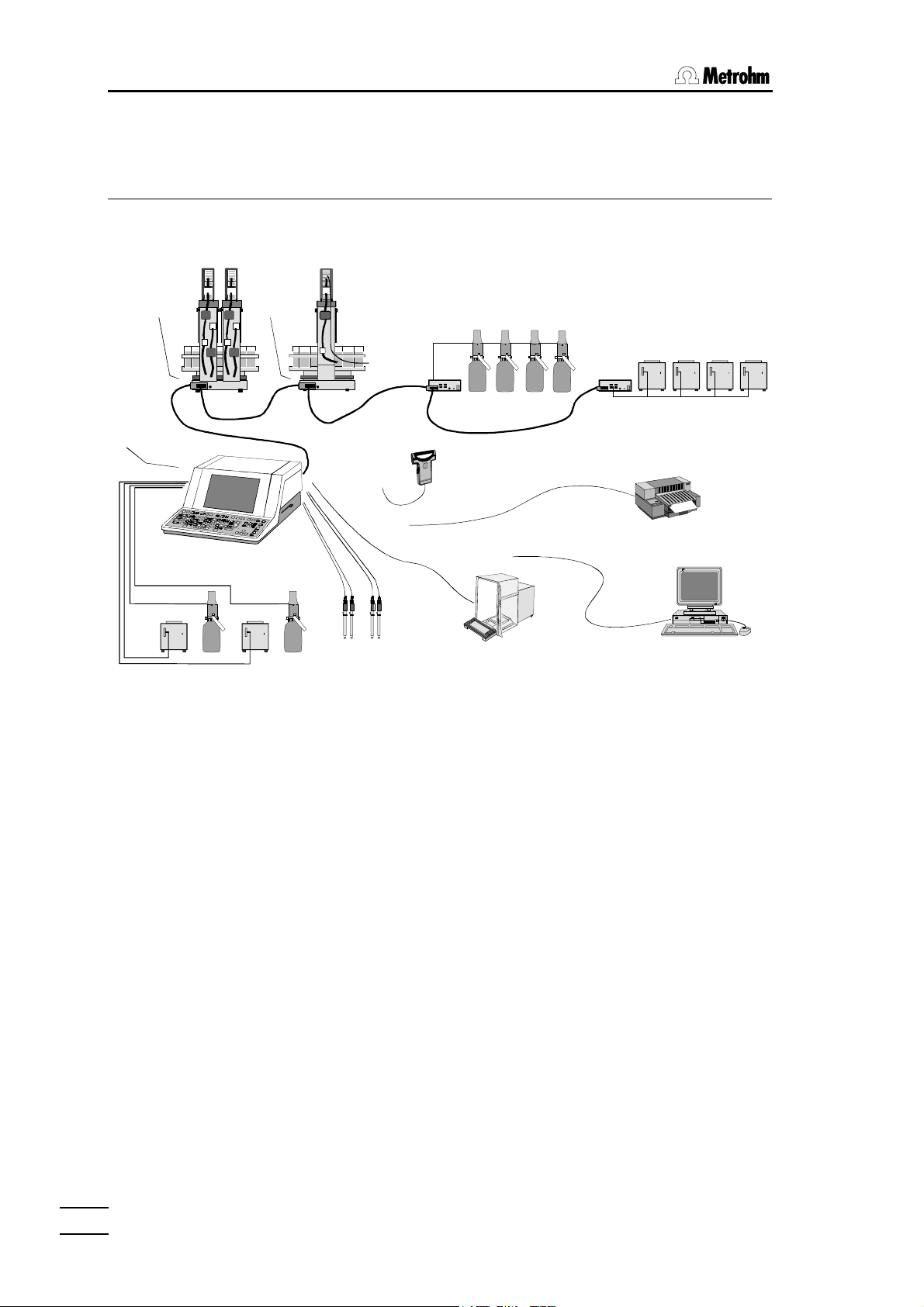

Dosinos /

external

2.6 Connections

2.6.1 System components and peripheral devices

717 Sample changer

external

71

796

devices

External bus

700 Dosinos

700

700

71

729

729 Dosimat

interface

bar-code reader

devices

external

devices

700

700

729

729 Dosimat

interface

685 Dosimats

685

685

printer

685 685

Dosimats

700685 700685

sensors

balance

PC / LIMS

The 796 Titroprocessor can be extended to provide an automated and

comprehensive analytical system.

Metrohm cables should always be used to connect Metrohm instruments

and accessories, as only these guarantee interference-free data transmission. For instruments from other manufacturers please observe the manufacturer's recommendations.

The Titroprocessor offers the following connections:

• 4 dosing devices, further (up to 8) dosing devices can be connected via

the 'External bus' (see below).

• 2 measuring groups (models 2.796.0010 and 2.796.0020 have only 1

measuring group) each with measuring inputs for 2 indicator electrodes

(or combined measuring electrodes), 1 reference electrode, 1 polarizable electrode (voltammetry/amperometry, KF titrations), 1 Pt100/Pt1000

temperature sensor connection, 1 stirrer connection

• 1 'External bus' connection for up to two 717 Sample changers and/or

up to 8 dosing devices, to be connected via Dosimat interfaces 729 (4

dosing devices per interface)

• 2 serial RS 232 connections (25-pole) for balance, printer or personal

computer (LIMS, automatic data storage or remote control of the 796 Titroprocessor)

2222

796 Titroprocessor, Instructions for use

Page 29

• 1 parallel printer connection for any external printer (only for models

• 1 bar-code reader connection (9-pole) for entering sample data

• 1 remote connector (25-pole) with 8 input and 8 output leads for control-

2.6.2 Dosing devices

22. . InstallationInstallation

2.796.0010 and 2.796.110)

ling external peripheral devices (e.g. Relay Box, KF Oven, etc.). Each

717 Sample changer has a further remote connector (25-pole) with 8 input and 14 output leads which can be directly addressed from the 796

Titroprocessor.

Dos. A1

Dos. A3

Up to 4 dosing devices can be

directly connected to the rear panel

of the Titroprocessor. For connecting a 685 Dosimat you need a

6.2134.000 cable.

Dos. A2

Dosing Units

A

Dos. A4

Dosing devices are recognized by

the addresses A1 to A4.

Two different types of Metrohm dosing device are available for selection:

• 685 Dosimat, with the normal exchange units.

• 700 Dosino, with 710 dosing unit

700 Dosino

10 ml

Dosinos are operated by the 796 Titroprocessor

in the standard configuration, i.e. the reagent is

drawn in from the bottle via Dosino port 2 (filling

port) and added via port 1 (dosing port). The port

occupancy cannot be changed when a Dosino is

used with the 796 Titroprocessor.

796 Titroprocessor, Instructions for use

685 Dosimats and 700 Dosinos can be combined

as required.

Switch off the 796 Titroprocessor before connecting an instrument

to it. When it is switched on again the Titroprocessor automatically

recognizes the new instrument.

If more than four dosing devices are to be connected then the additional

dosing devices should be connected via 729 Dosimat interface to the

'External bus' (for connections see sample changer below).

729

Plug the 729 Dosimat interface directly into the 'External bus' socket of the

Titroprocessor or, if installed, into the corresponding socket of the

717 Sample changer.

2323

Page 30

2.6 Safety information

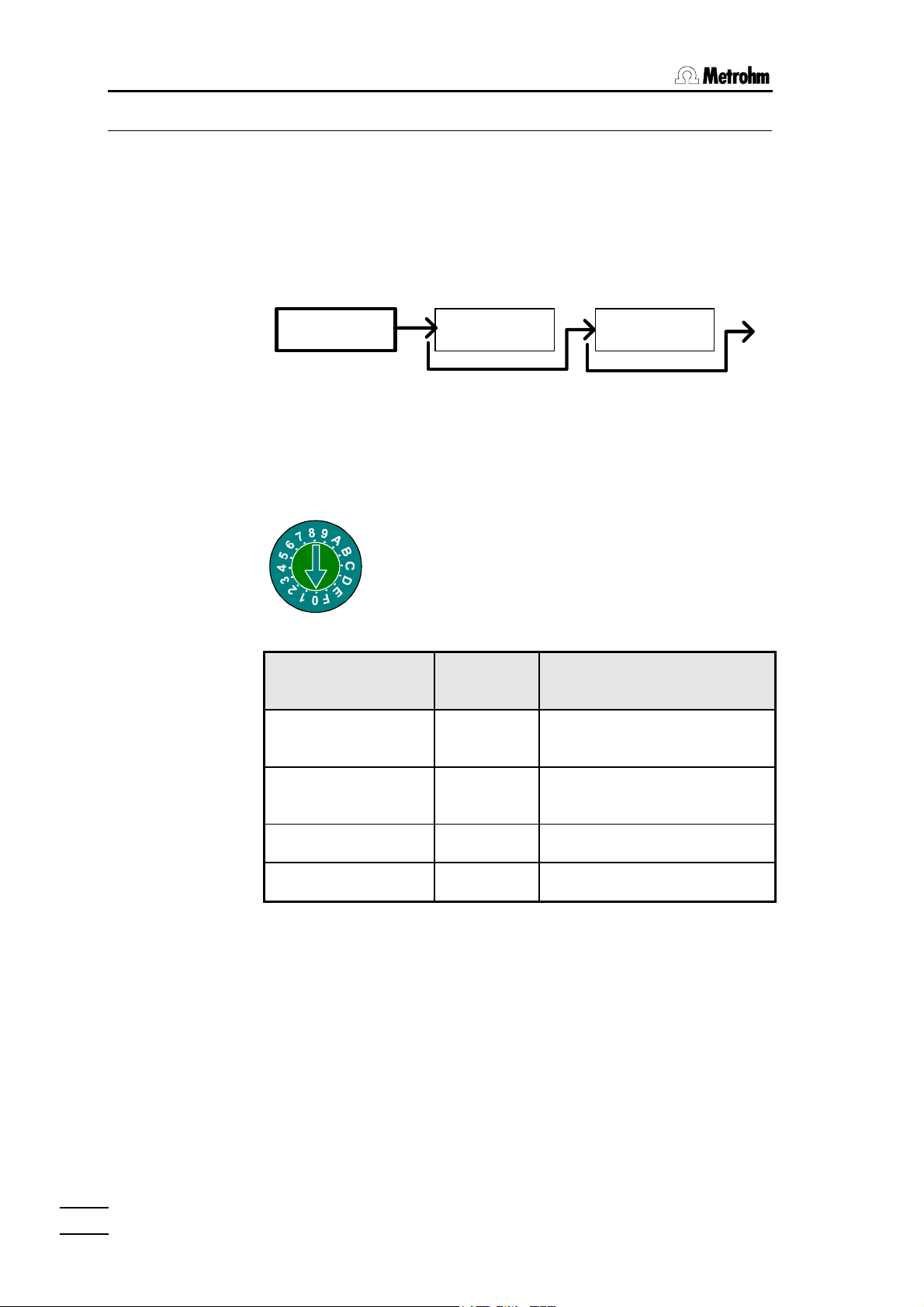

2.6.3 External bus

The external bus allows external instruments to be controlled by the 796 Titroprocessor. Sample changers and dosing devices such as the 685 Dosimat or the 700 Dosino can communicate bi-directionally with the Titroprocessor (=bus master).

External devices must be connected with EBus cables according to the following scheme:

Bus master

Each external instrument is identified by an EBus address. When the Titroprocessor is switched on they are automatically identified. An EBus address

must be set for each external device (1…9, A…F; 0 stands for the bus

master).

External device EBus

Sample changer 1

External device External device

External bus

Address selector

The corresponding EBus address can be set with

a screwdriver. The EBus address selector is usually located on the rear panel of the external device.

Corresponding

address

1

1…2 lifts, 0…4 pumps,

1…4 stirrers

peripherals

2424

Sample changer 2

Dosimat interface 1

Dosimat interface 2

Devices such as sample changers which consume a lot of current should

be connected in the first position of the EBus chain. This is particularly important if the relevant sample changer is equipped with more than one

pump. The 729 Dosimat interfaces should be connected to the 717 Sample

changer.

The 796 Titroprocessor and the Dosimat interfaces must be connected to

the same earth. A line distributor should be used to supply all devices on

the external bus.

The 796 Titroprocessor must be switched off before a peripheral device is connected.

2

1

2

1…2 lifts, 0…4 pumps,

1…4 stirrers

1…4 Dosimats (B1…B4)

1…4 Dosimats (C1…C4)

796 Titroprocessor, Instructions for use

Page 31

22. . InstallationInstallation

Dosing

devices

Dosimat A1

717 717

EBus

Address 1

External Bus

796

Dosimat A3

700685

700685

EBus

Address 2

Dosimat B3

EBus

Address 1

729

Dosimat B4

Dosimat C3

EBus

Address 2

729

Dosimat C4

Power cables

Line distributor

Dosimat B1

700685

Dosimat B2

Dosimat C1

700685

Dosimat C2

Dosimat A2

2.6.4 Sample changers

B

External Bus

Dosimat A4

One or two 717 Sample changers can be connected to the 'external

bus' sockets of the 796 Titroprocessor. Take care that the address

selector disk is set correctly (see above). Please connect up larger

systems according to the above diagram.

Two 717 Sample changers can be connected at the same time;

however, they cannot be used simultaneously in one automatic

method. It is possible to change the active sample changer within a

method (see command 'CHANGER').

Manual operation of a sample changer while the other sample

changer is busy carrying out a method is possible and does not

present any problems.

796 Titroprocessor, Instructions for use

2525

Page 32

2.6 Safety information

2.6.5 Sensors / Electrodes

1

Titroprocessor models 2.796.0110 and 2.796.0120 are supplied with two

built-in measuring interfaces (Sensors A and Sensors B). The models

2.796.0010 and 2.796.0020 only have one measuring interface (Sensors A)

but can be extended to two measuring interfaces at a later date with

upgrade set 6.5855.000.

The different measuring inputs of a measuring interface:

• Ind A1, A2

Input for indicator or measuring electrodes (single and combined electrodes) for potentiometric determinations.

It is possible to carry out a manual measurement at one measuring input

while the second input is carrying out a titration.

Ind A2 Ind A1 Ref Pol Pt100/1000

Sensors A

• Ref

Separate reference electrode input. If combined electrodes are used this

electrode input is not required.

• Pol

Connection for polarized electrodes for amperometric and voltametric

determinations (measuring modes Upol or Ipol).

• Pt100/1000

Inputs for Pt100 or Pt1000 temperature sensors (also used for electrodes

with built-in Pt100 or Pt1000 sensors).

• Stirrer connection

Stirrer power supply (12 V, 250 mA) for operation without sample

changer. Can be used with 728 Magnetic stirrer, 722 Rod stirrer and 727

and 703 Titration stands.

The measuring inputs Ref, Ind A1 and Ind A2 (or B1, B2) can be used together as a differential amplification switch for differential potentiometry. This

is recommended for measurements or titrations in low-conductivity media

(e.g. organic solvents).

2626

796 Titroprocessor, Instructions for use

Page 33

22. . InstallationInstallation

2.6.6 Connecting a balance

G

RS 232 Interface 1

The following balances can be connected to an RS 232

interface of the 796 Titroprocessor:

RS 232 Interface 2

Balance Cable

Sartorius MP8, MC1 6.2134.060

Mettler AB, AG, PR LC-RS25, supplied with balance

Mettler AM, PM from Mettler: ME 33995: green wire to pin 2, brown to pin

3, white to pin 7, yellow to pin 20 of the 25-pole plug

+ 6.2125.010 25-pole/9-pole adapter

Mettler interface 016 cable supplied with interface 016: red wire to pin 3, white

wire to pin 7 of the 25-pole plug

+ 6.2125.010 25-pole/9-pole adapter

Mettler interface 011 or 012 6.2125.020 + 6.2125.010

Mettler AT from Mettler: ME 33995: green wire to pin 2, brown to pin

3, white to pin 7, yellow to pin 20 of the 25-pole plug

+ 6.2125.010 25-pole/9-pole adapter

AND types ER-60, 120, 180, 182

6.2125.020 + 6.2125.010

types FR-200, 300

types FX-200, 300, 320

with RS 232 interface (OP-03)

Precisa, balances with RS 232C in-

6.2125.080 + 6.2125.010

terface

The type of balance must be entered in the Titroprocessor on the configuration page under [Interfaces].

796 Titroprocessor, Instructions for use

2727

Page 34

2.6 Safety information

The data transmitted from the balance are directly interpreted by the 796 Titroprocessor within the permitted input range for the sample weight including sign and decimal point. The units given in the following table are also

accepted:

Gram

Milligram

Kilogram

Pieces

Pieces

Carat

Pound

Ounce

Troy ounce

Grain

Pennyweight

g

mg

kg

pcs

PC

ct

lb

oz

ozt

GN

dwt

Units which are not listed and

which are transmitted directly

after the weight cannot be interpreted and will therefore be

rejected.

Any control characters which the balance may transmit will cause the Titroprocessor to produce an error message. Switch off all your balance's automatic status messages when it is connected to the 796 Titroprocessor.

With the aid of a special input unit supplied by the balance manufacturer it is

possible to enter the sample identification and method from the balance as

well as the sample weight. This is done by preselecting the addresses of the

identification and method on the input unit.

Balance Method Ident1 Ident2 Ident3

Sartorius METH or 27 ID.1 or 26 ID.2 or 24 C-20 or 23

Mettler (AT) D (Mthd)

C (ID#1) B (ID#2)

A (c20)

2828

796 Titroprocessor, Instructions for use

Page 35

2.6.7 Connecting an external printer

There are various ways of connecting an external printer to the 796 Titroprocessor.

Parallel printer interface (only for models 2.796.0010 and 2.796.0110)

Commercial printers for PCs (e.g. inkjet printers from Hewlett-Packard, Epson, Canon) can be connected without any problems to the 'Printer' connection on the rear panel of the Titroprocessor with the cable supplied by

the manufacturer.

So-called GDI printers (e.g. HP Deskjet 620 or 820) are specially

designed for use under MS-Windows© and can only be used under

MS-Windows© . They cannot be used with the 796 Titroprocessor.

22. . InstallationInstallation

Printer

F

Printer on the serial RS 232 interface

G

RS 232 Interface 1

RS 232 Interface 2

It is also possible to connect an external printer to models 2.796.0020 and

2.626.120. Printers which have their own serial RS 232 interface can be

connected directly to 'RS 232 Interface 1' or 'RS 232 Interface 2' with the

aid of cable 6.2125.050 (e.g. Epson LX-300).

If necessary commercial printers with a parallel Centronics interface can be

connected to one of the RS 232 interfaces of the Titroprocessor by means

of serial/parallel converter SP 1000 (2.145.0300). In addition a serial

6.2125.020 connection cable is required. Depending on the type of printer a

9V mains adapter for the SP 1000 converter and possibly an extension

cable between the converter and printer may be required. Please consult

your local Metrohm distributor.

796 Titroprocessor, Instructions for use

2929

Page 36

2.6 Safety information

The following table shows the settings and cables needed to connect printers to one of the serial interfaces.

Printer Cable RS232 settings Printer settings

IBM Proprinter

6.2125.050

or

compatibles

Epson

6.2125.040

with 6-pole

round plug

Epson LX-300 6.2125.050

HP Deskjet

with serial interface

HP Laserjet

with serial interface

(and compati-

6.2125.050

or adapter cable 25-pol.neg.

/ 9-pol.pos.

(e.g. HP

C2933A)

6.2125.050 or

adapter cable

25-pol. neg. /

9-pol. pos. (e.g.

HP C2933A)

Baud rate: 9600

Data bit: 8

Stop bit: 1

Parity: none

Handshake: HWshort

Printer: IBM Propr.

Baud rate: 9600

Data bit: 8

Stop bit: 1

Parity: none

Handshake: HWshort

Printer: Epson 80x60

Baud rate: 9600

Data bit: 8

Stop bit: 1

Parity: none

Handshake: HWshort

Printer: Epson 80x60

Baud rate: 9600

Data bit: 8

Stop bit: 1

Parity: none

Handshake: HWshort

Printer: HP Deskjet

Baud rate: 9600

Data bit: 8

Stop bit: 1

Parity: none

Handshake: HWshort

Printer: HP Deskjet

see printer manual

DIP switch settings:

SW1 SW2

on

off

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

see printer manual

DIP switch settings:

A B

on

off

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

see printer manual

bles)

HP Deskjet/

Laserjet

with parallel

interface

6.2125.020 +

serial/ parallel

converter

2.145.0300

Baud rate: 9600

Data bit: 8

Stop bit: 1

Parity: none

Handshake: HWshort

Printer: HP Deskjet

see printer manual

2.6.8 Connecting a bar-code reader

A bar-code reader can be connected to the bar-code reader socket on the

rear panel of the Titroprocessor. It can be used as a data input and transmits the coded data directly to the keyboard buffer of the Titroprocessor.

The plug occupancy and the transmission parameters of the reader must

correspond with the Metrohm specifications, see page 289. Please consult

your local Metrohm distributor to obtain a list of recommended bar-code

readers.

3030

Barcode

D

796 Titroprocessor, Instructions for use

Page 37

2.6.9 Devices on the remote interface

External peripheral devices such as pH meters, pumps, etc. can be controlled via the remote interface (25-pole socket) of the Titroprocessor. Each

717 Sample changer also has a remote socket which can be controlled via

the 'External bus'.

Remote

8 lines are available for signal output (Output 0-7). The remote socket of the

717 Sample changer has 14 output lines available (Output 0-13).

For receiving signals (e.g. the "ready" signal from a Metrohm instrument)

there are 8 lines available (Input 0-7).

The pin occupancy of the remote socket:

0 Volt

+5 Volt

Output 5

Output 3

Output 1

Output 12

Output 13

Input 0

Input 2

Input 4

Input 6

0 Volt

E

Output 6

Output 7

Output 4

Output 2

Output 0

Output 8

Output 9

Output 10

Input 1

Input 3

Input 5

Input 7

Output 11

+5V