Video Corner

Servicing the Hitachi VM Series

camcorder

By Timothy W. Durhan

VHS camcorders from all manufacturers have a lot in common. They have to

have a lot of similarities in order to record

and play back on the same VHS tape cassette. On the other hand, manufacturers

also have a great deal of freedom in the

details of how they design and construct

their camcorders.

This article will describe procedures

for servicing Hitachi models VM 3000

through VM 5000 camcorders. Many of

the problem symptoms and actions to correct the problems will also apply to other

brands and models of camcorder.

Hitachi manufactured thousands of

camcorders in the late 80’s as models VM

3000 to VM 5000. Radio Shack, RCA and

Sears sold these units too, using their own

names and model numbers. All feature

the same tape mechanism. The capstan,

Durhan is an independent consumer electronics

ing

technician

and a freelance

technical writer.

service

mode cam and tape wind functions are

actuated by belts.

Symptoms of worn rubber parts

You probably know rubber parts dete-

riorate in time, even if they’re not used

often. Chances are, a five or six year old

camcorder will need new rubber. Some

common symptoms of worn belt problems include:

l Tape starts to load, then camcorder

shuts off.

*Tape runs, then after a while, shuts off.

l Camcorder eats tapes.

l Tapes won’t play or record.

If you have serviced VCRs with similar problems, you know it’s not too difficult to replace worn rubber parts.

Many VCR technicians are reluctant to

service camcorders, even though they

wouldn’t think twice about opening up

and repairing a hand held remote control.

If you can repair a remote control unit

without destroying the case or losing any

of the buttons, performing a mechanical

repair on a camcorder shouldn’t be too

difficult. Lost screws, pinched wires and

broken pc boards can be avoided by using

a systematic disassembly and reassembly

procedure.

Getting started

Start by powering up the camcorder

using the customer’s ac adapter, since a

defective battery may also be the cause of

any of the symptoms mentioned earlier.

Moreover, there is nothing more frustrating than running out of power in the middle of a repair. If your customer didn’t include the adapter along with their camcorder, put this repair on hold until they do.

Slide the power switch to on, and press

eject. If the mode belt is in good shape,

the cassette lid should pop up. If it doesn’t

1. Upper Cylinder (Video Head)

2. Audio/Control (A/C Head)

3.

Dew Sensor

4.

Pressure Roller

5.

Capstan Motor

6.

Capstan Flywheel

7. Take-up End Sensor

8. Take-up Reel Disk

9.

End Lump

10. Take-up Guide Roller

11.

Supply Reed Disk

12.

Tension Band

13.

Tension Arm

14. Supply Guide Roller

15. Supply End Sensor

16.

Impedance Roller

17. Full Erase Head

18.

Cylinder Brush

Figure 1. Tape transport mechanism-Top View.

60 Electronic Servicing

&

Technology November 1993

open, you’ll have to trigger the carriage

latch manually.

To open this latch manually, unplug the

ac adapter and remove the two screws that

hold the cassette lid on. Carefully slide

off the lid, and set it out of your way. On

the right side at the top edge of the chassis is a tiny latch (Figure 1). Gently move

the latch to one side with a small screwdriver or pick. The housing should pop

up, and you can remove the video tape, if

one is stuck inside.

Performing the diagnosis

Once the cassette lid is off, power-up

the camcorder again. Cover up the sense

LED in the center of the transport with

black tape or other suitable light shield,

and press play. Again, if the mode belt is

in good shape, the guide posts should

move to their stoppers, and the drum will

start to spin.

To determine whether the tape-wind

belt is doing its job, use a torque gauge

on the take-up spindle. Hitachi recommends

80gm-cm

to 1 lOgm-cm. If you

lack such a handy tool, you can try to stop

the spindle with your fingers. Obviously,

if the spindle doesn’t turn, or stops very

easily, the tape-wind belt is defective. Is

the pinchroller turning?

If the take-up spindle and pinchroller

aren’t moving, the capstan belt is defective, or there may be an electronic fault.

Listen closely for the sound of the capstan motor spinning. You will have to

press the play button continually in this

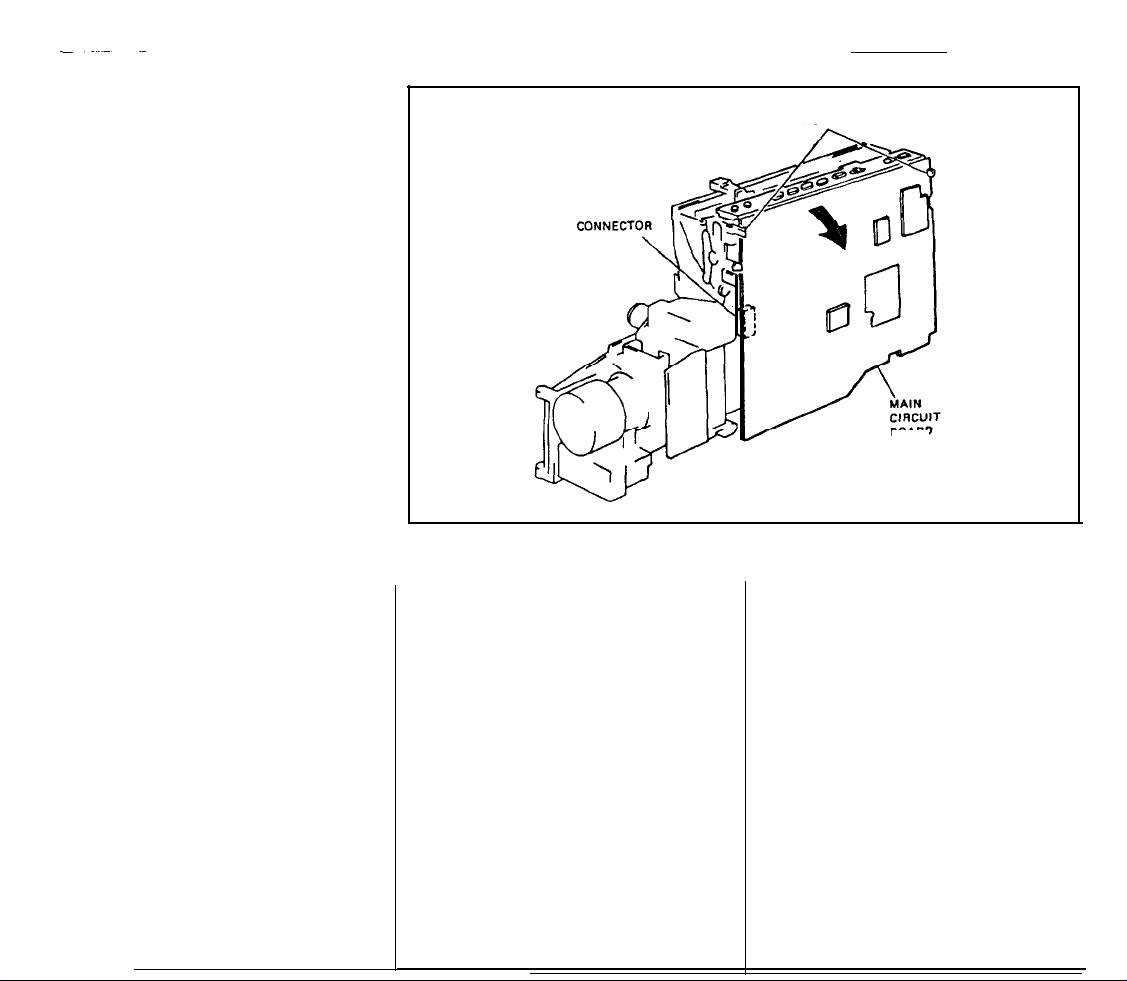

DISCONNECT

Figure 2. Jack circuit board removal

condition, because the lackofpulses from

the capstan and take-up sensors will alert

to order your parts from RCA instead of

ordering from Hitachi.

the system control microprocessor to

enter the protection mode, and the

cam-

corder will shut off.

If you have checked all of these func-

tions, and have determined that a belt may

need to be replaced; replace them all.

There are only three belts on the mech-

sense LED you put on earlier. Close the

cassette holder, (if you can). Unplug the

adapter cable to give yourself more room.

Unplug and remove the viewfinder.

anism, and since they were all manufac-

tured at the same time, if one is worn, the

other two can’t be far behind.

Belt part numbers 6356445, 6356472

and 6358012 should be available from

any Hitachi part distributor. Use numbers

cassette housing facing down, and the

lens assembly pointing to your left.

move the screws that hold the case shells

together. Next, carefully pull the shell

that’s facing you off and set it aside.

174757, 174758 and 174759 if you want

RELEASE

TWO TABS

BOARD

Getting to the belts

To begin, remove the covering from the

Lay the camcorder on its side, with the

Re-

Release the main pc board from the two

19.

Lower Cylinder

20. Mechanism State Switch

21.

Supply Loading

Cam

Gear

22. Take-up Loading Cam Gear

25.

Slider Arm

26.

PB/REC

27.Damper

28. Capstan Motor

23. Mode Motor and Belt 29. Capstan Flywheel

24.

Cam Gear

Figure 3. Tape transport mechanism- Bottom

white clips on both sides (Figure 2) and

slide the control pc board (buttons and all)

slowly toward you. Unplug the small connector from the bottom of the main pc

board, and remove the large wiring harness from its holder. This should allow

you to tilt the board for free access to the

tape mechanism.

Next, remove the plastic sheet covering the capstan pulley. Locate and remove

the screws and cover holding the flywheel

in place, and lift off the cover. Remove

the old belts and clean the gum deposits

off the pulleys with a solvent, such as alcohol or acetone.

vie

w.

inspect the area for wiring that may interfere with any movement of the mechanism. It’s a tight squeeze, but you can take

off the mode belt from the motor pulley

and worm gear pulley without removing

either one.

Located in the top left comer (Figure

3),

these pulleys should be cleaned too.

Again, make sure there are no twists or

excess grease on the new belt.

While you have the case off, it’s a good

idea to use a small soft brush to clean out

the dirt and dust that has found its way

inside. Reinstall the connector to the main

pc board, tuck the large wiring harness

back into its holder and slide the control

Replacing the belts

Replace the capstan belt, then the

tape-

wind belt. Rotate the flywheel by hand to

pc board into the slots on the top case.

Then snap the main pc board back into

the clips that hold it in place.

insure that there are no twists in the belts,

and remove any grease that may have

found its way onto the new belts.

Reinstall the flywheel cover and

screws. Reinstall the plastic sheet and

move the other side shell. Clean the video

heads, lower cylinder lip, guides, guide

The finishing touches

Next, turn the camcorder over and re-

Drive Arm

TOP EDGE

OF CHASSIS

rollers, pinchroller, ACE heads, impedance roller and capstan shaft with isopropyl alcohol (or other suitable chemical).

Always be extremely careful when

cleaning the video heads. Follow the

manufacturer’s directions carefully, and

use only specially made plastic foam or

chamois leather swabs.

Remove any excess grease and dirt

with Q-tips or a soft brush. Reinstall the

side shells and viewfinder.

Before powering up the camcorder,

clean the lens and viewfinder window

with a lens cleaning solution and lens tissue (available at any retail camera store).

Then connect the camcorder and TV (or

monitor) to the ac adapter and plug it in.

Slide the power switch to on, press eject

and put in a tape to test play quality. If

everything is in order, you should have a

clear picture on the screen and in the

viewfinder. Make sure that the audio is

playing back at the proper level and that

it is not distorted.

Perform a thorough operational test

Stop and eject your play test tape and

insert a tape you can record on. Remove

the lens cover and put the camcorder into

the record mode. While recording, use the

zoom, focus and other features on the

camcorder to verify that everything is

working properly, and that no connectors

are loose. Playback your recording and

check the video and sound for accurate

and natural qualities.

Because you didn’t disturb any electrical circuitry or tape path geometry, you

won’t need expensive jigs, charts or other

test equipment for a repairjob such as this.

Replacement of pc boards, power supply

components or the CCD and associated

parts would require a more involved repair

and adjustment procedure.

If, after a few belt and cleaning jobs,

you like the challenge that a camcorder

provides, there are books available from

Ryder Press, Howard Sams and others

that deal with camcorder theory and operation in full detail. Also, Philips of North

America, and others, have classroom

education on camcorder repair.

Camcorders manufactured in the 90’s

require more elaborate test jigs and contain exotic concepts never thought of in

the

80’s.

But isn’t the same true in other

areas of electronics?

n

62

Electronic Servicing & Technology November 1993

Loading...

Loading...