Page 1

793 IC Sample Prep Module

IC Sample Prep Module793

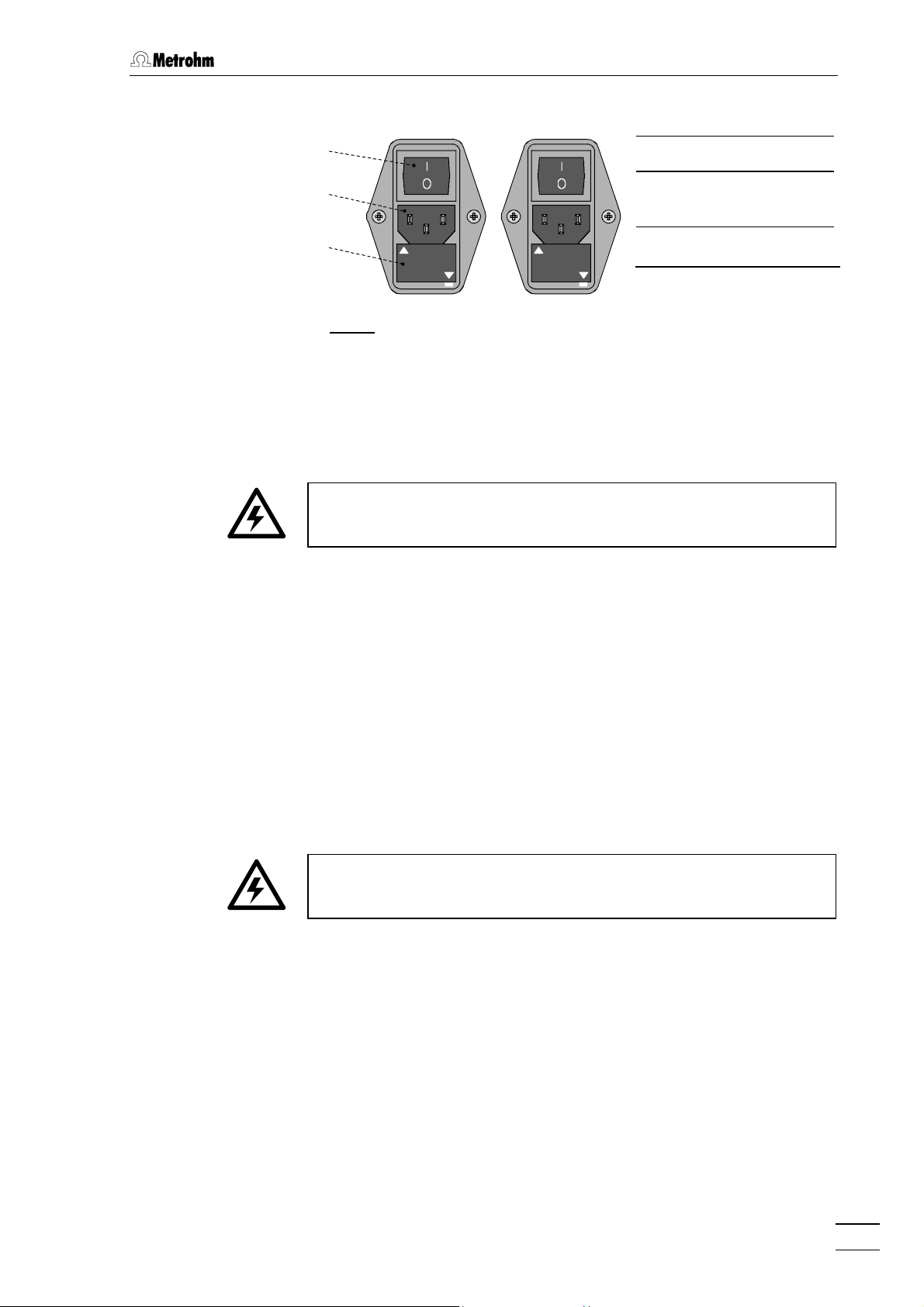

POWER

REMOTE

ON ON

PUMP

OFFOFF

REMOTE

ON

OFF

Met r ohm

ACTUATOR

STEP

CH-9101 Herisau/Schweiz

E-Mail info@metrohm.com

Internet www.metrohm.com

Instructions for Use

8.793.1003

Page 2

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

793 IC Sample Prep Module

Instructions for Use

8.793.1003 06.2001 / up

Page 3

Table of contents

Table of contents

1 Introduction

1.1 Instrument description ............................................................................ 1

1.2 Parts and controls .................................................................................... 2

1.3 Information about the Instructions for Use ......................................... 4

1.3.1 Organization.................................................................................. 4

1.3.2 Notation and pictograms.............................................................. 5

1.4 Safety notes............................................................................................... 6

1.4.1 Electrical safety............................................................................. 6

1.4.2 General precautionary rules ......................................................... 6

2 Installation

2.1 Setting up the instrument ....................................................................... 7

2.1.1 Packaging ..................................................................................... 7

2.1.2 Check............................................................................................ 7

2.1.3 Location ........................................................................................ 7

2.1.4 Arrangement of the instruments ................................................... 7

2.2 Mains connection ..................................................................................... 8

2.2.1 Setting the mains voltage ............................................................. 8

2.2.2 Fuses ............................................................................................ 9

2.2.3 Mains cable and mains connection ............................................. 9

2.2.4 Switching the instrument on/off .................................................... 9

2.3 Connection to a Modular IC System for Neutralization ................... 10

2.3.1 Electrical connection................................................................... 10

2.3.2 Connection of the SP Module A ................................................. 11

2.3.3 Settings in the «IC Net 2.1» program.......................................... 16

2.4 Connection to a Modular IC System for Cation Elimination ........... 18

2.4.1 Electrical connection................................................................... 18

2.4.2 Connection of the SP Module A ................................................. 19

2.4.3 Settings in the «IC Net 2.1» program.......................................... 22

............................................................................................

..............................................................................................

1

7

3 Operation

3.1 Handling the SP Module A .................................................................... 23

3.2 Manual operation .................................................................................... 24

3.3 Operation via IC Detector 732 .............................................................. 25

...............................................................................................

4 Malfunctions – Maintenance

4.1 Malfunctions and their rectification .................................................... 28

4.2 Maintenance and servicing................................................................... 30

4.2.1 Care............................................................................................. 30

4.2.2 Maintenance by Metrohm service .............................................. 30

4.2.3 Shutdown .................................................................................... 30

4.2.4 Exchanging the pump tubing ..................................................... 31

4.2.5 Regeneration of the cation exchange material .......................... 32

4.2.6 Cleaning the SP Module A.......................................................... 33

4.2.7 Exchanging the cation exchange material ................................. 35

4.2.8 Braking range adjustment .......................................................... 36

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

...........................................

23

28

I

Page 4

Table of contents

5 Appendix

5.1 Technical data......................................................................................... 38

5.2 Standard equipment .............................................................................. 40

5.3 Optional accessories ............................................................................. 41

5.4 Warranty and conformity ...................................................................... 42

5.4.1 Warranty.......................................................................................42

5.4.2 EU Declaration of conformity ......................................................43

5.4.3 Certificate of conformity and system validation ..........................44

5.5 Index ......................................................................................................... 45

.................................................................................................

38

List of figures

Fig. 1: Front of the 793 IC Sample Prep Module..........................................................2

: Rear of the 793 IC Sample Prep Module...........................................................3

Fig. 2

Fig. 3

: SP Module A (1.793.0110).................................................................................4

Fig. 4

: Setting the mains voltage ..................................................................................9

Fig. 5

: Connection 793 IC Sample Prep Module -

Modular IC System for Neutralization ..............................................................10

Fig. 6

: Connections at SP Module A...........................................................................12

Fig. 7

: Installing pump tubings ...................................................................................13

Fig. 8

: Connection 793 IC Sample Prep Module -

Modular IC System for cation elimination........................................................18

Fig. 9

: Assembling the actuator..................................................................................34

Fig. 10

: Adjusting the braking range ............................................................................37

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

II

Page 5

1.1 Instrument description

1 Introduction

1.1 Instrument description

The 793 IC Sample Prep Module consists of a reactor block (SP

Module A) with its corresponding control unit; this contains an addi-

tional 2-channel peristaltic pump.

Inline sample pretreatment like neutralization or cation exchange for ion

chromatographic analyses can be carried out with the cation exchanger

built into the SP Module A. The SP Module A contains three cation ex-

change units which are in turn used for cation exchange, regenerated

with acid and rinsed with water. In order to perform each analysis under

comparable conditions a freshly regenerated cation exchange unit is

normally used. Switching is either carried out automatically by the IC

system or manually. Due to possible interference of sulfate with the IC

determination, perchloric acid is normally used for cation exchanger regeneration of the SP Module A instead of sulphuric acid.

At the control unit the SP Module A can either be switched to the next

position manually or by remote control via the remote interface. The

built-in peristaltic pump, which delivers the solutions required for operating the SP Module A, can also be switched on by remote control or

manually.

The 793 IC Sample Prep Module is particularly suitable for retrofitting a

modular anion IC system for inline sample pretreatment in a simple

manner. Two typical applications are described in detail in these instructions for use: Neutralization (e.g. exchange of Na

Cation Separation (e.g. exchange of heavy metals by H

the 793 IC Sample Prep Module can also be combined with all other

HPLC components currently on the market.

Although in principle the techniques of cation exchange by the 793 IC

Sample Prep Module and suppression by the 753 Suppressor Module

are comparable, the 793 IC Sample Prep Module is not suitable for

chemical suppression after ion chromatographic separation of anions.

+

by H+) and

+

). Of course

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

1

Page 6

1 Introduction

1.2 Parts and controls

11114

IC Sample Prep Module793

POWER

REMOTE PUMP

ON ON

22223

OFFOFF

36

33

45

44

5

55

REMOTE

ACTUATOR

ON

OFF

67

66

Met r ohm

78

77

STEP

8

88

12 10

1212

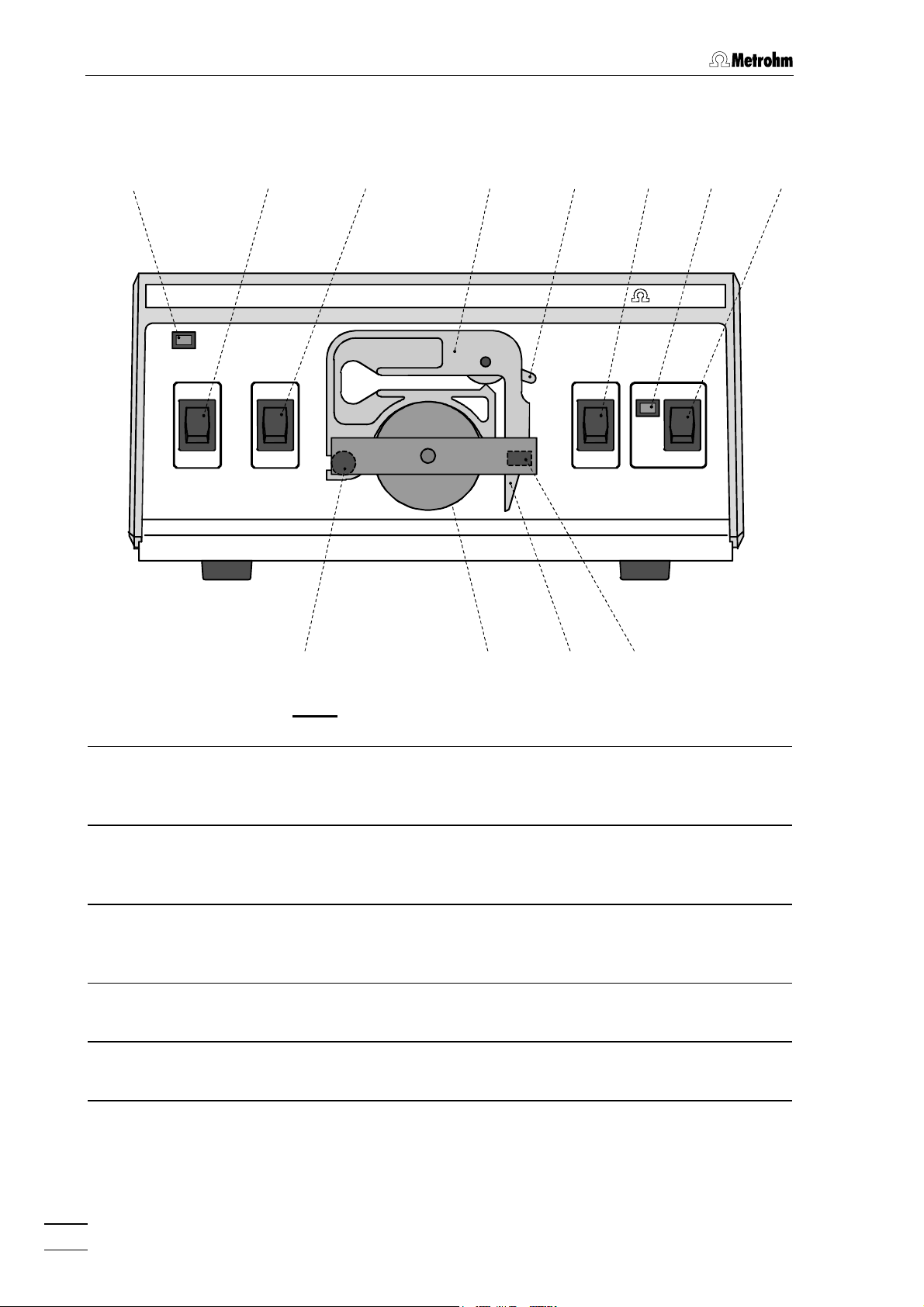

Fig. 1

: Front of the 793 IC Sample Prep Module

1111

Power on lamp

Lights up when instrument is switched

on

2222 Pump Remote ON/OFF

On/Off switch for remote control of the

pump

3333 Pump ON/OFF

On/Off switch for the pump (manual

operation mode)

4444 Tubing cartridge

For 6.1826.010 Pump tubing

5555 Contact pressure lever

For adjusting the contact pressure

6666 SP Module A Remote ON/OFF

On/Off switch for remote control of the

actuator

11

1112

1111

7777 SP Module A position display

Is lit up when the actuator is "in position"

8888 Actuator step

Switches the actuator to the next

position (manual operation mode)

9999 Holding clamp

For locking the tubing cartridge into

place

10

10 Snap-action lever

1010

For releasing the tubing cartridge

11

11 Pump drive

1111

Roller head with contact rollers

12

12 Mounting pin

1212

For attaching the tubing cartridge

10

1010

9999

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

2

Page 7

1.2 Parts and controls

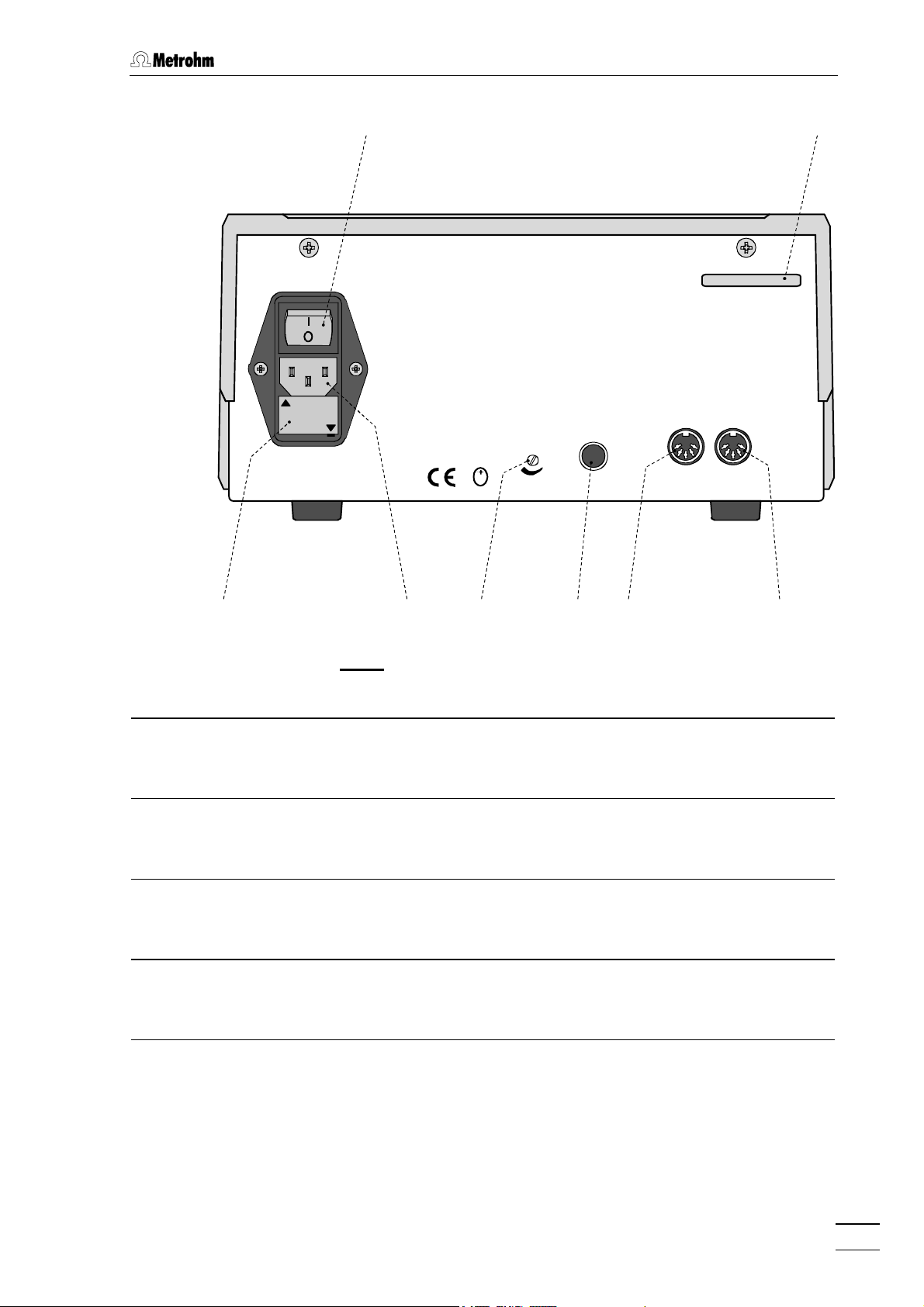

14

13

1313

Type

1413

1414

WARNING - Fire Hazard -

For continued protection replace only

with the same type and rating of fuse

20

20 16

2020

Fig. 2

13

13 Mains switch

1313

For switching the instrument on/off:

I = ON 0 = OFF

110V-120V

220V-240V

50 - 60 Hz 50 VA

0,5A(T)

0,25A(T)

Remote

PumpActuator

A

1718

1717

ActuatorBreakpoint

CB

Made by Metrohm Herisau Switzerland

1617

1616

''''t

S

19

19 15

1919

18

1818

: Rear of the 793 IC Sample Prep Module

17

17 Connection for SP Module A

1717

15

1515

14

14 Serial number 18

1414

15

15 Remote interface for pump

1515

18 Adjustment screw for braking

1818

19

19 Mains connection plug

1919

Remote I/O lines for connection of

external devices (e.g. 732 IC Detector)

16

16 Remote interface for actuator

1616

20

20 Fuse holder

2020

Remote I/O lines for connection of

external devices (e.g. 732 IC Detector)

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

range

Mains connection, see section 2.2

Changing the fuses, see section 2.2

3

Page 8

1 Introduction

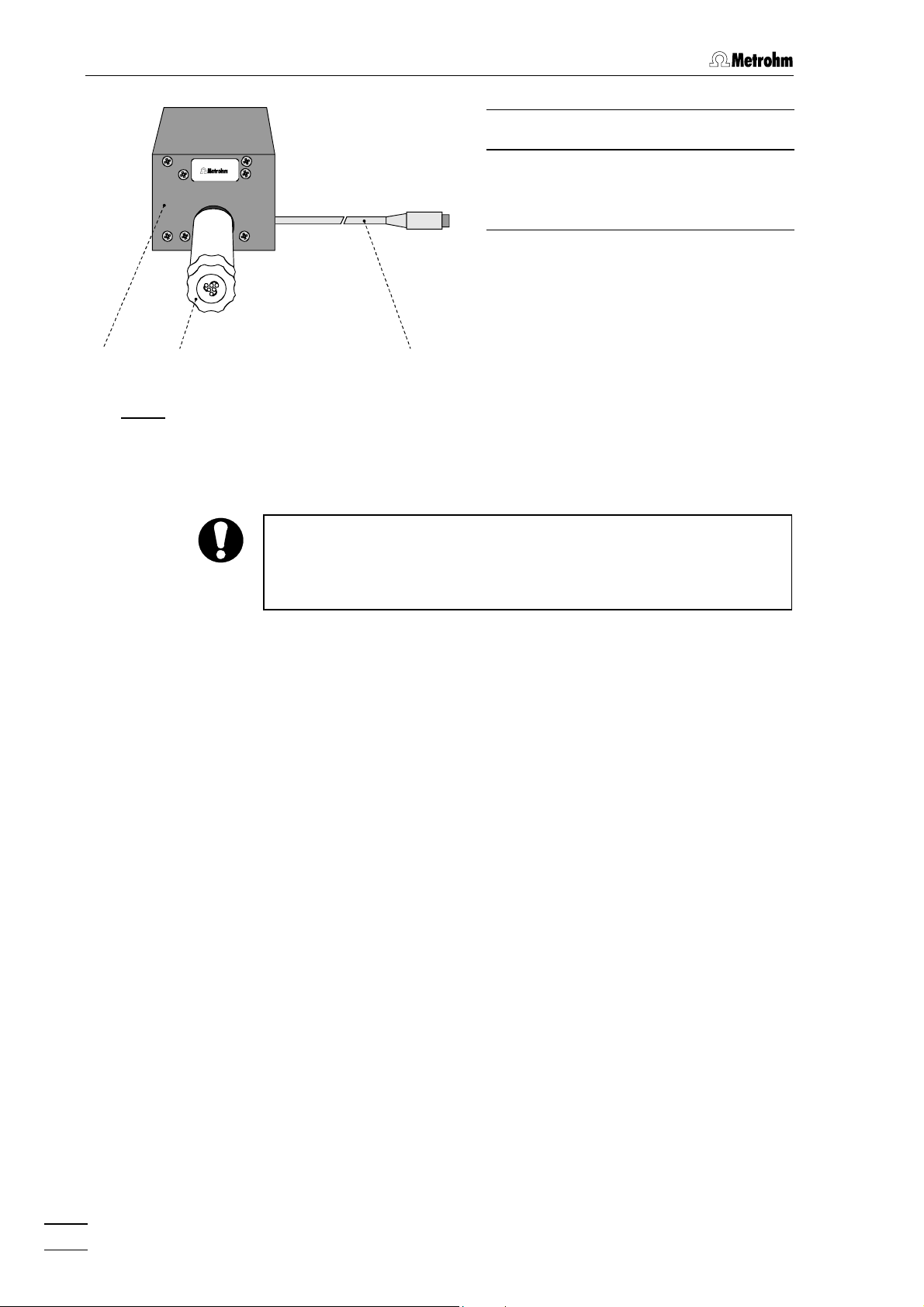

21

21

Reactor block

2121

SP Module A

Ion an alys is

22

22 Actuator connection

2222

with permanently fixed inlet and

outlet capillaries

23

23 Connection cable

2323

Connection cable to control unit

21

21 22

2121

22 23

2222

1

2

3

23

2323

Fig. 3

: 1.793.0110 SP Module A

1.3 Information about the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 793 IC Sample Prep Module into operation. The Instructions for

Use contain information and warnings to which the user must pay

attention in order to assure safe operation of the instruments.

1.3.1 Organization

These Instructions for Use 8.793.1003 for the 793 IC Sample Prep

Module provide a comprehensive overview of the startup procedure,

operation, fault rectification and technical specifications of these instruments. The Instructions for Use are organized as follows:

Section 1 Introduction

Section 2 Installation

Section 3 Operation

Section 4 Faults – Maintenance

Section 5 Appendix

General description of instruments, parts and controls

and safety notes

Setting up, mains connection, attachment of accessories, connection to IC system

Manual operation and operation via 732 IC Detector

Fault rectification, maintenance

Technical data, standard equipment, options, warranty,

declarations of conformity, index

To find the required information on the instruments please use either

the Table of contents or the Index at the back.

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

4

Page 9

1.3 Information about the Instructions for Use

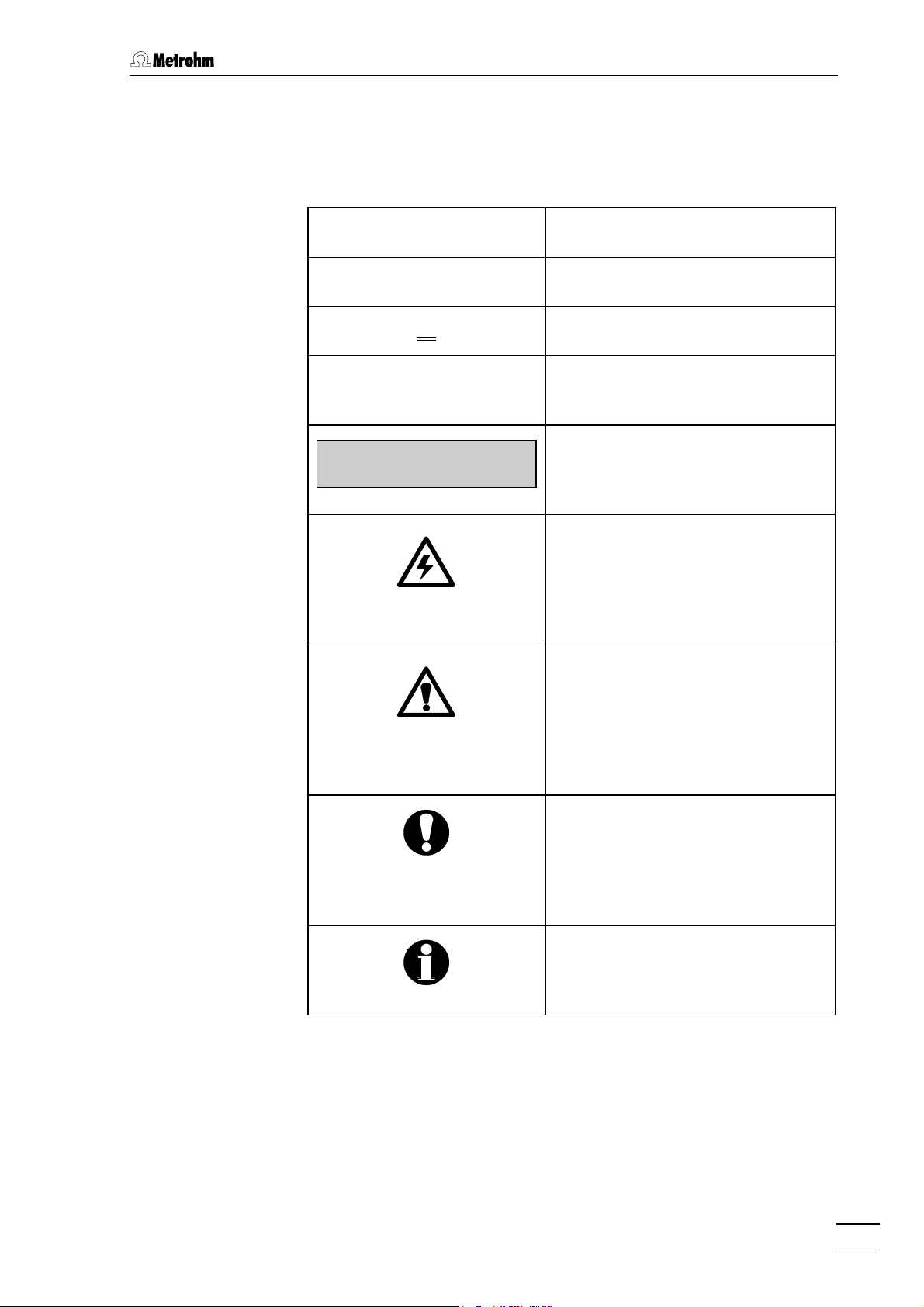

1.3.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these Instructions for Use:

<PUMP> Switch or key

15

15 Part or control of 793

1515

89

89 Part or control of 732/733

8989

"

Range

"

Parameter or entry value

at 732 IC Detector

>PARAM/detector

range: 1.00 mS/cm

Display

Text in display 1111 of the 732 IC

Detector

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

Caution

This symbol marks important

information. First read the associated directions before you continue.

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

Comment

This symbol marks additional

information and tips.

5

Page 10

1 Introduction

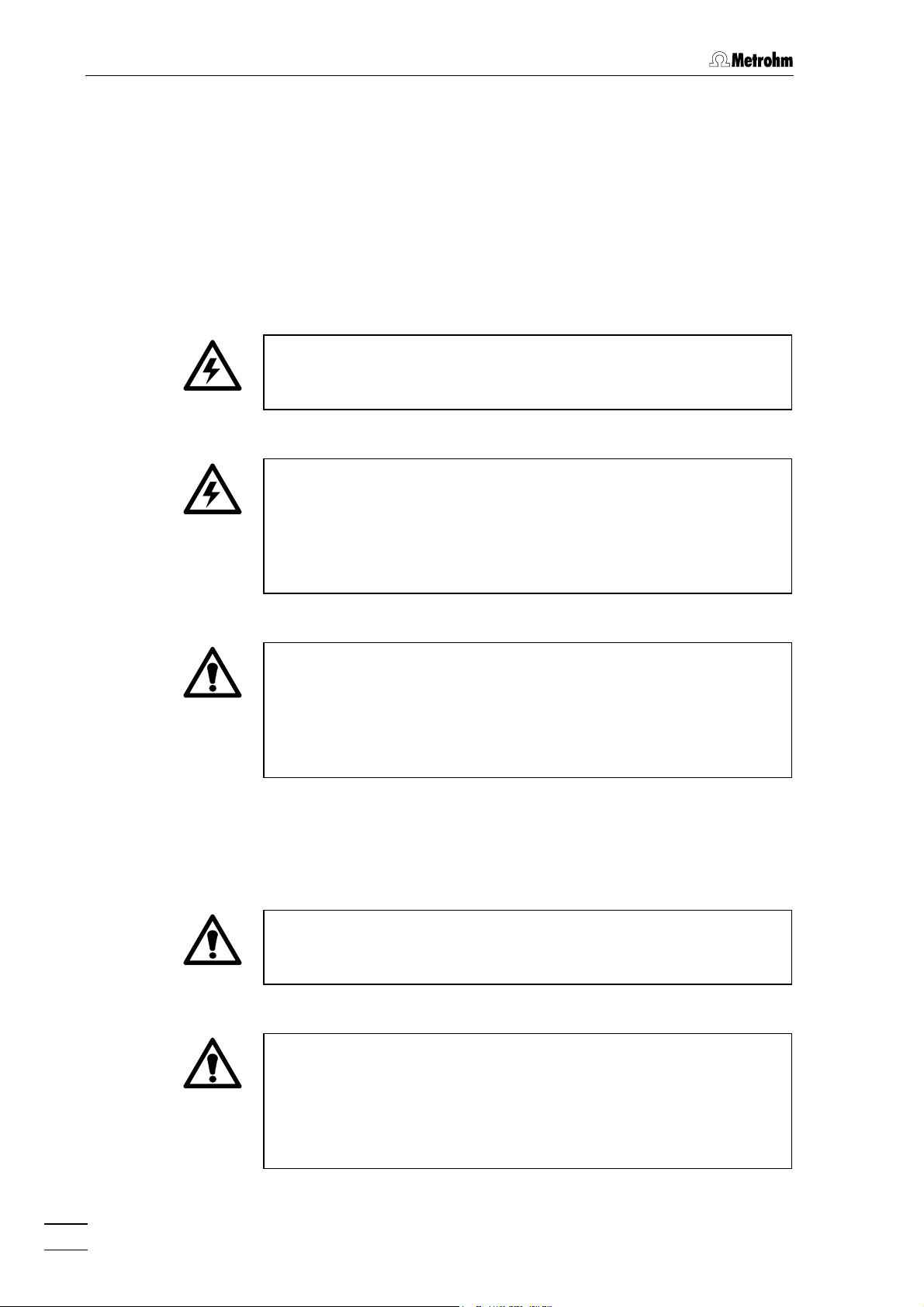

1.4 Safety notes

1.4.1 Electrical safety

While electrical safety in the handling of the 793 IC Sample Prep Module is assured in the context of the specifications IEC 1010-1 (protection

class I, degree of protection IP20), the following points should be noted:

x Mains connection

Setting the mains voltage, checking the mains fuse and the mains

connection must be effected in accordance with the instructions in

section 2.2.

x Opening the 793 IC Sample Prep Module

When the 793 IC Sample Prep Module is connected to the power

supply the instrument must neither be opened nor should parts be

removed from it, otherwise there is a danger of coming into contact

with components which are live. Always disconnect the instrument

from all voltage sources before you open it and ensure that the mains

cable is disconnected from mains connection 19

19 !

1919

x Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 793 IC Sample Prep Module, you should earth yourself and

any tools you are using by touching an earthed object (e.g. housing of

the instrument or a radiator) to eliminate any static charges which

exist.

1.4.2 General precautionary rules

x Handling of solvents

Check all pump tubings and all input and output lines periodically for

possible leaks. Follow the relevant instructions regarding the handling

of flammable and/or toxic solvents and their disposal.

x Regular exchange of pump tubings

Pump tubings are consumable material and must be replaced from

time to time (see Section 4.2.4). Suitable measures must be taken so

that any leak which might occur in the pump tubing or connections

during unattended operation will cause no damage (placing the

instrument at the bottom, collection device for any liquid which may

leak out).

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

6

Page 11

2.1 Setting up the instrument

2 Installation

2.1 Setting up the instrument

2.1.1 Packaging

The 793 IC Sample Prep Module is supplied together with the separately packed accessories in special packagings containing shockabsorbing foam linings designed to provide excellent protection. The

actual instrument is packed in an evacuated polyethylene bag to prevent the ingress of dust. Please store all these special packagings as

only they can assure damage-free transport of the instrument.

2.1.2 Check

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in section 5.2). In the case of transport damage, see

instructions in section 5.4.1 "Warranty".

2.1.3 Location

Position the instruments in the laboratory at a location convenient for

operation, free from vibrations and protected against a corrosive

atmosphere and contamination by chemicals.

2.1.4 Arrangement of the instruments

The best position for the 793 IC Sample Prep Module is beside the Modular IC System (e.g. 733 IC Separation Center).

The 793 IC Sample Prep Module should always be placed at the

bottom of the instrument stack so that any leaks which may occur in

the pump tubing or connections cannot cause damage to the other

instruments by leakage of corrosive liquids (e.g.acid).

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

7

Page 12

2 Installation

2.2 Mains connection

Follow the instructions below for connecting to the power supply. If

the instrument is operated with the mains voltage set wrongly and/or

wrong mains fuse there is a danger of fire!

2.2.1 Setting the mains voltage

Before switching on the 793 IC Sample Preparation Module for the first

time, check that the mains voltage set on the instrument (see Fig. 2)

matches the local mains voltage. If this is not

the mains voltage on the instrument as follows:

1 Disconnect mains cable

Disconnect mains cable from mains connection plug 19

793 IC Sample Preparation Module.

the case, you must reset

19 of the

1919

2 Remove fuse holder

Using a screwdriver, loosen fuse holder 20

connection 19

3 Check fuse

Carefully take the fuse installed for the desired mains voltage

out of fuse holder 20

of the fuse in the fuse holder is marked by the white arrow

imprinted next to the mains voltage range):

100}}}}120 V 0.5 A (slow-blow) Metrohm No. U.600.0013

220}}}}240 V 0.25 A (slow-blow) Metrohm No. U.600.0010

4 Insert fuse

Change fuse if necessary and reinsert in fuse holder 20

5 Install fuse holder

Depending on the desired mains voltage, insert fuse holder in

the 793 IC Sample Preparation Module so that the corresponding mains voltage range can be read normally and the adjacent

white arrow points to the white bar imprinted below the fuse

holder (see Fig. 4).

19 and take out completely.

1919

20 and check its specifications (the position

2020

20 below the mains

2020

20.

2020

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

8

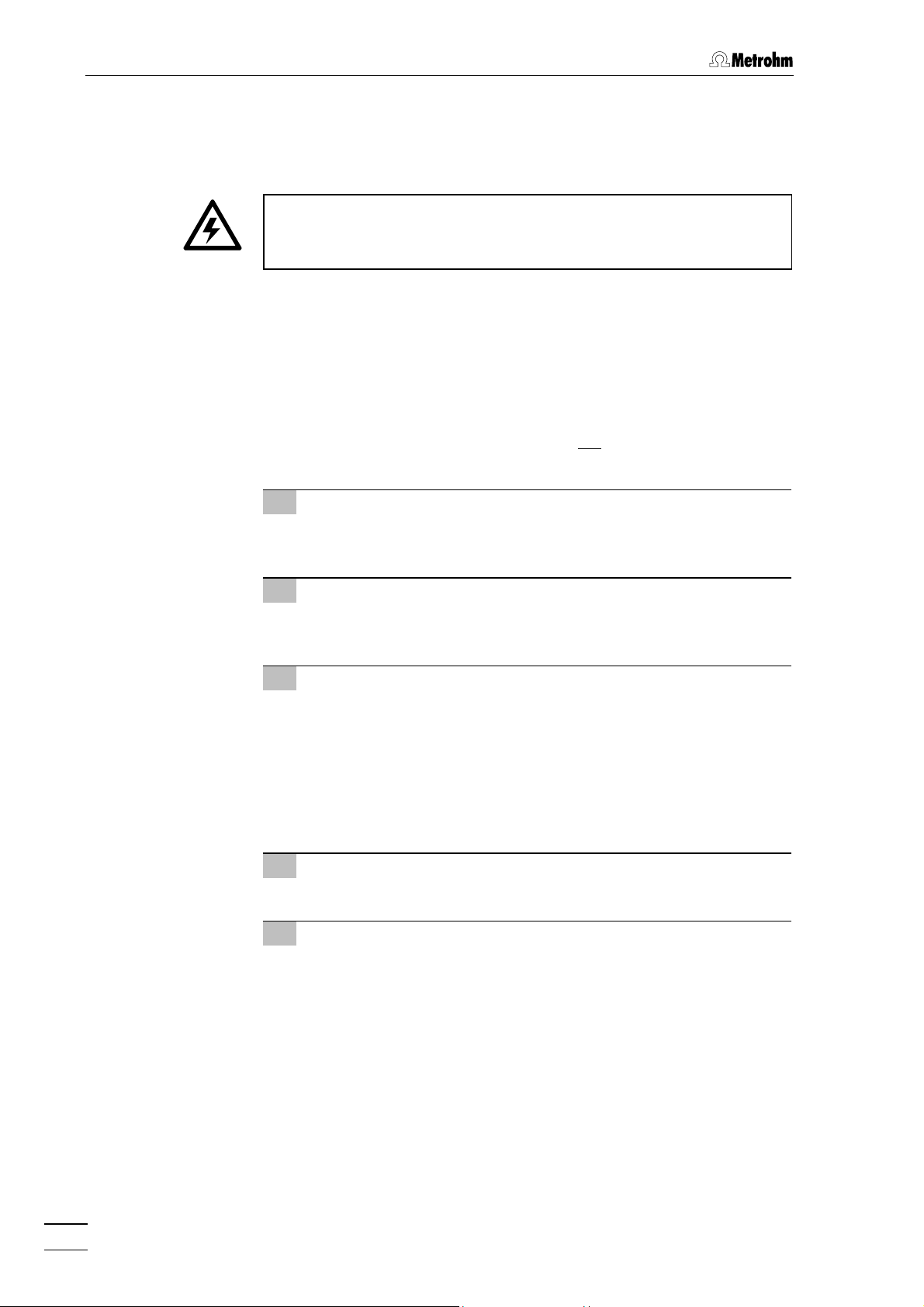

Page 13

2.2 Mains connection

2.2.2 Fuses

13

13

1313

19

19

1919

20

20

2020

220 – 240 V

100 ---- 120 V

220 ---- 240 V

100 – 120 V

220 ---- 240 V

100 ---- 120 V

13

13 Mains switch

1313

19

19 Mains connec-

1919

tion plug

22220000 Fuse holder

Fig. 4

: Setting the mains voltage

One of the two fuses 0.5 A/slow-blow for 100}120 V or 0.25 A/slowblow for 220}240 V is installed in fuse holder 20

20 of the 793 IC Sample

2020

Prep Module as standard.

Ensure that the instrument is never put into operation with fuses of

another type, otherwise there is danger of fire!

For checking or changing fuses, proceed as described in section 2.2.1.

2.2.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables:

x 6.2122.020 with plug SEV 12 (Switzerland, })

x 6.2122.040 with plug CEE(7), VII (Germany, })

x 6.2133.070 with plug NEMA 5-15 (USA, })

which are three-cored and fitted with a plug with an earthing pin. If a different plug has to be fitted, the yellow/green lead (IEC standard) must

be connected to protective earth (protection class I).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Mains connection

Plug the mains cable into mains connection plug 19

Sample Prep Module (see Fig. 4).

19 of the 793 IC

1919

2.2.4 Switching the instrument on/off

The 793 IC Sample Prep Module is switched on and off using mains

switch 13

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

13. When the instrument is switched on lamp 1111 lights up.

1313

9

Page 14

2 Installation

2.3 Connection to a Modular IC System for Neutralization

An important application for the 793 IC Sample Prep Module is neutralization of an alkaline sample for anion determination by IC with chemical

suppression. Strong bases (e.g. 30 % NaOH) should not be led unlimited to the SP Module A. To provide a sufficient capacity for exchanging

+

by H+ Ions, only a small fraction (e.g. 20 µL) is directed to the SP

Na

Module A using a sample loop. The analyte anions are preconcentrated

subsequently on a preconcentration column and finally eluted to the

separation column in counter flow by the eluent.

Therefore, such an IC system corresponds to the Modular IC System

6 (MIC 6: Anion system with chemical suppression, preconcentration

and matrix elimination) enhanced by the 793 IC Sample Prep Module.

If the sample doesn’t require matrix elimination and preconcentration, it

can be treated directly by the SP Module A. This could be an option for

samples containing only low amounts of the cations which have to be

eliminated. For this purpose, a system as described in section 2.4

should by used.

The following pages describe the electronic connections of this system

in combination with the 766 IC Sample Processor on the base of full

control by «IC Net 2.1».

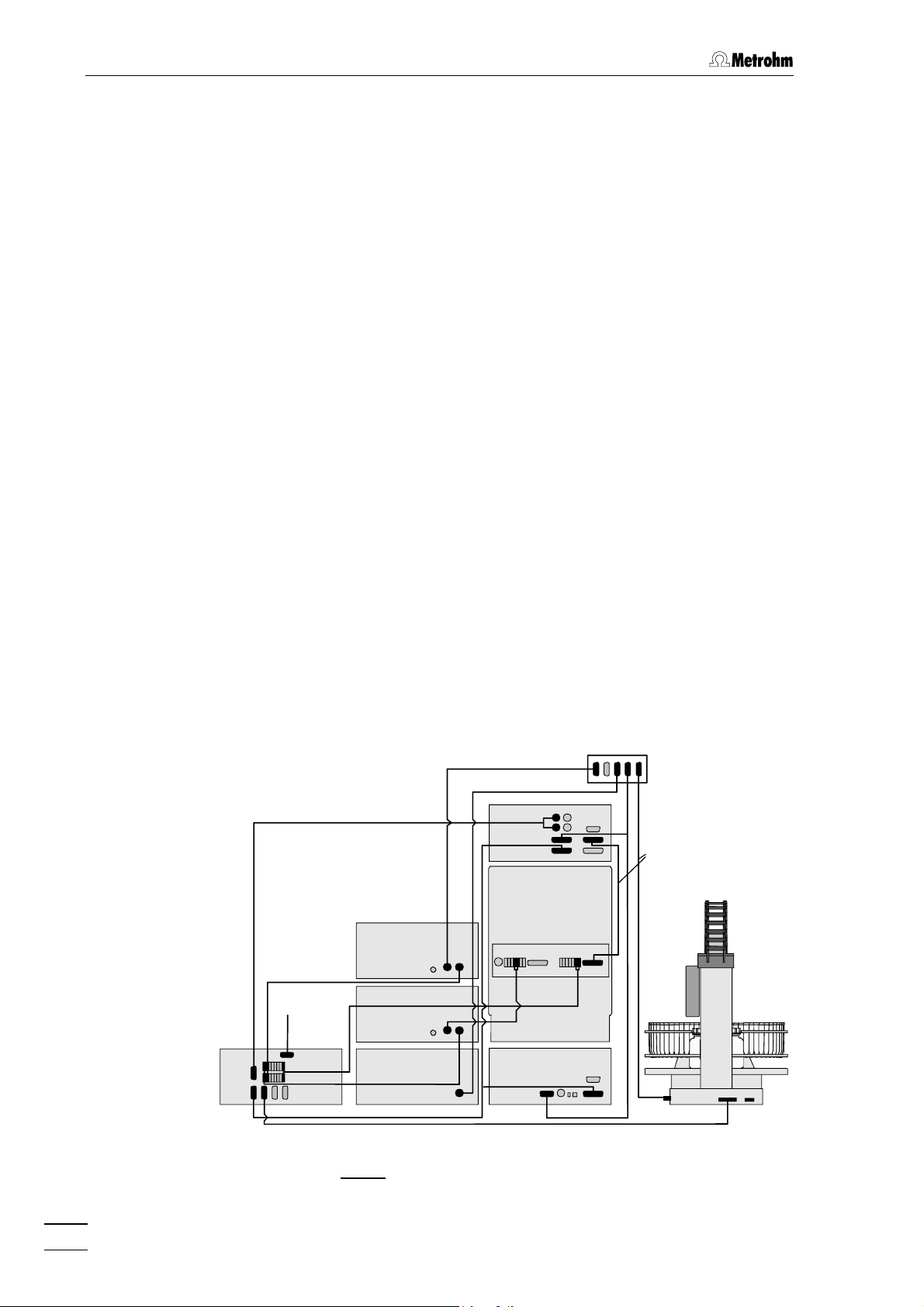

2.3.1 Electrical connection

The 793 IC Sample Prep Module is connected to an IC system consisting of 732 IC Detector, 733 IC Separation Center (two injectors), 709 IC

Pump, 752 IC Pump Unit, 753 IC Suppressor Module and 762 IC Interface as shown in Fig. 5.

6.2128.13 0

793

6.2128.180

753

PC

6.2134.100

6.2143.21 0

6.2125.120

6.2143.200

732

6.2125.090

733

B (LOOP) A (PCC)

6.2128 .180

6.2115.070

762

6.2134.09 0

Fig. 5

752

6.2128.180

709

6.2141.11 0

6.2134.08 0

: Connection 793 IC Sample Prep Module -

Modular IC System for Neutralization

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

10

Page 15

2.3 Connection to a Modular IC System for Neutralization

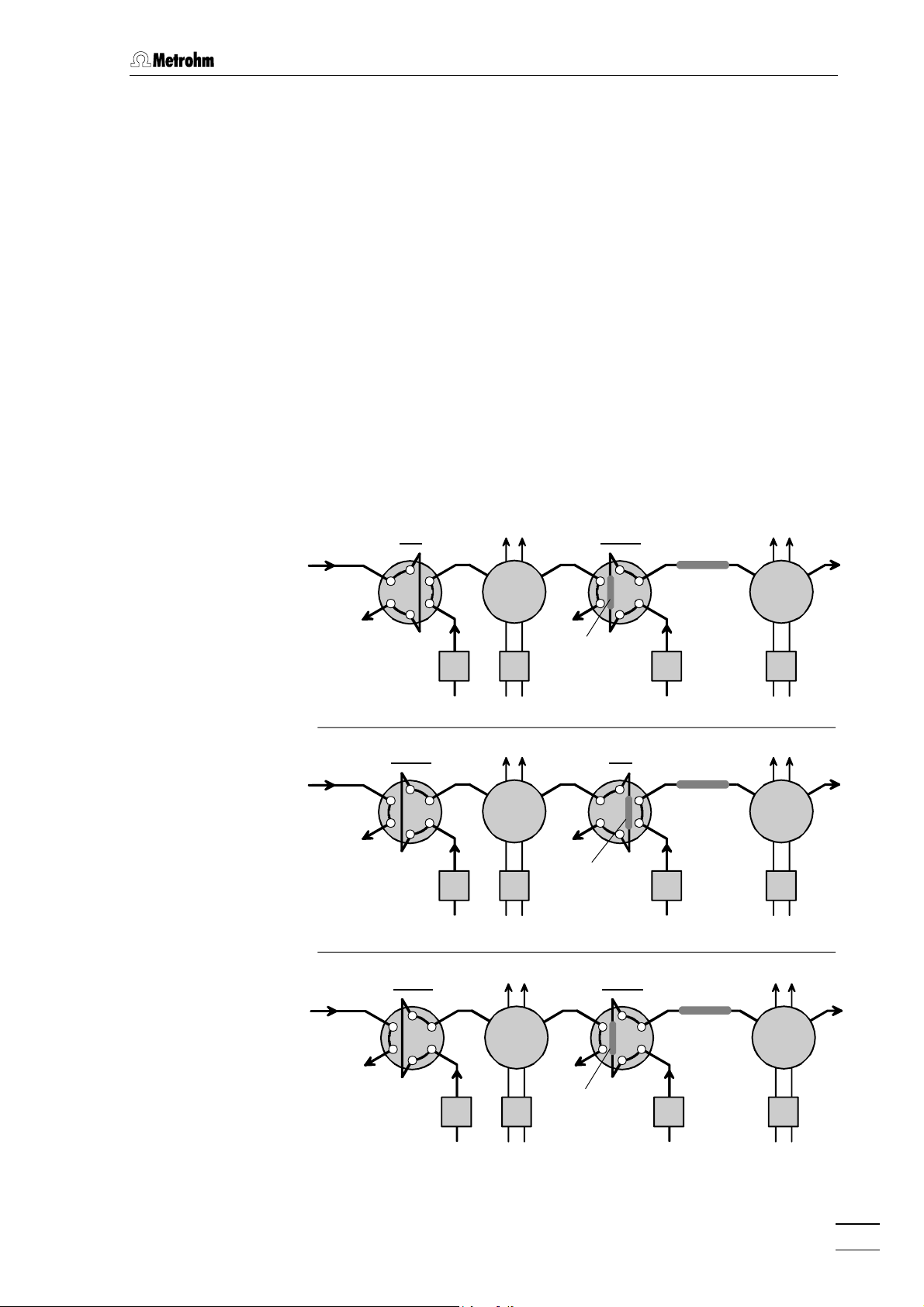

A

Please note, that the suppressor of the 753 IC Suppressor Module is

not switched by the 766 Sample Processor program. The remote connection 16

16 (suppressor/actuator) of the 753 IC Suppressor Module is

16 16

connected to the event line “fill” of the 733 valve B instead, using the

6.2128.180 cable. Thus the suppressor is switched when the fill position

is accessed by valve B.

2.3.2 Connection of the SP Module A

The following description implies the usage of the 2.733.0120 IC Separation Center (two injectors).

The 1.793.0110 SP Module A must first be inserted in the 733 IC Separation Center and connected to the 793 IC Sample Prep Module. Additionally, the suppressor block of the 753 Suppressor Module is inserted

and connected, which is described in detail in the corresponding

8.753.1001 Instructions for Use.

The connection of all parts should be done as described by the following scheme:

) Sample loop at valve B

is filled.

B) Sample is neutralized

by SP Module A;

Anions are preconcentrated via valve A..

sample

sample

Fill Inject

SP

B

Module

A

A

preconcentration

752 793 709

H2O Regenerant RegenerantEluentH2OH

column

Inject Fill

SP

B

Module

A

A

752 793 709

O Regenerant RegenerantEluentH2OH

H

2

preconcentration

column

Inject Inject

separation

column

separation

column

MSM

753

MSM

753

O

2

O

2

C) Preconcentrated

anions are eluted to

the separation column.

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

sample

SP

B

Module

A

752 793 709

O Regenerant RegenerantEluentH2OH

H

2

preconcentration

column

separation

A

column

MSM

753

O

2

11

Page 16

2 Installation

The inlet and outlet capillaries mounted on the SP Module A are then

connected up. Proceed as follows:

1 Insert SP Module A

x Place SP Module A 21

the 733 Separation Center.

2 Connect SP Module A

x Remove the plastic stopper from opening 41

733 IC Separation Center and push cable 23

SP Module A 21

x Connect cable 23

Sample Prep Module (see Fig. 5).

3 Connect sample line to 793 SP Module A

x Screw inlet capillary 24

A connection 22

valve B using a 6.2744.010 compression fitting.

21 on the floor of the inner chamber of

2121

41 or 43

43 on the

4141

4343

23 mounted on the

2323

21 through the opening.

2121

23 to connection 17

2323

24 marked with "Sample in" at SP Module

2424

22 (see Fig. 6) onto connection “5” of injection

2222

17 “Actuator“ of the 793 IC

1717

Regenerant

Waste

Sample in

25

2525

26

26

2626

4 Connect SP Module A to valve A (Preconcentration

column)

x Screw outlet capillary 29

connection “1” of injection valve A using a 6.2744.010 compression fitting.

x Please note, that the preconcentration column at valve A has

to be rinsed in counterflow when switched from “Fill” to “Inject”.

24

24

2424

29

2925

2929

1

2

3

28

28

2828

27

27

2727

Sample out

H2O

29 marked with “Sample out” onto

2929

24

24 Inlet capillary for sample

2424

25

25 Inlet capillary for acid

2525

26

26 Outlet capillary for acid

2626

27

27 Outlet capillary for H2O

2727

28

28 Inlet capillary for H2O

2828

29

29 Outlet capillary for sample

2929

: Connections at SP Module A

Fig. 6

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

12

Waste

Page 17

2.3 Connection to a Modular IC System for Neutralization

5 Attach pump tubings

x Loosen both tubing cartridges 4444 from the holding clamp 9999 by

pressing down snap-action lever 10

ing pin 12

x Press contact pressure lever 5555 on both tubing cartridges

down as far as it will go.

x Insert a length of pump tubing 33

into each of the tubing cartridges as shown in Fig. 7. The

white-white stopper 34

holder on the left-hand side of the tubing cartridge.

x Place the tubing cartridges on mounting pin 12

down on the right-hand side until snap-action lever 10

into position on holding clamp 9999. Take care that no kinks are

formed in the pump tubing.

30

30 32

3030

32 33

31 31

3232

3131

33 34

3333

34 44445

3434

12 on 793 Sample Prep Module (see Fig. 1).

1212

34 must click into the corresponding

3434

534

10 36

55

1010

10 and remove from mount-

1010

33 (6.1826.010, ~1.3 mL/min)

3333

12 and press

1212

10 clicks

1010

34 35

3434

35 25/28

3535

3631

3636

31

3131

25/2810

25/2825/28

: Installing pump tubings

Fig. 7

4444

Tubing cartridge 31

5555 Contact pressure lever 32

10

10 Snap-action lever 33

1010

25

25 SP Module A inlet capillary

2525

for HClO

28

28 SP Module A inlet capillary

2828

for H

30

30 PTFE tubing (6.1803.020) 36

3030

4

O

2

31 PEEK compression fitting

3131

(6.2744.010)

32 PEEK coupling (6.2744.030)

3232

33 Pump tubing (6.1826.010)

3333

34

34 Stopper (white-white)

3434

35

35 PEEK coupling (6.2744.110)

3535

36 PEEK filter unit (6.2821.100)

3636

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

13

Page 18

2 Installation

6 SP Module A connection 2: Regenerant

x Pull the inlet capillary 25

Module A connection 22

panel openings 41

x Mount a PEEK compression fitting 31

end of inlet capillary and screw this on to PEEK filter unit 36

25 marked with “Regenerant“ at SP

2525

22 (see Fig. 6) through one of the rear

2222

or 43

43 of the 733 IC Separation Center.

41

4343

4141

31 (6.2744.010) on the

3131

36

3636

(6.2821.100) (see Fig. 7).

x Mount coupling 35

35 on to the inlet of the PEEK filter unit and

3535

push this coupling on to outlet end of the first pump tubing

33

33 (see Fig. 7).

3333

x Mount suction tubing: cut a piece of PTFE Tubing 30

30

3030

(6.1803.020) to the desired length.

x Mount a PEEK compression fitting 31

end of PTFE tubing 30

30 and screw this on to coupling 32

3030

31 (6.2744.010) on one

3131

32 (see

3232

Fig. 7).

x Push coupling 32

33

33 (see Fig. 7).

3333

32 on to the inlet end of the first pump tubing

3232

x Immerse the other end of the suction tubing in a vessel

containing regeneration solution (normally 20 mmol/L HClO

)

4

and fix in place.

x Pull outlet capillary 26

connection 22

openings 41

22 (see Fig. 6) through one of the rear panel

2222

41 or 43

4141

x Lead outlet capillary 26

26 marked with "Waste" at SP Module A

2626

43 of the 733 IC Separation Center.

4343

26 to a sufficiently large waste container

2626

and fix in place.

7 SP Module A connection 3: H2O

x Pull the inlet capillary 28

connection 22

nings 41

22 (see Fig. 6) through one of the rear panel ope-

2222

or 43

43 of the 733 IC Separation Center.

41

4343

4141

x Mount a PEEK compression fitting 31

end of inlet capillary 28

PEEK filter unit 36

x Mount coupling 35

28 marked with “H2O“ at SP Module A

2828

31 (6.2744.010) on the

3131

28 and screw this on to the second

2828

36 (6.2821.100) (see Fig. 7).

3636

35 on to the inlet of the PEEK filter unit and

3535

push this coupling on to outlet end of the second pump tubing 33

33 (see Fig. 7).

3333

x Mount suction tubing: cut a piece of PTFE Tubing 30

(6.1803.020) to the desired length.

x Mount a PEEK compression fitting 31

end of PTFE tubing 30

30 and screw this on to coupling 32

3030

31 (6.2744.010) on one

3131

Fig. 7).

x Push coupling 32

tubing 33

33 (see Fig. 7).

3333

32 on to the inlet end of the second pump

3232

x Immerse the other end of the suction tubing in a vessel con-

taining rinsing solution (normally dist. H

x Pull outlet capillary 27

connection 22

nings 41

22 (see Fig. 6) through one of the rear panel ope-

2222

or 43

43 of the IC Separation Center 733.

41

4343

4141

x Lead outlet capillary 27

27 marked with “Waste“ at SP Module A

2727

27 to a sufficiently large waste container

2727

O) and fix in place.

2

and fix in place.

30

3030

32 (see

3232

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

14

Page 19

2.3 Connection to a Modular IC System for Neutralization

8 Startup of 793 IC Sample Prep Module

x Set switch <REMOTE> 2222 to "OFF".

x Switch on 793 IC Sample Prep Module with mains switch 13

13

1313

and set switch <PUMP> 3333 to "ON".

x Adjust the contact pressure for both tubing cartridges: press

contact pressure lever 5555 upwards until the solutions just start

to be drawn in. Then press the contact pressure lever upwards until it clicks once more to obtain optimal contact pressure.

x Check all tubing from the storage vessels through the tubing

cartridges and the SP Module A up to the waste containers

for leakage of liquids. If liquid escapes anywhere the corresponding compression fitting must be tightened further or

changed.

x Before using the SP Module A for sample pretreatment, its

cation exchange material should be conditioned. Inject 30%

sodium hydroxide 15 times (five injections per unit) using the

sample program of the system “Neutralization” as described

in the following section. The run time can be 20 min. each

while the separation column doesn’t have to be installed.

Pump tubings are consumable material with a lifetime which depends

on the contact pressure. This is why the tubing cartridges should be

raised completely by loosening snap-action lever

10

10

on the right-hand

1010

side if the pump is to remain switched off for a considerable length of

time (the set contact pressure remains unchanged).

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

15

Page 20

2 Installation

2.3.3 Settings in the «IC Net 2.1» program

During configuration of the 793 IC Sample Prep Module and 753 Suppressor Module the IC Net assistant “New system wizard” requires the

definition of “Event lines” for the SP Module A and suppressor, respectively. Although these lines are not installed you must enter any unused

“Event line” to enable the program to proceed. Actually, the SP Module

A is controlled by the 766 sample processor, while the suppressor is

controlled by the event line from 733 valve B (see Fig. 5).

A main program for the system “neutralization.smt“ is defined together

with two programs for extra systems for the 766 IC Sample Processor.

“start-neutralization.smt“ starts the 752 Pump. Furthermore, the SP

Module A is rinsed at all three positions. “end-neutralization.smt“ turns

off the 752 Pump..

The peristaltic pumps of the 753 IC Suppressor Module and 793 IC

Sample Prep Module are started when the IC system is activated

(measuring baseline). For this, the option ’Start pump with startup

hardware

hardware’ has to be selected for both devices.

hardwarehardware

neutralization.smt

Start pump with startup

Start pump with startup Start pump with startup

1. Program for the 766 IC Sample Processor:

001 Ctrl INIT 732

002 Move sample

003 Lift work

004 Ctrl FILL B / STEP 1

005 Pump 120 s

006 Ctrl FILL A 1

007 Ctrl INJECT B1

008 Wait 60 s

009 Ctrl ZERO 1

010 Ctrl INJECT A1

011 Ctrl STEP MSM 753

(*) The time for pumping the sample to the SP Module A should be as small as

possible to avoid contamination of the subsequent preconcentration column

by other anions from the water used for this line. For this reason, calibration

procedures should include blank measurements with this water.

Initialize remote interface

Move needle to sample position

Place lift with needle to working position

Switch injection valve B at 733 to "Fill"

Fill first sample loop (B) with sample

Switch injection valve A at 733 to "Fill"

Switch injection valve B at 733 to "Inject"

Pump sample to sample loop A via SP Module A (*)

Trigger autozero at 732 IC Detector

Switch injection valve A at 733 to "Inject"

Switch SP Module A to next position

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

16

Page 21

2.3 Connection to a Modular IC System for Neutralization

start-neutralization.smt

2. Save the system file “neutralization.smt” with a new name “startneutralization.smt“.

3. Remove the data recorder by clicking on the recorder icon with the

right mouse button an selecting 'unlink'.

4. Change this program for 'start-neutralization.smt' as follows and save

it again:

001 Ctrl INIT 732

002 Ctrl PUMP 752 on

003 Wait 300 s

004 Ctrl STEP MSM 753

005 Wait 300 s

006 Ctrl STEP MSM 753

007 Wait 300 s

end-neutralization.smt

5. Save the program for “start-neutralization.smt“ under a new name

„end-neutralization.smt“.

6. Change the program for “end-neutralization.smt' as follows and save

it again:

001 Ctrl INIT 732

002 Ctrl PUMP 752 off

Initialize remote interface

Start 752 Pump Unit

Rinsing time

Switch SP Module A to next position

Rinsing time

Switch SP Module A to next position

Rinsing time

Initialize remote interface

Stop 752 Pump Unit

7. The sample queue then contains the following entries, for example:

System Ident Vial Chrom.-No.

1

Start-Neutralization.smt dummy 1

2

Neutralization.smt Probe 1 1

3

Neutralization.smt Probe 2 2

4

Neutralization.smt Probe 3 3

5

Neutralization.smt Probe 4 4

6

Neutralization.smt Probe 5 5

7

End-Neutralization.smt dummy 5

This example describes the processing of a queue with five samples.

The column 'Chrom. No.' is just given for information.

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

1

2

3

4

5

-

17

Page 22

2 Installation

2.4 Connection to a Modular IC System for Cation Elimination

A second application for the 793 IC Sample Prep Module is cation

elimination before chromatographic separation of the sample on the

column (e.g. precolumn elimination of heavy metals). In this section a

system for determination of anions with chemical suppression is

described. It includes the application of the sample to the SP Module A

followed by filling the sample loop with this pretreated sample.

Therefore, such an IC system corresponds to the Modular IC System

2 (MIC 2: Anion system with chemical suppression) enhanced by the

793 IC Sample Prep Module.

If you are not sure about the required capacity for complete cation

elimination and/or if the sample requires matrix elimination and preconcentration in combination with cation elimination by the SP Module A, a

system as described in section 2.3 should by used.

The following pages describe the electronic connections of this system

in combination with the 766 IC Sample Processor on the base of full

control by «IC Net 2.1».

2.4.1 Electrical connection

The 793 IC Sample Prep Module is connected to an IC system

consisting of 732 IC Detector, 733 IC Separation Center (one injector +

MSM), 709 IC Pump, 752 IC Pump Unit and 762 IC Interface as shown

in Fig. 5.

6.2128.13 0

6.2128.180

PC

6.2134.100

762

793

752

6.2143.21 0

6.2125.120

732

6.2125.090

733

6.2115.070

709

6.2128.180

Abb. 8

6.2134.09 0

: Connection 793 IC Sample Prep Module -

6.2141.11 0

6.2134.08 0

Modular IC System for cation elimination

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

18

Page 23

2.4

A

2.4 Connection

Connection to

2.42.4

ConnectionConnection

to aaaa Modular

toto

2.4.2 Connection of the SP Module A

The following description implies the usage of the 2.733.0130 IC

Separation Center (one injector + MSM).

The 1.793.0110 SP Module A must first be inserted in the 733 IC

Separation Center and connected to the 793 IC Sample Prep Module.

The connection of all parts should be done as described by the

following scheme:

Modular IC

ModularModular

Fill

IC System

ICIC

System for Cation Elimination

SystemSystem

) In the SP Module A

Cations of the sample

are continuously

exchanged by H

+

;

Sample loop is filled.

B) Pretreated sample is

pumped to the

separation column.

Sample

Sample

Regenerant H

SP

Module

A

793 709

SP

Module

A

793 709

O

2

A

Inject

A

Separation

column

RegenerantEluent H

Separation

column

RegenerantEluent H2O

MSM

752

MSM

752

ORegenerant H2O

2

The inlet and outlet capillaries mounted on the SP Module A are then

connected up. Proceed as follows:

1 Insert SP Module A

x Place SP Module A 21

the 733 Separation Center.

2 Connect SP Module A

x Remove the plastic stopper from opening 41

733 IC Separation Center and push cable 23

SP Module A 21

x Connect cable 23

Sample Prep Module (see Fig. 8).

3 Connect sample line to 793 SP Module A

x Screw inlet capillary 24

A connection 22

coupling using a 6.2744.010 compression fitting. Connect

this PEEK coupling with the PEEK capillary from the 766 IC

Sample Processor using a 6.2744.010 compression fitting.

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

21 on the floor of the inner chamber of

2121

41 or 43

43 on the

4141

4343

23 mounted on the

2323

21 through the opening.

2121

23 to connection 17

2323

24 marked with "Sample in" at SP Module

2424

22 (see Fig. 6) onto a 6.2744.040 PEEK

2222

17 “Actuator“ of the 793 IC

1717

19

Page 24

2 Installation

4 Connect SP Module A to valve A

x Screw outlet capillary 29

29 marked with “Sample out” onto

2929

connection “1” of injection valve A using a 6.2744.010

compression fitting.

5 Attach pump tubings

x Loosen both tubing cartridges 4444 from the holding clamp 9999 by

pressing down snap-action lever 10

mounting pin 12

12 on 793 Sample Prep Module (see Fig. 1).

1212

10 and remove from

1010

x Press contact pressure lever 5555 on both tubing cartridges

down as far as it will go.

x Insert a length of pump tubing 33

33 (6.1826.010, ~1.3 mL/min)

3333

into each of the tubing cartridges as shown in Fig. 7. The

white-white stopper 34

34 must click into the corresponding

3434

holder on the left-hand side of the tubing cartridge.

x Place the tubing cartridges on mounting pin 12

down on the right-hand side until snap-action lever 10

12 and press

1212

10 clicks

1010

into position on holding clamp 9999. Take care that no kinks are

formed in the pump tubing.

6 SP Module A connection 2: Regenerant

x Pull the inlet capillary 25

Module A connection 22

panel openings 41

x Mount a PEEK compression fitting 31

25 marked with “Regenerant“ at SP

2525

22 (see Fig. 6) through one of the rear

2222

or 43

43 of the 733 IC Separation Center.

41

4343

4141

31 (6.2744.010) on the

3131

end of inlet capillary and screw this on to PEEK filter unit 36

(6.2821.100) (see Fig. 7).

x Mount coupling 35

35 on to the inlet of the PEEK filter unit and

3535

push this coupling on to outlet end of the first pump tubing

33

33 (see Fig. 7).

3333

x Mount suction tubing: cut a piece of PTFE Tubing 30

(6.1803.020) to the desired length.

x Mount a PEEK compression fitting 31

end of PTFE tubing 30

30 and screw this on to coupling 32

3030

31 (6.2744.010) on one

3131

Fig. 7).

x Push coupling 32

33

33 (see Fig. 7).

3333

32 on to the inlet end of the first pump tubing

3232

x Immerse the other end of the suction tubing in a vessel

containing regeneration solution (normally 20 mmol/L HClO

and fix in place.

x Pull outlet capillary 26

connection 22

openings 41

22 (see Fig. 6) through one of the rear panel

2222

41 or 43

4141

x Lead outlet capillary 26

26 marked with "Waste" at SP Module A

2626

43 of the 733 IC Separation Center.

4343

26 to a sufficiently large waste container

2626

and fix in place.

30

3030

32 (see

3232

36

3636

)

4

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

20

Page 25

2.4

2.4 Connection

2.42.4

7 SP Module A connection 3: H2O

x Pull the inlet capillary 28

connection 22

openings 41

x Mount a PEEK compression fitting 31

end of inlet capillary 28

PEEK filter unit 36

x Mount coupling 35

push this coupling on to outlet end of the second pump

tubing 33

x Mount suction tubing: cut a piece of PTFE Tubing 30

(6.1803.020) to the desired length.

x Mount a PEEK compression fitting 31

end of PTFE tubing 30

x Push coupling 32

tubing 33

x Immerse the other end of the suction tubing in a vessel con-

taining rinsing solution (normally dist. H

x Pull outlet capillary 27

connection 22

openings 41

x Lead outlet capillary 27

and fix in place.

Connection to

ConnectionConnection

41

4141

33 (see Fig. 7).

3333

33 (see Fig. 7).

3333

41

4141

to aaaa Modular

Modular IC

toto

ModularModular

28 marked with “H2O“ at SP Module A

2828

22 (see Fig. 6) through one of the rear panel

2222

or 43

43 of the 733 IC Separation Center.

4343

28 and screw this on to the second

2828

36 (6.2821.100) (see Fig. 7).

3636

35 on to the inlet of the PEEK filter unit and

3535

30 and screw this on to coupling 32

3030

32 on to the inlet end of the second pump

3232

27 marked with “Waste“ at SP Module A

2727

22 (see Fig. 6) through one of the rear panel

2222

or 43

43 of the IC Separation Center 733.

4343

27 to a sufficiently large waste container

2727

IC System

System for Cation Elimination

ICIC

SystemSystem

31 (6.2744.010) on the

3131

31 (6.2744.010) on one

3131

O) and fix in place.

2

30

3030

32..

3232

8 Startup of 793 IC Sample Prep Module

x Set switch <REMOTE> 2222 to "OFF".

x Switch on 793 IC Sample Prep Module with mains switch 13

13

1313

and set switch <PUMP> 3333 to "ON".

x Adjust the contact pressure for both tubing cartridges: press

contact pressure lever 5555 upwards until the solutions just start

to be drawn in. Then press the contact pressure lever

upwards until it clicks once more to obtain optimal contact

pressure.

x Check all tubing from the storage vessels through the tubing

cartridges and the SP Module A up to the waste containers

for leakage of liquids. If liquid escapes anywhere the

corresponding compression fitting must be tightened further

or changed.

x Before using the SP Module A for sample pretreatment, its

cation exchange material should be conditioned. Inject 30%

sodium hydroxide 15 times (five injections per unit) using the

sample program of the system “Neutralization” as described

in the following section. The run time can be 20 min. each

while the separation column doesn’t have to be installed.

Pump tubings are consumable material with a lifetime which depends

on the contact pressure. This is why the tubing cartridges should be

raised completely by loosening snap-action lever

side if the pump is to remain switched off for a considerable length of

time (the set contact pressure remains unchanged).

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

10

10

on the right-hand

1010

21

Page 26

2 Installation

2.4.3 Settings in the «IC Net 2.1» program

During configuration of the 793 IC Sample Prep Module, the IC Net

assistant “New system wizard” requires the definition of an “Event line”

for the SP Module A. Although this is not installed you must enter any

unused “Event line” to enable the program to proceed. Actually, the SP

Module A is controlled by the 766 sample processor (see Fig. 8).

The signal for switching the internal IC Suppressor Module is not

provided by the 766 program. For this purpose, in the IC Net program

the 733 IC Separation Center parameter “Auto Step” must be set to

“fill”.

The peristaltic pumps of the 752 IC Pump Unit and 793 IC Sample Prep

Module are started when the IC system is activated (measuring

baseline). For this , the option ’Start pump with startup hardware

to be selected for both devices.

catex.smt

Start pump with startup hardware’ has

Start pump with startup hardwareStart pump with startup hardware

Program for the 766 IC Sample Processor:

001 Ctrl INIT 732

002 Move sample

003 Lift work

004 Ctrl ZERO 1

005 Ctrl FILL A 1

006 Pump 120 s

007 Ctrl INJECT A1

008 Ctrl STEP MSM 753

Initialize remote interface

Move needle to sample position

Place lift with needle to working position

Trigger autozero at 732 IC Detector

Switch injection valve A at 733 to "Fill"

Pump sample to sample loop via SP Module A (*)

Switch injection valve A at 733 to "Inject"

Switch SP Module A to next position

(*) The time for pumping the sample to the SP Module A should be as small as

possible to minimize the loading of the cation exchange material.

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

22

Page 27

3.1 Handling the SP Module A

3 Operation

3.1 Handling the SP Module A

General

The SP Module A of the 793 Sample Prep Module consists of a total

of three cation exchange units which are in turn used for cation exchange, regenerated and rinsed with water. In order to record each new

chromatogram under comparable conditions a freshly regenerated

cation exchange unit is normally used. Switching is either carried out

automatically together with valve switching or manually.

Correct connections

The three inlets and outlets numbered 1...3 on the SP Module A each

have 2 permanently mounted PTFE capillaries, which must be connected as described in sections 2.3.2 or 2.4.2 respectively (see Fig. 6).

Flow direction

The cation exchange units must never be regenerated in the same

flow direction used for the sample. You should thus always install the

inlet and outlet capillaries as described in sections 2.3.2 or 2.4.2

respectively according to the scheme shown in Fig. 6.

Never switch when dry

The SP Module A must never

a danger of blocking.

No recycling

The recycling process (returning the eluent to the storage vessel)

must not be carried out when the SP Module A is in operation.

be switched in the dry state as there is

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

23

Page 28

3 Operation

3.2 Manual operation

The 793 IC Sample Prep Module cannot be manually operated unless

the installation has been carried out properly as described in section 2

(mains connection, attaching the pump tubing, connection to the IC

system).

REMOTE

PUMP

Switch instrument on/off

The 793 IC Sample Prep Module is switched on and off using

mains switch 13

I Instrument switched on

13 on the rear of the instrument (see Fig. 2):

1313

0 Instrument switched off

POWER

After the instrument has been switched on the power lamp 1111

lights up to show that the instrument is ready for use.

Switch off remote control of the pump

ON

In order to allow manual operation the remote control of the

pump must be switched off with switch 2222.

ON Remote control switched on

OFF

OFF Remote control switched off

Switch pump on/off

ON

The drive of the pump is switched on and off with the switch 3333

<PUMP>:

ON Pump switched on

OFF

OFF Pump switched off

REMOTE

ON

Switch off remote control of the SP Module A

In order to allow manual operation the remote control of the SP

Module A must be switched off with switch 6666.

ON Remote control switched on

OFF

ACTUATOR

STEP

OFF Remote control switched off

Rotate SP Module A

The SP Module A is switched to the next position by means of

switch 8888 <STEP>.

The position display 7777 beside the switch shows whether the SP

Module A is in the correct position:

Lamp on Right position

Lamp off Wrong position or blocked

(procedure see section 4.1)

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

24

Page 29

3.3 Operation via 732 IC Detector

3.3 Operation via 732 IC Detector

When operating the 793 IC Sample Prep Module together with the 732

IC Detector and the 733 IC Separation Center both pump and the SP

Module A on the 793 IC Sample Prep Module can be operated and

switched automatically without the program “IC Net”. To allow direct

remote control of SP Module A and pump by the 732 IC Detector the

793 remote interfaces 15

interface of the 732 IC Detector by means of the 6.2143.210 cable (available as an option).

15 and 16

1515

16 have to be connected to the remote

1616

REMOTE

Switch instrument on/off

The 793 IC Sample Prep Module is switched on and off using

mains switch 13

I Instrument switched on

13 on the rear of the instrument (see Fig. 2):

1313

0 Instrument switched off

POWER

After the instrument has been switched on the power lamp 1111

lights up to show that the instrument is ready for use.

Switch on remote control of the pump

ON

In order to allow remote operation via 732 IC Detector the remote

control must be switched on with switch 2222.

ON Remote control switched on

OFF

OFF Remote control switched off

Automatic pump switch-on when the 732 IC Detector is switched on

In order to start up the pump drive of the 793 IC Sample Prep

Module automatically when the 732 IC Detector is switched on

alterations must be made to the basic settings (Setup, see

section 4.4.1 of 732/733 Manual). The remote output lead 1 must

be set to 1 (on, active, 0 V):

When the 732 IC Detector is switched off the pump at the 793 IC

Sample Prep Module is also switched off.

Switch pump on/off in a program

In the 732 IC Detector the <PROGRAM> key can be used to

create time programs with a maximum of 20 program steps (see

section 4.7.1 of 732/733 Manual). The pump can be switched on

or off at any program step by setting the remote output lead 1 to

1 (on, active, 0 V) or 0 (off, inactive, open) respectively:

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

>SETUP/output

remote 10000000

25

Page 30

3 Operation

f

REMOTE

Switch on:

Switch off:

>PROGRAM/edit XXX.X min

remote 1

>PROGRAM/edit XXX.X min

remote 0

✴✴✴✴✴✴✴

✴✴✴✴✴✴✴

Switch pump on/off at an event

In the 732 IC Detector the <EVENT> key can be used to

program a maximum of 4 different events (see section 4.7.3 o

732/733 Manual). The pump can be switched on or off at any

event by setting the remote output lead 1 to 1 (on, active, 0 V) or

0 (off, inactive, open) respectively:

Switch on:

Switch off:

EVENT YY-MM-DD HH:MM:SS

remote 1

EVENT YY-MM-DD HH:MM:SS

remote 0

✴✴✴✴✴✴✴

✴✴✴✴✴✴✴

Switch on remote control of the SP Module A

ON

In order to bring the SP Module A automatically to the next

position via the 732 IC Detector the remote control of the SP

Module A must be switched on with switch 6666.

OFF

ON Remote control switched on

OFF Remote control switched off

Rotate SP Module A in a program

In the 732 IC Detector the <PROGRAM> key can be used to

create time programs with a maximum of 20 program steps (see

section 4.7.1 of 732/733 Manual ). With each program step the SP

Module A can be brought to the next position by setting remote

output lead 2 to 1 (on, active, 0 V). This lead must later be

returned to the setting 0 (off, inactive, open) before the SP

Module A can be switched to the next position.

Rotate:

Reset

output lead:

Example

Automatically changing the SP

Module A position in "inject"programs (for manual operation

or with autosamplers).

>PROGRAM/edit XXX.X min

remote ✴1

>PROGRAM/edit XXX.X min

remote ✴0

PROGRAM

progr.type: inject

0.0 remote

0.1 remote

✴✴✴✴✴✴

✴✴✴✴✴✴

✴✴✴✴1✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴

✴✴✴✴0✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴✴

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

26

Page 31

3.3 Operation via 732 IC Detector

f

ACTUATOR

STEP

Rotate SP Module A at an event

In the 732 IC Detector the <EVENT> key can be used to

program a maximum of 4 different events (see section 4.7.3 o

732/733 Manual ). At each event the SP Module A can be brought

into the next position by setting remote output lead 2 to 1 (on,

active, 0 V). This lead must later be returned to the setting 0 (off,

inactive, open) before the SP Module A can be switched to the

next position.

Rotate:

Reset

output lead:

EVENT YY-MM-DD HH:MM:SS

remote ✴1

EVENT YY-MM-DD HH:MM:SS

remote ✴0

✴✴✴✴✴✴

✴✴✴✴✴✴

SP Module A position display

The position display 7777 of the 793 IC Sample Prep Module beside

switch 8888 shows whether the SP Module A is in the right position:

Lamp on SP Module A in the right position

Lamp off SP Module A in the wrong position or blocked

(procedure see section 4.1)

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

27

Page 32

4 Malfunctions - Maintenance

4 Malfunctions – Maintenance

4.1 Malfunctions and their rectification

If difficulties appear with the IC system during analysis, their cause are

best investigated in the order separating column oooo pump oooo eluent

oooo IC system. An overview of possible malfunctions, their causes and

remedies can be found in the instruction manuals of both 690 Ion

Chromatograph (section 6.5) and 732/733 IC System (section 5.3.2).

In addition to these general malfunctions the table below contains others which might arise as a result of the operation of the 793 Sample

Prep Module.

Malfunction Cause Rectification

Insufficient or nonexisting flow rate

Leakage x Leaking tubing connectors x Tighten or replace the leaking tubing

x Contact pressure too low

x Pump tubing faulty

x Contamination of the filter in the

6.2821.100 Filter unit PEEK

x Blocked connections

x SP Module A blocked

x Set contact pressure correctly: Press

contact pressure lever 5555 on the tubing

cartridge down as far as it will go. Press

contact pressure lever 5555 upwards until the

solution just starts to be drawn in. Then

press contact pressure lever upwards until

it clicks once more to obtain optimal

contact pressure.

x Exchange pump tubing

(see section 4.2.4)

x Replace the 6.2821.110 Filter (see

connections description, section 2.3.2)

x Carry out a step-by-step check of the

connections and connectors and if necessary clean or replace them. If the

connections to or from the actuator are

blocked then remove the actuator and

clean it (see section 4.2.6).

x Exchange SP Module A

(see section 4.2.7).

connectors.

Air bubbles in pump

circuit

x Suction tubing is not immersed

x Leaking tubing connectors

x Immerse the suction tubing fully in the

regenerating or rinsing solution.

x Tighten or replace the leaking tubing

connectors.

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

28

Page 33

4.1 Malfunctions and their rectification

Actuator moves to next

position but display lamp

7777 no longer lights up

Actuator is not switched

to next position (display

lamp 7777 no longer lights up)

x SP Module A dry

x SP Module A temporarily in the

wrong position

x Braking range not correctly

adjusted

x Connection to SP Module A is

interrupted

x SP Module A dry

x Actuator temporarily blocked

x Actuator dirty

x Mechanical fault in Actuator

x Rinse all 3 actuator units with solution for

at least 10 min.

x Switch instrument off and then on again.

Switch off SP Module A remote operation

with key 6666 <REMOTE> and operate key

8888 <STEP>. Check whether display lamp

7777 lights up.

Repeat this procedure 2-3 times; wait at

least 10 s each time before the <STEP>

key is operated.

If display lamp 7777 does not light up each

time the position is changed then the

braking range must be readjusted (see

below).

x Readjust braking range

(see section 4.2.8).

x Check cable connection from SP Module

A block to 793 Sample Prep Module.

x Rinse all 3 actuator units with solution for

at least 10 min.

x Switch instrument off and then on again.

Switch off SP Module A remote operation

with key 6666 <REMOTE> and operate key

8888 <STEP>. Check whether display lamp

7777 lights up.

Repeat this procedure 2-3 times; wait at

least 10 s each time before the <STEP>

key is operated.

If display lamp 7777 does not light up each

time the position is changed then the

braking range must be readjusted (see

below).

x Clean actuator (see section 4.2.6).

x Exchange actuator (see section 4.2.7).

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

29

Page 34

4 Malfunctions - Maintenance

4.2 Maintenance and servicing

4.2.1 Care

The 793 IC Sample Prep Module requires proper care and attention.

Excessive contamination of the instrument could possibly lead to malfunctions and a shorter service life of the inherently rugged mechanical

and electronic parts.

Spilled chemicals and solvents should be wiped up immediately. It is

especially important to protect the plug connections at the rear of the

instrument (particular the mains plug) against contamination.

Although constructional measures have been designed to virtually

eliminate such a situation, should corrosive media penetrate the

interior of the instruments the mains plug of the 793 IC Sample Prep

Module must be immediately disconnected to prevent extensive

damage to the instrument electronics. Inform Metrohm service if your

instrument has been damaged in such a way.

The instrument must not be opened by untrained personnel. Please

comply with the safety notes in section 1.4.1.

4.2.2 Maintenance by Metrohm service

Maintenance of the 793 IC Sample Prep Module is best done as part of

an annual service performed by specialists from the Metrohm company.

Due to caustic and corrosive chemicals which are processed by this

device, it may be necessary to shorten the interval between servicing.

The Metrohm service department is always willing to offer expert advice

on the maintenance and servicing of all Metrohm instruments.

4.2.3 Shutdown

If the IC system is shut down for a considerable length of time, the entire IC system (without

rinsed free from salt with methanol/water (1:4) to avoid crystallization

of eluent salts with the corresponding subsequent damage. In order to

rinse them the separating column, suppressor and actuator are disconnected and the injector and detector are directly connected to each

other. Rinse with methanol/water (1:4) until the conductivity drops below

10 PS/cm.

column, suppressor and SP Module A) must be

All three suppressor and actuator units are then rinsed for about 5 min

with ultrapure water.

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

30

Page 35

4.2 Maintenance and servicing

4.2.4 Exchanging the pump tubing

Pump tubings are consumable material with a limited lifetime and

should be exchanged at regular intervals (approx. every 4 weeks under

continuous use).

The working life of pump tubing depends to a considerable extent on

the contact pressure. This is why the contact pressure must be correctly

set as described in section 2.3.2 or 2.4.2 respectively. If the pump is to

remain switched off for a lengthy period of time the tubing cartridges

should be raised completely by loosening snap-action lever 10

right-hand side (the set contact pressure remains unchanged).

As the pump is always operated on the same side the pump tubings

6.1826.010 supplied can be used on both sides. To exchange a pump

tubing proceed as follows:

1 Remove old pump tubing

x Press contact pressure lever 5555 on the tubing cartridge down

as far as it will go.

x Release tubing cartridge 4444 from holding clamp 9999 by pressing

down snap-action lever 10

10 and remove from mounting pin 12

1010

on the 793 IC Sample Prep Module (see Fig. 1).

x Remove old pump tubing.

10 on the

1010

12

1212

2 Insert new pump tubing

x Insert the new pump tubing 33

cartridge as shown in Fig. 7. The white-white stopper 34

click into the corresponding holder on the left-hand side of

the tubing cartridge.

x Place the tubing cartridge on mounting pin 12

down on the right-hand side until snap-action lever 10

into position on holding clamp 9999. Take care that no kinks are

formed in the pump tubing.

3 Set contact pressure

x Press contact pressure lever 5555 upwards until the solution just

starts to be drawn in. Then press contact pressure lever upwards until it clicks once more to obtain optimal contact pressure.

33 (6.1826.010) in the tubing

3333

34 must

3434

12 and press

1212

10 clicks

1010

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

31

Page 36

4 Malfunctions - Maintenance

4.2.5 Regeneration of the cation exchange material

If the actuator units are exposed to certain heavy metals (e.g. iron) or

organic contaminants for longer periods of time then these can no longer be removed completely by the regeneration solution normally used

(20 mmol/L HClO

such capacity problems occur then the actuator units must be treated

as follows:

1 Disconnect SP Module A from IC system

2 Regenerate cation exchange material

x Rinse all 3 actuator units one after another for about 10 min

with one of the following solutions:

For heavy metal contamination

0.2 mol/L HClO

+ 0.1 mol/L oxalic acid (in case of Fe+2/Fe+3)

For contamination with organic substances

0.2 mol/L HClO

The 6.1826.010 Pump tubing is made of PVC and must not be used

for rinsing with solutions which contain acetone. In such cases a

different pump tubing or a different pump (e.g. 709 IC Pump) must be

used for rinsing purposes.

). This diminishes the capacity of the actuator units. If

4

4

/ acetone t 20%

4

3 Connect SP Module A to IC system

x Reconnect SP Module A to IC system. If there are still prob-

lems with the capacity then the actuator rotor must be exchanged (see section 4.2.6).

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

32

Page 37

4.2 Maintenance and servicing

4.2.6 Cleaning the SP Module A

Cleaning the SP Module A may be necessary in the following cases

(see also section 4.1):

x Blockage of the SP Module A which cannot be remedied

(the SP Module A can no longer deliver solutions)

x Obstruction of the actuator which cannot be remedied

(the actuator can no longer be switched to next position)

To clean the connection piece and the rotor proceed as follows (see

Fig. 9):

1 Disconnect SP Module A from IC system

2 Dismantle SP Module A

x Unscrew nut 33337777 from actuator holder 40

x Pull out connection piece 38

38 and actuator rotor 33339999 from

3838

actuator holder (the connection piece and the rotor normally

stick together).

x Loosen connection piece from actuator rotor.

40.

4040

3 Clean input and output leads

x Each of the 6 capillary tubings attached to connection piece

are connected to the pump one after another and ultrapure

water pumped through.

x Check whether solution emerges from connection piece. If

one of the input or output leads remains blocked then the

connection piece must be replaced (order number

6.2835.010).

4 Clean actuator rotor

x Clean the sealing surface of actuator rotor 37

37 with the aid of a

3737

lint-free cloth and ethanol.

5 Insert actuator rotor

x Insert actuator rotor in actuator holder in such a way that the

tubing connections at the rear of the rotor fit in the corresponding openings inside the rotor and that one of the three

holes in the rotor can be seen from below in one of the openings of the holder.

x If the rotor has been inserted correctly its sealing surface will

be about 4 mm inside the holder. If this is not the case then

the rotor must be brought into the correct position from below

with the aid of a sharp object (e.g. screwdriver).

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

33

Page 38

4 Malfunctions - Maintenance

40

37

3737

Screw nut 39

37

37

3737

38

38 Connection piece (6.2835.010)

3838

with input and output leads

3837

3838

: Assembling the actuator

Fig. 9

3938

3939

39 Actuator rotor (6.2835.000)

3939

40

40 Actuator holder

4040

4039

4040

6 Clean connection piece

x Clean the sealing surface of connection piece 38

of a lint-free cloth and ethanol.

7 Insert connection piece

x Insert connection piece in actuator holder 40

that connection "1" is at the top and that the three lugs on the

connection piece fit in the corresponding openings of the

holder.

x Screw nut 37

not use tools).

8 Connect and condition the SP Module A

x Reconnect the SP Module A to the IC system (see section

2.3.2 and section 2.4.2).

x Before switching the actuator to the next position for the first

time rinse all 3 actuator units with solution for 5 min.

37 onto the thread of actuator holder manually (do

3737

38 with the aid

3838

40 in such a way

4040

793 IC Sample Prep Module/ 8.793.1003 Instructions for Use

34

Page 39

4.2 Maintenance and servicing

4.2.7 Exchanging the cation exchange material

Exchanging the cation exchange material in the SP Module A of the 793

IC Sample Prep Module may be necessary in the following cases (see

also section 4.1):

x Loss of cation exchange capacity which cannot be remedied

x Blockage of the SP Module A which cannot be remedied

Both the 6.2835.000 actuator rotor as well as the 6.2835.010 connection

piece with the input and output leads can be exchanged. To exchange

these components proceed as follows (see Fig. 9):

1 Disconnect SP Module A from IC system

x Disconnect all input and output leads of the SP Module A

from IC system and the pump of the 793 IC Sample Prep

Module.

2 Dismantle actuator

x Unscrew nut 37

x Pull out connection piece 38

actuator holder (the connection piece and the rotor normally

stick together).

x Loosen connection piece from actuator rotor.

37 from actuator holder 40

3737

38 and actuator rotor 39

3838

40.

4040

39 from

3939

3 Clean actuator rotor

x Clean the sealing surface of new actuator rotor (6.2835.000)

with the aid of a lint-free cloth and ethanol.

4 Insert actuator rotor

x Insert new actuator rotor in actuator holder in such a way that

the tubing connections at the rear of the rotor fit in the corresponding openings inside the rotor and that one of the three

holes in the rotor can be seen from below in one of the openings of the holder.

x If the rotor has been inserted correctly its sealing surface will

be about 4 mm inside the holder. If this is not the case then

the rotor must be brought into the correct position from below

with the aid of a sharp object (e.g. screwdriver).

5 Clean connection piece

x Clean the sealing surface of new connection piece

(6.2835.010) with the aid of a lint-free cloth and ethanol.

6 Insert connection piece

x Insert new connection piece in actuator holder in such a way

that connection "1" is at the top and that the three lugs on the