Hitachi SJ700-150LFF2, SJ700-055LFF2, SJ700-185LFF2, SJ700-220LFF2, SJ700-300LFF2 Instruction Manual

...

HITACHI INVERTER

SJ700-2 SERIES

INSTRUCTION MANUAL

Read through this Instruction Manual, and keep it handy for future reference.

NT204X

Introduction

Thank you for purchasing the Hitachi SJ700-2 Series Inverter.

This Instruction Manual describes how to handle and maintain the Hit achi SJ700 Series Inverter. Read

this Instruction Manual carefully before using the inverter, and then keep it handy for those who operate,

maintain, and inspect the inverter.

Before and during the installation, operation, inspection, and maintenance of the inverter, always refer to

this Instruction Manual to obtain the necessary related knowledge, and ensure you underst and and

follow all safety information, precautions, and operating and handling instructions for the correct use of

the inverter.

Always use the inverter strictly within the range of the specifications described in this Instruction Manual

and correctly implement maintenance and inspections to prevent faults occurring.

When using the inverter together with optional products, also read the manuals for those products. Note

that this Instruction Manual and the manual for each optional product to be used should be delivered to

the end user of the inverter.

Handling of this Instruction Manual

- The contents of this Instruction Manual are subject to change without prior notice.

- Even if you lose this Instruction Manual, it will not be resupplied, so please keep it carefully.

- No part of this Instruction Manual may be reproduced in any form without the publisher's permission.

- If you find any incorrect description, missing description or have a question concerning the contents of

this Instruction Manual, please contact the publisher.

Revision History

No. Revision content Date of issue Manual code

1 First edition July 2007 NT204X

- The current edition of this Instruction Manual also includes some corrections of simple misp rints,

missing letters, misdescriptions and certain added explanations other than those listed in the above

Revision History table.

Safety Instructions

Safety Instructions

Be sure to read this Instruction Manual and appended documents thoroughly before installing, operating,

maintaining, or inspecting the inverter.

In this Instruction Manual, safety instructions are classified into two levels, namely WARNING and

CAUTION.

: Indicates that incorrect handling may cause hazardous situations, which may result in

serious personal injury or death.

! WARNING

: Indicates that incorrect handling may cause hazardous situations, which may result in

moderate or slight personal injury or physical damage alone.

! CAUTION

Note that even a level situation may lead to a serious consequence according to

circumstances. Be sure to follow eve ry safe ty instructi on, which con tains imp ort ant safety information. Also

focus on and observe the items and instructions described under "Notes" in the text.

! CAUTION

CAUTION

Many of the drawings in this Instruction Manual show the inverter with covers and/or parts blocking your

view being removed.

Do not operate the inverter in the status shown in those drawings. If you have removed the covers

and/or parts, be sure to reinst all them in their original positions before starting operation, and follow all

instructions in this Instruction Manual when operating the inverter.

!

1. Installation

CAUTION

- Install the inverter on a non-flammable surface, e.g., metal. Otherwise, you run the risk of fire.

- Do not place flammable materials near the installed inverter. Otherwise, you run the risk of fire.

- When carrying the inverter, do not hold its top cover. Otherwise, you run the risk of injury by dropping

the inverter.

- Prevent foreign matter (e.g., cut pieces of wire, sputtering welding materials, iron chips, wire, and

dust) from entering the inverter. Otherwise, you run the risk of fire.

- Install the inverter on a structure able to bear the weight specified in this Instruction Manual.

Otherwise, you run the risk of injury due to the inverter falling.

- Install the inverter on a vertical wall that is free of vibrations. Otherwise, you run the risk of injury due

to the inverter falling.

- Do not install and operate the inverter if it is damaged or its parts are missing. Otherwise, you run the

risk of injury.

- Install the inverter in a well-ventilated indoor site not exposed to direct sunlight. Avoid places where

the inverter is exposed to high temperature, high humidity, condensation, dust, explosive gases,

corrosive gases, flammable gases, grinding fluid mist, or salt water. Otherwise, you run the risk of fire.

- The inverter is precision equipment. Do not allow it to fall or be subject to high impacts, step on it, or

place a heavy load on it. Doing so may cause the inverter to fail.

!

i

Safety Instructions

2. Wiring

WARNING

- Be sure to ground the inverter. Otherwise, you run the risk of electric shock or fire.

- Commit wiring work to a qualified electrician. Otherwise, you run the risk of electric shock or fire.

- Before wiring, make sure that the power supply is off. Otherwise, you run the risk of electric shock or

fire.

- Perform wiring only after installing the inverter. Otherwise, you run the risk of electric shock or injury.

- Do not remove rubber bushings from the wiring section. Otherwise, the edges of the wiring cover may

damage the wire, resulting in a short circuit or ground fault.

!

CAUTION

- Make sure that the voltage of AC power supply matches the rated voltage of your inverter. Otherwise,

you run the risk of injury or fire.

- Do not input single-phase power into the inverter. Otherwise, you run the risk of fire.

- Do not connect AC power supply to any of the output terminals (U, V, and W). Otherwise, you run the

risk of injury or fire.

- Do not connect a resistor directly to any of the DC terminals (PD, P, and N). Otherwise, you run the

risk of fire.

- Connect an earth-leakage breaker to the power input circuit. Otherwise, you run the risk of fire.

- Use only the power cables, earth-leakage breaker, and magnetic contactors that have the specified

capacity (ratings). Otherwise, you run the risk of fire.

- Do not use the magnetic contactor installed on the primary and secondary sides of the inverter to stop

its operation.

- Tighten each screw to the specified torque. No screws must be lef t loose. Otherwise, you run the risk

of fire.

- Before operating, slide switch SW1 in the inverter, be sure to turn off the power supply. Otherwise, you

run the risk of electric shock and injury.

- Since the inverter supports two modes of cooling-fan operation, the inverter power is not always off,

even when the cooling fan is stopped. Therefore, be sure to confirm that the power supply is off before

wiring. Otherwise, you run the risk of electric shock and injury.

!

ii

Safety Instructions

3. Operation

WARNING

- While power is supplied to the inverter, do not touch any terminal or internal part of the inverter, check

signals, or connect or disconnect any wire or connector. Otherwise, you run the risk of electric shock

or fire.

- Be sure to close the terminal block cover before turning on the inverter power. Do not open the

terminal block cover while power is being supplied to the inverter o r voltage remains inside. Ot herwise,

you run the risk of electric shock.

- Do not operate switches with wet hands. Otherwise, you run the risk of electric shock.

- While power is supplied to the inverter, do not touc h the terminal of the inverte r, even if it has stopped.

Otherwise, you run the risk of injury or fire.

- If the retry mode has been selected, the inverter will restart suddenly af ter a break in the tripping

status. Stay away from the machine controlled by the inverter when the inverter is under such

circumstances. (Design the machine so that human safety can be ensured, even when the inverter

restarts suddenly.) Otherwise, you run the risk of injury.

- Do not select the retry mode for controlling an elevating or traveling device because output

free-running status occurs in retry mode. Otherwise, you run the risk of injury or damage to the

machine controlled by the inverter .

- If an operation command has been input to the inverter before a short-term power failure, the inverter

may restart operation after the power recovery. If such a restart may put persons in danger, design a

control circuit that disables the inverter from restarting after power recovery. Otherwise, you run the

risk of injury.

- The [STOP] key is effective only when its function is enabled by setting. Prepare an emergency stop

switch separately. Otherwise, you run the risk of injury.

- If an operation command has been input to the inverter before the inverter enters alarm status, the

inverter will restart suddenly when the alarm status is reset. Before resetting the alarm status, make

sure that no operation command has been input.

- While power is supplied to the inverter, do not touch any internal part of the invert er or insert a bar in it.

Otherwise, you run the risk of electric shock or fire.

!

CAUTION

- Do not touch the heat sink, which heats up during the inverter operation. Otherwise, you run the risk of

burn injury.

- The inverter allows you to easily control the speed of motor or machine operations. Before operating

the inverter, confirm the cap acity and ratings of the motor or machine controlled by the inverter.

Otherwise, you run the risk of injury.

- Install an external brake system if needed. Otherwise, you run the risk of injury.

- When using the inverter to operate a standard motor at a frequency of over 60 Hz, check the allowable

motor speeds with the manufacturers of the motor and the machine to be driven and obtain their

consent before starting inverter operation. Otherwise, you run the risk of damage to the motor and

machine.

- During inverter operation, check the motor for the direction of rotation, abno rmal sound, and

vibrations. Otherwise, you run the risk of damage to the machine driven by the motor.

!

iii

Safety Instructions

4. Maintenance, inspection, and part s replacement

WARNING

- Before inspecting the inverter, be sure to turn off the power supply and wait for 10 minutes or more.

Otherwise, you run the risk of electric shock.

(Before inspection, confirm that the Charge lamp on the inverter is off and the DC voltage between

terminals P and N is 45 V or less.)

- Commit only a designated person to maintenance, inspection, and the replacement of part s.

(Be sure to remove wristwatches and metal accessories, e.g., bracelets, before maintenance and

inspection work and to use insulated tools for the work.)

Otherwise, you run the risk of electric shock and injury.

!

5. Others

WARNING

- Never modify the inverter. Otherwise, you run the ri sk of electric shock and injury .

!

CAUTION

- Do not discard the inverter with household waste. Contact an industrial wa ste management company

in your area who can treat industrial waste without polluting the environment.

!

iv

Safety Instructions

Precautions Concerning Electromagnetic Compatibility (EMC)

The SJ700 series inverter conforms to the requirements of Electromagnetic Compatibility (EMC) Directive

(2004/108/EC). However, when using the inverter in Europe, you must comply with the following

specifications and requirements to meet the EMC Directive and other stand ards in Europe:

WARNING: This equipment must be installed, adju sted, and mainta ined by qualified engineers who

have expert knowledge of electric work, inverter operation, and the hazardous circumstances that can

occur. Otherwise, personal injury may result.

!

1. Power supply requirements

a. Voltage fluctuation must be -15% to +10% or less.

b. Voltage imbalance must be ±3% or less.

c. Frequency variation must be ±4% or less.

d. Total harmonic distortion (THD) of voltage must be ±10% or less.

2. Installation requirement

a. A special filter intended for the SJ700 series inverter must be installed.

3. Wiring requirements

a. A shielded wire (screened cable) m ust be used fo r motor wi ring, a n d the length o f the cabl e m ust be

according to the following table (Table 1).

b. The carrier frequency must be set according to the following table to meet an EMC requirement

(Table 1).

c. The main circuit wiring must be sep arated from the control circuit wiring.

4. Environmental requirements (to be met when a filter is used)

a. Ambient temperature must be within the range -10°C to +40°C.

b. Relative humidity must be within the range 20% to 90% (non-condensing).

c. Vibrations mu st be 5.9 m/s

2

(0.6 G) (10 to 55 Hz) or less. (5.5-22kW)

2.94 m/s

2

(0.3 G) (10 to 55Hz) or less. (30 to 55kW)

d. The inverter must be installed indoors (not exposed to corrosive gases and dust) at an altitude of

1,000 m or less.

v

Safety Instructions

Precautions Concerning Compliance with UL and CUL Standards

(Standards to be met: UL508C and CSA C22.2 No. 14-05)

The SJ700 series inverter is an open-type AC inverter with 3-phase input and output, intended for use in

an enclosure. The inverter supplies both voltage and frequency, both of which are adjust able, to an AC

motor. The inverter can automatically maintain a constant volts/Hz ratio to enhance the motor capability

throughout its entire speed range.

1. Only 75C CU or equivalent wires must be used for wiring.

2. Inverter models with the suffix "L" (200 V class models) are suited to circuits that transmit current not

exceeding 100k rms symmetrical amperes and with voltage of no more than 240 V.

3. Inverter models with the suffix "H" (400 V class models) are suited to circuits that transmit current not

exceeding 100k rms symmetrical amperes and with voltage of no more than 480 V.

4. The inverter must be installed in an environment that is rated for at least Pollution Degree 2 or

equivalent.

5. The ambient temperature must not exceed 50°C.

6. The capacitor discharge time is 10 minutes or more. (Caution: Care must be taken to avoid the risk of

electric shock.)

7. Each model of the inverter has a solid-state overload protection circuit or an equivalent feature for the

motor.

8. The table below lists the tightening torque and wire range specifications for the field wiring of inverter

terminals.

Model No. Required torque (N-m) Wire range (AWG)

SJ700-055LFF2 2.5 8

SJ700-075LFF2 2.5 6

SJ700-110LFF2 4.9 4

SJ700-150LFF2 4.9 2

SJ700-185LFF2 4.9 1

SJ700-220LFF2 8.8 1 or 1/0

SJ700-300LFF2 8.8 2/0 or 1/0 (parallel)

SJ700-370LFF2 8.8 4/0 or 1/0 (parallel)

SJ700-450LFF2 8.8 4/0 or 1/0 (parallel)

SJ700-550LFF2 13.7 2/0 parallel

SJ700-055HFF2 2.5 12

SJ700-075HFF2 2.5 10

SJ700-110HFF2 4.9 8

SJ700-150HFF2 4.9 6

SJ700-185HFF2 4.9 6

SJ700-220HFF2 4.9 6 or 4

SJ700-300HFF2 4.9 3

SJ700-370HFF2 8.8 1

SJ700-450HFF2 8.8 1

SJ700-550HFF2 8.8 2/0

vi

Safety Instructions

9. This Instruction Manual indicates the sizes of the distribution fuse and circuit breaker that must be

connected to this inverter. The following table lists the inverse time and current ratings of the circuit

breakers (with rated voltage of 600 V) to be connected to the individual inverter models:

Model No. Fuse/circuit breaker (A)

Type Rating

SJ700-055LFF2 Inverse time 30 A

SJ700-075LFF2 Inverse time 40 A

SJ700-110LFF2 Inverse time 60 A

SJ700-150LFF2 Inverse time 80 A

SJ700-185LFF2 Inverse time 100 A

SJ700-220LFF2 Inverse time 125 A

SJ700-300LFF2 Inverse time 150 A

SJ700-370LFF2 Inverse time 175 A

SJ700-450LFF2 Inverse time 225 A

SJ700-550LFF2 Inverse time 250 A

SJ700-055HFF2 Inverse time 40 A

SJ700-075HFF2 Inverse time 40 A

SJ700-110HFF2 Inverse time 40 A

SJ700-150HFF2 Inverse time 40 A

SJ700-185HFF2 Inverse time 50 A

SJ700-220HFF2 Inverse time 60 A

SJ700-300HFF2 Inverse time 70 A

SJ700-370HFF2 Inverse time 90 A

SJ700-450HFF2 Inverse time 125 A

SJ700-550HFF2 Inverse time 125 A

10. Field wiring of the inverter must incorporate UL-listed, CSA-certified closed-loop terminal connectors

that match the wire gauge in terms of size. The crimping tool specified by the co nnector manufacturer

must be used to secure each connector.

vii

Contents

Chapter 1 Overview

1.1 Inspection of the Purchased Product························································································1 - 1

1.1.1 Inspecting the product··································································································1 - 1

1.1.2 Instruction manual (this manual)··················································································1 - 1

1.2 Method of Inquiry and Product Warranty··················································································1 - 2

1.2.1 Method of inquiry ·········································································································1 - 2

1.2.2 Product warranty··········································································································1 - 2

1.3 Exterior Views and Names of Parts··························································································1 - 3

Chapter 2 Installation and Wiring

2.1 Installation·································································································································2 - 1

2.1.1 Precautions for installation·······························································································2 - 2

2.1.2 Backing plate ···················································································································2 - 4

2.2 Wiring········································································································································2 - 5

2.2.1 Terminal connection diagram and explanation of terminals and switch settings·············2 - 6

2.2.2 Wiring of the main circuit ·································································································2 - 14

2.2.3 Wiring of the control circuit ······························································································2 - 21

2.2.4 Wiring of the digital operator····························································································2 - 22

2.2.5 Selection and wiring of regenerative braking resistor (on 5.5 kW to 22 kW models)······2 - 23

Chapter 3 Operation

3.1 Operating Methods ···················································································································3 - 1

3.2 How To Operate the Digital Operator························································································3 - 3

3.2.1 Names and functions of components ··············································································3 - 3

3.2.2 Code display system and key operations········································································3 - 4

3.3 How To Make a Test Run··········································································································3 - 10

Chapter 4 Explanation of Functions

4.1 Monitor Mode····························································································································4 - 1

4.1.1 Output frequency monitoring (d001)············································································4 - 1

4.1.2 Output current monitoring (d002)·················································································4 - 1

4.1.3 Rotation direction minitoring (d003)·············································································4 - 1

4.1.4 Process variable (PV), PID feedback monitoring (d004, A071, A075) ························4 - 1

4.1.5 Intelligent input terminal status (d005)·········································································4 - 2

4.1.6 Intelligent output terminal status (d006)·······································································4 - 2

4.1.7 Scaled output frequency monitoring (d007, b086)·······················································4 - 2

4.1.8 Actual-frequency monitoring d008, P011, H004, H204)··············································4 - 3

4.1.9 Torque command monitoring (d009, P033, P034)·······················································4 - 3

4.1.10 Torque bias monitoring (d010, P036 to P038)·····························································4 - 3

4.1.11 Torque monitoring (d012)·····························································································4 - 3

4.1.12 Output voltage monitoring (d013)················································································4 - 3

4.1.13 Power monitoring (d014) ·····························································································4 - 3

viii

Contents

ix

4.1.14 Cumulative power monitoring (d015, b078, b079) ······················································4 - 4

4.1.15 Cumulative operation RUN time monitoring (d016)·····················································4 - 4

4.1.16 Cumulative power-on time monitoring (d017) ·····························································4 - 4

4.1.17 Heat sink temperature monitoring (d018)····································································4 - 4

4.1.18 Motor temperature monitoring (d019, b98)··································································4 - 4

4.1.19 Life-check monitoring (d022)·······················································································4 - 5

4.1.20 Program counter display (easy sequence function) (d023)·········································4 - 5

4.1.21 Program number monitoring (easy sequence function) (d024)···································4 - 5

4.1.22 User monitors 0 to 2 (easy sequence function)···························································4 - 5

4.1.23 Pulse counter monitor··································································································4 - 5

4.1.24 Position command monitor (in absolute position control mode)··································4 - 5

4.1.25 Current position monitor (in absolute position control mode)······································4 - 5

4.1.26 Trip Counter (d080)······································································································4 - 5

4.1.27 Trip monitoring 1 to 6 (d081, d082 to d086) ································································4 - 6

4.1.28 Programming error monitoring (d090)·········································································4 - 6

4.1.29 DC voltage monitoring (d102)······················································································4 - 6

4.1.30 BRD load factor monitoring (d103, b090)····································································4 - 6

4.1.31 Electronic thermal overload monitoring (d104)····························································4 - 6

4.2 Function Mode··························································································································4 - 7

4.2.1 Output frequency setting (F001, A001, A020, C001 to C008)·····································4 - 7

4.2.2 Keypad Run key routing (F004)···················································································4 - 7

4.2.3 Rotational direction restriction (b035)··········································································4 - 7

4.2.4 Frequency source setting (A001) ················································································4 - 8

4.2.5 Run command source setting (A002, C001 to C008, C019, F004)·····························4 - 10

4.2.6 Stop mode selection (b091, F003, b003, b007, b088)················································4 - 11

4.2.7 STOP key enable (b087)·····························································································4 - 1

1

4.2.8 Acceleration/deceleration time setting (F002, F003, A004, P031, C001 to C008)······4 - 12

4.2.9 Base frequency setting (A003, A081, A082)································································4 - 13

4.2.10 Maximum frequency setting (A004)·············································································4 - 14

4.2.11 Carrier frequency setting (b083)··················································································4 - 14

4.2.12 External analog input setting (O, O2, and OI) (A005, A006, C001 to C008)···············4 - 15

4.2.13 Frequency operation function (A141 to A143, A001, A076) ········································4 - 15

4.2.14 Frequency addition function (A145, A046, C001 to C008)··········································4 - 16

4.2.15 Start/end frequency setting for external analog input (A011 to A015, A101 to A105,

A111 to A114)···············································································································4 - 18

4.2.16 External analog input (O/OI/O2) filter setting (A016)···················································4 - 20

4.2.17 V/f gain setting (A045, A082)·······················································································4 - 24

4.2.18 V/F characteristic curve selection (A044, b100, b101)················································4 - 25

4.2.19 T orque boost setting (A041, A042, A043, H003, H004)···············································4 - 25

4.2.20 DC braking (DB) setting (A051 to A059, C001 to C008)·············································4 - 26

4.2.21 Frequency upper limit setting (A061, A062) ································································4 - 30

4.2.22 Jump frequency function (A063 to A068) ····································································4 - 31

4.2.23 Acceleration stop frequency setting (A069, A070, A097)············································4 - 32

4.2.24 PID function (A001, A005, A071 to A076, d004, C001 to C008, C021 to C025,

C044)···························································································································4 - 33

4.2.25 Two-stage acceleration/deceleration function (2CH) (F002, F003, A092 to A096,

C001 to C008) ·············································································································4 - 36

4.2.26 Acceleration/deceleration curve selection (A097, A098, A131, A132) ························4 - 37

4.2.27 Energy-saver operation (A085, A086)·········································································4 - 39

4.2.28 Retry or trip after instantaneous power failure (b001 to b005, b0 07, b008,

C021 to C026) ·············································································································4 - 40

4.2.29 Phase loss power input protection (b006) ···································································4 - 37

4.2.30 Electronic thermal protection (b012, b013, b015, b016, C021 to C026, C061) ··········4 - 38

Contents

x

4.2.32 Overload restriction/overload notice (b021 to b026, C001 to C008, C021 to C026,

C040, C041, C111) ······································································································4 - 40

4.2.33 Overcurrent restraint (b027) ························································································4 - 41

4.2.34 Overvoltage restraint during deceleration (b130 to b132) ···········································4 - 42

4.2.35 Start frequency setting (b082)······················································································4 - 43

4.2.36 Reduced voltage start function (b036, b082)·······························································4 - 43

4.2.37 Dynamic braking (BRD) function (b090, b095, b096)··················································4 - 44

4.2.38 Cooling-fan operation setting (b092) ···········································································4 - 44

4.2.39 Intelligent input terminal setting (SET, SET3) (C001 to C008)····································4 - 45

4.2.40 Input terminal a/b (NO/NC) selection (C011 to C018, C019)·······································4 - 46

4.2.41 Multispeed select setting (CF1 to CF4 and SF1 to SF7) (A019, A020 to A035,

C001 toC008)···············································································································4 - 46

4.2.42 Jogging (JG) command setting (A038, A039, C001 to C008) ·····································4 - 48

4.2.43 2nd/3rd motor control function (SET and SET3)··························································4 - 49

4.2.44 Software lock (SFT) function (b031, C001 to C008)····················································4 - 50

4.2.45 Forcible-operation from digital operation (OPE) function (A001, A002,

C001 to C008)··············································································································4 - 50

4.2.46 Forcible-operation from terminal (F-TM) function (A001, A002, C001 to C008)··········4 - 50

4.2.47 Free-run stop (FRS) function (b088, b033, b007, b028 to b030, C001 to C008)········4 - 51

4.2.48 Commercial power source switching (CS) function (b003, b007, C001 to C008)·······4 - 52

4.2.49 Reset (RS) function (b003, b007, C102, C103, C001 to C008) ··································4 - 53

4.2.50 Unattended start protection (USP) function (C001 to C008)·······································4 - 55

4.2.51 Remote control function (UP and DWN) (C101, C001 to C008) ·································4 - 55

4.2.52 External trip (EXT) function (C001 to C008)································································4 - 56

4.2.53 3-wire interface operation function (STA, STP, and F/R) (C001 to C008)···················4 - 56

4.2.54 Control gain switching function (CAS) (A044, C001 to C008, H005, H050 to H052,

H070 to H072)··············································································································4 - 57

4.2.55 P/PI switching function (PPI) (A044, C001 to C008, H005, H050 to H052,

H070 to H072)··············································································································4 - 57

4.2.56 Analog command holding function (AHD) (C001 to C008)··········································4 - 58

4.2.57 Intelligent pulse counter (PCNT and PCC)··································································4 - 58

4.2.56 Intelligent output terminal setting (C021 to C026) ·······················································4 - 59

4.2.57 Intelligent output terminal a/b (NO/NC) selection (C031 to C036) ······························4 - 60

4.2.58 Running signal (RUN) (C021 to C025)········································································4 - 61

4.2.59 Frequency arrival signals (FA1, FA2, FA3, FA4, and F A 5) (C021 to C025, C042,

C043, C045, C046)······································································································4 - 61

4.2.60 Running time over and power-on time over signals (RNT and ONT)

(b034, C021to C026, d016, d017)···············································································4 - 63

4.2.61 0 Hz speed detection signal (ZS) (A044, C021 to C025, C063)··································4 - 63

4.2.62 Over-torque signal (OTQ) (A044, C021 to C025, C055 to C058) ·······························4 - 64

4.2.63 Alarm code output function (AC0 to AC3) (C021 to C025, C062)·······························4 - 64

4.2.64 Logical output signal operation function (LOG1 to LOG6) (C021 to C026,

C142 to C159)··············································································································4 - 65

4.2.65 Capacitor life warning signal (WAC) (C021 to C026)··················································4 - 66

4.2.66 Communication line disconnection signal (NDc) (C021 to C026, C077)·····················4 - 66

4.2.67 Cooling-fan speed drop signal (WAF) (C021 to C026, b092 to d022)·························4 - 67

4.2.68 Starting contact signal (FR) (C021 to C026)································································4 - 67

4.2.69 Heat sink overheat warning signal (OHF) (C021 to C026, C064) ·······························4 - 67

4.2.70 Low-current indication (LOC) signal (C021 to C026, C038, C039) ·····························4 - 68

4.2.71 Inverter ready signal (IRDY) (C021 to C026) ······························································4 - 68

4.2.72 Forward rotation signal (FWR) (C021 to C026)···························································4 - 68

4.2.73 Reverse rotation signal (RVR) (C021 to C026)···························································4 - 69

Contents

xi

4.2.74 Major failure signal (MJA) (C021 to C026)··································································4 – 69

4.2.77 Window comparators (WCO/WCOI/WCO2) (detection of terminal disconnection:

ODc/OIDc/O2Dc)·········································································································4 – 69

4.2.78 Output signal delay/hold function (C130 to C141)·······················································4 - 70

4.2.79 Input terminal response time ·······················································································4 - 70

4.2.80 External thermistor function (TH) (b098, b099, C085) ················································4 - 70

4.2.81 FM terminal (C027, b081)····························································································4 - 71

4.2.82 AM and AMI terminals (C028, C029, C106, C108 to C110)········································4 - 72

4.2.83 Initialization setting (b084, b085)·················································································4 - 73

4.2.84 Function code display restriction (b037, U001 to U012)·············································4 - 74

4.2.85 Initial-screen selection (selection of the initial screen to be displayed after

power-on) (b038)·········································································································4 - 76

4.2.86 Automatic user-parameter setting (b039, U001 to U012)············································4 - 77

4.2.87 Stabilization constant setting (H006)···········································································4 - 77

4.2.88 Selection of operation at option board error (P001, P002)··········································4 - 77

4.2.89 Optimum accel/decal operation function (A044, A085, b021, b022)···························4 - 78

4.2.90 Brake control function (b120 to b127, C001 to C008, C021, C025)····························4 - 79

4.2.91 Deceleration and stopping at power failure (nonstop deceleration at instantane ous

power failure) (b050 to b054) ······················································································4 - 81

4.2.92 Offline auto-tuning function (H001 to H004, H030 to H034, A003, A051, A082)·········4 - 82

4.2.93 Online auto-tuning function··························································································4 - 84

4.2.94 Secondary resistance compensation (temperature compensation) function

(P025, b098)················································································································4 - 84

4.2.95 Motor constants selection····························································································4 - 85

4.2.96 Sensorless vector control (A001, A044, F001, b040 to b044, H002 to H005,

H020 to H024,H050 to H052)······················································································4 - 86

4.2.97 Sensorless vector, 0 Hz domain control (A001, A044, F001, b040 to b044,

H002 to H005, H020to H024, H050 to H052, H060, H061) ········································4 - 87

4.2.98 T orque monitoring function (A044, C027 to C029, H003, H004)·································4 - 88

4.2.99 Pre-excitation function (FOC) (A044, C001 to C008)··················································4 - 88

4.2.100 Torque limitation function (A044, b040 to b044, C001 to C008, C021 to C025)·········4 - 89

4.2.101 Reverse Run protection function (A044, b046)···························································4 - 90

4.2.102 Torque LAD stop function (A044, b040 to b045)·························································4 - 91

4.2.103 High-torque multi-motor operation (A044, F001, b040 to b044, H002 to H005,

H020 to H024,H050 to H052)······················································································4 - 91

4.2.104 Easy sequence function (A017, P100 to P131)···························································4 - 92

4.3 Functions Available When the Feedback Option Board (SJ-FB) Is Mounted···························4 - 96

4.3.1 Functions requiring the SJ-FB·····················································································4 - 96

4.3.2 V2 control pulse setting ·······························································································4 - 96

4.3.3 Vector control with encoder feedback··········································································4 - 97

4.3.4 Torque biasing function································································································4 - 98

4.3.5 Torque control function································································································4 - 98

4.3.6 Pulse train position control mode ················································································4 - 99

4.3.7 Electronic gear function·······························································································4 - 101

4.3.8 Motor gear ratio setting function··················································································4 - 103

4.3.9 Position biasing function······························································································4 – 103

4.3.10 Speed biasing function·································································································4 - 103

4.3.11 Home search function··································································································4 - 104

4.3.12 Absolute position control mode ···················································································4 - 106

4.3.13 Operation in absolute position control mode·······························································4 - 107

4.3.14 Multistage position switching function (CP1/CP2/CP3)···············································4 - 108

4.3.15 Speed/position switching function (SPD)·····································································4 – 108

Contents

xii

4.3.16 Zero-return function ·····································································································4 - 109

4.3.17 Forward/reverse drive stop function (FOT/ROT)·························································4 - 110

4.3.18 Position range specification function ···········································································4 - 110

4.3.19 Teaching function·········································································································4 - 111

4.3.20 Servo-on function·········································································································4 - 112

4.3.32 Pulse train frequency input··························································································4 – 113

4.4 Communication Functions ········································································································4 - 116

4.4.1 Communication in ASCII mode····················································································4 - 108

4.4.2 Communication in Modbus-RTU mode········································································4 - 120

Chapter 5 Error Codes

5.1 Error Codes and Troubleshooting·····························································································5 - 1

5.1.1 Error codes ··················································································································5 - 1

5.1.2 Option boards error codes···························································································5 - 5

5.1.3 Trip conditions monitoring····························································································5 - 9

5.2 Warning Codes·························································································································5 - 10

Chapter 6 Maintenance and Inspection

6.1 Precautions for Maintenance and Inspection············································································6 - 1

6.1.1 Daily inspection············································································································6 - 1

6.1.2 Cleaning·······················································································································6 - 1

6.1.3 Periodic inspection·······································································································6 - 1

6.2 Daily and Periodic Inspections··································································································6 - 2

6.3 Ground Resistance Test with a Megger····················································································6 - 3

6.4 Withstand Voltage Test··············································································································6 - 3

6.5 Method of Checking the Inverter and Converter Circuits··························································6 - 4

6.6 DC-Bus Capacitor Life Curve····································································································6 - 5

6.7 Output of Life Warning··············································································································6 - 5

6.8 Methods of Measuring the Input/Output Voltages, Current, and Power···································6 - 6

Chapter 7 Specifications

7.1 Specifications····························································································································7 - 1

7.2 External dimensions··················································································································7 - 4

Chapter 8 List of Data Settings

8.1 Precautions for Data Setting·····································································································8 - 1

8.2 Monitoring Mode·······················································································································8 - 1

8.3 Function Mode··························································································································8 - 2

8.4 Extended Function Mode··········································································································8 - 3

Contents

xiii

Appendix

Appendix·············································································································································A - 1

Index

Index··············································································································································· Index - 1

Chapter 1 Overview

This chapter describes the inspection of the purchased product, the product

warranty, and the names of parts.

1.1 Inspection of the Purchased Product··············· 1 - 1

1.2 Method of Inquiry and Product Warranty ········· 1 - 2

1.3 Exterior Views and Names of Parts ················· 1 - 3

Chapter 1 Overview

1.1 Inspection of the Purchased Product

1.1.1 Inspecting the product

After unpacking, inspect the product as described below.

If you find the product to be abnormal or defective, contact your supplier or local Hitachi Di stributor.

(1) Check the product for damage (including falling of parts and dents in the inverter body) caused during

transportation.

(2) Check that the product package contains an inverter set and this Instruction Manual.

(3) Check the specification label to confirm that the product is the one you ordered.

Specification

label

Figure 1-1 Location of the specifications label

kW/(HP): 15/(20)

Model: SJ700-150HFF2

50Hz,60Hz 380-480V 3 Ph 35A

Output/Sortie: 0 -400Hz 380-480V 3 Ph 32A

Input/Entree: 50Hz,60Hz V 1 Ph A

MFGNo. 77AAT12345 A 001 Date: 0707

Hitachi Industrial Equipment

Systems Co.,Ltd.

MADE IN JAPAN

NE

Inverter model

Maximum applicable motor capacity

Input ratings

Output ratings

Serial number

Figure 1-2 Contents of the specifications label

1.1.2 Instruction manual (this manual)

This Instruction Manual describes how to operate the Hitachi SJ700-2 Series Inverter.

Read this Instruction Manual thoroughly before using the inverter, and then keep it handy for future

reference.

When using the inverter , together with o ptional prod ucts for the inverter, also refer to the manuals su pplied

with the optional products.

Note that this Instruction Manual and the manual for each optional product to be used should be delivered

to the end user of the inverter.

1 - 1

Chapter 1 Overview

1 - 2

1.2 Method of Inquiry and Product Warranty

1.2.1 Method of inquiry

For an inquiry about product damage or faults or a question about the product, notify your supplier of the

following information:

(1) Model of your inverter

(2) Serial number (MFG No.)

(3) Date of purchase

(4) Content of inquiry

- Location and condition of damage

- Content of your question

1.2.2 Product warranty

The product will be warranted for one year after the date of purchase.

Even within the warranty period, repair of a product fault will not be covered by the warranty (but the repair

will be at your own cost) if:

(1) the fault has resulted from incorrect usage not conforming to the instructions given in this Instruction

Manual or the repair or modification of the product carried out by an unqualified person,

(2) the fault has resulted from a cause not attributable to the delivered product,

(3) the fault has resulted from use beyond the limits of the product specifications, or

(4) the fault has resulted from disaster or other unavoidable events.

The warranty will only apply to the delivered inverter and excludes all damage to other equipment and

facilities induced by any fault of the inverter.

The warranty is effective only in Japan.

Repair at the user's charge

Following the one-year warranty period, any examination and repair of the product will be accepted at your

charge. Even during the warranty period, examination and repairs of faults, subject to the above scope of

the warranty disclaimer, will be available at charge.

To request a repair at your charge, contact your supplier or local Hitachi Distributor.

The Hitachi Distributors are listed on the back cover of this Instruction Manual.

1.2.3 Warranty Terms

The warranty period under normal installation and han dling conditions shall be two (2) years from the date

of manufacture (“DATE” on product nameplate), or one (1) year from the date of installation, whichever

occurs first. The warranty shall cover the repair or replacement, at Hitachi’s sole discretion, of ONLY the

inverter that was installed.

(1) Service in the following cases, even within the warranty period, shall be charged to the purchaser:

a. Malfunction or damage caused by mis-operation or modification or improper repair

b. Malfunction or damage caused by a drop after purchase and transportation

c. Malfunction or damage caused by fire, earthquake, flood, lightening, abnormal input voltage,

contamination, or other natural disasters

(2) When service is required for the product at your work site, all expenses associated with field rep air

shall be charged to the purchaser.

(3) Always keep this manual handy; please do not loose it. Please contact your Hitachi distributor to

purchase replacement or additional manuals.

Chapter 1 Overview

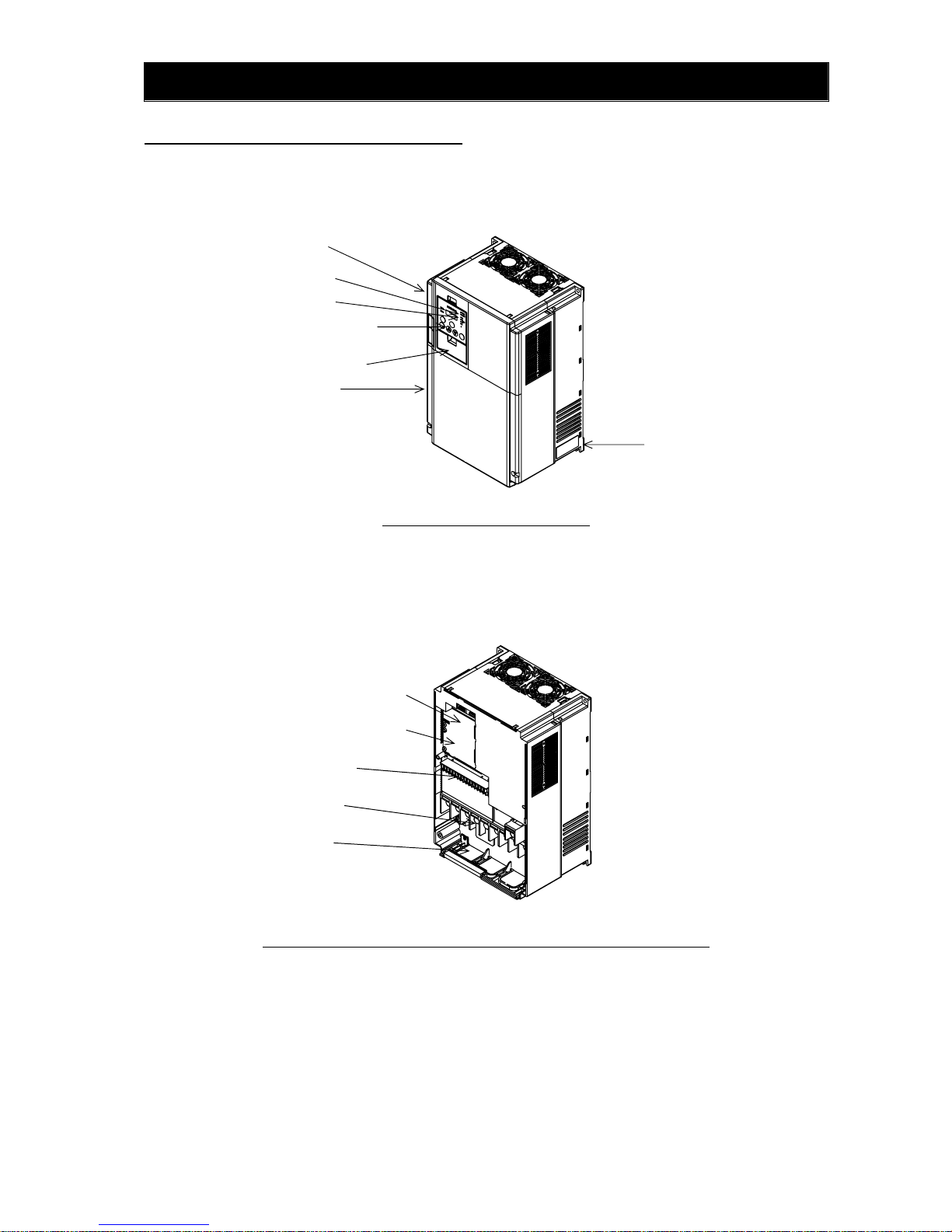

1.3 Exterior Views and Names of Parts

The figure below shows an exterior view of the inverter (model SJ700-150LFF2/HFF2 to

SJ700-220LFF2/HFF2).

Digital operator

Spacer cover

Terminal block cover

ALARM lamp

POWER lamp

Front cover

Specification label

Exterior view of shipped inverter

For the wiring of the main circuit and control circuit terminals, open the terminal block cover.

For mounting optional circuit boards, open the front cover.

Position to mount optional board 1

Main circuit terminals

Backing plate

Control circuit terminals

Position to mount optional board 2

Exterior view of inverter with front and terminal block covers removed

1 - 3

Chapter 2 Installation and Wiring

This chapter describes how to install the inverter and the wiring of main circuit

and control signal terminals with typical examples of wiring.

2.1 Installation ························································ 2 - 1

2.2 Wiring ······························································· 2 - 5

Chapter 2 Installation and Wiring

2.1 Installation

CAUTION

- Install the inverter on a non-flammable surface, e.g., metal. Otherwise, you run the risk of fire.

- Do not place flammable materials near the installed inverter. Otherwise, you run the risk of fire.

- When carrying the inverter, do not hold its top cover. Otherwise, you run the risk of injury by dropping

the inverter.

- Prevent foreign matter (e.g., cut pieces of wire, sputtering welding materials, iron chips, wire, and

dust) from entering the inverter. Otherwise, you run the risk of fire.

- Install the inverter on a structure able to bear the weight specified in this Instruction Manual.

Otherwise, you run the risk of injury due to the inverter falling.

- Install the inverter on a vertical wall that is free of vibrations. Otherwise, you run the risk of injury due

to the inverter falling.

- Do not install and operate the inverter if it is damaged or its parts are missing. Otherwise, you run the

risk of injury.

- Install the inverter in a well-ventilated indoor site not exposed to direct sunlight. Avoid places where

the inverter is exposed to high temperature, high humidity, condensation, dust, explosive gases,

corrosive gases, flammable gases, grinding fluid mist, or salt water. Otherwise, you run the risk of fire.

- The inverter is precision equipment. Do not allow it to fall or be subject to high impacts, step on it, or

place a heavy load on it. Doing so may cause the inverter to fail.

!

2 - 1

Chapter 2 Installation and Wiring

2.1.1 Precautions for installation

(1) Transportation

The inverter uses plastic parts. When carrying the inve rter, handle it carefully to prevent damage to the

parts.

Do not carry the inverter by holding the front or terminal block cover. Doing so may cause the inverter

to fall. Do not install and operate the inverter if it is damaged or its p arts are missing.

(2) Surface on which to install the inverter

The inverter will reach a high temperature (up to about 150°C) during operation. Install the inverter on

a vertical wall surface made of nonflammable material (e.g., metal) to avoid the risk of fire.

Leave sufficient space around the inverte r. In particular, keep sufficient distance between the in verter

and other heat sources (e.g., braking resistors and reactors) if they are installed in the vicinity.

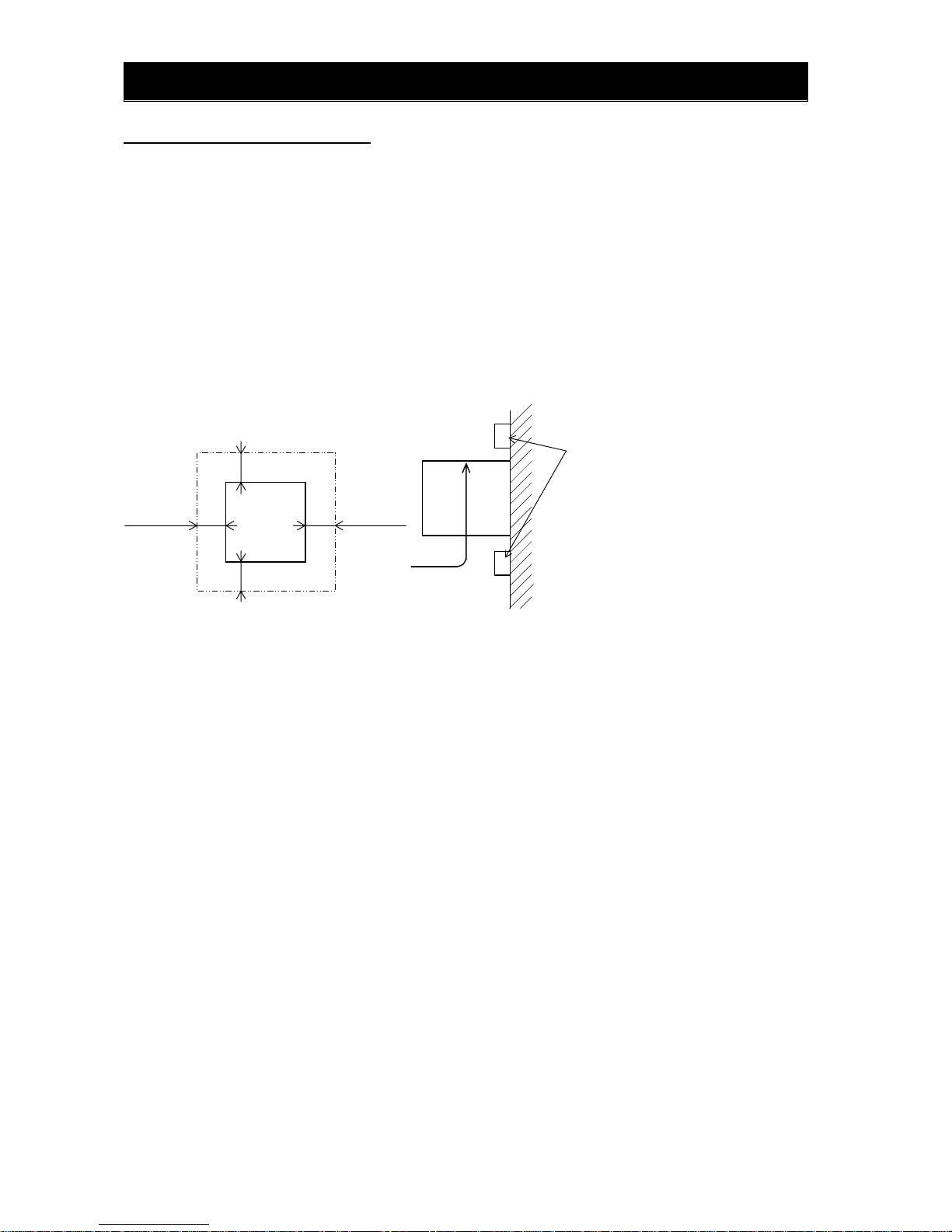

Keep enough clearance between the

inverter and the wiring ducts located

above and below the inverter to prevent

the latter from obstructing the ventilation

of the inverter.

*1 10 cm or more

*2 10 cm or more

A

clearance of 22 cm or more is required

for replacing the DC bus capacitors.

Inverter

(*2)

(*1)

5 cm or more 5 cm or more

Inverter

Wall

A

ir flow

(3) Ambient temperature

Avoid installing the inverter in a place where the ambient temperature goes above or below the

allowable range (-10°C to +50°C), as defined by the standard inverter specification.

Measure the temperature in a position about 5 cm distant from the bottom-center point of the inverter,

and check that the measured temperature is within the allowable range.

Operating the inverter at a temperature outside this range will shorten the inverter life (especially the

capacitor life).

(4) Humidity

Avoid installing the inverter in a place where the relative humidity goes above or below the allowable

range (20% to 90% RH), as defined by the standard inverter specification.

Avoid a place where the inverter is subject to con densation.

Condensation inside the inverter will result in short circuits and malfunctioning of electronic p arts. Also

avoid places where the inverter is exposed to direct sunlight.

(5) Ambient air

Avoid installing the inverter in a place where the inverter is subject to dust, corrosive gases,

combustible gases, flammable gases, grinding fluid mist, or salt water.

Foreign particles or dust entering the inverter will cause it to fail. If you use the inverter in a

considerably dusty environment, install the inverter inside a totally enclosed panel.

2 - 2

Chapter 2 Installation and Wiring

(6) Installation method and position

Install the inverter vertically and securely with screws or bolts on a surface that is free from vibrations

and that can bear the inverter weight.

If the inverter is not installed vertically, its cooling performance may be degraded and tripping or

inverter damage may result.

(7) Mounting in an enclosure

When mounting multiple inverters in an enclosure with a ventilation fan, carefully design the layout of

the ventilation fan, air intake port, and inverters.

An inappropriate layout will reduce the inverter-cooling effect and raise the ambient temperature. Plan

the layout so that the inverter ambient temperature will remain within the allowable range.

(Acceptable)

Ventilation fan

Inverter

(Unacceptable)

Ventilation fan

Inverter

Position of ventilation fan

(8) Reduction of enclosure size

If you mount the inverter inside an enclosure such that the heat sink of the inverter is positioned

outside the enclosure, the amount of heat produced inside the enclosure can be reduced and likewise

the size of the enclosure.

Mounting the inverter in an enclosure with the heat sink positioned outside requires an optional

dedicated special metal fitting.

To mount the inverter in an enclosure wit h the heat si nk positioned o utside, cut out the enclosure p anel

according to the specified cutting dimensions.

The cooling section (including the heat si nk) positioned outside the enclosure has a cooling fan.

Therefore, do not place the enclosure in any environment where it is exposed to waterdrops, oil mist,

or dust.

(9) Approximate loss by inverter capacity

Inverter capacity (kW) 5.5 7.5 11 15 18.5 22 30 37 45 55

Loss with 70% load (W) 242 312 435 575 698 820 1100 1345 1625 1975

Loss with 100% load (W) 325 425 600 800 975 1150 1550 1900 2300 2800

Efficiency at rated output (%) 94.4 94.6 94.8 94.9 95.0 95.0 95.0 95.1 95.1 95.1

2 - 3

Chapter 2 Installation and Wiring

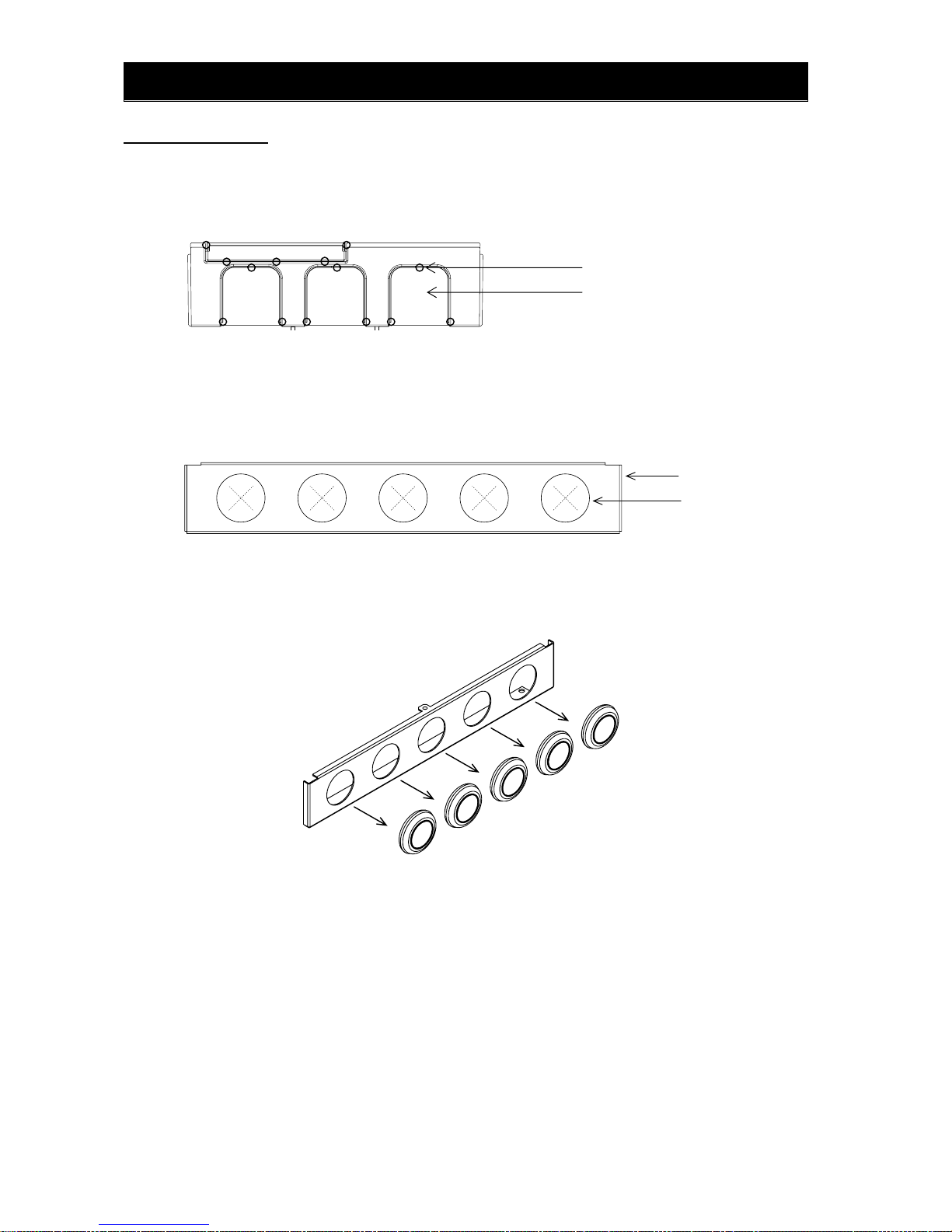

2.1.2 Backing plate

(1) For models with 22 kW or less capacity

On the backing plate, cut the joints around each section to be cut off with cutting pliers or a cutter,

remove them, and then perform the wiring.

Joint

Section to be cut off

(2) For the models with 30 kW or less capacity

1) For wiring without using conduits

Cut an X in each rubber bushing of the backing plate with cutting pliers or a cutter , and then perform

the wiring.

Backing plate

Rubber bushing

2) For wiring using conduits

Remove the rubber bushings from the holes to be used for wiring with conduit s, and then fit conduit s

into the holes.

Note: Do not remove the rubber bushing from holes that are not used for wiring with a conduit.

If a cable is connected through the plate hole without a rubber bushing and conduit, the cable

insulation may be damaged by the edge of the hole, resulting in a short circuit or ground fault.

2 - 4

Chapter 2 Installation and Wiring

2.2 Wiring

WARNING

- Be sure to ground the inverter. Otherwise, you run the risk of electric shock or fire.

- Commit wiring work to a qualified electrician. Otherwise, you run the risk of electric shock or fire.

- Before wiring, make sure that the power supply is off. Otherwise, you run the risk of electric shock or

fire.

- Perform wiring only after installing the inverter. Otherwise, you run the risk of electric shock or injury.

- Do not remove rubber bushings from the wiring section. Otherwise, the edges of the wiring cover may

damage the wire, resulting in a short circuit or ground fault.

!

CAUTION

- Make sure that the voltage of AC power supply matches the rated voltage of your inverter. Otherwise,

you run the risk of injury or fire.

- Do not input single-phase power into the inverter. Otherwise, you run the risk of fire.

- Do not connect AC power supply to any of the output terminals (U, V, and W). Otherwise, you run the

risk of injury or fire.

- Do not connect a resistor directly to any of the DC terminals (PD, P, and N). Otherwise, you run the

risk of fire.

- Connect an earth-leakage breaker to the power input circuit. Otherwise, you run the risk of fire.

- Use only the power cables, earth-leakage breaker, and magnetic contactors that have the specified

capacity (ratings). Otherwise, you run the risk of fire.

- Do not use the magnetic contactor installed on the primary and secondary sides of the inverter to stop

its operation.

- Tighten each screw to the specified torque. No screws must be lef t loose. Otherwise, you run the risk

of fire.

- Before operating, slide switch SW1 in the inverter, be sure to turn off the power supply. Otherwise, you

run the risk of electric shock and injury.

- Since the inverter supports two modes of cooling-fan operation, the inverter power is not always off,

even when the cooling fan is stopped. Therefore, be sure to confirm that the power supply is off before

wiring. Otherwise, you run the risk of electric shock and injury.

!

2 - 5

Chapter 2 Installation and Wiring

2.2.1 Terminal connection diagram and explanation of terminals and switch settings

3-phase power supply

200 V class: 200 to 240 V +10%, -15%

(50/60 Hz ±5%)

400 V class: 380 to 480 V +10%, -15%

(50/60 Hz ±5%)

utput

Jumper

When connecting separate

power supplies to main and

control circuits, remove J51

connector cables beforehand.

(See page 2-20)

Power supply for

control circuit

Forward rotation

command

Intelligent input

(8 contacts)

Digital monitor o

(PWM output)

Thermistor

Frequency

setting circuit

500 to 2,000Ω

0 to 10 VDC (12 bits)

-10 to +10 VDC (12 bits)

4 to 20 mA (12 bits)

Analog monitor

output (voltage

output)

Analog monitor

output (current

output)

0 to 10 V (10 bits)

4 to 20 mA (10 bits)

Motor

Jumper

bar

Braking resistor

(optional)

(Models with 22 kW

or less capacity

have a built-in BRD

circuit.)

The dotted line indicates the

detachable control terminal

board.

Intelligent relay output contact

(default: alarm output)

Intelligent output

(5 terminals)

For terminating

resistor

Option 1

Option 2

Type-D grounding (for 200 V class model)

Type-C grounding (for 400 V class model)

(See page 2-11.)

PLC

P24

DC24V

CM1

R

S

T

R0

T0

U

V

W

P

PD

RB

N

IM

FW

7

6

1

8

FM

CM1

H

O

O2

OI

L

AM

AMI

SP

SN

RP

SN

RS485

AL0

AL1

AL2

1

2

HITACHI

POWER

ALARM

Hz

V

A

%

kW

RUN

PRG

運転

RUN

機能

FUNC

記憶

STR

停止/

リセット

DC10V

100Ω

10kΩ

10kΩ

15

11

CM2

R

T

STOP/RESET

J51

TH

Default jumper position

for-xFEF2 models

(sourcing type inputs)

Default jumper position

for-xFUF2/xFF2 models

(sinking type inputs)

2 - 6

Chapter 2 Installation and Wiring

(1) Explanation of main circuit terminals

Symbol Terminal name Description

R, S, T

(L1, L2, L3)

Main power input

Connect to the AC power supply.

Leave these terminals unconnected when using a regenerative converter (HS900 series).

U, V, W

(T1, T2, T3)

Inverter output Connect a 3-phase motor.

PD, P

(+1, +)

DC reactor connection

Remove the jumper from terminals PD and P, and connect the optional power factor reactor

(DCL).

P, RB

(+, RB)

External braking

resistor connection

Connect the optional external braking resistor.

(The RB terminal is provided on models with 22 kW or less capacity.)

P, N

(+, -)

Regenerative braking

unit connection

Connect the optional regenerative braking unit (BRD).

G

Inverter ground

Connect to ground for grounding the inverter chassis by type-D grounding (for 200 V class

models) or type-C grounding (for 400 V class models).

(2) Explanation of control circuit terminals

Symbol Terminal name Description Electric property

L

Analog power

supply

(common)

This common terminal supplies power to frequency command terminals (O,

O2, and OI) and analog output terminals (AM and AMI). Do not ground this

terminal.

Power

supply

H

Frequency

setting power

supply

This terminal supplies 10 VDC power to the O, O2, OI terminals.

Allowable load current: 20

mA or less

O

Frequency

command

(voltage)

Input a voltage (0 to 10 VDC) as a frequency command. 10 V specifies the

maximum frequency.

To specify the maximum frequency with a voltage of 10 V or less, set the

voltage using function "A014".

Input impedance: 10kΩ

Allowable input voltages:

-0.3 to +12 VDC

O2

Auxiliary

frequency

command

(voltage)

Input a voltage (0 to ±10 VDC) as a signal to be added to the frequency

command input from the O or OI terminal. You can input an independent

frequency command from this terminal (O2 terminal) alone by changing the

setting.

Input impedance: 10kΩ

Allowable input voltages:

0 to ±12 VDC

Frequency setting input

OI

Frequency

command

(current)

Input a current (4 to 20 mA DC) as a frequency command. 20 mA specifies

the maximum frequency.

The OI signal is valid only when the AT signal is on. Assign the AT function

to an intelligent input terminal.

Input impedance: 10kΩ

Maximum allowable

current: 24 mA

AM

Analog monitor

(voltage)

This terminal outputs one of the selected "0 to 10 VDC voltage output"

monitoring items. The monitoring items available for selection include

output frequency, output current, output torque (signed or unsigned),

output voltage, input power, electronic thermal overload, LAD frequency,

motor temperature, heat sink temperature, and general output.

Maximum allowable

current: 2 mA

Analog

Monitor output

AMI

Analog monitor

(current)

This terminal outputs one of the selected "4 to 20 mA DC current output"

monitoring items. The monitoring items available for selection include

output frequency, output current, output torque (unsigned), output voltage,

input power, electronic thermal overload, LAD frequency, motor

temperature, heat sink temperature, and general output.

Allowable load impedance:

250Ω or less

Monitor output

FM

Digital monitor

(voltage)

This terminal outputs one of the selected "0 to 10 VDC voltage output

(PWM output mode)" monitoring items. The monitoring items available for

selection include output frequency, output current, output torque

(unsigned), output voltage, input power, electronic thermal overload, LAD

frequency, motor temperature, heat sink temperature, general output,

digital output frequency, and digital current monitor.

For the items "digital output frequency" and "digital current monitor," this

terminal outputs a digital pulse signal at 0/10 VDC with a duty ratio of 50%.

Maximum allowable

current: 1.2 mA

Maximum frequency: 3.6

kHz

P24

Interface power

supply

This terminal supplies 24 VDC power for contact input signals.

If the source logic is selected, this terminal is used as a common contact

input terminal.

Maximum allowable output

current: 100 mA

Power supply

CM1

Interface power

supply

(common)

This common terminal supplies power to the interface power supply (P24),

thermistor input (TH), and digital monitor (FM) terminals. If the sink logic is

selected, this terminal is used as a common contact input terminal. Do not

ground this terminal.

Operation

command

FW

Forward rotation

command

Turn on this FW signal to start the forw ard rot ation of the m otor; turn it of f to

stop forward rotation after deceleration.

Digital (contact)

Contact input

Function selection and logic

switching

1

2

3

4

5

6

7

8

Intelligent input

Select eight of a total 60 functions, and assign these eight functions to

terminals 1 to 8.

Note:

If the emergency stop function is used, terminals 1 and 3 are used

exclusively for the function. For details, see Item (3), "Emergency stop

function" (on page 2-8).

[Conditions for turning

contact input on]

Voltage across input and

PLC: 18 VDC or more

Input impedance between

input and PLC: 4.7kΩ

Maximum allowable voltage

across input and PLC: 27

VDC

Load current with 27 VDC

power: about 5.6 mA

2 - 7

Chapter 2 Installation and Wiring

Symbol Terminal name Description Electric property

Contact input

Function selection

and logic switching

PLC

Intelligent input

(common)

To switch the control logic between sink logic and source logic, change the

jumper connection of this (PLC) terminal to another terminal on the control

circuit terminal block.

Jumper terminals P24 and PLC for the sink logic; jumper terminals CM1

and PLC for the sink logic.

To use an external power supply to drive the contact inputs, remove the

jumper, and connect the PLC terminal to the external interface circuit.

11

12

13

14

15

Intelligent output

Select five of a total 51 functions, and assign these five functions to

terminals 11 to 15.

If you have selected an alarm code using the function "C062", terminals 11

to 13 or 11 to 14 ar e used ex clusiv ely for the outpu t of cau se code for ala rm

(e.g., inverter trip). The control logic between each of these terminals and

the CM2 terminal always follows the sink or source logic.

Open collector output

Status and factor

CM2

Intelligent output

(common)

This terminal serves as the common terminal for in telligent ou tpu t termina ls

[11] to [15].

Voltage drop between each

terminal and CM2 when

output signal is on: 4 V or

less

Maximum allowable

voltage: 27 VDC

Maximum allowable

current: 50 mA

Digital (contact)

Relay contact output

Status and alarm

AL0

AL1

AL2

Intelligent relay

output

Select functions from the 43 available, and assign the selected functions to

these terminals, which serve as C contact output terminals.

In the initial setting, these terminals output an alarm indicating that the

inverter protection function has operated to stop inverter output.

(Maximum contact

capacity)

AL1-AL0: 250 VAC, 2 A

(resistance) or 0.2 A

(inductive load)

AL2-AL0: 250 VAC, 1 A

(resistance) or 0.2 A

(inductive load)

(Minimum contact capacity)

100 VAC, 10 mA

5 VDC, 100 mA

Analog

Analog input

Sensor

TH

External

thermistor input

Connect to an external thermistor to make the inverter trip if an abnormal

temperature is detected.

The CM1 terminal serves as the common terminal for this terminal.

[Recommended thermistor properties]

Allowable rated power: 100 mW or more

Impedance at temperature error: 3kΩ

The impedance to detect temperature errors can be adjusted within the

range 0Ω to 9,999Ω.

Allowable range of input

voltages

0 to 8 VDC

[Input circuit]

CM1

TH

Thermistor

1kΩ

DC8V

10kΩ

(3) Explanation of switch settings

The internal slide switch (SW1) is used to enable or disable the emergency stop function (the function

is disabled by factory setting).

* For the location of the slide switch, see page 2-9.

2 - 8

Loading...

Loading...