MacDon 872 User Manual

INTRODUCTION

This Manual contains information on the adapter which is required to allow attachment of the MacDon Model 962 and 972 Harvest Header to the various models of combines (see list on cover).

NOTE: This supplement does not provide all the information required to operate the header. It must be used in conjunction with your Harvest Header and Combine Operator’s Manuals.

CAREFULLY READ ALL MANUALS TO BECOME FAMILIAR WITH RECOMMENDED PROCEDURES BEFORE ATTEMPTING TO UNLOAD, ASSEMBLE OR USE THE MACHINE.

This manual is divided into sections on: Safety, Attaching and Detaching the Header, Operation and Maintenance/Service. In addition, Assembly and Adapter Mounting Instructions for each type of combine are found at the back of this book.

Use the Table of Contents and the Index to guide you to specific areas. Study the Table of Contents to familiarize yourself with how the material is organized.

Keep this manual handy for frequent reference and to pass on to new operators or owners. Call your dealer if you need assistance, information or additional copies of the manual.

NOTE: Right hand (R/H), and Left hand (L/H) designations are determined from the operators position, facing forward.

1

TABLE OF CONTENTS |

|

INTRODUCTION ........................................................................................................................................ |

1 |

SPECIFICATIONS ...................................................................................................................................... |

3 |

SERIAL NUMBER LOCATION ................................................................................................................... |

3 |

SAFETY |

|

Safety Alert Symbol................................................................................................................................ |

4 |

Signal Words ......................................................................................................................................... |

4 |

Safety Signs........................................................................................................................................... |

5 |

HEADER ATTACHING & DETACHING |

|

Attaching Header to Combine and Adapter ........................................................................................ |

6-9 |

Detaching Header from Combine and Adapter............................................................................... |

10,11 |

Detaching Header and Adapter from Combine.................................................................................... |

12 |

Attaching Header and Adapter to Combine ......................................................................................... |

13 |

OPERATION |

|

Break-In Period.................................................................................................................................... |

14 |

Draper Speed Control .......................................................................................................................... |

14 |

Header Flotation .................................................................................................................................. |

15 |

Header Levelling .................................................................................................................................. |

16 |

Header Angle ....................................................................................................................................... |

16 |

Widening the Delivery Opening ........................................................................................................... |

17 |

Windrowing with the Combine (972 Feed Pan Clearance Adjustment)............................................... |

17 |

MAINTENANCE/SERVICE |

|

Service Procedures.............................................................................................................................. |

18 |

Recommended Lubricants................................................................................................................... |

18 |

Enclosed Drive Lubricant Capacities ................................................................................................... |

18 |

Sealed Bearing Installation .................................................................................................................. |

19 |

Greasing the Adapter...................................................................................................................... |

19,20 |

Hydraulic System |

|

Hydraulic System Safety ................................................................................................................... |

21 |

Hoses and Lines ............................................................................................................................... |

21 |

Hydraulic Schematic ......................................................................................................................... |

21 |

Hydraulic Oil...................................................................................................................................... |

22 |

Hydraulic Oil Filter............................................................................................................................. |

22 |

Flow Control Relief Pressure ............................................................................................................ |

23 |

Gearbox Lubrication............................................................................................................................. |

23 |

Retracting Tine Drum........................................................................................................................... |

24 |

Maintenance Schedule ........................................................................................................................ |

25 |

Maintenance Record............................................................................................................................ |

26 |

TROUBLESHOOTING........................................................................................................................ |

27, 28 |

ATTACHMENTS ....................................................................................................................................... |

29 |

ASSEMBLY |

|

962 Header Completion Parts ............................................................................................................. |

30 |

Header Side Drapers & Feeder Deck .................................................................................................. |

31 |

Feed Draper......................................................................................................................................... |

32 |

Center Link........................................................................................................................................... |

33 |

Position Retracting Tine Drum............................................................................................................. |

34 |

Electrical .............................................................................................................................................. |

35 |

Adjustments and Checks..................................................................................................................... |

36 |

ADAPTER MOUNTING INSTRUCTIONS |

|

John Deere ..................................................................................................................................... |

37-41 |

Case IH ........................................................................................................................................... |

42-47 |

Gleaner ........................................................................................................................................... |

48-54 |

New Holland.................................................................................................................................... |

55-61 |

Cat Lexion....................................................................................................................................... |

62-67 |

Attaching Adapter to Header (without combine) .................................................................................. |

68 |

Float Spring Removal or Installation .............................................................................................. |

69, 70 |

Float Limiter Installation: John Deere 50 Series, Contour Master & New Holland TR Combines ....... |

71 |

INDEX ....................................................................................................................................................... |

72 |

2

FEED DRAPER DRIVE |

Hydraulic: Pump driven from right side of feeder house, reversible |

|

with combine feeder chain |

FEED DRAPER SPEED |

522 to 652 feet/min. (159 to 199 metres/min.) varies with combine |

FEED DRAPER MATERIAL |

Self-tracking rubber coated polyester fabric with rubber slats |

FEED DRAPER WIDTH: |

|

|

John Deere & New Holland TX, Cat Lexion 460, 465, 480 & 485 ...................... |

55.9 inches (1420 mm) |

|

Case 80 & 88 Series, Cat Lexion 450, 470 & 475 .............................................. |

45.5 inches (1155 mm) |

|

Case 60 & 66 Series, Gleaner, & New Holland TR............................................... |

38.4 inches (975 mm) |

|

RETRACTING TINE DRUM DRIVE |

Hydraulic: Pump driven from right side of feeder house, reversible |

|

|

with combine feeder chain |

|

RETRACTING TINE DRUM SPEED |

173 to 216 RPM, varies with combine |

|

RETRACTING TINE DRUM DIA. |

|

|

John Deere & New Holland TX, Cat Lexion 460, 465, 480 & 485 ........................... |

12 inches (300 mm) |

|

Case, Gleaner, New Holland TR & Cat Lexion 450, 470 & 475.................................. |

11” (280 mm) with |

|

|

1 ¼” (32 mm) flighting on ends |

|

HEADER SIDE DRAPER DRIVE |

Hydraulic: Pump driven from right side of feeder house |

|

HEADER SICKLE DRIVE |

Mechanical: Driveline from left side of feeder house |

|

HEADER FLOTATION |

7 inches (175 mm) vertical and 4.5° lateral |

|

HEADER REEL DRIVE |

Hydraulic from combine oil supply |

|

|

|

|

SERIAL NUMBER LOCATION

Record the serial number in the space provided.

872 Combine Adapter:

Plate (A) is located on left side of adapter frame.

A

COMBINE ADAPTER SERIAL PLATE

NOTE: When ordering parts and service, be sure to give your dealer the complete and proper serial number.

3

SAFETY

SAFETY ALERT SYMBOL

This safety alert symbol indicates important safety messages in this manual and on safety signs on the header.

This symbol means:

ATTENTION !

BECOME ALERT !

YOUR SAFETY IS INVOLVED !

Carefully read and follow the safety message accompanying this symbol.

Why is SAFETY important to you?

· ACCIDENTS DISABLE AND KILL 3 BIG REASONS · ACCIDENTS COST

· ACCIDENTS CAN BE AVOIDED

SIGNAL WORDS

Note the use of the signal words DANGER, WARNING, and CAUTION with safety messages. The appropriate signal word for each message has been selected using the following guidelines:

DANGER – Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

WARNING – Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury. It is also used to alert against unsafe practices.

CAUTION – Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury. It is also used as a reminder of good safety practices.

4

SAFETY

SAFETY SIGNS

•The safety signs below appear on the combine adapter.

•Keep safety signs clean and legible at all times

•Replace safety signs that are missing or become illegible.

•If original parts on which a safety sign was installed are replaced, be sure the repair part also bears the current safety sign.

•Safety signs are available from your Dealer Parts Department.

To install safety signs:

1.Be sure the installation area is clean and dry.

2.Decide on the exact location before you remove the decal backing paper.

3.Remove the smaller portion of the split backing paper.

4.Place the sign in position and slowly peel back the remaining paper, smoothing the sign as it is applied.

5.Small air pockets can be smoothed out or pricked with a pin.

Rest header on ground or engage mechanical locks before going under unit.

5

HEADER ATTACHING & DETACHING

ATTACHING HEADER TO COMBINE AND ADAPTER

1.Attach adapter to combine feeder housing. See "Adapter Mounting Instruction" at back of book. NOTE: If header has been previously attached to windrower, remove linkage supports from header lower legs. Connector shaft on header back tube may remain installed.

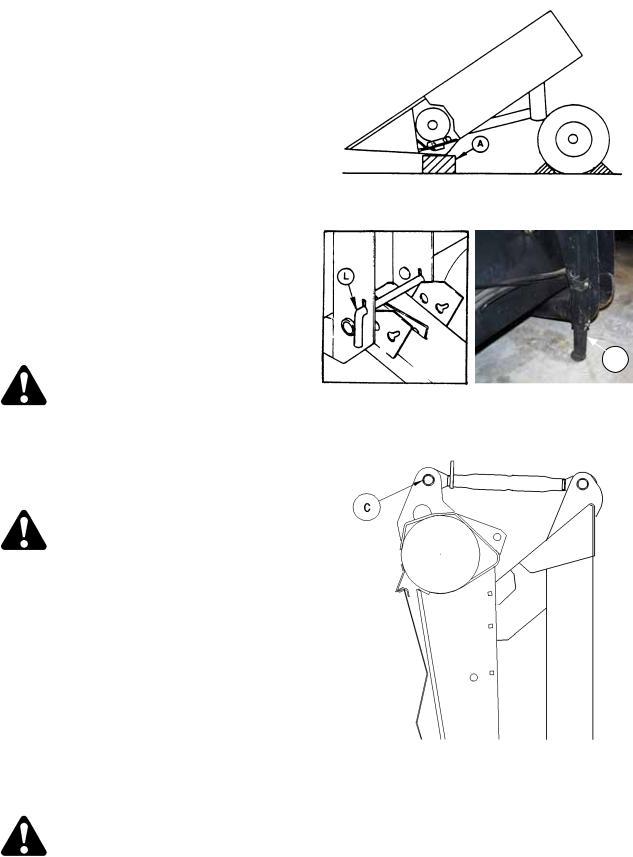

2.Choose an area that is as level as possible, and place supports (A) at both ends of cutterbar. For 962 Headers use 6" (150 mm) blocks. For 972 Headers use 2x4 (40 mm) blocks.

3.For 962 headers with gauge wheels, block both wheels front and rear, and be sure gauge wheel pins are in stand position (L), both sides, to support rear of header.

For 972 headers and 962 headers without gauge wheels, be sure header stand (B) is secure in the down position. For 962 Headers only, place a 4 inch (100 mm) block under stand.

BLOCK CUTTERBAR

B

CAUTION: Be sure area is clear of bystanders before starting engine.

4.Slowly drive combine forward, aligning float leaf springs under header legs, until top link can be connected. Connect top link (C).

NOTE: For headers with hydraulic top link, see instruction in “Unloading & Assembly” section.

CAUTION: Always connect top link before raising header.

IMPORTANT: Take care not to crush hydraulic hoses when driving into header.

IMPORTANT: For 972 Headers, when driving into header, align notches in adapter feed pan with retainers welded to cutterbar. Ensure that pan goes under the retainer and on top of cutterbar. The feeder house can be raised to lower the front edge of the pan, and vice versa. In soft ground conditions, a length of 2x4 under the pan will prevent scooping dirt

5.Raise adapter slowly, making sure float leaf springs engage in header legs. Continue to lift until header is fully raised. Stop engine and remove key.

GAUGE WHEELS - 962 HEADER STAND - 972

CONNECT TOP LINK BEFORE LIFTING

DANGER: To avoid bodily injury from fall of raised header, engage header lift cylinder stops when

working on or around raised header. See your Combine Operator’s Manual for details.

6

HEADER ATTACHING & DETACHING

ATTACHING HEADER TO COMBINE AND ADAPTER (continued)

6.Remove ¾ x 7 ½” bolt and lock nut from storage position (J) (or, on first use, from shipping position [G]) and install to lock adapter to header at (H). Move clevis pin from float lockout position (G) to storage position (J). Install split ring to capture clevis pin.

NOTE: It may be necessary to rock header by lifting at divider to properly position float frame at header leg joint.

Repeat at other leg.

PIN FROM FLOAT LOCKOUT TO STORAGE

7.Install sickle driveline on combine feeder house shaft. Ensure driveline locking mechanism engages. See your combine Operator's Manual.

DANGER: Entanglement with rotating driveline will cause serious personal injury or death. Keep all driveline shields in place. Close all hinged covers.

ATTACH DRIVELINE

7

HEADER ATTACHING & DETACHING

ATTACHING HEADER TO COMBINE AND ADAPTER (continued)

8.Make the hydraulic line connections:

Reel drive pressure and return lines: Connect two hoses between header and combine.

Reel lift line: Connect one hose between header and combine.

Draper drive pressure and return lines: Connect two hoses between header and adapter.

NOTE: As an aid in connecting hydraulics, the following colour coding has been used: ORANGE - Draper Drive Pressure

BLUE - Draper Drive Return YELLOW - Reel Drive Return

Reel fore-aft lines (if equipped): Connect two hoses between header and combine.

9.Connect wiring harness between header and combine. NOTE: A harness adapter is supplied with adapter completion package.

10.For 962 headers with gauge wheels, remove pins at gauge wheels and place in field position

(F). See “Cutting Height” in Header Operator’s Manual to choose between alternate field positions. (For headers with gauge wheel/transport option, gauge wheel support is not exactly as illustrated. See decal at support.) NOTE: Rotate pin to align roll pin with key slot for removal and installation. Roll pin locks inside to secure the position.

11.For 972 headers and 962 headers without gauge wheels, raise header stand to storage position (G).

12.For 972 Headers, for initial setting, set header at flattest angle (shortest top link length) and float header up. Ensure that feed pan is as far forward as possible and tighten pan hardware.

STEPS 13 to 16 ARE FOR 962 HEADERS ONLY.

13.Place 6" (150 mm) block under front of adapter feeder pan. Ensure all feed pan-to-cutterbar anchors are removed or turned sideways to prevent damage to anchors when cutterbar is lowered. Adjust feed pan fully forward for initial setting. (See next page.)

14.Disengage header lift cylinder stops and slowly lower header until adapter feed pan rests on block, and cutterbar rests on feed pan.

962 GAUGE WHEELS - FIELD POSITION

G

HEADER STAND - STORAGE POSITION

8

HEADER ATTACHING & DETACHING

ATTACHING HEADER TO COMBINE AND ADAPTER (continued)

15.Install anchors to clamp feed pan to cutterbar as shown.

16.Check for 0 to 5 mm (3/16 inch) clearance between front of adapter feed pan and cutterbar. Adjust clearance as follows:

a.Raise the header. Stop engine and remove key.

DANGER: To avoid bodily injury from fall of raised header, engage header lift cylinder stops when working on or around raised

header. See your Combine Operator’s Manual for details.

b.

•Loosen bolts (F) and (G).

•Adjust feed pan clearance to cutterbar to 0 to 5 mm (3/16 inch).

•Tighten bolts (F) and (G).

•Remove all blocks, disengage header lift cylinder stops and lower header to ground.

•Ensure that outside anchors (E) are installed as shown, with rubber seal (J) under top plate of anchor.

E J

G

0 to 5mm

F

SIDE VIEW

ADJUST FEED PAN - 962 HEADER

9

HEADER ATTACHING & DETACHING

DETACHING HEADER FROM COMBINE AND ADAPTER

Using this procedure, adapter will remain attached to the combine. This would be appropriate when header is to be used as a windrower. Instructions for detaching both header and adapter from combine are given on page 12.

1.Choose a level area. Lower the reel and raise the header. Stop engine and remove key.

DANGER: To avoid bodily injury from fall of raised header, engage header lift cylinder stops when working on

or around raised header. See your Combine Operator’s Manual for details.

DANGER: Wait for all movement to stop. A rotating driveline can cause entanglement resulting in serious

personal injury or death.

2.Disconnect driveline from feeder house shaft and store at bracket (A) on header left leg.

3.Disconnect hydraulic lines:

-Reel lift between header and combine.

-Reel drive pressure and reel return between header and combine.

-Draper return (blue) and draper drive pressure (orange) between adapter and header.

-Reel fore-aft hoses between header and combine (if equipped).

IMPORTANT: Couple or cap all lines to prevent hydraulic system contamination except as noted in Warning below. Be sure header stored hoses and combine stored hoses are not entangled.

WARNING: For headers with hydraulic reel fore-aft, never connect the fore-aft couplers to each other.

This would complete the circuit and allow the reel to creep forward in transport, resulting in instability.

4.Disconnect wiring harness between header and combine.

5.Remove split ring and clevis pin from storage position (E) and install in float lockout position

(C). Remove ¾ X 7 ½” bolt and lock nut from adapter lock position (B) and place in storage position (E). Repeat at other leg.

6.Remove plastic wear strip from under adapter pan, if equipped. Leave wear strip attached to clips on cutterbar.

STEPS 7 TO 12 ARE FOR 962 HEADERS ONLY. FOR 972 HEADERS, GO TO STEP 13.

7.Set 6" (150 mm) blocks under the adapter feeder pan.

8.Disengage header lift cylinder stops and lower header so feeder pan rests on blocks.

9.Loosen and rotate cutterbar anchors (D) away from cutterbar.

A

STORE DRIVELINE

ENGAGE FLOAT LOCK-OUT AND MOVE BOLT TO STORAGE POSITION

D

RELEASE CUTTERBAR ANCHORS –

962 HEADERS

10

HEADER ATTACHING & DETACHING

DETACHING HEADER FROM COMBINE AND ADAPTER (continued)

10.Raise header and engage header lift cylinder stops.

11.Move 6" (150 mm) blocks from under adapter feeder pan to the outside, about 18" (450 mm) from each end of header.

12.For 962 headers with gauge wheels, remove pins at gauge wheels and place in stand position (B). Block both gauge wheels.

For 962 headers without gauge wheels, lower header stand and place a 4 inch (100 mm) block beneath stand.

13.For 972 Headers, lower header stand (E). Place a 2x4 under stand only if required for stability on soft ground. Place 2x4’s (40 mm blocks) under cutterbar, about 18" (450 mm) from each end of header.

962 GAUGE WHEELS - STAND POSITION

E

HEADER STAND - LOWERED

14.Disengage header lift cylinder stops and lower header onto blocks. Lower adapter until top link is loose. Detach top link (F).

15.Lower adapter until float leaf springs are clear of header legs and slowly back away from header.

DISCONNECT TOP LINK

11

HEADER ATTACHING & DETACHING

DETACHING HEADER AND ADAPTER FROM COMBINE

Using this procedure, adapter will remain attached to the header. This would be appropriate when detaching header for transport. Instructions for detaching header only from adapter and combine are given on page 10.

1.Choose a level area. Lower the reel and raise the header. Stop engine and remove key.

DANGER: To avoid bodily injury from fall of raised header, engage header lift cylinder stops when working on or around raised header. See your Combine Operator’s Manual for details.

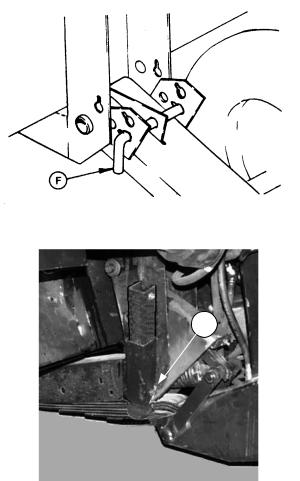

2.Remove split ring and clevis pin from storage position (A) and install in float lockout position (B). Repeat at other leg. Note that bolt in adapter lock position (C) remains in place.

3.Disconnect hydraulic lines between header and combine:

- Reel drive pressure line. |

|

|

- Reel drive return line. |

|

|

- Reel lift line. |

|

|

- Reel fore-aft lines (if equipped). |

|

|

NOTE: For units with hydraulic center link, before |

|

|

disconnecting cylinder hoses, turn off oil flow at shut- |

|

|

off valve. This allows easier reattachment of couplers |

|

|

at combine. Remember to restore oil flow at shut-off |

INSTALL PIN IN LOCKOUT POSITION |

|

valve before next use. |

||

|

IMPORTANT: Couple or cap all lines to prevent hydraulic system contamination except as noted in Warning below. Be sure header stored hoses and combine stored hoses are not entangled.

WARNING: For headers with hydraulic reel fore-aft, never connect the fore-aft couplers to each other. This would complete the circuit and allow the reel to creep forward in transport, resulting in instability.

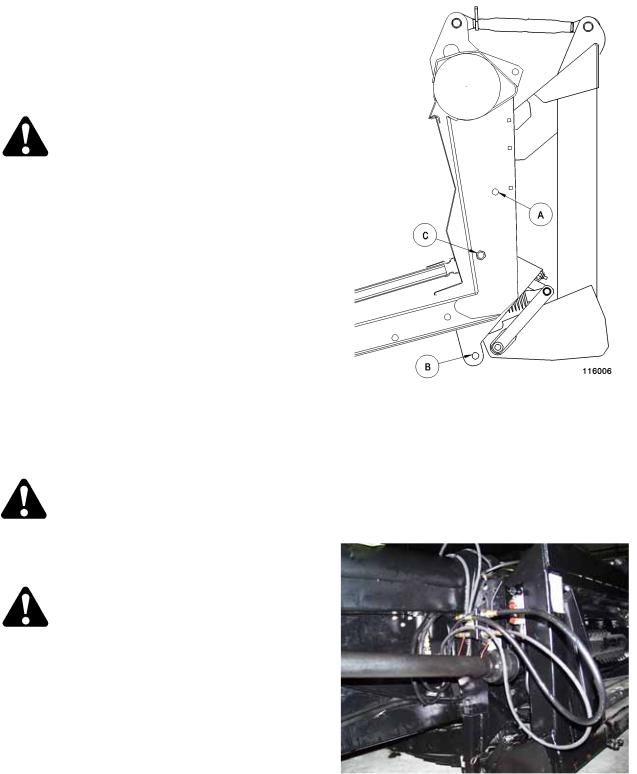

4.Disconnect wiring harness between header and combine.

DANGER: Wait for all movement to stop before approaching driveline. A rotating driveline can cause entanglement resulting in serious personal injury or death.

5.Disconnect driveline from combine feeder house output shaft and store at header left leg.

6.Disconnect pump from combine feeder house output shaft and store on adapter. See Mounting Instruction for your make of combine at back of book.

NOTE: Wear gloves when handling pump.

DISCONNECT AND STORE DRIVELINE

7. Disengage the header lock system. See Mounting Instruction for your make of combine at back of book.

8. Disengage header lift cylinder stops, start engine and lower header to ground.

9. Slowly back combine away from header.

12

HEADER ATTACHING & DETACHING

ATTACHING HEADER AND ADAPTER TO COMBINE

1.If applicable, block both gauge wheels front and rear (B).

NOTE: Choose an area that is as level as possible.

CAUTION: Be sure area is clear of bystanders before starting engine.

2.Drive combine slowly forward and engage feeder house lifting device in adapter top cross member. See Mounting Instruction for your make of combine at back of book for details.

3.Raise header, stop engine and remove key.

DANGER: To avoid bodily injury from fall of raised header, engage header lift cylinder stops when working on

or around raised header. See your Combine Operator’s Manual for details.

4.Connect feeder house lock system at bottom of adapter. See Mounting Instruction for your make of combine at back of book.

5.Install sickle driveline on L/H feeder house output shaft. Ensure driveline locking mechanism engages. See your combine Operator’s Manual.

DANGER: Entanglement with rotating driveline will cause serious personal injury or death. Keep all driveline shields in place.

6.Connect hydraulic lines between header and combine:

-Reel drive pressure line.

-Reel drive return line.

-Reel lift line.

-Reel fore-aft lines (if equipped).

7.Connect wiring harness between header and combine.

8.Remove split ring and clevis pin from float lockout position (A) and install in storage hole

(C). Repeat at other leg.

9.Install pump on R/H feeder house output shaft. See Mounting Instruction for your make of combine at back of book.

NOTE: Wear gloves when handling pump.

10.Disengage header lift cylinder stops and lower header.

BLOCK GAUGE WHEELS

REMOVE PIN FROM FLOAT LOCKOUT

13

OPERATION

BREAK-IN PERIOD

1.Run drapers slowly for 5 minutes to fill hydraulic lines, then check oil level at (A). Maintain level between LOW and FULL when oil is cold.

NOTE: Breather screw on cap (A) has been tightened for shipping. Loosen screw before operating adapter.

NOTE: When ambient temperatures are above 35º C (95º F), maintain oil level in the low portion of the range to prevent overflow at breather under operating temperatures.

2.Change the hydraulic oil filter (D) on combine adapter after 50 hours operation and every 250 hours thereafter.

3.Change gearbox oil after 50 hours operation and every 1000 hours or 3 years thereafter.

A

D

CHECK HYDRAULIC OIL LEVEL CHANGE OIL FILTER & GEARBOX OIL

See "Break-In Period" in Header Operator's Manual for further information on break-in maintenance.

DRAPER SPEED CONTROL

Speed of the header drapers is adjusted at the flow control on the combine adapter. Rotate flow control knob

(C) to a number suited to the crop. The higher the number, the faster the draper speed. The settings in the chart are recommended for optimum feeding capacity.

NOTE: If sufficient draper speed cannot be achieved, a possible cause is low relief pressure. See "Flow Control Relief Pressure" in Maintenance/Service section.

Needle Valve: When laying a windrow, turn needle valve control (B) fully open to stop flow to the feed draper and drum.

NOTE: Valve must be fully open to prevent rotation of feed draper and |

|

|

|

|

|

DIAL |

|

drum when oil is cold. It may also be necessary to secure drum to |

CROP |

|

|

|

NO. |

||

prevent rotation. |

|

||

For a complete list of steps to convert to windrowing mode, see “End |

Barley |

3 |

|

Delivery” in the Operation section of your Header Operator’s Manual. |

|||

When straight cutting and experiencing plugging at the rear of the feeder deck, turn control (B) to slow feed draper and drum.

NOTE: Slowing feed draper and drum too much will cause feeding problems. Turn needle valve control (B) in 1/16 turn increments.

C

B

Beans, Edible

Canola

Flax

Lentils

Milo

Oats

Peas

Rice

Safflowers

Soybeans

Sunflowers

Wheat

DRAPER SPEED CONTROL

14

OPERATION

HEADER FLOTATION

IMPORTANT:

To avoid:

-frequent breakage of sickle components

-scooping soil

-soil build-up at cutterbar in wet conditions,

set header float as light as possible without causing excessive bouncing.

To check header float:

1.Raise feeder house and engage lift cylinder stops.

2.Be sure float lock out pins are removed from position (C).

3.Disengage lift cylinder stops and lower header so the cutterbar is 1 to 6 inches (25 to 150 mm) above the ground.

NOTE: When cutterbar is in the range from 0 to 16 inches (400 mm) off ground, float arm should touch or be within ¼ inch (6 mm) of angle at (A). If gap at (A) is greater than ¼ inch, float is set too light, causing the header to float up.

NOTE: Header gets lighter and gap at (A) increases when steepening header angle. Adjust float after changing header angle or reel fore-aft position. For best float, gap at (A) should never exceed ¼ inch (6 mm).

4.With cutterbar 1 to 6 inches (25 to 150 mm) above the ground, grasp the crop divider rod and lift up. Under normal conditions it should require 50 to 70 lbs. force (220 to 310 N) to lift cutterbar off ground at either end. If adjustment is required, proceed as follows:

To adjust header float:

1.Raise feeder house and engage lift cylinder stops.

2.Tighten bolts (B) at both sides of adapter to increase float (which makes header lighter when lowered to ground).

Loosen bolts to decrease float (which makes header heavier when lowered).

IMPORTANT: For 21 ft. 972 headers only. If header still has excess float with float

adjustment bolt fully backed off, it may be necessary to remove the 3rd leaf spring from the top on both sides of the adapter to provide proper floatation. See Unloading and Assembly section for removal instructions.

FLOAT ADJUSTMENT

15

OPERATION

HEADER LEVELLING

Adjust header levelling with header at the flattest angle.

See Header Angle, below.

1.With header on level ground, lower header so cutterbar is 2 to 4 inches (50 to 100 mm) off the ground.

2.Check level of header by measuring cutterbar to ground at both ends.

3.To lower cutterbar on one end, remove a shim (C) from between rubber pads (D) and angle (E). Adjust shim quantity side to side, placing from 0 to 2 shims to level header. To add or remove a shim:

•Lower cutterbar to ground and continue lowering feeder house so gap at (A) increases.

•Remove nut (F) and add or remove shim(s) as required.

•Reassemble, maintaining 1/8 inch (3 mm) between angle and float support as shown.

HEADER ANGLE

The header (or guard) angle can be adjusted from 15° to 20° below horizontal. (Actual angle may vary with combine set-up.)

See Combine Operator’s Manual for header levelling and additional header angle adjustments.

IMPORTANT: The flat header angle (15°) is recommended for normal conditions. A flatter header angle reduces sickle section breakage and reduces soil

scooping or build-up at the cutterbar in wet conditions.

Use a steeper angle to cut very close to the ground, or HEADER LEVELLING in down crop for better lifting action.

IMPORTANT: Always check adapter drum clearance to header frame after adjusting header angle. Flattening the header angle will reduce the clearance to the drum fingers.

IMPORTANT: Header flotation gets lighter as header angle increases, and must be readjusted. See "Header Flotation", on page 15.

To adjust header angle with mechanical link:

1.Lower cutterbar to ground and continue lowering to drop feeder house another 2 to 5 inches (50 to 125 mm).

2.Back off the locking collar (A) on top link turnbuckle.

3.Using a punch in hole in turnbuckle (B), turn to adjust header angle.

Longer top link = steeper header angle ( = lighter float )

4.At desired adjustment, tighten locking collar (A) securely against turnbuckle to fix the position.

HEADER ANGLE HYDRAULIC ADJUSTMENT

An optional kit is available which allows adjustment

of header angle from the combine cab by means

of a hydraulic cylinder. HEADER ANGLE MECHANICAL ADJUSTMENT See “Unloading and Assembly” section for

information on assembly and use of this option.

16

OPERATION

WIDENING THE DELIVERY OPENING: Case, Gleaner & New Holland TR Combines:

In conditions where severe “bridging” is occurring (bulky crop being thrown across the opening), widen the header side draper opening to allow the crop to fall onto the feed draper. See “Delivery Opening” in your Header Operators’ Manual for procedure. To achieve smooth feeding after widening opening, add outboard tines to the adapter drum. See “Tine Installation”, page 24.

Combine Model |

New Delivery Opening |

Qty. of tines to be added to drum |

Case 60 & 66 Series, Gleaner, NH-TR |

1060 mm (41.7”) |

2 per side (4 total) |

Case 80 & 88 Series |

1260 mm (49.6”) |

1 per side (2 total) |

WINDROWING WITH THE COMBINE

To convert to windrowing mode (delivering crop to the end of the header) see “End Delivery” in the Operation section of your Header Operator’s Manual.

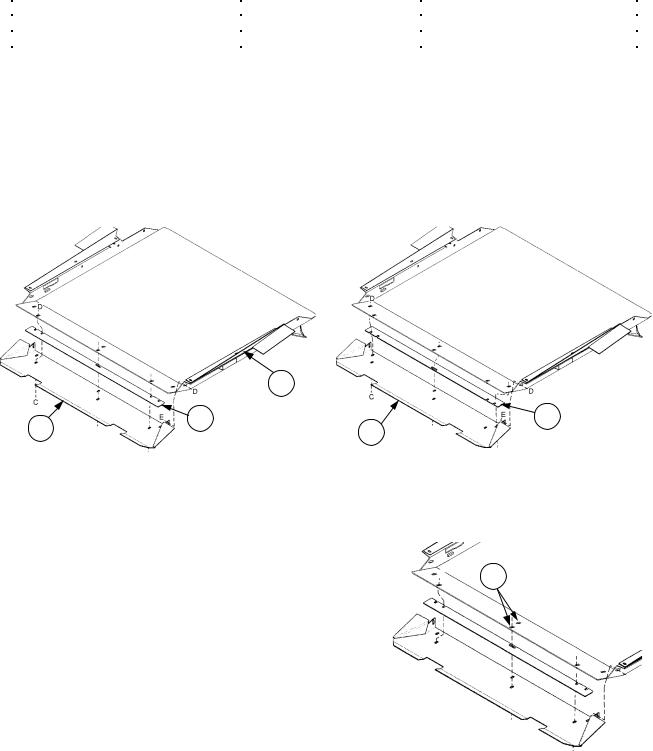

972 Feed Pan: Ground Clearance Adjustment

H

F

G

Assembled for Maximum Ground Clearance

Spacer plate (F) is factory assembled for best ground clearance, with plate (F) mounted to the forward set of holes in pan (G) as shown above left. When windrowing with the combine and in certain other conditions, clearances may be such that the header drapers catch on the deck or on angle (H). If so, move spacer plate (F) to rear set of holes in pan (G) as shown above right. To reposition spacer plate (F), proceed as follows:

•Remove two center bolts (K) and loosen bolts at outside ends of pan.

•Slide spacer out (forward) and slide it in from the back onto the loosened bolts.

•Replace the two center bolts, exchanging positions so the 1 ¼ bolt again goes through the spacer plate.

•Exchange positions of the bolts at outside ends of pan so the 1 ¼ bolts go through spacer plate.

F

G

Assembled for Windrowing with a Combine

K

17

MAINTENANCE/SERVICE

SERVICE PROCEDURES

CAUTION: To avoid personal injury, before servicing machine or opening drive covers: 1. Fully lower header and reel. If it is necessary to service in the raised position, first engage header lift cylinder stops and reel props.

2.Disengage header drive clutch.

3.Stop engine and remove key.

4.Engage park brake.

5.Wait for all moving parts to stop.

6.Park on level surface when possible. Block wheels securely. Follow all recommendations in your Combine Operator’s Manual.

7.Wear close-fitting clothing and cover long hair. Never wear dangling items such as scarves or bracelets.

8.Wear protective shoes with slip resistant soles, a hard hat, protective glasses or goggles and heavy gloves.

9.Be prepared if an accident should occur. Know where the first aid kit and fire extinguisher are located and how to use them.

10.Keep the service area clean and dry. Wet or oily floors are slippery. Wet spots can be dangerous when working with electrical equipment. Be sure all electrical outlets and tools are properly grounded.

11.Use adequate light for the job at hand.

12.Replace all shields removed or opened for service.

13.Use only service and repair parts made or approved by the equipment manufacturer. Substituted parts may not meet strength, design or safety requirements.

14.Keep the machine clean. Never use gasoline, naphtha or any volatile material for cleaning purposes. These materials may be toxic and/or flammable.

RECOMMENDED LUBRICANTS

GREASE

SAE Multi-Purpose High Temperature Grease with Extreme Pressure (EP) Performance and containing at least 1.5% molybdenum disulphide.

Also acceptable is an SAE Multi-Purpose Lithium Base Grease.

HYDRAULIC OIL

Use single grade trans-hydraulic oil. If an oil brand from the recommended list is not available, use 15W40 engine oil.

The following oil company and equipment manufacturer brand names are recommended: Petro Canada Duratran

Case IH Hy-Tran Plus® John Deere Quatrol® J20C Agco Power Fluid 821XL

GEARBOX OIL

SAE 85W-140 gear lubricant (API Service Classification GL-5)

CAPACITIES

Adapter Gearbox - 450 mL (15 U.S. oz.)

Adapter Hydraulic System (Draper Drive)

Full system: 25 litres (6.6 U.S. gals.)

Tanks only: 17 litres (4.5 U.S. gals.)

STORING AND HANDLING LUBRICANTS

Your machine can operate at top efficiency only if clean lubricants are used. Contaminant in lubricants is the most likely cause of bearing and hydraulic system failure. Use clean containers to handle all lubricants. Store lubricants in an area protected from dust, moisture and other contaminants. Keep hydraulic couplers and connectors clean.

18

MAINTENANCE/SERVICE

SEALED BEARING INSTALLATION

1.Clean shaft and coat with rust preventative.

2.Install flangette, bearing, flangette and lock collar. The locking cam is only on one side of the bearing.

3.Install and tighten the flangette bolts.

4.When the shaft is located correctly, lock the lock collar with a punch. The collar should be locked in the same direction the shaft rotates. Tighten the set screw in the collar.

5.Loosen the flangette bolts on the mating bearing one turn and re-tighten. this will allow the bearing to line up.

TIGHTEN COLLAR IN DIRECTION

SHAFT ROTATES

GREASING THE ADAPTER

See "Recommended Lubricants" in this section for recommended greases.

The adapter has four greasing points as shown on the following page. Use the hour meter in the combine cab and the "Maintenance Checklist" provided to keep a record of scheduled maintenance.

Procedure:

1.Wipe grease fitting with a clean cloth before greasing, to avoid injecting dirt and grit.

2.Inject grease through fitting with grease gun until grease overflows fitting.

3.Leave excess grease on fitting to keep out dirt.

4.Replace any loose or broken fittings immediately.

5.If fitting will not take grease, remove and clean thoroughly. Also clean lubricant passageway. Replace fitting if necessary.

19

MAINTENANCE/SERVICE

GREASING THE ADAPTER (continued)

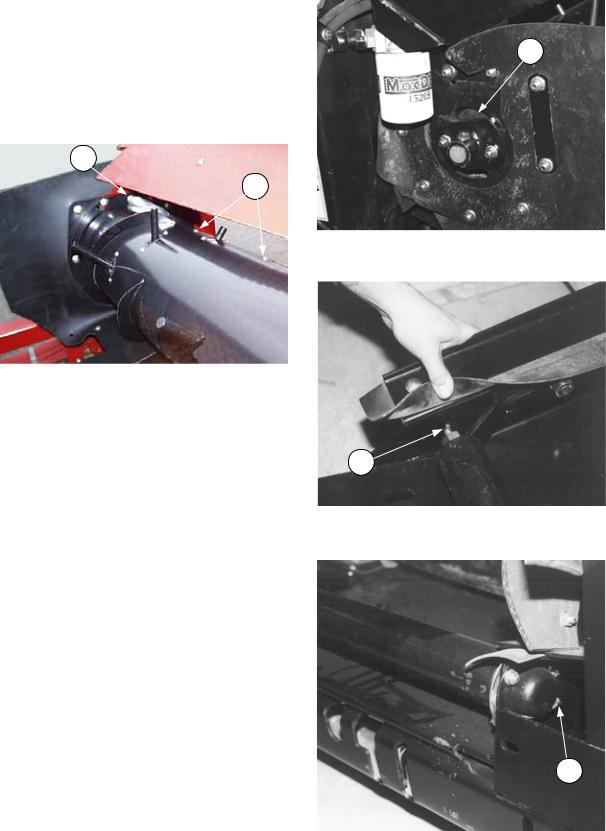

100 Hours or Annually:

1.Drum Bearing (B) - one fitting

For access to grease zerk, turn drum until drum access cover screws (E) are aligned with the long fore-aft adjustment slot (F) (approximately at the 1 o-clock position, viewed from the center of the adapter).

F

E

ALIGN COVER SCREWS WITH SLOT FOR ACCESS TO DRUM BEARING ZERK

2.Feed Draper Idler Roller Bearings (C) - two fittings

Replace bearings every 500 hours or annually.

3.Feeder Draper Drive Roller Bearing (D) - one fitting

NOTE: To avoid damage to bearing seal, when greasing drive roller bearing use a single slow stroke of grease gun.

Replace bearing every 500 hours or annually.

B

DRUM BEARING

C

FEEDER DRAPER IDLER ROLLER BEARINGS

D

FEEDER DRAPER DRIVE ROLLER BEARING

20

MAINTENANCE/SERVICE

HYDRAULIC SYSTEM

Hydraulic Hoses and Lines

Check hydraulic hoses and lines daily for signs of leaks.

WARNING: Avoid high-pressure fluids. Escaping fluid can penetrate the skin causing serious injury.

Relieve pressure before disconnecting hydraulic lines. Tighten all connections before applying pressure. Keep hands and body away from pinholes and nozzles that eject fluids under high pressure. Use a piece of cardboard or paper to search for leaks. IF ANY fluid is injected into the skin, a doctor familiar with this type of injury must surgically remove it within a few hours or gangrene may result.

IMPORTANT:

•Ensure all hydraulic couplings are fully engaged before operating header.

•Keep hydraulic coupler tips and connectors clean. Dust, dirt, water and foreign material are the major causes of hydraulic system damage.

•To prevent improper mixing of oils:

If header is to be switched back and forth from combine to windrower, change oil in windrower tractor (or Bi-Directional Tractor) hydraulic system to match combine hydraulic system.

AVOID HIGH PRESSURE FLUIDS

CHECK PROPERLY FOR LEAKS

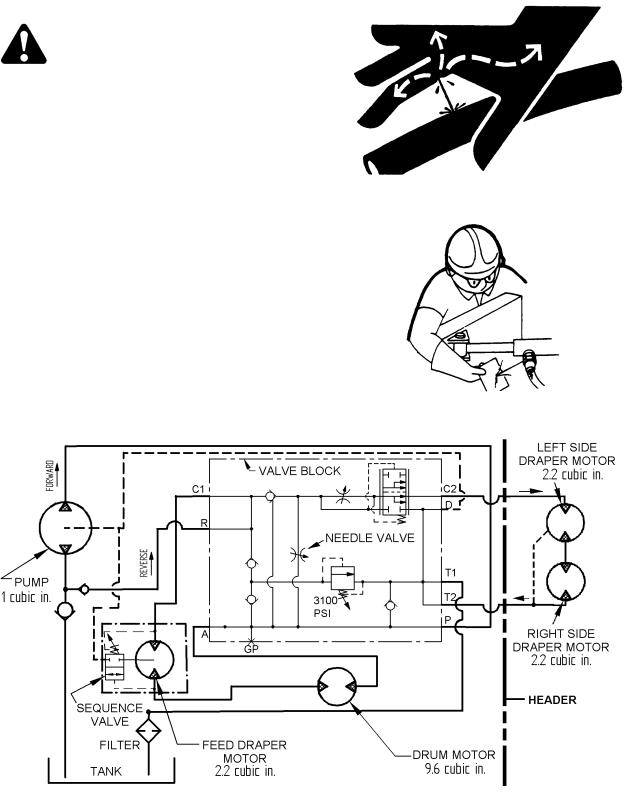

COMBINE ADAPTER HYDRAULIC SCHEMATIC

21

MAINTENANCE/SERVICE

HYDRAULIC SYSTEM (continued)

Hydraulic Oil

The combine adapter’s hydraulic system provides oil for the draper and feed drum drives.

Check oil level every 25 hours at dipstick (A). Maintain level between "LOW" and "FULL" marks when oil is cold.

Capacity:

-Full system: 25 litres (6.6 U.S. gallons)

-Tanks only: 17 litres (4.5 U.S. gals.)

Type – See recommended lubricants, page 18.

NOTE: When ambient temperatures are above 35º C (95º F), maintain oil level in the low portion of the range to prevent overflow at breather under operating temperatures.

Change hydraulic oil every 1000 hours or 3 years To change hydraulic oil:

1.Remove dipstick cap (A).

2.Remove plug (B) at right reservoir and hose (E) at left reservoir.

NOTE: A drain pan with a capacity of 15 litres (4 U.S. gallons) will be required for each reservoir.

3.Replace the hydraulic oil filter. See below.

4.Replace plug (B) and hose (E) and fill the reservoirs through female coupler (D) from a pressurized oil source.

NOTE: Do not use cap port (A) to fill system. Oil will not reach left reservoir. If a pressurized source of oil is not available, pump oil from right reservoir to left as follows:

•Fill R/H reservoir with oil through cap port (A).

•Run the adapter pump until feed drum stops turning.

•Re-fill R/H reservoir.

•Repeat procedure until oil level in R/H reservoir remains between LOW and FULL on dipstick.

5. Replace cap (A).

Hydraulic Oil Filter

Change hydraulic oil filter (C) after the first 50 hours operation and every 250 hours thereafter. To change:

1.Clean around the filter head.

2.Remove the filter and clean the gasket surface of the filter head.

3.Apply a thin film of clean oil to the gasket on the new filter.

4.Install the new filter. Turn the filter onto the mount until the gasket contacts the filter head. Tighten the filter an additional 1/2 to 3/4 turn by hand.

IMPORTANT: Do not use a filter wrench to install the filter. Over-tightening can damage gasket and filter.

A

C

B

RIGHT HYDRAULIC RESERVOIR

D

E

LEFT HYDRAULIC RESERVOIR

22

Loading...

Loading...