Hitachi SRL-7.5M6LL, SRL-11M6ML, SRL-11M6LL, SRL-7.5M6Ml, SRL-11M6LH Instruction Manual

...

Instruction Manual

SRL-Series

HITACHI OILFREE SCROLL COMPRESSOR

Model : SRL-7.5M6LL/SRL-7.5M6ML

SRL-7.5M6LH/SRL-7.5M6M

H

SRL-11M6LL/SRL-11M6ML

SRL-11M6LH/SRL-11M6M

H

SRL-16.5M6LL/SRL-16.5M6ML

SRL-16.5M6LH/SRL-16.5M6M

H

CM1E029-00 Jul. 2011

Thank you for the recent purchase of a HITACHI Oilfree Scroll Air Compressor.

Please read this instruction manual carefully for installation, maintenance and

inspection guidelines of the HITACHI Scroll Air Compressor. After reading this

instruction manual, please keep it on hand for future reference.

Pressure Units Clarification

Pressure is indicated in units of

"psig" in this Instruction Manual.

Please review the table below

fo r th e co nve rsio n of "p s ig"

units to "MPa" units.

Unit of pressure

measurement

psig 122 145

MPa 0.84 1.0

Conversion - 1 psig = 0.00689 MPa

Attention

● The SRL air compressor is a piece of equipment for producing compressed air. The use of the SRL air

compressor should be limited to general industry. Since handling compressed air can be dangerous, the

operator should use the SRL air compressor only after acquiring technical knowledge. HITACHI

assumes no responsibility for machine failure, personal injury or an accident caused by the use of the

SRL air compressor without the operator acquiring relevant technical knowledge.

● The SRL air compressor is designed for indoor use.

● Personnel in charge of operation, maintenance and inspections of the SRL air compressor should have

easy access to this instruction manual.

● Thoroughly read this instruction manual and the SRL warning label to obtain vital information regarding:

○ Proper Installation ○ Proper Operation ○ Maintenance and Inspection

○ Safety Guidelines

○ Warning and Caution Information

● Observe the operating ranges of the air compressor in the instruction manual prior to use. To prevent

failures from occurring, perform proper maintenance and inspection.

● Do not operate, handle or modify the air compressor in any way that is not described in the instruction

manual and use genuine HITACHI parts when performing maintenance. HITACHI shall assume no

responsibility for any accidents and/or failures to the air compressor attributed to the above.

● If any description in the instruction manual in unclear, please contact the local Hitachi distributor.

● Sections of this instruction manual may be subject to change without notice.

● If service is required and/or an alarm occurs, please contact the local Hitachi distributor with the

following information:

○ Model and Serial Number

○ Vital information regarding the status of the air compressor (for example, alarm information in as

much detail as possible).

● Do not reprint and/or reproduce any section of this instruction manual without permission from Hitachi.

Safety Precautions

Improper use of the Oilfree Scroll Air Compressor may result in an accident or injury. Thoroughly read the

instruction manual before proceeding with installation, operation, maintenance or inspection of the air

compressor. Before using the air compressor, become familiar with all of the air compressor equipment,

safety information and the safety precautions. Dangerous and important information are highlighted by

the WARNING and CAUTION graphics. These graphic descriptions are detailed below.

Serious injury :

Injury :

Property Damage :

These safety precautions cover vital safety aspects of the Oilfree Scroll Air Compressor. Make sure to

establish safety measures in accordance with local and national codes and standards.

Hitachi Industrial Equipment Systems Co., Ltd. shall assume no responsibility for anything resulting from

disregard to these safety precautions.

Graphic Descriptions

This is a warning. If handled improperly, death or severe injury could result.

This is a caution. If handled improperly, injury and/or physical damage could result.

WARNING

CAUTION

Serious injury indicates the following could occur: blindness, injury, burns (mild and

excessive), electric shock, and/or toxic poisoning that require hospitalization or long

term medical treatment.

Injury indicates the following could occur: burns, electric shock that does not require

hospitalization or long term medical treatment.

Property damage means the foll owing could occur: breaks and /or dama ge to

equipment.

This is a Prohibited Operation.

Any operation illustrated by this symbol is strictly prohibited.

Prohibition

S-1

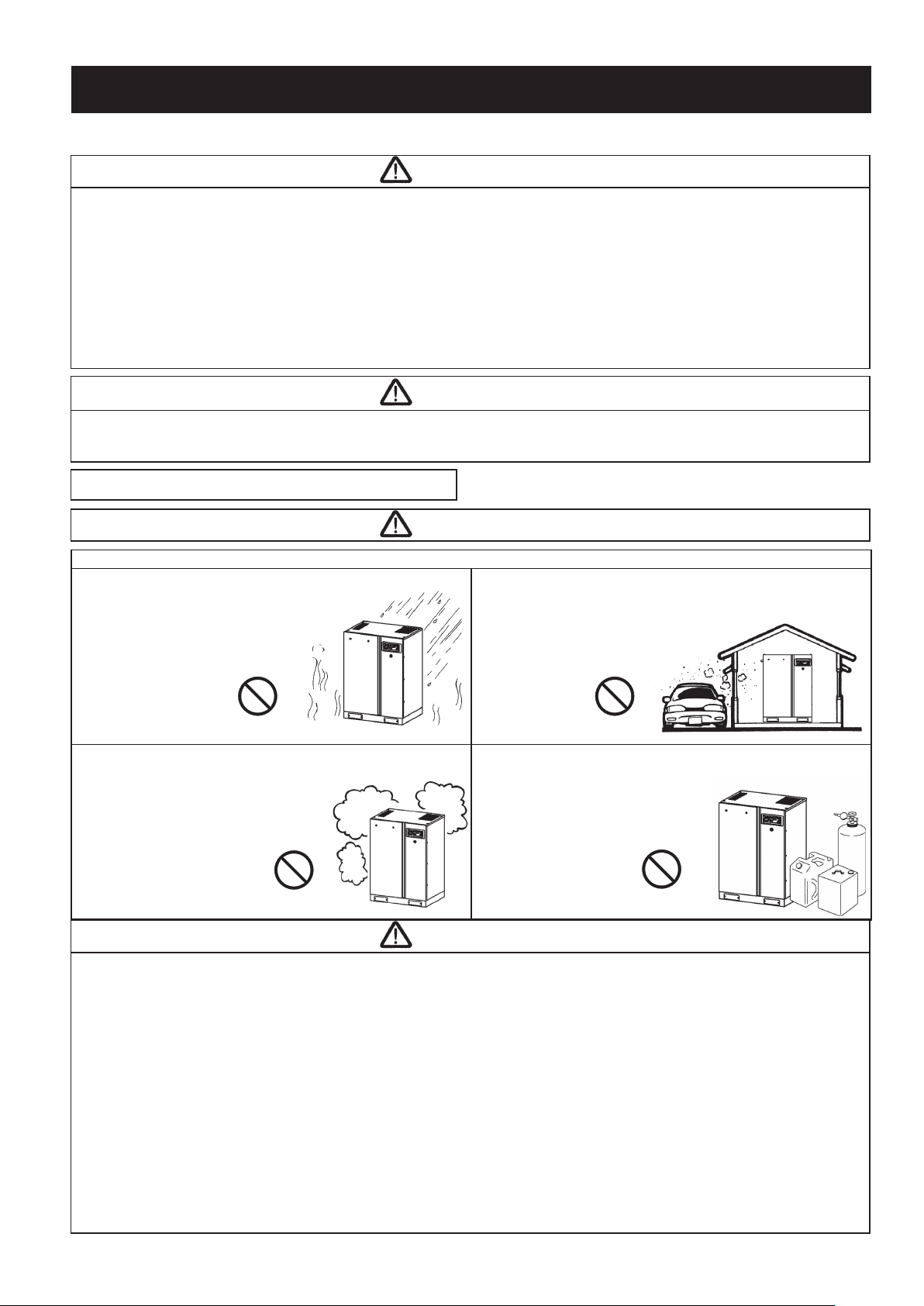

Avoid installing the air compressor in the dangerous areas described below:

● Avoid places subject to rain, water and/or high humidity.

Failure to adhere to this precaution

may cause electric current leakage,

rust and/or reduction in air compressor

life.

● Avoid outdoor installation or areas

subject to direct sunlight.

Failure to adhere to this

precaution may cause air

compressor overheating,

discoloration, alteration

and/or deterioration.

● Avoid areas subject to foreign matter, such as: iron powder,

sand dust, powdered dust, wood chips, textile waste, stone

powder, and fine iron powder fumes.

Failure to adhere to this precaution

may cause premature clogging of

the air filter and aftercooler fins,

excessive temperature rise,

air compressor

damage and

reduction in life

and/or explosive

accidents.

● Avoid areas where corrosive gases are present, such as:

organic solvents (benzene, toluene, etc.), acid, chloride gas,

ozone gas, ammonia, significant oil mists

and/or bromine.

Failure to adhere to this precaution may

cause rust to the air compressor components

and/or reduction in air compressor life.

● Avoid areas of close proximity to explosives and/or flammable

gases, such as: acetylene, propane gas, organic solvents,

explosive powdered dust and/or fire.

Failure to adhere to this precaution

may cause accidents.

Safety Precautions (continued)

S-2

Items requiring extra safety attention are described below. Observe the items described below, as well

as other items in the instruction manual that require safety attention.

● Do not use the air compressor to compress any gas other than air.

Using the air compressor to compress any gas other than air may lead to damage of the air compressor.

● SRL air compressors are not designed, intended or approved for breathing air applications. Hitachi does

not approve specialized equipment for breathing air applications and assumes no responsiblity or liability

for compressors used for breathing air services.

● If the scroll air compressor is used for any important production equipment, it is highly recommended to

utilize a back up air compressor.

A back up air compressor will keep production running in the event of a failure to an air compressor.

● Oil, dust and abrasive powder may be present in the air, and can be ingested into the air compressor

and mixed into the compressed air discharge.

Installation Safety Precautions

● Make sure that the installation ares has sufficient space for ventilation cooling. The compressor should

operate at room temperature in between 32 ゜ F and 104° F. If the room temperature exceeds104° F,

the air compressor's protective devices will stop compressor operation.

Excessive temperatures may lead to reduction in bearing life, seal life and seizure of the scroll head.

● Do not install the air compressors in a high location where the air compressor or air compressor parts

can be dropped.

● Install a pressure tight, heat resistant rubber hose at the compressed air discharge.

Do not use improper rubber hose or flexible tubing as they may crack and/or break.

● Verify that the power supply is 208/230/460 volt, 3 phase, 60 Hertz.

Failure to adhere to this precaution may cause motor and/or start failure.

● Do not install heavy objects, such as a filter, directly on the compressed air discharge.

Installing heavy objects on the compressed air discharge can cause damage to the piping and/or an accident.

WARNING

CAUTION

CAUTION

WARNING

Prohibition Prohibition

Prohibition

Prohibition

Safety Precautions (continued)

S-3

● If the Compressor Operation light is lit, keep all human body parts away from the rotating parts (pulley,

V-belt and ventilating fan) of the air compressor, as the air compressor will automatically start when

pressure drops.

Failure to adhere to this precaution may cause injury and/or accidents.

● Do not touch the air piping and check valve inside the air compressor package during operation and

immediately after the air compressor has stopped, as they will generate excessive heat.

Failure to adhere to this precaution may cause burns.

● Do not operate the air compressor with an inverter and/or generator.

Failure to adhere to this precaution may cause damage to the air compressor and/or accidents.

● Make sure to ground (earth) the air compressor.

Failure to adhere to this precaution may cause electric shock and/or injury.

● Remove all the transport fixtures prior to operation. (7.7/11kW : 2 locations, 16.5kW : 3 locations)

Failure to adhere to this precaution may cause excessive vibration and/or damage to the air compressor.

● Turn off the power supply during a power failure and/or electric storm.

Failure to adhere to this precaution may cause damage to the air compressor and/or accidents.

Operation Safety Precautions

WARNING

CAUTION

Maintenance and Inspection Safety Precautions

● Carry out the standard scheduled maintenance and service (See page 21).

Failure to adhere to this precaution may cause damage to the air compressor and/or accidents.

● Before performing any maintenance and/or inspection, ensure that the power supply has been

disconnected and all compressed air in the air receiver and air compressor piping has been released.

Failure to adhere to this precaution may cause electric shock and/or injury.

【122PSIG Model】

● Contact the local Hitachi distributor for the completion of the maintenance required every 10,000

hours or every 4 years of standard use. The maintenance has to be completed in this period, or earlier

depending on the operating environment. Do not operate beyond the scheduled period.

Failure to adhere to this precaution may cause damage to the air compressor and/or accidents.

For more details, contact the local Hitachi distributor.

【145PSIG Model】

● Contact the local Hitachi distributor for the completion of the maintenance required every 5,000 hours

or every 2 years of standard use. The maintenance has to be completed in this period, or earlier

depending on the operating environment. Do not operate beyond the scheduled period.

Failure to adhere to this precaution may cause damage to the air compressor and/or accidents.

For more details, contact the local Hitachi distributor.

【122PSIG Model】

● Contact the local Hitachi distributor for the completion of the overhaul required every 20,000 hours or

every 8 years of standard use. The overhaul has to be completed in this period, or earlier depending on

the operating environment. Do not operate beyond the scheduled period.

Failure to adhere to this precaution may cause damage to the air compressor and/or accidents.

For more details, contact the local Hitachi distributor.

【145PSIG Model】

● Contact the local Hitachi distributor for the completion of the overhaul required every 10,000 hours or

every 4 years of standard use. The overhaul has to be completed in this period, or earlier depending on

the operating environment. Do not operate beyond the scheduled period.

Failure to adhere to this precaution may cause damage to the air compressor and/or accidents.

For more details, contact the local Hitachi distributor.

● For maintenance and service inspections, please contact the local Hitachi distributor.

● Do not remove or modify the safety devices and/or insulating parts of the air compressor.

Failure to adhere to this precaution may cause damage to the air compressor and/or accidents.

● Use genuine HITACHI parts when maintaining or servicing the air compressor.

Failure to adhere to this precaution may cause damage to the air compressor and/or accidents.

● Do not use the air receiver if it has developed a leak. Do not attempt to repair or rework a leaking air

receiver.

Failure to adhere to this precaution may cause personal injury, damage to the air compressor and/or pressurized

rupture.

WARNING

Introduction

The instruction manual gives details related to the specifications, construction, installation, operation,

maintenance and inspection of the Oilfree Scroll Air Compressor.

This instruction manual describes the proper operation method to smoothly and safely utilize the

functions of the Oilfree Scroll Air Compressor.

Table of Contents

1

● Daily Operating Components

● Installation

1. Product Confirmation

2. Transporting the Air compressor

3. Installing the Air compressor

4. Piping the Air compressor

5. Wiring the Air compressor

● Operation

1. Control Panel Descriptions

2. Prior to Operation

3. Start Up

4. Daily Operation

● Maintenance and Inspection

● Troubleshooting

● Parts List

● Wiring Diagram

● Standard Specifications

● Aftermarket Ordering Procedure

・・・・・・・・・・ 2

・・・・・・・・・・ 4

・・・・・・・・・・ 4

・・・・・・・・・・ 4

・・・・・・・・・・ 5

・・・・・・・・・・ 7

・・・・・・・・・・ 8

・・・・・・・・・・ 12

・・・・・・・・・・ 12

・・・・・・・・・・ 14

・・・・・・・・・・ 19

・・・・・・・・・・ 20

・・・・・・・・・・ 21

・・・・・・・・・・ 29

・・・・・・・・・・ 33

・・・・・・・・・・ 34

・・・・・・・・・・ 36

・・・・・・・・・・ 37

Safety Precautions (continued)

● If the air compressor has not run in over one (1) month, carry out the long term storage operation

prior to restarting the air compressor (See page 28).

Failure to adhere to this precaution may cause abnormal wear to the air compressor components, damage to the air

compressor and/or accidents.

● Verify that the front door chain has been connected before closing the door.

● Make sure the V-belt is tightened properly prior to operation. If the V-belt is loose, tighten the V-belt

prior to operation.

Failure to adhere to this precaution may cause belt slippage, damage to the air compressor and/or excessive noise.

CAUTION

Daily Operating Components

2

Air Compressor Exterior

● Do not leave the front door open during operation.

Failure to adhere to this precaution may cause dust to be ingested, excessive vibration and/or noise to be

generated and/or reduction in air compressor life due to excessive temperature rise.

CAUTION

Air Exhaust

Air Intake

● Intake air and cooling

air is supplied to the air

compressor.

Compressed Air

Discharge Pipe

Power Cable Inlet

Control Panel

Locks for door

enclosure with Keys

Front Door

Emergency Stop

Switch

SRL-7.5M6LL/ML/LH/MH

SRL-11M6LL/ML/LH/MH

SRL-16.5M6LL/ML/LH/MH

● Make sure that front

door is closed during

the operation of the air

compressor.

Air Exhaust

Air Intake

● Intake air and cooling

air is supplied to the air

compressor.

Compressed Air

Discharge Pipe

Power Cable Inlet

Control Panel

Locks for door

enclosure with Keys

Front Door

Emergency Stop

Switch

● Make sure that front

door is closed during

the operation of the air

compressor.

Daily Operating Components(continued)

3

Air Compressor Interior

Check Valve

Scroll Head

Air Release Valve

Power Supply Panel

Electric Main Motor

Rubber Vibration

Isolators

V-BeltPrimary Cooler

Ventilating Fan

SRL-7.5M6LL/ML/LH/MH

SRL-11M6LL/ML/LH/MH

SRL-16.5M6LL/ML/LH/MH

Safety Relief Valve

Rubber Hose

Intake Air Filter

● 10HP (7.7kW) : 3 locations

● 15HP (11kW) : 4 locations

Transport Fixture

● 2 locations

Secondary Cooler

Main Power Supply

Terminal Block

Electromagnetic

Contactor

Check Valve

Scroll Head

Air Release Valve

Power Supply Panel

Electric Main Motor

Rubber Vibration

Isolators

V-Belt

Primary Cooler

Ventilating Fan

Safety Relief Valve

Rubber Hose

Intake Air Filter

● 6 locations

Transport Fixture

● 3 locations

Secondary Cooler

Main Power Supply

Terminal Block

Electromagnetic

Contactor

Ventilating Fan

Installation

4

● It is recommended that properly trained personnel move the air compressor.

● Operation of the air compressor with the transport fixtures installed will lead to excessive vibration

of the air compressor and the package may rupture. The transport fixtures must be removed prior

to operation of the air compressor.

WARNING

1 Product Confirmation

1. Check the air compressor nameplate to verify that

the proper model air compressor was delivered.

2. Verify that there has been no damage to the air

compressor during transportation.

3. Verify that the items shown below are included

with the air compressor.

Rubber

vibration

sheets for

installation -

4 Sheets

Instruction

Manual

1 copy

4 - Steel

plates

& 8 - Bolts

Model Nameplate

● Review the model

number, serial number,

power requirements and

compressor

specifications.

Warning Label

● Read the Warning Label

before use.

● Do not use an air compressor with

a power supply differing from the

specified power requirement.

Incorrect power supply may cause

fire and/or abnormal vibration.

CAUTION

2 Transporting the Air Compressor

Transporting the Air Compressor Removing the Transport Fixtures

Moving with a Forklift

P l a c e a bu f f e r pl a t e in

between the air compressor

and the forklif t to prote ct

the air compressor panels.

Do no t t i l t th e for k s o f

the forklift too much. Too

much tilt may cause the air

compressor to drop.

Remove the transport fixtures

Bolt

Fixture

Transport Fixtures Location

● After installing air compressor, please

be sure to attach the plates shown in

the figure to the right.

These plates are shipped with the

compressor and will greatly reduce

compressor noise during operation.

【Reference】

● Open the front door, remove the yellow bolts and

remove the transport fixtures prior to operating.

7.7/11kW : 2 locations

16.5kW : 3 locations

1. Install the air compressor inside a room with adequate space, ventilation and relatively low humidity.

2. Keep the operating room temperature in between 32° F and 104° F.

3. Install the air compressor with the recommended spacing shown in the figure below for ease of

maintenance and temperature control.

・The air compressor is designed to inhale air from the left side of the package and exhaust the air out

of the top of the package. It is recommended to provide suction and exhaust openings as shown in

the figure below to properly ventilate the room. If the suction and exhaust openings cannot be

provided, do not modify the air compressor without consulting the local Hitachi distributor.

4. The allotted space located to the right and to the rear of the air compressor must be maintained

to perform maintenance. Ensure that this space is maintained if the air compressor is going to be

permanently installed. (#)

A B

Installation(continued)

5

3 Installing the Air Compressor

Ventilating fan

● If the temperature exceeds 104° F in the

room, install a ventilating fan to keep the

room temperature below 104° F.

● Select a ventilating fan with more than

enough capacity to handle the air flow of

the room.

Maintenance Space,

Intake Air, Discharge

Piping and Wiring

● Secure enough space for proper ventilation.

● Absence of intake space causes the suction resistance to

increase, resulting in temperature rise in the package, which may

cause a reduction in the life of air compressor components.

● Secure enough space for wiring and piping.

Ventilation and

Exhaust Space

● Secure enough space for proper

ventilation.

● Absence of intake space causes

the suction resistance to increase,

resulting in temperature rise in the

package, which may cause a

reduction in the life of air

compressor components.

Maintenance Space for

Right & Rear Sides

● If a space of more than 12 in.

and/or 20 in. cannot be secured,

utilize a piping connection that

can be easily removed for

maintenance purposes.

Front Maintenance Space

● Secure the proper amount of

space to open the front door of

the air compressor for inspection.

Exhaust duct

● Do not directly connect the duct with the

air compressor. The ducting hood should

maintain a distance (indicated as “h”)

between the air compressor and the duct

that is larger than the diameter of the duct.

h

Exhaust

air

40 in. or more

Exhaust

Opening

Intake

Opening

Exhaust

air

I

ntake

air

I

ntake

air

12 in.

or more (#)

20 in.

or more (#)

Exhaust

air

40 in. or more

25 in. or more

Intake Opening

● The intake opening should be installed as

low as possible. The area of the opening

should be calculated as 1,550 sq in.(1m

2

)

per compressor1.

● Conditions of the ambient air, including

dust and toxic substances, should be

considered when selecting the location

for the intake air opening.

【Reference】

■ Guidance for construction of ventilating fan and exhaust duct

Exhaust Air

Exhaust Air

of air

compressor

Intake Air

■ Ventilating Fan

Refer to the v olu me of

necessary ventilation (1).

Intake Air

Ex h a u s t

Duct

■ Ventilating Fan

Refer to the v olu me of

necessary ventilation (2).

5. Install the Air Compressor on Level Ground with a Sufficient

Weight Load. If there is a gap between the air compressor

and the ground, adjust the gap with the attached rubber

vibration isolators to eliminate the gap.

6. For parallel operation, install the air compressors as shown

in the figure to the right. If the air compressors cannot be

installed as shown in the figure to the right, install in a way

that prevents the exhaust of one air compressor from

entering the air intake of the other air compressor.

Installation(continued)

6

● Keep the ambient room temperature in between 32° F and 104° F. If the temperature exceeds

104° F or there is a defect in the installation, the air compressor protective devices may stop air

compressor operation and/or damage or reduction in compressor life may occur.

● The air compressor discharges air exhaust from the top. Make sure that there are no items such as

lights, or wirings that are above the air compressor and can be affected by the exhaust air.

● Do not modify the intake or exhaust of the air compressor package, otherwise the temperature may

become unbalanced, resulting in the protective devices of the air compressor to function improperly.

● Do not install ducting on the intake or the exhaust of the Oilfree Scroll Air Compressor, as it may

cause damage to the air compressor.

● Do not install the air compressor in an area above the ground, as the air compressor and/or parts

of the air compressor may fall.

WARNING

● Do not install the air compressor on ground with

insufficient weight load. Do not operate the air

compressor attached to a pallet or packaging table.

● Do not install on any type of rubber other than the

attached rubber vibration isolators and do not bolt to

the concrete. This may result in excessive vibration

and/or damage to the air compressor.

WARNING

SRL-7.5M6LL

SRL-7.5M6ML

SRL-7.5M6L

H

SRL-7.5M6MH

SRL-11M6LL

SRL-11M6ML

SRL-11M6L

H

SRL-11M6MH

SRL-16.5M6LL

SRL-16.5M6ML

SRL-16.5M6L

H

SRL-16.5M6

MH

Generate Heat kJ/h

25,116 36,000 54,000

Cooling Air Flow CFM (㎥/min) 990 (28) 1,240 (35) 1,520 (43)

Cooling Air Differential Temperature

° F (℃ )

63 (35) 63 (35) 63 (35)

Required ventilating capacity (1)

CFM (㎥/min)

2,472 (70) 3,532 (100) 5,297 (150)

Required ventilating capacity (2)

CFM (㎥/min)

777 (22) 1,130 (32) 1,695 (48)

【Please see the table to the below for Reference】

■ Generated Heat & Required Ventilating Capacity Table

The required ventilating capacity value is the required capacity to keep the temperature rise in the room

within 9° F (5℃ ) when only one Oilfree Scroll Air Compressor is operating.

Item

Model

Install the Air Compressor

on Le v el Gro und with a

Sufficient Weight Load.

Rubber vibration

isolators

Exhaust air

Exhaust air

Intake air

Intake air

39 in. or more

1. Ensure that a properly sized air receiver is installed (80 gallons or more). Without a properly sized air

receiver it is possible that the air compressor can be damaged due to excessive starts and stops.

2. Use a textile reinforced, heat resistant rubber hose (hydraulic) of appropriate rating to connect the

Oilfree Scroll Air Compressor to the plant air system piping.

■ It is necessary to install a properly sized air receiver to this compressor in order to reduce excessive

starts and stops.

■ Without a properly sized air receiver, it is possible that the main motor or electromagnetic contactor may

receive unwarranted wear due to excessive starts and stops.

7

● Use a heat resistant, pressure tight rubber hose to connect the Oilfree Scroll Air Compressor to the

plant air system piping. The rubber hose will prevent damage to the plant air system piping due to

vibration.

● Use of an improper rubber hose may lead to cracks and/or leaks due to hose deterioration.

● Do not operate the air compressor when the stop valve between the air receiver and the air

compressor is closed.

● Do not install heavy objects, such as drain traps and filters, to the compressed air discharge as they

may damage the discharge line of the air compressor.

● If a remote vertical air receiver is installed, it is recommended to attach the air receiver to the ground

with foundation bolts.

WARNING

4 Piping the Air Compressor

Safety Relief Valve

● If a stop valve is installed

in the middle of the

compressed air piping,

install a safety relief valve

between the air

compressor and the stop

valve.

Vertical Air Receiver

● To avoid damage to the air

compressor due to excessive

starts and stops, a properly sized

air receiver must be installed.

Hose Fitting

Rubber Hose

● Use an appropriate

rubber hose to connect

with the equipment.

Stop Valve

● Make sure to install a

stop valve between the air

compressor and the air

receiver.

Installation(continued)

● Without a properly sized air receiver, it is possible that a serious accident may occur due to the

unwarranted wear of the main motor or electromagnetic contactor.

● For the protection of the air compressor, if excessive starts and stops occur the compressor will

shut off and display : cycle error [E.CY]. This will stop the supply of compressed air.

● The error message cycle error [E.CY] is an indication that the volume of air receiver is insufficient

for proper operation. An increase in the volume of the air receiver will eliminate the cycle error [E.CY].

WARNING

1. Carry out the electrical work according the local and

national electric codes and standards.

2. Connect the power supply for the main motor through

an earth leakage (ground) circuit breaker between the

main power and the Oilfree Scroll Air Compressor.

3. Wiring capacities are as follows.

1. Internal air compressor wiring has been

completed prior to shipment from the

factory.

2. Remove the front panel, open the door

to the power supply panel and connect

the main power supply cable to the

terminal block.

Installation(continued)

8

● Verify that the power supply for the facility corresponds with the power supply of the air

compressor.

Failure to adhere to this precaution may lead to starting failure, electric motor failure and/or damage to the air

compressor.

● The SRL air compressor should be wired per the local and national electric codes. Improper wiring

may lead to excessive voltage drops.

● Do not use a generator.

CAUTION

5 Wiring the Air Compressor

Connecting the Main Power

Model Power

Wiring Capacity

Minimum Wire Thickness

(mm/AWG)

Minimum Ground Line Wire

Thickness

(mm/AWG)

Circuit Breaker

Capacity

(A)

Fuse

Capacity

(A)

SRL-7.5M6LL

SRL-7.5M6LH

208/230V

3 Phase

60 Hertz

3.9/AWG8 3.9/AWG8 75 75

SRL-11M6LL

SRL-11M6LH

4.9/AWG6 4.9/AWG6 100 100

SRL-16.5M6LL

SRL-16.5M6LH

6.8/AWG4 6.8/AWG4 100 100

SRL-7.5M6ML

SRL-7.5M6MH

460V

3 Phase

60 Hertz

3.9/AWG8 3.9/AWG8 40 40

SRL-11M6ML

SRL-11M6MH

4.9/AWG6 4.9/AWG6 50 50

SRL-16.5M6ML

SRL-16.5M6MH

6.8/AWG4 6.8/AWG4 50 50

Wiring the Air Compressor

Terminal

Block

Main Power

Supply Cable

Ti g h ten th e n u t a f t er

conn e c t i n g th e po w e r

cable.

Note) 1. Use a UL489 listed circuit breaker or UL listed dual-element time delay branch circuit type fuses.

2. The Circuit Breaker and Fuse capacity depend on "UL standard".

Earth Leakage (Ground)

Circuit Breaker

Front panel

3. Make sure to ground the air compressor.

4. For AC208/230V models, the air compressor ships

wired for AC230V, to operate the air compressor at

AC208V, reconnect the wiring of the transformer

primary to the 208V terminal.

5. Turn ON the circuit breakers and motor breakers.

6. Turn on the main power to verify that the voltage

is the specified voltage and phase.

7. Press the start button to verify that the compressor

operates during a trial run. If [E.rE] is indicated on

the digital display, the air compressor is in a reverse

phase condition. To fix the problem, turn off the main

power and reconnect the power after switching two

of three wires of the main power. If nothing has

changed after reconnecting, please refer to P.29.

8. If the air compressor is rotating correctly, the cooling

air flows as shown in the figure to the right.

9

● Make sure to turn off the main power supply before carrying out any wire connections.

● Firmly tighten the screws connecting the main power wiring to the air compressor.

Loose wires may lead to excessive overheating and/or accidents.

CAUTION

Bolts

Terminal Block

Switch two of

the three wires.

Exhaust

Intake

230V

208V

Recon n e c t

the wiring

Do not

reconnect

the wiring

Transformer

Installation(continued)

ON

Ground

Terminal

Circuit Breaker Motor Breaker

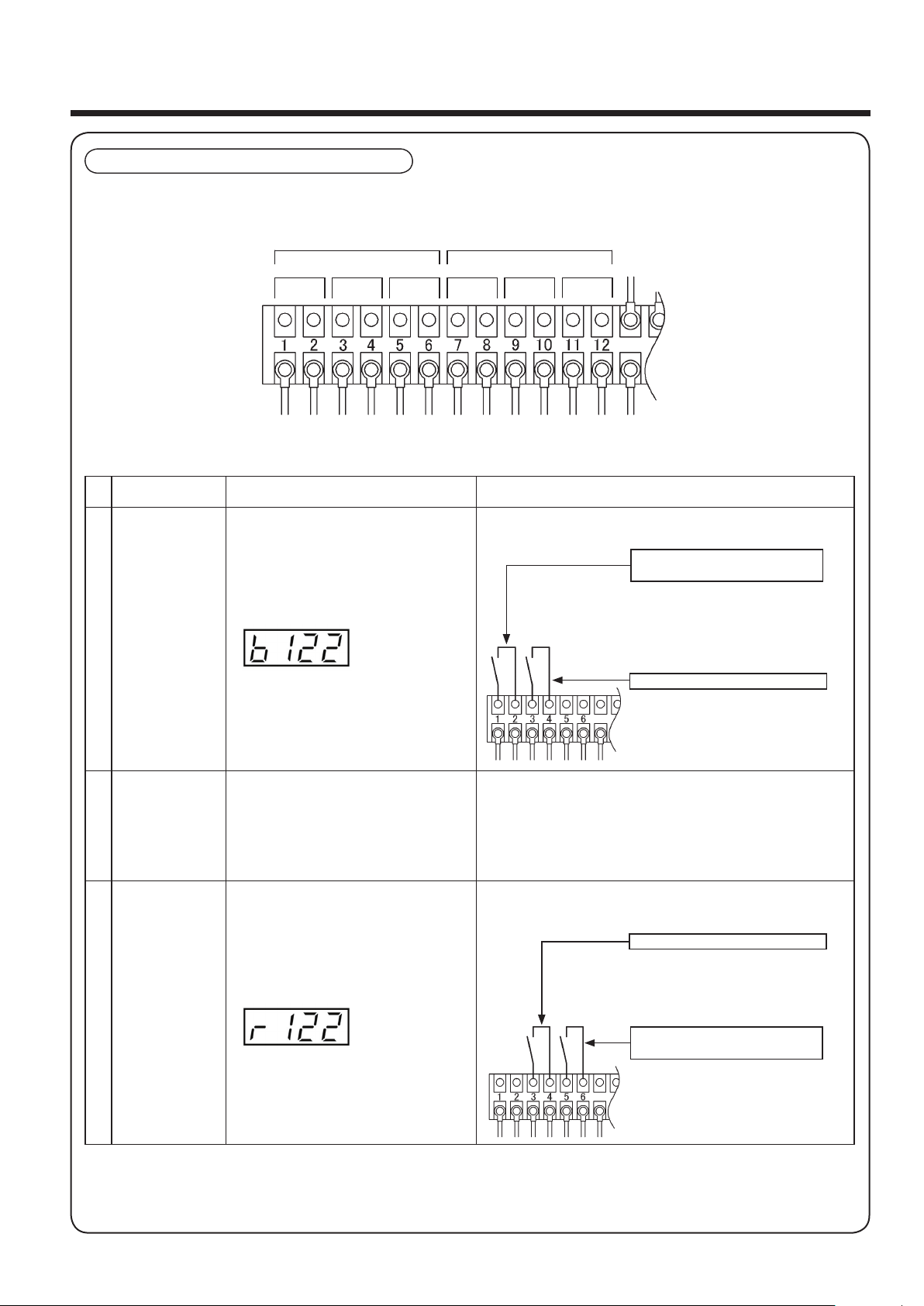

The following input and output signals terminal block is equipped in the power supply control panel.

No.

Terminal

Description

Content How to use

①

Customer Control

Run Change-over

Signal

When u ti lizing custom er control ru n,

connect this to the external terminals

of the cu stomer’ s controll er. When

controlled by a customer’s controller,

"b " will be indicat e d on the digital

display. (Only pressure switch control

mode is allowed.)

The input signal is approximately 5VDC, 10mA. Use a switch

or a relay contact with the minimum applicable load of this

value.

②

Remote Operation

Command Signal

Under remote operation, the operation

of t he ai r c ompr e s sor is c ontr o l led

by the input si gnal fro m the remot e

switch. Under customer control run,

the operation of the air compressor is

controlled by the input signal from the

control panel of the customer.

③

Remote Operation

C h a n g e - o v e r

Signal

Before the remote operation of the air

compressor can be used, the operation

switch must be activated. If the mode

of t he air compresso r is changed to

remote operation a change-over signal

wi ll occur . A charac ter “r” (R emot e

mo de) is dis played on t he left mos t

position of the digital display.

When remote control is to be used, the

remote operation change-over signal

must occur before activating the remote

operation command signal.

The input signal is approximately 5VDC, 10mA. Use a switch

or a relay contact with the minimum applicable load of this

value.

Installation(continued)

10

Remote Input and Output Signals

Customer Control Run

Change-over Switch

Inst a l l th e cu s t o m e r co n t r o l ru n

ch a n g e - o v e r sw i t c h near the ai r

compressor.

Sw i t c h ON : Cu s t o mer contr o l l ed

operation is running.

Swi t c h OF F : Lo c al o p e r a t i on i s

running.

① ②

③ ④ ⑤

⑥

# Input Signals Output Signals

# Use shielded wires as input signal wires.

Remote Operation & Stop Switch

Ins tall the remote o pe ration & stop

switch for remote control.

Switch ON : Compressor is running.

S w i t c h OF F : C o m p re s s o r ha s

stopped.

Remote Operation & Stop Switch

Ins tall the remote o pe ration & stop

switch for remote control.

Switch ON : Compressor is running.

S w i t c h OF F : C o m p re s s o r ha s

stopped.

Remote Operation Change-over

Switch

Install the remote operation changeover switch near the air compressor.

Sw i t c h ON : Remo t e opera t i o n is

running.

Swi t c h OF F : Lo c al o p e r a t i on i s

running.

Loading...

Loading...