Page 1

Contents: Basic Course G426 ISO Programming

No.

1

2

3

4

5

6

7

8

9

10

11

Title

Cartesian contour movements

Holes

Square

Rounding / chamfering corners

Contour approach / departure

Circular arc with CC, C

Tangential contour connection

Circular arc with CR

Circular arcs

Polar contour movements

Hexagon (polar)

Circle (polar) CP

Circular path with tang. connection (polar) CTP

PGM-No.

62151

62152

62153

62154

62155

62156

62157

62158

62159

62160

62161

12

13

14

15

16

17

Canned cycles

Drilling cycle

Slot plate

Die I

Program section repeats

Linear hole pattern

Hexagon

Drilled plate - slanted columns

62170

62172

62174

62180

62181

62182

HEIDENHAIN Basic Course ISO G

426

F10 IH1

Page 2

Contents: Basic Course G426 ISO Programming

No.

18

19

20

21

22

23

24

Title

Subprogramming Technique

Subprogram (groups of holes)

Bolt hole circle segments with several tools

Milling with several settings

Hole pattern

Contour Cycles

Contour cycles SL II, Roughing out kidney

Contour cycles SL II, Kidney-shaped island

Coordinate transformations

Datum shift and mirror images

PGM No.

62186

62187

62188

62189

62190

62191

62192

HEIDENHAIN Basic Course ISO G

426

F10 IH1

Page 3

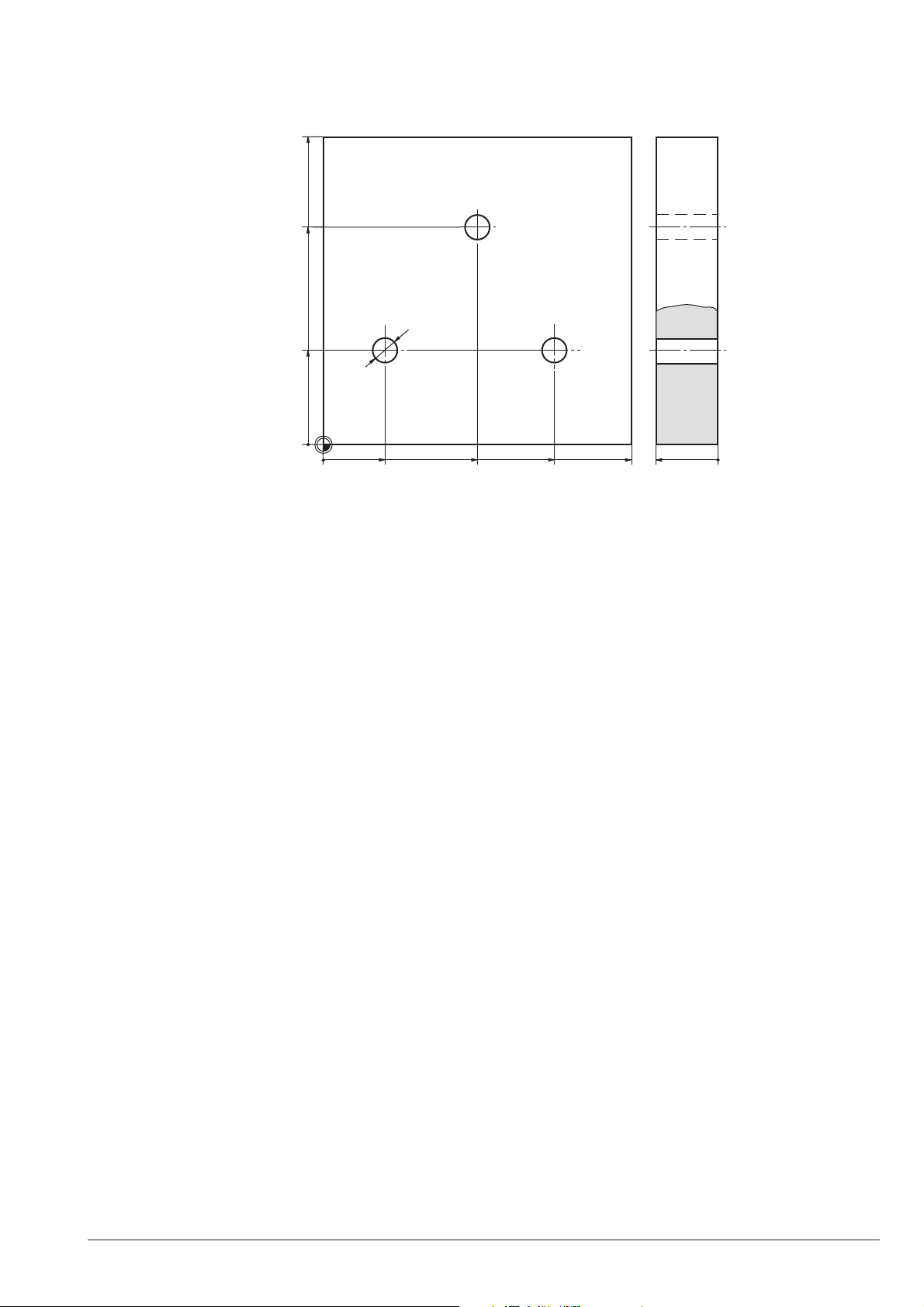

Task: Program(s):

Holes

100

70

8

30

0

0

20

50

75

100

20

0

HEIDENHAIN Basic Course ISO G

426

F06 62151/1

Page 4

Program layout:

Operating mode "Programming"

Holes

Begin program

Define workpiece blank

Define tool

Activate tool

Move to clearance height

Move to starting point

Move to setup clearance

Drill

Retract drill

PGM

MGT

%62151 G71

G30 . . . X . . . Y . . . Z . . .

G31 . . . X . . . Y . . . Z . . .

G99 T . . . L . . . R . . .

T . . . G . . . S . . .

G00 G40 G90 Z+100 M3

X . . . Y . . .

Z+ . . . M8

G01 Z– . . . F400

G00 Z+2

Next hole

Drill

Retract drill

Next hole

Drill

Return to clearance height

End of program

X . . . Y . . .

G01 Z– . . .

G00 Z+ . . .

X . . . Y . . .

G01 Z– . . .

G00 Z+100 M2 (M30)

HEIDENHAIN Basic Course ISO G

426

F06 62151/2

Page 5

Solution:

100

70

30

0

Holes

0

20

8

50

75

100

20

0

Complete program

%62151 G71 *

N10 G30 G17 X+0 Y+0 Z-20 *

N20 G31 G90 X+100 Y+100 Z+0 * ....................................

N30 G99 T1 L+0 R+4 * ...................................................

N40 T1 G17 S4000 * ......................................................

N50 G00 G90 Z+100 M03 * .............................................

N60 X+20 Y+30 * ...........................................................

N70 Z+2 M08 *

N80 G01 Z-22 F400 * ......................................................

N90 G00 Z+2 *

N100 X+50 Y+70 * ...........................................................

N110 G01 Z-22 *

N120 G00 Z+2 *

N130 X+75 Y+30 * ...........................................................

N140 G01 Z-22 *

N150 G00 Z+100 M30 *

N999999 %62151 G71 *

WORKPIECE BLANK DEFINITIONS

TOOL DEFINTION

TOOL CALL

CLEARANCE HEIGHT

1ST HOLE

DRILL

2ND HOLE

3RD HOLE

HEIDENHAIN Basic Course ISO G

426

62151/3F06

Page 6

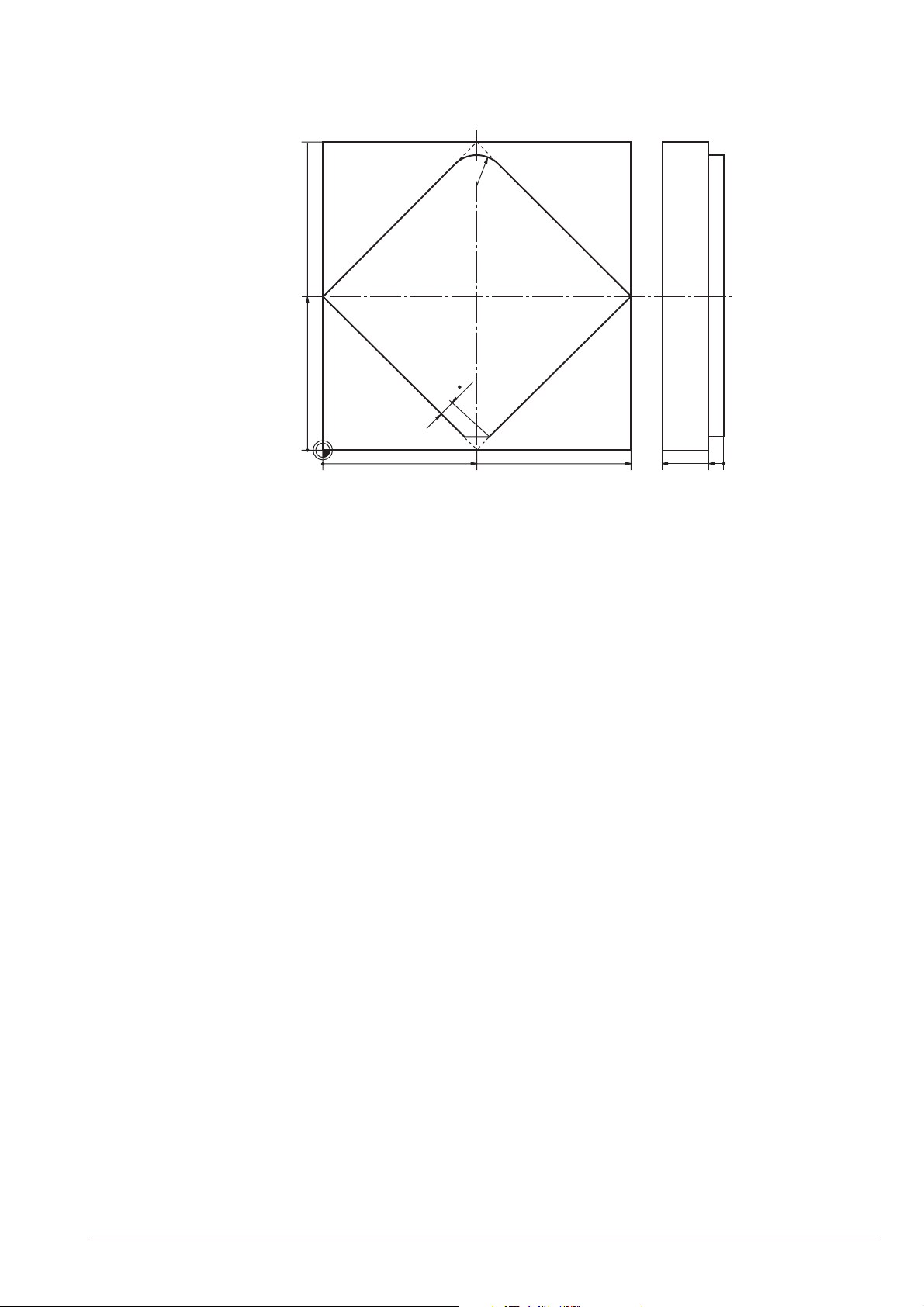

Task: Program(s):

100

50

Square

0

0

50

Create program

Define workpiece blank

Define tool

Activate tool

Move to clearance height

Move to auxiliary point G40

Plunging depth

Contour starting point G41/G42

Contour coordinates G41/G42

○○○

5

0

100

20

%62152 G71

G30 G . . . X . . . Y . . . Z . . .

G31 G . . . X . . . Y . . . Z . . .

G99 T . . . L . . . R . . .

T . . . G . . . S . . .

G00 G40 G90 Z+ . . .

X . . . Y . . .

Z –. . .

G01 G41 X . . . Y . . .

X . . . Y . . .

○○○

Last contour point G41/G42

Move to auxiliary point G40

Retract tool, PGM end

HEIDENHAIN Basic Course ISO G

426

X . . . Y . . .

G40 X . . . Y . . .

G00 Z+ . . . M2/M30

F06 62152/1

Page 7

Solution:

Square

100

50

0

5

0

50

100

20

0

Complete program

%62152 G71 *

N10 G30 G17 X+0 Y+0 Z-20 *

N20 G31 G90 X+100 Y+100 Z+0 * ....................................

N30 G99 T1 L+0 R+8 * ...................................................

N40 T1 G17 S4000 * ......................................................

N50 G00 G40 G90 Z+100 M03 * ......................................

N60 X-30 Y+50 * ............................................................

N70 Z-5 * ......................................................................

N80 G01 G41 X+0 Y+50 F400 * ........................................

N90 X+50 Y+100 *

N100 X+100 Y+50 *

N110 X+50 Y+0 *

N120 X+0 Y+50 * .............................................................

N130 G40 X-30 Y+50 * .....................................................

N140 G00 Z+100 M30 * ....................................................

N999999 %62152 G71 *

WORKPIECE BLANK DEFINITIONS

TOOL DEFINITION

TOOL CALL

CLEARANCE HEIGHT

AUXILIARY POINT (G40)

PLUNGING DEPTH

CONTOUR STARTING POINT

LAST CONTOUR POINT

AUXILIARY POINT

RETRACT TOOL / PGM END

HEIDENHAIN Basic Course ISO G

426

62152/2F06

Page 8

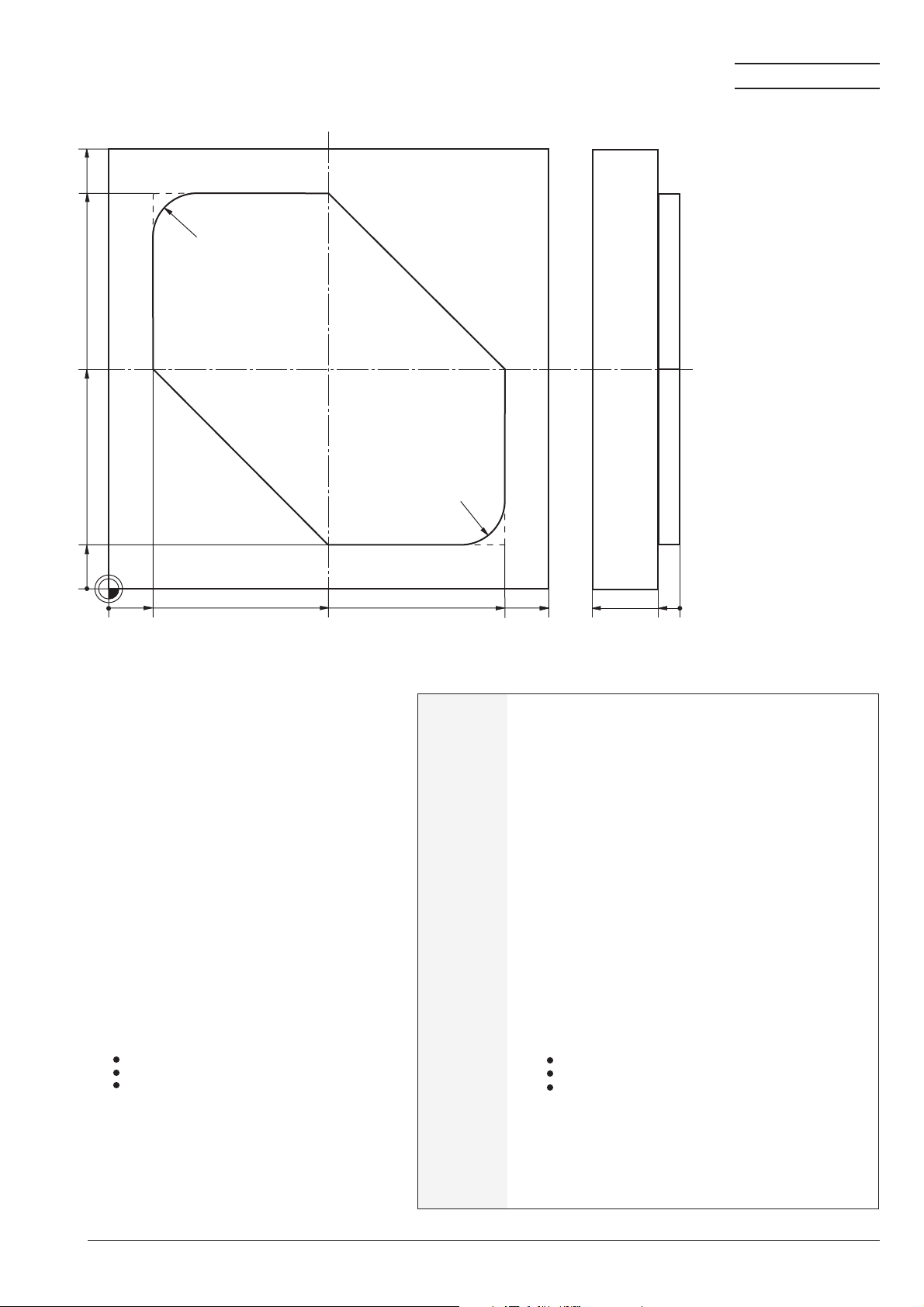

Task: Program(s):

Rounding / chamfering corners

100

R10

50

5 45°

0

5

0

50

100

100

20

0

HEIDENHAIN Basic Course ISO G

426

F06 62153/1

Page 9

Solution:

Rounding / chamfering corners

100

R10

50

5 45°

0

0

50

100

100

20

5

0

Complete program

%62153 G71 *

N10 G30 G17 X+0 Y+0 Z-20 *

N20 G31 G90 X+100 Y+100 Z+0 * ....................................

N30 G99 T1 L+0 R+8 * ...................................................

N40 T1 G17 S4000 * ......................................................

N50 G00 G40 G90 Z+100 M03 * ......................................

N60 X-30 Y+50 * ............................................................

N70 Z-5 *

N80 G01 G41 X+0 Y+50 F400 * ........................................

N90 X+50 Y+100 *

N100 G25 R10 F200 * ......................................................

N110 X+100 Y+50 *

N120 X+50 Y+0 *

N130 G24 R5 * ................................................................

N140 X+0 Y+50 *

N150 G40 X-30 Y+50 * .....................................................

N160 G00 Z+100 M30 * ....................................................

N999999 %62153 G71 *

WORKPIECE BLANK DEFINITION

TOOL DEFINITION

TOOL CALL

CLEARANCE HEIGHT

AUXILIARY POINT (G40)

CONTOUR STARTING POINT

ROUND CORNER

CHAMFER

AUXILIARY POINT (G40)

PGM END

HEIDENHAIN Basic Course ISO G

426

62153/2F06

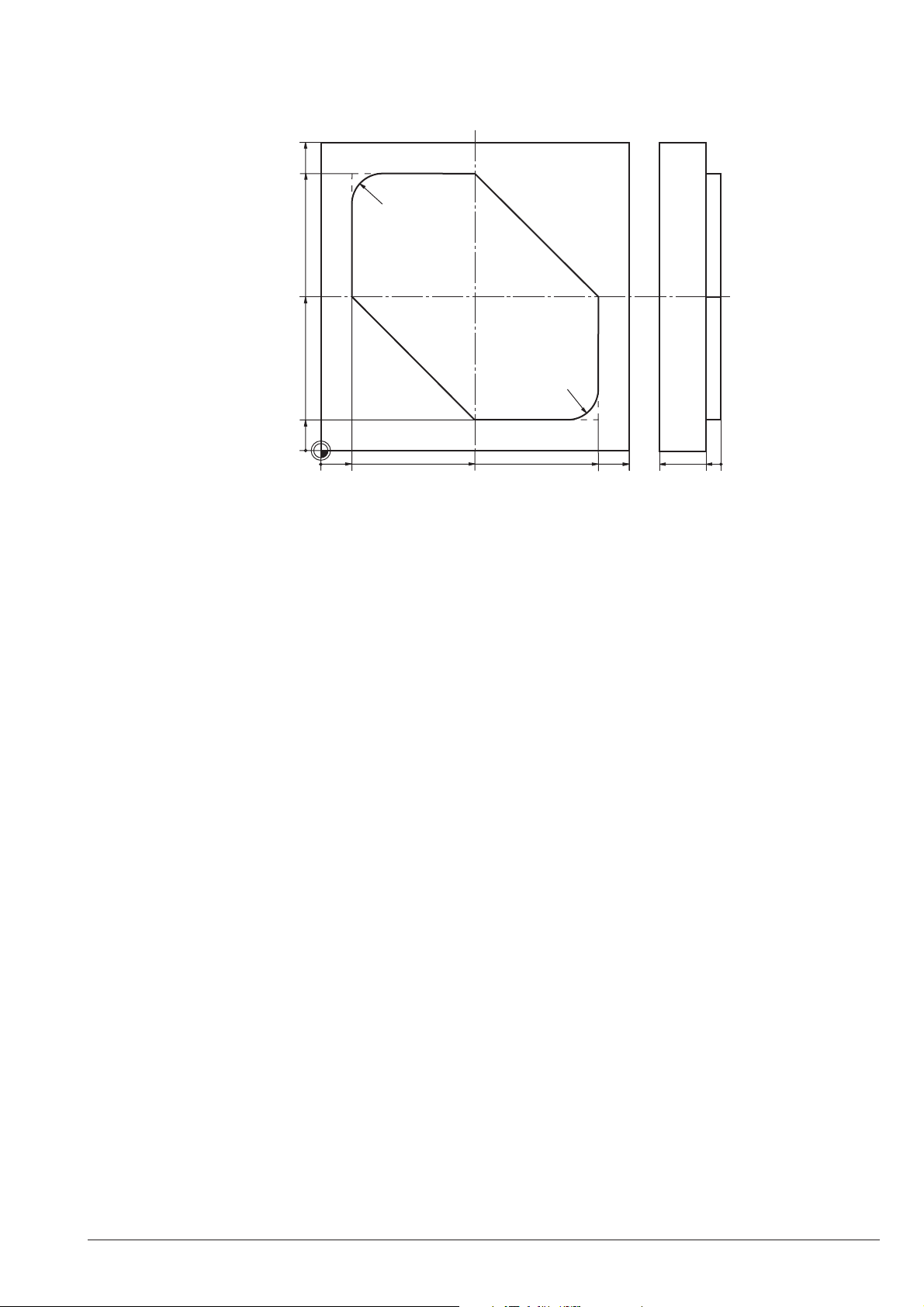

Page 10

Task: Program(s):

100

Contour approach / departure

90

50

10

R10

R10

0

0

10

50

90

100

100

20

0

5

Begin program

Define workpiece blank

Define tool

Activate tool

Move to clearance height

Move to auxiliary point

Plunging depth

First contour point

Smooth approach

Contour

○○○

Smooth departure

Auxiliary point

%62154 G71

G30 G . . . X . . . Y . . . Z . . .

G31 G . . . X . . . Y . . . Z . . .

G99 T . . . L . . . R . . .

T . . . G . . . S . . .

G00 G40 G90 Z+ . . .

X . . . Y . . .

Z– . . .

G01 G41 X . . . Y . . . F . . .

G26 R . . .

X . . . Y . . .

○○○

G27 R . . .

G40 X . . . Y . . .

Retract tool, PGM end

HEIDENHAIN Basic Course ISO G

426

G00 Z+ . . . M2/M30

F06 62154/1

Page 11

Solution:

Contour approach / departure

100

Complete program

90

50

10

0

R10

R10

0

10

50

%62154 G71 *

N10 G30 G17 X+0 Y+0 Z-20 *

N20 G31 G90 X+100 Y+100 Z+0 *

N30 G99 T1 L+0 R+8 *

N40 T1 G17 S4000 *

N50 G00 G40 G90 Z+100 M03 *

N60 X-30 Y+70 * ............................................................

N70 Z-5 *

N80 G01 G41 X+10 Y+70 F400 * ......................................

N80 G26 R3 * ................................................................

N90 Y+90 *

N100 G25 R10 *

N110 X+50 *

N120 X+90 Y+50 *

N130 Y+10 *

N140 G25 R10 *

N150 X+50 *

N160 X+10 Y+50 *

N170 Y+70 * ....................................................................

N180 G27 R3 * ................................................................

N190 G40 X-30 Y+70 * .....................................................

N200 G00 Z+100 M30 *

N999999 %62154 G71 *

90

0

5

20

100

100

AUXILIARY POINT (G40)

STARTING POINT

SMOOTH APPROCH TO

STARTING POINT

LAST CONTOUR POINT G41

SMOOTH DEPARTURE TO

AUXILIARY POINT

AUXILIARY POINT

HEIDENHAIN Basic Course ISO G

426

F06

62154/2

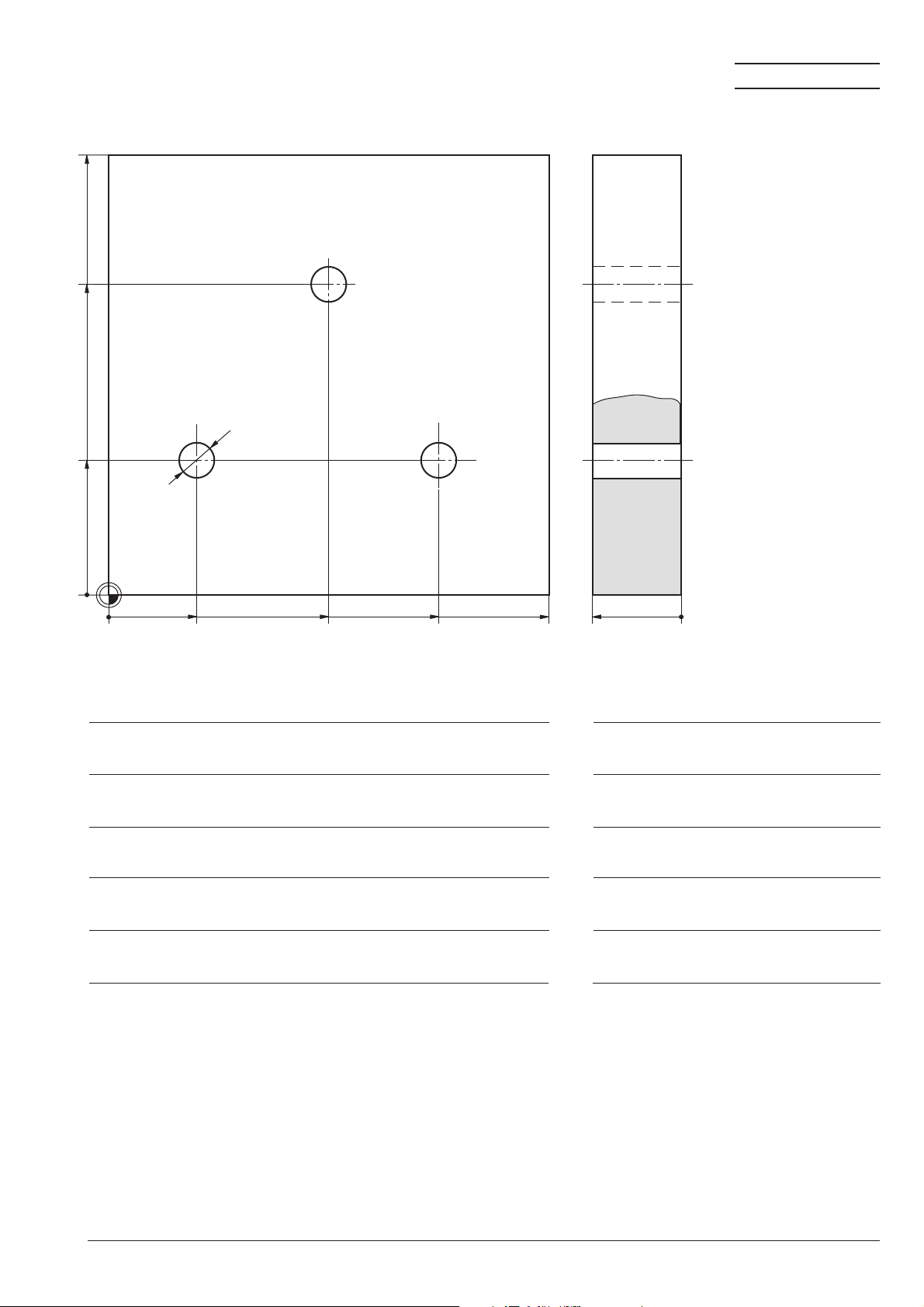

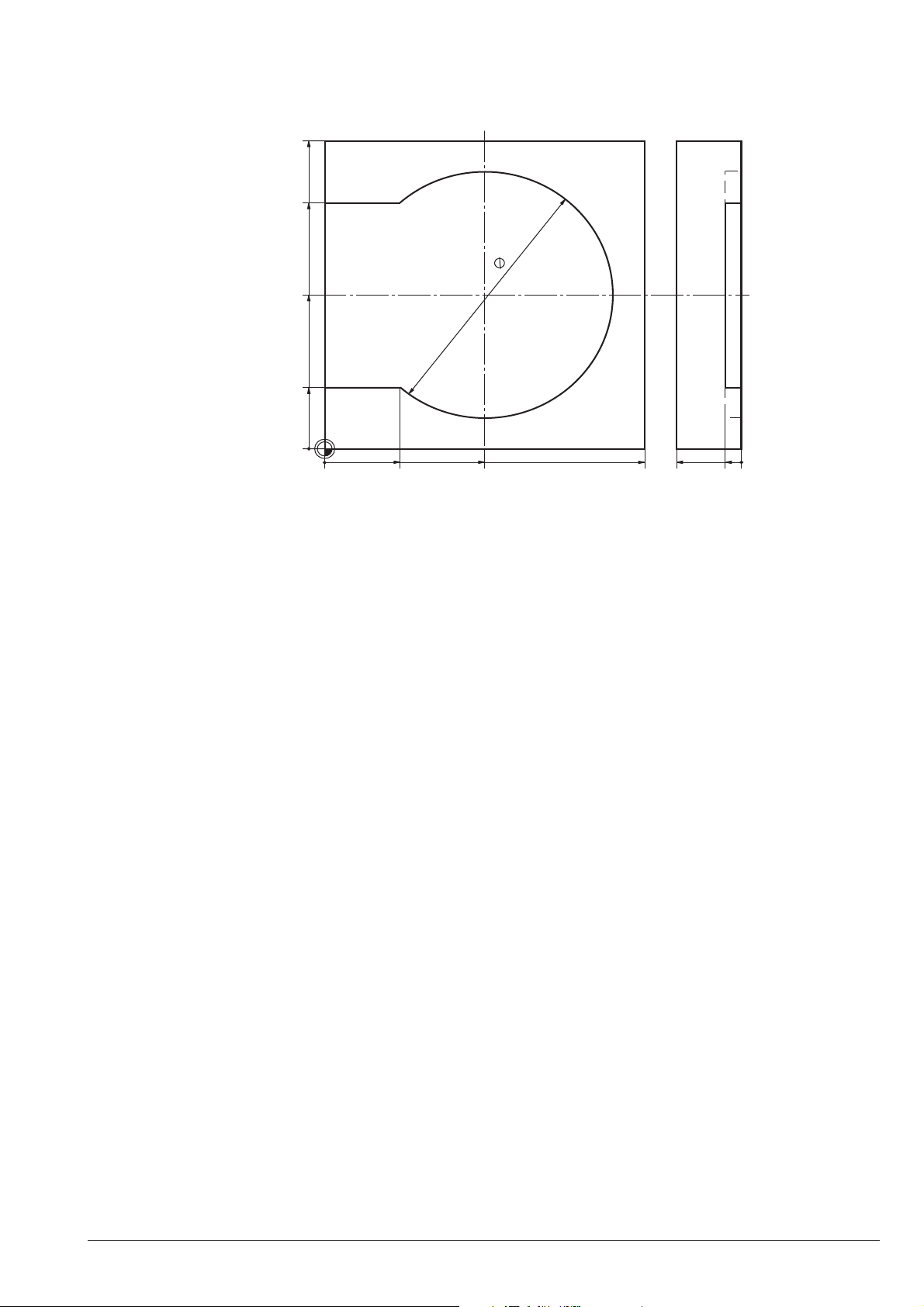

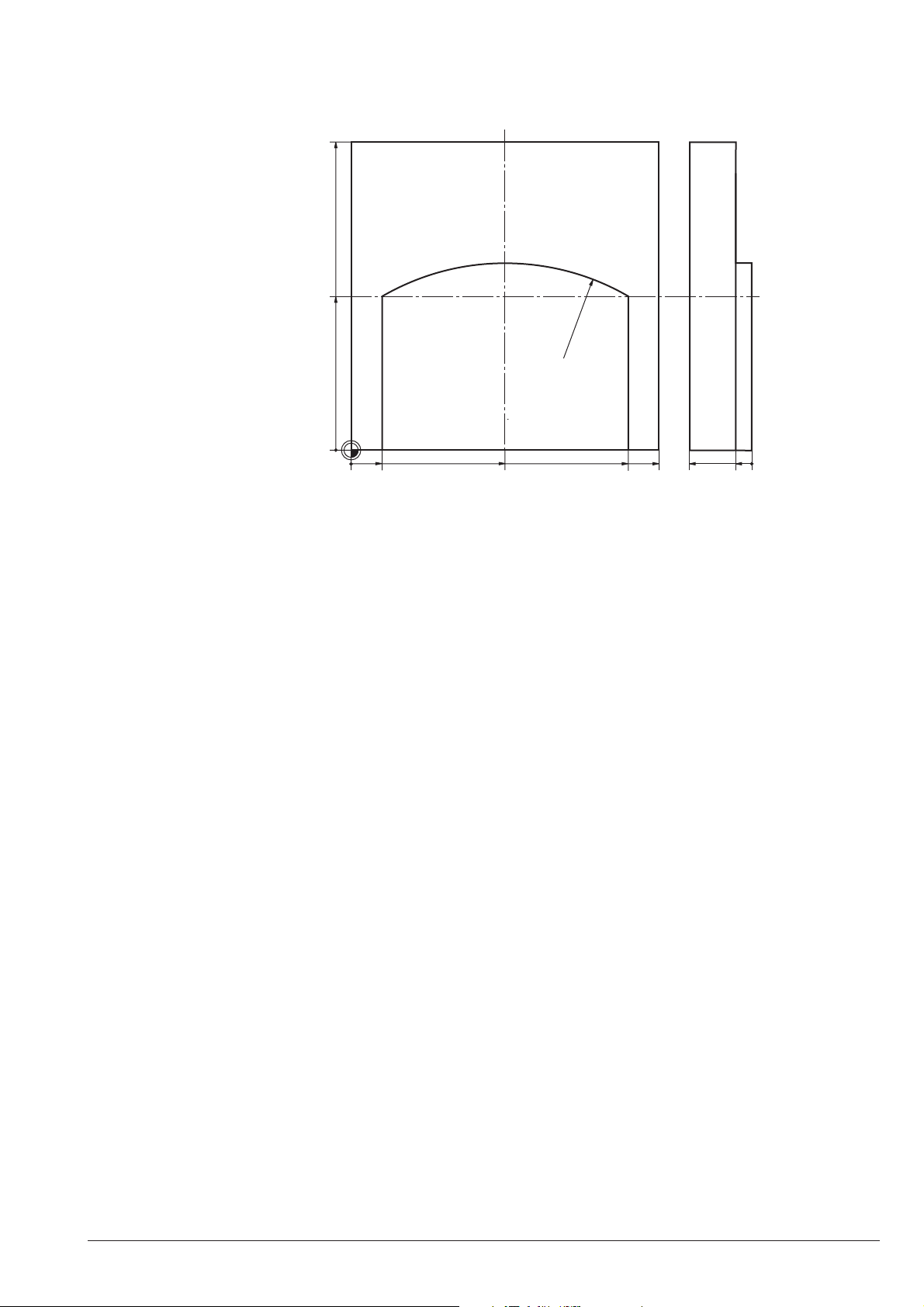

Page 12

100

80

50

20

Task:

Circular arc with CC, C

80

Program(s):

0

0

23,542

Begin program

Define workpiece blank

Activate tool

Move to clearance height

Move to auxiliary point R0

Plunging depth

Approach contour

Define circle center

Circular movement

50

5

0

100

20

%62155 G71

G30 G . . . X . . . Y . . . Z . . .

G31 G . . . X . . . Y . . . Z . . .

T . . . G . . . S . . .

G00 . . .

G01 G . . .

I . . . J . . .

G02/G03 . . .

Depart (aux. point)

Retract tool, PGM end

HEIDENHAIN Basic Course ISO G

426

G01 . . .

G00

F06 62155/1

. . .

Page 13

Solution:

Circular arc

with CC, C

100

80

50

20

0

0

23,542

50

80

100

20

5

0

Complete program

%62155 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T3 G17 S2500 * ...................................................

N20 G00 G40 G90 Z+100 M03 *

N25 X-30 Y+50 * ............................................................

N30 Z-5 *

N35 G01 G41 X-5 Y+20 F250 *

N40 X+23,542 Y+20 *

N45 I+50 J+50 * .............................................................

N50 G03 X+23,542 Y+80 *...............................................

N55 G01 X-5 *

N60 G40 X-30 Y+50 *

N65 G00 Z+100 M30 *

N999999 %62155 G71 *

R20

AUXILIARY POINT

CIRCLE CENTER

CIRCULAR MOVEMENT

HEIDENHAIN Basic Course ISO G

426

62155/2F06

Page 14

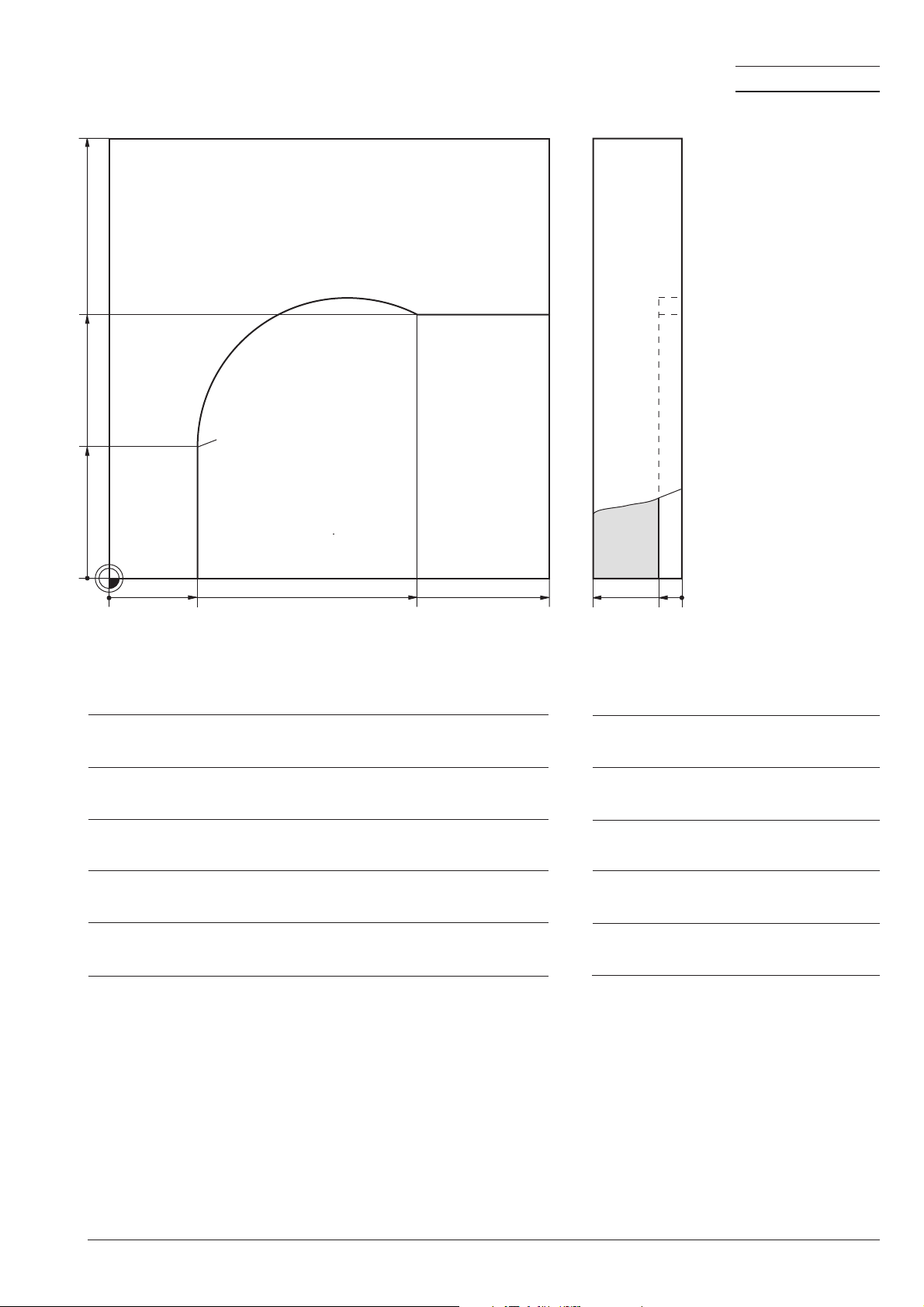

100

60

Task:

Tangential contour connection

(cartesian)

Program(s):

30

tangential

0

0

20

70

100

20

5

0

HEIDENHAIN Basic Course ISO G

426

F06 62156/1

Page 15

Solution:

Tangential contour connection

(cartesian)

100

60

Complete program

30

0

0

%62156 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T11 G17 S2500 * .................................................

N20 G00 G40 G90 Z+100 M03 * ......................................

N25 X+45 Y-25 * ............................................................

N30 Z-5 *

N35 G01 G42 X+20 Y-3 F250 *.........................................

N40 Y+30 *

N45 G06 X+70 Y+60 *.....................................................

N50 G01 X+103 *

N55 G40 X+110 Y+50 F500 *

N60 G00 Z+100 M30 *

N999999 %62156 G71 *

tangential

20

70

5

20

100

R10

CLEARANCE HEIGHT

AUXILIARY POINT

CONTOUR STARTING POINT

TANGENTIAL CIRCULAR PATH

0

HEIDENHAIN Basic Course ISO G

426

62156/2F06

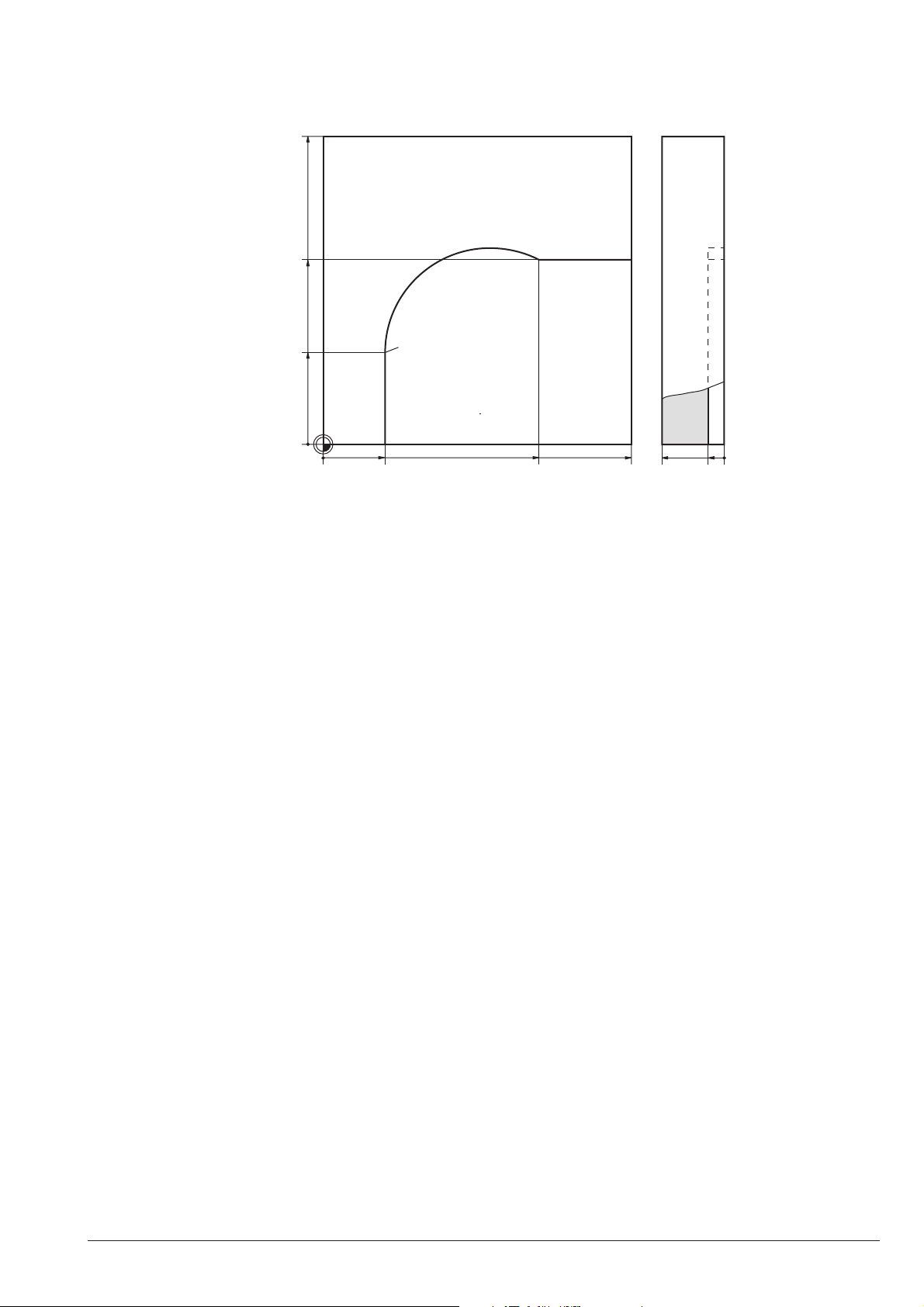

Page 16

100

50

Task:

Circular arc with CR

R80

Program(s):

0

0

10

50

90

100

20

5

0

HEIDENHAIN Basic Course ISO G

426

F06 62157/1

Page 17

Solution:

Circular arc with CR

100

50

0

0

10

50

R80

90

100

20

5

0

Complete program

%62157 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T13 G17 S2500 * .................................................

N20 G00 G40 G90 Z+100 M03 *

N25 X-30 Y-30 * .............................................................

N30 Z-5 *

N35 G01 G41 X+10 Y-3 F250 *.........................................

N40 Y+50 *

N45 G02 X+90 Y+50 R+80 * ............................................

N5 0 G01 Y-3 *

N55 G40 X+110 Y-30 F500 * ............................................

N60 G00 Z+100 M30 *

N999999 %62157 G71 *

R20

AUXILIARY POINT

APPROACH STARTING POINT

CIRCULAR ARC

DEPART (AUXILIARY POINT)

HEIDENHAIN Basic Course ISO G

426

62157/2F06

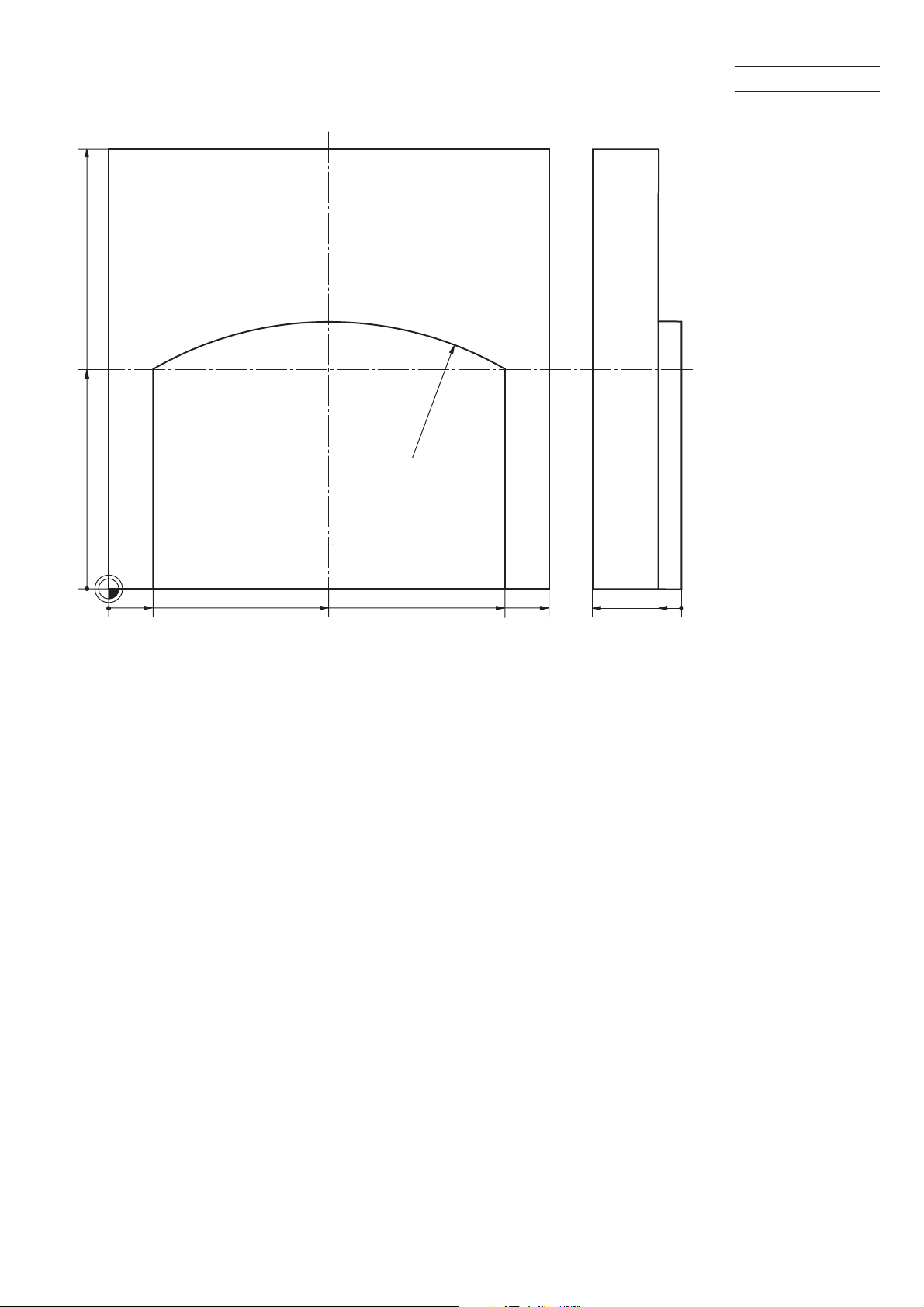

Page 18

100

Task:

Circular arcs

Program(s):

P

2

50

30

0

P

1

0

Point

P

1

R10

P

4

15

X

6.645

R80

R75

Y

35.495

R20

P

3

5

60

Point

P

3

100

X

58.995

20

0

Y

30.025

P

2

HEIDENHAIN Basic Course ISO G

55.505

69.488

426

P

4

F06 62158/1

19.732

21.191

Page 19

Solution:

Circular arcs

100

P

2

Complete program

50

30

R80

P

1

R10

P

4

0

0

15

R75

R20

P

3

60

%62158 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T13 G17 S2500 * .................................................

N20 G00 G40 G90 Z+100 M03 * ......................................

N25 X-30 Y+30 * ............................................................

N30 Z-5 * ......................................................................

N35 G01 G41 X+5 Y+30 F250 * ........................................

N35 G26 R3 * ................................................................

N40 I+15 J+30 * .............................................................

N45 G02 X+6,645 Y+35,495 *

N50 G06 X+55,505 Y+69,488 * ........................................

N55 G05 X+58,995 Y+30,025 R-20 * .................................

N60 G06 X+19,732 Y+21,191 *

N65 G02 X+5 Y+30 *

N70 G27 R3 * ................................................................

N75 G01 G40 X-30 Y+30 *

N80 G00 Z+100 M30 *

N999999 %62158 G71 *

5

100

20

0

R20

CLEARANCE HEIGHT

AUXILIARY POINT

DEPTH

APPROACH STARTING POINT OF

CONTOUR TANGENTIALLY

CIRCLE CENTER

TANGENTIAL CIRCULAR PATH

CIRCULAR PATH WITH RADIUS;

DIRECTION OF ROTATION

PROGRAMMED LAST

DEPART TANGENTIALLY

HEIDENHAIN Basic Course ISO G

426

62158/2F06

Page 20

50

0

Task:

Hexagon (polar)

Program(s):

60°

R40

-50

-50

Begin program

Define workpiece blank

Activate tool

Move to clearance height

Define pole

Auxiliary point in polar coord.

Plunging depth

First contour point

Approach tangentially

5

0

50

20

0

%62159 G71

G30 G . . . X . . . Y . . . Z . . .

G31 G . . . X . . . Y . . . Z . . .

T . . . G . . . S . . .

G00 Z . . .

I . . . J . . .

G10 R . . . H . . .

G00 Z . . .

G11 . . .

G26 R . . .

Contour

○○○

Depart tangentially

Retract tool, PGM end

HEIDENHAIN Basic Course ISO G

426

G11 . . .

○○○

G27 R . . .

G00 Z . . .

F06 62159/1

Page 21

Solution:

Hexagon (polar)

50

60°

Complete program

0

-50

-50

%62159 G71 *

N5 G30 G17 X-50 Y-50 Z-20 *

N10 G31 G90 X+50 Y+50 Z+0 *

N15 T13 G17 S2500 * .................................................

N20 G00 G40 G90 Z+100 M03 *

N25 I+0 J+0 *.................................................................

N30 G10 R+80 H+0 * ......................................................

N35 Z-5 *

N40 G11 G42 H+0 R+40 F250 * .......................................

N40 G26 R4 * ................................................................

N45 G11 H+60 *

N50 H+120 *

N55 H+180 *

N60 H+240 *

N65 H+300 *

N70 H+0 *

N75 G27 R4 * ................................................................

N80 G11 G40 H+0 R+80 * ...............................................

N85 G00 Z+100 M30 *

N999999 %62159 G71 *

0

R40

5

50

20

R20

POLE

POLAR AUXILIARY POINT

APPROACH STARTING POINT OF

CONTOUR TANGENTIALLY

DEPART TANGENTIALLY

POLAR AUXILIARY POINT

0

HEIDENHAIN Basic Course ISO G

426

62159/2F06

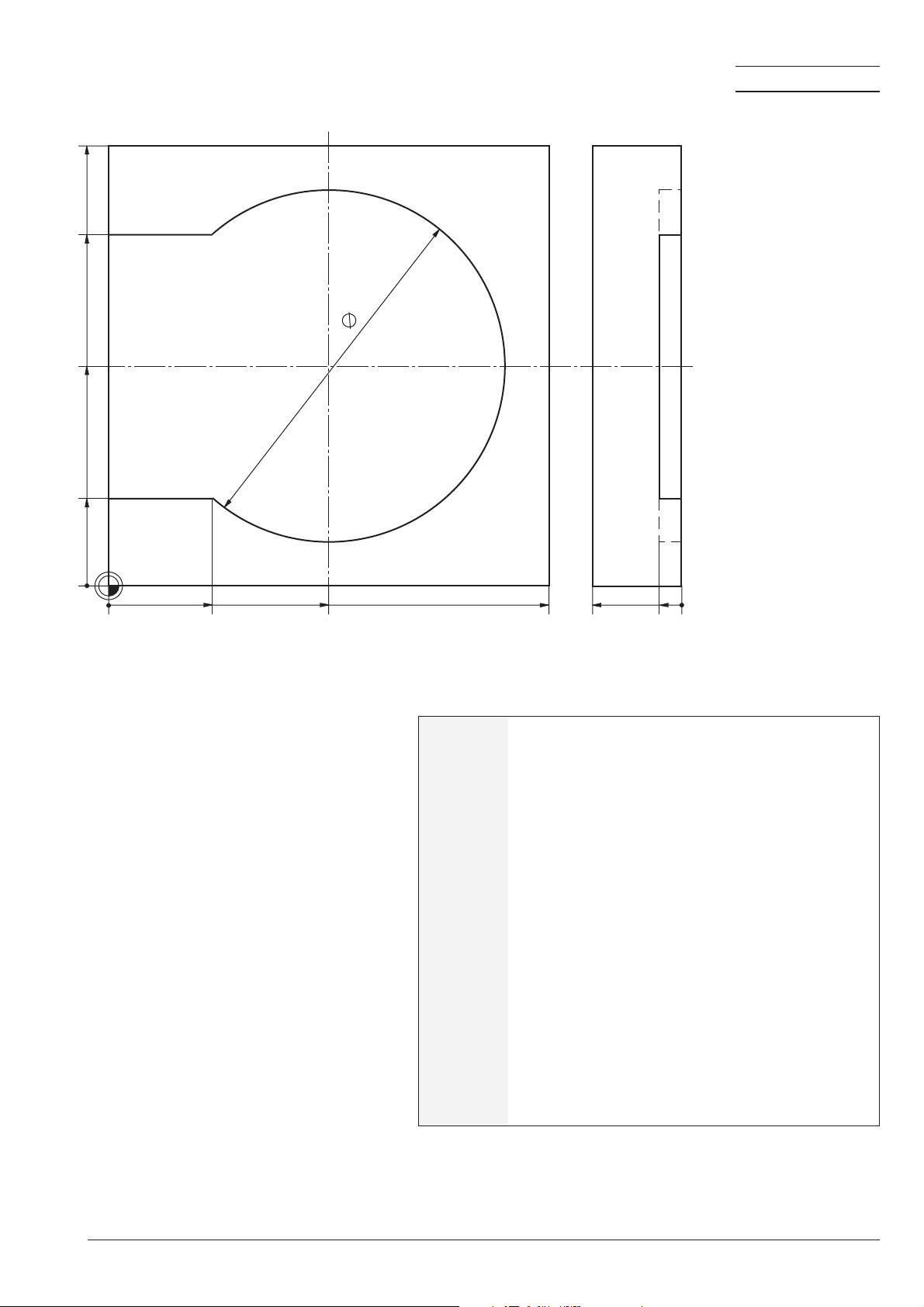

Page 22

100

Task:

Circle (polar) CP

R40

Program(s):

50

0

0

Begin program

Define workpiece blank

Activate tool

Move to clearance height

CC

50

0°

100

20

5

0

Define pole

Auxiliary point in polar coord.

Contour

Auxiliary point

Retract tool, PGM end

HEIDENHAIN Basic Course ISO G

426

F06 62160/1

Page 23

Solution:

Circle (polar) CP

100

R40

Complete program

50

0

0

%62160 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T13 G17 S2500 * .................................................

N20 G00 G40 G90 Z+100 M03 *

N25 I+50 J+50 * .............................................................

N30 G10 R+80 H+180 * ..................................................

N35 G00 Z-5 *

N40 G11 G41 R+40 H+180 F250 * ....................................

N45 G26 R3 * ................................................................

N50 G12 G91 H+360 * ....................................................

N55 G27 R3 * ................................................................

N60 G11 G40 G90 H+180 R+80 *

N65 G00 Z+100 M30 *

N999999 %62160 G71 *

CC

50

0°

5

20

100

R20

POLE

AUXILIARY POINT

APPROACH STARTING POINT OF

CONTOUR TANGENTIALLY

CIRCULAR PATH (POLAR)

DEPART TANGENTIALLY

0

HEIDENHAIN Basic Course ISO G

426

62160/2F06

Page 24

100

60

30

Task:

Circular path with tangential

connection (polar) CTP

76,158

Program(s):

20

0

0

20

Begin program

Define workpiece blank

Activate tool

Move to clearance height

Define pole

Auxiliary point

Contour

°

40

2

3

,

1

9

9

5

90

100

20

0

Auxiliary point

Retract tool, PGM end

HEIDENHAIN Basic Course ISO G

426

F06 62161/1

Page 25

Solution:

Circular path with tangential

connection (polar) CTP

100

76,158

60

30

Complete program

20

0

0

20

40

2

3

,

1

9

9

°

%62161 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T13 G17 S4000 * .................................................

N20 G00 G40 G90 Z+100 M03 *

N25 X-30 Y-30 * .............................................................

N30 Z-5 *

N35 G01 G41 X+0 Y+0 F250 * .........................................

N40 G26 R3 * ................................................................

N45 G01 Y+30 *

N50 X+40 Y+60 *

N55 I+20 J+20 * .............................................................

N60 G16 H+23,199 R+76,158 * ........................................

N65 G01 X+90 Y+0 *

N70 G40 X+110 Y+10 * ...................................................

N75 G00 Z+100 M30 *

N999999 %62161 G71 *

90

5

20

100

R20

AUXILIARY POINT

APPROACH STARTING POINT OF

CONTOUR TANGENTIALLY

POLE

TANGENTIAL CIRC. PATH (POLAR)

DEPART

0

HEIDENHAIN Basic Course ISO G

426

62161/2F06

Page 26

100

70

30

Task:

Drilling cycle

8

Program(s):

0

0

20

50

Begin program

Define workpiece blank

Activate tool

Define cycle

Move to clearance height

Starting point 1st hole / cycle call

2nd hole / cycle call

3rd hole / cycle call

Retract tool, PGM end

75

100

20

0

HEIDENHAIN Basic Course ISO G

426

F06 62170/1

Page 27

Solution:

Drilling cycle

100

70

30

0

0

20

8

50

75

100

20

0

Complete program

%62170 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T7 G17 S1000 * .....................................................

N20 G200

Q200=2 ....................................................................

Q201=-23 .................................................................

Q206=150 ................................................................

Q202=5 ....................................................................

Q210=0 ....................................................................

Q203=+0 ..................................................................

Q204=2 ....................................................................

Q211=0 * ...............................................................

N25 G00 G40 G90 Z+100 M03 *

N30 G00 X+20 Y+30 M99 * ................................................

N35 G00 X+50 Y+70 M99 * ................................................

N40 G00 X+75 Y+30 M99 * ..........................................

N45 G00 Z+100 M30 *

N999999 %62170 G71 *

R4

SETUP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SETUP CLEARANCE

DWELL TIME AT DEPTH

STARTING POSITION

2ND HOLE

3RD HOLE

HEIDENHAIN Basic Course ISO G

426

62170/2F06

Page 28

100

Task:

Slot plate

R25

Program(s):

35°

60

25

12

75

15

20°

0

0

40

50

100

20

10

0

HEIDENHAIN Basic Course ISO G

426

62172/1F06

Page 29

Solution:

Slot plate

100

Complete program

R25

60

75

25

0

0

40

%62172 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T8 G17 S1000 *

N20 G00 G40 G90 Z+100 M03 *

N25 G210

Q200=2 ..................................................................

Q201=-10 ...............................................................

Q207=100 ..............................................................

Q202=5 ..................................................................

Q215=0 ..................................................................

Q203=+0 ................................................................

Q204=2 ..................................................................

Q216=+50 ..............................................................

Q217=+25 ..............................................................

Q218=75 ................................................................

Q219=15 ................................................................

Q224=+20 ..............................................................

Q338=5 * ................................................................

N30 M99 *

50

12

35°

20°

15

10

0

20

100

SETUP CLEARANCE

DEPTH

FEED RATE FOR MILLING

PLUNGING DEPTH

MACHINING OPERATION

SURFACE COORDINATE

2ND SETUP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

1ST SIDE LENGTH

2ND SIDE LENGTH

ANGLE OF ROTATION

INFEED FOR FINISHING

HEIDENHAIN Basic Course ISO G

N35 G211

Q200=2 ..................................................................

Q201=-10 ...............................................................

Q207=100 ..............................................................

Q202=5 ..................................................................

Q215=0 ..................................................................

Q203=+0 ................................................................

Q204=2 ..................................................................

Q216=+40 ..............................................................

Q217=+60 ..............................................................

Q244=50 ................................................................

Q219=12 ................................................................

Q245=+35 ..............................................................

Q248=180 ..............................................................

Q338=5 * ................................................................

N40 M99 *

N45 G00 Z+100 M30 *

N999999 %62172 G71 *

426

SETUP CLEARANCE

DEPTH

FEED RATE FOR MILLING

PLUNGING DEPTH

MACHINING OPERATION

SURFACE COORDINATE

2ND SETUP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

PITCH CIRCLE DIAMETER

2ND SIDE LENGTH

STARTING ANGLE

ANGULAR LENGTH

INFEED FOR FINISHING

62172/2F06

Page 30

100

Task:

Die I

Program(s):

60

50

h7

30

90

R5,25

0

5

0

50

100

20

10

0

HEIDENHAIN Basic Course ISO G

426

62174/1F06

Page 31

Solution:

Die I

100

60

Complete program

50

R5,25

0

0

50

30

%62174 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T13 G17 S800 *

N20 G00 G40 G90 Z+100 M03 *

N25 G215 .....................................................................

Q200=2 ..................................................................

Q201=-10 ...............................................................

Q206=150 ..............................................................

Q202=10 ................................................................

Q207=200 ..............................................................

Q203=+0 ................................................................

Q204=50 ................................................................

Q216=+50 ..............................................................

Q217=+50 ..............................................................

Q222=140 ..............................................................

Q223=101 * ............................................................

N30 M99 *

N35 T7 DR+1 G17 S2000 *

N40 G00 G40 G90 Z+100 M03 *

N45 G75 .......................................................................

P01 2 ....................................................................

P02 -5 ....................................................................

P03 5 ....................................................................

P04 100 .................................................................

P05 X+60 ...............................................................

P06 Y+30 ...............................................................

P07 250 .................................................................

P08 7 *

N50 G00 X+50 Y+50 *

N55 Z+2 M99 *

N60 Z+100 M06*

h7

90

5

0

10

20

100

FINISH CYLINDRICAL STUD

SETUP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

FEED RATE FOR MILLING

SURFACE COORDINATE

2ND SETUP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

WORKPIECE BLANK DIAMETER

FINISHED PART DIAMETER

POCKET MILLING

SETUP CLEARANCE

DEPTH

PLUNGING DEPTH

FEED RATE FOR PLUNGING

LENGTH IN X

LENGTH IN Y

FEED RATE FOR MILLING

HEIDENHAIN Basic Course ISO G

426

62174/2F06

Page 32

Solution:

Die I

N65 T8 G17 S1000 *

N70 G00 G40 G90 Z+100 M03 *

N75 G212 .....................................................................

Q200=2 ..................................................................

Q201=-5 .................................................................

Q206=250 ..............................................................

Q202=5 ..................................................................

Q207=250 ..............................................................

Q203=+0 ................................................................

Q204=20 ................................................................

Q216=+50 ..............................................................

Q217=+50 ..............................................................

Q218=60 ................................................................

Q219=30 ................................................................

Q220=5,25 .............................................................

Q221=0 * ................................................................

N80 M99 *

N85 G215 .....................................................................

Q200=2 ..................................................................

Q201=-10 ...............................................................

Q206=250 ..............................................................

Q202=10 ................................................................

Q207=250 ..............................................................

Q203=+0 ................................................................

Q204=20 ................................................................

Q216=+50 ..............................................................

Q217=+50 ..............................................................

Q222=92 ................................................................

Q223=90 * ..............................................................

N90 M99 *

N95 G00 Z+100 M30 *

N999999 %62174 G71 *

POCKET FINISHING

SETUP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

FEED RATE FOR MILLING

SURFACE COORDINATE

2ND SETUP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

1ST SIDE LENGTH

2ND SIDE LENGTH

CORNER RADIUS

ALLOWANCE

FINISH CYLINDRICAL STUD

SETUP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

FEED RATE FOR MILLING

SURFACE COORDINATE

2ND SETUP CLEARANCE

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

WORKPIECE BLANK DIAMETER

FINISHED PART DIAMETER

HEIDENHAIN Basic Course ISO G

426

22

2

22

62174/3F0

Page 33

50

30

0

Task:

Program section repeats linear hole pattern

Program(s):

6

0

15

25

35

45

Begin program

Define workpiece blank

Activate tool

Define cycle

Move to clearance height

Move to pre-position

Define label

Traverse movement/

cycle call

Label call

55

65

75

85

100

40

%62180 G71

G30 G . . . X . . . Y . . . Z . . .

G31 G . . . X . . . Y . . . Z . . .

T . . . G . . . S . . .

G200 . . .

G00 G40 G90 Z . . .

X . . . Y . . .

G98 L . . .

G00 G91 X . . . M99

L . . . / . . .

20

0

Retract tool, PGM end

HEIDENHAIN Basic Course ISO G

426

. . .

F06 62180/1

Page 34

Solution:

Program section repeats linear hole pattern

50

Complete program

30

0

0

15

%62180 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+50 Z+0 *

N15 T1 G17 S4000 *

N20 G00 G40 G90 Z+100 M03 *

N25 G200

Q200=2 ..................................................................

Q201=-20 ...............................................................

Q206=150 ..............................................................

Q202=4 ..................................................................

Q210=0 ..................................................................

Q203=+0 ................................................................

Q204=2 ..................................................................

Q211=0 * ................................................................

N30 G00 X+5 Y+30 * ......................................................

N35 G98 L1 * .................................................................

N40 G00 G91 X+10 M99 *

N45 L1,7 * .....................................................................

N50 G00 Z+100 M30 *

N999999 %62180 G71 *

25

35

45

55

65

75

85

40

100

SETUP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SETUPT CLEARANCE

DWELL TIME AT BOTTOM

STARTING POSITION

DEFINE LABEL

LABEL CALL WITH REPEATS

20

6

0

HEIDENHAIN Basic Course ISO G

426

62180/2F06

Page 35

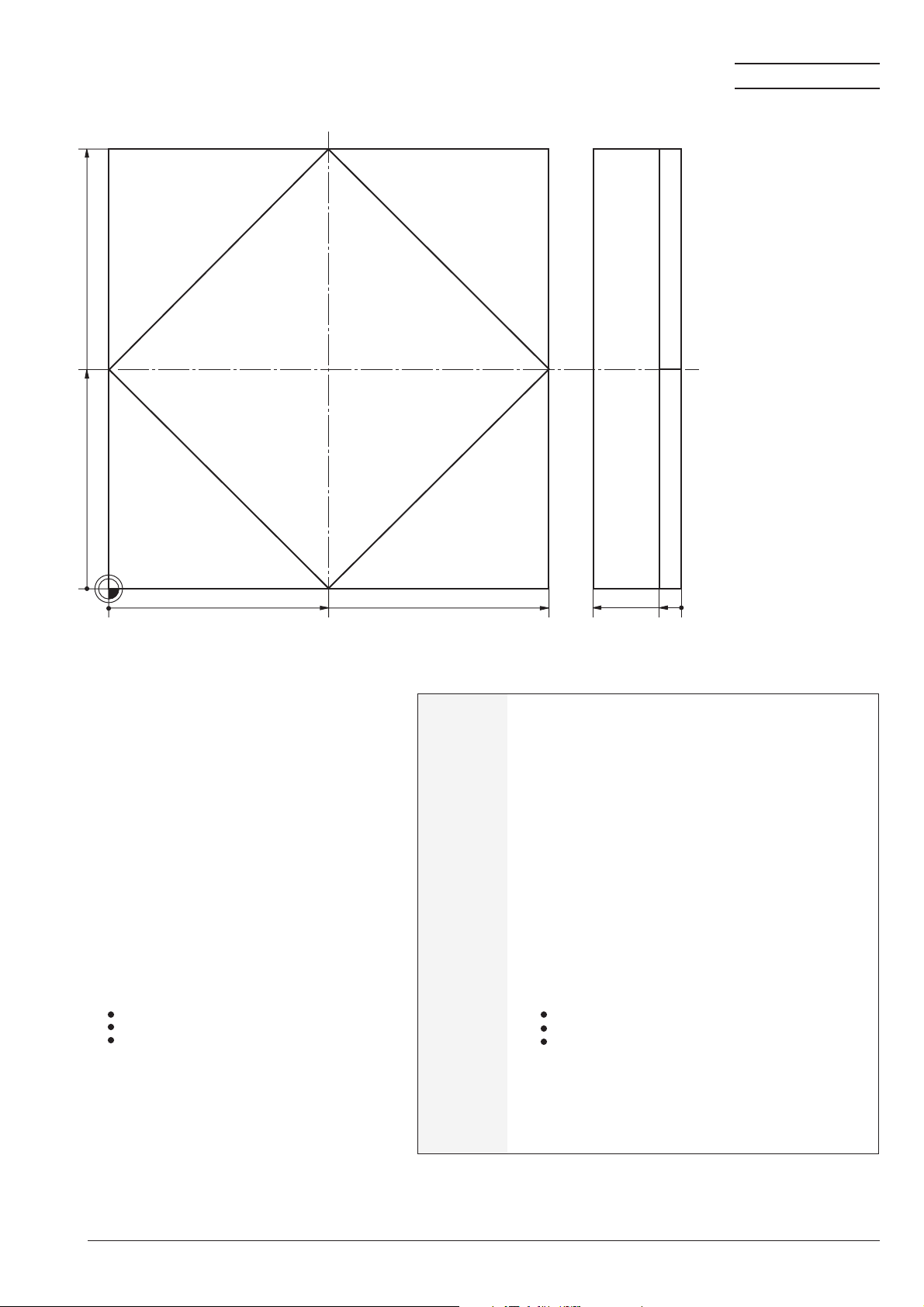

100

Task:

Hexagon

Program(s):

65

60°

50

0

4

0

Program layout:

Conventional

preparations:

3

50

G30/G31

R40

2

1

100

20

5

0

Define workp. blank

Activate tool

Starting position

Approach contour

Define label

Traverse movement

Label call

Retract tool

End

T . . .

G00 G40 G90 . . .

I . . . J . . .

G10 R . . . H . . .

G00 Z . . .

G11 . . . / G26 R . . .

G98 L . . .

G11 G91 H . . .

L . . . / . . .

G11 G40 G90 H . . .

G00 Z . . .

Pole

Auxiliary point

Infeed

1st contour point

Auxiliary point

HEIDENHAIN Basic Course ISO G

426

F06 62181/1

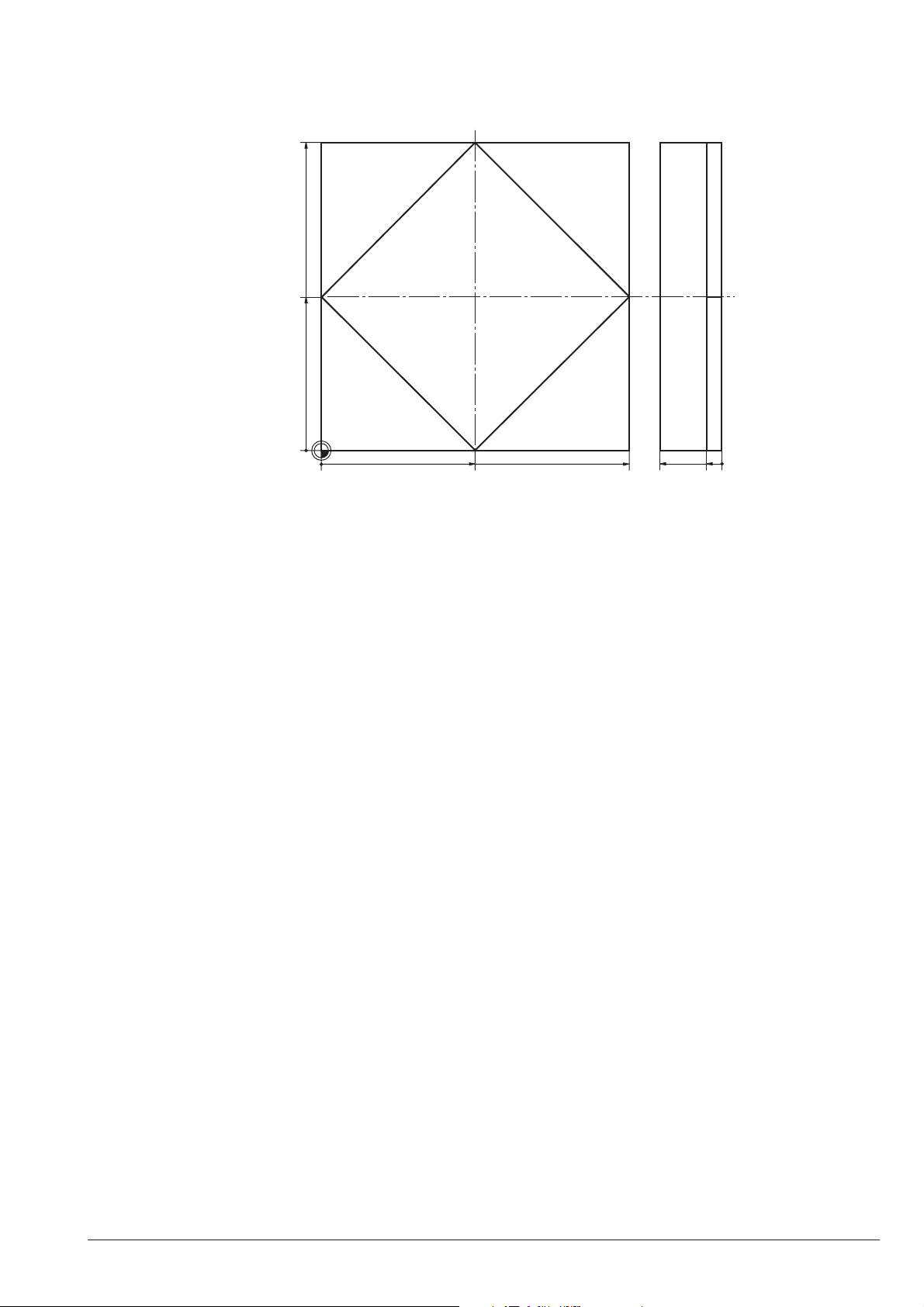

Page 36

Solution:

Hexagon

100

65

60°

Complete program

50

4

R40

3

0

0

%62181 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T12 G17 S2000 * ....................................................

N20 G00 G40 G90 Z+100 M03 *

N25 I+50 J+50 * .................................................................

N30 G10 R+80 H+0 * .........................................................

N35 G00 Z-5 *

N40 G11 G41 R+40 F250 * .................................................

N45 G25 R3 *

N50 G98 L1 * ....................................................................

N55 G11 G91 H-60 *

N60 L1,4 * ........................................................................

N65 G11 G91 H-60 *

N65 G26 R3 *

N70 G11 G40 G90 H+0 R+80 * ............................................

N75 G00 Z+100 M30 *

N999999 %62181 G71 *

50

2

1

5

20

100

R15

POLE

AUXILIARY POINT

CONTOUR STARTING POINT

DEFINE LABEL

LABEL CALL WITH REPEATS

AUXILIARY POINT

0

HEIDENHAIN Basic Course ISO G

426

62181/2F06

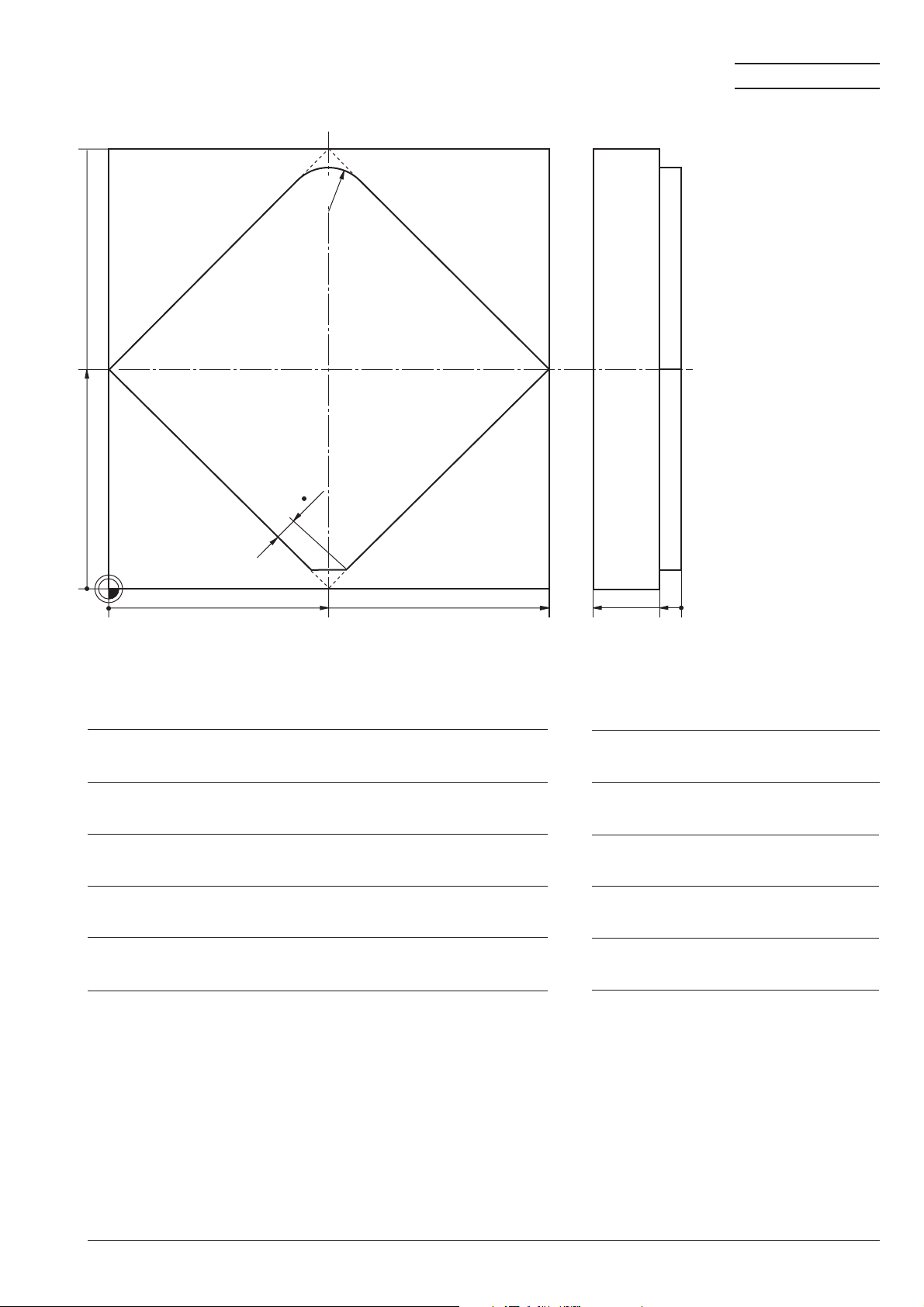

Page 37

100

85

70

55

40

25

Task:

Drilled plate - slanted columns

Program(s):

10

3

5

0

0

10

20

40

50

70

80

100

20

15

0

HEIDENHAIN Basic Course ISO G

426

F06 62182/1

Page 38

Program layout:

9

9

9

9

9

9

9

9

9

9

9

9

9

9

Drilled plate - slanted columns

Move up and

down columns

(meandering)

Vorposition

Drilling pattern

100

LBL 2

10

3

0

0

101520

G00 X . . . Y . . .

LBL 3

40

50

70

80

5

100

20

0

Absolut pre-position

G98 L 1

G91 X . . . M99

G98 L 2

X . . . Y . . . M99

L 2, . . .

X . . . M99

G98 L 3

X . . . Y . . . M99

L 3, . . .

L 1, . . .

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

Define label 1

Cross over to 1st hole

Define label 2

Move up the column

Cross over to 2nd

column

Define label 3

Move down the

column

Remaining groups

HEIDENHAIN Basic Course ISO G

426

G29F06

Page 39

Solution:

Drilled plate - slanted columns

100

85

70

55

40

25

MAIN PROGRAM

10

0

3

0

10

20

40

50

70

80

%62182 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T5 G17 S4000 * ......................................................

N20 G00 G40 G90 Z+100 M03 *

N25 G200 .....................................................................

Q200=2 ..................................................................

Q201=-15 ...............................................................

Q206=250 ..............................................................

Q202=8 ..................................................................

Q210=0 ..................................................................

Q203=+0 ................................................................

Q204=20 ................................................................

Q211=0 * .............................................................

N30 G00 X-10 Y+10 *

N35 G98 L1 *

N40 G00 G91 X+20 M99 *

N45 G98 L2 *

N50 G00 X+3 Y+15 M99 *

N55 L2,4 *

N60 G00 X+10 M99 *

N65 G98 L3 *

N70 G00 X-3 Y-15 M99 *

N75 L3,4 *

N80 L1,2 *

N85 G00 G90 Z+100 M30 *

N999999 %62182 G71 *

5

20

15

100

R2:5

DRILLING

SETUP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SETUP CLEARANCE

DWELL TIME AT DEPTH

0

HEIDENHAIN Basic Course ISO G

426

62182/2F06

Page 40

Task:

Subprogram (group of holes)

Program(s):

0

0

10

12

25

27

32

47

70

Begin program

20

➀

35

42

➂

% . . . G71

○○

57

63

➁

78

100

20

18

0

4

Retract tool, end

SPGM

T . . .

G . . .

G00 Z+ . . .

G00 X . . . Y . . .

L . . . , . . .

G00 X . . . Y . . .

L . . . , . . .

G00 X . . . Y . . .

L . . . , . . .

G00 G40 Z +100 M2

G98 L . . .

Activate tool

Define cycle

Move to clear. height

Start. pos. hole group

Call SPGM

Start. pos. hole group

Call SPGM

Start. pos. hole group

Call SPGM

À

Á

Â

SPGM end

HEIDENHAIN Basic Course ISO G

G98 L 0

426

F06 62186/1

Page 41

Solution:

Subprogram (group of holes)

MAIN PROGRAM

10

12

25

27

32

0

0

20

➀

35

42

57

63

78

➁

➂

47

70

%62186 G71 *

N10 G30 G17 X+0 Y-70 Z-20 *

N20 G31 G90 X+100 Y+0 Z+0 *

N30 T4 G17 S2000 * ......................................................

N40 G200 .....................................................................

Q200=2 ..................................................................

Q201=-18 ...............................................................

Q206=150 ..............................................................

Q202=7 ..................................................................

Q210=0 ..................................................................

Q203=+0 ................................................................

Q204=50 ................................................................

Q211=0 * ................................................................

N50 G00 G40 G90 Z+100 M03 * ......................................

N60 X+20 Y-10 * ............................................................

N70 L1,0 * .....................................................................

20

18

100

TOOL CALL, R2

DRILLING

SETUP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME ON TOP

SURFACE COORDINATE

2ND SETUP CLEARANCE.

DWELL TIME AT BOTTOM

CLEARANCE HEIGHT

STARTING POINT HOLE GROUP

CALL SPGM

0

4

À

Retract tool, end

SPGM

SPGM, END

N80 G00 X+63 Y-12 * .....................................................

N90 L1,0 * .....................................................................

N100 G00 X+42 Y-32 * .....................................................

N110 L1,0 * .....................................................................

N120 G00 G40 G90 Z+100 M30 *

N130 G98 L1 *

N140 M99 *

N150 G00 G91 X+15 M99 *

N160 G00 Y-15 M99 * .......................................................

N170 G00 X-15 M99 *

N180 G90 *

N190 G98 L0 *

N999999 %62186 G71 *

STARTING POINT HOLE GROUP

CALL SPGM

STARTING POINT HOLE GROUP

CALL SPGM

DRILLING PATTERN

Á

Â

HEIDENHAIN Basic Course ISO G

426

62186/2F06

Page 42

60

Task:

Bolt hole circle segments

with several tools

M6

Program(s):

110

90

60°

70

50

60°

30

0

0

40

110

150

20

15

12

0

HEIDENHAIN Basic Course ISO G

426

62187/1F06

Page 43

Program layout:

9

9

9

9

9

9

9

9

9

9

9

9

9

9

Nesting for double bolt-hole circles

Conventional

preparations:

Centering

Drilling

Tapping

Retract tool, end

SPGM1

G30/G31

T . . .

G200 . . . / G00 Z+100

L 1,0

T . . .

G . . .

L 1,0

T . . .

G . . .

L 1,0

G00 Z100 M2

G98 L 1

I . . . J . . .

L 2,0

I . . . J . . .

Circle center left

Call bolt-hole circle

segm.

Circle center right

End of SPGM1

SPGM2, bolt-hole

circle segm.

Partial repeats

End of SPGM2

L 2,0

G98 L 0

G98 L 2

G10 R . . . H . . . M3

G00 Z+2 M99

G98 L 3

L 3, . . .

LP PR . . . PA . . .

G98 L 4

L 4, . . .

G98 L 0

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

2345678

Call bolt-hole circle

segm.

Starting position

Remaining holes

HEIDENHAIN Basic Course ISO G

426

62187/2F06

Page 44

Solution:

Bolt hole circle segments with several tools

M6

60

60°

60°

0

0

40

110

30

50

70

90

110

150

20

15

12

0

MAIN PROGRAM

%62187 G71 *

N10 G30 G17 X+0 Y+0 Z-20 *

N20 G31 G90 X+150 Y+60 Z+0 *

N30 T4 G17 S2500 * ...................................................

N40 G00 G40 G90 Z+100 M03 *

N50 G200 .....................................................................

Q200=2 ..................................................................

Q201=-3,2 ..............................................................

Q206=150 ..............................................................

Q202=3,2 ...............................................................

Q210=0 ..................................................................

Q203=+0 ................................................................

Q204=2 ..................................................................

Q211=0 * ................................................................

N60 L1,0 *

N70 G00 Z+100 M06 *

N80 T5 G17 S2000 * ......................................................

N90 G00 G40 G90 Z+100 M03 *

N100 G203 .....................................................................

Q200=2 ..................................................................

Q201=-15 ...............................................................

Q206=150 ..............................................................

Q202=5 ..................................................................

Q210=0 ..................................................................

Q203=+0 ................................................................

Q204=2 ..................................................................

Q212=1 ..................................................................

Q213=0 ..................................................................

Q205=3 ..................................................................

Q211=0 ..................................................................

Q208=30000 ...........................................................

Q256=0,2 * .............................................................

N110 L1,0 *

R2

CIRCLE CENTER

SETUP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SETUP CLEARANCE

DWELL TIME AT BOTTOM

R2.5

UNIVERSAL DRILLING

SETUP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SETUP CLEARANCE

DECREMENT

NUMBER OF CHIP BREAKINGS

MIN. PLUNGING DEPTH

DWELL TIME AT BOTTOM

RETRACTION FEED RATE

CHIP BREAKING RETRACTION

HEIDENHAIN Basic Course ISO G

N120 G00 G90 Z+100 M06 *

N130 T6 G17 S300 * .....................................................

N140 G00 G40 G90 Z+100 M03 *

N150 G84 .......................................................................

P01 5

P02 -15

P03 0

P04 300 *

N160 L1,0 *

N170 G00 G40 G90 Z+100 M30 *

426

R3

TAPPING

62187/3F06

Page 45

Solution:

Bolt hole circle segments with several tools

SPGM

N180 G98 L1 *

N190 I+40 J+0 *

N200 L2,0 *

N210 I+110 J+0 *

N220 L2,0 *

N230 G98 L0 *

N240 G98 L2 *

N250 G10 G90 R+55 H+120 *

N260 G00 Z+5 M99 *

N270 G98 L3 *

N280 G10 G91 R-10 M99 *

N290 L3,3 *

N300 G10 G90 R+15 H+60 M99 *

N310 G98 L4 *

N320 G10 G91 R+10 M99 *

N330 L4,3 *

N340 G90 *

N340 G98 L0 *

N999999 %62187 G71 *

HEIDENHAIN Basic Course ISO G

426

62187/4F06

Page 46

100

Task:

Milling with several settings

Program(s):

90

50

10

R10

R20

R20

R20

R20

R10

0

0

10

50

90

100

40

30

0

HEIDENHAIN Basic Course ISO G

426

F06 62188/1

Page 47

Program layout:

Milling with several tools and settings

Conventional

preparations:

Roughing

Finishing

G30/G31

T . . .

G00 G40 G90 X . . . Y . . .

Z0 M3

G98 L 2

G91 Z-5

L 1,0

L 2, . . .

G00 Z+100 M6

T . . .

G00 G40 X . . . Y . . .

Z-30 M3

Workpiece blank

Tool call

Starting position

SPGM call

Tool exchange

Tool call

Starting position

Retract tool, end

SPGM, contour

L 1,0

G00 Z100 M2

G98 L 1

○○○○○○

G98 L 0

SPGM call

HEIDENHAIN Basic Course ISO G

426

G34F06

Page 48

Solution:

Milling with several settings

100

MAIN PROGRAM

90

50

10

0

%62188 G71 *

N10 G30 G17 X+0 Y+0 Z-40 *

N20 G31 G90 X+100 Y+100 Z+0 *

N30 T13 G17 S2000 * .................................................

N40 G00 G40 G90 Z+100 M03 *

N50 X-30 Y+70 * ............................................................

N60 Z+0 *

R10

R20

R20

R20

R20

0

10

50

R10

90

40

100

30

R20

AUXILIARY POINT

0

Retract tool, end

SPGM, contour

SPGM end

N70 G98 L2 *

N80 G01 G91 Z-5 F200 * .................................................

N90 L1,0 * .....................................................................

N100 L2,5 * .....................................................................

N110 G00 Z+100 M06 *

N120 T14 G17 S3000 *

N130 G00 G40 G90 Z+100 M03 *

N140 X-30 Y+70 *

N150 G01 Z-30 F500 *

N160 L1,0 *

N170 G00 Z+100 M30 *

N180 G98 L1 *

N190 G01 G41 G90 X+10 Y+70 F200 *

N190 G26 R3 *

N200 X+10 Y+90 *

N210 G25 R10 *

N220 G01 X+50 Y+90 *

N230 G25 R20 *

N240 G01 X+90 Y+50 *

N250 G25 R20 * ..............................................................

N260 G01 X+90 Y+10 *

N270 G25 R10 *

N280 G01 X+50 *

N290 G25 R20 *

N300 G01 X+10 Y+50 *

N310 G25 R20 *

N320 G01 Y+70 *

N330 G27 R3 *

N340 G01 G40 X-20 Y+70 *

N350 G98 L0 *

N999999 %62188 G71 *

SETTING

CALL CONTOUR

FURTHER CONTOUR SECTIONS

CONTOUR

HEIDENHAIN Basic Course ISO G

426

62188/2F06

Page 49

Task:

Hole pattern

Program(s):

100

30

10

20

15°

80°

15

R50

M6

0

0

30

90

100

20

17

14

0

HEIDENHAIN Basic Course ISO G

426

F06 62189/1

Page 50

Solution:

Hole pattern

MAIN PROGRAM

100

30

10

0

0

15

20

30

80°

15°

R50

%62189 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T4 G17 S1500 * ...................................................

N20 G00 G40 G90 Z+100 M03 *

N25 G200 .....................................................................

Q200=2 ..................................................................

Q201=-3,5 ..............................................................

Q206=150 ..............................................................

Q202=3,5 ...............................................................

Q210=0 ..................................................................

Q203=+0 ................................................................

Q204=2 ..................................................................

Q211=0 * .............................................................

N30 L1,0 *

N35 L2,0 *

N40 G00 Z+100 M06 *

90

M6

14

0

20

17

100

R2

CENTER

SETUP CLEARANCE

DEPTH

FEED RATE FOR PLUNGING

PLUNGING DEPTH

DWELL TIME AT TOP

SURFACE COORDINATE

2ND SETUP CLEARANCE

DWELL TIME AT DEPTH

Retract tool, end

HEIDENHAIN Basic Course ISO G

N45 T5 G17 S1500 * ...................................................

N50 D00 Q201 P01 -17 * .................................................

N55 D00 Q202 P01 +6 * ..................................................

N60 G00 G40 G90 Z+100 M03 *

N65 L1,0 *

N70 L2,0 *

N75 G00 Z+100 M06 *

N80 T6 G17 S300 *

N85 G85 .......................................................................

P01 2 ....................................................................

P02 -14 ..................................................................

P03 +1 * .................................................................

N90 G00 G40 G90 Z+100 M03 *

N95 L1,0 *

N100 L2,0 *

N105 G00 Z+100 M30 *

426

R2

DEPTH

PLUNGING DEPTH

RIGID TAPPING

SETUP CLEARANCE

DEPTH

PITCH

62189/2F06

Page 51

Solution:

Hole pattern

SPGM

N110 G98 L1 *

N115 G220 .....................................................................

Q216=+90 ..............................................................

Q217=+10 ..............................................................

Q244=100 ..............................................................

Q245=+90 ..............................................................

Q246=+180 ............................................................

Q247=+15 ..............................................................

Q241=7 ..................................................................

Q200=2 ..................................................................

Q203=+0 ................................................................

Q204=2 ..................................................................

Q301=1 * ................................................................

N120 G98 L0 *

N125 G98 L2 *

N130 G221 .....................................................................

Q225=+30 ..............................................................

Q226=+30 ..............................................................

Q237=+15 ..............................................................

Q238=+20 ..............................................................

Q242=5 ..................................................................

Q243=2 ..................................................................

Q224=+80 ..............................................................

Q200=2 ..................................................................

Q203=+0 ................................................................

Q204=2 ..................................................................

Q301=1 * ................................................................

N135 G98 L0 *

N999999 %62189 G71 *

POLAR PATTERN

CENTER IN 1ST AXIS

CENTER IN 2ND AXIS

PITCH CIRCLE DIAMETER

STARTING ANGLE

STOPPING ANGLE

STEPPING ANGLE

NUMBER OF REPETITIONS

SETUP CLEARANCE

SURFACE COORDINATE

2ND SETUP CLEARANCE

MOVE TO CLEARANCE

CARTESIAN PATTERN

STARTING POINT IN 1ST AXIS

STARTING POINT IN 2ND AXIS

SPACING IN 1ST AXIS

SPACING IN 2ND AXIS

NUMBER OF COLUMNS

NUMBER OF LINES

ANGLE OF ROTATION

SETUP CLEARANCE

SURFACE COORDINATE

2ND SETUP CLEARANCE

MOVE TO CLEARANCE

HEIDENHAIN Basic Course ISO G

426

62189/3F06

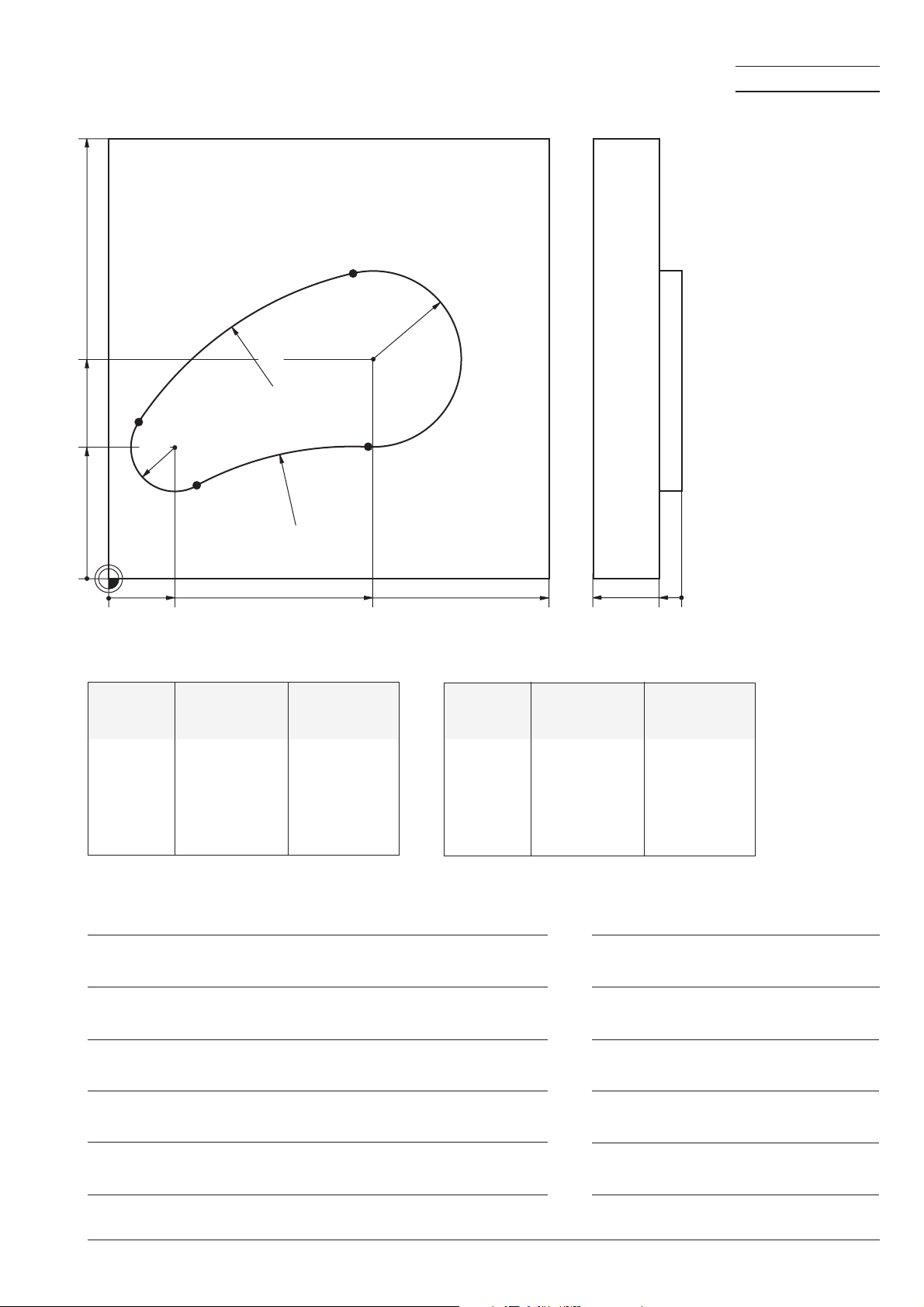

Page 52

100

Task:

Contour cycles SL II,

Roughing out kidney

P2

Program(s):

50

30

0

P1

0

Point

P

1

R10

P4

15

X

6.645

R80

P3

R75

Y

35.495

R20

60

Point

P

3

100

X

58.995

20

18

0

Y

30.025

P

2

HEIDENHAIN Basic Course ISO G

55.505

69.488

426

P

4

F06 62190/1

19.732

21.191

Page 53

Solution:

Contour cycles SL II,

Rouging out kidney

100

MAIN PROGRAM

50

30

0

R10

0

15

%62190 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T7 G17 S2500 * ...................................................

N20 G00 G40 G90 Z+100 M03 *

N25 G37 P01 1 * ............................................................

N30 G120 .....................................................................

Q1=-18 ...................................................................

Q2=1 .....................................................................

Q3=+0,5 .................................................................

Q4=+0,5 .................................................................

Q5=+0 ....................................................................

Q6=+2 ....................................................................

Q7=+10 ..................................................................

Q8=+0 ....................................................................

Q9=-1 * ..................................................................

N35 G122 .....................................................................

Q10=+10 ................................................................

Q11=100 ................................................................

Q12=200 ................................................................

Q18=0 ....................................................................

Q19=150 * ..............................................................

N40 M99 *

N45 G00 Z+100 M06 *

R80

R75

R20

60

20

18

100

R4

CONTOUR

CONTOUR DATA

MILLING DEPTH

TOOL PATH OVERLAP

ALLOWANCE FOR SIDE

ALLOWANCE FOR DEPTH

SURFACE COORDINATE

SETUP CLEARANCE

CLEARANCE HEIGHT

ROUNDING RADIUS

DIRECTION OF ROTATION

ROUGH OUT

PLUNGING DEPTH

FEED RATE

FEED RATE FOR ROUGHING OUT

COARSE ROUGHING TOOL

RECIPROCATION FEED RATE

0

Retract tool, end

HEIDENHAIN Basic Course ISO G

N50 T8 G17 S2000 * ...................................................

N55 G00 G40 G90 Z+100 M03 *

N60 G123 .....................................................................

Q11=100

Q12=200 *

N65 M99 *

N70 G124 .....................................................................

Q9=-1 ....................................................................

Q10=+10 ................................................................

Q11=100 ................................................................

Q12=200 ................................................................

Q14=+0 * ................................................................

N75 M99 *

N80 G00 Z+100 M30 *

426

R5

FLOOR FINISHING

SIDE FINISHING

DIRECTION OF ROTATION

PLUNGING DEPTH

FEED RATE

FEED RATE FOR ROUGHING OUT

ALLOWANCE FOR SIDE

62190/2F06

Page 54

Solution:

Contour cycles SL II,

Roughing out kidney

SPGM

N85 G98 L1 *

N90 G01 G42 X+5 Y+30 *

N95 I+15 J+30 *

N100 G02 X+6,645 Y+35,495 *

N105 G06 X+55,505 Y+69,488 *

N110 G05 X+58,995 Y+30,025 R-20 *

N115 G06 X+19,732 Y+21,191 *

N120 G02 X+5 Y+30 *

N125 G98 L0 *

N999999 %62190 G71 *

HEIDENHAIN Basic Course ISO G

426

62190/3F06

Page 55

100

Task:

Contour cycles SL II,

Kidney-shaped island

P2

Program(s):

50

30

0

P1

0

Point

P

1

R10

P4

15

X

6.645

R80

P3

R75

Y

35.495

R20

60

Point

P

3

100

X

58.995

20

18

0

Y

30.025

P

2

HEIDENHAIN Basic Course ISO G

55.505

69.488

426

P

4

F06 62191/1

19.732

21.191

Page 56

Solution:

Contour cycles SL II,

Kidney-shaped island

100

MAIN PROGRAM

50

30

R80

R10

R75

0

0

15

R20

60

%62191 G71 *

N5 G30 G17 X+0 Y+0 Z-20 *

N10 G31 G90 X+100 Y+100 Z+0 *

N15 T7 G17 S2500 * ...................................................

N20 G00 G40 G90 Z+100 M03 *

N25 G37 P01 1 P02 2 * ...................................................

N30 G120 .....................................................................

Q1=-18 ...................................................................

Q2=1 .....................................................................

Q3=+0,5 .................................................................

Q4=+0,5 .................................................................

Q5=+0 ....................................................................

Q6=+2 ....................................................................

Q7=+10 ..................................................................

Q8=+0 ....................................................................

Q9=-1 * ..................................................................

N35 G122 .....................................................................

Q10=+10 ................................................................

Q11=100 ................................................................

Q12=200 ................................................................

Q18=0 ....................................................................

Q19=150 * ..............................................................

N40 M99 *

N45 G00 Z+100 M06 *

20

18

100

R3

CONTOURS

CONTOUR DATA

MILLING DEPTH

TOOL PATH OVERLAP

ALLOWANCE FOR SIDE

ALLOWANCE FOR DEPTH

SURFACE COORDINATE

CLEARANCE HEIGHT

SETUP CLEARANCE

ROUNDING RADIUS

DIRECTION OF ROTATION

ROUGH OUT

PLUNGING DEPTH

FEED RATE

FEED RATE FOR ROUGHING OUT

COARSE ROUGHING TOOL

RECIPROCATION FEED RATE

0

Retract tool, end

HEIDENHAIN Basic Course ISO G

N50 T8 G17 S2000 * ...................................................

N55 G00 G40 G90 Z+100 M03 *

N60 G123 .....................................................................

Q11=100 ................................................................

Q12=200 * ..............................................................

N65 M99 *

N70 G124 .....................................................................

Q9=-1 ....................................................................

Q10=+10 ................................................................

Q11=100 ................................................................

Q12=200 ................................................................

Q14=+0 * ................................................................

N75 M99 *

N80 G00 Z+100 M30 *

426

R4

FLOOR FINISHING

FEED RATE

FEED RATE FOR ROUGHING OUT

SIDE FINISHING

DIRECTION OF ROTATION

PLUNGING DEPTH

FEED RATE

FEED RATE FOR ROUGHING OUT

ALLOWANCE FOR SIDE

62191/2F06

Page 57

Solution:

Contour cycles SL II,

Kidney-shaped island

SPGM

N85 G98 L1 *

N90 G01 G41 X+5 Y+30 *

N95 I+15 J+30 *

N100 G02 X+6,645 Y+35,495 *

N105 G06 X+55,505 Y+69,488 *

N110 G05 X+58,995 Y+30,025 R-20 *

N115 G06 X+19,732 Y+21,191 *

N120 G02 X+5 Y+30 *

N125 G98 L0 *

N130 G98 L2 *

N135 G01 G42 X-10 Y+10 *

N140 Y+110 *

N145 X+110 *

N150 Y-10 *

N155 X-10 *

N160 G98 L0 *

N999999 %62191 G71 *

HEIDENHAIN Basic Course ISO G

426

62191/3F06

Page 58

100

95

Task:

Datum shift and mirror images

Program(s):

60

40

60

➀

➃

80

100

40

20

0

➁

➂

5

0

0

20

40

%62192 G71

○○○○○○○○○○○○○○○○○○○○○

Datum shift

Part

SPGM call

➀

Retract tool, end

SPGM

SPGM end

G00 G40 Z +100 M2

G98 L . . .

G98 L 0

Part

Mirror images

➁

SPGM call

Part ➂ Mirror images

SPGM call

Part ➃ Mirror images

SPGM call

Reset cycles

HEIDENHAIN Basic Course ISO G

426

F06 62192/1

Page 59

Solution:

Datum shift and mirror images

100

95

MAIN PROGRAM

60

➀

➃

80

➁

60

40

➂

5

0

0

%62192 G71 *

N10 G30 G17 X+0 Y+0 Z-20 *

N20 G31 G90 X+100 Y+100 Z+0 *

N30 T7 G17 S4000 *

N40 G00 G40 G90 Z+100 M03 *

N50 G54 X+50 Y+50 *.....................................................

N60 L1,0 *

N70 G28 X * ..................................................................

N80 L1,0 *

20

40

40

100

DATUM

MIRROR IMAGE

20

0

Retract tool, end

SPGM, contour

N9 0 G28 X Y * ...............................................................

N100 L1,0 *

N110 G28 Y * ..................................................................

N120 L1,0 *

N130 G28 * .....................................................................

N140 G54 X+0 Y+0 * ........................................................

N150 G00 Z+100 M30 *

N160 G98 L1 *

N170 G00 X+0 Y+0 * ........................................................

N180 Z+2 *

N190 G01 Z-20 F200 * ......................................................

N200 G01 G41 X+10 Y+10 * ..............................................

N200 G26 R3 * ................................................................

N210 G01 Y+45 *

N220 X+30 Y+10 *

N230 X+10 *

N240 G27 R3 * ................................................................

N250 G01 G40 X+0 Y+0 *

N260 G98 L0 *

N999999 %62192 G71 *

MIRROR IMAGE

MIRROR IMAGE

RESET MIRROR IMAGE

RESET DATUM SHIFT

AUXILIARY POINT R0

PLUNGING DEPTH

CONTOUR STARTING POINT

APPROACH TANGENTIALLY

DEPART TANGENTIALLY

HEIDENHAIN Basic Course ISO G

426

62192/2F06

Loading...

Loading...