Page 1

791 VA Detector

Manual

8.791.1013

Page 2

Page 3

Metrohm AG

CH-9101 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

791 VA Detector

Manual

8.791.1013 01.2006 chs

Page 4

Teachware

Metrohm AG

CH-9101 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

Page 5

Table of contents

Table of contents

1 Introduction ........................................................................................... 1

1.1 Instrument description .............................................................................1

1.2 Parts and controls.....................................................................................2

1.3 Information on the Instructions for Use ................................................4

1.3.1 Organization ..................................................................................4

1.3.2 Notation and pictograms ..............................................................5

1.4 Safety notes................................................................................................6

1.4.1 Electrical safety..............................................................................6

1.4.2 General precautionary rules..........................................................6

2 Installation.............................................................................................. 7

2.1 Setting up the instrument.........................................................................7

2.1.1 Packaging......................................................................................7

2.1.2 Check ............................................................................................7

2.1.3 Location.........................................................................................7

2.1.4 Arrangement of the instruments....................................................7

2.2 Mains connection ......................................................................................8

2.2.1 Setting the mains voltage.............................................................. 8

2.2.2 Fuses ............................................................................................. 9

2.2.3 Mains cable and mains connection .............................................. 9

2.2.4 Switching the instrument on/off.....................................................9

2.3 656 Electrochemical detector................................................................10

2.3.1 Installation and startup ................................................................10

2.3.2 Connection to 791 VA Detector...................................................10

2.4 6.5303.030 ELCD cell for IC...................................................................11

2.4.1 Assembling the ELCD cell...........................................................11

2.4.2 Connection to 791 VA Detector...................................................13

2.5 Analog output connections ...................................................................14

791 VA Detector

3 Operation...............................................................................................15

3.1 Electrochemical detection .....................................................................15

3.1.1 Classes of substances which can be determined...................... 15

3.1.2 Influence on detector signal........................................................16

3.1.3 Selection of polarization voltage .................................................17

3.1.4 Procedure for unknown substances ...........................................17

3.1.5 Practical information about ELCD...............................................18

3.2 Electrodes.................................................................................................20

3.2.1 Working electrodes .....................................................................20

3.2.2 Reference electrode ....................................................................22

3.2.3 Auxiliary electrode .......................................................................22

3.3 Operating element functions.................................................................23

3.4 Startup.......................................................................................................26

3.4.1 Preparing the ELCD cell..............................................................26

3.4.2 Zero balancing and equilibration phase .....................................27

3.4.3 Measuring procedure..................................................................29

I

Page 6

Table of contents

4 Maintenance – Malfunctions.......................................... 31

4.1 Maintenance and servicing ...................................................................31

4.2 Shutdown..................................................................................................31

4.3 Malfunctions and their rectification .....................................................32

4.4 Instrument test with the dummy cell.................................................... 34

4.4.1 Check of "meas" and "damp" commutators and

of current amplifier offset ............................................................34

4.4.2 Check output voltage.................................................................. 35

4.4.3 Check of current compensation .................................................36

4.4.4 Check of current and voltage overload ...................................... 38

4.4.5 Check sensitivity knob

4.4.6 Check of noise from current amplifier......................................... 40

8 ............................................................. 39

5 Appendix................................................................................................. 41

5.1 Technical data..........................................................................................41

5.2 Standard equipment ...............................................................................43

5.2.1 2.791.0010 VA Detector for HPLC .............................................. 43

5.2.2 2.791.0020 VA Detector for IC ....................................................44

5.3 Optional accessories.............................................................................. 45

5.4 Warranty and conformity .......................................................................46

5.4.1 Warranty ......................................................................................46

5.4.2 EU Declaration of conformity ...................................................... 47

5.4.3 Certificate of conformity and system validation.......................... 48

5.5 Index..........................................................................................................49

List of figures

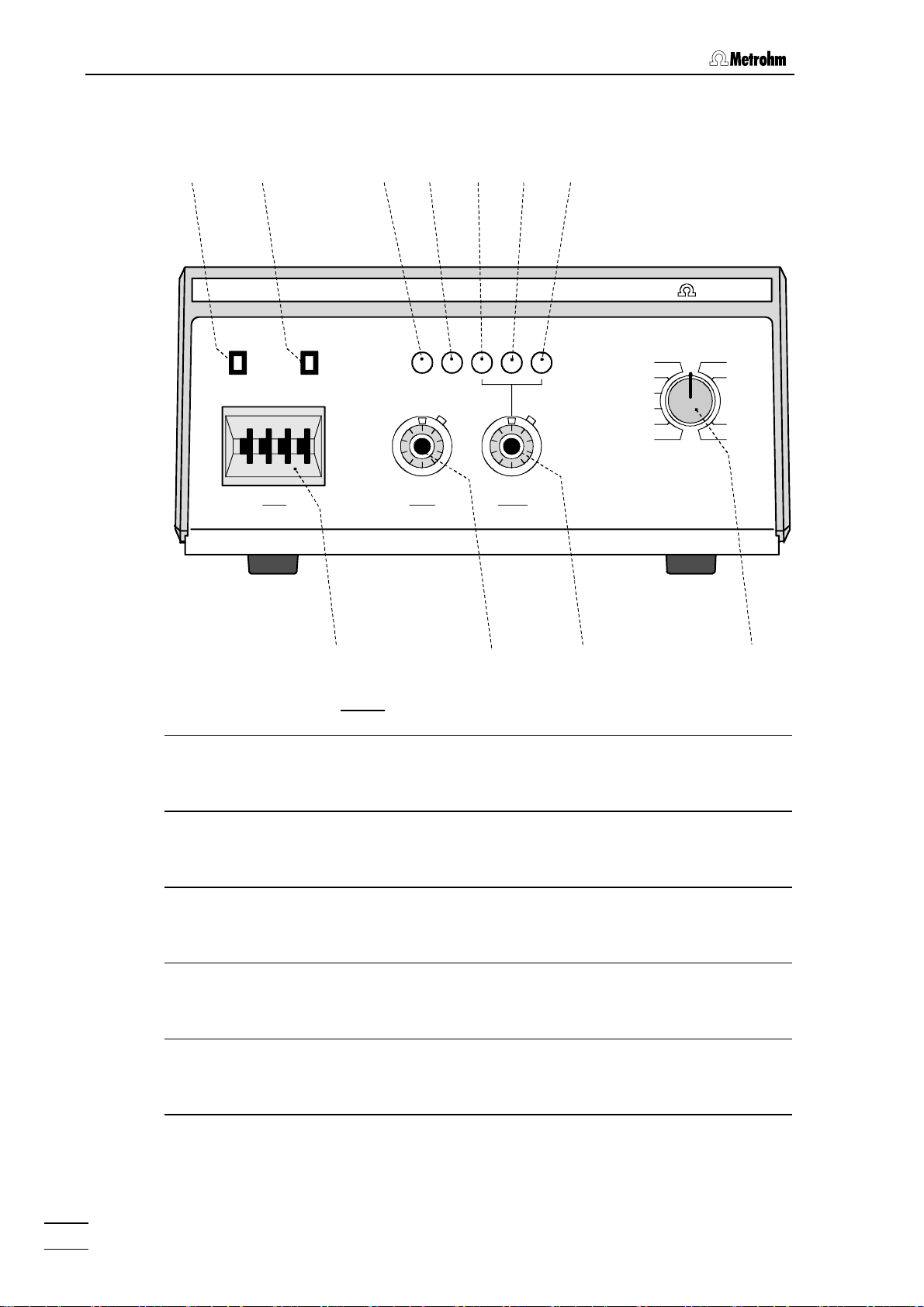

Fig. 1: Front of the 791 VA Detector ............................................................................. 2

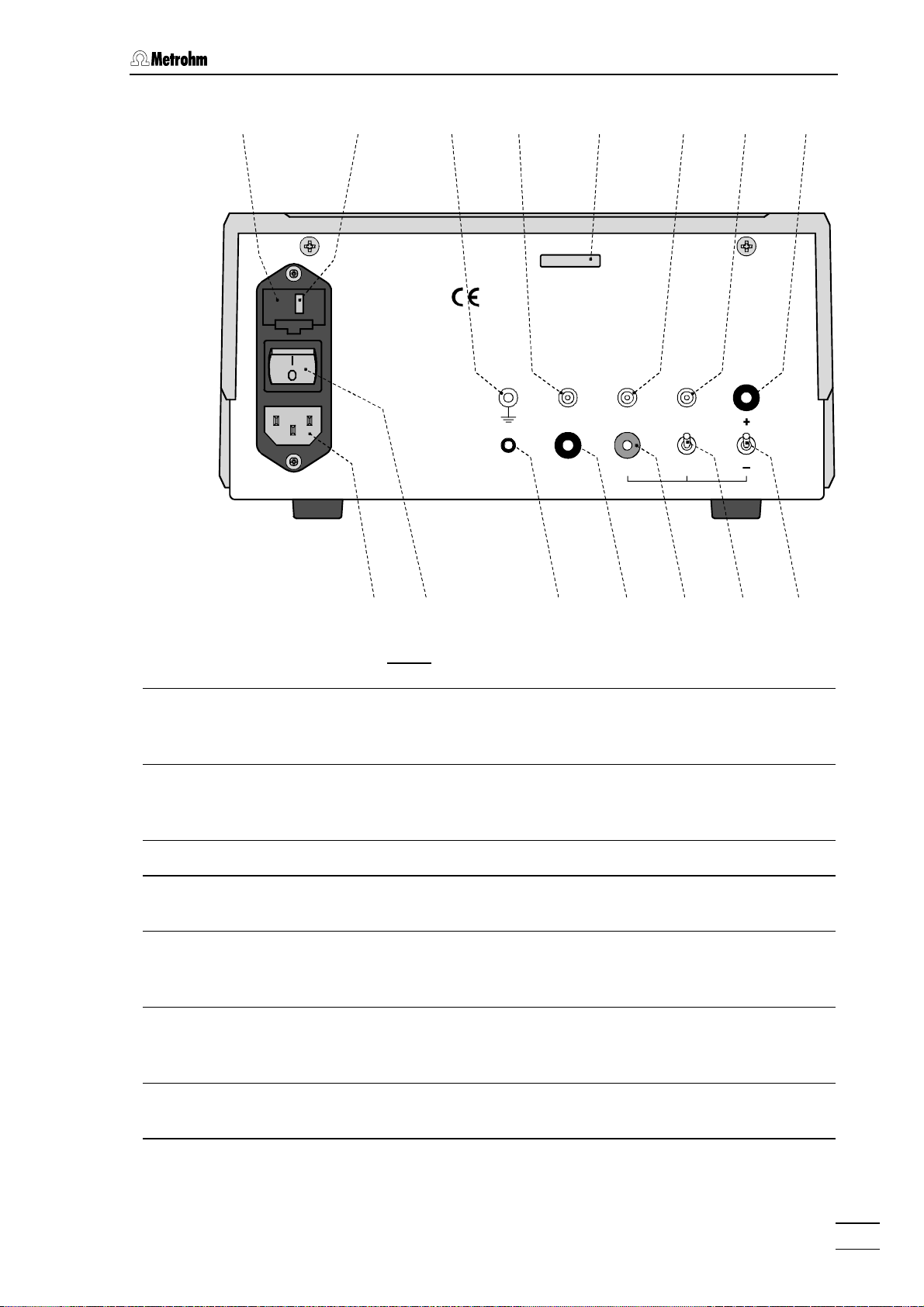

: Rear of the 791 VA Detector.............................................................................. 3

Fig. 2

Fig. 3

: Setting the mains voltage.................................................................................. 9

Fig. 4

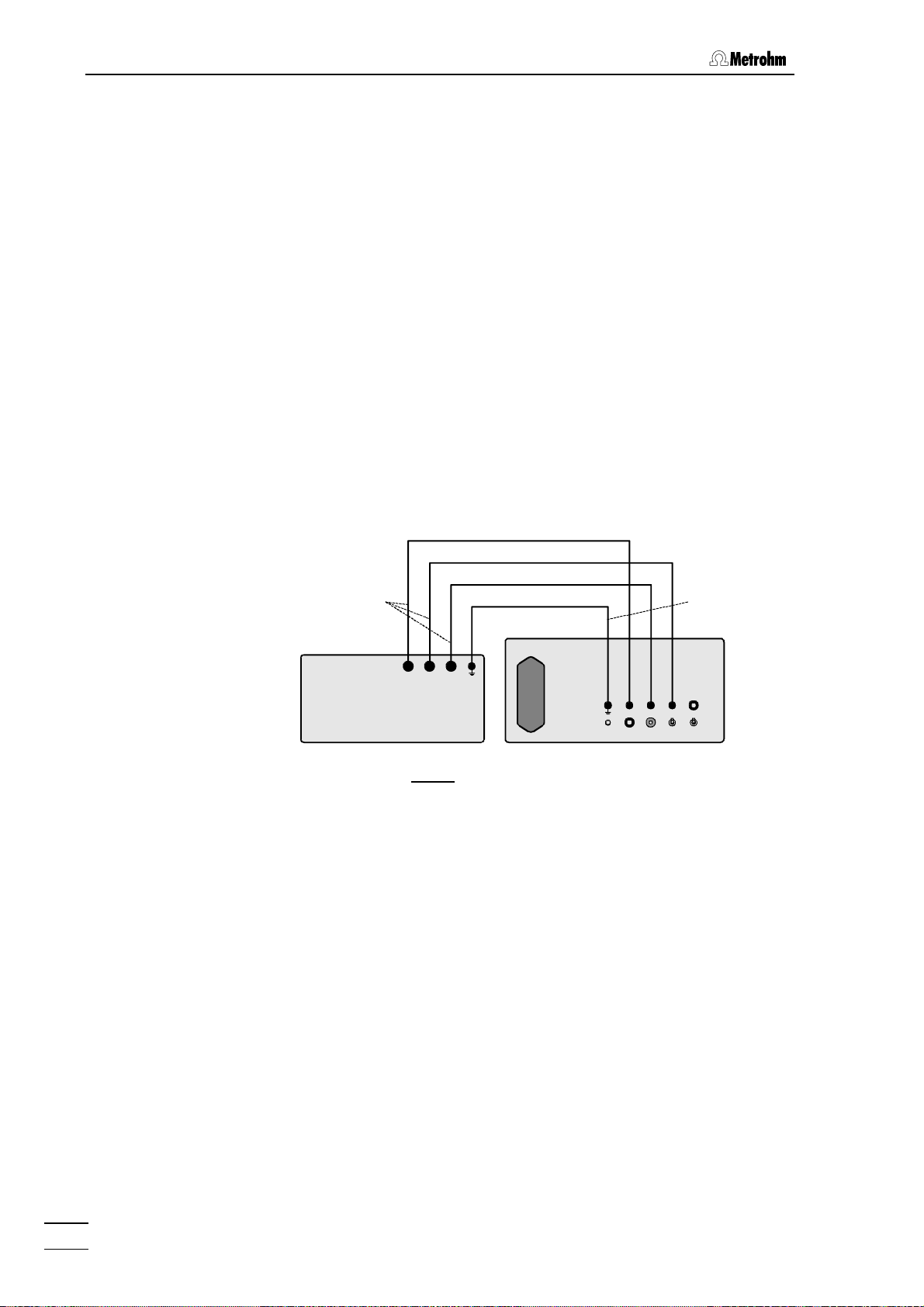

: Connection 656 – 791 .....................................................................................10

Fig. 5

: ELCD cell assembly ........................................................................................12

Fig. 6

: Connection of ELCD cell at detector block..................................................... 13

Fig. 7

: Connection of ELCD cell at 791 VA Detector.................................................. 13

Fig. 8

: Selection of polarization voltage .....................................................................17

Fig. 9

: Circuit of 6.2813.020 Dummy Cell................................................................... 34

791 VA Detector

II

Page 7

1.1 Instrument description

1 Introduction

1.1 Instrument description

The 791 VA Detector allows the use of electrochemical/amperometric

detection in IC and HPLC; various working electrodes are available depending on the application. It can be used in series with another detector (e.g. 732 Conductivity detector) or simply as a «stand alone» detector.

The self-ventilating measuring cell functions according to the timeproved wall-jet principle with three-electrode technology. A silver/silver

chloride system is used as the reference electrode and a solid gold pin

as the auxiliary electrode. The carbon paste electrode and the silver

electrode have proved to be the best working electrodes; but other

electrode materials such as glassy carbon, gold, platinum and impregnated graphite are available for special applications.

The 791 VA Detector is available in the two following versions:

• 2.791.0010 VA Detector for HPLC

The measuring cell is built into the 656 Electro chemical detector.

• 2.791.0020 VA Detector for IC

The measuring cell belongs to the accessories and

is built into the 733 IC Separation Center.

791 VA Detector

1

Page 8

1 Introduction

1.2 Parts and controls

13

2 4567

VA Detector791

I

comp

0.02 nA

+

~

+

overload meas

015

U

pol

10 mV

I

0.01

comp

x5damp

.

I

nAx50

50

10

0,5

0,1

5

1

Met rohm

I

(U = 1 V)

out

µ

0,1

0,5

1

5

100

10

A

4

11 89

Fig. 1

Mains pilot lamp

1

Lit up when instrument switched

: Front of the 791 VA Detector

10

7 Commutator

Changing the polarity of I

on

2 Overload display 8 Adjusting knob

Setting the current measuring sensitivity

3 Commutator

Changeover Stand-by/Measure

4 Commutator

Switching on/off damping

5 Commutator

Switching on/off multiplication of

by a factor of 5

I

comp

9 Potentiometer

Setting the absolute compensation

current I

comp

10 Potentiometer

Setting the relative compensation

current I

comp

11 Digital switch

Setting the polarization voltage

comp

6 Commutator

Switching on/off multiplication of

by a factor of 50

I

comp

791 VA Detector

2

Page 9

1.2 Parts and controls

12

151413

Type 1.791.0010

f = 50-60 Hz Made by Metrohm Herisau Switzerland

S = 5 VA

Fuse

100-240 V: 1A(T)

WARNING - Fire Hazard -

For continued protection replace only

with the same type and rating of fuse

pilot

voltage

Nr.

16 17 18 19

AE RE WE shield

output 0...1 V

com 0...10 mV

Fuse holder

12

changing the fuses, see section 2.2

26 20

25

Fig. 2

: Rear of the 791 VA Detector

20 Selector

Selection of polarity for analog

output

13 Mains voltage indicator 21 Selector

Selection of full-scale deflection for

analog output

14 Earthing socket 22 Analog output (live)

15 Connection AE

23 Analog output (common)

Connection of auxiliary electrode

16 Serial number 24 Pilot voltage

Input for external voltage input for

potentiostat control

17 Connection RE

Connection of reference electrode

25 Mains switch

To switch instrument on/off:

I = ON 0 = OFF

21222324

18 Connection WE

26 Mains connection plug

Connection of working electrode

19 Connection for protective screen

791 VA Detector

Mains connection, see section 2.2

3

Page 10

1 Introduction

1.3 Information on the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 791 VA Detector into operation. The Instructions for Use contain

information and warnings to which the user must pay attention in order

to assure safe operation of the instrument.

1.3.1 Organization

These 8.791.1013 Instructions for Use for the 791 VA Detector provide a comprehensive overview of the installation, startup procedure,

operation, fault rectification and technical specifications of this instrument. The Instructions for Use are organized as follows:

Section 1 Introduction

General description of instrument, parts and controls

and safety notes

Section 2 Installation

Installation of accessories, connection to IC system

Section 3 Operation

Electrodes, operating element functions,

startup

Section 4 Maintenance – Faults

Maintenance, fault rectification

Section 6 Appendix

Technical data, standard equipment, options, warranty,

declarations of conformity, index

To find the required information on the instruments you will find it an

advantage to use either the Table of contents or the Index at the

back.

791 VA Detector

4

Page 11

1.3 Information on the Instructions for Use

1.3.2 Notation and pictograms

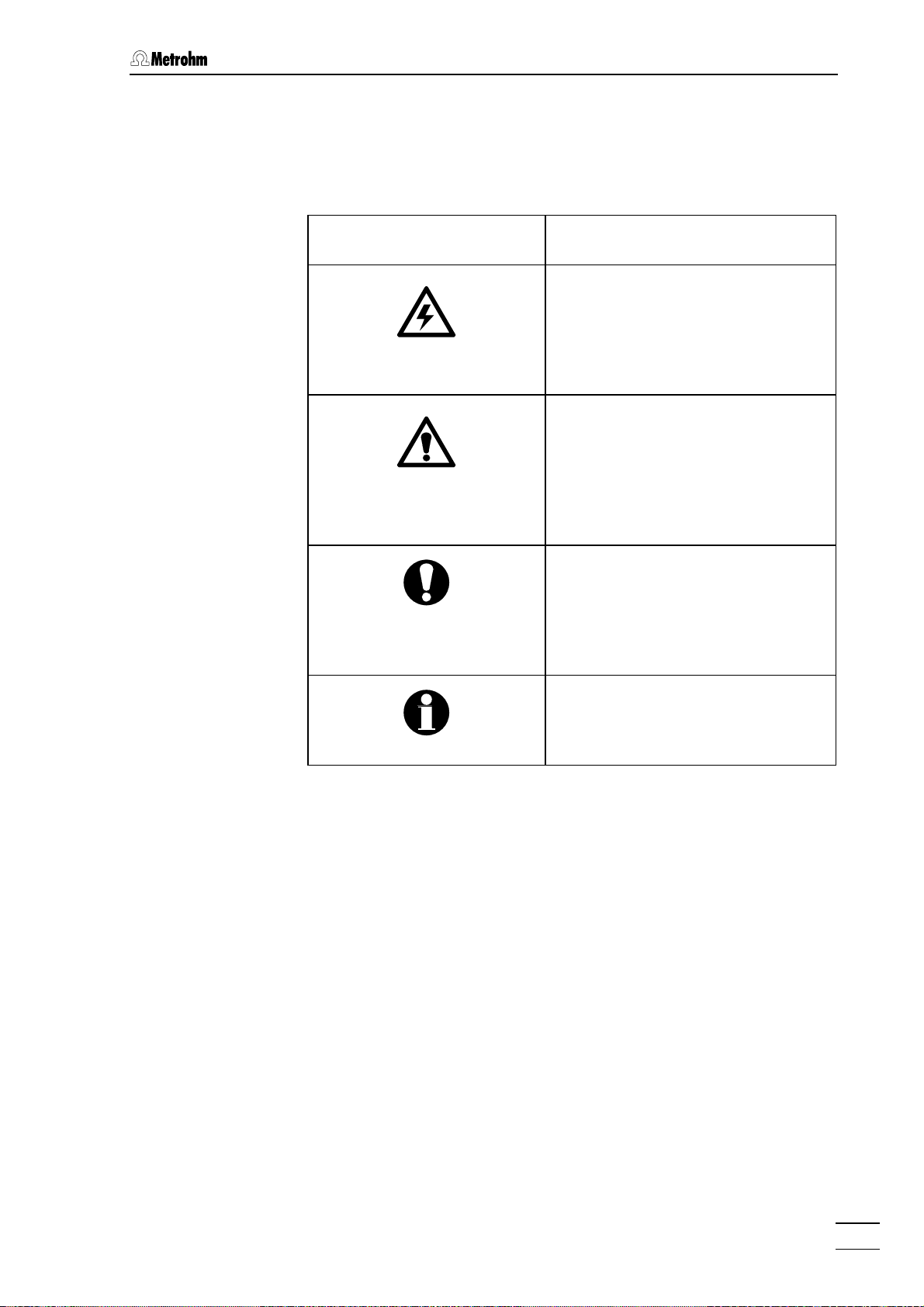

The following notations and pictograms (symbols) are used in these Instructions for Use:

15 Part or control of 791

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

Caution

This symbol marks important

information. First read the associated directions before you continue.

Comment

This symbol marks additional

information and tips.

791 VA Detector

5

Page 12

1 Introduction

1.4 Safety notes

1.4.1 Electrical safety

While electrical safety in the handling of the 791 VA Detector is assured

in the context of the specifications IEC 1010-1 (protection class 1, degree of protection IP40), the following points should be noted:

• Mains connection

Setting of the mains voltage, checking the mains fuse and the

mains connection must be effected in accordance with the instruc-

tions in section 2.2.

• Opening the 791 VA Detector

If the 791 VA Detector is connected to the power supply, the instrument must not be opened nor must parts be removed from it, otherwise there is a danger of coming into contact with components which

are live. Hence, always disconnect the instrument from all voltage

sources before you open it and ensure that the mains cable is

disconnected from mains connection 26 !

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 791 VA Detector, you should earth yourself and any tools

you are using by touching an earthed object (e.g. housing of the

instrument or a radiator) to eliminate any static charges which exist.

1.4.2 General precautionary rules

• Handling of solvents

Check all lines periodically for possible leaks. Follow the relevant

instructions regarding the handling of flammable and/or toxic solvents

and their disposal.

791 VA Detector

6

Page 13

2.1 Setting up the instrument

2 Installation

2.1 Setting up the instrument

2.1.1 Packaging

The 791 VA Detector is supplied together with the separately packed

accessories in special packagings containing shock-absorbing foam

linings designed to provide excellent protection. The instrument itself is

packed in an evacuated polyethylene bag to prevent the ingress of

dust. Please store all these special packagings as only they assure

transport of the instrument free from damage.

2.1.2 Check

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in section 5.2). In the case of transport damage, see

instructions in section 5.4.1 "Warranty".

2.1.3 Location

Position the instrument in the laboratory at a location convenient for

operation, free from vibrations and protected against a corrosive

atmosphere and contamination by chemicals.

2.1.4 Arrangement of the instruments

The 791 VA Detector can be placed on the 732 IC Detector or the 733

IC Separation Center.

791 VA Detector

7

Page 14

2 Installation

2.2 Mains connection

Follow the instructions below for connecting to the power supply. If

the instrument is operated with a mains voltage set wrongly and/or

wrong mains fuse, there is a danger of fire!

2.2.1 Setting the mains voltage

Before switching on the 791 VA Detector for the first time, check that the

mains voltage set on the instrument (see Fig. 3) matches the local

mains voltage. If this is not

on the instrument as follows:

the case, you must reset the mains voltage

1 Disconnect mains cable

Disconnect mains cable from mains connection plug 26 of the

791 VA Detector.

2 Remove fuse holder

Using a screwdriver, loosen fuse holder 12 and take out completely.

3 Change mains voltage

Completely remove voltage selection insert 13 by hand, rotate it

through 180° and reinsert it. The required mains voltage (115 or

230 V) must now be visible from the front.

4 Check fuses

Carefully take both fuses out of fuse holder 12 and check their

specifications:

100…240 V 1 A (slow-blow) Metrohm-No. U.600.0016

5 Insert fuses

Change both fuses if necessary and reinsert in fuse holder 12.

6 Install fuse holder

Push fuse holder 12 back into the opening of 791 VA Detector

by hand until it clicks into place properly.

791 VA Detector

8

Page 15

2.2 Mains connection

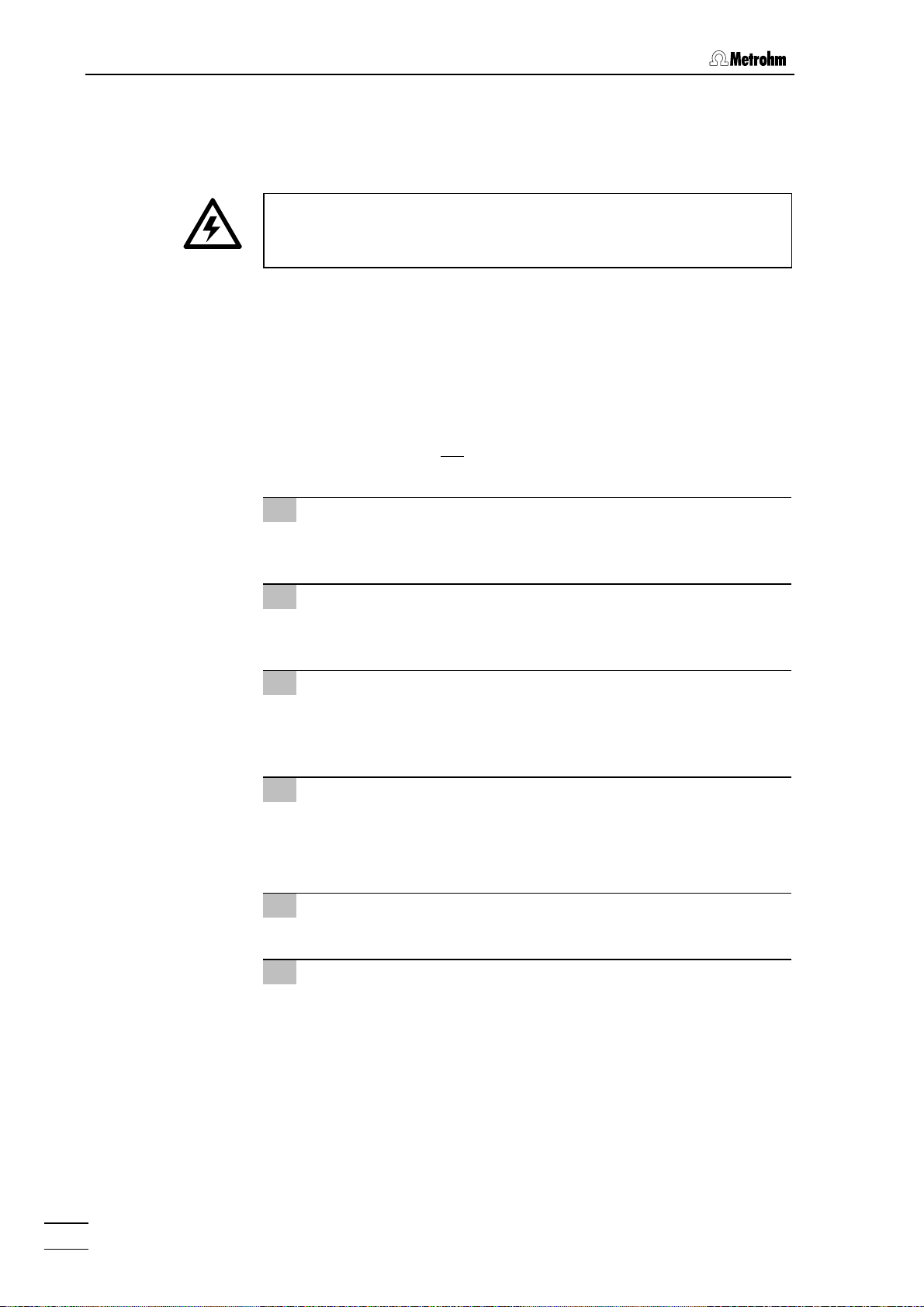

100 – 120 V220 – 240 V

13

12

230

115

12 Fuse holder

13 Voltage selection

insert with display

of voltage

25

26

Fig. 3

: Setting the mains voltage

2.2.2 Fuses

Two fuses 1 A/slow-blow for 100…240 V are installed in the fuse holder

12 of the 791 VA Detector as standard.

Ensure that the instrument is never put into operation with fuses of

another type, otherwise there is danger of fire!

For checking or changing fuses, proceed as described in section 2.2.1.

2.2.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables

25 Mains switch

26 Mains connection

plug

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin. If a different plug has to be fitted, the yellow/green lead (IEC standard) must

be connected to protective earth (protection class 1).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Mains connection

Plug the mains cable into mains connection plug 26 of the 791 VA Detector (see Fig. 3).

2.2.4 Switching the instrument on/off

The 791 VA Detector is switched on and off using mains switch 25.

When the instrument is switched on lamp 1 lights up.

791 VA Detector

9

Page 16

2 Installation

2.3 656 Electrochemical detector

2.3.1 Installation and startup

Inserting the detector cell in shield housing, fitting the electrodes and

startup of the 656 Electrochemical detector (order number 2.656.0020)

are described in detail in the 656 Instructions for use.

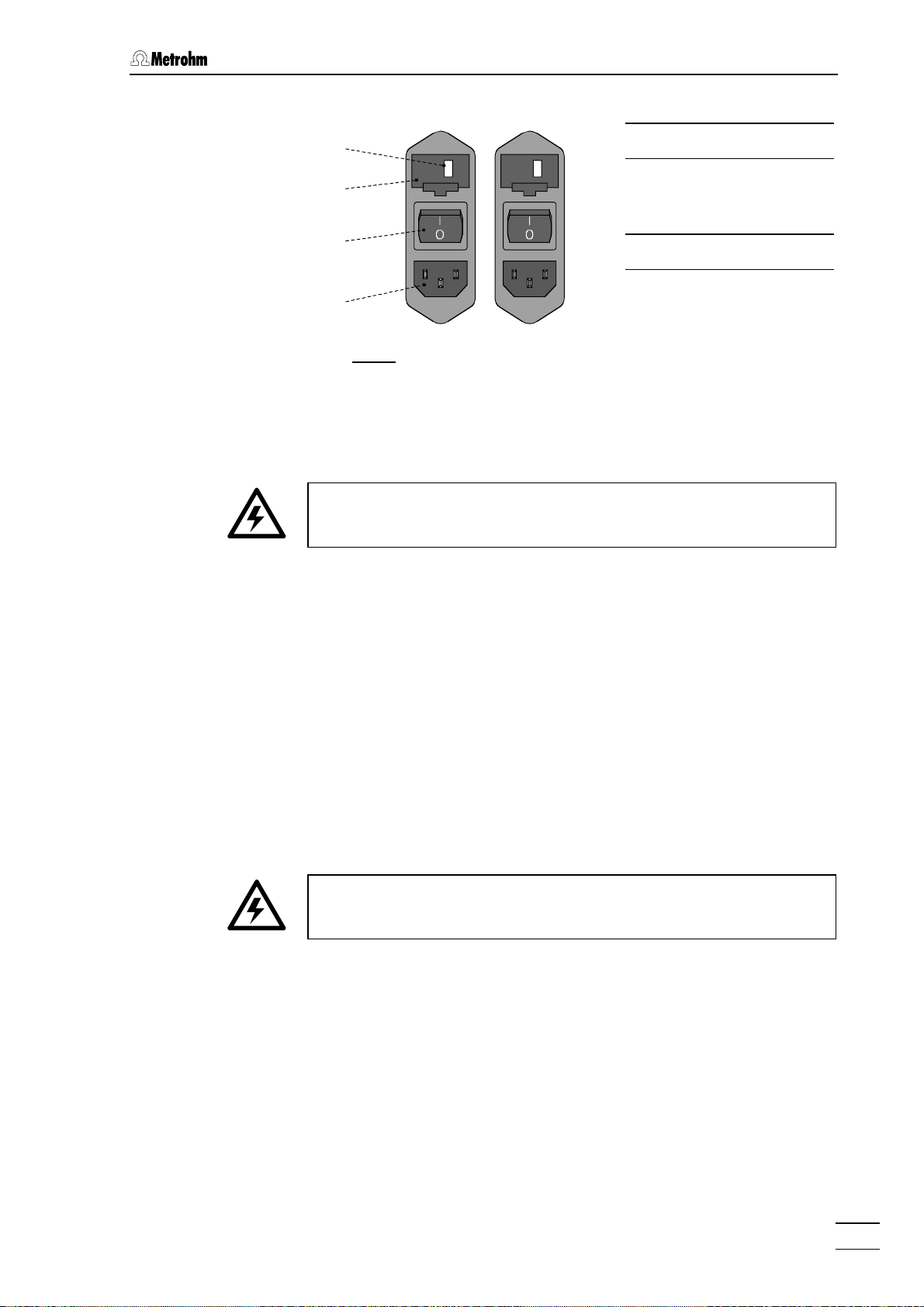

2.3.2 Connection to 791 VA Detector

The electrodes used in the detector cell are each connected to the corresponding connection of the 791 VA Detector with a 6.2120.020 Electrode cable as shown in Fig. 4. In addition the two earthing sockets are

connected with a 6.2106.020 Cable.

6.2120.0 20 6.2106.0 20

656

AE WE RE

Fig. 4

AE RE WE

: Connection 656 – 791

791

791 VA Detector

10

Page 17

2.4 6.5303.030 ELCD cell for IC

2.4 6.5303.030 ELCD cell for IC

2.4.1 Assembling the ELCD cell

The reference electrode and working electrode must be inserted in the

6.5303.030 ELCD Cell supplied with the 2.791.0020 VA Detector. The

cell is then screwed into the detector block built into the 733 IC Separation Center. Proceed as follows (see Fig. 5 and Fig. 6):

1 Insert reference electrode

Reference electrode 39 (6.0727.000, details see section 3.2.2)

included in the supply is already filled with c(KCl) = 3 mol/L and

protected with a cap. It is assembled as follows (see Fig. 5):

• Screw off the cap of electrolyte storage vessel 41 of reference

electrode 39. Normally PTFE gasket 31 remains in the cap

and can be left there.

• Insert one of the supplied PTFE gaskets 31 into the corre-

sponding opening of cell body 32 and screw reference electrode 39 into this opening.

2 Insert working electrode

Working electrode 28 is not supplied with the 791 VA Detector

and must be ordered separately. Details about the working

electrodes and information about pretreatment (e.g. polishing)

can be found in section 3.2.1. A working electrode is assembled

as follows (see Fig. 5):

• Insert working electrode 28 in screw nipple 29.

• Push one of the supplied PTFE gaskets 31 sufficiently far

along the working electrode from below.

• Carefully insert working electrode 28 into the corresponding

opening of cell body 32 from above and press it in until it

clearly clicks into position.

• Push screw nipple 29 downwards and screw it in.

3 Connect ELCD cell to the detector block

The ELCD cell is screwed onto the 1.733.0X10 Detector block

mounted inside the 733 Separation Center. Proceed as follows

(see Fig. 5 and Fig. 6):

• Screw cell body 32 onto detector block 42 with the help of

the two red knurled screws 43.

• Push one of the supplied PTFE gaskets 31 over screw nipple

33 and screw this into the corresponding opening of cell

body 32.

• Place a screw nipple 36 and a PTFE gasket 35 on the outlet

end of the outlet capillary 37 permanently connected to detector block 42.

• Insert outlet capillary 37 with screw nipple 36 in place into

screw nipple 33 and press in outlet capillary 37 until it

reaches the stop.

791 VA Detector

11

Page 18

2 Installation

• Screw nipple 36 onto screw nipple 33 to fix outlet capillary 37

is position.

4 Discharge

• Pull outlet capillary 38 which is already mounted on cell body

32 through one of the openings in the rear panel of the 733 IC

Separation Center so that it emerges outside the instrument.

• Insert outlet capillary 38 in a sufficiently large waste container

and fix it in position.

4139 3140

2731

28

29

30

31

35

36

38

: ELCD cell assembly

Fig. 5

27

ELCD cell (6.5303.030) 35 PTFE gasket (6.2704.020)

28 Working electrode 36 Screw nipple (4.420.2580)

29 Screw nipple (6.2730.000) 37 PEEK outlet capillary from

1.733.0X10 Detector block

32

31

33

34

35

36

37

30 Sealing ring (E.301.0028) 38 PTFE outlet capillary (6.1803.000)

31 PTFE gasket (6.2704.010) 39 Reference electrode (6.0727.000)

32 Cell body 40 Ag/AgCl Reference system

33 Screw nipple (6.2731.030) 41 Electrolyte vessel

34 Sealing ring (E.301.0004)

791 VA Detector

12

Page 19

2.4 6.5303.030 ELCD cell for IC

42

37

43

28

32

39

43

38

: Connection of ELCD cell at detector block

Fig. 6

Working electrode 39 Reference electrode

28

32 Cell body 42 Detector block (1.733.0X10)

37 PEEK outlet capillary from

1.733.0X10 Detector block

38 PTFE outlet capillary

(6.1803.000)

2.4.2 Connection to 791 VA Detector

The ELCD cell electrodes are each connected to the corresponding

connection of the 791 VA Detector with a 6.2120.020 Electrode cable as

shown in Fig. 7. The 791 VA Detector must be switched off and in the

"stand-by" position when this is taking place.

(6.0727.000)

43 Knurled screw (V.900.4006)

791 VA Detector

6.2120.020

RE

Fig. 7

6.2120.020

6.2120.020

WE

AE

AE

AE RE WE

: Connection of ELCD cell at 791 VA Detector

791

13

Page 20

2 Installation

2.5 Analog output connections

The 791 VA Detector has two analog output sockets: 22 (live) and 23

(common) for connecting a chart recorder of a different data recording

instrument. The full-scale deflection range for the analog output (1 V or

10 mV) can be set with switch 21; the polarity can be changed with

switch 20 (see section 3.3).

The 6.2115.010 Cable can be used for connecting recorders with banana plug connections; the 6.2115.060 Cable can be used for connecting data recording instruments with terminals.

791 VA Detector

14

Page 21

3.1 Electrochemical detection

3 Operation

3.1 Electrochemical detection

3.1.1 Classes of substances which can be determined

A precondition for the use of electrochemical detection is that the substances to be determined are electrochemically active on the particular

working electrode used, i.e. they can easily be oxidized or reduced. The

electrical current produced by this reaction is proportional to the concentration of the substance throughout a wide range. It is measured,

amplified and recorded as a function of time by the 791 VA Detector in

the form of a chromatogram.

The following table provides an overview of the classes of substances

and ions which can be detected by oxidation or reduction. The approximate polarization voltage obtained when an Ag/AgCl/c(KCl) =

3 mol/L reference electrode is used is given; this depends to a large extent on the working electrode and eluents used (see section 3.2). The

limits of detection which can be achieved are in the lower ppb range.

Structural formula Classes/substances Polarization voltage

R

OH

R

NH

2

5

3

N

H

Aromatic hydroxy compounds

Antioxidants

Catecholes

Flavones

Halogenated phenols

Hydroxybiphenyls

Hydroxycumarines

Methoxyphenols

Oestrogens

Phenols

Tocopherols

Aromatic amines

Anilines

Benzidines

Sulfonamides

Indols

Indolyl-3-compounds

5-Hydroxy-indols

+800 … +1200 mV

+ 800 mV

+ 1000 mV

+ 1200 mV

+ 800 mV

+ 1000 mV

+ 800 mV

+ 1000 mV

+ 1200 mV

+ 800 mV

+ 1000 mV

+ 600 mV

+ 1200 mV

+ 1000 mV

+ 800 mV

791 VA Detector

S

N

H

Phenothiazines + 1000 mV

15

Page 22

3 Operation

Structural formula Classes/substances Polarization voltage

RSH

O

O

R NO

R

R

Mercaptans + 800 mV

Miscellaneous

Ascorbic acid

Carotenes

Purine derivatives

Vitamin A

Quinones

Vitamin K

1

+ 800 mV

+ 800 mV

+ 1000 mV

+ 1000 mV

– 700 mV

2

Nitro compounds

Nitrophenol

Nitroglycerin

Isosorbidedinitrate

Inorganic anions

Nitrite

Sulfide

Thiosulfate

Chlorite

Bromide

Iodide

Cyanide

Thiosulfate

Thiocyanate

– 700 mV

– 800 mV

– 800 mV

+ 1100 mV

+ 0 mV

+ 1100 mV

+ 1100 mV

+ 150 mV

+ 150 mV

+ 0 mV

+ 1100 mV

+ 1200 mV

3.1.2 Influence on detector signal

The sensitivity of detection, i.e. the height of the detector signal and the

background current in the electrochemical detection depend on the following parameters:

• polarization voltage

• temperature (approx. 1.5 %/°C)

• flow rate of eluent

• surface of electrodes and interior of cell

• Eluent composition

(pH value, type and concentration of conductive salt,

type and concentration of organic components, etc.)

Each change of one of these parameters will change the background

current and the detector signal. Therefore, every parameter change

needs a stabilization time to elapse; this is normally a few minutes for

791 VA Detector

16

Page 23

3.1 Electrochemical detection

current ranges > 5 nA. Please pay particular consideration to this on

changing the eluent or the sample solution: the "same" eluent may have

a different background current because eluents are never exactly the

same (ionic strength, pH value, etc.!).

3.1.3 Selection of polarization voltage

The hydrodynamic voltammograms show the voltage limit from the

point where a substance is oxidized or reduced. This voltage limit is

generally higher than the voltage predicted by thermodynamics because of inhibitions of the electrode reaction. Increasing voltage values

give rise to increasing currents up to a maximum value, the diffusioncontrolled limiting current.

In Fig. 8 for example, analytes a, b, and c are detected at voltage U

whereas at voltage U

, component a is detected selectively. Therefore

1

the polarization voltage to be set has to be optimized for sensitivity on

one hand and selectivity on the other.

The polarization voltage to be set also depends on the type and condition of the working electrode (see section 3.5) as well as on the eluent.

The latter could be illustrated by Fig. 8, saying that the curves are from

one single analyte taken in 3 eluents with different pH values.

I

Diffusioncontrolled

limiting

current

abc

U

1

Fig. 8

: Selection of polarization voltage

U

2

Background

current

U

pol

;

2

3.1.4 Procedure for unknown substances

The hydrodynamic current/voltage curve of an analyte with unknown

electrochemical characteristics is recorded as follows:

• Short circuit the system, i.e. connect the injector directly (without

separating column) to the electrochemical detector.

• Set current range of 791 VA Detector to 100 … 500 nA.

• Set polarization voltage of 791 VA Detector to +1200 mV.

• Inject analyte (20 … 100 ng).

791 VA Detector

17

Page 24

3 Operation

If no signal is observed, change the pH value of the eluent (a protonated or deprotonated substance may be oxidized more easily). Generally, a higher polarization voltage has to be applied with lower pH values (approx. 50 … 100 mV per pH unit).

st

• 1

experiment with eluent of pH ≈ 6

nd

• 2

experiment with eluent of pH ≈ 3

If there is still no signal, the analyte is "inactive", i.e. not suitable for electrochemical detection.

As soon as a signal is observed, decrease the polarization voltage in

steps of 100 mV: a hydrodynamic current/voltage curve results.

For detection, select the lowest polarization voltage U

good signal is still observed.

3.1.5 Practical information about ELCD

In principle the electrochemical detector can be connected to all HPLC

and IC systems. In order to carry out work successfully, particularly in

trace-level quantities, all components such as pump, dampening system, injector, separating column, capillaries, couplings, etc. must be in

perfect condition. In electrochemical detection it is possible that interferences may occur which, for example, are not observed with UV or

conductivity detection. These can often be traced back to contaminants

from the water supply system (e.g. Fe(II) ions), contaminants from the

separating column (e.g. organic residues) or variations in pressure

caused by leaking connections.

Particular attention must be given to the following points:

Cleanliness

The general demands placed on trace analysis work also apply here.

Each possible source of corrosion of steel components must be

avoided as Fe(II) ions may interfere. The eluent should also not contain

any complexing agents.

at which a

pol

Pulsation

The noise of the detector signal depends on the pressure variation inside the cell and on the back-pressure (max. 1 bar), which is determined by the length of outlet capillary 38 (i.d. 0.3 mm). The use of a

pulsation dampener (e.g. Metrohm 6.2620.150 Pulsation dampener) for

dampening such pulsations has proved itself in practice and is also

adequate if only single-piston pumps are used.

Eluent

Most of the solvents normally used in HPLC and IC can be used to prepare eluents. The conductivity which is necessary for detection is

achieved by the addition of a conductive salt. Concentrations of 1…10

g/L are normally adequate for this purpose, this results in a conductivity

of approx. 1…10 mS/cm. Sulfates, nitrates, phosphates, acetic acid,

791 VA Detector

18

Page 25

3.1 Electrochemical detection

sulfuric acid, perchloric acid, lithium perchlorate, etc. can be used for

this. Chlorides and hydroxycarboxylic acids should not be used; some

reagents which form ion pairs can be used.

Solvent gradients can be used in less sensitive ranges (current range >

100 nA). The eluent is degassed as usual by vacuum or passing a

stream of helium through it.

Stationary phase

In principle all reversed-phase and ion exchanger materials can be

used. New columns must be purged well and for a sufficiently long time

for any contaminants which may be present to be washed out. This

"equlibration phase" of a column may take more than 24 hours in the

most sensitive areas.

Sample solution

Whenever possible, the eluent used should also be used as the solvent

for the sample in order to minimize interference owing to changing surroundings (as small a front peak as possible). Very small amounts of

the active substance should be used, in general < 100 ng.

791 VA Detector

19

Page 26

3 Operation

3.2 Electrodes

3.2.1 Working electrodes

The quality of a working electrode WE can be assessed in terms of the

following criteria:

• Background current (after adequate running-in time):

this should be small and constant

• Interference level ("noise"):

this should be low

• Response characteristics:

after switching on, the low background current should be

quickly reached

It should nevertheless be borne in mind that increases in both background current and noise levels are often due to other causes than a

poor-quality working electrode (for example, contamination of the HPLC

system, malfunction of the pulsation dampener, etc.). Generally speaking, both background current and noise levels tend to increase with

higher polarization voltages, and are usually greater in eluents based

on mixed solvents than in those composed of purely aqueous solutions.

Glassy carbon electrode GCE

Ordering designation 6.0805.010

Sensor material Glassy carbon, GC

Chemical resistance good resistance to acetonitrile, methanol, wa-

ter, etc.

Voltage range (–800) … 0 … +1200 mV (pH < 7)

Regeneration

Sprinkle a little aluminium oxide powder (Al

on the polishing cloth (ordering number of both these accessories: 6.2802.000) and moisten with distilled water. Hold the electrode vertically and polish with a circular motion for about

20…60 s, exerting only light pressure. Rinse with distilled water

and clean with dry cloth. A glassy carbon electrode should always

be polished for a short while immediately before being fitted to

the detector cell.

, grain size 0.3 µm)

2O3

Ultra-Trace graphite electrode

Ordering designations 6.1204.100 Ultra-Trace graphite tip

+ 6.2103.110 Contact pin

Sensor material Graphite (turnover is three times larger than in

GC-electrode; does not need tamping)

Chemical resistance good resistance to acetonitrile, methanol, wa-

ter, etc.

Voltage range –800 … 0 … +1200 mV (pH < 7)

Regeneration

With 6.2827.000 Trimming tool (see electrode data sheet).

791 VA Detector

20

Page 27

3.2 Electrodes

Carbon paste electrode CPE

Ordering designation 6.0807.000

Sensor material paste composed of spectroscopic grade car-

bon powder and paraffin

Chemical resistance good resistance to aqueous solutions; limited

resistance only to water/acetonitrile and water/methanol mixtures

Voltage range (–200) … 0 … +1200 mV (pH < 7)

Regeneration

The sensor surface of the CPE is more vulnerable to both mechanical damage and chemical attack than that of the GCE, it is

more easily regenerated: often it suffices merely to rub the tip of

the electrode backwards and forwards a few times against the

surface of a sheet of ordinary, smooth paper, or alternatively the

upper layer of carbon paste can be renewed (see below) and

then polished in this manner.

Filling

Carefully remove the old carbon paste from the approximately

2.5 mm deep cavity with a suitable sharp instrument. Take care

not to damage the platinum contact wire at the bottom of the cavity. Using a small spatula, fill bit by bit with the fresh 6.2801.020

carbon paste and tamp well down using the 6.2826.000 stopper.

The cavity should be filled over the brim with paste. Now rub off

the excess paste by continuous circular motion against a sheet of

paper with a hard, smooth, non-porous surface; the circular motion plus the light pressure will polish the surface of the paste,

which must be smooth and shiny when the operation is finished.

There should be no cracks in the peripheral zone where the paste

is up against the plastic material of the electrode shaft.

Metal electrodes

Ordering designations 6.1204.120 Pt tip

6.1204.130 Ag tip

6.1204.140 Au tip

+ 6.2103.110 Contact pin

Chemical resistance good resistance to acetonitrile, methanol, wa-

ter, etc.

Voltage range Pt: (–1200) … 0 … +200 mV (pH < 7)

Ag: (–800) … 0 … +400 mV (pH > 7)

Au: (–400) … 0 … +1200 mV (pH < 7)

Regeneration

Sprinkle a little aluminium oxide powder (Al

on the polishing cloth (ordering number of both these accessories: 6.2802.000) and moisten with distilled water. Hold the electrode vertically and polish with a circular motion for about

20…60 s, exerting only light pressure. Rinse with distilled water

and clean with dry cloth. A metal electrode should always be polished for a short while immediately before being fitted to the detector cell.

, grain size 0.3 µm)

2O3

791 VA Detector

21

Page 28

3 Operation

Amalgamated electrode

"Home-made" amalgamated electrodes are prepared as follows:

Base material 6.1204.140 Au tip

Preparation Put a few drops of Hg on the front side of the

electrode and leave it for a few minutes. Knock

off excess Hg and rinse electrode with distilled

water.

Chemical resistance good resistance to acetonitrile, methanol, water

Voltage range –1200 … 0 mV

Regeneration polish electrode with aluminium oxide and re-

amalgamate

3.2.2 Reference electrode

The reference system of the 6.0727.000 Reference electrode (RE) is

Ag/AgCl/c(KCl) = 3 mol /L (see Fig. 5). The electrolyte vessel 41 can be

refilled. The KCl solution has to be renewed every 1…2 months.

Ordering designations for KCl solutions: 6.2308.020 (250 mL)

3.2.3 Auxiliary electrode

A gold electrode is built-in in the detector cell as an auxiliary electrode.

6.2313.000 (1 L)

791 VA Detector

22

Page 29

3.3 Operating element functions

3.3 Operating element functions

Mains switch

The 791 VA Detector is switched on and off using mains switch

25 on the rear of the instrument (see Fig. 2):

I Instrument switched on

0 Instrument switched off

~

After the instrument has been switched on, the mains pilot lamp 1

lights up to show that the instrument is ready for use.

Relative compensation current

rel. is set using the

comp

I

comp

The relative compensation current I

potentiometer 10 (see Fig. 1). The value set is related to the

setting of the adjusting knob 8 (current I).

.

I0.01

Setting range –500 (red) … +500 (white) × 0.01 x I

Resolution 0.01 x I per scale division

Absolute compensation current

The absolute compensation current I

potentiometer 9 (see Fig. 1). The value set is not related to the

setting of the adjusting knob 8 (current I).

abs. is set using the

comp

I

comp

0.02 nA

Setting range

direct 0 … 1000 × 0.02 nA = 20 nA

with commutator 5 5 × 20 nA = 100 nA

with commutator 6 50 × 20 nA = 1000 nA

Resolution

direct 0.02 nA per scale division

with commutator 5 0.10 nA per scale division

with commutator 6 1.00 nA per scale division

The polarity of the absolute compensation current is set separately with commutator 7.

Changeover Stand-by/Measure

meas

For this changeover commutator 3 (see Fig. 1) is used.

Button depressed

Measuring position, i.e. measuring cell connected.

Button not depressed

Stand-by position, i.e. measuring cell disconnected.

791 VA Detector

23

Page 30

3 Operation

Damping

damp

The damping is switched on and off using commutator 4 (see

Fig. 1).

Button depressed

Signal damped for all ranges set on adjusting knob 8 in order to suppress interference (spurious signals).

Button not depressed

No signal damping (exception: the most sensitive range,

0.1 nA, is always damped to some extent).

x50

x5

Multiplication of I

For this changeover commutator 5 (see Fig. 1) is used.

Button depressed

abs. by a factor of 5

comp

Multiplication of the absolute compensation current by a

factor of 5.

Button not depressed

No multiplication of the absolute compensation current.

Multiplication of I

abs. by a factor of 50

comp

For this changeover commutator 6 (see Fig. 1) is used.

Button depressed

Multiplication of the absolute compensation current by a

factor of 50.

Button not depressed

No multiplication of the absolute compensation current.

+

Polarity of I

For this changeover commutator 7 (see Fig. 1) is used.

Button depressed

comp

abs.

All current values set on the potentiometer 9 have a positive

sign.

Button not depressed

All current values set on the potentiometer 9 have a negative sign.

791 VA Detector

24

Page 31

3.3 Operating element functions

overload

Overload display

If the electronic current measuring circuit is overloaded, the red

light 2 is lit up (see Fig. 1).

Remedies

Select a less sensitive current range with adjusting knob 8

or compensate current with potentiometer 9 and/or 10 (for

further measures see section 4.3).

Polarization voltage

is set using the digital switch 11 (see

pol

+

015

U

10 mV

The detection voltage U

Fig. 1).

Setting range –1990 … 0 … +1990 mV

pol

Resolution 10 mV

Current measuring sensitivity

nA

50

10

5

1

0,5 100

0,1

(U

out

I

= 1 V)

µ

A

The sensitivity of current measurement is set using adjusting

0,1

knob 8 (see Fig. 1). The set range applies to the full-scale

0,5

deflection of the analog signal at sockets 22 and 23 (1 V or

1

5

10 mV depending on the setting of switch 21).

4

10

Setting ranges 0.1, 0.5, 1, 5, 10, 50 nA

0.1, 0.5, 1, 5, 100, 10'000 µA

Polarity of analog output

The polarity (+ or –) of the analog output signal is set using

switch 20 (see Fig. 2).

Full-scale deflection of analog output

0...1 V

0...10 mV

The full-scale deflection (1 V or 10 mV) of the analog output

signal is set using switch 21 (see Fig. 2).

791 VA Detector

25

Page 32

3 Operation

3.4 Startup

3.4.1 Preparing the ELCD cell

The ELCD cell must be correctly connected to the HPLC or IC system

before it is filled (see section 2.3 and section 2.4). Then proceed as follows:

1 Fill reference electrode (only if necessary)

Reference electrode 39 (6.0727.000) is supplied in a filled

condition. However, the KCl electrolyte solution must be replaced every 1 to 2 months. Proceed as follows:

• Screw Ag/AgCl reference system 40 out of electrolyte vessel

41 (see Fig. 5).

• Fill electrolyte vessel 41 to the brim with c(KCl) = 3 mol/L.

• Screw Ag/AgCl reference system 40 back onto electrolyte

vessel 41. Take care that no air bubbles are found in the electrolyte vessel (to check: hold reference electrode against the

light).

2 Connect reference electrode

• Insert reference electrode 39 into cell body 32 (see Fig. 5).

• Connect reference electrode 39 to connection 17 of the 791

VA Detector with 6.2120.020 Cable (see Fig. 7).

3 Connect auxiliary electrode

• Connect the auxiliary electrode in cell body 32 to connection

15 of the 791 VA Detector 791 with 6.2120.020 Cable (see

Fig. 7).

4 Prepare working electrode

• Prepare and polish working electrode 28 according to section

3.2.1.

• Insert working electrode 28 into cell body 32 (see Fig. 5).

• Do not

at this point.

5 Start pump

• Switch on delivery drive of HPLC or IC pump.

connect working electrode 28 to the 791 VA Detector

791 VA Detector

26

Page 33

3.4 Startup

3.4.2 Zero balancing and equilibration phase

Before the first measurement is made the working electrode must be allowed to equilibrate and the chart recorder or data recording instrument

must be zero-balanced. Proceed as follows:

1 Chart recorder settings

If a chart recorder is used to record the analog signals then

proceed as follows (the working electrode must not

nected to the 791 VA Detector):

• Switch on 791 VA Detector.

• Set commutator 3 on the 791 VA Detector to "Stand-by".

• Set the required polarity (+ or –) with switch 20; use switch

21 to set the required voltage range for the analog output on

the 791 VA Detector (1 V or 10 mV).

• Set potentiometer 9 on the 791 VA Detector to 0.

• Use knob 8 on the 791 VA Detector to set the current sensitiv-

ity to 0.5 µA.

• Switch on recorder.

• Set the voltage measuring range on the recorder to the same

setting as on the 791 VA Detector (1 V or 10 mV).

• Use potentiometer 10 on the 791 VA Detector to adjust the

zero point of the recorder.

be con-

2 Settings with a data recording program

If a PC recording and evaluation program is used for recording

the analog signals then proceed as follows (the working electrode must not

be connected to the 791 VA Detector):

• Switch on 791 VA Detector.

• Set commutator 3 on the 791 VA Detector to "Stand-by".

• Set the required polarity (+ or –) with switch 20; use switch

21 to set the required voltage range for the analog output on

the 791 VA Detector (1 V or 10 mV).

• Set potentiometers 9 and 10 on the 791 VA Detector to 0.

• Use knob 8 on the 791 VA Detector to set the current sensitiv-

ity to 0.5 µA.

• Switch on the data recording program on the PC and start

recording data.

• If required, use potentiometer 10 on the 791 VA Detector to

adjust the zero point (so that the mV display on the PC shows

0).

791 VA Detector

27

Page 34

3 Operation

3 Overload test

For this test the working electrode must not be connected to the

791 VA Detector:

• Set the polarization voltage on the 791 VA Detector to the

required value for the following determinations with digital

switch 11.

• Set commutator 3 on the 791 VA Detector to "meas". Over-

load display 2 must light up briefly and then go out again.

• If overload display 2 remains lit up for a longer period of time

this indicates that there is a faulty electrical contact between

the reference electrode and the auxiliary electrode. Eliminate

the cause (e.g. air in the system or in the reference electrode,

blocked diaphragm, faulty cable connection) and repeat the

test.

• If the overload test is OK, set commutator 3 on the 791 VA

Detector back to "Stand-by".

4 Equilibrating the working electrode

• Connect working electrode 28 to connection 18 of the 791 VA

Detector with the 6.2120.020 Cable.

• Set commutator 3 on the 791 VA Detector to "meas".

• Observe equilibration curve: the curve should flatten out

noticeably within a relative short time (10…20 min), otherwise

the working electrode must be repolished or refilled.

• In current measuring ranges > 5 nA a constant base current

is usually achieved with one hour. At higher sensitivities the

working electrode should be equilibrated overnight.

5 Zero balancing the base current

(only for recorders)

• Set the current measuring sensitivity on the 791 VA Detector

with knob 8 to the required value.

• Use potentiometer 9 on the 791 VA Detector to adjust the

base current to the zero point of the recorder. If the setting

range of potentiometer 9 is not sufficient then it can be extended by using commutator 5 (× 5) or 6 (× 50).

791 VA Detector

28

Page 35

3.4 Startup

3.4.3 Measuring procedure

In order to be able to carry out measurements it is essential that the

working electrode has achieved a stable base current (see section

3.4.2). If the value of the base current regains its original value after the

determination then as many determinations as required can be carried

out. Attention should be given to the following points:

1 Carrying out the determination

• Inject the sample solution into the HPLC or IC system.

• Record and evaluate the current curve.

2 Allow ELCD system to run overnight

• If the ELCD system is to be used again on the following day

then the 791 VA Detector should not be switched off overnight. The working electrode is constantly under the polarization current and is quickly ready for new measurements.

• The HPLC or IC pump is set to a minimal flow rate and runs

overnight. This means that the base current is stabilized after

only a few minutes.

3 Switching off the ELCD system

• Set commutator 3 on the 791 VA Detector to "Stand-by".

• Unplug working electrode 28.

• Switch off the 791 VA Detector.

791 VA Detector

29

Page 36

3 Operation

791 VA Detector

30

Page 37

4.1 Maintenance and servicing

4 Maintenance – Malfunctions

4.1 Maintenance and servicing

Care

The 791 VA Detector requires proper care and attention. Excessive contamination of the instrument could possibly lead to malfunctions and a

shorter service life of the inherently rugged mechanical and electronic

parts.

Spilled chemicals and solvents should be wiped up immediately. It is

especially important to protect the plug connections at the rear of the

instrument (particular the mains plug) against contamination.

Although constructional measures have been designed to virtually

eliminate such a situation, should corrosive media penetrate the

interior of the instrument the mains plug of the 791 VA Detector must

be immediately disconnected to prevent extensive damage to the

instrument electronics. Inform Metrohm service if your instrument have

been damaged in such a way.

The instrument must not be opened by untrained personnel. Please

comply with the safety notes in section 1.4.1.

Maintenance by Metrohm service

Maintenance of the 791 VA Detector is best done as part of an annual

service performed by specialists from the Metrohm company. If work is

frequently performed with caustic and corrosive chemicals, it may be

necessary to shorten the interval between servicing.

The Metrohm service department is always willing to offer expert advice

on the maintenance and servicing of all Metrohm instruments.

4.2 Shutdown

If the ELCD cell is shut down for a considerable length of time, the entire HPLC or IC system (without

rinsed free from salt with methanol/water (1:4) to avoid crystallization

of eluent salts with the corresponding subsequent damage.

column and suppressor) must be

791 VA Detector

31

Page 38

4 Maintenance – Malfunctions

4.3 Malfunctions and their rectification

Malfunction Cause Rectification

No signal • VA Detector is in "stand-by"

mode.

• VA Detector switched off or

disconnected from mains

voltage.

• Recorder switched off or

disconnected from mains

voltage.

• Recorder disconnected from

VA Detector.

• Electrodes disconnected.

• Broken interconnecting

cables.

VA Detector

shows "overload"

• Current range set exceeded

by too high a concentration of

substance.

• The VA Detector is either

incorrectly balanced or not

balanced at all.

• Reference electrode discon-

nected.

• Auxiliary electrode discon-

nected.

• Polarization voltage badly

adjusted.

• Press "meas" button on VA

Detector.

• Connect VA Detector and

switch on.

• Connect recorder and switch

on.

• Connect recorder to the VA

Detector.

• Connect electrodes.

• Use new interconnecting

cables.

• Wait or set a higher current

range at the VA Detector.

• Balance the recording instru-

ment and VA Detector correctly.

• Connect reference electrode.

• Connect auxiliary electrode.

• Adjust polarization voltage

correctly.

Excessively high

background current

Baseline unstable

• Polarization voltage too high.

• Eluent contaminated.

• Eluent contaminated by Fe(II)

ions from rusty steel parts

(traces only suffice!)

• Highly retarded or enriched

components from the separating column.

• Pressure fluctuations due to

poor seals, blocked filters or

capillaries, defective pump,

etc.

• Eluent contaminated by Fe(II)

ions from rusty steel parts

(traces only suffice!).

• Defective reference electrode.

• Polarization voltage should

generally not be set higher than

1200 mV.

• Prepare fresh eluent using only

the purest (AR grad) chemicals.

• Check entire HPLC or IC system

for rust; check resistance of all

materials to the reagents in use.

• Rinse the column well with

eluent or regenerate it, use new

column if necessary.

• Check HPLC or IC system for

these faults.

• Check entire HPLC or IC system

for rust; check resistance of all

materials to the reagents in use.

• Replace reference electrode.

791 VA Detector

32

Page 39

4.3 Malfunctions and their rectification

Malfunction Cause Rectification

Noise level too high

Spikes on baseline

• Inadequate pulsation

damping.

• Electrostatic screening

defective.

• Background current too high.

• Eluent outlet tubing under

electrostatic influence.

• Defective working electrode.

• Defective 791 VA Detector.

• Air in detector cell.

• Air entering detector cell.

• If a CPE working electrode is

in use, the carbon paste is not

in good condition.

• Use pulsation dampener.

• Check screening, if necessary

connect steel column and/or its

outlet to socket 14 of the VA

Detector by means of a cable.

• Check screening, if necessary

connect steel column and/or its

outlet to socket 14 of the VA

Detector by means of a cable.

• Immerse eluent outlet tubing

completely in spent solution in

waste recipient or renew PTFE

tubing if necessary.

• Replace working electrode.

• Check 791 VA Detector using

the dummy cell (see section

4.1.4)

• Unscrew working electrode and

deaerate detector cell.

• Degas eluent or subject it to

appropriate treatment.

• Refill CPE and ensure paste is

well tamped down.

Isolated spikes on

baseline

Substance turnover

too low or nonexistent

Substance turnover

falls off

Front peak too high • Environment altered by

• Electrostatic discharges from

operating personnel on the

apparatus.

• Mains interference.

• Electromagnetic interference

from environment.

• Polarization voltage too low.

• Active surface of working

electrode blocked by substances.

• Active surface of working

electrode blocked by substances.

• Quantity of substance too

great.

sample solution.

• Eluent contaminated by Fe(II)

ions from rusty steel parts

(traces only suffice!).

• Such discharges cannot be

completely avoided, but are not

usually too troublesome at

normal (i.e. not too dry) atmospheric humidity.

• Connect all instruments to the

power supply via a suitable filter

(e.g. Metrohm 615 Mains Distributor).

• Change "environment".

• Increase polarization voltage.

• Polish working electrode or

renew paste in CPE.

• Polish working electrode or

renew paste in CPE.

• The sample quantity should be

less than 100 ng per injection to

avoid blocking of the electrode

surface.

• Whenever possible, use eluent

as solvent for the sample solution.

• Check entire HPLC or IC system

for rust; check resistance of all

materials to the reagents in use.

791 VA Detector

33

Page 40

4 Maintenance – Malfunctions

4.4 Instrument test with the dummy cell

The correct functioning of the 791 VA Detector can be checked with the

included 6.2813.020 Dummy cell. Several simple checks can be carried

out with this extremely simplified electrical simulation of a detector cell.

Fig. 9 shows the construction of the dummy cell. The checks described

below can be carried out with the recording instrument which is connected (chart recorder, integrator, PC data recording program) or, for

precise measurements, with a voltmeter which is connected to analog

outputs 22 and 23. The dummy cell is connected to the corresponding

cable instead of the electrode. Each test can be carried out separately.

The settings of any operating elements which are not mentioned are irrelevant.

AE

10 M

Ω

1%

Ω

10

1 µF

RE

Fig. 9

: Circuit of 6.2813.020 Dummy Cell

WE

4.4.1 Check of "meas" and "damp" commutators and of current amplifier offset

1 Set digital switch 11 U

to +1000 mV.

pol

+

100

2 Set adjusting knob 8 to 0.1 µA.

3 Set potentiometer 9 I

791 VA Detector

34

abs. to 0.

comp

50

10

5

1

0,5 100

0,1

0.02 nA

I

comp

0,1

0,5

1

5

4

10

Page 41

4.4 Instrument test with the dummy cell

4 Set all commutators 3 … 7 to "off" position

(non-depressed position).

5 Set selector 20 on the rear panel to +.

6 Set selector 21 on the rear panel to 0…10 mV.

7 Bring recorder of voltmeter to 0 using potenti-

ometer 10 I

rel.. The value shown on the

comp

knob scale must not vary from 0 by more than

120 scale divisions.

8 Depress commutator 3 "meas": The recorder or

voltmeter should read –10 mV.

9 Depress commutator 4 "damp" and wait until

recorder of voltmeter have attained a stable

position.

0...1 V

0...10 mV

I

comp

meas

damp

.

I0.01

10 Set commutator 3 "meas" to "off" position: The

time constant τ to be measured, i.e. the time

which has to elapse until 63.2 % of full-scale

deflection is reached, should have a value of

app. 3 s (consider τ of recorder or voltmeter).

4.4.2 Check output voltage

1 Set digital switch 11 U

2 Set adjusting knob 8 to 0.1 µA.

to 0 mV.

pol

meas

+

000

50

10

5

1

0,5 100

0,1

0,1

0,5

1

5

4

10

791 VA Detector

3 Set commutators 4 … 7 to "off" position (non-

depressed position).

35

Page 42

4 Maintenance – Malfunctions

4 Set selector 20 on the rear panel to –.

5 Set selector 21 on the rear panel to 0…1 V.

6 Set recorder sensitivity to 1000 mV.

7 Set commutator 3 "meas" to "on" position

(depressed position).

8 Set potentiometer 9 I

abs. to 0.

comp

9 Bring recorder of voltmeter to 0 using potenti-

ometer 10 I

10 Alter the settings of digital switch 11 U

comp

rel..

pol

in

steps of 100 mV and 10 mV: The settings

shown on the digital switch should be reproduced on the recorder or voltmeter within a

tolerance of <12.5 mV and <1.25 mV respectively.

0...1 V

0...10 mV

meas

I

comp

0.02 nA

+

I

comp

.

I0.01

140

11 Set digital switch 11 U

to – and alter the

pol

settings in steps of 100 mV and 10 mV: The

settings shown on the digital switch should be

reproduced on the recorder or voltmeter within

a tolerance of <12.5 mV and <1.25 mV respectively.

4.4.3 Check of current compensation

1 Set digital switch 11 U

2 Set adjusting knob 8 to 0.1 µA.

to 0 mV.

pol

250

+

000

50

10

5

1

0,5 100

0,1

0,1

0,5

1

5

4

10

791 VA Detector

36

Page 43

4.4 Instrument test with the dummy cell

3 Set selector 20 on the rear panel to –.

4 Set selector 21 on the rear panel to 0…1 V.

5 Set commutator 3 "meas" to "on" position

(depressed position).

6 Set potentiometer 9 I

abs. to 0.

comp

7 Bring recorder of voltmeter to 0 using potenti-

ometer 10 I

8 If potentiometer 10 I

comp

rel..

rel. is now moved

comp

counterclockwise by 100 divisions (= 1 turn)

then this should correspond to 1000 mV on the

recording instrument or voltmeter.

0...10 mV

0.02 nA

0...1 V

meas

I

comp

I

comp

I

comp

.

I0.01

.

I0.01

9 If potentiometer 9 I

abs. is now moved

comp

clockwise by 100 divisions (= 1 turn) then this

should correspond to the following values on

the recording instrument or voltmeter:

direct: +20 mV

×5 button 5 depressed: +100 mV

×50 button 6 depressed: +1000 mV

10 Set commutator 7 (+) to "on" position

(depressed position).

11 Similarly check the functioning of potentiometer

10 I

rel. according to items 7…9.

comp

I

comp

0.02 nA

I

comp

+

.

I0.01

791 VA Detector

37

Page 44

4 Maintenance – Malfunctions

4.4.4 Check of current and voltage overload

1 Set digital switch 11 U

to +10 mV or

pol

–10 mV.

2 Set adjusting knob 8 to 50 nA.

3 Set selector 20 on the rear panel to –.

4 Set selector 21 on the rear panel to 0…1 V.

5 Set potentiometer 9 I

abs. to 0.

comp

+

001

50

10

5

1

0,5 100

0,1

0...1 V

0...10 mV

I

comp

0.02 nA

0,1

0,5

1

5

4

10

6 Set commutators 3 … 7 to "off" position (non-

depressed position).

7 Bring recorder of voltmeter to 0 using potenti-

ometer 10 I

comp

rel..

8 Set commutator 6 "×50" to "on" position

(depressed position).

9 Turn potentiometer 9 I

abs. clockwise until

comp

overload display 2 lights up: The voltage at the

recorder output should be app. 10.5…12 V.

Without digital voltmeter, read the value on the

scale of potentiometer 9: The value should be

between 500 and 620 scale divisions.

10 Reset potentiometer 9 I

abs. to 0: The

comp

overload display 2 extinguishes.

I

comp

.

I0.01

x50

I

comp

0.02 nA

0.02 nA

791 VA Detector

38

I

comp

Page 45

4.4 Instrument test with the dummy cell

11 Set commutator 3 "meas" to "on" position

(depressed position).

12 Unplug dummy cell at "AE": the overload

display 2 lights up.

4.4.5 Check sensitivity knob 8

1 Unplug dummy cell.

2 Set adjusting knob 8 to 50 nA.

3 Set commutators 3 … 7 to "off" position (non-

depressed position).

meas

50

10

5

1

0,5 100

0,1

0,1

0,5

1

5

4

10

4 Set potentiometer 9 I

abs. to 0.

comp

5 Set selector 21 on the rear panel to 0…1 V.

6 Bring recorder of voltmeter to 0 using potenti-

ometer 10 I

rel. (set line recorder first to mid-

comp

scale).

7 Turn adjusting knob 8 through all positions and

check the deviation from zero after a waiting

time of app. 5 s. Deviation should be < ±1 V.

I

comp

0.02 nA

0...1 V

0...10 mV

I

comp

.

50

10

5

1

0,5 100

0,1

I0.01

0,1

0,5

1

5

4

10

791 VA Detector

39

Page 46

4 Maintenance – Malfunctions

4.4.6 Check of noise from current amplifier

1 Connect dummy cell.

2 Set digital switch 11 U

to 0 V.

pol

3 Set adjusting knob 8 to 1 nA.

4 Set commutator 3 "meas" to "on" position

(depressed position).

5 Set commutators 4 … 7 to "odd" position

(non-depressed position).

6 Set selector 21 on the rear panel to 0…1 V.

+

000

50

10

5

1

0,5 100

0,1

meas

0...1 V

0...10 mV

0,1

0,5

1

5

4

10

7 Allow the recording instrument to record for a

longer period of time (first adjust chart recorder

to middle of the scale). Typical deflections

caused by noise are about 10 mVpp or less (the

656 housing must be earthed).

791 VA Detector

40

Page 47

5.1 Technical data

5 Appendix

5.1 Technical data

Measuring instrument

Measuring technique Direct current amperometry

Polarization voltage U

Current measurement Measurement: direct, not integrated

Damping Switchable

Compensation current I

absolute

Range: –1990 … 0 … +1990 mV

pol

Resolution: 10 mV

Deviation: ± 1 % ± 1 mV

Sensitivity: 0.1, 0.5, 1, 5, 10, 50 nA

0.1, 0.5, 1, 5, 100, 10'000 μA

Deviation: ± 15 % for 0.1 nA … 5 nA

± 1.5 % for 10 nA … 0.1 μA

± 1.0 % for 0.5 … 100 μA

± 4.0 % for 10'000 μA

Time constants: ≈ 5.0 s for < 0.1 nA

≈ 0.6 s for 0.1 ... 0.5 nA

≈ 0.3 s for 0.5 ... 1 nA

≈ 0.1 s for 1 ... 5 nA

Time constant: 1.7 s

comp

Basic range: –20 … 0 … +20 nA

Resolution: 0.02 nA

Multiplication: 5 ×, 50 ×

relative

Potentiostat Input resistance: 1012 Ω (typ. value)

Analog output

Signal U = f ( I )

Polarity Switchable

Max. load < 5 mA

Input resistance at

connected instrument

Range: –5.00 … 0 … +5.00· I

Resolution: 0.01· I

Input current: < 5 pA (typ. value)

Zero-point drift: 20 μV/K (typ. value)

Output voltage: ± 10 V

Output current: ≤ 10 mA

1 V or 10 mV DC for the full current range I

> 2 kΩ

791 VA Detector

41

Page 48

5 Appendix

Mains connection

Voltage 115 V: 100...120 V ± 10 %

230 V: 220...240 V ± 10 %

Switchable with voltage selector insert in the fuse

holder (see section 2.2.1)

Frequency 50...60 Hz

Power consumption 5 VA

Fuse 5 mm dia., 20 mm length

100…240 V: 1 A (slow-blow)

Safety specifications

Construction/testing According to IEC 1010 / EN 61010 / UL 3101-1,

protection class 1, degree of protection IP40

Safety directions The Instructions for Use include information and

warnings which must be heeded by the user to

assure safe operation of the instrument.

Electromagnetic compatibility (EMC)

Emitted interference Standards met:

EN55011 (class B), EN55022 (class B),

EN 50081-1/2

Immunity to interference Standards met:

IEC801-2/IEC1000-4-2 (class 3), IEC801-4/

IEC1000-4-4 (class 3), IEC1000-3/EN61000-3,

IEC1000-4-11/EN61000-4-11

Ambient temperature

Nominal operating range +5…+40°C

(at 20…80 % atmospheric humidity)

Storage, transport –40…+70°C

Housing

Material of cover Polyurethane rigid foam (PUR) with fire protection

for fire class UL94VO, CFC-free

Material of base Steel, enameled

Dimensions

Width 260 mm

Height 129 mm

Depth 366 mm

Weight 3.6 kg (with accessories)

791 VA Detector

42

Page 49

5.2 Standard equipment

59

5.2 Standard equipment

Subject to changes !

All dimensions are given in mm.

5.2.1 2.791.0010 VA Detector for HPLC

The 2.791.0010 VA Detector includes the following parts:

Quant. Order No. Description

1 6.2105.030 Cable

Connection cable 791 VA Detector

(analog output) – recorder

1 6.2122.0X0 Mains cable

to customer's specifications:

Cable socket Cable connector

Type IEC 320/C 13 Type SEV 12 (CH…)............................... 6.2122.020

Type IEC 320/C 13 Type CEE (7), VII (D…) .......................... 6.2122.040

Type CEE (22), V Type NEMA 5-15 (USA…)...................... 6.2122.070

1 6.2813.020 Dummy Cell

Electrical simulation of the ELCD cell for

testing and checking functions

1 8.791.1013 Instruction for Use (English)

for 791 VA Detector

1.2 m

791 VA Detector

43

Page 50

5 Appendix

67

∅

∅

59

5.2.2 2.791.0020 VA Detector for IC

The 2.791.0020 VA Detector includes the following parts:

Quant. Order No. Description

1 6.0727.000 Reference electrode

Mini reference electrode for ELCD

cell with Ag/AgCl/c(KCl) = 3 mol/L

reference system;

including cap

3 6.2120.020 Electrode cable

Electrode cable with mini socket

for connection pins 2 mm and mini

plug type F

1 6.2122.0X0 Mains cable

to customer's specifications:

Cable socket Cable connector

Type IEC 320/C 13 Type SEV 12 (CH…) ...............................6.2122.020

Type IEC 320/C 13 Type CEE (7), VII (D…) ...........................6.2122.040

Type CEE (22), V Type NEMA 5-15 (USA…).......................6.2122.070

1 6.2617.000 Tool for PTFE gasket

To remove 6.2704.010 and 6.2704.020

PTFE gaskets

∅ 18

83

2 m

4

67

4 6.2704.010 PTFE gasket

Gasket for reference electrode,

working electrode and eluent inlet

3 6.2704.020 PTFE gasket

Gasket for eluent inlet

1 6.2813.020 Dummy Cell

Electrical simulation of the ELCD cell for

testing and checking functions

1 6.5303.030 ELCD cell

1 8.791.1013 Instruction for Use (English)

for 791 VA Detector

4.3

∅ 12

6

4.5

791 VA Detector

44

Page 51

5.3 Optional accessories

∅

∅

M3

∅

5.3 Optional accessories

Order No. Description

6.0805.010 Mini Glassy Carbon electrode

Diameter of active zone: 2.8 mm.

6.0807.000 Mini Carbon paste electrode

Diameter of active zone: 3 mm.

6.1204.XXX Electrode tips for working electrode

Together with 6.2103.110 Contact pin forms the working

electrode. The following electrode tips are available:

Order No. Disk material Shaft material

6.1204.100 Ultra Trace Graphite PVC

6.1204.120 Pt PEEK

6.1204.130 Ag PEEK

6.1204.140 Au PEEK

Disk diameter: 2.0 +0 / –0.05 mm

6.2103.110 Contact pin

Together with 6.1204.1X0 Electrode tip forms the

working electrode.

7

45

7

45

52.5

21.3

7

6.2801.020 Carbon paste

Carbon paste for 6.0807.000 Mini carbon

paste electrode

6.2826.000 Filling tool

Filling tool for 6.0807.000 Mini carbon paste

electrode

20

83

791 VA Detector

45

Page 52

5 Appendix

5.4 Warranty and conformity

5.4.1 Warranty

The warranty on our products is limited to defects that are traceable to

material, construction or manufacturing error which occur within 12

months from the day of delivery. In this case, the defects will be rectified in our workshops free of charge. Transport costs are to be paid by

the customer.

For day and night operation, the warranty is limited to 6 months.

Glass breakage in the case of electrodes or other parts is not covered

by the warranty. Checks which are not a result of material or manufacturing faults are also charged during the warranty period. For parts of

outside manufacture insofar as these constitute an appreciable part of

our instrument, the warranty stipulations of the manufacturer in question

apply.

With the regard to the guarantee of accuracy, the technical specifications in the instruction manual are authoritative.

Concerning defects in material, construction or design as well as the

absence of guaranteed features, the orderer has no rights or claims except those mentioned above.

If damage of the packaging is evident on receipt of a consignment or if

the goods show signs of transport damage after unpacking, the carrier

must be informed immediately and a written damage report demanded.

lack of an official damage report releases Metrohm from any liability to

pay compensation.

If any instruments and parts have to be returned, the original packaging

should be used if at all possible. This applies above all to instruments,

electrodes, burette cylinders and PTFE pistons. Before embedment in

wood shavings or similar material, the parts must be packed in a dustproof package (for instruments, use of a plastic bag is imperative). If