Page 1

96M11667

Ultra-small Digital Laser Sensor

LV-S Series (Type B)

Instruction Manual

■ Symbols

The following warning symbols are used to alert you to safety precautions and

to prevent human injury and/or damage to property when using this product.

Accessories

■ Amplifier

Mounting bracket: 1 End unit: 2 Instruction Manual: 1

Supplied with LV-11SB (P) Supplied with LV-12SB (P)

■

LV-S31 dedicated accessories

Mounting bracket: 1

Plate nut: 1

M3 x 15 screw: 2

Adjustment screwdriver: 1

■

LV-S62 dedicated accessories

Reflector (R-6L): 1

■

LV-S41/S41L dedicated accessories

Mounting bracket: 1

Warning

Important

Failure to follow instructions may lead to injury.

Indicates warnings and restrictions that must be followed during

operations.

Note

Provides additional information on proper operations that can be easily mistaken.

Safety Information for LV-S series

•

Warning

This product is just intended to detect the object(s). Do not use this

product for the purpose to protect a human body or a part of human

body.

•

This product is not intended for use as explosion-proof product. Do not

use this product in hazardous location and/or potentially explosive

atmosphere.

Safety precautions on laser products

Warning

FDA(CDRH) Part 1040.10* Class 1 Laser Product

* The classification is implemented based on IEC60825-1 following the

requirements of Laser Notice No.50 of FDA (CDRH).

• U se of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

• This product employs a semiconductor laser for its light source.

• Follow the instructions mentioned in this manual. Otherwise, injury

to the human body (eyes and skin) may result.

Precautions on class 1 laser products

•

Do not disassemble this product. Laser emission from this product

is not automatically stopped when it is disassembled.

•

Do not stare into the beam.

Sensor head LV-S31/S41/S41L/S61/S71/S72 LV-S62/S63

Wavelength 655 nm 660 nm

Output 290 μW

IEC 60825-1 Class 1 Laser Product

■

LV-S61 dedicated accessories

Mounting bracket: 1

Plate nut: 1

M2 x 12 screw: 2

Reflector (R-6): 1

■

L-shaped mounting bracket: 1

M4 nut: 3

M4 x 30 screw: 3

Reflector (R-9): 1

■ LV-S71/S72 dedicated accessories

Mounting bracket: 2 Nut: 4

Facing ring: 2

Washer: 2

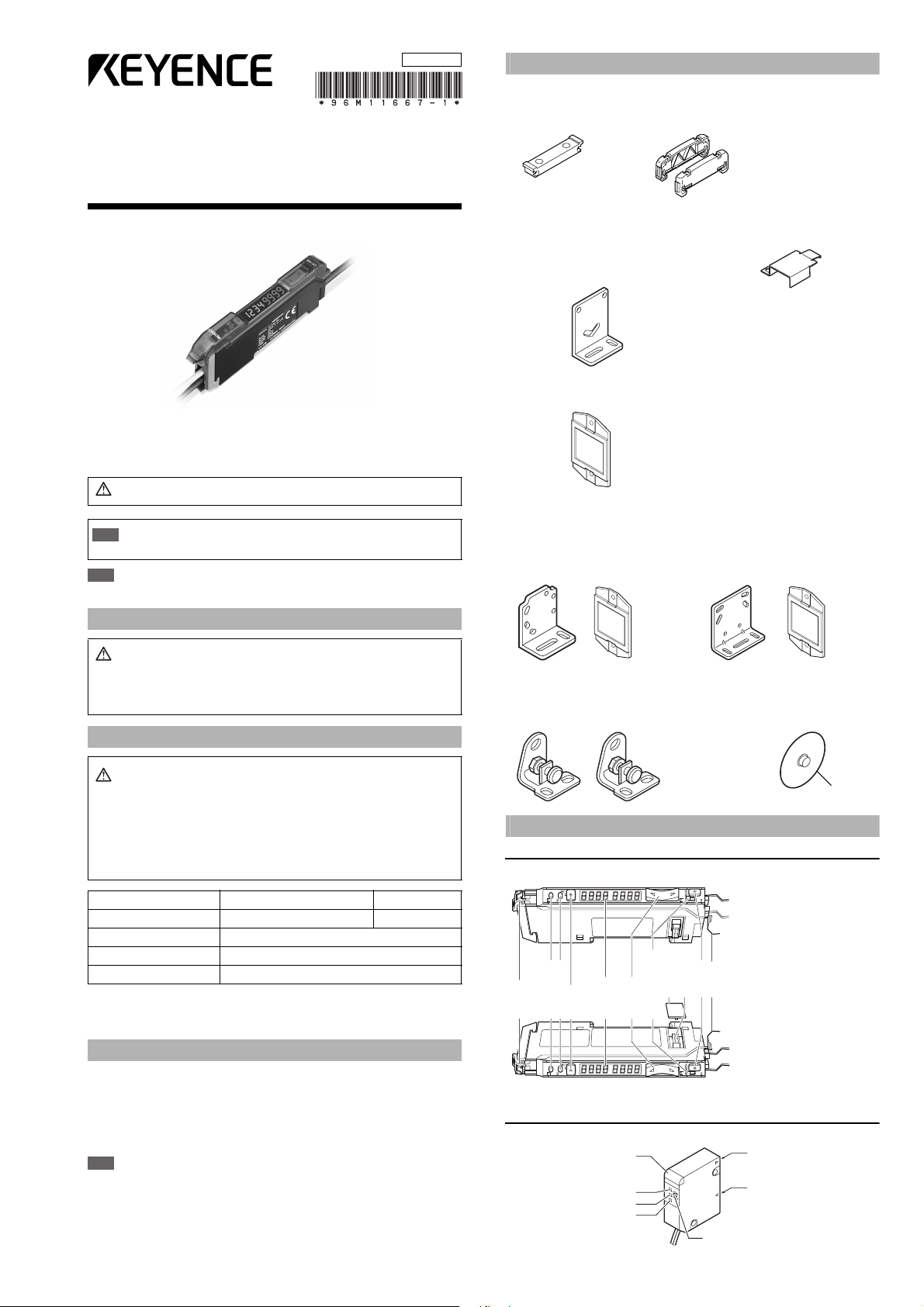

Identifying Part Names

Amplifier

■ LV-12SB (P) (Expansion unit)

Connector protection

cover

Extension connector

MODE button

Output indicator lamp

(for control output 1)

Hold lock bar

Output indicator lamp

(for control output 2)

SET button

Digital monitor

Manual button

Channel selection switch

(display settings)

LV-S63 dedicated accessories

Beam axis adjustment cap: 1

ø30

Dust cover

Safety Measures for the Laser

■ Laser emission stop input

The laser emission can be stopped by selecting the “Laser emission stop” signal

(20 ms or more) from the input functions and inputting it externally.

The emission stops while the signal is being input. The laser beam is emitted in 20 ms

after the signal input is canceled. The control output functions according to the

received light intensity even while laser emission stop is input.

Note

When the power is turned on, even when the laser emission stop signal is

input, the laser is emitted for about 60 ms for self-diagnostic purpose.

E LV-S-IM

■ LV-11SB (P) (Main unit)

Sensor head

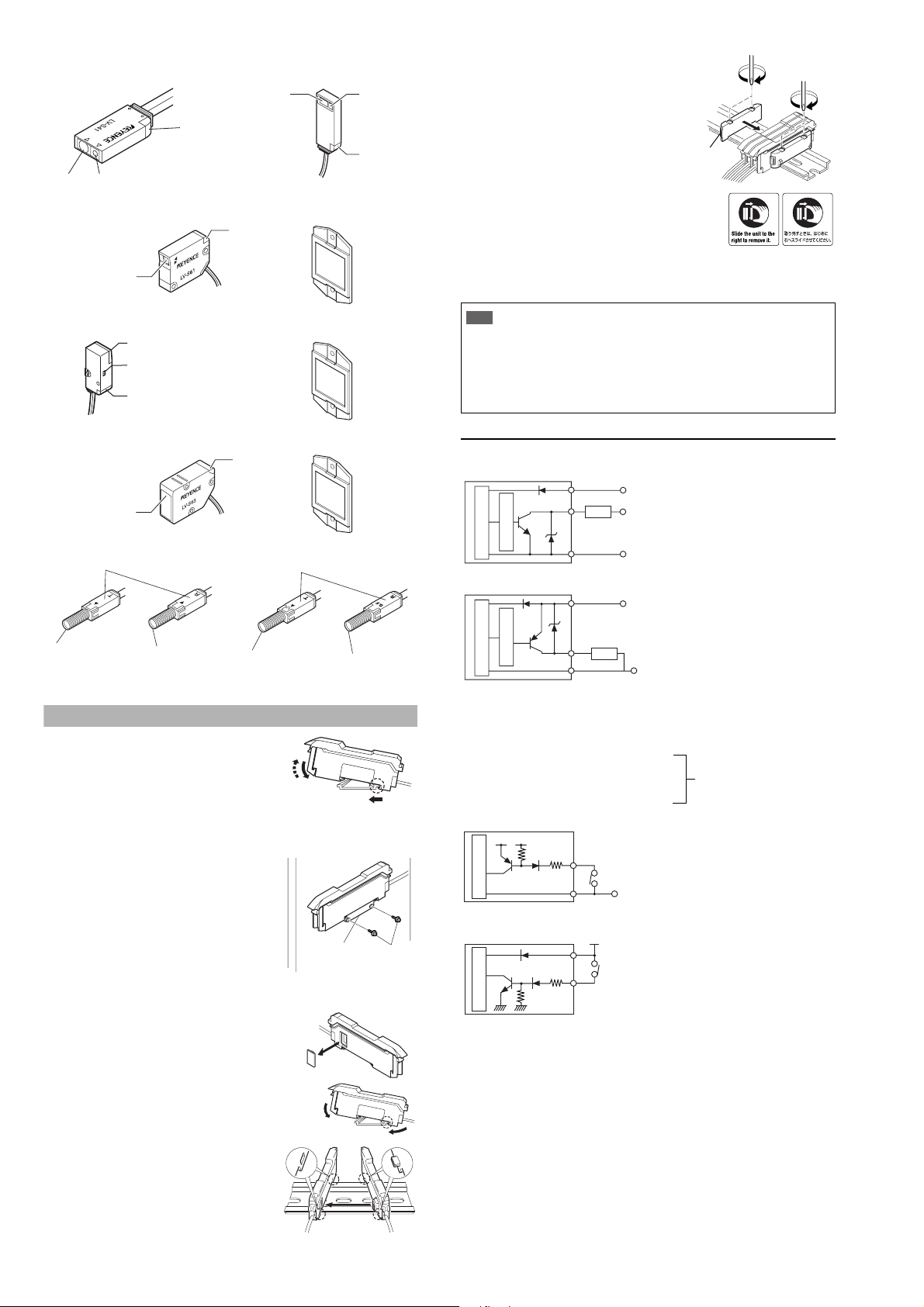

■ LV- S3 1

Operation indicator (red)

FAR indicator (red)

J

U

T

S

i

i

n

d

c

a

NEAR indicator (red)

1

Transmitting section

F

F

J

N

o

t

g

(

r

r

e

e

n

N

)

Receiving section

Adjustment trimmer

Page 2

■ LV- S 41

r

Receiving

Transmitting section

section

■ LV- S 61

Transmitting section,

Receiving section

■ LV- S 62

■ LV- S 63

Transmitting section,

Receiving section

Operation

indicator

(red)

Transmitting section,

Receiving section

Spot selection switch

Operation indicator

(red)

■ LV- S4 1 L

Receiving

section

Operation

indicator (red)

Operation

indicator (red)

Transmitting

section

Operation

indicator

(red)

Reflector (accessory)

Reflector (accessory)

Reflector (accessory)

4 Install the end units on both ends of

the amplifier unit.

Fasten the screws on the top of the

end units (at two positions on both

end units) with the Philips screwdriver.

Two end units are

supplied with an

expansion unit.

OP-26751

* The stickers on the right are provided. Attach

the sticker on the place near the amplifier unit.

■ Removing the amplifier unit

1 Remove the end units.

2 Slide the expansion unit and remove it one by one.

•

Important

Input/Output Circuit Schematic

■ Output circuit

LV-11SB/12SB (NPN output type)

When installing additional expansion unit, be sure to use the DIN rail and the end units.

• Turn off the power when installing or removing the unit.

• Do not remove the protective cover of the extension connector on the

amplifier expansion unit that is added at the end.

•

Do not remove the amplifier unit with all added units attached, from the DIN rail.

•

Verify the operation ambient temperature after addi tional installati on. (“Specifications” page 11)

•

Do not use full calibration functions or stability output when the expansion unit of

the LV-S Series is connected to a device with full calibration functions (such as

FST or PS-T) via external input. Doing so may lead to product malfunctions.

Brown *

Black/white (control output 1/2)

Load

DC12-24V

DC5-40V

■ LV-S71

Operation indicator (red)

Tra ns mi t te r

Transmitting section

Receiver

Receiving section

■ LV- S7 2

Operation indicator (red)

Tra ns m it te r

Transmitting section

Receive

Receiving section

The operation indicator works in conjunction with the Output selected at the

channel selection switch. (It does with Output 1 in area detection mode.)

Mounting the Amplifier Unit

■ Mounting on a DIN rail

.

(3)

(2)

Mounting bracket

(OP-25431)

(1)

M3 screw

1)

Align the claw at the bottom of the main body with the

DIN rail. While pushing the main body in the direction

of the arrow 1, slant it in the direction of the arrow 2

2)

To dismount the sensor, raise the main body

in the direction of the arrow 3 while pushing

the main body in the direction of the arrow 1.

■

Installation using the mounting bracket (accessory) (LV-11SB/11SBP only)

Mount the amplifier unit using the supplied

mounting bracket as shown in the figure.

■ Connecting several amplifier units

Up to 16 expansion units LV-12SB can be installed to the main unit LV-11SB.

1 Remove the protection cover on the side of the

main unit.

Overcurrent protection circuit

Sensor main circuit

Blue *

0V

* LV-11SB only

LV-11SBP/12SBP (PNP output type)

Overcurrent protection circuit

Sensor main circuit

Brown *

Black/white (control output 1/2)

Blue *

DC12-24V

Load

0V

* LV-11SBP only

The power of the expansion unit LV-12SB (P) is supplied by the Extension connector on the side of the main unit LV-11SB (P). The power wires (brown and blue) of

the main unit and those of the expansion unit are unified inside by the connector.

■ Input circuit

• Not to be used

• Light emission stop input

• External calibration input

• Setting value bank selection input

• Received light intensity shift input

LV-11SB/12SB (NPN output type)

DC3.3V

Pink (input)

PLC etc.

(Short-circuit current 1 mA max.)

Sensor main circuit

Blue *

0V

* LV-11SB only

LV-11SBP/12SBP (PNP output type)

DC12-24V

Brown *

PLC etc.

Pink (input)

Sensor main circuit

* LV-11SBP only

(Short-circuit

current 2 mA max.)

Select either one.

(switched by the amplifier

function selection)

2 Install the amplifier one by one on the DIN rail.

3 Engage the two claws of the expansion

unit with the recesses on the main unit

side until you hear a click sound.

(2)

(1)

2

E LV-S-IM

Page 3

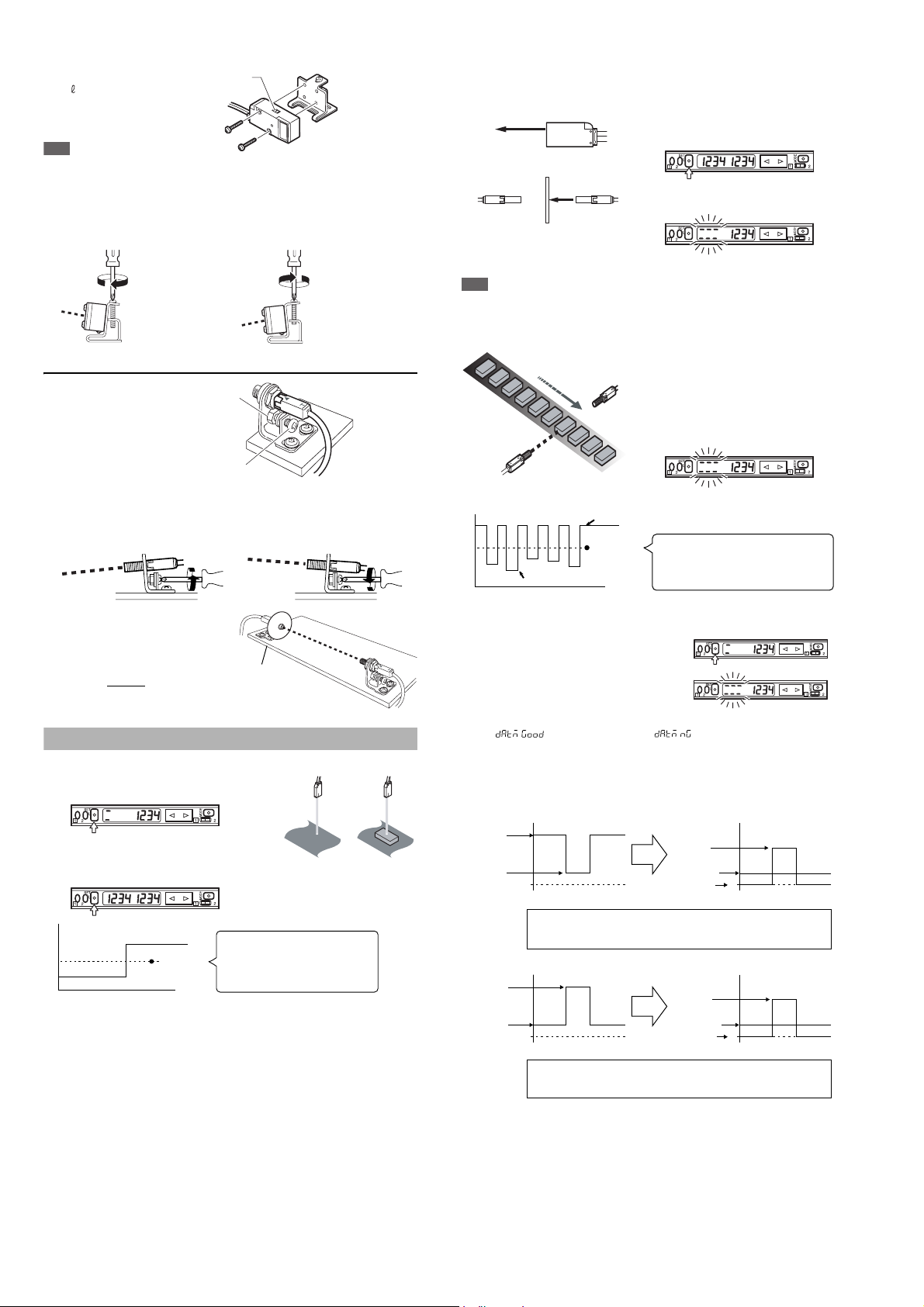

Connecting the Sensor Head and the Amplifier Unit

■ How to connect the amplifier unit and the connector

1 Open the dust cover, and tilt the

hold-lock lever.

LV-S41/S41L

Be sure to use the supplied mounting bracket.

1 Press the mounting bracket on the sensor head.

Be sure to hook the A portion of the mounting bracket on the B portion of

the sensor head.

A

2 Raise the hook, and insert the

connector to the very end.

3

Lower the hook and

hook the part shown

in the figure, and

then raise the holdlock lever.

Note

When shortening the sensor head cable, follow the instructions given in the

“Sensor Head Connector Assembly Procedures” included with the sensor

head.

Mounting and Adjusting the Sensor Head

LV- S3 1

■ Adjusting the trimmer (detection position)

The detection range can be selected as desired by adjusting the trimmer.

When detecting the target

from a long distance, turn the

trimmer clockwise to adjust.

F

F

J

N

N

■ Adjusting the center of detection

1

When detecting the target

from a short distance, turn the

trimmer counterclockwise to

F

F

adjust.

J

N

N

Place the workpiece at the position you

want to set as the center of detection.

2 Turn the trimmer until JUST

indicator (2) illuminates in green.

When (1) illuminates, turn the

trimmer clockwise until (2)

(1)

(2)

(3)

Finer adjustment is possible by looking at the display on the amplifier (page 9).

■ Detecting a height difference

A stable detection is made possible by

adjusting the trimmer so that the middle

point of the height comes to the center of

detection.

Middle point

illuminates.

F

F

When (2) illuminates, the

J

N

N

adjustment is complete.

When (3) illuminates, turn the

trimmer counterclockwise

until (2) illuminates.

B

2 Install the sensor head on the flat surface with the

M3 screws as shown in the following figure.

(The M3 screw is not an accessory.)

LV-S62

Mount the sensor head using either L-shaped mounting bracket (OP-84350),

rear mounting bracket (OP-84349), side mounting bracket (OP-84351) sold

separately.

■ L-shaped mounting bracket (sold separately: OP-84350)

Mounting bracket 1

Plate nut 1

M3 x 7.3 screw 1

1 Insert the plate nut to the head.

2 Insert the protrusion on the amplifier for

securing the bracket into the hole at the

upper part of the bracket.

Limit the tightening torque

up to 0.5Nm

■ Rear mounting bracket (sold separately: OP-84349)

Mounting bracket 1

M3 x 18 screw 2

Limit the tightening

torque up to 0.5Nm

• Adjusting the beam axis

(1) The beam axis angle can be adjusted horizontally by swinging the

bracket to the left and right with screws (a), (b) and (c) loosened. In order

to tighten the screws, be sure to tighten screw (b) first.

(a)

(c)

(b)

(a)

(2) The angle of the beam axis can be changed downward if the screw indi-

cated by the arrow is tightened, and upward if loosened.

When you want to lower the beam axis. When you want to raise the beam axis.

(c)

(b)

■ Movement directions of the workpiece

Movement

direction

Detecting

object

Movement

direction

Detecting

object

Detecting

object

E LV-S-IM

Movement

direction

3

Be sure to adjust the beam axis in the order of (1) and (2).

Important

If the order is reversed, the screws in (1) may be damaged.

Page 4

■ Side mounting bracket (sold separately: OP-84351)

Mounting bracket 1

M3 x 18 screw 2

Note

When mounting the sensor head in the opposite direction as described previously, set the spot toggle switch before mounting.

• Adjusting the beam axis

The angle of the beam axis can be changed upward if the screw indicated by

the arrow is tightened, and downward if loosened.

When you want to raise the beam axis. When you want to lower the beam axis.

Spot toggle

switch

Limit the tightening

torque up to 0.5Nm

LV-S71/S72

Mount the sensor head such

that the letter “T” (on the

transmitter) or “R” (on the

receiver) faces upward. The

side where the operation indicator illuminates should face

upward.

• Adjusting the beam axis

The angle of the beam axis can be changed downward if the screw indicated

by the arrow is tightened, and upward if loosened.

When you want to lower the beam axis When you want to raise the beam axis

Adjust the spot to be emitted at the

center on the receiver.

The adjustment is facilitated by

attaching the beam-axis adjustment

cap supplied with the sensor head to

the tip of the receiver

. Once the

adjustment is complete, remove the

beam-axis adjustment cap.

Fixing nut

Beam axis

adjusting screw

Beam axis

adjustment cap

Limit the tightening

torque up to 1.2 Nm.

Setting Sensitivity

■ 2-point calibration

1 Press the SET button once without a

workpiece being placed.

12

2 Place a workpiece at the designated

position, and quickly press the SET

button once again.

2

1

Received light intensity

*

If the sensitivity difference does not have enough room, “

the calibration is complete. The setting value is changed at this time, too.

Setting value

The value set at the intermediate point

between the received light intensity

measured when the SET button is pressed

for the first time and that measured when it

is pressed for the second time.

Time

++++

” flashes after

■ Maximum sensitivity setting

Set the sensitivity without a workpiece in the case of the reflective type, and with

a workpiece in the case of the transmission type.

Reflective type

1 Press the SET button for three

seconds in the state as shown in

With no workpiece

Transmission type

the figure on the left.

The indication flashes when the setting

is complete.

With workpiece

2 Release the SET button.

Note

In the transmission type, if the value for the maximum sensitivity setting is the same as

DSC, the device will not operate correctly, so do not use the same value.

■ Full-auto calibration (not available for the LV-S31)

1

Let the workpiece pass while the SET

button is being pressed for three

seconds. (The sensitivity is set

according to the received light intensity

while the SET button is pressed.)

2

The indication flashes when the

setting is complete.

3 Release the SET button.

MAX

The value is set at the intermediate point

between the MAX value and the MIN value

of the received light intensity measured

while the SET button is pressed.

Received light intensity

MIN

Setting value

Time

Perform 2-point calibration if the setting cannot be configured as desired.

■ Zero datum calibration (not available for the LV-S31)

1 Press the SET button quickly without a

workpiece being placed.

2 Press the SET button for at least three

seconds. When the indication flashes,

release the button.

3 The calibration is complete when

" " is displayed. When " " is displayed, switch the

channel toggle switch to "2" and check the contents of the alarm.

*The alarm contents are only displayed when "Auto" is selected for "ALrt",

the operation of control output 2 in "4. Detection mode selection". (For

information about the display, see "Toggling the display" on page 9.)

Transmission/retro-reflective types

Received light

intensity without

workpiece

Received light

intensity with

workpiece

(Blocked light)

0 0

Reflective type

Received light

intensity with

workpiece

(Entered light)

Received light

intensity without

workpiece

0 0

In the transmission or retro-reflective type, when zero datum calibration is performed

without a workpiece, the received light intensity without a workpiece is used as zero and

the value indicates the amount of blocked light. The setting value is set automatically.

In the reflective type, when zero datum calibration is performed without a

workpiece, the received light intensity without a workpiece is used as zero and the

value indicates the amount of entered light. The setting value is set automatically.

Blocked light

Setting value

Received light

intensity without

workpiece

Entered light

Setting value

Received light

intensity without

workpiece

4

E LV-S-IM

Page 5

Note

• The zero datum calibration cannot be used when bank selection (bAnk) is

set for the control input function.

• The zero datum calibration can only be used with Output 1.

• When zero datum calibration is performed on models other than LV-S41/

S41L, the DSC function is turned on.

• When zero datum calibration is performed on LV-S41/S41L, the DSC function is turned off.

• After zero datum calibration is performed, the minus sign will not be displayed. In situations when the minus sign is supposed to be displayed, the

display stay as zero.

■ Positioning calibration (not available for the LV-S31)

1 Press the SET button quickly

without a workpiece being placed.

2

Place a workpiece on the position

where you want to perform positioning.

Setting value

Received light intensity

The sensitivity is set at the point where the value

becomes ON exactly when a workpiece comes

to the point where you want to position it.

Note

• Output 2 for Bank A and Outputs 1 or 2 for Bank B can be used.

• When the control input function is set to bank select (bAnk), Output 1 on

Bank A can be used.

3 Press the SET button for at least

three seconds. When the indication

flashes, release the button.

Time

■ % calibration (not available for the LV-S31)

This is a calibration method that can set the setting value by percentage with

reference to the received light intensity at the time of sensitivity setting. For

example, if the target value is set to –10P, the setting value is determined 10%

lower than the received light intensity when the SET button is pressed.

By regularly performing external calibration from the device such as a PLC,

even a little sensitivity difference can be steadily detected.

Note

The % calibration function cannot be used when the DSC function is turned

on or the zero datum calibration is being used.

1 When selecting the sensitivity

setting method (page 7, No. 5),

select the % calibration, and set

the target value of calibration.

(The value can be set by 1%.)

2 Taking the desired light intensity as

a reference (normally without a

workpiece), press the SET button.

* While the % calibration is in use, other calibrations (sensitivity setting) can-

not be used.

* The setting value is calculated based on the intermediate value between

MAX. and MIN. of the received light intensity while the SET button is being

pressed. The conditions in acquiring the sampling value can be changed

using the procedure to set the special modes.

■ Edge detection (not available for the LV-S31)

Detects the change in the received light intensity during a given period of time.

In the detection mode (page 7, No. 4), select the following edge detection

mode and the detection time.

Rising detection Detects the increase (rising edge) of

Falling detection Detects the decrease (falling edge) of

Rising/falling

(both-edge) detection

Sensitivity setting

The sensitivity is set to maximum when the SET button is pressed once.

(If the SET button is pressed and held for a while, changes in the light intensity during that period are ignored.)

Output status

Setting Operation

L-ON Always OFF. Turns ON only when the light intensity changes.

D-ON Always ON. Turns OFF only when the light intensity changes.

the received light intensity

the received light intensity

Detects both the rising and falling

edges of the received light intensity.

■ External calibration

1 Select the external calibration with the menu switch.

2 Short-circuiting the pink wire 20 ms or more as follows for each model is

equivalent to pressing the SET button.

LV-11SB/12SB LV-11SBP/12SBP

* LV-11SB/11SBP only

* The maximum number of times of writing is one million.

* Input is not accepted while setting any mode (page 7).

Brown*

Blue*

Pink

+V

0 V

Brown*

Pink

Blue*

+V

0 V

Fine-adjusting Sensitivity

The setting value can be directly changed by pressing the manual button.

When “five-digit display” is set (page 7, No.11) for the number of digits to be displayed for the received light intensity

1

Press the manual button quickly once, and check that the setting value flashes.

2 While the setting value is flashing, change the setting value with the

Manual button.

Note

When DSC and zero datum are activated, perform fine-adjustment without a

workpiece.

Area Detection Mode

This mode is suited to detecting the received light intensity only of a certain range.

To set this mode, select the area

detection mode among the

detection modes. (page 7, No. 4,

or page 8 No. 5)

The display of the setting values

of the upper and lower limits can

be switched with the channel

selection switch.

Keep the range of setting value 1 > setting value 2.

Nothing is detected when setting value 1 ≤ setting value 2.

Output 2 cannot be used while the area detection mode is in use.

Setting value 1

(Upper limit)

Setting value 2

(Lower limit)

Received light intensity

1: Setting value upper limit

2: Setting value lower limit

■ Sensitivity setting method 1 (Normal sensitivity)

OFF

ON

OFF

1 Place a workpiece on the upper

limit of the received light intensity

that you want the sensor to detect,

and press the SET button once.

1: Upper limit

2

2: Lower limit

If the sensitivity difference does not have enough room, “+++” flashes after

the calibration is finished. The setting value is changed at this time, too.

Place a workpiece on the lower limit

of the received light intensity that

you want the sensor to detect, and

press the SET button once again.

■ Sensitivity setting method 2 (when % calibration is selected)

1 Place a workpiece on the

designated position, and press the

SET button once.

Specify the setting values to the

upper and lower limits of the time

when you press the SET button.

Example: When the setting value of the % calibration is set to 10P

The value that is the received light intensity when the SET button is pressed

plus 10% is set for the setting value 1, and minus 10% for the setting value 2.

■ Bank function

Normally, up to two setting values can be set, but by using the bank function,

up to four setting values can be set.

E LV-S-IM

5

Page 6

Note

The zero datum calibration cannot be used when using the bank function.

1 When selecting the control input function (page 7, No.8, or page 8, No. 7),

select the bank selection.

2 Normal bank A becomes bank B when the external input wire (pink wire)

is short-circuited.

LV-11SB/12SB LV-11SBP/12SBP

Brown*

Blue*

Pink

+V

0 V

* LV-11SB/11SBP only

Set or change the bank B while the input signal is input.

Setting the Display Scaling (not available for the LV-S31)

This is the function to adjust the received light intensity during operation to the

“scaling target value”.

Note

This function cannot be used when zero datum calibration is being used.

1

When setting a display scaling (page 7, No. 6), select to use the display

scaling, and set the target value. (The explanation here deals with the case

where the target value is set to 2000.)

2

During the normal display, press the SET button while pressing the MODE button.

The display changes as follows, and the target value (which is 2000) to be

set as a scale is displayed.

Brown*

Pink

Blue*

+V

0 V

•

When connected to LV-S41/S41L, the DSC function turns off when the zero datum

calibration is performed and operates while turned on when there is entered light.

■ Alarm output level (ALrt) setting

Specify the operation for control output 2 when the DSC function is set to ON.

Mode Operation

Auto Control output 2 acts as an alarm output.

uSEr Control output 2 performs a usual operation.

■ Alarm output level (rtio) setting

Specify the level at which to output an alarm when the received light intensity

changes as moderately as the control output stays off (specifying the moderate fluctuation alarm level).

DSC is not performed during a period when the received light intensity falls

below the alarm level.

Specified range: 0 to 100%

100%: The moderate fluctuation alarm is not output.

50%: An alarm is output when the received light intensity changes from the

background state up to half the setting value.

0%: An alarm is output when the received light intensity gets any closer to

the setting value from the background state.

Note

Normally use the setting at 50%. Smaller values can affect the response and

prevent the alarm from becoming cleared.

Timing chart

Ex: When using a transmission or retro-reflective type

rtio

100%

Output 1 (Control output)

Output 2 (Alarm output)

Received light intensity

Received light intensity

Alarm state

Workpiece detection

Alarm level

Setting value

(no alarm)

The display scaling is performed.

↓

The reference light intensity can be set in the following range in reference with

the currently received light intensity:

Power mode Minimum value Maximum value

HSP Approx. 1/20 times Approx. 16 times

FINE Approx. 1/40 times Approx. 8 times

TURBO Approx. 1/80 times Approx. 4 times

SUPER Approx. 1/160 times Approx. 2 times

ULTRA Approx. 1/320 times Approx. 1 time

The error is indicated

when the value is out of

the range.

Special function

After an external calibration, the scaling can be externally performed by

inputting the signal again in three seconds.

• In the case of the % calibration (example)

Input ON

Input OFF

Input ON

Input OFF

%calibration Display scaling

Within 3

seconds

%calibration %calibration

3 seconds

or more

* Input is not accepted while setting any mode. (page 7)

DSC (Dynamic Stability Control)

DSC automatically corrects the setting value according to the changes in the

received light intensity when there is no workpiece (output OFF).

This function is effective when the light intensity difference is small when

judging whether or not there is a workpiece. At Detection mode selection

(page 7, No.4), select " ".*

How to set the sensitivity is the same as in the normal mode.

* The value is stored in memory even after the power is turned off.

Note

•

When connected to a sensor head other than LV-S31/S41/S41L, the DSC function turns on automatically when the zero datum calibration is performed and

operates while turned on when there is blocked light. When other calibrations are

performed in this state, the DSC function is turned off.

Shift Function

Forcibly synchronizes the received light intensity with the preset value (shift

target value). (Adds and subtracts the received light intensity.)

Regular synchronization inputs from a PLC or other device stabilizes the

detection of the target that has a little light intensity difference.

Note

The shift function cannot be used when the DSC function is turned on or the

zero datum calibration is being used.

1 When setting a shift function (page 7, No. 7, or page 8, No. 6), select to

activate the shift function, and set the shift target value.

LV-11SB/12SB LV-11SBP/12SBP

Brown*

Blue*

Pink

+V

0 V

* LV-11SB/11SBP only

Whether or not to save the current display status changed by an external input

*

can be selected in the special mode (See “How to set the special mode” on

page 9). The default is to “Save”.

It is recommended that you set “Do not save” when the external input is frequently performed. The maximum number of times of writing is one million.

Hold Function

This function holds the peak value and the bottom value of the received light

intensity during operation.

At Hold mode selection (page 7, No.9), select the hold mode.

Hold mode Operation

Updates the peak and bottom values every time the current light

intensity exceeds or drops below the specified value.

Displays the maximum and minimum peak values since the

power is turned on (total number).

Displays the maximum and minimum bottom values since the

power is turned on (total number).

Displays the minimum peak value and the maximum bottom

value since the power is turned on (total number).

Displays the maximum peak value and the minimum bottom

value since the power is turned on (total number).

Brown*

Pink

Blue*

+V

0 V

6

E LV-S-IM

Page 7

How to Set up Each Mode (Models other than LV-S31)

The settings of Output 1 and 2 can be divided into common settings and individual settings depending on the modes. Change the mode by using the

channel selection switch. To exit the mode setting while it is not completely

finished, press the MODE button for over 2 seconds. Refer to page 8 when

using the LV-S31.

MODE

Press for two seconds

Selecting output

1

Press the or button to select.

•

•

2

Press the or button to select.

• HIGH SPEED:80

• FINE:250s

• TURBO:500s

• SUPER:2 ms

• ULTRA:4 ms

* Cannot be selected when LV-S62/S63 is being used.

Output 1/2 indiv idual setting

Turns ON while the light enters.

Turns ON while the light is shielded.

Selecting the power mode (response time)

When the power mode is changed, redo the calibration.

MODE

When Timer

OFF

is selected

a

When Output 1 is set

and zero datum

calibration is selected

When Output 2

When a mode

Normal or

Area detection

is selected.

MODE MODE

When a mode

DSC is

selected.

is set.

When zero

datum calibration

is selected for

Output 1

B

When a mode DSC is

selected for Output 1

and a mode Normal is

selected for Output 2

C

Output 1/2 common

µ

s

Selecting the Timer mode

3

Press the or button to select.

• Timer OFF

• OFF delay

When other

setting than

Timer OFF

is selected

OR

• ON delay

• One-shot

•

•

Timer setting

Press the or button to select.

MODE

When selecting a timer mode,

If other setting than *1 is selected → a

If *1 is selected → b

b

MODE

Can be set between 0.1 and 5000 ms.

When *1 is selected, the ON delay

timer is activated.

Timer setting 2

Sets an OFF delay (one-shot) time.

Press the or button to select.

Can be set between 0.1 and

5000 ms.

A

(If the sensor head is “LV-S41/S41L”

Selecting the detection mode

4

Press the or button to select.

When a mode other

than Normal, DSC,

or Area detection

is selected

• Normal (light intensity) mode

• Area detection mode

• Area detection mode

•

•

•

of the received light intensity

The % calibration function cannot b e used when the

DSC function is turned on or the zero datum

calibration is being used.

The shift function cannot be used w hen the DSC

function is tur ned on or the zero datum calibration is

being used.

Selecting the derivation time

Press the or button to select.

The time can be selected from 0.25/0.5/1/2.5/

B

5/10/25/50/100 ms. (The available times vary

A

depending on the power mode.)

Selecting the detection operation

Press the or button to select.

•

[light intensity with workpiece >

light intensity without workpiece]

(The output is on when the light

enters)

•

[light intensity with workpiece <

light intensity without workpiece]

(The output is on when the light

is blocked.)

Output 1/2 indiv idual setting*

Detects the rising edge of the received light intensity.

Detects the falling edge of the received light intensity.

Detects both the rising and falling edges

or more

MODE

MODE

When Output 2 is

set, Alarm output is

selected, and

"Auto" is selected

End of the basic

menu display

Output 1/2 indiv idual setting

ON delay, OFF delay *1

ON delay, one-shot *1

B

L-on Mainly for reflective type

d-on Mainly for thrubeam type

Selecting the correction speed

Press the or button to select.

The correction is made faster as

the number b ecomes larger (1 to 3).

(Select 1 for normal cases.)

Mode LEv1 LEv2 LEv3

Correction 104.86s 1.64s 25.6ms

speed

Selecting the operation for control output 2

Press the or button to select.

•

Uses normal operations for

control output 2.

•

Uses alarm output for control

output 2.

Setting the range for alarm output level

Press the or button to select.

Set in the range between 0 and 100P.

* Normally use the setting at 50% .

B

Selecting the sensitivity selecting method

5

Press the or button to select.

• Normal sensitivity setting

• % calibration

Setting the target value of the %

calibration

Press the or button to select.

From –99% to +99% can be set.

Setting the display scaling

6

Press the or button to select.

• Normal display

• Display scaling

Setting the display scaling target value

Press the or button to select.

It can be set by the unit of 100.

Output 1/2 common

Output 1/2 common

C

MODE

MODE

When OFF

is selected

When zero datum

calibration or % or

calibration is selected

When zero datum

calibration are selected

C

When %

calibration

is selected

When ON is

selected

DSC

MODE

MODE

MODE

B

Setting the shift function

7

MODE

When OFF

is selected

When ON is

selected

B

MODE

MODE

)

MODE

MODE

When DSC mode,

display scaling,

or zero datum

calibration are

MODE

selected

Press the or button to select.

• Do not use shift

• Use shift

Setting the shift target value

Press the or button to select.

It can be set by the unit of 1.

Selecting the control input function

8

Press the or button to select.

• Does not use the control input

• External calibration

• Bank selection

• Laser emission stop

Selecting the hold function

9

Press the or button to select.

•

Updates the peak/bottom value every time that the

current light intensity is less than or more than the set value

•

Displays the maximum and minimum peak values

since the power was turned on (total number)

•

Displays the maximum and minimum bottom values

since the power was turned on (total number)

•

Displays the minimum peak value and the maximum

bottom value since the power was turned on (total number).

•

Displays the maximum peak value and the minimum bottom

value since the power was turned on (total number).

Selecting the display mode

10

Press the or button to select.

• Normal screen display mode

• Full screen display mode

Selecting the number of digits of light intensity display

11

Press the or button to select.

•

Four-digit display (the setting value is also displayed)

• Five-digit display

Output 1/2 common

Output 1/2 common

Output 1/2 common

Output 1/2 common

Output 1/2 common

End program

* When Area detection mode is selected in "4.Selecting the detection mode", "----" is displayed in

the Output 2 setting and Output 2 cannot be selected.

If a mode other than the Normal/Dsct Area detection mode is selected for either Output 1 or 2, the

setting of item 5 or 6 or 7 cannot be selected for both Output 1 and 2.

E LV-S-IM

7

Page 8

How to Set up Each Mode (LV-S31)

The settings of Output 1 and 2 can be divided into common settings and individual settings depending on the modes. Change the mode by using the

channel selection switch. To exit the mode setting while it is not completely

finished, press the MODE button for over 2 seconds.

MODE

Press for two

1

Selecting output

Output 1/2 individual setting

Press the or button to select.

Turns on the output nearer to the sensor.

•

•

Turns on the output farther to the sensor.

2

Selecting the power mode

Press the or button to select.

• Normal mode

•

High-speed mode (response time 250 µs)

3

Selecting the response time

Press the or button to select.

Varies depending on the power mode.

SPEED Response time

1 500µs

2 2ms

3 8ms

4 32ms

When the power mode is HSP, the

response time is fixed to 250 µs.

Output 1/2 common

Output 1/2 common

seconds or more

MODE

MODE

When Std is selected

MODE

When

HSP is

selected

When OFF

is selected

MODE

MODE

MODE

6

Setting the shift function

When

ON is

selected

MODE

Press the or button to select.

• Do not use shift.

• Use shift.

7

Selecting the control input function

Press the or button to select.

• Does not use the control input

• External calibration

• Bank selection

• Laser emission stop

8

Setting the hysteresis mode

Press the or button to select.

•

•

Hysteresis: large

(End Program)

Output 1/2 common

Setting the shift target value

Press the or button to select.

It can be set by the unit of 1.

Output 1/2 common

Output 1/2 common

Hysteresis: small

When Timer

OFF

is selected

MODE

a

MODE

4

Press the or button to select.

• Timer OFF

When other

setting than

Timer OFF

is selected

b

• OFF delay

• ON delay

• One-shot

•

•

MODE

When selecting a timer mode,

If other setting than *1 is selected → a

If *1 is selected → b

OR

MODE

5

Press the or button to select.

• Normal detection mode

• Area detection mode

End of the basic

menu display

Selecting the timer mode

Selecting the detection mode

Output 1/2 individual setting

ON delay, OFF delay *1

ON delay, One-shot *1

Timer setting

Press the or button to select.

Can be set between 0.1 and 5000 ms.

When *1 is selected, the ON delay timer is

activated.

Timer setting 2

Sets an OFF delay (one-shot) time.

Press the or button to select.

Can be set between 0.1 and 5000 ms.

Output 1/2 individual setting

* Output 2 cannot be used when the Area detection mode is selected.

If a mode other than the Normal/Area detection mode is selected for either Output 1 or 2, the

setting of item 5 or 6 cannot be selected for both Output 1 and 2.

How to set up special modes

■ When using a model other than LV-S31

MODE SET

Press , , and for three seconds or more at the same time.

Selecting the Power saving function (Eco mode)

Press the or button to select.

MODE

MODE

MODE

MODE

• Normal use

• Eco-half

• Eco-all

Selecting the memory of value set by an

external input while using the shift function

Press the or button to select.

• Saves the value *1

•

Does not save the value (clears data at power-off)

*1 Data can be saved up to one million times.

Selecting the acquisition of the sampling

value* (received light intensity)

Press the or button to select.

Use the average value from sampling

•

• Use the peak value from sampling

• Use the bottom value from sampling

* Used during % calibration or display scaling.

Selecting the shift function input time

Press the or button to select.

• 5ms

• 20ms

The input time is fixed to 20 ms for all other functions.

Switching zero datum settings

Press the or button to select.

• Standard

• Hight-accuracy

* When Hi (High-accuracy) is selected, the width for the zero

datum setting value becomes smaller. During this state, be

especially aware of shocks and other causes of fluctuation.

(End Program)

8

E LV-S-IM

Page 9

■ When using the LV-S31

MODE SET

Press , , and for three seconds or more at the same time.

Selecting the Power saving function (Eco mode)

MODE

MODE

MODE

Press the or button to select.

• Normal use

• Eco-half

• Eco-all

Selecting the memory of value set by an

external input while using the shift function

Press the or button to select.

• Saves the value *1

•

Does not save the value (clears data at power-off)

*1 Data can be saved up to one million times.

Selecting the shift function input time

Press the or button to select.

• 5ms

• 20ms

The input time is fixed to 20 ms for all other

functions.

(End Program)

Toggling the Display

■ When using a model other than LV-S31

• When "duAl" is selected for the number of digits of light intensity display and "Std" is selected for display mode

When zero datum calibration is not selected

Setting value Current value Margin Current value

When zero datum calibration is selected

Press

Press

MODE

MODE

When zero datum calibration is selected

MODE

Press

Current value after

zero datum calibration

Current value before

zero datum calibration

Bar display*2Current value after

Current value after

zero datum calibration

MODE

Press

Margin*1Current value before

zero datum calibration

MODE

Press

Current value before

zero datum calibration

MODE

Press

zero datum calibration

Press

MODE

Output status Power mode

Peak value

margin

Peak value before

zero datum calibration

MODE

Press

Bottom value

3

margin*

MODE

Press

Bottom value before

zero datum calibration

Flashes

alternately

Flashes

alternately

*1 The received light intensity is displayed in percentage with reference to

the setting value.

*2 Its stability is indicated between 85 to 115 %. The number is varied by

the unit of 5 %.

*3 The peak- and bottom-hold values since the power-on are displayed.

The hold values can be reset by pressing the manual button.

• When "rE" is selected for the number of digits of light intensity display

MODE

Press

Flashes

alternately

Current value

Peak-hold value

Bottom-hold value

■ When using the LV-S31

Setting value Current value

When "Auto" is selected for the operation of control output 2 and

the channel setting is switched to "2"

after zero datum

calibration

When zero datum calibration is completed without errors

When zero datum calibration is completed with errors

(The display shown to the left appears after " " is

displayed during zero datum calibration)

(The display shown to the left appears after " " is

displayed during zero datum calibration)

Alarm contents*

Margin Current value

before zero datum

calibration

* The displayed number indicates the following type of alarm.

For more information about remedies to errors, see "Error indication" on page 10.

1: Over DSC correction limit

2: DSC small fluctuation detection

3: Invalid DSC EEPROM contents

4: Over fluctuation width during zero datum calibration

5: DSC speed limit alarm

• When "duAl" is selected for the number of digits of light intensity display and "FuLL" is selected for display mode

When zero datum calibration is selected

MODE

Press

Setting value Current value

1

Margin*

Bar display*

Press

Current value

Press

2

Current value

MODE

MODE

Press

Output status Power mode

Peak value

margin

MODE

Peak value Bottom value*

MODE

Press

Bottom value

margin*

MODE

Press

Flashes

alternately

3

Flashes

alternately

3

Setting value Current value

(1)

MODE

Press

Position display

(2)

(1)

Digital display (The position of the target from the center position

Press

Press

MODE

(3)

Peak value Bottom value

MODE

[5000] is displayed in number.)

Outside of the detection range

The workpiece is near the sensor with reference

to the digital display range.

With 5000 being the middle, the value

increases as the distance from the sensor increases.

The workpiece is far from the sensor with reference to

the digital display range.

Outside of the detection range

(2)

Position display (The position of the target with reference to the

center position is displayed.)

Outside of the detection range

The number of bars increases as the distance from

the sensor increases, taking the state of "A" as the

center.

When adjusting the center position with the trimmer

A

(3)

The peak/bottom hold value since the power is turned on is displayed.

on the sensor head, adjust it to the state of "A".

Outside of the detection range

Pressing the Manual button can reset the hold value.

Flashes

alternately

E LV-S-IM

9

Page 10

Interference Protection Function

The LV-S Series can prevent mutual interference by connecting amplifier units.

■ When using a model other than LV-S31

Power mode HSP (HIGH SPEED) FINE/TURBO

Number of units required to

prevent interference

Unavailable 2 units 4 units

■ When using the LV-S31

Power mode HSP (HIGH SPEED) STD

Number of units required to

prevent interference

2 units 4 units

SUPER/ULTRA

Caution on a lustrous workpiece (LVS31)

If the workpiece is lustrous, the trimmer adjustment may not succeed or

detection may be unstable. In such a case, install the sensor slightly tilted.

Keylock

You can lock the operation buttons to prevent the settings from being

changed by careless operation of the buttons.

Setting operations for sensitivity or modes are disabled during keylock, but

the display can be switched.

While pressing the

MODE button, press

the or button for

at least three seconds.

The indicator shows that keylock is activated.

• The same steps can be taken to deactivate keylock.

Power-save (Eco Mode)

The numerical display disappears, and the current consumption is reduced.

If a key operation is performed during the Eco mode, the display returns to

normal. If no more key operation is performed for 4 seconds, the display

returns to the Eco mode.

Cautions on Installing the Reflector (LV-S61/S62/S63)

Be sure to install the reflector so that it is vertical or horizontal against the sensor unit.

If the reflector is installed diagonally against the sensor unit, the received light

intensity will decrease significantly.

Error Indication

The following indications on the LCD display show the error events. Correct

the problem using the following countermeasures.

Error indication Cause Remedy

ErH

ErC

ErE

Sensor head is not

connected.

Head cable is broken.

Overcurrent flows through

the output wire.

Data write/read error • Per form initialization.

Data has been written in

the EEPROM more than

one million times and can

no longer be updated.

The following table shows the alarms when "Auto" is selected for the operation

of control output "2"and channel setting is switched to "2". Refer to the following table to remedy the alarms.

Display Alarm contents Remedy

Over DSC correction limit:

Received light intensity

during OFF exceeds the

DSC correction limit.

DSC small fluctuation

detection:

There are fluctuations

within the range for the

alarm output level (rtio).

Invalid DSC EEPROM

contents:

Failed to write data to

EEPROM.

Over fluctuation width during

zero datum calibration:

The fluctuations of

received light intensity

during calibration are too

large.

DSC speed limit alarm:

The received light intensity

fluctuated a large amount

in a short period of time.

• Check that the sensor head is

connected.

• Check that the head cable is

not broken.

• Check the connection of the

head cable to the connector.

• After checking these points,

turn on the power again.

• Check the load and reduce

the current to be within the

rated range.

• Check that the output wire

does not touch another wire or

a frame.

• If you need to write more data,

replace the amplifier unit.

Change the setup conditions or

replace the sensor, and secure

the correct received light

intensity during OFF.

Move the workpiece to the

correct position.

Restart the power or initialize.

Take anti-vibration measures in

order to suppress fluctuations

during calibration.

• Move the workpiece to the

correct position.

• Take anti-vibration measures

in order to suppress

fluctuations in the received

light intensity.

10

E LV-S-IM

Page 11

Specifications

■ Sensor head

Shearing machine

type

Model LV-S31 LV-S41 LV-S41L LV-S61 LV-S62 LV-S63 LV-S71 LV-S72

Light source

FDA (CDRH)

Part1040.10

IEC 60825-1 Class 1 Laser Product

Detecting range

Spot diameter Approx. ø2 mm

Indicator

Standard detecting

object

Operating ambient

temperature

Operating ambient light

Vibration resistance 10 to 55 Hz, 1.5 mm double amplitude in the X, Y, and Z directions, 2 hours respectively

Material

*1 When Spot 2 x 10 mm is selected (Values inside the parentheses ( ) indicate when Spot 2 x 2 mm is selected)

*2 When detecting a transparent glass object, install and set the LV-S63 so that the received light intensity without the glass object becomes 1000 or more.

Housing

material

Display

section

Lens

section

Cable PVC

Mounting

bracket

Reflector

(R-4, R-6L, R-9)

Weight Approx. 75 g Approx. 70 g Approx. 70 g Approx. 65 g Approx. 110 g Approx. 70 g

■ Amplifier

Shearing machine type Main unit Expansion unit

NPN output LV-11SB LV- 12 SB

1

Model

*

PNP output LV-11SBP LV- 12 SB P

Sensor head LV-S Series (LV-S31 / S41 / S41L / S61 / S62 /S63 / S71 / S72)

Response time *

Control output

Control input

Power voltage *

Rating

Vibration resistance 10 to 55 Hz, 1.5 mm double amplitude in the X, Y, and Z directions, 2 hours respectively

*1 The model with B (BP) at the end of the name has additional functions such as zero datum function.

*2 The response time during Edge detection mode is the detection mode set on Page 7. Also, when one side of the output is used for Edge detection mode while HSP mode

*3 When you connect eight or more amplifiers, limit the power voltage to 24 VDC ripple (P-P) 10 %.

*4 When several units are connected, the operating ambient temperature varies depending on the number of units to be connected. When connecting several units, be sure to

Current

consumption

Operating ambient

temperature

Material Housing material: Polycarbonate

Weight (including

cable)

The LV-S62/S63 operates normally only with an amplifier unit that has B (BP) at the end of the model name.

The LV-S31/S61 operates normally only with an amplifier unit that has A (AP) or B (BP) at the end of the model name.

is selected, the response time is 125 μs even when Normal detection or Area detection modes are selected. LV-S62/S63 does not handle HSP mode.

mount the units on the DIN rail (mounted on a metal plate), and keep the output current at 20 mA or less.

When 1 to 2 units are connected : -10°C to +50°C

When 3 to 10 units are connected : -10°C to +50°C

When 11 to 16 units are connected : -10°C to +45°C

2

4

*

Distance setting

type

Visible light semiconductor laser Wavelength 655 nm Output 290 μW

50 to 200 mm

(Adjustment

range)

Operation

indicator lamp

Red LED x 1

Beam axis

adjustment

indicator lamp

Red LED x 2,

Green LED x 1

100 mm blank

paper

0 to +50 °C

(No freezing)

Norbomenic

resin

Polyarylate

- - - Polycarbonate, Acrylic resin - -

3

Reflective type

ULTRA : 500 mm

SUPER : 400 mm

TURBO : 300 mm

FINE : 200 mm

HSP : 150 mm

Approx. ø1.2 mm Approx. ø1.2 mm Approx. ø2.5 mm

2 mm blank paper

Polycarbonate Polyarylate Polycarbonate

Norbornenic

resin

HSP : 80 μs

FINE : 250 μs

TURBO : 500 μs

SUPER : 2 ms

ULTRA : 4 ms

Light emission stop input/external calibration input/Setting value bank selection input/received light intensity shift input

Reflective, side

view type

ULTRA : 400 mm

SUPER : 320 mm

TURBO : 240 mm

FINE : 160 mm

HSP : 120 mm

Glass reinforced resin

Acrylic resin Acrylic resin

Only when using the LV-S31

When the detection mode is HSP: Response time 250 μs

When the detection mode is STD

Input time (other than shift input) 20 ms fixed, (shift input) 5 ms/20 ms selectable

Normal: 1.7 W max. (140 mA max. at 12 V, 70 mA max. at 24 V)

Eco-all/Eco-half: 1.55 W max (130 mA max. at 12 V, 65 mA max. at 24 V)

Straight beam,

retro-reflective type

Class 1 Laser Product

ULTRA : 2000 mm

SUPER : 1500 mm

TURBO :1000 mm

FINE : 750 mm

HSP : 500 mm

Operation indicator lamp

Red LED x 1

Opaque object

of

ø2.5 mm

-10 to +50 °C (No freezing)

Incandescent lamp : 10,000lx Sun light 20,000lx

SUS304

NPN (PNP) open collector x 2ch

40 VDC (30 V) max

100 mA max per output

12-24 VDC, Ripple (P-P): 10% max, Class2

-10 to +50 °C (No freezing)

Approx. 80 g

Area retro-reflective Transmission type

Visible light semiconductor laser

Wavelength 660 nm

Output 290 μW

ULTRA :

1

10m (5m)

*

SUPER : 8m (3.5m)

TURBO : 5m (2m)

FINE : 2.5m (0.7m)

Switch with two levels:

Approx. 2 x 10 mm /

Approx. 2 x 2

(within 500 mm

When spot 2 x 10

mm is selected:

2 x 10mm,

0.5-mm-thick

transparent glass

(no AR coated)

When spot 2 x 2 mm

is selected:

0.5-mm-thick opaque

1

*

1

*

1

*

distance)

2

*

2 x 2mm,

2

glass

*

Speed 1 2 3 4

Response time 500μs 2ms 8ms 32ms

ULTRA : 30m

SUPER : 25m

TURBO : 15m

FINE : 8m

Approx. 8 x 12 mm

(within 3.5 m

distance)

8 x 12 mm,

0.5-mm-thick

transparent

glass (no AR

2

coated)

*

Visible light semiconductor laser

Approx. ø1.2 mm

(one on each of the transmitter and

Opaque object of

ø1.5 mm

Transmitter lens:

Norbornenic resin

Receiver lens:

Polyarylate

Wavelength 655 nm

Output 290 μW

500 mm

Operation indicator lamp

Red LED x 1

receiver)

(detection distance 0

Metallic section: SUS304

Resin section: Polyarylate

Norbornenic resin

Approx. ø6 mm

(with 500 mm

distance)

Opaque object of

ø1.0 mm

to 100 mm)

Opaque object of

ø0.8 mm

(detection distance

100 to 250 mm)

Opaque object of

ø0.8 mm

(detection distance

250 to 500 mm)

Transmitter lens:

Receiver lens:

Glass

E LV-S-IM

11

Page 12

Default Mode Settings (Initialization)

Model

Control output L-on no

Operation mode - - - - Std (standard)

Power mode FinE - - - -

Response time - - - - 4

END/FULL END END

Timer mode toFF toFF

Detection mode Std (standard) Std (standard)

Sensitivity setting method Std (standard) - - - -

Display scaling oFF - - - -

Shift function oFF oFF

Control input function oFF oFF

Hold function Std (standard) - - - -

Hysteresis setting - - - - LEV2

Display mode Std (standard) - - - -

Displayed digits of received light intensity

Power saving function oFF oFF

Memory function YES (save) YES (save)

Sampling value Std (average) - - - -

Shift function input time 20 (ms) 20 (ms)

Zero datum Settig Std (standard) - - - -

Setting value 1/2 50 5000

■ Resetting to the factory default settings

LV-S41 (L)/S61/S62/S63/S71/S72

duAl (four digits) - - - -

LV- S31

1 While pressing the MODE button, press the left side of the Manual button

five times. “ ” is displayed.

2 Press the Manual button, and select “ “.

3 Press the MODE button or the SET button.

The sensor returns to the default state.

Tips on Correct Use

• To extend the amplifier unit cable, use the cable with the nominal crosssectional area no less than 0.3 mm

m. (Contact your nearest KEYENCE office when in the event of additional

installation.)

• Separate the wiring of the sensor cable from the power line or the high voltage line, since the use of these lines in the same pipe generates noise,

which may cause malfunction or product breakdown.

• If you use a commercially available switching regulator, be sure to ground

the frame GND terminal and the GND terminal.

• Do not use the LV-S Series at a location where external light directly falls on

the light-receiving surface.

• When setting the sensitivity, the detection distance may vary depending on

the individual characteristics.

• If you wire the unit incorrectly, the LV-S Series may become hot, or the sensitivity may change.

• Do not connect the sensor head connector to the amplifier unit more than

100 times.

• Displayed values may slightly change depending on the environment (temperature shift, dust, etc.).

2

, and with the length no more than 100

WARRANTIES AND DISCLAIMERS

(1) KEYENCE warrants the Products to be free of defects in materials and

workmanship for a period of one (1) year from the date of shipment. If any

models or samples were shown to Buyer, such models or samples were

used merely to illustrate the general type and quality of the Products and

not to represent that the Products would necessarily conform to said

models or samples. Any Products found to be defective must be shipped

to KEYENCE with all shipping costs paid by Buyer or offered to KEYENCE

for inspection and examination. Upon examination by KEYENCE,

KEYENCE, at its sole option, will refund the purchase price of, or repair or

replace at no charge any Products found to be defective. This warranty

does not apply to any defects resulting from any action of Buyer, including

but not limited to improper installation, improper interfacing, improper

repair, unauthorized modification, misapplication and mishandling, such

as exposure to excessive current, heat, coldness, moisture, vibration or

outdoors air. Components which wear are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various

Products. They are only suggestions, and it is Buyer's responsibility to

ascertain the fitness of the Products for Buyer’s intended use. KEYENCE

will not be responsible for any damages that may result from the use of the

Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer

are not to be used internally in humans, for human transportation, as

safety devices or fail-safe systems, unless their written specifications

state otherwise. Should any Products/Samples be used in such a manner

or misused in any way, KEYENCE assumes no responsibility, and

additionally Buyer will indemnify KEYENCE and hold KEYENCE harmless

from any liability or damage whatsoever arising out of any misuse of the

Products/Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE

PROVIDED WITH NO OTHER WARRANTIES WHATSOEVER. ALL

EXPRESS, IMPLIED, AND STATUTORY WARRANTIES, INCLUDING,

WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT

OF PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED.

IN NO EVENT SHALL KEYENCE AND ITS A FFILIATED ENTITIES BE

LIABLE TO ANY PERSON OR ENTITY FOR ANY DIRECT, INDIRECT,

INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES

(INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING

FROM LOSS OF USE, BUSINESS INTERRUPTION, LOSS OF

INFORMATION, LOSS OR INACCURACY OF DATA, LOSS OF

PROFITS, LOSS OF SAVINGS, THE COST OF PROCUREMENT OF

SUBSTITUTED GOODS, SERVICES OR TECHNOLOGIES, OR FOR

ANY MATTER ARISING OUT OF OR IN CONNECTION WITH THE USE

OR INABILITY TO USE THE PRODUCTS, EVEN IF KEYENCE OR ONE

OF ITS AFFILIATED ENTITIES WAS ADVISED OF A POSSIBLE THIRD

PARTY’S CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST

BUYER. In some jurisdictions, some of the foregoing warranty disclaimers

or damage limitations may not apply.

BUYER'S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or delivered

to a third party, Buyer must provide such third party with a copy of this

document, all specifications, manuals, catalogs, leaflets and written

information provided to Buyer pertaining to the Products/Samples.

E 1110-2

11666E 1041-1 96M11667

12

2011

E LV-S-IM

Loading...

Loading...