Page 1

Designjet T9x0, T15x0 ePrinter Series and

T25x0, T3500 eMultifunction Series

Service Manual

Page 2

Edition 3, February 17, 2017

Legal notices

Warranty

© 2016 HP Development Company, L.P.

This document contains proprietary information

that is protected by copyright. All rights are

reserved. No part of this document may be

photocopied, reproduced, or translated to

another language without the prior written

consent of HP Development Company.

The information contained in this document is

subject to change without notice.

HP makes no warranty of any kind with regard

to this material, including, but not limited to, the

implied warranties of merchantability and

tness for a particular purpose.

HP shall not be liable for errors contained herein

or for incidental or consequential damages in

connection with the furnishing, performance, or

use of this material.

Page 3

Safety

The Warning symbol calls attention to a

procedure, practice, or the like, which, if not

correctly performed or adhered to, could result

in personal injury. Do not proceed beyond a

Warning symbol until the indicated conditions

are fully understood and met.

The Caution symbol calls attention to an

operating procedure, practice, or the like, which,

if not correctly performed or adhered to, could

result in damage to or destruction of part or all

of the printer. Do not proceed beyond a Caution

symbol until the indicated conditions are fully

understood and met.

Page 4

Page 5

Table of contents

1 Printer fundamentals ............................................................................................................................................................................... 1

Introduction ............................................................................................................................................................................... 2

Theory of operation ................................................................................................................................................................. 6

2 Troubleshooting ..................................................................................................................................................................................... 34

The front panel ....................................................................................................................................................................... 35

Service keys combination ..................................................................................................................................................... 37

Troubleshooting tree (T920 and T1500 only) ................................................................................................................... 39

Product Troubleshooting trees (T2500 and T3500 only) ............................................................................................... 41

Scanner Troubleshooting Tree ............................................................................................................................................ 42

Scanner CIS Troubleshooting ............................................................................................................................................... 43

Troubleshooting using board LEDs ..................................................................................................................................... 44

Paper handling problems ..................................................................................................................................................... 50

Ink supply problems .............................................................................................................................................................. 70

Print-quality problems .......................................................................................................................................................... 84

Connectivity problems ........................................................................................................................................................ 104

Scanning Problems .............................................................................................................................................................. 109

HP 727 Printhead Troubleshooting .................................................................................................................................. 111

Videos for replacing CSR parts and HP 727 printhead .................................................................................................. 113

Firmware upgrades ............................................................................................................................................................. 114

3 System error codes .............................................................................................................................................................................. 115

Introduction .......................................................................................................................................................................... 116

What to do if the front panel fails to initialize ................................................................................................................. 118

System error codes in brief ................................................................................................................................................ 121

System error codes in full .................................................................................................................................................. 124

Appendix A: How to troubleshoot system error 79:04 and 79.2:04 ........................................................................... 164

Appendix B: Updating rmware in boot mode ................................................................................................................ 176

Appendix C: Obtaining the diagnostics package ............................................................................................................. 177

ENWW v

Page 6

4 Diagnostics, Service Utilities and Calibrations ................................................................................................................................. 179

Introduction .......................................................................................................................................................................... 180

Diagnostic Tests and Utilities ............................................................................................................................................. 181

Service Utilities ..................................................................................................................................................................... 203

Service Calibrations ............................................................................................................................................................. 232

5 Parts and diagrams .............................................................................................................................................................................. 240

Introduction .......................................................................................................................................................................... 240

Printer support ..................................................................................................................................................................... 241

Center and Roll covers ........................................................................................................................................................ 242

Rear covers ........................................................................................................................................................................... 243

Cover Front Panel Side ........................................................................................................................................................ 244

Cover SVS Side ...................................................................................................................................................................... 245

Center Assemblies ............................................................................................................................................................... 246

Front Panel Side Assemblies .............................................................................................................................................. 248

SVS Side Assemblies ........................................................................................................................................................... 249

Scan Axis Assemblies .......................................................................................................................................................... 250

Paper Path Assemblies (Front) .......................................................................................................................................... 251

Paper Path Assemblies (Center) ........................................................................................................................................ 253

Stacker Parts (Rear) ............................................................................................................................................................. 255

Stacker Parts (Front) ........................................................................................................................................................... 256

Carriage Assembly ............................................................................................................................................................... 260

Electrical Parts ..................................................................................................................................................................... 261

Miscellaneous Parts ............................................................................................................................................................. 263

CIS Unit Construction ........................................................................................................................................................... 265

Scanner Control Unit ........................................................................................................................................................... 266

6 Removal and installation .................................................................................................................................................................... 269

Parts list; all models ............................................................................................................................................................ 270

Parts list; HP Designjet T2500 and T3500 eMultifunction Series only ....................................................................... 272

Parts list; HP Designjet T2500 eMultifunction Series only ............................................................................................ 273

Parts list; HP Designjet T3500 eMultifunction Series only ............................................................................................ 274

Introduction .......................................................................................................................................................................... 275

Customer Self Repair parts ................................................................................................................................................ 277

Service Calibration Guide to Removal and Installation .................................................................................................. 278

Main cover (front panel side) .............................................................................................................................................. 281

Main cover (service station side) ....................................................................................................................................... 283

Center cover (T920 only) .................................................................................................................................................... 285

Converger Assembly ........................................................................................................................................................... 287

Cleanout ................................................................................................................................................................................ 288

vi ENWW

Page 7

Output platen ....................................................................................................................................................................... 290

Fixed tray cover (Front Panel side) .................................................................................................................................... 291

Fixed tray cover (service station side) .............................................................................................................................. 292

Arch sidewall cover (front panel side) ............................................................................................................................... 293

Arch sidewall cover (service station side) ........................................................................................................................ 294

Rear cover ............................................................................................................................................................................. 295

Window Sensor .................................................................................................................................................................... 296

HP 727 Printhead installation tips and tricks .................................................................................................................. 298

Ink Service kit ....................................................................................................................................................................... 303

Open the E-Box .................................................................................................................................................................... 304

E-Box fan ............................................................................................................................................................................... 308

Jester PCA ............................................................................................................................................................................. 310

Power supply unit ................................................................................................................................................................ 311

Hard disk drive ..................................................................................................................................................................... 313

Engine PCA ............................................................................................................................................................................ 314

Formatter PCA ...................................................................................................................................................................... 315

Front panel ............................................................................................................................................................................ 318

Carriage ................................................................................................................................................................................. 322

Line Sensor ........................................................................................................................................................................... 326

Carriage PCA ......................................................................................................................................................................... 327

Rail Oiler Kit ........................................................................................................................................................................... 329

PRS Actuator ......................................................................................................................................................................... 330

Belt ......................................................................................................................................................................................... 332

Encoder Strip ........................................................................................................................................................................ 333

Scan Axis Motor .................................................................................................................................................................... 335

Drop Detector ....................................................................................................................................................................... 338

Service Station with Drop Detector ................................................................................................................................... 339

Primer Assembly .................................................................................................................................................................. 343

ISS (Ink Supply Station) Front Panel Side ......................................................................................................................... 346

ISS SVS Side .......................................................................................................................................................................... 350

Ink Tubes and Trailing Cable .............................................................................................................................................. 354

Media Sensor ........................................................................................................................................................................ 357

Bottom Rewinder Support ................................................................................................................................................. 359

Top Rewinder Support ........................................................................................................................................................ 361

Top Tip Support .................................................................................................................................................................... 363

Bottom Tip Support ............................................................................................................................................................. 364

Vertical Media Guide ............................................................................................................................................................ 366

Center Support ..................................................................................................................................................................... 368

Full Bleed ............................................................................................................................................................................... 369

Auto Pinch Lifter ................................................................................................................................................................... 370

Pinch Wheel Assembly ........................................................................................................................................................ 376

ENWW vii

Page 8

Motor Media Advance Transmission with Encoder ......................................................................................................... 379

Starwheel Motor .................................................................................................................................................................. 387

Starwheel Support ............................................................................................................................................................... 392

Second Starwheel Rail ........................................................................................................................................................ 394

Overdrive ............................................................................................................................................................................... 396

Cutter Platten ....................................................................................................................................................................... 398

Sensor Valves ....................................................................................................................................................................... 401

Valves Motor ......................................................................................................................................................................... 404

Stacker ................................................................................................................................................................................... 405

Stacker adaptor for MFP ..................................................................................................................................................... 407

Stacker Pinches .................................................................................................................................................................... 411

Stacker Hand O .................................................................................................................................................................. 412

Stacker Hand O Assy Service Kit (CR357-67041) ........................................................................................................ 413

OPTO Sensor ......................................................................................................................................................................... 417

REDI sensor ........................................................................................................................................................................... 419

OVD Transmission with Motor ........................................................................................................................................... 420

Ramps Motor ........................................................................................................................................................................ 422

Stacker Arm Sensor ............................................................................................................................................................. 424

Bump Cutter Actuator ......................................................................................................................................................... 426

How to release Service Station Caps ................................................................................................................................ 427

How to manually move Valves .......................................................................................................................................... 428

How to manually move Stacker Ramps ........................................................................................................................... 429

Scanner Controller Unit (SUP) ............................................................................................................................................ 430

CIS Tiles ................................................................................................................................................................................. 431

CIS Modules .......................................................................................................................................................................... 432

CIS FFC Cables ...................................................................................................................................................................... 433

CIS Glass ................................................................................................................................................................................ 434

Stepper Motor Assembly (taco sensor, and belt) ........................................................................................................... 435

Stepper Motor Assembly (cable) ....................................................................................................................................... 437

Paper and Lid Sensors ........................................................................................................................................................ 438

Paper and Lid Sensor Cable ............................................................................................................................................... 440

USB & Awake / Power Cable .............................................................................................................................................. 441

CIS Bridge Damper ............................................................................................................................................................... 443

CIS Scanner Latch ................................................................................................................................................................ 445

Pressure Rollers ................................................................................................................................................................... 446

Front panel side scanner cover ......................................................................................................................................... 447

Service station side scanner cover .................................................................................................................................... 448

Rear scanner cover .............................................................................................................................................................. 449

Bumper bracket ................................................................................................................................................................... 450

Deector hinge ..................................................................................................................................................................... 451

Lift assembly ........................................................................................................................................................................ 452

viii ENWW

Page 9

Scanner front beam bumper assembly ........................................................................................................................... 453

Scanner latch hook assembly ............................................................................................................................................ 454

Top scanner cover ................................................................................................................................................................ 455

Batch scanning piece ........................................................................................................................................................... 456

Card Reader Accessory ....................................................................................................................................................... 457

7 Maintenance .......................................................................................................................................................................................... 458

Preventive Maintenance ..................................................................................................................................................... 459

Preventive Maintenance Kits .............................................................................................................................................. 472

8 Customer Self Repair Flyers ............................................................................................................................................................... 473

Starwheel .............................................................................................................................................................................. 474

Cutter ..................................................................................................................................................................................... 476

Stacker arm .......................................................................................................................................................................... 478

Ink covers .............................................................................................................................................................................. 479

Leg, front-panel side ........................................................................................................................................................... 481

Leg, service-station side ..................................................................................................................................................... 484

Bottom roll cover ................................................................................................................................................................. 487

Top roll cover ........................................................................................................................................................................ 489

Carriage latch ....................................................................................................................................................................... 491

Basket .................................................................................................................................................................................... 494

Pinch arm top roll ................................................................................................................................................................ 496

Pinch arm bottom roll ......................................................................................................................................................... 497

Scanner’s glass plate .......................................................................................................................................................... 498

ENWW ix

Page 10

x ENWW

Page 11

1 Printer fundamentals

●

Introduction

●

Theory of operation

ENWW 1

Page 12

Introduction

This service manual contains information necessary to test, maintain, and service the following:

●

HP DesignJet T920 ePrinter

●

HP DesignJet T920 PostScript ePrinter

●

HP DesignJet T930 ePrinter

●

HP DesignJet T930 PostScript ePrinter

●

HP DesignJet T1500 ePrinter

●

HP DesignJet T1500 PostScript ePrinter

●

HP DesignJet T1530 ePrinter

●

HP DesignJet T1530 PostScript ePrinter

●

HP DesignJet T2500 eMultifunction

●

HP DesignJet T2500 PostScript eMultifunction

●

HP DesignJet T2530 eMultifunction

●

HP DesignJet T2530 PostScript eMultifunction

●

HP DesignJet T3500 Production eMultifunction

●

HP DesignJet T3500 Production PostScript eMultifunction

For information about using these printers, see the user's guide.

Features overview

There are 13 versions of the HP DesignJet T9x0-T15x0–T25x0–T3500 series:

●

CR354A HP DesignJet T920 36-in ePrinter

●

CR355A/B HP DesignJet T920 36-in PostScript ePrinter

●

L2Y21A HP DesignJet T930 36-in ePrinter

●

L2Y22A/B HP DesignJet T930 36-in PostScript ePrinter

●

CR356A HP DesignJet T1500 36-in ePrinter

●

CR357A/B HP DesignJet T1500 36-in PostScript

●

L2Y23A HP DesignJet T1530 36-in ePrinter

●

L2Y24A/B HP DesignJet T1530 36-in PostScript

●

CR358A HP DesignJet T2500 eMultifunction

●

CR358A/B HP DesignJet T2500 PostScript eMultifunction

●

L2Y25A HP DesignJet T2530 eMultifunction

2 Chapter 1 Printer fundamentals ENWW

Page 13

●

L2Y26A/B HP DesignJet T2530 PostScript eMultifunction

●

B9E24A/B HP DesignJet T3500 Production eMFP

NOTE: As of August 2013 there are no plans for an upgrade to enable PostScript features from non-PostScript

capabilities.

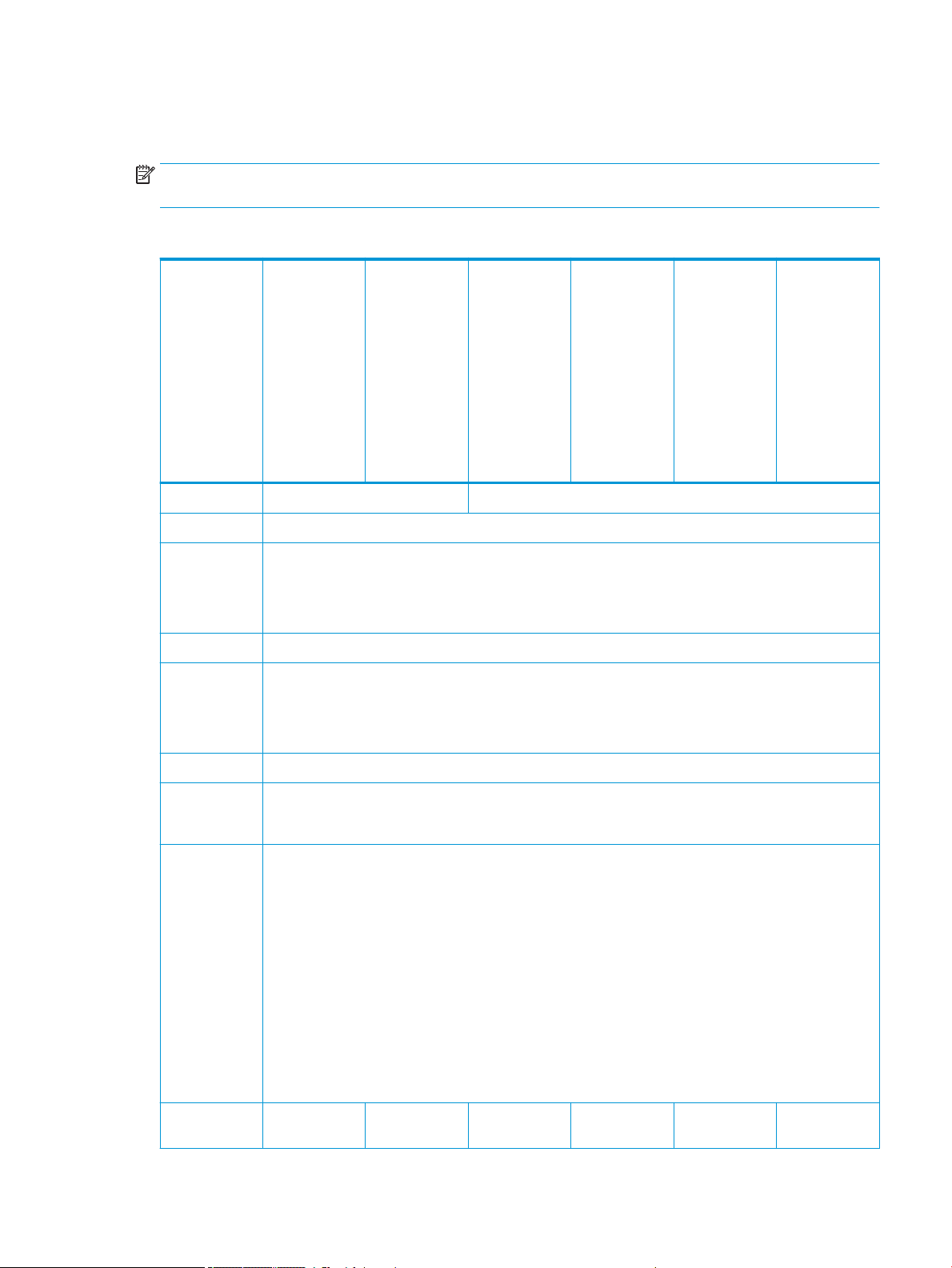

The dierent sku features are:

CR358A HP

DesignJet T2500

eMultifunction,

CR358A/B HP

DesignJet T2500

CR355A/B HP

DesignJet T920

CR354A HP

DesignJet T920

36-in ePrinter

and L2Y21A HP

DesignJet T930

Feature

Paper source One 36-in roll, and single sheets Two 36-in rolls, and single sheets

Paper output Stacker, accepting up to 50 A1 plain-paper sheets, and basket

Connectivity Gigabit Ethernet LAN (1000 base T)

36-in ePrinter

36-in PostScript

ePrinter and

L2Y22A/B HP

DesignJet T930

36-in PostScript

ePrinter

CR356A HP

DesignJet T1500

36-in ePrinter

and L2Y23A HP

DesignJet T1530

36-in ePrinter

CR357A/B HP

DesignJet T1500

36-in PostScript

and L2Y24A/B

HP DesignJet

T1530 36-in

PostScript

PostScript

eMultifunction,

L2Y25A

DesignJet T2530

eMultifunction

and L2Y26A/B

T2530 PostScript

eMultifunction

B9E24A/B HP

DesignJet T3500

Production eMFP

One USB HS host connector in the front panel, for USB ash drives

IPv4, IPv6, IPSec, TCP9100, LPR, DHCP, AutoIP/Zeroconf, Bonjour, SNMP/v3, Airprint

Web services Automatic rmware upgrade, HP DesignJet ePrint & Share, printing by email

Speed Line-drawing, fast, plain paper: 21.6 s mono or color on A1&D

Color image, normal, plain paper: 69 s on A1&D

Color image, best, glossy paper: 246 s on A1&D

Resolution Up to 2400×1200 optimized dpi from 1200×1200 input ppi

Memory 1.5GB RAM (2.5GB RAM T3500);1GB in Formatter and 512MB in Engine PCA), 320 GB hard disk (500 GB hard disk for

T1530 and T2530), 32 GB Dedicated le-processing memory, 32GB (T920 series), 64 GB (T1500 series), and 128 GB

(T2500 and T3500 series), Virtual Memory

Supplies O-axis ink cartridges:

●

Introductory supplies: 69 ml (40 ml T3500) matte black, photo black, gray, cyan, magenta, yellow

●

Replacement supplies: 69 ml / 300 ml (130 ml T3500) matte black, for other colors 40 ml / 130 ml; photo black,

gray, cyan, magenta, yellow

●

Can be replaced by the customer

One printhead for all colors:

●

9/8-in length

●

Drop size: 9 pl matte black / 6 pl other inks

●

Can be replaced by the customer

Hardware

dierentiation:

X X X X

ENWW Introduction 3

Page 14

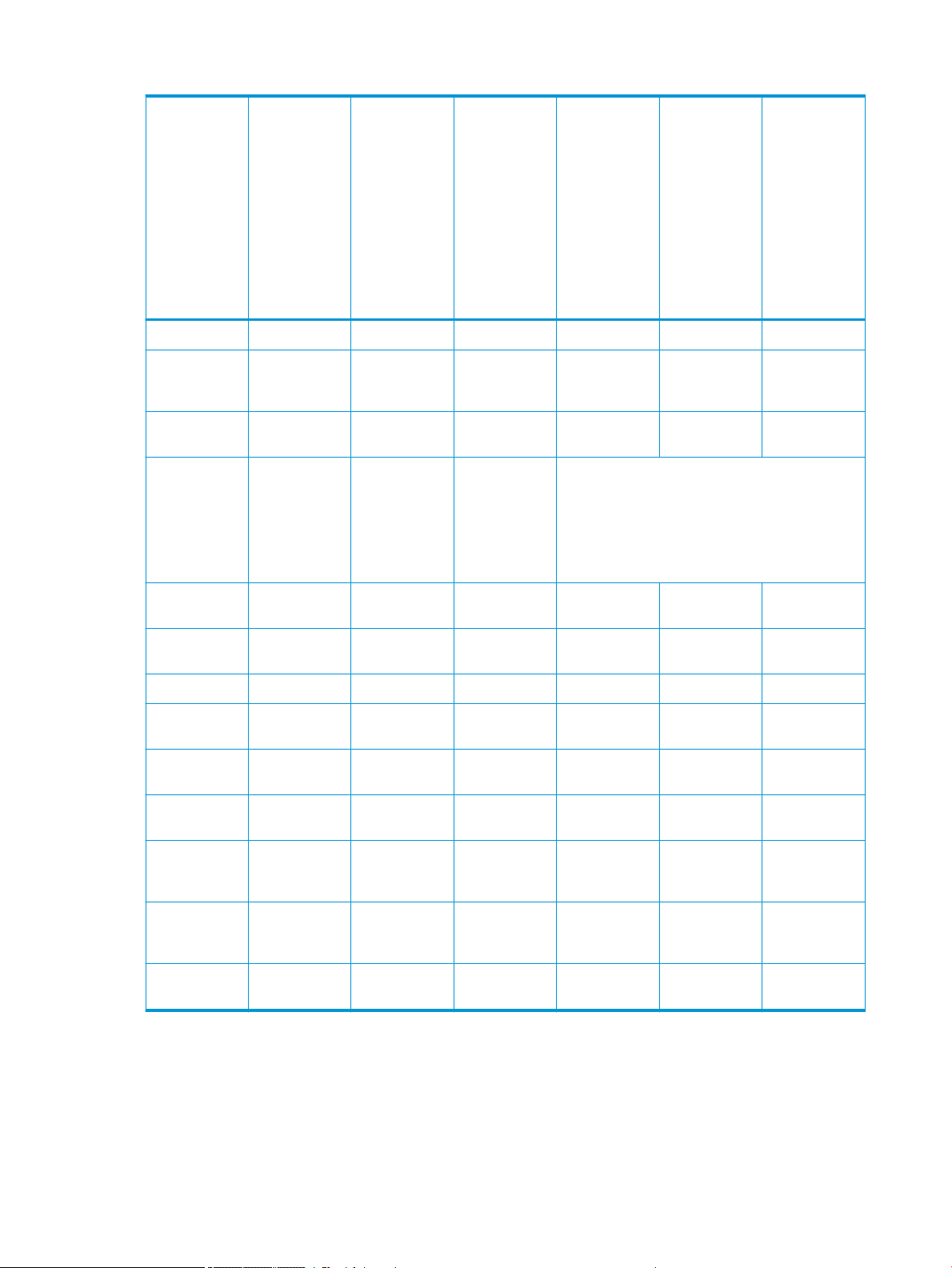

CR358A HP

DesignJet T2500

eMultifunction,

CR358A/B HP

DesignJet T2500

CR355A/B HP

DesignJet T920

CR354A HP

DesignJet T920

36-in ePrinter

and L2Y21A HP

DesignJet T930

Feature

Second roll X X X X

36-in ePrinter

36-in PostScript

ePrinter and

L2Y22A/B HP

DesignJet T930

36-in PostScript

ePrinter

CR356A HP

DesignJet T1500

36-in ePrinter

and L2Y23A HP

DesignJet T1530

36-in ePrinter

CR357A/B HP

DesignJet T1500

36-in PostScript

and L2Y24A/B

HP DesignJet

T1530 36-in

PostScript

PostScript

eMultifunction,

L2Y25A

DesignJet T2530

eMultifunction

and L2Y26A/B

T2530 PostScript

eMultifunction

B9E24A/B HP

DesignJet T3500

Production eMFP

Borderless

printing on roll

photo media

Other

dierentiations:

Languages

supported

Virtual Memory

[GB]

1 job in queue

(last job reprint)

Job queues X X X X X

Job preview from

queue

Crop marks and

nesting

EWS job

submmital

X X X X

X X X X

HP-GL/2, HPRTL, TIFF, JPEG,

CALS G4, HP PCL

3 GUI, URF

32 32 64 64 128 128

X

Adobe PostScript

3, Adobe PDF

1.7ext3 HPGL/2, HP-RTL,

TIFF, JPEG, CALS

G4, HP PCL 3 GUI,

URF

X X X X X

HP-GL/2, HPRTL, TIFF, JPEG,

CALS G4, HP PCL

3 GUI, URF

X X X X

X X X X

Adobe PostScript 3, Adobe PDF 1.7ext3 HP-GL/2, HPRTL, TIFF, JPEG, CALS G4, HP PCL 3 GUI, URF

Job on-hold for

media

(mummify)

Auto rotate,

automatic blank

area removal

Accounting in

EWS

X X X X X X

X X X X X

X X X X

Readership

The procedures described in this service manual are to be performed by HP Certied service personnel only.

4 Chapter 1 Printer fundamentals ENWW

Page 15

Part numbers

Part numbers for printer service parts are located in Parts and diagrams on page 240.

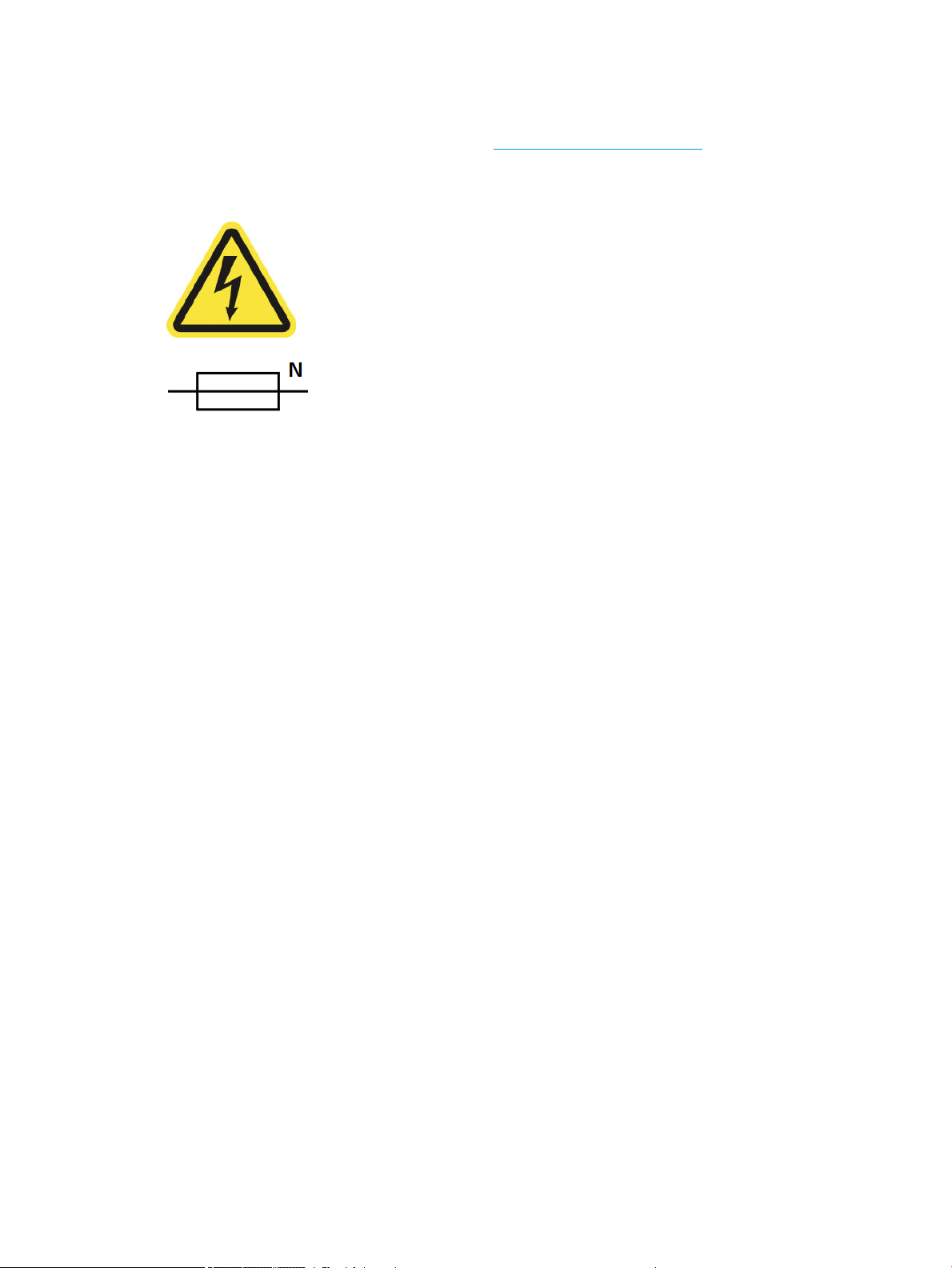

Warning labels

Electric shock hazard

Hazardous voltage inside the printer (built-in power supply) could result in death or serious personal

injury. See the installation instructions before connecting power. Ensure that the input voltage is within

the printer's rated voltage range. Use only earthed mains outlets and the power cords supplied by HP

with the printer. There are no operator-serviceable parts inside the printer. Refer servicing to qualied

service personnel. Disconnect the power cord before servicing. Voltage is still present in the built-in

power supply after the main switch is turned o.

Double pole/neutral fusing

Electric shock hazard. The built-in power supply incorporates a fuse on each conductor, therefore the

printer could be energized even when one fuse has blown. There are no operator-replaceable fuses

inside. Refer servicing to qualied service personnel. Disconnect the power cord before servicing.

ENWW Introduction 5

Page 16

Theory of operation

Schematics

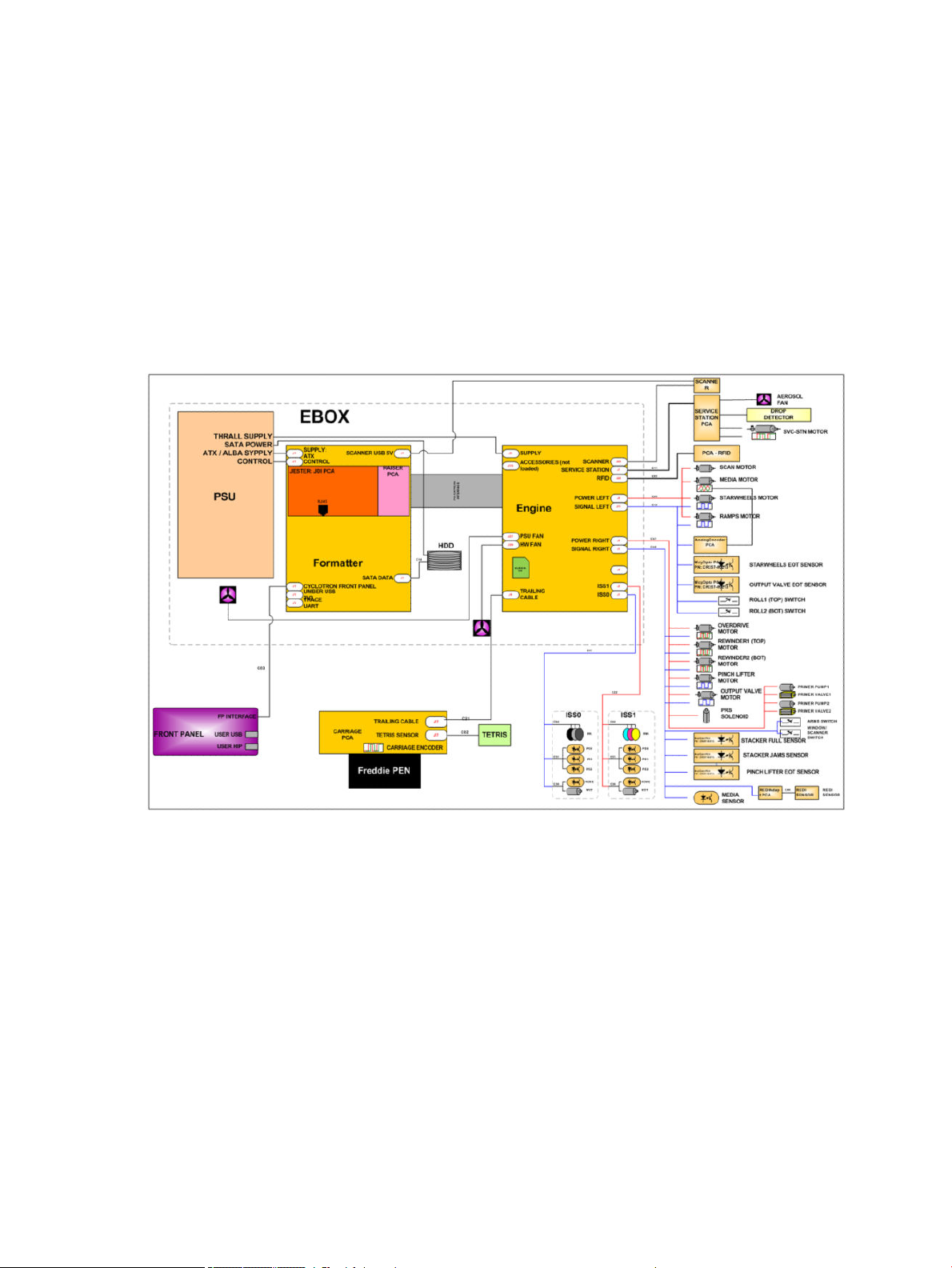

Electronics are based on 3 main components:

●

E-box - contains the power supply and all the PCAs (driving the printer), plus the Ethernet port.

●

Carriage PCA - drives the printhead.

●

Front Panel - user interface and USB port.

The following diagram describes the connections between components and electronic boards and the data line

type for T920, T1500 and T2500.

Block Diagram

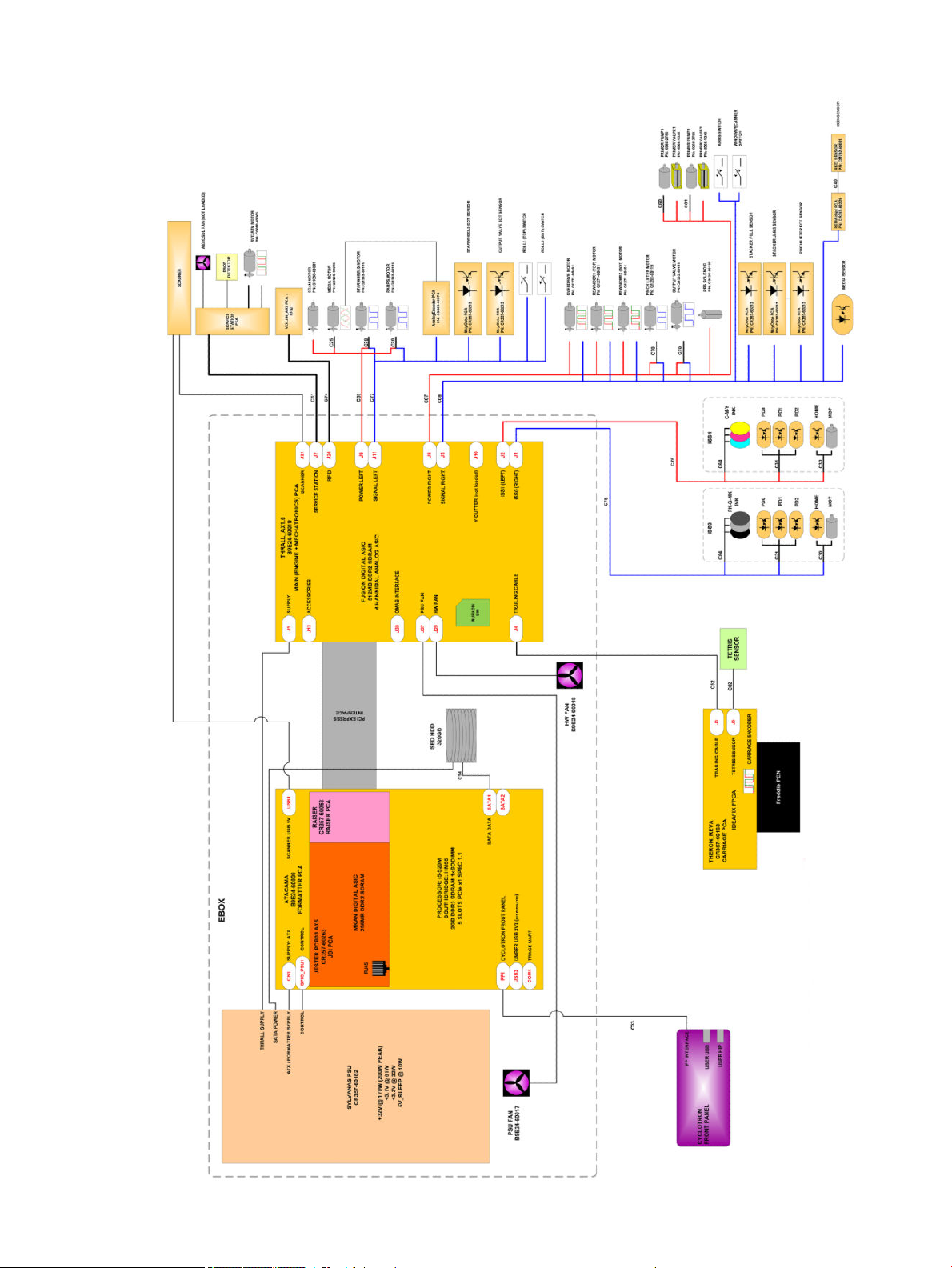

(HP DesignJet T3500 eMultifunction Series only)

6 Chapter 1 Printer fundamentals ENWW

Page 17

ENWW Theory of operation 7

Page 18

Block Diagram

(HP DesignJet T2500 and T3500 eMultifunction Series only)

Wiring Diagram

(HP DesignJet T2500 and T3500 eMultifunction Series only)

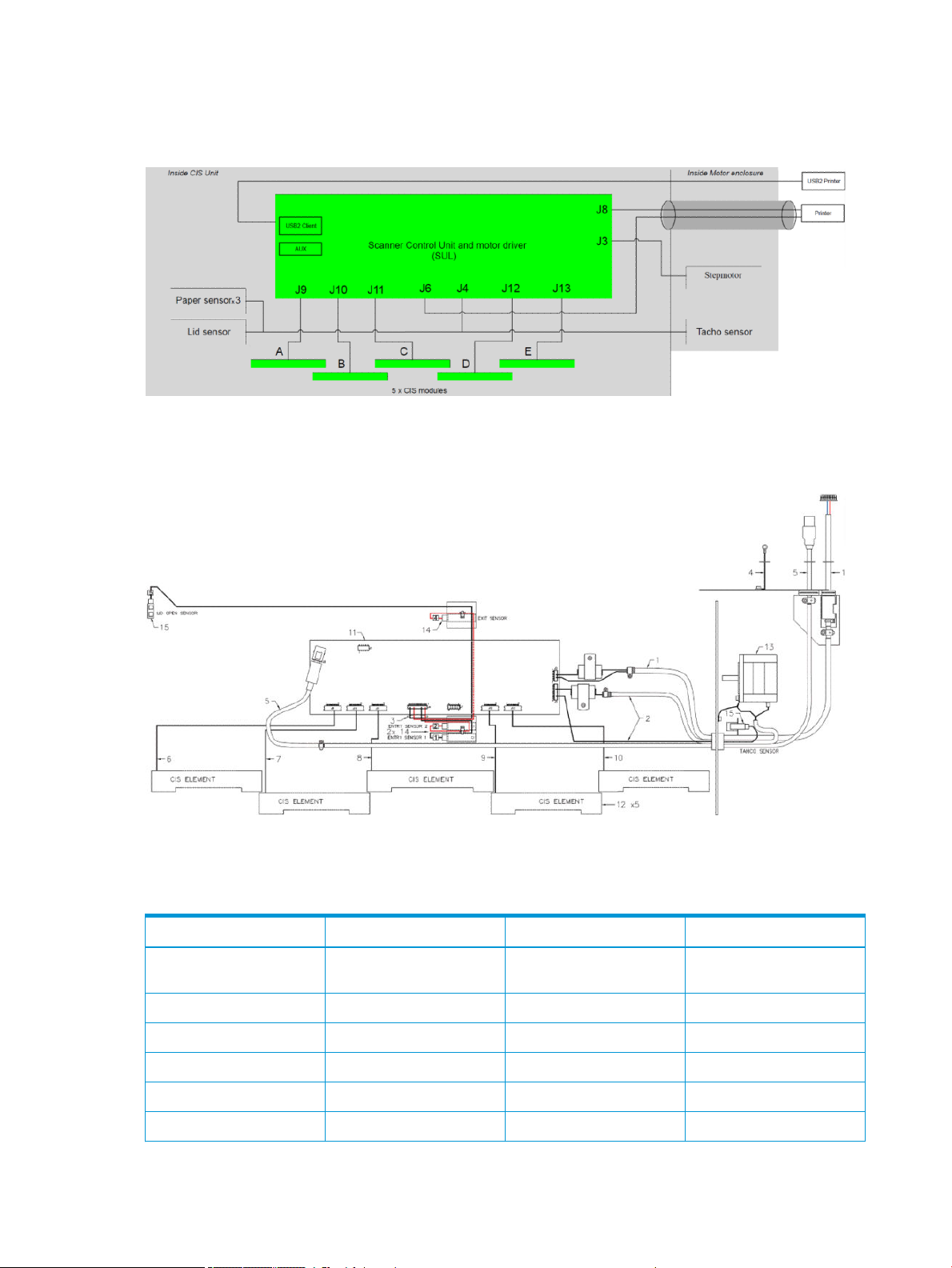

Scanner Controller Board Layout (SULG)

(HP DesignJet T2500 and T3500 eMultifunction Series only)

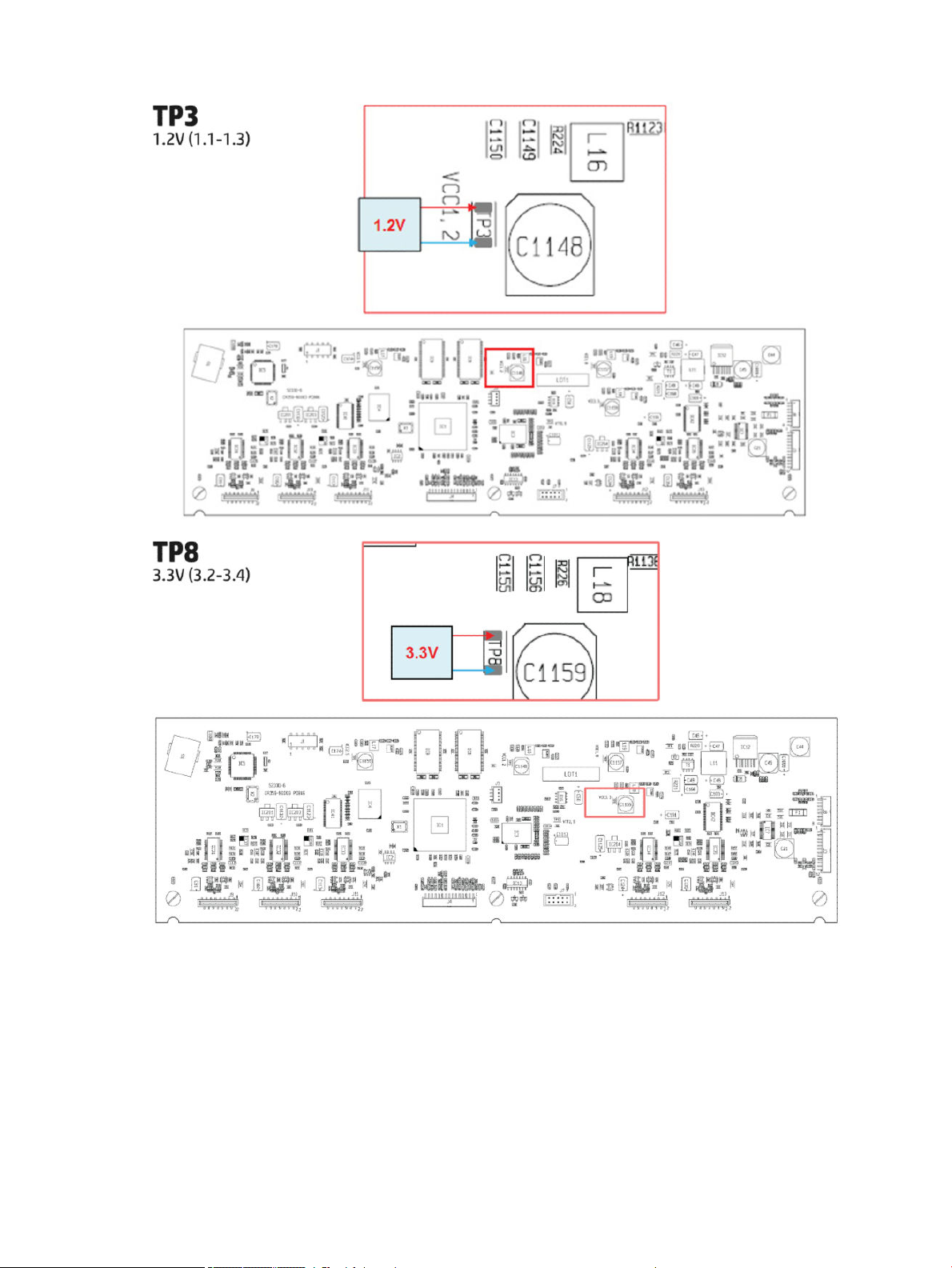

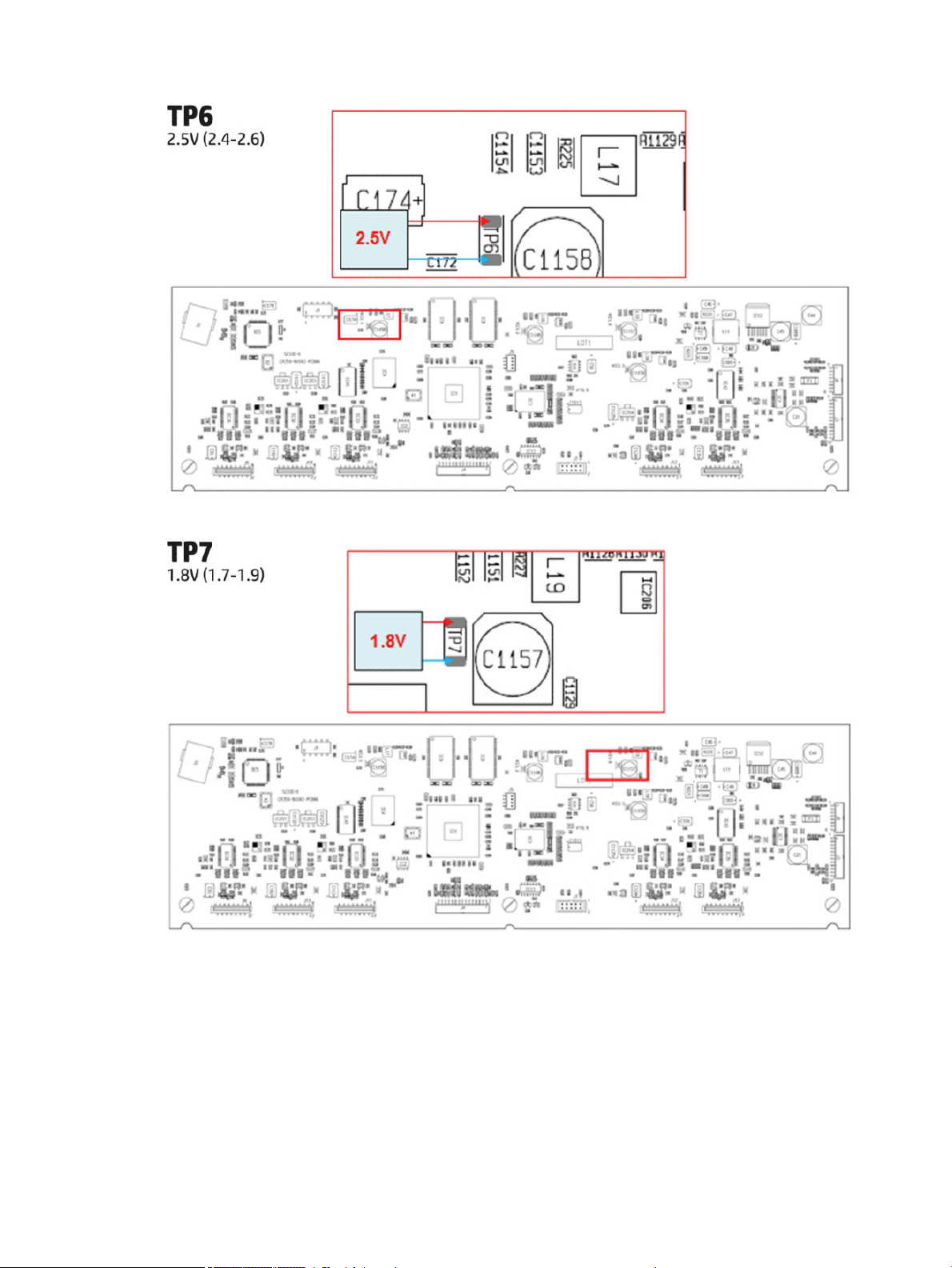

Voltage Min limit Max limit

TP1 5V-Main (Always on when there

is power to the board)

TP2 5V 4.75 5.25

TP3 1.2V 1.1 1.3

TP8 3.3V 3.2 3.4

TP6 2.5V 2.4 2.6

TP7 1.8V 1.7 1.9

8 Chapter 1 Printer fundamentals ENWW

4.75 5.25

Page 19

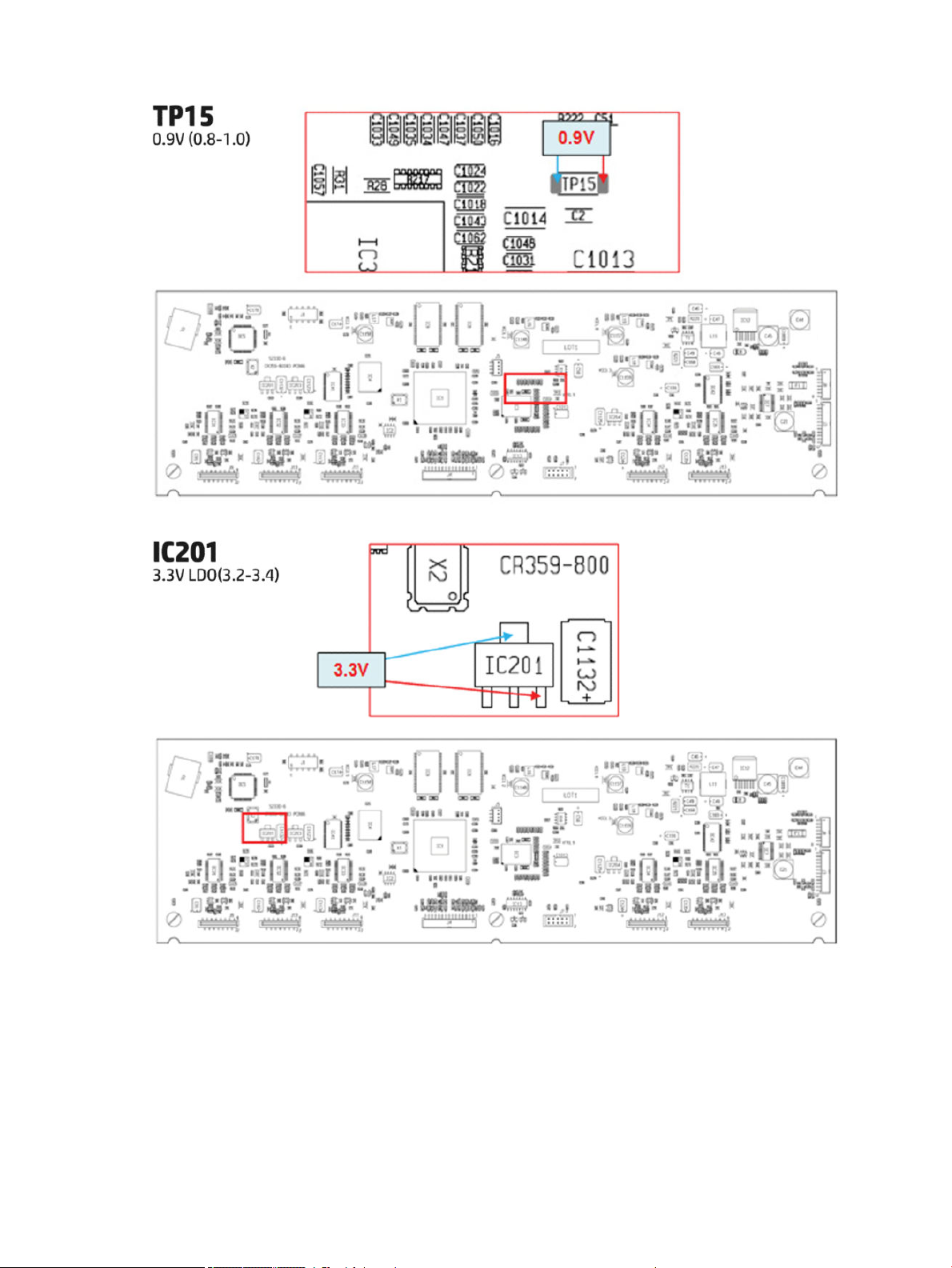

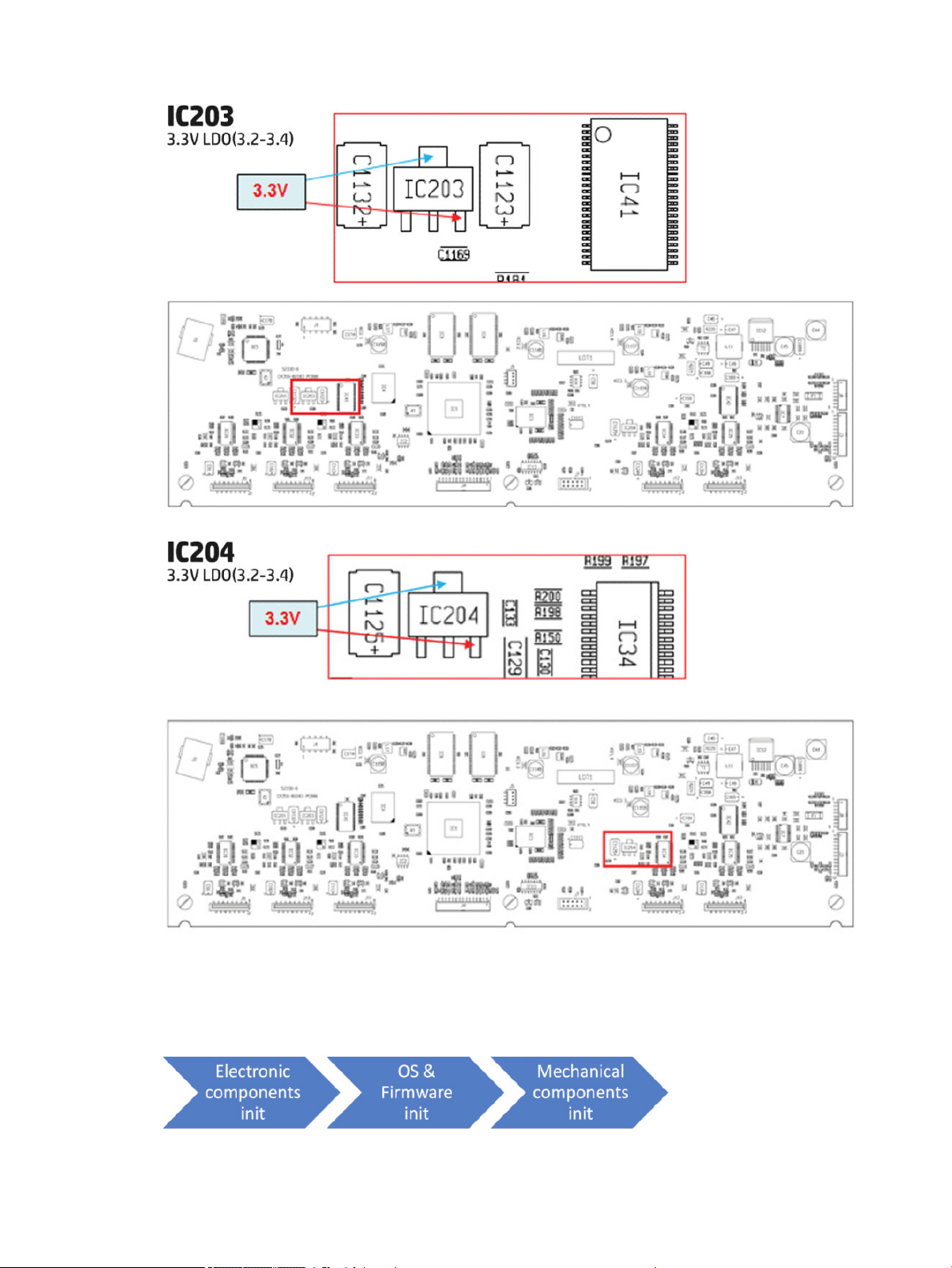

Voltage Min limit Max limit

TP15 0.9V 0.8 1.0

IC201 3.3VLDO 3.1 3.5

IC203 3.3VLDO 3.1 3.5

IC204 3.3VLDO 3.1 3.5

ENWW Theory of operation 9

Page 20

10 Chapter 1 Printer fundamentals ENWW

Page 21

ENWW Theory of operation 11

Page 22

12 Chapter 1 Printer fundamentals ENWW

Page 23

Printer Initialization

There are 3 main blocks to be initialized before the printer can be operated:

ENWW Theory of operation 13

Page 24

Electronic components init

1. The front panel shows a white background and blue HP logo.

2. The upper LED in the formatter is ON, indicating that the formatter has been initialized.

3. The middle LED in the formatter blinks, indicating that the HDD has been initialized.

NOTE: Steps 2&3 are the same when waking from Sleep Mode except the 3 LEDs are not on but; ON-

Blinking-OFF

OS & Firmware init

1. The OS is loaded into RAM. The Front Panel blinks for a second.

2. If boot up is after a bad power-o, the boot sequence automatically runs a le system check.

a. The Front Panel shows the FSCK, text.

b. First, FSCK runs on the root partition.

c. If FSCK is successful, the OS boots up from the root partition and runs FSCK on the data partition.

3. After FSCK, the OS nishes booting from the HDD.

4. The home button lights up to allow stopping the boot sequence, and entry to the diagnostics menu, see

Diagnostics, Service Utilities and Calibrations on page 179.

Mechanical components init

1. The Front Panel shows a black background with a blue circle in the middle. The “Initializing” message

appears. A progress bar shows the percentage of subsystems that have been initialized.

2. The printer moves the carriage from side to side to validate its position within the scan axis. The printer

initializes the service station, moving the caps from bumper to bumper.

14 Chapter 1 Printer fundamentals ENWW

Page 25

3. The pinches move down into position.

4. T2500 and T3500 only: The printer will initialize the Scanner and start checking it.

5. The carriage and service station move to the home position

6. The printer checks the status of supplies and the printhead, and then initializes the Ink Supply Stations.

7. Servicing routines are launched. The routines refresh the printhead depending on the time that the printer

has been o. The Front Panel shows “Preparing Print System”.

8. The paper path subsystems are initialized by exercising the ramps and rewinder, checking if there is media

present over the Media Sensor.

9. At the end of the process, the home screen appears in the Front Panel.

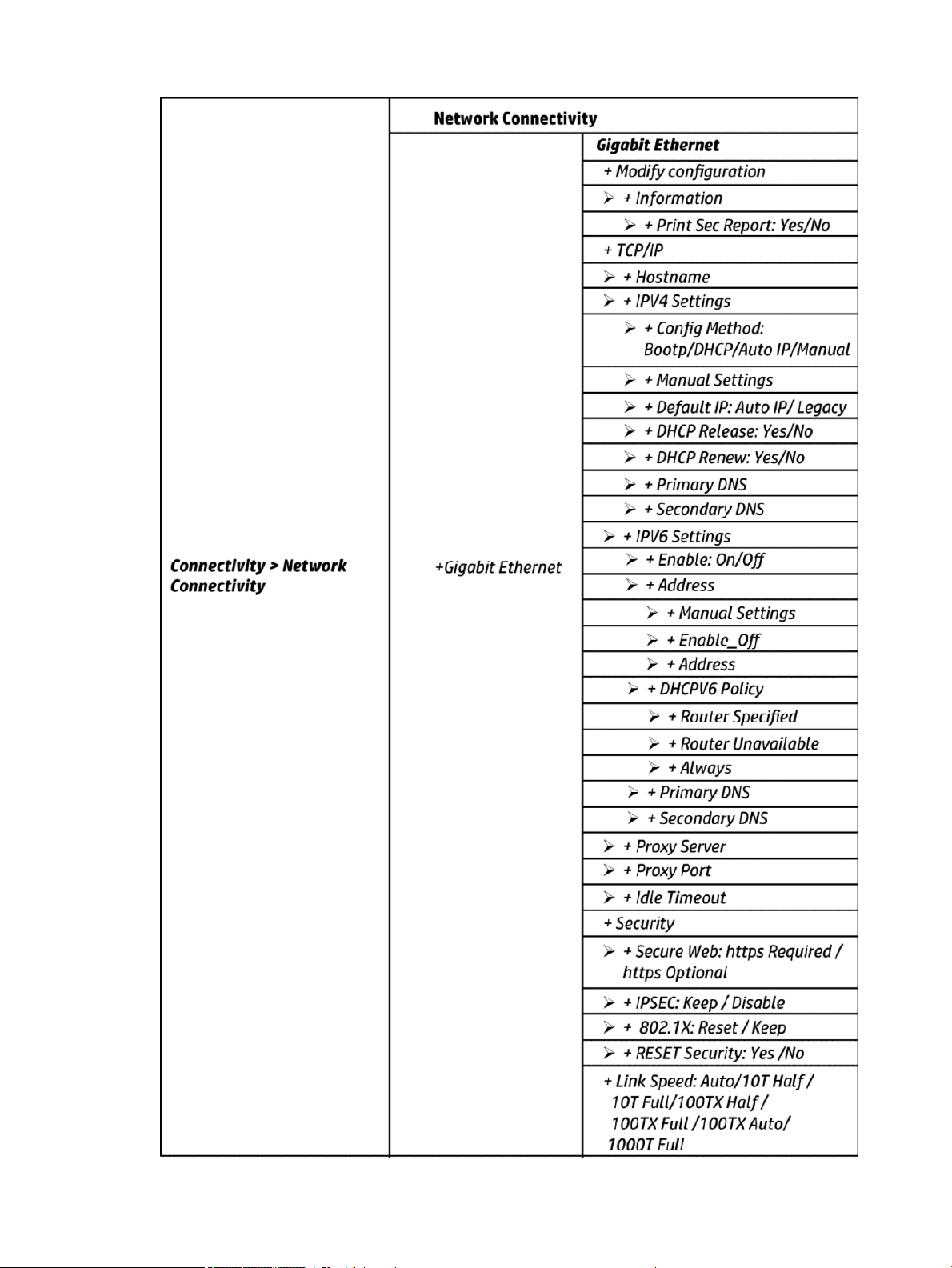

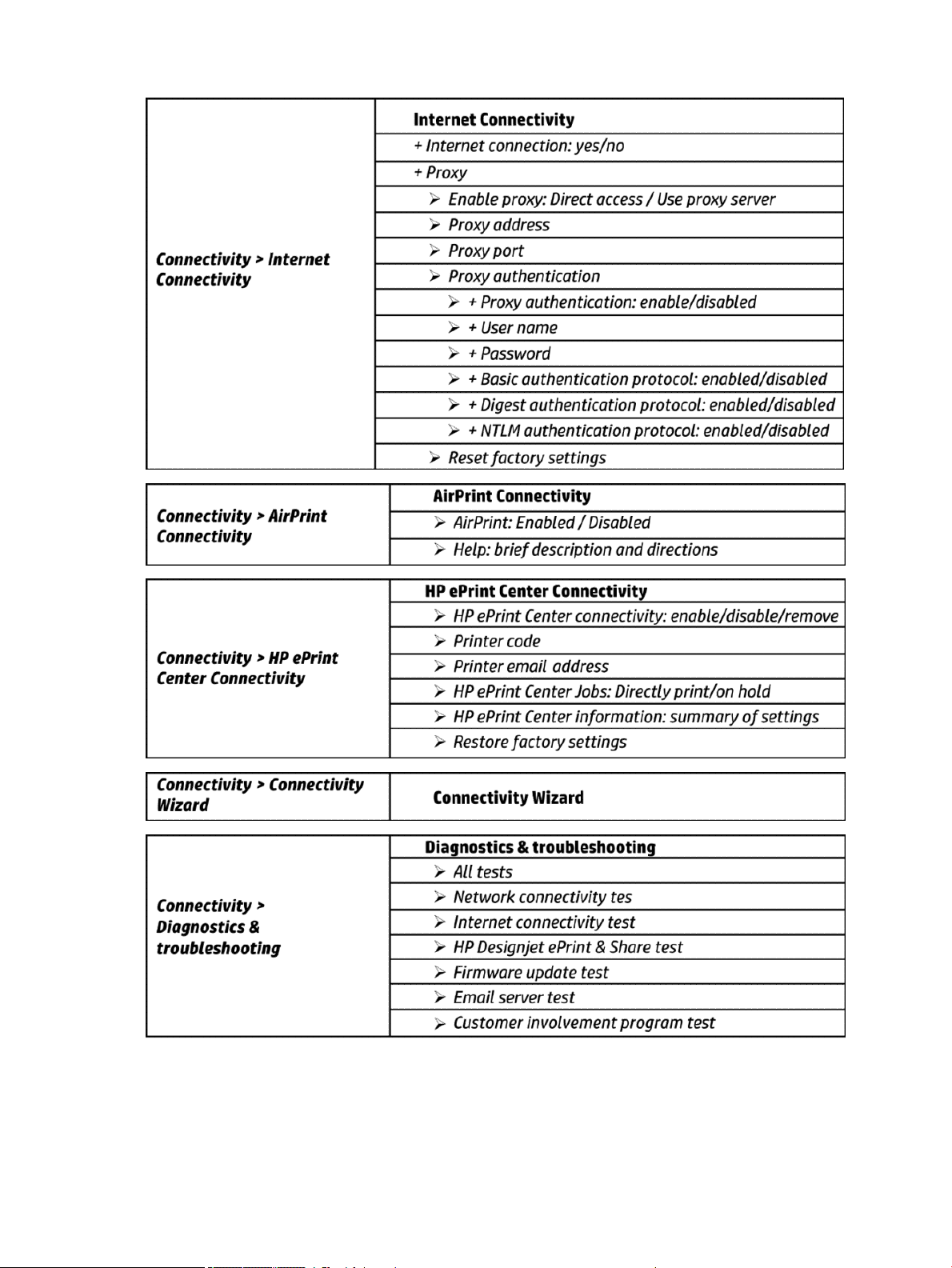

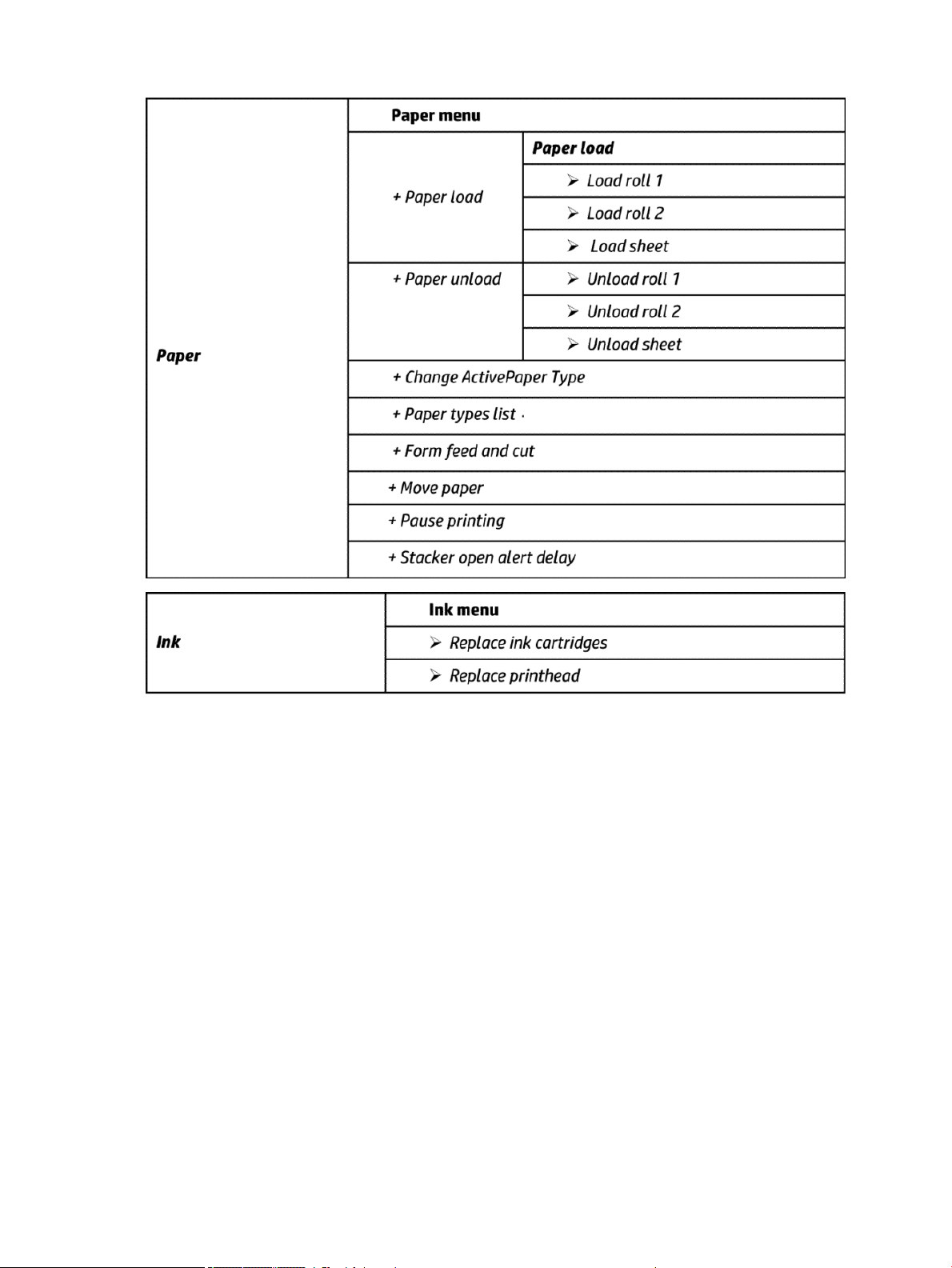

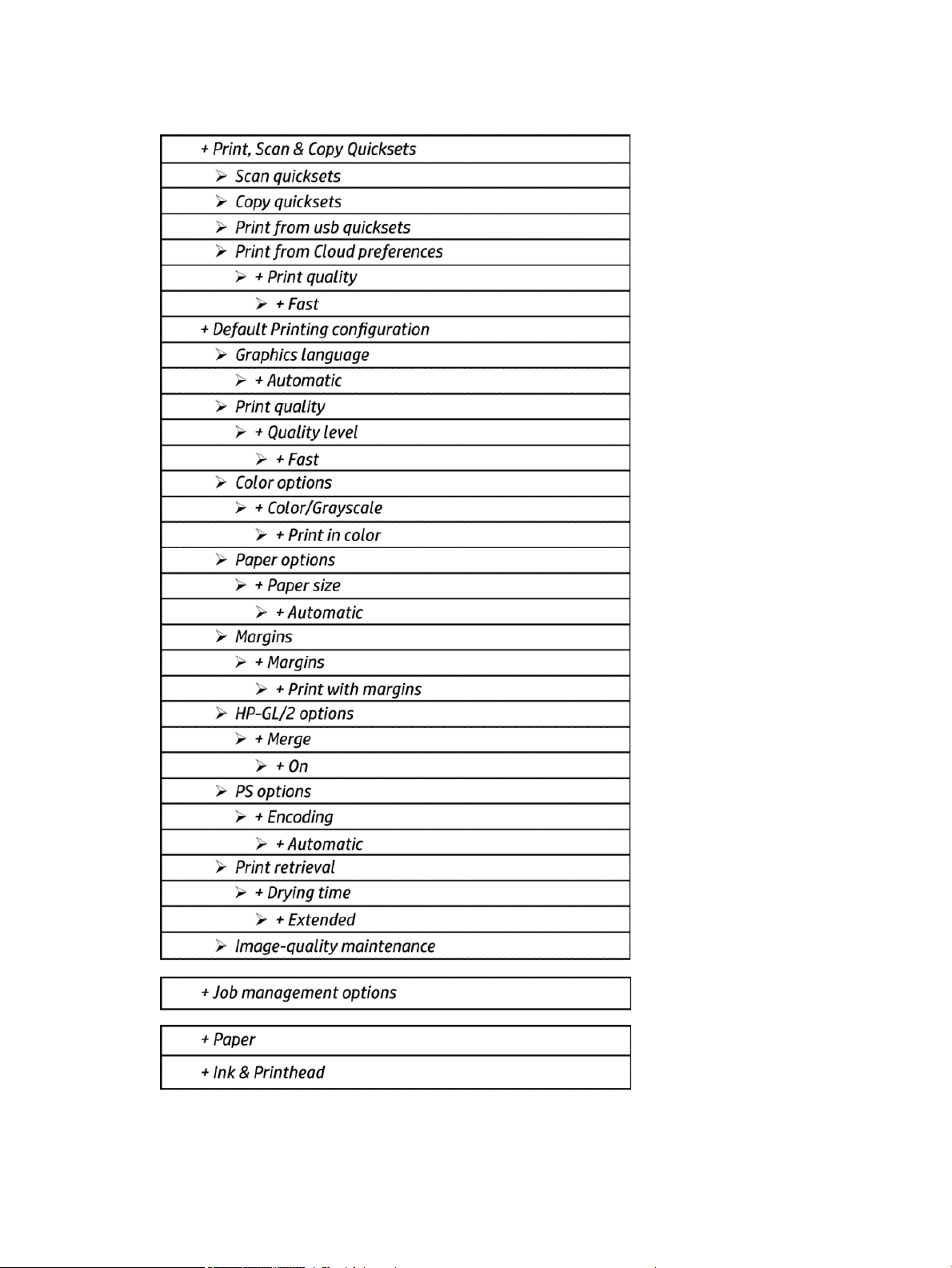

Front Panel Menu Map

The following tables show the front panel menu layout.

ENWW Theory of operation 15

Page 26

16 Chapter 1 Printer fundamentals ENWW

Page 27

ENWW Theory of operation 17

Page 28

18 Chapter 1 Printer fundamentals ENWW

Page 29

ENWW Theory of operation 19

Page 30

20 Chapter 1 Printer fundamentals ENWW

Page 31

ENWW Theory of operation 21

Page 32

22 Chapter 1 Printer fundamentals ENWW

Page 33

ENWW Theory of operation 23

Page 34

24 Chapter 1 Printer fundamentals ENWW

Page 35

ENWW Theory of operation 25

Page 36

26 Chapter 1 Printer fundamentals ENWW

Page 37

Front Panel Menu Map (T3500 only)

ENWW Theory of operation 27

Page 38

HP 727 Printhead Start-up process

1. Insert cartridges: If the printhead is initialized during the installation of the printer, the printer will rst

check for new supplies.

28 Chapter 1 Printer fundamentals ENWW

Page 39

“Ink cartridge missing. Install ink cartridge.”

”Change cartridges now. Press OK to continue.”

If the printer still needs to purge the ink tubes and there are cartridges already installed in it, the printer will

reject the supplies, reporting them as “Not Valid” and will request to “remove and reinsert” the supplies.

Cartridges can be reseated in order to be accepted by the printer before the tubes are purged. This allows

the printer to do a full validation of the supply before running a tube purge.

If the cartridges used for installation do not contain the required 60cc of ink for purging, the printer will

report that “cartridge is not valid for setup”.

NOTE: keep in mind that to initialize a printhead you need 40ml of Matte Black ink and 30ml of ink for the

rest of the colors. To purge ink tubes, you need 60cc of all colors. If in doubt, use 130ml cartridges.

ENWW Theory of operation 29

Page 40

2. After inserting the cartridges, the printer requests the printhead.

“Preparing for printhead replacement”

“Open window to access printheads or press Cancel to quit”

NOTE: If printhead insertion is completed during printer installation, remember to remove the orange

caps.

3. After inserting the printhead, the printer will check electronic connections. If the check fails, the printer will

ask to reseat the printhead.

“Checking printheads. Please wait”

30 Chapter 1 Printer fundamentals ENWW

Page 41

4. Once it is certain that the printhead is recognized, the printer will purge the ink tubes if they are empty. It

will also ll the printhead.

“Preparing the printhead for rst usage”

If the process nishes OK, the printer will ag the printer tubes and printhead as lled with ink.

If during the process the printer detects that a cartridge has been removed it will show the message “A

supply has been removed” and it will go back to step 1.

After this step, all ink tubes should be completely lled. The circles on top of the printhead should also look

lled.

5. At this point, the printer will run 2 checks to validate the start-up: rst will check for ink pressure and

second for printhead temperature while spitting. If the pressure fails, it will be logged as a SE 93.0.n:10 in

the service plot (where n is the failing color). If the temperature check fails, it will be logged as a SE 93.2.n:

10 in the service plot (where n is the failing color). The SE are not shown in the front panel. In both cases,

the printer will request to Reseat the printhead. After the reseat the printer will try to

and printhead by going to step 3.

ll again the tubes

n indicates the missing color:

●

n=0 stands for photo black

●

n=1 stands for gray

●

n=2 stands for matte black

●

n=3 stands for cyan

●

n=4 stands for magenta

●

n=5 stands for yellow

6. After this second trial, the pressure and temperature tests will be repeated. If the pressure fails, it will be

logged as a SE 93.1.n:10 in the service plot (where n is the failing color). If the temperature check fails, it

will be logged as a SE 93.3.n:10 in the service plot (where n is the failing color). The SE are not shown in the

front panel. In any case, the printer will move to step 3 and try to execute it.

ENWW Theory of operation 31

Page 42

7. After the printhead and tubes are lled, the printer completes some printhead servicing to nalize the

initialization.

“Preparing print system”

If successful. If the printhead is properly initialized, the printer shows the following message:

“Printhead replacement. Printhead successfully replaced. Press OK to continue.”

If unsuccessful. If there is a problem the printer, depending on the problem, one of the two following

messages appears:

“Replace printhead. The printhead failed to complete the replacement process. Replace printhead. Press

OK to continue with printhead replacement.”

“Reseat the printhead. Press OK to continue.”

32 Chapter 1 Printer fundamentals ENWW

Page 43

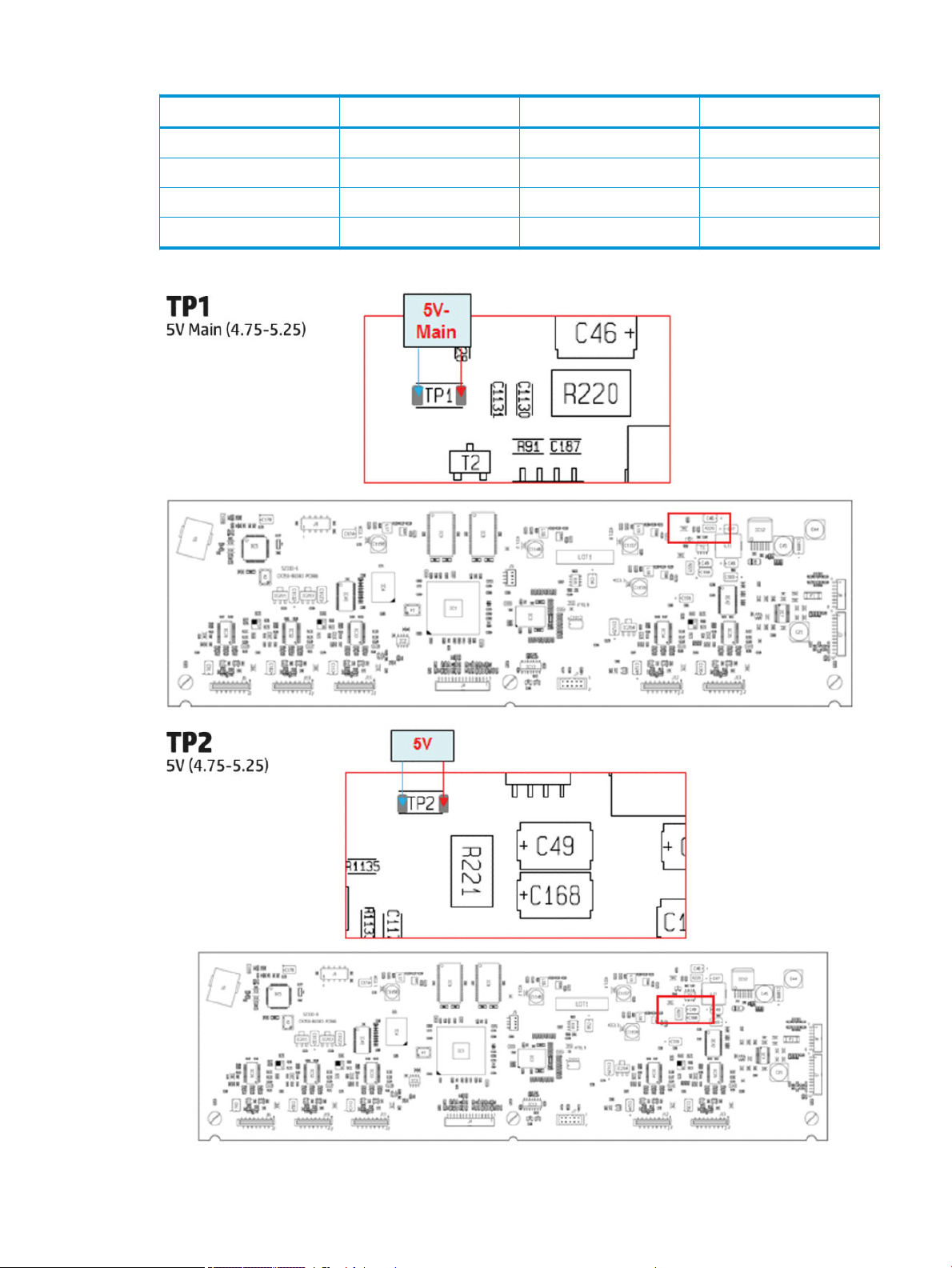

CIS Technology

Example of a CIS Element, Contact Image Sensor:

The CIS Element consist of 3 major parts:

●

Sensor

●

Lens

●

Light source

The Light source is 3 RGB LEDs that are lit one at a time. The sensor consists of 10368 individual monochrome

sensors.

The purpose of the lens is to channel the light from the “pixels” on the image to the sensors. There is no

magnication in the lens (1x1).

Due to the very short focal length, the focus depth is limited. The original has to be in contact with the surface of

the glass plate in order to be in focus.

The LED’s ash one at a time, capturing one color at a time.

ENWW Theory of operation 33

Page 44

2 Troubleshooting

●

The front panel

●

Service keys combination

●

Troubleshooting tree (T920 and T1500 only)

●

Product Troubleshooting trees (T2500 and T3500 only)

●

Scanner Troubleshooting Tree

●

Scanner CIS Troubleshooting

●

Troubleshooting using board LEDs

●

Paper handling problems

●

Ink supply problems

●

Print-quality problems

●

Connectivity problems

●

Scanning Problems

●

HP 727 Printhead Troubleshooting

●

Videos for replacing CSR parts and HP 727 printhead

●

Firmware upgrades

34 Chapter 2 Troubleshooting ENWW

Page 45

The front panel

The front panel is located on the front right of the printer. It gives you complete control of your printer: from the

front panel, you can print, view information about the printer, change printer settings, perform calibrations and

tests, and so on. The front panel also displays alerts (warning and error messages) when necessary.

For more information about front panel, refer to the users guide.

Sleep mode

Sleep mode puts the printer into a reduced power state after a period of inactivity, turning o the front panel

display to save energy. Printer features can be enabled from this mode, and the printer maintains network

connectivity, waking up only as necessary. The printer can be woken from sleep mode by the Power button, by

sending a print job, or by opening the window, the roll cover, or the stacker cover. The printer wakes up in several

seconds, more quickly than if it is completely turned o. While in sleep mode, the Power button blinks.

To change the time that elapses before sleep mode, press , then , then Setup > Front panel options

> Sleep mode wait time. You can set a time between 5 and 240 minutes; the default time is 30 minutes.

Printer Monitoring (with thde Print Spooler) and Remote Printer Management with the HP Utility and Web

JetAdmin continue to be available during sleep mode. Some remote management tasks oer the option of

remotely waking up the printer if needed to perform the task.

Other Power States

Besides sleep mode, the printer has 5 dierent power states (including ready and sleep). Depending on the

power state, the printer has dierent subsystems wake up and ready for use.

ENWW The front panel 35

Page 46

(1) After 50 cycles of sleep-mode, the printer performs an auto-reboot, done between 22h00 and 06h00.

Background information

* Assumes printer is never switched o.

** Total DECC equiv. CO2 footprint of all IB during 5 years May-2013 / May-2018 assuming 20%, switches-o

printer or oce power and 33% programs schedule on/o.

Auto-o

Auto-o sets the printer to "soft-o" mode after the period of time set by the user can in the Front Panel. This

feature is disabled when the printer is connected to the LAN, and in this case, the printer can't go to soft-o

automatically. The default value from factory for the Auto-o time out is 120min.

NOTE: In some situations this can be confusing since printers without LAN will be set to o automatically

during the night. Furthermore, once the printer has been switched o automatically it needs to be turned on with

the Blue Power Button on the printer. Switching on from the rear button will not wake up the printer.

36 Chapter 2 Troubleshooting ENWW

Page 47

Service keys combination

Entering the User Diagnostics Menu

1. Go to Printer Main Menu.

2. Go to Diagnostics Menu.

3. Type code “1714”.

4. Go to Diagnostic Tests.

5. Allow the printer to reboot.

Printer will remain in “User Diagnostics Menu” until it’s setup to go back to Printer mode.

To go back to Printer mode:

1. From “User Diagnostics Menu” go to “Reboot in printer mode”.

2. Allow the printer to reboot.

The “User Diagnostics Menu” has a limited set of Diagnostics and allows only to perform the following actions:

●

Scan Axis Motor on page 335

●

Paper Drive Test on page 186

●

Electronics Module Test on page 187

●

Sensors Test on page 191

●

Stacker Jam Sensor Test on page 196

●

Stacker Capacity Sensor Test on page 196

●

Stacker Empty Sensor Test on page 191

●

Output Valve Test on page 192

●

Pinches Lifter Test on page 194

●

Stacker Ramps Test on page 194

●

Stacker Overdrive Test on page 195

●

Ink Delivery System (IDS) Test on page 196

●

Service Station with Drop Detector on page 339

●

Enable I/O Interfaces Utility on page 200

●

Unit Information Utility on page 200

Entering the Diagnostics Menu when booting the printer

1. Make sure the product is switched o with the Power button on the side of the Front Panel, and not with

the power switch on the back of the product.

2. Press and release the Power key to switch on the product.

ENWW Service keys combination 37

Page 48

3. Wait for the Home button light to come on.

4. Press the Home button; the button will acknowledge by blinking.

5. All LEDs will come on; press and release them one after another:

●

The Cancel icon

●

The Home icon

●

The Help icon

NOTE: Do not push the icons all at the same time, push each one in the order shown above and release

each icon before pressing on the next icon

6. The 6 buttons on the Front Panel then blink 4 times; wait until the product completes the initialization

sequence and shows the Diagnostics menu.

7. In the Diagnostics menu, scroll up and down sliding a nger vertically on the Front Panel, and press on the

desired option.

NOTE: The Diagnostic Tests and Utilities work in a special mode that does not require the full initialization of

the product. Therefore, whenever a test is nished a test, switch o the product and switch it on again before

printing, or executing another test.

NOTE: A quick press of a button on the Front Panel frame may not be recognized by the product. When

pressing a button, be sure to press it for about 1 second.

NOTE: If the product hangs up during a test; switch the product o and restart from step 1.

Entering the service utilities menu

1. From the home screen, select the Information icon in the top left corner. For information about the Front

Panel keys, see using The front panel on page 35 or:

2. From the product information area, press the main menu / tool icon on the bottom right corner of the

screen.

3. Scroll down to the lowest menu option and select the Service menu option.

4. Enter the 4-digit 1st level access code “3174” and press OK.

5. Select the Service utilities menu option.

6. From the service utilities menu you can scroll up and down to see all the available utilities. Press on the

selected menu option.

38 Chapter 2 Troubleshooting ENWW

Page 49

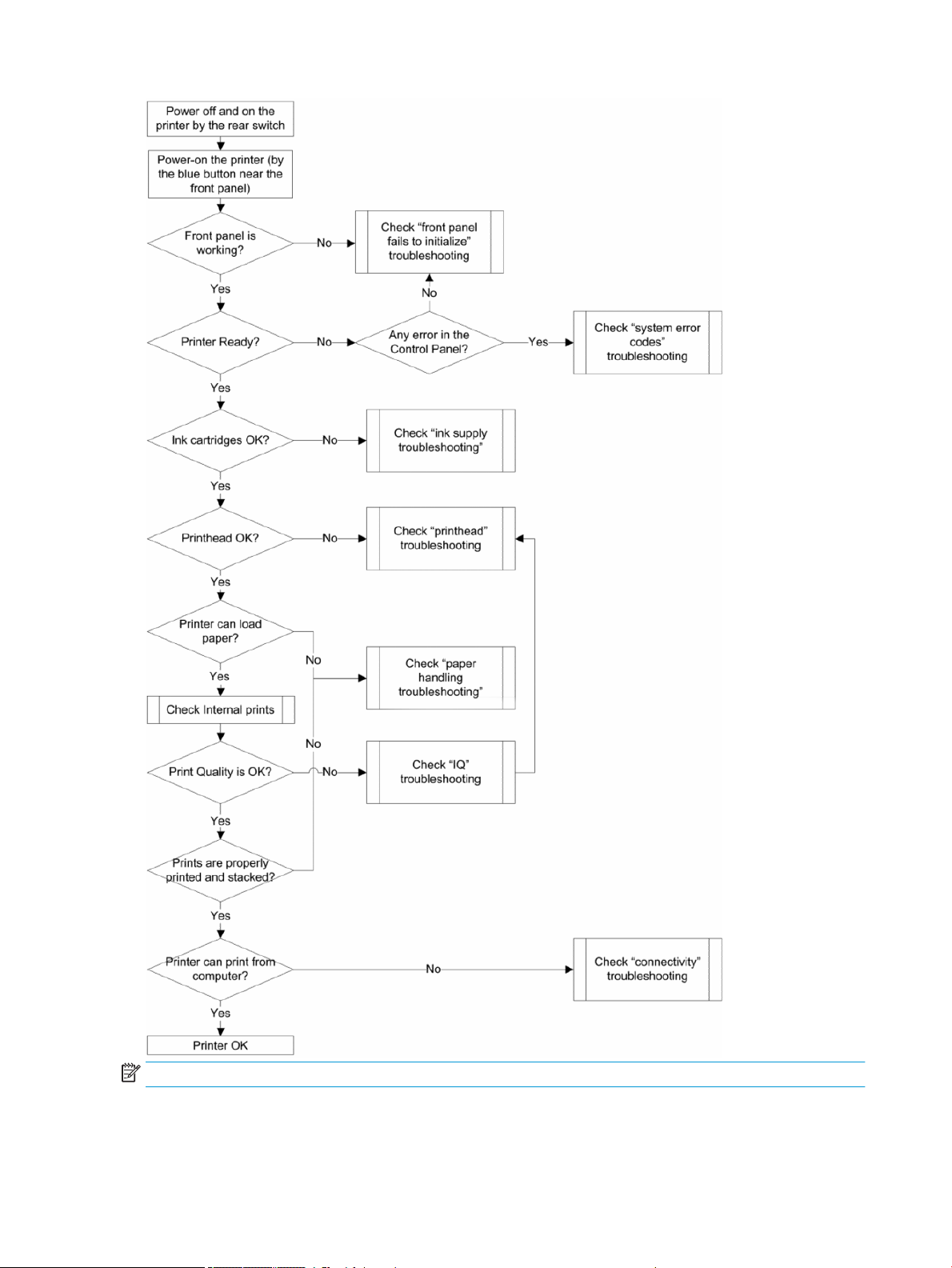

Troubleshooting tree (T920 and T1500 only)

As a general approach, the following tree should be followed to troubleshoot any issue. This helps understand at

which point the problem was caused. The tree is sequential; before checking a subsystem, the previous steps

need to be working. Once a sub system is identied as causing the problem, the service and utilities related to

that component can be used to troubleshoot further. See Diagnostics, Service Utilities and Calibrations

on page 179.

ENWW Troubleshooting tree (T920 and T1500 only) 39

Page 50

NOTE: Once an issue is conrmed, check that printer has latest rmware installed.

40 Chapter 2 Troubleshooting ENWW

Page 51

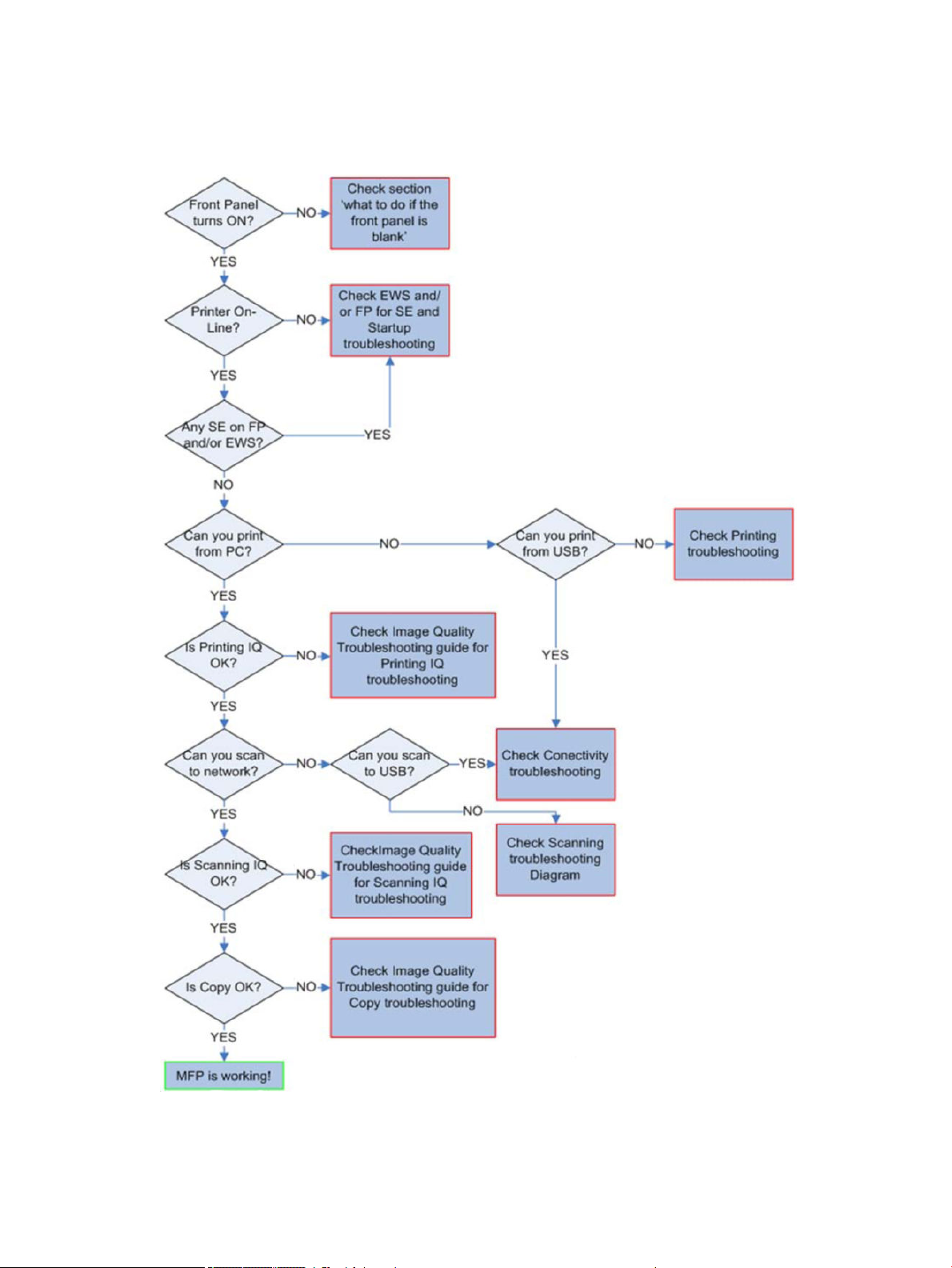

Product Troubleshooting trees (T2500 and T3500 only)

Figure 1-1 Troubleshooting

ENWW Product Troubleshooting trees (T2500 and T3500 only) 41

Page 52

Scanner Troubleshooting Tree

Figure 1-2 Scanner Troubleshooting

42 Chapter 2 Troubleshooting ENWW

Page 53

Scanner CIS Troubleshooting

Figure 1-3 Scanner Troubleshooting

ENWW Scanner CIS Troubleshooting 43

Page 54

Troubleshooting using board LEDs

All the printer boards have diagnostic LEDs to help in the troubleshooting. Although some LED information is

redundant and also known by the printer rmware, using the board LEDs can be very useful when trying to

diagnose power or communication problems. The following sections provide information on the physical location

and meaning of each board’s diagnostic LEDs.

For further information regarding electric and electronic interactions, see the subsystems’ block diagrams in

section Theory of operation on page 6.

Board name: Formatter PCA

Meaning of LEDs:

44 Chapter 2 Troubleshooting ENWW

Page 55

ENWW Troubleshooting using board LEDs 45

Page 56

46 Chapter 2 Troubleshooting ENWW

Page 57

Board name: Carriage PCA

Meaning of LEDs:

State Orange LED DS3 Orange LED DS4 Red LED DS1 Orange LED DS2

32V Power input OFF OFF ?? ?? ??

Vcc Power OFF ?? OFF OFF OFF

32V Power input ON ON ?? ?? ??

Vcc Power ON ?? ON ?? ??

FPGA not programmed ?? ON ON ON

FPGA programmed in

Reset State

FPGA out of reset but no

clock

FPGA out of reset, HCI

clock OK, HCI not

initialized

FPGA out of reset, HCI

clock OK, HCI Id initialized

FPGA out of reset, PLL

unlocked

?? ON OFF OFF

?? ON Regular blinking Not blinking

?? ON ?? Slow blinking

?? ON ?? Fast blinking

?? ON Two-pulse blinking ??

ENWW Troubleshooting using board LEDs 47

Page 58

Board name: Jester PCA

Meaning of LEDs:

There is only one LED left on Jester. It is a Green/Red LED able to code the following states:

Board status LED status Period

Some Voltage/Temperature out of range Fix Red -

Monokhan does not respond (possibly in

reset)

Mismatching Hardware/Software version Quick Red 5 Hz

Monokhan unexpected reset Fix Green -

Normal operation Quick Green 5 Hz

Slow Red 0.4 Hz

48 Chapter 2 Troubleshooting ENWW

Page 59

Board name: Engine PCA

Meaning of LEDs:

State Green LED DS5 Green LED DS11

32V Power input OFF O O

32V Power input ON On O

Sleep mode activated O On

ENWW Troubleshooting using board LEDs 49

Page 60

Paper handling problems

●

The paper has jammed in the print platen

●

The paper has jammed in the stacker

●

Thin paper is jamming in the stacker

●

High density plots jamming in the stacker

●

Several stacker paper jams

●

Stacker capacity lower than expected

●

The stacker detects "Stacker is full" permanently

●

The stacker detects "Stacker jam" permanently

●

The printer rejects the paper during paper load

●

Prints do not fall neatly into the basket

●

Using the stacker

●

The paper type is not in the list

●

The printer printed on the wrong paper type

●

An “on hold for paper” message

●

The printer displays out of paper when paper is available

●

The print remains in the printer after printing has completed

●

The cutter does not cut well

●

The roll is loose on the spindle

●

The roll is unloaded unexpectedly

The paper has jammed in the print platen

When a paper jam occurs, you normally see the Possible paper jam message in the front panel display, and a

system error 81:01 or 86:01.

1. Open the window.

50 Chapter 2 Troubleshooting ENWW

Page 61

2. Move the carriage manually to the left side of the printer, if feasible.

3. Go to the paper path.

ENWW Paper handling problems 51

Page 62

4. Cut the paper with a pair of scissors.

5. Open the roll cover.

52 Chapter 2 Troubleshooting ENWW

Page 63

6. Manually rewind paper onto the roll.

ENWW Paper handling problems 53

Page 64

7. If the leading edge of the paper is ragged, trim it carefully with scissors.

NOTE: In the T3500 the guide can be used for cutting.

54 Chapter 2 Troubleshooting ENWW

Page 65

8. Remove the paper left in the printer.

9. Make sure you have removed every fragment of paper.

IMPORTANT: Remove remaining paper by carefully pulling it out in the direction of the paper axis.

ENWW Paper handling problems 55

Page 66

10. Close the window and the roll cover.

11. Restart the printer by holding down the power button for a few seconds, or by turning the power switch at

the rear o and then on.

12. Reload the roll, or load a new sheet.

NOTE: If you nd that there is still some paper causing an obstruction within the printer, restart the procedure

and carefully remove all pieces of paper.

The paper has jammed in the stacker

When a stacker jam is detected, printing is paused, and the front panel asks you to open the stacker cover and

clear the jam by pulling out the paper.

IMPORTANT: Remove remaining paper by carefully pulling it out in the direction of the paper axis.

When the stacker arms cover is closed and the printer detects no jammed paper, the front panel requests

conrmation to continue printing.

Thin paper is jamming in the stacker

When using a media thinner than 75gsm, the blue lever needs to be pulled forwards so that there is a larger gap

between the arms and stacker tray when the arms are closed.

56 Chapter 2 Troubleshooting ENWW

Page 67

After printing with thin media, remember to return the blue lever so that there is a small gap between the arms

and stacker tray.

High density plots jamming in the stacker

If you are printing high-density plots (over 15ngrs ink density) with media below 80grs/m2, and you encounter

that plots have problems curving at the end of the stacker, or do not stack properly, and cause jams:

●

Use Manual mode.

●

Print to the basket.

●

Use thicker media; over 80grs/m2.

ENWW Paper handling problems 57

Page 68

●

Use the CR357-67089 “Stacker tray ller” (CSR)

To improve the performance of the stacker when printing high density graphic content customers can use

the “Stacker tray ller” that guides stacker paper exit.

Place the parts of the Stacker tray ller as illustrated below:

Several stacker paper jams

Call agent:

1. Ask customer for Media type used and plot content.

2. Ask customer to check there is free space between top of the stacker and the wall.

3. Ask customer to check if one or several wheels of the arms cover is stuck in the paper path.

4. Exclude the cause to be any of the previously described issues. See Thin paper is jamming in the stacker

on page 56 and High density plots jamming in the stacker on page 57.

A root cause can be one or several wheels of the arm cover stuck in the paper path.

Ask the customer to perform the following actions:

5. Check that no cable routing is blocking the paper path.

6. Remove all paper from the stacker.

7. Detach the stacker arms cover from the printer.

8. Visually check that there are no missing wheel supports in the stacker cover (there are 25 wheel supports).

9. Shake the stacker cover a couple of times so all the wheel supports can move freely.

10. Ensure that all wheel supports in the cover can rotate freely (by pushing them, and checking that they

return to their position). If any of them are stuck, try to move slightly to free them.

11. If any of the wheel supports are stuck or are missing, send a new stacker arms cover to the customer.

12. If all the wheel supports are free and there are none missing, then arrange an on-site visit with a new

stacker and stacker cover arms.

Service engineer:

Items required:

Take a stacker

Take stacker cover arms

58 Chapter 2 Troubleshooting ENWW

Page 69

1. Remove all paper from the stacker.

2. Detach the stacker cover from the printer.

3. Visually check that there are no missing wheel supports in the stacker cover (there are 25 wheel supports).

4. Shake the stacker cover a couple of times so all the wheel supports can move freely.

5. Ensure that all wheel supports in the cover can rotate freely (by pushing them, and checking that they

return to their position). If any of them are stuck, try to move slightly to free them.

6. If any of the wheel supports are stuck or are missing, send a new stacker arms cover to the customer.

7. If all the wheel supports are free and there are none missing, check that there are no free or misplaced

pieces at the bottom of the stacker (pinches, rst wheel holder, wheels, etc.).

ENWW Paper handling problems 59

Page 70

8. Check that Ramps are broken are not broken and are aligned.

9. Report root cause in cso and change Stacker.

Stacker capacity lower than expected

Stacker capacity is dened as up to 50 pages (T920/T1500/T2500), and 100 pages (T3500), A1/D size line

drawing plots in landscape on bond media, but stacker capacity depends on media thickness and page size. If

you are printing plots shorter than A1 and you experience a reduction in the stacker capacity because they

collapse and the curling lls the available stacking space:

●

Try to increase the length of the plots when printing A2 and A3 sizes:

60 Chapter 2 Troubleshooting ENWW

Page 71

–

Print A2 sizes in portrait position, using low-width rolls or nesting to minimize waste of paper.

–

For A3 size, group dierent jobs in the same plot.

The stacker detects "Stacker is full" permanently

Even when there are no pages in the stacker, it detects that is it full.

●

Remove the stacker arm and check the stacker wheels. If you nd a stacker wheel in the upper position,

get it down with the hand.

●

Run the capacity sensor diagnostic.

●

Run the ramps motor diagnostic.

●

Check that when the ramps are up all are at the same height.

If ramps are not aligned, replace the stacker.

●

Run the capacity sensor diagnostic. If it fails, replace Hand o Assy sensor.

The stacker detects "Stacker jam" permanently

Even when there are no pages in the stacker, it detects a jam.

●

Run the capacity sensor diagnostic. If it fails, replace Hand o Assy sensor.

The printer rejects the paper during paper load

If the roll load process is too long and unsuccessful, check the following items:

●

Roll paper is properly inserted in the spindle and pressed uniformly by the hubs.

●

The core of the roll paper is not misplaced. If this is the case, try to correct its position.

●

Check if the black hub of the spindle is damaged. If any part of the spindle is damaged, it could cause roll

load problems.

If the roll aected is from a polyester or lm type, it is possible that the edges of the paper are not properly

detected during the paper load process:

●

Upgrade to the latest FW release to solve the problem, as the paper load algorithm has been improved.

Prints do not fall neatly into the basket

●

Ensure that the network and power cables are not getting in the way.

●

Ensure that the basket is correctly installed.

ENWW Paper handling problems 61

Page 72

●

Ensure that the basket is open.

●

Ensure that the basket is not full.

●

Ensure that the paper is not jammed.

●

Paper often tends to curl near the end of a roll, which can cause output problems. Load a new roll, or

remove prints manually as they are completed.

If you see the message Please remove the print from the basket and press OK to continue, empty the basket,

check that there is no paper in the path to the basket, then press OK. The printer checks that the problem has

xed.

been

Using the stacker

Installation

Prevent interruptions:

1. Open the basket; this indicates the clear space required at the back of the printer.

2. Route the cables to the side desired to attach the power cable; the left side is shown here.

62 Chapter 2 Troubleshooting ENWW

Page 73

Removing prints from the stacker tray

Sheets can be removed from the stacker while printing. It is recommended to remove all prints when not

printing.

NOTE: Once removed, do not put prints back into the tray as this can collapse output.

If prints are replaced in the stacker tray; make sure that they reach the bottom of the stacker and don’t overlap

the page that is being printed, or the small black plastic piece.

ENWW Paper handling problems 63

Page 74

Printing high quality prints

To obtain the best possible quality, consider:

High quality photo media graphics

Use instant dry photo media such as HP Instant Dry Photo or Satin paper to get ready-to-use and robust

prints.

Optimize quality when printing solid black areas; use Manual mode (print with the stacker open), and

carefully remove the output immediately after printing.

High quality matte media graphics

HP Heavy Coated Paper and Super Heavy Coated Paper reproduce deeper blacks and more saturated colors

than bond paper due to heavier coating.

When printing solid black areas, carefully remove output immediately after printing to prevent the next

print covering it.

Utilize full stacker capacity

The stacker is optimized for plain paper use (the most common size ISO A1/D). Capacity is up to 50 pages. When

the printer detects that the stacker is full, an alert appears to empty the stacker. The actual capacity may dier

depending on the combination of paper size printed and media type; for example, heavyweight coated is a media

with a higher grammage than plain paper, therefore the number of pages that the stacker can handle is less.

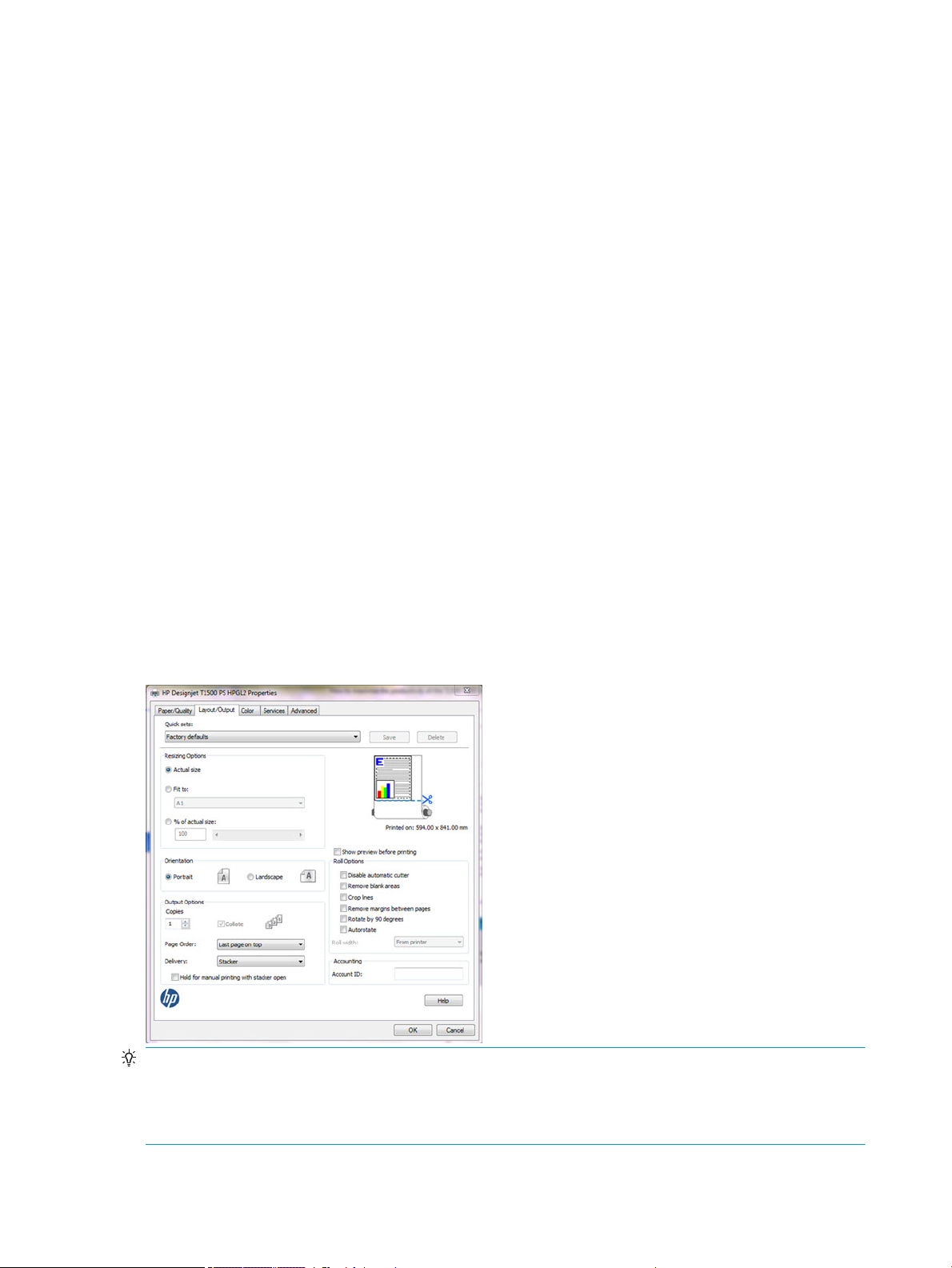

How to switch from stacker to basket and vice versa

The default output is the Stacker, however, switching to the basket is very easy:

In driver properties, select the Layout/Output tab, then in Output options select Basket for Delivery:

TIP: Also use this setting together with the Quick sets in the driver or as a driver default by going to Windows

Start, then Device and printers and editing the Printing properties.

TIP: At any time, the jobs appearing in the queue can be redirected and sent to either the stacker or the basket

by modifying the job setting in the Front Panel.

64 Chapter 2 Troubleshooting ENWW

Page 75

Manual mode

Manual mode is designed to help maximum print quality with photo media. The driver automatically enables

Manual mode when photo media is selected in the driver; the job now waits in queue for the stacker to open, and

to be activated. This ensures the stacker doesn’t touch the print while drying. If jobs are not required to be "Hold

for manual mode" there are 2 options:

1. Manual mode can be enabled/disabled in the Layout/options tab in the driver by clicking in the checkbox

2. Disable the driver check for photo media so Manual mode is not enabled automatically. Press the Start

Hold for manual printing with stacker open.

button, select Devices and Settings, and right-click the printer’s icon. Select Printer Properties. Select

Device Settings.

NOTE: When a job is put "On hold for manual mode" the printer doesn’t stop; while this job is waiting, and if the

stacker is closed, other jobs can still be sent and printed.

NOTE: After printing the job sent in Manual mode with the stacker open, the printer stops until the stacker is

closed, or another job is sent from the queue.

Resuming print interruptions

The stacker has a sensor to prevent unexpected behavior of the media in the tray, and ensure that the jams

never reach the printhead. Eventually, when prompted by the printer, it’s required to go to the stacker and

correct it by attening the paper. Once xed, printing will resume.

Media jam frequency may increase under certain conditions; when printing images with very high ink density on

light media like Bond or Coated under specic environmental conditions such as 30ºC-86ºF/70%. In such cases,

switching to a media with higher grammage such as HP Heavy Weight Coated can help to increase productivity.

The paper type is not in the list

To work with a paper that does not appear in the list in the driver or front panel, you can choose one of the other

papers in the list. However, you should at least choose a paper of the same type: transparent or translucent,

photo or bond, coated or technical.

ENWW Paper handling problems 65

Page 76

NOTE: For photo paper, it is important to select a photo paper type, as the printer adjusts its use of ink for

photo paper.

Transparent or translucent lm

If your paper is a transparent lm (for example, a transparency), select paper type Film > Transparent/Clear lm.

If your paper is a translucent paper or lm (for example, technical paper), select paper type Film > Matte lm.

Photo paper

If your paper is a photo paper, use the Photo Paper category. For gloss or high-gloss paper, select paper type

Photo Gloss Paper. For semi-gloss, satin, pearl, or luster nishes, select paper type Photo Semi-gloss/Satin

Paper.

To increase gamut on photo paper, select paper type HP Universal Gloss Photo Paper or HP Universal Satin

Photo Paper, depending on the nish.

Bond and coated or technical paper

Your paper type selection for generic paper depends on the paper’s ink absorption capacity.

●

For thin papers (< 90 g/m2) or uncoated papers (for example plain paper or bright white paper), select

paper type Bond and Coated Paper > Plain Paper. You can also select Recycled Bond Paper.

●

For light coated papers (< 110 g/m2), select paper type Bond and Coated Paper > HP Coated Paper.

●

For heavyweight coated papers (< 200 g/m2), select paper type Bond and Coated Paper > Heavyweight

Coated Paper.

Black ink is easily removed when touched

This happens when your paper is incompatible with matte black ink. To use an optimized ink combination, select

paper type Photo Paper > Photo Gloss Paper.

After printing, the paper has wrinkles or there is too much ink

Reduce the quantity of ink, or use thicker paper. Matte paper categories from thinnest to thickest are:

●

Plain Paper

●

Coated Paper

●

Heavyweight Coated Paper

●

Super Heavyweight Plus Matte Paper

TIP: If you load paper that is slightly thicker than the paper type you selected, the printer will use less ink than

usual for the loaded paper.

The printer printed on the wrong paper type

If the printer prints your job before you were able to load your desired paper, you may have Any or Use printer

settings selected for the Paper Type in the printer driver. In this case, the printer will print immediately on

whichever paper is loaded. Load your desired paper, and select your paper type specically in the driver.

66 Chapter 2 Troubleshooting ENWW

Page 77

●

In the Windows driver dialog: select the Paper/Quality tab, then select your paper type from the Paper Type