Page 1

NEF TIER 2 SERIES

Power generation application

NEF 45

GE NEF 45M

GE NEF 60M

GE NEF 75M

GE NEF 85M

GE NEF 100M

GS NEF 45M

GS NEF 60M

GS NEF 75M

GS NEF 85M

GS NEF 100M

NEF 60

GE NEF 200E

GS NEF 200E

NEF 67

GE NEF 125M

GE NEF 130M

GE NEF 160M

GS NEF 125M

GS NEF 130M

GS NEF 160M

Technical and Repair manual

Page 2

This publication describes the characteristics, data and correct

methods for repair operations on each component of the vehicle.

If the instructions provided are followed and the specified

equipment is used, correct repair operations in the programmed time will be ensured, safeguarding against possible

accidents.

Before starting to perform whatever type of repair, ensure that

all accident prevention equipment is available and efficient.

All protections specified by safety regulations, i.e.: goggles,

helmet, gloves, boot, etc. must be checked and worn.

All machining, lifting and conveying equipment should be i nspected before use.

The data contained in this publication was correct at the time

of going to press but due to possible modifications made by

the Manufacturer for reasons of a technical or commercial nature or for adaptation to the legal requirements of the different countries, some changes may have occurred.

No part of this publication, including the pictures, may be reproduced in any form or by any means.

Publication edited by

Iveco Motors

Iveco SpA

PowerTrain

Mkt. Advertising & Promotion

Viale dell’Industria, 15/17

20010 Pregnana Milanese

Milano (Italy)

nd

Print P4D32N001 E -2

Ed. 04.2007

Produced by:

B.U. TECHNICAL PUBLISHING

Iveco Technical Publications

Lungo Stura Lazio, 15/19

10156 Turin - Italy

Page 3

RYR

NEF POWER GENERATION ENGINES

3

PRELIMINA

Manuals for repairs are split into Parts and Sections, each one of which is marked by a numeral; the contents of these sections are

indicated in the general table of contents.

The sections dealing with things mechanic introduce the specifications, tightening torque values, tool lists, assembly

detaching/reattaching operations, bench overhauling operations, diagnosis procedures and maintenance schedules.

The sections (or parts) of the electric/electronic system include the descriptions of the electric network and the assembly’s

electronic systems, wiring diagrams, electric features of components, component coding and the diagnosis procedures for the

control units peculiar to the electric system.

The manual uses proper symbols in its descriptions; the purpose of these symbols is to classify contained information. In particular,

there have been defined a set of symbols to classify warnings and a set for assistance operations.

EMARKS

SYMBOLS - WARNINGS

Danger for persons

Missing or incomplete observance of these prescriptions can cause serious danger for persons’ safety.

Danger of serious damage for the assembly

Failure to comply, both fully or in part, with such prescriptions will involve serious damage to the assembly and may

sometimes cause the warranty to become null and void.

!

NOTE

General danger

It includes the dangers of above described signals.

Environment protection

Moreover, it describes the correct actions to be taken to ensure that the assembly is used in such a way so as to protect

the environment as much as possible.

It indicates an additional explanation for a piece of information.

Print P4D32N001 E Base - April 2007

Page 4

4

GENERAL WARNINGS

Warnings shown cannot be representativeof all dangersituations possiblyoccurring. Therefore, it issuggested to contact

immediate superiors where a danger situation occurs which is not described.

!

Use both specific and general-purpose toolings according to the prescriptions contained in respective use and

maintenance handbooks. Check use state and suitability of tools not subjected to regular check.

The manual handling of loads must be assessed in advance because it also depends, besides weight, on its size and on

the path.

Handling by mechanical means must be with hoisters proper as for weight as well as for shape and volume. Hoisters,

ropes and hooks used must contain clear indications on maximum carrying capacity acceptable. The use of said means

is compulsorily permitted to authorised personnel only. Stay duly clear of the load, and, anyhow, never under it.

In disassembling operations, always observe provided prescriptions; prevent mechanical parts being taken out from

accidentally striking workshop personnel.

Workshop jobs performed in pairs must always be performed in maximum safety; avoid operations which could be

dangerous for the co-operator because of lack of visibility or of his/her not correct position.

Keep personnel not authorised to operations clear of working area.

You shall get familiar with the operating and safety instructions for the assembly prior to operating on the latter. Strictly

follow all the safety indications found on the assembly.

NEF POWER GENERATION ENGINES

Do not leave the running assembly unattended when making repairs.

When carrying out work on the assembly lifted off the ground, verify that the assembly is firmly placed on its supporting

stands, and that the manual/automatic safety devices have been actuated in the event that the assembly is to be lifted

by means of a hoist.

When you have to operate on assemblies powered by natural gas, follow the instructions contained in the document,

as well as all the specific safety standards provided for.

Only remove radiator cap when the engine is cold by cautiously unscrewing it in order to let system residual pressure

out.

Inflammable fuel and all inflammable fluids and liquids must be handled with care, according to what contained on harmful

materials 12-point cards. Refuelling must be performed outdoors with the engine off, avoiding lit cigarettes, free flames

or sparks in order to prevent sudden fires/bursts. Adequately store inflammable, corrosive and polluting fluids and liquids

according to what provided by regulations in force. Compulsorily avoid to use food containers to store harmful liquids.

Avoid to drill or bore pressurised containers, and throw cloths impregnated with inflammable substances into suitable

containers.

Worn out, damaged or consumable parts must be replaced by IVECO Motors original spares.

During workshopactivity, always keep the work place clean; timely clear or clean floors from accidental liquid or oil spots.

Electric sockets and electric equipment necessary to perform repair interventions must meet safety rules.

Base - April 2007 Print P4D32N001 E

Page 5

NEF POWER GENERATION ENGINES

GENERALWARNINGS

Put on, where required by the intervention, garments and protections provided in accident prevention rules; contact

with moving parts can cause serious injuries. Use suitable, preferably tight-fitted garments, and avoid to use jewels,

scarves, etc.

Do not leave the engine in motion at workshop locations not provided with a pipe to scavenge exhaust gas outside.

Avoid to breathe fumes coming from heating or from paint welding because they can cause damages to health; operate

outdoors or in suitably ventilated areas. Put on proper inspirator if paint powder is present.

Avoid contact with hot water or steam coming from the engine, radiator and pipings because they could cause serious

burns. Avoid direct contact with liquids and fluids present in vehicle systems; where an accidental contact has occurred,

refer to 12-point cards for provisions to make.

Clean the assemblies and carefully verify that they are intact prior to overhauling. Tidy up detached or disassembled

parts with their securing elements (screws, nuts, etc.) into special containers.

Check for the integrity of the parts which prevent screws from being unscrewed: broken washers, dowels, clips, etc.

Self-locking nuts with an insert made of nylon must always be replaced.

5

Avoid contact of rubber parts with diesel oil, petrol or other not compatible substances.

Before washing under pressure mechanical parts, protect electric connectors, and central units, if present.

Tightening screws and nuts must always be according to prescriptions; IVECO Motors commercial and assistance

network is available to give all clarifications necessary to perform repair interventions not provided in this document.

Before welding:

- Disconnect all electronic central units, take power cable off battery positive terminal (connect it to chassis bonding)

and detach connectors.

- Remove paint by using proper solvents or paint removers and clean relevant surfices with soap and water.

- Await about 15 minutes before welding.

- Equip with suitable fire resistant protections to protect hoses or other components where fluids or other materials

flow which may catch fire easily on welding.

Should the vehicle be subjected to temperatures exceeding 80°C (dryer ovens), disassemble drive electronic central

units.

The disposal of all liquids and fluids must be performed with full observance of specific rules in force.

Print P4D32N001 E Base - April 2007

Page 6

6

GENERALWARNINGS ON THE ELECTRIC SYSTEM

If an intervention has to be made on the electric/electronic system, disconnect batteries from the system; in this case,

!

always disconnect, as a first one, the chassis bonding cable from batteries negative terminal.

Before connecting the batteries to the system, make sure that the system is wel l isolated.

Disconnect the external recharging apparatus from the public utility network before taking apparatus pins off battery

terminals.

Do not cause sparks to be generated in checking if the circuit is energised.

Do not use a test lamp in checking circuit continuity, but only use proper control apparatuses.

Make sure that the electronic devices wiring harnesses (length, lead type, location, strapping, connection to screening

braiding, bonding, etc.) comply with IVECO Motors system and are carefully recovered after repair or maintenance

interventions.

Measurements in drive electronic central units, plugged connections and electric connections to components can only

be made on proper testing lines with special plugs and plug bushes. Never use improper means like wires, screwdrivers,

clips and the like in order to avoid the danger of causing a short circuit, as well as of damaging plugged connections, which

would later cause contact problems.

NEF POWER GENERATION ENGINES

To start up the engine, do not use fast chargers. Start up must only be performed with either separate batteries or special

truck.

A wrong polarisation of supply voltage in drive electronic central units (for instance, a wrong polarisation of batteries)

can cause them to be destroyed.

Disconnect the batteries from the system during their recharging with an external apparatus.

On connecting, only screw up connector (temperature sensors, pressure sensors etc.) nuts at prescribed tightening

torque.

Before disconnecting the junction connector from an electronic central unit, isolate the system.

Do not directly supply electronic central units servo components at nominal vehicle voltage.

Cables must be arranged such as to result to be parallel to reference plane, i.e. as close as possible to chassis/body

structure.

Once the intervention on the electric system has been completed, recover connectors and wiring harnesses according

to original arrangement.

NOTE

Connectors presentmust be seen from cable side. Connectors views contained in the manualare representative of cable

side.

Base - April 2007 Print P4D32N001 E

Page 7

NEF POWER GENERATION ENGINES

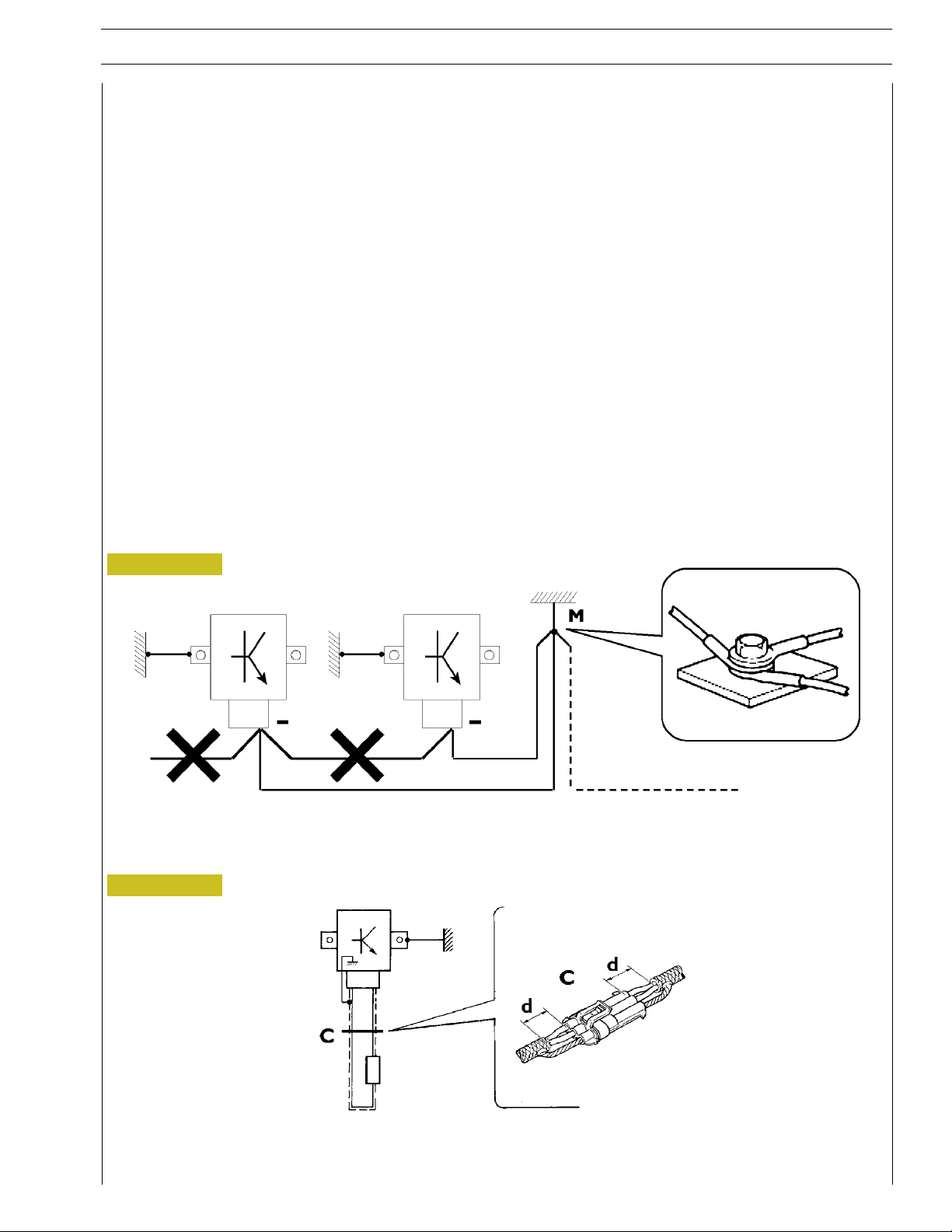

Bonding and screening

Negative leads connected to a system bonded point must be both as short and possible and “star“-connected to each other, trying

then to have their centering tidily and properly made (Figure 1, re. M).

Further, following warnings are to be compulsorily observed for electronic components:

- Electronic central units must be connected to system bonding when they are provided with a metallic shell.

- Electronic central units negative cables must be c onnected both to a system bonding point such as the dashboard opening

bonding (avoiding “serial“ or “chain“ connections), and to battery negative terminal.

- Analog bonding (sensors), although not connected to battery negative system/terminal bonding, must have optimal isolation.

Consequently, particularly considered must be parasitic resistances in lugs: oxidising, clinching defects, etc.

- Screened circuits braiding must only electrically contact the end towards the central unit entered by the signal (Figure 2).

- If junction connectors are present, unscreened section d, near them, must be as short as possible (Figure 2).

- Cables must be arranged such as to result to be parallel to reference plane, i.e. as close as possible to chassis/body structure.

7

Figure 1

1. NEGATIVE CABLES “STAR“ CONNECTION TO SYSTEM BONDING M

Figure 2

88039

2. SCREENING THROUGH METALLIC BRAIDING OF A CABLE TO AN ELECTRONIC COMPONENT — C. CONNECTOR

d. DISTANCE ! 0

Print P4D32N001 E Base - April 2007

Page 8

8

NEF POWER GENERATION ENGINES

OPTIONAL ELECTRICAL AND MECHANICAL PARTS INSTALLATIONS

Assemblies shall be modified and equipped with additions - and their accessories shall be fitted - in accordance with the assembling

directives issued by IVECO Motors.

It is reminded that, especially about the electric system, several electric sockets are provided for as series (or optional) sockets in

order to simplify and normalise the electrical intervention that is care of preparation personnel.

It is absolutely forbidden to make modifications or connections to electric central units wiring harnesses; in particular,

the data interconnection line between central units (CAN line) is to be considered inviolable.

CONVERSIONS BETWEEN THE MAIN UNITS OF MEASUREMENT OF THE INTERNATIONAL SYSTEM AND MOST USED DERIVED QUANTITIES

Power

1 kW = 1.36 metric HP

1 kW = 1.34 HP

1 metric HP = 0.736 kW

1 metric HP = 0.986 HP

1 HP = 0.746 kW

1 HP = 1.014 metric HP

Torque

1 Nm = 0.1019 kgm

1 kgm = 9.81 Nm

Revolutions per time unit

1 rad/s = 1 rpm x 0.1046

1 rpm = 1 rad/s x 9.5602

Pressure

1 bar = 1.02 kg/cm

1 kg/cm

1bar = 10

2

= 0.981 bar

5

2

Pa

Where accuracy is not particularly needed:

- Nm unit is for the sake of simplicity converted into kgm according to ratio 10:1

1 kgm = 10 Nm;

2

- bar unit is for the sake of simplicity converted into kg/cm

2

1 kg/cm

=1bar.

according to ratio 1:1

Temperature

0° C=32° F

1° C = (1 x 1.8 + 32) ° F

Base - April 2007 Print P4D32N001 E

Page 9

NEF POWER GENERATION ENGINES 1

NEF POWER GENERATION ENGINES

F4GE NEF engines Part 1

F4AE NEF engines Part 2

Main electrical power and Troubleshooting Part 3

Print P4D32N001 E Base - April 2007

Page 10

2

NEF POWER GENERATION ENGINES

Base - April 2007 Print P4D32N001 E

Page 11

F4GE NEF ENGINES

1

Part 1

F4GE NEF ENGINES

Section

General specifications

Fuel 2

Power Generation application 3

Overhaul and technical specifications 4

Tools 5

Safety prescriptions Appendix

1

PREFACE TO USER’S GUIDELINE MANUAL

Section 1 describes the NEF engine illustrating its features

and working in general.

Section 2 describes the type of fuel feed.

Section 3 relatesto the specific duty and is divided in four separate parts:

1. Mechanical part, related to the engine overhaul,

limited to those components with different characteristics

based on the relating specific duty.

2. Electrical part, concerning wiring harness, electrical

and electronic equipment with different characteristics

based on the relating specific duty.

3. Maintenance planning and specific overhaul.

4. Troubleshooting part dedicated to the operators who,

being entitled to provide technical assistance, shall have simple

and directinstructions to identify the cause of the major inconveniences.

Sections 4 and 5 illustrate the overhaul operations of the engine overhaul on stand and the necessary equipment to execute

such operations.

Print P4D32N001 E Base - April 2007

Page 12

2

F4GE NEF ENGINES

F4GE NEF ENGINES

Base - April 2007 Print P4D32N001 E

Page 13

F4GE NEF ENGINES

3

SPECIAL REMARKS

Diagrams and symbols have been widely used to give a clearer and more immediate illustration of the subject being dealt with, (see

next page) instead of giving descriptions of some operations or procedures.

Example

∅

Ø 1 = housing for connecting rod small end bush

1

Ø 2 = housing for connecting rod bearings

∅

2

Tighten to torque

Tighten to torque + angular value

α

Print P4D32N001 E Base - April 2007

Page 14

4

F4GE NEF ENGINES

SYMBOLS - ASSISTANCE OPERATIONS

F4GE NEF ENGINES

Removal

Disconnection

Refitting

Connection

Removal

Disassembly

Fitting in place

Assembly

ρ

Tighten to torque

Tighten to torque + angle value Rolling torque

α

Press or caulk Rotation

Regulation

Adjustment

Visual inspection

Fitting position check

Intake

Exhaust

Operation

Compression ratio

Tolerance

Weight difference

Angle

Angular value

Preload

Measurement

Value to find

Number of revolutions

Check

Equipment Temperature

Surface for machining

Machine finish

Interference

Strained assembly

Thickness

Clearance

Lubrication

Damp

Grease

Sealant

Adhesive

bar

Pressure

Oversized

Higher than….

Maximum, peak

Undersized

Less than….

Minimum

Selection

Classes

Oversizing

Temperature < 0 °C

Cold

Winter

Temperature > 0 °C

Air bleeding

Hot

Summer

Replacement

Original spare parts

Base - April 2007 Print P4D32N001 E

Page 15

F4GE NEF ENGINES

UPDATING

Section Description Page Date of revision

5

Print P4D32N001 E Base - April 2007

Page 16

6

F4GE NEF ENGINES

F4GE NEF ENGINES

Base - April 2007 Print P4D32N001 E

Page 17

F4GE NEF ENGINES

SECTION 1 - GENERAL SPECIFICATIONS 1

SECTION 1

General specifications

Page

ELECTRICAL SPECIFICATIONS

OF THE GENERATING SETS 3............

CORRESPONDENCE BETWEEN TECHNICAL

CODE AND COMMERCIAL CODE 4.......

LUBRICATION 5..........................

OIL VAPOUR RECIRCULATING SYSTEM 6.....

COOLING SYSTEM 7......................

AIR INDUCTION BOOST DIAGRAM 8........

- Description 8...........................

Print P4D32N001 E Base - April 2007

Page 18

2

SECTION 1 - GENERAL SPECIFICATIONS

F4GE NEF ENGINES

Base - April 2007 Print P4D32N001 E

Page 19

F4GE NEF ENGINES

ggR

ating

GENEF45MNEF45AM

1

GENEF60MNEF45SM

1

GENEF75MNEF45SM

2

GENEF85MNEF45TM

1

GENEF100MNEF45TM2

GENEF125MNEF67SM1

GENEF130MNEF67TM2

GENEF160MNEF67TM3

GSNEF45MNEF45AM

1

GSNEF60MNEF45SM

1

GSNEF75MNEF45SM

2

GSNEF85MNEF45TM

1

GSNEF100MNEF45TM2

GSNEF125MNEF67SM1

GSNEF130MNEF67TM2

GSNEF160MNEF67TM3

ELECTRICAL SPECIFICATIONS OF THE GENERATING SETS

Electrical specifications

Generating set Assembled Engine

s

Prime 45 36 50 40

Stand By 50 40 55 44

Prime 60 48 66 53

Stand By 66 53 73 58

Prime 75 60 75 60

Stand By 82 66 82 66

Prime 85 68 100 80

Stand By 94 75 110 88

Prime 100 80 110 88

Stand By 110 88 121 97

Prime 125 100 145 116

Stand By 138 110 160 128

Prime 130 104 145 116

Stand By 143 114 160 128

Prime 160 128 170 136

Stand By 176 141 187 150

Prime 45 36 50 40

Stand By 50 40 55 44

Prime 60 48 66 53

Stand By 66 53 73 58

Prime 75 60 75 60

Stand By 82 66 82 66

Prime 85 68 100 80

Stand By 94 75 110 88

Prime 100 80 110 88

Stand By 110 88 121 97

Prime 125 100 145 116

Stand By 138 110 160 128

Prime 130 104 145 116

Stand By 143 114 160 128

Prime 160 128 170 136

Stand By 176 141 187 150

50 Hz 60 Hz

kVA kW (*) kVA kW (*)

SECTION 1 - GENERAL SPECIFICATIONS 3

(*) Power factor 0.8.

Prime Power

The Prime Power is the maximum power available with varying loads for an unlimited number of hours. The average power output

during a 24 h period of operationmust not exceed 80% of the declared prime power between the prescribed maintenance intervals

and at standard environmental conditions. A 10% overload is permissible for 1 hour every 12 hours of operation.

Stand-by Power

This is the maximumpower available for a period of 500 hours/year with a mean loadfactor of 90% of the declared stand-by power.

No kind of overload is permissible for this use.

Print P4D32N001 E Base - April 2007

Page 20

4

SECTION 1 - GENERAL SPECIFICATIONS

CORRESPONDENCE BETWEEN TECHNICAL CODE AND COMMERCIAL CODE

Technical Code Commercial Code

F4GE0405A*F600 GE NEF 45M

F4GE0405B*F600 GE NEF 45M

F4GE0455A*F600 GE NEF 75M

F4GE0455B*F600 GE NEF 75M

F4GE0455C*F600 GE NEF 60M

F4GE0485C*F600 GE NEF 85M

F4GE0485A*F600 GE NEF 100M

F4GE0655B*B600 GE NEF 125M

F4GE0685D*F601 GE NEF 130M

F4GE0685B*F601 GE NEF 160M

F4GE NEF ENGINES

Technical Code Commercial Code

F4GE0405A*F600 GS NEF 45M

F4GE0405B*F600 GS NEF 45M

F4GE0455A*F600 GS NEF 75M

F4GE0455B*F600 GS NEF 75M

F4GE0455C*F600 GS NEF 60M

F4GE0485C*F600 GS NEF 85M

F4GE0485A*F600 GS NEF 100M

F4GE0655B*B600 GS NEF 125M

F4GE0685D*F601 GS NEF 130M

F4GE0685B*F601 GS NEF 160M

Base - April 2007 Print P4D32N001 E

Page 21

F4GE NEF ENGINES

SECTION 1 - GENERAL SPECIFICATIONS

5

LUBRICATION

Lubrication by forced circulation is achieved through oil

rotary expansion pump, placed in the front part of the

basement, driven by the straight-tooth gear splined to the

shaft’s bar hold.

From the pan, the lubrication oil flows to the driving shaft, to

the camshaft and to the valve drive.

Figure 1

Lubrication involves the heat exchanger (2,3), the

turboblower for turbocompressed versions, and for an y

compressed air system.

All these components may often vary according to the

specific duty.

Lubrication delivery oil

106533

Oil returning to sump

LUBRICATION SYSTEM LAYOUT (6 cyl. engines)

Print P4D32N001 E Base - April 2007

Page 22

6

SECTION 1 - GENERAL SPECIFICATIONS

OIL VAPOUR RECIRCULATING SYSTEM

Figure 2

F4GE NEF ENGINES

1

2

3

3240t

1. Valve - 2. Breather pipe - 3. Tappet Cap.

On the tappet cap (3) there is a valve (1) whose duty is to condense oil vapour inducing these to fall down because of gravity,

to the Tappet cap underneath.

The remaining non-condensed vapours shall be properly conveyed through the breather pipe (2), by suction as an example (connection towards these vapours shall be designed by the Engineer).

Base - April 2007 Print P4D32N001 E

Page 23

r

t

F4GE NEF ENGINES

SECTION 1 - GENERAL SPECIFICATIONS

7

COOLING SYSTEM

The engine cooling system, closed circuit forced circulation

type, generally incorporates the following components:

- expansion tank; placement, shape and dimensions are

subject to change according to the engine’s equipment;

- radiator, which has the duty to dissipate the heat

subtracted to the engine by the cooling liquid. Also th is

component will have specific peculiarities based on the

equipment developed, both for what concerns the

placement and the dimensions;

- visc pusher fan, having the duty to increase the heat

dissipating power of the radiator. This component as

well will be specifically equipped based on the engine’s

development;

Figure 3

- heatexchange

o coolthe lubrication oil: eventhis

component is part of the engine’s specific equipment;

- centrifugal water pump, placed in the front part of the

engine block;

- thermostat regulating the circulation of the cooling

liquid;

- the circuit may eventu ally be extended to the

compressor, if this is included in the equipment.

117585

COOLING SYSTEM LAYOUT (6 cyl. engines)

Print P4D32N001 E Base - April 2007

Page 24

8

SECTION 1 - GENERAL SPECIFICATIONS

AIRINDUCTION BOOST DIAGRAM

Figure 4

F4GE NEF ENGINES

AIR FILTER

AIR FILTER

RADIATOR

4 cylinders version

TURBOCHARGER

EXHAUST

74195

TURBOCHARGER

EXHAUST

RADIATOR

6 cylinders version

Description

The turbocharger is composed by the following main parts:

one turbine, one transforming valve to regulate the boost

feeding pressure , one main body and one compressor.

During engine working process, the exhaust emission flow

through the body of the turbine, provoking the turbine disk

wheel’s rotation.

The compressor rotor, being connected by shaft to the

turbine disk wheel, rotates as long as this last one rotates,

compressing the sucked air through the air filter.

The above mentioned air is then cooled by the radiator and

flown through the piston induction collector.

74195

The turbocharger is equipped with a transforming valve to

regulate the pressure , that is located on the exhaust

collector before the turbine and connected by piping to the

induction c ollec t or.

It’s duty is to choke the exhaust of the emissions , releasing

part of them directly to the exhaust tube when the boost

feeding pressure, over the compressor, reaches the

prescribed bar value.

The cooling process an d the lubrication of the turbocharger

and of the bearings is made by the oil of the engine.

Base - April 2007 Print P4D32N001 E

Page 25

F4GE NEF ENGINES

SECTION 2 - FUEL 1

SECTION 2

Fuel

Page

INJECTION FEED SYSTEM BY MECHANICAL

ROTARY PUMP 3.......................

- General information 3.....................

- Description of working principles 3...........

FEED PUMP 4............................

- STANADYNE DB4 pump 4................

- Description of operation 4.................

PRIMING PUMP 5.........................

FUEL FILTER 6............................

Print P4D32N001 E Base - April 2007

Page 26

2

SECTION 2 - FUEL

F4GE NEF ENGINES

Base - April 2007 Print P4D32N001 E

Page 27

F4GE NEF ENGINES

INJECTION FEED SYSTEM BY MECHANICAL ROTARY PUMP

General information

Fuel feed system is composed by:

- Fuel tank

- Fuel delivery and back-flow to tank

- Fuel pre-filter

- Priming pump, assembled to the engine and driven by the camshaft

- Fuel filter

- Fuel feed rotary pump

- Injector feed pipeline

- Injectors

SECTION 2 - FUEL

3

Figure 1

(6-cylinder version)

106534

Description of working principles

Fuel is sucked from the fuel tank by the priming pump. This

last one is placed on the engine basement and is driven by

the camshaft.

Throughout the filter, the fuel is piped to the union fitting

vacuum chamber of the tran sfer pump.

Transfer pump is placed inside the feed pump, and is bladed

The fuel arrives therefore to the valve gauging the pressure

inside feed pump.

The distribution plunger further increases this pressure and

delivers fuel throughout the delivery pipe fitting to the

injectors.

The fuel drawing from the injectors is recovered and

delivered to the tank again.

type; its duty is to increase fuel pressure in co rrespondence

with the increase of the number of revolutions.

Print P4D32N001 E Base - April 2007

Page 28

4

SECTION 2 - FUEL

FEED PUMP

The rotary type pump is driven by a gear mating the camshaft’s one.

STANADYNE DB4 pump

Figure 2

F4GE NEF ENGINES

1. Camshaft - 2. Distributor rotor - 3. Transfer pump vanes - 4. Pump element pistons (4) -

5. Cam - 6. Hydraulic head - 7. Pressure regulator unit - 8. Regulator - 9. Automatic advance - 10. Casing -

11. Metering valve- 12. Delivery valve - 13. Electrical power cut-off solenoid.

Description of operation

The main rotating components are propeller shaft (1),

distributor rotor (2), transfer pump vanes (3) and regulato r

(8). With reference to the Figure 2, the propeller shaft

engages the distributor rotor inside the hydraulic head.

The four pistons are driven simultaneously, one towards the

other, by a cam by means of rollers and pads positioned on

the peripheral part of the rotor. There is one cam lobe for

each engine cylinder.

The transfer pump, positioned on the rear part of the rotor,

is sealed inside by the end cap. This also contains the filter

mesh and the transfer pump pressure regulator.

106514

The upper part of the regulat or unit is pressed against the

distributor rotor and acts as a seal for the transfer pump.

The distributor rotor incorporates two fuel inputs, an axial

hole and an exhaust that serves all the outputs to the

injection ports.

The hydraulic head contains the head in which the rotor

turns, the metering valve seat, the fuel inputs and the

connectors to the injectors. The high pressure injection

pumps, connected to the injectors, are fastened to the above

connectors.

Base - April 2007 Print P4D32N001 E

Page 29

F4GE NEF ENGINES

SECTION 2 - FUEL

PRIMING PUMP

This pump h as the specific duty to prime the fuel available in the tank and convey it to the feed pump inlet. It is assembled to

the engine basement and driven by the camshaft.

Figure 3

1

5

Figure 4

1. Priming pump - 2. Camshaft.

2

3246t

88209

1. Priming pump - 2. Drive lever - 3. Camshaft.

Print P4D32N001 E Base - April 2007

Page 30

6

SECTION 2 - FUEL

F4GE NEF ENGINES

FUEL FILTER

The filter is assembled close to the feed and priming pump an d has the specific duty to provide barrier to the impurities and

separation of water from fuel.

On the filter cartridge base there is a water dump screw, th roughout which it is possible to provide regular drainage; on the

bearing for th ose equipment applications requiring it (cold climate areas), there can be a heater assembled to and a temperature

sensor. On some versions, a water presence sensor is present at filtering cartridge base.

Figure 5

106515

1. Fuel filter bearing- - 2. Filter cartridge - 3. Water dump screw.

Base - April 2007 Print P4D32N001 E

Page 31

F4GE NEF ENGINES

SECTION 3 - POWER GENERATION APPLICATION

SECTION 3

Power Generation application

Page

GENERAL INFORMATION 3................

- Clearance data - 4 cyl. 4...................

- Clearance data - 6 cyl. 7...................

PART ONE - MECHANICAL COMPONENTS 9

REMOVING AND REFITTING

THE SOUND-PROOFING UNIT 11.........

- Removal 11.............................

- Refitting 12..............................

REMOVING AND REFITTING THE ENGINE/

GENERATOR 13.........................

1

- Removal 13.............................

- Refitting 13..............................

SEPARATING THE GENERATOR FROM

THE ENGINE 14.........................

DETACHING THE TANK FROM THE BASE 15..

OVERHAULING THE 6-CYLINDER ENGINE 16..

- Introduction 16..........................

- Operations of preparing the engine for assembly

on the rotary stand 16.....................

- Installation of rear components 25............

- Flywheel installation 28.....................

- Installation of front components 28...........

- Completing the engine 37..................

- Rotary feed pump disassembly and assembly

procedure 39............................

- Disassembly 40...........................

- Rotary feed pump setting check 41...........

- Assembly 41.............................

Print P4D32N001 E Base - April 2007

Page 32

2

SECTION 3 - POWER GENERATION APPLICATION

Page

ASSEMBLY PROCEDURE OF THE ”ADC100” ELEC-

TRONIC ACTIVATOR ON STANADYNE SERIES ”D”

INJECTION PUMPS 43....................

- Assembly of the actuator 44................

PASSAGE FROM 50 HZ TO 60 HZ FOR NEF MOTORS

WITH STANADYNE PUMP 45..............

- Passage from 50 Hz to 60 Hz 45.............

- Passage from 60 Hz to 50 Hz 47.............

- Stabilization of t h e rotation regime 47.........

- Identification tag 47........................

REPLACEMENT OF THE ELECTRO-VALVE AND THE

SOLENOID VALVE THROTTLE ON STANADYNE

PUMPS 48..............................

- Electro-valve replacement 49................

- Replacement of the soleno id valve throttle 51...

- Checks and controls 52....................

F4GE NEF ENGINES

PART FOUR -

MAINTENANCE PLANNING 53...........

MAINTENANCE PLANNING 55..............

- Recovery 55.............................

- Planning of controls and periodical intervention 55

- Checks not included in maintenance

planning-daily checks 56....................

MAINTENANCE PROCEDURES 56............

- Checks and controls 56....................

- Engine oil level check. 56...............

- Check of fuel system 57................

- Cooling system check 57...............

- Lubricating system check 57.............

- Check for any water in the fuel filter 57....

- Check of drive belt tensioning 58.........

- Check of belt’s tear and wear status 58....

- Check and setting of tappet clearance 58...

- Oil motor and filter replacement 59.......

- Changing the coolant 59................

- Fuel filter replacement 60...............

- Alternator belt replacement 60...........

Base - April 2007 Print P4D32N001 E

Page 33

F4GE NEF ENGINES

GENERAL INFORMATION

Figure 1

SECTION 3 - POWER GENERATION APPLICATION 3

ENGINE WITH 6 CYLINDERS

The NEF engines have been specifically designed by Iveco

Motors for the power generation application.

They are internal combustion engines, with a 4-stroke Diesel

cycle, 4 or 6 cylinders and 2 valves per cylinder.

They are fueled by a rotary mechanical pump.

Data, technical specifications and performances

granted shall be valid only if the Setter will follow and

!

comply with all installation prescriptions provided by

Iveco Motors.

Furthermore, the expanders assembled by the Setter

must always comply with couple, power and number

of revolutions based on which the engine has been

designed.

106522

The section herein described is composed or four directories:

- directory of mechanical overhaul prescribed i n

accordance to the engine’s specific duty, illustrating all

necessary operations to remove and assembly the

external components of the engine, including cylinder

heads, gearbox of the timing system and of the front part

cover;

- electrical directory, describing the connections of the

different components, of the pre-post heating gearbox

(only for some versions) and of the sensors assembled to

the engine;

- troubleshooting directory;

- directory of preventive and regular maintenance

operations, providing instructions for the execution of the

main operations.

Print P4D32N001 E Base - April 2007

Page 34

4

SECTION 3 - POWER GENERATION APPLICATION

Clearance data - 4 cyl.

F4GE NEF ENGINES

bar

ρ

Type

Compression ratio 17.5:1

Working power kW

rpm

Working torque Nm

rpm

Loadless engine

idling rpm

Loadless engine

peak rpm rpm

Borexstroke mm

Displacement cm

LUBRICATION

Oil pressure

(warm engine)

3

F4GE0405A*F600 F4GE0405B*F600

50

1500

318

1500

. -

- 104 x 132

4485

Forced by gear pump, relief valve single action

oil filter

52

1800

-

-

15W40 ACEA E3

- idling bar

- peak rpm bar

COOLING

Water pump control

Thermostat

- start of opening ºC

FILLING

engine sump liters

engine sump

+ filter liters

0.70

3.50

By centrifugal pump, regulating thermostat, heat

exchanger, intercooler

Through belt

81 ± 2

-

-

NOTE

Base - April 2007 Print P4D32N001 E

Data, features and performances are valid only if the setter fully complies with all the installation prescriptions provided

by Iveco Motors.

Furthermore, the users assembled by the setter shall always be in conformance to couple, power and number of turns

based on which the engine has been designed.

Page 35

F4GE NEF ENGINES

Clearance data - 4 cyl.

SECTION 3 - POWER GENERATION APPLICATION 5

ρ

Type

Compression ratio 17.5:1

Working power kW

rpm

Working torque Nm

rpm

Loadless engine

idling rpm

Loadless engine

peak rpm rpm

Borexstroke mm

Displacement cm

SUPERCHARGING

Turbocharger type HOLSET HX25 HOLSET HX25W HOLSET HX25

F4GE0455A*F600 F4GE0455B*F600 F4GE0455C*F600

74

1500

471

1500

. - -

- - -

3

Without intercooler

74

1800

393

1800

104 x 132

4485

direct injection

60

1500

382

1500

bar

15W40 ACEA E3

LUBRICATION

Oil pressure

(warm engine)

- idling bar

- peak rpm bar

COOLING

Water pump control

Thermostat

- start of opening ºC

FILLING

engine sump liters

engine sump

+ filter liters

Forced by gear pump, relief valve single action

oil filter

0.70

3.50

By centrifugal pump, regulating thermostat, heat

exchanger, intercooler

Through belt

81 ± 2

-

-

NOTE

Print P4D32N001 E Base - April 2007

Data, features and performances are valid only if the setter fully complies with all the installation prescriptions provided

by Iveco Motors.

Furthermore, the users assembled by the setter shall always be in conformance to couple, power and number of turns

based on which the engine has been designed.

Page 36

6

SECTION 3 - POWER GENERATION APPLICATION

Clearance data - 4 cyl.

F4GE NEF ENGINES

ρ

Type

Compression ratio 17.5:1

Working power kW

rpm

Working torque Nm

rpm

Loadless engine

idling rpm

Loadless engine

peak rpm rpm

Borexstroke mm

Displacement cm

SUPERCHARGING

Turbocharger type HOLSET HX27W

3

F4GE0485A*F600 F4GE0485C*F600

98

1500

471

1500

. -

- 104 x 132

4485

With intercooler

direct injection

87

1500

554

1500

bar

15W40 ACEA E3

LUBRICATION

Oil pressure

(warm engine)

- idling bar

- peak rpm bar

COOLING

Water pump control

Thermostat

- start of opening ºC

FILLING

engine sump liters

engine sump

+ filter liters

Forced by gear pump, relief valve single action

oil filter

0.70

3.50

By centrifugal pump, regulating thermostat, heat

exchanger, intercooler

Through belt

81 ± 2

-

-

NOTE

Base - April 2007 Print P4D32N001 E

Data, features and performances are valid only if the setter fully complies with all the installation prescriptions provided

by Iveco Motors.

Furthermore, the users assembled by the setter shall always be in conformance to couple, power and number of turns

based on which the engine has been designed.

Page 37

F4GE NEF ENGINES

ype

Typ

e

F4GE065

5

Clearance data - 6 cyl.

SECTION 3 - POWER GENERATION APPLICATION 7

bar

ρ

T

Compression ratio 17.5:1

Working power kW

rpm

Working torque Nm

rpm

Loadless engine

idling rpm

Loadless engine

peak rpm

Borexstroke mm

Displacement cm

SUPERCHARGING

Turbocharger type HOLSET HX35W

LUBRICATION

Oil pressure

(warm engine)

3

F4GE0655

B*B600

125

1500

796

1500

- - -

- - -

Without

intercooler

direct injection

Forced by gear pump, relief valve single action

D*F601 B*F601

104 x 132

oil filter

F4GE0685

130

1500

815

1500

6728

With intercooler

direct injection

156

1500

969

1500

NOTE

- idling bar

- peak rpm bar

COOLING

Water pump control

Thermostat

- start of opening ºC

15W40 ACEA E3

Data, features and performances are valid only if the setter fully complies with all the installation prescriptions provided

by Iveco Motors.

Furthermore, the users assembled by the setter shall always be in conformance to couple, power and number of turns

based on which the engine has been designed.

FILLING

engine sump* liters

engine sump + filter* liters

* First filling operation

0.70

3.50

Liquid

Through belt

81 ± 2

15

16

Print P4D32N001 E Base - April 2007

Page 38

8

SECTION 3 - POWER GENERATION APPLICATION

F4GE NEF ENGINES

Base - April 2007 Print P4D32N001 E

Page 39

F4GE NEF ENGINES

SECTION 3 - POWER GENERATION APPLICATION 9

PART ONE - MECHANICAL COMPONENTS

Print P4D32N001 E Base - April 2007

Page 40

10

SECTION 3 - POWER GENERATION APPLICATION

F4GE NEF ENGINES

Base - April 2007 Print P4D32N001 E

Page 41

F4GE NEF ENGINES

SECTION 3 - POWER GENERATION APPLICATION

11

REMOVING AND REFITTING THE SOUND-PROOFING UNIT

Removal

Figure 2

Figure 3

115047

Operate inside the soundproofing unit and move back the

exhaust pipe cover (1) in order to reach the stop collar (2),

then loosen the fastening screw (3).

114332

Operate from the control board side and disconnect the

electric connection (1) from the stop button.

Figure 4

114334

Operate from the exhaust pipes side and loosen the covering

panel (2) fastening nuts (1) and remove it.

Print P4D32N001 E Base - April 2007

Page 42

12

SECTION 3 - POWER GENERATION APPLICATION

F4GE NEF ENGINES

Figure 5

Remove pipe (1) from its seat.

114335

Figure 7

114337

Secure hooks with c h ain catches (1) into the slots (2)

provided for the purpose and, by means of a proper hoisting

device, lift the soundproofing unit (3) and remove it with the

aid of another operator.

NOTE

Figure 6

When removing pipe (1), pay attention not to

damage the coolin g unit air ducts (2).

NOTE

Make su re that the rods have all the same length

in order to lift the soundproofing unit along the

vertical axis, thus reducing interferences.

Refitting

To refit, reverse the removal in structions.

114336

Operate along the perimeter and loosen the soundproofing

unit (2) fastening screws (1).

Base - April 2007 Print P4D32N001 E

Page 43

F4GE NEF ENGINES

REMOVING AND REFITTING THE ENGINE/GENERATOR

Figure 8

SECTION 3 - POWER GENERATION APPLICATION

13

107479

Removal

Disconnect the electrical system by detaching the cables

from the battery.

Disconnect the positive and negative cables from any clamps,

detach them from their attachments on the starter motor,

then remove them.

Remove the fan safety grilles (4) by undoing the relevant

fasteners.

Place a container under the cock (10) to collect the coolant.

Disconnect and remove the pipes (1) and (16) together with

the sleeves by undoing the clamps. Block the radiator suitably

and remove it from its seat after disconnec ting the brackets

(3) from the engine and the nuts (12) from the support (11).

Disconnect the diesel pipes (6) from the engine and fromthe

Disconnect the air hose (19) from the turbocharger of the

turbine and the oil vapour recovery pipe from the cover of

the cylinder head. Remove the air cleaner (18) by undoing

the fasteners (← ) and remove it from its seat together with

the support (17).

Fit a lifting tool onto the specific h ooks on the engine and

keep it under tension.

Remove the fixing nuts from the four supports (5) of the

engine/generator assembly.

Separate the engine/generator assembly from the crankcase.

Refitting

To refit, reverse the removal instructions; restore the coolant

system as described in the procedure on page 49.

tank, taking care to collect any diesel coming down, then

remove them from their seat.

Disconnect the electrical c onnection (7) of the diesel level

signal (8) and earth (9).

NOTE

Check the integrity of the rubber-type blocks in

the supports (5) of the pipes and electrical

connections.

Print P4D32N001 E Base - April 2007

Page 44

14

SECTION 3 - POWER GENERATION APPLICATION

SEPARATING THE GENERATOR FROM THE ENGINE

Figure 9

F4GE NEF ENGINES

107480

Remove the fan (1), the brackets of the supports (4) and the

support (3).

Separate the generator from the engine as follows:

- disconnect the wiring (10) from the engine at each of its

points of connection with the parts of the engine: starter

- removethe safety grilles (5) by u ndoing the fasteners (7),

unscrew all the nuts (6) connecting the generator (8) to

thehousingoftheengineflywheel;

- block the generator suitably and separate it from the

engine.

motor, alternator, various sensors, etc. Then fasten it

appropriately to the control panel (9) so as not to hinder

operations when separating the two assemblies;

Base - April 2007 Print P4D32N001 E

Page 45

F4GE NEF ENGINES

DETACHING THE TANK FROM THE BASE

Figure 10

SECTION 3 - POWER GENERATION APPLICATION

15

107477

The tank is blocked inside the base (1) with angular brackets

(3).

To remove the tank (2) from its seat, remove the brackets

(3) by undoing the relevant fasteners.

NOTE

At the time of assembly, check that the adhesive

rubber blocks (4) are sound and positioned by the

brackets (3).

At the time of assembly, check that the adhesive rubber

blocks (4) are sound and positioned by the brackets (3).

Print P4D32N001 E Base - April 2007

Page 46

16

SECTION 3 - POWER GENERATION APPLICATION

F4GE NEF ENGINES

OVERHAULING THE 6-CYLINDER ENGINE

Introduction

The following description concerns the operations of overhauling the engine restricted to the components that differentiate

it acco rding to its specific use.

NOTE

Due to requirements dictated by the application, some assemblies may be located on the engine in different positions.

The “General Overhaul” section contains all the operations of overhauling t h e engine block and this sect ion is therefore to be

considered as following this topic.

NOTE

The operations of removing the engine, as those for overhauling, must be performed by skilled personnel with specific

tools.

Operations of preparing the engine for assembly on the rotary stand

Figure 11

108987

- Remove the intake manifold (1) and the sleeve (6).

- Remove the fuel hoses (2).

- Place a container under the diesel filter and unscrew the

condensation bleed cock located under the filter; drain

- Remove the fuel filter mounting (4) from the bracket

secured to the cylinder head.

- Remove the priming pump (5).

- Disconnect the pipes (3) from the injection pump.

off all the diesel it contains.

- Fully unscrew the cock and, using tool 99360076,

remove the diesel filter (4).

Base - April 2007 Print P4D32N001 E

NOTE

Removing the injection pump requires a specific

procedure described in this section.

Page 47

F4GE NEF ENGINES

Figure 12

SECTION 3 - POWER GENERATION APPLICATION

17

- Disconnect the pipe (1) delivering oil to the turbine (3).

- Disconnect the pipe (4) returning oil to the turbine (3).

- Remove the turbine (3).

- Remove the oil filter (6) with tool 99360076.

- Remove the starter motor (5).

- Remove the exhau st manifold (2).

NOTE

Warning: the oil filter contain s inside aprx. 1 kg. of

engine oil.

Provide tank with sufficient capacity to contain the

liquid.

Warning: avoid contact of engine oil with the skin:

in case of skin contamination rinse in running

water.

Engine oil is highly pollutant: provide for disposal

in compliance with the law and regulations in force.

Figure 13

NOTE

108988

70126

To disconnect fuel pipelines (2, Figure 11), in low

pressure from the relating pipe fittings, it is

Necessary to press the locking fastener (1) as

showninpictureB.

After having disconnected the pipeline, reset the

locking fastener (1) in lock position as shown in.

picture A, to avoid any possible deformation of the

fastener itself.

Print P4D32N001 E Base - April 2007

Page 48

18

SECTION 3 - POWER GENERATION APPLICATION

F4GE NEF ENGINES

Figure 14

76147

- Assemble th e bracket bearing 99361037 using the four

screw threaded ports (1).

Figure 16

88143

- Disconnect the supply pipe unit from the injectors (1).

- Remove fuel exhaust pipe (2) from the injectors by

removing screw (4) and seal (3).

Figure 15

106554

- Assemble the second bracket 99361037 throughout the

screw-threaded ports (1).

- Lift the engine usin g the rocker arm 99360595 and put

it on the turning stand 99322205.

- Remove the oil level rod together with guide pipe;

(loosen the guide pipe disassembling from the block);

properly pipe the screw-threaded port to avoid inlet of

foreign matters.

- Drain the oil through the c ap underneath the plug.

Figure 17

(Demonstration)

76150

- Loosen the screws (1) holding the fixing brackets of such

pipelines; pipe the pipeline ends.

Base - April 2007 Print P4D32N001 E

Page 49

F4GE NEF ENGINES

SECTION 3 - POWER GENERATION APPLICATION

19

Figure 18

(Demonstration)

76149

- Remove tappet caps: loosen the fixing sc rews (1) and lift

the caps (2); remove the gaskets.

NOTE

On the tappet cap there is a blow-by valve for t he

lubrication oil vapours.

All the gaskets shall always be replaced durin g

assembly.

Figure 20

(Demonstration)

76151

- Disassemble suction and exhaust manifolds: loosen the

screws (1) fixing the suction manifold plate to the

cylinder head (some of them have already been

screwed-out sinc e fixing the pipe brackets to the

injectors).

From the exhaust manifold side loosen the (2) fixing

screws; remove the gaskets.

Figure 19

84082

- Remove injectors (2) with tool 99340205 (1) and take

out the cylinder head.

Figure 21

2

1

75683

- Disassemble rocker arm bearings; loosen the two fixing

screws (2) and remove the complete rocker arm bearing;

withdraw tappet rods. Repeat the operation for all the

remaining rocker arm bearings.

- Disassemble water temperature transmitter (1).

Print P4D32N001 E Base - April 2007

Page 50

20

SECTION 3 - POWER GENERATION APPLICATION

F4GE NEF ENGINES

Figure 22

88089

- Loosen screw (1) and relevant nut on belt stretcher

bracket (3).

- Loosen screw (2) in order to slide out POLY-V belt (2).

- Remove belt stretcher bracket (3).

- Remove the coolin g fan.

- Disassemble the control pipe pulleys and the guide

rollers.

Figure 24

1

2

75686

- Properly hold the alternator (1) separating it from its

bearing by loosening the screw (2); remove screw nut

and washer.

Figure 23

117588

- Disassemble thermostat unit; loosen the three fixing

screws (1) and disassemble the thermostat unit (2)

together with the bracket (3); remove the gasket (4) and

the thermostat (5).

- In order to facilitate head overhauling operations at the

test bench keep bracket (3) assembled on it by fixing it

with the thermostat unit screws.

Figure 25

106544

- Loosen the screws (1) and withdraw the alternator

bearing (2).

NOTE

The shape and the dimensions of the support of

the alternator vary according to the use of the

engine. The relevant pictures provide a general

trace of the intervention that is to be carried out.

The procedures described are always applicable.

Base - April 2007 Print P4D32N001 E

Page 51

F4GE NEF ENGINES

SECTION 3 - POWER GENERATION APPLICATION

21

Figure 26

106545

- Loosen the screws (4) and disassemble the oil

pressure/temperature sensor (3) (if fitted).

- Disassemble injection pump (see specific procedure).

Figure 28

2

1

3

4

75692

- Apply the suitable tool (2) on the flywheel covering box

(1) in order to lock flywheel (3) rotation. (use the starting

motor fixing nuts and studs).

- Loosen the flywheel fixing screws (4) to engine drive

shaft.

Figure 27

- Disassemble cylinder head;

loosen the screws (1) and (2) fixing the cylinder head (3);

hook the brackets with metal ropes and, throughout a

hoist withdraw cylinder head from the block.

76152

Figure 29

106546

- Unloose the screws (3) and disassemble the damping

flywheel (2) and the pulley (1).

- The engine flywheel lock tool can facilitate the removal

of damper flywheel (2) installed on pulley (1).

Print P4D32N001 E Base - April 2007

Page 52

22

SECTION 3 - POWER GENERATION APPLICATION

F4GE NEF ENGINES

Figure 30

106547

- Remove the screws (1) and disconnect the water pump

(2).

- Remove the screw (3) and the roller (4).

- Remove the screw (5) and disconnect the engine speed

sensor (6).

Figure 32

00904t

- Using the specially provided tie rod (3) for the tool

99363204 and the lever (4), withdraw the external

holding ring (2) from the front cover (1).

Figure 33

Figure 31

00900t

- Remove the engine drive shaft fixing ring from the front

cover. Use the tool 99340055 (4) to operate on the

front tang (2) of the engine drive shaft. Throughout the

tool guide ports, drill the internal holding ring (1) using

Ø 3,5 mm drill for a 5mm depth. Fix the tool to the ring

tightening the 6 screws specially provided.

Proceed withdrawing the ring (1) tightening the screw

(3).

70149

- Loosen the screws (1) and remove the front cover (2).

NOTE

Take note of the screw (1) assembly position, since

the screws have different length.

Figure 34

75811

- Loosen the screws (1) and remove oil pump (2).

Base - April 2007 Print P4D32N001 E

Page 53

F4GE NEF ENGINES

SECTION 3 - POWER GENERATION APPLICATION

23

Figure 35

1

2

4

3

75691

- Screw out the opposite screws (1) from the ports where

the withdrawal pins shall be introduced (see picture

following).

- Loosen remaining flywheel fixing screws (3) to the

engine drive shaft (4).

- Remove the flywheel block tool (2).

Figure 37

00903t

- Remove the flywheel cover box fixing ring using the tool

99340056 (3) to operate on the back tang (5) of the

engine drive shaft. Throughout t he tool guide ports, drill

the internal holding ring using Ø 3,5 mm drill for a 5mm

depth.

- Fix the tool 99340056 (3) to the ring (1) tightening the

6 screws specially provided (4).

- Proceed with drawing the ring (1) tightening the screw

(2).

- Using the specially provided tie rod (3) for the tool

99363204 and the lever (4), withdraw the external

holding ring of the flywheel cover box.

Figure 36

1

4

Figure 38

2

3

75690

- Screw up two medium length screws in the ports (4) to

slingtheflywheelwithahoist.

- Loosen the screws (2) and remove the flywheel cover

box (1).

70153

Throughout two guide pins (2) previously screwed up

into the engine drive shaft ports (3) control the engine

flywheel withdrawal by means of a hoist.

NOTE

Take note of the screw (1) assembly position, since

the screws have different length.

Print P4D32N001 E Base - April 2007

Page 54

24

SECTION 3 - POWER GENERATION APPLICATION

F4GE NEF ENGINES

Figure 39

88076

- Turntheengineupside-down.

- Loosen the screws (2), disassemble th e plate (3) and

remove the oil pan (1).

NOTE

The shape and dimensions of the pan and of the

rose pipe may vary according to the engine

application. The relating illu strations provide

general guidelines of the operation to be

performed. The procedures described are

applicable anyway.

Figure 41

70156

- Loosen the screws (1) and disassemble the gear from the

camshaft (2).

Figure 40

87261

- Loosen the screws (1) and disassemble the oil suction

rose pipe (3).

- Loosen the screws (2) and remove the stiffening plate

(4).

Figure 42

106540

- Loosen the screws (2) and disassemble the timing

gearbox (1).

NOTE

Take note of the screw (2) assembly position, since

the screws have different length.

Base - April 2007 Print P4D32N001 E

Page 55

F4GE NEF ENGINES

SECTION 3 - POWER GENERATION APPLICATION

25

Installation of rear components

Figure 43

1

75712

DIAGRAM SHOWING SEALING LOCTITE 5205

APPLICATION WITHIN GEARBOX AREAS

- Accurately clean the timing gearbox (1) and the engine

block.

NOTE

It is necessary and essential to clean th e surface to

be sealed in order to achieve excellent tight seal.

Apply sealing LOCTITE 5205 on the box in order

to form a kerbstone of a few mm. Diameter.

It must be uniform (no crumbs), with no air blisters,

thinneror irregularzones.

Any eventual imperfection shall be correct as soon

as possible.

Avoid using material in excess to seal the joint. Too

much sealing material would drop out on both

sides of t he joint and obstruct lubricant passages.

Couplings must be assembled within 10 minu t es

after completing the sealing operation.

Figure 44

1

910

6

8

4

3

2

7

1

5

75711

DIAGRAM SHOWING SCREW

TIGHTENING TO FIX REAR GEARBOX

- Reassemble to box (1) to the engine block.

- Tighten the fixing screws in the same position as found

out during disassembly and fix the sc rews to the locking

couples listed here below, following the order as shown

in the picture.

Screws M12 65 ÷ 89 Nm

Screws M8 20 ÷ 28 Nm

Screws M10 42 ÷ 52 Nm

NOTE

Before assembly, always check that the threads of

the ports and of the screws have no evidence of

tear and wear nor dirt.

Figure 45

70211

- With a pen marker, mark the tooth (1) of the driving gear

assembled to the engine drive shaft with (2) (→) timing

notch.

NOTE

Screw up two pins to facilitate operation of engine

drive shaft rotation.

Print P4D32N001 E Base - April 2007

Page 56

26

SECTION 3 - POWER GENERATION APPLICATION

F4GE NEF ENGINES

Figure 46

106541

- Orient enginedrive shaft (3) and camshaft (4) taking care

that in phase o f assembly of the driving gear (2) to the

camshaft, the notches marked on the gears (1 and 2)

shall match.

Figure 48

106543

- Tighten the screws (1) fixing the gear to the camshaft (3)

and lock them to the prescribed couple.

Figure 47

106542

- Position comparator (1) on timing system gear (2) and

check that the clearance between gears (2) and (3) is

within 0.076 ÷ 0.280 mm range.

Figure 49

1

75708

DIAGRAM SHOWING SEALING LOCTITE 5205

APPLICATION.

Base - April 2007 Print P4D32N001 E

Page 57

F4GE NEF ENGINES

SECTION 3 - POWER GENERATION APPLICATION

27

NOTE

It is necessary and essential to clean th e surface to

Figure 51

be sealed in order to achieve excellent tight seal.

Apply sealing LOCTITE 5205 on the box in order

to form a kerbstone of a few mm. Diameter. It must

be uniform (no crumbs), with no air blisters,

thinneror irregularzones.

Any eventual imperfection shall be correct as soon

as possible.

Avoid using material in excess to seal the joint. Too

much sealing material would drop out on both

sides of t he joint and obstruct lubricant passages.

Couplings must be assembled within 10 minu t es

after completing the sealing operation.

0901t

- Apply to engine drive sh aft rear tang (6), the detail (5)

of the tool 99346252, fix it tightening the screws (4) and

key the new holding ring on it (3).

- Place detail (1) on detail (5), tighten the screw nu t (2)

until complete assembly of the fixing ring (3) into th e

flywheel cover box (7).

Figure 50

1

16

15

14

17

8

7

6

18

19

13

5

12

11

20

2

1

21

4

9

10

3

75709

DIAGRAM SHOWING SCREW

TIGHTENING TO FIX FLYWHEEL COVER BOX.

- Reassemble the box (1) to the engine block, tighten the

fixing screws in the same position as found out during

disassembly and fix the screws to the locking couples

listed here below, following the order as sh own in the

picture.

Screws M12 75 ÷ 95 Nm

Screws M10 44 ÷ 53 Nm

Figure 52

12

75696

- Check the conditions of the rim tooth (2). Whether

tooth break or excessive wear is detected, disassemble

the rim from the engine flywheel using a common willow

and replace with a new one, previously heated to

150º C degrees for 15’ ÷ 20’; seconds; bevelling must

be made towards engine flywheel direction.

NOTE

Tightening to angle is performed using tool

99395216.

Print P4D32N001 E Base - April 2007

Page 58

28

SECTION 3 - POWER GENERATION APPLICATION

F4GE NEF ENGINES

Flywheel installation

Figure 53

1

2

3

- Screw up two hooks or trail rings in the flywheel (1)

threaded ports (4) for handling .

- Usinga hoist, handle the flywheel to place it in its housing

inside the flywheel cover box.

- Screw up to pins (2) having appropriate length, in the

shaft ports (3) and using them as guide, assemble the

engine flywheel (1) properly placing it inside the flywheel

cover box.

4

75690

Figure 55

α

1

2

75695

Tighten the engine flywheel (1) fixing screws (2) in two

phases:

- 1stphase; tightening by means of dynamometric wrench

to couple 30 ± 4 Nm;

- 2nd phase, 60º ± 5º angle dwell.

NOTE

Angle dwell shall always be performed using

99395216 tool.

Before assembly, always check that the threads of

the ports and of the screws have no evidence of

tear and wear nor dirt.

Figure 54

2

1

3

4

75692

- Tighte n the screws (4) fixing the engine flywheel (3) to

the engine shaft. Use tool 99360339 (2) to operate on

the flywheel cover box (1) to block engine flywheel

rotation.

Installation of front components

Figure 56

70220

- Assemble oil pump (1).

- Tighten fixing sc rews (2) and lock them to the prescribed

couple.

Base - April 2007 Print P4D32N001 E

Page 59

F4GE NEF ENGINES

SECTION 3 - POWER GENERATION APPLICATION

29

Figure 57

- Apply to the water pump (1) a new fixing ring (2).

Figure 58

Figure 60

70221

75710

76112

- Assemble the water pump (1).

- Tighten the screws (2) and lock them to the prescribed

couple.

Figure 59

- Accurately clean the contact surface of engine block and

apply sealing LOCTITE 5205 on it in order to form a

uniform and continuous kerbstone with no crumbs.

Figure 61

106550

106549

- Remove the fixing ring (2) from the front cover (1),

- Assemble the front cover (2) to the block and tighten

the screws (1) fixing them to the prescribed couple.

accurately clean the plug surface.

Print P4D32N001 E Base - April 2007

Page 60

30

SECTION 3 - POWER GENERATION APPLICATION

F4GE NEF ENGINES

Figure 62

00902t

- Apply on engine drive shaft front tang (6) the detail (4)

of the tool 99346252, fix it with the screws (5) and key

the new holding ring on it (7).

- Place the detail (2) on the detail (4), screw-up the

threaded nut until carrying out the complete assembly

of the holding ring (7) to the front cover.

Figure 64

88075

- Providefor new gasket replacement (1) of the oil pan (2).

NOTE

The pictures illustrating the pan and of the rose

pipe may not correspond to the ones of your

model.

However the procedures described are applicable

anyway.

Figure 63

88074

- Assembleplate (4),suction rose (3) andtighten the fixing

screws (2 and 1) locking them on the prescribed torque.

Figure 65

88076

- Assemble oil pan (1), apply the plate over it (2). Tighten

the screws (2) and lock them to the prescribed couple.

NOTE

Before assembly, always check that the threads of

the ports and of the screws have no evidence of

tear and wear nor dirt.

Base - April 2007 Print P4D32N001 E

Page 61

F4GE NEF ENGINES

SECTION 3 - POWER GENERATION APPLICATION

31

Figure 66

106546

- Assemble the pulley (1) and the dumping flywheel (2) to

the driving shaft.

- Tighten the fixing screws (3) and clamp them to the

couple 68 ± 7 Nm.

Figure 68

106552

- Lubricate the fixing ring (2) using engine oil and place it

on the oil filter (3).

- Manually start the oil filter (3) on the bearing union (1)

until counter-boring, further screw up the oil filter (3) by

3/4 turn.

- Place a new fixing ring on the block housing (4).

Figure 67

106551

- Assemble the following elements to the block: new

gasket (1), heat exchanger (2), new gasket (3), oil filter

bearing (4).

Tighten the screws (5) and lock them to the prescribed

couple.

NOTE

In some applications, the bearing of the exchanger

shall be assembled to a screw t hreaded union

connected to the filter on the opposite side of the

engine, throughout two pipelines.

Figure 69

106553

- Assemble the alternator bearing (1) ensuring that the

pins (3 and 4) are against the engine block.

- Tighten the screws (2) and lock them to the prescribed

couple.

NOTE

Before assembly, always check that the threads of

NOTE

the ports and of the screws have no evidence of

tear and wear nor dirt.

Print P4D32N001 E Base - April 2007

Before assembly, always check that the threads of

the ports and of the screws have no evidence of

tear and wear nor dirt.

Page 62

32

SECTION 3 - POWER GENERATION APPLICATION

F4GE NEF ENGINES

Figure 70

12

- Connect the alternator (1) to the support.

- Tighten without locking th e screw (2).

75686

Figure 72

- Place the gasket (1) over the block.

The choice of the gasket’s thickness shall be made i n

consideration of the cylinder protrusion measured w ith

respect to the block’s upper surface.

NOTE

Verify that the engin e block stand is clean.

Do not grease the gasket. It is recommended to

keep the gasket inside packaging until assembly to

the cylinder head.

1

88092

Figure 71

88090

To refit the POLY-V belt, perform the steps described in

Figure 22 in reverse order.

NOTE

For belt stretching rotate the alternator as

indicated in the figure, lock screw (1) and screw (2,

Figure 70).

NOTE

In case the same belt priory removed is assembled

again, proceed examining it carefully to check

there

Base - April 2007 Print P4D32N001 E

Page 63

F4GE NEF ENGINES

SECTION 3 - POWER GENERATION APPLICATION

33

Figure 74

76152

- Place the head (3) over the block and insert screws (1)

and (2).

NOTE Before using the fixing screws again, measure them

twice as indicated in the picture, c h eckin g D1 and

D2 diameters:

if D1 - D2 < 0,1 mmthe screw can be utilised again;

if D1-D2>0,1mmthescrewmustbereplaced.

D1D2

Figure 73

4 cylinder engine

10

45

1

11

α

13 14

7

9

2

3

8

6

12

76115

6 cylinder engine

76214

- Lubricate c ylinder head bolts and install to head.

- Bolts must be torqued using stitching pattern starting

with the centre bolts and moving out. Bolts to be

torqued in stages: all bolts torqued to snug torque, then

90 degrees rotation for all bolts. Then a further 90

degrees for the M12 x 140 and M12 x 180.

NOTE

75703

If the valves have been removed from the head, it

is necessary to assemble them before assembling

the head itself on the engine block.

M12 x 70 50 Nm + 90 deg’s

M12 x 140 40 Nm + 180 deg’s

M12 x 180 70 Nm + 180 deg’s

Figure 75

4

1

3

2

2

1

3

75705

ROCKER ARM UNIT COMPONENTS:

1. Elastic ring - 2. Spacer- 3. Rocker arms-

4. Support.

- Carry out the assembly of the rocker arms after previous

check of the components.

Print P4D32N001 E Base - April 2007

Page 64

34

SECTION 3 - POWER GENERATION APPLICATION

F4GE NEF ENGINES

Figure 76

18.975

18.963

19.000

19.026

SHAFT AND ROCKER ARM BASIC DATA

Check the coupling surfacesof bearing and shaft: no evidence

of excessive wear shall be detected or damages.

Replace if necessary.

Figure 77

19.000

19.026

75704

Figure 79

D1D2

75703

Insert the tappet driving rods and the Rocker Arm unit.

Before using the fixin g screws again, measure them twice as

indicated in the picture, checking D1 and D2 diameters:

- if D1 - D2 < 0,1 mm the screw can be utilised again;

- if D1-D2>0,1mmthescrewmustbereplaced.

Figure 80

13.00

11.00

116391

ROCKER ARM ADJUSTMENT SCREW

If the adjuster screw has been removed, check the

adjustment distance.

Tighten the screw-threaded nut (1) to the 4 - 6 Nm couple.

Figure 78

2

1

75683

- Tighten the screws (2) to the prescribed couple and

assemble water temperature sensor (1).

32655

Before executing assembly, check the Rocker Arm driving

rods: these shall not be deformed; the spherical ends in

contact with the Rocker Arm adjustment screw and with the

tappet(arrows) shall not present evidenceof seizure or wear:

in case of detection proceed replacing them.

The rods driving the suction and exhaust valves are identical

and therefore interchangeable.

Base - April 2007 Print P4D32N001 E

Page 65

F4GE NEF ENGINES

SECTION 3 - POWER GENERATION APPLICATION

35

Figure 81

2

75806

Adjust the slack between rocker arms and valves using socket

wrench (1), point wrench (3) and feeler gauge (2).

Correct slack is:

- su ction valves 0.25 0.05 mm

- exhaust valves 0.50 0.05 mm.

NOTE

In order carry out a quicker adjustment of the

working slack between rocker arms and valves,

proceed as following:

6 cylinder engine

Rotate the engine drive shaft, balance the valves of

cylinder 1 and adjust the valves identified by star

symbol, as indicated in the following table:

Cylinder n.

Suction

Exhaust

1

234

-

-

-

*

*

-

*

56

*

*

-

*

Rotate the engine drive shaft, balance the valves of

cylinder 6 and adjust the valves identified by star

symbol, as indicated in the following table:

Figure 82

1

3

1

75707

- Assemble injectors after having replaced the sealing

gasket (1).

NOTE

During assembly of injectors, verify that the

injector sphere is correctly positioned on the head

housing.

Figure 83

(Demonstration)

Cylinder n.

Suction

Exhaust

1

234

** -

*- *

*

-

56

-

-

-

*

4 cylinder engine

Rotate the engine drive shaft, balance the valves of

cylinder 1 and adjust the valves identified by star

76149

symbol, as indicated in the following table:

- Assemble cylinder covers (2) with the respective gaskets;

Cylinder n.

Suction

Exhaust

1

-

-*-

234

-

*

*

*

- Fit the seal nods and tighten the screws (1) fixing them

to the prescribed couple.

Rotate the engine drive shaft, balance the valves of

cylinder 4 and adjust the valves identified by star

symbol, as indicated in the following table:

NOTE

Always replace the gaskets using new ones.

Check the threads of the fixing screws: there shall

Cylinder n.

Suction

1