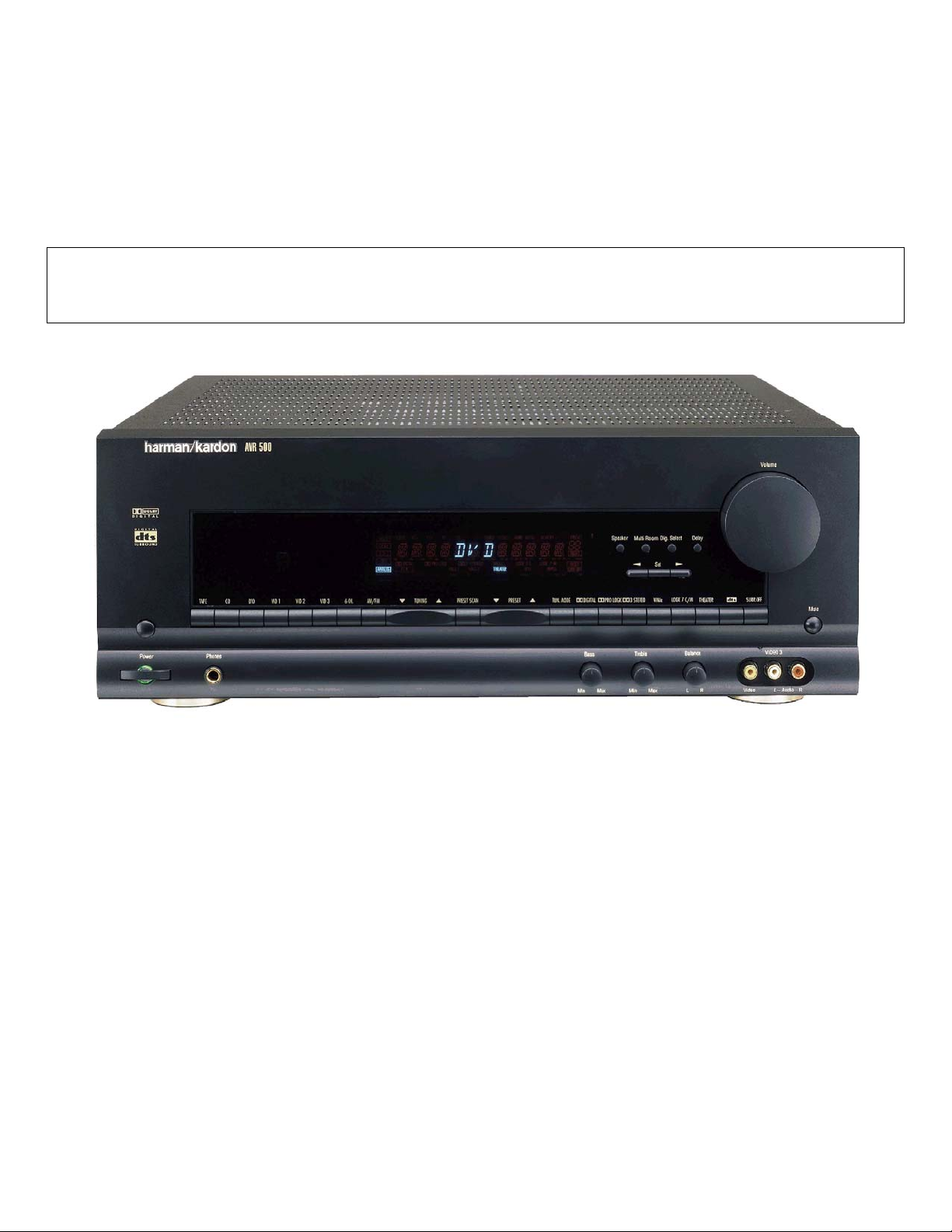

Harman Kardon AVR-500 Service manual

harman/kardon

AVR500

A/V DOLBY DIGITAL RECEIVER

SERVICE MANUAL

CONTENTS

SPECIFICATIONS ………………………………..…2

ESD WARNINGS…………………………………… 4

LEAKAGE TEST……………………………………. 5

CONTROLS AND FUNCTIONS……………………6

SERVICE PROCEDURE………………………….. .9

TEST EQUIPMENT REQUIRED……………… …9

ALIGNMENT PROCEDURES………………………9

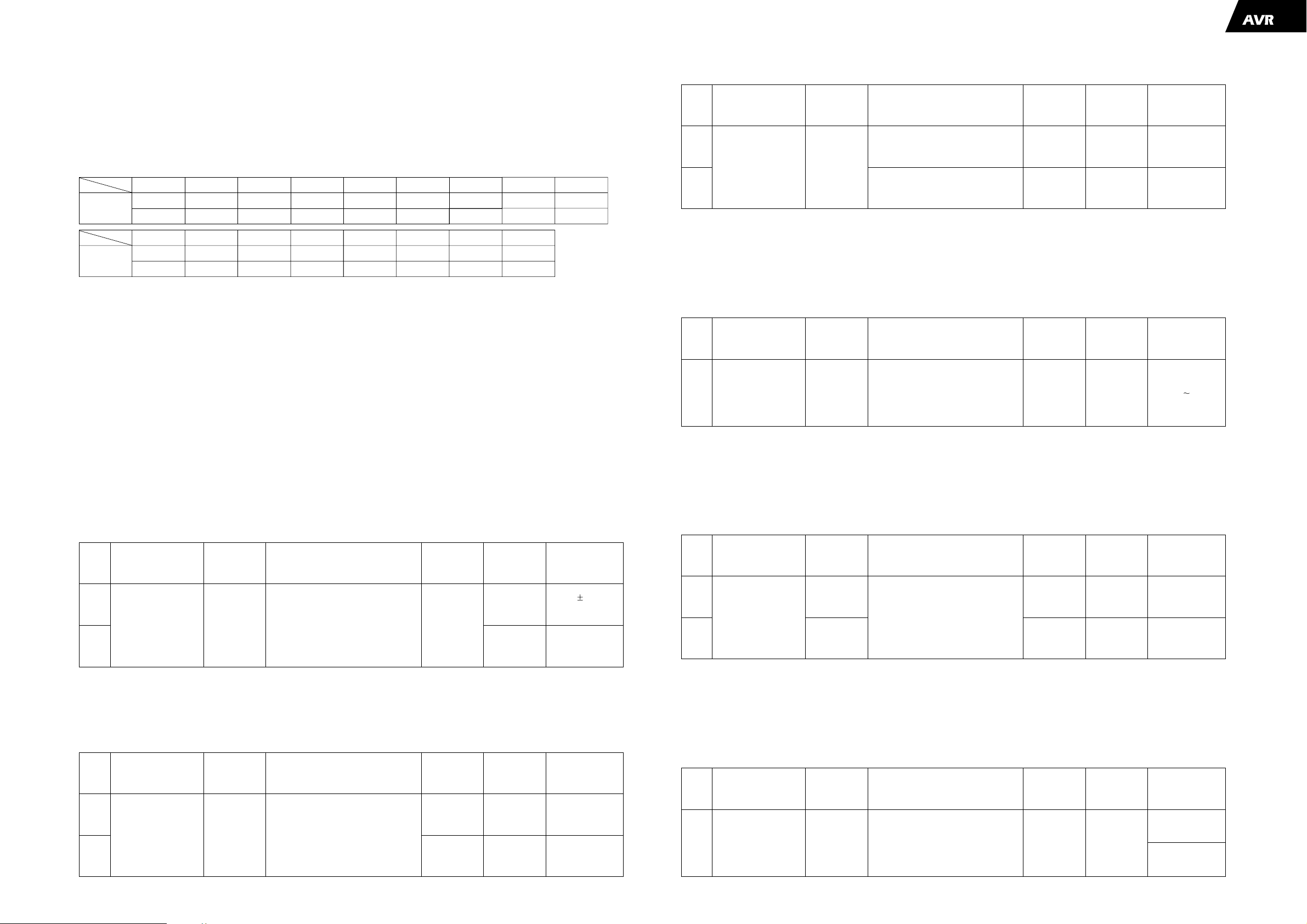

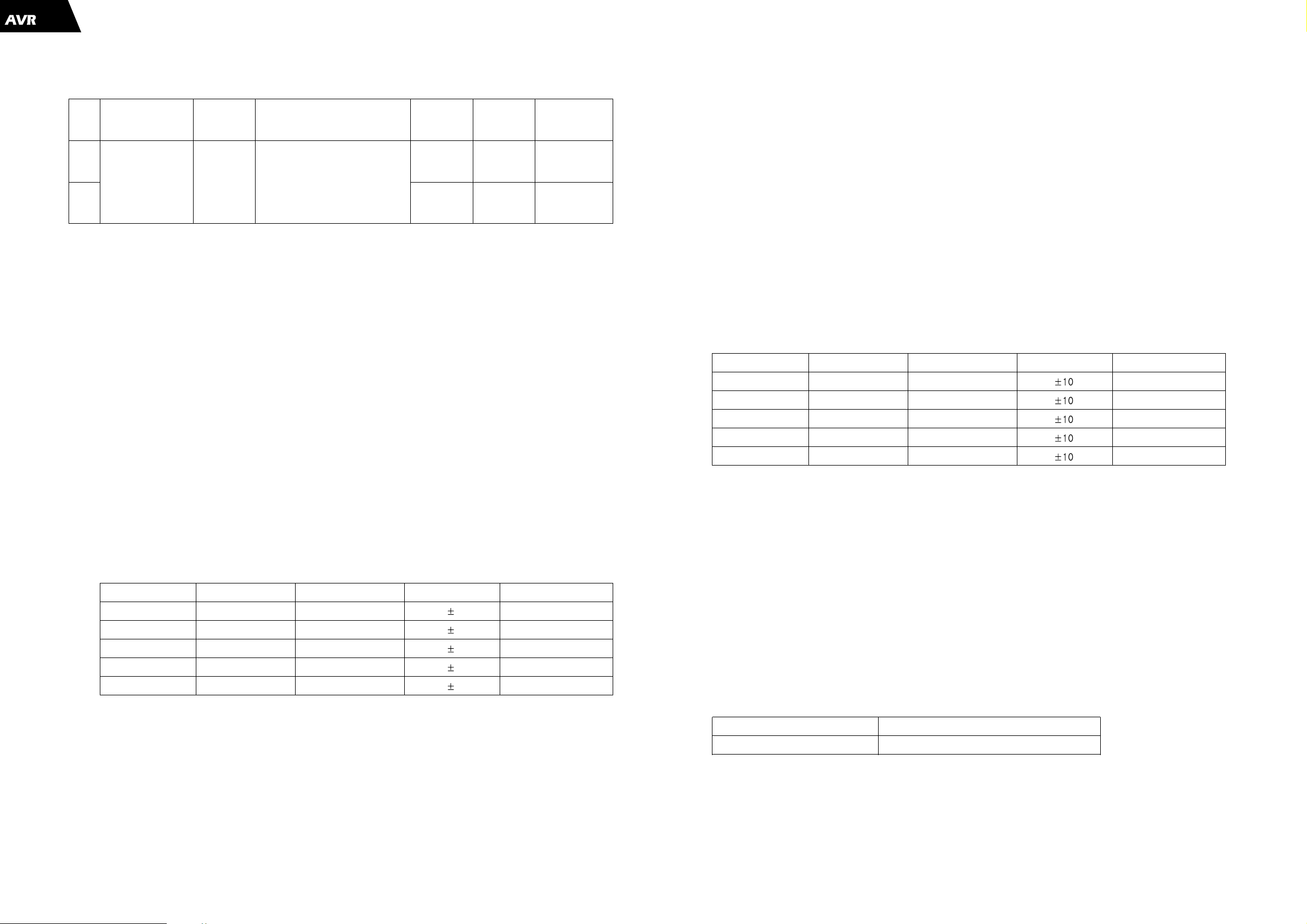

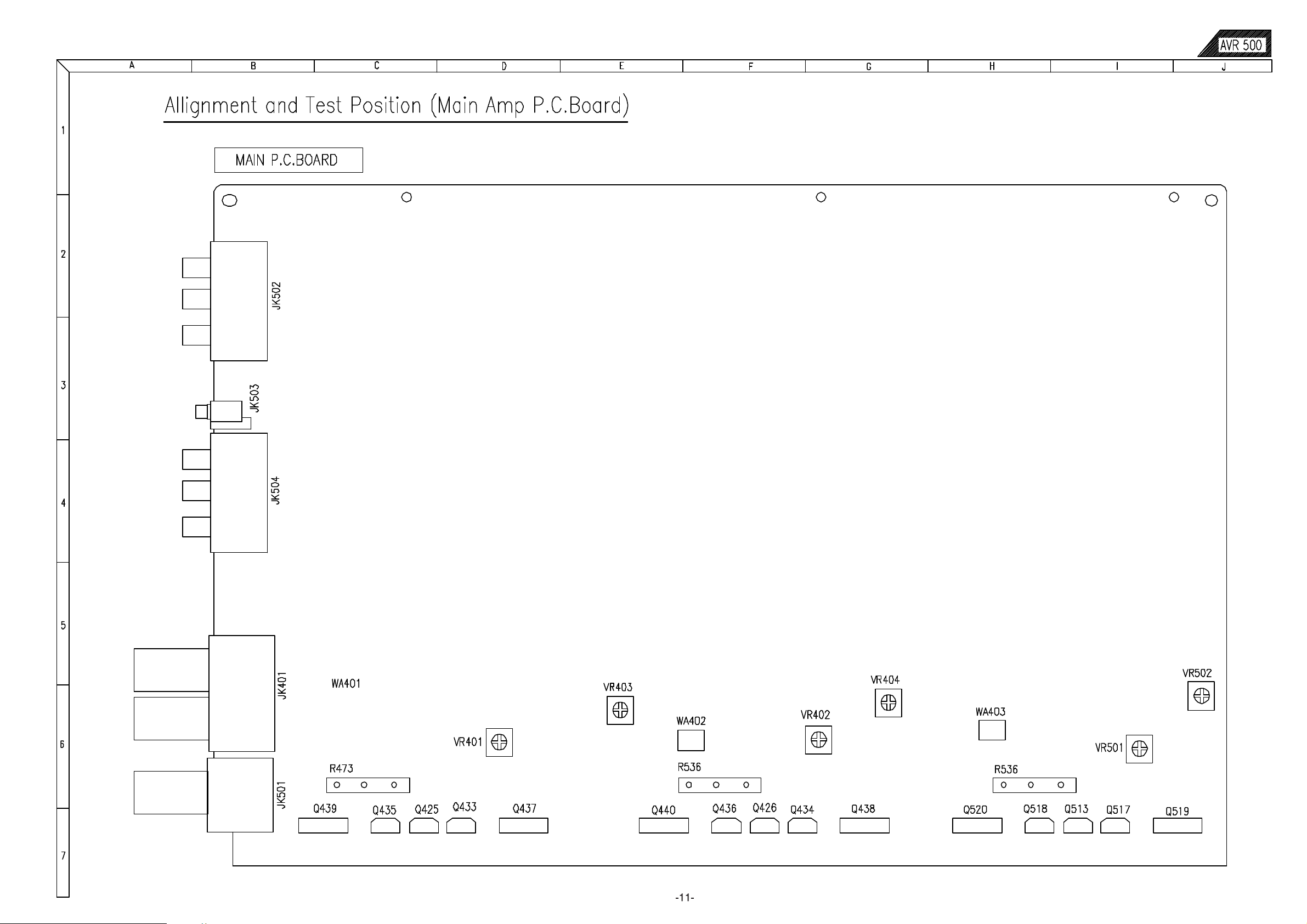

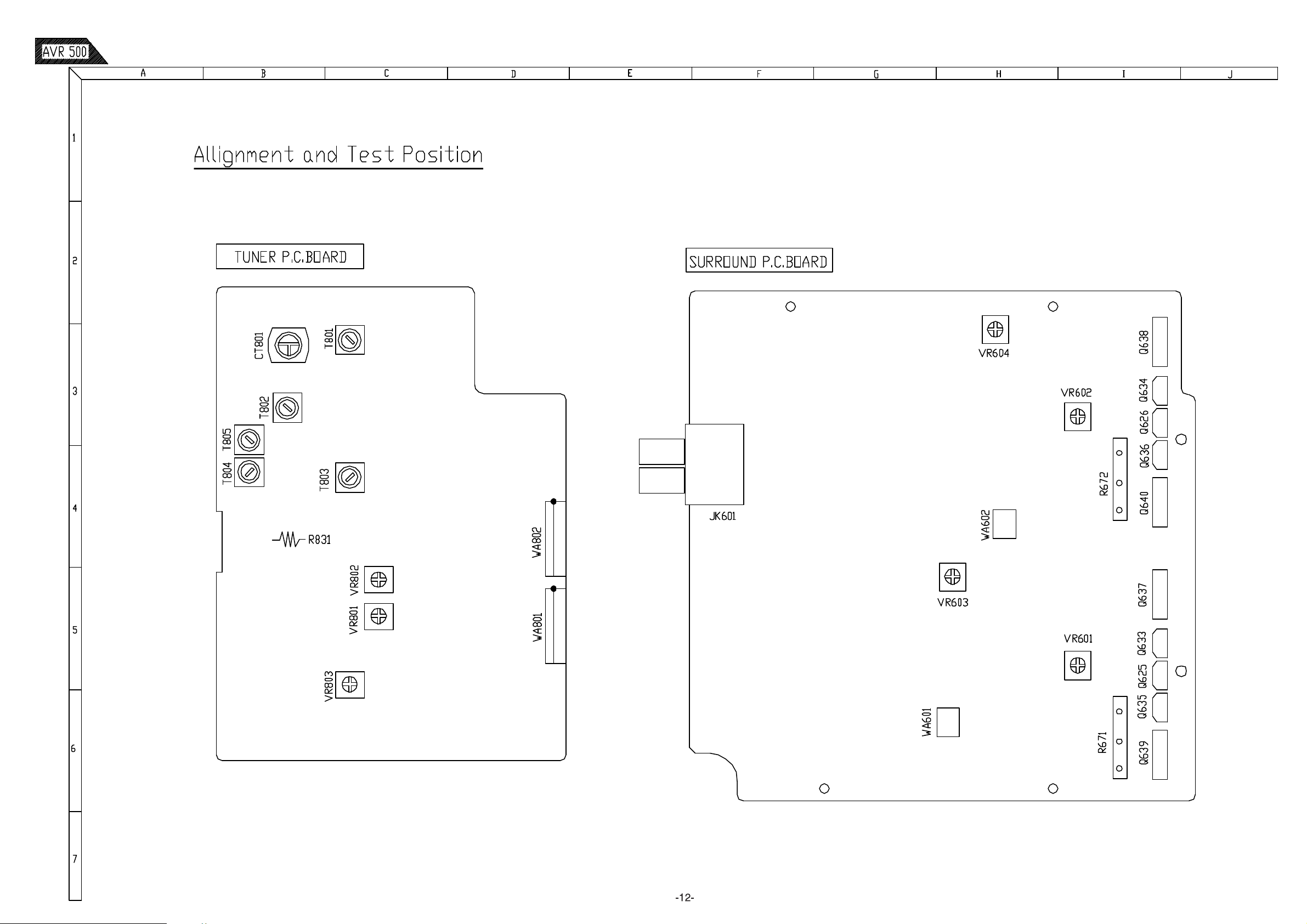

ALIGNMENT AND TEST POINTS……………….. 11

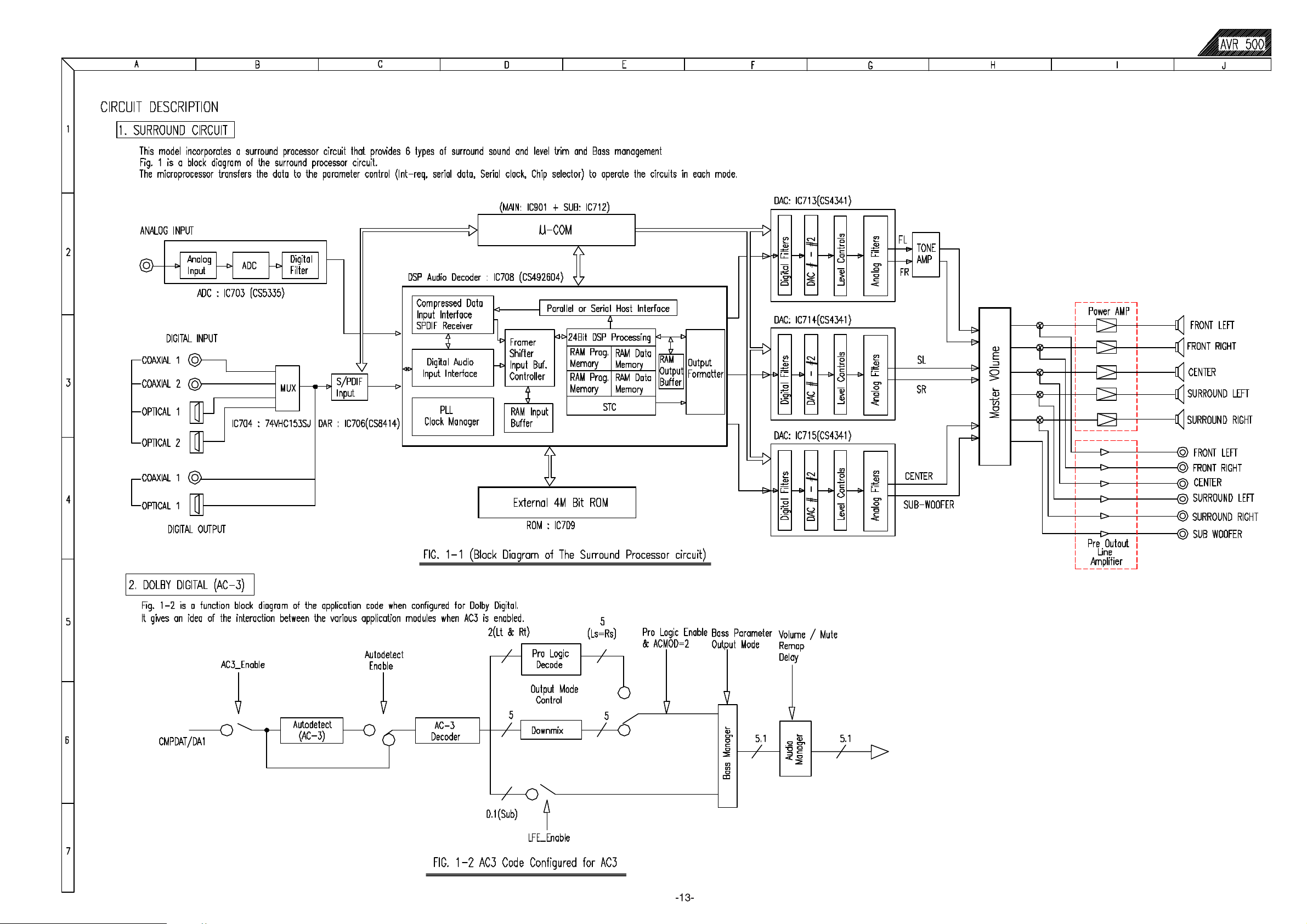

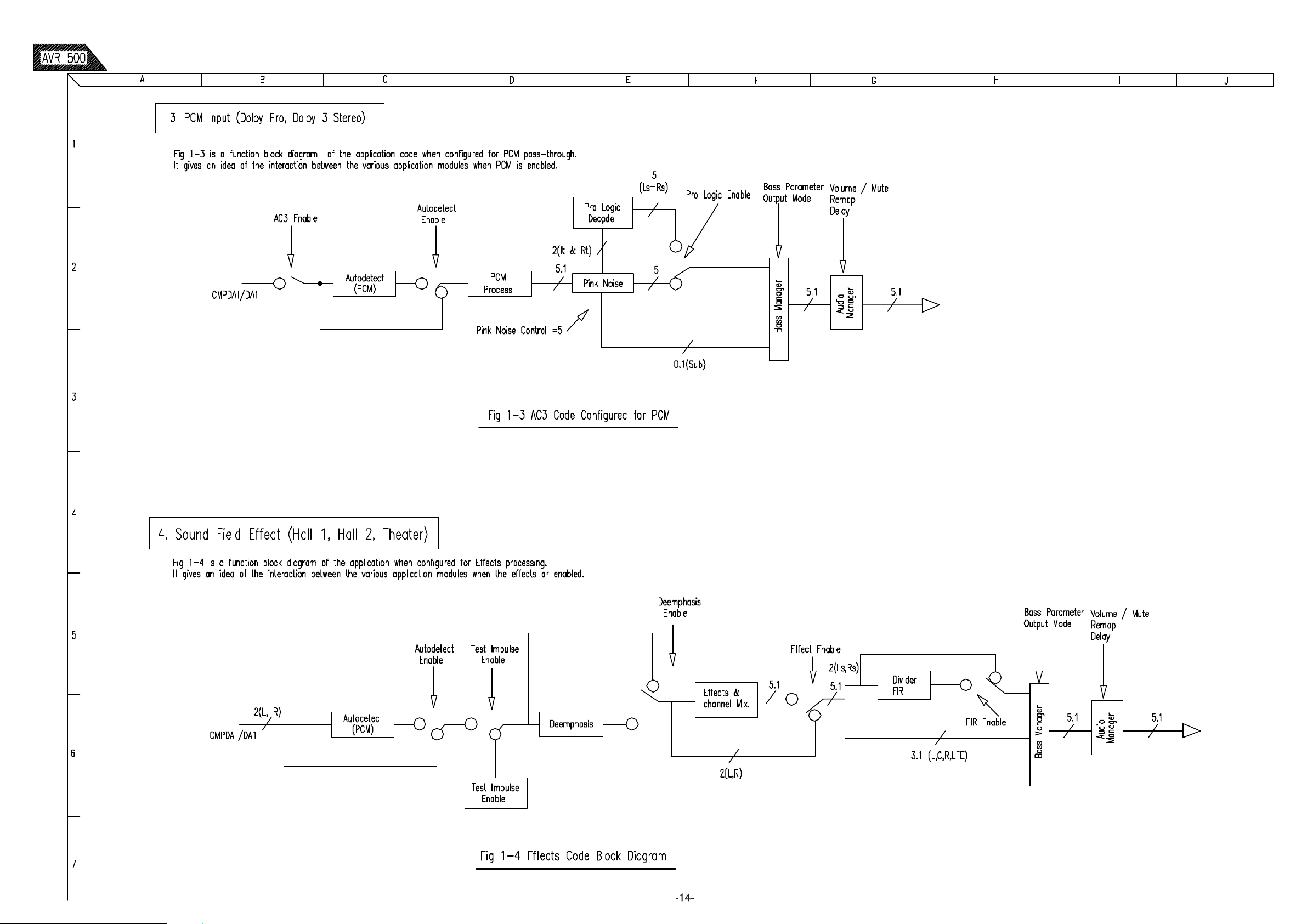

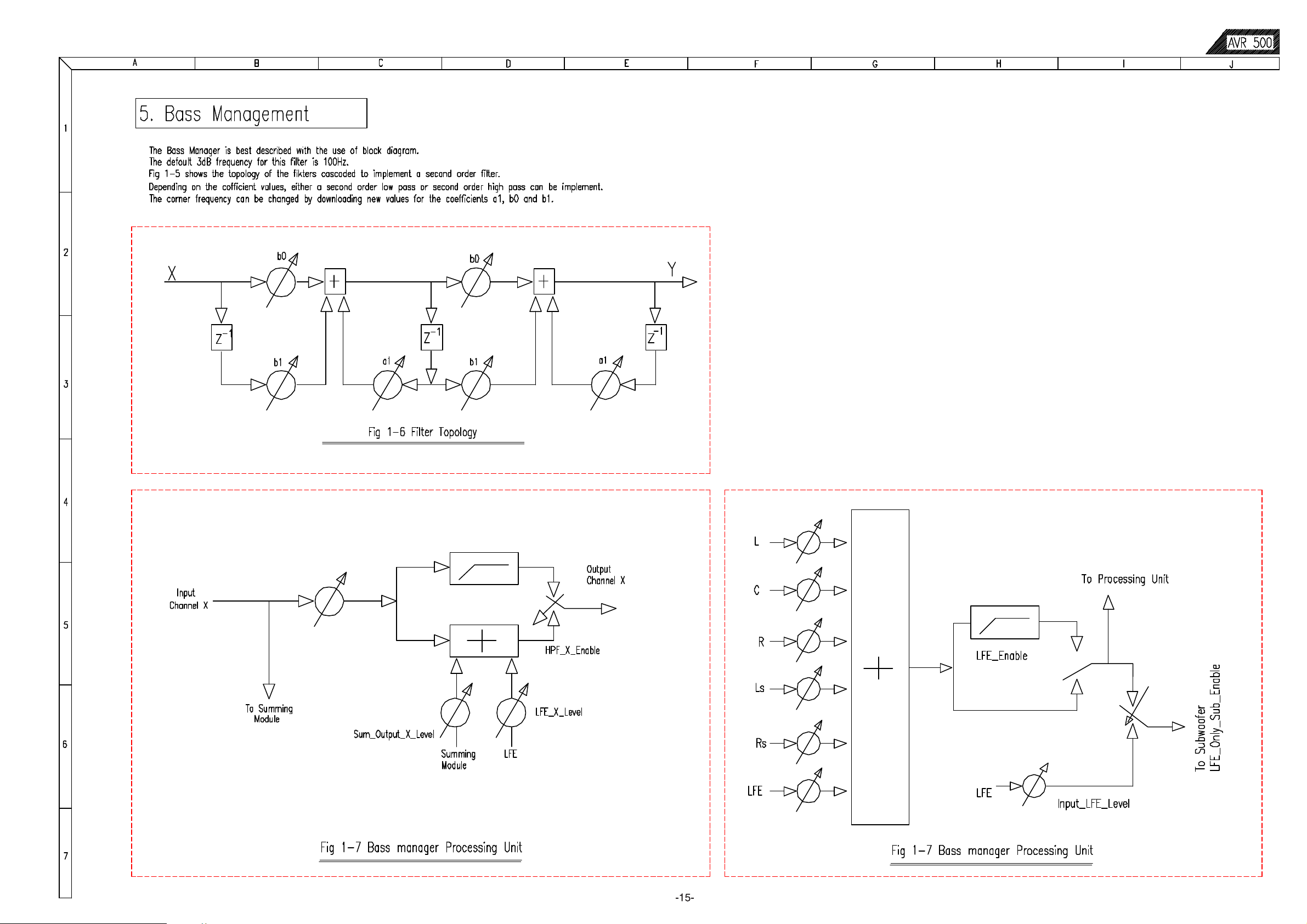

CIRCUIT DESCRIPTION…………………………..13

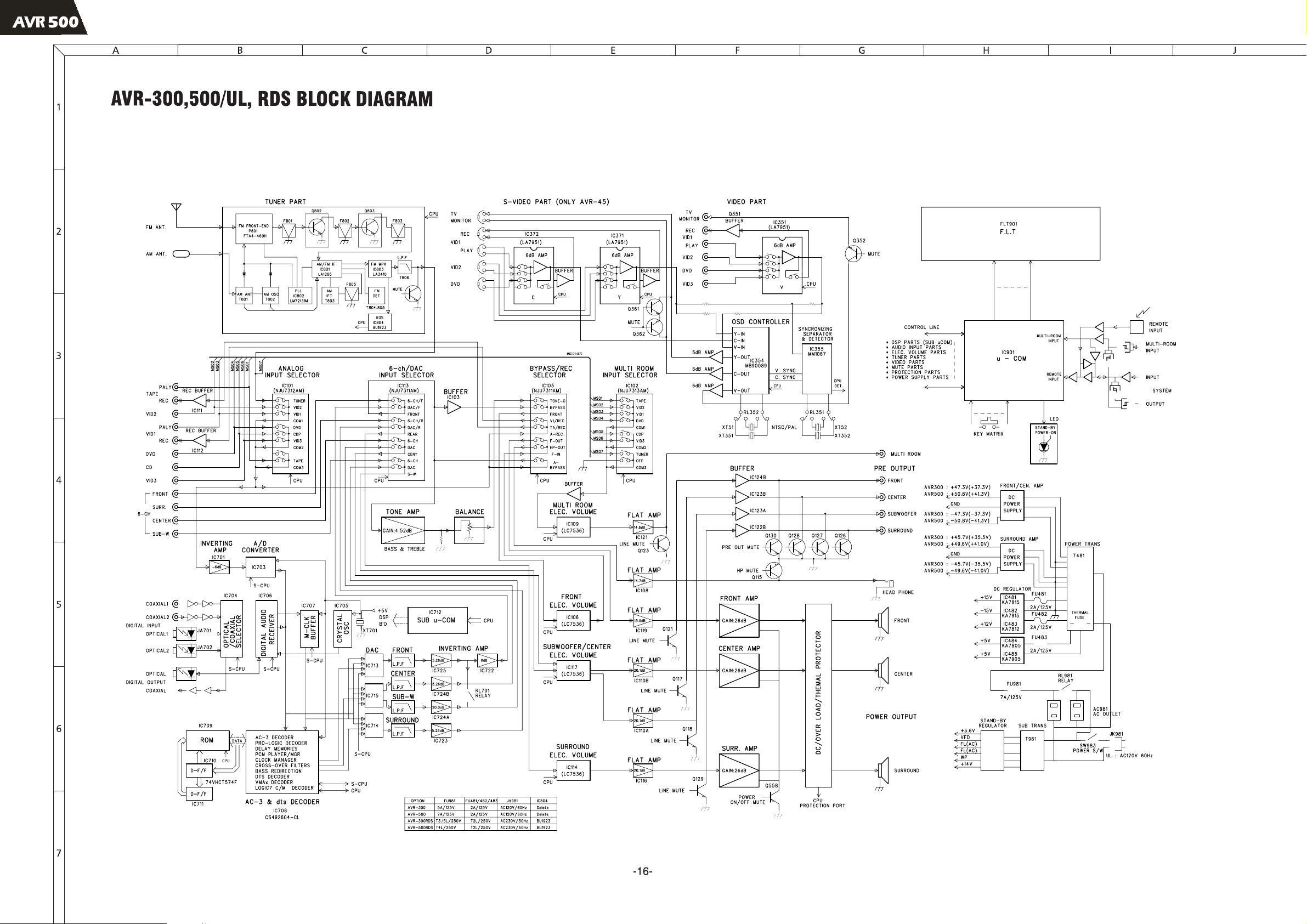

BLOCK DIAGRAM ………………………………….16

BULLETIN HK2000-02……………..………..……..17

BULLETIN HK2000-04………………...….………..19

BULLETIN HK2000-05………………...….………..21

DISASSEMBLY PROCEDURES ………… .……23

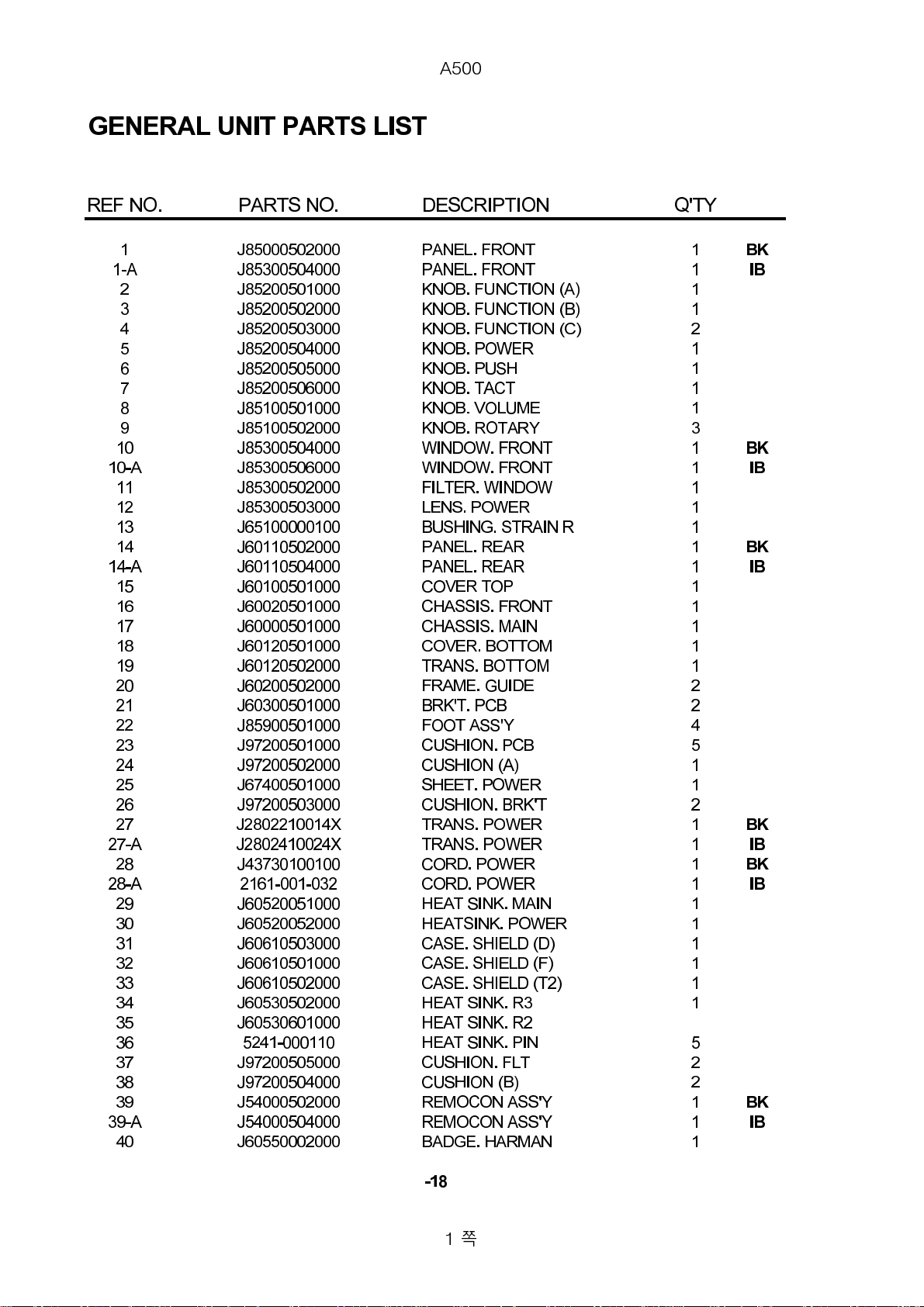

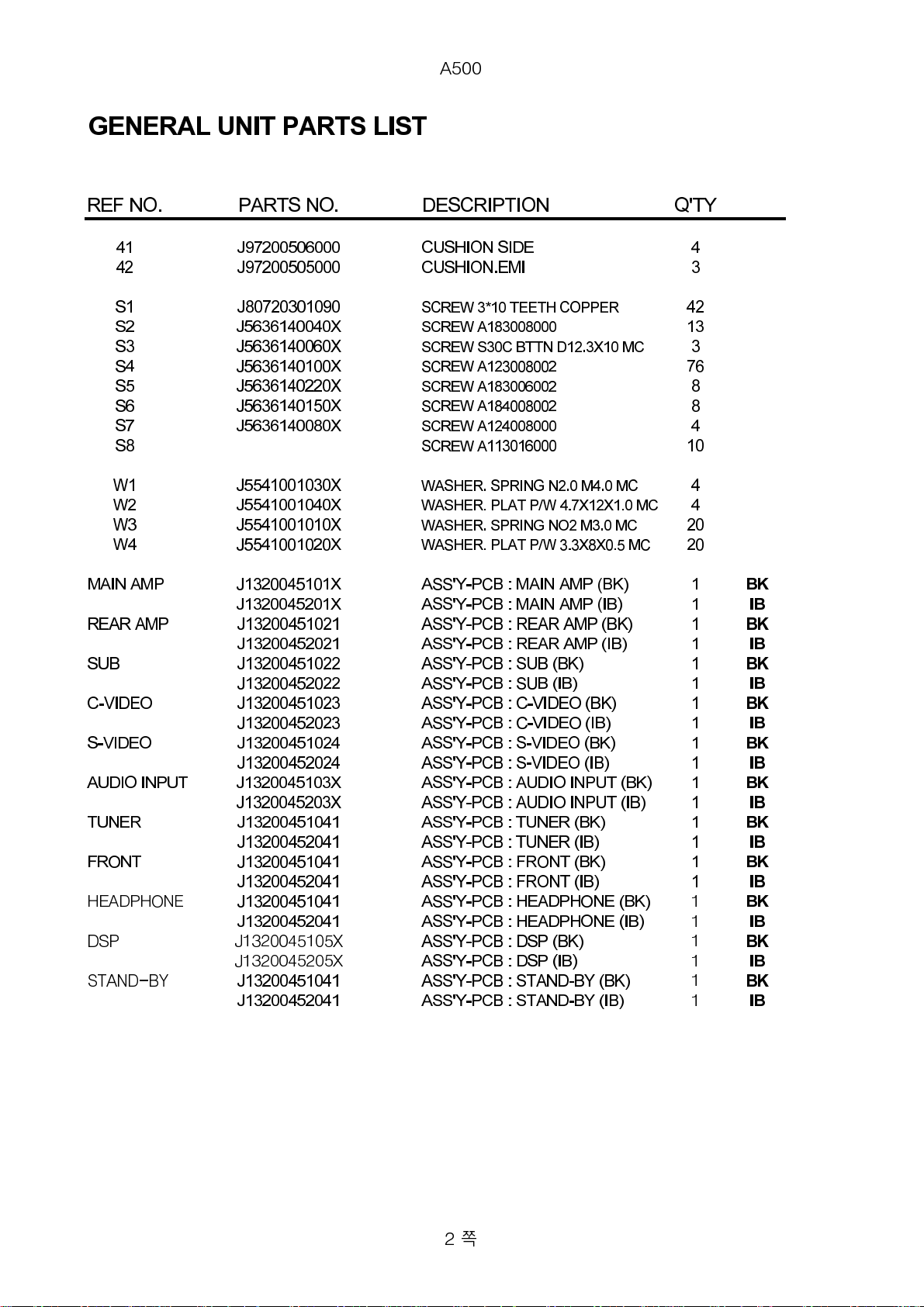

GENERAL UNIT PARTS LIST …………………..24

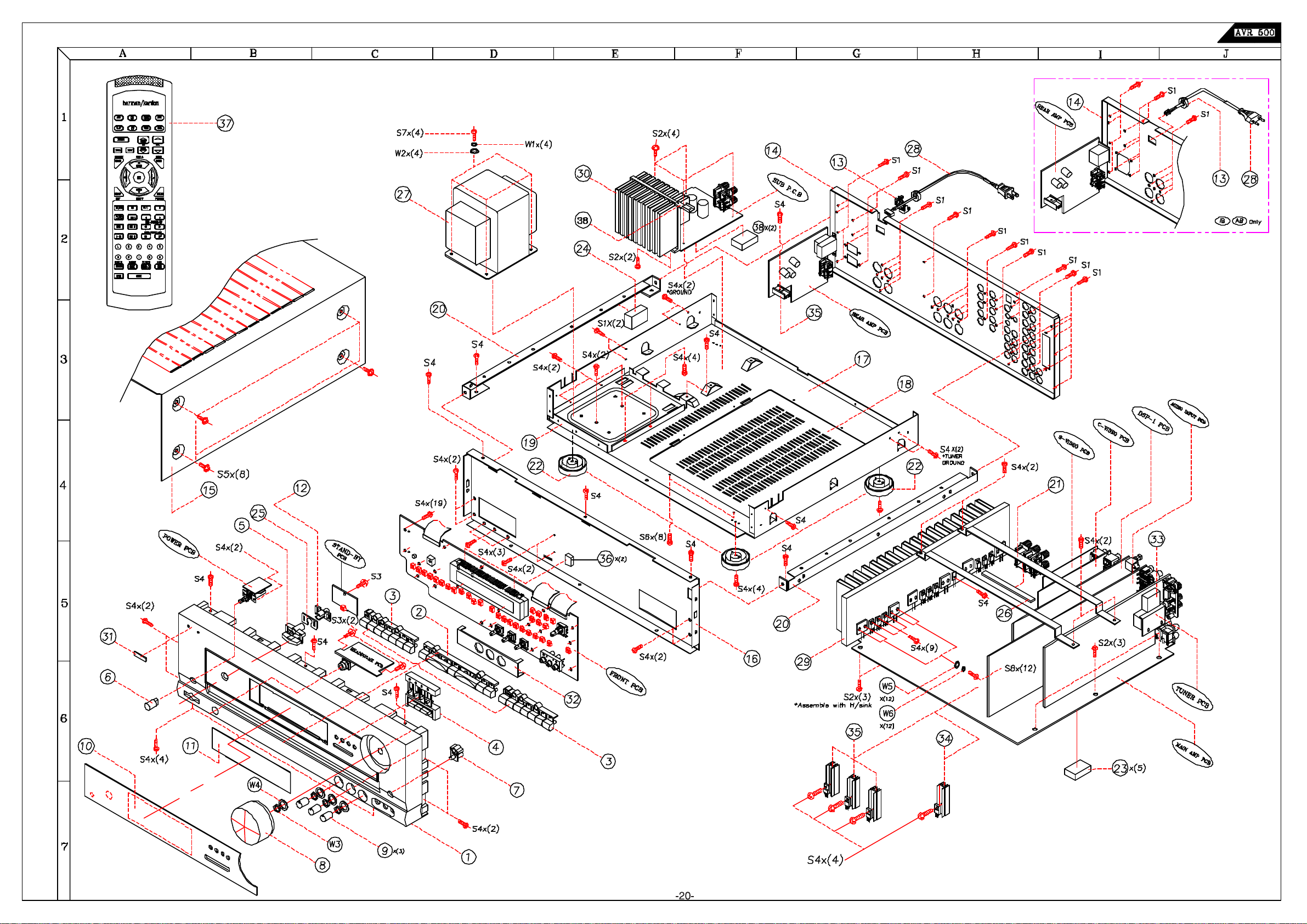

GENERAL UNIT EXPLODED VIEW………..….. 26

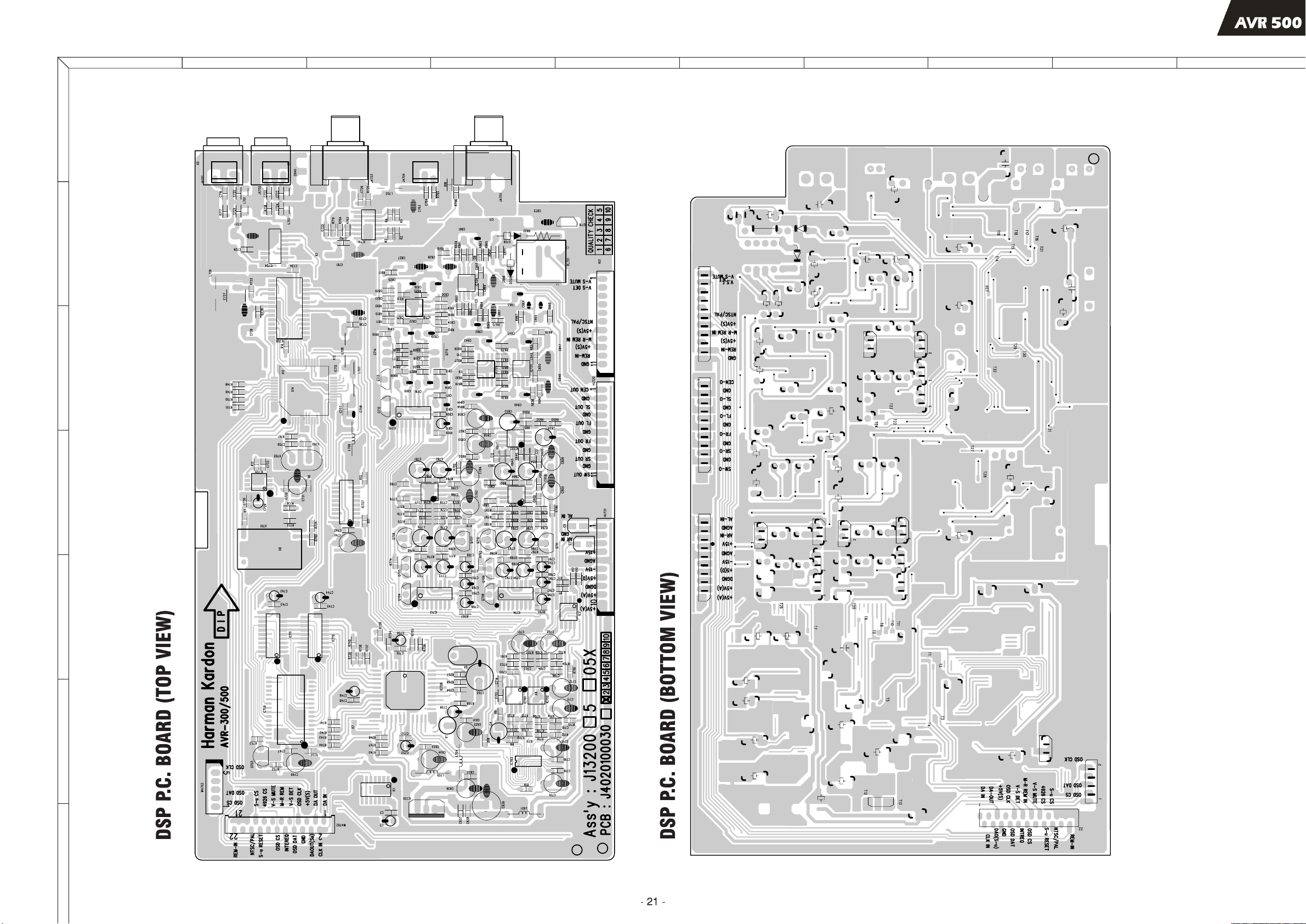

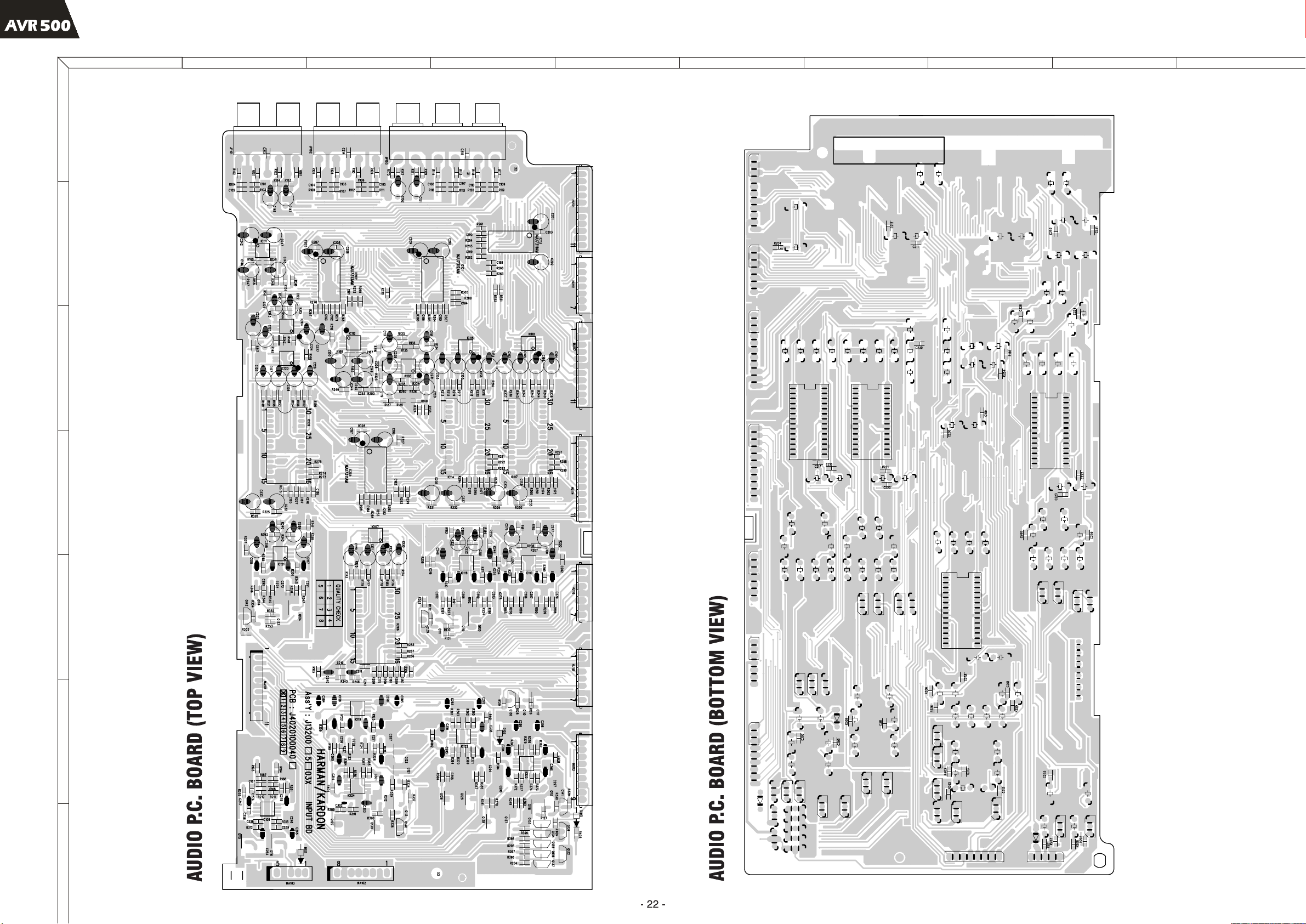

PC . BOARDS …………………………………..…27

ELECTRICAL PARTS LIST ………………….…..32

IC BLOCK DIAGRAMS …………………….….….55

CPU PIN CONFIGURATION……………….…….75

FLT PIN CONFIGURATION………………….…. 76

SCHEMATIC DIAGRAMS ……………..…….…..83

PIN CONNECTION DIAGRAM …………….……92

WIRING DIAGRAM ………………………….……93

PACKING MATERIAL AND PARTS LIST………94

harman/kardon, Inc.

250 Crossways Park Dr.

Woodbury, New York 11797 Rev1 – 11/2003

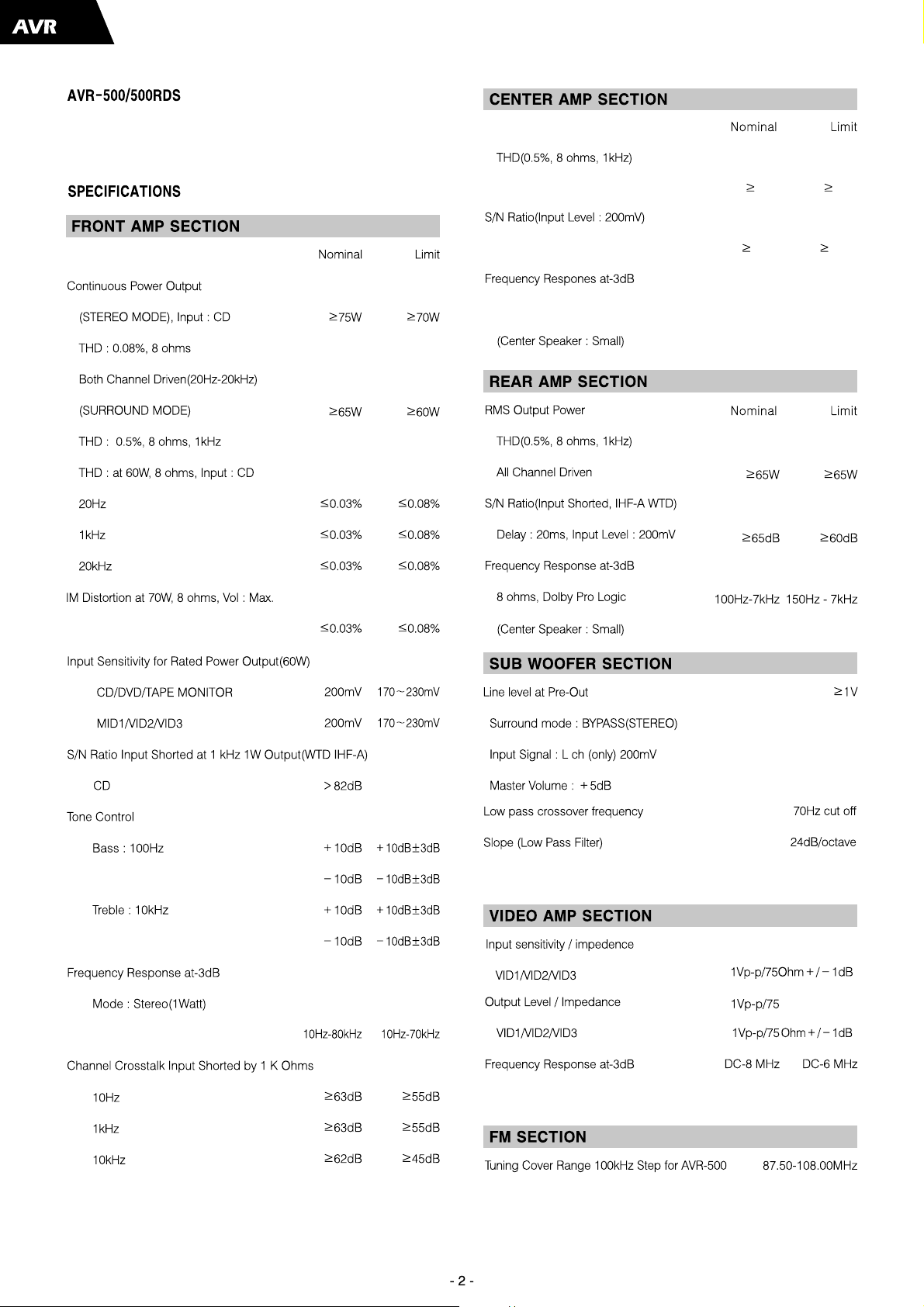

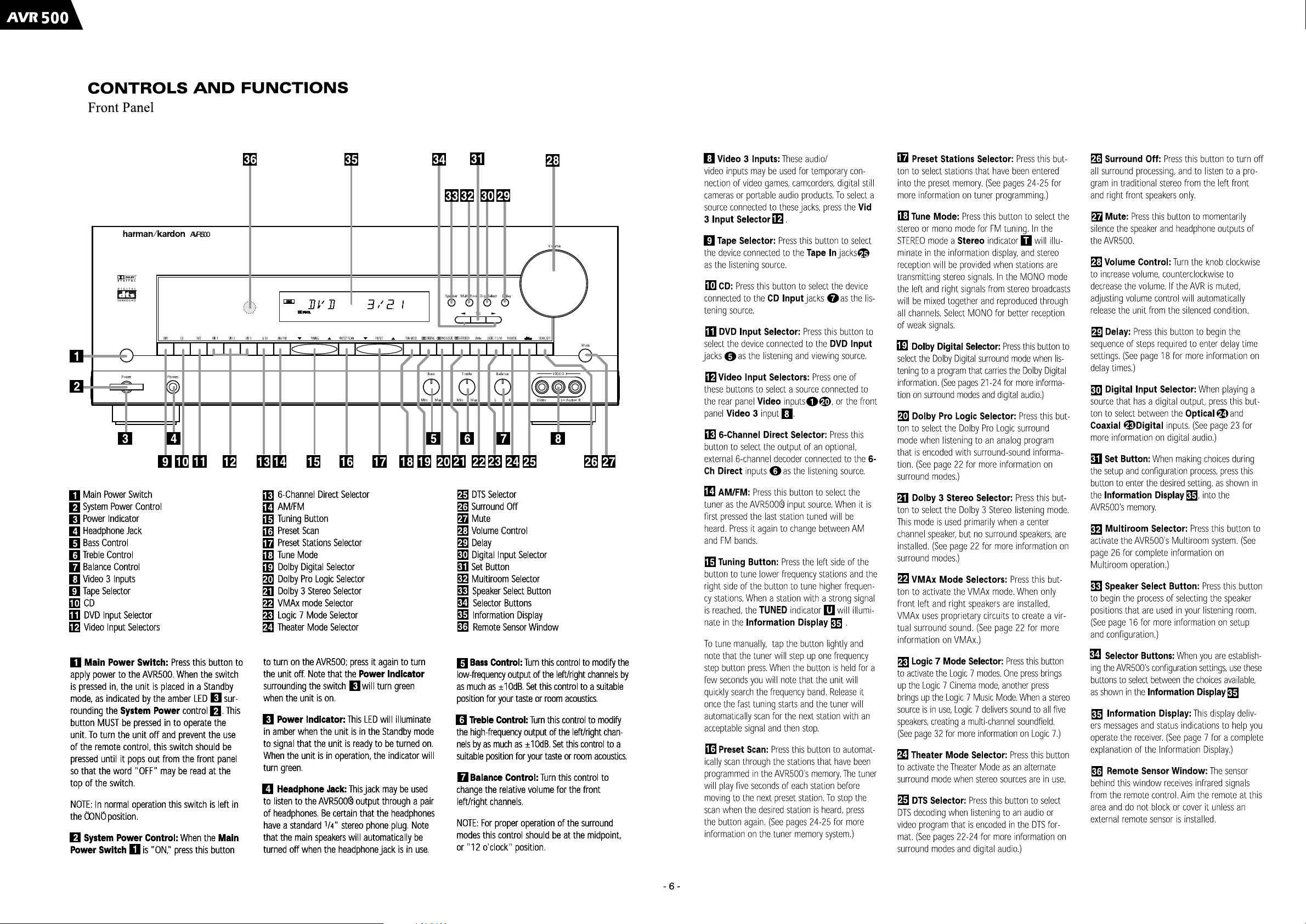

8 ohms, Dolby Pro Logic

100Hz-20kHz 150Hz-20kHz

All Channel Driven

65W 65W

Input Shorted, IHF-A WTD

65dB 60dB

RMS Output Power

500

500

Each precaution in this manual should be followed during servicing.

Components identified with the IEC symbol in the parts list are special significance to safety. When replacing a component identified with

, use only the replacement parts designated, or parts with the same ratings or resistance, wattage, or voltage that are designated in the

parts list in this manual. Leakage-current or resistance measurements must be made to determine that exposed parts are acceptably

insulated from the supply circuit before retuming the product to the customer.

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field effect transistors and

semiconductor "chip" components.

The following techniques should be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any electrostatic charge on

your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to

prevent electrostatic charge build-up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can generate electrical charges

sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical change sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most replacement

ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material.)

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material to the

chassis or circuit assembly into which the device will be installed.

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing together

or your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient to damage an ES devices.

CAUTION :

-4-

500

1. lnspect all lead dress to make certain that

leads are not pinched or that hardware is not

lodged between the chassis and other metal

parts in the unit.

2. Be sure that any protective devices such as

nonmetallic control knobs, insulating fish-

papers, cabinet backs, adjustment and

compartment covers or shields, isolation

resistor-capacity networks, mechanical

insulators, etc. Which were removed for the

servicing are properly re-installed.

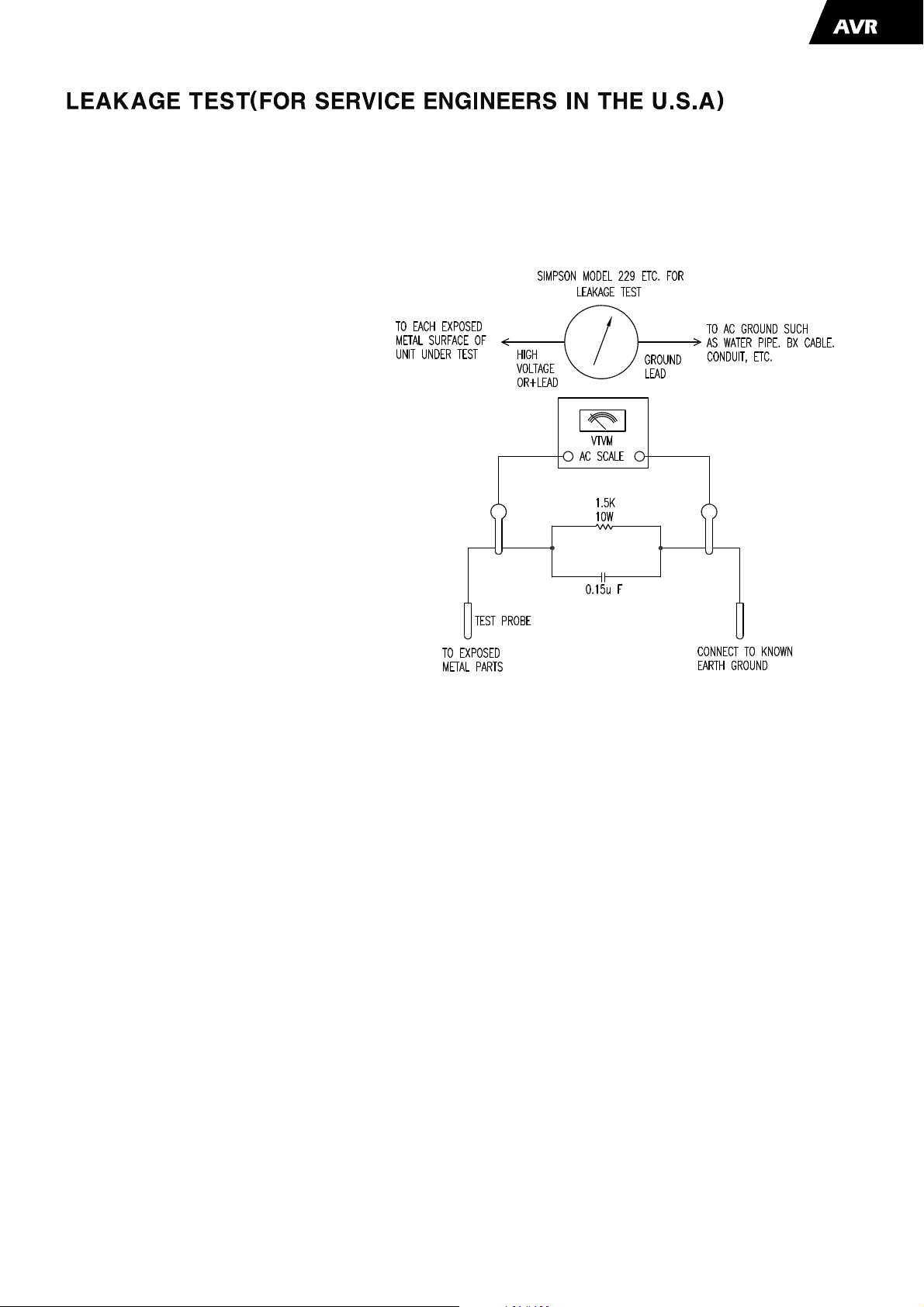

Before returning the unit to the user, perform the following safety checks :

3. Be sure that no shock hazard exists ; check for leakage

current using Simpson Model 229 Leakage Tester, standard

equipment item No. 21641, RCA Model WT540A or use

alternate method as follows : Plug the power cord directly

Into a 120 volt AC receptacle (do not use an Isolation

Transformer for this test). Using two clip leads, connect a

1500 ohms, 10watt Resistor paralleled by a 0.15uF capacitor, in series with all exposed metal cabinet parts and a known earth ground, such

as a water pipe or conduit. Use a VTVM or VOM with 1000 ohms per volt, or higher sensitivity to measure the AC voltage drop across the

resistor. (See diagram) Move the resistor connection to each exposed metal part having a return path to the chassis (antenna, metal, be

performed with the 0.35 volt RMS or more is excessive and indicates a potential shock hazard which must be corrected before returning the

unit to the owner.

-5-

500

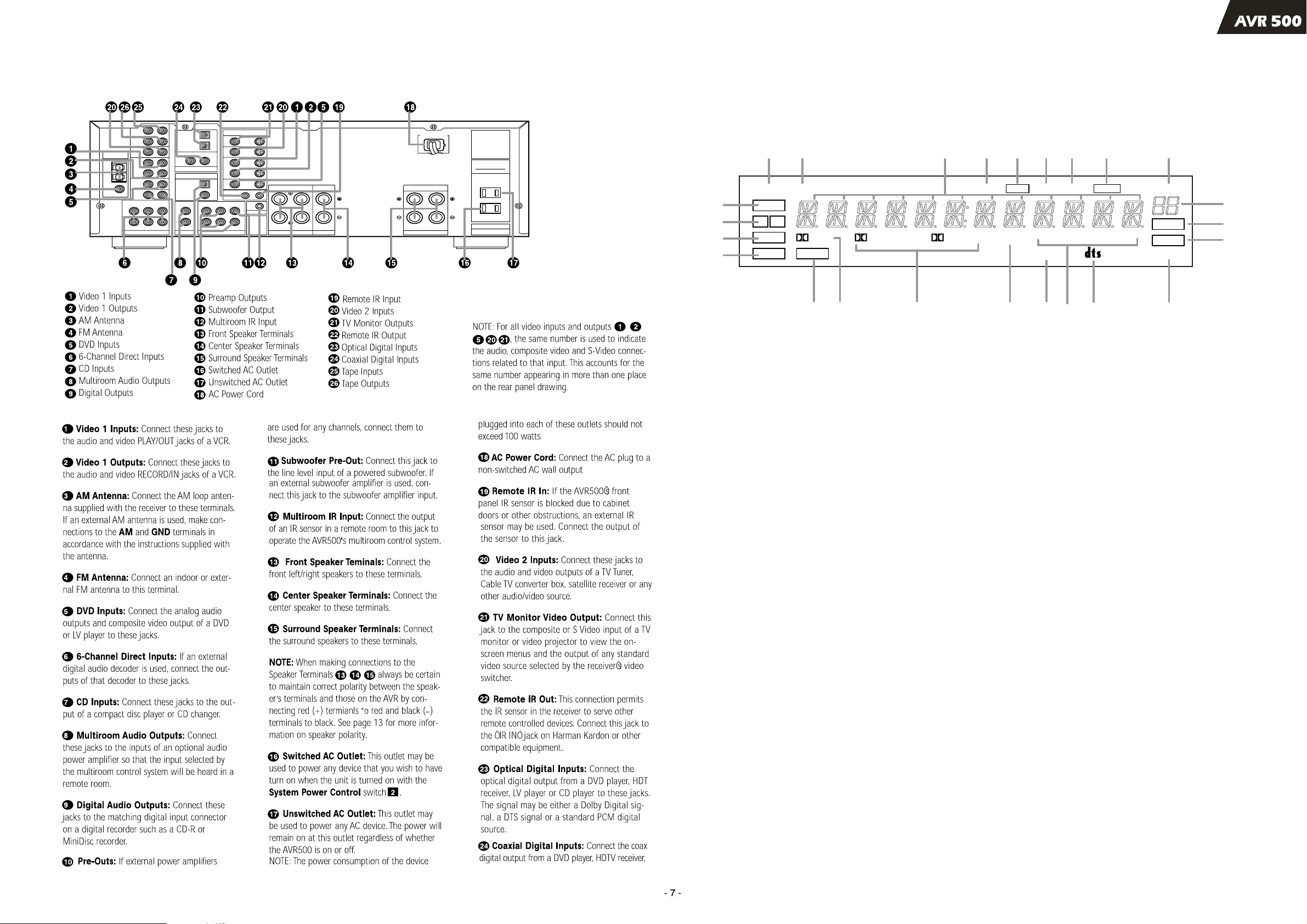

SWITCHED

TOTAL 150W or 0.5A MAX.

UNSWITCHED

TOTAL 100W or 1A MAX.

(120V.60Hz)

TOTAL 150W or 1.5A MAX

MODEL NO. AVR 500

HARMAN KARDON

NORTHRIDGE

CALIFORNIA, USA

FM

(75½)

AM

ANTENNA

GND

AC

~

120V 60 Hz

IN

LR

OUT

TAPE

VIDEO

2

IN

OUT

VIDEO

1

DVD

CD

SL

FLCENTER

COAXIAL 2 COAXIAL 1

SR FRSUB WOOFER

SL

SUB WOOFERFL

ML

SR CENTERFR

MR

6 CH. DIRECT MULTI OUT PRE OUT

SERIAL NO.

AC OUTLETS

RIGHT

SPEAKERS 8 Ohms

LEFT

SURROUND

OUT IN

TV

MONITOR

OUT

VIDEO 2

IN

OUT

DVD

VIDEO 1

OPTICAL

2

OPTICAL

1

OPTICAL

1

COAXIAL

1

DIGITAL OUTPUT

MULTI IN

DIGITAL INPUT

VIDEO

REMOTE

CONTROL

RIGHT

SPEAKERS 8 Ohms SPEAKER 8 Ohm

LEFT CENTER

FRONT

CENTER

VIDEO 1

DIGITAL INPUT

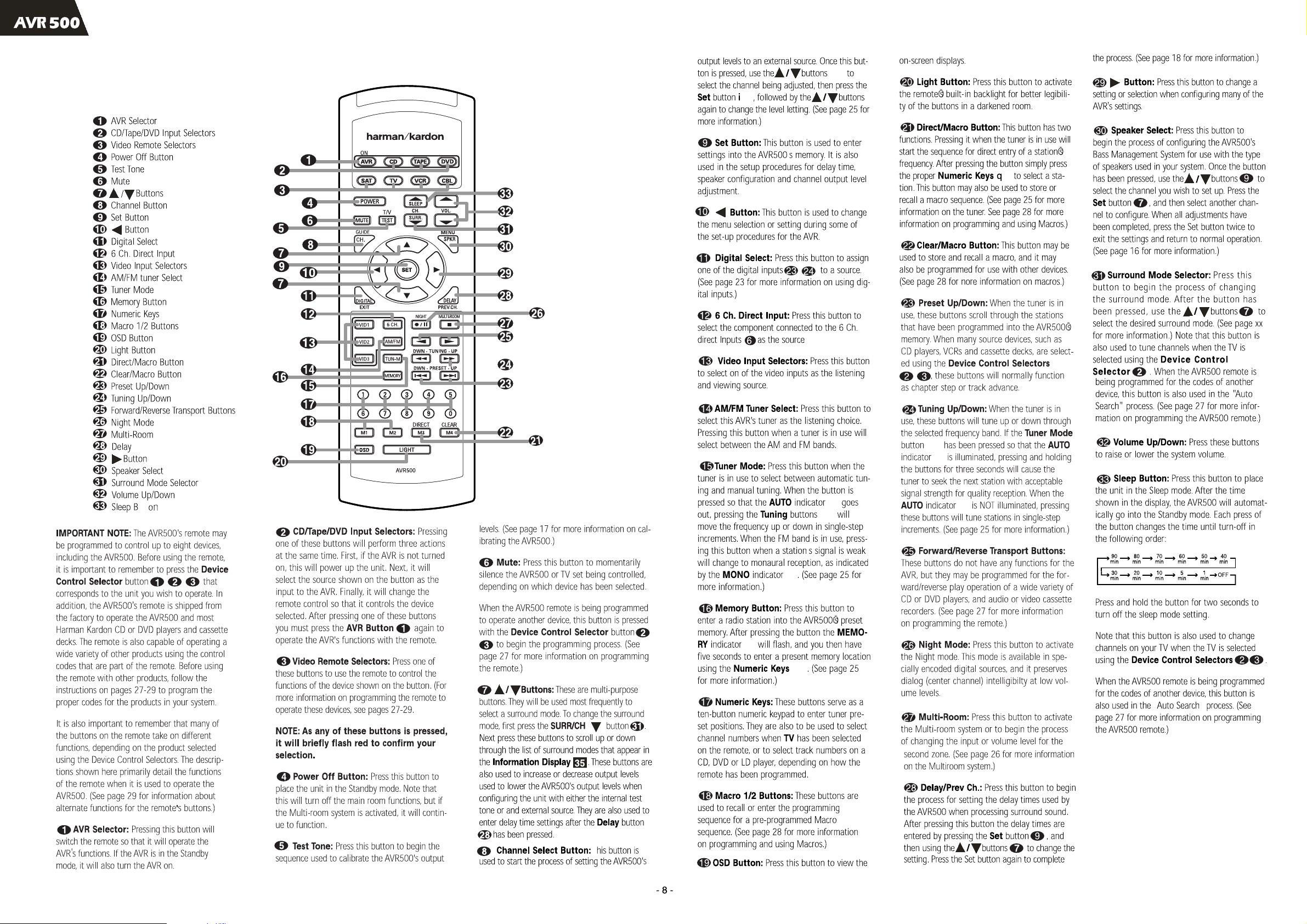

SLEEP TUNED

STEREO

AUTOMONO PRESET

SURR. OFF

MUTE

PCM THEATER

LOGIC 7 C LOGIC 7 MVMAx3

-

STEREOPRO LOGICDIGITAL

COAX

OPT

12

ANALOG

NIGHT

MULTI

MEMORY

A

B

C

D

EG

N

O

K

M

L

X

WTUSRQ PV

F

H

I

J

A Coax Source

B Digital Source Input Number

C Optical Source

D Analog Source Indicator

E PCM Indicator

F Dolby Digital Indicator

G Analog Dolby Surround Mode Indicators

H VMAx Mode Indicator

I Theater Mode Indicator

J Logic 7 Mode Indicators

K DTS Mode Indicator

L Surround Off

M Multiroom System Indicator

N Night Mode Indicator

O Preset Number

P Preset Indicator

Q Memory

R Auto

S Mono Indicator

T Stereo Indicator

U Tuned Indicator

V Main Information Display

W Sleep Indicator

X Mute

A Coax Source:This indicator illuminates

when a digital source is in use via a connection

to the Coaxial Digital inputs e.

B Digital Source Input Number:These

indicators tell you which of the two digital

inputs is selected.This indicator works in cojunc-

tion with the Coax Source A and Optical

Source C indicators to show which form of

digital signal is in use.

C Optical Source:This indicator illuminates

when a digital source is in use via a connection

to the Optical Digital input d.

D Analog Source Indictor: This indicator

illuminates when an analog input source is in use.

E PCM Indicator:This indicator illuminates

to show that a standard PCM (S/P-DIF) digital

audio signal is being decoded by the digital-to-

analog converter.

F Dolby Digital Indicator:This indicator

illuminates when a Dolby Digital source is

being played.

G Analog Dolby Surround Mode

Indicators:These indicators illuminate when

one of the analog (matrix) Dolby Surround

modes is in use.

H VMAx Mode Indicator: This indicator illu-

minates to show that the VMAx mode is in use.

I Theater Mode Indicator: This indicator illu-

minates to show that the Theater mode is in use.

J Logic 7 Mode Indicators:These indica-

tors illuminate when the Logic 7 mode is in

use.LOGIC 7C appears for the Cinema ver-

sion of Logic 7, LOGIC 7M appears for the

Music version of Logic 7.

K DTS Mode Indicator:This indicator illumi-

nates when a DTS-encoded source is playing.

L Surround Off:This indicator illuminates

when the surround processing has been dis-

abled by pressing the Surround Off button

Ù.When this indicator is lit, the AVR 500 will

play traditional stereo sound using the front-left

and front-right speakers only.

M Multiroom System Indicator:This indica-

tor illuminates when the multiroom system is in

operation.(See page 26 for more information

on the multiroom system.)

N Night Mode Indicator:This indicator

lights when the AVR 500 is in the Night mode,

which preserves the dynamic range of digital

program material at low volume levels.

O Preset Number:This two-digit display

indicates the station preset number that is

currently in use,or that is being entered.

P Preset Indicator:This indicator illuminates

when a station previously entered into the preset

memory is tuned.The number that appears below

the indicator is the preset station’s memory.

Q Memory:This indicator flashes when

entering presetsand other information into the

tuner’smemory.

R Auto: This indicator illuminates when the

Auto mode is in use for FM tuning.

S Mono Indicator:This indicator illuminates

when the tuner has been placed in the monaural

mode by pressing the Tune Mode button *.

Set the tuner for mono listening to reduce noise

and improve the quality of distant stereo signals.

T Stereo Indicator:This indicator illuminates

when an FM station is being tuned in stereo.

U Tuned Indicator:This indicator illuminates

when a station is being received with sufficient sig-

nal strength to provide acceptable listening quality.

V Main Information Display:This display

shows messages relating to the status,input

source,surround mode,tuner,volume level or

other aspects of unit’s operation.

W Sleep Indicator:This indicator is illumi-

nated when the Sleep function is in use.The

number that appears above the indicator is

the number of minutes remaining before the

AVR 500 will return to the Standby mode.

X Mute:This indicator illuminates to remind

you that the AVR 500’s output has been

silenced by pressing the Mute button ıf.

Press the Mute button again to return to the

previously selected output level.

SERVICE PROCEDURE

TEST EQUIPMENT REQUIRED

1) AM/FM Signal generator

2) Digital Multimeter

3) Distortion lever meter

2. VFD segment illumination & text

This set do not have VFD segment check function because lack of u-com memory size

So For your checking VFD states according to each function

Please refer to owners manual process.

1. All Clear

This service program can clear all memorized operations and functions.

When the POWER ON, press the "AM/FM" button while pressing the "PRO LOGIC"button.

After this, Preset memory will be set to these frequencies.

FM

AM

VERSION

120

230RDS

VERSION

120

230RDS

P1

87.5

87.50

P9

520

522

P2

88.0

88.00

P10

600

594

P3

90.0

90.00

P11

610

999

P4

95.0

95.00

P12

1000

1395

P5

98.0

98.00

P13

1400

1611

P6

99.0

99.00

P14

1500

P7

106.0

106.00

P15

1710

P8

108.0

108.00

ALIGNMENT PROCEDURES

1. FM MONO. Distortion adjustment

step

1

2

Input Signal Source

Connection

Signal generator

output to FM

antenna

terminal.(750hm)

Signal

Frequency

98MHz

Source Signal Output Level and

Modulation

1000uV/m (60dBu)

MONO 1kHz/

Dev. 75kHz

Reception

Frequency

98MHz

(P5)

Adjustment

Point

T804

T805

Adjustment

Value

0mV 0.5mV

(R831)

Distortion

level

at

TAPE-OUT

Minimum

4. FM STEREO Separation Adjustment

step

1

2

Input Signal Source

Connection

Signal generator

output to FM

antenna

terminal.(750hm)

Signal

Frequency

98MHz

Source Signal Output Level and

Modulation

same specification as

distortion adjustment.

Input only L channel

FM STEREO

same specification as

distortion adjustment.

Input only R channel

FM STEREO

Reception

Frequency

98MHz

(P5)

98MHz

(P5)

Adjustment

Point

VR803

VR803

Adjustment

Value

Output level

at TAPE-OUT

channel R

Minimum

Output level

at TAPE-OUT

channel R

Minimum

2. FM MUTING LEVEL ADJUSTMENT

Turn variable resistor VR801 and stop at position "TUNED" is not shown (not indicated), then again turn the variable resistor VR801 to the

opposite revolution and stop at a position "TUNED" is shown.

step

1

2

Input Signal Source

Connection

Signal generator

output to FM

antenna

terminal.(750hm)

Signal

Frequency

98MHz

Source Signal Output Level and

Modulation

10uV/m (20dBu)

MONO 1kHz/

Dev. 75kHz

Reception

Frequency

98MHz

(P5)

AUTO

SCAN

Adjustment

Point

VR801

Only confirm

Adjustment

Value

"TUNED"

indicate on VFD

"TUNED"

indicate on VFD

-9-

2

step

Input Signal Source

Connection

Signal

Frequency

Source Signal Output Level and

Modulation

Reception

Frequency

Adjustment

Point

Adjustment

Value

1

1395kHz

(230,230RDS)

1400kHz(120)

CT801

5. AM-Tracking Adjustment (MW)

Signal Generator

output to transmission

loop antenna

(standard required loop)

5mV/m(74dBu)

400Hz

MOD.30%

594kHz

(230,230RDS)

600kHz(120)

594kHz

(230,230RDS)

600kHz(120)

T801

Output level(L or R)

at

TAPE-OUT

Minimum

Output level(L or R)

at

TAPE-OUT

Minimum

6. AM IF Adjustment

step

Input Signal Source

Connection

Signal

Frequency

Source Signal Output Level and

Modulation

Reception

Frequency

Adjustment

Point

Adjustment

Value

T803

Output level(L or R)

at

TAPE-OUT

Maximum

Signal Generator

output to transmission

loop antenna

(standard required loop)

5mV/m(74dBu)

400Hz

MOD.30%

999kHz

(230,230RDS)

1000kHz

(120)

999kHz

(230,230RDS)

1000kHz(120)

Output level(L or R)

at

TAPE-OUT

Maximum

1

step

Input Signal Source

Connection

Signal

Frequency

Source Signal Output Level and

Modulation

Reception

Frequency

Adjustment

Point

Adjustment

Value

1

522kHz

(230,230RDS)

520kHz(120)

5mV/m(74dBu)

400Hz

MOD.30%

Signal Generator

output to transmission

loop antenna

(standard required loop)

522kHz

(230,230RDS)

520kHz

(120)

(P9)

T802

1.1V 1.2V

4. AM OSC Adujstment

500

2

step

Input Signal Source

Connection

Signal

Frequency

Source Signal Output Level and

Modulation

Reception

Frequency

Adjustment

Point

Adjustment

Value

1

7. AM auto stop Adjustment

Signal Generator

output to transmission

loop antenna

(standard required loop)

1000uV/m(60dBu)

400Hz

MOD.30%

AUTO SCAN

"TUNED"

indicate on

VFD

999kHz

(230,230RDS)

1000kHz

(120)

999kHz

(230,230RDS)

1000kHz(120)

Only

Confirm

VR802

"TUNED"

indicate on

VFD

8. Main Amp ldling current Adjustment

(4) CAUTION

should be adjusted again

* FRONT AMP : Q433~Q440

* CENTER AMP : Q517~Q520

* SURROUND AMP : Q633~Q640

1) In case that POWER TR or DREVE TR is needed to be replaced for repairing, the corresponding channel

(1) SET CONDITION

1) SEMI VOLUME POSITION at MAIN/SURROUND AMP Board; CENTER

MAIN : VR401, VR402, VR501

SURROUND : VR601, VR602

2) NO signal / NO LOAD

3) AC LINE VOLTAGE : 120V/60Hz, 230V/50Hz

(2) After turning on the unit, keep it over than 5MIN. (Keep the Power/Drive TR as normal temperature)

(3) Adjust the voltage value of primary & secondary of wafer to be 10mV by rotating the semi-volume

of each channel to the right

R401:22.7mA

R472:22.7mA

R501:22.7mA

R601:22.7mA

R602:22.7mA

FRONT-L ch

FRONT-R ch

CENTER ch

SURROUND-L ch

SURROUND-R ch

VR401

VR402

VR501

VR601

VR602

WA401

WA402

WA501

WA601

WA602

CHANNEL ADJUSTMENT MEASUREMENT OTHERS

-10-

10 3mV

10 3mV

10 3mV

10 3mV

10 3mV

VOLAGE

9. Main Amp DC OFFSET VOLTAGE Adjustment

(4) CAUTION

should be adjusted again

* FRONT AMP : Q401~Q440, Q411~Q414

* CENTER AMP : Q501, Q502, Q506, Q507

* SURROUND AMP : Q601~Q604, Q611~Q614

1) In case that POWER TR or DREVE TR is needed to be replaced for repairing, the corresponding channel

(1) SET CONDITION

1) SEMI VOLUME POSITION at MAIN/SURROUND AMP Board; CENTER

MAIN : VR403, VR404, VR502

SURROUND : VR603, VR604

2) NO signal / NO LOAD

3) AC LINE VOLTAGE : 120V/60Hz, 230V/50Hz

(2) After turning on the unit, keep it over than 5MIN. (Keep the Power/Drive TR as normal temperature)

(3) Adjust the voltage value of primary & secondary of wafer to be 10mV by rotating the semi-volume

of each channel to the right

FRONT-L ch

FRONT-R ch

CENTER ch

SURROUND-L ch

SURROUND-R ch

VR403

VR404

VR502

VR603

Vr604

JK401

JK402

JK501

JK601

JK601

CHANNEL ADJUSTMENT MEASUREMENT OTHERS

0mV

0mV

0mV

0mV

0mV

VOLAGE

10. Cautions for main Amp adjustment

(1) At MAIN/SURROUND BOARD, use the below condensors after discharging for sufficent time

for preventing possible damage from electrical spark.

(2) The checker for MAIN/SURROUND BOARD should have the discharging circuit.

Discharge over 30sec. through (407ohm 10w) resistor after turning off

MAIN BOARD C481, C482 (10000/63V, 8200uF/63V)

SURROUND BOARD C691, C692 (6800/63V, 6800uF/50V)

500

17

1

harman/kardon Service Bulletin

Service bulletin # H/K2000-02 Rev1 January 2001 Warranty labor rate: MAJOR repair

To: All harman/kardon Service Centers

Models: AVR300, AVR500

Subject: Random Noise, Erratic Output in DTS Mode

In the event you receive an AVR300 or AVR500 receiver with the complaint “there is distortion, random

noise or gaps in the program material when in the DTS mode”, perform the following procedure:

REMOVAL AND MODIFICATION OF THE DSP BOARD

1) Remove the top cover, (14) Black Phillips screws.

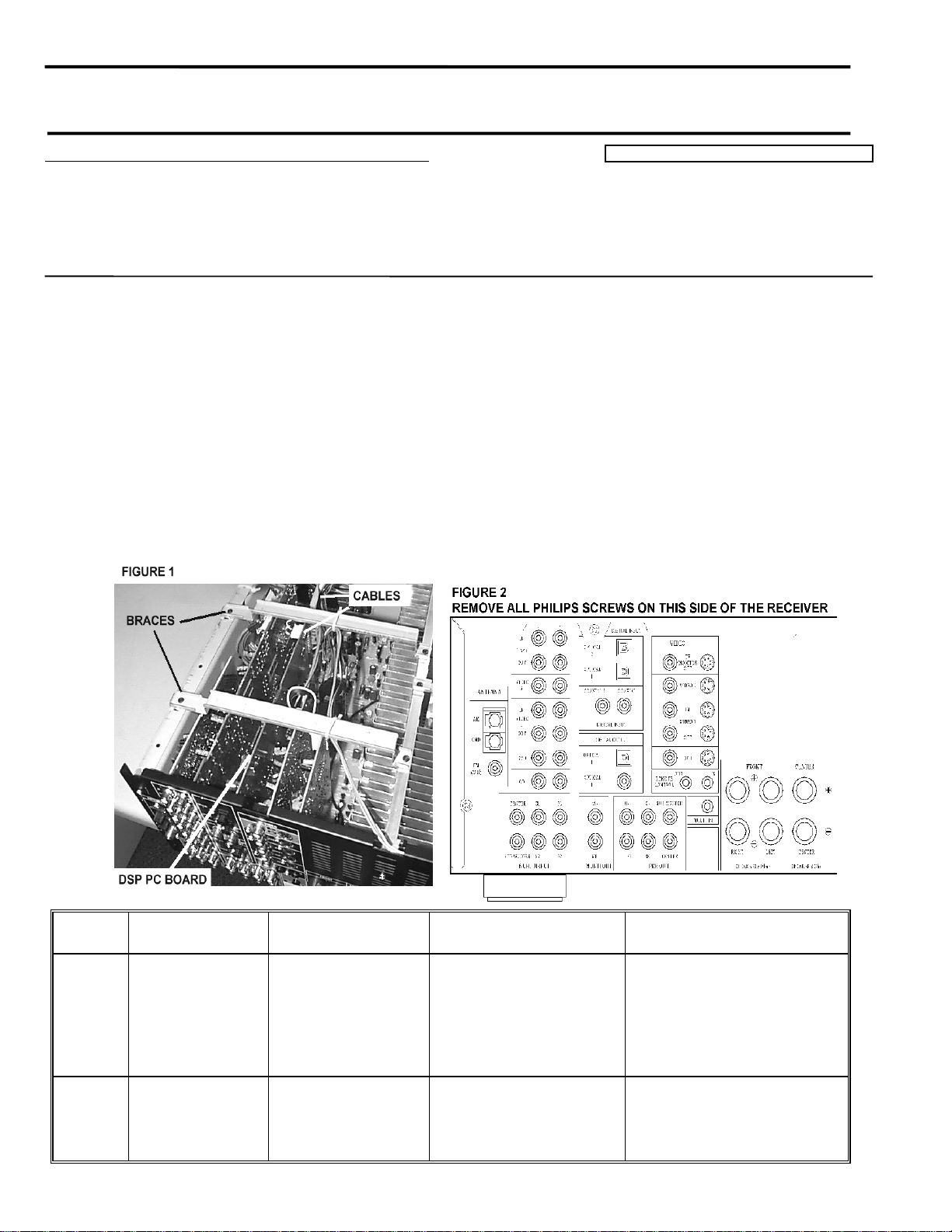

2) Locate the DSP PC Board; Figure 1. Remove the two metal braces at the top of the unit. If necessary, cut

the cable ties attached to the braces to move any wires away from the area.

3) Pull the white 22 conductor ribbon cable at the rear of the DSP PC Board straight out of its receptacle.

4) Unplug the white 5 conductor molex cable at the top of the DSP PC Board.

5) Remove the (33) plated Phillips screws on the left side of the rear backplate; see Figure 2. Do not remove

any additional screws on the right side. If using a power tool, use care and minimum effort to avoid damaging

the various plastic receptacles.

6) Remove all three black plastic plugs that cover the optical inputs at the rear of the DSP PC Board.

7) Pull on the left side of the rear backplate, away from the receiver chassis; you should be able to pull it away

enough to allow the DSP PC Board to be pulled straight up and out of the receiver.

8) Proceed with the modifications on page 2.

Model Serial Number

120V

Serial Number

230V RDS

STATUS ACTION

AVR300

AVR500

TH0001-01000

To

TH0001-13886

TH0002-01000

To

TH0002-10460

TH0005-01000

To

TH0005-03317

TH0006-01000

To

TH0006-02795

Random Noise, Erratic

Output or Gaps in Program

Material when in DTS Mode

Modifications to DSP Board:

Add ground wire;

Change R756 & R755

from 600W resistor or Capacitor

to 33W resistor

AVR300

AVR500

TH0001-13887

Or higher

TH0002-10461

Or higher

TH0005-03318

Or higher

TH0006-02796

Or higher

Modified by factory NONE REQUIRED

18

2

Models: AVR300, AVR500 Subject: Random Noise, Erratic Output in DTS Mode

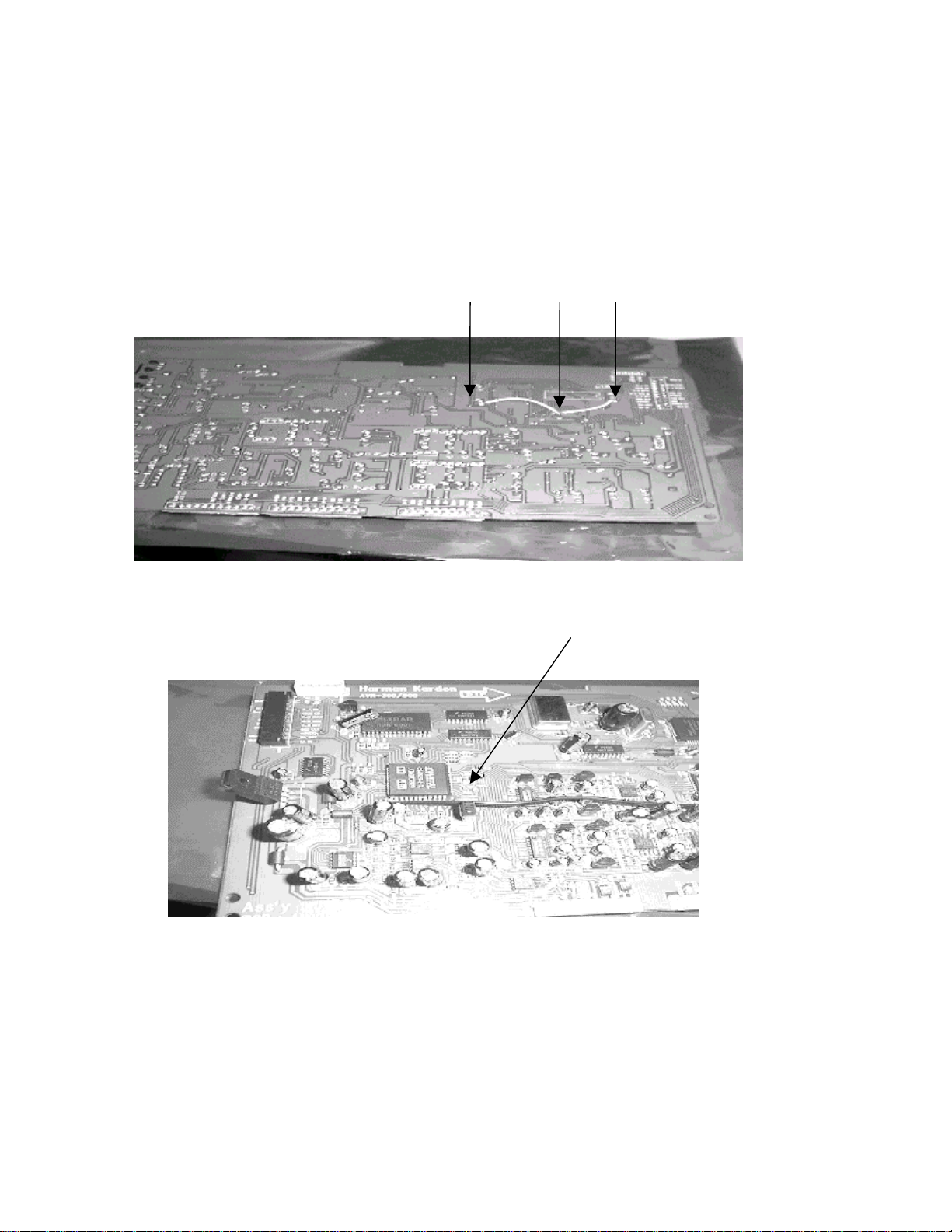

9) Ground Reinforcement:

Using an insulated 16AWG wire, Connect Negative sides of the following capacitors on the bottom side of the

PCB as shown below. Negative side of each cap will have a white mark on the component side of the PCB.

A. Negative polarity of C746 Elec Cap (1uF/50V) in the proximity of ROM IC709

B. Negative polarity of C749 Elec Cap (1uF/50V) in the proximity of IC708 DSP IC

C. Negative polarity of C744 Elec Cap (1uF/50V) in the proximity of IC710 74VHC574

C B A

10) Replace:

R756 & R755. Original parts may be 600W resistors, or Capacitors. Change both to 33W 1/10W

SMD resistors (h/k part#

292-33.2). See location below.

11) Replace DSP PC Board back into its (3) receptacle plugs atop the MAIN PCB.

12) Replace all screws, braces, and any cable ties that were cut during disassembly. Before tightening the

screws, make sure all PCB’s and their RCA jacks are firmly seated in their respective holes in the rear

backplate. If using a power tool, use care and minimum effort to avoid damaging the various plastic

receptacles.

13) Plug both the 22 conductor ribbon cable and the 5 conductor molex cable back into their receptacles.

14) Replace the top cover and optical plugs.

15) Test unit by powering up the receiver and playing a source with DTS encoded material; confirm the complaint

of Random Noise or Erratic Output is no longer occurring.

19

harman/kardon Service Bulletin

Service bulletin # H/K2000-04 Rev1 February 2003

Warranty labor rate:

AVR500 MAJOR repair

To: All harman/kardon Service Centers AVR7000 MINOR repair

Models: AVR500/AVR7000

Subject: Noise in Logic 7 Mode

In the event you receive an AVR500 or AVR7000 receiver with the complaint “There is crackling, noise,

or distortion coming from my loudspeakers when my receiver is in the Logic 7 mode with certain

program material playing”, perform the following procedure:

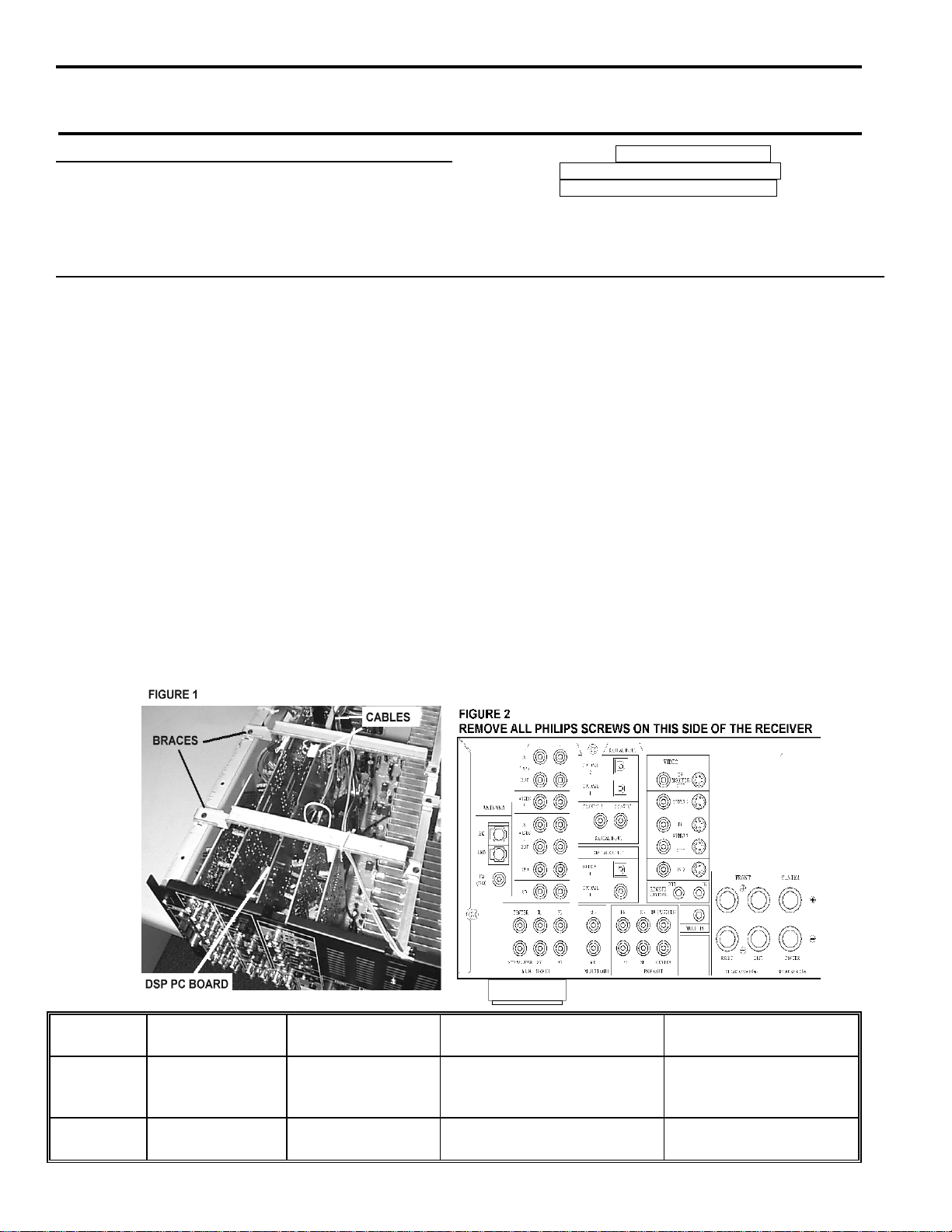

AVR500 ONLY: REMOVAL AND MODIFICATION OF THE DSP BOARD (replace IC709 TRAD ROM-0001)

WARNING: FOLLOW PROPER STATIC CONTROL PROCEDURES and use caution during the removal of the

DSP board, and during installation of new IC709 to prevent damage.

1) Remove the top cover, (14) Black Phillips screws at the sides and rear of the unit.

2) Locate the DSP PC Board; Figure 1. Remove the two metal braces at the top of the unit. If necessary, cut

the cable ties attached to the braces to move any wires away from the area.

3) Pull the white 22 conductor ribbon cable at the rear of the DSP PC Board straight out of its receptacle.

4) Unplug the white 5 conductor molex cable at the top of the DSP PC Board.

5) Remove the (33) plated Phillips screws on the left side of the rear backplate; see Figure 2. Do not remove

any additional screws on the right side. If using a power tool, use care and minimum effort to avoid

damaging the various plastic receptacles.

6) Remove all three black plastic plugs that cover the optical inputs at the rear of the DSP PC Board.

7) Pull on the left side of the rear backplate, away from the receiver chassis; you should be able to pull it away

enough to allow the DSP PC Board to be pulled straight up and out of the receiver.

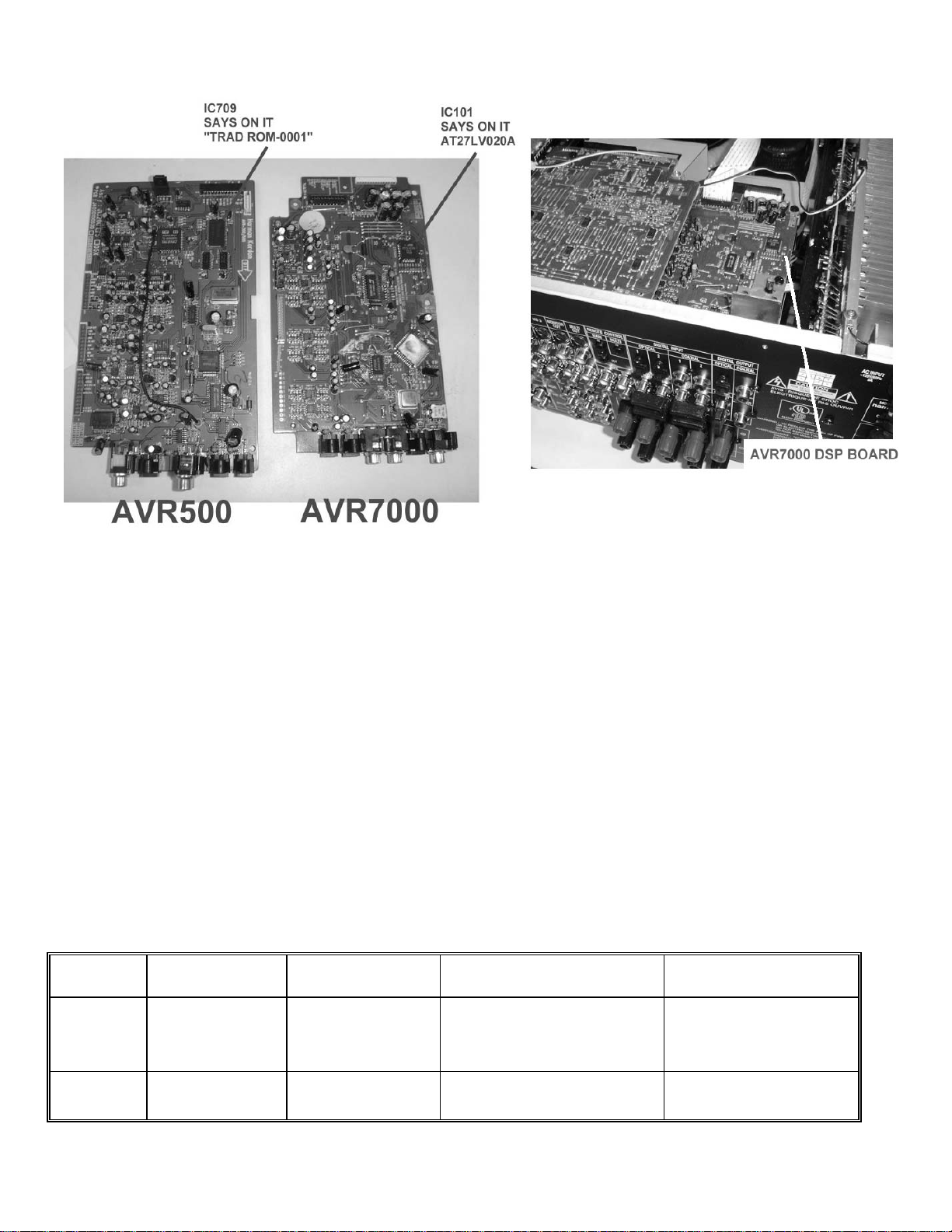

8) Unsolder IC709 TRAD ROM-0001 and replace with hk part# J21310030011. See illustration on following

page for location on PCB.

Model Serial Number

120V

Serial Number

230V RDS

STATUS

ACTION

AVR500

TH0002-01000

To

TH0002-14977

TH0006-01000

To

TH0006-05105

Noise in Logic 7 Mode

Replace IC709

TRAD ROM-0001

AVR500

TH0002-14978 or

higher

TH0006-05106 or

higher

Modified by factory

NONE REQUIRED

20

Location of IC upgrade for the AVR500/AVR7000:

9) Replace DSP PC Board back into its (3) receptacle plugs atop the MAIN PCB.

10) Replace all screws, braces, and any cable ties that were cut during disassembly. Before tightening the

screws, make sure all PCB’s and their RCA jacks are firmly seated in their respective holes in the rear

backplate. If using a power tool, use care and minimum effort to avoid damaging the various plastic

receptacles.

11) Plug both the 22 conductor ribbon cable and the 5 conductor molex cable back into their receptacles.

12) Replace the top cover and optical plugs.

13) Test unit by powering up the receiver and playing a music source in the Logic 7 mode.

AVR7000 ONLY: MODIFICATION OF THE DSP BOARD (replace IC101 AT27LV020A)

WARNING: FOLLOW PROPER STATIC CONTROL PROCEDURES and use caution during the installation of

new IC101 to prevent damage.

1) Remove the top cover, (16) Black Phillips screws at the sides and rear of the unit.

2) Locate the DSP PC Board and IC101 with the illustrations above.

3) Unsolder IC101 AT27LV020A and replace with hk part# 55172540AVR7000. See illustration above for

location on PCB.

4) Replace top cover and all Phillips screws.

5) Test unit by powering up the receiver and playing a music source in the Logic 7 mode.

Model Serial Number

120V

Serial Number

230V RDS

STATUS

ACTION

AVR7000

TH0003-01000

To

TH0003-05222

Modified by factory

Noise in Logic 7 Mode

Replace IC101

AT27LV020A

AVR7000

TH0003-05223

Or higher

Modified by factory

Modified by factory

NONE REQUIRED

21

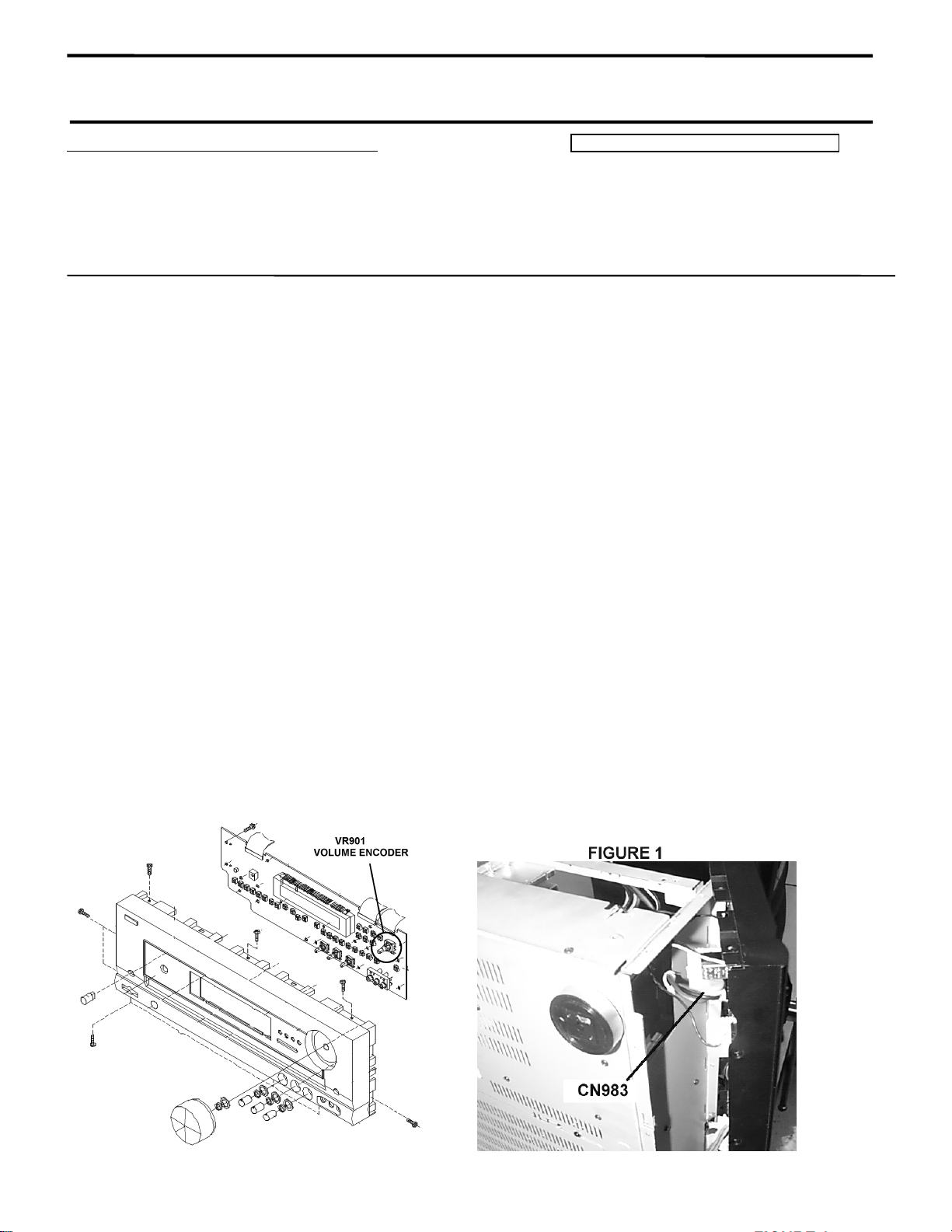

harman/kardon Service Bulletin

Service bulletin # H/K2000-05 May 2000 Warranty labor rate: MAJOR repair

To: All harman/kardon Service Centers

Models: AVR300, AVR500

Subject: Volume Level Changes

On early versions of the AVR300 or AVR500 the volume level may change by itself, or when the volume knob

is tapped. This may happen on an occasional random basis and depends on where the volume control knob is

positioned after a volume adjustment. During a running production change, new volume encoders were

installed.

In the event you receive an AVR300 or AVR500 with the complaint “The volume on my receiver

changes by itself”, perform the following procedure:

REPLACE VR901 VOLUME ENCODER

1) Remove the top cover, (14) Black Phillips screws.

2) Remove the (11) Black Phillips screws holding the plastic front panel to the chassis.

3) Remove the single Phillips screw on both right & left side of the chassis with a dual black ground wire.

4) Remove the volume, bass, treble and balance knobs by pulling them straight off.

5) Remove the single nut holding the volume encoder to the front panel.

6) Pull the loaded front panel off the chassis; cut any plastic cable ties necessary to fully disengage it

7) Lift and set the receiver on its right side for the remainder of the procedure.

8) Remove molex connector CN983 at the power switch; see Figure 1.

9) Pull the front panel as far away as the remaining connecting wires will allow.

10) Unsolder the connections at the rear of the front PCB to the volume encoder.

11) Using a “stubby” Phillips screwdriver, remove the (19) Black Phillips screws holding the front PCB to the

front panel; two plated screws at the rear of the headphone jack also must be removed.

12) Pull the front PCB away from the front panel.

13) Remove and replace the volume encoder with h/k part# J32612050102; resolder the new encoder in place.

14) Replace the front PCB and reassemble the receiver in reverse order, following the instructions above.

Replace all cable ties that were cut, and reattach any connectors that were unplugged. Make sure the two

ground wires on both sides of the receiver are reattached.

15) Power up receiver, and test volume control to assure it no longer changes settings by itself, or when the

volume knob is tapped.

22

Models: AVR300, AVR500 Subject: Volume Level Changes

Model Serial Number

120V

Serial Number

230V RDS STATUS ACTION

AVR300

AVR500

TH0001-01000

To

TH0001-08402

TH0002-01000

To

TH0002-05565

TH0005-01000

To

TH0005-01001

TH0006-01000

To

TH0006-01001

Volume level changes by

itself or when volume

knob is tapped

Change VR901

Rotary encoder

AVR300

AVR500

TH0001-08403

Or higher

TH0002-05566

Or higher

TH0005-01002

Or higher

TH0006-01002

Or higher

Modified by factory NONE REQUIRED

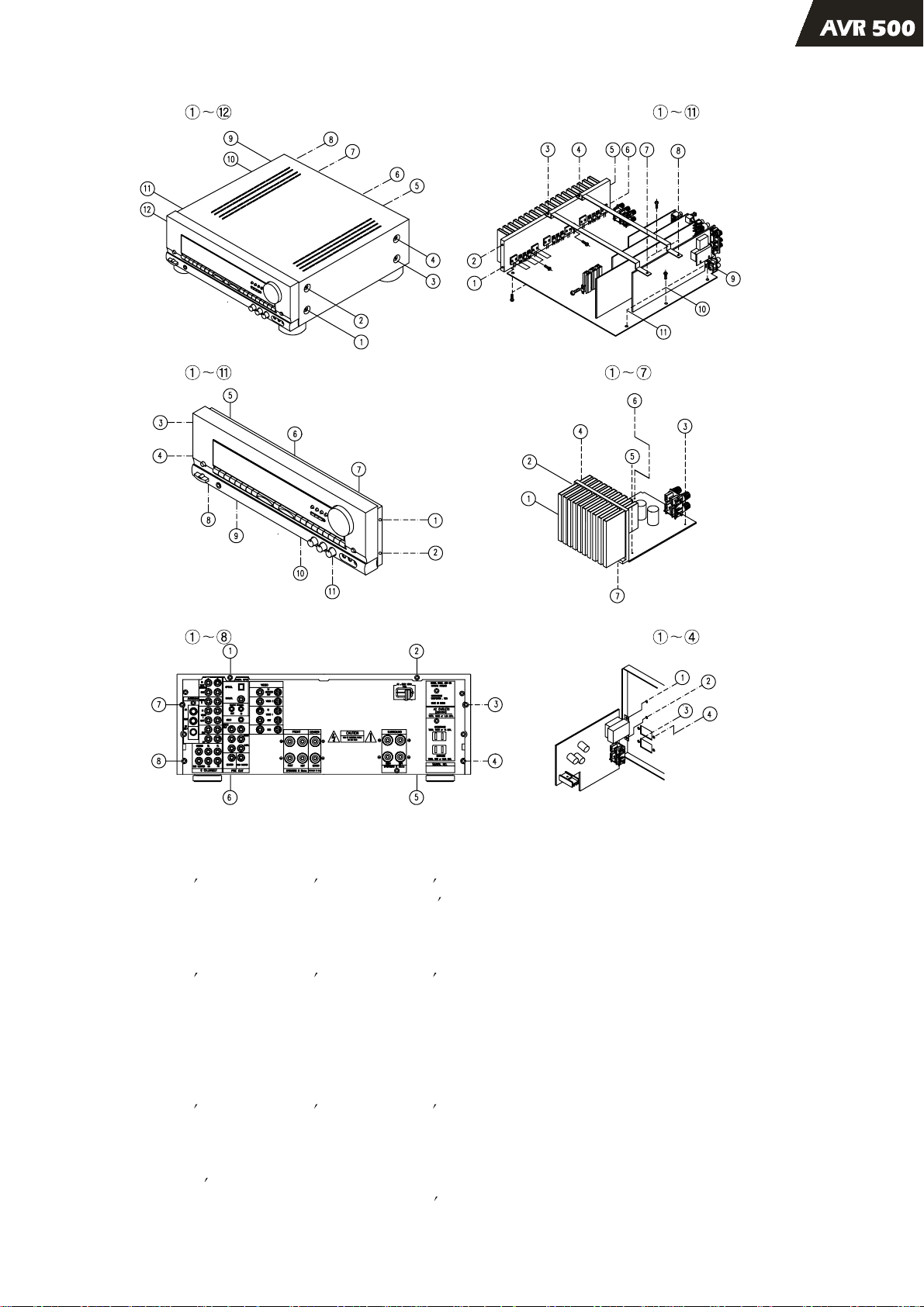

DISASSEMBLY PROCEDUREDISASSEMBLY PROCEDURE

1. Removingthe top cover, and

Removescrews

4. Removingthe main PCBblock, and

Removescrews

2. Removingthe front panel, and

Removescrews

5. Removingthe power PCBblock, and

Remove

3. Removingthe rear panel, and

Removescrews

1. Removeall of the screwson Rearpanel.

2. Removethe Rearpanel.

3. RemovePCBBrk t and Guide

5. Removethe Main PCBblock.

Brk t from Main Assy.

4. Removeall of the screwsthat connect with main Assy.

1. Remove4 screwson Rearpanel.

2. Removethe Rearpanel.

3. RemovePCBBrk t and Guide

4. Removethe SUBPCBblock.

Brk t from Main Assy.

1. RemoveMain

2. Removevolume and rotary knob from the front

3. Removeall of the screwson back sideof Front function PCB.

4. Removethe Front function PCB.

Assy.

Assy.

1. RemovePCBBrk t and Guide

3. Removethe POWERPCBblock.

Brk t from Main Assy.

2. Remove4 screwsfor Power PCBmounting

6. Removingthe sub PCBblock, and

Removescrews

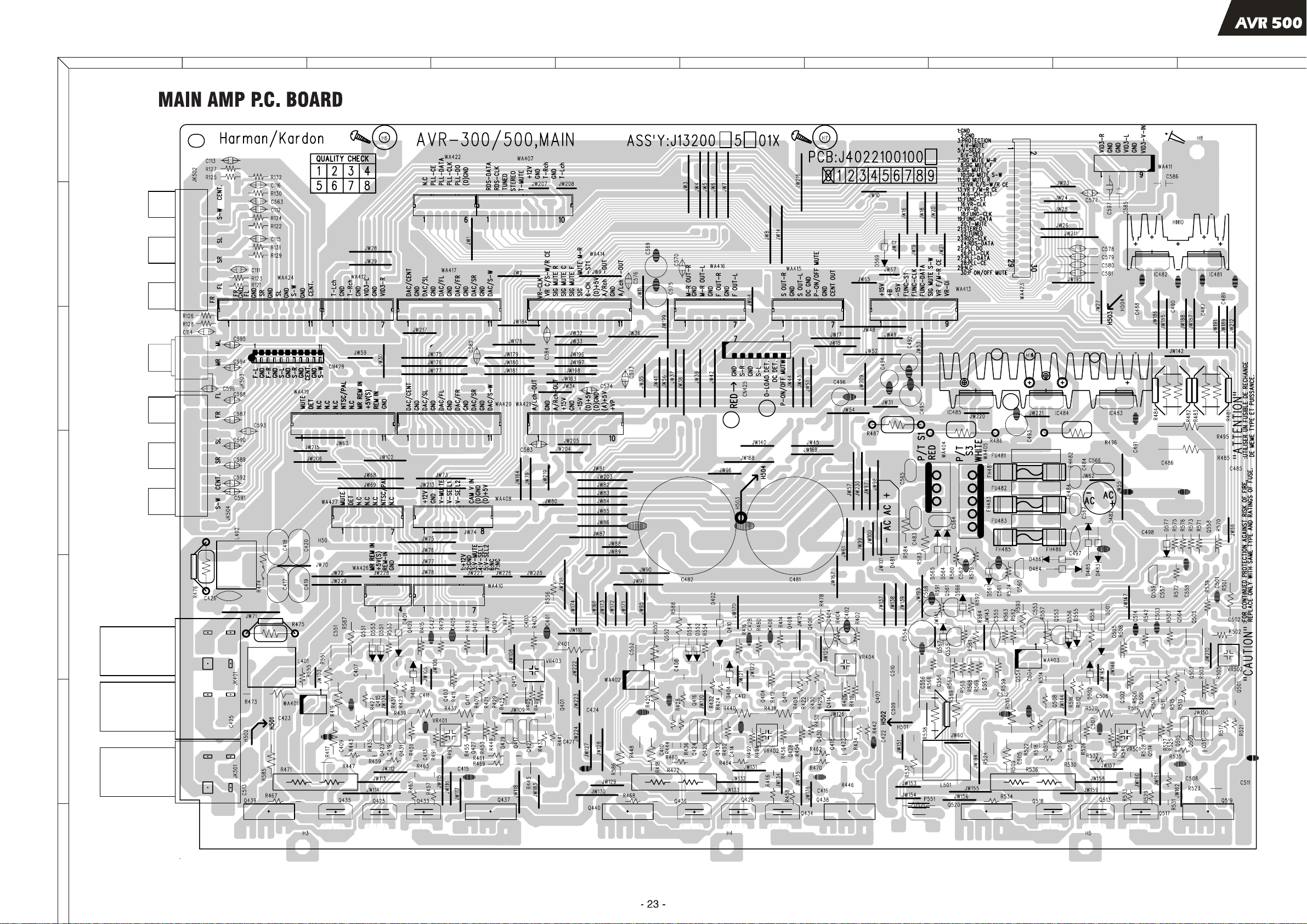

MAIN AMP PCB BLOCKMAIN AMP PCB BLOCK

SUB PCB BLOCKSUB PCB BLOCK

FRONT PCB BLOCKFRONT PCB BLOCK

POWER PCB BLOCKPOWER PCB BLOCK

23

24

25

26

1

2

3

4

5

6

7

B C D E F G H I JA

27

1

2

3

4

5

6

7

B C D E F G H I JA

28

1

2

3

4

5

6

7

B C D E F G H I JA

29

Loading...

Loading...