Page 1

Instruction

Manual

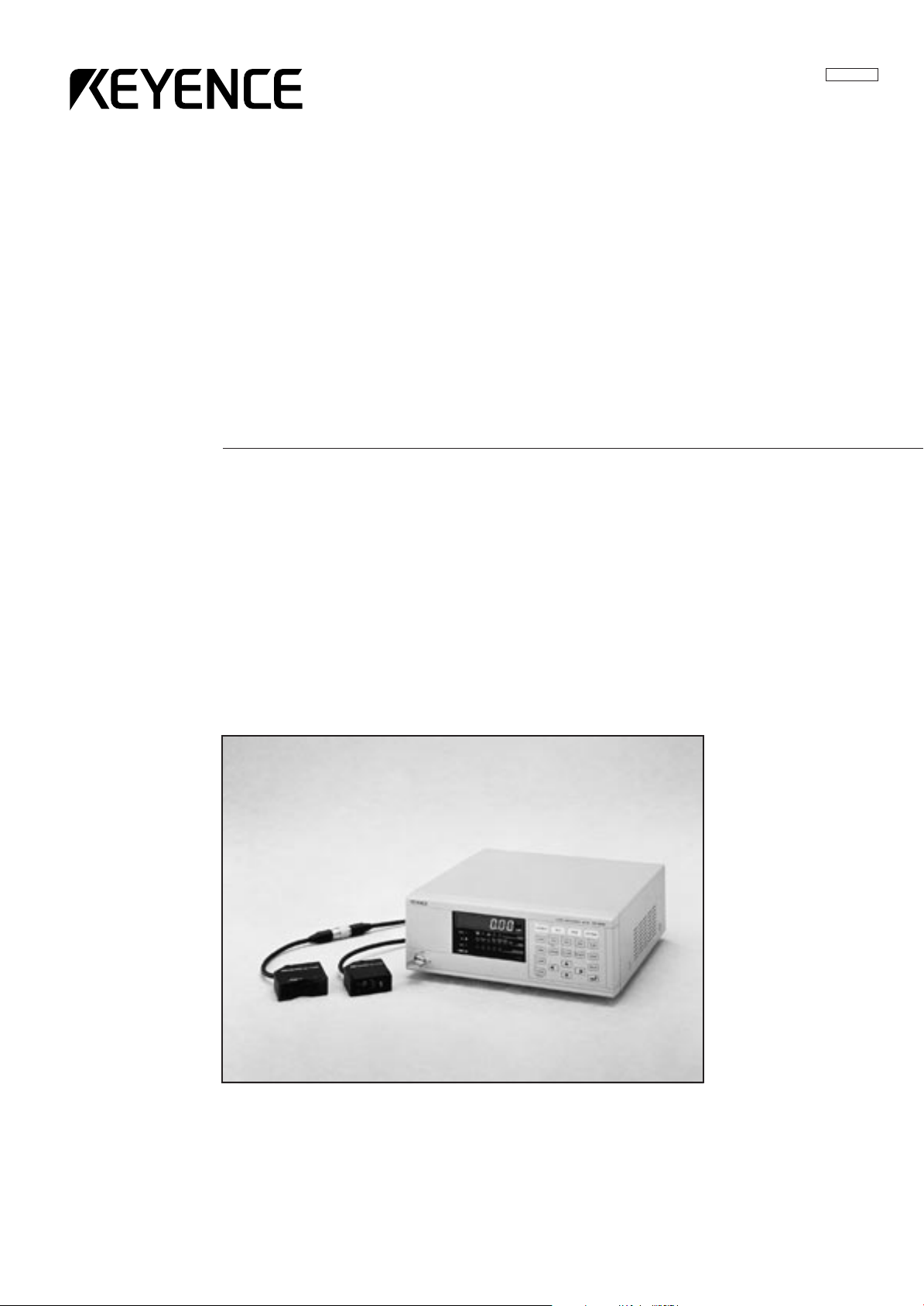

Ultra High Accuracy Laser Displacement Meter

96M1119

LC-2400 Series

Page 2

Safety Precautions

This manual describes how to install the LC-2400 Series as well as its

operating procedures and precautions. Please read this manual carefully to

get the best from your LC-2400 Series.

Symbols

General Precautions

The following symbols alert you to important messages. Be sure to read

these messages carefully.

WARNING

CAUTION

Note

• At startup and during operation, be sure to monitor the functions and

performance of the LC-2400 series.

• We recommend that you take substantial safety measures to avoid any

damage in the event a problem occurs.

• Do not open or modify the LC-2400 series or use it in any way other than

described in the specifications.

• When the LC-2400 series is used in combination with other instruments,

functions and performance may be degraded, depending on operating

conditions and the surrounding environment.

Failure to follow instructions may lead to injury.

(electric shock, burn, etc.)

Failure to follow instructions may lead to product

damage.

Provides additional information on proper operation.

CAUTION

• Do not use the LC-2400 series for the purpose of protecting the human

body.

Turn the power OFF when connecting or disconnecting the sensor

head connector, power supply cables, or any of the optional boards.

Otherwise, the laser diode or other electronic components may become degraded or damaged.

i

Page 3

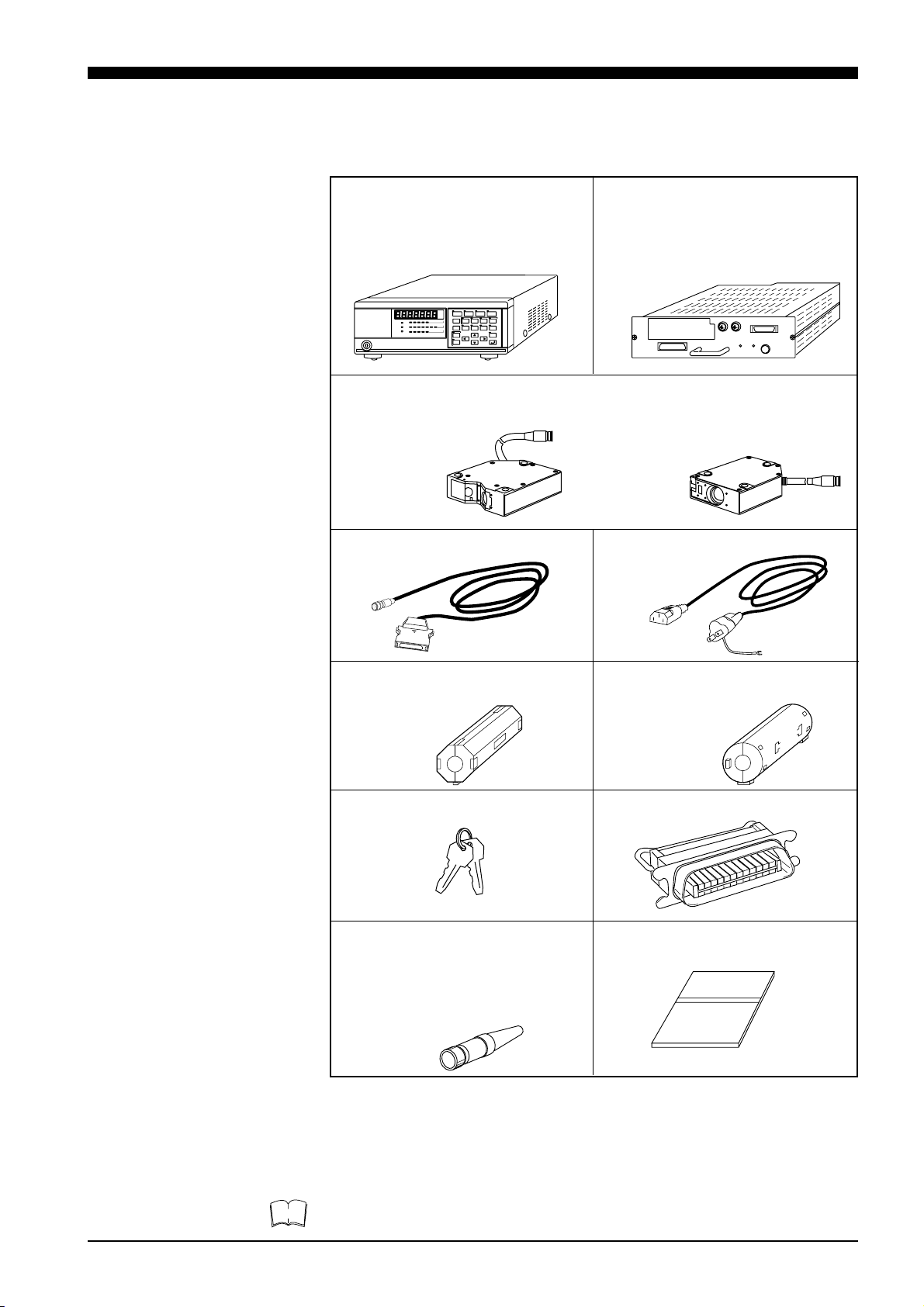

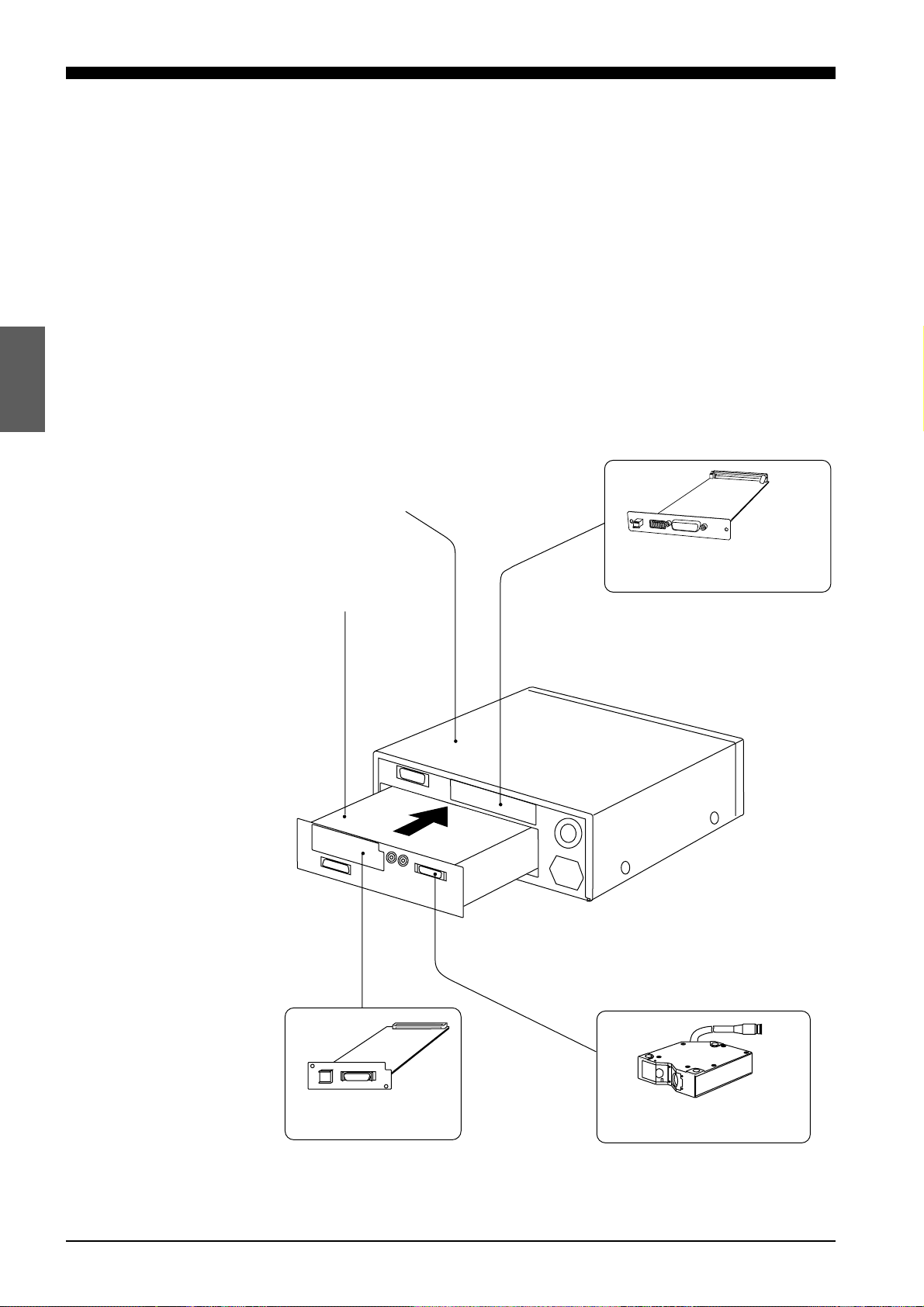

Contents of the Package

The LC-2400 series includes the following items. Check that none of the

items are missing or damaged.

● Display unit model:

LC-D1A/LC-D1W (Qty: 1)

If the control unit was ordered separately, the display unit is not included.

● Control unit model:

LC-C1A / LC-C1W/LC-C2(1)

If the display unit was ordered, the

control unit is incorporated in the display

unit.

● Sensor head

1.

Check that the requested sensor head is included in the contents.

model: LC-2420 model: LC-2440

LC-2430 LC-2450

● 3-m connecting cable (1)

1., 2.

● 2-m power cable (1)

Note

● Ferrite core

ESD-SR-25 (TOKIN) for RS-232C

cable (2)

3.

● Ferrite core

ZCAT3035-1330 (TDK) for CONTROL I/O cable (2)

3.

● Power supply key (2) ● 24-pin control I/O connector (1)

● 4-pin laser remote grounding

● Instruction manual (1)

plug (1)

Inserting this plug into the LASER

REMOTE connector on the rear panel

LC–2400 Series

enables laser emission. (See page 15.)

Instruction Manual

1. Depends on quantity ordered

2. 5-m or 10-m cable is also available.

(To use a 5-m or 10-m cable with the LC-2400 series that has been calibrated for

a 3-m cable the unit must be recalibrated by KEYENCE. We also offer the LC2400 series configured for 5-m and 10-m cables.)

3. Included with the LC-2400W series.

• The 5-m or 10-m cable is not available for the LC-2400W series.

• The LC-C1W cannot be used seperately from the display unit.

ii

Page 4

WARRANTIES AND DISCLAIMERS

Sea page 113.

Conventions The following symbols are used in this manual:

Failure to follow instructions may lead to injury.

WARNING

CAUTION

(electric shock, burn, etc.)

Cautions against procedures which may result in

malfunctions or measurement errors as well as

hazardous operating conditions. Be sure to read

this information carefully.

Turn to this page for more detailed information on

a given subject.

Note

Read here for more details or for reference information on a given subject. This information can be

read as required.

LC-2400 operation keys.

iii

Page 5

How to Use This

Instruction Manual

This instruction manual is composed of 9 chapters. An introduction to each

chapter is given below:

Users who are using the LC-2400 series for the first time are encouraged to

read through the entire instruction manual.

Chapter Guide

1. LASER SAFETY PRECAUTIONS

This chapter describes the safety precautions for

dealing with the laser in the LC-2400 series.

2. SYSTEM CONFIGURATION

This chapter introduces the LC-2400 series measurement system. A "Quick Reference Table" is also

included to help you quickly locate the information

and procedures that you require.

3. PART NAMES AND FUNCTIONS

This chapter identifies parts used in the LC-2400

series.

4. OPERATING INSTRUCTIONS

This chapter explains in detail how to operate the

LC controller. Please read and follow the instructions in this chapter carefully before operating the

LC.

5. CONNECTIONS

This chapter explains the procedures for installing

a sensor and connecting it to the LC controller.

6. SETTING UP

This chapter explains how to set the parameters

quickly and easily for obtaining accurate measurements with the LC-2400 series. Read how to set

the parameters in this chapter after checking the

system setup against the table given in Chapter 2-4

"Quick Reference Table".

7. MEASUREMENT PROCEDURE

This chapter explains measurement procedures

using various targets.

8. EXTERNAL I/O FUNCTIONS

This chapter explains how to communicate with

external I/O devices such as a personal computer.

9. APPENDIX

The appendix includes a troubleshooting guide, a

glossary, and a description of the expansion I/Os.

iv

Page 6

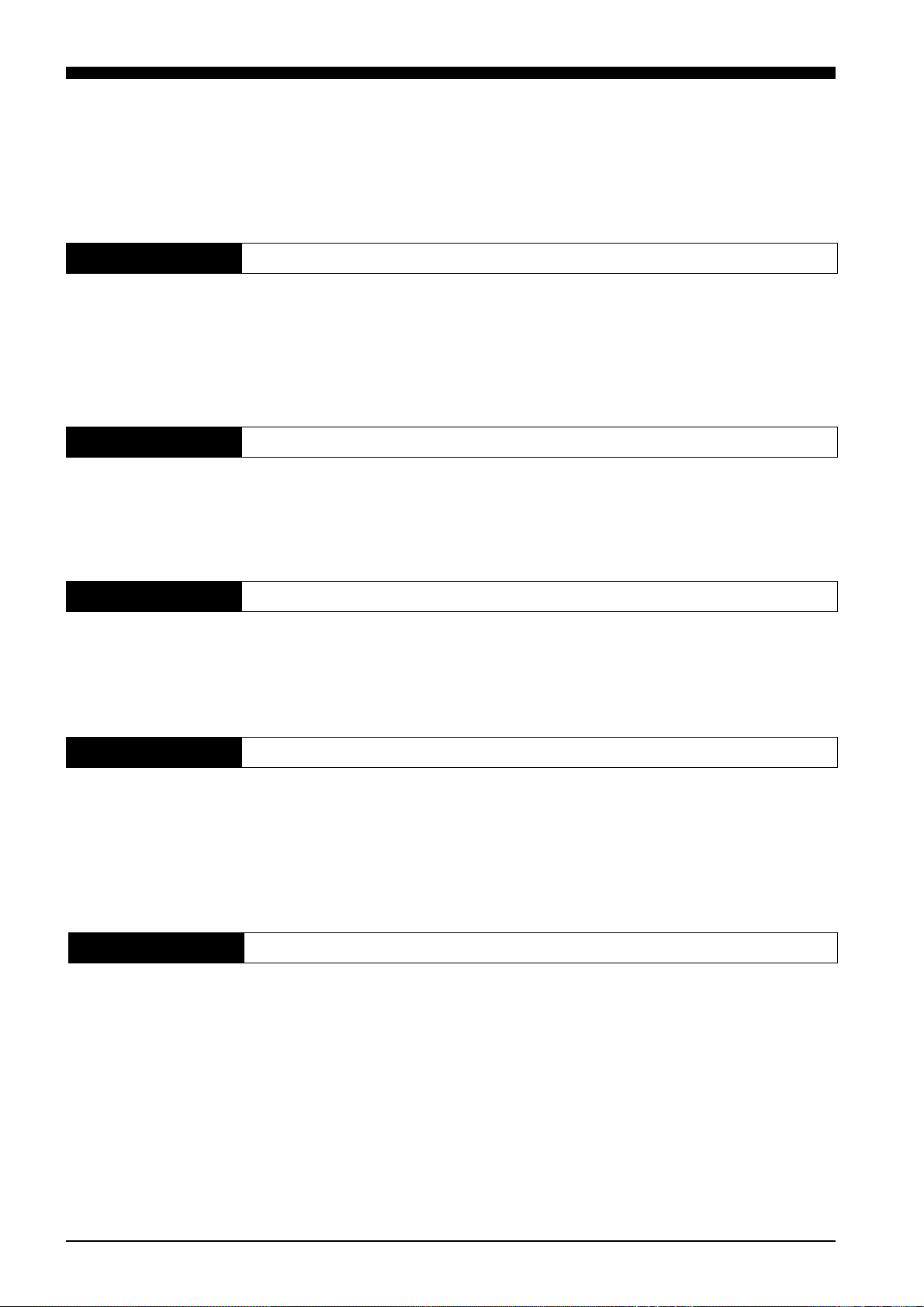

TABLE OF CONTENTS

CHAPTER 1 LASER SAFETY PRECAUTIONS 1

1-1 Classification...................................................................................2

1-2 Warning Label.................................................................................2

1-3 Label Location ................................................................................3

1-4 Safety Consideration ......................................................................3

1-5 Safety Features Provided with the LC-2400 Series........................4

CHAPTER 2 SYSTEM CONFIGURATION 5

2-1 Basic System Configuration............................................................6

2-2 Expansion System Configuration....................................................7

2-3 Sensor Head Types and Functions ................................................8

2-4 Quick Reference Table ...................................................................9

CHAPTER 3 PART NAMES AND FUNCTIONS 11

3-1 Controller ......................................................................................12

Front Panel ..............................................................................12

Rear Panel...............................................................................14

3-2 Sensor Head.................................................................................16

CHAPTER 4 OPERATING INSTRUCTIONS 17

4-1 Instructions for Using Controller and Sensor Head ......................18

After Receiving the LC-2400 Series ........................................18

Daily Maintenance Instructions................................................18

Replacing Battery ....................................................................19

Instructions for Sensor Setup ..................................................20

Hints on Correct Use ...............................................................10

CHAPTER 5 CONNECTIONS 21

5-1 Connecting Controller to Sensor Head .........................................22

5-2 Connecting Power Supply Cable ..................................................22

Connecting Controller to Sensor Head

When Using the Display Unit.................................................22

Connecting the Power Supply Unit

to a Separate Control Unit ....................................................23

5-3 Grounding Controller ....................................................................23

Grounding the Controller

When Using the Display Unit.................................................23

Grounding the Control Unit......................................................23

5-4 Installing LC-B3 Board (2CH Sensor Head Board).......................24

5-5 Installing GP-IB or DIGITAL I/O Board .........................................24

5-6 Adjusting Sensor Head Position ...................................................25

v

Page 7

CHAPTER 6 SETTING UP 27

6-1 Basic Operation of Controller........................................................28

6-2 Selecting Measurement Mode ......................................................30

6-3 Calibrating Sensitivity (Gain Selection).........................................30

6-4 Selecting the Display/Output Mode ..............................................31

6-5 Correcting Measurement Error (Calibration).................................32

6-6 Offset Values ................................................................................35

6-7 Reducing Variation in Measurement Data

(Setting Number of Averaging Measurements) ..........................36

6-8 Reducing the Effect of Target Surface Irregularities

(Setting Low-pass Filter Value)...................................................36

6-9 Setting Range for Light Intensity (INT. LIMIT) ..............................37

6-10 Setting Upper/Lower Limits for Measurements

(Setting Tolerance) .....................................................................39

6-11 Setting Number of Digits Displayed ..............................................40

6-12 Storing and Loading Settings (Programming)...............................41

CHAPTER 7 MEASUREMENT PROCEDURE 43

7-1 Measuring with One Sensor Head................................................44

7-2 Measuring with Two Sensor Heads ..............................................45

CHAPTER 8 EXTERNAL INPUT/OUTPUT 49

8-1 RS-232C Interface ........................................................................50

8-2 Control I/O (Standard Equipment on Display Unit) .......................71

8-3 Analog Voltage Output (Standard Equipment) .............................73

8-4 Digital I/O (Standard Equipment on Control Unit).........................74

CHAPTER 9 APPENDIX 79

9-1 Trouble-Shooting Guide................................................................80

9-2 Hints on Highly Accurate Measurement .......................................83

9-3 Specifications................................................................................84

9-4 Dimensions ...................................................................................85

9-5 Characteristics ..............................................................................87

9-6 Initial Setting List...........................................................................89

9-7 Glossary........................................................................................90

9-8 Expansion I/O (Optional) ..............................................................94

9-9 Index ...........................................................................................111

WARRANTIES AND DISCLAIMERS 113

vi

Page 8

CHAPTER 1

LASER SAFETY PRECAUTIONS

1-1 Classification ................................................................... 2

1-2 Warning Labels ................................................................ 2

1-3 Label Location ................................................................. 3

1-4 Safety Consideration ....................................................... 3

1-5 Safety Features Provided with the LC-2400 Series ......... 4

Page 9

1-1 Classification

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

1-2 Warning Labels

1-1 Classification

1-2 Warning Labels

The LC-2400 series employs a visible semiconductor laser as its light source

classified as follows:

Model LC-2420 LC-2430 LC-2440 LC-2450

Class FDA (CDRH) Class II

IEC/EN 60825-1:1993+

A2: 2001

DIN EN 60825-1 2001 Klasse 2

Class 2

Warning Labels

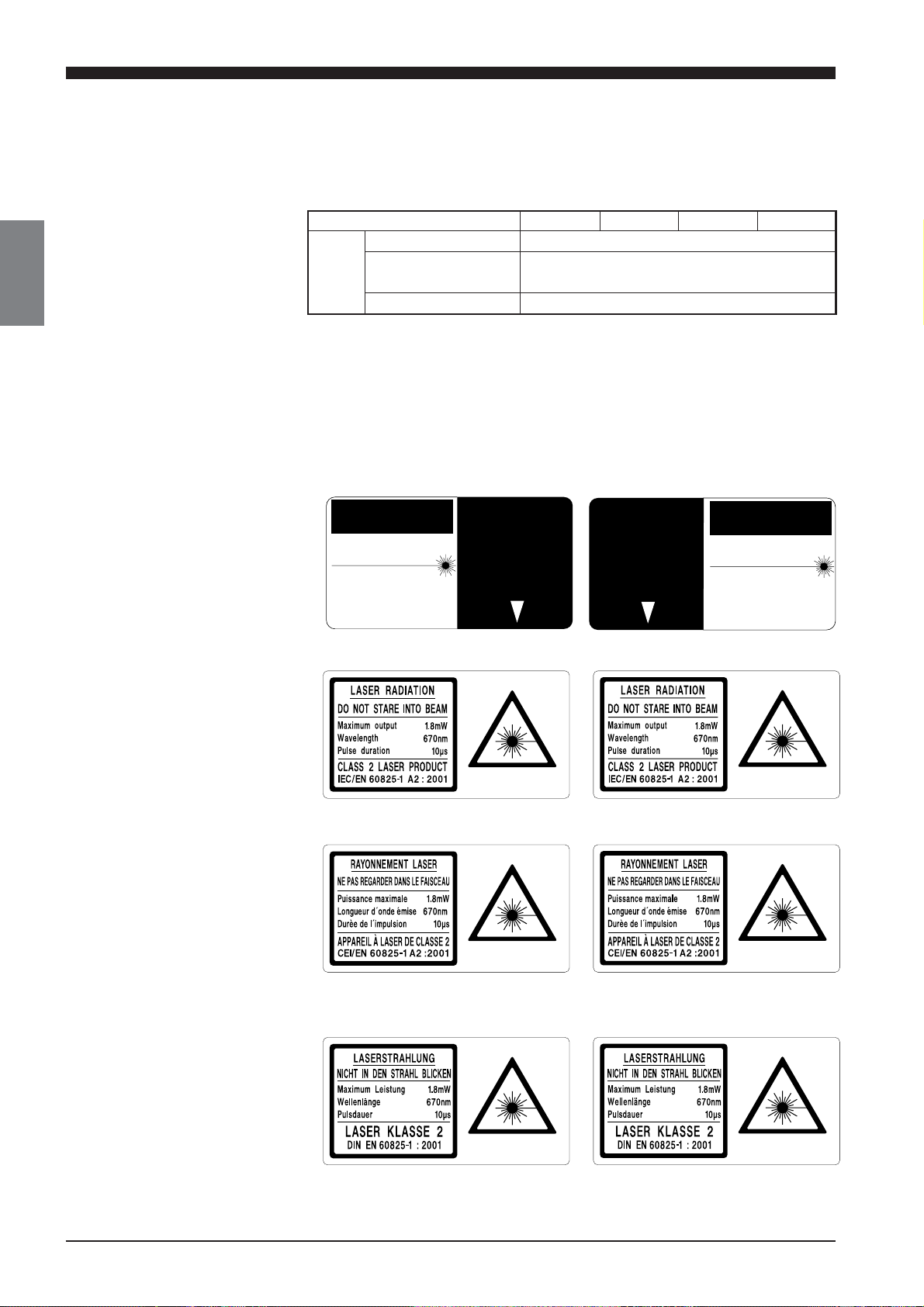

1) Warning labels

FDA Class II

CAUTION

LASER RADIATIONDO NOT STARE INTO BEAM

SEMICONDUCTOR LASER 670nm

MAXIMUM OUTPUT 1.9mW

(AVERAGE OUT PUT 950µW)

PULSE DURATION 10µSEC

CLASS II LASER PRODUCT

IEC Class 2

IEC (French) Classe 2

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

CAUTION

LASER RADIATIONDO NOT STARE INTO BEAM

SEMICONDUCTOR LASER 670nm

MAXIMUM OUTPUT 1.9mW

(AVERAGE OUT PUT 950µW)

PULSE DURATION 10µSEC

CLASS II LASER PRODUCT

2

DIN

Klasse 2

CHAPTER 1 Laser Safety Precautions

Page 10

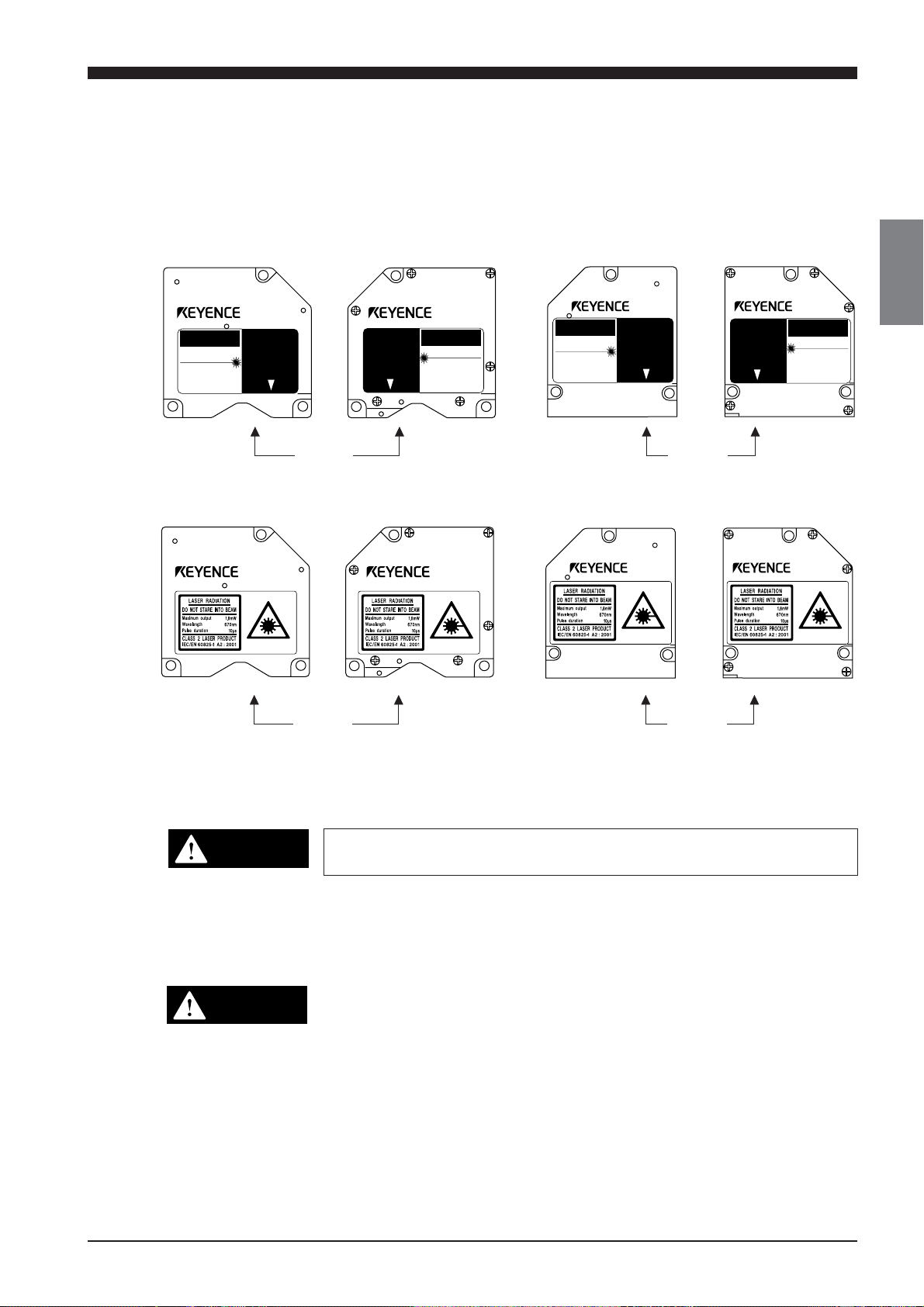

1-3 Label Location

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

CAUTION

CAUTION

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

CAUTION

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

CAUTION

FDA

• LC–2420/2430

1-3 Label Locations

1-4 Safety Consideration

FDA Warning labels are attached to the sensor head as shown below. The

IEC/DIN Warning labels are packaged with the LC-2400 Series. Affix the

Warning labels on the sensor head as shown below.

• LC–2440/2450

CAUTION

LASER RADIATIONDO NOT STARE INTO BEAM

SEMICONDUCTOR LASER 670nm

MAXIMUM OUTPUT 1.9mW

(AVERAGE OUT PUT 950µW)

PULSE DURATION 10µSEC

CLASS II LASER PRODUCT

IEC/DIN

• LC–2420/2430

LC–2420 LC–2420

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

CAUTION

LASER RADIATIONDO NOT STARE INTO BEAM

SEMICONDUCTOR LASER 670nm

MAXIMUM OUTPUT 1.9mW

(AVERAGE OUT PUT 950µW)

PULSE DURATION 10µSEC

CLASS II LASER PRODUCT

CAOTION-LASER RADIATION WHEN OPEN

DO NOT STARE INTO BEAM

Aperture Aperture

LC–2420 LC–2420

Aperture Aperture

CAUTION

LASER RADIATIONDO NOT STARE INTO BEAM

SEMICONDUCTOR LASER 670nm

MAXIMUM OUTPUT 1.9mW

(AVERAGE OUT PUT 950µW)

PULSE DURATION 10µSEC

CLASS II LASER PRODUCT

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

• LC–2440/2450

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

LC–2440LC–2440

CAUTION

LASER RADIATIONDO NOT STARE INTO BEAM

SEMICONDUCTOR LASER 670nm

MAXIMUM OUTPUT 1.9mW

(AVERAGE OUT PUT 950µW)

PULSE DURATION 10µSEC

CLASS II LASER PRODUCT

CAOTION-LASER RADIATION WHEN OPEN

DO NOT STARE INTO BEAM

LC–2440LC–2440

1-4 Safety Consideration

Use of controls or adjustments or the performance of procedures other than

those specified herein may result in hazardous radiation exposure.

The laser beam is not harmful to the skin. There is, therefore, no danger in

exposing arms or hands to the beam. The only possible health hazard is in

exposing the eyes to the laser beam. Damage to the eyes can occur if the

operator stares directly into the beam.

Follow the safety precautions below to ensure operator safety:

• Operate the LC-2400 series only according to the procedures described in this instruction manual.

Otherwise, injury may occur due to expose to the laser beam.

• Do not disassemble the sensor head.

Laser emission from the LC-2400 series is not automatically stopped if

the sensor head is disassembled. If you disassemble the sensor head

for inspection or repair, you may be exposed to the laser beam. If the

LC-2400 series malfunctions, contact KEYENCE immediately.

• Do not look directly at the laser beam.

Looking directly at the laser beam may result in serious eye injury.

CAUTION

WARNING

CHAPTER 1 Laser Safety Precautions

3

Page 11

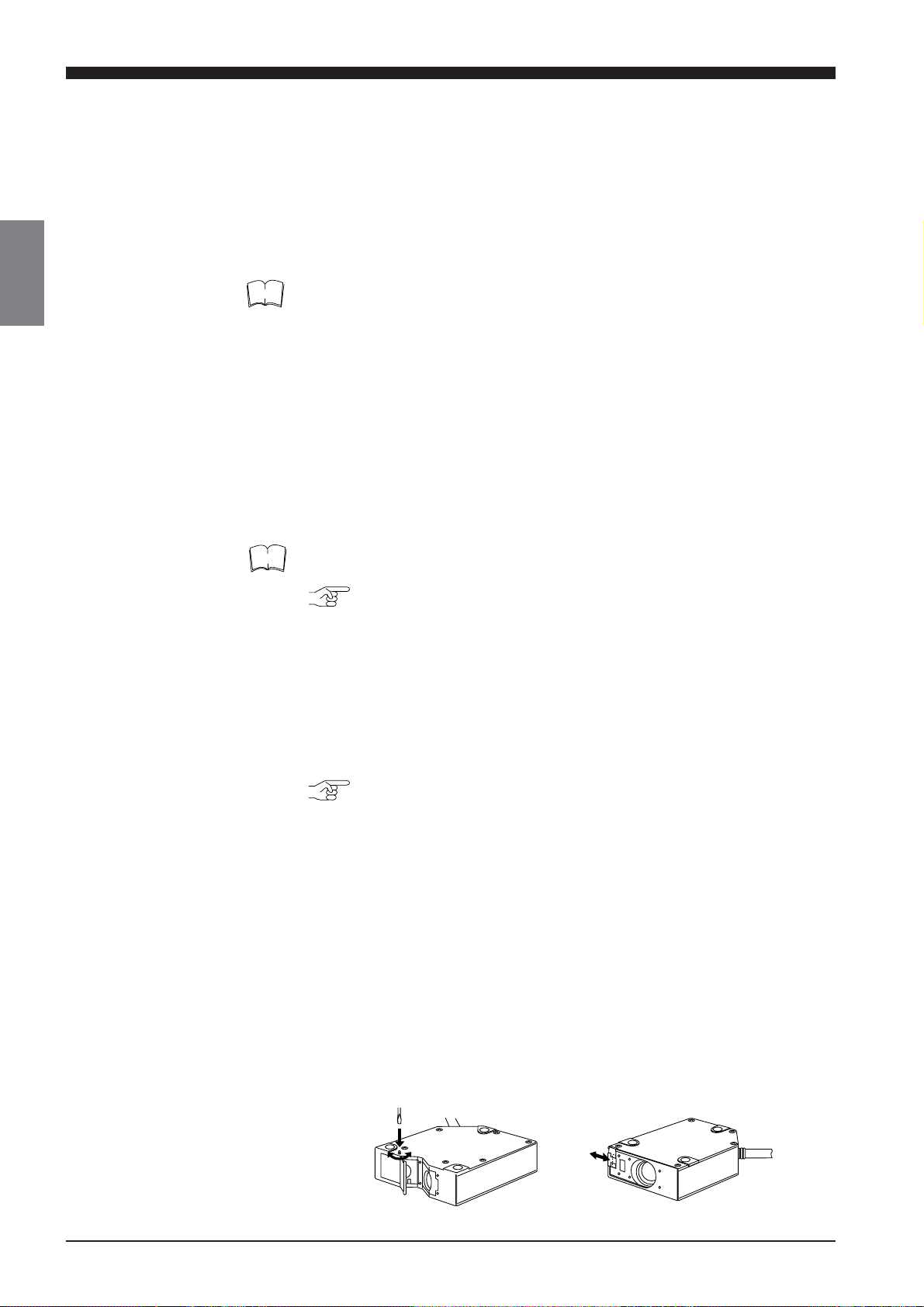

1-5 Safety Features Provided with the LC-2400 Series

• Diffuse-reflective sensor head

(LC-2440/LC-2450)

• Regular-reflective sensor head

(LC-2420/LC-2430)

Open

Close

Open

Close

• Protective enclosure

We recommend that you install a protective enclosure around the sensor

head to prevent any person from getting near the sensor head during

operation.

• Protective goggles

We recommend that you wear protective goggles when using the LC2400 series.

Note

The intense light from this laser can be harmful to the eyes during prolonged

viewing. Normal reflex blinking is usually enough to prevent any eye damage. However, it is best to wear laser protective glasses whenever working

around a sensor head.

1-5 Safety Features Provided with the LC-2400 Series

The LC-2400 series comes with the following safety features:

■ Laser ON alarm LED

Both the sensor head and the controller panel have a visible LED that lights

when laser is ready to be and is being emitted.

Note

LEDs can be checked to see if they are lit even when you are wearing laser

protective glasses.

Reference: Laser ON alarm LED (p.12, 14, 16)

■ Delay of laser beam emission

To prevent an operator from being exposed to the laser beam, the laser

beam is emitted three seconds after the laser ON alarm LED lights.

■ Laser emission remote control input connector

The laser emission control connector is located on the rear panel of the

control unit. The laser can be turned on or off by a remote control signal

through this connector.

Reference: Laser Remote Grounding Connector (p.15)

4

■ Key-operated power switch

The controller power switch can be locked using the attached key.

When the LC-2400 controller is OFF, the key can be removed.

■ Laser beam shield

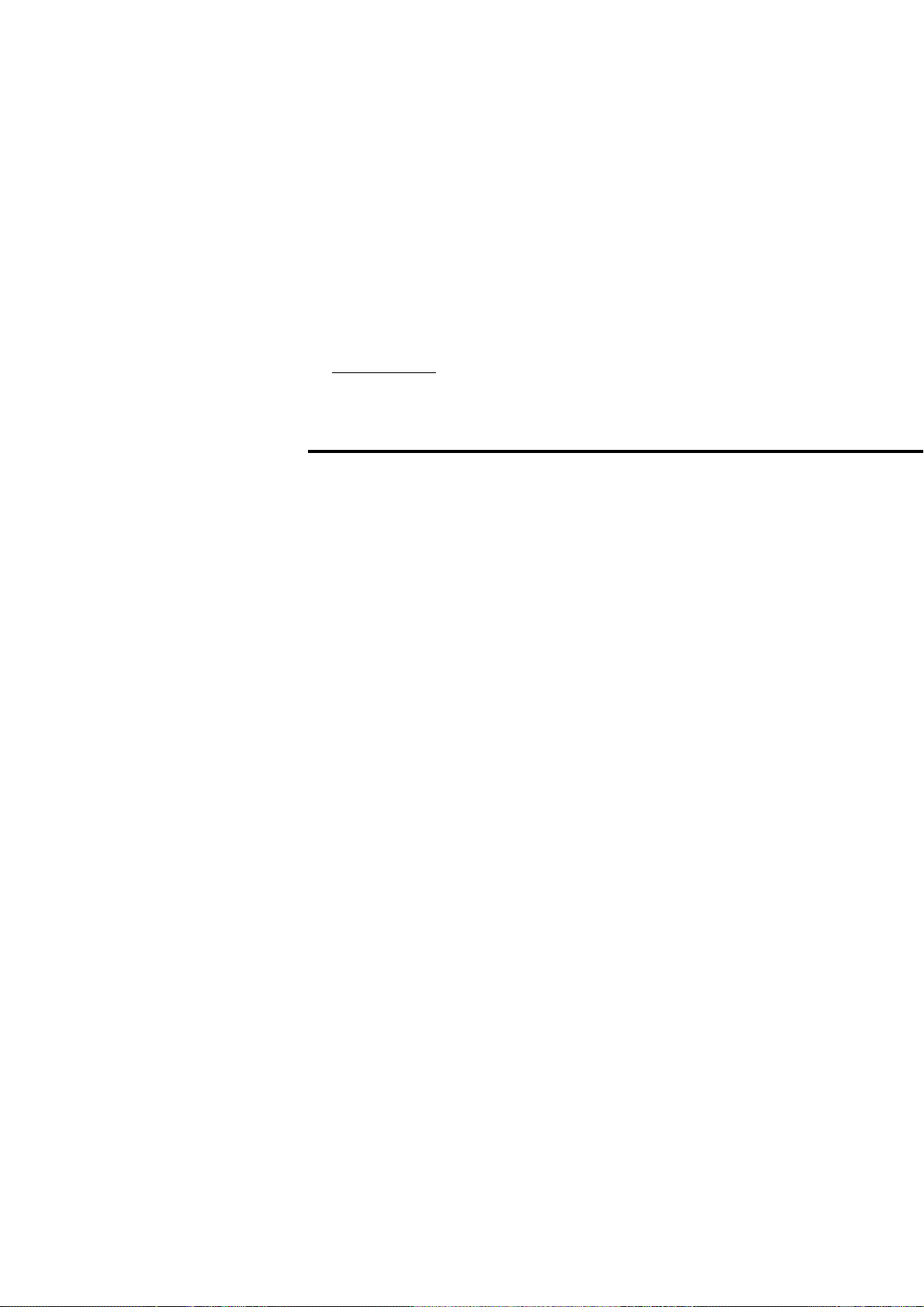

The sensor head transmitter comes with a laser beam shield.

Precautions for parameter setup and measurements

If there is a danger of an operator looking into the laser beam when working

in front of the sensor head, close the laser beam shield as shown below

before starting operations.

Close or open the laser beam shield as shown below:

CHAPTER 1 Laser Safety Precautions

Page 12

CHAPTER 2

SYSTEM CONFIGURATION

2-1 Basic System Configuration ............................................ 6

2-2 Expansion System Configuration .................................... 7

2-3 Sensor Head Types and Functions ................................. 8

2-4 Quick Reference Table.................................................... 9

Page 13

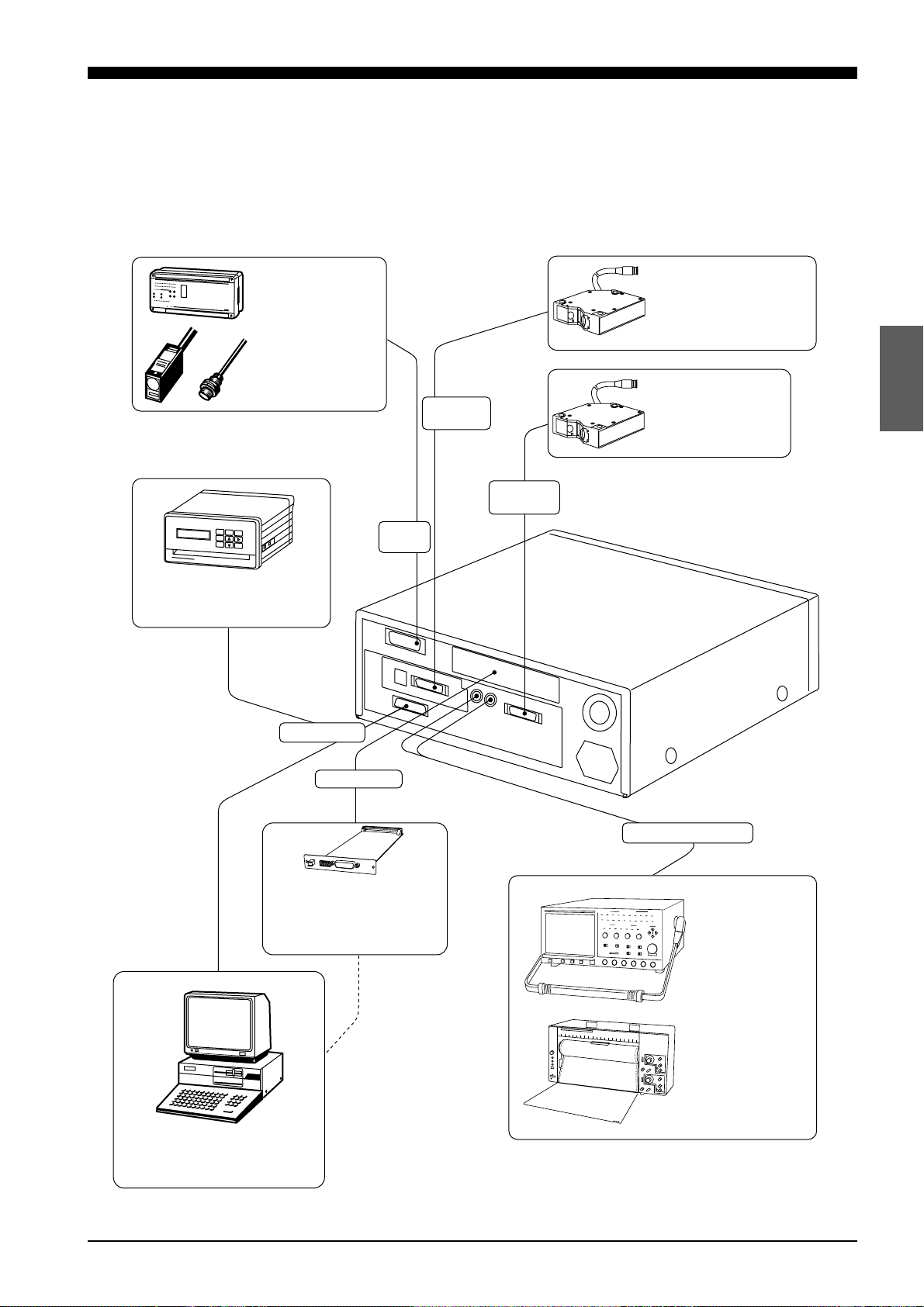

2-1 Basic System Configuration

The LC-2400 series is equipped with I/O ports for connecting to external

equipment and a slot for installing an optional expansion board. By connecting personal computers or other devices to the LC-2400 series, measurement data obtained with the LC-2400 series can be used for various applications.

2-1 Basic System Configuration

The LC controller consists of a display unit and control unit. If required, the

control unit can be used separately from the display unit. There are also two

expansion slots; one for the optional LC-B3 board which, when installed,

allows the use of a second sensor head and a second slot for either a

DIGITAL I/O board or GP-IB board.

However, the LC-2400W series does not incorporate these expansion slots.

Display unit

(model: LC-D1A/LC-D1W)

Control unit

(model: LC-C1A/LC-C1W/LC-C2)

Expansion slot for

DIGITAL I/O board* (model: LC-B1)

or GP-IB board*(model: LC-B2)

1., *2.

CHAPTER 2 System Configuration

6

Expansion slot for

LC-B3 2CH sensor

head board*

1., *2.

1CH sensor head port: for

LC-2420/LC-2430/LC-2440/LC-2450

*1. Optionally available from KEYENCE

*2. Cannot be used with the LC-2400W series.

Page 14

2-2 Expansion System Configuration

For flexible expansion, a variety of external equipment can be connected to

the LC-2400 series, as shown below.

2-2 Expansion System Configuration

Connect a PLC ,

photoelectric sensor ,

or proximity sensor .

This port is used to

switch memory banks,

input auto-zero and

hold signals, and output

alarm signals.

With a commercially available

printer connected, you can record

measurement results.

*1.

*1.

*1.

2ch sensor

head port

1ch sensor

head port

Control

I/O port

With the optionally available

2CH board (model: LC-B3),

you can connect the second

sensor head (model: LC-2420

/-2430/-2440/-2450) to the

controller.

Connect the first sensor

head (model: LC-2420

/-2430/-2440/-2450).

*1., *2.

RS-232C port

With the DIGITAL I/O board

(model: LC-B1) or GP-IBboard

(model: LC-B2), you can send

data to and receive it from

a personal computer.

You can send data to and receive

it from a personal computer through

one of the interface (RS-232C,

DIGITAL I/O , GP-IB ).

*1. *1.

Expansion slot

Analog voltage output

*1., *2.

*1., *2.

With an oscilloscope

or pen recorder

connected, you can

monitor changes

in light intensity and

target displacement

through analog

voltage signals.

*1. Optionally available from KEYENCE

*2. Cannot be used with the LC-2400W series.

CHAPTER 2 System Configuration

7

Page 15

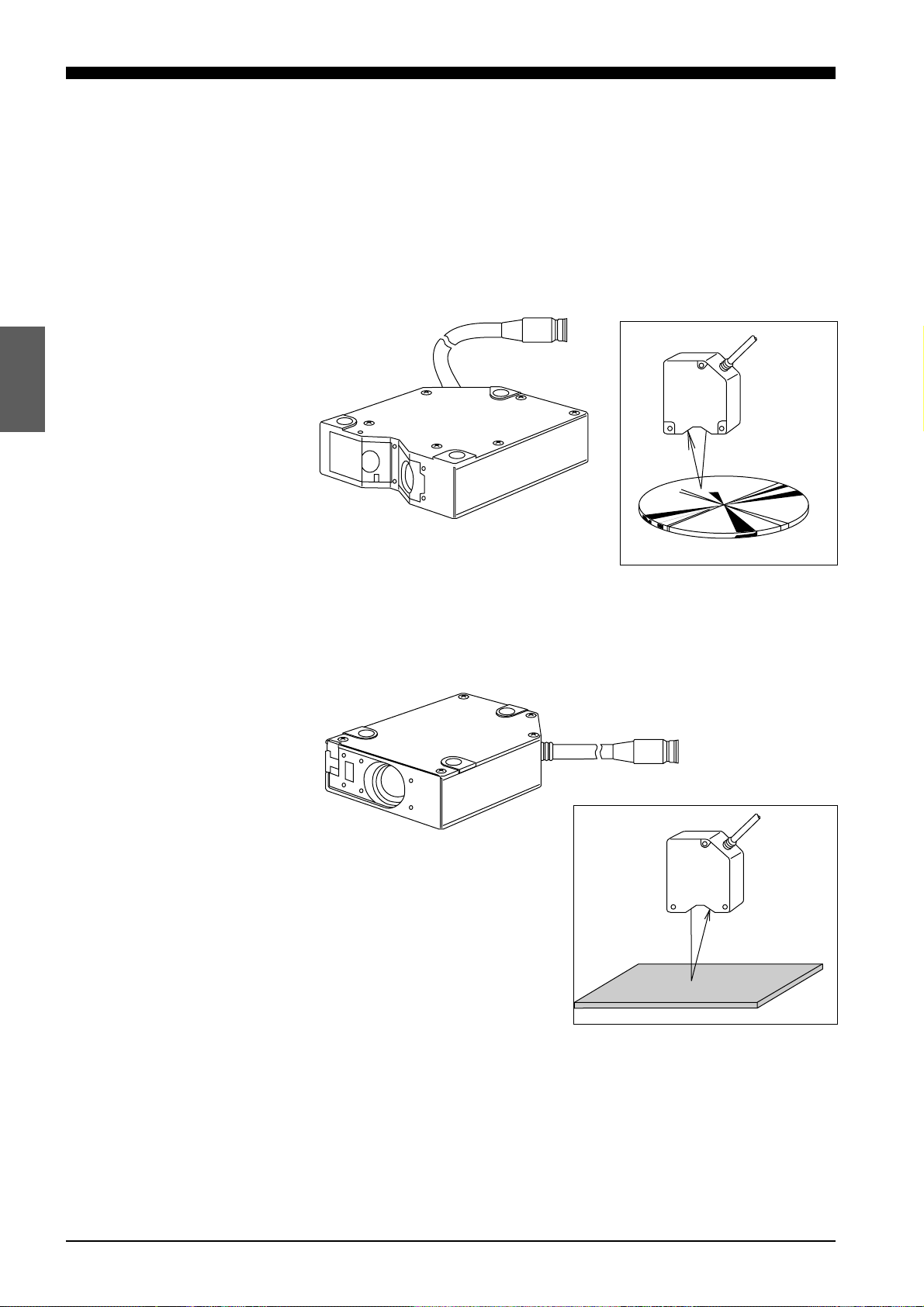

2-3 Sensor Head Types and Functions

2-3 Sensor Head Types and Functions

The LC-2400 Series gives you a choice of 4 sensor head models.

LC-2420/LC-2430: Regular-reflective sensor heads

Regular-reflective sensor heads are used to measure targets having a highly

reflective or mirror-like surface.

LC-2440/LC-2450: Diffuse-reflective sensor heads

Diffuse-reflective sensor heads are used to measure targets having a lowreflective or opaque surface.

CHAPTER 2 System Configuration

8

Page 16

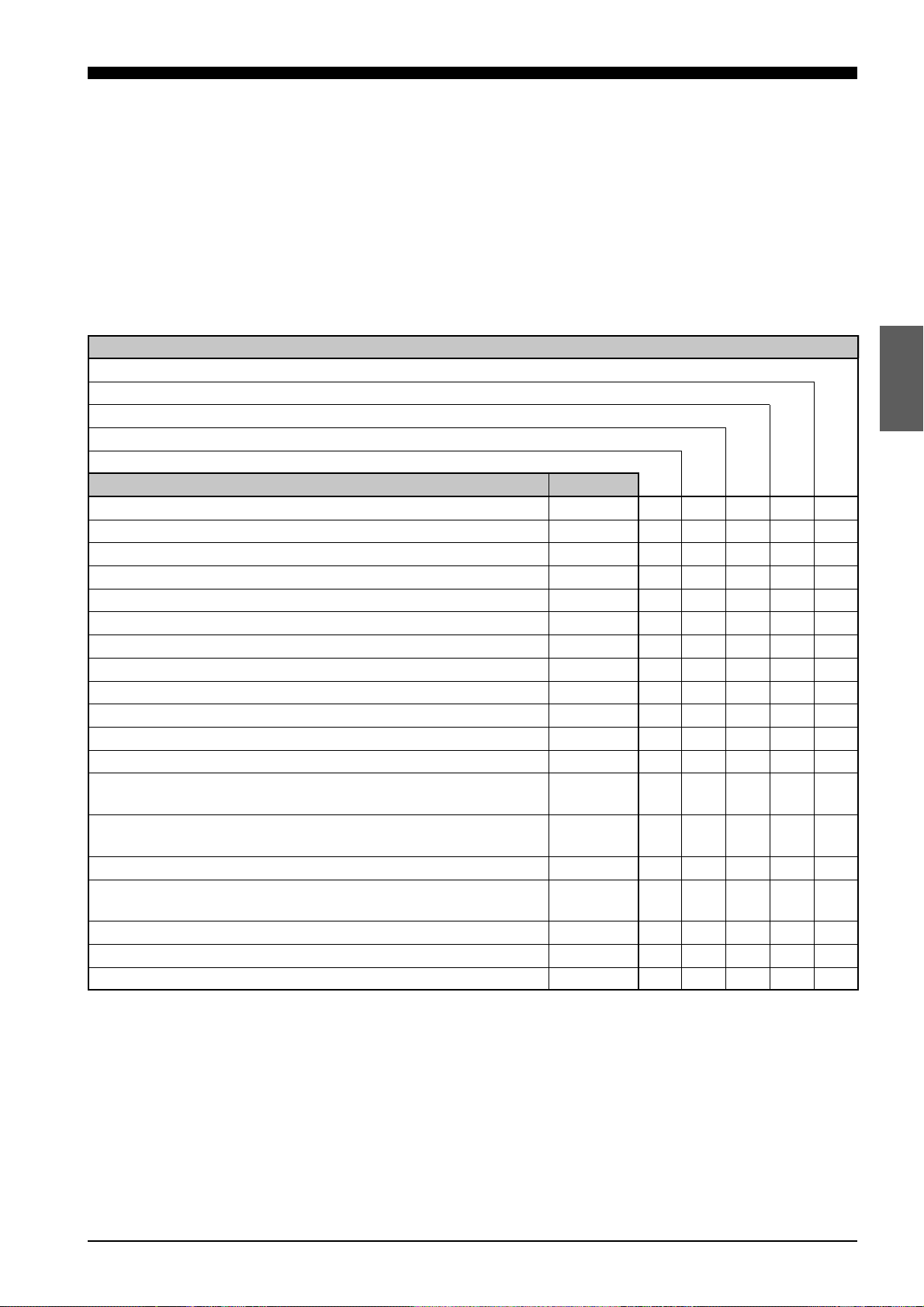

2-4 Quick Reference Table

2-4 Quick Reference Table

Sensor setup, cable connections, and various parameters must be set

before starting measurement. However, some of the parameters are not

necessary, depending on system configuration and the type of measurements being done. The following table shows the procedures to follow, in

sequential order, before starting measurement. Find the items pertaining to

your setup in the table to determine which sections of the manual are required reading.

Type of measurement

Trial measurement

Measuring height

Measuring eccentricity

Measuring thickness

Measuring difference in height

Section No. Page No.

5-1 Connecting Controller to Sensor Head p.22 R R R R R

5-2 Connecting Power Supply Cable p.22 R R R R R

5-3 Grounding Controller p.23 R R R R R

5-4 Installing LC-B3 Board (2CH Sensor Head Board) p.24 R R

5-5 Installing GP-IB or DIGITAL I/O Board p.24

5-6 Adjusting Sensor Head Position p.25 R R R R R

6-1 Basic Operation of Controller p.28 R R R R

6-2 Selecting Measurement Mode p.30 R R R R R

6-3 Calibrating Sensitivity (Gain Selection) p.30 R R R R

6-4 Selecting the Display/Output Mode p.31 R R

6-5 Correcting Measurement Error (Calibration) p.32 R R R R

6-6 Offset Values p.35 O O O O

6-7 Reducing Variation in Measurement Data

(Setting Number of Averaging Measurements)

6-8 Reducing the Effect of Target Surface Irregularities

(Setting Low-pass Filter Value)

6-9 Setting Range for Light Intensity (INT. LIMIT) p.37 O O O O

6-10 Setting Upper/Lower Limits for Measurements

(Setting Tolerance)

6-12 Storing and Loading Settings (Programming) p.41 R R R R

7-1 Measuring with One Sensor Head p.44 R R

7-2 Measuring with Two Sensor Heads p.45 R R

p.36 R R R R

p.36 O O O O

p.39 O O O O

R: Required reading

O: Optional reading

CHAPTER 2 System Configuration

9

Page 17

CHAPTER 2 System Configuration

10

Page 18

CHAPTER 3

PART NAMES AND FUNCTIONS

3-1 Controller ....................................................................... 12

3-2 Sensor Head.................................................................. 16

Page 19

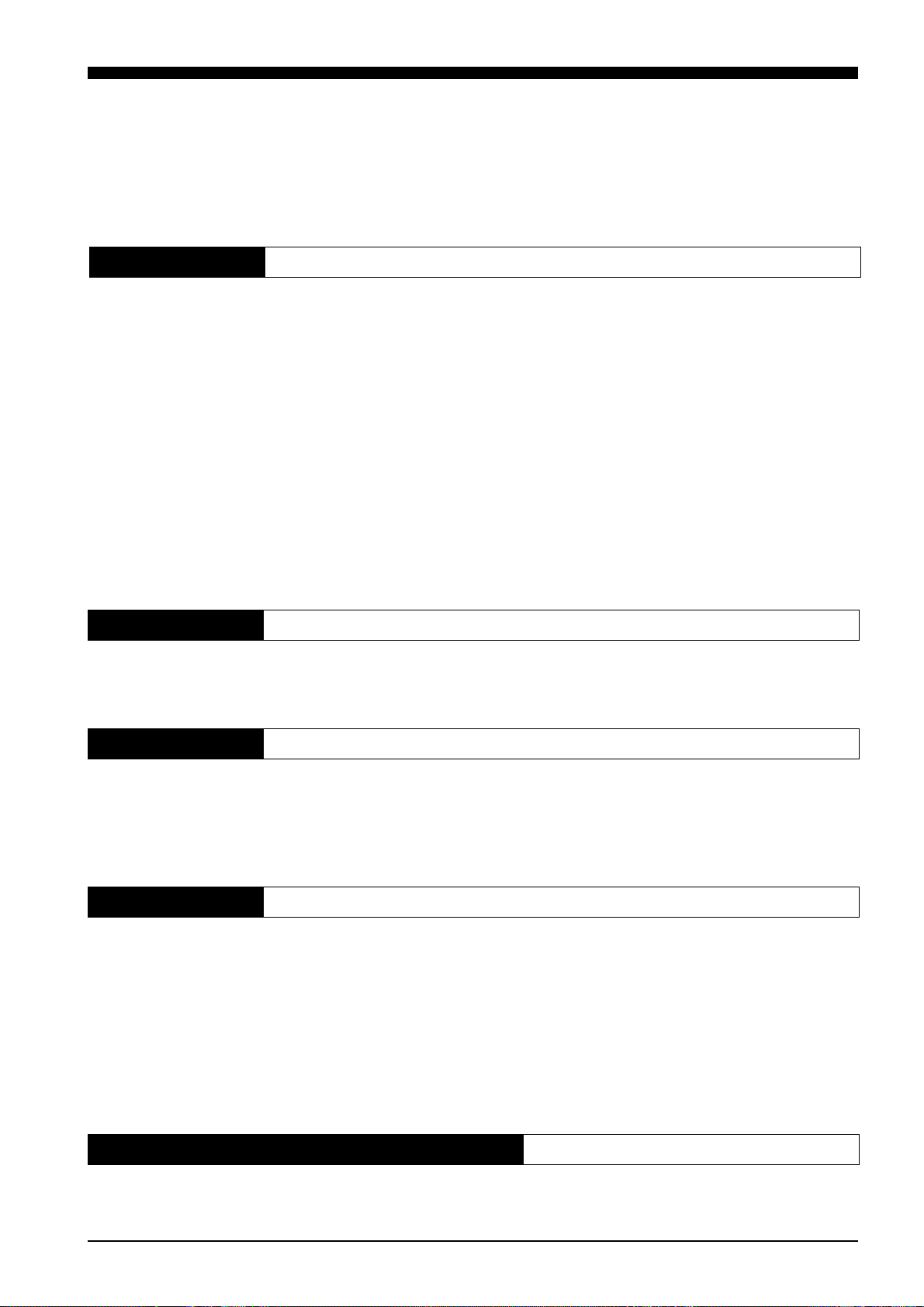

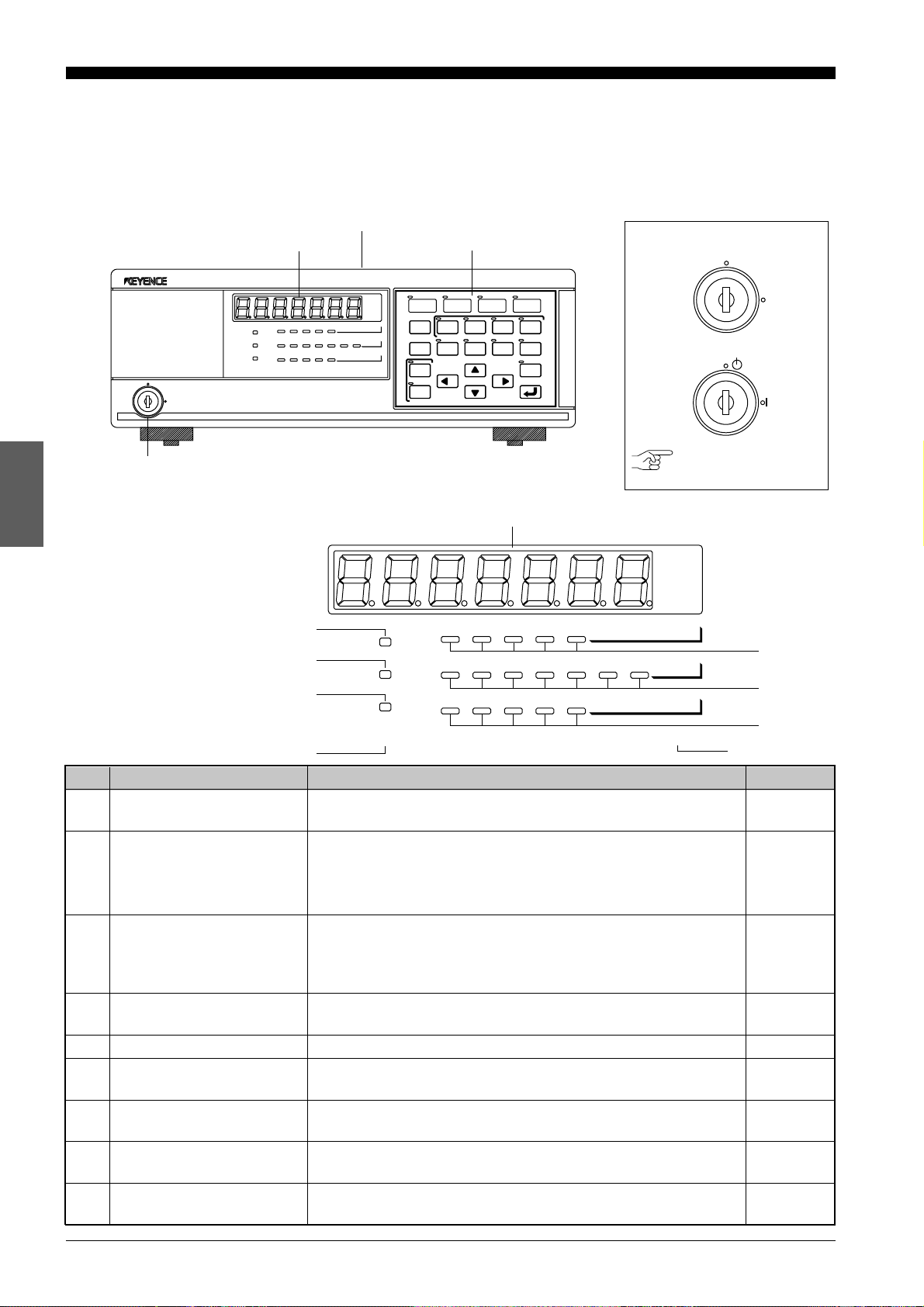

3-1 Controller

mm

µ m

1

6

mm

µ m

3-1 Controller

Front Panel

OFF

POWER

Key-operated power switch

Display

ON

HIGH

GO

LOW

LASER ON

Display

AUTO 1 2 3 4

INT.

LIMIT OFFSET CAL

LIMIT

12345

9

8

7

Display unit

ANALOG

BAUD

DIGIT

RATIO

RATE

PROGRAM

LOCK

HIGH

GO

LOW

LASER ON

Operation keys

LASER DISPLACEMENT METER

NORMAL P–P

1CH 2CH

GAIN

GAIN

PRM

PRM

LOAD

SAVE

PROGRAM

2–HEAD

AVERAGE

FILTER

PEAK

ADD SUB

INTENSITY

LC-2400A

BOTTOM

ZERO

HOLD

LC-2400A

OFF

ON

POWER

LC-2400W

STAND-BY

ON

POWER

Reference: Refer to P.44.

AUTO 1 2 3 4

ANALOG

LIMIT OFFSET CAL

12345

INT.

LIMIT

RATIO

BAUD

RATE

DIGIT

PROGRAM

GAIN

2

PRM

3

4

LOCK

5

No. Name Function Ref. page

1 Display panel Displays measured values, preset values and error mes-

sages.

p.82

2 GAIN LEDs Indicates the receiver sensitivity. One of the four LEDs

corresponding to the current sensitivity will be lit.

When the receiver sensitivity is set to AUTO, one of the four

p.30

LEDs and the AUTO LED will be lit.

3 PARAMETER LEDs Lights when setting parameters such as upper/lower toler-

ance limits, offset, calibration, intensity limit, analog ratio,

baud rate and display digit. The LED corresponding to the

p.28

parameter currently being changed lights.

4 PROGRAM LEDs The LED corresponding to the selected program number will

be lit. The LEDs blink during program selection.

5 PANEL LOCK LED Lights when the operation keys are disabled.

6 Laser ON alarm LED Lights when the laser beam is ready to be and is being

emitted from the sensor head.

7 LOW LED Lights when a measured value falls below the preset lower

limit in each measurement mode.

8 GO LED Lights when a measured value is within the preset tolerance

range of that measurement mode.

9 HIGH LED Lights when a measured value exceeds the preset upper limit

of that measurement mode.

p.41

p.55

p.4., 26

p.39

p.39

p.39

CHAPTER 3 Part Names and Functions

12

Page 20

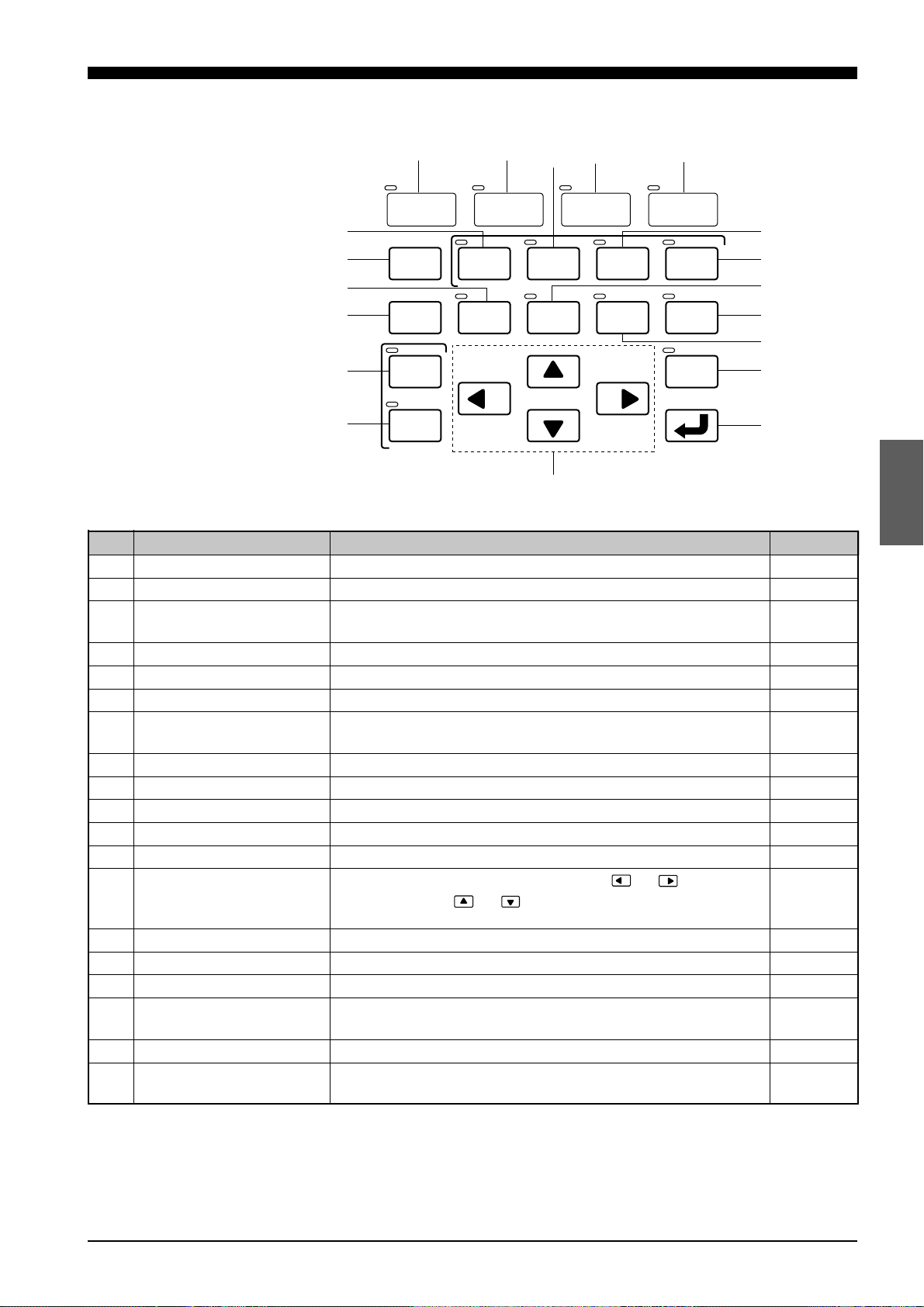

Operation Keys

3-1 Controller

p.

P

O

N

R

Q

M

0

NORMAL P–P

GAIN

PRM

LOAD

SAVE

PROGRAM

A

1CH 2CH

2–HEAD

AVERAGE

B

FILTER

L

C

PEAK

ADD SUB

INTENSITY

D

BOTTOM

ZERO

HOLD

E

F

G

H

I

J

K

No. Name Function Ref. page

0 NORMAL key Press this key to measure targets in the NORMAL mode. p.30

A P-P key Press this key to measure targets in the Peak-to-Peak mode. p.30

B 2CH key Press this key to measure targets with the second sensor

head (2CH slot) when two sensor heads are connected.

p.31, 45

C PEAK key Press this key to measure target in the PEAK mode. p.30

D BOTTOM key Press this key to measure target in the BOTTOM mode. p.30

E ADD key Press this key to measure thickness using two sensor heads. p.31, 46

F SUB key Press this key to measure height deviation using two sensor

heads.

p.31, 47

G FILTER key Press this key to set a (Low-pass) FILTER value. p.36

H ZERO key Press this key to reset a measured value to "0". p.29

I INTENSITY key Press this key to display received laser beam intensity. p.29

J HOLD key Press this key to hold a measured value. p.29

K ENTER key. Press this key to enter the value you set. p.28

L Numeral change keys Press this key to change values. Press or to shift

digits and press or to increase or decrease values as

p.28

well as change signs.

M SAVE key Press this key to save a measured value. p.41

N LOAD key Press this key to load stored parameter settings. p.41

O PRM key Press this key to change parameter settings. p.28

P AVERAGE key Press this key to set the number of averaging measure-

ments.

p.36

Q GAIN key Press this key to change receiver sensitivity. p.30

R 1CH key Press this key to use the first sensor head (1CH port) when

two sensor heads are connected.

p.31,44

CHAPTER 3 Part Names and Functions

13

Page 21

3-1 Controller

Rear Panel

a

Display unit

Control unit

S

CONTROL I/O

HEAD No.

INTENSITY

RS-232C

`

T

U

MONITOR

DISPLACEMENT

BATTERY LASER ON LASER

LC–C1

]

HEAD No.

\

V

W

REMOTE

[

Z

X

100~240V AC

FUSE 3.15A

Y

POWER

ON

OFF

No. Name Function Ref. page

S CONTROL I/O port Inputs signals (program, hold on/off, auto-zero on/off, etc.)

from and outputs signals to external equipment.

T INTENSITY output connector Outputs the laser beam intensity measured with the LC in

analog voltage.

U DISPLACEMENT output Outputs the measured displacement value as an analog

connector voltage.

p.71

p.74

p.73

V Expansion I/O slot Install GP-IB board* or digital I/O board* in this slot. p.24, 95

W 1CH sensor head connector Connect the 1CH sensor head to this connector. p.22

X Ventilating fan Radiates heat from the controller. p.16

Y Power supply connector Connect the power supply cable to this connector. p.22

Z F.G. terminal Ground the controller through this terminal. p.23

[ LASER REMOTE connector The LASER REMOTE connector is used to control laser

emission by an external input signal. When this connector

is not used, be sure to connect the attached laser remote

p.11

grounding plug to this connector.

\ Laser ON alarm LED Lights when a laser beam is ready to be and is being

emitted from the sensor head.

p.18, 26

] BATTERY LED Lights when the internal backup battery is exhausted. p.15

^ RS-232C I/O port Connect a personal computer or other device to this port

to externally control the LC.

p.50

a LC-B3 board slot Install the optional LC-B3 board in this slot. p.24

The LC-B3 cannot be used with the LC-2400W series.

b Power switch Use this switch to turn the main power supply on or off.

(LC-2400W only)

b

* Optionally available

CHAPTER 3 Part Names and Functions

14

Page 22

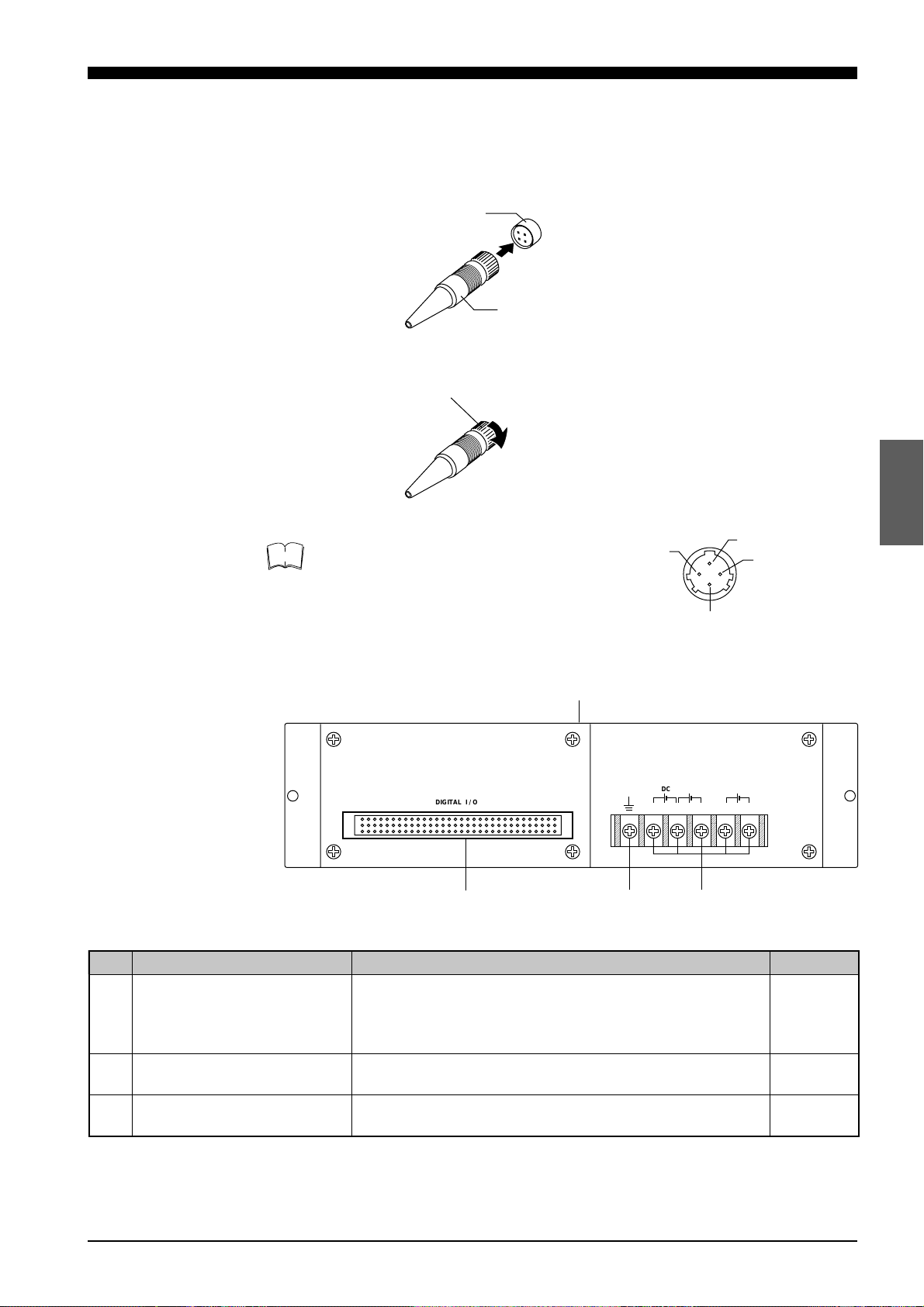

3-1 Controller

DIGITAL I / O

DC DC DC

+15V –15V +5V0V 0V

d

c

b

Control unit

Laser Remote Grounding

Plug

Note

Follow the instructions below to insert this plug into the LASER REMOTE

connector.

1. Check the connector’s orientation before insertion.

LASER REMOTE

connector

Laser remote

grounding plug

2. Turn the stopper clockwise to lock it in place.

Stopper

Laser emission is enabled when pins 1 and 2

of the connector are shorted.

4

1

2

3

Control Unit Face

No. Name Function Ref. page

b 96-pin DIGITAL I/O port The control unit is connected to the display unit via this

connector. Digital signals are output through this connector when the control unit is used separately from the

display unit.

c Earth ground terminal Ground the control unit through this terminal when using

the control unit separately from the display unit.

d Power supply terminals Connect the power supply cable to these terminals when

using the control unit separately from the display unit.

p.74

p.23

p.23

CHAPTER 3 Part Names and Functions

15

Page 23

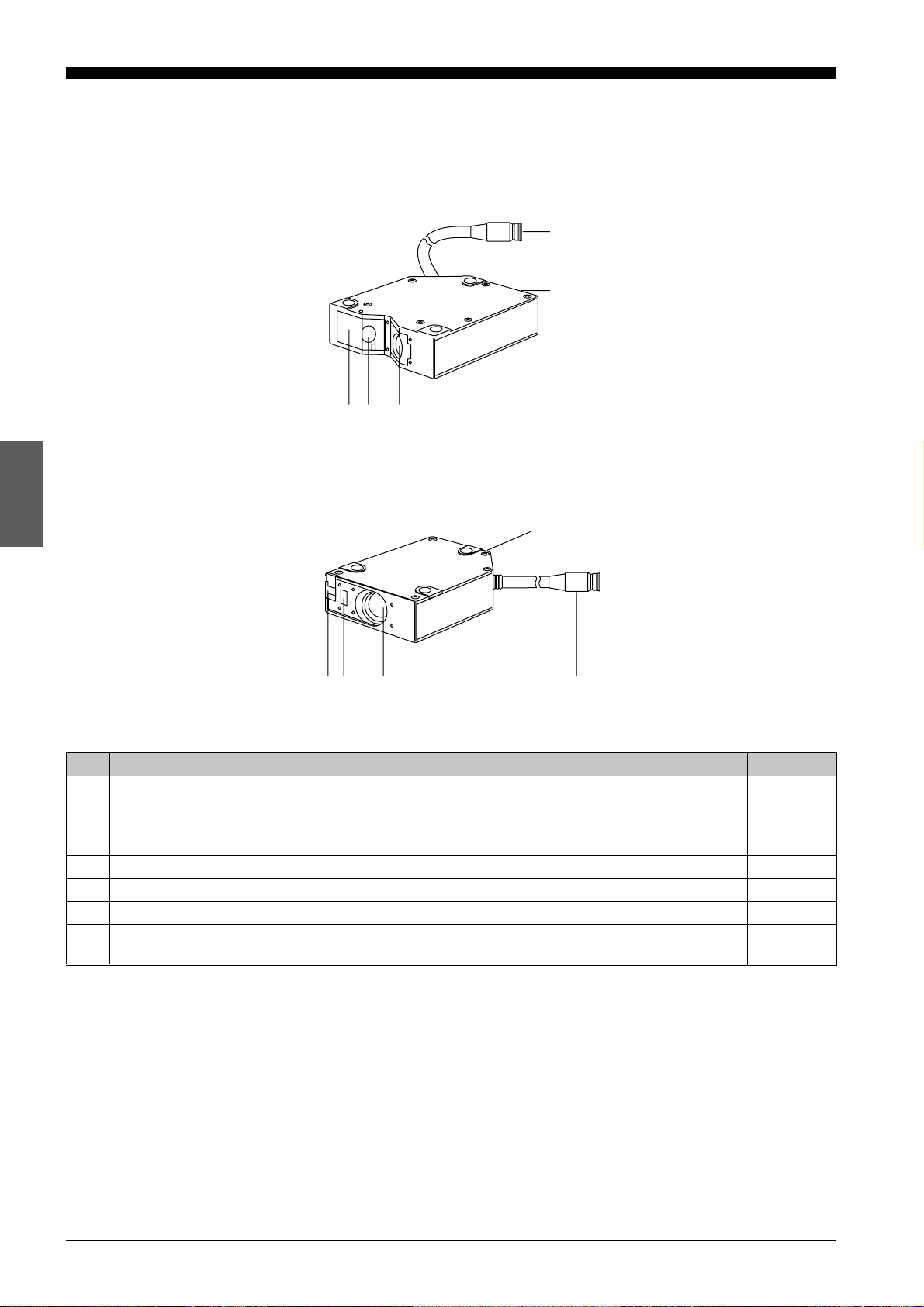

3-2 Sensor Head

3-2 Sensor Head

LC-2420/2430 (Regular-reflective)

h

i

ef g

LC-2440/2450 (Diffuse-reflective)

i

feg

No. Name Function Ref. page

e Laser beam shield The laser beam shield is used to cover the laser beam

transmitter. When operators are working near the sensor

head, if there is a risk of looking directly at the laser beam,

be sure to cover the transmitter with the shield.

f Transmitter Emits laser beams. p.18

g Receiver Receives the reflected laser beam. p.18

h Cable connector Connects the sensor head cable to the controller. p.22

i Laser ON alarm LED Lights when a laser beam is ready to be and is being

emitted from the sensor head.

h

p.4

p.4, 26

CHAPTER 3 Part Names and Functions

16

Page 24

CHAPTER 4

OPERATING INSTRUCTIONS

4-1 Instructions for Using Controller and Sensor Head............. 18

Page 25

4-1 Instructions for Using Controller and Sensor Head

Before operating the LC-2400 series, read the following instructions carefully. If you encounter any problems, please contact us.

4-1 Instructions for Using Controller and Sensor Head

After Receiving the

LC-2400 Series

Daily Maintenance

Instructions

• After receiving the LC, check the contents to see if any items were damaged during transportation.

• Check that all the items were included.

Reference: Contents of the Package (p.ii)

• Before using the LC, be sure to read this instruction manual for details on

the correct use of this product.

• Do not try to disassemble the LC or use a disassembled unit. Do not

disassemble the sensor head in particular, since all of the sensor head

parts have been factory-calibrated.

• Please handle the controller and sensor head with care. The precision

optical components in the sensor head are especially susceptible to

shock.

• The receiver and transmitter lenses are the critical components for

accurate measurement. Any flaw or dust on the lenses may result in

measurement errors. If dust has accumulated on the transmitter and

receiver lenses, clean the lens surface by following the procedures given

below.

1. Blow the dust off the receiver and transmitter lenses using a manual

blower.

2. If dust persists, wipe the lens surface gently using a cotton swab dipped

in alcohol.

CHAPTER 4 Operating Instructions

18

Page 26

4-1 Instructions for Using Controller and Sensor Head

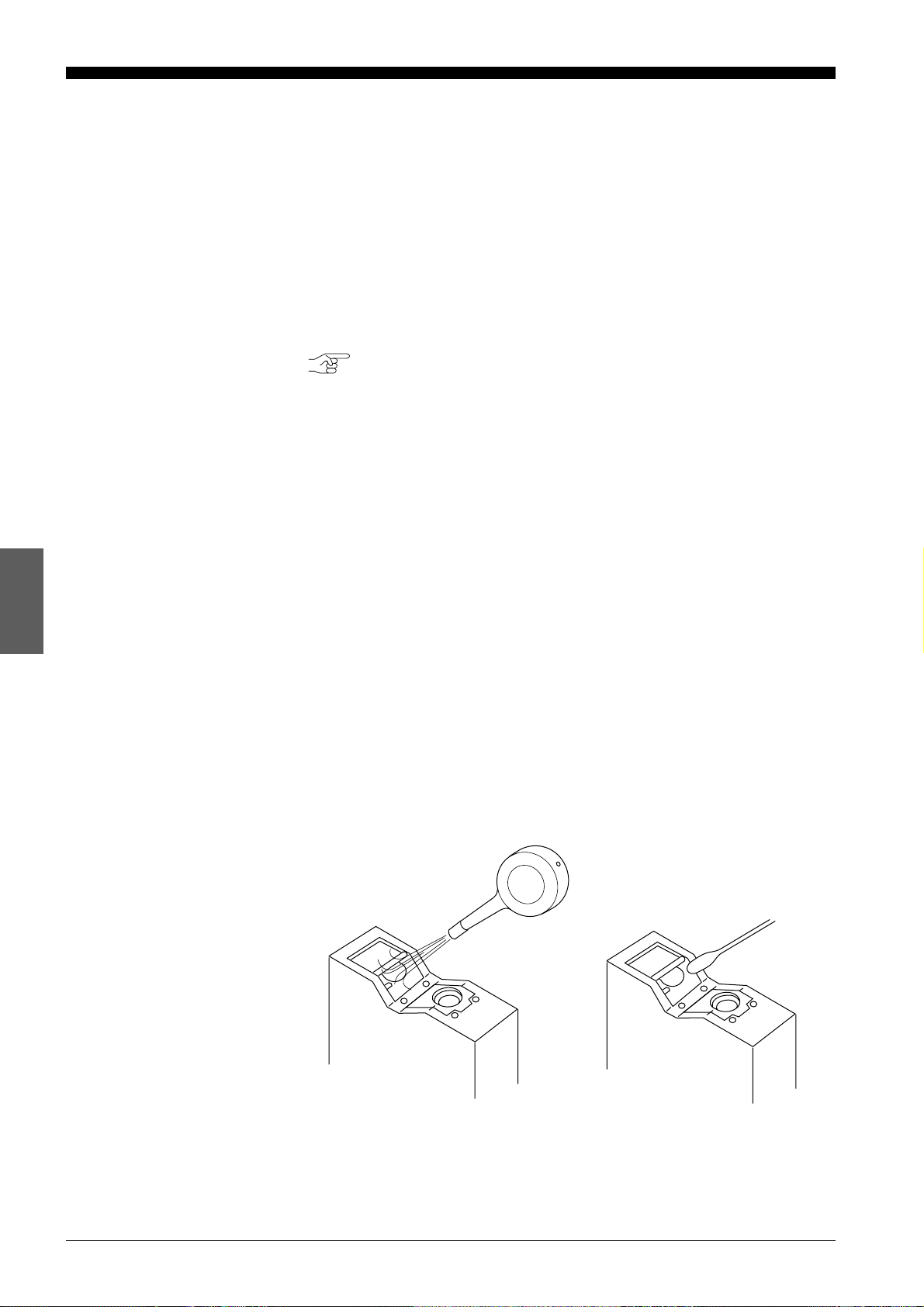

Replacing Battery

WARNING

CAUTION

The LC controller has an internal backup battery for storing parameter

settings. The expected battery life is 1 to 2.5 years. When the battery is

exhausted, the BATTERY LED lights. When this LED is lit, replace the

battery by following the procedure given below.

Danger of explosion if battery is incorrectly replaced. Replace only with the

same or equivalent type recommended by the manufacturer. Dispose of

used batteries according to the manufacturer's instructions.

Turn the power OFF and unplug the power cable from the wall outlet.

1. Remove the two screws from the back of the display unit and remove the

control unit.

Upper cover

Expansion slot

Control unit

Screws

2. Turn the control unit upside down, remove the six cover screws from the

cover and then remove the cover.

Locate the battery holder in the control unit.

Screws

Cover

Battery holder

Screws

3. Remove the battery from the battery holder.

Positive side

Flat lithium battery: CR2032

Internal backup battery

Battery holder

4. Install the new battery in the battery holder with the positive side facing

up. When installing a new battery, be sure that the polarity of the battery is

correct.

CHAPTER 4 Operating Instructions

19

Page 27

4-1 Instructions for Using Controller and Sensor Head

5. Put the cover back on the control unit and secure it with the six cover

screws.

6. Reinsert the control unit into the display unit with the top of the control unit

facing up, and secure the control unit with the two retaining screws.

Instructions for Sensor

Setup

CAUTION

Turn the power OFF when connecting or disconnecting the sensor

head connector, power supply cables, or any of the optional boards.

Otherwise, the laser diode or other electronic components may become degraded or damaged.

• Place the LC in a location that meets the following requirements:

Temperature: 0 to 40°C

Humidity: 35 to 85% RH (No condensation)

Placing the LC in a location that does not meet these requirements may

cause the controller and sensor head to malfunction.

Do not operate the LC in a location where extreme temperature variations

are expected.

• Do not operate the LC where volatile flammable objects or corrosive

gases are present.

• Do not expose the LC to extremely high humidity or water splashes.

• When using the control unit separately from the display unit, be sure to

provide a protective cover for the control unit during operation.

• To prevent noise, keep the connection cables separate from the power

cables. If this is not possible, shield or ground the connection cables.

Hints on Correct Use

• Insulate the sensor head if noise is transferred through the sensor head.

• Do not block the ventilation port or the ventilation fan of the controller. If

they are blocked, the controller may overheat, resulting in a malfunction.

Note also that a ventilation fan is not provided with the control unit. When

using the control unit separately from the display unit, make sure that the

room is sufficiently ventilated.

Ventilation port

Ventilation fan

• Keep the ambient temperature at a constant level during measurement.

• If the sensor head is operating in a location where there is thick fog or hot

air, measurement errors may result.

• Be sure to leave the power on for at least 60 minutes before starting

measurements.

CHAPTER 4 Operating Instructions

20

Page 28

CHAPTER 5

CONNECTIONS

5-1 Connecting Controller to Sensor Head.......................... 22

5-2 Connecting Power Supply Cable................................... 22

5-3 Grounding Controller ..................................................... 23

5-4 Installing LC-B3 Board (2CH Sensor Head Board) ....... 24

5-5 Installing GP-IB or DIGITAL I/O Board .......................... 24

5-6 Adjusting Sensor Head Position .................................... 25

Page 29

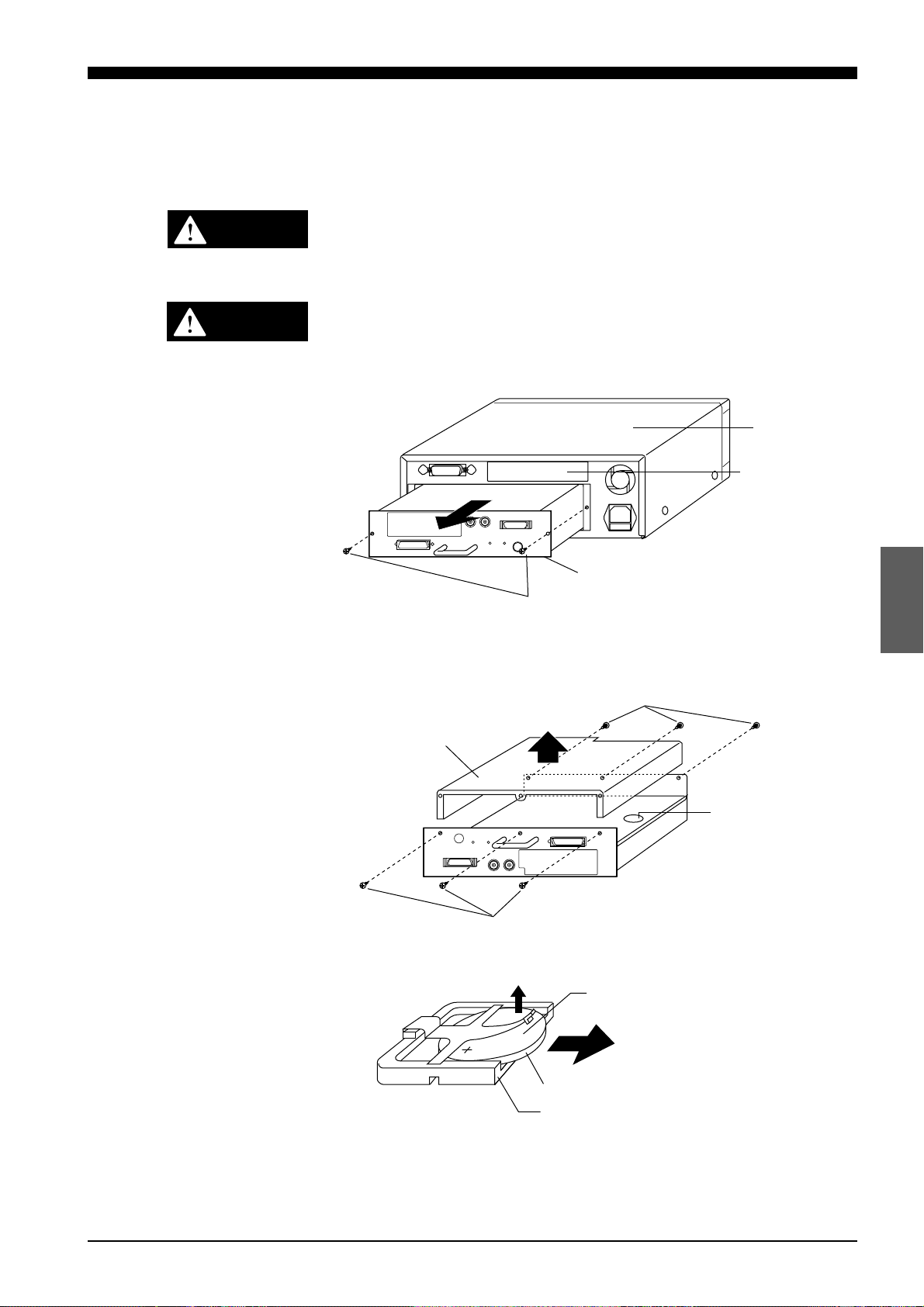

5-1 Connecting Controller to Sensor Head

5-2 Connecting Power Supply Cable

5-1 Connecting Controller to Sensor Head

The 2CH sensor head cannot be used with the LC-2400W series.

CAUTION

Turn the power OFF when connecting or disconnecting the sensor

head connector, power supply cables, or any of the optional boards.

Otherwise, the laser diode or other electronic components may become degraded or damaged.

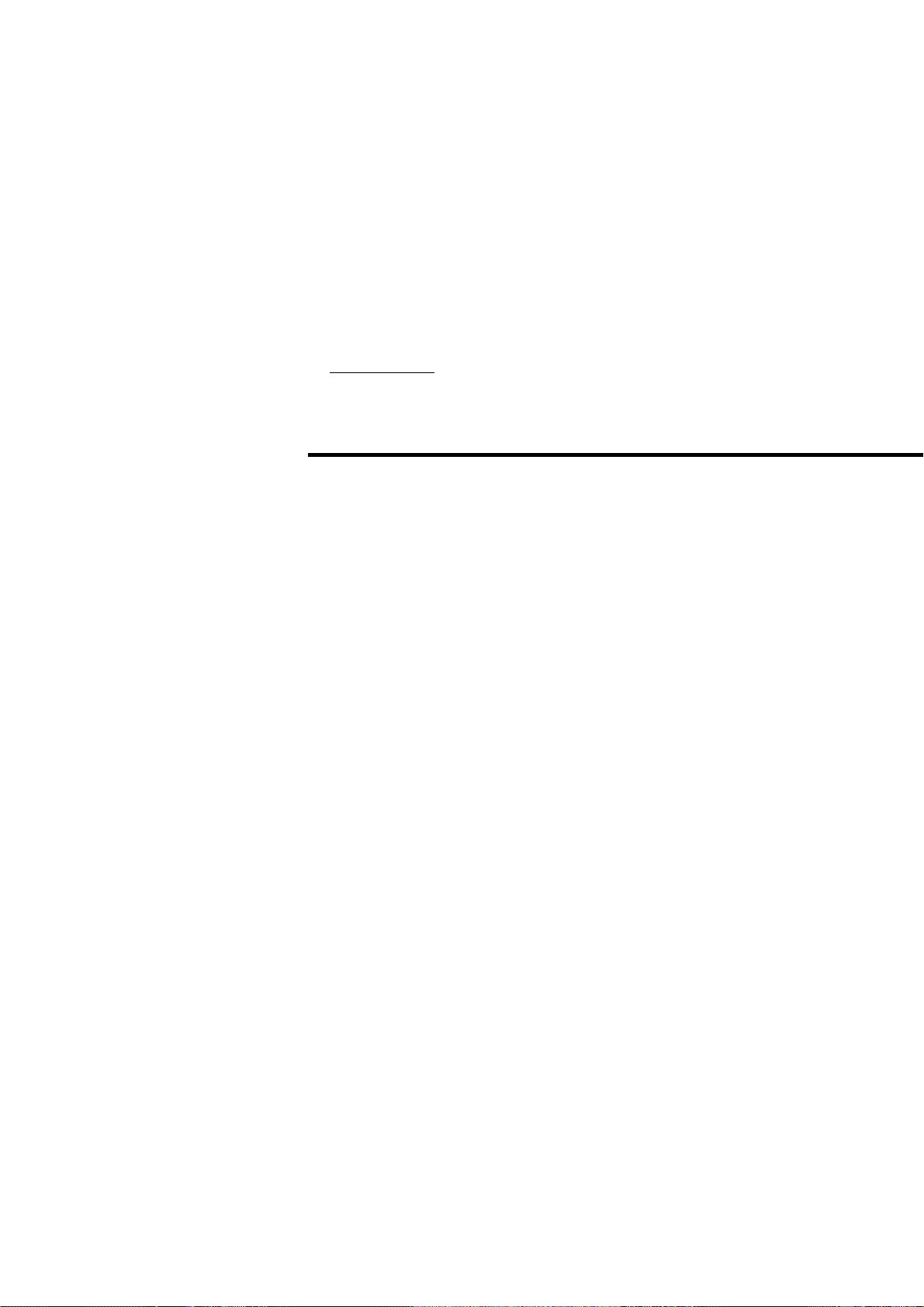

Connect the controller to the sensor head using the supplied connecting

cable. At this time, make sure that the control unit and sensor head have the

same serial number.

Options

Connecting cable

Sensor heads

2CH sensor head 1CH sensor head

If you purchase the LC-B3 and sensor head later, you can connect them to

the controller without adjustment because the sensor head and the LC-B3

have been factory-calibrated as a pair.

5-2 Connecting Power Supply Cable

Connecting the Power

Supply Cable When

Using the Display Unit

Turn OFF the LC controller before starting the following procedure.

CAUTION

Plug the power supply cable into the power supply socket located on the

rear of the display unit, and then into a wall outlet.

Power must be 100 to 240 VAC (50/60 Hz).

CHAPTER 5 Connections

22

Page 30

Connecting the Power

;

Supply Unit to a

Separate Control Unit

5-2 Connecting Power Supply Cable

5-3 Grounding Controller

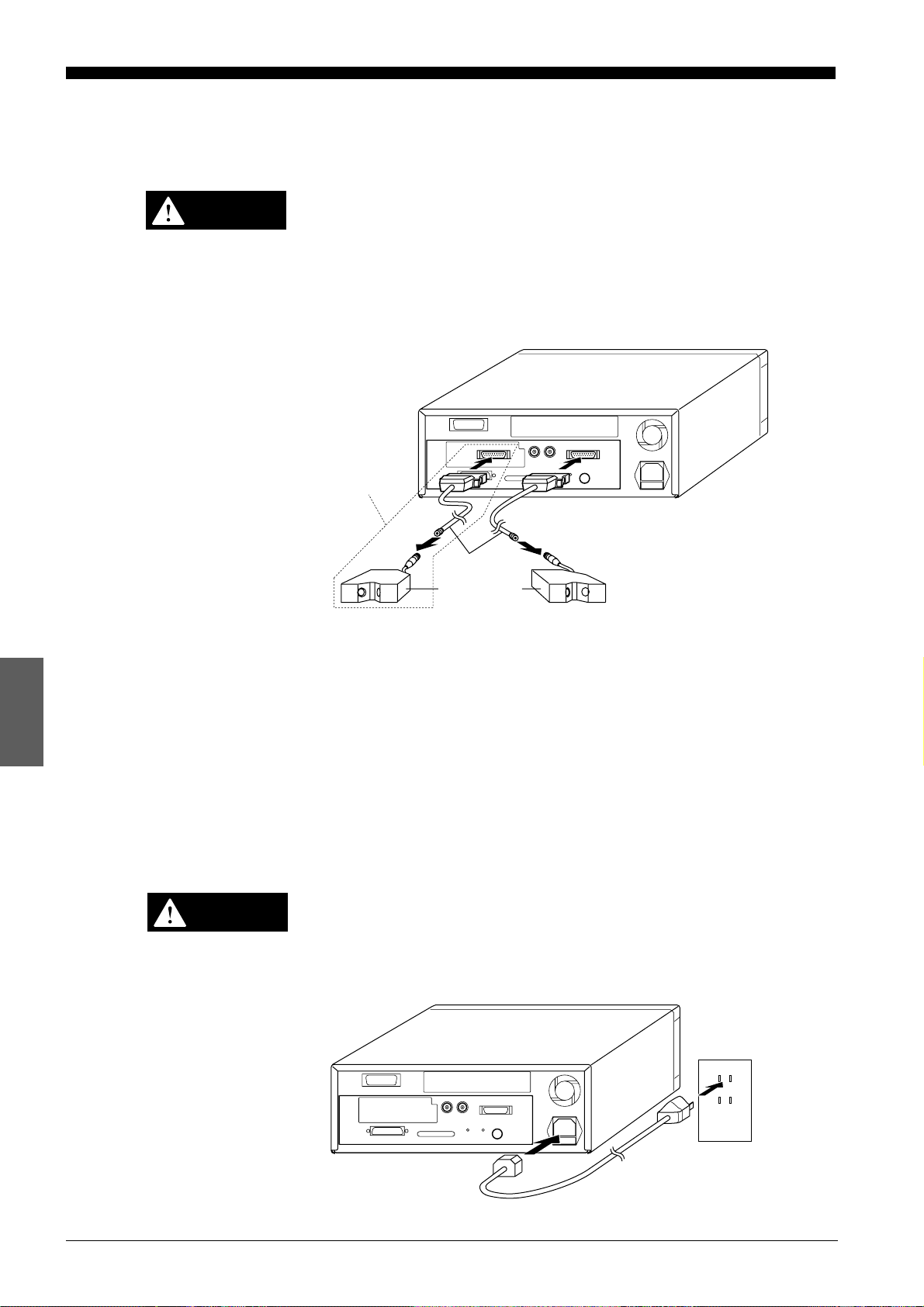

Cannot be used with the LC-2400W series.

CAUTION

CAUTION

Turn OFF the power supply unit before starting the following procedure.

Connect the power supply unit to the power

supply terminals located on the front of the

control unit.

Note that the control unit uses the following types of power:

• ±15 VDC (±3%), 0.5A

• ±5 VDC (±5%), 3A, ripple (p-p): 100 mV max.

Be sure to supply

Supplying only +5 VDC may cause a malfunction.

5-3 Grounding Controller

The controller can be grounded either by connecting the earth ground

terminal located on the rear of the display unit to a grounding electrode or by

connecting the ground wire of the power supply cable to the ground screw of

a wall outlet. To prevent any risk of malfunction, ground the LC both ways as

shown below.

DC DC DC

+15V –15V +5V0V 0V

±15 VDC and +5 VDC at the same time.

CAUTION

Grounding the

Controller When Using

the Display Unit

Grounding the Control

Unit

Be sure to ground the controller separately from other devices.

Earth-ground the controller through the earth ground terminal located on the

rear of the display unit with the ground wire of the power supply cable.

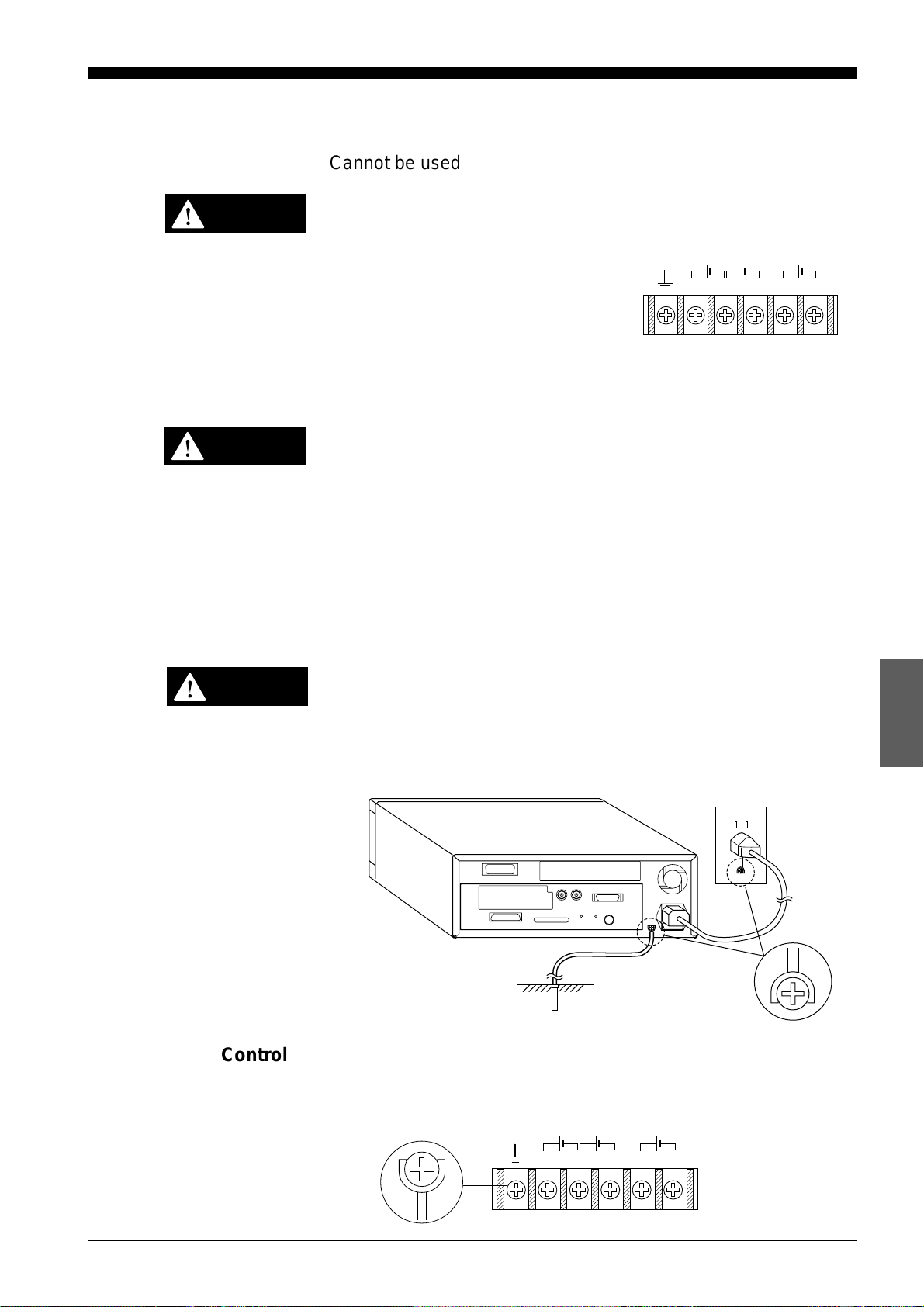

Cannot be used with the LC-2400W series.

Earth-ground the control unit through the earth ground terminal located on

the front of this unit.

DC DC DC

+15V –15V +5V0V 0V

CHAPTER 5 Connections

23

Page 31

5-4 Installing LC-B3 Board (2CH Sensor Head Board)

5-5 Installing GP-IB or Digital I/O Board

5-4 Installing LC-B3 Board (2CH Sensor Head Board)

Cannot be used with the LC-2400W series.

To use two sensor heads with the LC controller, the LC-B3 board must be

inserted into the LC-B3 board slot located at the rear of the control unit. (The

LC-B3 board is optional. Contact KEYENCE for details.)

CAUTION

Turn OFF the LC and unplug the power cable from the wall outlet

before starting the following procedure.

1. Remove the two screws securing the LC-B3 board slot cover on the rear

of the control unit.

2. Align the LC-B3 board with the grooves of the LC-B3 board slot, insert the

LC-B3 board all the way into the slot, and secure the board using the two

screws removed in step (1).

4-5 Installing GP-IB or Digital I/O Board (Options)

Cannot be used with the LC-2400W series.

CAUTION

Turn OFF the controller and unplug the power cable from the wall

outlet.

Insert the GP-IB or Digital I/O Board into the expansion slot on the display

unit as shown in the following figure. (See chapter 9.)

1. Remove the two screws securing the expansion slot cover at the rear of

the display unit.

CHAPTER 5 Connections

24

Page 32

2. Align the board with the grooves of the expansion slot, insert the GP-IB or

DIGITAL I/O board all the way into the slot, and secure the board using

the two screws removed in step (1).

5-6 Adjusting Sensor Head Position

1. Align the sensor head using the following three positions as alignment

points:

(1) The three mounting holes on each side of the sensor head

(2) The sides of the sensor head

(3) The front (laser-emitting surface) of the sensor head

5-5 Installing GP-IB or Digital I/O Board

5-6 Adjusting Sensor Head Position

Rear view of the controllerExpansion slot cover

(1)

(2) (2)

(3)

Right angle

LC±2420

LC±2440

Parallel

TargetTarget

(1)

(3)

Right angle

When there is a significant change in target color, material, or height,

measurement errors may result depending on the orientation of the

sensor head. Proper orientation is shown below.

Protrusion

Incorrect Correct Incorrect Correct

Recess

Color change

Rotating shaft

CHAPTER 5 Connections

Rotating shaft

25

Page 33

5-6 Adjusting Sensor Head Position

2. Turn on the LC controller and adjust the sensor head position so that the

laser ON alarm LED located on the sensor head lights orange. The sensor

head is at the "reference distance" from the target when the above LED

lights orange.

Checking for Reference

Distance

When the distance between the target and sensor head is within the reference distance range, the laser ON alarm LED lights orange. The sensor

head can be easily positioned even when the control unit is used without the

display unit.

Laser ON alarm LED

NEAR FAR

Green Orange Green

Measuring range

Reference distance

Sensor head Range the LED lights orange

LC-2420 ±0.02 mm

LC-2430 ±0.05 mm

LC-2440 ±0.3 mm

LC-2450 ±0.8 mm

CHAPTER 5 Connections

26

Page 34

CHAPTER 6

SETTING UP

6-1 Basic Operation of Controller ........................................ 28

6-2 Selecting Measurement Mode....................................... 30

6-3 Calibrating Sensitivity (Gain Selection) ......................... 30

6-4 Selecting Display/Output Mode ..................................... 31

6-5 Correcting Measurement Error (Calibration) ................. 32

6-6 Offset Values ................................................................. 35

6-7 Reducing Variation in Measurement Data

(Setting Number of Averaging Measurements) ............. 36

6-8 Reducing Effect of Target Surface Irregularities

(Setting Low-pass Filter Value) ..................................... 36

6-9 Setting Range for Light Intensity (INT. LIMIT) ............... 37

6-10 Setting Upper/Lower Limits for Measurements

(Setting Tolerance) ........................................................ 39

6-11 Setting Number of Displayed Digits............................... 40

6-12 Storing and Loading Settings (Programming) ............... 41

Page 35

6-1 Basic Operation of Controller

PRM

PRM PRM PRM PRM PRM PRM

LIMIT OFF SET CAL

INT.

LIMIT

ANALOG

RATIO

BAUD

RATE

DIGIT

PRM

mm

µ

m

6-1 Basic Operation of Controller

This section describes the basic operation procedures of the controller.

Selecting a Parameter

PRM

(

key)

Entering Numerical

Values ( , , ,

and keys)

1. Press the

PRM

key.

One of the PARAMETER LEDs lights, and the current value for the

parameter appears on the display panel. The LC is now in the setting

mode.

2. Press the

PRM

key repeatedly.

The PARAMETER LEDs go on and off one after another as shown below.

The illuminated LED means that the corresponding parameter is selected.

1. Select the desired parameter. The LC is ready to accept a numerical

value.

2. Select a digit.

Press the key. The selected digit starts flashing.

Press the key to shift the selection to the right, and press the

key to shift it to the left.

CHAPTER 6 Setting Up

28

to the left to the right

3. Change the digit.

Press the or key while the digit is flashing. Press the key

to increase the value. Press the key to decrease it.

0

234567 981

4. Confirm the setting.

Press the key to confirm the new setting.

Page 36

6-1 Basic Operation of Controller

mm

µ

m

Displaying Light

Intensity

INTENSITY

(

key)

Automatic Zero

Function (

ZERO

key)

Note

A function is available to display the intensity of reflected light from the

target. The light intensity is displayed and output within a range of 1 to

50000. If possible, the target should have a light intensity of 00050 or greater

for accurate displacement measurement.

1. Position a target for measurement.

2. Press the

The LED above the

INTENSITY

key.

INTENSITY

key lights, and the light intensity appears on

the display panel.

An analog voltage equivalent to the light intensity is always output.

3. Press the

The LED above the

INTENSITY

key again.

INTENSITY

key goes off, and the system will return to the

measuring mode.

This function sets the current measurement and displayed values to +0.0000

mm in the NORMAL, BOTTOM, or PEAK mode. After the function is executed, the LC will display and output displacement relative to the new

reference (zero) point.

Hold Function

HOLD

(

key)

Note

1. Execute the automatic zero function.

Press the

The LED above the

ZERO

key.

ZERO

key lights and the displayed value turns to

+0.0000 mm. Now the display will show the displacement relative to the

new reference point.

2. Cancel the automatic zero setting function.

Press the

ZERO

key again.

The display restores the value before the automatic zero function was

executed.

• This function can be operated even when the ADD or SUB key is used.

• The automatic zero function can also be operated via the CONTROL

I/O port.

The hold function is used to retain and output the last measured value. This

function enables reading and recording of a specific analog value at a given

moment.

1 Press the

The LED above the

HOLD

key.

HOLD

key lights and the last measured value is

displayed as well as output.

2 Press the

HOLD

key again.

The hold function is deactivated and the LC-2400 series returns to the

measurement mode.

CHAPTER 6 Setting Up

29

Page 37

6-2 Selecting Measurement Mode

6-3 Calibrating Sensitivity (Gain Selection)

Note

The HOLD function can also be operated via the CONTROL I/O port.

Activating or deactivating the hold function in the P-P, PEAK, or

BOTTOM mode will cause the LC to return to the measurement mode

and reset the measurements.

6-2 Selecting Measurement Mode

Four measurement modes are available. Measurements from each mode

can be displayed as well as output to external equipment.

Measurement mode Function

NORMAL Measures displacement from reference point

P-P Measures displacement between maximum and

(Peak-to-Peak) minimum values

PEAK Measures maximum value from reference point

BOTTOM Measures minimum value from reference point

Factory setting: NORMAL

Press the mode selector key (

The LED of the selected mode lights, confirming that the controller is now in

that measurement mode. Note that the measurements in any of the P-P,

PEAK, or BOTTOM mode can be reset by pressing the same mode selector

key again.

NORMAL

P–P

,

PEAK

,

, or

BOTTOM

key).

NORMAL P±P PEAK BOTTOM

Note

The measurements can also be reset by pressing

6-3 Calibrating Sensitivity (Gain Selection)

Light sensitivity of the sensor head can be adjusted through gain selection.

The LC calculates a measurement based on the intensity of reflected light

from the target. Because the light intensity varies with the reflectance of the

target surface, the sensitivity of the sensor head must be optimized accordingly. The system offers four levels of sensitivity, which can be identified by

the GAIN LEDs on the display unit. The correlation between the GAIN LEDs

and light sensitivity of the sensor head is as shown below.

1234

AUTO

Reflectance of target

High Low

GAIN

HOLD

twice.

CHAPTER 6 Setting Up

30

Factory setting: AUTO

Reference: Displaying Light Intensity (P. 29)

Page 38

6-3 Calibrating Sensitivity (Gain Selection)

6-4 Selecting the Display/Output Mode

1 Press the

GAIN

key. The AUTO LED and one of the four GAIN LEDs will

light. When measurements are performed with these two LEDs on, the

sensitivity will change automatically according to the light intensity received.

12 34

AUTO

GAIN

key again to select the lit LED.

Note

2 Press the

For a target whose reflectance varies greatly, the AUTO function can be

selected. However, the measurement may show some variation when

sensitivity is changed.

6-4 Selecting Display/Output Mode

The 2CH mode cannot be used with the LC-2400W series.

Any of the following modes can be selected when two sensor heads are

used during measurements.

Mode Function

1 CH Displays/outputs the 1CH measurement.

2 CH Displays/outputs the 2CH measurement.

ADD Adds the 1CH and 2CH measurements and displays/

outputs the negative of this result. – (l 1 + l 2)

SUB Subtracts the 2CH measurement from the 1CH meas-

urement. (l 1 – l 2)

GAIN

Factory setting: 1CH

• Measurement example in the ADD mode

Thickness

• Measurement example in the SUB mode

1CH head

l 1

1CH head

l

1

l

2

2CH head

2CH head

Height

difference

l 2

CONTROL I/O

CONTROL I/O

RS-232C

RS-232C

MONITOR

INTENSITY

DISPLACEMENT

MONITOR

INTENSITY

DISPLACEMENT

BATTERY LASER ON LASER

HEAD No.

BATTERY LASER ON LASER

LC±C1

LC±C1

HEAD No.

REMOTE

REMOTE

100~240V AC

F.G.

FUSE 3.15A

100~240V AC

F.G.

FUSE 3.15A

CHAPTER 6 Setting Up

31

Page 39

6-4 Selecting Display/Output Mode

6-5 Correcting Measurement Error (Calibration)

• Only one of the four modes can be selected at a time.

• None of these modes can be selected when only one sensor head is

• In the ADD or SUB mode the 1CH intensity is displayed/output.

used.

To enter any of the above modes, press the desired key (

ADD

, or

SUB

key) and the LED above the key pressed will light.

6-5 Correcting Measurement Error (Calibration)

Calibrating the LC corrects the difference between the actual displacement

and that measured by the LC. Always calibrate the LC after having moved

the sensor head or having changed over the target types.

There are two ways to calibrate the LC; calibration with a target (target

positioning), and calibration without a target (entering a numerical value).

Calibrate the LC using one of these methods. If frequent product changeover

occurs, it is useful to record the calibration value for each product after

calibration. The LC can then be re-calibrated simply by entering the calibration value recorded.

Factory settings: LC-2420: 200.00 µm LC-2430: 500.00 µm

LC-2440: 3.0000 mm LC-2450: 8.0000 mm

Calibration by Target

Position

The LC is calibrated based on measurements of the target position.

1 Position the target within the measuring range.

1CH

2CH

,

,

Sensor head

Measuring range

2 Press the

3 Press the

NORMAL

PRM

key. The LED above the key will light.

key repeatedly until the CAL LED lights.

Target Actual displacement range

The LED lights and the LC continues to measure.

INT.

LIMIT OFFSET

CAL

LIMIT

ANALOG

RATIO

BAUD

RATE

DIGIT

PRM

CHAPTER 6 Setting Up

32

Page 40

6-5 Correcting Measurement Error (Calibration)

4 Shift the target to either end of the actual displacement range (closest or

farthest from the sensor head).

Sensor head

Shift the target

to either end

Actual displacement

range

Measuring range

• Be careful not to position the target outside of the measuring range.

• Instead of the target, the sensor head may be shifted during calibration.

5. Press the

ZERO

key.

The displayed value changes to zero.

6. Shift the target to the other end of the displacement range. Again, the

sensor head may be shifted instead of the target.

Shift the target to the other end of the displacement range.

Shift the target to the other

end of the displacement range

Note

Be careful not to position the target outside of the measuring range.

7 Press the key.

The digits on the display start flashing and the LC switches to the calibration mode.

During calibration, pressing the

PRM

key, then the key will cancel

calibration. When the calibration mode is canceled, the LC will return to the

measurement mode.

8 Change the value on the display panel to the actual distance the target

was moved.

Reference: Entering Numerical Values (P.28)

9 Press the key.

Calibration is complete. The LC returns to the measuring mode.

CHAPTER 6 Setting Up

33

Page 41

6-5 Correcting Measurement Error (Calibration)

Note

• Calibrate the LC by shifting the target only within the measuring range.

• If the calibration measurement is unacceptable, the error message "C-Err"

(Calibration Error) appears on the display when the key is pressed. If

this occurs, repeat the calibration.

Note

The calibration range is as follows:

Value to be entered in step 8

Calibration by Entering

a Numerical Value

0.9 ≤

Measurement obtained with factory settings

The LC can be calibrated simply by entering previously recorded calibration

values.

≤ 1.1

Check and record the calibration values by following the procedures shown

below. The LC can then be calibrated simply by entering this value.

Checking Calibration Value Check the calibration value obtained from the calibration procedure using a

target.

1. Calibrate the LC using a target.

Note

Reference: Calibration by Target Position (P.32)

2. To interrupt the laser beam, close the laser beam shield or insert a lightshielding object at the closest possible position to the sensor head,

between the sensor head and target.

The message "dar" appears on the display panel.

When interrupting the laser beam, be careful not to touch the glass window

of the sensor head.

3. Press the

LIMIT OFFSET

PRM

key repeatedly until the CAL LED lights.

INT.

CAL

LIMIT

ANALOG

RATIO

BAUD

RATE

DIGIT

PRM

4. Press the key.

The LC is ready to accept a new calibration value, and the calibration

value appears on the display. Record the value.

5. Press the key again.

The LC returns to the measuring mode.

CHAPTER 6 Setting Up

34

Page 42

6-5 Correcting Measurement Error (Calibration)

6-6 Offset Values

Entering Calibration Value Enter the calibration value by following the procedures shown below.

1. Follow the same procedures used for checking the calibration value.

2. Change the displayed value to the recorded calibration value.

Reference: Entering Numerical Values (P.28)

Note

Note

6-6 Offset Values

Press the

PRM

key first, then the key as many times as required to

return to the measuring mode. The entered value and calibration mode are

canceled.

3 Press the key.

Calibration is complete. The LC returns to the measuring mode.

To calibrate the LC through the RS-232C interface, enter the following

calibration coefficient:

Calibration coefficient =

Desired preset value

Factory setting value

Offset values are added to or subtracted from a measurement before displaying or outputting it. Offset values are used for displaying or outputting the

target height or thickness as an absolute value. This function is also used to

tune the LC to the input requirements of the equipment that is connected to

it.

The maximum and minimum offset values available depend on the sensor

head as shown below.

Sensor head Offset value range Max. output range

LC-2420 +199.99 µm ±327.66 µm

LC-2430 +499.98 µm ±655.32 µm

LC-2440 +2.9998 mm ±6.5532 mm

LC-2450 +7.9995 mm ±16.3830 mm

Note

Factory setting: 0

If a displayed value with a offset becomes beyond the maximum output

range is specified, "- - - - -" will appear.

1. Press the

PRM

key repeatedly until the OFFSET LED lights.

The current offset value appears on the display panel and the LC is ready

to accept a new offset value.

LIMIT OFFSET

CAL

LIMIT

ANALOG

RATIO

BAUD

RATE

DIGIT

PRM

INT.

2. Enter an offset value.

To cancel entry of the offset value, press the

PRM

key first, then the

key as many times as required to return to the measuring mode. The entered

value and offset mode are canceled.

CHAPTER 6 Setting Up

35

Page 43

6-7 Reducing Variation in Measurement Data (Setting Number of Averaging Measurements)

6-8 Reducing the Effect of Target Surface Irregularities (Setting Low-pass Filter Value)

(Setting Low-pass Filter Value)

3. Press the key.

The offset value is stored, and the LC will returns the measurement

mode.

6-7 Reducing Variation in Measurement Data

(Setting Number of Averaging Measurements)

The LC has a function for creating an average measurement value from a

series of measurements. The more variation occurring in measurements, the

higher the number of measurements should be taken in order to attain a

stable, average measurement. The number of measurements can be selected from 18 different settings ranging from 1 to 131072.

This averaging function and the filtering function explained in Section 6-8

cannot be used at the same time.

Factory setting: 2048

Reference: Number of averaging measurements vs. response frequency (P.83)

Averaging method (P.91)

AVERAGE

key.

AVERAGE

key lights, and the current number of averag-

AVERAGE

key remains lit during

Note

1. Press the

The LED above the

ing measurements appears on the display panel.

2. Press the or key to change the value. Every time the key is

pressed, the number of measurements increases or decreases to twice or

half the original value (1, 2, 4, 8, 16, 32, 64, 128 ..... 131072).

To cancel entry of the number of measurements, press

mode is canceled and the LC returns to the measuring mode.

3. Press the key.

The number of measurements chosen is set, and the LC returns to the

measuring mode. The LED above the

measurements.

6-8 Reducing Effect of Target Surface Irregularities

(Setting Low-pass Filter Value)

AVERAGE

key. This

CHAPTER 6 Setting Up

36

A low-pass filter is used to attenuate measurements at frequencies higher

than the preset limit. The preset frequency is referred to as the cutoff frequency.

This is useful for targets with treated surfaces (e.g. hairline finish). When

measuring these targets, the sensor detects surface irregularities (picks up

noise), preventing accurate measurement. By setting a filter value, the LC

can more accurately measure the displacement of the target without distortion from the texture of the target surface.

Factory setting: FILTER OFF, cutoff frequency: 100

Page 44

6-8 Reducing Effect of Target Surface Irregularities (Setting Low-pass Filter Value)

6-9 Setting Range for Light Intensity (INT. LIMIT)

• A digital low-pass filter is used.

• The filtering function cannot be used when using the control unit independently.

• This function and the averaging function explained in the previous

section cannot be used at the same time.

1. Press the

FILTER

key.

The LED above the key flashes and the current cutoff frequency appears

on the display.

2. Set the cutoff frequency

The cutoff frequency can be set between 0100 and 4999 Hz.

Note

If this frequency is set below 0100, the error message

"f-Err" appears.

Note

To cancel entry of the cutoff frequency, press the

canceled, and the LC returns to the measuring mode.

3. Press the key.

The new cutoff frequency is set, and the LC returns to the measuring

mode. The LED above the

FILTER

key remains lit during measurements.

6-9 Setting Range for Light Intensity (INT. LIMIT)

The range for light intensity can be set. The upper/lower limits are referred to

as the "HIGH-INTENSITY LIMIT" and "LOW-INTENSITY LIMIT", respectively. Also, the measurement of displacement just before the light intensity

exceeds the HIGH-INTENSITY LIMIT or falls below the LOW-INTENSITY

LIMIT can be retained. The duration to retain the measurement is referred to

as a "level-cut time". This can eliminate inaccurate measurements resulting

from sudden changes in the light intensity or presence of dents or grooves

on the target surface.

FILTER

key. The setting is

Factory settings:

LOW-INTENSITY LIMIT: 50 (selectable between 00000 and 49998)

HIGH-INTENSITY LIMIT: 49750 (selectable between 00000 and 49998)

Level-cut time: 0000.0 ms (selectable between 0000.0 and 2999.9 ms or

9999.9 [infinity])

• A level-cut time must be set each for the LOW-INTENSITY LIMIT and

HIGH-INTENSITY LIMIT.

• The HIGH-INTENSITY LIMIT must be greater than the LOW-INTEN-

SITY LIMIT.

1. Measure the light intensity of the irregular portion of the surface and

record the value.

Reference: Displaying Light Intensity (P.29)

CHAPTER 6 Setting Up

37

Page 45

6-9 Settings Range for Light Intensity (INT. LIMIT)

Note

2. Press the

PRM

key repeatedly until the INT. LIMIT LED lights.

The HIGH LED lights and the LC switches to the entry mode. Also, the

current HIGH-INTENSITY LIMIT appears on the display panel.

INT.

HIGH

GO

LOW

LIMIT OFFSET CAL

LIMIT

ANALOG

RATIO

BAUD

RATE

DIGIT

PRM

3. Change the displayed value to the desired HIGH-INTENSITY LIMIT.

To use the current HIGH-INTENSITY LIMIT, press the key. The

setting remains unchanged, and the LC will proceed to the setting of the

HIGH-INTENSITY LIMIT (Step 5).

4. Press the key.

Simultaneously, the HIGH and GO LEDs light and the LC is ready for

setting the INTENSITY LIMIT TIME. The current INTENSITY LIMIT TIME

appears on the display panel.

Note

HIGH

GO

LOW

5. Change the displayed value to the desired INTENSITY LIMIT TIME.

To use the current INTENSITY LIMIT TIME, press the key. The

setting remains unchanged, and the LC will proceed to the setting of the

LOW-INTENSITY LIMIT (Step 7).

6. Press the key.

The new INTENSITY LIMIT TIME is set and the HIGH and GO LEDs go

off. Simultaneously, the LOW LED lights and the LC is ready to accept a

new LOW-INTENSITY LIMIT. The display indicates the current LOWINTENSITY LIMIT.

HIGH

GO

LOW

CHAPTER 6 Setting Up

38

Note

7. Change the displayed value to the desired LOW-INTENSITY LIMIT.

To use the current LOW-INTENSITY LIMIT, press the key. The

setting remains unchanged, and the LC will proceed to setting of the levelcut time for LOW-INTENSITY LIMIT (Step 9).

8. Press the key.

The new LOW-INTENSITY LIMIT is set. Simultaneously, the LOW and GO

LEDs light and the system is switched to the setting mode. The display

indicates the current INTENSITY LIMIT TIME.

Page 46

6-9 Setting Range for Light Intensity (INT. LIMIT)

6-10 Setting Upper/Lower Limits for Measurements (Setting Tolerance)

HIGH

GO

LOW

9. Change the displayed value to the desired INTENSITY LIMIT TIME.

Note

To use the current INTENSITY LIMIT TIME, press the key. The

setting remains unchanged, and the LC will return to the measuring mode.

10. Press the key.

The new INTENSITY LIMIT TIME is set, the LOW and GO LEDs go off,

and the LC will return to the measuring mode.

Note

To cancel the entry of light intensity parameters, press the

then the key as many times as required to return to the measuring

mode. The entered value will also be canceled.

The light intensity parameters are set only after the LOW-INTENSITY

LIMIT TIME has been entered and the key pressed. If you stop

before entering all the parameters, the parameters entered will be

canceled.

6-10 Setting Upper/Lower Limits for Measurements

(Setting Tolerance)

The LC can set upper/lower limits for measurements in each measurement

mode. Measurements outside the preset range is indicated by the display or

output signal. The upper/lower limits range differs, depending on the sensor

head as shown below. Numbers in parentheses are factory settings.

PRM

key first,

Note

LC-2420: +299.99 µm (±200.00 µm)

LC-2430: +599.98 µm (±500.00 µm)

LC-2440: +5.9998 mm (±3.0000 mm)

LC-2450: +15.9995 mm (±8.0000 mm)

Upper and lower measurement limits can be set for each measurement

mode.

1. Choose the measurement mode and press the key.

2. Press the

PRM

key. The LIMIT LED lights.

The HIGH LED lights and the LC is ready to accept a new upper limit. The

display indicates the current upper limit.

LIMIT OFFSET CAL

LIMIT

ANALOG

RATIO

BAUD

RATE

DIGIT

PRM

INT.

3. Change the displayed value to the desired upper limit.

CHAPTER 6 Setting Up

39

Page 47

6-10 Setting Upper/Lower Limits for Measurements (Setting Tolerance)

6-11 Setting Number of Displayed Digits

4 .Press the key.

The new upper limit is set. The LOW LED lights and the LC is ready to

accept a new lower limit. The display now indicates the current lower limit.

HIGH

GO

LOW

5. Change the displayed value to the desired lower limit.

6. Press the key.

The new lower limit is set, and the LC returns to the measuring mode.

The upper/lower limits are set only after the key has been pressed.

If you stop before entering the lower limit, the new upper limit will be

canceled.

6-11 Setting Number of Displayed Digits

Follow the procedure below to set the number of displayed digits.

Factory setting: All digits

1. Press the

The display starts flashing.

LIMIT OFFSET

2. Press the or key to set the number of displayed digits.

Every time the key is pressed, the number of digits on the display increases or decreases by one, thus activating or deactivating the last four

digits. Press the key to increase the number of displayed digits;

press the key to decrease it.

If you choose not to display integer digits, "0" will be displayed in these

digits.

3. Press the key.

Measurements will be displayed as specified.

PRM

key repeatedly until the DIGIT LED lights.

INT.

LIMIT

ANALOG

RATIO

CAL

BAUD

RATE

DIGIT

PRM

CHAPTER 6 Setting Up

40

Note

To cancel entry of the number of displayed digits, press the

PRM

key

first, then the key as many times as required to return to the measuring mode.

Page 48

6-12 Storing and Loading Settings (Programming)

6-12 Storing and Loading Settings (Programming)

A set of parameters, including an offset value and upper and lower measurement limits, can be stored as a program. Up to five different programs can be

stored. By storing programs prepared for each target, the need for setting

individual parameters is eliminated. This is useful when frequent product

changeover is required.

Factory setting: See the factory setting of each parameter.

Storing Settings (SAVE)

Note

1. Set the parameters required for measurement, then switch the LC to the

measuring mode.

2. Press the

SAVE

key. The LED above the key starts flashing and one of

the five PROGRAM LEDs lights.

2345

1

PROGRAM

3. Press the or key to select a program number.

• To cancel the saving of a program, press the

SAVE

key.

• When overwriting a previously saved program (corresponding PRO-

GRAM indicator is lit) be sure that this program does not contain

settings that should be retained.

4. Press the key.

The message "rEAdy" appears on the display panel.

Press the key again to store the parameter settings. The LC is ready

to measure using these settings.

5. Press the key.

Loading Stored Settings

(LOAD)

Note

Follow the steps below to load the stored program.

1. Press the

LOAD

key. The LED above the key starts flashing and one of

the five PROGRAM LEDs lights.

2345

1

PROGRAM

2. Press the or key to select a program number.

245

1 3

To cancel the loading of a program, press the

PROGRAM

LOAD

key. The selected

program will be canceled and the LC will return to the measurement

mode.

CHAPTER 6 Setting Up

41

Page 49

6-12 Storing and Loading Settings (Programming)

3. Press the key.

The setting is loaded, and the LC switches to the measurement mode.

The LED above the

remains lit. At this time, if any parameter is changed the LED will go off.

1 3

LOAD

key goes off, but the selected PROGRAM LED

245

PROGRAM

CHAPTER 6 Setting Up

42

Page 50

CHAPTER 7

MEASUREMENT PROCEDURE

7-1 Measuring with One Sensor Head................................. 44

7-2 Measuring with Two Sensor Heads............................... 45

Page 51

7-1 Measuring with One Sensor Head

The versatile LC-2400 Series can measure height or eccentricity as well as

displacement. With an optional board installed, the LC can measure thickness or height deviation using two sensor heads. Stored parameters can be

quickly called up by using the LOAD function.

Note

• The LC requires 60 min. to warm up. Turn on the controller and wait at

least 60 min. before starting measurements.

• If you find displayed values or output measurements incorrect, check the

sensor head position as well as parameters.

Reference: Storing and Loading Settings (Programming) (P.41)

Error Message List (P.82)

7-1 Measuring with One Sensor Head

Measuring Target Height

Measure the target height with respect to the reference surface by following

the procedures shown below.

[LC-2400A]

1. Turn the key-operated power switch to the

ON position to turn on the LC controller.

2. Position the sensor head. Keep in mind

the measuring range and angle of the

sensor heads.

LC-2400A

OFF

ON

POWER