KitchenAid 710-0003 User Manual

Natural Gas Conversion Kit

Instructions

For questions about features, operation/performance, parts, accessories or service, call:

1-877-373-2301

Ensemble de Conversion Pour Gaz Naturel

Instructions

Pour des questions à propos des caractéristiques, du fonctionnement/rendement, des pièces, des accessoires ou du service,

composer le : 1-877-373-2301

Juego de Conversión a Gas Natural

Instrucciones

Para consultas respecto a características, funcionamiento, rendimiento, piezas, accesorios o servicio técnico, llame al:

1-877-373-2301

Models / Modelos / Modèles: 710-0003

Table of Contents / Índice / Table des matières …………….2

19000375A0

TABLE OF CONTENTS

Safety Instruction---------------------------------------

Tools and parts for Gas Conversion.............................

Conversion from LP Gas to Natural Gas……………....

Check and adjust burner………………………………...

Limited Warranty………………………………………….

ÍNDICE

Instrucciones de Seguridad…………………………...

Herramientas y piezas para la conversión de gas……..

Conversión de gas LP a gas natural………………….....

Revise y regule los quemadores…………………………

Garantía Limitada………………………………………….

TABLE DES MATIÈRES

Instructions de sécurité………………………….………

Outils et pièces pour conversion de gaz.........................

Conversion de propane à gaz naturel …………...……...

Contrôle et réglage des brûleurs...……………………….

Garantie Limitée……………………………………..…….

21

22

23-26

27

28

12

13

14-17

18

19

3

4

5-8

9

10

2

SAFETY INSTRUCTIONS

DANGER

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, keep away from the

WARNING

1. Do not store or use gasoline or other

flammable liquids or vapors in the vicinity of

this or any other appliance.

2. An LP cylinder not connected for use shall

not be stored in the vicinity of this or any other

3

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire injury to persons, or damage when using NG Conversion Kit & and outdoor cooking

gas appliance, follow basic precautions, including the following:

Gas conversions must be done by a qualified installer.

The connector is intended only for use outdoors with portable appliance that may be moved for convenience of

operation.

Connectors are designed for movement after installation, but must not be kinked, twisted or torque. Periodic visual

inspection should be made to determine that the connector is suitable for continued use.

Connect with damaging foreign objects or substances must be avoided.

Connected hose assembly shall be of adequate length and capacity for intended application. Final assembly must be

tested for leaks.

Caution: Test for leaks only with leak test solution. Rinse with clear water after leak test to remove any corrosive residue.

DO NOT USE OPEN FLAME TO TEST FOR GAS LEAKS.

SAVE THESE INSTRUCTIONS

appliance and immediately call your gas

supplier or your fire department

appliance.

In the State of, the following installation instructions apply:

Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or

licensed by the State of Massachusetts.

If using a ball valve, it shall be a T-handle type.

A flexible gas connector, when used, must not exceed.

Tools and Parts for Gas Conversion

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

Phillips screwdriver

Pipe wrench

Adjustable wrench

6 mm socket and wrench or

6 mm nut driver

Thin flat-blade screwdriver

Pliers

Pipe thread sealant certified

for LP gas

IMPORTANT:

Gas conversions must be done by a qualified

installer. Before proceeding with conversion, shut off the

gas supply to the appliance prior to disconnecting the

electrical power.

If there are damaged or missing parts when you unpack

this kit, call 1-877-373-2301. DO NOT have your

QUALIFIED GAS TECHNICIAN attempt to install this kit

until you receive replacement for any damaged or

missing parts.

Parts needed

Natural gas orifices (supplied with grill)

Note: This manual covers several different models. The grill

you have purchased may have some or all of the features

listed. The locations and appearances of the features shown

here may not match those of your model. Please refer to

your grill’s manual for specific instructions or contact

customer service for information at 1-877-373-2301.

10 ft (3.0 m) Natural gas hose with quick connector

5.9" (150 mm) Natural gas regulator hose

6 mm nut driver

6 mm wrench

Hex Key

Parts supplied

Natural gas regulator 4" W.C. (marked “Natural Gas

Regulator)

4

Conversion from Liquid Propane (LP) to Natural Gas (NG)

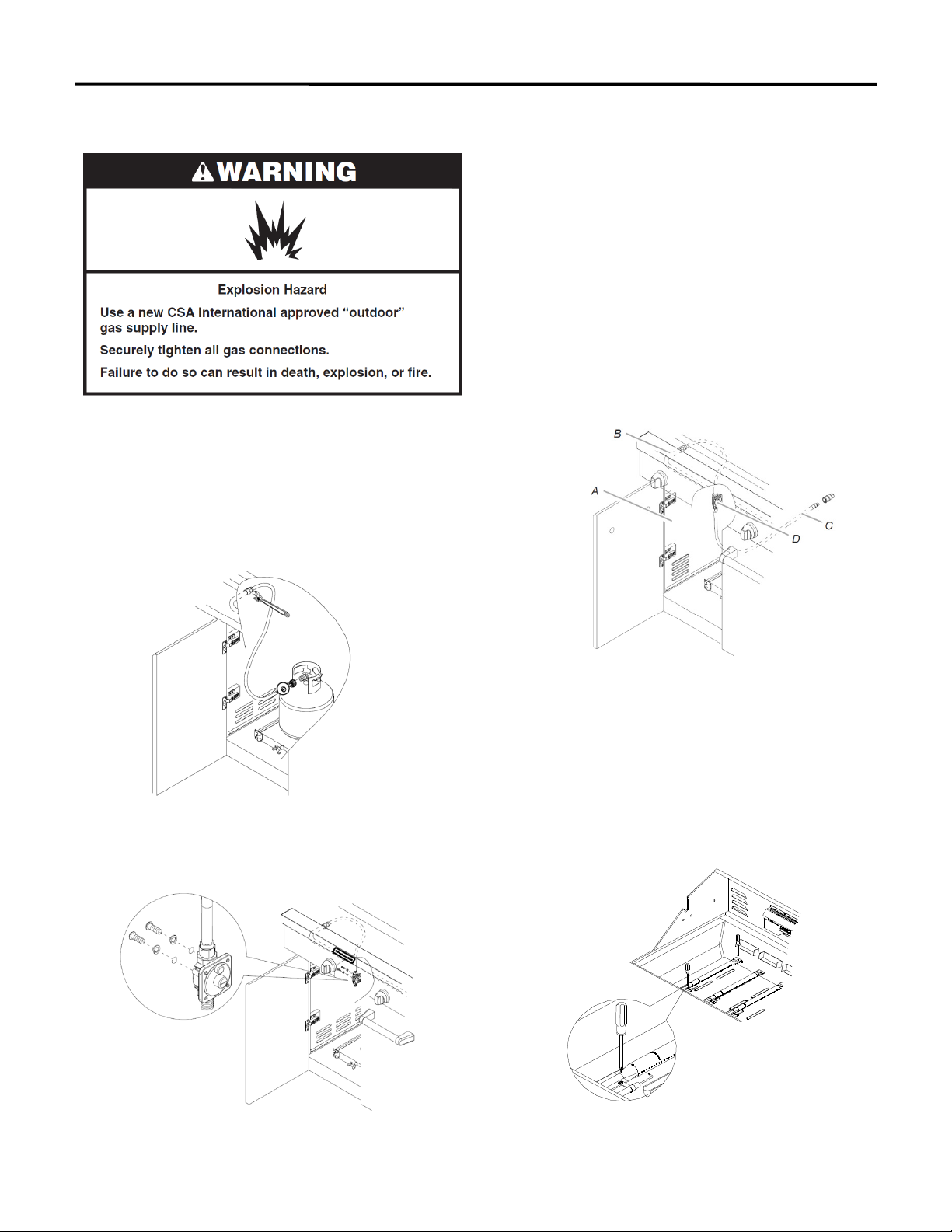

Installation of the regulator

1. Turn off the main gas supply valve.

2. Unplug grill or disconnect power.

3. Disconnect 20 lb LP gas fuel tank (if present).

4. Turn off all burner control valves.

5. Remove the 20 lb LP gas fuel tank (if present) from the grill

cart.

6. Use an adjustable wrench to remove the LP regulator from

the manifold.

Make Gas Connection

1. A combination of pipe fittings must be used to

connect the grill to the existing gas line.

The 10 ft (3.0 m) PVC flexible gas supply hose design-

certified by CSA must be used.

Pipe-joint compounds suitable for use with Natural gas

must be used. Do not use Teflon®† tape.

There must be a certified manual shutoff valve in the

gas supply line near the grill for easy access.

2.Connect the brass connector on one end of the 10 ft

(3.0 m) PVC flexible gas supply hose (supplied) to the

Natural gas pressure regulator.

3.Connect the quick connector on the other end of the

10ft (3.0 m) PVC flexible gas supply hose to the rigid

Natural gas supply pipe.

7. Use an adjustable wrench to install the Natural gas

regulator hose to the manifold and secure. Attach the

Natural gas regulator to the side panel inside the grill cart

with the two screws that are preassembled on the

regulator.

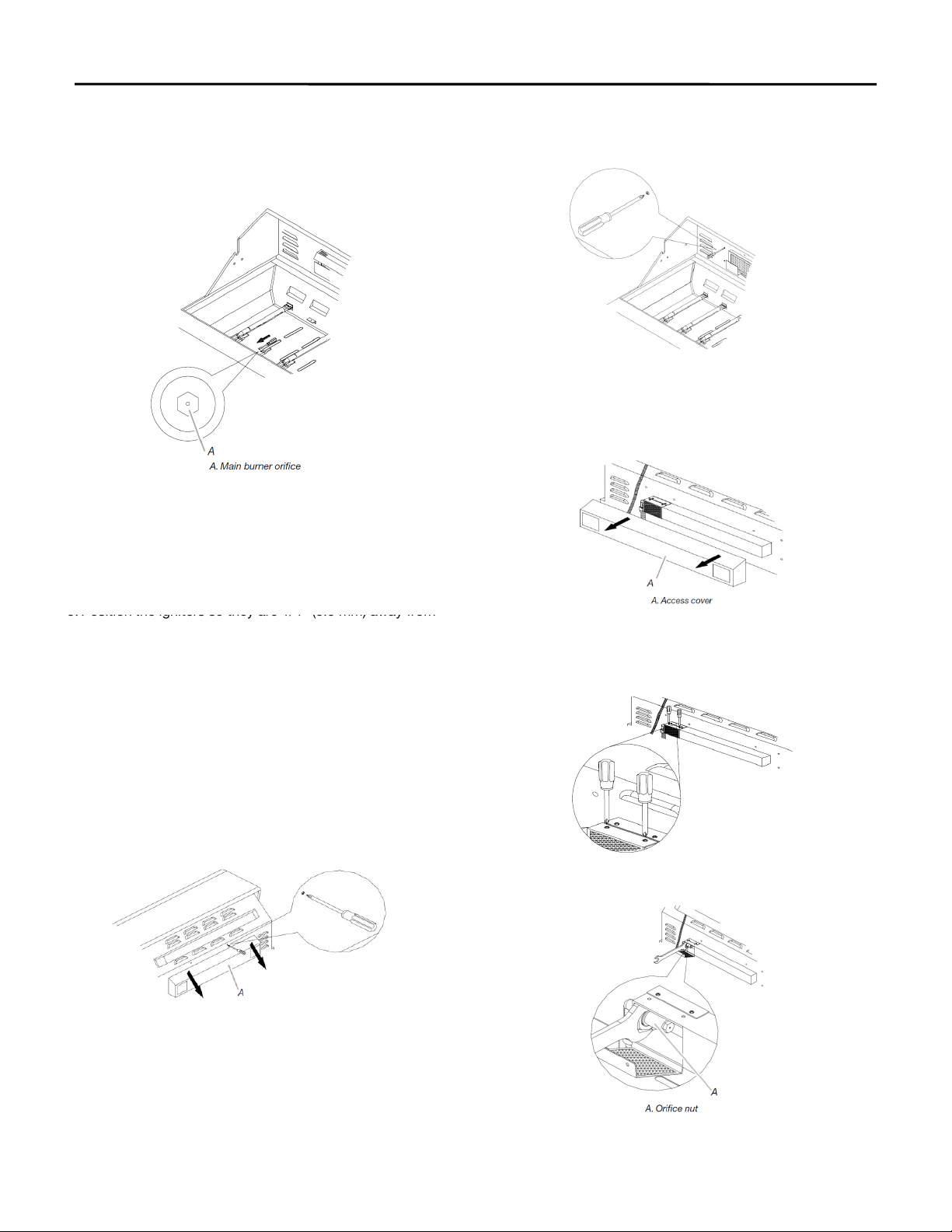

Change Grill Burner Valve Orifices

1. Remove the grates and flame tamers.

2. Remove the screws and pin that hold the burner in

place. Set the screws and pin aside. Remove the

burner from the grill by lifting the burner out.

A.Side panel

B.Manifold

C.10ft. (3.0m) PVC gas hose

D.Natural gas pressure regulator/hose assembly

5

†®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

3. Use a 6 mm socket and wrench or 6 mm nut driver to

remove the brass orifice from the end of gas valve. The

main burner NG orifice is located behind the LP orifice, so

no additional orifice needs to be installed.

4. Reinsert the burner and reattach using the 2 screws or

pin previously removed. Repeat the procedure for each

main burner.

2. Using a Phillips screwdriver, remove the screws at the

back of grill from inside the grill.

IMPORTANT: Check that the NG orifice is properly

installed inside of the burner opening.

3. Remove the access cover at the back of the grill hood by

removing the 4 screws (2 screws on each side of the

rotisserie infrared burner).

5.

Position the igniters so they are 1/4" (6.0 mm) away from

each burner.

IMPORTANT: Only Main Burners have the NG orifice pre-

installed behind the LP orifice. All other burners required LP

orifice to be removed and NG orifice to be installed.

Change the Rotisserie/Infrared Burner Orifice

1. Using a Phillips screwdriver, unscrew the screws and

remove the rotisserie/infrared burner wind baffle.

4. Using a Phillips screwdriver, remove the screws holding

the spider guard to the burner.

5. Use 24 mm wrench to remove the orifice nut.

6

A. Wind Baffle

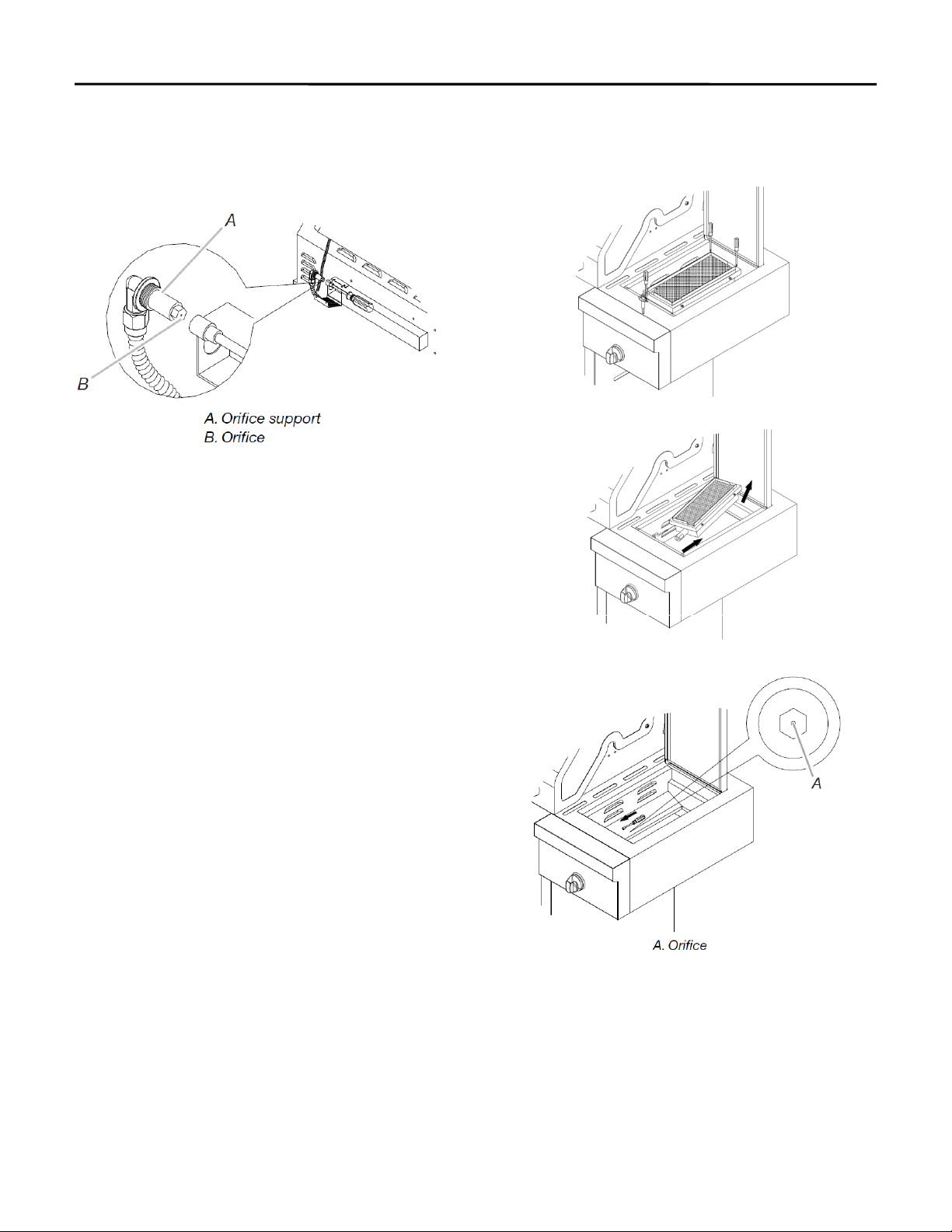

6. Take out the orifice support, and then use a 6 mm socket

and wrench or 6 mm nut driver to remove the LP orifice at

the end of the supply pipe. Replace with Natural gas

orifice.

Change the Sear burner orifices

1. Remove the screw securing the igniter and the 2 searing

side burner screws.

2. Lift the searing side burner out of the grill.

IMPORTANT: Check that the orifice is properly installed

inside of supply pipe.

7. Reinstall the orifice support and supply pipe and tighten the

nut with a 24 mm wrench.

8. Reinstall the spider guard, access cover, and wind baffle.

4. Use 6 mm socket wrench or 6 mm nut driver to remove

the orifice. Replace with the Natural gas orifice.

3. Locate the LP gas orifice to the end of the valve.

7

Adjust High Flame Setting Screw

When converting from LP to Natural gas, you will need to

adjust the high flame setting screw for ideal burner flame

height.

1. Remove each control knob for the main burners and side

burner.

Record Conversion

1. The appliance nameplate is located inside the grill cabinet

on the left-hand cabinet side or inside of the cabinet door.

With a permanent marker, check the box next to ‘’Natural

gas’’ and mark through ‘’LP -Propane.’’ In the last page of

the Use and Care Guide, write ‘’Converted to Natural

Gas.’’ Also record the conversion date and the

technician/company that performed the conversion.

NOTE: Place LP gas parts in plastic parts bag for future use

and keep with pack containing literature.

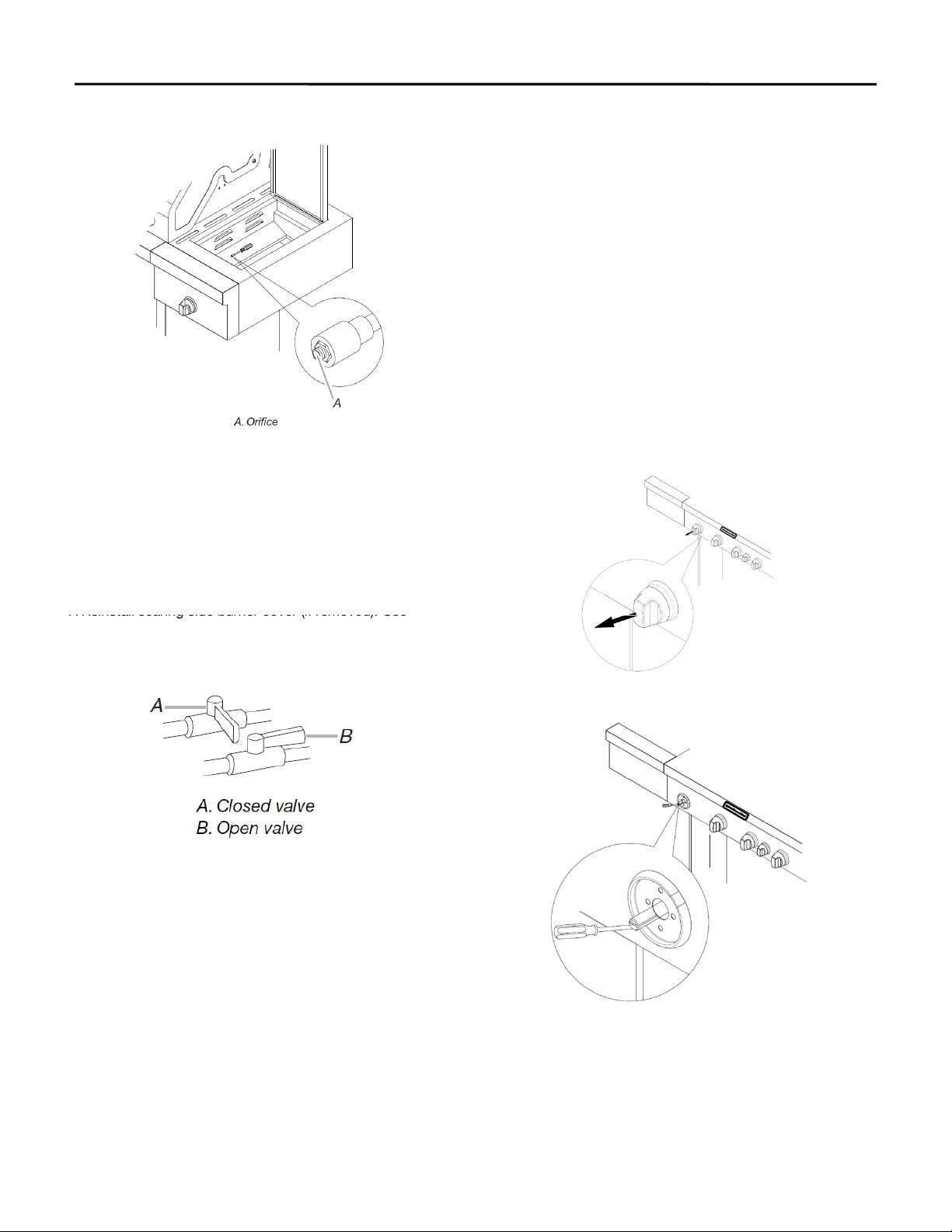

5. Reinstall the searing side burner. Make sure that the igniter

is out of the way to allow proper positioning of burner. Use

Phillips screwdriver to attach the mounting screws.

6. Use Phillips screwdriver to reattach the igniter and searing

side burner plate.

IMPORTANT: Check that the orifice is properly installed

inside of valve.

2. Use a flat-blade screwdriver to turn the high flame setscrew

counterclockwise approximate 90 degree.

3. Check that burner operates at the new high flame setting. It

may be necessary to adjust the screw setting slightly more to

get the ideal burner flame height.

7.

Reinstall searing side burner

cover (if removed).

Use

Phillips screwdriver to attach mounting screws.

8. Open the manual shutoff valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

9. Test all connections using an approved noncorrosive leak-

detection solution. Bubbles will show a leak. Correct any

leak found.

8

Check and Adjust Burner

The burners are tested and factory-set for most efficient

operation. However, variations in gas supply and other

conditions may make minor adjustments to air shutter or

low flame setting necessary.

It is recommended that a qualified technician make burner

adjustments.

NOTE: The rotisserie burner cannot be adjusted.

Checking and adjusting the grill burner flames requires

removing the grates and flame tamers.

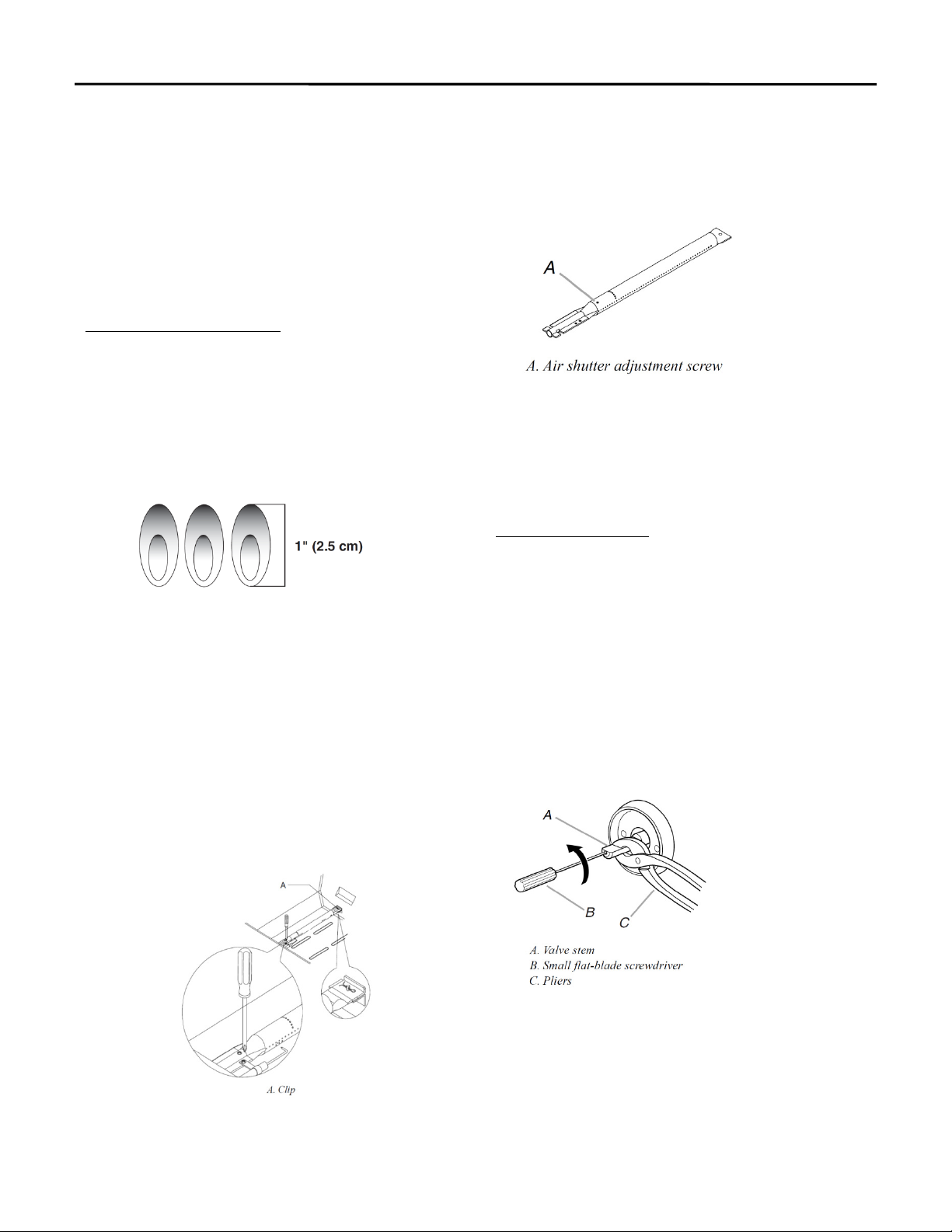

Burner Flame Characteristics

The flames of the grill burners and side burners (on some

models) should be blue and stable with no excessive noise

or lifting (LP gas flames will have a slightly yellow tip). A

yellow flame indicates not enough air. If flame is noisy or

lifts away from the burner, there is too much air. Some

yellow tips on flames when the burner is set to HIGH

setting are acceptable as long as no carbon or soot

deposits appear. The flames should be approximately 1"

(2.5 cm) high.

6. If flame is yellow (not enough air), turn air shutter

adjustment screw counterclockwise. If flame is noisy or

lifts away from burner (too much air), turn air shutter

adjustment screw clockwise.

Adjustment should be made clockwise or

counterclockwise from 1/8" (3.2 mm) to 1/4" (6.4 mm).

7. Replace gas burner, flame tamers and grates.

8. Light grill using information in the “Outdoor Grill

Use” section. See “Burner Flame Characteristics.”

Low Flame Adjustment

If flame goes out on the “LOW” setting, the low flame

setting must be adjusted.

1. Turn off the valve and wait until grill and burners are

cool.

9

Check that burners are not blocked by dirt, debris, insect

nests, etc., and clean burners as necessary. If they are clean,

adjust air shutters as needed.

IMPORTANT: Before adjusting air shutters, let burners cool

completely.

To Adjust:

1. Light grill using information in the “Outdoor Grill Use”

section.

2. Observe flame to determine which burners need

adjustment and how the flame is acting.

3. Turn off the valve and wait until grill and burners cool

completely.

4. Remove grill grates and flame tamers.

5. Remove the screw and cotter clip that hold the burner in

place. Remove gas burner from the grill.

2.

Remove grill grates and flame tamers.

3. Light grill using information in the “Outdoor Grill

Use” section.

4. Turn burner to its lowest setting.

5. Pull out each control knob for the main burner and

side burner.

6. Hold valve stem with pliers and insert a small flat-

blade screwdriver into the shaft.

7. Watch the flame and slowly turn the screwdriver

counterclockwise.

8. Adjust flame to minimum stable flame.

9. Replace the control knob and turn off the burner.

10.Repeat steps 3 through 9 for each burner if needed.

11.Replace the flame tamers and grates after the burners

have cooled.

Loading...

Loading...