gsk GSK980TD User Manual

GSK980TD

Turning Machine CNC System

User Manual

Preface

Warning

Please read the user manual and a user manual from machine manufacturer completely before installation, programming and operation, and operate the system and machine according to user manuals, otherwise which may damage the system and machine, workpiece and even injure the operator.

Notice

Functions, technical indexes described in the user manual are for the system. Actual functions and technical performance of CNC machine tool with the system are defined by machine manufacturer, and refer to its user manual

The system is employed with intergrated machine control panel and press keys on machine control panel are defined by PLC program. Functions of press keys in the user manual are for standard PLC program. Please notice it!

Refer to user manual from machine manufacturer about functions and meanings of press keys on machine control panel.

This manual suits for software version:V06.03.23.

All specification and designs are subject to change without notice.

Notice

Notice

■ Delivery and storage

There are 6-layer packing box at most in pile

Never climb the packing box, neither stand on it, nor place heavy items on it

Do not use cable connected with product to drag or move it

Forbid crash, hurt panel and display

Packing box is protected from damp, sun and rain

■ Open packing box to check

Ensure things in packing box are the required ones Ensure it is not damaged in delivery

Ensure things in packing box are these of order

Contact with us in time if its type is inconsistent with the order, there is short of accessories, or it is damaged in delivery

■ Connection

Only qualified persons can connect the system or check the connection.

The system must be earthed, its resistance must be less than 4 Ω and the ground wire cannot be replaced by zero wire

Connection must be correct and firm to avoid the product to be damaged or other unexpected result Connect with surge diode in the specified direction to avoid to damage the system

Switch off power supply before pulling out plug or opening electric box

■ Troubleshooting

Switch off power supply before troubleshooting or changing components

Troubleshoot and then startup the system when there is short circuit or overload

Do not switch off it and a meantime is 1 minute at least after it is switched on again.

BOOK 1

PROGRAMMING

Chapter1 Programming Fundamentals

Chapter2 M.S.F.T Instructions

Chapter3 G Instructions

Chapter4 Tool Nose Radius Compensation (G41 G42)

fundamentals Programming 1 okBo

Contents

Chapter 1 |

PROGRAMMING FUNDAMENTALS............................................................................ |

-1 |

|

1.1 |

INTRODUCTION of GSK980TD ........................................................................................ |

-1 |

|

1.2 |

CNC SYSTEMS of MACHINE TOOLS and CNC MACHINE TOOLS ............................. |

-6 |

|

1.3 |

PROGRAMMING FUNDAMENTALS................................................................................ |

-9 |

|

1.3.1 |

Coordinates Definition................................................................................................. |

-9 |

|

1.3.2 Machine Coordinate System and Machine Reference Point ..................................... |

-10 |

||

1.3.3 Workpiece Coordinate System and Program Reference Point .................................. |

-10 |

||

1.3.4 |

Interpolation Function ............................................................................................... |

-11 |

|

1.3.5 Absolute Programming and Incremental Programming ............................................ |

-12 |

||

1.3.6 Diameter and Radius Programming........................................................................... |

-12 |

||

1.4 |

STRUCTURE of an NC PROGRAM.................................................................................. |

-13 |

|

1.4.1 General Structure of Program.................................................................................... |

-14 |

||

1.4.2 Main Program and Subprogram................................................................................. |

-17 |

||

1.5 |

PROGRAM RUN ................................................................................................................ |

-18 |

|

1.5.1 Sequence of Program Run ......................................................................................... |

-18 |

||

1.5.2 Execution Sequence of Word..................................................................................... |

-19 |

||

Chapter 2 |

M.S.F.T INSTRUCTION................................................................................................... |

-1 |

|

2.1 |

M INSTRUCTION AUXILIARY FUNCTION ............................................................. |

-1 |

|

2.1.1 End of Program M02 ................................................................................................... |

-1 |

||

2.1.2 End of Program Run M30............................................................................................ |

-1 |

||

2.1.3 |

Subprogram Call M98 ................................................................................................. |

-2 |

|

2.1.4 Return from Subprogram M99 .................................................................................... |

-2 |

||

2.1.5 |

Macro Program Call .................................................................................................... |

-3 |

|

2.1.6 M Instructions Defined by Standard PLC Ladder Diagram ........................................ |

-4 |

||

2.1.7 |

Program Stop M00....................................................................................................... |

-4 |

|

2.1.8 |

Spindle Control M03 M04 M05 ............................................................................ |

-4 |

|

2.1.9 |

Coolant Control M08 M09 ....................................................................................... |

-5 |

|

2.1.10 |

Tailstock Control M10 M11.................................................................................... |

-5 |

|

2.1.11 |

Chuck Control M12 M13........................................................................................ |

-5 |

|

2.1.12 Lubrication Control M32 M33 .................................................................................. |

-5 |

||

2.1.13 Spindle Automatic Gear Shifting M41, M42, M43, M44.......................................... |

-5 |

||

2.2 |

SPINDLE FUNCTION S FUNCTION .......................................................................... |

-6 |

|

2.2.1 Spindle Speed Switching Value CONTROL ............................................................... |

-6 |

||

2.2.2 |

Spindle Speed Analog Voltage Control ....................................................................... |

-7 |

|

2.2.3 Constant Surface Speed Control G96, Constant Rotational Speed Control G97 ........ |

-7 |

||

2.2.4 |

Spindle Override........................................................................................................ |

-10 |

|

2.3 |

TOOL FUNCTION T FUNCTION ............................................................................ |

-10 |

|

2.4 |

FEEDRATE FUNCTION (F FUNCTION) ......................................................................... |

-14 |

|

2.4.1 |

Cutting Feed G98/G99 F Instruction ............................................................... |

-14 |

|

2.4.2 |

Thread Cutting........................................................................................................... |

-16 |

|

2.4.3 |

Manual Feed .............................................................................................................. |

-16 |

|

2.4.4 |

Handwheel/Step Feed ................................................................................................ |

-15 |

|

2.4.5 Automatic Acceleration/Deceleration........................................................................... |

-15 |

||

Chapter 3 |

G INSTRCUTIONS........................................................................................................... |

-1 |

|

3.1 |

INTRODUCTION ................................................................................................................. |

-1 |

|

fundamentals grammingPro 1 Book

I

fundamentals Programming 1 Book

|

|

GSK980TD Turning Machine CNC System |

|

|

|

|

|

|

3.1.1 Modal, Non-modal and Initial Mode ........................................................................... |

-2 |

|

|

3.1.2 |

Omit a Word................................................................................................................. |

-2 |

|

3.1.3 |

Related Definitions ...................................................................................................... |

-4 |

3.2 |

RAPID TRAVERSE MOVEMENT G00 .............................................................................. |

-4 |

|

3.3 |

LINEAR INTERPOLATION G01......................................................................................... |

-5 |

|

3.4 |

CIRCULAR INTERPOLATION G02, G03 .......................................................................... |

-6 |

|

3.5 |

DWELL G04.......................................................................................................................... |

-9 |

|

3.6 |

MACHINE REFERNCE POINT RETURN G28................................................................ |

-10 |

|

3.7 |

WORKPIECE COORDINATE SYSTEM G50................................................................... |

-11 |

|

3.8 |

FIXED CYCLE INSTRUCTIONS...................................................................................... |

-13 |

|

|

3.8.1 Axial Cutting Cycle G90 ........................................................................................... |

-13 |

|

|

3.8.2 Radial Cutting Cycle G94.......................................................................................... |

-16 |

|

|

3.8.3 Cautions of Fixed Cycle Instructions ........................................................................ |

-19 |

|

3.9 |

MULTIPLE CYCLE INSTRUCTIONS .............................................................................. |

-19 |

|

|

3.9.1 Axial Roughing Cycle G71 ....................................................................................... |

-19 |

|

|

3.9.2 Radial Roughing Cycle G72...................................................................................... |

-24 |

|

|

3.9.3 Closed Cutting Cycle G73 ......................................................................................... |

-28 |

|

|

3.9.4 |

Finishing Cycle G70 .................................................................................................. |

-33 |

|

3.9.5 Axial Grooving Multiple Cycle G74 ......................................................................... |

-34 |

|

|

3.9.6 Radial Grooving Multiple Cycle G75........................................................................ |

-37 |

|

3.10 |

THREAD CUTTING......................................................................................................... |

-41 |

|

|

3.10.1 Thread Cutting with Constant Lead G32................................................................. |

-41 |

|

|

3.10.2 Thread Cutting with Variable Lead G34.................................................................. |

-43 |

|

|

3.10.3 Thread Cutting in Z Direction G33 ......................................................................... |

-45 |

|

|

3.10.4 Thread Cutting Cycle G92....................................................................................... |

-47 |

|

|

3.10.5 Multiple Thread Cutting Cycle G76 ........................................................................ |

-50 |

|

3.11 CONSTANT SURFACE SPEED CONTROL G96, CONSTANT ROTATIONAL SPEED |

|||

|

CONTROL G97................................................................................................................... |

-54 |

|

3.12 FEEDRATE per MINUTE G98, FEEDRATE per REV G99............................................ |

-57 |

||

3.13 |

MACRO INSTRUCTIONS............................................................................................... |

-58 |

|

|

3.13.1 |

Macro Variables ....................................................................................................... |

-58 |

|

3.13.2 Operation and Jump Instruction G65....................................................................... |

-60 |

|

|

3.13.3 PROGRAM EXAMPLE with MACRO INSTRUCTION ...................................... |

-64 |

|

Chapter 4 TOOL NOSE RADIUS COMPENSATION (G41 G42)................................................. |

-1 |

||

4.1 |

APPLICATION...................................................................................................................... |

-1 |

|

|

4.1.1 |

Overview...................................................................................................................... |

-1 |

|

4.1.2 Imaginary Tool Nose Direction ................................................................................... |

-2 |

|

|

4.1.3 |

Compensation Value Setting........................................................................................ |

-5 |

|

4.1.4 |

Instruction Format ....................................................................................................... |

-6 |

|

4.1.5 |

Compensation Direction .............................................................................................. |

-6 |

|

4.1.6 |

Cautious ....................................................................................................................... |

-8 |

|

4.1.7 |

Application .................................................................................................................. |

-9 |

4.2 |

TOOL NOSE RADIUS COMPENSATION OFFSET PATH.............................................. |

-10 |

|

|

4.2.1 Inner and Outer Side.................................................................................................. |

-10 |

|

|

4.2.2 Tool Traverses when Starting Tool ............................................................................ |

-10 |

|

|

4.2.3 Tool Traversing in Offset Mode................................................................................. |

-13 |

|

|

4.2.4 Tool Traversing in Offset Canceling Mode ............................................................... |

-18 |

|

Contents

4.2.5 |

Tool Interference Check............................................................................................. |

-19 |

4.2.6 Instructions for Canceling Compensation Vector Temperarily.................................. |

-21 |

|

4.2.7 |

Particular.................................................................................................................... |

-23 |

fundamentals grammingPro 1 Book

III

Chapter 1 Programming Fundamentals

Chapter 1 PROGRAMMING FUNDAMENTALS

1.1INTRODUCTION of GSK980TD

With 32-bit high performance CPU and super-large-scale programmable FPGA, the new generation widespread GSK980TD Turning Machine CNC System developed by us (GSK CNC Equipment Co., Ltd.) is the upgraded product of GSK980TA, applying the real time multitasking control and hardware interpolation technology to realize μm-level precise motion and PLC logic control.

Technical characteristics:

Link axes (X, Z), μm-level interpolation precision and max. rapid traverse speed 16 m/min(option: 30m/min)

Embedded PLC to control various of automatic toolposts and spindle automatic shifting gear, edit, transmit and download ladder diagrams; expendable I/O interfaces(option function)

Pitch error compensation, backlash compensation, tool length compensation and tool nose radius compensation

S, exponential acceleration/deceleration control to meet high speed and high precision machining Tapping to machine metric/inch single/multiple straight, taper thread, end face thread, variable pitch thread, high speed thread run out with set retraction distance, angle and speed

fundamentals Programming 1 Book

-1

fundamentals Programming 1 Book

GSK980TD Turning Machine CNC System

Chinese and English display interface selected by parameters

Large memory capacity( 6144KB,384 part programs) with full screen edit

Convenient management for the system with multilevel operation password

Bidirectional communication between CNC and PC, CNC and CNC; communication upgrading

CNC software and PLC programs

Installing dimension, electric interfaces, instruction system and operating windows being

compatible with those of GSK980TA Turning CNC System

Technical specifications

Motion control

instructions

Thread machining

Precision compensation

M instructions

Controllable axes: 2(X, Z); simultaneous controllable axes: 2 (X, Z)

Interpolation: linear, arc interpolation in X, Z direction

Dimension for programs: -9999.999 9999.999mm; min. unit: 0.001mm

Electronic gear instruction multiplying 1 32767 and dividing 1 32767

Rapid traverse speed: max. 16000mm/min(option:30000mm/min) Rapid override: time real tuning F0, 25%, 50%,100%

Cutting feedrate: max.8000mm/min(option:15000mm/min) or 500mm/rev (feedrate per rev)

Feedrate override: 16 steps real time tuning for 0 150%

Manual feedrate: 16 steps real time tuning for 0 1260mm/min

Handwheel feedrate: 0.001, 0.01, 0.1mm

Acceleration/deceleration: S acceleration/deceleration for rapid traverse movement and exponential acceleration/deceleration for cutting feed

28 kinds of G instructions: G00, G01, G02, G03, G04, G28, G32, G33, G34, G40, G41, G42, G50, G65, G70, G71, G72, G73, G74, G75, G76, G90, G92, G94, G96, G97, G98, G99 and macro instruction G65 to execute 27 kinds of calculation, logic operation and program skipping

Tapping to machine metric/inch single/multiple straight thread, taper thread, end face thread, variable pitch thread. High speed thread run out with set retraction distance, angel and speed; pitch: 0.001 500mm or 0.06 25400 tooth/inch

Spindle encoder: lines can be set 100 5000p/r

Drive ratio between encoder and spindle: 1 255 1 255

Backlash compensation: X, Z 0 2.000mm

Pitch error compensation: 255 compensation points with ± 0.255mm × compensation override for each one in X, Z direction

Tool compensation: 32 groups tool length compensation, tool nose radius compensation (tool compensation C)

Toolsetting method: fixed-point toolsetting, trial cutting toolsetting

Tool compensation executing methods: traversing tool or coordinate offset

M instructions(no repetition): M02, M30, M98, M99, M9000 M9999 Other M□□ instructions are defined and executed by PLC programs

M instructions defined by standard PLC program: M00, M03, M04, M05, M08, M09, M10, M11, M12, M13, M32, M33, M41, M42, M43, M44

-2

Chapter 1 Programming Fundamentals

|

Most 32 tool selections T01□□T32□□, the time sequence of tool change |

|

T |

is defined by PLC programs. The tool selection is set to 1 and the tool change is |

|

not executed by PLC when the line-up toolpost is employed. The standard PLC |

||

instruction |

||

programs is s is optional to 2 8 tool selections toolpost, clockwise rotation for |

||

|

||

|

selecting tools and counterclockwise rotation for clamping toolpost. |

|

|

Speed switching value control: S□□ instruction is defined and executed by |

|

|

PLC programs, direct output of S1, S2, S3, S4 is controlled by the standard PLC |

|

Spindle speed |

programs and S0 is used for stopping output of S1, S2, S3, S4 |

|

Speed analog voltage control: S instructions specifying the spindle speed per |

||

|

||

|

minute or the cutting surface speed (constant surface speed control) , the |

|

|

system outputting 0 10V voltage to spindle converter, 4 gears spindle speed |

|

|

with stepless shifting gear |

|

|

9 kinds of elementary instruction, 23 kinds of function instruction, 2 grades PLC |

|

|

program, max. 5000 steps and 2μs for each step, refresh cycle for the first |

|

PLC |

grade program is 8ms, ladder diagram editing software, PLC program |

|

communication download |

||

function |

Integrated machine control panel: 41 input points (press keys), 42 output points |

|

|

(LED) |

|

|

Basic I/O interfaces: 16 input points /16 output points (optional I/O interface: 16 |

|

|

input points /16 output points) |

|

Displaying |

Display: 320×240 lattice, 5.7” monochrome liquid crystal display(LCD), CCFL in |

|

a poor light |

||

window |

||

Display method: Chinese or English window is set by parameter, displaying |

||

|

||

|

machining path of workpiece |

|

Program |

Program capacity: 6144KB, max. 384 programs, supporting user macro program |

|

calling and four-embedded subprogram |

||

editing |

||

Editing method: incremental coordinates, absolute coordinate and compound |

||

|

||

|

coordinates programming with full screen edit |

|

|

Bidirectional communication for programs and parameters between CNC and |

|

Communication |

PC, CNC and CNC; communication upgrading and downloading CNC software |

|

|

and PLC programs |

|

Optional |

DA98 Series Digital AC Servo or DY3 Series Stepper Driver with input pulse and |

|

driving |

||

direction signal |

||

|

||

|

|

|

G instructions |

|

Instructions |

|

Functions |

|

|

G00 |

Rapid traverse movement |

|

||

G01 |

Linear interpolation |

|

|

|

G02 |

Circular interpolation CW |

|||

G03 |

Circular interpolation CCW |

|||

G04 |

Dwell time preset |

|

|

|

|

|

|

|

|

G28 |

Machine |

reference |

point |

automatic |

|

return |

|

|

|

G32 |

Thread cutting with constant lead |

|||

|

||||

|

|

|

||

G33 |

Tapping cycle in Z direction |

|

||

G34 |

Thread cutting with variable lead |

|||

G40 |

Canceling |

tool |

nose |

radius |

Instructions |

Functions |

G70 |

Finishing cycle |

G71 |

Axial roughing cycle |

G72 |

Radial roughing cycle |

|

|

G73 |

Closed cutting cycle |

|

|

G74 |

Axial grooving cycle |

|

|

G75 |

Radial grooving cycle |

|

|

|

|

G76 |

Multiple thread cutting |

|

cycle |

G90 |

Axial cutting cycle |

|

|

G92 |

Thread cutting cycle |

|

|

G94 |

Radial cutting cycle |

|

|

fundamentals Programming 1 Book

-3

fundamentals Programming 1 Book

GSK980TD Turning Machine CNC System

|

compensation |

|

|

G41 |

Tool nose radius compensation left of |

G96 |

Constant surface speed |

|

contour |

|

ON |

G42 |

Tool nose radius compensation right of |

G97 |

Constant surface speed |

|

contour |

|

OFF |

G50 |

Setting workpiece coordinate system |

G98 |

Feed per minute |

G65 |

Macro instruction |

G99 |

Feed per rev |

|

|

|

|

PLC instruction list

Elementary |

Functions |

Function |

Functions |

instructions |

|

instructions |

|

LD |

Read normally-open contact |

TMRB |

Timer |

|

|

|

|

LDI |

Read normally-closed contact |

CODB |

Binary conversion |

|

|

|

|

OUT |

Output coil |

ROTB |

Binary rotation control |

|

|

|

|

AND |

Normally-open contact in series |

MOVN |

Data copy |

|

|

|

|

ANI |

Normally-closed contact in series |

DECB |

Binary decoding |

|

|

|

|

OR |

Parallel normally-open contact |

JMPB |

Program skipping(jumping) |

|

|

|

|

ORI |

Parallel normally-closed contact |

SP |

Subprogram |

|

|

|

|

ORB |

Parallel series circuit block |

SPE |

End of subprogram |

|

|

|

|

ANB |

Parallel circuit block in series |

ADDB |

Binary data adding |

|

|

|

|

|

|

SUBB |

Binary data subtracting |

|

|

|

|

Function |

Functions |

ALT |

Alternative output |

instructions |

|

||

|

|

|

|

END1 |

End of grade one program |

DIFU |

Up set |

|

|

|

|

END2 |

End of grade two program |

DIFD |

Down set |

|

|

|

|

SET |

Set |

MOVE |

And |

|

|

|

|

RST |

Reset |

PARI |

Parity check |

|

|

|

|

CMP |

Comparative set |

LBL |

Program skipping label |

|

|

|

|

CTRC |

Counter |

CALL |

Subprogram calling |

|

|

|

|

-4

Chapter 1 Programming Fundamentals

Type significations

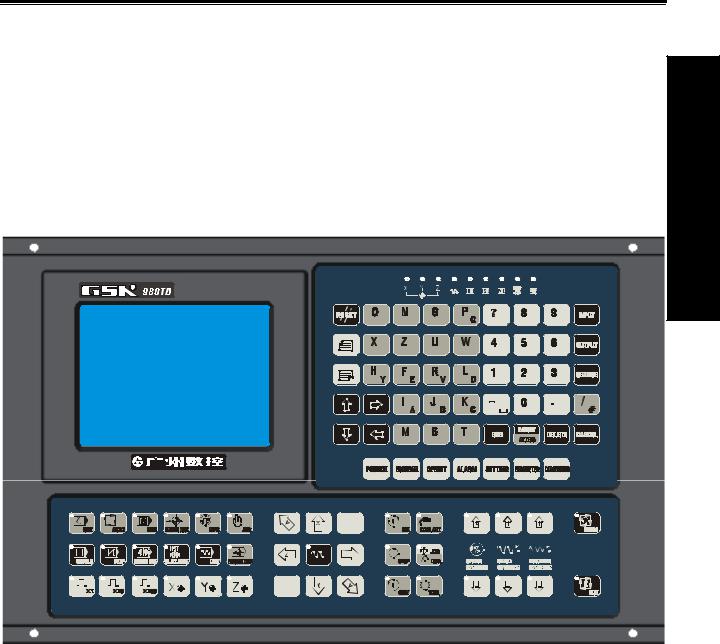

GSK 980TD—□

Assembly form none standard panel 420×260mm B boxed assembly

980TD Turning Machine CNC

Symbol of GSK CNC Equipment Co., Ltd.

Type |

Specification |

|

GSK980TD |

420×260mm aluminium alloy solid operator panel |

|

|

|

|

GSK980TD-B |

GSK980TD matching with AP01 445mm ×345mm × |

|

182mm |

||

|

Standard functions

All optional functions without being remarked in the provided technical specifications are as follows: Max. rapid traverse speed 16m/min, max. feedrate 8m/min, pitch error compensation, tool nose radius compensation, spindle analog voltage control(converter spindle),communication, 16 input points, 16 output points, standard PLC ladder, I/O interfaces being compatible with those of GSK980TA CNC system, 4-gear spindle automatic shifting gear(only test 1st and 2nd gear), hydraulic chuck, hydraulic tailstock, 4 8 tool selections toolpost(unidirectional selecting tool), safeguard, low pressure alarm etc.

Note 1: Modify or redesign PLC ladder diagram when other functions including executing the bidirectional tool change or testing 4-gear spindle are incompatible with those of 980TA CNC System.

Note 2: Please remark the detailed control requirements in order lists when special PLC ladder diagram (I/O interfaces are incompatible with those of GSK 980TA CNC System) is required.

fundamentals Programming 1 Book

Optional functions

1 Max. rapid traverse speed 30m/min and max. feedrate 15m/min;

2.I/O expansion: 16 input points (XS41 interface) and 16 output points (XS42 interface);

Standard accessories

Power switch: GSK-PB (assembled)

Connector: CNC interfaces are connected by one set of plug( DB9 female×3, DB15 male×3, DB25 female×1, DB25 male×1)

Note: Corresponding plugs along with cables are supplied when they along with other components including driver are delivered.

Accessory cables: 12m 10-core shield cable (3m for each X axis, Z axis, input interface XS40, output interface XS39);

9m 8-core shield cable with (3m for spindle encoder, input interface XS40, output interface XS39);

-5

fundamentals Programming 1 Book

GSK980TD Turning Machine CNC System

3m 4-core shield cable (converter interface);

Note: The above-mentioned cables as wires are supplied. Signal cables with welded plugs are supplied when a whole set of driver and toolpost controller is delivered. The requirements for cable length and welding should be remarked in the order list.

Anti-interference components: 1N4007×8 0.1μF/630V×6

Technical documents: GSK980 Turning Machine CNC System User Manual(without PLC User Manual)

Optional accessories

Communication components: one piece of 5m communication cable and one installation diskette of communication software TDComm2;

Power filter FN2060-6-06

Handwheel: Dongxin RE45T1SO5B1(option: AP01) or Changchun LGF-001-100(option: AP02); Additional panel AP01 aluminum alloy 420×71 can be assembled under of GSK980TD operator

panel;

AP02 aluminum alloy 100×260 can be assembled at the side of GSK980TD operator panel;

Emergent stop button: LAY3-02ZS/1( it has been installed when GSK980TD-B is delivered); No self-locking button: KH-516-B11(blue or red);

Self-locking button: KH-516-B21(blue or red); GSK980TD PLC User Manual

Ladder diagram programming software: one GSKCC installation diskette

Note 1: Communication functions are standard ones but communication components are optional accessories;

Note 2: Optional accessories as product ones (without being installed and connected) are supplied and it should be remarked in the order list when they are required to install and connect.

1.2CNC SYSTEMS of MACHINE TOOLS and CNC MACHINE TOOLS

CNC machine tool is an electro-mechanical integrated product, composed of Numerical Control Systems of Machine Tools, machines, electric control components, hydraulic components, pneumatic components, lubricant, coolant and other subsystems (components), and CNC systems of machine tools are control cores of CNC machine tools. CNC systems of machine tools are made up of computerized numerical control(CNC), servo (stepper) motor drive devices, servo (or stepper) motor and etc.

Operational principles of CNC machine tools: according to requirements of machining technology, edit user programs and input them to CNC, then CNC outputs motion control instructions to the servo (stepper) motor drive devices, and last the servo (or stepper) motor completes the cutting feed of machine tool by mechanical driving device; logic control instructions in user programs to control spindle start/stop, tool selections, coolant ON/OFF, lubricant ON/OFF are output to electric control systems of machine tools from CNC, and then the electric control systems control output components including buttons, switches, indicators, relays, contactors and so on. Presently, the electric control systems are employed with Programmable Logic Controller (PLC) with characteristics of compact, convenience and high reliance. Thereof, the motion control systems and logic control systems are the

-6

Chapter 1 Programming Fundamentals

main of CNC machine tools

GSK980TD Turning Machine CNC system has simultaneously motion control and logic control function to control two axes of CNC machine tool to move, and has embedded PLC function. Edit PLC programs (ladder diagram) according to requirements of input and output control of machine tool and then download them to GSK980TD Turning Machine CNC system, which realizes electric control requirements of required machine tool, is convenient to electric design of machine tool and reduces lost of CNC machine tool.

Software used for controlling GSK980TD Turning Machine CNC system is divided into system software (NC for short) and PLC software (PLC for short). NC system is used for controlling display, communication, edit, decoding, interpolation and acceleration/deceleration, and PLC system for controlling explanations, executions, inputs and outputs of ladder diagrams.

Standard PLC programs are loaded(except for the special order) when GSK980TD Turning Machine CNC System is delivered, concerned PLC control functions in following functions and operations are described according to control logics of standard PLC programs, marking with “Standard PLC functions” in GSK980TD Turning Machine CNC System User Manual. Refer to Operation Manual from machine manufacturer about functions and operations of PLC control because the machine manufacturer may modify or edit PLC programs again.

Fig. 1-1

Programming is a course of workpiece contours, machining technologies, technology parameters and tool parameters being edit into part programs according to special CNC programming instructions. CNC machining is a course of CNC controlling a machine tool to complete machining of workpiece according requirements of part programs. Technology flow of CNC machining is as follows Fig. 1-2.

fundamentals Programming 1 Book

-7

fundamentals Programming 1 Book

-8

GSK980TD Turning Machine CNC System

Confirm machining technologies after analyzing workpiece drawings

Edit part programs and record into CNC

Test part programs and execute trial running

Execute toolsetting and set tool offsets and coordinates

Run part programs and machine workpieces

Check part dimension and modify part programs and compensations

The machining ends and the workpiece is formed

Fig. 1-2

O0001

G00 X3.76 Z0

G01 Z-1.28 F50

…

M30

Chapter 1 Programming Fundamentals

1.3PROGRAMMING FUNDAMENTALS

1.3.1Coordinates Definition

Sketch map of CNC turning machine is as follows:

fundamentals Programming 1 Book

Fig. 1-3

The system is employed with a rectangular coordinate system composed of X, Z axis. X axis is perpendicular with axes of spindle and Z axis is parallel with axes of spindle; negative directions of them approach to the workpiece and positive ones are away from it.

There are a front toolpost and a rear toolpost of NC turning machine according to their relative position between the toolpost and the spindle, Fig. 1-4 is a coordinate system of the front toolpost and Fig. 1-5 is a rear toolppost one. It shows exactly the opposite direction in X direction but the same direction in Z direction from figures. In the manual, it will introduce programming application employed with the front toolpost coordinate system in following figures and examples.

Z

X

Fig.1-4 Front toolpost coordinate system

X |

Z |

Fig. 1-5 Rear toolpost coordinate system

-9

fundamentals Programming 1 Book

GSK980TD Turning Machine CNC System

1.3.2Machine Coordinate System and Machine Reference Point

Machine tool coordinate system is a benchmark one used for CNC counting coordinates and a fixed one on the machine tool. Machine tool origin is named machine reference point or machine zero. The position of machine reference point is specified by a reference point return switch on the machine tool. Usually, the reference point return switch is installed on max. stroke in X, Z positive direction. The system considers the current coordinates of machine tool as zeroes and sets the machine tool coordinate system according to the current position as the coordinate origin after having executed the machine reference point return.

Note: Do not execute the machine reference point return without the reference point switch installed on the machine tool.

1.3.3Workpiece Coordinate System and Program Reference Point

Workpiece coordinate system is set to a rectangular coordinate system according to part drawings named floating coordinate system. After the workpiece is clamped on the machine tool, G50 is executed to set an absolute coordinates of tool’s current position according to the relative position of tool and workpiece, and so the workpiece system has been created. The current position of tool is named program reference point and the tool returns to the position after executing the program reference point return. Usually, Z axis is consistent with the axes of spindle and X axis is placed on the heading or the ending of workpiece. The workpiece will be valid until it is replaced by a new one.

The current position of workpiece coordinate system set by G50 is named the program reference point and the system returns to it after executing the program reference point return.

Note: Do not execute the machine reference point return without using G50 to set the workpiece coordinate system after power on.

Workpiece Rod

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Z1 (Z2) |

|

|

|

|

|

|

|

|

|

|

|||

|

O2 |

|

|

|

|

|

|

O1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

x1/2 |

|

(x2/2) |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

z1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

z2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(x,z) |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(x1,z1) |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

x |

/2 |

|

|

|

||||||||

|

|

X2 |

|

|

|

|

|

|

X1 |

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

(x2,z2) |

|

|

|

|

|

|

|

|

|

|

z |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

z |

|

|

|

|

|

O |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0,0 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

Fig.1-6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tool X1Ox1Z1 |

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

In the above figure, XOZ is the |

coordinate |

system of machine |

is the workpiece |

||||||||||||||||||||||||||||

-10

Chapter 1 Programming Fundamentals

coordinate system of X axis located at the heading of workpiece, X2O2Z2 is the one of X axis located at the ending of workpiece, O point is the machine reference point, A point is the tool nose and coordinates of A point in the above-mentioned coordinate systems is as follows:

A point in the machine tool coordinate system: (x,z)

A point in X1O1Z1 coordinate system: (x1,z1)

Apoint in X2O2Z2 coordinate system: (x2,z2)

1.3.4Interpolation Function

Interpolation is defined as a planar or three dimensional contour formed by path of 2 or multiple axes moving at the same time, also called Contour control. The controlled moving axis is called link axis when the interpolation is executed. The moving distance, direction and speed of it are controlled synchronously in the course of running to form the required complex motion path. Fixed point control is defined that the motion path in the course of running are not controlled but end point of one axis or multiple axes moving.

X and Z in the system are link axes and 2 axes link CNC system. The system possesses linear, circular and thread interpolation function.

Linear interpolation: Complex motion path in X, Z direction is a straight line from starting point to end point.

Circular interpolation: Complex motion path in X, Z direction is arc radius defined by R or the circle center (I, K)

from starting point to end point.

Thread interpolation: Moving distance in X or Z direction or X and Z direction is defined by rotation angle of spindle to form spiral cutting path on the workpiece surface to realize the thread cutting. For thread interpolation, the feed axis rotates along with the spindle, the long axis moves one pitch when the spindle rotates one rev, and the short axis and the long axis directly interpolate.

Example:

Fig. 1-7

…

fundamentals Programming 1 Book

-11

fundamentals Programming 1 Book

GSK980TD Turning Machine CNC System

G32 W-27 F3 B→C thread interpolation G1 X50 Z-30 F100

G1 X80 Z-50 D→E linear interpolation G3 X100 W-10 R10 E→F circular interpolation

…

M30

1.3.5Absolute Programming and Incremental Programming

Specify coordinate values of path’s end point or target position in programming and there are 3 kinds of programming method according to coordinate values in programming: absolute programming, incremental programming and compound programming

Absolute coordinate value to program present with X, Z in X, Z direction is absolute programming; Incremental movement to program present with U, W in X, Z direction is incremental programming; In the system, X,Z axis is separately employed with absolute programming and incremental program, which is called compound programming

Example A→B linear interpolation

Fig. 1-8

Absolute programming G01 X200. Z50.

Incremental programming G01 U100. W-50.

Compound programming G01 X200. W-50. or G01 U100. Z50.

Note: When there are instruction address X, U or Z, W simultaneously, X,Z are valid.

Example G50 X10. Z20.;

G01 X20. W30. U20. Z30.; End point of the block X20 Z30

1.3.6Diameter and Radius Programming

Diameter programming: when NO.001 Bit2 is 0, input instruction value in diameter in X direction and coordinate in X direction is in diameter at the moment;

Radius programming: when NO.001 Bit2 is 1, input instruction value in diameter in X direction and coordinate in X direction is diameter at the moment

Table 1-1: Address, data related to diameter or radius programming

-12

|

|

|

|

Chapter 1 |

Programming Fundamentals |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Address, data |

|

Explanation |

|

|

Diameter |

Radius |

|

|

||

|

|

|

|

|

|

|

|

|

|

programming |

programming |

|

|

|

programmingradiusor |

diametertorelateddataAddress, |

|

|

Coordinate in X direction |

|

|

|

|

||||

|

X |

In diameter |

In radius |

|

fundamentalsProgramming1Book |

||||||||

|

|

|

|

G50 setting X axis |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Increment in X direction |

|

In diameter |

In radius |

|

|

|||

|

|

|

U |

|

Allowance of finishing in X |

In diameter |

In radius |

|

|

||||

|

|

|

|

|

direction in G71 G72 G73 |

|

|

||||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

Moving |

|

distance |

of |

tool |

|

|

|

|

|

|

|

|

|

retraction |

after cutting in |

In diameter |

In radius |

|

|

|||

|

|

|

R |

|

G75 |

|

|

|

|

|

|

|

|

|

|

|

|

Moving |

distance |

of |

tool |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

retraction when cutting to |

In diameter |

In radius |

|

|

||||

|

|

|

|

|

the end point in G74 |

|

|

|

|

|

|||

Except for addresses and data in Table 1-1, others (arc radius, taper in G90) are unrelated to diameter or radius programming, and their input values in X direction are defined by the radius.

It is employed with the diameter programming except for the special indication in the following explanation.

1.4STRUCTURE of an NC PROGRAM

User needs to compile part programs (called program) according to instruction formats of CNC system. CNC system executes programs to control the machine tool movement, the spindle starting/stopping, the coolant and the lubricant ON/OFF to complete the machine of workpiece.

Program example:

|

|

Fig. 1-9 |

O0001 |

|

Program name |

N0005 |

G0 X100 Z100 |

Rapid positioning to A point |

N0010 |

M12 |

Workpiece clamped |

N0015 |

T0101 |

Changing No.1 tool and execute its offset |

N0020 |

M3 S600 |

Starting the spindle with 600 rev/min |

N0025 |

M8 |

Coolant ON |

N0030 |

G1 X50 Z0 F600 |

(Approaching B point with 600mm/min |

-13

fundamentals Programming 1 Book

|

|

GSK980TD Turning Machine CNC System |

|

|

|

N0040 |

W-30 F200 |

Cutting from B point to C point |

N0050 |

X80 W-20 F150 |

Cutting from C point to D point |

N0060 |

G0 X100 Z100 |

Rapid retracting to A point |

N0070 |

T0100 |

Canceling the tool offset |

N0080 |

M5 S0 |

Stopping the spindle |

N0090 |

M9 |

Coolant OFF |

N0100 |

M13 |

Workpiece unclamped |

N0110 |

M30 |

End of program, spindle stopping and coolant OFF |

The tool leaves the path of A→B→C→D→A after the above-mentioned programs are executed.

1.4.1General Structure of Program

A program consists of a sequence of blocks, beginning with “OXXXX”program name and ending with “%”; a block begins with block number (omitted) and ends with “;” or “*”. See the general structure of program as follows:

Explanation of program

Program name

Skipping character |

|

|

|

|

|

Word |

|

|

|

|

|||

|

||||||

of block |

|

|

|

|

|

Block |

|

|

|

|

|

|

Block Number

Ending character

Ending character of program of program

Program

Fig. 1-10 General structure of program

Program name

There are most 384 programs stored in the system. To identify it, each program has only one program name(there is no the same program name)beginning with instruction address O and the following 4-bit digits.

○ □□□□

Program number 0000 9999 the leading zero can be omitted

Program number 0000 9999 the leading zero can be omitted  Instruction address O

Instruction address O

Word

A word is the basic instruction unit to command CNC system to complete the control function, composed of an English letter (called instruction address) and the following number (operation instruction with/without sign). The instruction address describes the meaning of its following operation instruction and there may be different meaning in the same instruction address when the different words are combined together. See Table 1-2 words in the system.

-14

Chapter 1 Programming Fundamentals

X1000

Instruction instruction address value

W ord

|

Table 1-2 |

Word list |

|

Instruction |

Range of instruction value |

|

Function |

address |

|

||

|

|

|

|

O |

0 9999 |

|

Program name |

N |

0 9999 |

|

Block number |

G |

00 99 |

|

Preparatory function |

X |

-9999.999 9999.999(mm) |

|

Coordinate in X direction |

0 9999.999(s) |

|

Dwell time |

|

|

|

||

Z |

-9999.999 9999.999 mm |

|

Coordinate in Z direction |

|

-9999.999 9999.999 mm |

|

Increment in X direction |

|

0 9999.999(s) |

|

Dwell time |

|

-99.999 99.999 mm |

|

Finishing allowance in X direction in G71, |

U |

|

G72, G73 |

|

|

|

||

|

0.001 99.999 mm |

|

Cutting depth in G71 |

|

-9999.999 9999.999 mm |

|

Moving distance of tool retraction in X |

|

|

|

direction in G73 |

|

-9999.999 9999.999 mm |

|

Increment in Z direction |

|

0.001 9999.999 mm |

|

Cutting depth in G72 |

W |

-99.999 99.999 mm |

|

Finishing allowance in Z direction in |

|

|

G71,G72, G73 |

|

|

|

|

|

|

-9999.999 9999.999 mm |

|

Moving distance of tool retraction in Z |

|

|

|

direction in G73 |

|

-9999.999 9999.999 mm |

|

Arc radius |

|

0.001 9999.999 mm |

|

Moving distance of cycle tool retraction |

|

|

|

in G71,G72 |

|

1 9999 (times) |

|

Cycle times of roughing in G73 |

R |

0.001 9999.999 mm |

|

Moving distance of tool retraction after |

|

|

Cutting in G74, G75 |

|

|

|

|

|

|

0.001 9999.999 mm |

|

Moving distance of tool retraction after |

|

|

|

cutting to the end point in G74, G75 |

|

0.001 9999.999 mm |

|

Finishing allowance in G76 |

|

-9999.999 9999.999 mm |

|

Taper in G90, G92, G94, G96 |

|

-9999.999 9999.999 mm |

|

Vector of arc center relative to starting point |

I |

|

|

in X direction |

|

0.06 25400 tooth/inch |

|

Inch thread tooth |

K |

-9999.999 9999.999 mm |

|

Vector of arc center relative to starting point |

|

|

in Z direction |

|

|

|

|

|

fundamentals Programming 1 Book

-15

|

|

|

|

|

GSK980TD Turning Machine CNC System |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Instruction |

Range of instruction value |

Function |

|

|

|

|

address |

|

||

|

|

|

|

|

|

|

|

|

|

|

0 8000 mm/min |

Feedrate per minute |

|

1 Book |

|

|

F |

|||

|

|

0.0001 500(mm/r) |

Feedrate per rev |

|

||

|

|

|

0.001 500 mm |

Metric thread lead |

|

|

Programming |

|

|

|

|

|

|

|

|

S |

0 9999 rev/min |

Specified spindle speed |

|

|

|

|

|

|

|||

|

|

|

00 04 |

Multi-gear spindle output |

|

|

|

|

|

|

|

||

|

|

|

T |

01 32 |

Tool function |

|

|

|

|

|

00 99 |

Auxiliary function output, program executed |

|

fundamentals |

|

|

M |

|

flow, subprogram call |

|

|

|

|

0 999 |

Calling times of subprogram |

|

|

|

|

|

|

9000 9999 |

Subprogram call |

|

|

|

|

|

0 9999999 0.001s |

Dwell time |

|

|

|

|

|

0 9999 |

Called subprogram number |

|

|

|

|

|

|

|

|

|

|

|

P |

0 9999999 0.001mm |

Circular moving distance in X direction in |

|

|

|

|

||||

|

|

|

G74, G75 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Thread cutting parameter in G76 |

|

|

|

|

|

0 9999 |

Initial block number of finishing in the |

|

|

|

|

|

compound cycle instruction |

|

|

|

|

|

|

|

|

|

|

|

|

|

0 9999 |

Terminative block number of finishing in the |

|

|

|

|

|

|

compound cycle instruction |

|

|

|

|

Q |

0 9999999 0.001mm |

Circular moving distance in Z direction in |

|

|

|

|

|

G74, G75 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 9999999 0.001mm |

The first cutting depth in G76 |

|

|

|

|

|

1 9999999 0.001mm |

Min. cutting depth in G76 |

|

|

|

|

|

|

|

|

|

|

|

H |

01 99 |

Operator in G65 |

|

Block

A block which is basic unit of CNC program consists of a sequence of words, ending with “;” or “*” . There is the character “;” or “*” between blocks. “;” is employed to separate blocks in the manual as follows:

/ N0030 G0 X20 Z30

Ending character of block

Block number

Skipping character of block

One block may be with a number of words or only with“ ”(ending character) instead of words. There must be one or more blank space between words.

There is only one for other addresses except for N, G, S, T, H, L in one block, otherwise the system alarms. The last word in the same address is valid when there are more N, G, S, T, H, L in the same block. The last G instruction is valid when there are more G instructions which are in the same group in one block.

-16

Chapter 1 Programming Fundamentals

Block number

A block number consists of an address N and its following 4-bit digit as N0000 N9999,and the leading zero can be omitted. The block number must be at the beginning of block, otherwise the block is invalid.

The block number can be omitted, but there must be the block number when the program calls/skips the target block. The increment of block number is at will and it better to increase or decrease the sequence of block number in order to conveniently search and analyze programs.

When “Block number” is set to “ON”, block numbers will be automatically created incrementally and their increment is defined by №42.

Block skipping character

Insert “/” in the front of block and startup SKIP when some block cannot be executed (cannot be deleted), and the system skips the block and executes the next one. The block with “/” in the front of it

will be executed if SKIP is not started.

fundamentals Programming 1 Book

Ending character of program

“ %” is an ending character of program. “%” is a mark of communication ended when the program is transmitted. The system will automatically insert “ ” at the end of program.

Program annotation

A program annotation has less than 20 characters (10 Chinese characters) for each program, lies in a bracket following its program name and is expressed only in English and digitals in CNC system; it can be edit in Chinese in PC and displayed in Chinese in CNC system after being downloaded.

1.4.2Main Program and Subprogram

To simply the programming, when the same or similar machining path and control procedure is used many times, its program instructions are edited to a sole program to call. The main program is defined to call others and the subprogram is to be called. They both take up the program capacity and storage space of system. The subprogram has own name, and can be called at will by the main program and also can run separately. The system returns to the main program to continue when the subprogram ends as follows:

-17

fundamentals Programming 1 Book

GSK980TD Turning Machine CNC System

0001; |

|

1006; |

|

|

|

||

G50 X100 Z100; |

|

G1 X50 Z50; |

|

|

|

||

M3 S1 T0101; |

Call |

U100 W200; |

|

|

|||

G0 X0 Z0; |

|

||

|

U30 W-15 R15 F250; |

||

|

|

||

G1 U200 Z200 F200; |

Return |

M99; |

|

|

|||

M98 P21006; |

% |

||

|

|||

|

|

||

G0 X100 Z100; |

|

|

|

M5 S0 T0100; |

|

|

|

M30; |

|

|

|

% |

|

|

|

Main program |

Fig.1-11 |

Subprogram |

|

|

|

1.5PROGRAM RUN

1.5.1Sequence of Program Run

Open the current program in Auto mode. The system only open one program, and so only one run any time. When opening the first block, the cursor located in the heading of the first block and can be

moved in Edit mode. The program stops in Auto mode and starts run after the cycle start signal

( |

|

RUN is pressed or external cycle start signal startups the program to run from a block pointed by |

current cursor, usually blocks are executed one by one according to programming sequence, the program stops run after executing M02 or M30. The cursor moves along with program and is located at the heading of current block. Sequence and state of program run are changed in the followings:

The program stops run after pressing |

RESET |

or emergent stop button; |

The program stops run when the system or PLC alarms;

Single block stops run (the current block pauses after it runs completely) in Edit, MDI mode, and then a block pointed by the current cursor starts run after the system switches into Auto mode,

RUN is pressed or external cycle start signal is switched on;

The program stops run in Manual(Jog), Handwheel(MPG), Single Block, Program Reference Point Return, Machine Reference Point Return mode and it continuously runs from current position after

the system is switched into Auto mode and |

RUN |

is pressed or the external cycle start signal is |

|||

|

|||||

switched on; |

|

|

|

|

|

The program pauses after pressing |

PAUSE |

or the external cycle start signal is switched off, and it |

|||

continuously runs from current position after pressing |

RUN |

or the external cycle start signal is |

|||

|

|||||

switched on;

When Single Block is ON, the program pauses after every block is executed completely and then

it continuously runs from the next block after RUN is pressed or the external cycle start signal is

-18

Chapter 1 Programming Fundamentals

switched on;

Block with “/” in the front of it is not executed when the block skipping switch is ON; The system skips to the target block to run after executing G65;

Please see Section Three G Instructions about execution sequence of G70~73;

Call corresponding subprograms or macro program to run when executing M98 or M9000~M9999; the system returns to main program to call the next block when executing M99(if M99 specifies a target block number, the system returns to it to run) after the subprograms or macro programs run completely;

The system return to the first block to run and the current program is executed repetitively when M99 is executed in a main program.

1.5.2Execution Sequence of Word

There are many words(G, X, Z, F, R, M, S, T and so on ) and most of M, S, T is transmitted to PLC by NC explanation and others is directly executed by NC. M98, M99, M9000 M9999, S word for specifying spindle speed (rev/min, m/min) is directly executed by NC.

NC firstly executes G and then M instructions( without transmitting M signal to PLC) when G instructions and M98, M99, M9000 M9999 are in the same block.

When G instructions and M, S, T executed by PLC are in the same block, PLC defines M, S, T and G to be executed simultaneously, or execute M, S ,T after G instructions. Please see User Manual of machine manufacturer for execution sequence of instructions.

Execution sequence of G, M, S, T in the same block defined by GSK980TD standard PLC program is as follows:

M3, M4, M8, M10, M12, M32, M41, M42 ,M43,M44,S□□, T□□□□ and G instructions are executed simultaneously;

M5, M9, M11, M13, M33 after G instructions are executed;

M00, M02, M30 after other instructions of current block are executed.

fundamentals Programming 1 Book

-19

Loading...

Loading...