Page 1

Operating Instructions

IK 5000

QUADRA-CHEK

(QC 5000)

Video Edge Detection Systems

English (en)

2/2010

Page 2

Page 3

Video Edge Detection Systems

QC5200, QC5210, QC5230 and QC5240

Page 4

QC5200 Series User’s Guide

Video edge detection systems: QC5200, QC5210, QC5230, and QC5240

Printed in the United States of America

All information set forth in this document, all rights to such information, any and all inventions disclosed

herein and any patents that might be granted by employing the materials, methods, techniques or apparatus

described herein are the exclusive property of Metronics Inc., Bedford, New Hampshire.

Terms, conditions and features referenced in this document are subject to change without notice

No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by

any means, electronic, mechanical, photocopying, recording, or otherwise, without prior written permis-

sion of Metronics, Inc.. Requests to Metronics, Inc. for permission should be addressed to the Technical

Services Department, Metronics, Inc., 30 Harvey Road, Bedford, New Hampshire 03110. The Technical

Services Department can be reached by phone at (603)-622.0212.

Limit of liability and disclaimer of warranty

While Metronics, Inc. exercised great care in the preparation of this book, Metronics makes no representa-

tions or warranties with respect to the accuracy or completeness of the contents of this book and specifi-

cally disclaims any implied warranties of merchantability or fitness for a particular purpose. The advice,

methods and instructions contained in this book might not be suitable for your situation. When in doubt

regarding suitability, you are encouraged to consult with a professional where appropriate. Metronics

shall not be liable for any loss of profit or any damages, including but not limited to special, incidental,

consequential or other damages.

Trademarks

Metronics is a registered trademark of Metronics, Inc. and its subsidiaries in the United States and other

countries and may not be used without written permission. Other trademarks are the property of their

respective owners.

Metronics part number: 11A10558

Publishing date: June, 2005

Page 5

This User Guide describes the operation of the video edge series of QC5200 metrology products. This series

of QC5200 instruments conducts a wide variety of precise 2-D measurements using a wide assortment of

video edge detection probes. The QC5200 software supports manual part positioning and feature measure-

ment under user control, and CNC part positioning and automated measurement under program control.

While it is likely that this Guide includes some material that doesn’t apply to your specific QC5200 system,

information pertaining to your system will be easy to find using the Table of Contents and Index.

Who should read this Guide?

This Guide is necessary for the efficient operation of the QC5200 system. Operators and supervisors will

find the contents invaluable in conducting measurements, programming automatic functions and reporting

results. User setup functions are also described that will help users and supervisors customize the QC5200

measurement tools, user interface screens and report formats.

Operators and supervisors are assumed to have a good basic understanding of dimensional metrology

theory and practice, and a good understanding of Microsoft Windows use and conventions.

The conventions used to call attention to notes, cautions and warnings, and the shorthand used to show

menu navigation paths are described below:

This guide uses the following icons to highlight

note, warning and caution

information:

NOTE

The note icon indicates additional or supplementary information about an activity or

concept. Notes are sh

own in bold type.

Page 6

CAUTION

The exclamation point icon indicates a situation or condition that can lead to

equipment malfunction or da

mage. Do not proceed until the caution message is read

and thoroughly understood. Caution messages are shown in bold type.

WARNING

The raised hand icon warns of a situation or condition that can lead to serious

equipment damage, personal injury or death. Do not proceed until the warning is

read and thoroughly understood. Warning messages are shown in bold type.

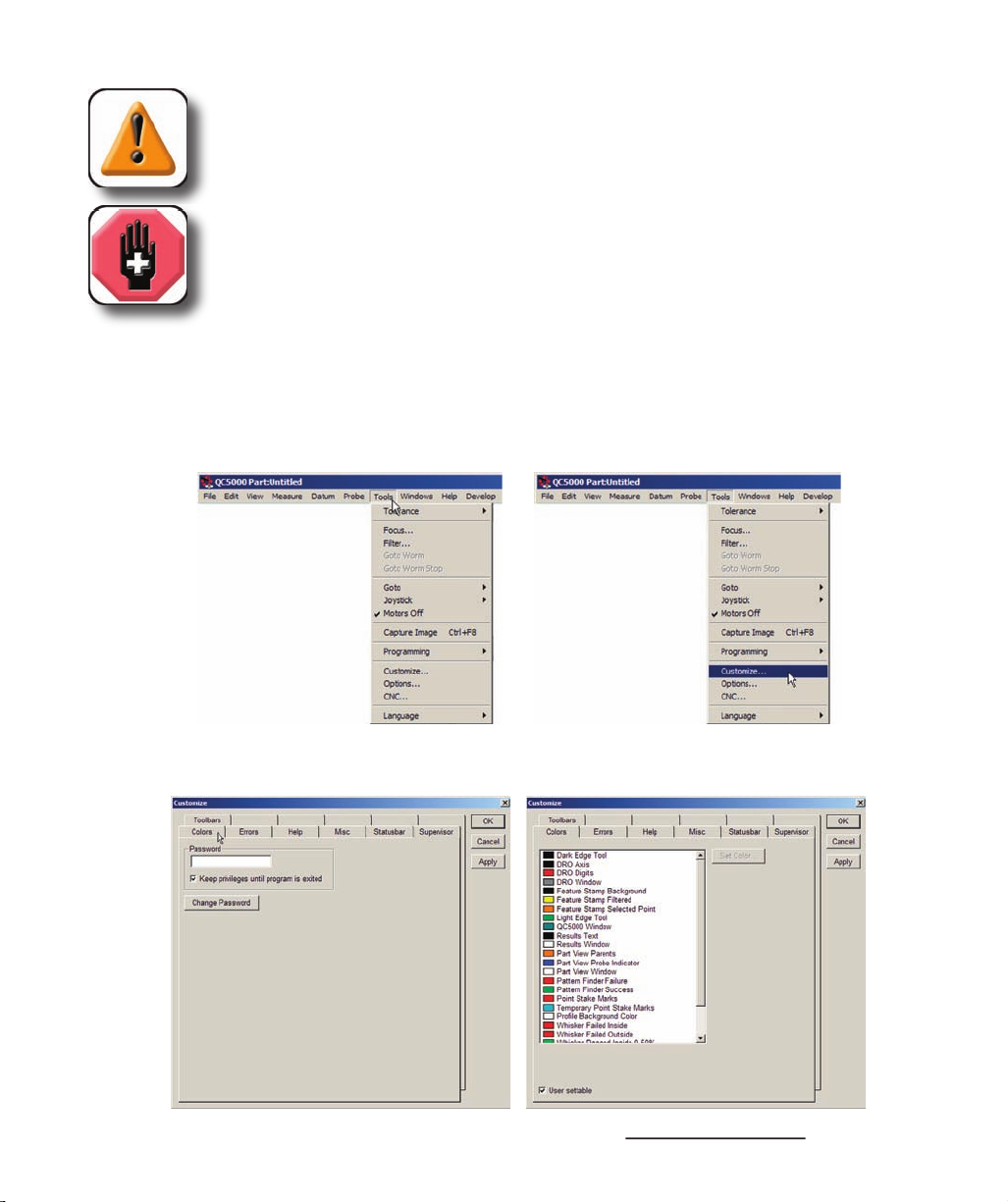

Throughout the Guide, many references are made to screens that must be displayed by clicking the mouse

cursor on a series of menu items and screen tabs. This kind of navigation path is demonstrated in this

example of displaying the

screen, shown in text as: Tools/Customize/Colors.

then clicking the Colors tab...

then clicking the Customize menu item...

displays the

screen

Page 7

Introduction

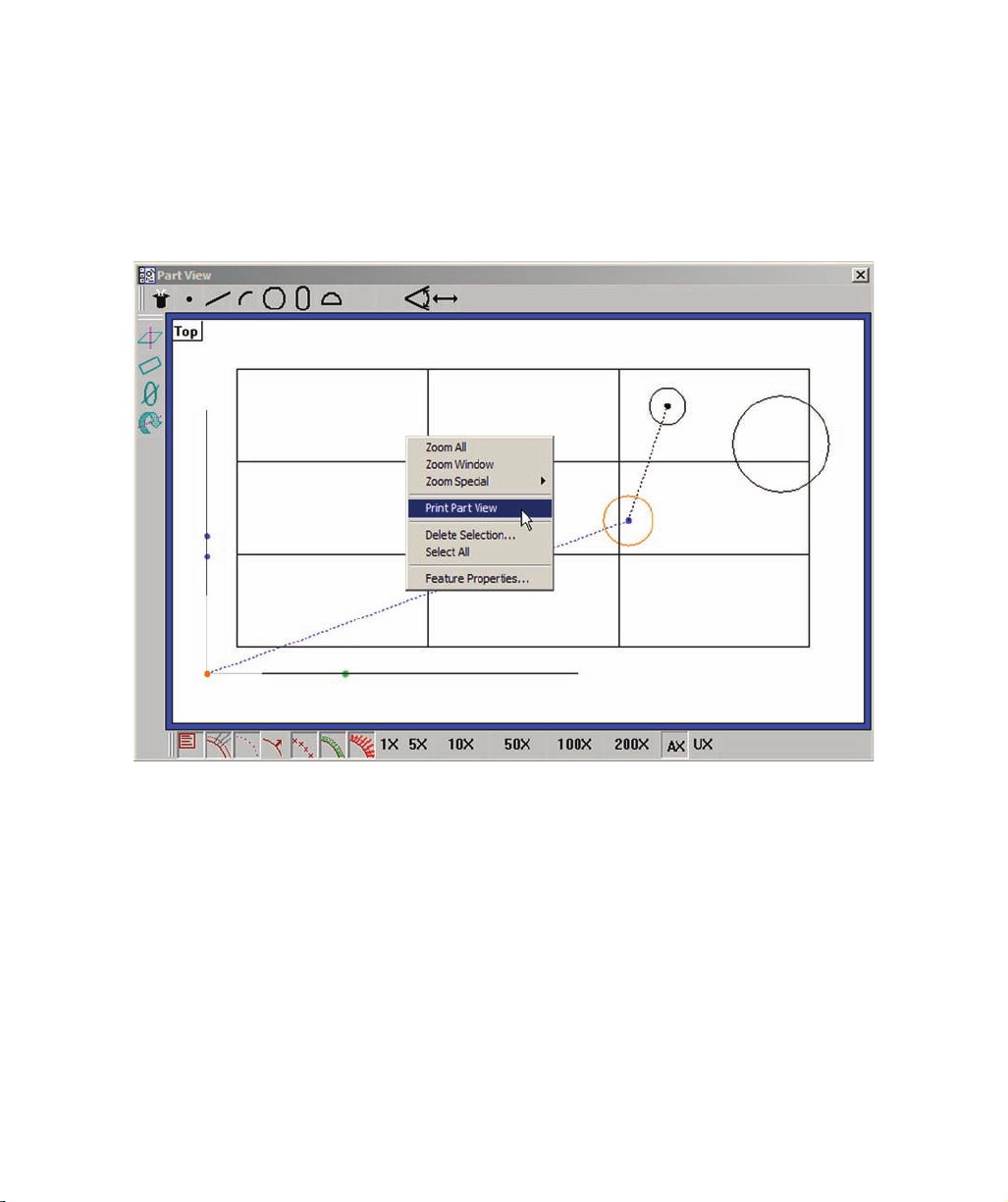

Many commands are displayed by right-clicking the mouse cursor in a window, and then on one or a

series of menu items. This kind of command path is demonstrated in this example of using the Part View

window/Print Part View command to print the part view. The command is shown in text as: Part View

window/Print Part View.

Right-clicking the Part View window, then clicking Print Part View

prints the current part view

Page 8

This Guide contains eleven chapters and three reference appendices. An overview of the contents is pro-

vided below. Experienced users are encouraged to familiarize themselves with the first six chapters before

beginning to use the QC5200. Users that are new to the QC5200 and similar Metronics products should

read the first six chapters carefully and then follow the tutorial in

Chapter 3:

Chapter 3:

Quick Start Demonstartion

Quick Start Demonstartion

before beginning.

Brief introduction to the QC5200 series features and benefits

Comprehensive description of the user interface covering screens, menus, toolbars the statusbar and work-

spaces.

Brief demonstration of using the basic functions of the QC5200 including:

• Organizing the workspace

• Selecting and teaching the probe

• Recording measurement activities as a program

• Measuring & constructing datums

• Measuring features

• Applying tolerances

• Exporting data

• Reporting

• Saving the part and program

Probes

Instructions for calibrating and using video edge detection measurement probes

Instructions for constructing datums and measuring, constructing and creating features.

Instructions for applying tolerances to measurements.

Instructions for organizing, formatting, exporting and printing measurement results.

Descriptions of programming functions and instructions for creating, editing, and debugging programs.

Page 9

Introduction

v

Instructions for calibrating and configuring axis encoders.

Descriptions of setup tools and screens used to configure and customize measurement, programming and

display parameters

Basic troubleshooting guide in the form of a simple table of symptoms, probable causes and recommended

solutions.

Appendi

Appendi

x B:

ASCII Codes

Appendi

x C:

Index

Page 10

vi

The QC5200 is inherently safe, and in proper use few if any potential safety hazards exist. However, many

systems include motorized CNC stages that, as is the case with all motorized equipment, must be treated

with caution to avoid collision and pinch injuries. Also, an entire system often consists of electrical equip-

ment connected by many cables, which must be treated with care to avoid shock and tripping injuries.

Be prepared to depress the emergency off mushroom switch or other similar device

quickly in the event of an emergency when motor axes are active.

on or create a tripping hazard.

The system components are equipped with 3-wire power plugs that include a separate ground

connection, or are grounded through a separate wire. Always connect the power plug to a 3-wire

grounded outlet. The use of 2-wire power plug adapters or any other connection accessories that

remove the third grounded connection create a safety hazard and should not be permitted. If a

3-wire grounded outlet is not available, ask your electrician to provide one. Never disconnect any

separate ground wire.

Do not open the QC5200 enclosure. There are no user-serviceable components or assemblies

inside.

General safety precautions must be followed when configuring, maintaining or operating the system.

Failure to observe these precautions could result in damage to the equipment, or injury to personnel.

It is understood that safety rules within individual companies vary. If a conflict exists between the material

contained in this guide and the rules of a company using this system, the more stringent rules should take

precedence.

Additional safety information is included throughout the remainder of this guide.

WARNINGS - AXIS MOTION

Always stay clear of axis motion paths.

Disconnect axis motor power when motor activities are not required.

WARNINGS - ELECTRICAL

Disconnect the system components from electrical sources before cleaning or

servicing.

Do not allow any power cord or signal cable to be located such that it can be walked

Page 11

Introduction

vii

Disconnect the QC5200 from the power source and seek the assistance of a qualified service

technician if:

• The power cord is frayed or damaged or the power plug is damaged

• Liquid is spilled or splashed onto the enclosure

• The QC5200 has been dropped or the exterior enclosure has been damaged

• The QC5200 exhibits degraded performance or indicates a need for service some other way

Use only a cloth dampened with water and a mild detergent for cleaning the exterior surfaces and display

screens. Never use abrasive cleaners, and never use strong detergents or solvents. Only dampen the cloth,

do not use a cleaning cloth that is dripping wet.

Display resolutions in this guide are examples. User display resolutions are likely to vary according to the

specific application. Metric units of measure are used in examples.

Accuracy & Precision

Measurement accuracy is determined by many factors, such as the resolution of the encoders connected to

axis inputs. Generally, the display resolution of the QC5200 can exceed encoder resolutions. Setting the

display resolution to exceed the encoder resolution does not increase measurement accuracy.

Help is available in this printed Guide, in the electronic version of this Guide accessed from the Help

menu of the QC5200 software, from your Metronics distributor or system provider and directly from

Metronics.

The information contained in this guide should be adequate to customize the measurement, display and

programming aspects of system, and to perform the minimal setup and troubleshooting required beyond

the services provided by your Metronics distributor or system provider. However, in the event that your

Metronics distributor or system provider cannot provide the assistance you need, our support staff is com-

mitted to insuring your positive experience with the QC5200 series of products. To receive technical

support:

Routine issues

e-mail our support staff at: techsupport@metronics.com

Page 12

viii

Telephone your Metronics distributor, or telephone our support staff at: (603) 622.0212

• A description of the equipment attached to the QC5200 computer, including the

manufacturer and model number

• The QC5200 software version number, found on the Help/About QC5000

menu screen

The most recent version of the QC5200 software can be downloaded from the

Product Support

Product Support

section of

our web site at:

http://www.metronics.com

Please carefully read all the instructions and cautions published on our site regarding your software update

before attempting to perform the update.

Additional publications for the QC5200

Additional application or instructional information is sometimes available for download from the Product

http://www.metronics.com

NOTE

If it becomes necessary to contact us directly, be prepared to supply the following

information:

• The QC5200 series serial number

(5-Digit number printed on back label)

Page 13

w

Overview of system features

............................................................................

Introduction

......................................................................................................

7

Windows

...................................................................................................

8

DRO

...................................................................................................

8

Templates

..........................................................................................

8

Results

...............................................................................................

8

Part View

...........................................................................................

8

Live Video

.........................................................................................

8

Menus

.......................................................................................................

9

Toolbars

....................................................................................................

9

...................................................................................................

0

Windows

..........................................................................................................

DRO window

............................................................................................

Part View window

....................................................................................

2

Adding feature data

...........................................................................

3

Live Video window

..................................................................................

5

Results window

.........................................................................................

7

Template Windows

...................................................................................

8

separating templates

.....................................................

8

Adding and

deleting

template content

...............................................

9

Features template

..............................................................................

0

Program template

..............................................................................

2

0

Report template

.................................................................................

0

Tolerance templates

...........................................................................

2

Menus

...............................................................................................................

2

2

Menubar menus

........................................................................................

File menu

...........................................................................................

2

3

Edit menu

...........................................................................................

5

View menu

.........................................................................................

2

9

Measure menu

...................................................................................

3

5

Datum menu

3

5

Probe menu

........................................................................................

3

5

Page 14

Tools menu

........................................................................................

3

6

Windows menu

..................................................................................

3

9

On-screen

menus

Template window menus

...................................................................

4

Template edit menus

..................................

Program edit menus

4

4

Results window menus

...............................................................

6

Part View window menus

..........................................................

5

0

Toolbar menus

............................................................................

5

3

Toolbars

...........................................................................................................

5

5

Changing

toolbar shape

............................................................................

5

6

Docking and

undocking toolbars

..............................................................

5

6

Customizing and

creating toolbars

...........................................................

5

7

...........................................................................................................

5

8

Workspaces

......................................................................................................

5

9

Creating

custom workspaces

....................................................................

5

9

.......................................................................

6

0

Opening custom workspaces

....................................................................

6

0

Demonstration steps

.........................................................................................

6

Organizing the

workspace

................................................................................

6

5

..........................................................................................

6

5

T

eaching the

video

probe

.................................................................................

6

6

Turning

program

recording ON

.......................................................................

6

6

Measuring

part

skew and

datum

...............................................................

6

7

..................................................................................................

6

7

Datum

................................................................................................

6

7

Measuring

features

....................................................................................

6

9

Applying

feature

tolerances

......................................................................

7

0

Adding

data to the

Runs template

.............................................................

7

Exporting data

...........................................................................................

7

Printing

reports

.........................................................................................

7

3

Turning program recording OFF

.....................................................................

7

3

.................................................................................................

7

4

Running the program

.......................................................................................

7

4

4 Probes

Preparing to

use video probes

..........................................................................

7

7

part condition

........................................................................

7

7

video

magnification

..................................................................

7

7

Page 15

Adjusting

light control

..............................................................................

7

7

Associating

lighting with magnifications

.................................................

7

7

Enabling and

disabling light associations

.................................................

7

8

Using video probes

..........................................................................................

7

8

probe type

...............................................................................

7

9

Changing

probe

position

...........................................................................

7

9

Changing

probe

orientation

......................................................................

7

9

Changing

probe

size

.................................................................................

8

0

Changing

scan

direction

...........................................................................

8

0

Changing

edge detection order

.................................................................

8

Enabling and disabling

high accuracy scanning

.......................................

8

2

Firing video probes

...................................................................................

8

3

Dry firing probes

...............................................................................

8

3

Continuous probe firing

.....................................................................

8

3

Loading a

video

chart

...............................................................................

8

4

Video

probe descriptions

.................................................................................

8

5

Crosshair probe

.........................................................................................

8

6

.............................................................................................

8

7

Buffer Probe

..............................................................................................

8

9

Average probe

...........................................................................................

9

Nearest probe

............................................................................................

9

3

Farthest probe

...........................................................................................

9

4

Height probe

.............................................................................................

9

5

Width Probe

..............................................................................................

9

7

Circle Probe

..............................................................................................

9

8

Circles

................................................................................................

9

8

Arcs

....................................................................................................

9

9

Blob Probe

................................................................................................

Worm probe

..............................................................................................

2

New probe

.................................................................................................

5

Pattern Finder probe

.................................................................................

8

Initial setup of the video probe system

............................................................

Adding

magnifications with associated

zooms

.........................................

6

Adding magnifications to the

Probe toolbar

......................................

7

Adding the

highest magnification to the

probe library

......................

8

Adding other magnifications and

associating

Zoom positions

.........

9

Deleting

magnifications

............................................................................

0

Configuring the

highest

magnification

.....................................................

Configuring the

lower

magnifications

......................................................

Calibrating

auto

focus

...............................................................................

2

Calibrating

video

edge recognition (

Teach)

.............................................

Advanced

Edge

Teach

......................................................................

6

Page 16

Calibrating

pixel

resolution

......................................................................

7

Calibrating

offset

......................................................................................

9

Compensating for

camera

skew

................................................................

Configuring

video

probe

data collection parameters

................................

5

Measurement activities

....................................................................................

8

The

measurement workspace

...........................................................................

8

The

measurement process

................................................................................

8

Preparing to use video probes

...................................................................

9

Establishing the

measurement

reference

..................................................

9

Leveling the part (optional)

......................................................................

9

Creating a

skew

alignment

........................................................................

0

Creating a

datum

zero point

......................................................................

Probing a datum zero point

................................................................

Constructing a datum zero point

........................................................

Probing and

measuring features

................................................................

4

Measure Magic

.........................................................................................

4

Probing features

...............................................................................................

Probing specific feature types

...................................................................

6

Points

.................................................................................................

6

Lines

..................................................................................................

7

Arcs

....................................................................................................

8

Circles

................................................................................................

9

...................................................................................................

Distances

............................................................................................

2

Angles

................................................................................................

3

Blobs

..................................................................................................

5

Profile measurements

........................................................................

6

Constructing features

.......................................................................................

Point constructions

....................................................................................

3

Line constructions

.....................................................................................

8

Distance constructions

..............................................................................

5

Circle

constructions

..................................................................................

Arc constructions

......................................................................................

4

Creating features

..............................................................................................

6

Creating a point

.........................................................................................

7

Creating a line

...........................................................................................

7

Creating a distance

....................................................................................

8

Creating a circle

........................................................................................

8

Creating an arc

..........................................................................................

9

Page 17

Applying tolerances to features

.......................................................................

20

3

Tolerance screens

......................................................................................

20

3

Tolerance menu

........................................................................................

20

4

Tolerance toolbar

......................................................................................

20

Display of

tolerance results

......................................................................

20

5

Naming and saving tolerances

..................................................................

20

6

Deleting

Named Tolerances

.....................................................................

20

6

Tolerance types

................................................................................................

20

7

Bidirectional

.............................................................................................

20

7

True position

.............................................................................................

20

8

MMC/LMC (Material condition)

.............................................................

20

9

Runout

.......................................................................................................

21

0

Circularity

.................................................................................................

...............................................................................................

21

Concentricity

.............................................................................................

Profile

.......................................................................................................

21

2

Parallelism

................................................................................................

3

Perpendicularity

........................................................................................

3

Angularity

.................................................................................................

21

3

Angle

.........................................................................................................

Width

........................................................................................................

21

4

Template descriptions

......................................................................................

7

Features template

......................................................................................

21

7

Program template

......................................................................................

8

Runs template

...........................................................................................

9

Runs charts

................................................................................................

22

0

Report template

.........................................................................................

Tolerance templates

..................................................................................

22

3

Opening templates

...........................................................................................

Generating new default templates

....................................................................

22

4

Editing templates

.............................................................................................

5

Adding and

deleting data

..........................................................................

22

5

Adding data

.......................................................................................

5

Adding multiple data fields as a single new column

.........................

6

A

dding multiple data fields as multiple new columns

......................

22

7

Appending data fields to an existing column

....................................

8

Deleting data

......................................................................................

22

9

Deleting

rows

............................................................................................

9

Page 18

Deleting

columns

......................................................................................

23

0

....................................................................

23

0

Aligning column titles and data

................................................................

23

Changing the

order of columns

.................................................................

23

Displaying

horizontal and

vertical

grid line

.............................................

23

Headers and

footers

..........................................................................................

23

2

...........................................................................

23

Editing headers and footers

..............................................................................

23

3

Adding text

...............................................................................................

23

3

Editing text

................................................................................................

23

3

Formatting

text

..........................................................................................

23

4

Including

automatic

text entry

..................................................................

23

5

Prompting the user for alphanumeric information

....................................

23

5

Deleting text

..............................................................................................

23

6

Enabling

text to

speech output

..................................................................

23

6

Adding

graphics from files

.......................................................................

23

6

Drawing

graphics

......................................................................................

23

8

Printing

reports

.................................................................................................

24

Exporting data

..................................................................................................

DDE Output

.....................................................................................................

24

3

Output parameters

.....................................................................................

3

Connection

................................................................................................

24

3

Data

...........................................................................................................

General guidelines

....................................................................................

24

4

8 Programming

Introduction

......................................................................................................

24

9

Creating Programs

...........................................................................................

25

0

Creating the new part

................................................................................

25

program

recording

.......................................................................

25

Performing a

skew and

datum

..................................................................

25

Choosing a

measurement

programming method

......................................

25

Adding tolerances

.....................................................................................

25

4

Reporting results

.......................................................................................

25

Optimizing program steps

.........................................................................

25

4

Adding

special steps to a program

............................................................

25

5

Finalizing

feature properties

.....................................................................

25

7

Finalizing

program properties

...................................................................

25

8

program

recording

.....................................................................

26

..........................................................................................

26

Page 19

Editing Programs

.............................................................................................

26

Part fixturing

.............................................................................................

26

2

Program runtime environment

..................................................................

26

Palletizing multiple parts

..........................................................................

26

2

Editing

initial

program settings

................................................................

26

5

Probe

position indicator

............................................................................

26

6

Template state

...........................................................................................

26

6

Light controls

............................................................................................

26

7

Optical

magnification

...............................................................................

26

7

Probe selection

..........................................................................................

26

7

High accuracy mode

.................................................................................

26

8

Focus lock

.................................................................................................

26

8

Units of measure

.......................................................................................

26

8

Editing

feature properties

.........................................................................

26

9

Hiding features

..........................................................................................

26

9

Displaying

phantom features

....................................................................

26

9

Displaying

guide features

.........................................................................

26

9

note with a feature

..................................................................

27

0

feature name

........................................................................

27

0

Editing

feature

point

filtration

..................................................................

27

0

filtration

error limit

..............................................................

27

filtration

standard deviation range

.......................................

27

Adding

special and CNC program steps

..........................................................

27

Comment

...................................................................................................

27

2

Delay

.........................................................................................................

27

3

Play

sound

.................................................................................................

27

3

Program

image

..........................................................................................

27

4

User message

............................................................................................

27

Enabling or

disabling

run time

graphic displays

......................................

27

5

Enabling or

disabling

full

CNC mode

......................................................

27

5

Enabling or

disabling

power assist mode

.................................................

27

6

Enabling or

disabling

focus lock

..............................................................

27

6

output lines

...................................................................................

27

7

program

steps

...................................................................................

27

8

.........................................................................

27

8

..........................................................................

27

8

Clearing

step selections

............................................................................

28

Editing individual steps

....................................................................................

28

2

Changing the

target position for

probing

..................................................

28

Changing

parents of

construction features

...............................................

28

3

Requiring

user interaction to

complete a measurement

............................

28

Optimizing program steps

.........................................................................

28

5

Page 20

Cutting,

copying,

pasting and

deleting program steps

..............................

28

5

Cutting steps

......................................................................................

28

5

Copying steps

....................................................................................

28

5

Pasting steps

......................................................................................

28

5

Deleting steps

....................................................................................

8

5

Inserting new program steps

.....................................................................

28

6

Debugging programs

........................................................................................

28

7

9 Encoders

TTL encoders

...................................................................................................

28

9

Analog encoders

...............................................................................................

29

0

Joystick setup and

limiting

maximum

axis velocity

........................................

29

0

Axis velocity

.............................................................................................

29

Curvature joystick parameter

....................................................................

29

Axis displacement

.....................................................................................

29

Counter setup

...................................................................................................

29

Limit Switch setup

...........................................................................................

29

2

Calibrating

analog

encoders

.............................................................................

29

3

QC5200

encoder setup

.....................................................................................

29

6

encoder

resolution

..................................................................

29

6

encoder

unit of measure

.........................................................

29

6

encoder

count direction

..........................................................

29

6

encoder

reference marks

.........................................................

29

6

r

eference offsets

.....................................................................

29

7

Tools/Customize menu item screens

...............................................................

29

9

Including a

startup message

......................................................................

30

0

Customizing

colors

...................................................................................

30

on-screen

help tips

..................................................................

30

5

error messages

........................................................................

30

6

status bar information

.............................................................

30

8

Customizing

toolbars

................................................................................

30

9

Tools/Options menu item screens

....................................................................

3

programming parameters

.........................................................

31

4

maximum program executions

.........................................

31

7

Restricting

access to setup screens

...........................................................

31

8

Configuring

measurement parameters

......................................................

32

0

Displaying

parts and

probe position

.........................................................

32

Configuring

joystick and

footswitch buttons

............................................

32

7

display of

resolution,

time and

date

........................................

33

0

Page 21

encoder parameters

.................................................................

33

file names, locations and backups

..........................................

33

2

serial port,

machine zero and

general parameters

........................

33

7

video

probes

.......................................................................

34

0

Tools/CNC menu item screens

.......................................................................

350

joystick

..............................................................................

35

0

QC5200

settings or

appearance have changed. Everything looked

okay the last time you were on the system, now it’s different

....................

35

5

A QC5200

Window is missing from the screen, but is enabled

in the

QC5200 Windows menu

..................................................................

35

5

Measurements are inaccurate or inconsistent

..................................................

35

5

axis

counts in the

wrong direction

.............................................................

35

6

Cannot drag data fields from the Results window into a template

..................

35

7

Changes

to the QC5200 settings, window positions, etc.

are not saved

..........

35

7

The

QC5200 program doesn’t launch, but other Windows programs do

........

35

8

Cannot print from the QC5200 program

..........................................................

35

9

default

template contains

unwanted data or formatting

...............................

36

0

Cannot make changes to the QC5200 settings

.................................................

36

The system seems slow

....................................................................................

36

Cannot see image in the live video window

....................................................

36

3

The auto focus does not work properly

............................................................

36

The measurements finish before I’m ready

.....................................................

36

5

Cannot find captured images

...........................................................................

36

5

Appendix A Import File Formats

Appendix B ASCII Codes

Appendix C Tolerances

Concentricity toleranc

e

Reference Feature

s

Reference feature called for in

MMC or

LMC circle toleranc

e

Projected zon

e

Page 22

Page 23

1 System Overview

The Metronics QC5200 series of metrology instruments is a family of Windows PC-based products for

conducting precision dimensional measurements on 2-D parts. Systems can be supplied with video sys-

tems and measuring microscopes. Systems support manual part positioning and feature measurement

under user control, or CNC part positioning and automated measurement under program control.

All QC5200 systems consist of a Windows-based user interface and a dedicated Metronics

axis

PC card.

All axis cards include input circuitry for reading the axis position. Axis cards in systems capable of CNC

axis motion control also include circuitry for driving

CNC stepper motor or

CNC servo motor amplifiers.

All systems measure

2-D part features in the X–Y plane. Additionally, systems can include a Z-axis input

for height measurements and part leveling and a Q-axis for rotational measurements.

Basic QC5200 for video systems or microscopes with

joystick part positioning

Page 24

Part

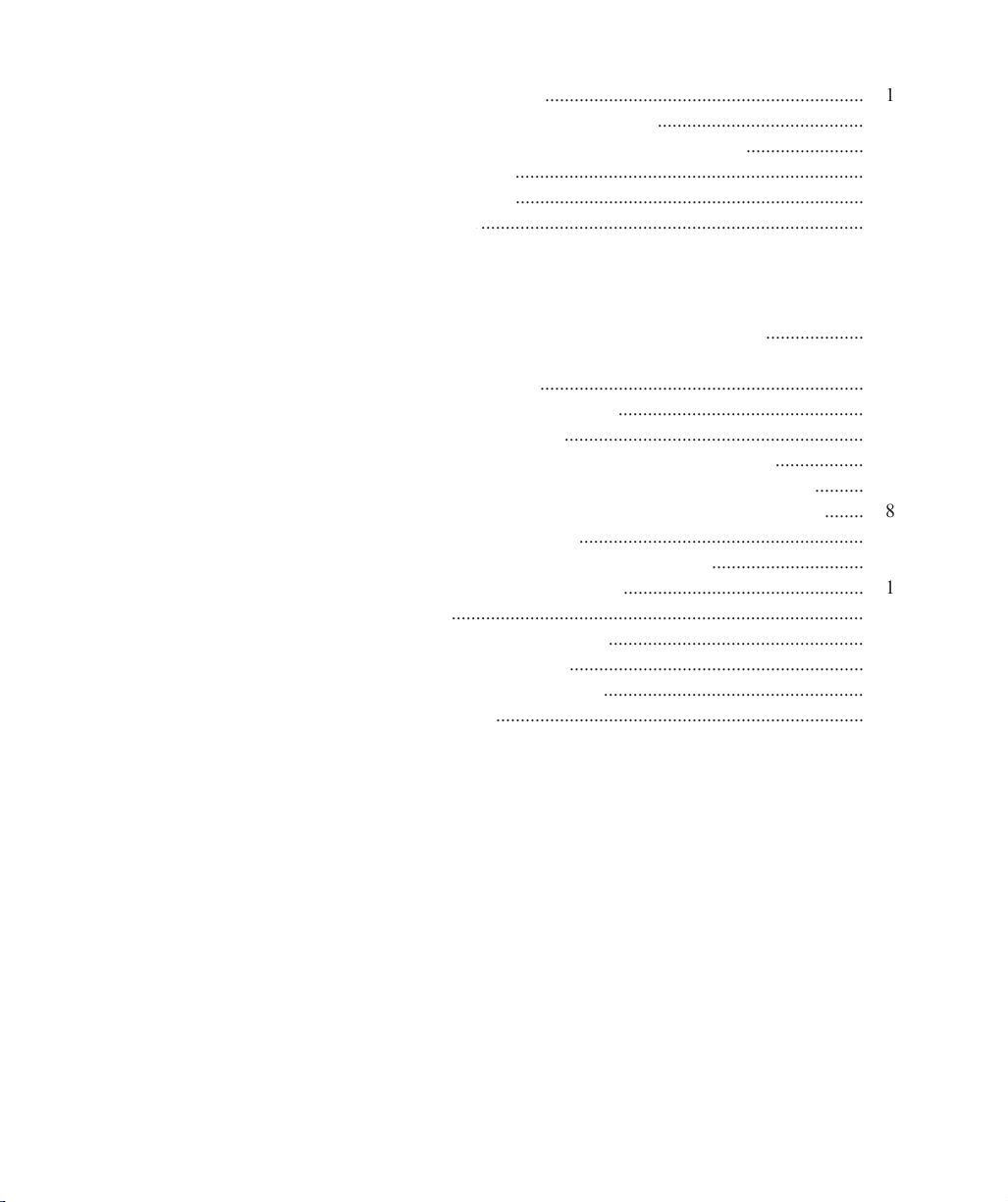

features can be measured, constructed from measured features, created from user data, copied from

existing features or imported from .dxf, .igs and other files.

Geometric

tolerances include location,

form, orientation, runout and size. In

addition, tolerances can be applied to

groups of selected features.

Tolerances are context sensitive. For

example, straightness is provided for

lines and circularity is provided for

circles. Tolerances can be displayed

for evaluation and the tolerance criteria

can be edited with a few clicks of the

mouse, as shown in this example of a

form tolerance.

Measured feature

Measured feature

Page 25

1 System Overview

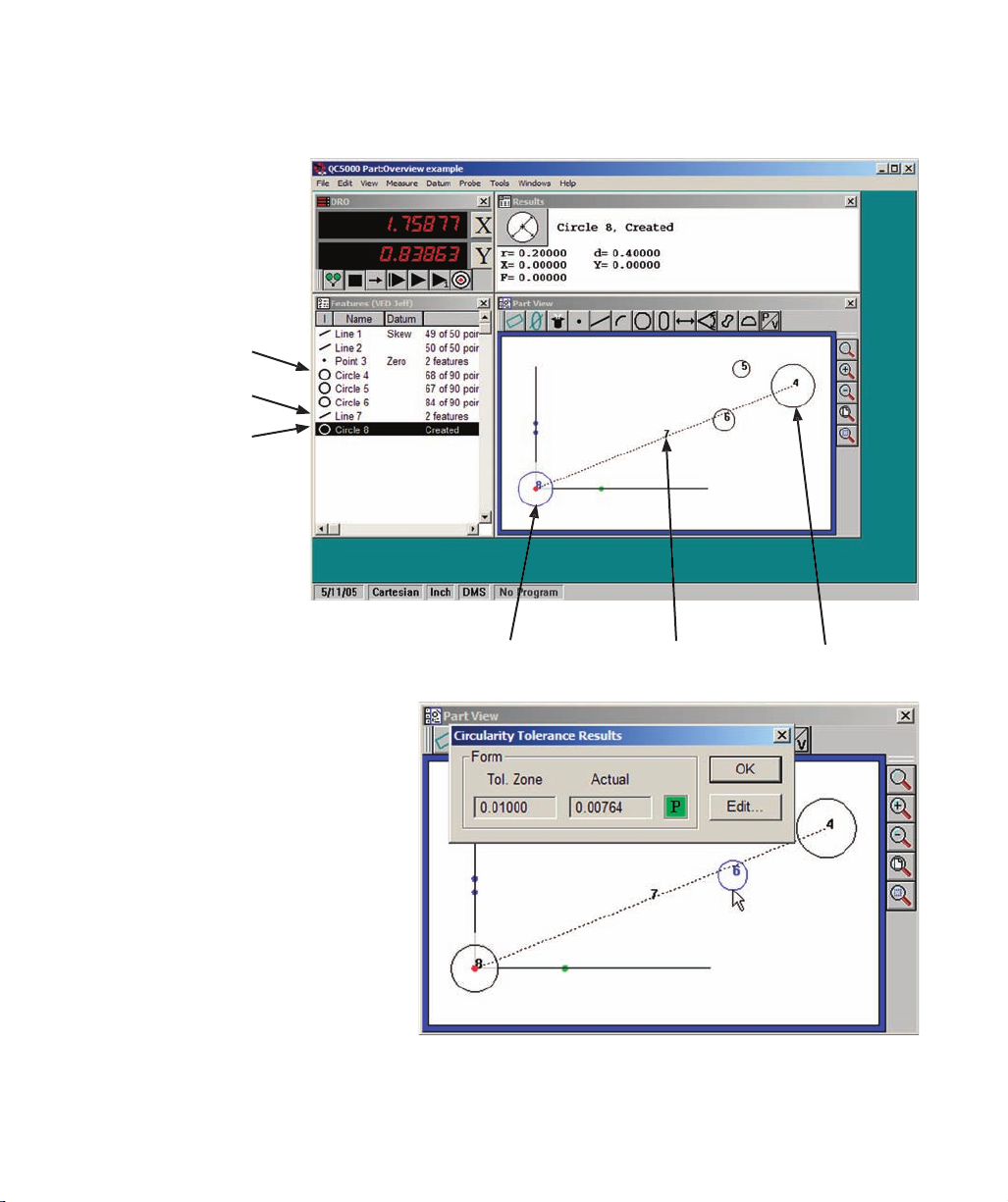

Programs can be created in manual sys-

tems to semi-automate repetitive tasks

and simplify operator interactions, or

in systems that include

CNC control

to automate measurements eliminat-

ing measurement errors and increasing

throughput. Programs can be recorded

automatically as a series of measure-

ments are performed, can be created

to include conditional branching and

messages, can be edited in static or

single-step modes and can be created

from imported

CAD files. The task of

programming is simplified by

programming wizards and a comprehensive program debugging environ-

ment.

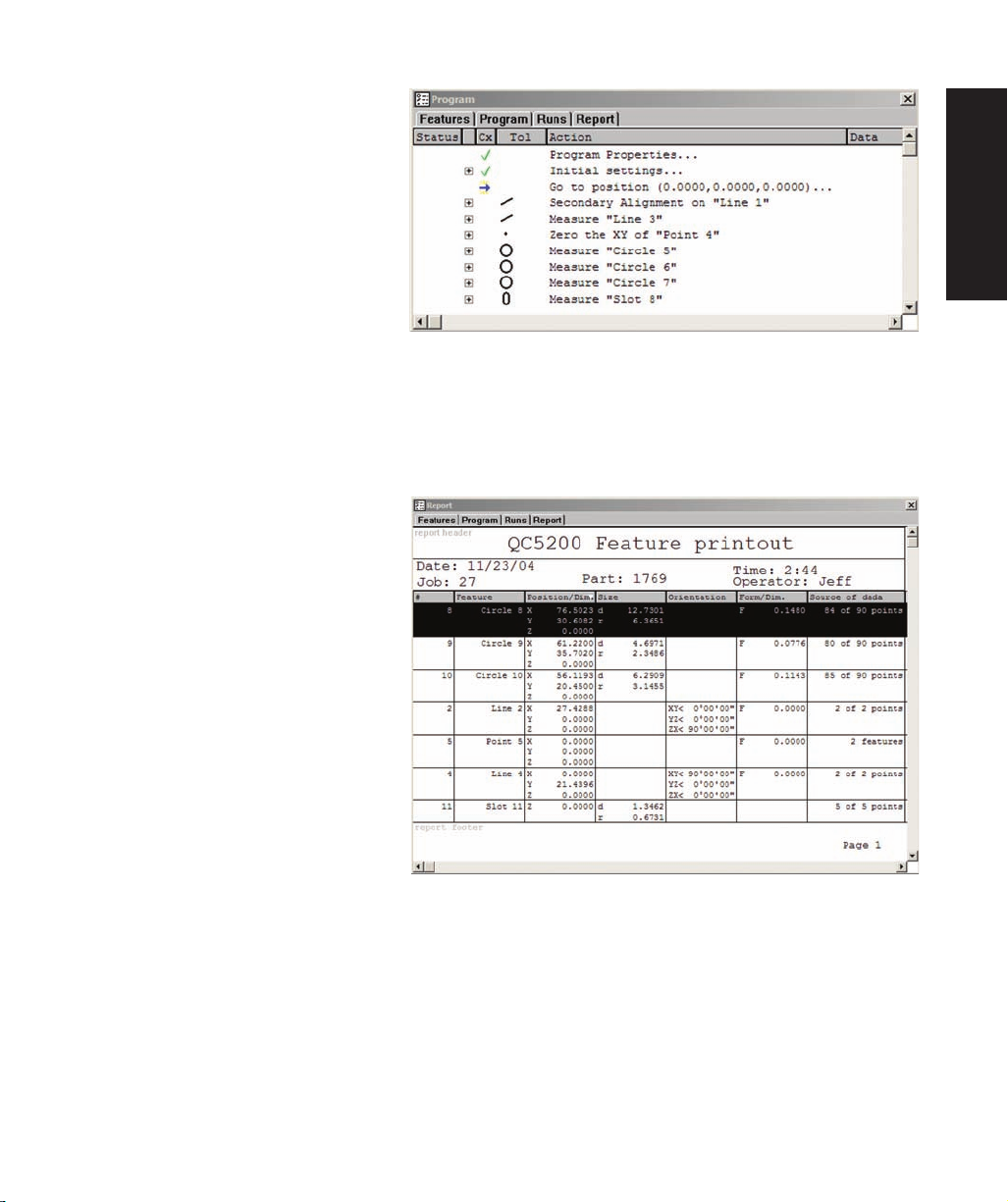

Reports can be custom-formatted in a

wide variety of formats to satisfy the

requirements of different audiences

by simply dragging and dropping data

selections into templates.

Templates

can easily be customized. Completed

reports can be archived, printed, ex-

ported or saved for e-mailing.

Exported

data can be sent to CAD applications,

Microsoft

Excel and

Microsoft

Access

for processing.

The user interface conforms to stan-

dard Windows conventions and can

be quickly mastered by experienced

Windows users. Task-specific menus,

icons and toolbars further simplify in-

teractions with QC5200 features and measurement functions. Many aspects of the user interface can be

customized to suit the needs of each user.

Customized arrangements of windows and toolbars can be saved

as unique workspaces to facilitate the most efficient use of the system by different users.

This User’s Guide can be accessed and displayed from the

Help menu, and includes links from all page

references in the Table of Contents and Index to Guide content.

Example of a program recorded automatically as measurements

were performed

Example of a report of feature data

Page 26

4

Page 27

2 User Interface

The QC5200 user interface is a

workspace consisting of

menus,

windows,

toolbars and a

statusbar. The

overall appearance of the user interface can vary greatly and can be customized to satisfy the requirements

and personal preferences of the user. The following pages contain a detailed description of the QC5200

user interface. Here’s what you’ll find in this chapter:

Introduction

...............................................................................................

7

Windows

............................................................................................

8

Menus

.................................................................................................

9

Toolbars

.............................................................................................

9

.............................................................................................

0

Windows

...................................................................................................

DRO window

.....................................................................................

Part View window

..............................................................................

2

Live Video window

............................................................................

5

Results window

..................................................................................

7

Template Windows

............................................................................

8

separating templates

..............................................

8

Adding and

deleting

template content

........................................

9

Features template

........................................................................

2

0

Program template

........................................................................

2

0

Report template

...........................................................................

0

Tolerance templates

....................................................................

2

Menus

........................................................................................................

Menubar menus

..................................................................................

22

File menu

....................................................................................

3

Edit menu

....................................................................................

2

5

View menu

..................................................................................

9

Measure menu

.............................................................................

3

5

Datum menu

................................................................................

3

5

Probe menu

.................................................................................

3

5

Tools menu

.................................................................................

3

6

Windows menu

..................................................................................

3

9

Page 28

On-screen

menus

.......................................................................................

Template window menus

...................................................................

4

Template edit menus

...................................................................

Program edit menus

...........................................................................

4

4

Results window menus

......................................................................

6

Part View window menus

..................................................................

5

0

Live

Video window menus

................................................................

5

Toolbar menus

...................................................................................

5

3

Toolbars

...........................................................................................................

55

Changing

toolbar shape

.............................................................................

5

6

Docking and

undocking toolbars

..............................................................

5

6

Customizing and

creating toolbars

............................................................

5

7

Workspaces

......................................................................................................

5

9

Creating

custom workspaces

.....................................................................

5

9

.......................................................................

6

0

Opening custom workspaces

.....................................................................

6

0

Launching the QC5200 program into a specific workspace

.....................

6

Page 29

2 User Interface

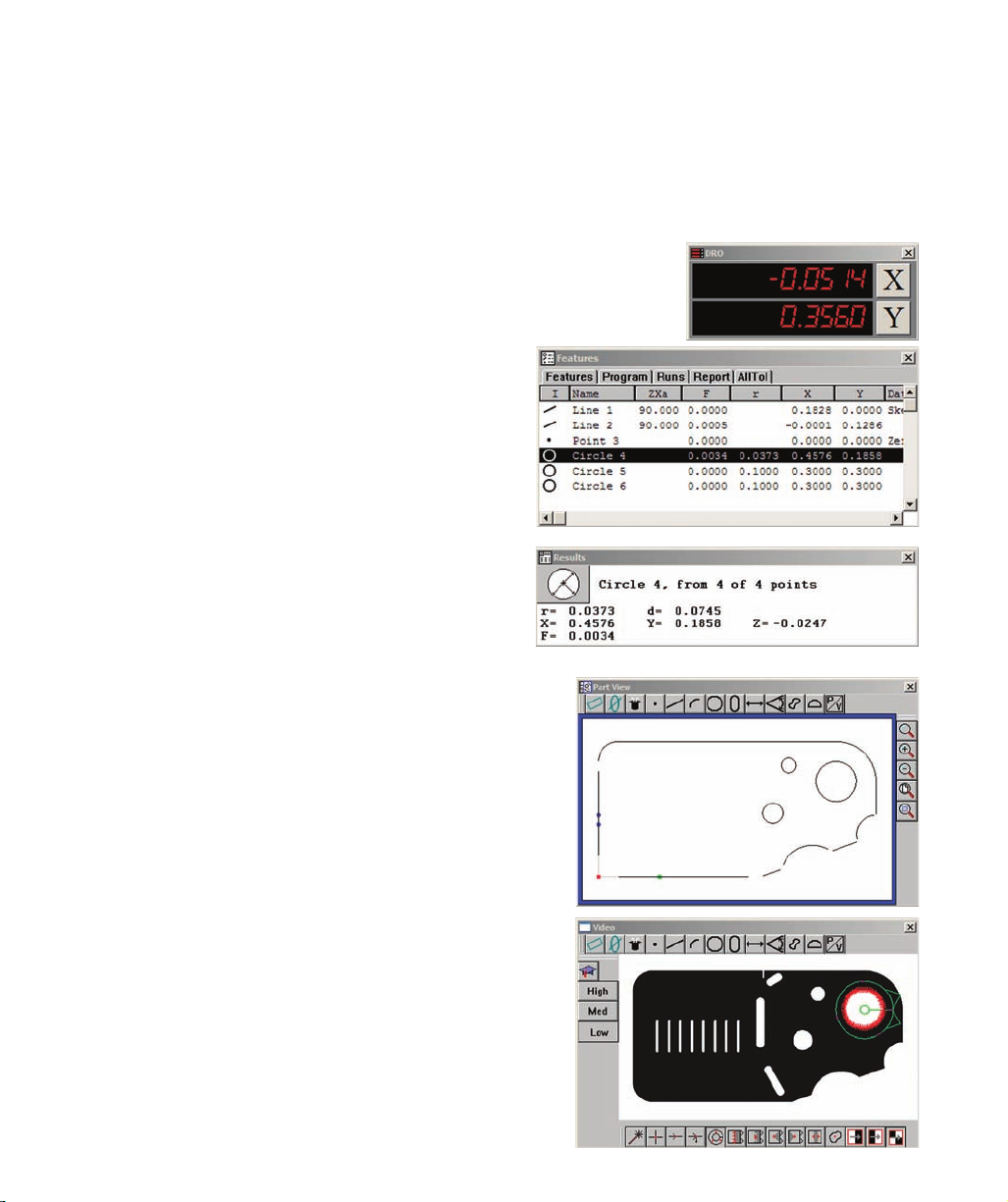

The QC5200

user interface is a workspace consisting of windows, menus, toolbars and a statusbar. The

overall appearance of the user interface can vary greatly and can be customized to satisfy the requirements

and personal preferences of the user. However, the individual elements of every workspace are consistent

in purpose and function, and do not significantly change. Workspace elements include:

• The DRO, Template, Results, Part View and Live Video windows

• Menu bar and on-screen menus

• Toolbars

• Statusbar

The overall appearance of the user interface, or workspace,

can be customized to vary greatly as shown here, but indi-

vidual workspace elements remain essentially unchanged.

DRO window

Results window

Part View window

to the

Part View window

Statusbar

Menubar menus

Introduction

Page 30

Windows

Four window types are used to present numeric, text and graphic information:

• DRO • Templates • Results • Part View • Live Video

DRO

The Digital Readout (DRO) presents numeric position information for

each axis.

Template windows present tabular data describing fea-

tures, programs, runs database contents and tolerance

measurements. The template windows shown here

are stacked. However, each window can be presented

alone.

Results

The Results window contains measurement data related

to a feature selected in a template or in the Part View

window.

Part View

The Part View window contains a graphic display of the

measurement reference frame and measured features.

Live Video

The Part View window contains a real-time display of the

video camera image including the part view at the active

magnification with the active video probe superimposed

over the part image.

Page 31

9

2 User Interface

Menus contain functions that control

file operations,

editing, measurements, displayed information and

overall system configuration and setup. Menus can be accessed by clicking on a menu item in the menubar,

or by right-clicking areas in the workspace.

Toolbars

Toolbars like the examples below contain

icons that provide quick access to functions that are also pro-

vided by menus. Toolbars can be located nearly anywhere within the workspace, and can be docked to

most windows.

Menu accessed from the menubar

Menu accessed by right-clicking a window

Measure toolbar

Program toolbar

Datum toolbar

Separate toolbars

Introduction

Page 32

The statusbar presents information regard-

ing

units of measure, current measure-

ments, programming and other

system

status information across the bottom of

the workspace. The information in the

statusbar changes to support current ac-

tivities.

The statusbar changes to display brief

definitions when the

mouse hovers over a

menu command, as in this example of a

statusbar definition displayed when hover-

ing over the Datum zero menu command.

Statusbar

Page 33

2 User Interface

Windows

Windows present numeric, text and graphic information describing

probe position,

feature measurement

results,

tolerance measurement results,

program content and

measurement database statistics.

Windows include:

• DRO (digital readout) window: Probe position referred to the current measurement reference

(machine zero or part zero)

• Part View window: Graphic display of measured features

• Results window: Measurement result data

• Live Video window: Real-time display of video camera image and active video probe

• Templates: Eight default templates display feature data, program steps,

database and report statistics and tolerance measurement results.

Additional custom templates can be created by the user.

The DRO window shows the current probe position with respect to the zero position

of the current reference frame.

Check the Windows/DRO menu item to display the DRO window, or clear the check

mark to hide it.

The zero location of each axis can be

temporarily changed by clicking the

axis button on the right side of the DRO

window.

Cartesian coordinates are changed to R and Ө for

polar

coordinate

The DRO window can be resized by clicking and dragging the side

or corner of the window.

Axis zero buttons

NOTE

The X and Y axis

systems.

Page 34

The

Part View window contains a

graphic display of the current measure-

ment

reference frame and all measured

features. This Part View window

shows features of the Metronics quickie

slide and

docked

toolbars. Check the

Windows/Part View

menu item to dis-

play the Part View

window, or clear

the check mark to

hide it.

The current reference frame is shown as X and Y axes and a coordinate zero point. The X-axis is identified

by a single green dot and the Y-axis by two blue dots.

A single part feature or multiple features can be selected by clicking features while pressing the Control

key, or by dragging a marquee across the desired features.

Selecting features by clicking them

Selecting features by dragging a marquee

Axis identifiers

Page 35

2 User Interface

When the marquee is dragged across fea-

tures from left to right, all features touched

by the marquee are selected.

When the marquee is dragged across

features from right to left, only features

completely enclosed by the marquee are

selected.

Adding feature data

Feature data can be added to the Part View window by clicking and dragging the desired data for a selected

feature from the Results window to the Part View window.

Dragging the marquee from left to right selects all features

touched by the marguee

Dragging the marquee from right to left selects only features

completely enclosed by the marguee

Data for the selected feature is clicked and dragged...

into the Part View window

clicked and dragged to the desired position

Page 36

Zoom and other Part View window functions can be accessed by clicking the Windows/View menu or by

right-clicking in the window. These functions are described in detail later in the Menus section of this

chapter.

The Part View window can be resized by click-

ing and dragging a corner of the window.

Accessing functions from the Menubar

Accessing functions from the on-screen menu

Page 37

2 User Interface

The Live Video window displays a real-

time image from the

video camera. The

active video probe is shown superimposed

over the image.

Check the Windows/

Live Video menu

item to display the

Live Video window,

or clear the check

mark to hide it.

The image size is controlled by the

Probe/Magnification menu and the Probe

toolbar.

Click the desired Probe/Magnification

menu item or

Probe toolbar button to

change the

camera

magnification.

or Probe toolbar to change the camera magnification

Page 38

The display of live video typically appears in its own

screen space when two monitors are used.

However, the display can be toggled between the Live Video window and the Part View window to con-

serve screen space when only a

single

monitor is used. Position the Live Video window directly over

the Part View window, matching the window sizes, then click the

P/V toolbar button

to toggle

between the two windows.

Page 39

2 User Interface

The

Results window contains measure-

ment data for the selected feature.

Check the Windows/Results menu item

to display the Results window, or clear

the check mark to hide it.

All basic

feature data is displayed for

the current coordinate system. The

information changes to reflect the new

coordinate system when the measure-

ment coordinate system is changed by

the user.

Results window functions can be accessed by right-clicking the window. These functions are described in

detail later in the Menus section of this chapter.

The size and shape of the Results window can be changed by clicking and

dragging a corner, but the content’s text format remains unchanged when this

method is used.

To change the text formatting of the Results window, right-click the title bar

of the Results window to display the Results window menu, then highlight the

desired Results window text format and release the mouse. The new format

will be displayed.

Simply changing the over-

all shape doesn’t change

the text formatting

changed from the Results

window menu

Page 40

Template Windows

Template Windows present tabular data and information

describing

features,

programs, runs

database content and

tolerance measurements. Template Windows can ap-

pear separately, or can be tabbed and stacked to

save screen space.

Check the desired template title in the recent template portion of the Windows menu

to display the template, or clear the check mark to hide it.

If the desired template is not shown in the list of recent templates, click the Windows/

Open Template menu item to select and open it, or right-click the Template window

and open a new template from the on-screen menu. Menubar and on-screen menu

functions are described in detail later in the Menus section of this chapter.

separating templates

and dropping one template onto

another.

Unstack templates that you wish

to appear separately by clicking

and dragging the title tab of one

template away from the stack.

windows presented separately

windows tabbed and stacked

onto the template stack

Page 41

2 User Interface

Eight default templates are included in the QC5200 system. These default templates include:

• Features

• Program

• Report

• Runs

• Tolerance (four tolerance templates are available)

Adding and

Each template contains default columns for displaying information appropriate for the template type.

However, columns can be deleted or added to suit the needs of the user. Columns are deleted using the on-

screen template menu described later in the Menus section of this chapter. Columns are added by dragging

and dropping data fields from the Results window as shown in the example below.

Template scrollbars provide access to information that extends

beyond the fixed boundaries of the template window.

Diameter is clicked in the Results

window and dragged...

from the Results window to the

Features template...

to create a diameter column in the

Features template

Scrollbars

NOTE

When the Results window is locked in the Tools/Options/Locks setup screen, data

fields cannot be dragged and dropped from the Results window into templates.

Page 42

Features template

The

Features template displays

dimensional

data for all measured, created or constructed

features. Default columns include the

feature icon, tolerance, feature name and

datum.

Use of the Features template is described in

detail in

Chapter 5: Measuring

Chapter 5: Measuring

Program template

The

Program template displays a list of

pro-

gram steps with information that includes

program status, tolerances, current step, ac-

tions to be performed and the program data

such as loop executions completed.

Use of the program template is described in

detail in

Chapter 8: Programming

Chapter 8: Programming

Report template

The

Report template displays a

tabular summary of

feature data

intended as the basis of printed re-

ports of measurement results.

Use of the report template is de-

scribed in detail in

Chapter 7: Reporting and Tem-

Chapter 7: Reporting and Tem-

plates

plates

Page 43

2 User Interface

Tolerance templates display tabular summaries of tolerance measurement results.

Four default Tolerance templates are available. Each template contains a feature icon, tolerance flag (pass-

fail), tolerance symbol, feature name, nominal value, actual value and deviation. Tolerance templates

include:

AllTol: Complete tolerance information for all features

•

EuroTol: Cartesian +/- tolerance values formatted for European users

TolRep: Complete tolerance information for only toleranced features

•

QDAS: Report of feature data formatted for European users

Use of Tolerance templates is described in detail in

Chapter 7: Database, Reporting and Templates

Chapter 7: Database, Reporting and Templates

Page 44

Menus can be displayed by clicking a menu title in the menubar, or by right-clicking certain items within

the workspace area.

Most menus accessed by right-clicking in the workspace area are also available in the menubar.

The menubar includes the following categories of menus:

File: Typical Windows file and print functions

•

Edit: Functions for editing features and programs

View: Workspace viewing alternatives

•

Measure: Feature measurement selections

•

Datum: Reference frame creation

Probe: Measurement probe selection and adjustment

•

Tools: Tolerance, CNC, programming, setup and language functions

Windows: Window selection and template functions

•

Help: User guide, backup and diagnostic utilities

A menu is displayed by clicking a menubar title

Another menu is displayed by right-clicking an item

within the workspace area

Page 45