MacDon 962 User Manual

INTRODUCTION

Your new 962 Harvest Header is designed to serve a dual function in your grain and specialty crop harvesting operation:

1.Teamed with your self-propelled windrower power unit, the header will cut and lay crop into uniform fluffy windrows. Windrowing allows starting the harvest earlier, protects the crop from wind damage, and gives you more flexibility in scheduling combine time. (The left deck of the 962 Header can be manually shifted over the center opening to deliver crop to the end of the header, which allows using your combine as the power unit when windrowing.)

2.When conditions are right for straight cutting, the header can quickly be attached directly to your combine with the addition of an adapter. When weather is not a critical factor, straight cutting eliminates the windrowing operation.

NOTE: This manual contains information on the Harvest Header. It must be used in conjunction with your Windrower, Tractor and/or Combine Operator’s Manual. As well, a separate manual is provided for the adapter that is required to allow attachment of the header to the various makes and models of combines and tractors.

CAREFULLY READ ALL MANUALS TO BECOME FAMILIAR WITH RECOMMENDED PROCEDURES BEFORE ATTEMPTING TO UNLOAD, ASSEMBLE OR USE THE MACHINE.

Use this manual as your first source of information about the header. If you follow the instructions given in this manual your Harvest Header will work well for many years.

This manual contains information on "Safety", "Operation" and "Maintenance/Service". In addition, "Unloading and Assembly" instruction is given towards the back of this book.

Use the Table of Contents and the Index to guide you to specific areas. Study the Table of Contents to familiarize yourself with how the material is organized.

Keep this manual handy for frequent reference and to pass on to new operators or owners. Call your dealer if you need assistance, information or additional copies of the manual.

NOTE: Right hand (R/H), and Left hand (L/H) designations are determined from the operators position, facing forward.

1

TABLE OF CONTENTS |

|

INTRODUCTION ........................................................................................................................................ |

1 |

SERIAL NUMBER LOCATION ................................................................................................................... |

4 |

SAFETY |

|

Safety Alert Symbol................................................................................................................................ |

4 |

Signal Words ......................................................................................................................................... |

5 |

Safety Signs........................................................................................................................................... |

6 |

General Farm Safety........................................................................................................................... |

7,8 |

SPECIFICATIONS |

|

962 Harvest Header............................................................................................................................... |

9 |

Hardware Torque Specifications.......................................................................................................... |

10 |

Hydraulic Fittings Torque Specifications.............................................................................................. |

11 |

HEADER OPERATION |

|

Your Responsibilities as an Owner/Operator....................................................................................... |

12 |

Break-In Period.................................................................................................................................... |

13 |

Pre-Starting Checks: Annual ............................................................................................................... |

14 |

Pre-Starting Checks: Daily................................................................................................................... |

14 |

Operate Correctly................................................................................................................................. |

15 |

Header Controls................................................................................................................................... |

16 |

Header Lift Cylinder Stops ................................................................................................................... |

16 |

Reel Props ........................................................................................................................................... |

16 |

Operating Variables |

|

Ground Speed................................................................................................................................... |

17 |

Cutting Height ................................................................................................................................... |

18 |

Gauge Wheel Field Positions............................................................................................................ |

18 |

Skid Shoes (Attachment) .................................................................................................................. |

19 |

Header Flotation................................................................................................................................ |

20 |

Header Angle .................................................................................................................................... |

20 |

Draper Speed.................................................................................................................................... |

20 |

Delivery Opening Width ............................................................................................................... |

20-22 |

End Delivery...................................................................................................................................... |

23 |

Reel Speed / Reel Height / Reel Position - Fore & Aft ...................................................................... |

24 |

Divider Angle..................................................................................................................................... |

25 |

Shut-Down Procedure.......................................................................................................................... |

25 |

Windrowing |

|

Effects of Operating Variables on Windrow Formation................................................................ |

26,27 |

Windrow Characteristics .............................................................................................................. |

28,29 |

TRANSPORT |

|

Transporting the Header on Windrower or Combine........................................................................... |

30 |

Gauge Wheel / Transport Option |

|

Converting from Field Position to Transport ................................................................................ |

31,32 |

Attaching to Towing Vehicle.............................................................................................................. |

33 |

Towing the Header............................................................................................................................ |

33 |

Converting from Transport to Field Position ................................................................................ |

34,35 |

STORAGE |

|

Storage Procedure............................................................................................................................... |

35 |

2

TABLE OF CONTENTS |

|

MAINTENANCE/SERVICE |

|

Service Procedures.............................................................................................................................. |

36 |

Closing L/H Drive Shield ...................................................................................................................... |

36 |

Recommended Lubricants................................................................................................................... |

37 |

Enclosed Drive Lubricant Capacities ................................................................................................... |

37 |

Sealed Bearing Installation .................................................................................................................. |

37 |

Greasing the Header....................................................................................................................... |

38-40 |

Hydraulic System |

|

Hydraulic System Safety ................................................................................................................... |

40 |

Hoses and Lines ............................................................................................................................... |

40 |

Hydraulic Schematic ......................................................................................................................... |

41 |

Electrical ............................................................................................................................................. |

41 |

Sickle and Sickle Drive |

|

Sickle Lubrication .............................................................................................................................. |

42 |

Sickle Sections.................................................................................................................................. |

43 |

Sickle Removal and Installation ................................................................................................... |

43,44 |

Sickle Head Needle Bearing Installation ........................................................................................... |

44 |

Sickle Guards and Hold-Downs ........................................................................................................ |

45 |

Sickle Drive Belt Tension .................................................................................................................. |

46 |

Wobble Box....................................................................................................................................... |

46 |

Drapers |

|

Draper Tension Adjustment .............................................................................................................. |

47 |

Replacing Drapers ............................................................................................................................ |

47 |

Moving Draper Motors....................................................................................................................... |

47 |

Draper Drive and Idler Rollers........................................................................................................... |

48 |

Installation of Draper Seals ............................................................................................................... |

48 |

Reel and Reel Drive |

|

Reel Clearance from Cutterbar ......................................................................................................... |

49 |

Centering the Reel ............................................................................................................................ |

49 |

Reel Drive Chain ............................................................................................................................... |

50 |

Gauge Wheels |

|

Wheel Bolts....................................................................................................................................... |

50 |

Gauge Wheel/Transport Casters ...................................................................................................... |

50 |

Tire Inflation and Safety .................................................................................................................... |

51 |

Maintenance Schedule ........................................................................................................................ |

52 |

Maintenance Record............................................................................................................................ |

53 |

TROUBLE SHOOTING |

|

Crop Loss at Cutterbar ........................................................................................................................ |

54 |

Cutting Components ....................................................................................................................... |

54-56 |

Reel................................................................................................................................................. |

56,57 |

Drapers ................................................................................................................................................ |

57 |

Windrow Formation.............................................................................................................................. |

58 |

OPTIONS AND ATTACHMENTS |

|

Pick-Up Reel, Gauge Wheels, Gauge Wheel/Transport Option.......................................................... |

59 |

Skid Shoes, Hydraulic Reel Fore-Aft Kit, Reel Arm Slope Kit.............................................................. |

60 |

UNLOADING AND ASSEMBLY |

|

Unloading............................................................................................................................................. |

61 |

Assembling Header ........................................................................................................................ |

62-73 |

Preparing Header For Combine........................................................................................................... |

74 |

Converting Sickle Drive Assembly.................................................................................................. |

75,76 |

Moving Draper Motors Inboard/Outboard ....................................................................................... |

77,78 |

Adjustments and Checks ..................................................................................................................... |

79 |

Hydraulic Fore-Aft Reel Positioner (Option) Assembly................................................................... |

80-83 |

INDEX .................................................................................................................................................. |

84,85 |

3

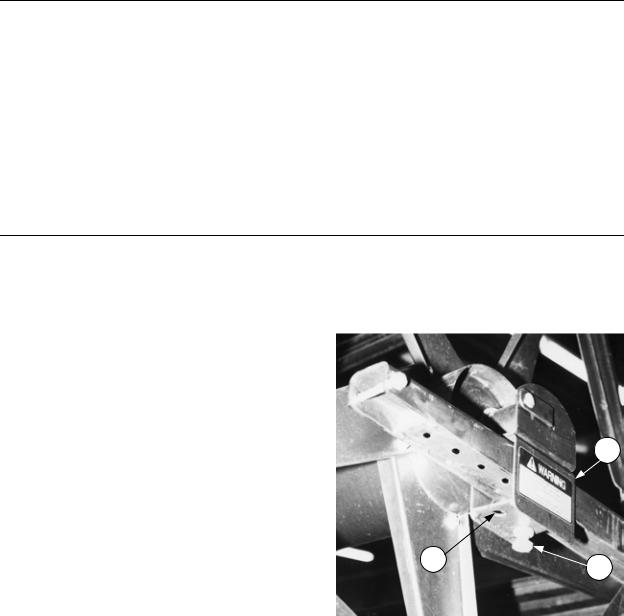

SERIAL NUMBER LOCATION

Record the serial number in the space provided.

Harvest Header:

Plate is located on gusset at left hand end sheet, near main tube.

HEADER SERIAL PLATE

NOTE: When ordering parts and service, be sure to give your dealer the complete and proper serial number.

SAFETY

SAFETY ALERT SYMBOL

This safety alert symbol indicates important safety messages in this manual and on safety signs on the header.

This symbol means: ATTENTION !

BECOME ALERT !

YOUR SAFETY IS INVOLVED !

Carefully read and follow the safety message accompanying this symbol.

Why is SAFETY important to you?

• ACCIDENTS DISABLE AND KILL 3 BIG REASONS • ACCIDENTS COST

• ACCIDENTS CAN BE AVOIDED

4

SAFETY

SIGNAL WORDS

Note the use of the signal words DANGER, WARNING, and CAUTION with safety messages. The appropriate signal word for each message has been selected using the following guidelines:

DANGER – Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

WARNING – Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury. It is also used to alert against unsafe practices.

CAUTION – Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury. It is also used as a reminder of good safety practices.

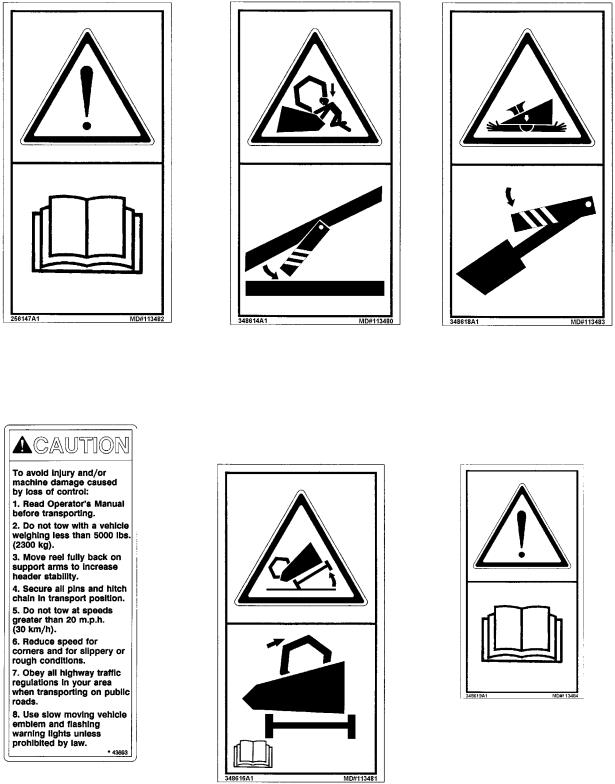

SAFETY SIGNS

•The safety signs reproduced below and on the next page appear on the header at the locations listed.

•Keep safety signs clear and legible at all times.

•Replace safety signs that are missing or become illegible.

•If original parts on which a safety sign was installed are replaced, be sure the repair part also bears the current safety sign.

•Safety signs are available from your Dealer Parts Department.

To install safety signs:

1.Be sure the installation area is clean and dry.

2.Decide on the exact position before you remove the backing paper.

3.Remove the smaller portion of the split backing paper.

4.Place the sign in position and slowly peel back the remaining paper, smoothing the sign as it is applied.

5.Small air pockets can be smoothed out or pricked with a pin.

DRIVELINE

5

SAFETY

SAFETY SIGNS

BACK TUBE Refer to Operator’s manual for recommended safety practices.

HITCH

(TRANSPORT OPTION)

BACK TUBE Engage mechanical lock on each reel support arm before working on or under reel.

BACK TUBE Rest header on ground or engage mechanical lock before going under unit.

HITCH (TRANSPORT OPTION) Refer to transport section of Operator’s Manual for recommended safety practices.

R/H WHEEL BEAM (TRANSPORT OPTION) To avoid injury caused by machine tip-over, move reel back on support arms before converting to transport. Do not move reel forward while machine is in transport.

6

SAFETY

GENERAL SAFETY

The following are general farm safety precautions that should be part of your operating procedure for all types of machinery.

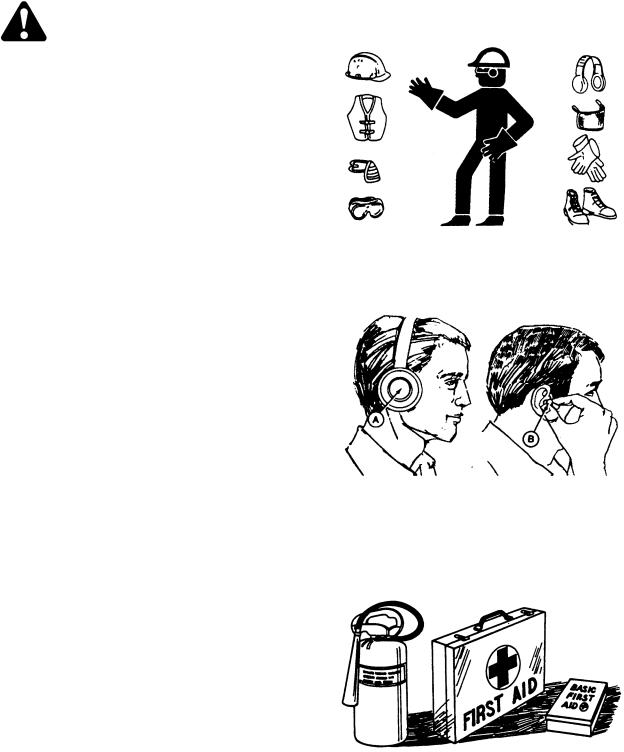

1.Protect yourself.

When assembling, operating and servicing machinery, wear all the protective clothing and personal safety devices that COULD be necessary for the job at hand. Don’t take chances.

You may need:

·a hard hat.

·protective shoes with slip resistant soles.

·protective glasses or goggles.

·heavy gloves.

·wet weather gear.

·respirator or filter mask.

·hearing protection. Be aware that prolonged exposure to loud noise can cause impairment or loss of hearing. Wearing a suitable hearing protective device such as ear muffs (A) or ear plugs (B) protects against objectionable or loud noises.

2.Provide a first-aid kit for use in case of emergencies.

3.Keep a fire extinguisher on the machine. Be sure the extinguisher is properly maintained and be familiar with its proper use.

4.Keep young children away from machinery at all times.

5.Be aware that accidents often happen when the operator is tired or in a hurry to get finished. Take the time to consider the safest way. Never ignore warning signs of fatigue.

PROTECT YOURSELF

PROTECT AGAINST NOISE

BE PREPARED FOR EMERGENCIES

7

SAFETY

GENERAL SAFETY (continued)

6.Wear close-fitting clothing and cover long hair. Never wear dangling items such as scarves or bracelets.

7.Keep hands, feet, clothing and hair away from moving parts. Never attempt to clear obstructions or objects from a machine while the engine is running.

8.Keep all shields in place. Never alter or remove safety equipment. Make sure driveline guards can rotate independent of the shaft and can telescope freely.

9.Use only service and repair parts made or approved by the equipment manufacturer. Substituted parts may not meet strength, design, or safety requirements.

10.Do not modify the machine. Unauthorized modifications may impair the function and/or safety and affect machine life.

11.Stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine.

12.Keep the area used for servicing machinery clean and dry. Wet or oily floors are slippery. Wet spots can be dangerous when working with electrical equipment. Be sure all electrical outlets and tools are properly grounded.

13.Use adequate light for the job at hand.

14.Keep machinery clean. Straw and chaff on a hot engine are a fire hazard. Do not allow oil or grease to accumulate on service platforms, ladders or controls. Clean machines before storage.

15.Never use gasoline, naphtha or any volatile material for cleaning purposes. These materials may be toxic and/or flammable.

16.When storing machinery, cover sharp or extending components to prevent injury from accidental contact.

NEVER WEAR LOOSE

OR DANGLING CLOTHES

KEEP AWAY FROM MOVING PARTS

KEEP SERVICE AREA CLEAN AND DRY

8

SPECIFICATIONS

962 HARVEST HEADER

SICKLE DRIVE

SICKLE SPEED

SICKLE TYPE

DELIVERY OPENING WIDTH (between rollers)

DELIVERY OPENING HEIGHT at 8" (200 mm) cutting height

CUTTERBAR RANGE ground to guard tip, (varies with guard angle and options)

GUARD & DRAPER ANGLE:

-at 8" (200 mm) cutting height

-with cutterbar on ground

DRAPER TYPE

DRAPER WIDTH

DRAPER DRIVE

DRAPER SPEED

FEEDER DRAPER SPEED

FEEDER AUGER SPEED

REEL TYPE

REEL DRIVE

REEL SPEED

HEADER FLOTATION

GAUGE WHEELS (no transport package) Recommended Pressure

TRANSPORT PACKAGE GAUGE WHEELS Recommended Pressure

WINDROWER |

COMBINE |

(Specs listed may vary depending on combine)

"C" belt to single wobble box (enclosed oil bath) 1300 strokes/minute 1150 strokes/minute Over-serrated, bolted sections

35" (890 mm) to 66" (1676 mm)

34" to 37" |

|

(880 to 950 mm) |

|

2.5" (65 mm) below ground |

determined by combine |

to 42" (1080 mm) above |

|

9° to 13° |

13° to 16° |

13° to 21° |

|

|

|

Self-tracking rubber coated polyester with rubber slats 41.5" (1055 mm)

Hydraulic

170 to 500 ft./minute |

|

0 to 450 ft./minute |

||

|

||||

(50 to 155 m/min.) |

|

(135 m/min.) |

||

|

|

|

|

see Adapter Manual |

|

|

|

|

see Adapter Manual |

5 |

Bat metal, or |

|

Cam action pick-up reel |

|

|

||||

|

Hydraulic |

|||

20 to 60 |

RPM |

|

|

determined by combine |

|

|

|||

|

|

|

|

see Adapter Manual |

|

|

|

|

|

6.70-15 I1 Rib Implement

24 to 28 psi (165 to 195 kPa)

9.5L-14 8 ply I1 Rib Implement

42 to 46 psi (290 to 315 kPa)

HEADER WEIGHT (Sample weights shown are without adapter and will vary with attachments)

30 ft. with bat reel, without gauge wheels |

3060 lbs. (1388 kg) |

30 ft. with pick-up reel and gauge wheels |

3560 lbs. (1615 kg) |

36 ft. with bat reel and gauge wheels |

3760 lbs. (1706 kg) |

36 ft. with pick-up reel and transport package |

4484 lbs. (2034 kg) |

(SPECIFICATIONS AND DESIGN ARE SUBJECT TO CHANGE WITHOUT NOTICE OR OBLIGATION TO REVISE PREVIOUS UNITS.)

9

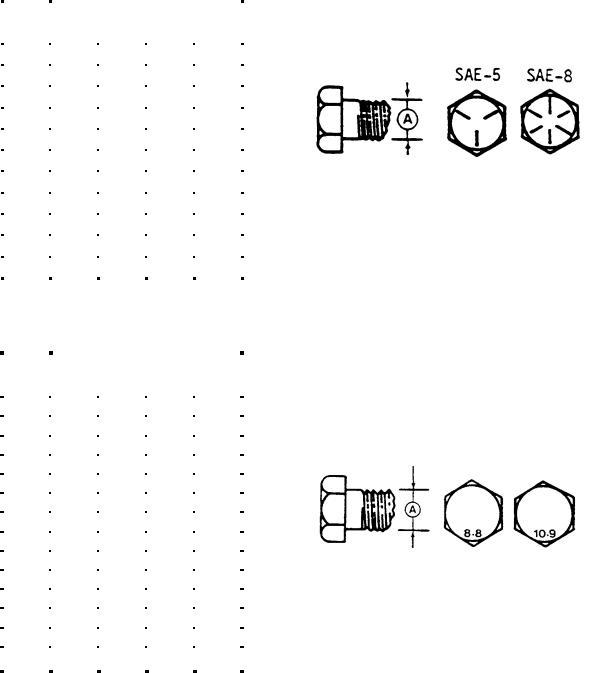

TORQUE SPECIFICATIONS

CHECKING BOLT TORQUE

The tables shown below give correct torque values for various bolts and capscrews. Tighten all bolts to the torques specified in chart unless otherwise noted throughout this manual. Check tightness of bolts periodically, using bolt torque chart as a guide. Replace hardware with the same strength bolt.

ENGLISH TORQUE SPECIFICATION

Bolt |

|

NC Bolt Torque* |

|

||

SAE 5 |

|

SAE 8 |

|||

|

|||||

Dia. |

|

||||

"A" |

N·m |

[lb-ft] |

|

N·m |

[lb-ft] |

1/4" |

12 |

[9] |

|

15 |

[11] |

5/16" |

24 |

[18] |

|

34 |

[25] |

3/8" |

43 |

[32] |

|

56 |

[41] |

7/16" |

68 |

[50] |

|

95 |

[70] |

1/2" |

102 |

[75] |

|

142 |

[105] |

9/16" |

149 |

[110] |

|

202 |

[149] |

5/8" |

203 |

[150] |

|

271 |

[200] |

3/4" |

359 |

[265] |

|

495 |

[365] |

7/8" |

569 |

[420] |

|

813 |

[600] |

1" |

867 |

[640] |

|

1205 |

[890] |

|

|

|

|

|

|

METRIC TORQUE SPECIFICATIONS

|

|

|

|

|

|

|

|

|

|

|

Bolt |

|

|

|

|

Bolt Torque* |

|

|

|||

Dia. |

|

|

8.8 |

|

10.9 |

|||||

|

|

|

||||||||

"A" |

|

|

|

|||||||

|

N·m |

|

|

[lb-ft] |

|

|

N·m |

|

[lb-ft] |

|

|

|

|

|

|

|

|

||||

M3 |

0.5 |

|

[.4] |

|

1.8 |

[1.3] |

||||

M4 |

3 |

|

[2.2] |

|

4.5 |

[3.3] |

||||

M5 |

6 |

|

[4] |

|

9 |

[7] |

||||

M6 |

10 |

|

[7] |

|

15 |

[11] |

||||

M8 |

25 |

|

[18] |

|

35 |

[26] |

||||

M10 |

50 |

|

[37] |

|

70 |

[52] |

||||

M12 |

90 |

|

[66] |

|

125 |

[92] |

||||

M14 |

140 |

|

[103] |

|

200 |

[148] |

||||

M16 |

225 |

|

[166] |

|

310 |

[229] |

||||

M20 |

435 |

|

[321] |

|

610 |

[450] |

||||

M24 |

750 |

|

[553] |

|

1050 |

[774] |

||||

M30 |

1495 |

|

[1103] |

|

2100 |

[1550] |

||||

M36 |

2600 |

|

[1917] |

|

3675 |

[2710] |

||||

|

|

|

|

|

|

|

|

|

|

|

Torque figures indicated above are valid for non-greased or non-oiled threads and heads unless otherwise specified. Do not grease or oil bolts or capscrews unless specified in this manual. When using locking elements, increase torque values by 5%.

* Torque value for bolts and capscrews are identified by their head markings.

10

TORQUE SPECIFICATIONS

TIGHTENING O-RING FITTINGS*

1.Inspect O-ring and seat for dirt or obvious defects.

2.On angle fittings, back the lock nut off until washer bottoms out at top of groove.

3.Hand tighten fitting until back-up washer or washer face (if straight fitting) bottoms on face and O-ring is seated.

4.Position angle fittings by unscrewing no more than one turn.

5.Tighten straight fittings to torque shown.

6.Tighten angle fittings to torque shown while holding body of fitting with a wrench.

*The torque values shown are based on lubricated connections as in reassembly.

|

|

|

|

|

|

|

|

|

|

|

|

|

Nut Size |

|

|

|

|

|

Recommended |

||

|

|

Across |

|

|

|

|

|

Turns to Tighten |

||

Thread |

|

Flats |

|

|

|

|

|

(after finger |

||

Size |

|

(in.) |

|

Torque Value* |

|

tightening) |

||||

(in.) |

|

|

|

N·m |

|

[lb-ft] |

|

Flats |

|

Turns |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

||||

3/8 |

1/2 |

8 |

[6] |

2 |

1/3 |

|||||

7/16 |

9/16 |

12 |

[9] |

2 |

1/3 |

|||||

1/2 |

5/8 |

16 |

[12] |

2 |

1/3 |

|||||

9/16 |

11/16 |

24 |

[18] |

2 |

1/3 |

|||||

3/4 |

7/8 |

46 |

[34] |

2 |

1/3 |

|||||

7/8 |

1 |

62 |

[46] |

1-1/2 |

1/4 |

|||||

1-1/16 |

1-1/4 |

102 |

[75] |

1 |

1/6 |

|||||

1-3/16 |

1-3/8 |

122 |

[90] |

1 |

1/6 |

|||||

1-5/16 |

1-1/2 |

142 |

[105] |

3/4 |

1/8 |

|||||

1-5/8 |

1-7/8 |

190 |

[140] |

3/4 |

1/8 |

|||||

1-7/8 |

2-1/8 |

217 |

[160] |

1/2 |

1/12 |

|||||

|

|

|

|

|

|

|

|

|

|

|

TIGHTENING FLARE TYPE TUBE FITTINGS*

1.Check flare and flare seat for defects that might cause leakage.

2.Align tube with fitting before tightening.

3.Lubricate connection and hand tighten swivel nut until snug.

4.To prevent twisting the tube(s), use two wrenches. Place one wrench on the connector body and with the second, tighten the swivel nut to the torque shown.

*The torque values shown are based on lubricated connections as in reassembly.

|

|

|

|

|

|

|

|

|

|

|

|

|

Nut Size |

|

|

|

|

|

Recommended |

||

Tube |

|

Across |

|

|

|

|

|

Turns to Tighten |

||

Size |

|

Flats |

|

|

|

|

|

(after finger |

||

O.D. |

|

(in.) |

|

Torque Value* |

|

tightening) |

||||

(in.) |

|

|

|

N·m |

|

[lb-ft] |

|

Flats |

|

Turns |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

||||

3/16 |

7/16 |

8 |

[6] |

1 |

1/6 |

|||||

1/4 |

9/16 |

12 |

[9] |

1 |

1/6 |

|||||

5/16 |

5/8 |

16 |

[12] |

1 |

1/6 |

|||||

3/8 |

11/16 |

24 |

[18] |

1 |

1/6 |

|||||

1/2 |

7/8 |

46 |

[34] |

1 |

1/6 |

|||||

5/8 |

1 |

62 |

[46] |

1 |

1/6 |

|||||

3/4 |

1-1/4 |

102 |

[75] |

3/4 |

1/8 |

|||||

7/8 |

1-3/8 |

122 |

[90] |

3/4 |

1/8 |

|||||

|

|

|

|

|

|

|

|

|

|

|

11

OPERATION

YOUR RESPONSIBILITIES AS AN OWNER/OPERATOR

CAUTION:

1.It is your responsibility to read and understand this manual and the Windrower or Combine Operator’s Manual completely before operating the header. Contact your dealer if an instruction is not clear to you.

2.Follow all safety messages in the manuals and on safety signs on the machine.

3.Remember that YOU are the key to safety. Good safety practices protect you and the people around you.

4.Before allowing anyone to operate the machine, for however short a time or distance, make sure they have been instructed in its safe and proper use.

5.Review the manual and all safety related items with all operators annually.

6.Be alert for other operators not using recommended procedures or not following safety precautions. Correct these mistakes immediately, before an accident occurs.

7.Do not modify the machine. Unauthorized modifications may impair the function and/or safety and affect machine life.

8.The safety information given in this manual does not replace safety codes, insurance needs, or laws governing your area. Be sure your machine meets the standards set by these regulations.

TO THE NEW OPERATOR

It’s natural for an operator to be anxious to get started with a new machine. Please take the time to familiarize yourself with the header by reading the Operator’s Manuals and safety signs before attempting operation.

12

HEADER OPERATION

BREAK-IN PERIOD

1.After attaching header to combine or windrower tractor for the first time, operate the machine with reel, drapers and sickle running slowly for 5 minutes, watching and listening FROM THE OPERATOR’S SEAT for binding or interfering parts.

CAUTION: Before investigating an unusual sound or attempting to correct a problem, shut off engine,

engage parking brake and remove key.

NOTE: Reel and side drapers will not operate until oil flow fills the lines.

2.Change hydraulic oil filter(s) as recommended in combine or windrower tractor Operator’s Manual.

3.Adjust the tension of sickle drive belt (A) after a 5 hour run-in period.(See Maintenance/ Service section, page 46.) Continue to check the belt tension periodically for the first 50 hours.

4. Tighten any loose hardware after the first

5 hours operation. See Specifications section, page 10 for recommended torque values.

5.For headers with gauge wheels, check gauge wheel bolt torque after the first 10 hours operation and periodically thereafter (at least

every 100 hours). Torque:

4 bolt hub - 50 to 60 ft.lbs. (70 to 80 N m)

6 bolt hub - 80 to 90 ft.lbs. (110 to 120 N m)

6.Tighten the four wobble box mounting bolts (B) after the first 10 hours operation and every 100

hours thereafter. Torque to 200 ft.lbs. (270 N m), starting with the side mounting bolts.

7.Change wobble box lubricant after the first 50 hours operation and every 1000 hours (or 3 years) thereafter. See Maintenance/Service section, page 46.

A

CHECK SICKLE DRIVE BELT TENSION

B

TIGHTEN FOUR WOBBLE BOX

MOUNTING BOLTS

13

HEADER OPERATION

PRE-STARTING CHECKS: ANNUAL

Do the following at the start of each operating season.

CAUTION:

1.Review the Operator’s Manuals to refresh your memory on safety and operating recommendations.

2.Review all safety signs and other decals on the machine and note hazard areas.

3.Be sure all shields and guards are properly installed and secured. Never alter or remove safety equipment.

4.Be sure you understand and have practised safe use of all controls. Know the capacity and operating characteristics of the machine.

5.Check the first aid kit and fire extinguisher. Know where they are and how to use them.

Also:

6.Install drapers. See "Drapers" in Maintenance /Service section, page 47.

7.Adjust belt, draper and chain tension. See Maintenance/Service section.

8.Perform all Annual Maintenance. See Maintenance/Service section, page 52.

PRE-STARTING CHECKS: DAILY

Do the following each day before start-up:

CAUTION:

1.Clear the area of other persons, pets etc. Keep children away from machinery. Walk around the header to be sure no one is under, on or close to it.

2.Remove foreign objects from the machine and surrounding area.

3.Wear close fitting clothing and protective shoes with slip resistant soles.

As well, carry with you any protective clothing and personal safety devices that COULD be necessary through the day. Don’t take chances.

You may need:

-hard hat

-protective glasses

-heavy gloves

-respirator or filter mask

-wet weather gear.

4.Protect against noise. Wear a suitable hearing protective device such as ear muffs or ear

plugs to protect against objectionable or uncomfortably loud noises.

5.Check the machine for leaks or any parts that are missing, broken, or not working correctly.

NOTE: Use proper procedure when searching for pressurized fluid leaks. See "Hydraulic System" in Maintenance/Service section, page 40.

6.Clean all lights and reflective surfaces on the machine.

7.Perform all Daily maintenance. See Maintenance/Service section, page 52.

14

HEADER OPERATION

OPERATE CORRECTLY

CAUTION:

1.Follow all safety and operational instructions given in your Operator’s Manuals. If you do not have a windrower tractor and/or combine manual, get one from your dealer and read it thoroughly.

2.Never attempt to start the engine or operate the machine except from the operator’s seat.

3.Check the operation of all controls in a safe clear area before starting work.

4.Do not allow riders on windrower or combine.

5.Never start or move the machine until you are sure all bystanders have cleared the area.

6.Avoid travelling over loose fill, rocks, ditches or holes.

7.Drive slowly through gates and doorways.

8.When working on inclines, travel uphill or downhill when possible. Be sure to keep transmission in gear when travelling downhill.

9.Never attempt to get on or off a moving machine.

10.Do not leave the operator’s station while the engine is running.

11.Stop engine and remove key before adjusting or removing plugged material from the machine. A child or even a pet could engage the drive.

12.Check for excessive vibration and unusual noises. If there is any indication of trouble, shut-down and inspect the machine. Follow proper shutdown procedure:

-engage brake

-disengage header drive

-turn off engine and remove key

-wait for all movement to stop

-dismount and engage cylinder stops before inspecting raised machine.

13.Operate only in daylight or good artificial light.

DO NOT ALLOW RIDERS

CLEAR THE AREA BEFORE OPERATING

15

HEADER OPERATION

HEADER CONTROLS

CAUTION: Be sure all bystanders are clear of machine before starting engine or engaging any header drives.

See your Windrower Tractor or Combine Operator’s Manual for identification of in-cab controls for:

•Header Drive Clutch

•Header Height

•Ground Speed

•Reel Speed

•Reel Height

HEADER LIFT CYLINDER STOPS

DANGER: To avoid bodily injury or death from fall of raised header, always engage cylinder stops before

going under header for any reason. See your Windrower Tractor or Combine Operator’s Manual for instruction regarding the use and storage of header lift cylinder stops.

REEL PROPS

WARNING: To avoid bodily injury from fall of raised reel, always engage reel props before going under raised reel for any reason.

IMPORTANT: To prevent damage to reel support arms, do not transport header with reel props engaged.

Reel props are located at each reel support arm.

To engage reel props:

1.Raise reel to maximum height.

2.Move props (B) to engaged position.

3.Lower reel until props contact end frames.

NOTE: Keep pivot bolt (C) properly tightened so prop remains in stored position when not in use, yet can be engaged with hand force.

For 36 foot header, be sure hoses are positioned to pass through slot (D) in center arm prop.

C

B

REEL PROP - ENGAGED

C

D B

36 FT. CENTER ARM REEL PROP - ENGAGED

16

HEADER OPERATION

Operating Variables

Satisfactory function of the header requires making the proper adjustments to suit various crops and conditions.

Correct operation reduces crop loss and allows cutting of more acres. As well, proper adjustments and timely maintenance will increase the length of service you receive from the machine.

The variables listed at right will affect the performance of the header. You will quickly become adept at adjusting the machine to give you the desired results.

OPERATING VARIABLES

1.Ground Speed

2.Cutting Height

3.Header Flotation

4.Header Angle

5.Draper Speed

6.Delivery Opening Width

7.Reel Speed

8.Reel Height

9.Reel Fore-Aft Position 10. Divider Angle

GROUND SPEED

•Ground speed should be such that the sickle can cut crop smoothly and cleanly, while giving the desired delivery of material to the opening. Excessive ground speed results in "ragged" cutting. See "Windrowing" for affects of ground speed on windrow formation.

•In tough-to-cut crops like flax, reduce ground speed to reduce loads on cutting components and drives.

•Higher ground speeds require heavier float settings to prevent excessive bouncing. This will result in increased cutting component damage.

•As ground speed is increased, draper and reel speed should be increased to handle the extra material.

The chart below indicates the relationship between ground speed and area cut for the two header sizes.

Example shown: At a ground speed of 5 miles per hour (8 km/h) with a 36 ft. header, the area cut would be approximately 22 acres (9 hectares) per hour.

17

HEADER OPERATION

Operating Variables (continued)

CUTTING HEIGHT

Cutting height will vary, depending on whether windrowing or straight-cutting, type of crop, etc. See "Windrowing" for stubble height recommendations.

Gauge Wheel Field Positions: |

|

|

For headers equipped with gauge wheels or the |

|

|

gauge wheel/transport package, choose Field |

|

|

Position 1 or 2 to maintain proper gauge wheel |

|

|

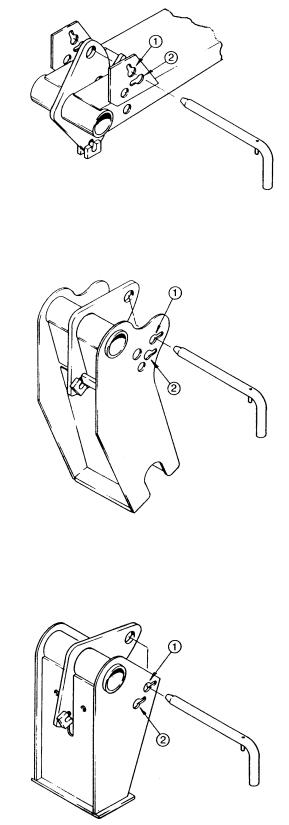

STANDARD GAUGE WHEEL SUPPORT |

||

spring force at desired cutting height. |

||

Field Position 1 when cutterbar is above the |

|

|

|

||

ground (4 to 12 in. [100 to 300 mm] cutting height. |

|

|

Field Position 2 when cutterbar is on the ground |

|

|

(0 to 4 in. [100 mm] cutting height). |

|

|

NOTE: When changing gauge wheel field position, |

|

|

readjust header flotation. See "Header Flotation" in |

|

|

Windrower Tractor or Combine Adapter Operator’s |

|

|

Manual. |

|

|

NOTE: Gauge wheel field position should also be |

|

|

related to Header Angle. Use Position 2 for flatter |

|

|

header angles and Position 1 for steeper header |

|

|

angles. |

|

TRANSPORT PACKAGE -

LEFT WHEEL SUPPORT

TRANSPORT PACKAGE -

RIGHT WHEEL BEAM SUPPORT

18

HEADER OPERATION

Operating Variables

CUTTING HEIGHT (continued)

Skid Shoes (Attachment)

Skid shoes are available as an attachment. The primary benefits of skid shoes are:

1.Help prevent damage to cutting components.

2.Reduce scooping of dirt onto cutterbar.

3.Provide a method of setting a minimum cutting height.

To adjust skid shoes:

1. |

Raise header and engage lift cylinder stops. |

|

|

DANGER: To avoid bodily injury or |

|

|

death from fall of raised header, |

|

|

always engage cylinder stops before |

|

|

going under header. |

|

2. |

Remove one of the guard bolts securing |

|

|

support (S). |

|

3. |

Remove rods from supports and position shoe |

|

|

at desired setting. Adjust both shoes to the |

|

|

same position to provide an even cutting |

|

|

height. |

|

|

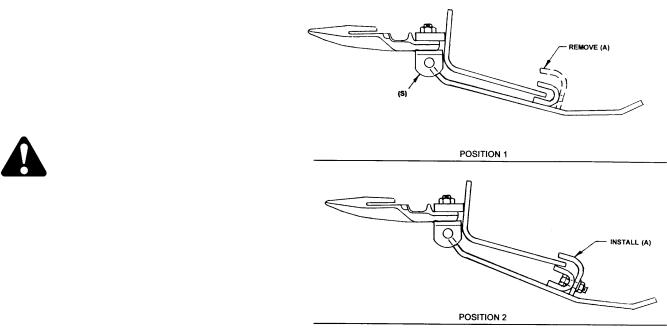

NOTE: When using the "flattest" setting, |

|

|

(Position 1), ensure angle (A) is removed to |

SKID SHOE POSITIONS |

|

prevent draper damage. |

|

|

|

|

4. |

Replace rods in supports and replace guard |

|

|

bolt. |

|

NOTE: The skid shoe kit includes two shoes.

Additional skid shoes may be installed if required.

19

HEADER OPERATION

Operating Variables (continued)

HEADER FLOTATION

IMPORTANT: To avoid frequent breakage of sickle components, scooping soil, or soil build-up at cutterbar in wet conditions, set header float as light as possible without causing excessive bouncing.

Under normal conditions, adjust float spring tension so 50 to 70 lbs. force (220 to 310 N) is required to lift cutterbar off ground at each end.

See "Header Flotation" in Windrower or Combine Adapter Operator’s Manual for adjustment details.

HEADER ANGLE

The header (or guard) angle can be set between 9° and 13° below horizontal on the windrower.

The header (or guard) angle can be set between 13° and 16° below horizontal on the combine. (Actual range may vary with combine set-up.)

IMPORTANT: The flattest header angles are recommended for normal conditions. A flatter header angle reduces sickle section breakage and reduces soil scooping or build-up at the cutterbar in wet conditions. Use a steeper angle to cut very close to the ground, or in down crop for better lifting action.

See "Windrowing" for the effects of header angle on windrow formation. See "Header Angle" in Windrower or Combine Adapter Operator’s Manual for adjustment details.

For headers with gauge wheels, see "Gauge Wheel Field Positions", page 18 for proper relationship between gauge wheel setting and header angle.

DRAPER SPEED

Draper speed affects the orientation of stalks in the delivered crop. See "Windrowing", page 26 for the affect of draper speed on windrow formation. See Windrower or Combine Adapter Operator’s Manual for adjustment details.

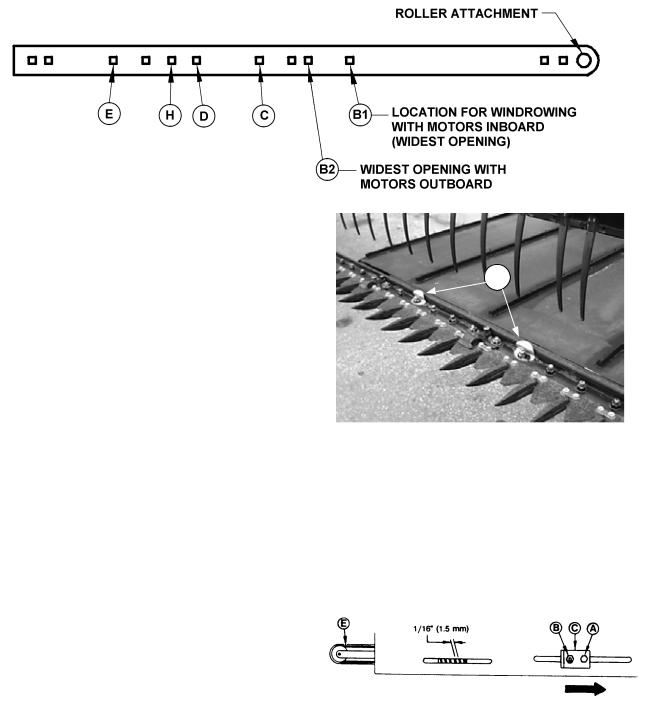

DELIVERY OPENING WIDTH

For windrower, the width and position of the delivery opening affects the width and configuration of the windrow. See "Windrowing", page 26 for more information.

For straight cutting, the side draper opening must be set to properly overlap feeder draper.

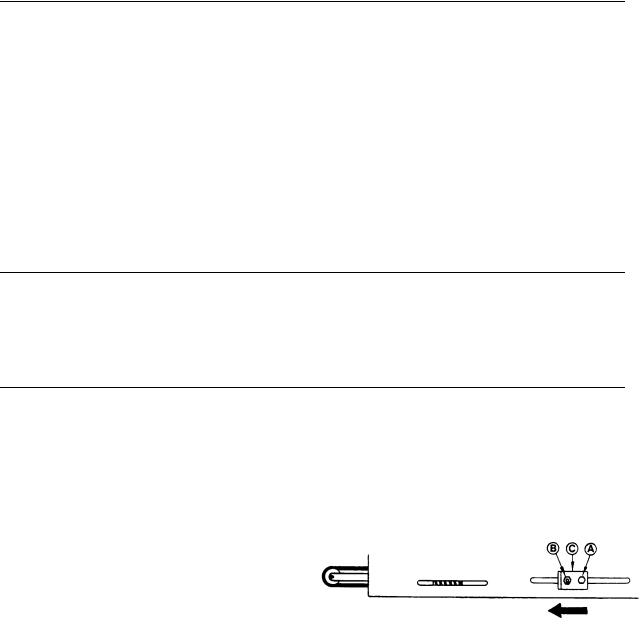

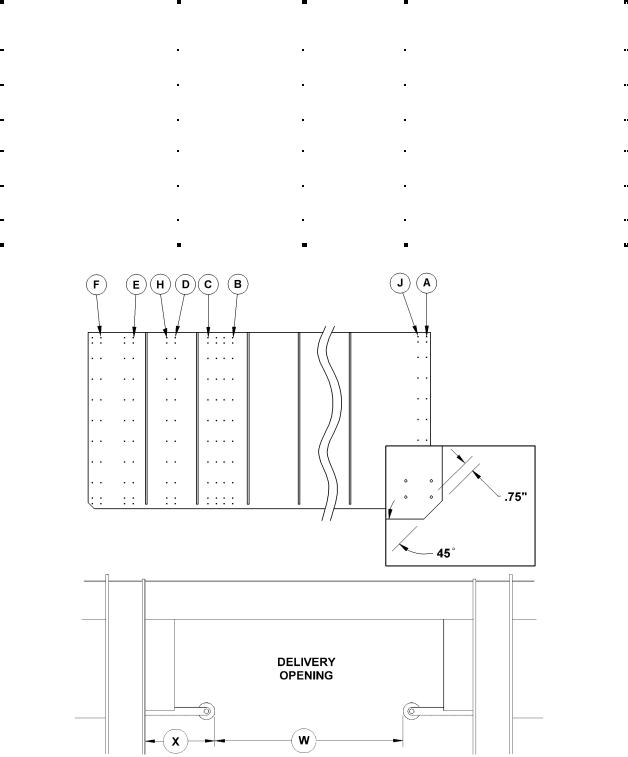

The center delivery opening can be adjusted to widths between 32.3" (820 mm) and 65.8" (1670 mm) measured between rollers.

NOTE: End delivery opening size is limited by windrower drive tires and/or deck contacting header frame. When shifting deck to end delivery, ensure center delivery opening size is 61" (1549 mm) or narrower.

To adjust delivery opening width:

1. Release draper tension as follows:

•Loosen bolt (A) and nut (B).

•Slide bracket (C) towards outboard roller. NOTE: It may be necessary to tap bracket (C)

with a hammer to start it moving.

RELEASE DRAPER TENSION

20

HEADER OPERATION

Operating Variables

To adjust delivery opening width (continued)

2.Remove screws from draper connector slat.

3.Use the following chart to position draper connector tubes at the appropriate rows of holes and position rollers at center opening for the desired application.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CENTER DELIVERY |

|

LEG TO |

|

|

CONNECTION |

|

OPENING WIDTH (W) |

|

ROLLER EDGE |

|

DESIGNATED APPLICATION |

|

|

(between rollers) |

|

(DIM. X) |

|

and COMMENTS |

|

||||||

Row A to Row F (both drapers) |

|

33.9" (860 mm) |

|

22.4" (568 mm) |

|

Opening for combine models: Case 60 & 66 |

|

|

|

|

|

|

Series, NH-TR and Gleaner |

Row A to Row E (both drapers) |

|

41.7" (1060 mm) |

|

18.4" (468 mm) |

|

Opening for combine models: Case 80 & 88 |

|

|

|

|

|

|

Series |

Row A to Row H (both drapers) |

|

49.6" (1260 mm) |

|

14.4" (365 mm) |

|

Opening for Cat 450 & 470 Series |

|

|

|

|

|

|

|

Row J to Row D (both drapers) |

|

53.5" (1360 mm) |

|

12.4" (315 mm) |

|

Opening for combine models: JD STS, |

|

|

|

|

|

|

CTS, 9500, 9510 and NH-TX |

Row A to Row C (both drapers) |

|

59.5" (1510 mm) |

|

9.6" (243 mm) |

|

Opening for combine models: JD 9600, |

|

|

|

|

|

|

9610, 9650 and Cat 460 & 480 Series |

Row A to Row B (both drapers) |

|

65.8" (1670 mm) |

|

6.4" (163 mm) |

|

Maximum opening for windrowing |

|

|

|

|

|

|

|

21

HEADER OPERATION

Operating Variables

To adjust delivery opening width

3.continued)

Bolt opening adjustment bars to deck at the hole corresponding to the draper row. For example if drapers are to be connected at row E (from chart on previous page), move roller until hole (E) aligns with deck mounting slot. Use a carpenter’s square to ensure roller is square to deck and tighten hardware.

NOTE: For access to bolt securing the adjustment bar at cutterbar on L/H (moveable) deck, remove retainer clips (G) and, if installed, the front edge draper seals and clips (see page 48). Raise front of deck for access to bolt.

4.Cut excessive flap off of draper, leaving 3/8" (10 mm) extending above the connector. Trim the new ends at the front corners as shown on page 21. This allows draper to fit properly under front draper seal to prevent tearing of front edge. Use the cut-offs as a guide for trimming. Keep the cut-offs for use as a splice.

5.NOTE: Place connector tube so holes closest to end of tube are at the cutterbar.

Connect draper with screw heads facing center opening.

NOTE: To reduce the opening size after it has been enlarged, a short section of draper (available from your dealer) can be added to increase draper length.

6.Slide bracket (C) away from outboard roller as far as hand force allows. Check that draper V- guide (E) is properly engaged in grooves at rear of both rollers.

7.Tighten nut (B) to secure the position of bracket (C).

8.Apply draper tension by turning bolt (A) clockwise until gap between idler spring coils is 1/16 inch (1.5 mm).

IMPORTANT: Do not collapse spring. The spring maintains draper tension and prevents over-tension. If spring is collapsed, damage to draper and rollers may result from excessive draper tension.

G

REMOVE CLIPS ON LEFT DECK

FOR BOLT ACCESS

APPLY DRAPER TENSION

22

HEADER OPERATION

Operating Variables

END DELIVERY: The left deck of the 962 header can be manually shifted to close off the center opening and deliver crop to the left end of the header. This provides the capability of windrowing with a combine or non-windrower tractor as the power unit.

To shift left deck:

1.Reverse draper travel by disconnecting hydraulic hoses at (B) and connect to opposite lines.

2.Remove deck retainer clips at cutterbar, item (G) on previous page. (If front edge draper seals are installed at cutterbar, remove these seals and clips as well.)

3.For Model 872 Adapters, turn needle valve control (D) on adapter valve fully open to stop hydraulic flow to the feed draper and drum. Valve must be fully open to prevent rotation of feed draper and drum when oil is cold.

4.Lower the header to the ground and continue until adapter lowers.

5.Lengthen center link between header and adapter to steepest header angle to increase clearance to header back sheet

6.Loosen bolts (C) at both clamps on left deck. Attach a "Come-Along" from a sickle guard to the deck cross member (A) as shown. Move deck to the right until there is approximately 2 inches (50

mm)clearance between the rollers of the two decks.

IMPORTANT: This clearance is required to prevent contact between draper connectors or slats as they pass between decks.

NOTE: If there is interference between deck backsheet and combine adapter upper feed device (auger or retracting tine drum) move auger/drum back to provide clearance. See Drum Fore-Aft Adjustment in 872 Adapter Manual.

7.Tighten bolts (C) at both clamps.

8.Readjust center link to achieve desired header operating angle.

9.Reinstall deck retainer clips (and front edge draper seals, if required).

10.With header and combine feed chain drum floated up, check clearances: There should be 1 to 2 inches (25 to 50 mm) clearance between adapter drum and combine feed chain drum, while still providing adequate clearance to header backsheet. If repositioning adapter drum does not provide enough clearance both fore and aft, remove one row of tines from drum (2 or 3 tines, depending on drum size).

11.Adjust header flotation to compensate for the shift in weight. See "Header Flotation" in Windrower or Combine Adapter Operator’s Manual.

12.For rotary combines with narrow feeder opening, increase delivery opening width to be suitable for windrowing. See "Delivery Opening Width", beginning on page 20.

B

REVERSE HOSES AT HYDRAULIC LINES

D

STOP FLOW TO ADAPTER DRAPER & DRUM

C

LOOSEN CLAMPS

A

USE "COME-ALONG" TO MOVE DECK

23

HEADER OPERATION

Operating Variables (continued)

REEL SPEED

•Reel speed affects the smoothness and evenness of the delivered crop. Operating the reel too fast or too slow relative to ground speed will cause bunching.

•In standing crop, reel speed should be just faster than ground speed, sweeping crop across the sickle.

•A faster reel speed may be necessary in leaning or down crop.

•Excessive shattering of grain heads or crop loss over the header back tube may be indications that reel speed is too fast.

REEL HEIGHT

•In standing crop, adjust reel height so bat contacts the plants just below the head, and carries material through the sickle onto the drapers.

•Down crop may require a lower reel height to wipe crop off the sickle.

•Bushy crop may require raising the reel to prevent unevenness in delivery.

•Indications that reel may be too low are crop loss over the header back tube, or disturbance of crop on the drapers by the reel bats.

•For reel clearance to cutterbar adjustment, see Maintenance/Service section, page 49.

REEL POSITION - FORE & AFT

Reel fore-aft position can be adjusted to suit various crop conditions:

•For straight standing crop, the reel position is normally centered above the cutterbar.

•For crops that are down, tangled, or leaning, move reel ahead of cutterbar.

•Disturbance of crop on the drapers by the reel bats may be an indication that the reel is too far back.

To adjust reel fore-aft position:

1.Lower reel so support arms are horizontal.

2.Back off jam nut on positioning screw (A) at each arm.

3.Loosen screw (A) and slide reel mounting channel (B). Pry bar may be used at hole (C).

4.Tighten screw into selected hole position and secure with jam nut.

5.Be sure screw is in the same hole at each arm.

6.Check reel clearance to cutterbar. See Maintenance/Service section.

NOTE: If reel fore-aft position is changed by more than two holes, check and adjust header flotation.

NOTE: For 36’ center arm, positioning screw is on top of mounting channel. (There is no jam nut on positioning screw at center arm.)

B

C

A

REEL FORE-AFT POSITION ADJUSTMENT

24

HEADER OPERATION

Operating Variables |

|

|

DIVIDER ANGLE |

|

|

The dividers can be angled in or out to provide |

|

|

proper separation and clean entry in a variety of |

A |

|

crops. Divider gather is factory set at |

||

|

||

approximately 1.5 inches (40 mm). In tangled |

|

|

crops like canola, it may be necessary to reduce |

|

|

gather. |

|

|

To adjust angle, loosen hardware (A), position |

|

|

divider and tighten hardware. |

|

|

NOTE: On left side, ensure that front hinge pin of |

|

|

side shield remains covered. |

|

|

|

DIVIDER ANGLE ADJUSTMENT |

|

|

|

Shut Down Procedure

CAUTION: Before leaving operator’s seat for any reason:

1.Park on level ground if possible.

2.Lower the header and reel fully.

3.Place all controls in NEUTRAL or PARK.

4.Disengage header drive.

5.Engage the park brake.

6.Stop engine and remove key from ignition.

7.Wait for all movement to stop.

25

HEADER OPERATION

Windrowing

The factors listed below will all affect the formation of the windrow. You will quickly become adept at adjusting these variables to achieve the desired results.

NOTE: Crop condition is a major factor in forming a good windrow. While standing or uniformly leaning crops can generally be easily formed into an acceptable windrow, such is not the case when stalks are tangled or leaning in several directions.

GROUND SPEED

Ground speed should be such that the sickle can cut crop smoothly and cleanly, while giving the desired windrow formation.

Ground speed affects the orientation of stalks in the windrow. Increasing ground speed will cause the configuration of the windrow to go from parallel formation to herringbone or dovetail. See "Windrow Characteristics" in this section.

CUTTING HEIGHT

For grain crops the windrow should normally be laid on stubble from 6 to 8 inches high (150 - 200 mm).

Benefits of a stubble of this height:

•Allows free circulation of air under the windrow for more even drying.

•Supports the windrow without bending.

•Keeps grain heads from contacting ground. Heads that touch the ground are difficult to pick up and will sprout in damp weather.

HEADER ANGLE

Steeper draper angles tend to form herringbone or dovetail configurations, while flatter draper angles form parallel or fantail windrows. See "Windrow Characteristics" in this section.

DRAPER SPEED

Draper speed affects the orientation of stalks in the windrow. Faster draper speeds will tend to form herringbone or dovetail configurations. See "Windrow Characteristics" in this section.

REEL SPEED

Reel speed affects the smoothness and evenness of the windrow. Operating the reel too fast or too slow relative to ground speed will cause bunching.

26

Loading...

Loading...