Hitachi G13SE2 User Manual

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

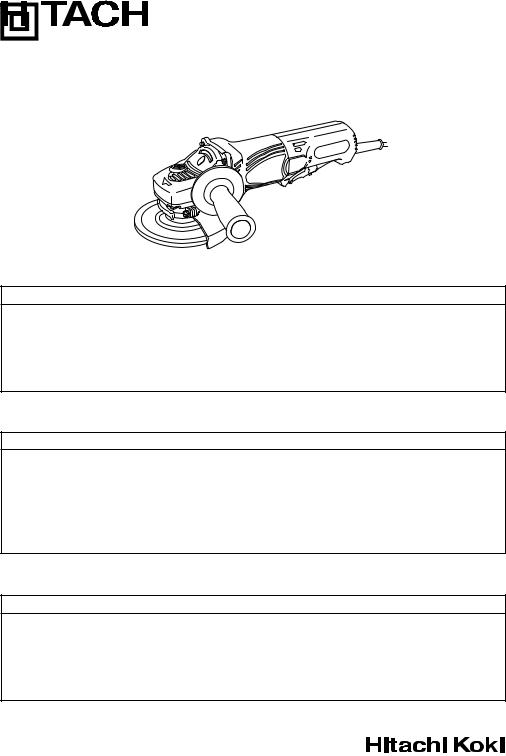

Model |

G 12SE2 • G 13SE2 |

Disc grinder |

|

||||

Modèle |

Meuleuse |

|

|||||

Modelo |

|

|

|

Amoladora angular |

|

||

G13SE2

SAFETY INSTRUCTIONS AND INSTRUCTION MANUAL

WARNING

WARNING

IMPROPER OR UNSAFE use of this power tool can result in death or serious bodily injury!

This manual contains important information about product safety. Please read and understand this manual BEFORE operating the power tool. Please keep this manual available for other users and owners before they use the power tool.

This manual should be stored in safe place.

INSTRUCTIONS DE SECURITE ET MODE D’EMPLOI

AVERTISSEMENT

AVERTISSEMENT

Une utilisation INCORRECTE OU DANGEREUSE de cet outil motorisé peut entraîner la mort ou de sérieuses blessures corporelles!

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de ce produit. Prière de lire et de comprendre ce mode d’emploi AVANT d’utiliser l’outil motorisé. Garder ce mode d’emploi à la disponibilité des autres utilisateurs et propriétaires avant qu’ils utilisent l’outil motorisé. Ce mode d’emploi doit être conservé dans un endroit sûr.

INSTRUCCIONES DE SEGURIDAD Y MANUAL DE INSTRUCCIONES

ADVERTENCIA

ADVERTENCIA

¡La utilización INAPROPIADA O PELIGROSA de esta herramienta eléctrica puede resultar en lesiones de gravedad o la muerte!

Este manual contiene información importante sobre la seguridad del producto. Lea y comprenda este manual ANTES de utilizar la herramienta eléctrica. Guarde este manual para que puedan leerlo otras personas antes de utilizar la herramienta eléctrica. Este manual debe ser guardado en un lugar seguro.

DOUBLE INSULATION

DOUBLE ISOLATION

AISLAMIENTO DOBLE

CONTENTS

English

Page |

Page |

IMPORTANT SAFETY INFORMATION ................ |

3 |

MEANINGS OF SIGNAL WORDS ........................ |

3 |

SAFETY ...................................................................... |

4 |

GENERAL SAFETY RULES ................................... |

4 |

SPECIFIC SAFETY RULES AND |

|

SYMBOLS ....................................................... |

6 |

DOUBLE INSULATION FOR SAFER |

|

OPERATION ................................................... |

8 |

FUNCTIONAL DESCRIPTION .................................... |

9 |

NAME OF PARTS .................................................. |

9 |

SPECIFICATIONS .................................................. |

9 |

ASSEMBLY AND OPERATION ............................... |

10 |

APPLICATIONS ................................................... |

10 |

PRIOR TO OPERATION ....................................... |

10 |

GRINDER OPERATION ....................................... |

12 |

DEPRESSED CENTER WHEEL |

|

ASSEMBLY AND DISASSEMBLY ............... |

13 |

MAINTENANCE AND INSPECTION ....................... |

14 |

ACCESSORIES ......................................................... |

16 |

STANDARD ACCESSORIES ............................... |

16 |

PARTS LIST .............................................................. |

49 |

TABLE DES MATIERES

Français

Page |

Page |

INFORMATIONS IMPORTANTES DE |

|

SÉCURITÉ ..................................................... |

17 |

SIGNIFICATION DES MOTS |

|

D’AVERTISSEMENT .................................... |

17 |

SECURITE ................................................................ |

18 |

REGLES GENERALE DE SECURITE ................... |

18 |

REGLES DE SECURITE SPECIFIQUES |

|

ET SYMBOLES ............................................. |

20 |

DOUBLE ISOLATION POUR UN |

|

FONCTIONNEMENT PLUS SUR ................. |

23 |

DESCRIPTION FONCTIONNELLE ........................... |

24 |

NOM DES PARTIES ............................................ |

24 |

SPECIFICATIONS ................................................ |

24 |

ASSEMBLAGE ET FONCTIONNEMENT ................ |

25 |

UTILISATIONS .................................................... |

25 |

AVANT L’UTILISATION ...................................... |

25 |

UTILISATION DE LA MEULEUSE ...................... |

27 |

ASSEMBLAGE ET DESASSEMBLAGE |

|

DE LA MEULE A DEPRESSION |

|

CENTRALE .................................................... |

29 |

ENTRETIEN ET INSPECTION .................................. |

30 |

ACCESSOIRES ......................................................... |

32 |

ACCESSOIRES STANDARD ............................... |

32 |

LISTE DES PIECES ................................................... |

49 |

ÍNDICE

Español

Página |

Página |

INFORMACIÓN IMPORTANTE SOBRE |

|

SEGURIDAD ................................................. |

33 |

SIGNIFICADO DE LAS PALABRAS DE |

|

SEÑALIZACIÓN ............................................ |

33 |

SEGURIDAD ............................................................. |

34 |

NORMAS GENERALES DE SEGURIDAD ........... |

34 |

NORMAS Y SÍMBOLOS ESPECÍFICOS |

|

DE SEGURIDAD ........................................... |

36 |

AISLAMIENTO DOBLE PARA OFRECER UNA |

|

OPERACIÓN MÁS SEGURA ........................ |

39 |

DESCRIPCIÓN FUNCIONAL .................................... |

40 |

NOMENCLATURA ............................................... |

40 |

ESPECIFICACIONES ............................................ |

40 |

MONTAJE Y OPERACIÓN ...................................... |

41 |

APLICACIONES ................................................... |

41 |

ANTES DE LA OPERACIÓN ................................ |

41 |

OPERACIÓN DE LA AMOLADORA |

|

ANGULAR .................................................... |

43 |

MONTAJE Y DESMONTAJE DE LA |

|

RUEDA DE DISCO ABOMBADO ................. |

45 |

MANTENIMIENTO E INSPECCIÓN ........................ |

46 |

ACCESORIOS ........................................................... |

48 |

ACCESORIOS ESTÁNDAR ................................. |

48 |

LISTA DE PIEZAS .................................................... |

49 |

English

IMPORTANT SAFETY INFORMATION

Read and understand all of the safety precautions, warnings and operating instructions in the Instruction Manual before operating or maintaining this power tool.

Most accidents that result from power tool operation and maintenance are caused by the failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing a potentially hazardous situation before it occurs, and by observing appropriate safety procedures.

Basic safety precautions are outlined in the “SAFETY” section of this Instruction Manual and in the sections which contain the operation and maintenance instructions.

Hazards that must be avoided to prevent bodily injury or machine damage are identified by WARNINGS on the power tool and in this Instruction Manual.

NEVER use this power tool in a manner that has not been specifically recommended by HITACHI.

MEANINGS OF SIGNAL WORDS

WARNING indicates a potentially hazardous situations which, if ignored, could result in death or serious injury.

CAUTION indicates a potentially hazardous situations which, if not avoided, may result in minor or moderate injury, or may cause machine damage.

NOTE emphasizes essential information.

3

English

SAFETY

GENERAL SAFETY RULES

WARNING: Read and understand all instructions.

WARNING: Read and understand all instructions.

Failure to follow all instructions listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

1.Work Area

(1)Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

(2)Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust of fumes.

(3)Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

2.Electrical Safety

(1)Double Insulated tools are equipped with a polarized plug (one blade is wider than the other.) This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified

electrician to install a polarized outlet. Do not change the plug in any way. Double Insulation  eliminates the need for the three wire grounded power cord and grounded power supply system.

eliminates the need for the three wire grounded power cord and grounded power supply system.

(2)Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is grounded.

(3)Don’t expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

(4)Do not abuse the cord. Never use the cord to carry the tools or pull the plug from a receptacle. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

(5)When operating a power tool outside, use an outdoor extension cord marked “W- A” or “W”. These cords are rated for outdoor use and reduce the risk of electric shock.

3.Personal Safety

(1)Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury.

(2)Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

4

English

(3)Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with your finger on the switch or plugging in tools that have the switch on invites accidents.

(4)Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is left attached to a rotating part of the tool may result in personal injury.

(5)Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

(6)Use safety equipment. Always wear protective glasses. Dust mask, non-skid safety shoes, hard hat, or ear plugs must be used for appropriate conditions.

4.Tool Use and Care

(1)Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may lead to loss of control.

(2)Do not force tool. Use the correct tool for your application. The correct tool will do the job better and safer at the rate for which it is designed.

(3)Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with the switch is dangerous and must be repaired.

(4)Disconnect the plug form the power source before making any adjustments, changing accessories, or storing the tool. Such preventive safety measures reduce the risk of starting the tool accidentally.

(5)Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

(6)Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools, with sharp cutting edges are less likely to bind and are easier to control.

(7)Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the tool's operation. If damaged, have the tool serviced by a Hitachi authorized service center before using. Many accidents are caused by poorly maintained tools.

(8)Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used with another tool.

5.Service

(1)Tool service must be performed only by a Hitachi authorized service center. Service or maintenance performed by unqualified personnel could result in a risk of injury.

(2)When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance section of this manual. Use of unauthorized parts or failure to follow Maintenance Instruction may create a risk of electric shock or injury.

5

English

SPECIFIC SAFETY RULES AND SYMBOLS

1.ALWAYS use proper guard with depressed center wheel. A guard protects operator from broken wheel fragments.

2.Accessories must be rated for at least the speed recommended on the tool warning label. Wheels and other accessories running over rated speed can fly apart and cause injury.

3.Hold tools by insulated gripping surfaces when performing an operation where the tool may contact hidden wiring or its own cord. Contact with a “live” wire will make exposed metal parts of the tool “live” and shock the operator.

4.ALWAYS wear ear plugs when using the tool for extended periods.

Prolonged exposure to high intensity noise can cause hearing loss.

5.Use only a depressed center wheel with a rated capacity which is GREATER than 13300 RPM for G12SE2 and 12000 RPM for G13SE2. Using any wheel a rated capacity LESS than 13300 RPM and/or an incorrect sized wheel (see SPECIFICATIONS at page 9) may result in wheel breakage, flying wheel fragments, and resulting in death or serious injury.

6.NEVER touch moving parts.

NEVER place your hands, fingers or other body parts near the tool’s moving parts.

7.NEVER operate without all guards in place.

NEVER operate this tool without all guards or safety features in place and in proper working order. If maintenance or servicing requires the removal of a guard or safety feature, be sure to replace the guard or safety feature before resuming operation of the tool.

8.Use right tool.

Don’t force small tool or attachment to do the job of a heavy-duty tool.

Don’t use tool for purpose not intended —for example— don’t use circular saw for cutting tree limbs or logs.

9.NEVER use a power tool for applications other than those specified.

NEVER use a power tool for applications other than those specified in the Instruction Manual.

10.Handle tool correctly.

Operate the tool according to the instructions provided herein. Do not drop or throw

6

English

the tool. NEVER allow the tool to be operated by children, individuals unfamiliar with its operation or unauthorized personnel.

11.Keep all screws, bolts and covers tightly in place.

Keep all screws, bolts, and plates tightly mounted. Check their condition periodically.

12.Do not use power tools if the plastic housing or handle is cracked.

Cracks in the tool’s housing or handle can lead to electric shock. Such tools should not be used until repaired.

13.Blades and accessories must be securely mounted to the tool.

Prevent potential injuries to youself or others. Blades, cutting implements and accessories which have been mounted to the tool should be secure and tight.

14.Keep motor air vent clean.

The tool’s motor air vent must be kept clean so that air can freely flow at all times. Check for dust build-up frequently.

15.Operate power tools at the rated voltage.

Operate the power tool at voltages specified on its nameplate.

If using the power tool at a higher voltage than the rated voltage, it will result in abnormally fast motor revolution and may damage the unit and the motor may burn out.

16.NEVER use a tool which is defective or operating abnormally.

If the tool appears to be operating unusually, making strange noises, or otherwise appears defective, stop using it immediately and arrange for repairs by a Hitachi authorized service center.

17.NEVER leave tool running unattended. Turn power off.

Don’t leave tool until it comes to a complete stop.

18.Carefully handle power tools.

Should a power tool be dropped or struck against hard materials inadvertently, it may be deformed, cracked, or damaged.

19.Do not wipe plastic parts with solvent.

Solvents such as gasoline, thinner benzine, carbon tetrachloride, and alcohol may damage and crack plastic parts. Do not wipe them with such solvents.

Wipe plastic parts with a soft cloth lightly dampened with soapy water and dry thoroughly.

20.NEVER use a depressed center wheel which is cracked or deformed or worn away (see the MAINTENANCE AND INSPECTION section on page 14).

21.NEVER use the grinder in places where the sparks generated by the grinder can cause explosion, such as where flammable materials or gases are present.

22.NEVER push in the push button while the spindle is running.

23.ALWAYS wear eye protection that meets the requirement of the latest revision of ANSI

Standard Z87.1.

24.ALWAYS wear a mank or respirator to protect yourself from dust or potentially harmful particles generated during the grinding operation.

7

English

25.ALWAYS firmly grip the body handle and side handle while operating the grinder.

26.ALWAYS have a trial run before grinding commence. (see Test the grinder before using on page 11).

27.ALWAYS follow the instructions contained in this manual when replacing the depressed center wheel.

28.ALWAYS be careful with buried objict such as an underground wiring.

Touching these active wiring or electric cable with this tool, you may receive an electric shock.

Comfirm if there are any buried object such as electric cable within the wall, floor or ceiling where you are going to operate here after.

29.Definitions for symbols used on this tool

V ............. |

volts |

Hz ........... |

hertz |

A ............. |

amperes |

no ........... |

no load speed |

W ............ |

watt |

............ |

Class II Construction |

---/min .... |

revolutions per minute |

DOUBLE INSULATION FOR SAFER OPERATION

To ensure safer operation of this power tool, HITACHI has adopted a double insulation design. “Double insulation “ means that two physically separated insulation systems have been used to insulate the electrically conductive materials connected to the power supply from the outer frame handled by the operator. Therefore, either the symbol “ ” or the words “Double insulation” appear on the power tool or on the nameplate.

” or the words “Double insulation” appear on the power tool or on the nameplate.

Although this system has no external grounding, you must still follow the normal electrical safety precautions given in this Instruction Manual, including not using the power tool in wet environments.

To keep the double insulation system effective, follow these precautions:

Only HITACHI AUTHORIZED SERVICE CENTER should disassemble or assemble this power tool, and only genuine HITACHI replacement parts should be installed.

Clean the exterior of the power tool only with a soft cloth moistened with soapy water, and dry thoroughly.

Never use solvents, gasoline or thinners on plastic components; otherwise the plastic may dissolve.

SAVE THESE INSTRUCTIONS

AND

MAKE THEM AVAILABLE TO OTHER USERS AND OWNERS OF THIS TOOL!

8

English

FUNCTIONAL DESCRIPTION

NOTE: The information contained in this Instruction Manual is designed to assist you in the safe operation and maintenance of the power tool.

NEVER operate, or attempt any maintenance on the tool unless you have first read and understood all safety instructions contained in this manual.

Some illustrations in this Instruction Manual may show details or attachments that differ from those on your own power tool.

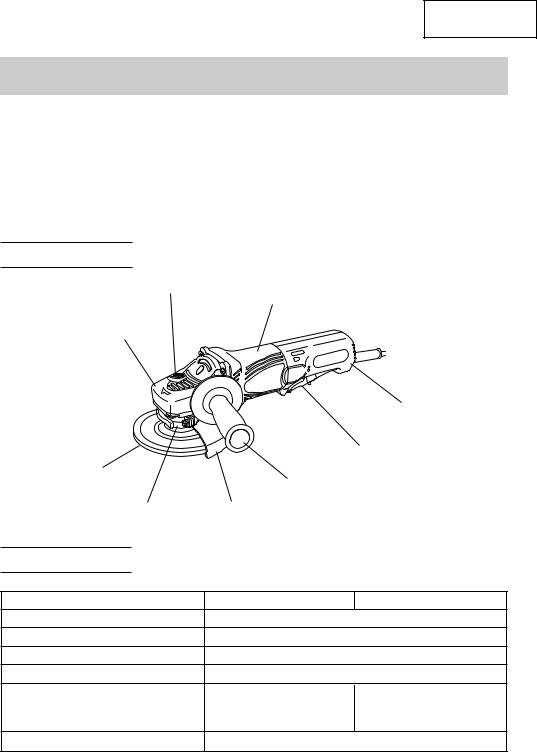

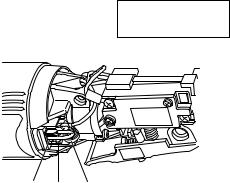

NAME OF PARTS

Push Button

Housing

Gear Cover

|

|

Tail Cover |

|

Paddle Lever |

|

Depressed Center Wheel |

Side Handle |

|

|

|

|

Packing Gland |

Wheel Guard |

|

|

Fig.1 |

|

SPECIFICATIONS |

|

|

Model |

G12SE2 |

G13SE2 |

Motor |

Single-Phase Series Commutator Motor |

|

Power Source |

Single-Phase 120 V AC 60 Hz, 120V DC |

|

Current |

9.5 A |

|

No-Load Speed |

10000/min |

|

Wheel Size: |

|

|

external diam. |

4-1/2" (115 mm) |

5" (125 mm) |

hole diam. |

7/8" (22 mm) |

7/8" (22 mm) |

Weight |

4.2 lbs (1.9 kg) |

|

9

English

ASSEMBLY AND OPERATION

APPLICATIONS

Removal of casting fin and finishing of various type of steel, bronze and aluminum materials and castings.

Grinding of welded sections or sections cut by means of an acetylene torch.

Grinding of synthetic resins, slate, brick, marble.

WARNING: To avoid the risk of serious injury, NEVER use this grinder with cup wheels and/or saw blades.

WARNING: To avoid the risk of serious injury, NEVER use this grinder with cup wheels and/or saw blades.

PRIOR TO OPERATION

1.Power source

Ensure that the power source to be utilized conforms to the power source requirements specified on the product nameplate.

2.Power switch

Ensure that the switch is in the OFF position. If the plug is connected to a receptacle while the switch is in the ON position, the power tool will start operating immediately and can cause serious injury.

3.Extension cord

When the work area is far away from the power source, use an extension cord of sufficient thickness and rated capacity. The extension cord should be kept as short as practicable.

WARNING:

WARNING:

Damaged cord must be replaced or repaired.

4.Check the receptacle

If the receptacle only loosely accepts the plug, the receptacle must be repaired. Contact a licensed electrician to make appropriate repairs.

If such a fautly receptacle is used, it may cause overheating, resulting in a serious hazard.

5.Check your work environment

Ensure the following before operation;

No flammable gas, liquid, or object at worksite.

When grinding thin steel sheet it may cause a high booming noise. To avoid such noise, place a rubber mat under the workpiece.

Clear the area of children or unauthorized personnel.

10

English

6.Mounting the wheel guard

Be sure to mount the wheel guard at an angle that will protect the operator’s body from injury by a broken wheel piece.

[How to attach and adjust the wheel guard](Fig. 2)

Set the wheel ass’y to the packing gland.

Tighten M5 screw to secure the wheel guard while the lever is in closed position.

Perform the adjustment, of the wheel guard while the lever is released. (Loosen M5 screw and readjust if the wheel guard does not rotate smoothly.)

After adjustment, if grinder operation is required, perform the operation only after setting the lever in closed position.

Lubricate the sliding section of the set piece (B) and the lever if the lever does not move smoothly.

WARNING:

WARNING:

If the wheel guard is not attached properly, a broken wheel may result in and cause death or serious injury.

Lever

Set piece (B)

M5 screw

Fig. 2

7.Thoroughly check that the depressed center wheel is free of cracks, splits and other abnomalities before mounting. Make sure it is firmly clamped and has been properly mounted. Refer to page 13 of this manual for Depressed Center Wheel Assembly and Disassembly

8.Test the grinder before using.

Before actually beginning the grinding work, test the grinder by first clearing the area of all other personnel. Make sure the wheel guard is in place and that you are wearing eye protection. Turn the grinder “on”, and make sure the grinder runs smoothly and shows no abnormalities.

Duration of the trial run is as follows:

When depressed center wheel is replaced .................. 3 minutes or more When starting daily work .............................................. 1 minute or more

9.Use only properly rated depressed center wheels.

Use only depressed center wheels rated at 13300 RPM or more for G12SE2 and 12000 RPM or more for G13SE2.

Using a depressed center wheel rated less can lead to wheel disintegration during operation and cause serious bodily injury.

10.Check the push button.

Make sure that the push button is disengaged by pushing push button two or three times before turning on the grinder. (Fig. 5)

11

English

GRINDER OPERATION

1.Hold the grinder firmly by its body handle and side handle (Fig. 1)

The grinder produces a counterforce which must be controlled by firmly holding onto the grinder.

2.Switch operation

Switch On: To switch on, slide the lock lever in the direction of A and press the paddle lever in the direction of B as shown in Fig. 3-a.

Furthermore, slide the lock lever in the direction of C shown in Fig.3-b while pressing the paddle lever to lock and enable continuous operation.

Switch OFF: To release the locking mode, press the paddle lever in the direction of B shown in Fig.3-a, and release the paddle lever to switch off.

(a) |

(b) Switch with locking mechanism |

Lock Paddle Tail cover lever lever

Fig. 3

3.Use light grinding pressure.

There is no need to press hard when grinding. Usually the grinder's own weight is sufficient to allow the required light contact with the surface to be ground.

WARNING: Do not press the grinder forcibly against the surface to be ground. Heavy pressure can result in wheel breakage and serious injury. It can also damage the surface being ground or damage the grinder’s motor.

WARNING: Do not press the grinder forcibly against the surface to be ground. Heavy pressure can result in wheel breakage and serious injury. It can also damage the surface being ground or damage the grinder’s motor.

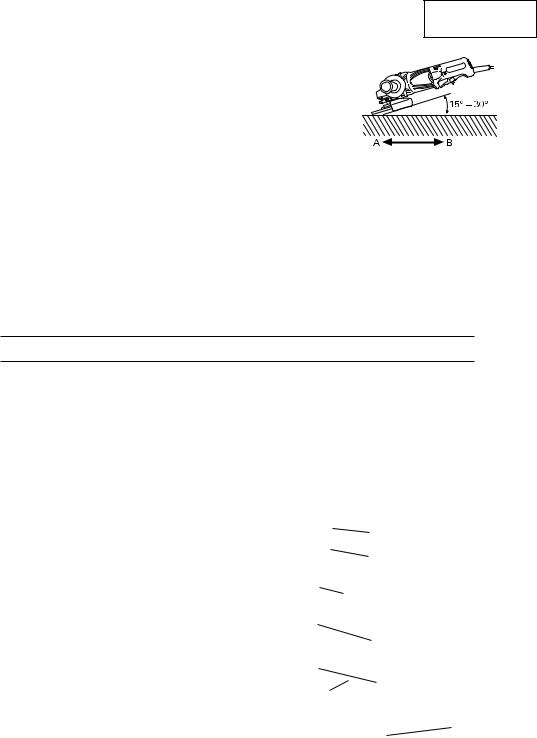

4.Use proper grinding angle.

Grind only with the wheel’s edge by lifting the grinder 15° to 30°, as shown in Fig. 4.

CAUTION:

CAUTION:

●Do not use the entire surface of the depressed center wheel. Use only the edge of the depressed center wheel.

12

English

5. Move the grinder in the proper direction.

When using a new depressed center wheel in direction A (Fig. 4), the wheel edge may

cut into the workpiece. In this case, grind in direction B (Fig. 4).

Once the wheel edge is worn, the workpiece

can be ground in both directions.

Fig. 4

NOTE: The wheel provided (resinoid wheel) is rated as Class A grain and # 36 grain size. It is most suitable for heavy grinding of steel and other types of materials.

6.Adjust operation to desired finish.

For a fine finish, decrease pressure by lifting slightly. Grind slowly and at the appropriate speed.

CAUTION:

CAUTION:

●The revolving depressed center wheel will create air turbulence.

●Do no lay the grinder down in areas of dust or dirt until it has come to a complete stop.

DEPRESSED CENTER WHEEL ASSEMBLY AND DISASSEMBLY

WARNING: Never attempt to assemble or disassemble the depressed center wheel, unless the power switch is in the “OFF” position and the electrical cord has been disconnected from the receptacle.

WARNING: Never attempt to assemble or disassemble the depressed center wheel, unless the power switch is in the “OFF” position and the electrical cord has been disconnected from the receptacle.

1. Assembly

(1)Turn the disc grinder upsidedown so that the spindle is facing upward.

(2)Align the across flats of the wheel washer with the notched part of the spindle, then attach them.

(3)Fit the protuberance of the depressed center wheel onto the wheel washer.

(4)Screw the wheel nut onto the spindle.

(5)While pushing the push button with one hand, lock the spindle by turning the depressed center wheel slowly with the other hand.

Tighten the wheel nut by using the supplied wrench as shown in Fig. 5.

CAUTION:

CAUTION:

●Tighten the wheel nut securely and confirm that the depressed center wheel does not wobble.

2.Disassembly

To remove the depressed center wheel, simply reverse the above-mentioned procedure.

Wrench

Wheel

Nut

Depressed

Center

Wheel

Wheel

Washer

(G13SE2)

Spindle

Wheel

Guard

Fig. 5

(G12SE2)

Push

Button

13

English

MAINTENANCE AND INSPECTION

WARNING: Be sure to switch power OFF and disconnect the plug from the receptacle during maintenance and inspection.

WARNING: Be sure to switch power OFF and disconnect the plug from the receptacle during maintenance and inspection.

Using cracked, deformed or damaged wheels can lead to wheel breakage and resulting serious injury.

1.Replacing the depressed center wheel

Replace the depressed center wheel when it has been worn out to about 2-3/8" (60mm) in external diameter. Confirm that there is no crack or any damage to the depressed center wheel. If there is a crack or a transformation in the wheel, replace it immediately.

2.Inspecting the screws

Regularly inspect all screws and ensure that they are fully tightened. Should any of the screws be loosened, retighten them immediately.

WARNING: Using this grinder with loosened screws is extremely dangerous.

WARNING: Using this grinder with loosened screws is extremely dangerous.

3.Confirm that there is no damage in the wheel guard, the cord and housing, etc. Furthermore, confirm that there is no sbnormality in the activation of the switch.

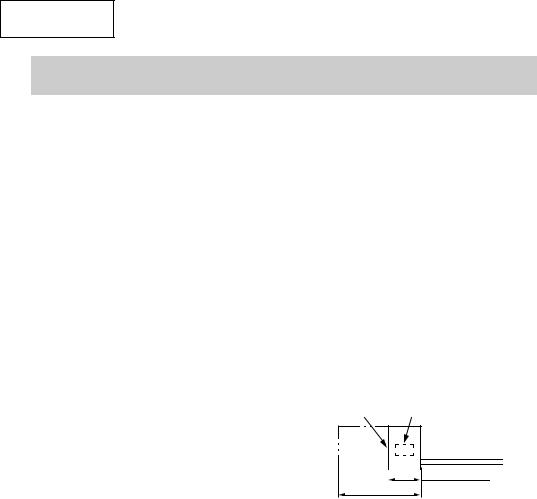

4.Inspecting the carbon brushes (Fig. 6)

The Motor employs carbon brushes which are consumable parts. When they become worn to or near the ”wear limit“, it could result in motor trouble. When an auto-stop carbon brush is equipped, the motor will stop automatically. At that time, replace both carbon brushes with new ones which have the same carbon brush Numbers shown in the figure. In addition, always keep carbon brushes clean and ensure that they slide freely within the brush holders.

CAUTION:

CAUTION:

No. of carbon

Wear limit brush

0,24" (6mm)

0,24" (6mm)

0,67" (17mm)

|

No. of |

|

carbon brush |

|

|

Usual carbon brush |

88 |

|

|

Auto-stop carbon brush |

76 |

|

|

Fig. 6

●Using this grinder with a carbon brush which is worn in excess of the wear limit will damage the motor.

NOTE: Use HITACHI carbon brush No. 76 or No. 88 indicated in Fig. 6.

14

English

Replacing carbon brushes (Fig. 7): <Disassembly>

(1)Loosen the D4 tapping screw retaining the tail cover and remove tha tail cover.

(2)Use the auxiliary hexagonal wrench or small screwdriver to pull up the edge of the spring that is holding down the carbon brush. Remove the edge of the spring toward the outside of the brush holder.

(3)Remove the end of the pig-tail on the carbon brush from the terminal section of brush holder and then remove the

carbon brush from the brush holder. <Assembly>

Carbon Brush Spring

Brush Holder

Fig. 7

(1)Insert the end of the pi-tail of the carbon brush in the terminal section of brush holder.

(2)Insert the carbon brush in the brush holder.

(3)Use the auxiliary hexagonal wrench or small screwdriver to return the edge of the spring to the head of the carbon brush.

(4)Mount the tail cover and tighten the D4 tapping screw.

5.Service and repairs

All quality power tools will eventually require servicing or replacement of parts because of wear from normal use. To assure that only authorized replacement parts will be used, all service and repairs must be performed by a HITACHI AUTHORIZED SERVICE CENTER, ONLY.

6.Service parts list

CAUTION:

CAUTION:

Repair, modification and inspection of Hitachi Power Tools must be carried out by an Hitachi Authorized Service Center.

This Parts List will be helpful if presented with the tool to the Hitachi Authorized Service Center when requesting repair or other maintenance.

In the operation and maintenance of power tools, the safety regulations and standards prescribed in each country must be observed.

MODIFICATIONS:

Hitachi Power Tools are constantly being improved and modified to incorporate the latest technological advancements.

Accordingly, some parts (i.e. code numbers and/or design) may be changed without prior notice.

15

English

ACCESSORIES

WARNING: Never use any accessories other than those mentioned below.

WARNING: Never use any accessories other than those mentioned below.

The use of any accessories other than those mentionded below or attachments not intended for use such as cup wheel, cut-off wheel or saw blade is dangerous and may cause personal injury or property damage.

NOTE: Accessories are subject to change without any obligation on the part of the HITACHI.

STANDARD ACCESSORIES |

|

Depressed center wheel..................................................................................................... |

1 |

4-1/2" (115 mm) external dia. × 1/4" (6 mm) thickness × 7/8" (22 mm) hole dia. |

|

(Code No. 701045 or 326203) ................ |

G12SE2 |

5" (125mm) external dia. × 1/4” (6 mm) thickness × 7/8” (22 mm) hole dia. |

|

(Code No. 701050 or 326205) ................ |

G13SE2 |

Wrench (Code No. 938332Z) .............................................................................................. |

1 |

Side Handle (Code No. 956633)......................................................................................... |

1 |

NOTE: Specifications are subject to change without any obligation on the part of the HITACHI

16

Loading...

Loading...