Page 1

CH-9101 Herisau/Switzerland

Phone ++41 71 353 85 85

Fax ++41 71 353 89 01

Internet www.metrohm.com

E-Mail info@metrohm.com

792 Basic IC

Program «792 PC Software 1.0»

Basic IC792

Basic

Basic

BasicBasic

POWER

8.792.1003 Instructions for Use

11.04.2001 / dö

Page 2

Table of contents

Table of contents

1 Introduction

1.1 Instrument description.......................................................................................... 1

1.2 Parts and controls.................................................................................................. 3

1.3 Information on the Instructions for Use............................................................. 8

1.3.1 Organization ........................................................................................... 8

1.3.2 Notation and pictograms........................................................................ 9

1.4 Safety notes ..........................................................................................................10

1.4.1 Electrical safety..................................................................................... 10

1.4.2 General precautionary rules ................................................................. 10

2 Installation

2.1 Overview ................................................................................................................ 11

2.1.1 Flow chart ............................................................................................. 11

2.1.2 Connections in the 792 Basic IC .......................................................... 11

2.2 Setting up the instrument ................................................................................... 13

2.2.1 Packaging............................................................................................. 13

2.2.2 Check.................................................................................................... 13

2.2.3 Location ................................................................................................ 13

2.3 Attaching the accessories .................................................................................. 13

2.3.1 Connection of detector block............................................................... 13

2.3.2 Connection of syringe and aspirating tubing....................................... 14

2.3.3 Connection of the 6.5324.000 Bottle rack (option) .............................. 14

2.3.4 Connection of PEEK capillaries............................................................ 15

2.3.5 Filter unit PEEK ..................................................................................... 16

............................................................................................................

..........................................................................................................

1

11

2.4 Mains connection ................................................................................................. 17

2.4.1 Setting the mains voltage..................................................................... 17

2.4.2 Fuses .................................................................................................... 18

2.4.3 Mains cable and mains connection ..................................................... 18

2.4.4 On/off switching of the instrument ....................................................... 18

2.5 Connection to the PC ..........................................................................................19

2.5.1 Connecting cable ................................................................................. 19

2.5.2 Software installation.............................................................................. 19

2.5.3 Basic settings ....................................................................................... 20

2.6 High-pressure pump............................................................................................ 23

2.6.1 Removing the transport security screws.............................................. 23

2.6.2 Installing the pulsation dampener (option) .......................................... 23

2.6.3 Connecting the eluent bottle ................................................................ 25

2.6.4 Deaerating the pump and rinsing the pulsation dampener................. 25

2.7 Precolumns and separating columns............................................................... 28

2.7.1 General information on precolumns..................................................... 28

2.7.2 Precolumns with twin cartridge holder ................................................. 28

2.7.3 Precolumn glass cartridges with cartridge holder ............................... 30

2.7.4 IC anion precolumn SUPERSEP ..........................................................31

2.7.5 General information on separating columns........................................ 32

2.7.6 Selection of the sample loop................................................................ 32

2.7.7 Installation of the separating column without suppressor................... 32

2.7.8 Installation of the separating column with suppressor ........................ 34

792 Basic IC

I

Page 3

Table of contents

2.8 Suppressor module ............................................................................................. 35

2.8.1 General information on suppressor module........................................ 35

2.8.2 Preparation of the peristaltic pump...................................................... 35

2.8.3 Connection of supply bottles ............................................................... 38

2.8.4 Connection of the suppressor module ................................................ 39

2.9 Putting into operation ......................................................................................... 41

2.9.1 Putting into operation without suppressor........................................... 41

2.9.2 Putting into operation with suppressor ................................................ 42

3 Operating tutorial

3.1 Requirements ....................................................................................................... 45

3.2 Preparations.......................................................................................................... 46

3.3 Calibration ............................................................................................................. 47

3.4 Sample determination ......................................................................................... 54

4 Operation

4.1 Fundamentals of the operation ......................................................................... 57

...............................................................................................................

4.1.1 Starting/closing the program ............................................................... 57

4.1.2 Glossary................................................................................................ 58

4.1.3 Overview of program windows............................................................. 59

4.1.4 Main window elements......................................................................... 60

4.1.5 Icons of the main window..................................................................... 60

4.1.6 Overview of file types............................................................................ 61

4.1.7 Context sensitive menus ...................................................................... 62

4.1.8 Keyboard and mouse functions........................................................... 62

4.1.9 Help ...................................................................................................... 63

.......................................................................................

45

57

4.2 Instrument and software settings ..................................................................... 64

4.2.1 Fonts..................................................................................................... 64

4.2.2 Security system .................................................................................... 64

4.2.3 Global settings ..................................................................................... 65

4.2.4 COM port.............................................................................................. 67

4.3 Systems ................................................................................................................. 68

4.3.1 System window .................................................................................... 68

4.3.2 System file handling ............................................................................. 68

4.3.3 System functions .................................................................................. 69

Start/stop hardware and record baseline .................................... 69

Start/stop determinations............................................................. 69

Print system parameters .............................................................. 70

4.3.4 PC icon ................................................................................................. 71

4.3.5 Watch window ...................................................................................... 71

4.3.6 Instrument icon..................................................................................... 72

Menu options for instrument icon ................................................ 72

System parameters for disconnected system ............................. 72

Instrument control for connected system .................................... 73

Time program ............................................................................... 74

Configuration ................................................................................ 76

Hardware settings ........................................................................ 76

4.3.7 System state window............................................................................ 78

Status messages.......................................................................... 78

Error messages ............................................................................ 79

II

792 Basic IC

Page 4

Table of contents

4.4 Methods .................................................................................................................80

4.4.1 Method file handling ............................................................................. 80

4.4.2 Passport................................................................................................ 80

General ......................................................................................... 81

Sample.......................................................................................... 82

Column ......................................................................................... 83

Eluent ............................................................................................ 84

Comment ...................................................................................... 84

Method Log .................................................................................. 85

Data Log ....................................................................................... 86

4.4.3 Method setup........................................................................................ 87

General ......................................................................................... 87

Processing.................................................................................... 87

Math .............................................................................................. 88

4.4.4 Integration............................................................................................. 90

Setup............................................................................................. 91

Events ........................................................................................... 92

4.4.5 Calibration and quantification............................................................... 94

General information ...................................................................... 94

Notations....................................................................................... 95

External standard calibration........................................................ 96

Component table.......................................................................... 96

Peak identification ........................................................................ 98

Concentration table .................................................................... 100

Calibration curve......................................................................... 102

Update calibration ......................................................................104

Load and save calibration data.................................................. 105

Import and export calibration data ............................................. 105

Put out calibration curves ........................................................... 105

4.4.6 Report output...................................................................................... 106

Report options ............................................................................ 106

4.5 Chromatograms.................................................................................................. 118

4.5.1 Chromatogram window ...................................................................... 118

4.5.2 Chromatogram file handling............................................................... 119

Open chromatogram.................................................................. 119

Save chromatogram ................................................................... 120

Close chromatogram.................................................................. 120

Delete chromatogram................................................................. 120

Export chromatogram................................................................. 121

4.5.3 Graphical representation.................................................................... 122

Appearance ................................................................................ 122

Other graphical functions ........................................................... 126

4.5.4 Peak editor.......................................................................................... 127

Switching on/off the peak editor................................................. 127

Peak editor functions.................................................................. 127

Moving the cursor....................................................................... 128

4.5.5 Printing................................................................................................ 129

Page layout for printing .............................................................. 129

Printer settings ............................................................................ 130

Print preview ............................................................................... 130

Printing........................................................................................ 130

4.5.6 Miscellaneous functions ..................................................................... 130

Reintegration............................................................................... 130

Recalibration............................................................................... 130

Subtraction of a chromatogram ................................................. 131

Data compression ......................................................................131

Invert chromatogram .................................................................. 131

792 Basic IC

III

Page 5

Table of contents

4.6 Batch reprocessing ...........................................................................................132

4.6.1 Batch reprocessing queue file handling ............................................ 132

Open batch reprocessing queue ............................................... 132

Create new batch reprocessing queue...................................... 132

Save batch reprocessing queue ................................................ 132

4.6.2 Perform batch reprocessing............................................................... 133

Reprocess options window........................................................ 133

Merge chromatograms .............................................................. 136

4.6.3 Batch reprocessing queue editor....................................................... 137

Open batch reprocessing queue editor window ....................... 137

Batch reprocessing queue editor functions............................... 138

Print batch reprocessing queue................................................. 138

Close batch reprocessing queue editor .................................... 138

5 Notes – Maintenance – Faults

5.1 Practical notes on ion chromatography ........................................................ 139

5.1.1 Separating columns ........................................................................... 139

5.1.2 High-pressure pump .......................................................................... 140

5.1.3 Eluents ................................................................................................ 141

5.1.4 Peristaltic pump.................................................................................. 141

5.1.5 Suppressor module............................................................................ 142

5.1.6 Connections ....................................................................................... 142

...................................................

139

5.2 Maintenance and servicing .............................................................................. 143

5.2.1 General information............................................................................ 143

5.2.2 Passivation ......................................................................................... 143

5.2.3 Recycling ............................................................................................ 144

5.2.4 Shutdown............................................................................................ 144

5.2.5 Changing separating columns........................................................... 144

5.2.6 Maintenance work at the pump head ................................................ 146

5.2.7 Regeneration of the suppressor module ........................................... 150

5.2.8 Cleaning the suppressor.................................................................... 151

5.2.9 Replacing the suppressor.................................................................. 153

5.2.10 Exchanging the pump tubing............................................................. 155

5.3 Faults and malfunctions ................................................................................... 156

5.3.1 Error messages .................................................................................. 156

5.3.2 Malfunctions and their rectification .................................................... 156

5.4 Diagnostic tests / Validation / GLP ................................................................. 158

IV

792 Basic IC

Page 6

Table of contents

6 Appendix

6.1 Technical data..................................................................................................... 159

6.2 Standard equipment ..........................................................................................164

6.3 Optional accessories.........................................................................................167

6.4 Warranty and conformity .................................................................................. 176

..............................................................................................................

6.1.1 Conductivity measurement................................................................. 159

6.1.2 Conductivity detector.......................................................................... 159

6.1.3 Injection valve ..................................................................................... 160

6.1.4 High-pressure pump .......................................................................... 160

6.1.5 Peristaltic pump.................................................................................. 161

6.1.6 Suppressor module ............................................................................ 161

6.1.7 RS232 interface .................................................................................. 161

6.1.8 Mains connection ............................................................................... 162

6.1.9 Safety specifications........................................................................... 162

6.1.10 Electromagnetic compatibility (EMC)................................................. 162

6.1.11 Ambient temperature.......................................................................... 163

6.1.12 Housing............................................................................................... 163

6.3.1 Accessories for 792 Basic IC .............................................................167

6.3.2 Separating columns and precolumns................................................ 169

6.3.3 Additional devices and cables ........................................................... 175

6.4.1 Warranty.............................................................................................. 176

6.4.2 EU Declaration of conformity.............................................................. 177

6.4.3 Certificate of conformity and system validation ................................. 178

159

6.4 Index ..................................................................................................................... 179

792 Basic IC

V

Page 7

Table of contents

List of figures

Fig. 1: Front of the 792 Basic IC ................................................................................ 3

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

: Rear of the 792 Basic IC................................................................................. 4

: Interior of the 792 Basic IC .............................................................................6

: Connecting diagram for 792 Basic IC without suppressor.......................... 12

: Connecting diagram for 792 Basic IC with suppressor ............................... 12

: Connectors for capillaries.............................................................................15

: 6.2821.100 Filter unit PEEK .......................................................................... 16

: Setting the mains voltage ............................................................................. 18

: Connection of the pulsation dampener (option) .......................................... 24

Fig. 10

Fig. 11

Fig. 12

Fig. 13

Fig. 14

Fig. 15

Fig. 16

Fig. 17

Fig. 18

Fig. 19

: Installing precolumn cartridges .................................................................... 29

: Installation of precolumn glass cartridges with cartridge holder ................. 31

: Installation of column without suppressor.................................................... 33

: Installing pump tubings ................................................................................ 36

: Installation of column with suppressor......................................................... 37

: Connections at suppressor module ............................................................. 40

: Components of the pump head ................................................................. 147

: Replacement of the piston seal 89

: Components of inlet valve 90

: Assembling the suppressor.......................................................................

89............................................................. 147

8989

90 and outlet valve 91

9090

91 ..................................... 149

9191

153

VI

792 Basic IC

Page 8

Table of contents

List of numbered parts and controls

1111 Door to interior ....................................3,6

2222 Mains pilot lamp.....................................3

3333 Feedthrough for syringe tubing .............3

4444 Feedthrough for aspirating tubing......... 3

5555 Opening for detector cable....................4

6666 Rear panel opening ...............................4

7777 Opening for outlet capillaries.................4

8888 Knurled screw ........................................4

9999 Detachable rear panel ...........................4

10

10 Transport security screws...................... 4

1010

11

11 Mains switch ..................................... 4,18

1111

12

12 Mains connection plug .....................4,18

1212

13

13 Fuse holder ....................................... 4,18

1313

14

14 RS232 interface...................................... 4

1414

15

15 Connection for detector block ............... 4

1515

16

16 Connection for service...........................4

1616

17

17 Serial number.........................................4

1717

18

18 Inlet capillary for injector ...................6,24

1818

19

19 Mounting rail ................................ 6,33,37

1919

20

20 Column connection

2020

capillary ..............................6,29,31,33,37

21

21 Sample loop...........................................6

2121

22

22 Injection valve..........................6,24,33,37

2222

23

23 Aspirating tubing....................................6

2323

24

24 Coupling................................................. 6

2424

25

25 Syringe tubing ........................................ 6

2525

26

26 PEEK coupling ............................. 6,29,37

2626

27

27 Connection capillary .........................6,24

2727

28

28 Filter unit PEEK ..................6,16,24,36,37

2828

29

29 Connection capillary .........................6,24

2929

30

30 Connection capillary ..............................6

3030

31

31 Purge valve........................................6,24

3131

32

32 Aspirating capillary................................. 6

3232

33

33 Fastening screws...................................6

3333

34

34 Pump head......................................6,147

3434

35

35 Connection capillary .............................. 6

3535

36

36 Connection capillary .............................. 6

3636

37

37 Inlet capillary for

3737

detector block .............................. 6,33,37

38

38 Detector block.............................. 6,33,37

3838

39

39 Suppressor module ..........................6,37

3939

40

40 Tubing cartridge ...........................6,36,37

4040

41

41 Contact pressure lever.................6,36,37

4141

42

42 Holding clamp.................................. 6,37

4242

43

43 Snap-action lever .........................6,36,37

4343

44

44 Pump drive ........................................6,37

4444

45

45 Mounting pin .....................................6,37

4545

46

46 Compression fitting ......... 15,16,29,31,36

4646

47

47 Compression fitting ..............................15

4747

48

48 Capillary......................................15,16,31

4848

49

49 Connector with filter..............................16

4949

50

50 Housing for filter unit PEEK..................16

5050

51

51 Connector without filter ........................16

5151

52

52 Pulsation dampener .............................24

5252

53

53 Connection to injection valve...............24

5353

54

54 Connection to purge valve...................24

5454

55

55 Inlet capillary.........................................29

5555

56

56 Manufit housing....................................29

5656

57

57 PTFE gasket .........................................29

5757

58

58 2 Steel meshes.....................................29

5858

59

59 Precolumn cartridge.............................29

5959

60

60 Manufit pressure screw........................29

6060

61

61 Outlet capillary......................................29

6161

62

62 End fitting .............................................31

6262

63

63 Sleeve for precolumn cartridge............31

6363

64

64 Precolumn cartridge.............................31

6464

65

65 Connection piece .................................31

6565

66

66 Separating column.....................29,33,37

6666

67

67 Column holder.................................33,37

6767

68

68 Aspirating tubing for H

6868

69

69 Aspirating tubing for H

6969

70

70 Coupling ..........................................36,37

7070

71

71 Pump tubing for H

7171

72

72 Pump tubing for H

7272

73

73 Stopper................................................ 36

7373

74

74 Coupling ......................................... 36,37

7474

75

75 Suppressor inlet capillary

7575

O ................36,37

2

.............36,37

2SO4

...................36,37

2SO4

O.......................36,37

2

for eluent......................................... 37,40

76

76 Suppressor outlet capillary

7676

for eluent......................................... 37,40

77

77 Suppressor inlet capillary

7777

for H

O....................................... 36,37,40

2

792 Basic IC

VII

Page 9

Table of contents

78

78 Suppressor inlet capillary

7878

for H

79

79 Suppressor outlet capillary

7979

for H

80

80 Suppressor outlet capillary

8080

for H

81

81 Screw ................................................. 147

8181

82

82 Zircon piston ...................................... 147

8282

83

83 Spring retainer ................................... 147

8383

84

84 Spring................................................. 147

8484

85

85 Piston cartridge.................................. 147

8585

86

86 Piston guide sleeve............................147

8686

87

87 Sapphire supporting ring................... 147

8787

88

88 Piston guide sleeve............................147

8888

89

89 Piston seal .........................................147

8989

90

90 Inlet valve ....................................147,149

9090

2SO4

2

2SO4

....................................36,37,40

O ............................................37,40

.........................................37,40

91

91 Outlet valve..................................147,149

9191

92

92 Screw holder ......................................147

9292

93

93 Special tool ........................................147

9393

94

94 Special tool ........................................147

9494

95

95 Valve housing.....................................149

9595

96

96 Sealing ring ........................................149

9696

97

97 Sleeve.................................................149

9797

98

98 Sapphire sleeve .................................149

9898

99

99 Sapphire sphere.................................149

9999

100

100 Ceramic holder...................................149

100100

101

101 Seal ....................................................149

101101

102

102 Screw nut ...........................................153

102102

103

103 Connection piece...............................153

103103

104

104 Suppressor rotor ................................153

104104

105

105 Suppressor holder .............................153

105105

VIII

792 Basic IC

Page 10

1.1 Instrument description

1 Introduction

1.1 Instrument description

2.792.0020 Basic IC with suppressor module

The

system for ion chromatographic analyses. The extremely compact

housing of the 792 Basic IC contains everything needed to carry out ion

chromatography at a high quality level:

is a PC-controlled

x Injection valve

x High-pressure pump

pump with a flow range from 0.2 } 2.5 mL/min and a maximum

pressure of 25 MPa (250 bar)

x Column chamber

not only thermally stable conditions for the separation column but

also shields the system against electromagnetic interference

x Columns

separation columns for cations or organic acids – the 792 Basic IC

can accommodate them all

x Suppressor

pressure-resistant, with fully automatic regeneration, highest performance and optimal reproducibility

x Peristaltic pump

flow rate of 0.5 } 0.6 mL/min for regeneration and rinsing of the

suppressor module

x Detector

stability. The detector temperature of 40 °C varies by less than

0.01°C.

– conductivity detector with outstanding temperature

– for individual injections

– extremely low-pulsation double piston

– the perfect insulation of the housing provides

– whether anion columns with or without suppression,

– integrated Metrohm Suppressor Module (MSM),

– integrated two-channel peristaltic pump with a

792 Basic IC

All components, which come into contact with eluent and sample are

metal-free.

operation of the

The

the RS232 interface with the help of the control and evaluation program

«792 Basic IC»

tems for recording and evaluating chromatograms and modify them if

need be. Time programs can also be created in which a large number

of instrument functions can be triggered for each program step.

792 Basic IC takes place via a PC connected to

. This PC program can be used to open prepared sys-

1

Page 11

1 Introduction

The operating software for the 792 Basic IC meets all the requirements

you could place today on a modern integration software: single or multipoint calibration, internal or external standard, selectable algorithms for

non-linear calibration, various integration modes with integration parameters and integration events, different methods for peak recognition,

peak editor, free scaling, superimposing several chromatograms, batch

reprocessing; a powerful and GLP-conform report generator with output

interfaces for monitor, printer and external databases.

792 Basic IC

2

Page 12

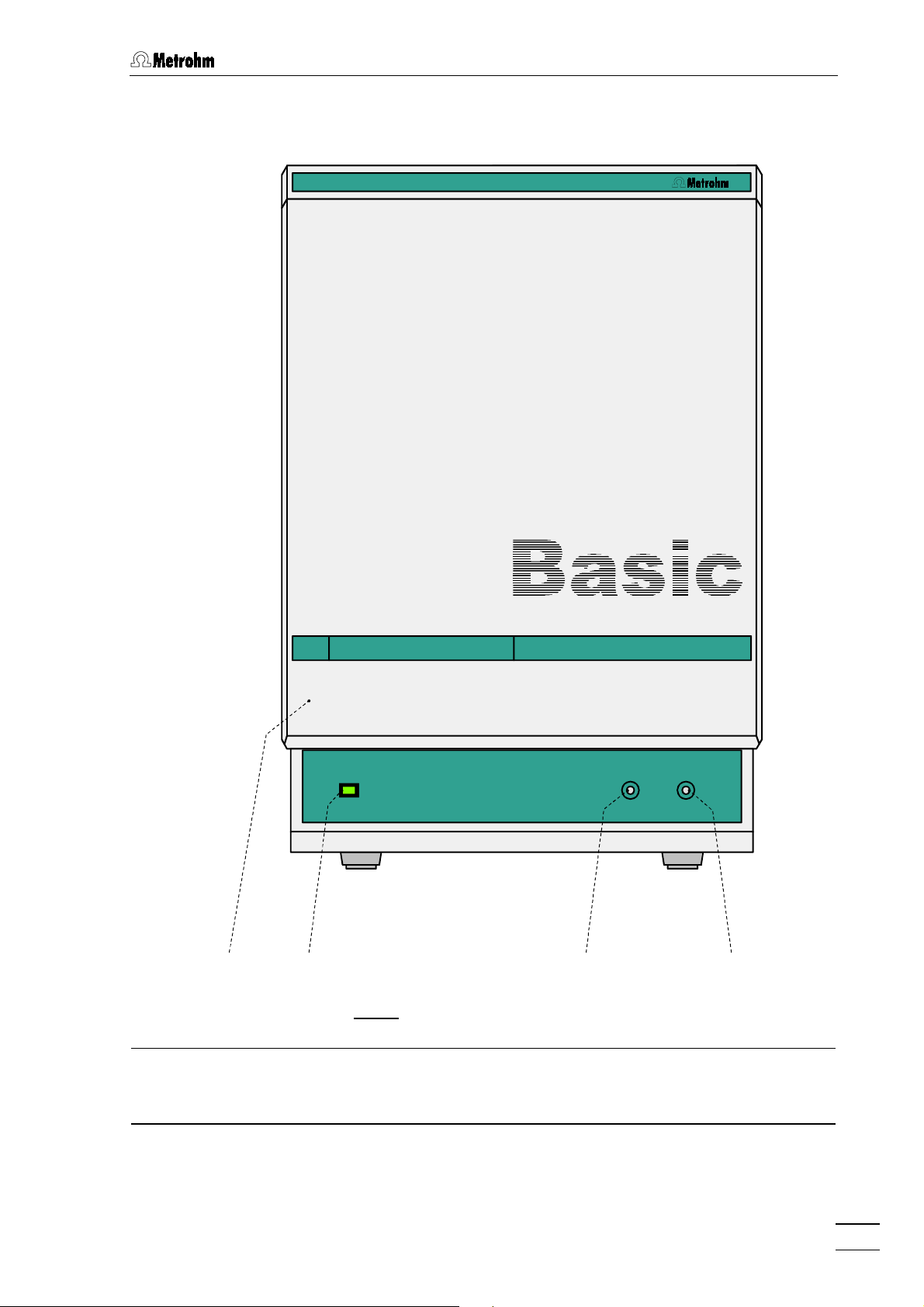

1.2 Parts and controls

1.2 Parts and controls

Basic I C792

Basic

Basic

BasicBasic

POWER

222211113

Fig. 1

: Front of the 792 Basic IC

34

33

4

44

Door to interior

1111

Mains pilot lamp

2222

lit up when instrument switched on

792 Basic IC

3333 Feedthrough for syringe tubing

for connection of the 6.2816.020 syringe

used für aspirating the sample

Feedthrough for aspirating tubing

4444

3

Page 13

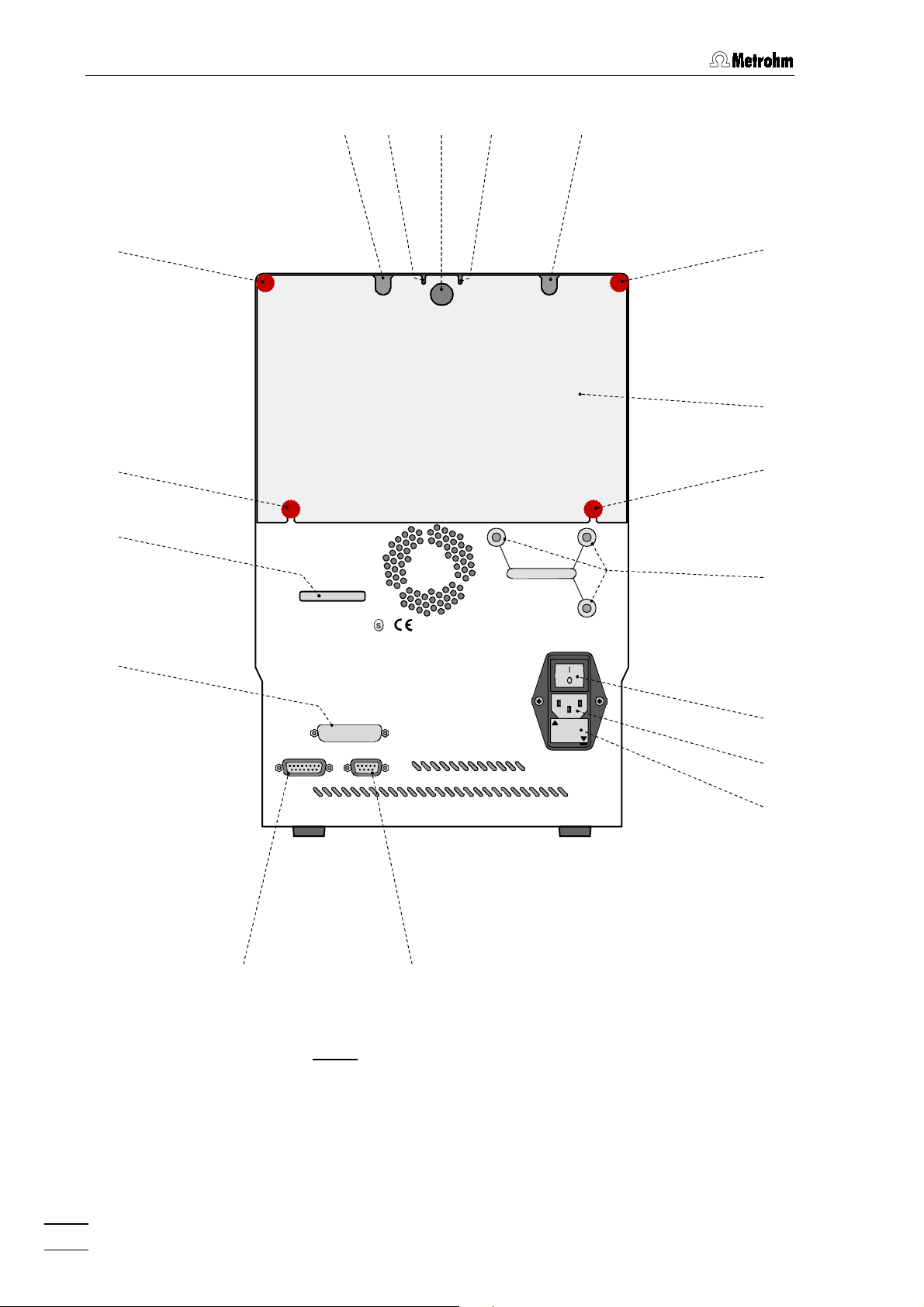

1 Introduction

8888

8888

17

17

1717

5555

Type

WARNING - Fire Hazard -

For conti nued protectio n replace only

with the sam e type and rating of fuse

66667

76

77

Waste B

Waste A

65

66

Transport security screws

5

55

8888

9999

8888

10

10

1010

16

16

1616

Service only

Detector Block

15

15 14

1515

RS 232

14

1414

: Rear of the 792 Basic IC

Fig. 2

f = 50-60 H z

S = 100 VA

Fuse

100-120V :

1,0A(T)

220-240V :

0,5A(T)

Made by Metrohm Herisau Switzerland

11

11

1111

12

12

1212

13

13

1313

792 Basic IC

4

Page 14

1.2 Parts and controls

Opening for detector cable

5555

Opening for outlet capillaries

6666

for discharge of eluent, regeneration

solution, and rinsing solution from the

inner compartment

Rear panel opening

7777

(closed with plastic stopper) for

additional supply and discharge lines to

and from the inner compartment

Knurled screw

8888

for fastening the rear panel

Detachable rear panel

9999

access to upper part of inner

compartment

10

10 Transport security screws

1010

to secure the pump head when the

instrument is transported

9999

12

12 Mains connection plug

1212

mains connection, see

13

13 Fuse holder

1313

changing the fuses, see

RS232 interface

14

14

1414

connection of the PC

15

15 Connection for detector block

1515

Connection

16

16

1616

To be used only for Metrohm Service!

Serial number

17

17

1717

section 2.4

section 2.4

Mains switch

11

11

1111

to switch instrument on and off:

I = ON 0 = OFF

792 Basic IC

5

Page 15

1 Introduction

38

38

3838

37

37

3737

36

36

3636

35

35

3535

34

34

3434

33

33

3333

32

32

3232

18

18

1818

19

19

1919

20

20

2020

21

21

2121

39

39

3939

1111

31

31

3131

30

30

3030

POWER

29

29

28

28 27

2929

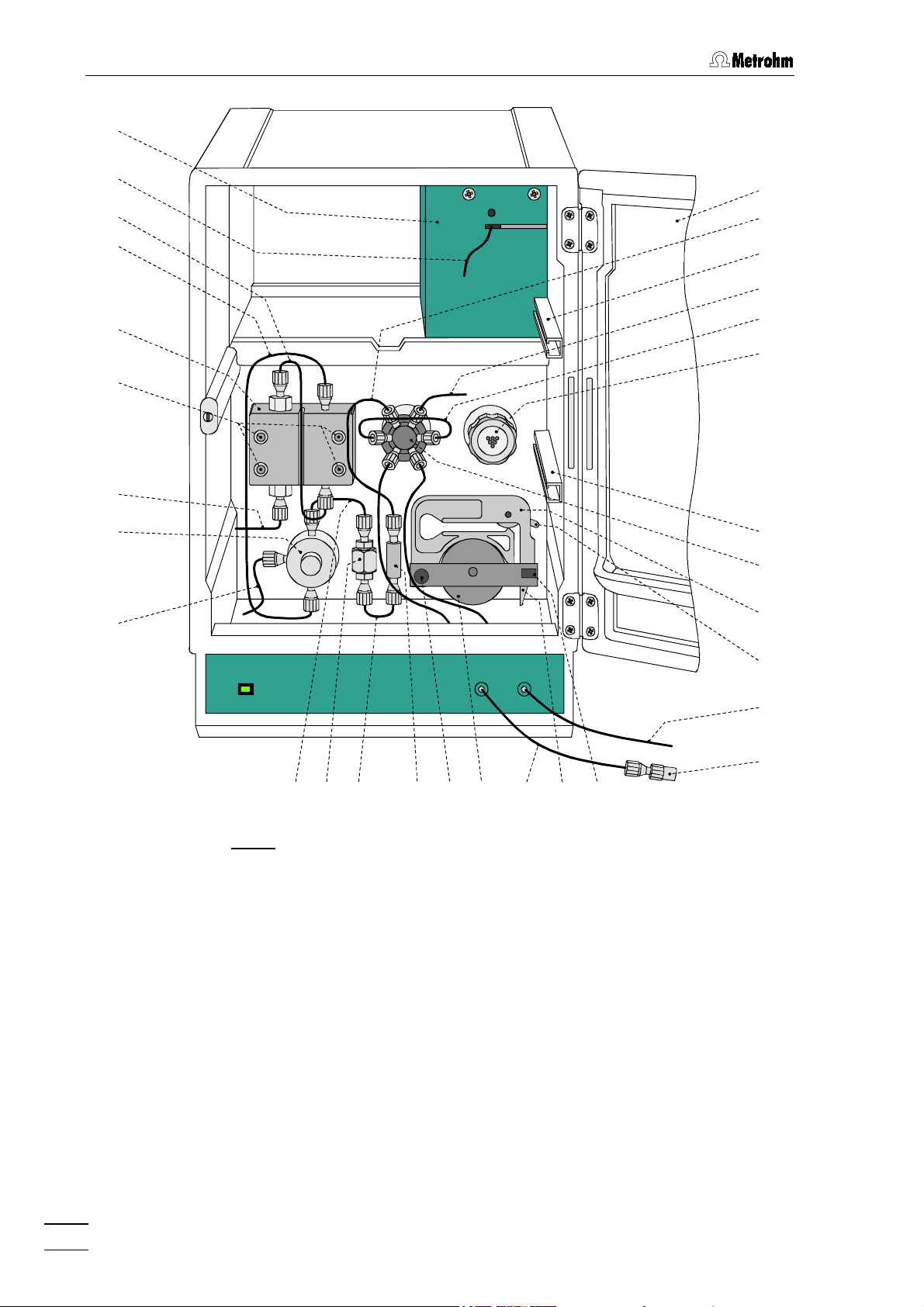

Fig. 3: Interior of the 792 Basic IC

27

2828

2727

(with permanently attached accessories and

1.733.0110 Detector block)

26

26

2626

45

45 44

44

4545

4444

25

25

2525

43

4343

42

4243

4242

19

19

1919

22

22

2222

40

40

4040

41

41

4141

23

23

2323

24

24

2424

792 Basic IC

6

Page 16

1.2 Parts and controls

Door to interior

1111

Inlet capillary for injector

18

18

1818

PEEK capillary,

length L = 24 cm

19

19 Mounting rail

1919

for 6.2027.0X0 column holder

Column connection capillary

20

20

2020

PEEK capillary,

length L = 30 cm

Sample loop 20 PPPPL

21

21

2121

6.1825.210 PEEK sample loop

Injection valve

22

22

2222

Aspirating tubing

23

23

2323

PTFE tubing for aspirating the sample;

length L = 65 cm

Aspirating capillary

32

32

3232

Connection for 6.1834.010 aspirating

tubing

Fastening screws

33

33

3333

for pump head

Pump head (6.2824.100)

34

34

3434

35

35 Connection capillary

3535

Connection pump head – purge

valve, fixed mounting

36

36 Connection capillary

3636

in pump head, fixed mounting

37

37 Inlet capillary for detector block

3737

PEEK capillary, fixed mounting

38

38 Detector block (1.732.0110)

3838

34

34

3434

Coupling (6.2744.120)

24

24

2424

for connection of the 6.2816.020 syringe

Syringe tubing

25

25

2525

PTFE tubing for connection of the

syringe,

length L = 35 cm

26

26 PEEK coupling (6.2744.040)

2626

27

27 Connection capillary

2727

PEEK capillary,

length L = 13 cm

28

28 Filter unit PEEK (6.2821.100) 43

2828

Connection capillary

29

29

2929

PEEK capillary,

length L = 13 cm

30

30 Connection capillary

3030

PTFE capillary for connection of the

6.2816.020 syringe,

length L = 70 cm

39

39 Suppressor module

3939

40

40 Tubing cartridge (6.2755.000)

4040

41

41 Contact pressure lever

4141

42

42 Holding clamp

4242

43 Snap-action lever

4343

44

44 Pump drive

4444

44445555 Mounting pin

(inlet and outlet capillaries are not

shown)

for 6.1826.060 pump tubing

for adjusting the contact pressure

for locking the tubing cartridge into

place

for releasing the tubing cartridge

roller head with contact rollers

for attaching the tubing cartridges

Purge valve

31

31

3131

792 Basic IC

7

Page 17

1 Introduction

1.3 Information on the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 792 Basic IC into operation. The Instructions for Use contain

information and warnings to which the user must pay attention in order

to assure safe operation of the instrument.

1.3.1 Organization

These

comprehensive overview of the installation, startup procedure, operation, fault rectification and technical specifications of this instrument.

The Instructions for Use are organized as follows:

To find the required information on the instruments, you will find it an

advantage to use either the

back.

8.792.1003 Instructions for Use

Section 1 Introduction

General description of instrument, parts and controls

and safety notes

Section 2 Installation

Installation of accessories and putting instrument into

operation

Section 3 Operating tutorial

Introduction to the operation using an example

Section 4 Operation

Detailed description of the operation

Section 5 Notes – Maintenance – Faults

Notes on ion chromatography, maintenance, fault rectification, diagnostic tests, validation

Section 6 Appendix

Technical data, standard equipment, options, warranty,

declarations of conformity, index

Table of contents

for the 792 Basic IC provide a

or the

Index

at the

As a supplement to the Instructions for Use, the

Monograph "Ion chromatography"

an introduction to the theoretical fundamentals and general information

on separating columns and sample pretreatment.

8.792.5003 Metrohm Monograph "Practical Ion Chromatog-

The

raphy"

tion to the basic principles of ion chromatography and also describes

22 experiments covering the whole world of ion chromatography.

The

tains all the

792 Basic IC

8

is a practical textbook, which provides an illustrative introduc-

8.732.2013 IC Applications Collection

Application Notes

on the subject of ion chromatography.

is also supplied. This provides

8.732.2003 Metrohm

is also supplied; this con-

Page 18

1.3 Information on the Instructions for Use

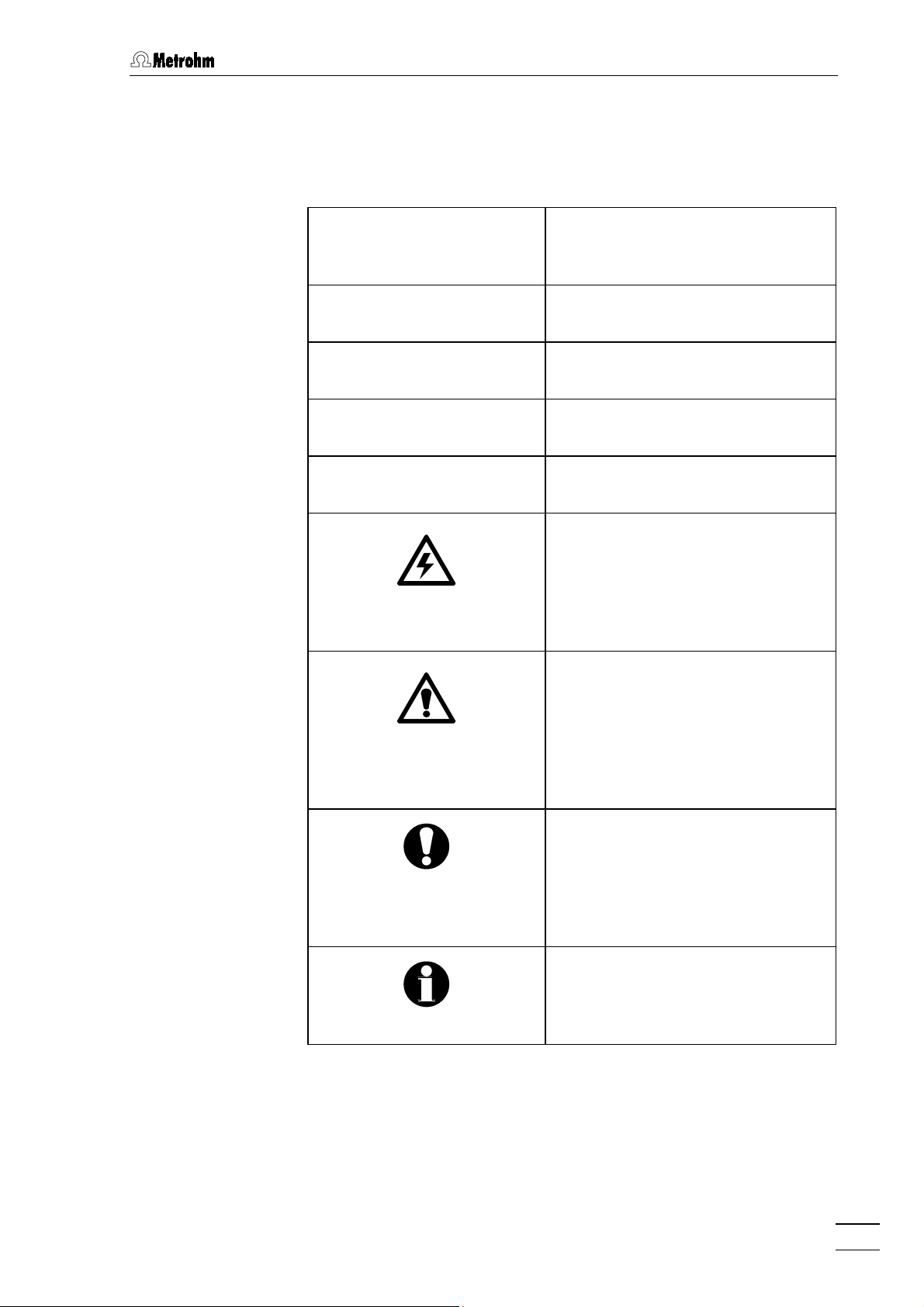

1.3.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these Instructions for Use:

Range

SYSTEM STATE

<OK>

[ Ctrl ]

35

35

3535

Menu item, parameter or entry

value

Program window

Button

Key

Part or control of 792

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

792 Basic IC

Caution

This symbol marks important

information. First read the associated directions before you continue.

Comment

This symbol marks additional

information and tips.

9

Page 19

1 Introduction

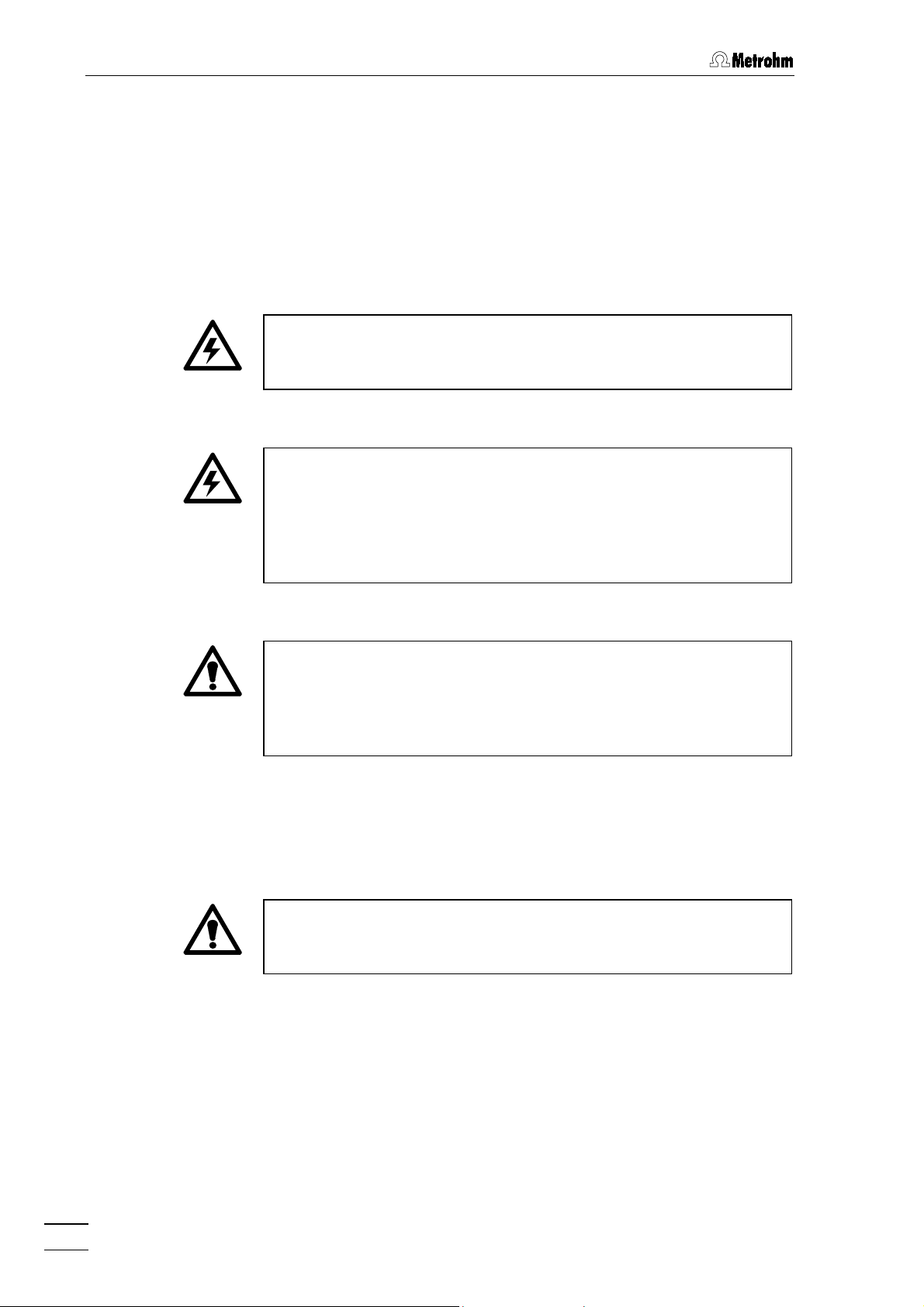

1.4 Safety notes

1.4.1 Electrical safety

While electrical safety in the handling of the 792 Basic IC is assured in

the context of the specifications IEC 1010-1 (protection class 1, degree

of protection IP20), the following points should be noted:

x Mains connection

Setting of the mains voltage, checking the mains fuse and the

mains connection must be effected in accordance with the instruc-

tions in section 2.4.

x Opening the 792 Basic IC

If the 792 Basic IC is connected to the power supply, the instrument

must not be opened nor must parts be removed from it, otherwise

there is a danger of coming into contact with components which are

live. Hence, always disconnect the instrument from all voltage sources

before you open it and ensure that the mains cable is discon-

nected from mains connection 12

x Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 792 Basic IC, you should earth yourself and any tools you

are using by touching an earthed object (e.g. housing of the instrument or a radiator) to eliminate any static charges which exist..

12 !

1212

1.4.2 General precautionary rules

x Handling of solvents

Check all lines of the IC system periodically for possible leaks. Follow

the relevant instructions regarding the handling of flammable and/or

toxic solvents and their disposal.

792 Basic IC

10

Page 20

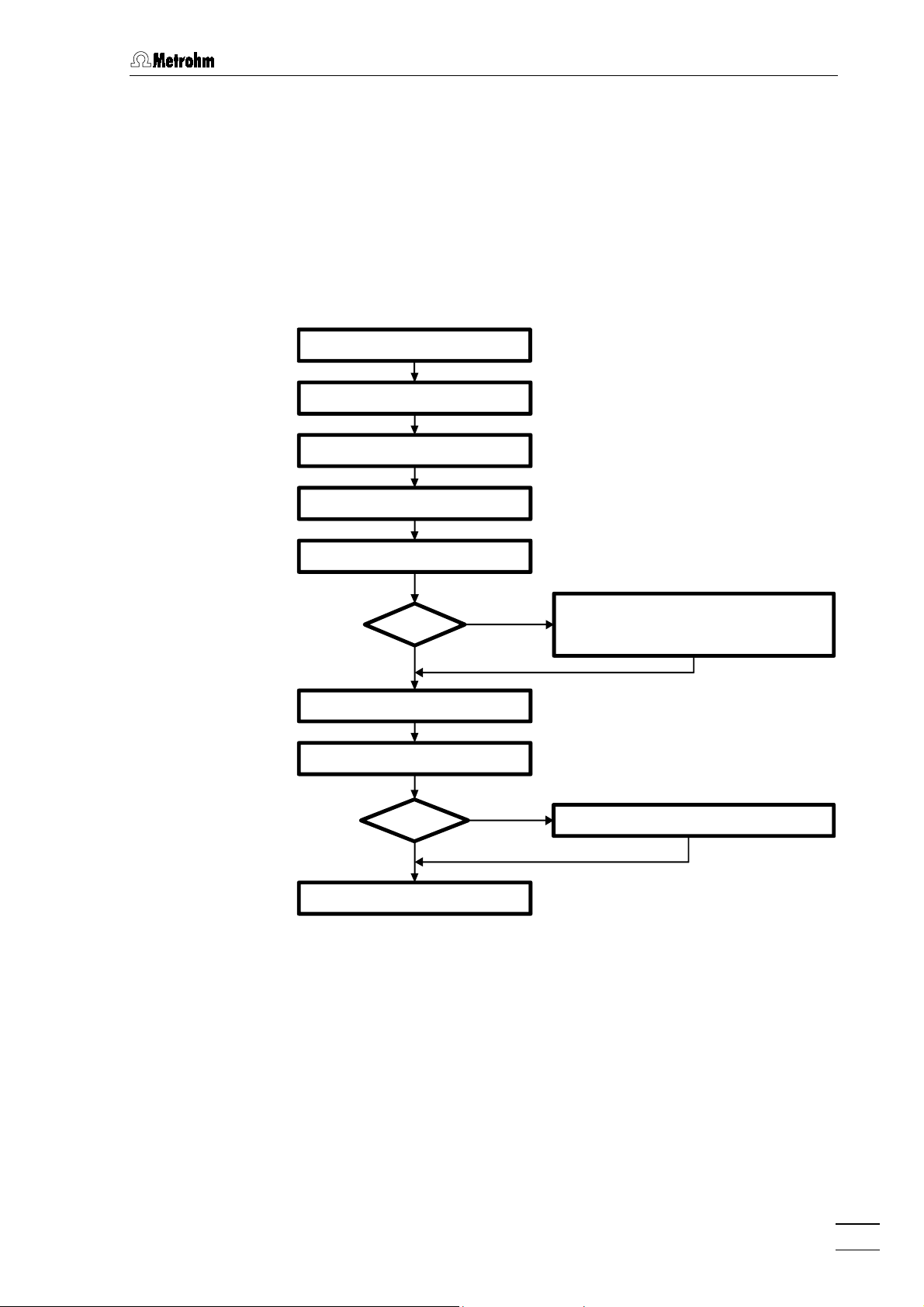

2.1 Overview

2 Installation

2.1 Overview

2.1.1 Flow chart

The following flow chart provides an overview of all installation work. You

will find more detailed information in the relevant sections.

Setting up

Setting up sect. 2.2

Setting upSetting up

Installing accessories

Installing accessories sect. 2.3

Installing accessoriesInstalling accessories

Mains connection

Mains connection sect. 2.4

Mains connectionMains connection

Connecting PC

Connecting PC sect. 2.5

Connecting PCConnecting PC

sect. 2.2

sect. 2.2sect. 2.2

sect. 2.3

sect. 2.3sect. 2.3

sect. 2.4

sect. 2.4sect. 2.4

sect. 2.5

sect. 2.5sect. 2.5

Connecting high pr. pump

Connecting high pr. pump sect 2.6

Connecting high pr. pumpConnecting high pr. pump

Precolumn

Precolumn

PrecolumnPrecolumn

No

No

NoNo

Installing sample loop

Installing sample loop sect. 2.7.6

Installing sample loopInstalling sample loop

Connecting column

Connecting column sect. 2.7.7/8

Connecting columnConnecting column

Suppressor

Suppressor Connecting suppressor module

SuppressorSuppressor

No

No

NoNo

Conditioning

Conditioning sect. 2.9

ConditioningConditioning

sect 2.6

sect 2.6sect 2.6

Yes

Yes

YesYes

sect. 2.7.6

sect. 2.7.6sect. 2.7.6

sect. 2.7.7/8

sect. 2.7.7/8sect. 2.7.7/8

Yes

Yes

YesYes

sect. 2.9

sect. 2.9sect. 2.9

Precolumn with twin cartridge holder

Precolumn with twin cartridge holder sect. 2.7.2

Precolumn with twin cartridge holderPrecolumn with twin cartridge holder

Precolumn cat. with cartr. holder

Precolumn cat. with cartr. holder sect. 2.7.3

Precolumn cat. with cartr. holderPrecolumn cat. with cartr. holder

IC anion precolumn SUPERSEP

IC anion precolumn SUPERSEP sect. 2.7.4

IC anion precolumn SUPERSEPIC anion precolumn SUPERSEP

Connecting suppressor module sect. 2.8

Connecting suppressor moduleConnecting suppressor module

sect. 2.7.2

sect. 2.7.2sect. 2.7.2

sect. 2.7.3

sect. 2.7.3sect. 2.7.3

sect. 2.7.4

sect. 2.7.4sect. 2.7.4

sect. 2.8

sect. 2.8sect. 2.8

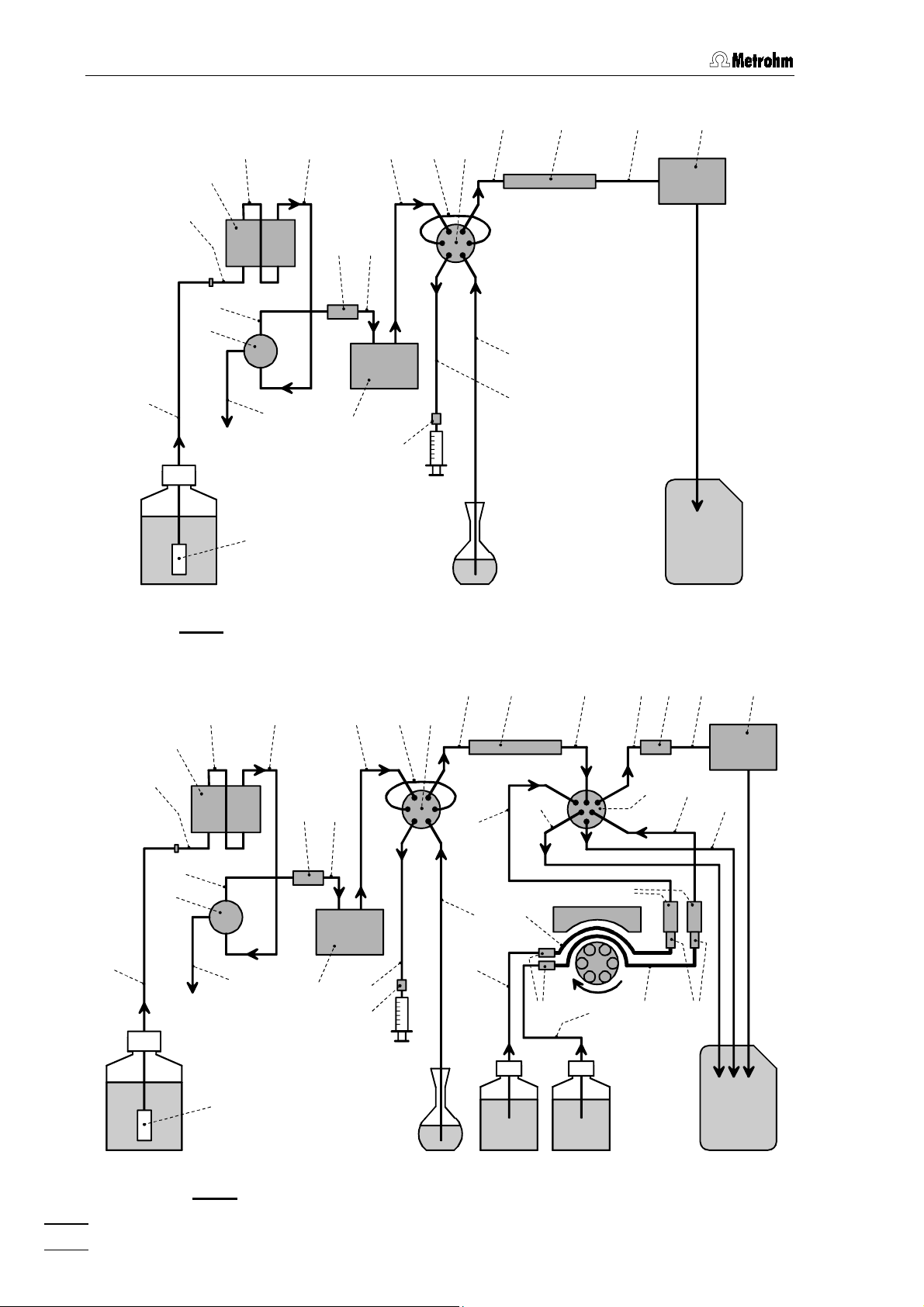

2.1.2 Connections in the 792 Basic IC

The two following illustrations show the internal connections in the 792

Basic IC in schematic form. The meanings of the various numbered

components are given in the detailed illustrations and descriptions in

ections 2.2 – 2.9

s

792 Basic IC

.

11

Page 21

2 Installation

20

32

32

3232

31

31

3131

34

34

3434

29

29

2929

36

36 35

3636

35

3535

28

28 27

27

2828

2727

18

18 21

21 22

1818

2121

20 66

2020

22

2222

Injection valve

Column

23

23

2323

66 37

6666

37 38

3737

38

3838

Detector

6.1834.010

32

32

3232

30

30

3030

6.2821.090

Eluent

Fig. 4:

36

36 35

3636

34

34

3434

Connecting diagram for 792 Basic IC without suppressor

35

3535

28

28

2828

52

52

5252

18

18 21

1818

27

27

2727

24

24

2424

21 22

2121

22

2222

20

20 66

2020

78

78

7878

25

25

2525

Sample

66 75

6666

Column

80

80

8080

Waste

75

7575

76

76 26

26 37

7676

2626

39

39

3939

37 38

3737

Detector

77

77

7777

79

79

7979

38

3838

29

29

2929

28

28

H2O

68

68

6868

2828

72

7272

74

74

7474

31

31

3131

6.1834.010

12

30

30

3030

6.2821.090

Eluent

792 Basic IC

: Connecting diagram for 792 Basic IC with suppressor

Fig. 5

52

52

5252

25

25

2525

24

24

2424

Sample

69

69

6969

23

23

2323

71

71

7171

70

70 72

7070

H2SO

4

Waste

Page 22

2.2 Setting up the instrument

2.2 Setting up the instrument

2.2.1 Packaging

The 792 Basic IC is supplied together with the separately packed

accessories in special packagings containing shock-absorbing foam

linings designed to provide excellent protection. The instrument itself is

packed in an evacuated polyethylene bag to prevent the ingress of

dust. Please store all these special packagings as only they assure

transport of the instrument free from damage.

2.2.2 Check

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in

instructions in

2.2.3 Location

section 6.2

section 6.4.1

). In the case of transport damage, see

"Warranty".

Position the instrument in the laboratory at a location convenient for operation, free from vibrations and protected against a corrosive atmosphere and contamination by chemicals.

To avoid disturbing temperature influences on the insulated column

compartment, the instrument must be protected against direct

sunlight.

2.3 Attaching the accessories

2.3.1 Connection of detector block

The metal-free

livery of the 792 Basic IC; it must be inserted in the instrument and connected up. Proceed as follows:

1 Note the cell constant

x

1.732.0110 Detector block

The cell constant

detector block. Note this value; it must subsequently be entered in the software in order to ensure that an exact display

of the conductivity is obtained (see

c = XX,X /cm

belongs to the scope of de-

is printed on the rear of the

section 2.5.3

).

792 Basic IC

2 Install detector block

x

Unscrew the four knurled screws

of the 792 Basic IC and remove rear panel (see

x

Position detector block

vided in the 792 Basic IC and push fully to the front (see

3

).

8888

from the top rear panel

Fig. 2

38

38

from the back in the space pro-

3838

).

9999

Fig.

13

Page 23

2 Installation

x

Insert the cable permanently attached to the detector block

38

38

in one of the openings

3838

the openings

x

Replace rear panel

four knurled screws

3 Connect detector block

x

Plug the gray connecting cable permanently attached to the

detector block

792 Basic IC and fasten to the instrument by tightening the

screws in the cable connector (see

4 Connect waste container

x

Lead the outlet capillary of the detector block

ciently large waste container and fix in place.

7777

of the rear panel

9999

38

38

into connection

3838

5555

and the outlet capillary in one of

9999

.

and screw to the 792 Basic IC using the

8888

.

15

15

"Detector Block" of the

1515

Fig. 2

).

38

38

to a suffi-

3838

2.3.2 Connection of syringe and aspirating tubing

22

For manual filling of the sample loop

the 6.2816.020 Syringe, the syringe tubing

23

PTFE aspirating tubing

as follows:

1 Connect syringe to syringe tubing

x

Pull syringe tubing

hand out of feedthrough

x

Mount a PEEK compression fitting

the end of the syringe tubing

(6.2744.120) to the compression fitting

x

Push 6.2816.020 Syringe (without needle) as far as it will go

into the connection of coupling

2 Install aspirating tubing

x

Pull aspirating tubing

hand out of feedthrough

23

are needed. These accessories are mounted

2323

25

25

2525

22

mounted on the injection valve,

2222

25

25

with coupling

2525

connected to injection valve

3333

as far as desired (see

46

46

(see

4646

25

25

and screw the coupling

2525

24

24

.

2424

23

23

connected to injection valve

2323

4444

as far as desired (see

section 2.3.4

46

46

.

4646

24

24

2424

22

22

2222

Fig. 3

Fig. 3

and the

by

).

) to

24

24

2424

22

22

by

2222

).

2.3.3 Connection of the 6.5324.000 Bottle rack (option)

The optional available 6.5324.000 Bottle rack for supply vessels can be

placed on top of the 792 Basic IC. The accessories include the supply

vessels for eluent (2 L), regeneration solution (1 L) and rinsing solution

(1 L).

792 Basic IC

14

Page 24

2.3 Attaching the accessories

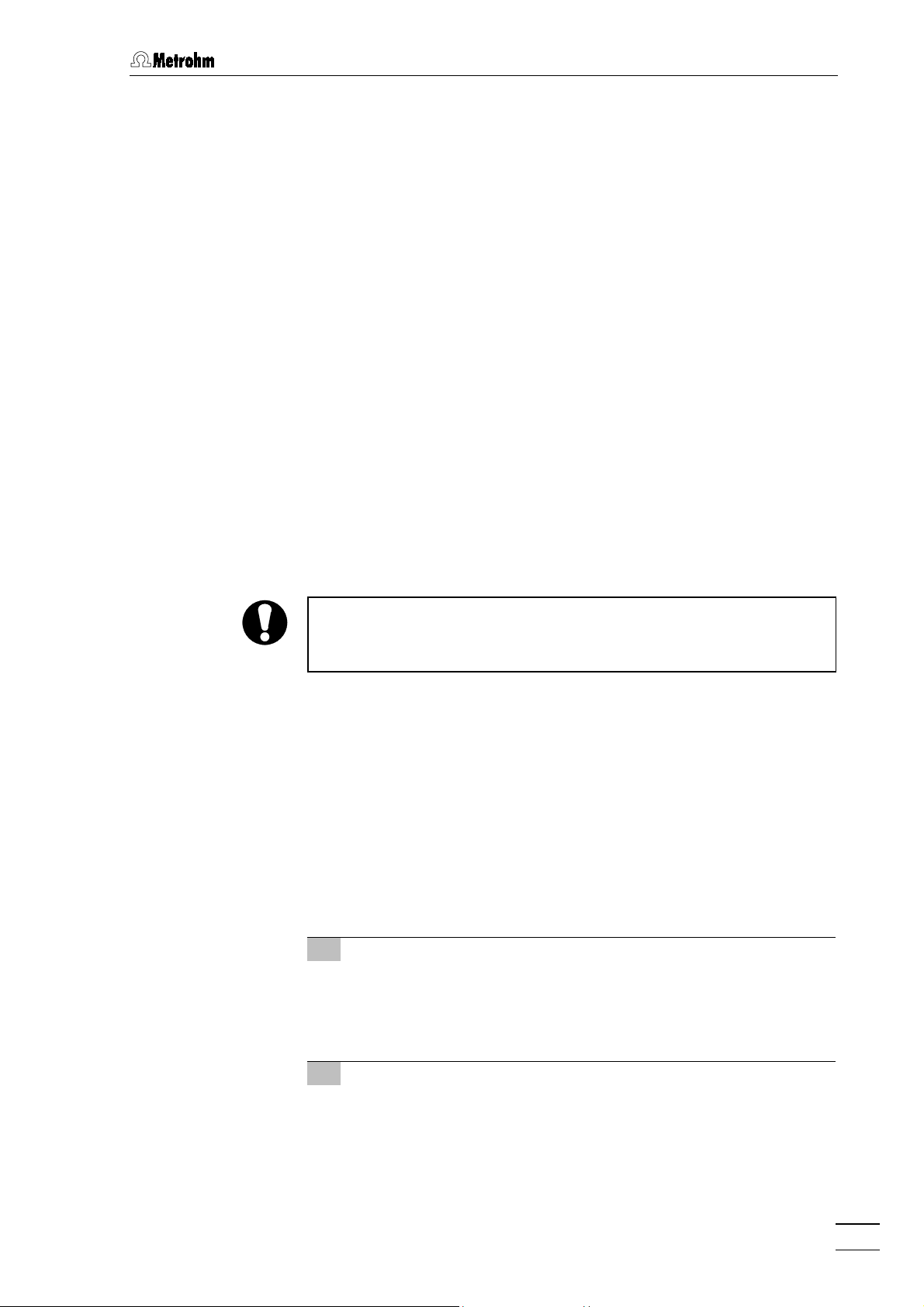

2.3.4 Connection of PEEK capillaries

For the connections between high-pressure pump and detector block

6.1831.010 PEEK capillaries

which are connected using either

tings (long)

These PEEK connectors can also be used to connect 6.1822.010 PTFE

microcapillaries (i.d. = 0.3 mm). Proceed as follows:

Capillaries fitted with new connectors must have a perfectly flat cut

surface. To cut PEEK or PTFE capillaries it is best to use the

6.2621.080 Capillary tubing cutter.

1 Mount compression fitting

Slide a compression fitting

fitting

fastened as shown in

2 Insert capillary in connection

Push capillary end in the corresponding connection as far as it

will go (to avoid dead volume).

6.2744.070 PEEK compression fittings (short)

or

47

47

(6.2744.070) over the end of the capillary

4747

(i.d. = 0.25 mm, e.d. =

6.2744.010 PEEK compression fit-

46

46

(6.2744.010) or a compression

4646

Fig. 6

.

1

16

"

/

) are used

48

48

to be

4848

.

46

46 48

4646

Fig. 6

: Connectors for capillaries

48 47

4848

3 Tighten compression fitting

46

46

47

Tighten compression fitting

47

4747

46

46

4646

47

47

4747

48

48

4848

47

or

4646

4747

Compression fitting

(6.2744.010)

Compression fitting

(6.2744.070)

Capillary

6.1831.010 PEEK capillary or

6.1822.010 PTFE microcapillary

by hand (never use tools).

792 Basic IC

15

Page 25

2 Installation

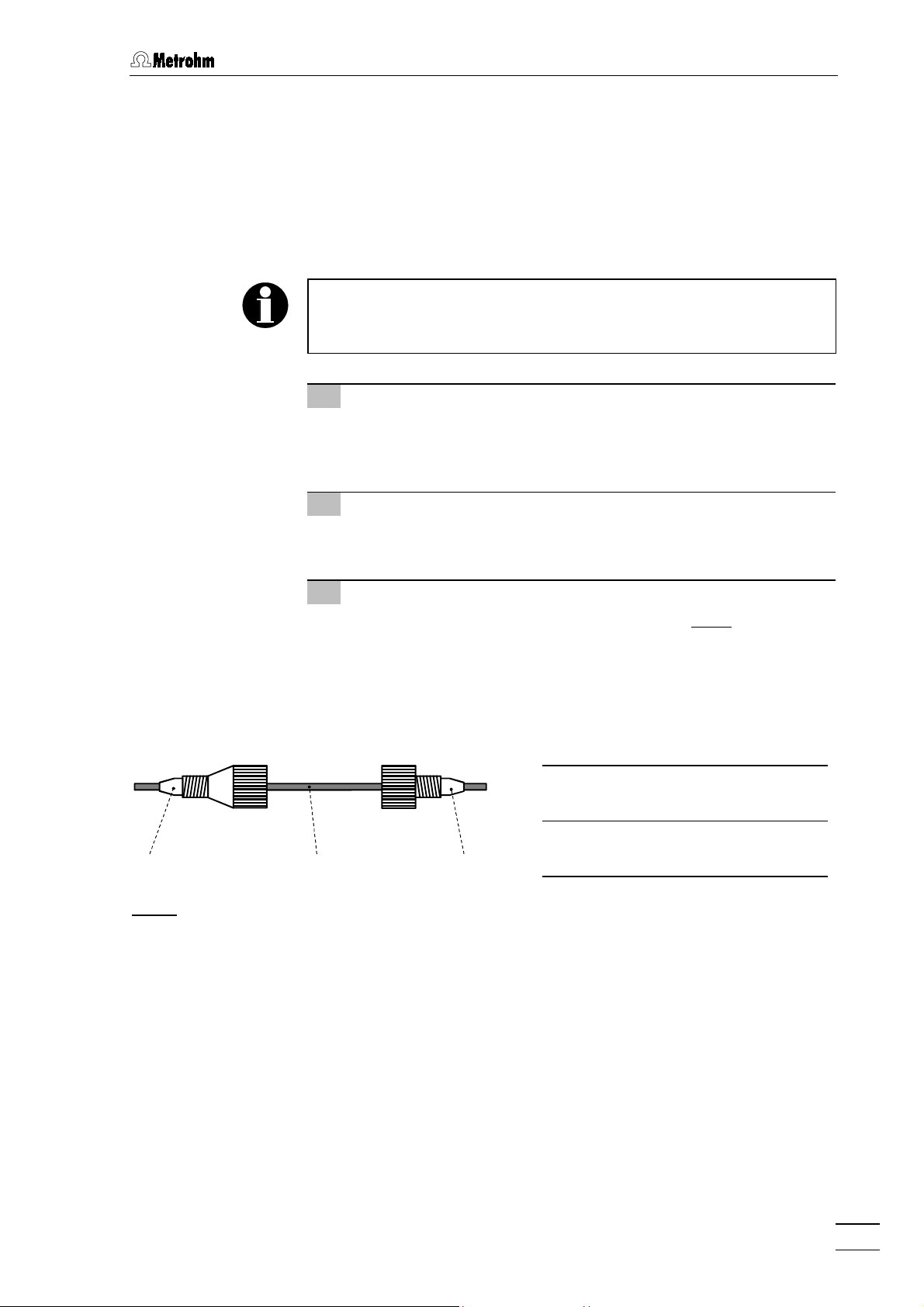

2.3.5 Filter unit PEEK

6.2821.100 Filter unit PEEK

One

tween the high-pressure pump and the injection valve

sic IC. This filter unit serves to avoid contamination by abrasive particles

of the piston seals.

The two other filter units PEEK supplied with the 792 Basic IC are installed between the pump tubings of the peristaltic pump and the inlet

capillaries for regeneration and rinsing solution (see

These filter units serve to protect the suppressor module from foreign

particles and bacterial growth.

28

The Filter unit PEEK

49

49

tors

For the connection of capillaries

(6.2744.010) or

filter are available as an option with the ordering number 6.2821.110

(set of 10).

(with filter) and

4949

For the connection of the filter unit, please note the flow direction

arrow printed on the housing.

28

consists of the housing

2828

51

51

(without filter) screwed into the housing

5151

47

47

(6.2744.070) must be used. New connectors

4747

28

28

2828

Fig. 7

(see

48

48

, PEEK compression fittings

4848

) is already installed be-

22

22

at the 792 Ba-

2222

section 2.8.2

50

50

and the two connec-

5050

49

49

4949

).

50

50

5050

46

46

4646

with

.

48

48 46

4848

Filter unit PEEK (6.2821.100)

28

28

2828

Compression fitting (6.2744.010)

46

46

4646

Capillary

48

48

4848

6.1831.010 PEEK capillary or

6.1822.010 PTFE microcapillary

792 Basic IC

16

46 49

4646

49 50

4949

: 6.2821.100 Filter unit PEEK

Fig. 7

50 51

5050

Connector with filter (6.2821.110)

49

49

4949

Part of 6.2821.100 Filter unit

50

Housing for filter unit

50

5050

Part of 6.2821.100 Filter unit

Connector without filter

51

51

5151

Part of 6.2821.100 Filter unit

51 46

5151

46 48

4646

48

4848

Page 26

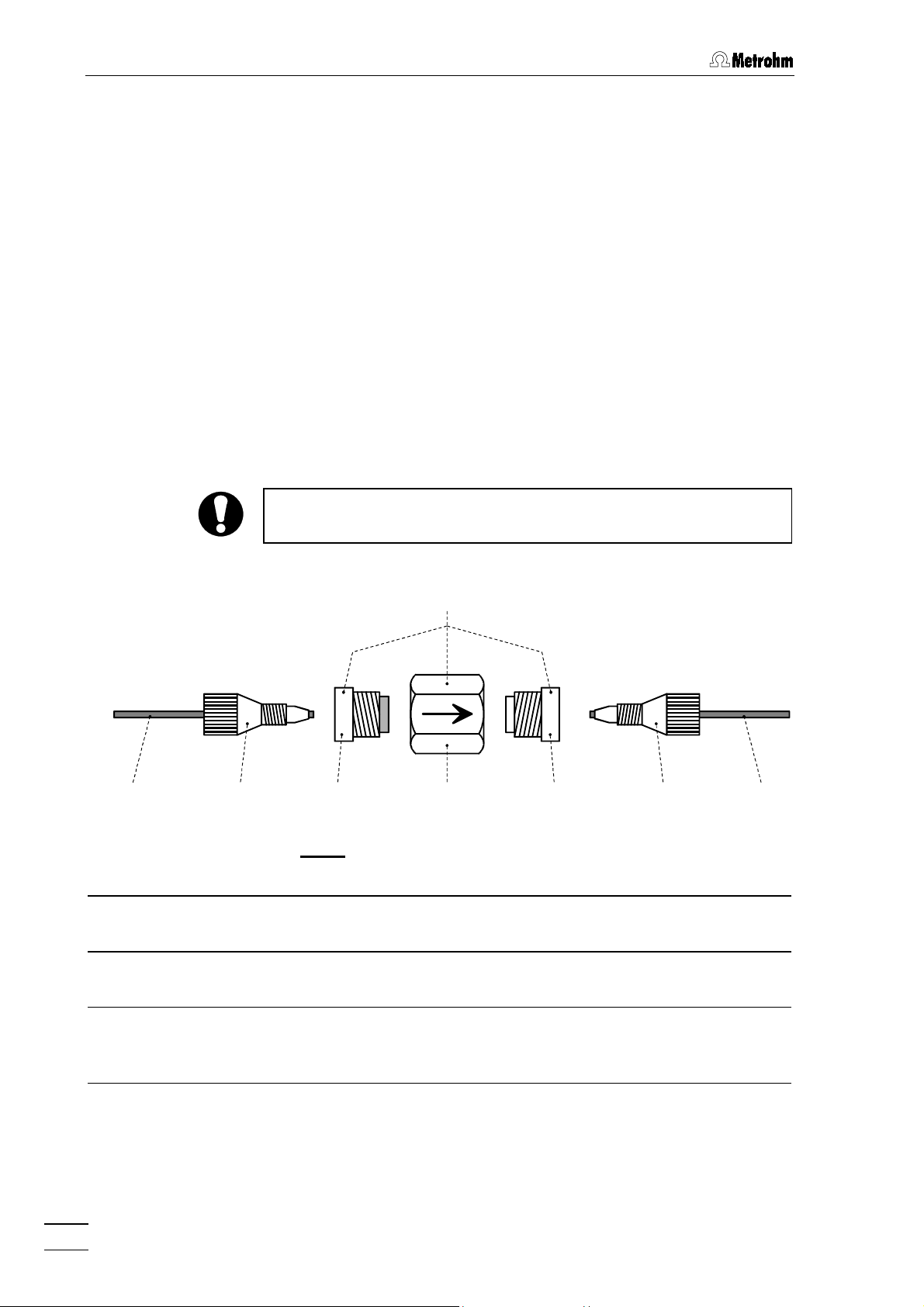

2.4 Mains connection

2.4 Mains connection

Follow the instructions below for connecting to the power supply. If

the instrument is operated with a mains voltage set wrongly and/or

wrong mains fuse, there is a danger of fire!

2.4.1 Setting the mains voltage

Before switching on the 792 Basic IC for the first time, check that the

mains voltage set on the instrument (see

mains voltage. If this is not

on the instrument as follows:

1 Disconnect mains cable

Disconnect mains cable from mains connection plug

792 Basic IC.

the case, you must reset the mains voltage

Fig. 8

) matches the local

12

12

1212

of the

2 Remove fuse holder

13

Using a screwdriver, loosen fuse holder

12

connection plug

3 Check and change fuse if necessary

Carefully take the fuse installed for the desired mains voltage out

of fuse holder

fuse in the fuse holder is marked by the white arrow imprinted

next to the mains voltage range):

100}}}}120 V 1.0 A (slow-blow)

220}}}}240 V 0.5 A (slow-blow)

4 Insert fuse

Change fuse if necessary and reinsert in fuse holder

5 Install fuse holder

Depending on the desired mains voltage, insert fuse holder

the 792 Basic IC so that the corresponding mains voltage range

can be read normally and the adjacent white arrow points to the

white bar imprinted below the fuse holder (see

12

and take out completely.

1212

13

13

and check its specifications (the position of the

1313

13

below the mains

1313

Metrohm No. U.600.0016

Metrohm No. U.600.0013

13

13

1313

Fig. 8

).

.

13

13

in

1313

792 Basic IC

17

Page 27

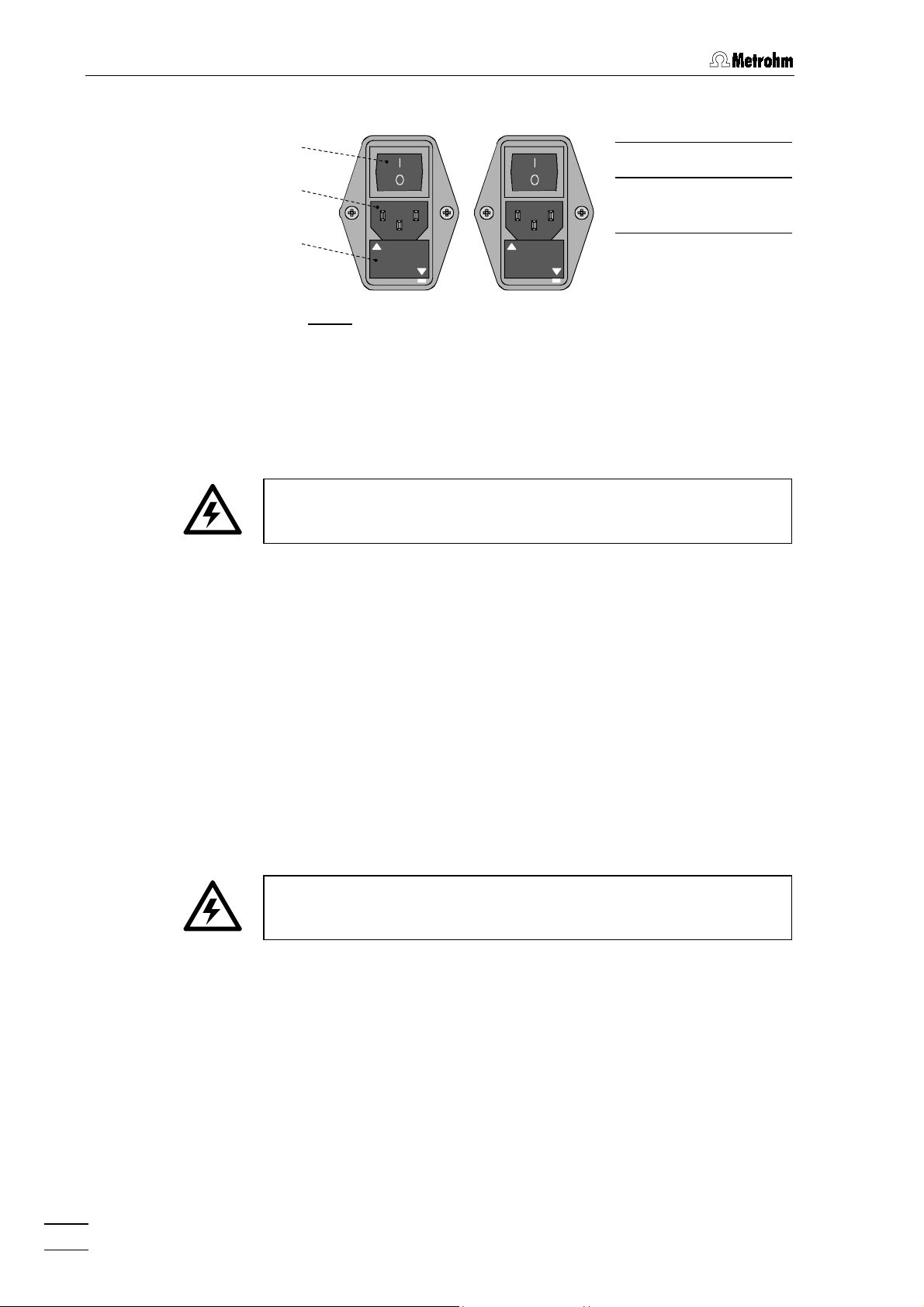

2 Installation

2.4.2 Fuses

100 – 120 V

Mains switch

11

11

1111

Mains connec-

12

12

1212

11

11

1111

12

12

1212

220 – 240 V

tion plug

220

240 V

100

----

120 V

----

13

13 Fuse holder

1313

13

13

1313

220

----

240 V

100

120 V

----

Fig. 8

: Setting the mains voltage

One of the two fuses 1 A/slow-blow for 100}120 V or 0.5 A/slow-blow

13

for 220}240 V is installed in fuse holder

13

of the 792 Basic IC as

1313

standard.

Ensure that the instrument is never put into operation with fuses of

another type, otherwise there is danger of fire!

For checking or changing fuses, process as described in

2.4.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables

x

6.2122.020 with plug SEV 12 (Switzerland, })

x

6.2122.040 with plug CEE(7), VII (Germany, })

x

6.2133.070 with plug NEMA 5-15 (USA, })

which are three-cored and fitted with a plug with an earthing pin. If a different plug has to be fitted, the yellow/green lead (IEC standard) must

be connected to protective earth (protection class 1).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Mains connection

Plug the mains cable into mains connection plug

Fig. 8

(see

).

section 2.4.1

12

12

of the 792 Basic IC

1212

.

2.4.4 On/off switching of the instrument

The 792 Basic IC is switched on and off using mains switch

the instrument is switched on, the mains pilot lamp

792 Basic IC

18

2222

lights up.

11

11

. When

1111

Page 28

2.5 Connection to the PC

2.5 Connection to the PC

2.5.1 Connecting cable

Always switch off 792 Basic IC and PC before you connect the two

instruments with the 6.2134.100 Cable.

14

Connect the RS232 interface

COM ports at the PC using the 6.2134.100 Cable (9 pin/9 pin). If only a

25-pin COM interface is available on the PC then the optionally available 6.2125.110 Cable (9 pin/25 pin) or a commercially available

adapter must be used.

2.5.2 Software installation

14

at the 792 Basic IC to one of the serial

1414

The PC program

«792 Basic IC 1.0»

is required for the operation of

the 792 Basic IC; this is contained on the 6.6045.003 CD included in the

accessories. This program runs under Windows 95, Windows 98, Windows NT and Windows 2000 operating systems and is installed as follows:

1 Install program

x

Insert 6.6045.003 Installation CD into CD drive.

x

Select

<Start>

installation CD and click on

x

Click on "

792

and

Run

. Browse for the

<OK>

.

setup.exe

file on the

" and follow the instructions given in the setup

program.

The software package will be installed in the desired direc-

tory. In addition to the program files, the following folders are

installed:

Data

Folder for storage of chromatogram files

Devices

Methods

Reports

Systems

*.chw

) and batch reprocessing files (

(

Folder for storage of device files (

Folder for storage of method files (

Folder for storage of report files (

*.wmf

and graphic files (

)

Folder with subfolders with system files

*.smt

).

(

*.dev

*.mtw

*.txt

*.bar

)

)

)

)

792 Basic IC

2 Registrierung

x

Please send us your 8.792.8007 Registration card as soon as

possible. Only registered users will get updated program versions at a special price.

19

Page 29

2 Installation

2.5.3 Basic settings

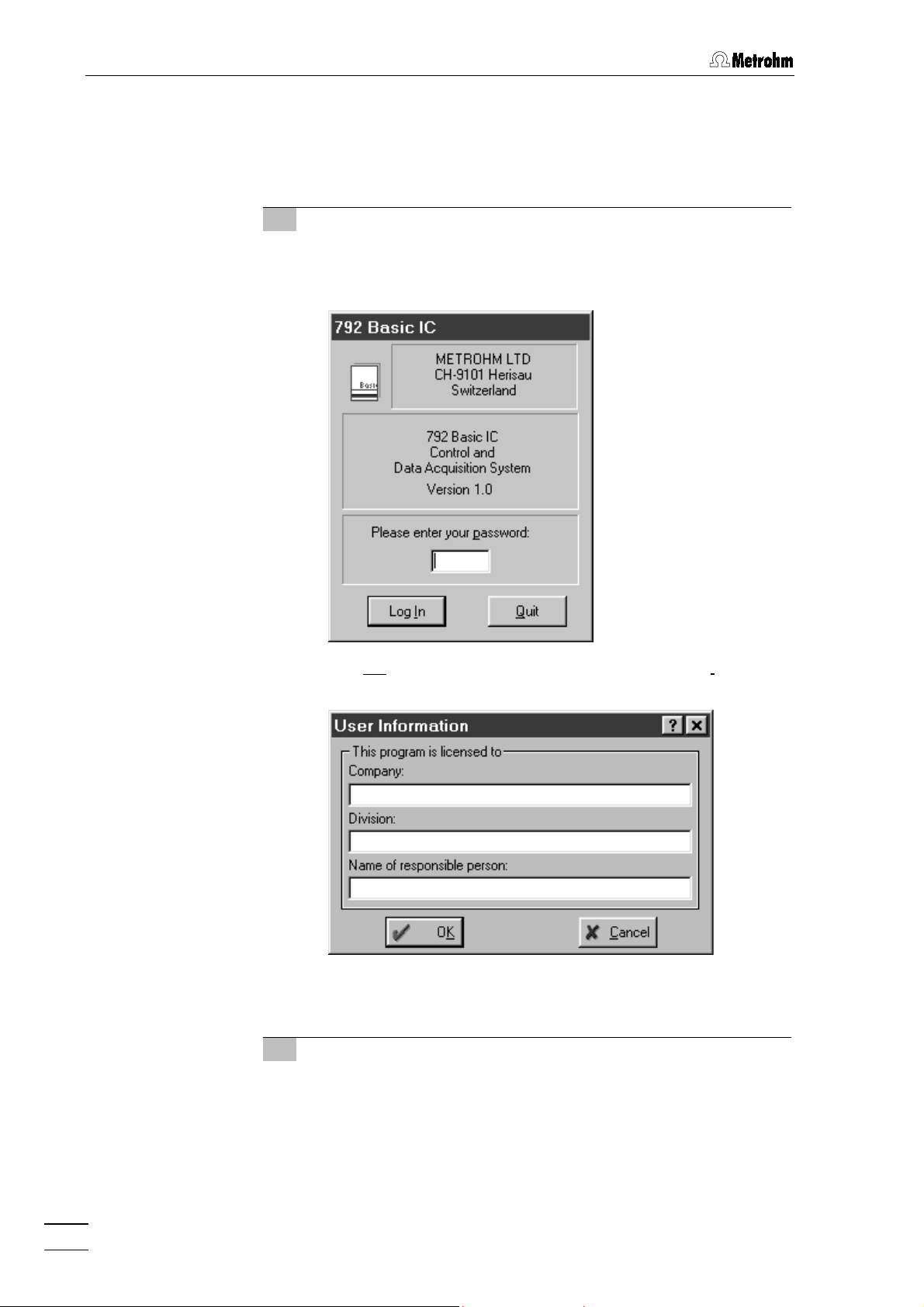

When the program is started for the first time several basic settings

must be made for the 792 Basic IC. Proceed as follows:

1 Start program

x

Double-click the software icon to start the program. The

program window with the opening picture is opened and the

Log In window appears on the screen:

x

Do not

enter any password here, just click on

<Log In>

following window appears:

x

Enter company, division and name and click on

<OK>

window appears only one time after software installation.

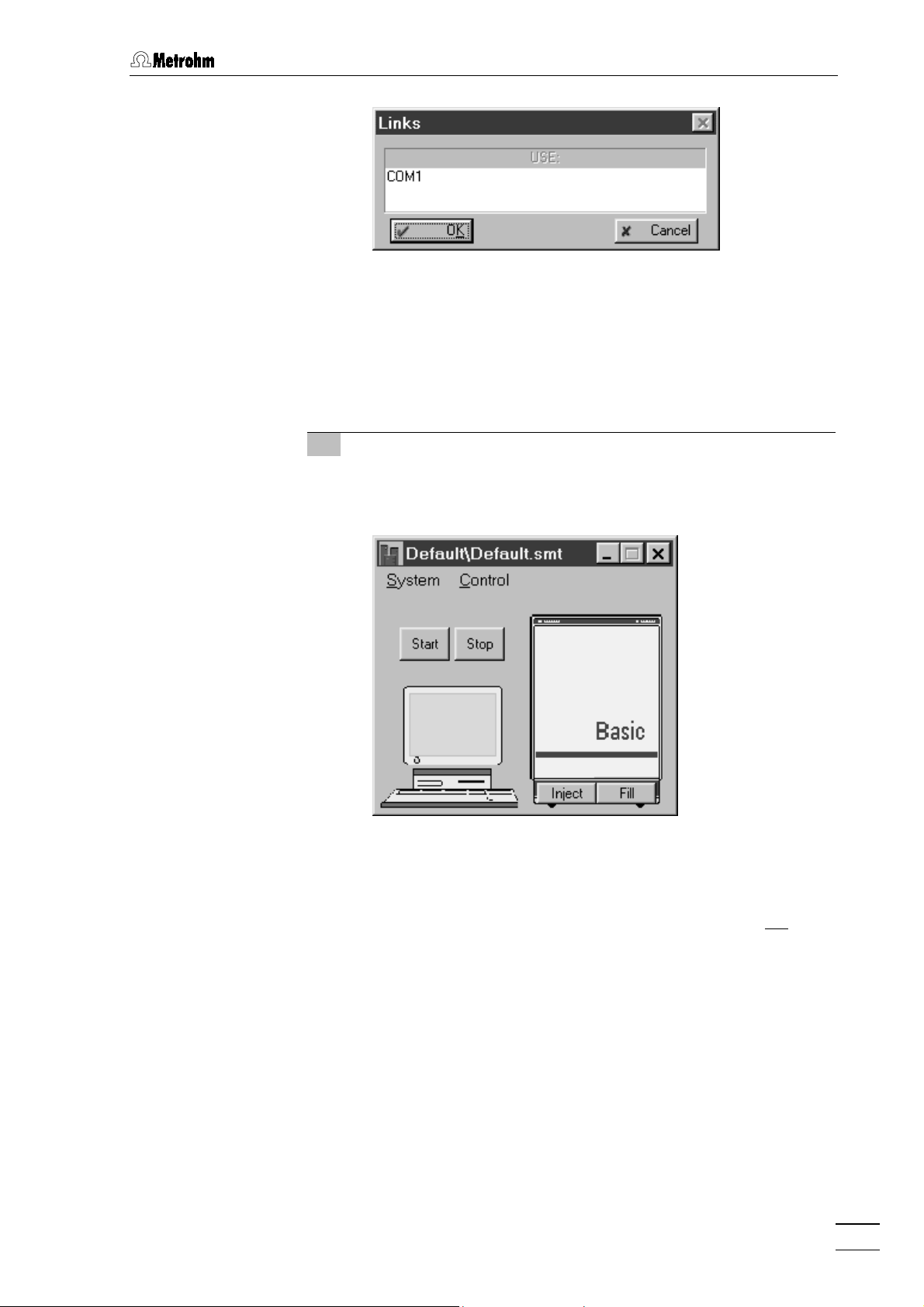

2 COM port settings

This step must only be carried out if a different COM interface

from COM1 is used for connection to the 792 Basic IC.

x

Click on

Options / 792 Basic IC:COM1

to open the

Links

. The

. This

window:

792 Basic IC

20

Page 30

2.5 Connection to the PC

x

Click on

Change

COM1

menu item to open a window listing all available COM

ports at the PC.

x

Select the desired COM port to which the 792 Basic IC has

been connected and click on

x

Close the

Links

3 Open a system

x

Click on

folder

<Open>

File / Open / System

Default

. Select the system file

. The corresponding system window is opened:

using the right mouse button and select the

<OK>

. The window is closed.

window by clicking on

<OK>

.

in the main window. Open the

Default.smt

and click on

792 Basic IC

x

If the connection between PC and 792 Basic IC is working the

message

'#####' not found! Create?

create the configuration file

x

If the connection between PC and Personal IC does not

then the message

COM# ]]

Hardware settings file for 792 unit with serial number

will appear. Click

#####.792

Detection of hardware failed[792 Basic IC [

appears in the

SYSTEM STATE

<Yes>

in order to

for this instrument.

window. In this case

check whether the instrument has been switched on, whether

the connection cable is connected up properly and whether

the COM interface has been set correctly (see point 2). Then

repeat point 3.

work

21

Page 31

2 Installation

4 Hardware settings

Of the general hardware settings only the input of the cell constant

is described. Standard settings can normally be used for all other

parameters.

x

Click the 792 icon using the right mouse button and select

the

Hardware

item. The

Hardware settings

window is opened:

In the

Cell constant

field enter the cell constant which is

x

printed on the 1.732.0110 Detector block (see

x

Click on

<OK>

to close the window and save the settings.

section 2.3.1

).

792 Basic IC

22

Page 32

2.6 High-pressure pump

2.6 High-pressure pump

In order to avoid damage to the pump it must never be operated dry.

Each time that the pump is switched on always first check that the

eluent supply has been connected up correctly and that sufficient

eluent is present in the eluent bottle.

2.6.1 Removing the transport security screws

In order to prevent the pump drive from being damaged during trans-

10

port the pump head is fitted with three transport security screws

Fig. 2

). These transport security screws must be removed before the

high-pressure pump is started up. Also remove the red sticker attached

34

to the pump head

In order to avoid damage to the pump head these three security

screws should be attached to the pump head each time that it is to be

transported.

34

3434

.

10

1010

(see

2.6.2 Installing the pulsation dampener (option)

To protect the column material of sensitive separating columns (e.g.

methacrylate-based columns) against pressure drops caused by the injector, the use of the optional

recommended. It has to be installed between the high-pressure pump

and the injection valve of the 792 Basic IC as follows (see

1 Install pulsation dampener

x

Position the pulsation dampener

Basic IC on the base.

2 Connection to the pump

x

Unscrew PEEK capillary

54

connection

3 Connection to injection valve

x

Unscrew PEEK capillary

connection

The pulsation dampener is filled with isopropanol and must be rinsed

with eluent before connection to a separating column (see section

2.6.4).

54

of the pulsation dampener

5454

53

53

of the pulsation dampener

5353

6.2620.150 Pulsation dampener MF

52

52

in the interior of the 792

5252

27

27

of coupling

2727

18

18

of coupling

1818

Fig. 9

26

26

and attach it to

2626

52

52

.

5252

26

26

and attach it to

2626

52

52

.

5252

is

):

792 Basic IC

The 6.2620.150 Pulsation dampener can be operated in both directions.

23

Page 33

2 Installation

18

18

1818

29

29

2929

31

31

3131

POWER

28

28 27

2828

Fig. 9

: Connection of the pulsation dampener (option)

Inlet capillary for injector

18

18

1818

PEEK capillary,

length L = 24 cm

22

22 Injection valve 52

2222

27

27 Connection capillary

2727

PEEK capillary,

length L = 13 cm

28

28 Filter unit PEEK (6.2821.100) 54

2828

29

29 Connection capillary

2929

PEEK capillary,

length L = 13 cm

27 54

2727

31

31 Purge valve

3131

52 Pulsation dampener (6.2620.150)

5252

53

53 Connection to injection valve

5353

54 Connection to purge valve

5454

54 22

5454

53

53

5353

52

52

5252

22

2222

792 Basic IC

24

Page 34

2.6 High-pressure pump

2.6.3 Connecting the eluent bottle

To connect the eluent bottle with the high-pressure pump, insert the

supplied 6.1834.010 aspirating tubing (i.d. = 1.5 mm, e.d. = 2.5 mm,

5555

length = 2.5 m) into one of the openings

Basic IC. Pull the aspirating tubing sufficiently far into the interior of the

792 Basic IC and push at least 5 mm of it onto aspirating capillary

Fig. 3

(see

) of the high-pressure pump (it may be necessary to use emery paper). Screw on the 6.2821.090 aspirating filter at the other end of

the aspirating tubing and insert it into the eluent bottle.

7777

or

in the interior of the 792

32

32

3232

Only degassed (with N

, He or vacuum) and microfiltered (0.45 Pm

2

filter) eluents should be used!

Care must be taken that the eluent used is freely miscible with any

solvent remaining in the pump head (the pump head leaves the

factory filled with either isopropanol or methanol/water). If this is not

the case then the pump must first be rinsed with a solvent which is

miscible with both the previous eluent and the following eluent (e.g.

acetone).

2.6.4 Deaerating the pump and rinsing the pulsation dampener

The first time that it is started up the high-pressure pump must be

deaerated. Proceed as follows:

1 Prepare for deaeration

31

x

Open the rotary knob on purge valve

the counterclockwise direction (see

x

Mount a PEEK compression fitting

30

the end of capillary

the compression fitting

x

Push 6.2816.020 Syringe (without needle) into the connection

24

on coupling

24

2424

30

and screw coupling

3030

46

46

.

4646

until the stop is reached.

31

by approx. ½ turn in

3131

Fig. 3

).

46

46

4646

section 2.3.4

(see

24

24

2424

(6.2744.120) to

) to

792 Basic IC

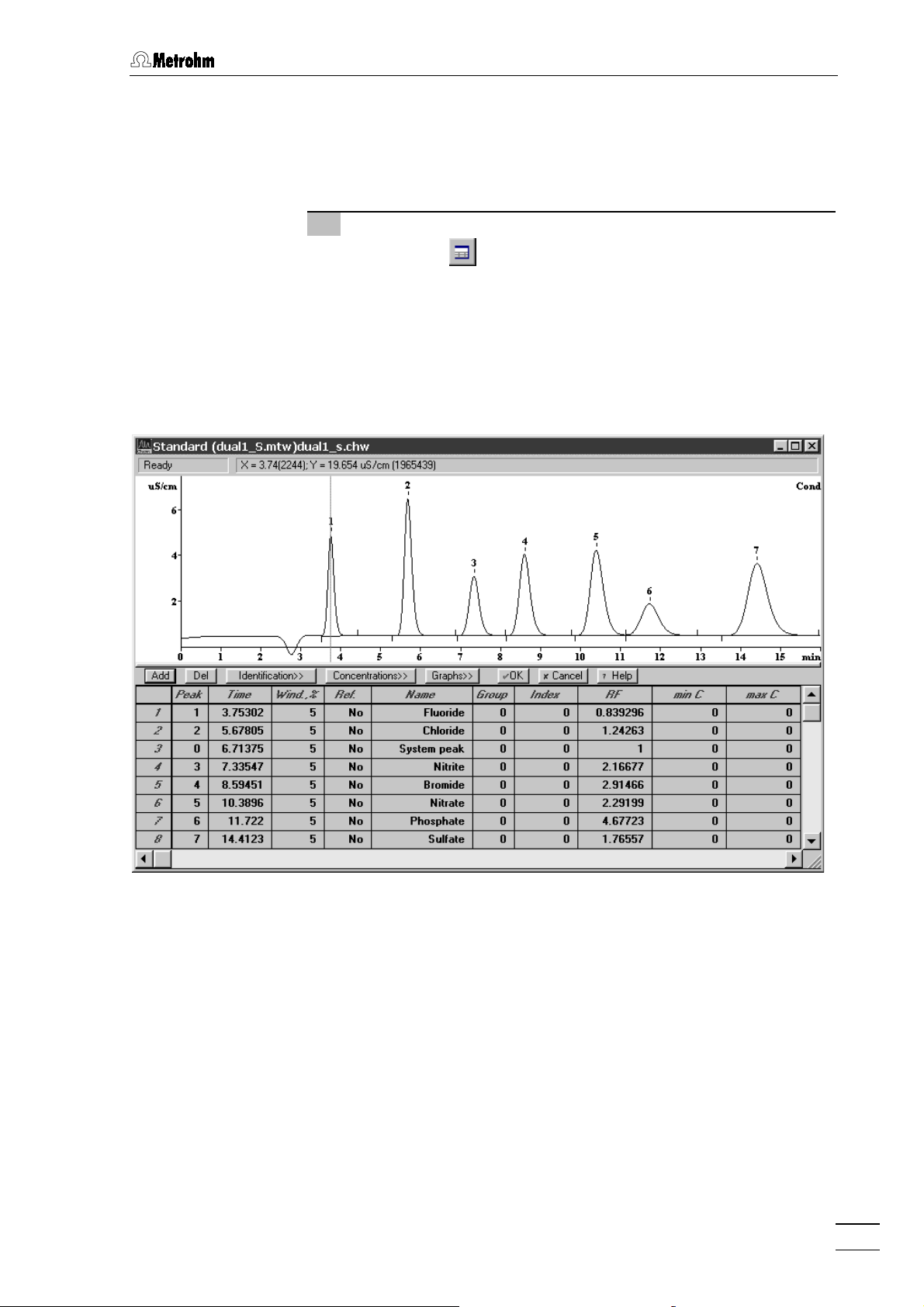

2 Open system

x

Start the «792 Basic IC» PC program, if it has not been already been started (see

x

Select

folder

<Open>

File / Open / System

Default

. The corresponding system window is opened:

section 2.5.3

in the main window and open the

. Select the system file

).

Default.smt

and click on

25

Page 35

2 Installation

3 Set flow rate to 2 mL/min

x

Double-click the 792 icon in the system window to open the

window for manual control of the 792 Basic IC (see below).

x

Set the flow rate to

x

Click to

<Send to unit>

2 mL/min

to send this value to the 792 Basic IC.

in the

Flow

field.