Page 1

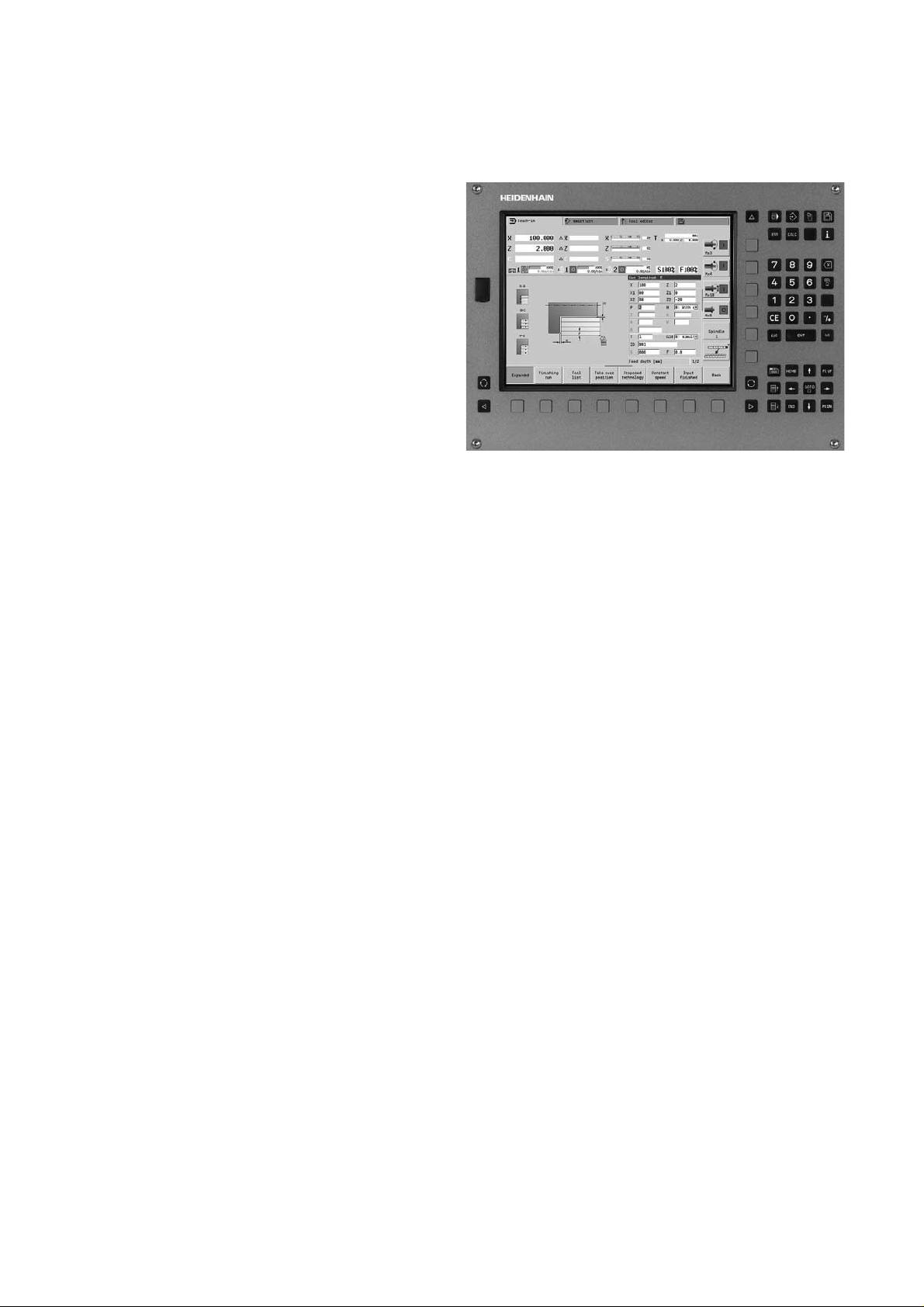

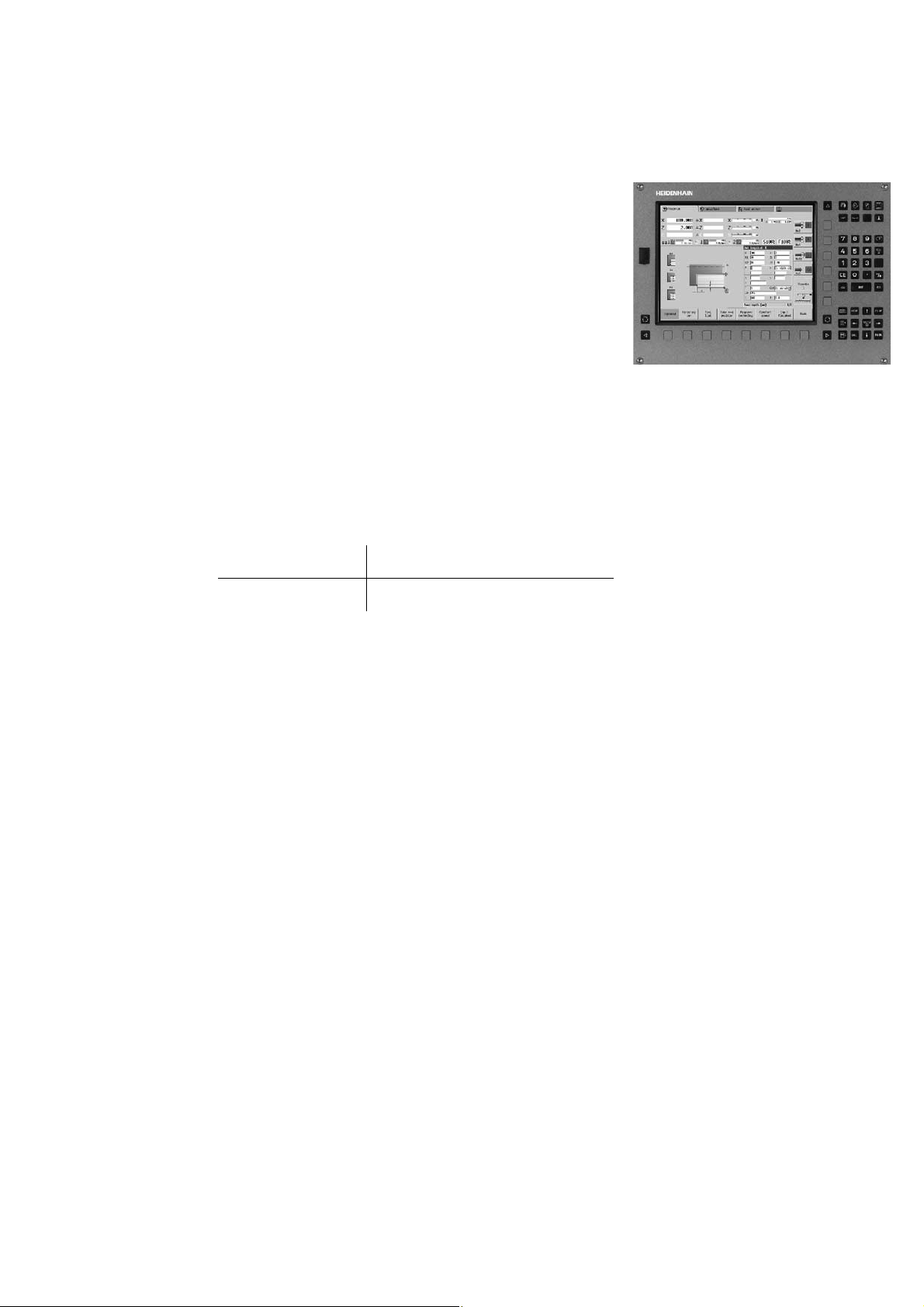

MANU ALplus 620

HSCI

The Contouring Control for

CNC and Cycle Lathes

Infor mation f or the

Machine T ool Builder

August 2010

Page 2

MANU ALplus 620

Contouring Control with Driv e S yst em fr om HEIDENHAIN

MANUALplus 620

Contouring control for lathes with up to 3 axes (X, Z and Y), •

controlled spindle, C axis and driven tools

In addition, a parallel W axis can be offset to the Z axis•

HEIDENHAIN inverter systems and motors recommended•

Compact design: Screen, keyboard and main computer all in one •

unit

12.1-inch TFT color fl at-panel display•

Storage medium for NC programs. CompactFlash memory card•

Cycle programming for t urning, drilling, boring and milling •

operations

smart.Turn programming for turning, boring, drilling and milling •

operations

DIN programming for turning, boring, drilling and milling •

operations

Free ICP contour programming f or t urning and milling contours•

The MANUALplus supports quick change tool posts (Multifi x) •

and tool turrets. The tool carrier can be located in front of or

behind the workpiece.

The MANUALplus also supports vertical lathes.•

USB removable media can be connected•

MANUALplus 620 (MC 6110 T)

System tests

Parts subject t o

wear

Standards

2

Controls, motors and encoders from HEIDENHAIN are in most

cases integrated as components in larger systems. In these cases,

comprehensive tests of the complete system are required,

irrespective of the specifi cations of the individual devices.

In particular the following parts in controls from HEIDENHAIN are

subject to wear:

Buff er battery•

Fan•

Standards (ISO, EN, etc.) apply only where explicitly stated in the

catalog.

Page 3

Contents

Tables with Technical Specifi cations, Mac hine Interf acing,

User Functions and A ccessories

Digital Control Design

Control Systems

Cable Overviews

Technical Description

Overall Dimensions

Documentation

Service

Subject Index

Please refer to the page r eferences in the tables with the

specifi cations.

Page

4

13

14

26

30

46

59

60

61

The feat ures and specifi cations described here apply f or the

following control and NC sof tware v ersion:

MANUALplus 620 ID 548 328-03

Some of these specifi cations require particular machine

confi gurations. Please note also that, for some functions, a special

PLC program must be created by the manufacturer.

This catalog supersedes all previous editions, which thereb y

become invalid.

Subject to change without notice

3

Page 4

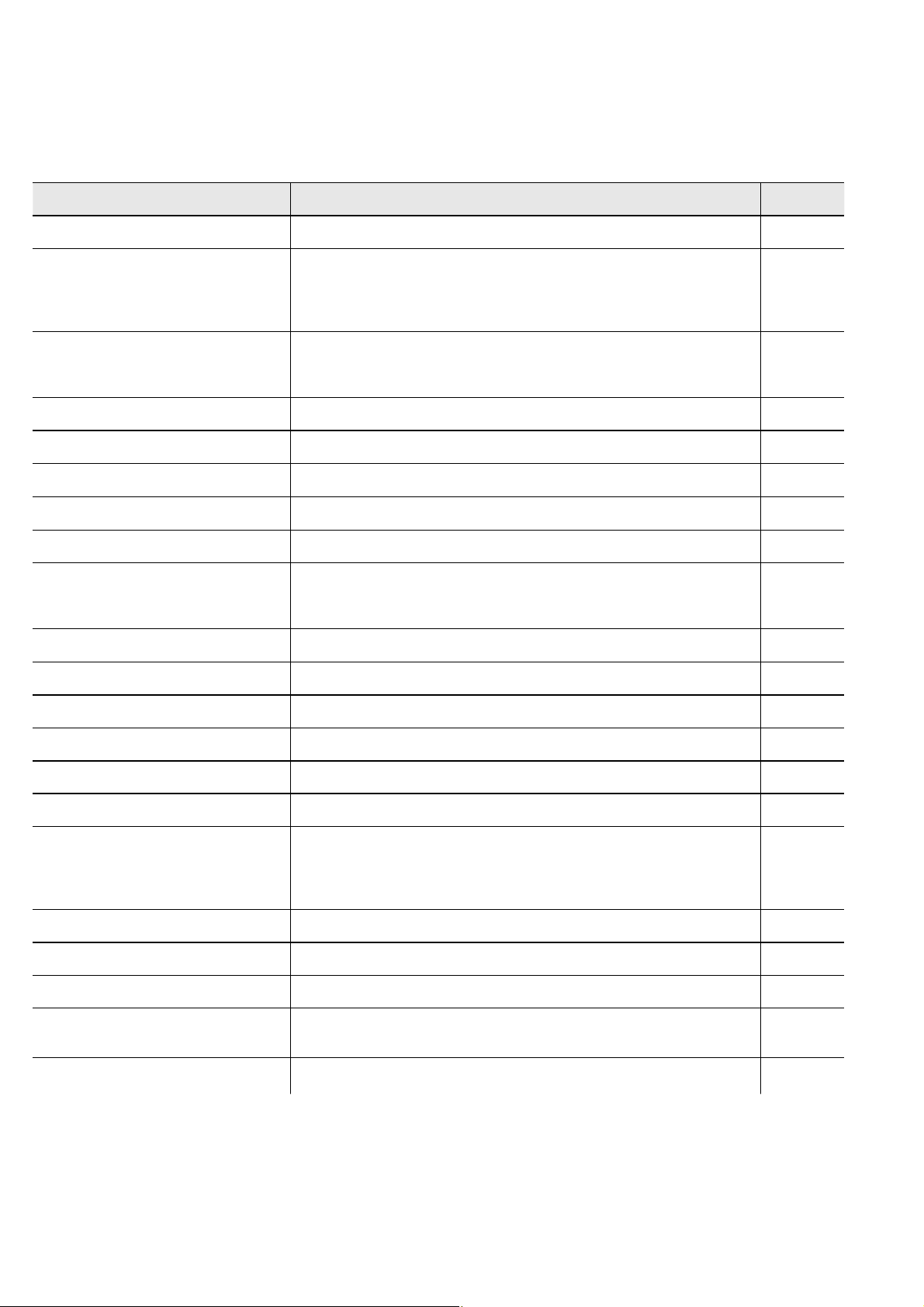

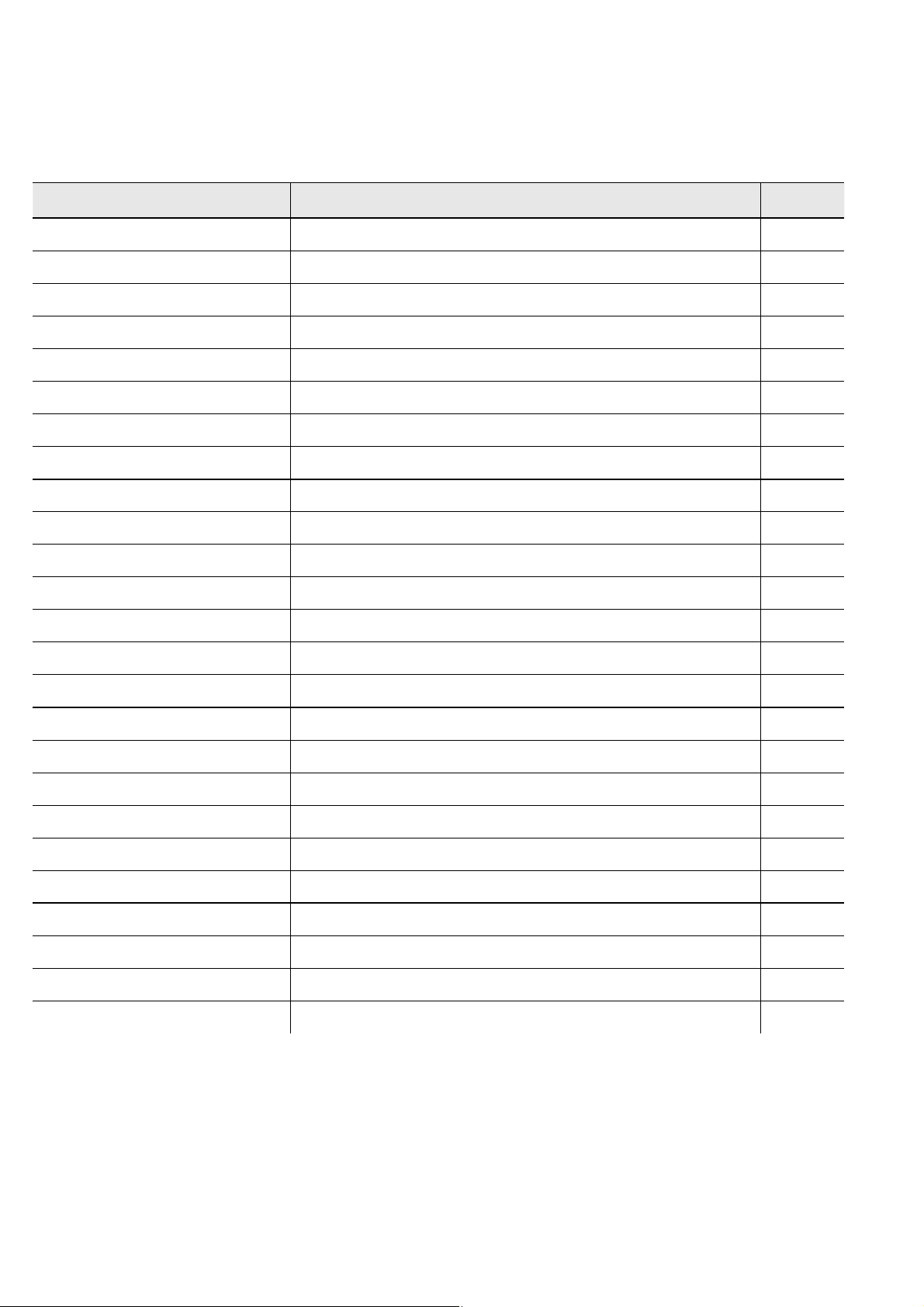

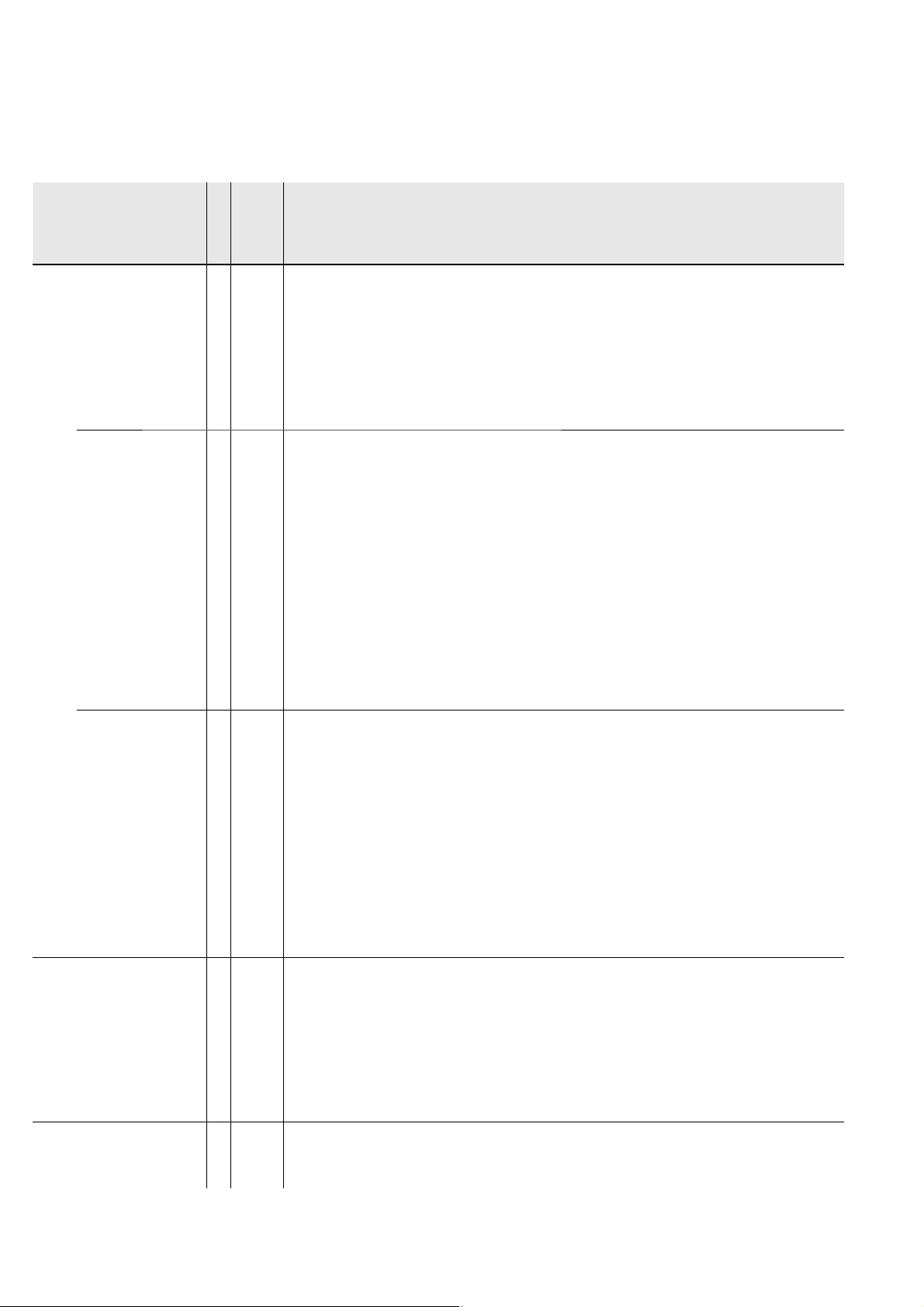

Specifi cations

Specifi cations MANUALplus 620 Page

Control systems 14

Main computer MC 611 0 T main computer•

Integrated 12.1-inch TFT color fl at-panel display•

Integral MANUALplus operating panel•

HSCI interface•

Controller unit CC 61xx or

UEC 111 (inverter and system PL integrated) or

UEC 112 (in v erter and sy stem PL integrated)

PLC inputs/outputs PL 6xxx series or on UEC 11x series

Invert er syst ems *

Compact inverter

Modular inverters

1)

Axes

and spindles

Axes Up to 4 closed-loop axes

C axis With spindle motor or separate drive (option)

Driven tool Option

Spindle

Shaft speed

2)

✔

✔

X, Z: standard

Y, W: option

Closed-loop

Max. 60 000 min

–1

15

17

19

*

*

31

31

32

32

32

32

NC program memory

Input resolution and display step

Linear axes X axis: 0.5 µm (diameter: 1 µm)

C axis 0.001°

Interpolation

Straight line In 2 axes (max. ±100 m), optional in 3 principal axes

Circle In 2 axes (radius max. 999 m), optional additional linear interpolation of the

C axis Interpolation of X and Z linear axes with the C axis (option)

1)

As ordered

2)

On motors with two pole pairs

* For further information, refer to the Inverters broc hure (ID 622 420-xx)

** For further information, refer to the brochure MANUALplus 620

250 MB

Z axis: 1 µm

Y axis: 1 µm

W axis: 1 µm

third axis

**

**

**

4

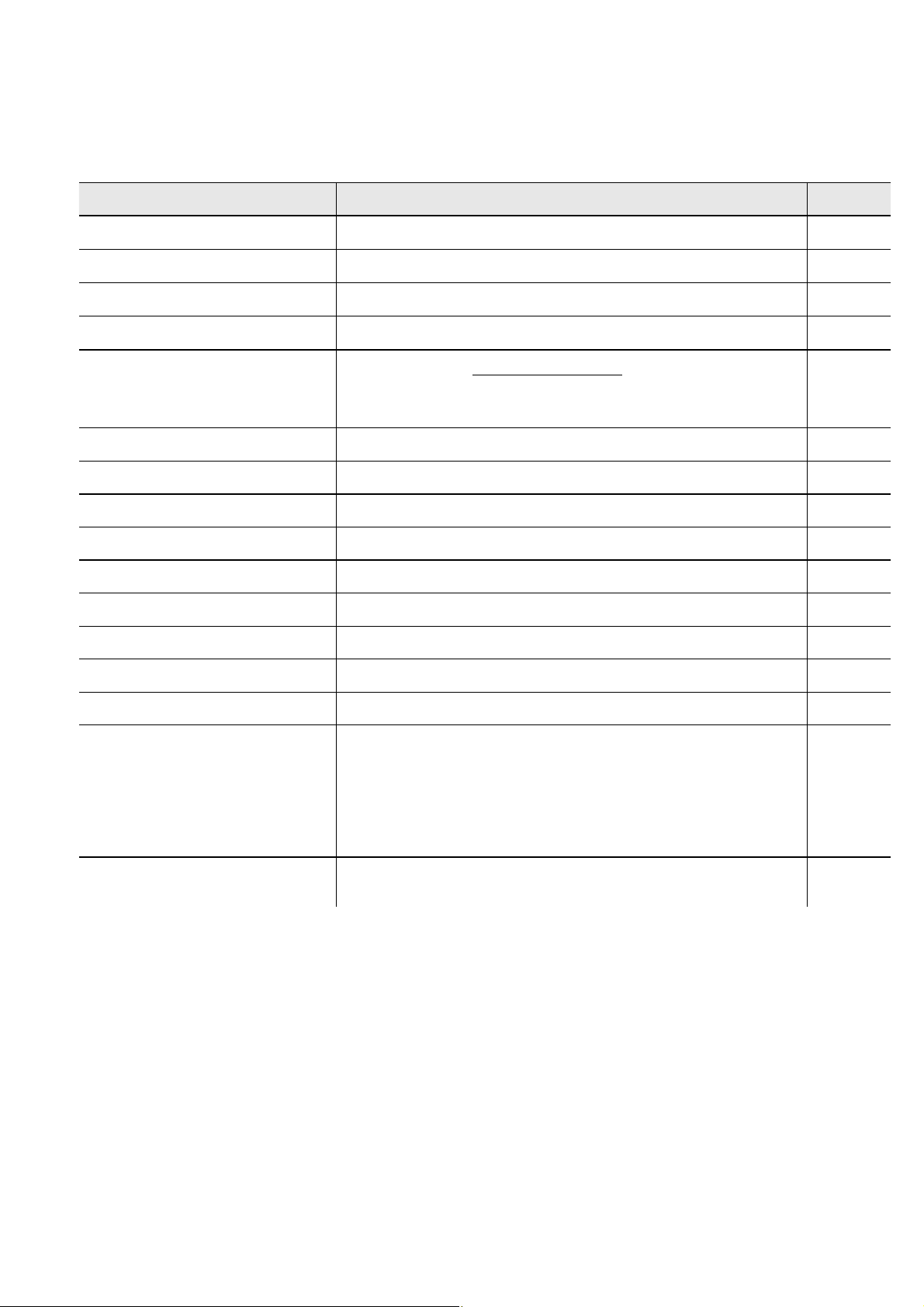

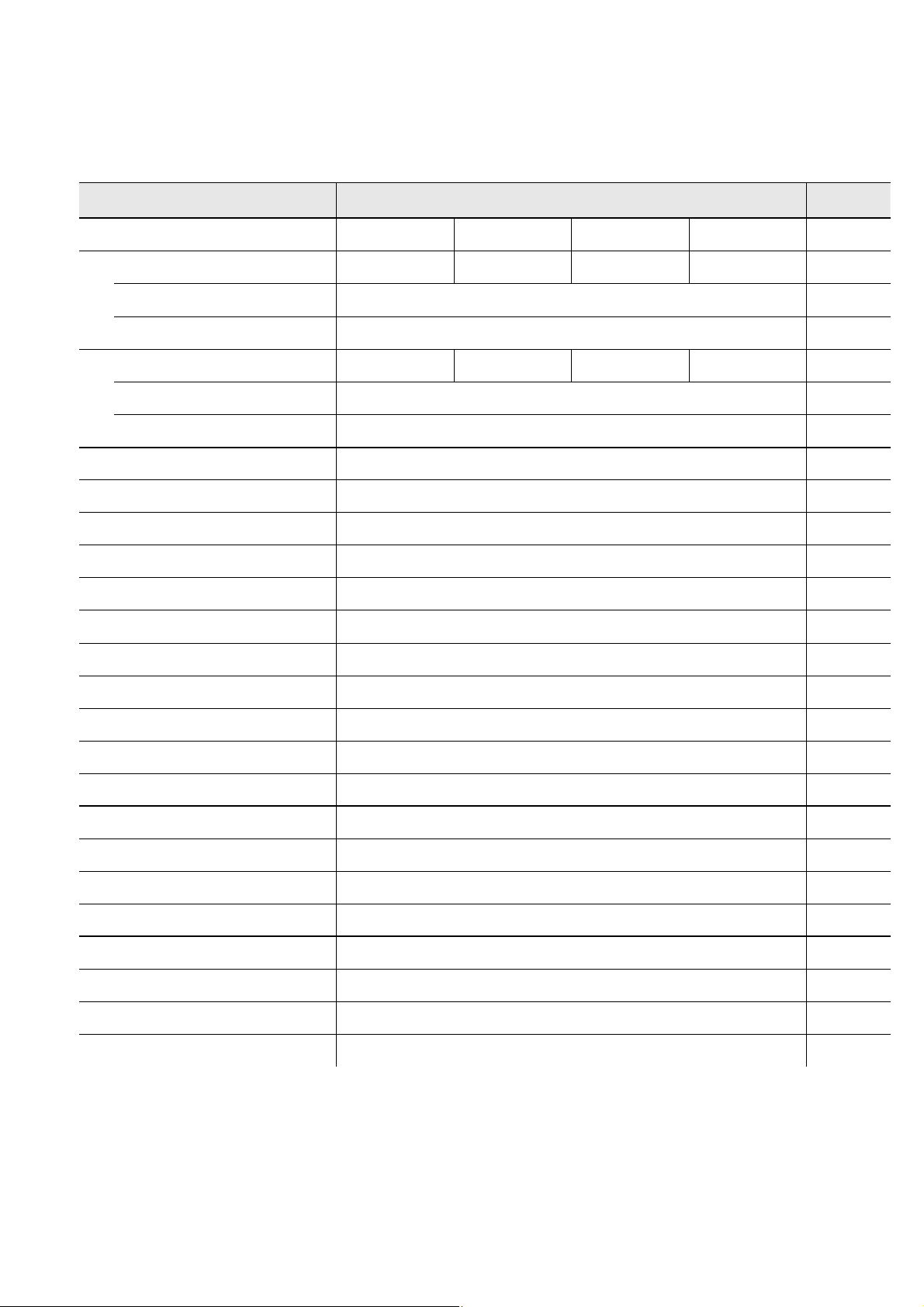

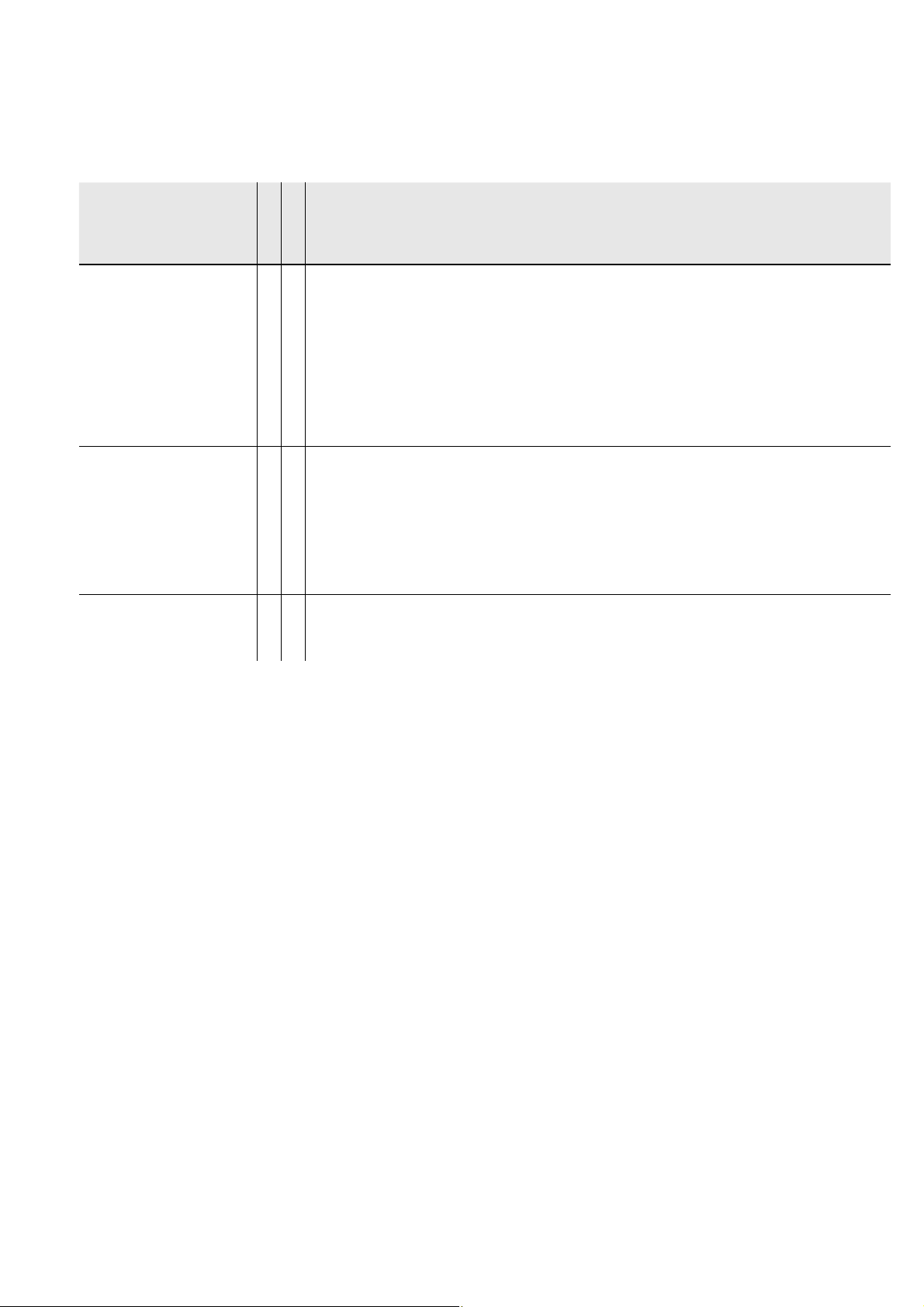

Page 5

Specifi cations MANUALplus 620 Page

Axis feedback contr ol 33

With following error

With feedforward

With jerk limiting

✔

✔

✔

Feed rate

Constant surface speed

Maximum feed rate: · screw pitch [mm]

at f

= 5 000 Hz

PWM

✔

No. of pole pairs in motor

Input mm/min or mm/rev olution

Cycle times of main computer MC 611 0 T

Block processing 3 ms

Cycle times of controller unit

CC 610x/UEC 11x 34

Path interpolation 3 ms

Fine interpolation 0.2 ms

Position controller 0.2 ms

Speed controller 0.2 ms

60 000 min

33

33

35

–1

31

31

31

34

34

34

34

34

34

Current controller f

Per missible t emper at ur e r ang e

T

PWM

INT

3 333 Hz 150 µs

4 166 Hz 120 µs

5 000 Hz 100 µs

6 666 Hz 75 µs

8 333 Hz 60 µs

10 000 Hz 50 µs

Operation: 0 °C to 50 °C

Storage: –20 °C to 60 °C

34

5

Page 6

Mac hine Interf acing

Machine Interf acing MANUALplus 620 Page

Error compensation 37

Linear axis errors

Nonlinear axis errors

Backlash

Hysteresis, reversal peaks

Thermal expansion

Stick-slip friction

Sliding friction

Integral PLC 41

Program format Statement list

Program input via the control Via external USB ke yboard or via soft keys

Program input via PC

Symbolic PLC-NC interface

PLC memory 50 MB

PLC cycle time 21 ms, adjustable

✔

✔

✔

✔

✔

✔

✔

✔

✔

37

37

37

37

37

37

37

41

41

41

41

41

41

PLC inputs/outputs

PLC inputs, 24 V– Via PL or UEC 11x, max. 1024

PLC outputs, 24 V– Via PL or UEC 11x, max. 512

Analog inputs, ±1 0 V Via PL

Inputs for PT 100 thermistors Via PL

Analog outputs, ±1 0 V Via PL

PLC functions

PLC soft keys

PLC positioning

PLC basic program

Max. eight PL 6xxx (one PL 62xx or UEC 11x and max. seven PL 61xx)

✔

✔

✔

✔

19

19

19

19

19

19

41

41

41

42

6

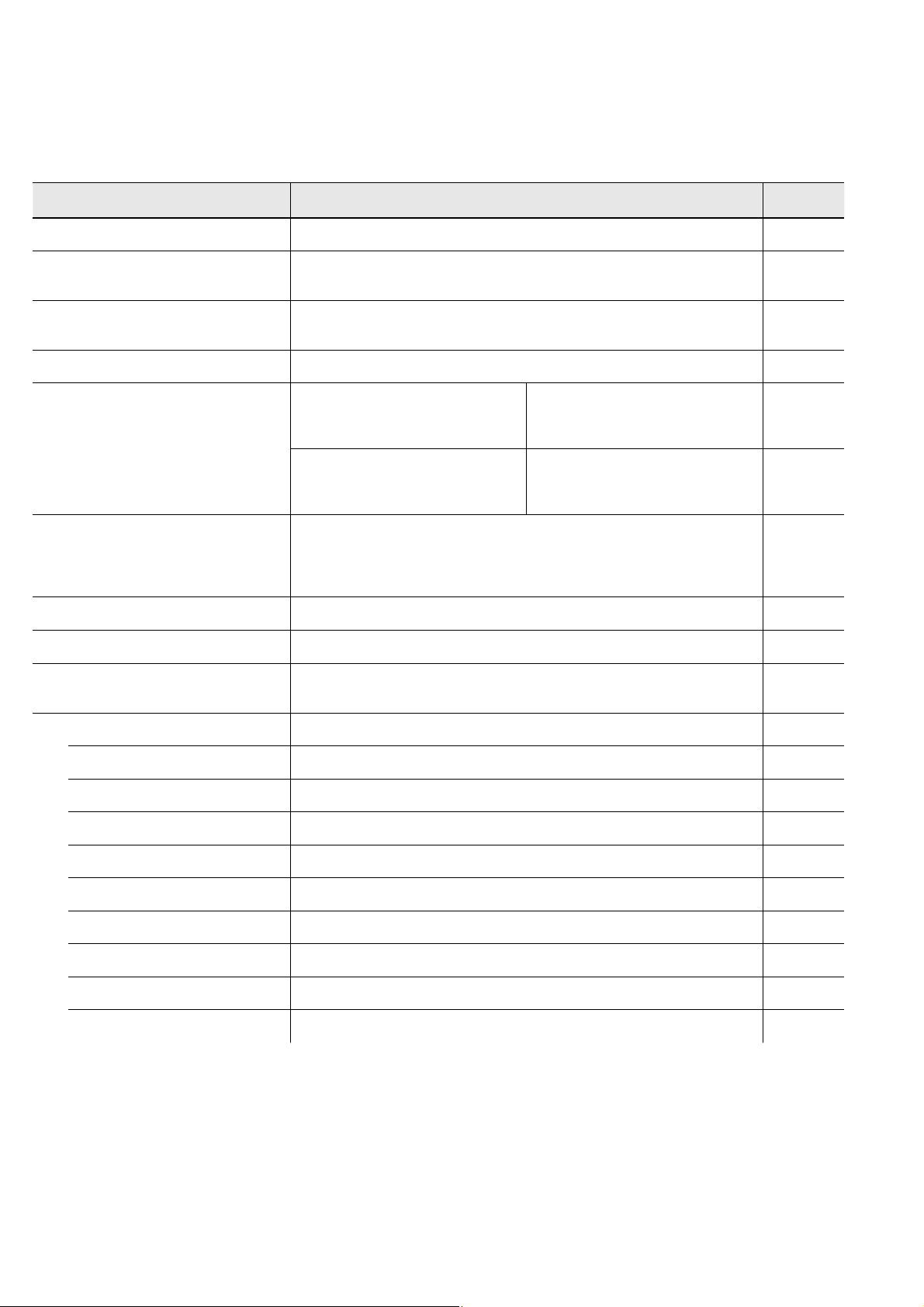

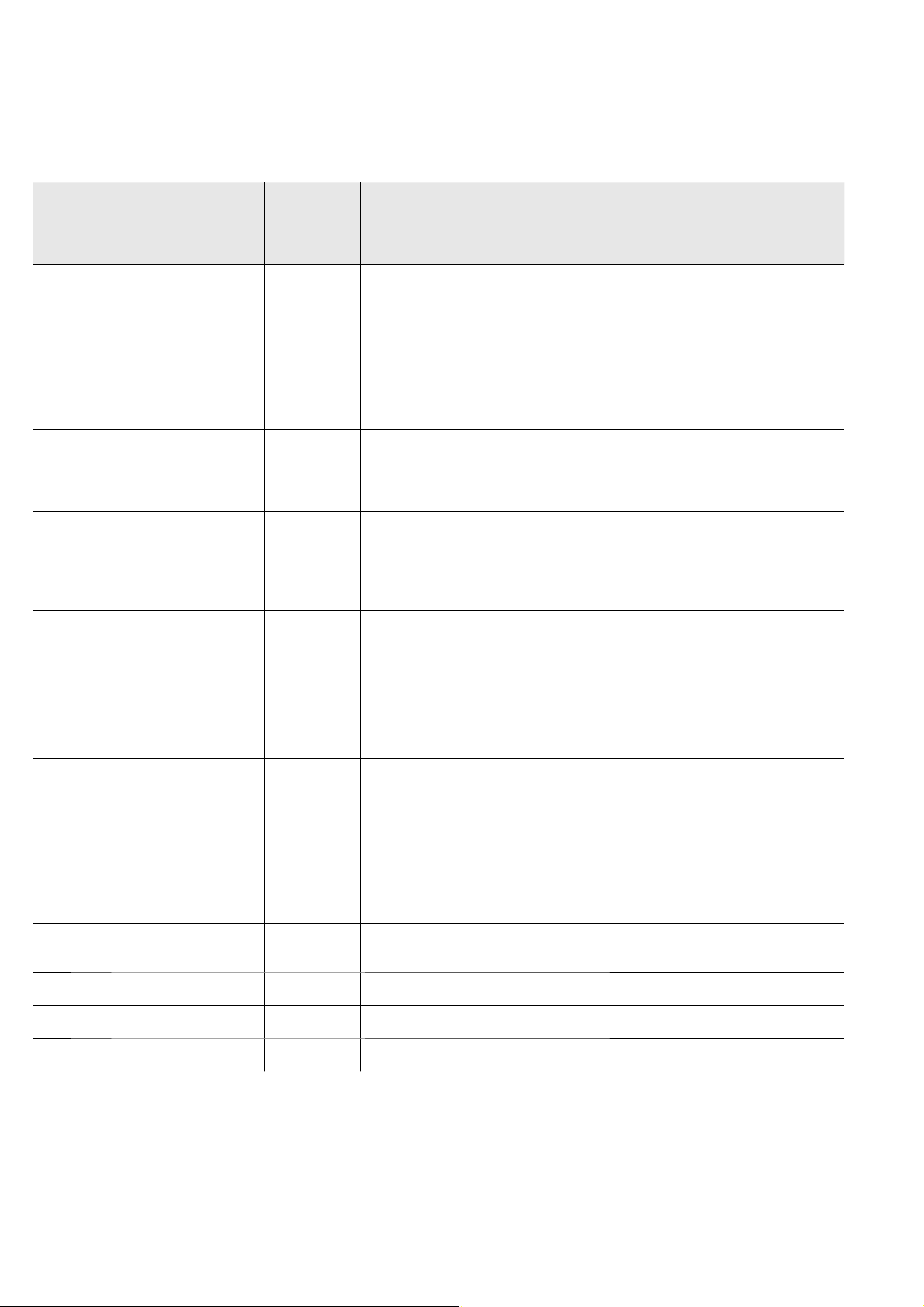

Page 7

Mac hine Interf acing, A ccessories

Machine Interf acing MANUALplus 620 Page

Encoder inputs

UEC 111 UEC 112 CC 61 06 CC 6108

Position 4 5 6 8

Incremental 1 V

PP

Absolute EnDat

Rotational speed 4 5 6 8

Incremental 1 V

PP

Absolute EnDat

36

36

36

36

36

36

36

Commissioning and diagnostic aids 39

DriveDiag Software for diagnosis of digital drive sy stems

TNCopt Software for putting digital control loops into service

Integrated oscilloscope

Trace function

Logic diagram

API DATA function

✔

✔

✔

✔

39

39

40

40

40

40

Table function

OnLine Monitor (OLM)

Log

TNCscopeNT

✔

✔

✔

✔

40

39

40

40

Data interf aces 43

Ethernet (1 00BaseT)

✔

USB 2.0 3 (1 on the front, 2 on the rear)

RS-232-C/V.24 Can only be controlled via PLC

43

43

43

Protocols 43

Standard data transfer

Blockwise data transfer

LSV2

✔

✔

✔

43

43

43

7

Page 8

Accessories MANUALplus 620 Page

Machine operating panel

Electronic handwheels

MB 620 T

One HR 41 0, one HR 130, or up to three HR 150 via HRA 110•

21

22

Up to two HR 180•

Touch probes

One TS 220, TS 440, TS 444, TS 640 or TS 740 workpiece touch probe•

23

One TT 140 tool touch probe•

PLC input/output systems With HSCI interface 19

Basic module System PL

1)

PLB 6204 for 4 I/O modules

19

PLB 6206 for 6 I/O modules

PLB 6208 for 8 I/O modules

Expansion PL

PLB 61 04 f or 4 I/O modules

19

PLB 61 06 f or 6 I/O modules

PLB 61 08 f or 8 I/O modules

I/O modules PLD-H 16-08-00: 1 6 digital inputs and 8 digital outputs, 24 V

19

PLD-H 08-16-00: 8 digital inputs and 16 digital outputs, 24 V

PLA-H 08-04-04: 8 analog inputs ± 1 0 V , 4 analog outputs ± 10 V and 4 analog

PT 1 00 inputs

USB hub

PLC basic program

2)

Programming station

✔

✔

Control software for PCs f or programming, archiving, and training

43

42

*

DataPilot MP/CP 620

Softwar e

PLCdesignNT

KinematicsDesign

TNCremoNT

TNCremoPlus

TNCscopeNT

Driv eDiag

IOconfi g

TNCopt

TeleService

2)

2)

2)

2)

2)

2)

Data transfer software

2)

PLC software dev elopment en vironment

Software for kinematic confi guration

Data transfer software with liv e-screen function

Software for data recording

Software for diagnosis of digital drive sy stems

Software for confi guring PLC I/O and PROFIBUS-DP components

Software for putting digital control loops into service

Software for remote diagnostics, monitoring, and operation

* For further inf ormation, refer to the brochure MANUALplus 620

1)

Integrated in UEC 11x, otherwise necessary once in each HSCI control system

2)

These software products are available to registered customers for do wnloading from the Internet.

42

38

44

44

40

39

19

39

40

8

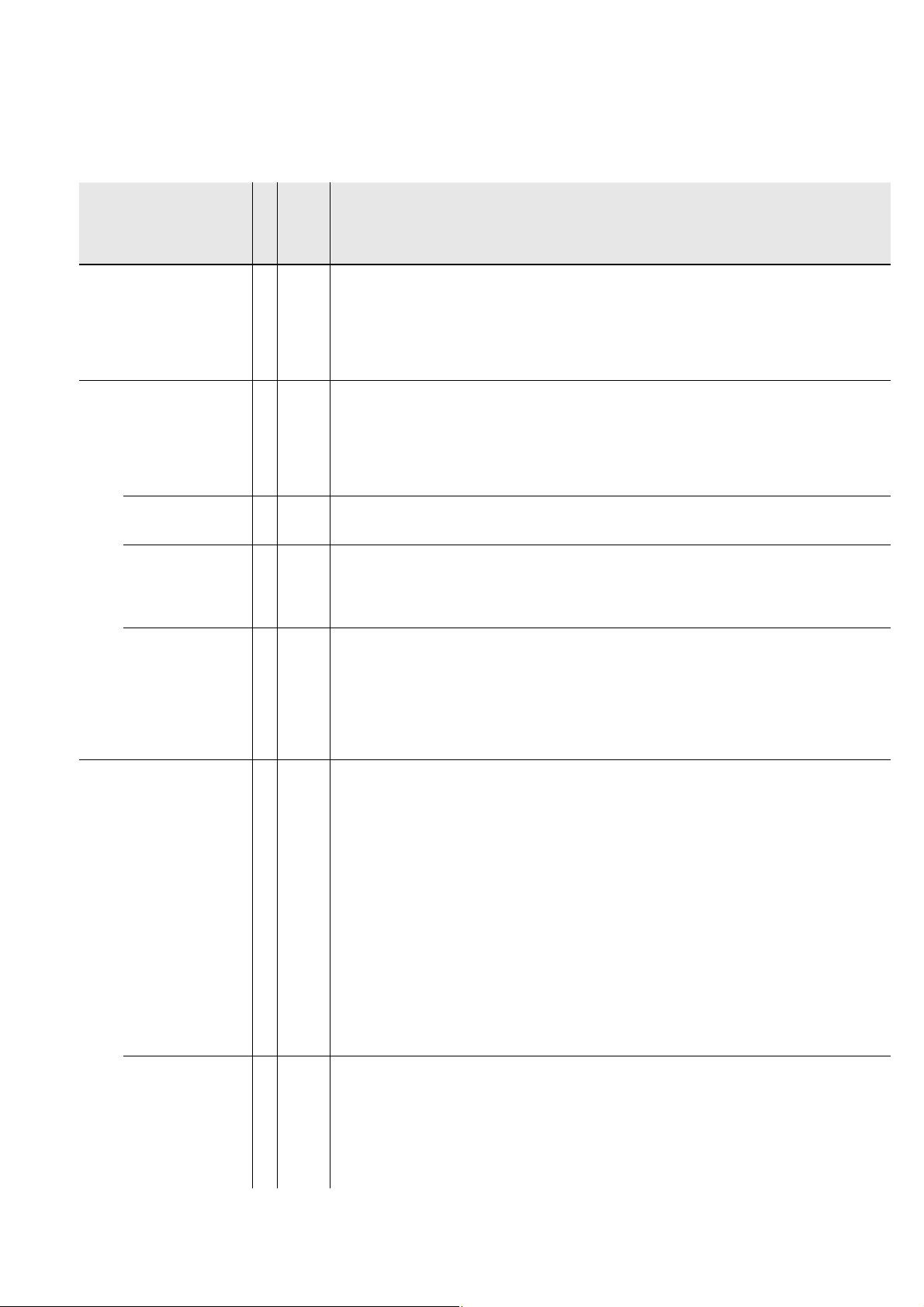

Page 9

User F unctions

User functions

Standard

Confi guration

Operating modes

Manual operation

Teach-in mode 8 Sequential linking of fi xed cycles, where eac h cy cle is r un immediately after input, or is

Program run

Setup functions •

•

55+0-3

70+0-3

94+0-3

•

•

•

•

•

•

•

Option

Basic version: X and Z axis, spindle

0-3

Positionable spindle and driv en tool

C axis and driven tool

Y axis

W axis (as closed-loop PLC axis)

Digital current and speed control

Manual slide movement through manual direction ke y s, intermediate switch or electronic

handwheels

Graphic support for entering and running cycles without sa ving the machining steps in

alternation with manual machine operation

11

Thread reworking (thread repair in a second w orkpiece set up)

graphically simulated and subsequently saved.

All are possible in single-block and full-sequence modes

DIN PLUS programs

9

smart.Turn programs

8

Cycle programs

Workpiece datum setting

Defi nition of tool-change position

Defi nition of protection zone

Tool measurement by touc hing the w orkpiece

17

Tool measurement with a TT tool touch probe

17

Tool measurement with an optical gauge

17

Workpiece measurement with a TS workpiece touch probe

Programming

Cycle programming

Interactive Contour

Programming (ICP)

8

8

8

8

8

8

8

8+55

8+55

8+55

8+55

8+55

8

8

8

8+9

8/9

8/9

8/9

8/9

8/9

8/9

8/9

Turning cycles for simple and complex contours, as w ell as contours defi ned with ICP

Contour-parallel turning cycles

Recessing cycles for simple or comple x contours, or contours defi ned with ICP

Repetitions with recessing cycles

Recess turning cycles f or simple and comple x contours, as w ell as contours defi ned with ICP

Undercut and parting cycles

Threading cycles for single or multi-start longitudinal, taper or API threads

Cycles for axial and radial drilling, pecking and tapping operations with the C axis

Thread milling with the C axis

Axial and radial milling cycles for slots, fi gures, single surfaces and polygons as well as for

complex contours defi ned with ICP for machining with the C axis

Helical slot milling with the C axis

Linear and circular patterns for drilling, boring and milling operations with the C axis

Context-sensitive help graphics

Transfer of cutting values from technology database

Use of DIN macros in cycle programs

Conversion of cycle programs to smart.Turn programs

Contour defi nition with linear and circular contour elements

Immediate display of entered contour elements

Calculation of missing coordinates, intersections, etc.

Graphic display of all solutions for selection by the user if more than one solution is possible

Chamfers, rounding arcs and undercuts av ailable as f orm elements

Input of form elements immediately during contour creation or by superimposition later

Changes to existing contours can be programmed

9

Page 10

User functions

Standard

Option

ICP (continued) 8/9+55

9+70

8/9+42

C-axis machining on face and lateral surf ace:

Description of individual holes and hole patterns (only in smart.Turn)

Description of fi gures and fi gure patterns for milling (only in smart.Turn)

Creation of freely defi nable milling contours

Y-axis machining on the XY and ZY planes (only in smart.Turn):

Description of individual holes and hole patterns

Description of fi gures and fi gure patterns for milling

Creation of freely defi nable milling contours

DXF import: Import of contours for lathe and milling operations

smart.Turn

programming

DIN PLUS

programming

9+55/70

•

•

•

•

•

•

•

•

•

•

9

9

9

9

9

9

9

9

9+55

9

9

9

9

55

70

8/9

9

The basis is the unit, which is the complete description of a machining block (geometry,

technology and cycle data)

Dialog boxes divided into ov erview and detail forms

Fast navigation between the fi llable forms and input groups via the “smart” keys

Context-sensitive help graphics

Start unit with global settings

Transfer of global values from the start unit

Transfer of cutting values from technology database

Units for all turning and recessing operations for simple contours and ICP contours

Units for boring, drilling and milling operations with the C and Y axes for simple holes, milling

contours and drilling and milling patterns or those programmed with ICP

Special units for activating/deactivating the C axis, subprograms and section repeats

V erifi cation graphics for blank and fi nished part and for C and Y axis contours

Turret assignment and other setup information in the smart.Turn program

Parallel programming

Parallel simulation

Programming in DIN 66025 format

Extended command format (IF... THEN ... ELSE...)

Simple geometry programming (calculation of missing data)

Po w erful machining cycles for turning, recessing, recess turning and thread machining

Po w erful machining cycles for boring, drilling and milling with the C axis

Po w erful machining cycles for boring, drilling and milling with the Y axis

Subroutines

Programming with variables

Contour description with ICP

Program verifi cation graphic for workpiece blank and fi nished part

Turret assignment and other setup information in the DIN PLUS program

Conversion of smart.Turn units into DIN PLUS command sequences

Parallel programming

Parallel simulation

Program verifi cation

graphics

Machining time analysis

10

•

•

•

•

•

•

•

•

•

•

•

Graphic simulation of the cycle process or of the cycle, smart.Turn or DIN PLUS program

Display of the tool paths as wire-frame or cutting-path graphics, special identifi cation of the

rapid-traverse paths

Machining simulation (2-D material-remov al graphic)

Side or face view, or 2-D view of cylindrical surface for v erifi cation of C-axis machining

Display of programmed contours

View of face and YZ plane for verifi cation of Y-axis machining

Three-dimensional display of the workpiece blank and fi nished part

Shifting and magnifying functions

Calculation of machining time and idle machine time

Consideration of switching commands triggered by the CNC

Representation of times per individual cycle or per tool change

Page 11

User functions

Tool database

Standard

Option

•

For 250 tools

10

For 999 tools

•

Tool description can be entered for every tool

•

Automatic inspection of tool-tip position with respect to the contour

•

Compensation of tool-tip position in the X/Y/Z plane

•

Precision path correction via handwheel, transfer ring compensation v alues to the tool table

•

Automatic tool-tip and cut ter radius compensation

•

Tool monitoring for lifetime of the insert (tool tip) or the number of w orkpieces produced

Tool monitoring with automatic tool change after tool insert wear

10

•

Management of multipoint tools (multiple inserts or reference points)

Technology database

Conversational languages

Access to cutting data after defi nition of workpiece material, cutting material and machining

8/9

mode. The MANUALplus distinguishes between 16 mac hining modes. Each workpiecematerial/tool-material combination includes the cutting speed, the main and secondary feed

rates, and the infeed for 16 machining modes.

Automatic determination of the mac hining modes from the cy cle or the machining unit

8/9

The cutting data are entered in the cycle or in the unit as def ault v alues

8/9

9 workpiece-material/tool-material combinations (144 entries)

8/9

62 workpiece-material/tool-material combinations (992 entries)

10

•

Chinese (simplifi ed), Chinese (traditional), Czech, Danish, Dutch, English, Finnish, French,

German, Hungarian, Italian, Polish, P ortuguese, Russian, Spanish, Swedish

41

For more conv ersational languages, see Option

11

Page 12

Options

Option

number

0

1

2

3

8

9

10

11

Option ID Comment

Additional axis 354 540-01

353 904-01

353 905-01

367 867-0 1

Software option 1

Teach-in

Software option 2

smart.Turn

Software option 3

Tools and technology

Software option 4

Thread cutting

632 226-01

632 227-0 1

632 228-01

632 229-01

Additional control loops 1 to 4

Cycle programming

Contour description with ICP•

Cycle programming•

Technology database with 9 workpiece-material/tool-material combinations•

smart.Turn

Contour description with ICP•

Programming with smart.Turn•

Technology database with 9 workpiece-material/tool-material combinations•

Tools and technology

Tool database expanded to 999 entries•

Technology database expanded to 62 w orkpiece-material/tool-material •

combinations

Tool life monitoring with ex change tools•

Threads

Thread recutting•

Handwheel superimposition during thread cutting•

17

41

42

55

70

94

Touch probe functions 632 230-01

Additional language 530 184-01

530 184-02

530 184-03

530 184-04

530 184-06

530 184-07

530 184-08

530 184-09

530 184-1 0

DXF- import 632 231-01

C-axis machining 633 944-01

Y-axis machining 661 881 -01

W-axis machining 679 67 6-01

Tool measurement and workpiece measur ement

Determining tool-setting dimensions with a tool touch probe•

Determining tool-setting dimensions with an optical gauge•

Automatic workpiece measurement with a touch probe•

Slovenian

Slovak

Latvian

Norwegian

Korean

Estonian

Turkish

Romanian

Lithuanian

DXF import

Import of DXF contours•

C-axis machining

Y-axis machining

Support of W axis

12

Page 13

Digital Control Design

Digital in every

way

HSCI

In the uniformly digital control design from HEIDENHAIN, all

components are connected to each other via purely digital

interfaces: The control components are connected via HSCI

(HEIDENHAIN Serial Controller Interface), the new real-time

protocol from HEIDENHAIN for Fast Ethernet, and the encoders

are connected via EnDat 2.2, the bidirectional interface from

HEIDENHAIN. This achieves a high degree of av ailability for the

entire system. It can be diagnosed and is immune to noise—from

the main computer to the encoder . These outstanding properties

of the uniformly digital design from HEIDENHAIN guarantee not

only very high accuracy and surface quality, but rapid tra v erse

speeds as well. Please refer to the Unif ormly Digital tec hnical

Information sheet for more detailed information.

HSCI, the HEIDENHAIN Serial Controller Interface, connects the

main computer , controller(s) and other control components.

HSCI is based on 1 00BaseT Ethernet hardw are. A special interf ace

component developed by HEIDENHAIN has shortened cy cle times

for data transfer.

Main advantages of the contr ol design with HSCI:

Hardware platform for fl exible and scalable control system •

(e.g. local axis systems)

High noise immunity due to digital communication between •

components

Greater permissible cable lengths within the overall system•

More PLC inputs and outputs•

Simpler wiring (initial operation, confi guration)•

Inverters connected as before via w ell-pro v en PWM interf ace•

CC or UEC controller units, up to eight PL 6xxx input/output

modules, and an MB machine operating panel can be connected

to the serial HSCI bus of the MC main computer . The HR

handwheel is connected directly to the machine operating panel.

The combination of visual display unit and main computer housed

in the operating panel is especially advantageous. All that is

required is the power supply and an HSCI line to the controller in

the electrical cabinet.

HSCI HSCI HSCI

HSCI

MC main computer

PLC inputs/

outputs PL

CC controller unit Touch probe

13

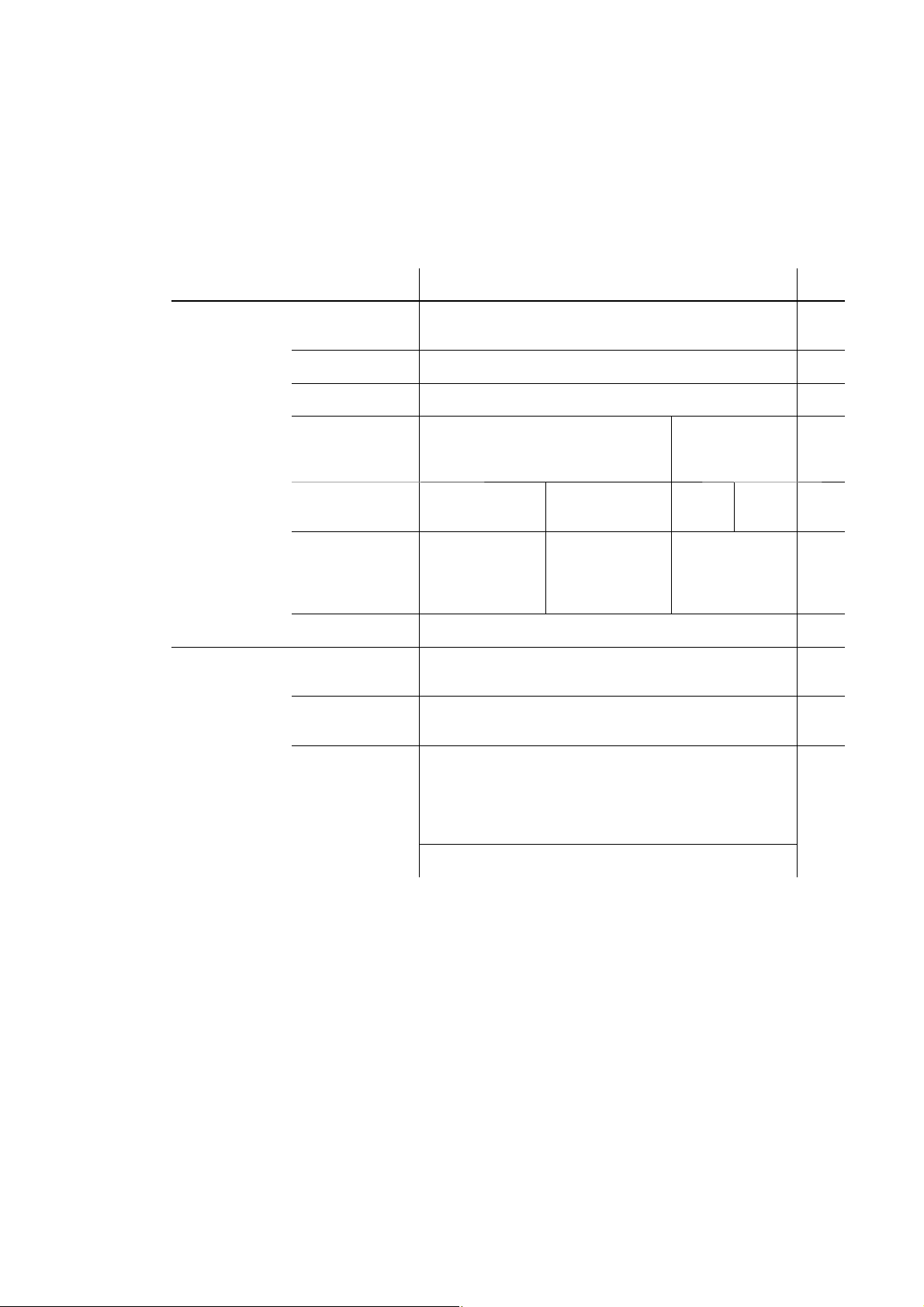

Page 14

HSCI Control S yst em MANU ALplus 620

Overview

The MANUALplus 620 contouring control consists of the follo wing

components:

Type Page

MANUALplus 620

Accessories Machine operating

Main computer

with 12.1

Memory card

NC software license

Pow er supply unit

Controller unit

Control loops

PLC inputs/

outputs

System PL

Expansion PL

Connecting cables 26

panel

Electronic

handwheels

Touch probes

,,

screen

MC 6110 T 15

CFR 16

SIK component 16

PSL 130 (as required)

PSL 135 (for use with non-HEIDENHAIN

inverter systems)

UEC 11 1

Max. 4

PL 6xxx series

Integrated

Max. 7 PLB 61 0x

MB 620 T 21

HR 410, HR 1 80, HR 130 or HR 150 22

TS 220 or

TS 440 or

TS 444 or

TS 640 or

TS 740

1)

UEC 112

Max. 5

PL 6xxx series

Integrated

Max. 7 PLB 61 0x

1)

PSL 130 20

CC 6106

Max. 6

PL 6xxx series

One PLB 620x

Max. 7 PLB 61 0x

CC 6108

Max. 8

17

19

24

14

1)

Inverter and system PL integrated

TT 140

Page 15

Main Computer

Main computer

MC 6110 T

The MC 6110 T main computer consists of

1.0 GHz Celeron M processor•

1 GB RAM memory•

MANUALplus control panel•

12.1-inch TFT color fl at-panel display with soft keys, •

resolution: 1 024 x 768 pixels

HSCI interface to the controller unit and to other control •

components

Further interf aces, such as Ethernet, USB, RS-232-C/V.24•

To be ordered separately , and installed in the main computer by

the OEM:

CFR• memory card with the NC sof tware

SIK component• (System Identifi cation Key) for enabling control

loops and options

The following HSCI components are necessary for operation of the

MANUALplus 620:

PL 62xx• PLC input/output unit (system PL; integrated in

UEC 11x)

Weight 5.6 kg

ID 731 604-xx

Po w er supply If a CC 61 0x controller unit is used, the PSL 130 supplies 24 V of

power to the main computer and other HSCI components. If a

UEC controller unit is used, a PSL 130 is only required if the

current consumption is greater than 3.5 A.

Options

The capabilities of the MANUALplus 620 can also be adapted

retroactively with options to meet new requirements. These

options are described on page 11. T he y are enabled b y entering

keywords based on the SIK number, and are saved in the SIK

component. Please indicate your SIK number when ordering new

options.

15

Page 16

Main Computer—CFR Memory Card, SIK Component

CFR CompactFlash

SIK component

Master keyword

(general key)

The NC software f or the MANUALplus 620 is on the

CFR CompactFlash memory card (CFR = CompactFlashRemovable).

It is also the memory medium for NC programs (up to 250 MB)

and the PLC program (up to 50 MB).

MANUALplus 620 ID 733 606-51

The SIK component contains the NC software license for enabling

control loops and software options. It gives the main computer an

unambiguous ID code—the SIK number . The SIK component is

ordered and shipped separately . It must be inserted in a special

slot in the MC 611 0 T main computer .

The SIK component with the NC software license is a v ailable in

various versions, depending on the enabled control loops.

Additional control loops can be enabled later by entering a

keyword. HEIDENHAIN pro vides the k e yw ord, which is based on

the SIK number . When ordering, please indicate the SIK number of

your control. When the keywords are entered in the control, they

are saved in the SIK component. This enables and activates the

options. Should service become necessary, the SIK component

must be inserted in the replacement control to enable all required

options.

There is a master keyw ord (general k e y) f or putting the

MANUALplus 620 into service that will unlock all control loop

options for a duration of 90 days. After this period, only those

options with the correct keywords will be activ e. The general key is

activated using a soft k e y.

SIK component

NC softwar e

license and

enabling of control

loops

NC softwar e license SIK with software license and enabling for ID

Additional axes Option

There are always 3 control loops enabled in the basic version. The

controller unit must be capable of handling the number of

activated control loops. Maximum numbers:

UEC 111: 4 control loops•

UEC 112: 5 control loops•

CC 61 06: 6 control loops•

CC 61 08: 7 control loops•

Three control loops, including options:

Teach-in (option 8)•

smart.Turn (option 9)•

Thread recutting (option 11)•

C-axis machining (option 55)•

number

1st additional axis (4th control loop) 0 354 540-01

733 604-53

ID

16

2nd additional axis (5th control loop) 1 353 904-01

3rd additional axis (6th control loop) 2 353 905-01

4th additional axis (7th control loop) 3 367 867-01

Page 17

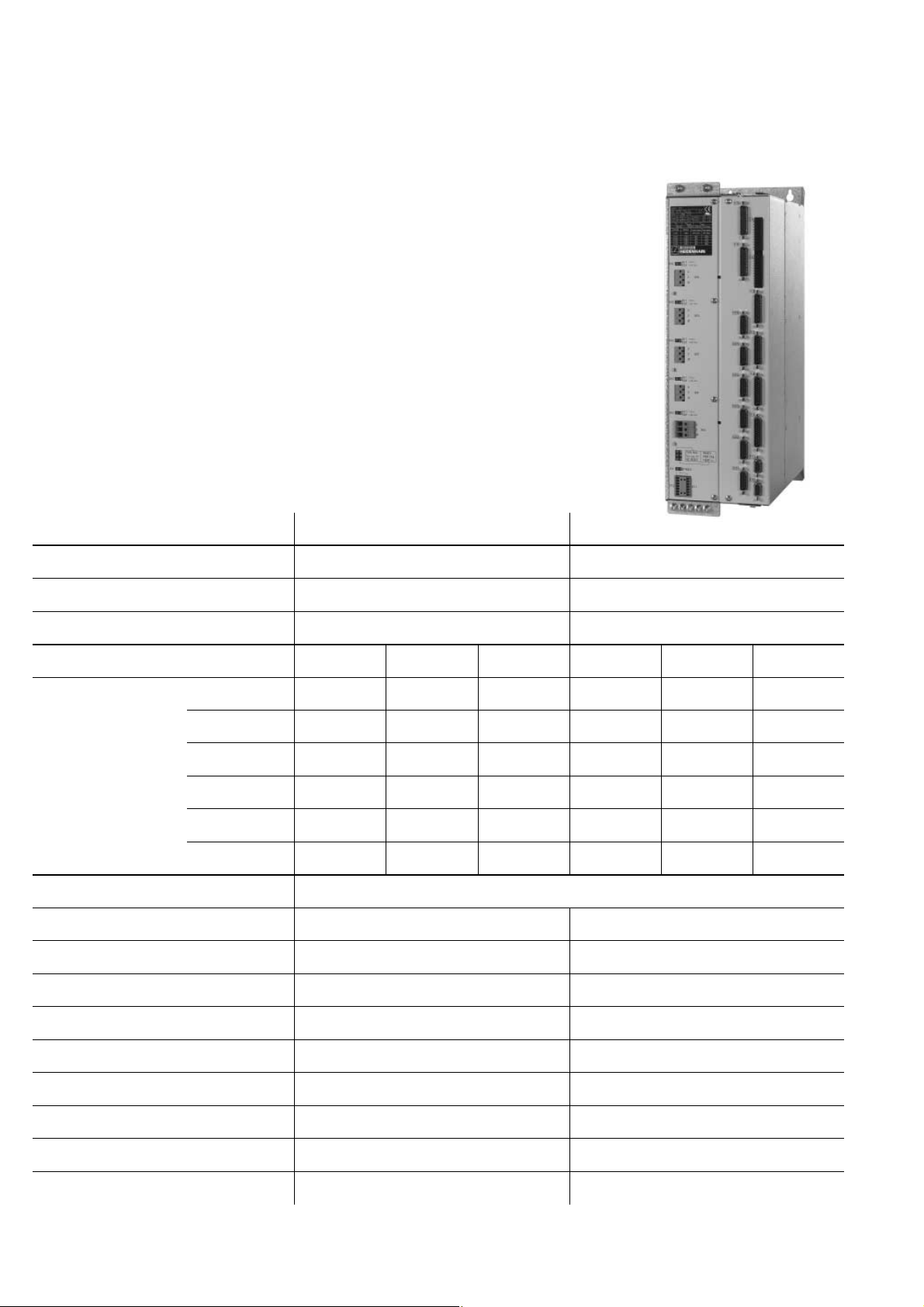

Controller Unit

Controller unit

Number of

control loops

V ersions Controller units and main computers operate in any desired

CC 610x

Due to the very short cycle times of the position, velocity and

current controllers, the controller units from HEIDENHAIN are

equally suited for conventional driv es, f or direct driv es (linear

motors, torque motors) and for HSC spindles. They permit a high

loop gain and short reaction times to changing machining forces,

and so make the high contour accuracy and surface quality of the

workpiece possible.

The number of enabled control loops depends on the SIK (see

Main Computer ), or on additionally enabled control loops, which

can also be ordered as needed at a later date.

combination. HEIDENHAIN off ers the f ollo wing v ersions:

Modular CC 61 0x controller unit with PWM interf ace to the •

inverters

Compact UEC 11x controller units with integrated inverter•

The CC 61 0x controller unit features:

Position controller•

Speed controller•

Current controller•

HSCI interfaces•

PWM interfaces to the UM 1xx, UR 2xx, and UE 2xx power •

modules

Interfaces to the speed encoders•

Interfaces to the position encoders•

Interfaces for the pow er supply (supply via UVR 1xx D, UE 2xx D •

or UR 2xx)

CC 6106

CC 6106 CC 6108

Digital control loops

Speed inputs

Position inputs

PWM outputs

Weight

ID

Max. 6 Max. 8

PP

PP

or

or

6 x 1 V

EnDat 2.2

6 x 1 V

EnDat 2.2

68

4.1 kg 4.7 kg

662 636-xx 662 637-01

8 x 1 V

EnDat 2.2

8 x 1 V

EnDat 2.2

PP

PP

or

or

CC 6108

17

Page 18

UEC 11x

Controller Position controller•

Inverters Po w er electronics•

System PL Interfaces for one workpiece touch probe and one tool •

Along with the controller with PLC inputs and outputs, the

UEC 11x compact controller units also include an inverter with

integrated braking resistor . They offer a complete solution for

machines with a limited number of axes and lo w po w er demands.

Speed controller•

Current controller•

HSCI interface•

Interfaces to the speed and position encoders•

Connections for axis motors and spindle motor•

Braking resistor•

Connections for motor holding brakes•

touch probe

PLC with 38 inputs and 23 outputs (of which 7 outputs can be •

switched off) freely available (expandable via PL 61xx)

Confi guration with IOconfi g • PC software

UEC 111 UEC 112

Controller

Speed inputs

Position inputs

Inverters

Rated curr ent I

Max. current I

N

max

/

1)

for PWM frequency

Pow er supply

Rated power of DC link

Peak pow er

2)

of DC link 18 kW/25 kW 18 kW/25 kW

Pow er loss (appr ox.) at I

4 digital control loops 5 digital control loops

4 x 1 V

4 x 1 V

or EnDat 2.2 5 x 1 V

PP

or EnDat 2.2 5 x 1 VPP or EnDat 2.2

PP

or EnDat 2.2

PP

2 axes 1 axis Spindle 3 axes 1 axis Spindle

3 333 Hz 6.0/12.0 A 9.0/18.0 A 24.0/36.0 A 6.0/12.0 A 9.0/18.0 A 24.0/36.0 A

4 000 Hz 5.5/11 .0 A 8.3/16.5 A 22.0/33.0 A 5.5/11.0 A 8.3/1 6.5 A 22.0/33.0 A

5 000 Hz 5.0/1 0.0 A 7.5/1 5.0 A 20.0/30.0 A 5.0/1 0.0 A 7.5/1 5.0 A 20.0/30.0 A

6 666 Hz 4.2/8.4 A 6.3/12.6 A 16.8/25.2 A 4.2/8.4 A 6.3/1 2.6 A 1 6.8/25.2 A

8 000 Hz 3,6/7.3 A 5.5/1 1.0 A 1 4.6/21.9 A 3,6/7.3 A 5.5/11.0 A 14.6/21.9 A

10 000 Hz 3.0/6.0 A 3.0/6.0 A 12.2/1 8.3 A 3.0/6.0 A 3.0/6.0 A 12.2/18.3 A

3 x 400 V (± 10 %); 50 Hz to 60 Hz or 3 x 480 V (± 10 %); 50 Hz to 60 Hz

14 kW 14 kW

N

450 W 450 W

DC-link voltage

Integral braking r esistance

Pow er pac k f or HSCI components

Module width

Weight (approx.)

ID

1)

Axes: 0.2 s Cyclic duration factor for duty cycle time of 10 s with 70 % rated current preload

Spindle: 10 s Cyclic duration factor f or duty cycle time of 60 s with 70 % rated current preload

2)

1st value: 40 % Cyclic duration f actor f or duty cycle time of 10 minutes (S6-40 %)

565 V 565 V

2.1 kW/27 kW 2.1 kW/27 kW

24 V/3.5 A 24 V/3.5 A

175 mm 175 mm

20 kg 20 kg

625 777-xx 625 779-xx

2nd value: 4 s Cyclic duration factor f or duty cycle time of 20 s

18

Page 19

PL 6xxx PLC Input/Output Sy stems with HSCI

Basic modules

System PL

PLB 6204

PLB 6206

PLB 6208

Expansion PL

PLB 61 04

PLB 61 06

PLB 61 08

The PLC inputs and outputs are available via e xternal modular

PL 6xxx PLC input/output systems. These consist of a basic

module and one or more I/O modules, and are connected to the

MC main computer via the HSCI interface. The PL 6xxx units are

confi gured with the PC software IOconfi g.

There are basic modules with HSCI interf ace a v ailable f or 4, 6 or

8 I/O modules. They are mounted on standard NS 35 rails

(DIN 46 227 or EN 50 022).

Supply voltage 24 V–

Po w er consumption Appro x. 20 W

Weight 0.36 kg (bare)

One required per control system•

Includes connections for TS touch probes (except with UEC)•

Safety-relev ant inputs/outputs•

For 4 I/O modules ID 591 832-01

For 6 I/O modules ID 630 054-01

For 8 I/O modules ID 630 055-01

For connection to the system PL to increase the number of PLC

inputs/outputs

For 4 I/O modules ID 591 828-01

For 6 I/O modules ID 630 058-01

For 8 I/O modules ID 630 059-01

PL 62xx

Up to eight PL 6xxx units can be connected to the control (one

PLB 62xx or UEC 11x and up to seven PLB 61xx). The maximum

cable length results from the maximum permissible length of the

HSCI chain of 100 m.

I/O modules With HSCI interface:

There are I/O modules with digital and analog inputs and outputs.

For partially occupied basic modules, the unused slots must be

occupied by an empty housing.

PLD-H 16-08-00

PLD-H 08-16-00

PLA-H 08-04-04 Analog module for PL 6xxx with

Empty housing

I/O module with 16 digital inputs and 8 digital outputs

I/O module with 8 digital inputs and 16 digital outputs

Total current Outputs 0 to 7: † 8 A per output

(† 8 A simultaneously)

Po w er output Max. 200 W

Weight 0.2 kg

PLD-H 16-08-00 ID 594 243-01

PLD-H 08-16-00 ID 650 891-01

8 analog inputs for ±10 V

4 analog outputs for ±10 V

4 analog inputs for PT 100 thermistors

Weight 0.2 kg

ID 675 572-01

For unused slots

ID 383 022-01

PL 61xx

IOconfi g

(accessory)

PC software for confi guring the PL 6xxx and PL 550 (PROFIBUS-DP)

components

19

Page 20

P o w er Supply f or HSCI Components

To power the HSCI components HEIDENHAIN offers the PSL 1 3x

power supply units.

The PSL 13x is pro vided either with line and DC-link v oltage or only

with line voltage.

The PSL 13x pro vides the safely separated +24 volt NC power

supply required for the HSCI components by EN 61 800-5-1. The

NC and PLC are powered by two separate, metallically isolated

power supply units.

Supply voltage Line voltage: 400 V~ ± 10 % 50 Hz, and

DC-link voltage 400 V– to 750 V–

Po w er consumption: Max. 1000 W

Outputs NC: 24 V–/† 20 A (double isolation)

5 V–/† 1 6 A (only with PSL 135)

electrically connected with 24 V NC

PLC: 24 V–/† 20 A (basic isolation)

Total: Max. 32 A/750 W

The PSL 130 serves as a 24-V power supply unit for supplying the

HSCI components. If a UEC controller unit is used, then the

PSL 130 is not necessary if the total current consumption of the

connected HSCI components does not exceed 3.5 A.

PSL 130

PSL 130

PSL 135

Conductor bars

HSCI component MC 6120 TE 615 QT PL 62xx

(incl. TS

and TT)

Current

consumption

When a non-HEIDENHAIN inverter system is used (e.g. Siemens

SIMODRIVE 611 D), the PSL 135 power supply unit is required for

supplying the CC controller unit and the MC main computer .

Module width Degree of

50 mm IP 20 2.1 kg 575 047-xx

50 mm IP 20 2.5 kg 627 032-xx

For connecting the PSL 1 30 to the dc-link v oltage.

If the 24 V po w er supply unit PSL 130 is arranged to the left ne xt

to the UV(R) 1xx D or UE 2xx D/UR 2xx D, it can be connected

directly to the DC link through special conductor bars. The

conductor bars are insulated. The +U

blue. The following lengths are available:

1.8 A 1.1 A 0.5 A 0.2 A

Weight ID

protection

bar is red and the –Uz bar is

z

PL 61xx

PSL 135

20

Length Red Blue

150 mm (UVR 120 D/1 30 D/UV 130) 682 996-0 1 682 996-51

200 mm (UVR 140 D/150 D/UE 21x D) 682 996-02 682 996-52

250 mm (UVR 160 D/UR 2xx D) 682 996-03 682 996-53

Page 21

Accessories

Mac hine Operating Panel

Machine operating

panel

MB 620 T

HSCI adapter

21 exc hangeable snap-on k e y s, freely defi nable via PLC•

Operating elements: 12 axis ke y s, 16 function keys, NC start•

NC stop

Snap-On Keys); emergency stop button, control voltage on

2 holes for additional keys or detachable-key switch

HSCI interface•

8 PLC inputs and 8 PLC outputs•

Spindle-speed and feed-rate ov erride potentiometers•

Weight 0.9 kg

ID 737 610-01

Po w er supply: 24 V , current consumption: 1 A•

Confi guration of the PLC inputs/outputs with the IOconfi g •

PC software

1)

Keys illuminated

For the OEM mac hine operating panel.

The PLB 600 1 HSCI adapter is required in order to connect an

OEM-specifi c machine operating panel to the iTNC 620 HSCI. The

override potentiometers of the TE 6xx and the HR xxx handwheel

for spindle speed and feed rate are also connected to this adapter.

1)

, spindle start, spindle stop (all are snap-on keys; see

1)

,

1)

;

MB 620 T

PLB 6001 HSCI interface•

Connection for HR xxx•

Terminal for 64 inputs and 32 outputs (inputs/outputs for keys/•

key illumination)

Connection for spindle speed override and feed-rate override•

Screw fastening or DIN-rail mounting•

Confi guration of the PLC inputs/outputs with the IOconfi g •

PC software

Weight Approx. 1.2 kg

ID 668 792-01

21

Page 22

Electronic Handwheels

Function

HR 180

The standard MANUALplus 620 supports the use of electronic

handwheels.

The following handwheels can be installed:

For connection to the position inputs,•

up to two HR 180 panel-mounted handwheels

For connection to the handwheel input of the MB mac hine •

operating panel or the PLB 6001 HSCI adapter,

one HR 410 portable handwheel, or

one HR 130 panel-mounted handwheel, or

up to three HR 150 panel-mounted handwheels through the

HRA 110 handwheel adapter

Any combination is possible. Cycle machines, for example,

typically use HR 180 and—if required—one HR 41 0, or if there are

not enough position inputs, up to three HR 150 handwheels via

the HRA 11 0 handwheel adapter. CNC machines usually require

only one HR 130 or HR 410.

Incremental traverse of the slide:•

1 µm/1 0 µm/100 µm per increment

The handwheels with detent have 100 stops per revolution•

Positioning the slide to the starting position of MANUALplus •

cycles

Fine adjustment of tool position•

Panel-mounted handwheel with ergonomic control knob for

connection to a position encoder input.

HR 130

HRA 110

Weight Approx. 0.7 kg

HR 180 with detent ID 540 940-08

Panel-mounted handwheel with ergonomic control knob for

connection to the handwheel input.

Weight Approx. 0.7 kg

HR 130 without detent ID 254 040-05

HR 130 with detent ID 540 940-01

Handwheel adapter for connection of up to three HR 150 panelmounted handwheels and two switches for axis selection and f or

selecting the interpolation factor. The fi rst two handwheels are

permanently assigned to axes 1 and 2. The third handwheel is

assigned to the axes over a selection switch (accessory) or by

machine parameters. The position of the second selection switch

(accessory) is evaluated by the PLC, for example to set the proper

interpolation.

HRA 110

ID 261 097-xx

Weight Approx. 1.5 kg

Handwheel selection switch with knob and cable

ID 270 908-xx

HR 150

22

Panel-mounted handwheel with ergonomic control knob for

connection to the HRA 110 handwheel adapter.

Weight Approx. 0.7 kg

HR 150 without detent ID 540 940-06

HR 150 with detent ID 540 940-07

Page 23

HR 410

HR 41 0 v ersion Mechanical detent

With Without

Portable electronic handwheel with

Keys for the selection of 5 axes•

Traverse direction keys•

Keys for three preset feed rates•

Actual-position-capture k e y•

Three keys with machine functions (see below)•

Two permissive buttons (24 V)•

Emergency stop button (24 V)•

Magnetic holding pads•

All keys are designed as snap-on keys and can be replaced by keys

with other symbols. (For ke y symbols see Snap-On Keys.)

Weight Approx. 1 kg

Standard assignment with the

FCT A, FCT B, FCT C function

keys

For PLC basic program with

NC start/stop, spindle start

With spindle right/left/stop – 296 469-54

– 296 469-53

535 220-05 296 469-55

HR 410

23

Page 24

Touch P robes

Wor kpiece

measurement

TS 220 TTL version

TS 440 Compact dimensions

TS 444 Compact dimensions, battery-free power supply through

TS 640 Standard touch probe with wide-range infrared transmission and

Touch probes f or w orkpiece measurement are connected via the

system PL 62xx or the UEC 11x. T hese touch probes generate a

trigger signal that saves the current position value to the NC. For

more information on the touch probes, ask f or our brochure or

CD-ROM entitled Touch Probes.

The TS touch trigger probe has a stylus with which it probes

workpieces. The MANUALplus 620 provides a sample cycle for

measuring workpieces. Additionally, the machine manufacturers

off er specially de v eloped measuring cy cles that are individually

adapted to the machine series. The touch probes are av ailable with

various taper shanks. Assorted styli are available as accessories.

Touch probe with cable connection f or signal tr ansmission for

machines with manual tool change:

Touch probe with infr ar ed signal tr ansmission f or machines with

automatic tool change (e.g. turret magazine):

integrated air turbine generator over central compressed air supply

long operating time

TS 220

TS 740 High probing accuracy and repeatability, low probing force

The infrared transmission is established between the TS touch

probe and the SE transceiver unit. The following SE units can be

combined with the TS touch probes:

SE 640 for integration in the machine’ s w orkspace

SE 540 for integration in the spindle head

Tool calibration

TT 140 With the triggering TT 140 touch pr obe, the cuboid probe contact

Cuboid probe

contact

The touch probe f or tool measurement from HEIDENHAIN is suited

for probing tools directly on the machine. The MANUALplus 620

off ers standard cycles. The MANUALplus 620 automatically sav es

the results of measurement in a tool table. It is also possible to

measure tool wear between two machining steps. After measuring

the tool, the MANUALplus 620 compensates the tool data

automatically for subsequent machining.

is defl ected from its rest position upon contact with a stationary or

rotating tool, sending a trigger signal to the MANUALplus 620.

The standard TT 140 is shipped with a disk-shaped probe contact.

For use with lathes, it must be replaced by the cuboid probe

contact.

ID 67 6 497-01

TS 440 with SE 640

TT 140

24

Page 25

Snap-On Keys

The snap-on keys make it easy to replace the key symbols. In this way, the MB machine operating panel and the

HR 41 0 handwheel can be adapted to different requirements.

The snap-on keys are available in packs of 5 keys.

Axis keys

Orange

ID 330 816-42

ID 330 816-24

ID 330 816-43

ID 330 816-37

Gray

Machine functions

ID 330 816-26

ID 330 816-23 ID 330 816-25

ID 330 816-95

ID 330 816-96

ID 330 816-97

ID 330 816-98

ID 330 816-99

ID 330 816-0A

ID 330 816-0B

ID 330 816-0C

ID 330 816-70

ID 330 816-0X

ID 330 816-36

ID 330 816-69

ID 330 816-0G

ID 330 816-0H

ID 330 816-71

ID 330 816-72

ID 330 816-63

ID 330 816-64

ID 330 816-18

ID 330 816-17

ID 330 816-75

ID 330 816-38

ID 330 816-45

ID 330 816-0W

ID 330 816-0V

ID 330 816-0N

ID 330 816-0M

ID 330 816-67

ID 330 816-68

ID 330 816-21

ID 330 816-20

ID 330 816-0P

ID 330 816-0T

Y

Y

Z

ID 330 816-0R

ID 330 816-0D

ID 330 816-0E

ID 330 816-65

ID 330 816-66

ID 330 816-19

ID 330 816-16

ID 330 816-0L

ID 330 816-0K

ID 330 816-86

Spindle functions

Other keys

ID 330 816-1Y

ID 330 816-30

ID 330 816-31

ID 330 816-32

ID 330 816-73

ID 330 816-74

ID 330 816-08

ID 330 816-09 ID 330 816-46

ID 330 816-01

ID 330 816-61

(green)

ID 330 816-11

(red)

ID 330 816-12

ID 330 816-76

ID 330 816-77

ID 330 816-78

ID 330 816-79

ID 330 816-80

ID 330 816-0S

ID 330 816-41

ID 330 816-50

ID 330 816-33

ID 330 816-34

ID 330 816-35

ID 330 816-81

ID 330 816-82

ID 330 816-83

ID 330 816-84

ID 330 816-89

ID 330 816-85

(red)

ID 330 816-47ID 330 816-40

(green)

ID 330 816-90

ID 330 816-27

ID 330 816-28

ID 330 816-29

ID 330 816-87

ID 330 816-88

ID 330 816-94

ID 330 816-0U

ID 330 816-91

ID 330 816-3L

ID 330 816-48

ID 330 816-93

0

ID 330 816-0Y

ID 330 816-4M

ID 330 816-3M

ID 330 816-49

ID 330 816-22

ID 330 816-92

ID 330 816-3N

25

Page 26

Cable Overview

Control Sy stem with UEC 11x

60m

07.06.2010

12m

VL: Extension cable

for separation points with connecting cable

HSCI total length 100 m

for extending existing connecting cable

PP

1 V

PP

1 V

RCN 729

RCN 226

RCN 228

LC

LC x83

631-xx max. 6m

533

60m

RCN 729

RCN 226

RCN 228

60m

PP

1 V

30m

LC x83

1m

1m

LC x83

631-xx max. 6m

533

60m

LB/LS

max. 9m

PP

1 V

298 429-xx

298 430-xx

MB 620 T

739 545-xx

MC 6110 T

X500

X502

X

X500

310 199-xx

309 783-xx

X502

UEC 11x

558 714-xx

Position inputs

X201 ... X204 (UEC 111)

X201 ... X205 (UEC 112)

PLC I/O

VL

323 897-xx

332 115-xx

X15 ... X18 (UEC 111)

X15 ... X19 (UEC 112)

23 outputs

38 inputs

509 667-xx

Adapter connector 544 703-01

for spindle (if necessary)

Only for connection of the KTY

2)

1)

1)

289 440-xx

VL

323 897-xx

2)

Voltage controller 5 V

368 210-01

336 376-xx

Speed inputs

289 440-xx

KTY

KTY

Voltage controller 5 V

383 951-01

289 440-xx

1)

336 376-xx

Axes: 15m

26

HSCI

618 893-xx

HSCI

618 893-xx

PP

1 V

VL

336 847-xx

VL (max. 6m)

30m

Axes + spindle:

Voltage controller 5 V

336 847-xx

60m

Axes + spindle:

VL

340 302-xx

370 226-01

Voltage controller 5 V

370 224-01

VL (max. 6m)

340 302-xx

EnDat 2.1 interface

Axes: 60m

Page 27

Control Sy stem with CC 610x

60m

07.06.2010

12m

PP

1 V

PP

1 V

RCN 729

RCN 226

RCN 228

LC

LC x83

631-xx max. 6m

533

60m

RCN 729

RCN 226

RCN 228

60m

PP

1 V

30m

LC x83

1m

1m

LC x83

631-xx max. 6m

533

60m

LB/LS

PP

1 V

VL: Extension cable

HSCI total length 100 m

for separation points with connecting cable

for extending existing connecting cable

MC 6110 T

X500

298 429-xx

298 430-xx

X502

MB 620 T

739 545-xx

X

310 199-xx

X500

309 783-xx

558 714-xx

Position inputs

X201 ... X206

CC 6106

X502

VL

323 897-xx

332 115-xx

X15 ... X20

X500

X51...X56

PWM

out

Adapter connector 544 703-01

1)

509 667-xx

Voltage controller 5 V

for spindle (if necessary)

Only for connection of the KTY

2)

1)

289 440-xx

289 440-xx

VL

323 897-xx

2)

368 210-01

336 376-xx

Speed inputs

1)

KTY

Axes: 15m

Voltage controller 5 V

383 951-01

max. 9m

KTY

289 440-xx

336 376-xx

HSCI

618 893-xx

X502

HSCI

618 893-xx

VL

340 302-xx

370 226-01

Voltage controller 5 V

370 224-01

VL (max. 6m)

340 302-xx

EnDat 2.1 interface

Axes: 60m

VL (max. 6m)

336 847-xx

60m

Axes + spindle:

Voltage controller 5 V

VL

336 847-xx

PL 610x

HSCI

PL 620x

30m

PP

1 V

X502

X500

HSCI

618 893-xx

Axes + spindle:

27

Page 28

Inv erter S y stems

X51 ... X62

(if needed)

250 479-07...-16

24V

X51 ... X62

250 479-07...-16

325 817-xx

X79

X69

325 816-xx

X69

See Motors catalog

for power cable to motor

UM 1xx UP 110

250 479-07 ... -16

(if needed)

ZKF 1xx

UM 1xxUM 1xx

250 479-07 ... -16

CC 6106

UM 111

Compact inverter (regenerative)

UR 2xx

Uz Uz Uz

X69

325 817-xx

325 816-xx

See Motors catalog

for power cable to motor

PSL 130

15m

D

Uz Uz Uz Uz Uz Uz Uz

UVR

1xx

24V

PSL 130

EPCOS xx

Line filter

X79

X69

15m

Three-phase

ac capacitor

348 993-01

KDR 120

Line filter

EPCOS 35 A

L1 L2 L3

L1 L2 L3

Compact inverter (nonregenerative)

L1 L2 L3

HSCI

Uz Uz Uz Uz

UEC 11x

Uz

CC 6106

CC 42x

UV 105

(if needed)

UM 111

(if needed)

B

UE 2xx

24V

PSL 130

24V

PSL 130

X51 ... X62

250 479-07...-16

PW 210

Three-phase

ac capacitor

325 817-xx

X79

348 993-01

X69

325 816-xx

X69

(if needed)

L1 L2 L3

KDR 1xx

See Motors catalog

for power cable to motor

15m

X69

250 479-07...-16

See Motors catalog

for power cable to motor

X51 ... X62

325 817-xx

X79

325 816-xx

X69

CC 6106 CC 6106

15m

UM 1xxUM 1xxUM 1xx

250 479-07...-16

250 479-07...-16

See Motors catalog

for power cable to motor

15m

Modular inverter (nonregenerative) Modular inverter (regenerative)

Uz Uz Uz Uz Uz

UV

D

130

24V

PSL 130

28

(if needed)

PW 210

PW 210

Page 29

Accessories

HR 410

296 469-xx

535 220-xx

50m

3m

HR 130

540 940-01

-03

HR 150

540 940-06

03.08.2007

-07

296 467-xx

296 687-xx

312 879-01

296 466-xx

VL

281 429-xx

50m

max. 20 m

3 inputs

HRA 110

261 097-xx

683 259-xx

X23

20m

366 964-xx

PC

V.24/RS-232-C

274 545-xx

HSCI total length 100 m

VL: Extension cable

for separation points with connecting cable

for extending existing connecting cable

SE 640

631 225-xx

0.5m

633 611-xx

633 608-xx

TS 640

620 189-xx

517 375-xx

TS 220

293 488-xx

TS 44x

SE 540

626 001-xx

30m

588 008-xx

50m

TT 140

527 797-xx

Accessories

USB hub

582 884-01

MB 620 T

Adapter 25 pin

Adapter 9 pin

363 987-02

355 484-xx

Ethernet

X26

310 085-01

365 725-xx

X27

5m

354 770-xx

X141

X142

624 775-xx

X112

633 613-xx

633 616-xx

X500

X113

PL 61xx

7 x max.

PLC

MC 6110 T

PL 62xx

UEC 11x

29

Page 30

MANU ALplus 620

The Contouring Control for CNC and Cycle Lathes

The MANUALplus 620 for cy cle lathes

Conceived for general repairs, thread repairs, single parts and •

short production runs

Supports action-oriented machining•

Quickly learned—requires minimum training time•

Supports boring, drilling and milling operations on the face and •

lateral surface

Features a wide machining spectrum, from simple turned parts •

to complex workpieces

The MANUALplus 620 for CNC lathes

Conceived for medium-sized and large production r uns•

Programming via smart.Turn and/or DIN PLUS•

smart.Turn is quickly learned and requires v ery little training time•

Supports boring, drilling and milling operations on the face and •

lateral surface

Features a wide machining spectrum, from simple turned parts •

to complex workpieces

30

Page 31

Technical Description

Axes

The MANUALplus 620 is a contouring control f or lathes with one

spindle and a slide (X, Z and Y) for tool movement. The control can

also offset the display of mo v ements in the Z axis with those of its

secondary axis W.

The MANUALplus supports both horizontal and vertical lathes.

Display and

programming

Traverse range –99 999.9999 to +99 999.9999 [mm]

Tool carriers The MANUALplus 620 supports quic k change tool posts (Multifi x)

Feed rate in

mm/min•

mm/revolution•

Feed rate ov erride: 0 to 150%•

Maximum feed rate at f•

60 000 min

No. of pole pairs in motor

The machine tool builder defi nes the traverse range. It is also

possible for the operator to limit the traverse range if he wishes to

reduce the working space (with software limit switches).

A protection zone for the spindle (Z–) can also be specifi ed.

and tool turrets. The tool carriers can be located in front of or

behind the workpiece.

–1

= 5 000 Hz:

PWM

· screw pitch [mm]

C1(S4)

Y1 Z1

31

Page 32

Spindle

For machines featuring a higher le v el of automation, y ou can

position the spindle or switch to C-axis operation.

Display and

programming

Spindle positioning Input resolution and display step: 0.001°

Spindle override 50 to 150%

Maximum speed n

Speed limiting The MANUALplus monitors the actual speed.•

Gear ranges A specifi c parameter can be defi ned for each gear range. The

C-axis operation For milling, drilling and boring cycles, either the spindle is switched

Spindle speed:

Constant shaft speed: 1 to 99 999 rpm•

Constant surface speed: 1 to 9 999 m/min•

max

f

PWM

NPP = number of pole pairs

Speed limiting can be adjusted via parameter and in the feed •

rate/spindle/tool menu.

gears are switched via the PLC. Up to 10 gear ranges are

supported.

to C-axis operation or a separate C-axis drive is activated.

Input resolution and display step: 0.00 1°

NPP · 5 000 Hz

= PWM frequency in Hz

f

· 60 000 min

PWM

=

–1

Driven T ool

The live (i.e. driv en) tool is used f or drilling and tapping holes as

well as for milling in M1 9 or C-axis operation. P rograms f or a driv en

tool can be entered in manual operation, via cycles with smart.Turn

or in the DIN editor .

Display and

programming

Speed limiting The MANUALplus monitors the actual speed.•

Speed of the driven tool:

Constant shaft speed: 1 to 99 999 rpm•

Constant surface speed: 1 to 9 999 m/min•

Speed limiting can be defi ned via parameter and in the feed-rate/•

spindle/tool menu (TSF menu).

32

Page 33

Digital Control

Integrated in v er t er

Servo drive control

Velocity

Nominal

velocity

Nominal

position

feedforward

Position

controller

Position controllers, speed controllers, current controllers and

inverters are integrated in the control. HEIDENHAIN sync hronous

and asynchronous motors are connected to the MANU ALplus 620.

Inverter

Acceleration

Nominal

acceleration

Nominal

speed

feedforward

Speed

controller

Nominal

current

Current

controller

Power stage

Actual current

Actual speed

Motor with

rotary encoder

for shaft speed

and rotor position

Machine

Machine slide

with linear or

angle encoder

Axis feedback

control

Operation with

following er r or

(servo lag)

Servo control with

feedforw ar d

Actual position

The MANUALplus 620 operates with f eedf orward control.

The term “f ollo wing er ror” denotes the distance between the

momentary nominal position and the actual position of the axis.

The velocity is calculated as follows:

v = k

· s

v

a

k

s

v = velocity

= position loop gain

v

= following error

a

Feedforward control means that a velocity and acceleration input

is adapted to the machine while taking the jerk limiting into

account. Together with the values calculated from the f ollo wing

error , it f orms the nominal v alue. This greatly reduces the following

error (to within a few µm).

The feedf orward is adjustable from 0 to 1 00 % via a mac hine

parameter .

33

Page 34

Compensation of

torque r ipples

The torque of synchronous, torque and linear motors is subject to

periodic oscillations, one cause of which can be permanent

magnets. The amplitude of these oscillations depends on the

motor design, and under certain circumstances can have an eff ect

on the workpiece surface. After the axes have been commissioned

with the TNCopt software, the Torque Ripple Compensation (TRC)

of the CC 61 0x or UEC 11x can be used to compensate this torque

ripple.

Control loop

cycle times

CC 6xxx/UEC 11x

Path interpolation

Fine interpolation

Position controller

Speed controller

Current controller

The cycle time for path int erpolation is defi ned as the time

interval during which interpolation points on the path are

calculated. The cycle time for fi ne interpolation is defi ned as the

time interval during which interpolation points are calculated that

lie between the interpolation points calculated for path

interpolation. The cycle time for the position controller is defi ned

as the time interval during which the actual position v alue is

compared to the calculated nominal position value. The cycle time

for the speed controller is defi ned as the time interval during

which the act ual speed v alue is compared to the calculated

nominal speed value. The cycle time for the curr ent contr oller is

defi ned as the time interval during which the actual current v alue

is compared to the calculated nominal current value.

3 ms

0.2 ms

0.2 ms

0.2 ms

0.1 ms at f

PWM

Position

Time

= 5 000 Hz

Fast Machining

Look-ahead

34

The MANUALplus 620 calculates the geometry ahead of time in

order to adjust the feed rate. In this wa y directional changes are

detected in time to accelerate or decelerate the appropriate

NC axes.

Page 35

Jerk Limiting

Jerk

Jerk limiting

Jerk smoothing

The derivative of acceleration is referred to as jerk. A linear c hange

in acceleration causes a jerk step. This jerk causes oscillations that

result in contour damage.

To prevent machine oscillations, the jerk is limited to attain

optimum path control. The MANUALplus 620 produces smooth

surfaces at the highest possible feed rate, and y et k eeps the

contour accurate. The machine manufacturer sets the permissible

tolerance via parameter .

The jerk is smoothed by nominal position value fi lters. The

MANUALplus 620 mac hines smooth surf aces at the highest

possible feed rate. The machine manufact urer sets the permissible

tolerance via parameter .

v

a

j

t

t

t

Mac hine Confi guration

A control must have access to specifi c machine data (e.g. traverse

distances, acceleration, speeds) before it can execute its

programmed instructions. These data are defi ned in machine

parameters. Every machine has its own set of parameters.

Structur ed

organization of

machine parameters

Quick access using

MP numbers

The MANUALplus 620 f eat ures a simplifi ed confi guration editor.

The machine parameters are displa y ed on the control's screen in a

clear tree structure. Mov e through the structure with the operating

panel keys or a USB mouse. The parameters are entered in

windows, similar to a PC.

As an alternative, the confi guration editor can display a table view.

This is especially useful when confi guring the parameter blocks,

since the parameters of all axes are then visible at a glance.

Each machine parameter has a unique 6-digit MP number. The

GOTO function can be used for quic k access to an y machine

parameter .

35

Page 36

Encoders

For speed and position control of the axes and spindle,

HEIDENHAIN off ers both incremental as well as absolute

encoders.

Incremental

encoders

Incremental encoders have as measuring standard a grating

consisting of alternate lines and spaces. Relative mov ement

between the scanning head and the scale causes output of

sinusoidal scanning signals. The measured value is calculated by

counting the signals.

Reference mark When the machine is switc hed on, the machine axes need to

traverse a ref erence mark f or an accurate reference to be

established between measured value and machine position. F or

encoders with distance-coded reference marks, the maximum

travel until automatic ref erence mark e v aluation f or linear encoders

is only 20 mm or 80 mm, depending on the model, or 1 0° or 20°

for angle encoders.

Reference mark

evaluation

The routine for trav ersing the reference marks can also be started

for specifi c axes via the PLC during operation (reactivation of

parked axes).

Output signals Incremental encoders with sinusoidal output signals with

» 1 V

levels are suitable for connection to HEIDENHAIN

PP

numerical controls.

Absolute encoders

With absolute encoders, the position information is contained in

several coded trac ks. Thus, an absolute reference is a v ailable

immediately after switch-on. Reference-mark tra v erse is not

necessary. A dditional incremental signals are output for

highly-dynamic control loops.

EnDat interface The MANUALplus 620 is fi tted with the serial EnDat 2.2 interface

for the connection of absolute encoders.

Note: The EnDat interface on HEIDENHAIN encoders diff ers in its

pin assignment from the interface on Siemens motors with

integrated absolute ECN/EQN rotary encoders. Special adapter

cables are available.

Encoder inputs

Incremental and absolute linear, angle or rotary encoders from

HEIDENHAIN can be connected to all position encoder inputs of

the controller unit.

Incremental and absolute rotary encoders from HEIDENHAIN can

be connected to all speed encoder inputs of the CC controller

unit.

Inputs Signal level/

Interface

1)

Input frequency

1)

Position Rotational

speed

Incremental » 1 V

PP

Absolute EnDat 2.2 / 02

» 1 V

EnDat 2.2

1)

Switc hable

2)

EnDat 2.2 includes EnDat 2.1

PP

2)

36

33 kHz/350 kHz 350 kHz

–

33 kHz/350 kHz–350 kHz

/22 – –

Page 37

Types of Error Compensation

Linear error

Nonlinear error

Backlash

Hysteresis

Reversal peaks

The MANUALplus 620 f eat ures functions f or automatic

compensation of mechanical errors of the machine.

Linear error can be compensated over the entire trav el range f or

each axis.

The MANUALplus 620 compensates for axis er rors and errors that

result from other axes (spindle-pitch er ror, sagging, misaligned

axes, etc.).

The play between table movement and rotary encoder movement

on direction changes can be compensated in length

measurements by spindle and rotary encoder. This backlash is

outside the controlled system.

The hysteresis between table mov ement and motor mo v ement is

also compensated in length measurements. In this case the

hysteresis is within the controlled system.

In circular movements, rev ersal peaks can occur at quadrant

transitions due to mechanical infl uences. T he MANU ALplus 620

can compensate for these reversal peaks.

Stick-slip friction

Sliding friction

Thermal expansion

At very low feed rates, high static friction can cause the slide to

stop and start repeatedly for short periods. This is also known as

stiction. The MANUALplus 620 can compensate for this problem

condition.

Sliding friction is compensated by the speed controller of the

MANUALplus 620.

To compensate thermal expansion, the mac hine's e xpansion

behavior must be known.

The temperature can be recorded via temperature measurement

thermistors connected to the analog inputs of the

MANUALplus 620. The PLC evaluates the temperature information

and transfers the compensation value to the NC.

37

Page 38

Monitoring F unctions

During operation, the MANUALplus 620 monitors:

Amplitude of the encoder signals•

Edge separation of the encoder signals•

Absolute position with encoders with distance-coded •

reference marks

Current position (following error monitoring)•

Actual path trav ersed (mo v ement monitoring)•

Position de viation at standstill•

Nominal speed value•

Checksum of saf ety-related functions•

Supply voltage•

Buff er battery voltage•

Operating temperature of the MC and CPU•

Running time of the PLC program•

Motor current and temperature•

Temperature of pow er module•

DC-link voltage•

With EnDat 2.2 encoders:

CRC checksum of the position value•

EnDat-Alarm Error1 • EnDat status alarm register (0xEE)

EnDat alarm Error2•

Edge speed of 5 µs (monotime)•

Transmission of the absolute position value on the time grid•

In the case of hazardous errors, an EMERGENCY STOP message

is sent to the external electronics via the control-is-ready output,

and the axes are brought to a stop. The correct connection of the

MANUALplus 620 into the mac hine ’s EMERGENCY STOP loop is

checked when the control system is switc hed on. In the e v ent of

an error , the MANU ALplus 620 displa y s a message in plain

language.

Context-sensitive

help

KinematicsDesign

The HELP and ERR keys provide the user with context-sensitive

help. This means that in the event of an error message, the

MANUALplus 620 displays inf ormation on the cause of the er ror

and proposes solutions. The machine manufacturer can also use

this function for PLC error messages.

KinematicsDesign is a PC program for creating adaptable fl exible

kinematic confi gurations. When used with MANU ALplus 620, it

supports:

Complete kinematic confi gurations•

Transfer of confi guration fi les between control and PC•

Activation of dif ferent kinematics confi gurations•

Visualization of transformation c hains•

38

Page 39

Commissioning and Diagnostic Aids

DriveDiag (accessory) The DriveDiag sof tware f or PCs permits a simple and f ast

TNCopt (accessory) PC software for commissioning digital control loops

The MANUALplus 620 provides comprehensiv e, internal

commissioning and diagnostic aids. In addition, highly eff ectiv e

PC software for diagnosis, optimization and remote control is

available.

diagnosis of the drives. It also makes it possible to display and

evaluate the electronic ID labels.

The following diagnostic functions are a v ailable:

Reading and displaying the electronic ID labels of QS Y motors •

with EQN 13xx or ECN 13xx

Reading and displaying the electronic ID labels of the UVR 1xx D •

and UM 1xx D inverter modules

Displaying and evaluating the internal control conditions and the •

status signals of the inverter components

Displaying the analog values av ailable to the driv e controller•

Automatic test for proper function of motors and inv erters•

Automatic test of position and speed encoders•

Functions:

Commissioning the current controller•

(Automatic) commissioning of the speed controller•

(Automatic) optimization of sliding-friction compensation•

(Automatic) optimization of the reversal-peak compensation•

(Automatic) optimization of kV factor•

Circular interpolation test, contour test•

Requirements DriveDiag and TNCopt place the following demands on the PC:

Windows 2000/XP/Vista/7 operating system•

At lease VGA—XGA recommended•

At least 16 MB RAM•

At least 15 MB of free hard-disk space•

Serial or Ethernet interface•

DriveDiag and TNCopt for MANUALplus 620 are available for

downloading as PC software from the HEIDENHAIN “HESIS-Web

Including Filebase “ on the Internet.

OLM

Online monitor

The online monitor (OLM) supports the commissioning and

diagnosis of control components through:

Display of control-internal variables for ax es and channels•

Display of controller-internal variables (if a CC is present)•

Display of hardware signal states•

Various trace functions•

Activation of spindle commands•

Enabling control-internal debug outputs•

The online monitor is a component part of the MANUALplus 620

and is called over a code number.

39

Page 40

Oscilloscope

Logic signals Simultaneous graphic representation of the logic states of

The MANUALplus 620 f eat ures an integrated oscilloscope. B oth

X/t and X/Y graphs are possible. The following characteristic curves

can be recorded and saved in six c hannels:

Actual value of axis feed rate•

Nominal value of axis feed rate•

Contouring feed rate•

Actual position•

Nominal position•

Following error of the position controller•

Nominal values for speed, acceleration and jerk•

Actual values f or speed, acceleration and jerk•

Content of PLC operands•

Encoder signal (0° – A)•

Encoder signal (90° – B)•

Diff erence between position and speed encoder•

Nominal velocity value•

Integral-action component of the nominal current value•

Torque-determining nominal current value•

up to 16 operands (markers, w ords, inputs, outputs, counters,

timers)

Marker (M)•

Input (I)•

Output (O)•

Timer (T)•

Counter (C)•

IpoLogik (X)•

TNCscopeNT

(accessory)

API DATA

Table function

Trace function

Log

TeleService

(accessory)

PC software for transferring the oscilloscope fi les to the PC.

Note: The trace fi les are saved in the TNCscopeNT data format.

The API DATA function enables the control to display the states or

contents of the symbolic API markers and API double w ords. This

function requires that your PLC program use the new symbolic

memory interface.

The current conditions of the markers, words, inputs, outputs,

counters and timers are displayed in tables. The conditions can be

changed through the ke yboard.

The current content of the operands and the accumulators is

shown in the instruction list in each line in HEX or decimal code.

The active lines of the instruction list are mark ed.

For the purposes of error diagnosis, there is one log for all er ror

messages and one for all key strok es.

PC software for remote diagnosis, remote monitoring, and remote

control of the MANUALplus 620. For further inf ormation, ask f or

the Remote Diagnosis with TeleService T echnical Information

sheet.

40

Page 41

Integral PLC

The PLC program is created by the mac hine manuf acturer either

with the PLC development sof tware PLCdesignNT (accessory) or

at the control with an external PC keyboard with a USB connection.

Machine-specifi c functions are activated and monitored through

the PLC inputs/outputs. The number of PLC inputs/outputs

required depends on the complexity of the machine.

PLC inputs/outputs

PLC programming

PLC inputs and outputs are available via the external PL 6xxx

PLC input/output systems or the UEC 11 .

The PLC inputs/outputs and the PROFIBUS-DP -capable input/

output system must be confi gured with the PC software IOconfi g.

Format Statement list

Memory 50 MB

Cycle time 21 ms, adjustable

Instruction set • Bit, byte and word commands

• Logical operations

• Arithmetic commands

• Comparisons

• Nested calculations (parentheses)

• Jump commands

• Subroutines

• Stack operations

• Submit Programs

• 952 timers

• 48 counters

• Comments

• PLC modules

• 100 strings

PLC soft ke ys

PLC positioning

PLC axes

The machine manuf acturer can display his own PLC sof t keys in

the vertical soft-k e y ro w on the screen.

All closed-loop axes can be also positioned through the PLC.