Page 1

User's Manual

ISO Programming

TNC 426

TNC 425

Oktober 1995

TNC 415

B

TNC 407

Page 2

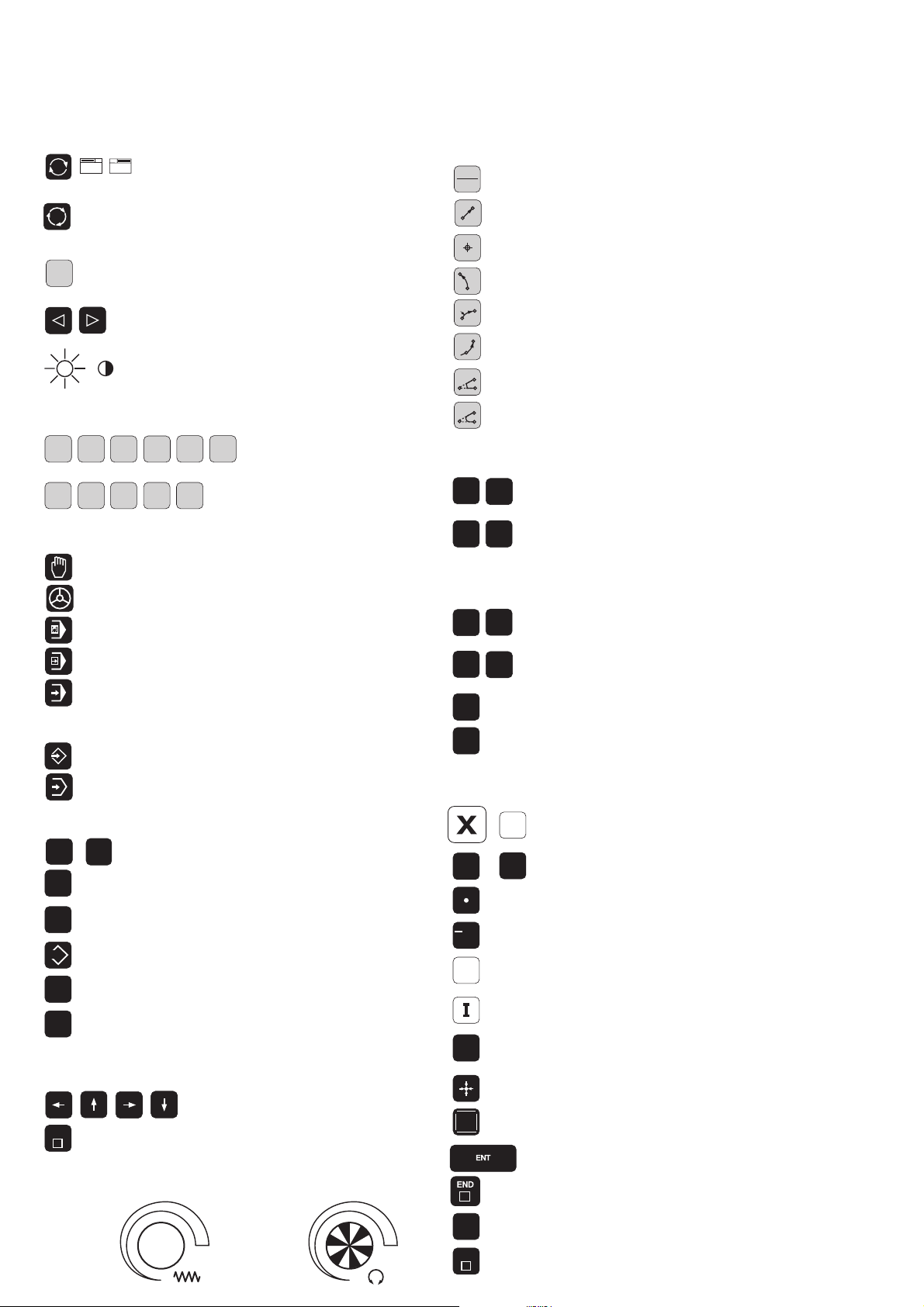

Controls on the TNC 426, TNC 425, TNC 415 B and

TNC 407

Controls on the visual display unit

Toggle display between machining and

programming modes

GRAPHICS

TEXT

SPLIT

SCREEN

Split screen layout

Soft keys for selecting functions in screen

Shift keys for the soft keys

Brightness, contrast

Typewriter keyboard for entering letters and symbols

Q

W

E

R

G F S T

T

M

Y

...

File names/

comments

ISO

programming

Machine operating modes

MANUAL OPERATION

EL. HANDWHEEL

POSITIONING WITH MDI

PROGRAM RUN/SINGLE BLOCK

PROGRAM RUN/FULL SEQUENCE

Programming modes

PROGRAMMING AND EDITING

Programming path movements

(conversational programming only)

APPR

DEP

L

CC

C

CR

CT

CHF

RND

Tool functions

TOOL

TOOL

DEF

CALL

R

R

R

+

Approach/depart contour

Straight line

Circle center/pole for polar coordinates

Circle with center

Circle with radius

Tangential circle

Chamfer

Corner rounding

(conversational programming only)

Enter or call tool length and radius

L

Activate tool radius compensation

-

(not on TNC 426)

Cycles, subprograms and program section repeats

(conversational programming only)

CYCL

CYCL

DEF

LBL

SET

STOP

TOUCH

PROBE

CALL

LBL

CALL

Define and call cycles

Enter and call labels for subprogramming

and program section repeats

Enter program stop in a program

Enter touch probe functions in a program

TEST RUN

Program and file management

PGM

MGT

CL

PGM

PGM

CALL

EXT

MOD

CALC

PGM

NAME

Select programs and files

Delete programs and files

Enter program call in a program

External data transfer

(not on TNC 426)

MOD functions

Pocket calculator

(TNC 426 only)

Moving the cursor and going directly to

blocks, cycles and parameter functions

Move the cursor (highlight)

GOTO

Go directly to blocks, cycles and

parameter functions

Override control knobs

100

Feed rate Spindle speed

50

1

50

0

F %

50

(not on TNC 426)

100

1

0

S %

Coordinate axes and numbers, editing

...

...

0

Select coordinate axes or enter

V

them into a program

Numbers

9

Decimal point

/

+

P

Arithmetic sign

Polar coordinates

Incremental dimensions

Q parameters for part families or

Q

mathematicalfunctions

Capture actual position

NO

ENT

Skip dialog questions, delete words

Confirm entry and resume dialog

End block

Clear numerical entry or TNC message

Abort dialog, delete program sections

50

CE

DEL

Page 3

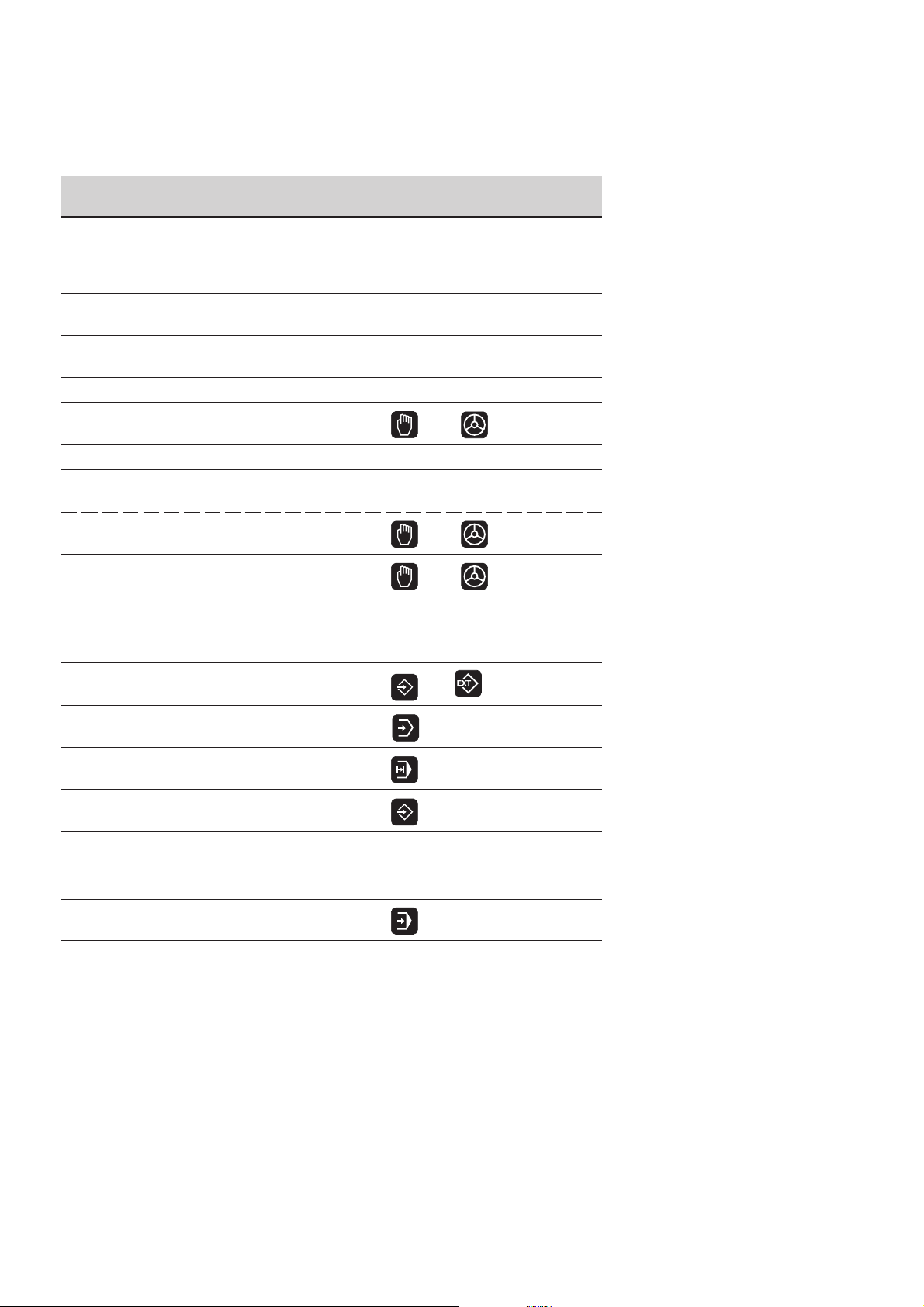

TNC Guideline

From the workpiece drawing to

program-controlled machining

Step Task TNC operating Section in

mode manual

Preparation

1 Select tools —— ——

2 Set workpiece datum for

coordinate system —— ——

3 Determine spindle speeds

and feed rates —— ——

4 Switch on the machine —— 1.3

5 Cross over reference marks 1.3, 2.1

6 Clamp workpiece —— ——

7 Set datum /

Reset position display ...

7a ... with 3D touch probe 2.5

or

or

7b ... without

Entering and testing part programs

8 Enter part program or download

over external data interface 5 to 8, 9

9 Test part program for errors

10 Test run: Run the program

block by block without tool 3.2

11 Optimize the part program

(if necessary) 5 to 8

Machining the workpiece

12 Insert tool and run program 3.2

3D touch probe 2.3

or

or

3.1

Page 4

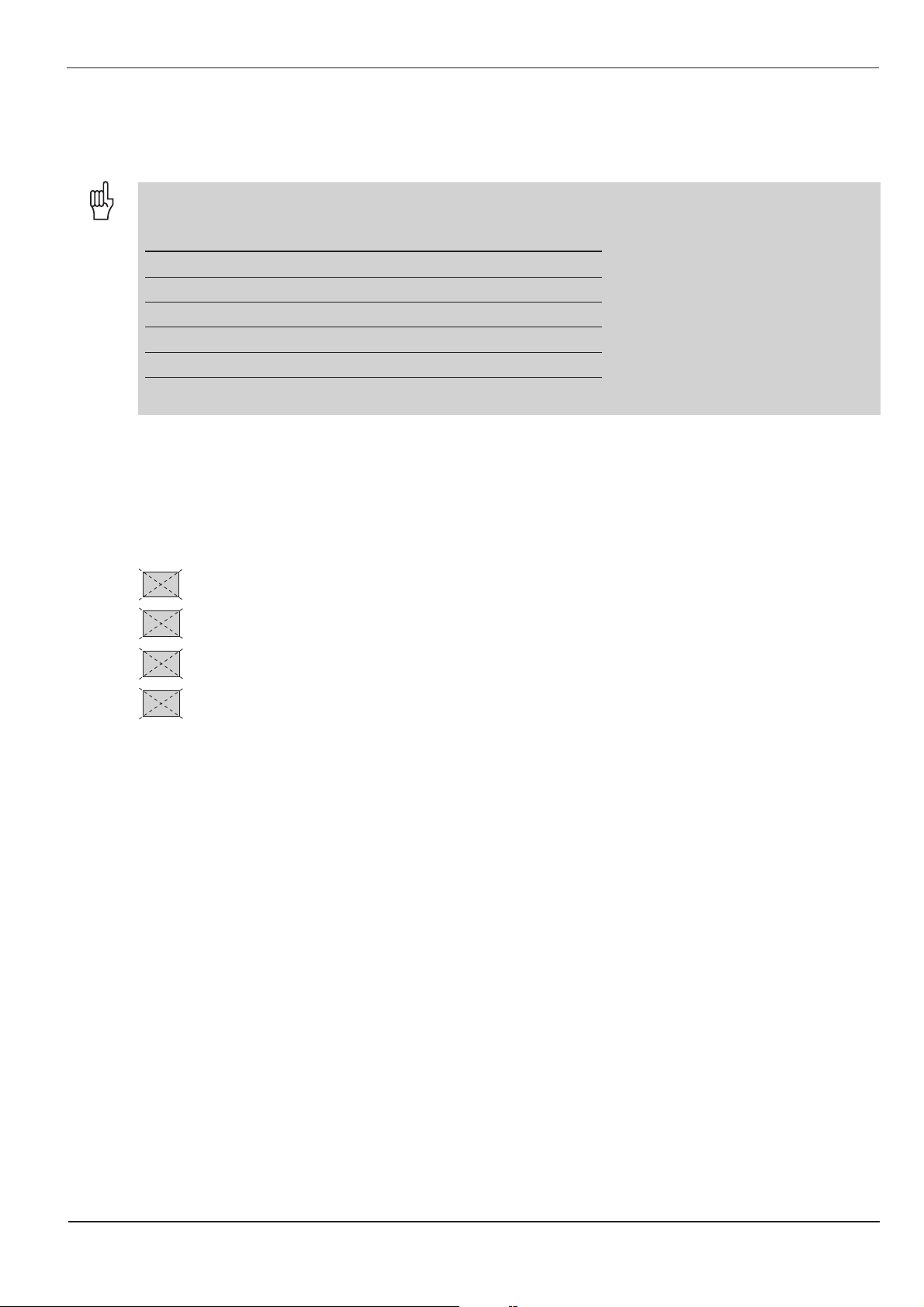

How to use this manual

This manual describes functions and features available on TNCs as of the following NC software numbers:

TNC 407 280 580 04

TNC 415 B, TNC 425 280 540 04

TNC 415 F, TNC 425 E 280 560 04

TNC 426 CA, TNC 426 PA 280 462 01

TNC 426 CE, TNC 426 PE 280 482 01

The suffixes E and F indicate export versions of the TNC.

The export versions TNC 415 F, TNC 425 E, TNC 426 CE, and

TNC 426 PE have the following limitations:

• Input and machining accuracy are limited to 1 µm

• Simultaneous linear movement in up to 4 axes

Some of the functions described in this manual are not available on all

TNCs. These functions are marked with symbols:

NC Software No.

407

415

425

426

The machine manufacturer adapts the features offered by the TNC to the

capabilities of the specific machine tool by setting machine parameters.

This means that not every machine tool will have all of the functions

described in this manual.

Some of the TNC functions which are not available on every machine are:

• Probe functions for the 3D touch probe

• Digitizing option

• Measuring tools with the TT 120 touch probe

• Rigid tapping

• Re-approaching a contour after an interruption

Your machine manual provides more detailed information. If you think a

function may be unavailable because of a defect, please contact the

machine tool builder.

Many machine manufacturers and HEIDENHAIN offer programming

courses for the TNCs. We recommend these courses as an effective way

of improving your programming skill and sharing information and ideas with

other TNC users.

Function not available on the TNC 407

Function not available on the TNC 415

Function not available on the TNC 425

Function not available on the TNC 426

(conversational programming only)

(conversational programming only)

TNC 426/TNC 425/TNC 415 B/TNC 407

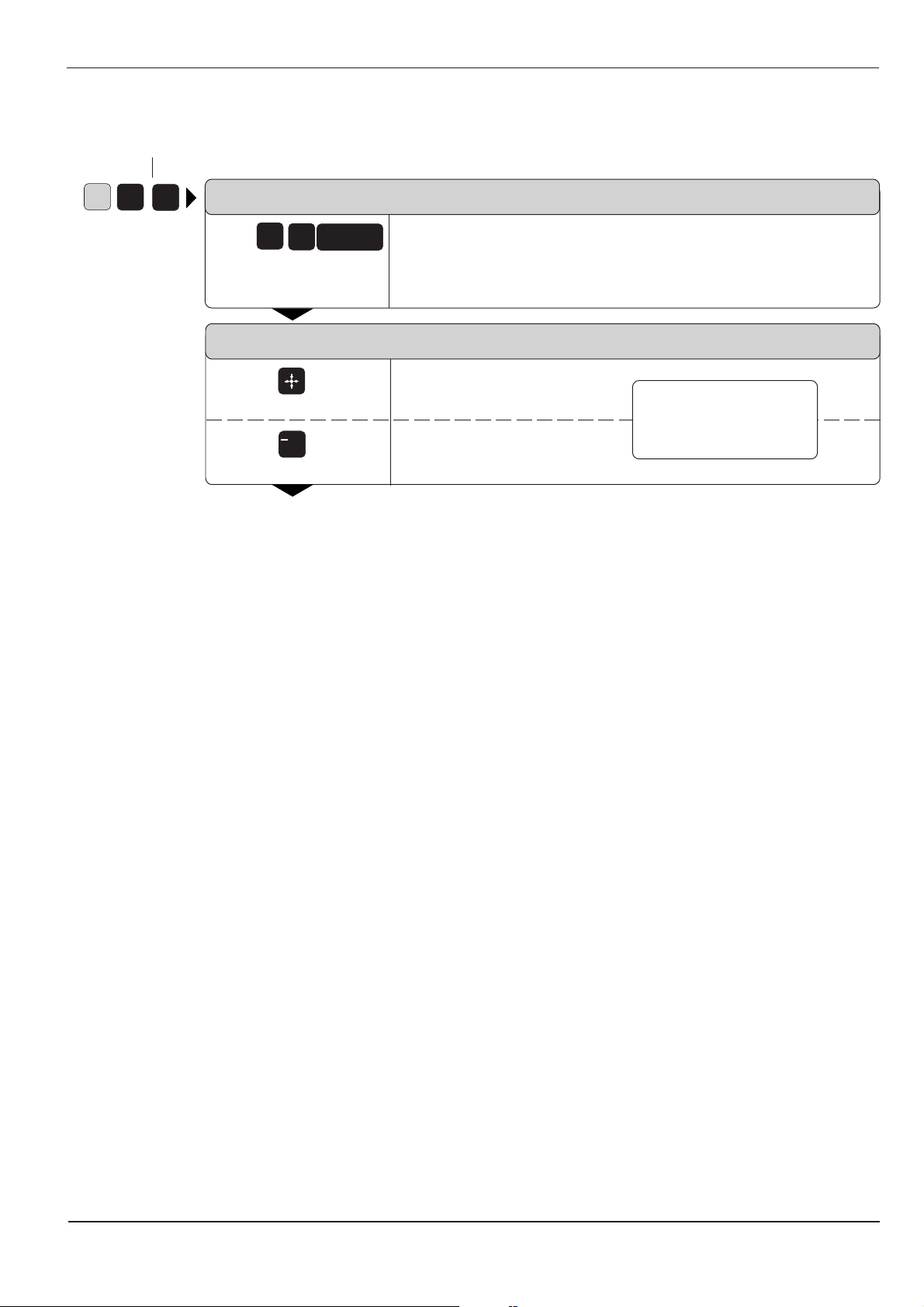

Page 5

This manual is intended both for the TNC beginner and the TNC expert.

The TNC beginner can use it as a step-by-step workbook. The manual

begins with an explanation of the basics of numerical control (NC) and

provides a glimpse into their application in the TNC. It then introduces

the technique of conversational programming. All of the examples can

be practiced directly on the TNC. Each function is explained thoroughly

when it is used for the first time.

The TNC beginner should work through this manual completely from

beginning to end to ensure that he is capable of fully exploiting the

features of this powerful tool.

The TNC expert can use the manual as a comprehensive review and

reference work. The table of contents and numerous cross references

help him quickly find the topics and information he needs. Easy-to-read

dialog flowcharts show him how to enter data for the desired function.

The dialog flowcharts aid the beginner by providing a description of the

function of each key in a box to its right. If the user already knows the

keys, he can concentrate on the illustrated input overview at the left of

the flowchart. The TNC dialog messages are represented in shaded

boxes above the answering input sequence.

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 6

Layout of the dialog flowcharts

Dialog initiation key

G

8

3

DIALOG PROMPT (ON THE TNC SCREEN)

3

8

e.g.

Answer the prompt with

these keys

NEXT DIALOG PROMPT

Press this key

/

Or this key

ENT

+

Here the manual explains the function of the keys.

Function of the key

Function of the alternative key

.

.

The trail of points means that:

.

• the dialog is not completely illustrated, or

• the dialog continues on the next page.

Abbreviated dialog flowcharts

In abbreviated flowcharts an arrow (➤) is used to indicate new entries or

work steps.

A broken line indicates that

either the key above it or

below it can be pressed.

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 7

Contents User's Manual TNC 407, TNC 415 B, TNC 425, TNC 426

(280 5x0-xx, 280 462-xx)

ISO Programming

Introduction

Manual Operation and Setup

Test Run and Program Run

Programming

Programming Tool Movements

Subprograms and Program Section Repeats

Programming with Q Parameters

Cycles

External Data Transfer

MOD-Functions

Tabels, Overviews and Diagrams

1

2

3

4

5

6

7

8

9

10

11

Page 8

1 Introduction

1.1 The TNC 400 Series ............................................................................1-2

Keyboard........................................................................................................................ 1-4

Visual display unit .......................................................................................................... 1-5

TNC Accessories ........................................................................................................... 1-9

1.2 Fundamentals of NC.........................................................................1-10

Introduction .................................................................................................................. 1-10

What is NC? ................................................................................................................. 1-10

The part program .........................................................................................................1-10

Programming ............................................................................................................... 1-10

Reference system ........................................................................................................ 1-11

Cartesian coordinate system ....................................................................................... 1-11

Additional axes............................................................................................................. 1-12

Polar coordinates ......................................................................................................... 1-12

Setting the pole ............................................................................................................ 1-13

Datum setting ............................................................................................................... 1 -13

Absolute workpiece positions .......................................................................................1-15

Incremental workpiece positions .................................................................................. 1-15

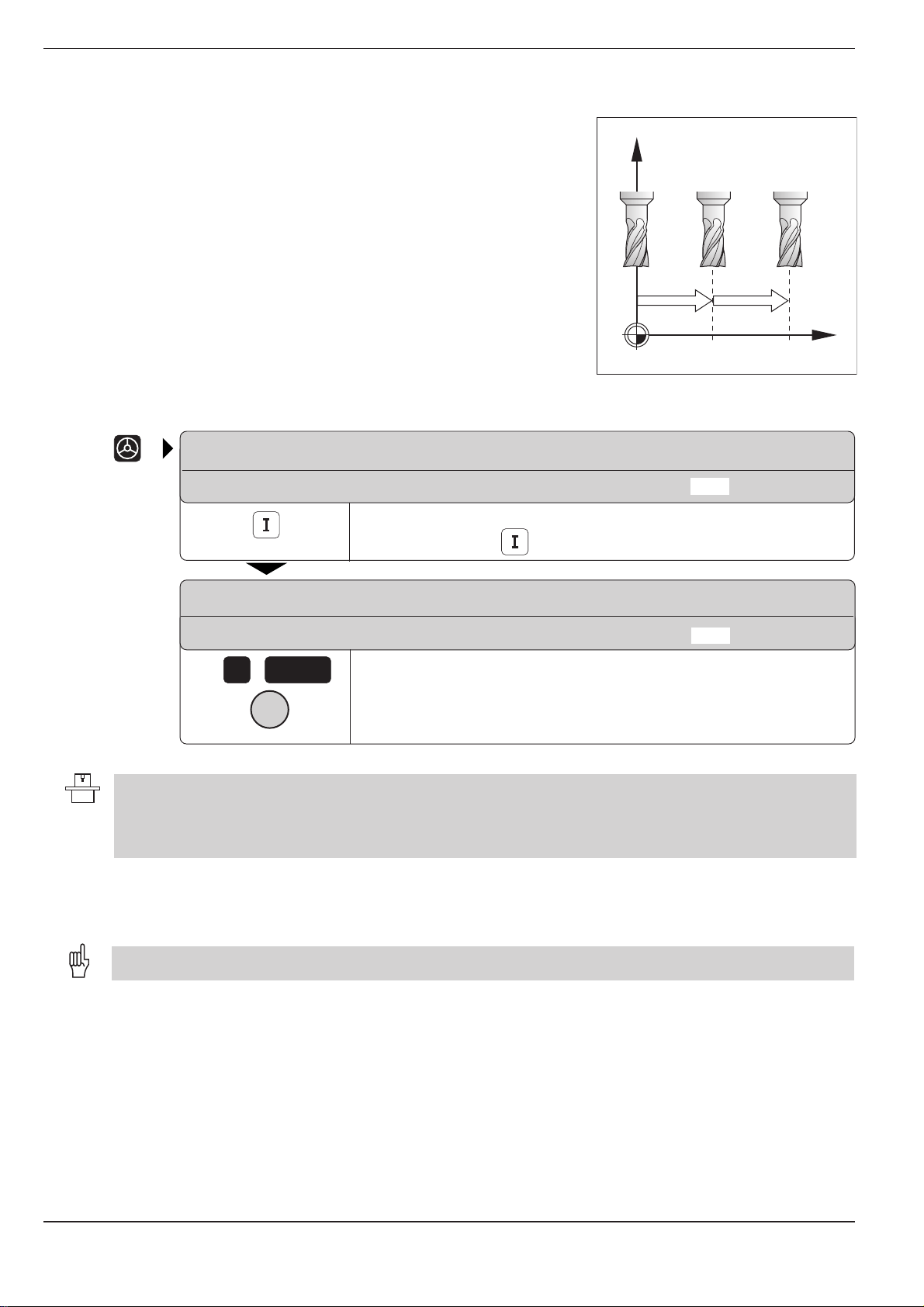

Programming tool movements ..................................................................................... 1-18

Position encoders ........................................................................................................ 1-18

Reference marks......................................................................................................... 1-18

1.3 Switch-On ..........................................................................................1-19

1.4 Graphics and Status Displays .........................................................1-20

Graphics during program run ....................................................................................... 1-20

Plan view...................................................................................................................... 1-21

Projection in 3 planes................................................................................................... 1-22

Cursor position during projection in 3 planes ...............................................................1-23

3D view ........................................................................................................................ 1-23

Magnifying details ........................................................................................................ 1-25

Repeating graphic simulation....................................................................................... 1-26

Measuring the machining time ..................................................................................... 1-26

Status displays ............................................................................................................. 1-27

Additional status displays............................................................................................. 1-27

1.5 File Management on the TNC 426 ...................................................1-30

Data security ................................................................................................................1-30

Calling the file manager ............................................................................................... 1-31

Functions for file management..................................................................................... 1-35

Selecting file types .......................................................................................................1-36

To copy individual files .................................................................................................1-36

To copy several files into another directory ................................................................. 1-37

To erase a file ..............................................................................................................1-38

To rename a file ...........................................................................................................1-38

To protect a file ............................................................................................................ 1-38

To cancel file protection ...............................................................................................1-38

To convert a file ........................................................................................................... 1-39

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 9

1.6 File Management on the TNC 425, TNC 415 B and TNC 407 ........1-40

File directory ................................................................................................................ 1-40

File status..................................................................................................................... 1-41

Selecting a file.............................................................................................................. 1-41

To copy a file................................................................................................................ 1-42

To erase a file ..............................................................................................................1-42

To rename a file ...........................................................................................................1-42

To protect a file ............................................................................................................ 1-42

To cancel file protection ...............................................................................................1-42

To convert a file ........................................................................................................... 1-43

File management for files on external data media .......................................................1-43

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 10

2 Manual Operation and Setup

2.1 Moving the Machine Axes...................................................................2-2

Traversing with the machine axis direction buttons................................................... 2-2

Traversing with an electronic handwheel .................................................................. 2-3

Using the HR 330 electronic handwheel ................................................................... 2-3

Incremental jog positioning........................................................................................ 2-4

Positioning with manual data input (MDI) ..................................................................2-4

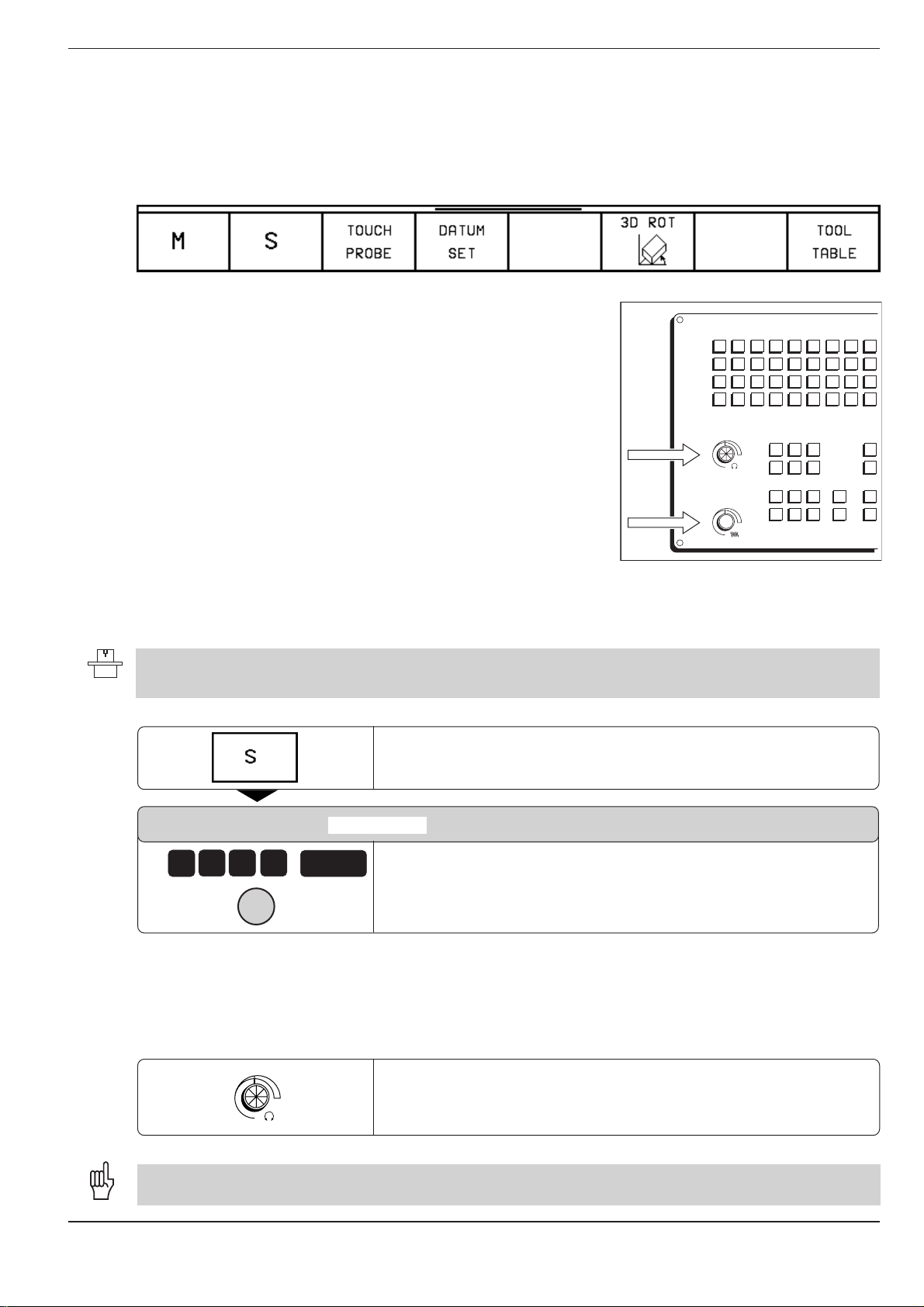

2.2 Spindle Speed S, Feed Rate F and Miscellaneous Functions M.....2-5

To enter the spindle speed S .................................................................................... 2-5

To change the spindle speed S ................................................................................. 2-5

To change the feed rate F .........................................................................................2-6

To enter a miscellaneous function M......................................................................... 2-6

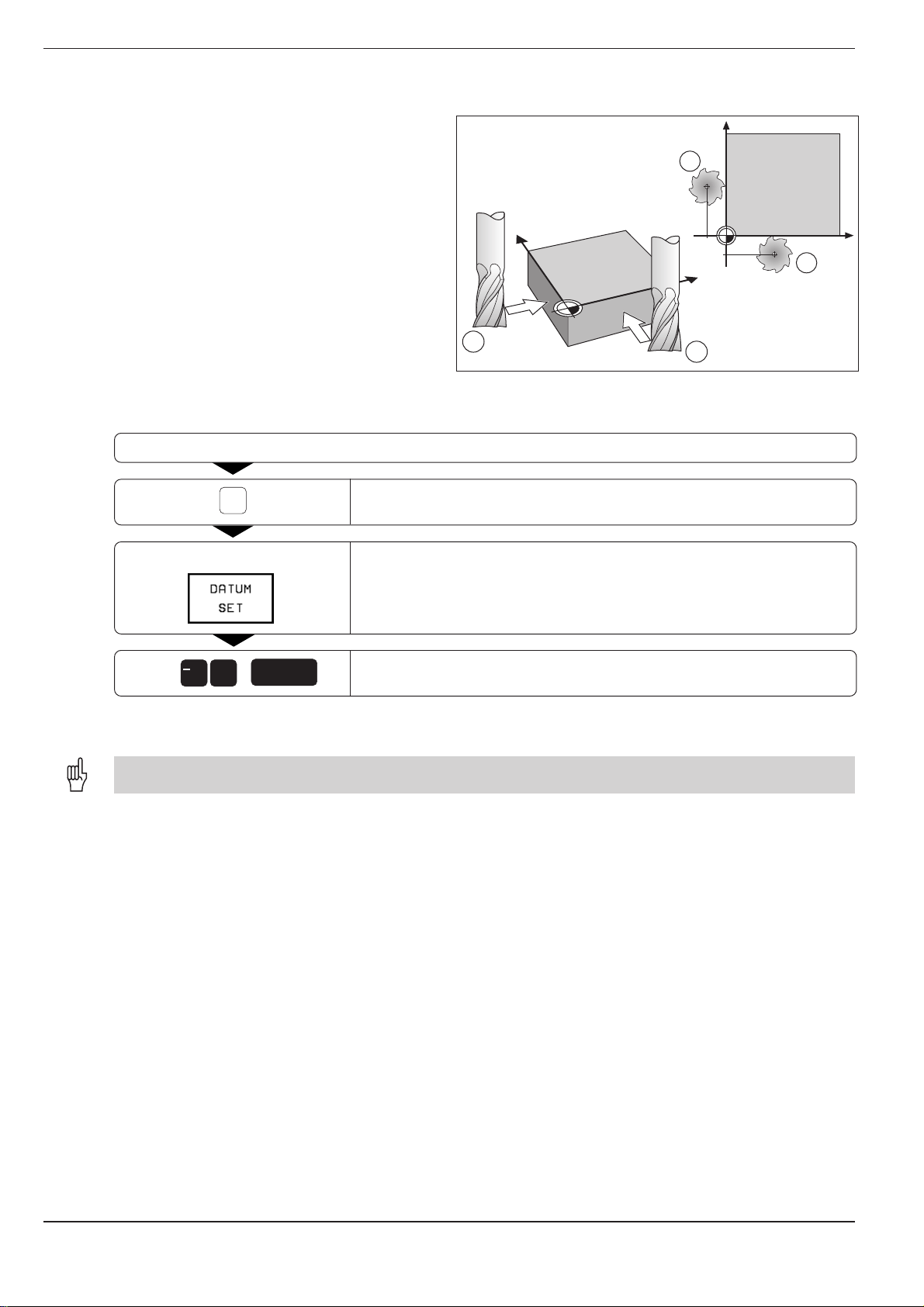

2.3 Setting the Datum Without a 3D Touch Probe ..................................2-7

Setting the datum in the tool axis .............................................................................. 2-7

To set the datum in the working plane ...................................................................... 2-8

2.4 3D Touch Probes .................................................................................2-9

3D Touch probe applications..................................................................................... 2-9

To select the touch probe functions ..........................................................................2-9

Calibrating the 3D touch probe................................................................................ 2-10

Compensating workpiece misalignment .................................................................. 2-12

2.5 Setting the Datum with a 3D Touch Probe ......................................2-14

To set the datum in an axis ..................................................................................... 2-14

Corner as datum ......................................................................................................2-15

Circle center as datum ............................................................................................ 2-17

2.6 Measuring with a 3D Touch Probe ...................................................2-20

To find the coordinates of a position on an aligned workpiece................................ 2-20

Finding the coordinates of a corner in the working plane ........................................ 2-20

Measuring workpiece dimensions ........................................................................... 2-21

Measuring angles ....................................................................................................2-22

2.7 Tilting the Working Plane .................................................................2-24

Traversing reference points with tilted axes ............................................................ 2-25

Setting the datum in a tilted coordinate system....................................................... 2-25

Position display in the tilted system......................................................................... 2-25

Limitations on working with the tilting function ........................................................ 2-25

To activate manual tilting......................................................................................... 2-26

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 11

3 Test Run and Program Run

3.1 Test Run ...............................................................................................3-2

To run a program test ................................................................................................3-2

To run a program test up to a certain block............................................................... 3-3

The display functions for test run .............................................................................. 3-3

3.2 Program Run ........................................................................................ 3-4

To run a part program ............................................................................................... 3-4

Interrupting machining ............................................................................................... 3-5

Moving machine axes during an interruption............................................................. 3-6

Resuming program run after an interruption ............................................................. 3-6

Mid-program startup .................................................................................................. 3-8

Returning to the contour ............................................................................................ 3-9

3.3 Optional Block Skip...........................................................................3-10

3.4 Blockwise Transfer: Testing and Running Long Programs .......... 3-11

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 12

4 Programming

4.1 Creating Part Programs ......................................................................4-2

Layout of a program .................................................................................................. 4-2

Editing functions ........................................................................................................ 4-3

4.2 Tools .....................................................................................................4-5

Setting the tool data .................................................................................................. 4-5

Oversizes for lengths and radii: delta values ............................................................ 4-6

Entering tool data into the program ........................................................................... 4-7

Entering tool data in tables ........................................................................................4-8

Tool data in tables ...................................................................................................4-10

Pocket table for tool changer................................................................................... 4-14

Calling tool data .......................................................................................................4-15

Tool change .............................................................................................................4-15

Automatic tool change: M101 .................................................................................. 4-16

4.3 Tool Compensation Values ..............................................................4-17

Effect of tool compensation values.......................................................................... 4-17

Tool radius compensation .......................................................................................4-17

Machining corners ................................................................................................... 4-19

4.4 Program Creation ..............................................................................4-20

Defining the blank form ........................................................................................... 4-20

To create a new part program .................................................................................4-21

4.5 Entering Tool-Related Data ..............................................................4-23

Feed rate F .............................................................................................................. 4-23

Spindle speed S ......................................................................................................4-24

4.6 Entering Miscellaneous Functions and Program Stop ..................4-25

4.7 Actual Position Capture ....................................................................4-26

4.8 Integrated Pocket Calculator ............................................................4-27

4.9 Marking Blocks for Optional Block Skip .........................................4-28

4.10 Text Files ............................................................................................4-29

Finding text sections ................................................................................................4-31

To erase and insert characters, words and lines..................................................... 4-32

Editing text blocks ...................................................................................................4-33

4.11 Creating Pallet Files ..........................................................................4-35

4.12 Adding Comments to the Program ..................................................4-37

Adding comments to program blocks ...................................................................... 4-37

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 13

5 Programming Tool Movements

5.1 General Information on Programming Tool Movements .................5-2

5.2 Contour Approach and Departure .....................................................5-4

Starting point and end point ...................................................................................... 5-4

Tangential approach and departure ..........................................................................5-6

5.3 Path Functions..................................................................................... 5-7

General information ...................................................................................................5-7

Machine axis movement under program control ....................................................... 5-7

Overview of path functions ........................................................................................ 5-9

5.4 Path Contours – Cartesian Coordinates .........................................5-10

G00: Straight line with rapid traverse ...................................................................... 5-10

G01: Straight line with feed rate F ... .......................................................................5-10

G24: Chamfer .......................................................................................................... 5-13

Circles and circular arcs .......................................................................................... 5-15

Circle center I, J, K ..................................................................................................5-16

G02/G03/G05: Circular path around pole I, J, K ..................................................... 5-18

G02/G03/G05: Circular path with defined radius..................................................... 5-21

G06: Circular path with tangential connection ......................................................... 5-24

G25: Corner rounding.............................................................................................. 5-26

5.5 Path Contours – Polar Coordinates .................................................5-28

Polar coordinate origin: Pole I, J, K .........................................................................5-28

G10: Straight line with rapid traverse ..................................................................... 5-28

G11: Straight line with feed rate F … ...................................................................... 5-28

G12/G13/G15: Circular path around pole I, J, K ..................................................... 5-30

G16: Circular path with tangential transition ............................................................5-32

Helical interpolation .................................................................................................5-33

5.6 M Functions for Contouring Behavior and Coordinate Data ........5-36

Smoothing corners: M90 ......................................................................................... 5-36

Machining small contour steps: M97 ....................................................................... 5-37

Machining open contours: M98 ............................................................................... 5-38

Programming machine-referenced coordinates: M91/M92 ..................................... 5-39

Feed rate factor for plunging movements: M103 F… .............................................. 5-40

Feed rate at circular arcs: M109/M110/M111.......................................................... 5-41

Insert rounding arc between straight lines: M112 E... ............................................. 5-41

Automatic compensation of machine geometry when working with

tilted axes: M114 ..................................................................................................... 5-42

Feed rate in mm/min on rotary axes A, B, C: M116 ................................................ 5-43

Reduce display of a rotary axis to a value less than 360°: M94.............................. 5-43

Optimized traverse of rotary axes: M126 ................................................................5-44

5.7 Positioning with Manual Data Input: System File $MDI .................5-45

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 14

6 Subprograms and Program Section Repeats

6.1 Subprograms .......................................................................................6-2

Operating sequence ..................................................................................................6-2

Operating limitations .................................................................................................. 6-2

Programming and calling subprograms .....................................................................6-3

6.2 Program Section Repeats ................................................................... 6-5

Operating sequence ..................................................................................................6-5

Programming notes ................................................................................................... 6-5

Programming and executing a program section repeat ............................................ 6-5

6.3 Program as Subprogram .................................................................... 6-8

Operating sequence ..................................................................................................6-8

Operating limitations .................................................................................................. 6-8

Calling a program as a subprogram ..........................................................................6-8

6.4 Nesting .................................................................................................6-9

Nesting depth ............................................................................................................ 6-9

Subprogram within a subprogram ............................................................................. 6-9

Repeating program section repeats ........................................................................ 6-11

Repeating subprograms ..........................................................................................6-12

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 15

7 Programming with Q Parameters

7.1 Part Families — Q Parameters in Place of Numerical Values .........7-4

7.2 Describing Contours Through Mathematical Functions .................7-7

Overview ................................................................................................................... 7-7

7.3 Trigonometric Functions ..................................................................7-10

Overview ................................................................................................................. 7-10

7.4 If-Then Decisions with Q Parameters ..............................................7-11

Jumps ..................................................................................................................7-11

Overview ................................................................................................................. 7-11

7.5 Checking and Changing Q Parameters ...........................................7-13

7.6 Diverse Functions .............................................................................7-14

Displaying error messages ...................................................................................... 7-14

Output through an external data interface ...............................................................7-16

Formatted output of texts and Q parameter values .................................................7-17

Reading system data............................................................................................... 7-18

Transfer to the PLC .................................................................................................7-19

7.7 Entering Formulas Directly...............................................................7-20

Overview of functions .............................................................................................. 7-20

7.8 Measuring with the 3D Touch Probe During Program Run ...........7-23

7.9 Programming Examples ...................................................................7-25

Rectangular pocket with island, corner rounding and tangential approach ............. 7-25

Bolt hole circles ....................................................................................................... 7-27

Ellipse .................................................................................................................. 7-29

Hemisphere machined with end mill ........................................................................7-31

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 16

8 Cycles

8.1 General Overview of Cycles ...............................................................8-2

8.2 Simple Fixed Cycles ............................................................................8-4

8.3 SL Cycles (Group I) ...........................................................................8-17

8.4 SL Cycles (Group II) ..........................................................................8-31

Programming a cycle................................................................................................. 8-2

Dimensions in the tool axis........................................................................................ 8-3

PECKING (G83) ........................................................................................................ 8-4

TAPPING with floating tap holder (G84) ................................................................... 8-6

RIGID TAPPING (G85) ............................................................................................. 8-8

THREAD CUTTING (G86) ........................................................................................ 8-9

SLOT MILLING (G74) .............................................................................................8-11

POCKET MILLING (G75/G76) ................................................................................ 8-13

CIRCULAR POCKET MILLING (G77/G78) ............................................................. 8-15

CONTOUR GEOMETRY (G37) .............................................................................. 8-18

ROUGH-OUT (G57) ................................................................................................8-19

Overlapping contours .............................................................................................. 8-21

PILOT DRILLING (G56) .......................................................................................... 8-27

CONTOUR MILLING (G58/G59) ............................................................................. 8-28

CONTOUR DATA (G120) .......................................................................................8-32

PILOT DRILLING (G121) ........................................................................................ 8-33

ROUGH-OUT (G122) .............................................................................................. 8-34

FLOOR FINISHING (G123)..................................................................................... 8-34

SIDE FINISHING (G124) .........................................................................................8-35

CONTOUR TRAIN (G125) ...................................................................................... 8-37

CYLINDER SURFACE G127 .................................................................................. 8-39

8.5 Coordinate Transformations ............................................................8-42

DATUM SHIFT (G54) .............................................................................................. 8-43

DATUM SHIFT with datum tables (G53) .................................................................8-45

MIRROR IMAGE (G28) ...........................................................................................8-48

ROTATION (G73) .................................................................................................... 8-50

SCALING FACTOR (G72)....................................................................................... 8-51

8.6 Other Cycles ......................................................................................8-53

DWELL TIME (G04) ................................................................................................8-53

PROGRAM CALL (G39).......................................................................................... 8-53

ORIENTED SPINDLE STOP (G36) ........................................................................ 8-54

WORKING PLANE (G80) ........................................................................................ 8-55

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 17

9 External Data Transfer

9.1 Data Transfer with the TNC 426 .........................................................9-2

To copy individual files into the TNC .........................................................................9-2

To copy multiple files into the TNC ............................................................................9-3

Copying files out of the TNC ..................................................................................... 9-3

9.2 Data Transfer with the TNC 425, TNC 415 B and TNC 407...............9-4

Selecting and transferring files .................................................................................. 9-5

Blockwise transfer ..................................................................................................... 9 -6

9.3 Pin Layout and Connecting Cable for the Data Interfaces ..............9-7

RS-232-C/V.24 Interface ........................................................................................... 9-7

RS-422/V.11 Interface ............................................................................................... 9-9

9.4 Preparing the Devices for Data Transfer .........................................9-10

HEIDENHAIN devices .............................................................................................9-10

Non-HEIDENHAIN devices ..................................................................................... 9-10

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 18

10 MOD Functions

10.1 Selecting, Changing and Exiting the MOD Functions ...................10-3

10.2 Software Numbers and Option Numbers ........................................10-3

10.3 Code Numbers ...................................................................................10-3

10.4 Setting the External Data Interfaces ................................................10-4

Setting the RS-232 interface ................................................................................... 10-4

Setting the RS-422 interface ................................................................................... 10-4

Selecting the OPERATING MODE.......................................................................... 10-4

Setting the BAUD RATE ..........................................................................................10-4

ASSIGN .................................................................................................................. 10-5

10.5 Machine-Specific User Parameters..................................................10-6

10.6 Showing the Workpiece in the Working Space ..............................10-6

Overview of functions .............................................................................................. 10-7

10.7 Position Display Types .....................................................................10-8

10.8 Unit of Measurement ......................................................................... 10-9

10.9 Programming Language for $MDI....................................................10-9

10.10 Selecting the Axes for Generating L Blocks

(conversational programming only) ................................................10-9

10.11 Axis Traverse Limits .......................................................................10-10

10.12 HELP files .........................................................................................10-11

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 19

11 Tables, Overviews and Diagrams

11.1 General User Parameters..................................................................11-2

Input possibilities for machine parameters .............................................................. 11-2

Selecting general user parameters ......................................................................... 11-2

External data transfer ..............................................................................................11-3

3D touch probes and digitizing ................................................................................11-4

TNC displays, TNC editor........................................................................................ 11-7

Machining and program run .................................................................................. 11-13

Electronic handwheel ............................................................................................ 11-15

11.2 Miscellaneous Functions (M Functions) .......................................11-16

Miscellaneous functions with predetermined effect ............................................... 11-16

Vacant miscellaneous functions ............................................................................11-18

11.3 Preassigned Q Parameters .............................................................11-19

11.4 Features, Specifications and Accessories....................................11-21

Accessories ........................................................................................................... 11-24

11.5 TNC Error Messages .......................................................................11-26

TNC error messages during programming ............................................................ 11-26

TNC error messages during test run and program run .........................................11-27

11.6 Address Letters (ISO)......................................................................11-31

Parameter definitions ............................................................................................ 11-34

TNC 426/TNC 425/TNC 415 B/TNC 407

Page 20

1 Introduction

1.1 The TNC 400 Series

The TNCs are shop-floor programmable contouring controls for boring

machines, milling machines and machining centers with up to 5 axes.

They also feature oriented spindle stop.

Two operating modes are always active simultaneously: one for machine

movements (machining modes) and one for programming or program

testing (programming modes).

TNC 426

The TNC 426 PA features digital control of machine axis speed. This

provides high geometrical accuracy, even with complex workpiece

surfaces and at high machining speeds.

An integrated 170 megabyte hard disk provides storage for programs that

were created on external devices. The TNC 426 also offers an on-screen

pocket calculator.

TNC 425

The TNC 425 also features digital control of machine axis speed. This

results in high geometrical accuracy, even with complex workpiece

surfaces and at high machining speeds.

TNC 415 B

The TNC 415 B uses an analog method of speed control in the drive

amplifier. All the programming and machining functions of the TNC 425

are also available on the TNC 415 B.

TNC 407

The TNC 407 uses an analog method of speed control in the drive

amplifier. Some functions are not available on the TNC 407, such as:

• Graphics during program run

• Tilting the machining plane

• Linear movement in more than three axes

Technical differences between the TNCs

TNC 426 PA TNC 426 CA TNC 425 TNC 415 B TNC 407

Speed control Digital Analog Digital/analog Analog Analog

Block processing time 4 ms 4 ms 4 ms 4 ms 24 ms

Control loop cycle time:

Contouring interpolation 3 ms 3 ms 3 ms 2 ms 6 ms

Control loop cycle time:

Fine interpolation 0.6 ms --- 0.6 ms 0.6 ms --Program memory 170 M byte 170 M byte 256 K byte 256 K byte 128 K byte

(hard disk) (hard disk)

Input resolution 0.1 µm 0.1 µm 0.1 µm 0.1 µm 1 µm

TNC 426/TNC 425/TNC 415 B/TNC 4071-2

Page 21

1 Introduction

1.1 The TNC 400 Series

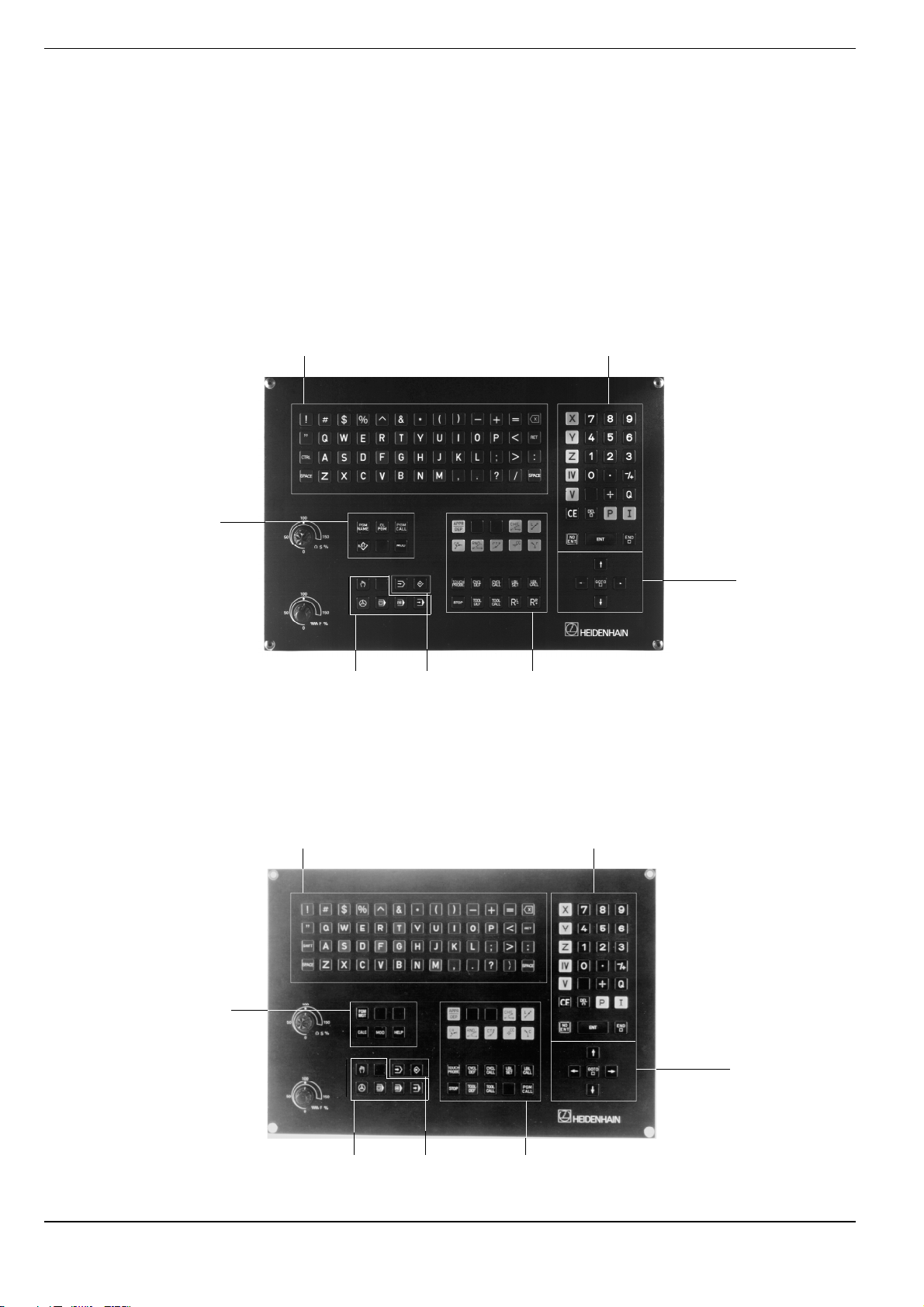

Visual display unit and keyboard

The 14-inch color monitor displays all the information necessary for

effective use of the TNC's capabilities.

The keys are grouped on the keyboard according to function. This makes it

easier to create programs and to use the TNC’s functions.

Programming

The TNCs are programmed in ISO format.

It is also possible to program in easy-to-understand HEIDENHAIN

conversational format (a separate User's Manual is available for this).

Graphics

Workpiece machining can be graphically simulated both during machining

(except on TNC 407) or before actual machining. Various display modes are

available.

Compatibility

The TNCs can execute all part programs written on HEIDENHAIN

TNC 150 B controls or later.

TNC 426/TNC 425/TNC 415 B/TNC 407 1-3

Page 22

1 Introduction

1.1 The TNC 400 Series

Keyboard

The keys on the TNC keyboard are marked with symbols and abbreviations that make them easy to remember. They are grouped according to

the their functions. The functions of the individual keys are described in the

front cover fold-out of the TNC user's manual. A description of machine

panel buttons is provided in the manual for your machine tool.

The keyboard of TNC 407, TNC 415 and TNC 425 controls

Typewriter-style keyboard for entering

file names, comments and other texts,

as well as programming in ISO format

Numerical input and axis selection

Program and file

management

Machine

operating

modes

The keyboard of TNC 426 controls

Typewriter-style keyboard for entering

file names, comments and other texts,

as well as programming in ISO format

Programming

modes

Arrow keys and

GOTO key

Dialog initiation for

conversational

programming

Numerical input and axis selection

File management,

pocket calculator,

MOD functions,

HELP functions

Machine

operating

modes

Programming

modes

Arrow keys and

GOTO key

Dialog initiation

TNC 426/TNC 425/TNC 415 B/TNC 4071-4

Page 23

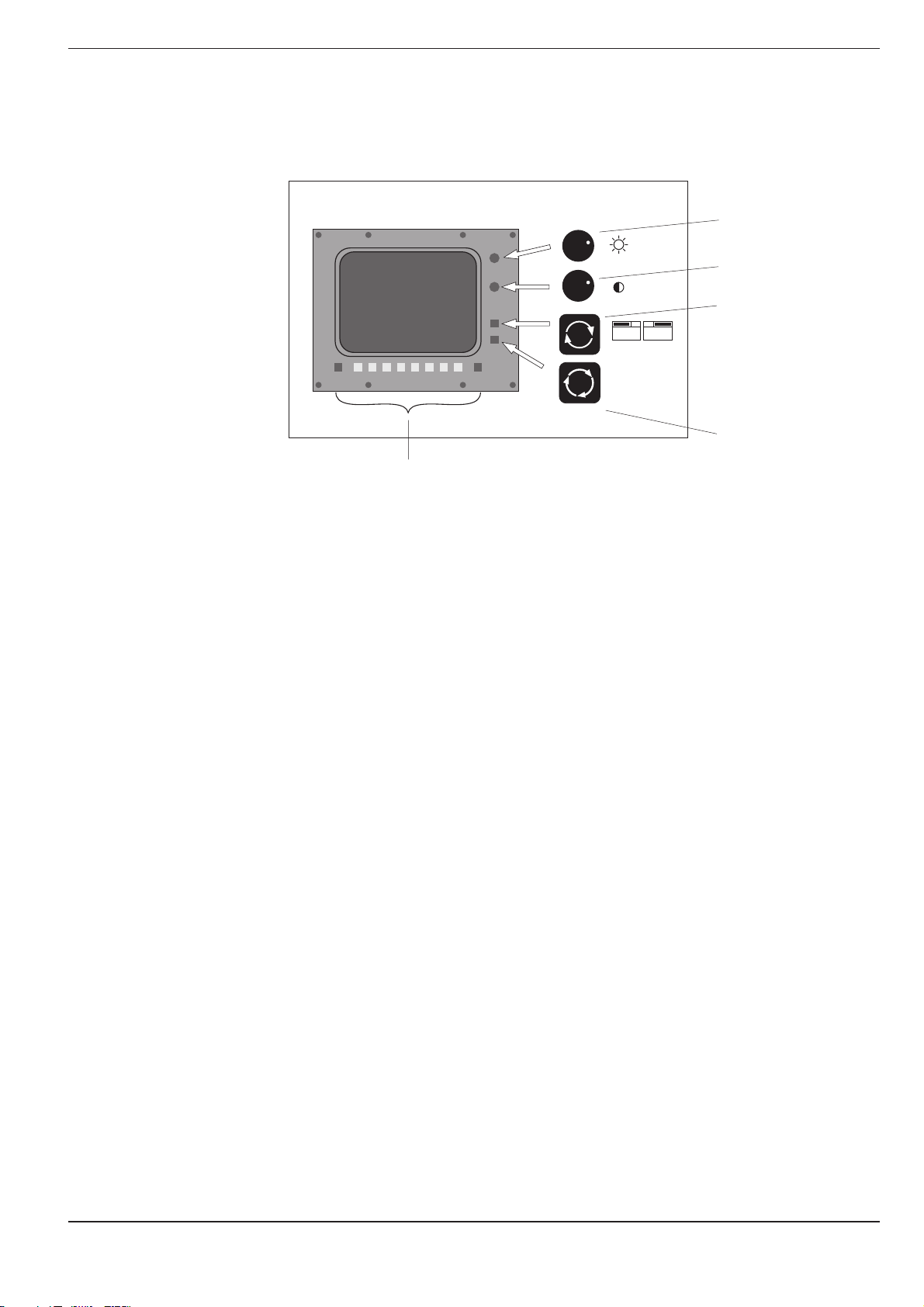

1 Introduction

1.1 The TNC 400 Series

Visual display unit

Soft keys with context-specific

functions, and two shift keys

for additional soft-key rows

Brightness control

Contrast control

Switchover between

the active programming and machining

modes

GRAPHICS

TEXT

SPLIT

SCREEN

SPLIT SCREEN key

for switching screen

layout (see page 1-6)

Headline

The two selected TNC modes are shown in the screen headline:

the machining mode to the left and the programming mode to the right.

The currently active mode is displayed in the larger box, where dialog

prompts and TNC messages also appear.

Soft keys

The soft keys select the functions shown in the soft-key row immediately

above them. The shift keys to the right and left call up additional soft-key

rows. Colored lines above the soft-key row indicate the number of

available rows. The line representing the active row is highlighted.

TNC 426/TNC 425/TNC 415 B/TNC 407 1-5

Page 24

1 Introduction

1.1 The TNC 400 Series

Screen layout

You can select the type of display on the TNC screen by pressing the

SPLIT SCREEN key and one of the soft keys listed below. Depending on

the active mode of operation, you can select:

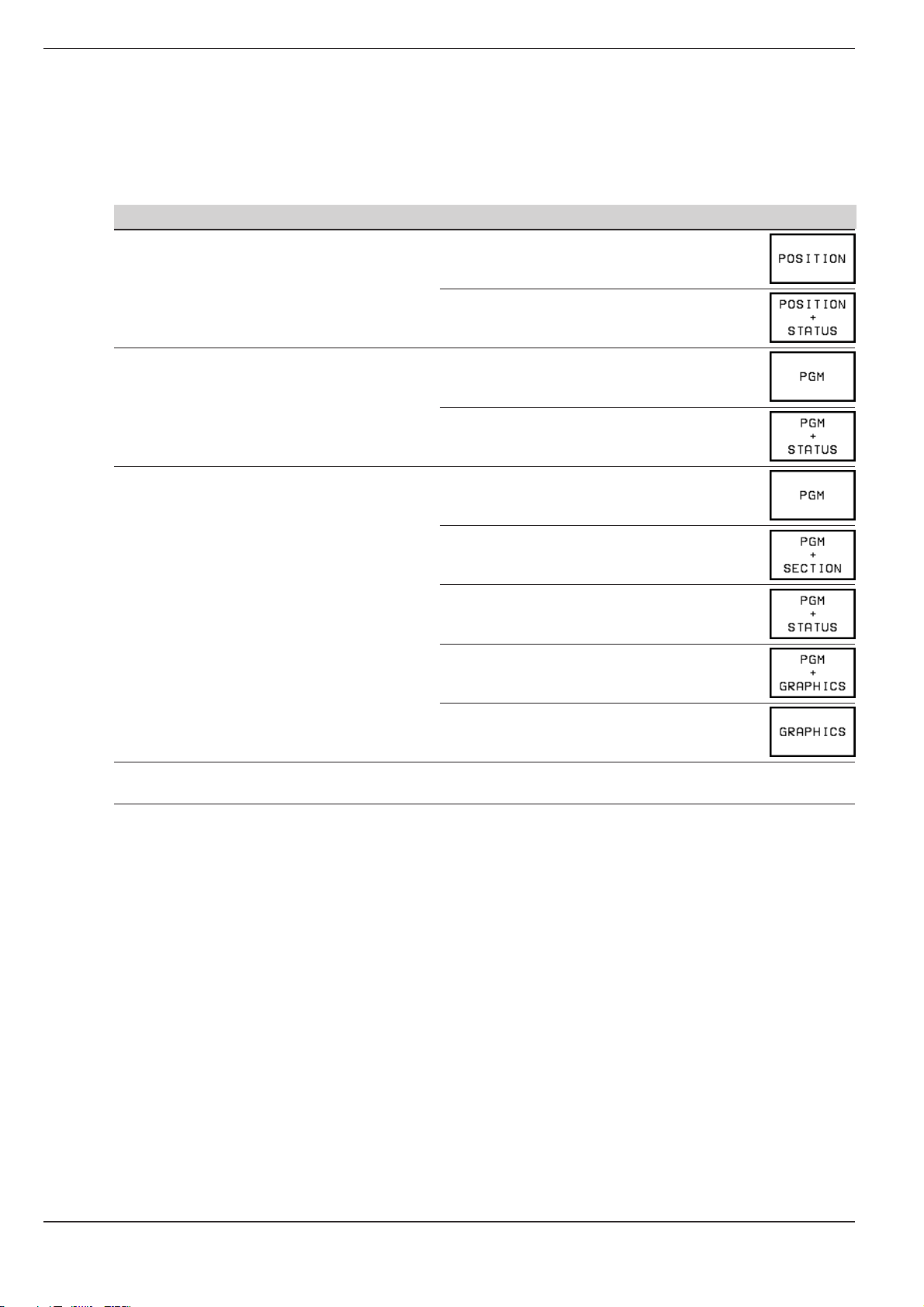

Mode of operation Screen layout Soft key

MANUAL Positions

ELECTRONIC HANDWHEEL

POSITIONING WITH MDI Program blocks

PROGRAM RUN/FULL SEQUENCE Program blocks

PROGRAM RUN/SINGLE BLOCK

TEST RUN

Left: positions

Right: STATUS

Left: program blocks

Right: STATUS

Left: program blocks

Right: program structure

(

conversational programming only

Left: program blocks

Right: STATUS

)

Left: program blocks

Right: graphics

Graphics

PROGRAMMING AND EDITING No screen selection possible, the TNC

displays program blocks only

TNC 426/TNC 425/TNC 415 B/TNC 4071-6

Page 25

1 Introduction

1.1 The TNC 400 Series

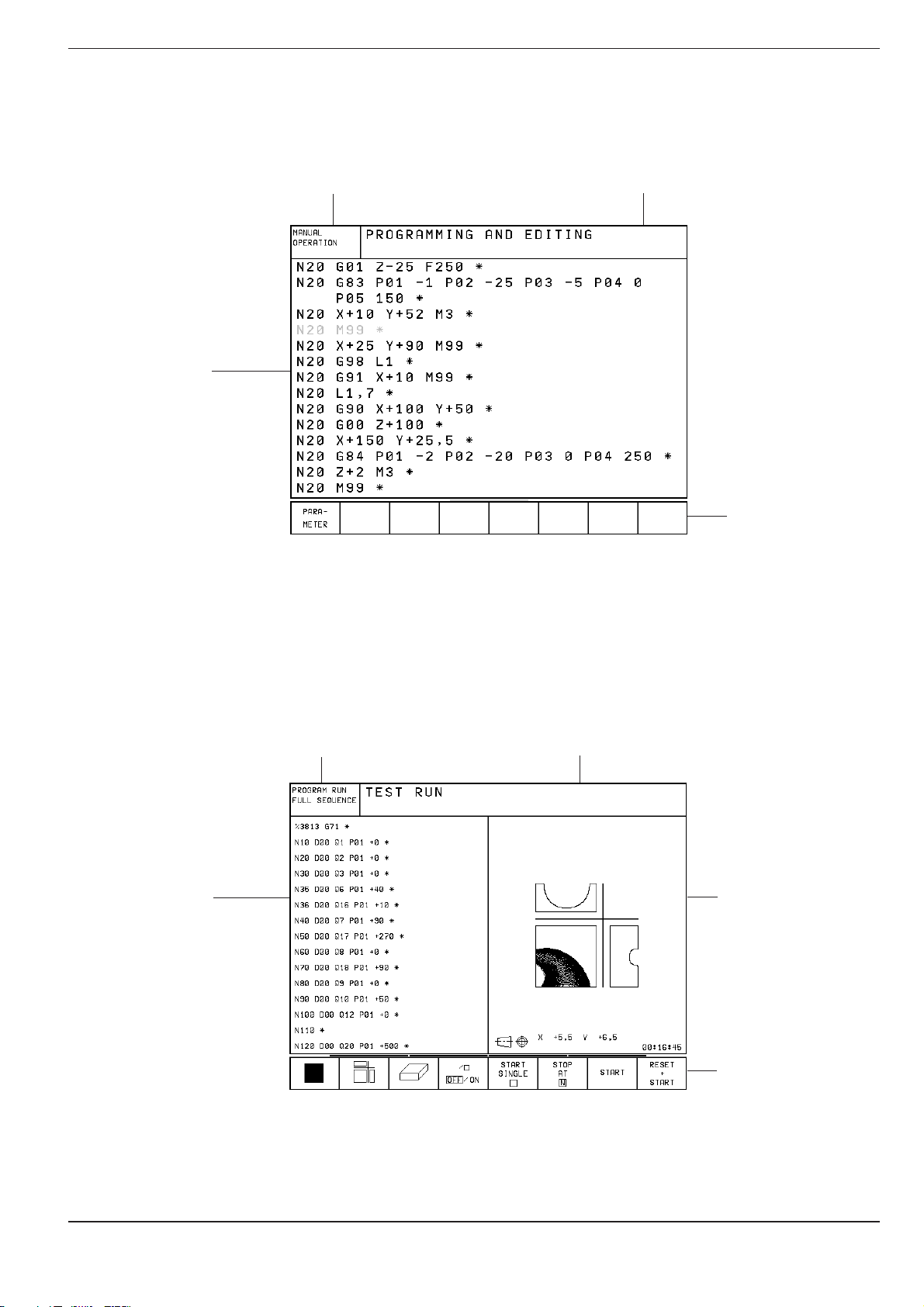

Screen layout of modes

PROGRAMMING AND EDITING:

Text of the

selected

program

Machining

mode

Programming mode is selected

TEST RUN:

Text of the

selected

program

Machining

mode

Soft-key row

Programming mode is selected

Graphics

(or additional

status display)

Soft-key row

TNC 426/TNC 425/TNC 415 B/TNC 407 1-7

Page 26

1 Introduction

1.1 The TNC 400 Series

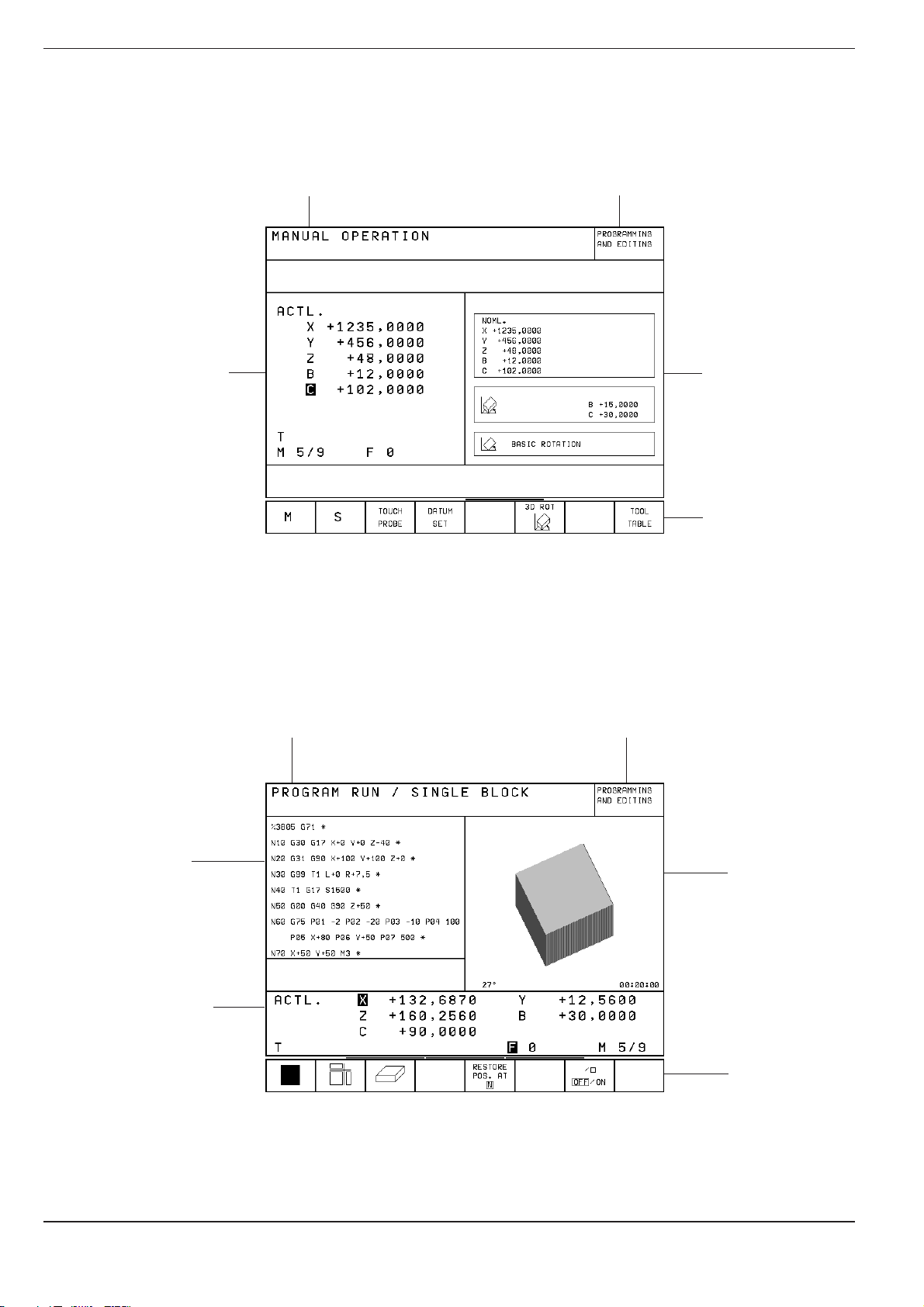

MANUAL OPERATION and ELECTRONIC HANDWHEEL modes:

• Coordinates

• Selected axis

• ❊ means TNC

in operation

• Status display,

e.g. feed rate F,

miscellaneous

function M,

symbols for basic

rotation and/or tilted

working plane

A machining mode is

selected

Programming

mode

Additional

status display

Soft-key row

PROGRAM RUN/FULL SEQUENCE, PROGRAM RUN/SINGLE BLOCK

A machining mode is

selected

Text of the

selected

program

Status display

Programming

mode

Graphics

(or additional

status display,

or program

structure)

Soft-key row

TNC 426/TNC 425/TNC 415 B/TNC 4071-8

Page 27

1 Introduction

1.1 The TNC 400 Series

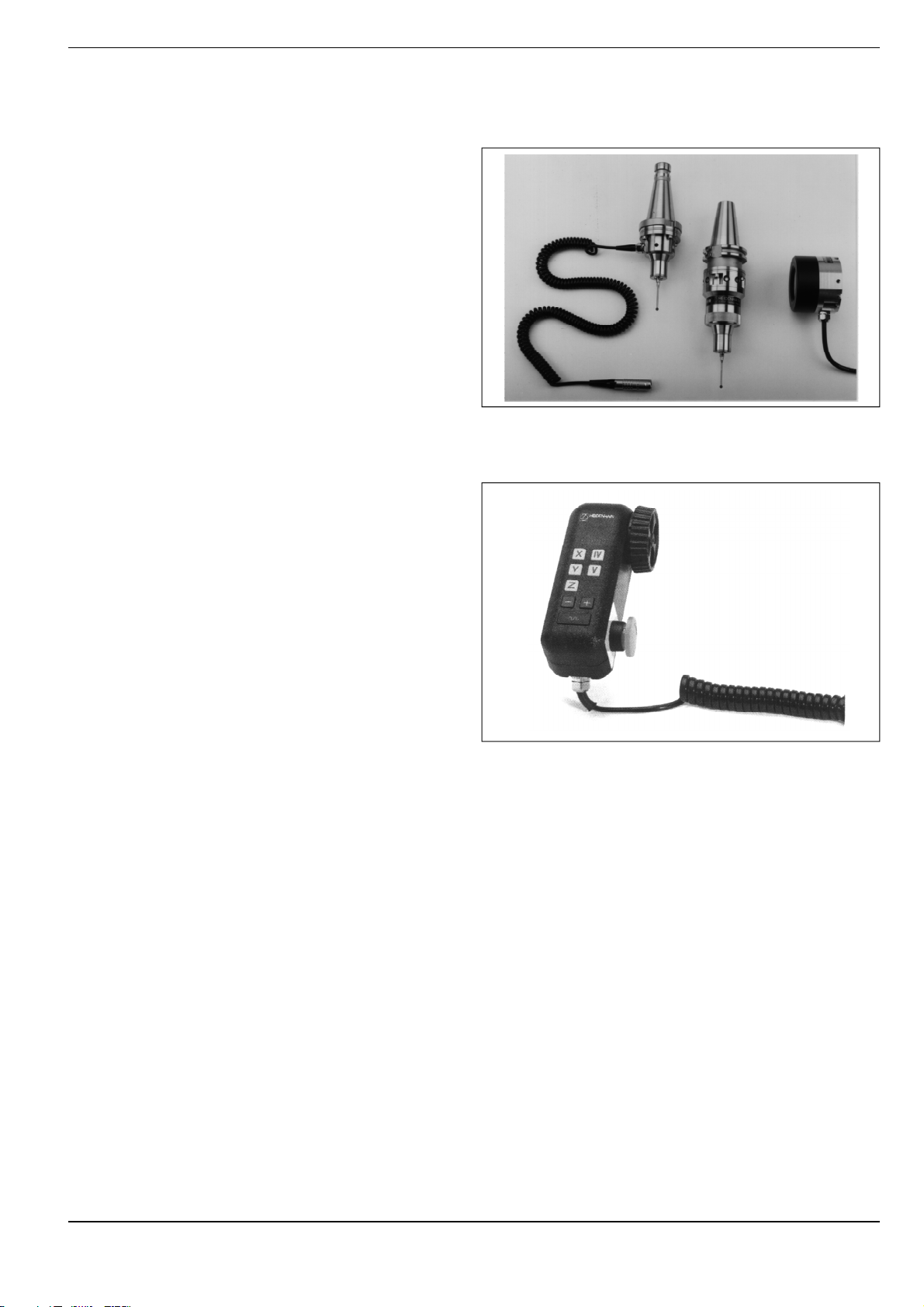

TNC Accessories

3D Touch Probe Systems

The TNC provides the following features when used

in conjunction with a HEIDENHAIN 3D touch probe:

• Electronic workpiece alignment (compensation

of workpiece misalignment)

• Datum setting

• Measurement of the workpiece during

program run

• Digitizing 3D surfaces (optional, only available

with conversational programming)

• Measuring tools with the TT 120 touch probe

(only available)

Fig. 1.6: TS 220 and TS 630 3D-touch probes

Electronic Handwheels

Electronic handwheels facilitate precise manual

control of the axis slides. Similar to a conventional

machine tool, the machine slide moves in direct

relation to the rotation of the handwheel. A wide

range of traverses per handwheel revolution is

available.

Portable handwheels such as the HR 330 are

connected via cable to the TNC. Integral handwheels such as the HR 130 are built into the

machine control panel. An adapter permits connection of up to three handwheels.

Your machine manufacturer can tell you more about

the handwheel configuration of your machine.

Fig. 1.7: HR 330 electronic handwheel

TNC 426/TNC 425/TNC 415 B/TNC 407 1-9

Page 28

1 Introduction

1.2 Fundamentals of NC

Introduction

This chapter discusses the following topics:

• What is NC?

• The part program

• Programming

• Reference system

• Cartesian coordinate system

• Additional axes

• Polar coordinates

• Setting the pole

• Datum setting

• Absolute workpiece positions

• Incremental workpiece positions

• Programming tool movements

• Position encoders

• Reference marks

What is NC?

NC stands for Numerical Control, that is, the operation of a machine tool

by a series of coded instructions comprised of numbers. Modern controls

such as the TNC have a built-in computer for this purpose and are therefore called CNC (Computerized Numerical Control).

The part program

The part program is a complete list of instructions for machining a part.

It contains such information as the target position of a tool movement, the

path function (how the tool should move toward the target position) and

the feed rate. Information on the radius and length of the tool, spindle

speed and tool axis must also be included in the program.

Programming

ISO programming is partially dialog-guided. The programmer is free to

enter the individual commands (words) in each block in any sequence

(except with G90/G91). The commands are automatically sorted by the

TNC when the block is concluded.

TNC 426/TNC 425/TNC 415 B/TNC 4071-10

Page 29

1 Introduction

0° 90°90°

0°

30°

30°

60°

60°

Greenwich

+X

+Y

+Z

+X

+Z

+Y

1.2 Fundamentals of NC

Reference system

In order to define positions, a reference system is necessary. For

example, positions on the earth's surface can be defined “absolutely” by

their geographic coordinates of longitude and latitude. The word

coordinate

network of horizontal and vertical lines around the globe constitute an

absolute reference system — in contrast to the relative definition of a

position that is referenced to a known location.

comes from the Latin word for “that which is arranged.” The

Cartesian coordinate system

On a TNC-controlled milling machine, workpieces are normally machined

according to a workpiece-based Cartesian coordinate system (a

rectangular coordinate system named after the French mathematician

and philosopher Renatus Cartesius, who lived from 1596 to 1650). The

Cartesian coordinate system is based on three coordinate axes X, Y and Z

which are parallel to the machine guideways.

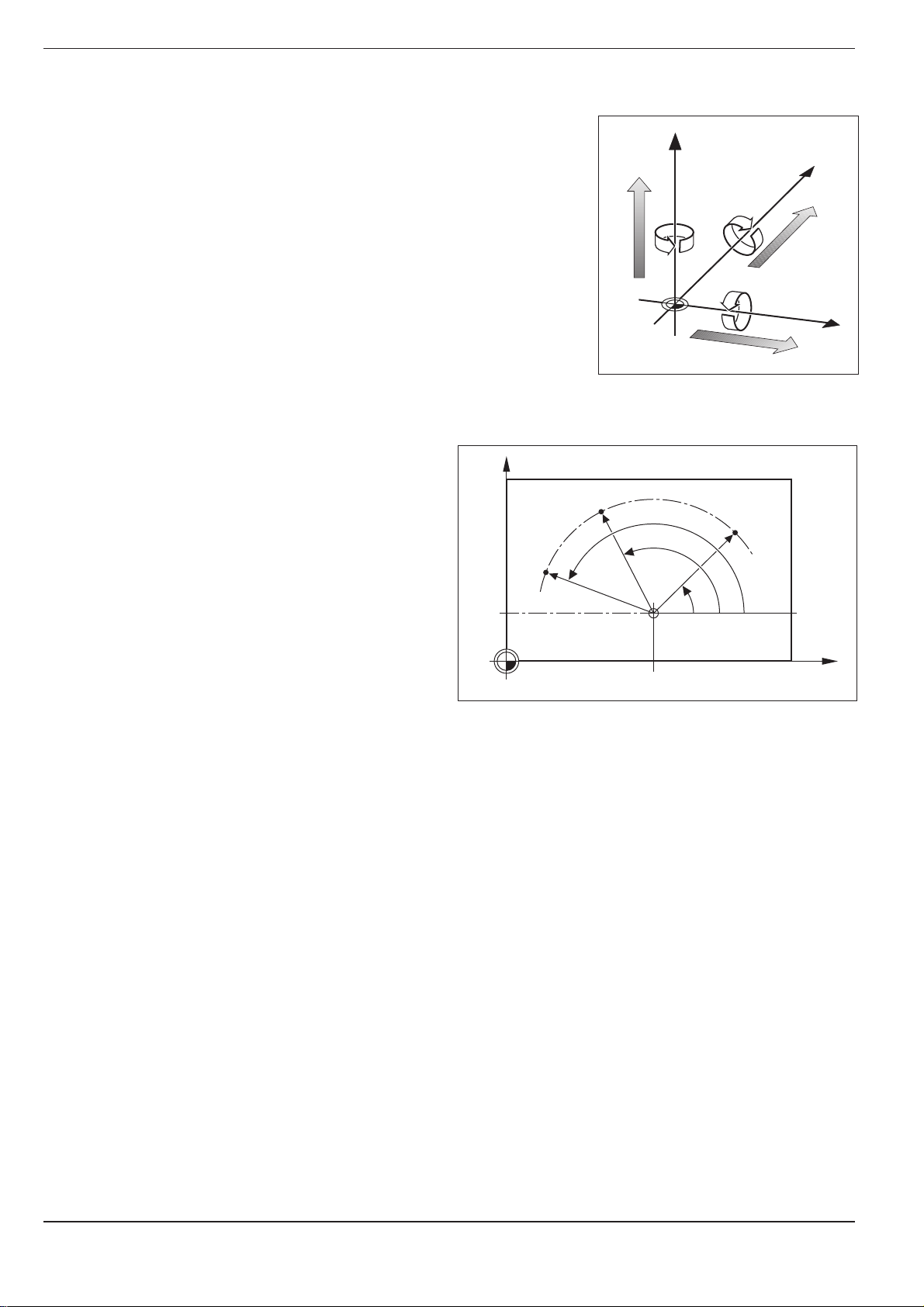

The figure to the right illustrates the “right-hand rule” for remembering the

three axis directions: the middle finger is pointing in the positive direction

of the tool axis from the workpiece toward the tool (the Z axis), the thumb

is pointing in the positive X direction, and the index finger in the positive Y

direction.

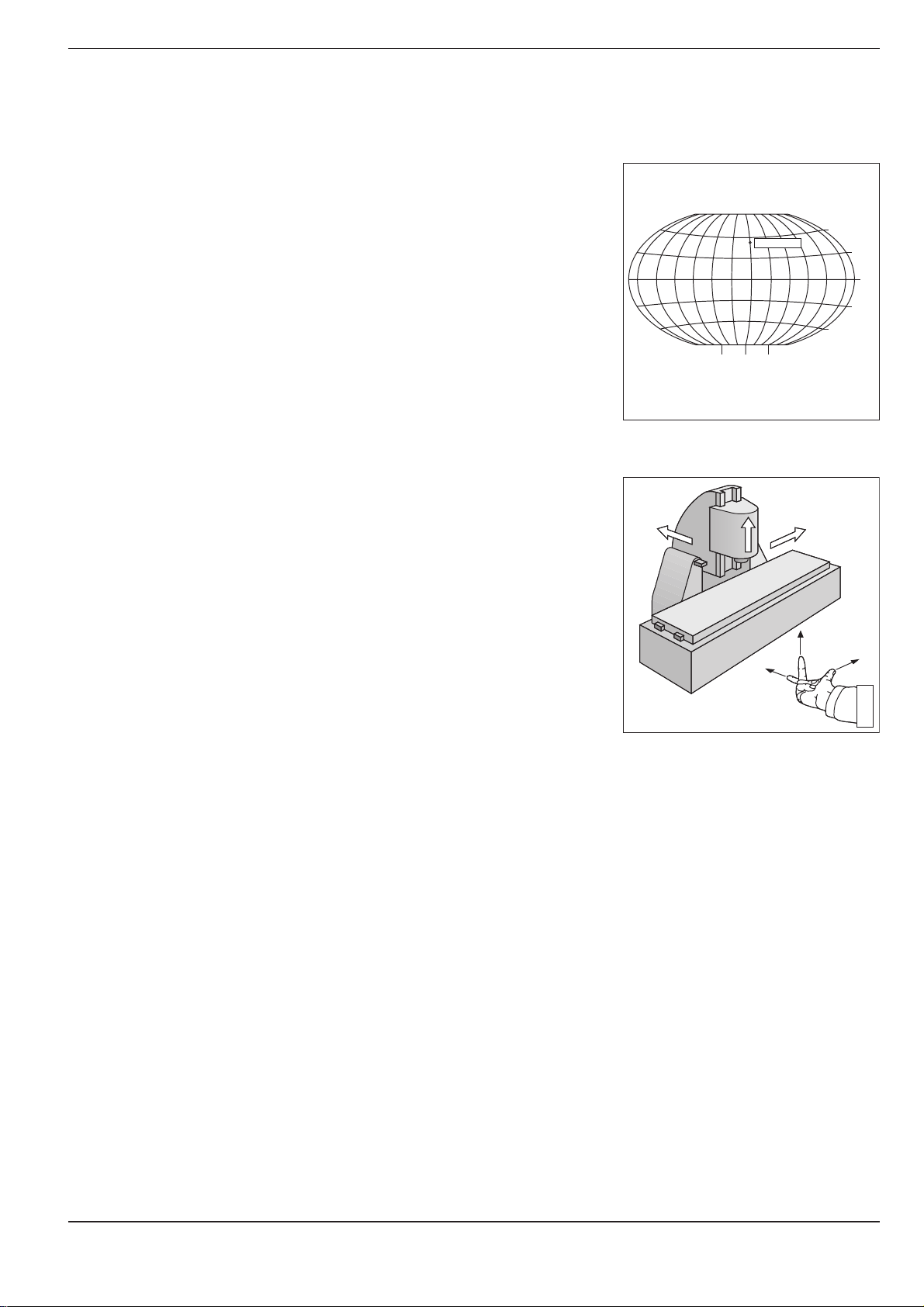

Fig. 1.8: The geographic coordinate system

is an absolute reference system

Fig. 1.9: Designations and directions of the

axes on a milling machine

TNC 426/TNC 425/TNC 415 B/TNC 407 1-11

Page 30

1 Introduction

1.2 Fundamentals of NC

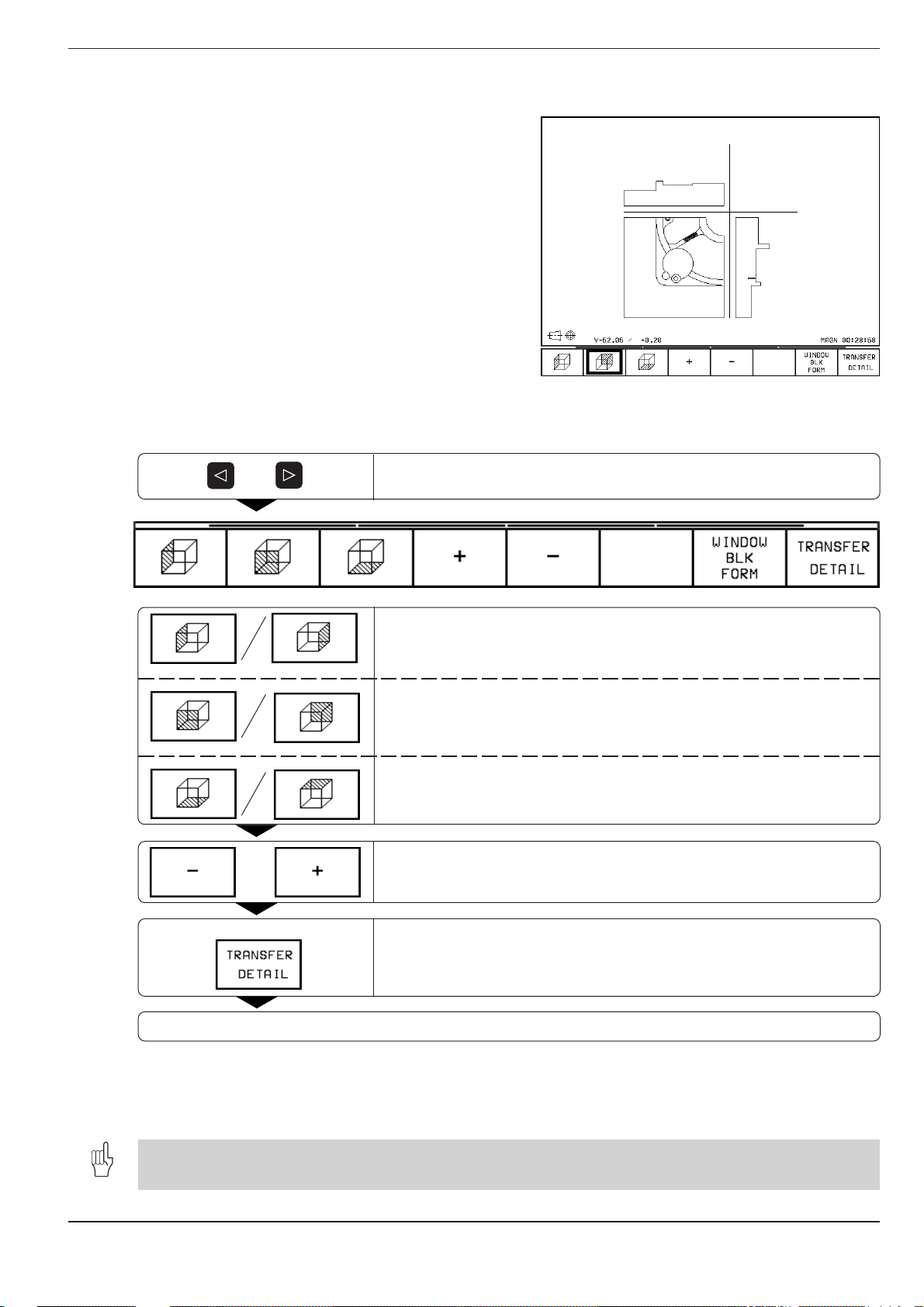

Additional axes

The TNC can control the machine in more than three axes. Axes U, V and

W are secondary linear axes parallel to the main axes X, Y and Z, respec-

tively (see illustration). Rotary axes

as A, B and C.

are also possible, and are designated

W+

Z

Y

C+

B+

V+

A+

Polar coordinates

Although the Cartesian coordinate system is

especially useful for parts whose dimensions are

mutually perpendicular, in the case of parts containing circular arcs or angles it is often simpler to give

the dimensions in polar coordinates. While Cartesian coordinates are three-dimensional and can

describe points in space, polar coordinates are twodimensional and describe points in a plane.

Polar coordinates have their datum at a pole I, J, K

from which a position is measured in terms of its

distance from the pole and the angle of its position

in relation to the pole.

You could think of polar coordinates as the result of

a measurement using a scale whose zero point is

fixed at the datum and which you can rotate to

different angles in the plane around the pole.

The positions in this plane are defined by the

U+

Fig. 1.10: Direction and designation of

additional axes

Y

R

X

H

3

R

J = 10

Fig. 1.11: Identifying positions on a circular arc with polar coordinates

H

I = 30

R

2

H

1

0

°

X

• Polar Radius R, the distance from the circle

center I, J to the position, and the

• Polar Angle H, the size of the angle between

the reference axis and the scale.

TNC 426/TNC 425/TNC 415 B/TNC 4071-12

Page 31

1 Introduction

Y

X

Z

1.2 Fundamentals of NC

Setting the pole

The pole is set by entering two Cartesian coordinates. These coordinates

also determine the reference axis for the polar angle H.

Coordinates of the pole Angle reference axis

I J +X

J K +Y

K I +Z

Z

Z

Y

+

J

I

Fig. 1.12: Polar coordinates and their associated reference axes

Datum setting

The workpiece drawing identifies a certain point on the workpiece (usually

a corner) as the “absolute datum” and perhaps one or more other points

as relative datums. The datum setting procedure establishes these points

as the origin of the absolute or relative coordinate system. The

workpiece, which is aligned with the machine axes, is moved to a certain

position relative to the tool and the display is set either to zero or to

another appropriate value (e.g., to compensate the tool radius).

0°

X

K

J

+

Z

Y

Y

0°

0°

+

K

X

I

X

Fig. 1.13: The workpiece datum represents

the origin of the Cartesian

coordinate system

TNC 426/TNC 425/TNC 415 B/TNC 407 1-13

Page 32

1 Introduction

Y

X

Z

1

10

5

1.2 Fundamentals of NC

Example:

Drawing with several relative datums

(ISO 129 or DIN 406 Part 11, fig. 171)

1225

750

320

125

250

216,5

216,5

250

-250

-125

-216,5

0

125

0

-125

-216,5

-250

150

0

-150

300±0,1

0

0

0

325

450

700

900

950

Example:

Coordinates of point ➀ :

X = 10 mm

Y = 5 mm

Z = 0 mm

The datum of the Cartesian coordinate system is located 10 mm from

point ➀ on the X axis and 5 mm from it on the Y axis.

The 3D Touch Probe System from HEIDENHAIN is an especially

convenient and efficient way to find and set datums.

Fig. 1.14: Point ➀ defines the coordinate

system

TNC 426/TNC 425/TNC 415 B/TNC 4071-14

Page 33

1 Introduction

IZ=–15mm

Y

X

Z

2

10

5

5

15

20

10

10

I

X=10mm

I

Y=10mm

3

0

0

Y

X

Z

1

20

10

Z=15mm

X=20mm

Y=10mm

15

1.2 Fundamentals of NC

Absolute workpiece positions

Each position on the workpiece is uniquely defined by its absolute

coordinates.

Example:

Absolute coordinates of position ➀:

X = 20 mm

Y = 10 mm

Z = 15 mm

If you are drilling or milling a workpiece according to a workpiece drawing

with absolute coordinates, you are moving the tool to the value of the

coordinates.

Incremental workpiece positions

A position can also be referenced to the preceding nominal position. In

this case the relative datum is always the last programmed position. Such

coordinates are referred to as incremental coordinates (increment =

increase). They are also called chain dimensions (since the positions are

defined as a chain of dimensions). Incremental coordinates are designated

with the prefix I.

Example:

Incremental coordinates of position ➂ referenced to position ➁

Absolute coordinates of position ➁ :

X = 10 mm

Y = 5 mm

Z = 20 mm

Incremental coordinates of position ➂ :

IX = 10 mm

IY = 10 mm

IZ = –15 mm

If you are drilling or milling a workpiece according to a drawing with

incremental coordinates, you are moving the tool

coordinates.

An incremental position definition is therefore a specifically

definition. This is also the case when a position is defined by the

distance-to-go to the nominal position. The distance-to-go has a negative

sign if the target position lies in the negative axis direction from the actual

position.

by

the value of the

relative

Fig. 1.15: Position definition through

absolute coordinates

Fig. 1.16: Position definition through

incremental coordinates

TNC 426/TNC 425/TNC 415 B/TNC 407 1-15

Page 34

1 Introduction

1.2 Fundamentals of NC

The polar coordinate system can also express both

types of dimensions:

• Absolute polar coordinates

pole (I, J) and the reference axis.

• Incremental polar coordinates always refer to

the last nominal position of the tool.

always refer to the

Y

J = 10

G91R

R

G91H G91H

R

R

H

0

°

I = 30

Fig. 1.17: Incremental dimensions in polar coordinates

(designated by G91)

X

TNC 426/TNC 425/TNC 415 B/TNC 4071-16

Page 35

1 Introduction

1.2 Fundamentals of NC

Example:

Workpiece drawing with coordinate dimensioning

(according to ISO 129 or DIN 406, Part 11; figure 179)

2.1

2.2

2.3

3.4

3.5

3.6

r

3.7

3

3.8

3.9

3.10

Y2

2 1.3

X2

3.3

3.11

3.2

3.1

3.12

ϕ

1.21.1

Y1

1

X1

Dimensions in mm

Coordinates

Coordinate

origin Pos. X1 X2 Y1 Y2 r

1100 –

1 1.1 325 320 Ø 120 H7

1 1.2 900 320 Ø 120 H7

1 1.3 950 750 Ø 200 H7

1 2 450 750 Ø 200 H7

1 3 700 1225 Ø 400 H8

2 2.1 –300 150 Ø 50 H11

2 2.2 –300 0 Ø 50 H11

2 2.3 –300 –150 Ø 50 H11

3 3.1 250 0° Ø 26

3 3.2 250 30° Ø 26

3 3.3 250 60° Ø 26

3 3.4 250 90° Ø 26

3 3.5 250 120° Ø 26

3 3.6 250 150° Ø 26

3 3.7 250 180° Ø 26

3 3.8 250 210° Ø 26

3 3.9 250 240° Ø 26

3 3.10 250 270° Ø 26

3 3.11 250 300° Ø 26

3 3.12 250 330° Ø 26

ϕϕ

ϕ d

ϕϕ

TNC 426/TNC 425/TNC 415 B/TNC 407 1-17

Page 36

1 Introduction

Y

X

Z

1.2 Fundamentals of NC

Programming tool movements

During workpiece machining, an axis position is changed either by movement of the tool or movement of the machine table on which the workpiece is fixed.

You always program as if the tool moves and the workpiece remains

stationary.

If the machine table moves, the corresponding axes are identified on the

machine operating panel with a prime mark (e.g., X’, Y’). The programmed

direction of such axis movement always corresponds to the direction of

tool movement relative to the workpiece but in the opposite direction.

+Y

+Z

+X

Position encoders

Position encoders convert the movement of the machine axes into

electrical signals. The control constantly evaluates these signals to

calculate the actual position of the machine axes.

If there is an interruption in power, the calculated position will no longer

correspond to the actual position. When power is restored, the TNC can

re-establish this relationship.

Reference marks

The scales of the position encoders contain one or more reference marks.

When a reference mark is crossed over, it generates a signal which

identifies that position as the machine axis reference point. With the aid of

this reference mark the TNC can re-establish the assignment of displayed

positions to machine axis positions.

If the position encoders feature distance-coded reference marks, each

axis need only move a maximum of 20 mm (0.8 in.) for linear encoders,

and 20° for angle encoders.

Fig. 1.18: On this machine the tool moves in

the Y and Z axes, and the table

moves in the +X' axis.

Fig. 1.19: Linear position encoder, here for

the X axis

Fig. 1.20: Linear scales: with distance-coded

reference marks

and one reference mark

illustration)

(upper illustration)

(lower

TNC 426/TNC 425/TNC 415 B/TNC 4071-18

Page 37

1 Introduction

1.3 Switch-On

Switch-on and traversing the reference points can vary depending on the individual machine tool. Your machine

manual provides more information on these functions.

Switch on the TNC and machine tool. The TNC automatically initiates the

following dialog:

MEMORY TEST

The TNC memory is automatically checked.

POWER INTERRUPTED

CE

TRANSLATE PLC PROGRAM

The PLC program of the TNC is translated automatically.

RELAY EXT. DC VOLTAGE MISSING

I

MANUAL OPERATION

TRAVERSE REFERENCE POINTS

I

X

The TNC is now ready for operation in the

MANUAL OPERATION mode.

Y

TNC message indicating that the power was interrupted.

Clear the message.

Switch on the control voltage.

The TNC checks the EMERGENCY OFF circuit.

Move the axes over the reference marks in the displayed sequence:

For each axis press the START key, or

Cross the reference points in any sequence:

Press the machine axis direction button for each axis,

until the reference point has been traversed.

The reference points need only be traversed if the machine axes are to be moved. If you intend only to write, edit

or test programs, you can select the PROGRAMMING AND EDITING or TEST RUN modes of operation immediately after switching on the control voltage. The reference points can then be traversed later by pressing the

PASS OVER REFERENCE soft key in the MANUAL mode of operation.

Traversing reference points with a tilted working plane

In a tilted coordinate system, the reference points are traversed by

pressing the machine axis direction buttons. To enable this function, set

TILT WORKING PLANE to ACTIVE in the MANUAL OPERATION mode

(see page 2-26). The TNC then interpolates the tilted axes as soon as the

corresponding axis direction buttons are pressed.

The NC START key is disabled; pressing this key will display an error

message.

The angular values entered in the menu must correspond to the actual

angle of the tilt axis.

TNC 426/TNC 425/TNC 415 B/TNC 407 1-19

407

Page 38

1 Introduction

1.4 Graphics and Status Displays

In the program run operating modes (except on TNC 407) and test run

operating modes, the TNC provides the following three display modes:

• Plan view

• Projection in three planes

• 3D view

The display mode is selected with the soft keys.

On the TNC 415 B, TNC 425 and TNC 426, workpiece machining can also

be graphically simulated in real time.

The TNC graphic depicts the workpiece as if it were being machined by a

cylindrical end mill. If tool tables are used, a spherical cutter can also be

depicted (see page 4-10).

The graphics window will not show the workpiece if

• the current program has no valid blank form definition

• no program is selected

With machine parameters MP7315 to MP7317 a graphic is generated

even if no tool axis is defined or moved.

The graphics cannot show rotary axis movements (error message).

Graphics during program run

A graphical representation of a running program is not possible if the

microprocessor of the TNC is already occupied with complicated machining tasks or if large areas are being machined.

Example:

Stepover milling of the entire blank form with a large tool.

The TNC interrupts the graphics and displays the text “ERROR” in the

graphics window. The machining process is continued, however.

407

TNC 426/TNC 425/TNC 415 B/TNC 4071-20

Page 39

1 Introduction

1.4 Graphics and Status Displays

Plan view

The depth of the workpiece surface is displayed

according to the principle “the deeper, the

darker.”

The number of displayable depth levels can be

selected with the soft keys:

• TEST RUN mode: 16 or 32

• PROGRAM RUN modes: 16 or 32

Plan view is the fastest of the three graphic

display modes.

or

Fig. 1.21: TNC graphics, plan view

Show 16 or 32 shades of depth.

TNC 426/TNC 425/TNC 415 B/TNC 407 1-21

Page 40

1 Introduction

1.4 Graphics and Status Displays

Projection in 3 planes

Similar to a workpiece drawing, the part is

displayed with a plan view and two sectional

planes. A symbol to the lower left indicates

whether the display is in first angle or third angle

projection according to ISO 6433 (selected with

MP 7310).

Details can be isolated in this display mode for

magnification (see page 1–25).

Shifting planes

The sectional planes can be shifted as desired.

The positions of the sectional planes are visible

during shifting.

Fig. 1.22: TNC graphics, projection in three planes

Fig. 1.23: Shifting sectional planes

or

or

or

Shift the soft-key row.

Shift the vertical sectional plane to the right or left.

Shift the horizontal sectional plane upwards or downwards.

TNC 426/TNC 425/TNC 415 B/TNC 4071-22

Page 41

1 Introduction

1.4 Graphics and Status Displays

Cursor position during projection in 3 planes

The TNC shows the coordinates of the cursor

position at the bottom of the graphics window.

Only the coordinates of the working plane are

shown.

This function is activated with machine parameter

MP 7310.

Cursor position during detail magnification

During detail magnification, the TNC displays the

coordinates of the axis that is currently being

moved.

The coordinates describe the area determined for

magnification. To the left of the slash is the

smallest coordinate of the detail in the current axis,

to the right is the largest.

Fig. 1.24: The coordinates of the cursor position are

displayed to the lower left of the graphic

3D view

Here the workpiece is displayed in three

dimensions, and can be rotated about the vertical

axis.

The shape of the workpiece blank can be depicted

by a frame overlay at the beginning of the graphic

simulation.

In the TEST RUN mode of operation you can isolate

details for magnification.

Fig. 1.25: 3D view

TNC 426/TNC 425/TNC 415 B/TNC 407 1-23

Page 42

1 Introduction

1.4 Graphics and Status Displays

To rotate the 3D view:

or

Shift the soft-key row.

Rotate the workpiece in 27° steps about the vertical axis.

or

The current angular attitude of the display is

indicated at the lower left of the graphic.

To switch the frame overlay display on/off:

or

Show or omit the frame overlay of the workpiece blank form.

Fig. 1.26: Rotated 3D view

TNC 426/TNC 425/TNC 415 B/TNC 4071-24

Page 43

1 Introduction

1.4 Graphics and Status Displays

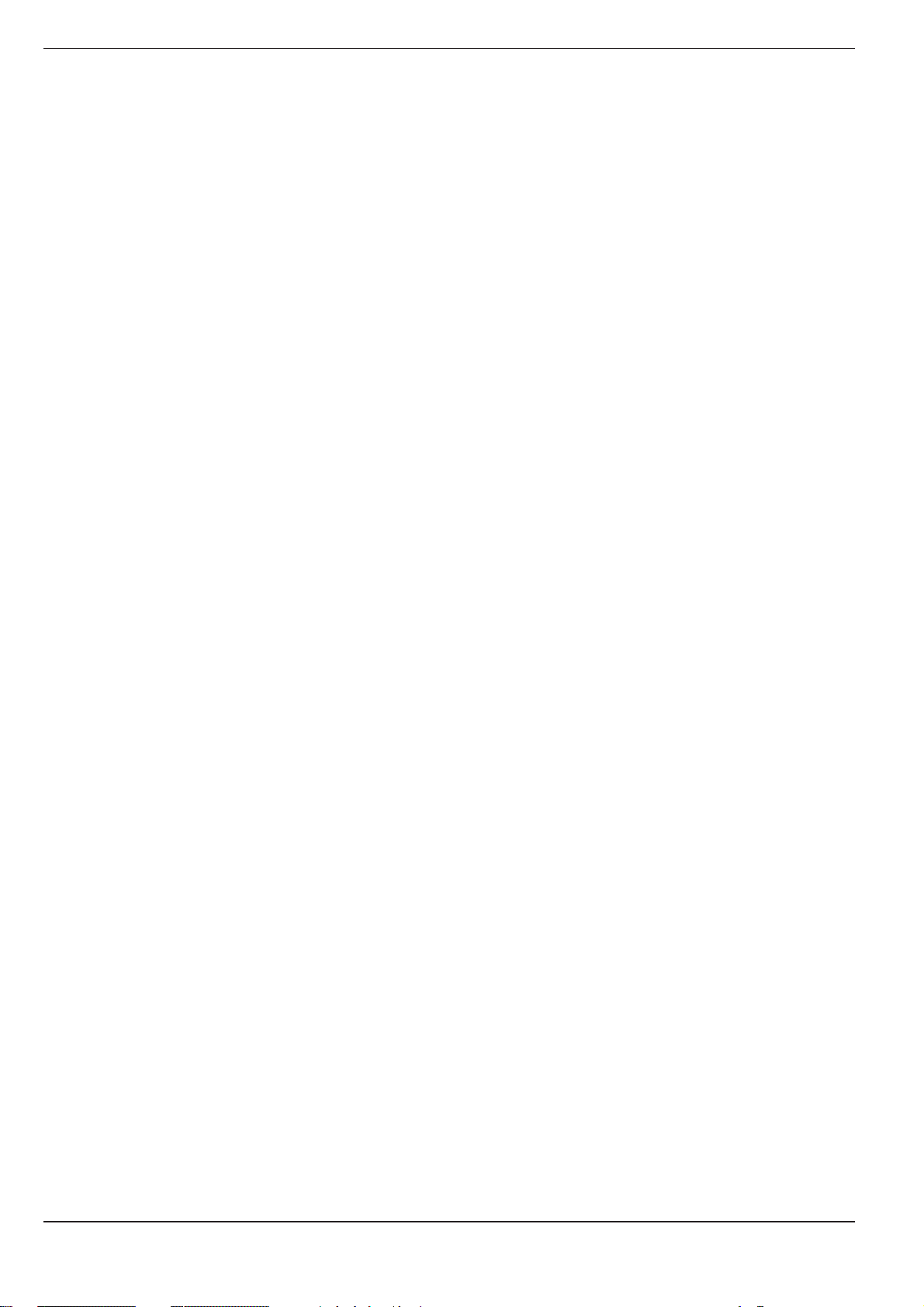

Magnifying details

You can magnify details in the TEST RUN mode of

operation in the following display modes:

• projection in three planes

• 3D view

provided that the graphic simulation is stopped. A

detail magnification is always effective in all three

display modes.

To select detail magnification:

Fig. 1.27: Magnifying a detail of a projection in three planes

or

Shift the soft-key row.

Select the left/right workpiece surface.

Select the front/back workpiece surface.

Select the top/bottom workpiece surface.

or

Shift sectional plane to reduce/magnify the blank form.

If desired

Select the isolated detail.

Restart the test run or program run.

If a graphic display is magnified, this is indicated with MAGN at the lower

right of the graphics window. If the detail is not magnified with TRANSFER

DETAIL, you can make a test run of the shifted sectional planes.

If the workpiece blank cannot be further enlarged or reduced, the TNC displays an error message in the graphics

window. The error message disappears when the workpiece blank is enlarged or reduced.

TNC 426/TNC 425/TNC 415 B/TNC 407 1-25

Page 44

1 Introduction

1.4 Graphics and Status Displays

Repeating graphic simulation

A part program can be graphically simulated as often as desired, either

with the complete workpiece blank or with a detail of it.

Function Soft key

Restore workpiece blank as it was last shown

Show the complete BLK FORM as it appeared

before a detail was magnified via TRANSFER

DETAIL

The WINDOW BLK FORM soft key will return the blank form to its original shape and size, even if a detail has

been isolated and not yet magnified with TRANSFER DETAIL.

Measuring the machining time

At the lower right of the graphics window the TNC

shows the calculated machining time in

hours : minutes : seconds

(maximum 99 : 59 : 59)

• Program run:

The clock counts and displays the time from

program start to program end. The clock stops

whenever machining is interrupted.

• Test run:

The clock shows the time which the TNC

calculates for the duration of tool movements.

To activate the stopwatch function:

or

Fig. 1.28: The calculated machining time is shown at the

lower right of the workpiece graphic

Press the shift keys until the soft-key row with the stopwatch

functions appears.

The soft keys available to the left of the stopwatch function depend on the selected display mode.

TNC 426/TNC 425/TNC 415 B/TNC 4071-26

Page 45

1 Introduction

1.4 Graphics and Status Displays

Stopwatch functions Soft key

Store displayed time

Show the sum of the stored time and

the displayed time

Clear displayed time

Status displays

During a program run mode of operation the status

display contains the current coordinates and the

following information:

• Type of position display (ACTL, NOML, ...)

• Number of the current tool T

• Tool axis

• Spindle speed S

• Feed rate F

• Active M functions

• “Control in operation” symbol: ❊

• “Axis is locked” symbol:

• Axis can be moved with the handwheel:

• Axes are moving in a tilted working plane:

• Axes are moving under a basic rotation:

Fig. 1.29: Status display in a program run mode of operation

Additional status displays

The additional status displays contain further information on the program

run.

To select additional status displays:

or

Set the STATUS soft key to ON.

Shift the soft-key row.

TNC 426/TNC 425/TNC 415 B/TNC 407 1-27