gsk GSK928TD User Manual

This manual is used for both GSK928TD system and GSK928TD-L system. However, the contents are described based on GSK928TD system.

This manual is used for both GSK928TD system and GSK928TD-L system. However, the contents are described based on GSK928TD system.

This manual describes the various matters concerning the operations of this CNC system as much as possible. However, it is impossible to give detailed descriptions to all the unnecessary or unallowable operations due to space limitation and product specific applications. Therefore, the matters not specially described herein should be considered as “impossible” or “unallowable”.

This manual describes the various matters concerning the operations of this CNC system as much as possible. However, it is impossible to give detailed descriptions to all the unnecessary or unallowable operations due to space limitation and product specific applications. Therefore, the matters not specially described herein should be considered as “impossible” or “unallowable”.

This user manual is the property of GSK CNC Equipment Co., Ltd. All rights are reserved. It is illegal for any organization or individual to publish or reprint this manual. GSK CNC Equipment Co., Ltd. reserves the right to ascertain their legal liability.

This user manual is the property of GSK CNC Equipment Co., Ltd. All rights are reserved. It is illegal for any organization or individual to publish or reprint this manual. GSK CNC Equipment Co., Ltd. reserves the right to ascertain their legal liability.

GSK928TD Turning CNC System User Manual

Preface

Dear users,

It is our pleasure for your patronage and purchase of this GSK928TD turning machine CNC system (hereafter referred to as “system”) produced by GSK CNC Equipment Co., Ltd.

This manual covers the use of the system and related precautions.

Warnings

Improper operations may cause unexpected accidents.

Improper operations may cause unexpected accidents.

Before using the system, please read this manual thoroughly.

Note the following precautions before using the manual:

●Connect the Emergency Stop button of the system. As the emergency stop input of the system adopts a normally closed contact, the system will issue an alarm (not a system fault) after Power On if the emergency button is poorly connected or connected as a normal-open contact.

●Set the program reference point according to the actual installation position of the tool. If the Program Reference Point Return function is used before the reference point is set, unexpected accidents may occur.

Special notes: The power supply fixed on/in the cabinet is exclusively used for the CNC systems developed by GSK.

It cannot be applied for other purposes. Otherwise it may result in serious danger.

II

Safety and Precautions

Declaration!

zWe try to describe all the various matters as much as possible in this manual. However, it is impossible to give detailed descriptions to all the unnecessary or unallowable operations because there are too many possibilities. Therefore, the matters not specially described herein should be considered as “impossible” or “unallowable”.

Warning

zBefore installing, connecting, programming and operating the product, please read this manual and the manual provided by the machine tool builder carefully, and operate the product according to these manuals. Otherwise, the operation may cause damage to the product and machine tool, or even cause personal injury.

Caution

zThe functions and specifications (e.g., precision and speed) described in this manual are only for this product itself. For those CNC machine tools with this product installed, the actual function configuration and specifications depend on the designs of the machine tool builders. Moreover, the function configuration and specifications of the CNC machine tool are subject to the manual provided by the machine tool builder.

zPlease refer to the user manual issued by the machine tool builder for the function and meaning of each key on the panel.

All specifications and designs in this manual are subject to change without notice.

III

GSK928TD Turning CNC System User Manual

Safety precautions

Please read the safety precautions carefully before connecting and using the system.

The user must observe the safety operation specifications to ensure personal and equipment safety.

The user must observe the related safety specifications described in the user manual issued by GSK. Never attempt to operate the system before you are fully familiar with its contents.

The user must observe the safety operation specifications about the machine tool described in the user manual issued by the machine tool builder.

The user must be fully familiar with the contents of this manual and the one issued by the machine tool builder before operating the machine tool or controlling the machine tool by editing programs.

|

Meanings of signs |

Warning |

Failure to observe the specified operation methods or |

|

procedures may cause death. |

Caution |

Improper operation may cause personal injury or equipment |

|

damage. |

Note |

Improper use may cause damage to the equipment and |

|

product. |

|

It reminds the user of important contents. |

IV

Safety and Precautions

Precautions

1)Inspection and acceptance

Caution ● It is not allowed to use damaged or defective products.

Caution ● It is not allowed to use damaged or defective products.

2)Transport and storage

Note |

● Guard the products against moisture during transit and storage; |

|

do not climb up or stand on the packages of the products, or |

|

place heavy objects on the packages; do not pile up the |

|

packages more than 5 layers; avoid impact and scratch to the |

|

front panel and LCD screen. |

3 Installation

Caution ● Protect the system from sunlight and raindrops because the shell of the system is not waterproof.

Caution ● Protect the system from sunlight and raindrops because the shell of the system is not waterproof.

Note

Note

zPrevent dust, corrosive air, liquid, conductors and inflammable substances from entering the system.

zKeep the system away from inflammable and explosive substances. Avoid places where there is powerful electromagnetic interference.

zInstall the system firmly in case of vibration.

4 Connection

Warning ● Only qualified persons can connect the system or check the connection. No damage should be caused to the connecting wires. Do not press or open the cover of the system with power on.

Warning ● Only qualified persons can connect the system or check the connection. No damage should be caused to the connecting wires. Do not press or open the cover of the system with power on.

V

|

GSK928TD Turning CNC System User Manual |

Caution |

● The voltage and the polarity of connecting plugs must |

|

accord with the manual. |

|

● Wet hands are dangerous to grasp the plug or the switch. |

Note |

● The connection must be proper and firm. |

|

● The system must be earthed. |

5 Debugging

Warning ● Make sure that the parameters of the system are correct before running.

Warning ● Make sure that the parameters of the system are correct before running.

●No parameter should be beyond the setting limit in the manual.

6 Operation

Warning ● Only qualified operators can operate the system.

Warning ● Only qualified operators can operate the system.

● Ensure the switch is OFF before connecting the power supply.

Warning ● The operator can not leave the system to work alone.

Warning ● The operator can not leave the system to work alone.

●Make sure the connection is correct before Power On.

●The emergency stop button should be able to cut off all power supplies when the system breaks down. Do not switch on/off the system frequently.

Warning ● Prevent the system from environmental interference.

Warning ● Prevent the system from environmental interference.

7 Troubleshooting

Caution ● Unqualified persons cannot repair the system.

Warning ● After an alarm occurs, do not restart the system until the breakdown is fixed.

VI

Safety and Precautions

Safety and precautions for programming

1)Coordinate system

Incorrect coordinate system may cause the machine not to work as expected even if the instruction is correct, which may injure the operator, and damage the machine as well as its tool and workpiece.

2)G00 rapid traverse

G00 rapid traverse performs nonlinear motion between its starting point and end point. Make sure that the path for the tool is safe before G00 rapid traverse starts, otherwise the tool, the machine and the workpiece may be damaged, and even the operator injured.

3)Use of this manual

This manual introduces in details all functions of the system, including optional functions and max. controllable ranges, which are subject to change with the machine. Therefore, some functions described in this manual may not be applicable to a specific machine tool. If there is any doubt, please read the instruction for the machine.

4) Functions of the CNC and machine tool

The functions of CNC machines not only depend on CNC systems, but also power voltage cabinets, servo systems, CNC and the operator panels. It is hard to explain all the integrated functions, programming and operation. Do not use integrated instructions not included in the manual until they have been tested successfully.

VII

GSK928TD Turning CNC System User Manual

Precautions and warnings for operation

1 Before machining a part

First check whether the machine tool works normally. Make sure that the machine tool works normally by means of trial run before machining, with no workpiece and tool mounted on the machine tool.

2 Before operating the machine tool

Check the input data of the system carefully before operating the machine. Incorrect input data may cause the machine to work improperly, and thus damage the workpiece and the tool, as well injure the operator.

3)Make sure the system input feedrate is suitable for the expected operation.

In general, there is a maximum feedrate for each machine tool. The proper feedrate varies with different operations. Please refer to the user manual to determine the maximum feedrate. If the user doest not operate the machine tool at a proper speed, the machine tool may work incorrectly, thus causing damage to the workpiece or the machine tool itself, or even cause personal injury.

4 Compensation function

When tool compensation is needed, check the direction and the amount of the compensation. Improper compensation causes the machine to work wrongly, so as to damage the workpiece and the tool, as well injure the operator.

5 Manual operation

If the machine is to run in Manual Mode, check the current position of the tool and the workpiece, and correctly specify the moving axis, moving direction and the feedrate. During MPG feed, rotating the MPG (previously called electronic handwheel) with a large override, such as 100%, causes the tool and worktable to move rapidly. In such a case, the tool and worktable will not stop immediately even when the MPG is not rotated. Therefore, MPG movement with a large override may cause damage to the tool or machine, or even injury to the operator.

6 Manual reference point return

VIII

Safety and Precautions

If manual reference point return is required, make sure that the machine has been equipped with the detecting element for the reference point. If the manual reference point return is performed without installing the detecting element, the tool keeps moving until it hits the stroke limit, which may cause damage to the machine, workpiece and tool, or even injury to the operator.

IX

GSK928TD Turning CNC System User Manual

Safety responsibility

Manufacturer Responsibility

——Be responsible for the danger which should be eliminated on the design and configuration of the provided CNC systems

——Be responsible for the safety of the provided CNC and its accessories ——Be responsible for the provided information and advice

User Responsibility

——Be trained with the safety operation of CNC system operation procedures and familiar with the safety operation.

——Be responsible for the dangers caused by adding, changing or modifying the original CNC systems and accessories.

——Be responsible for the danger caused by failing to observe the operation, maintenance, installation and storage in the manual.

This user manual shall be kept by the end user.

Thank you for your support when you are using the products of Guangzhou CNC Equipment Co., Ltd.

X

Contents

OPERATION

introduces the operation methods, technical specifications and parameter setting for GSK928TD turning machine CNC system.

PROGRAMMING

introduces the instruction codes and program formats of the CNC system.

Connection

introduces the installation and connection of the CNC system.

Appendix

introduces the supplementary explanations for the installation and connection of the CNC system.

XI

GSK928TD Turning CNC System User Manual

XII

Contents

CONTENTS

OPERATION ·································································································································3

CHAPTER ONE OVERVIEW···············································································································3

CHAPTER TWO TECHNICAL SPECIFICATION ············································································5

2.1 928TD Technical Specifications ··········································································································· 5

CHAPTER THREE OPERATION PANEL ·························································································7

3.1LCD························································································································································· 7

3.2LED Status Indicator ····························································································································· 7

3.3Keyboard ················································································································································ 7

3.3.1Character Key································································································································· 7

3.3.2Operation Mode Select Key·········································································································· 8

3.3.3Function Key··································································································································· 8

3.3.4Cycle Start Key and Cycle Pause Key (Feed Hold key) ···························································· 9

3.3.5Manual Axis Control Key ··············································································································· 9

3.3.6Manual Auxiliary Function Key ··································································································· 10

3.3.7Edit Key········································································································································· 11

3.3.8Reset Key ····································································································································· 12

CHAPTER FOUR SYSTEM OPERATION ······················································································13

4.1System Power-on, Power-off, Initial State, Modal State, and Safety Protection ·························· 13

4.1.1Power On ······································································································································ 13

4.1.2Power Off ······································································································································ 14

4.1.3Initial State and Modal State of System and Program······························································ 14

4.1.3.1Initial State and Modal State of System·············································································· 14

4.1.3.2Initial State and Modal State of Program············································································ 15

4.1.4Safety Protection·························································································································· 15

4.1.4.1Hard Limit Protection············································································································ 15

4.1.4.2Soft Limit Protection ············································································································· 16

4.1.4.3Emergency Stop Alarm (Stopping System Emergently) ··················································· 17

4.1.4.4Drive Unit Alarm···················································································································· 19

4.1.4.5Other Alarms ························································································································· 19

4.1.4.6Power Off······························································································································· 20

4.1.4.7Reset Operation···················································································································· 20

4.2Operation Mode Selection for CNC System····················································································· 21

4.3Edit Operation Mode ··························································································································· 21

4.3.1Part Program Directory Search ·································································································· 22

4.3.2Selecting, Creating, Deleting, Renaming and Copying a Part Program ································ 23

4.3.2.1Selecting and Creating a Part Program ············································································· 23

4.3.2.2Deleting a Part Program ······································································································ 24

4.3.2.3Deleting All Part Programs··································································································· 24

4.3.2.4Renaming a Part Program··································································································· 24

4.3.2.5Copying a Part Program ········································································································· 25

4.3.3Part Program Communication ···································································································· 25

4.3.3.1Sending Part Program (CNC→PC, CNC→USB, CNC→CNC) ······································· 25

4.3.3.2Receiving Part Programs (PC→CNC, USB→CNC, CNC→CNC) ·································· 26

4.3.3.3Standard Format of TXT Part Program on PC··································································· 27

4.3.4Inputting and Editing the Contents of Part Program································································· 28

4.3.4.1Inputting Program Contents································································································· 31

4.3.4.2Inserting a Block ··················································································································· 32

4.3.4.3Deleting a Block ···················································································································· 32

4.3.4.4Inserting a Character in a Block·························································································· 33

4.3.4.5Deleting a Character in a Block··························································································· 33

4.3.4.6Altering Contents of a Block ································································································ 33

4.3.4.7Inserting a Macro String ······································································································· 34

4.3.4.8Storage Capacity for Programs ··························································································· 34

4.3.4.9Operating No. 253 Program ································································································ 34

4.3.4.10Operating No. 254 program······························································································· 35

XIII

GSK928TD Turning CNC System User Manual

4.3.5 Function of hp5 Key···················································································································35

4.3.5.1Help for Part Program Command························································································35

4.3.5.2Help for Obtaining Relative Parameters of Arc ··································································36

4.3.5.3Rearrangement of Program Line Numbers ········································································37

4.3.5.4Replacement of Strings ········································································································37

4.3.5.5Cursor Position ······················································································································37

4.3.5.6Cursor Movement by MPG···································································································37

4.3.6Compiling a Part Program ···········································································································38

4.3.6.1hp3 Compiling Command·····································································································38

4.3.6.2Result Analysis of Program Compilation ············································································38

4.3.6.3Prompts of Program Compound Check··············································································39

4.4JOG Operation Mode ··························································································································40

4.4.1Coordinate Axis Movement··········································································································42

4.4.1.1JOG movement ·····················································································································42

4.4.1.2Step Movement······················································································································42

4.4.1.3MPG Control Movement·······································································································43

4.4.1.4Selecting Rapid Traverse Rate····························································································44

4.4.1.5Selecting Speed for Low-speed Feed·················································································45

4.4.1.6Inputting a Word to Move, Setting Feedrate ······································································45

4.4.1.7Drive Unit Enabling Control··································································································47

4.4.1.8Alarm Prompts for Coordinate Axis Movement··································································47

4.4.2Establishing a Coordinate System······························································································48

4.4.2.1Establishing Machine Coordinate System—Machine Zero Return (Machine Reference Point Return) ·········································································································································48

4.4.2.2Establishing Machine Coordinate System— without Machine Zero (No Machine Reference Point) ···································································································································50

4.4.2.3Setting Workpiece Coordinate System ···············································································50

4.4.2.4Setting Program Reference Point························································································52

4.4.2.5Program Reference Point Return ························································································52

4.4.2.6Recovering Workpiece Coordinate System and Program Reference Point ···················53

4.4.3Spindle Control Function··············································································································53

4.4.3.1Spindle Start/Stop Control ····································································································53

4.4.3.2Spindle S Command – Gear Shift Control··········································································55

4.4.3.3Spindle S Command— Rotating Speed Control ································································56

4.4.4Coolant Control·····························································································································59

4.4.5Manual Tool Change Control·······································································································59

4.4.6Manual Tool Change ····················································································································61

4.4.7Hydraulic Chuck Control Function ······························································································65

4.4.8Hydraulic Tailstock Control Function ··························································································67

4.4.9Other Option Functions················································································································69

4.4.9.1Triple-color Indicator Control································································································69

4.4.9.2Lubricant Control ···················································································································70

4.4.9.3Machine Electricity Delay Power-on Control ······································································70

4.4.9.4Safety Door Detection Function ··························································································70

4.4.9.5Low-pressure Detection Function························································································71

4.4.10Viewing Operation Information in Manual Mode ·····································································71

4.4.11Appendix Table····························································································································71

4.4.11.1List of M function Commands Controlled by MDI Input···················································71

4.5Auto Operation Mode ··························································································································73

4.5.1System Working States in Auto Operation Mode ······································································74

4.5.2Explanations for Function Key Operation in Auto Operation Mode ········································74

4.5.2.1Switching between Single and Continuous Operation ······················································74

4.5.2.2Switching bewteen Dry Run and Machining Run ······························································75

4.5.2.3Switching between Coordinate Display and Graph Display ·············································76

4.5.2.4Starting Execution from First Block of Program ·································································76

4.5.2.5Starting Execution from a Specified Block··········································································76

4.5.3Display during Program Execution ·····························································································77

4.5.3.1Definition of Graph Display Data ·························································································77

4.5.3.2Inputting Graph Display Data·······························································································78

4.5.3.3Part Count and Timing··········································································································79

4.5.4Manual Operation for Machine Auxiliary Functions ··································································80

4.5.5Speed Override Adjustment in Auto Operation Mode·······························································80

4.5.5.1Speed Override Adjustment ·································································································80

XIV

Contents

4.5.5.2MPG Speed Control·············································································································· 81

4.5.6Interruption Operation during Program Execution···································································· 82

4.5.6.1Interruption with Keys during Program Execution····························································· 82

4.5.6.2External feed/Spindle hold Knob························································································· 83

4.5.6.3External Start and Pause Signals ······················································································· 84

4.5.6.4Feeding Device Alarm Function ·························································································· 84

4.5.7Modifying Tool Offset during Program Execution ····································································· 84

4.5.7.1Methods of Modifying Tool Offsets during Program Execution········································ 84

4.5.7.2Modifying Validity of Tool Offsets during Program Execution··········································· 85

4.5.8Viewing Running Information in AUTO Operation Mode ························································· 85

4.5.9Return to Program Reference Point in AUTO Operation Mode ·············································· 87

4.5.10System Reset Key and Emergency Stop Signal Processing in Auto Mode ························ 87

4.5.11Adjusting Brightness of LCD screen in AUTO, MANUAL Operation Mode·························· 87

4.5.12Displaying Executing States of M Commands in Auto, Manual Operation Mode ··············· 88

4.5.13Additional Operation in Auto Operation Mode ········································································ 88

4.6Parameter Operation Mode················································································································ 89

4.6.1Parameter Overview···················································································································· 90

4.6.1.1Parameter Authority·············································································································· 90

4.6.1.2Entering an Operation Level································································································ 90

4.6.1.3Parameter Management ······································································································ 90

4.6.2Modifying Parameters·················································································································· 92

4.6.2.1Searching Parameters ········································································································· 92

4.6.2.2Modifying Parameters ·········································································································· 92

4.6.3Parameter hp6 Function·············································································································· 93

4.6.3.1Parameter Communication and Standard Format ···························································· 93

4.6.3.2Parameter Extraction and Solidification ············································································· 96

4.6.3.3System Software Upgrade and Internal Memory Update················································· 97

4.6.3.4Function Command Authority ······························································································ 98

4.6.4Description of Parameters··········································································································· 98

4.6.4.1Parameters of Reference Point, Soft Limit __ P000 P020 ············································ 98

4.6.4.2Parameters of Zero Return Function__ P021 P026, P109 P111, P406 P407······· 99

4.6.4.3Parameters of Movement Speed and Acceleration Time __P100 P108, P112 P119

······························································································································································ 101

4.6.4.4Parameters of Drive and Compensation P200 P209, P411, P1000 P1905············ 103

4.6.4.5Parameters of Spindle and Coolant __ P300 P317, P326, P329, P341, P410········· 106

4.6.4.6Parameters of Tool Post __ P318 P325, P408 ····························································· 109

4.6.4.7Parameters of Chuck and Tailstock __ P327 P328, P409··········································· 112

4.6.4.8Bit Parameters of Running and Efficiency__ P400 P401 ············································ 113

4.6.4.9Relationship between Path and Parameters of Running and Efficiency ······················ 115

4.6.4.10Bit Parameters of Safety and Debugging__ P402 P404, P419································ 116

4.6.4.11Bit Parameter of Motor Driver__ P405 ··········································································· 121

4.6.4.12Parameters of Other Interfaces__ P412, P330 P332 ············································· 121

4.6.4.13Other Parameters__ P413 P416, P333 ······································································ 123

4.6.4.14Parameters of Interface __P500 P556········································································ 126

4.6.4.15Initial Values of Variables __P600 P639······································································ 127

4.6.4.16Parameters of G76 __P336 P339················································································ 127

4.6.5 Appendix Parameter List ········································································································ 128

4.6.5.1Reference Parameter List·································································································· 128

4.6.5.2Motion Parameter List ········································································································ 129

4.6.5.3Drive Parameter List··········································································································· 130

4.6.5.4Auxiliary Parameter List ····································································································· 130

4.6.5.5Bit Parameter List ··············································································································· 131

4.6.5.6Interface Parameter List····································································································· 132

4.6.5.7Variable Initial Value List ···································································································· 133

4.6.5.8Pitch Error Compensation Parameter List ······································································· 134

4.6.5.9List of Parameters Relative to Command Disabling ······················································· 134

4.6.5.10List of Parameters Relative to Output Interface Releasing·········································· 135

4.6.5.11List of Parameters Related to Input Interface Releasing·············································· 135

4.7Tool Offset Operation Mode ············································································································· 137

4.7.1Searching Tool Offset Value······································································································ 138

4.7.2Inputting Tool Offset Data from Keyboard ··············································································· 138

XV

GSK928TD Turning CNC System User Manual

4.7.3Clearing Offset Values of Each Group ·····················································································139

4.7.4Tool Compensation hp6 Function ·····························································································139

4.7.4.1Communication and Standard Format of Tool Offset Data ·············································140

4.7.4.2Tool Compensation Data Clearing·····················································································141

4.8Diagnosis Operation Mode ···············································································································142

4.8.1Searching Interface Signal ········································································································142

4.8.2Explanations for Display of Interface Signals Names·····························································143

4.8.3Explanation of Input Interface Diagnosis ·················································································143

4.8.4Explanation of Output Interface Diagnosis ··············································································143

4.8.5Output Interface Operation Function ························································································144

4.8.6Spindle Encoder and Spindle Speed Detection·······································································144

4.8.7Diagnosis hp6 Function ·············································································································144

4.8.7.1Display of Alarm Record·····································································································145

4.8.7.2Searching Alarm Record·····································································································146

4.8.7.3Alarm Record hp6 Function ·······························································································147

4.8.8Machine Auxiliary Function Control ··························································································148

CHAPTER FIVE RS232 AND USB SYSTEM COMMUNICATION ········································· 149

5.1RS232 Communication ·····················································································································149

5.1.1Communication between CNC and PC····················································································149

5.1.2Communication between CNC and CNC·················································································150

5.2USB Communication ·························································································································150

5.2.1USB Operation····························································································································151

5.2.2USB File Directory Requirements·····························································································151

PROGRAMMING ····················································································································· 155

CHAPTER ONE PROGRAMMING FUNDAMENTAL································································ 155

1.1Coordinate Axis and Its Direction·····································································································155

1.2Machine Coordinate System, Machine Zero···················································································156

1.3Program Reference Point ·················································································································156

1.4Machine 2nd, 3rd Program Reference Point ··················································································156

1.5Workpiece Coordinate System·········································································································156

1.6Programming Coordinate··················································································································157

1.6.1Absolute Coordinate Values ······································································································157

1.6.2Relative Coordinate Values ·······································································································157

1.6.3Compound Coordinate Values ··································································································158

1.7Diameter Programming and Radius Programming ········································································158

1.8Interpolation Function························································································································158

CHAPTER 2 PROGRAM CONFIGURATION·············································································· 160

2.1Character ············································································································································160

2.2Word····················································································································································160

2.3Block Number·····································································································································161

2.4Block····················································································································································161

2.5Block Skip Symbol and Comment····································································································162

2.6Program Structure······························································································································163

CHAPTER 3 MSTF COMMANDS AND FUNCTIONS ······························································· 164

3.1M — Auxiliary Function (Command List)·························································································164

3.1.1M00 — Pause ·····························································································································165

3.1.2M02 — End of Program ·············································································································165

3.1.3M20 — Program End Cycle Machining····················································································165

3.1.4M30 — End of Program, Spindle OFF, Cooling OFF······························································166

3.1.5M03, M04, M05 —Spindle Control····························································································166

3.1.6M08, M09 —Coolant Control·····································································································166

3.1.7M10 M11, M12 — Clamping/Releasing Chuck, Cancelling Chuck Output Signal············167

3.1.8M32, M33 — Lubricating ON/OFF····························································································167

3.1.9M41, M42, M44, M43 — Spindle Automatic Gear Shift Control ············································167

3.1.10M78, M79, M80 —Tailstock Advancing and Retracting, Tailstock Output Signal Cancelling

··································································································································································168

3.1.11M96 —Calling Cycle Execution·······························································································168

3.1.12M97 — Program Transfer········································································································169

3.1.13M98, M99 — Subprogram Call and Subprogram Return·····················································169

XVI

Contents

3.1.14M21, M22, M23, M24 —User Output Control ······································································· 171

3.1.15M91, M92, M93, M94 — User Input Control ········································································· 171

3.1.16M60~M74 — Custom Command ··························································································· 172

3.2M81, M82, M83—User Input/Output Condition Control ································································ 172

3.2.1M82— Output Control and Detection······················································································· 173

3.2.2M81—Control According to Input Signal State········································································ 173

3.2.3M83—Control According to Output Signal State····································································· 174

3.3S function — Spindle Function········································································································· 174

3.3.1Spindle Motor Controlled by Gear Shift ··················································································· 174

3.3.2Variable-frequency Motor Controlled by Speed ······································································ 175

3.4T Function — Tool Function ············································································································· 176

3.4.1Tool Offset Execution Mode-Moving Slide Carriage······························································· 176

3.4.2Tool Offset Execution ModeModifying Coordinates ····························································· 177

3.5F Function — Feedrate Function ······························································································· 177

CHAPTER FOUR G COMMANDS AND FUNCTIONS ······························································180

4.1G00 — Rapid Positioning G00········································································································· 180

4.2G01 — Linear Interpolation ·············································································································· 182

4.3G02, G03, G05 —Circular Interpolation·························································································· 183

4.4Thread Cutting Command ················································································································ 188

4.4.1G33 — Thread Cutting ·············································································································· 188

4.5G32 —Tapping Cycle························································································································ 196

4.6G50 — Setting Workpiece Coordinate System·············································································· 197

4.7G51 — Recovering Workpiece Coordinate System Setting ························································· 198

4.8G26 — X, Z Reference Point Return······························································································· 199

4.9G28 — Return to Machine Zero (Machine Reference Point) ······················································· 200

4.10G30 — 2nd, 3rd Program Reference Point Return ········································································ 201

4.11G04 — Timing Delay······················································································································· 201

4.12G96 —Constant Surface Speed Control, G97 —Constant Surface Speed Cancel ················· 202

4.13Single Canned Cycle ······················································································································ 205

4.13.1G90 —Outer Cylinder Face Turning Cycle (Axial Cutting Cycle) ······································· 205

4.13.2G92 —Thread Cutting Cycle ·································································································· 208

4.13.3G94 — Inner/outer End (Taper) Face Turning Cycle ··························································· 216

4.13.4G74 —End Face Deep Hole Machining Cycle ····································································· 219

4.13.5G75 —Grooving Cycle ············································································································ 221

4.14Compound Cycle····························································································································· 223

4.14.1G71 —Axial Plane Rough and Finish Command Group ····················································· 223

4.14.2G72 —End Face Roughing/Finishing Command Group ····················································· 228

4.14.3G73 — Closed-loop Cutting Cycle Command Group ·························································· 232

4.14.4G76 —Multiple Repetitive Threading Cycle·········································································· 236

4.15G22, G80 —Program Local Cycle································································································· 241

4.16G98 — Feed per Minute, G99 — Feed per Revolution ······························································ 243

4.17G31 — Skip Function······················································································································ 244

4.18G66 -Memorizing Current Coordinates, G67-Return to Memorized Coordinates···················· 246

4.19Appendix: G function and Its Explanation Table (Table 4-3)······················································· 246

4.20Appendix G and Its Relative Parameter Explanation (Table 4-4)············································ 248

CHAPTER FIVE GENERAL PROGRAMMING RULES AND EXAMPLES ···························249

5.1General Programming Rules············································································································ 249

5.2Programming Rules for Commands in One Block········································································· 250

5.3Command Execution Sequence ······································································································ 251

5.4Programming Example ····················································································································· 253

5.4.1Outer Machining Example········································································································· 253

5.4.2Thread Machining Example ······································································································ 254

5.4.3Compound Machining Example ······························································································· 257

CHAPTER SIX ALARM MESSAGE·······························································································261

6.1Emergency Stop Alarm ····················································································································· 261

6.2Alarm Table in PARAMETER, OFFSET Operation Mode (i.e. E001~E009)······························· 261

6.3Table of Alarm in Edit Operation Mode(i.e. E100~ E199) ····························································· 263

6.4Table of Alarms Relative to Program (i.e.E200~ E299, E600~ E699)········································· 265

6.4.1Alarm in Program Command (i.e. E200~299)········································································· 265

6.4.2Alarm in Program Comprehensive Check Alarm (E600~E699)············································ 268

6.5Table of Alarm in JOG or AUTO Operation Mode (i.e. E300~ E499)··········································· 270

XVII

GSK928TD Turning CNC System User Manual

6.5.1Alarm in Executing Relative Operations (i.e. E300~E399) ····················································270

6.5.2Relative Alarm in Executing Statement (E400~ E499) ···························································274

CHAPTER SEVEN STATEMENT PROGRAMMING (not for GSK928TD)··························· 276

7.1Variable ···············································································································································276

7.1.1Variable Expression Method······································································································276

7.1.2Classification of Variable············································································································276

7.1.2.1Command Variable··············································································································277

7.1.2.2Pointer Variable ···················································································································279

7.1.2.3Interface Variable ················································································································280

7.1.2.4Keyboard Scan Register r5001··························································································281

7.1.2.5Display Window Register r5002 ························································································282

7.1.2.6Display Value Register r5003·····························································································285

7.1.2.7Graph Refresh Register r5004···························································································285

7.1.2.8Program Control Register r5008························································································286

7.1.2.9System Special Variable Group 1······················································································287

7.1.2.10System Special Variable Group 2····················································································288

7.2Statement············································································································································289

7.2.1Assignment Statement ···········································································································289

7.2.2Conditional Statement············································································································290

7.2.3Statement Program Example ································································································290

7.3Process Monitoring and Execution ··································································································292

7.3.1Process Monitor Description (r7000)····················································································292

7.3.2Process Monitor ON/OFF ······································································································293

7.3.3Monitor Program Example·····································································································295

7.3.4Pulse Monitoring (r7100) ·······································································································297

7.3.5Pulse Monitoring Programming Example ············································································298

7.3.6Variable Transfer Register (r7900) ·······················································································299

7.4Attached List·······································································································································300

7.4.1ASCII List·································································································································300

7.4.2Corresponding List between Common Colors and Code Values······································300

CHAPTER EIGHT CUSTOMIZED COMMAND PROGRAMMING ········································· 301

8.1Customized Command······················································································································301

8.1.1Programming Format of Customized Command ····································································301

8.2Customized Command Library (P254) ····························································································301

8.2.1Programming Format and Debugging of Customized Command Library ····························302

8.2.2Use of Customized Command Library ·····················································································302

8.3. Foot Switch of M61 command·········································································································303

CONNECTION·························································································································· 307

CHAPTER ONE INTERFACE OVERVIEW·················································································· 307

1.1Rear Cover Interface Layout ············································································································307

1.2Overall Frame·····································································································································308

CHAPTER TWO INTERFACE TABLE·························································································· 309 CHAPTER THREE CNC DEVICE CONNECTION ······································································311

3.1Communication Interface ··················································································································311

3.1.1USB Interface······························································································································311

3.2X1, X2 Interface ·································································································································311

3.2.1X1, X2 Interface Signal Definition·····························································································311

3.2.2Connection Method of Input Signal ··························································································314

3.2.3Connection Method of Output Signal ·······················································································316

3.2.4Input/Output Signal Specification······························································································318

3.3Machine Zero Return Function and Connection·············································································318

3.4Tool Change Control Function and Connection··············································································321

3.4.1Definition of Tool Change Control Signal ·················································································321

3.4.2Signal Connection ······················································································································321

3.4.3Function Description ··················································································································321

3.4.3.1Tool Change Mode 0···········································································································322

3.4.3.2Tool Change Mode 1···········································································································322

3.4.3.3Tool Change Mode 2···········································································································323

3.4.3.4Tool Change Mode 3···········································································································323

XVIII

Contents

3.4.3.5Tool Change Mode 4 ·········································································································· 325

3.4.4Tool Signal Check and Parameter Setting ·············································································· 326

3.4.4.1Default mode (P408_d7=0) ······························································································· 326

3.4.4.2Table Checking Mode········································································································· 327

3.5X3 Motor Interface····························································································································· 328

3.5.1Signal Definition ························································································································· 328

3.5.2Technical Specifications ············································································································ 329

3.5.3Equivalent Circuit ······················································································································· 329

3.5.3.1Drive Unit Alarm Signal Xalm, Zalm ················································································· 329

3.5.3.2Enable Signal Xen, Zen ····································································································· 330

3.5.3.3Pulse Signal and Direction Signal····················································································· 330

3.5.4Connection between CNC System and Drive Unit of Compound Stepper Motor ··············· 330

3.5.5Connection between CNC and Drive Unit of Reaction Stepper Motor································· 333

3.5.6Connection between CNC and AC Servo Drive Unit ····························································· 335

3.5.7Connection Diagram between CNC and Panasonic Drive Unit············································ 337

3.5.8Connection Diagram between CNC and Yaskawa Drive Unit··············································· 338

3.6X4 Spindle Interface·························································································································· 339

3.6.1Signal Definitions ······················································································································· 339

3.6.2Converter Technical Specification ···························································································· 339

3.6.3Encoder Technical Specifications····························································································· 340

3.6.4Connection Diagram of Converter Analog Voltage Interface················································· 340

3.6.5Encoder Interface Principle······································································································· 340

3.6.6Encode Interface Connection Diagram···················································································· 340

3.7X5 MPG Interface······························································································································ 341

3.7.1Signal Definition ························································································································· 341

3.7.2MPG Interface Principle ············································································································ 341

3.7.3MPG Interface Connection Diagram ···················································································· 341

CHAPTER FOUR USE AND MAINTENANCE INFORMATION···············································342

4.1Ambient Condition····························································································································· 342

4.2Earthing ·············································································································································· 342

4.3Power Supply Requirements············································································································ 342

4.4Protection ··········································································································································· 342

4.5Use after Long-time Unuse ·············································································································· 342

Appendix 1 CNC System Electrical Symbol Explanations ··················································345

Appendix 2 CNC System Tool Post Controller Circuit Method Layout····························346

Appendix 3 Interface Schematic Circuit····················································································347

Appendix 4 External Control Connection Diagram································································350

Appendix 5 GSK928TD CNC System Appearance Installation Dimension·····················351

Appendix 6 GSK928TD-L CNC System Appearance Installation Dimension ·················352

Supplementary Explanation·············································································································353

1.Modified Functions and Commands······················································································353

1.1Newly-added Interface Parameter P538, P539, P540—Z/X/Y Move Limit································· 353

1.2Newly-added Interface Parameter P351 — Alarm of Lubrication Check before Machining ····· 353

1.3G76 Command Modification············································································································· 353

1.4Diagnosis Operation Mode··············································································································· 354

1.5AUTO Operation Mode ····················································································································· 354

2.Newly-added M Command: M50—M59, M84········································································354

2.1Customized Commands Expanded to M50-M74 from M60-M74.················································ 354

2.2Newly-added Function of Calling M50-M72 before Machining····················································· 354

2.3M84 — Input Signal Check within a Specified Time······································································ 355

3.Newly-added G Commands and Functions ·········································································355

3.1G38 — Rigid Taping, Threading ······································································································ 355

3.2G21, G20— Metric, Inch Input ········································································································· 357

3.3Detailed Explanation of Metric/Inch Switch ···················································································· 358

3.3.1Metric/Inch Switch Parameter······························································································· 358

XIX

GSK928TD Turning CNC System User Manual

XX

Chapter One Overview

OPERATION

OPERATION

1

GSK928TD Turning CNC System User Manual

OPERATION

2

Chapter One Overview

OPERATION

CHAPTER ONE OVERVIEW

The GSK928TD system employs a 32-bit high performance CPU and a complex programmable logic device of very-large-scale programmable array integrated circuits as its control center, thus realizing the movement control with a μm-level precision. The product, equipped with a true color LCD with resolution of 480×234, uses the international standard NC language, also known as ISO codes, to write part programs. It is characterized by the full-screen program editing, Chinese/English operation interface, real-time track and display of the part graph and simple operation as well as the high cost performance. It can be matched with stepper motors or AC servo drive units, and by means of programming, it is capable of machining outer cylinders, end faces, grooves, tapers, circular arcs, threads, etc.

Technical specifications

9Link axes: 2 (X, Z axes), short linear smooth interpolation at a high speed realizable; Interpolation precision: 0.001mm, max. rapid traverse: 15m/min

9Flexible and convenient programming

9USB interface communication, fast and easy to operate

9Least command increment: 0.001mm, electronic gear ratio: 1 99999 / 1 99999

9Realizing controls like automatic tool post, spindle automatic gear shift.

9Backlash compensation, tool length compensation

9Exponential acceleration/deceleration control, applicable to high-speed and high-precision machining

9Tapping function

9Available to cut inch/metric thread, end face thread, continuous thread; with thread high-speed run-out

9Full-screen part program editing, capable of storing 255 programs; a capacity of 4 MB for No. 253 program

9True color LCD with a large screen, color profiles selected by parameters

9Real-time tracking and display of MSTF status during processing

9Multi-level passwords, convenient for equipment management

9Parameter backup function

9Communication of parameters and tool compensation data

9Support for two-way communication between CNC and CNC, and between CNC and PC; CNC software upgraded through a serial port

9Support for two-way communication between CNC and USB; CNC software upgraded through USB

OPERATION

3

GSK928TD Turning CNC System User Manual

OPERATION

9 Installation dimension, electrical characteristics and part of interfaces compatible with GSK928TC turning machine NC system

Note

1.Neither the parameters nor the functions of Y axis described in this manual are valid.

2.The interface RS232 of the system has not been led out; to lead it out from the inside of the system, special tools and professional technician are required.

4

Chapter Two Technical Specification

CHAPTER TWO TECHNICAL SPECIFICATION

2.1928TD Technical Specifications

Motion control

G codes

Thread machining

Precision compensation

M codes

T codes

Spindle speed control

I/O function

Display interface

Program edit

Simultaneously controlled axes (interpolation axes): 2 (X, Y axes)

Interpolation function: linear, circular, and thread interpolation of X and Z axes

Position command range: -9999.999 mm 9999.999mm; least command increment: 0.001mm

Electronic gear: Command multiplier coefficient 1 99999, command division coefficient 1 99999

Rapid traverse rate: Max. 15000mm/min; rapid override: F25%, 50%, 75%, 100% four-level real time adjustment

Cutting feedrate: Max. 4000mm/min; feedrate override: 16-level real time adjustment from 0 150% (increment 10%)

Manual feedrate: 0mm/min 1260mm/min 16-level real time adjustment, or user-defined speed in real time

MPG feed: Three gears, 0.001mm, 0.01mm, 0.1mm

Acceleration/deceleration: Either exponential or linear acceleration/deceleration can be selected for cutting feed.

G codes: G00, G01, G02, G03, G04, G05, (G22/G80), G26, G28, G30, G31, G32, G33, G50, G51, G66, G67, G71, G72, G73, G74, G75, G76, G90, G92, G94, G96, G97, G98, G99

Capable of machining single /multiple metric/inch straight thread, taper thread and end face thread; Thread run-out length, angle and speed characteristics settable, with high-speed run-out processing; thread pitch: 0.001mm 500mm or 0.06 teeth/inch ~ 25400 teeth/inch; taping function available

Spindle encoder: Setting range of encoder lines: 100 p/r 5000p/r; drive ratio between encoder and spindle: 1 1

Backlash compensation: 0 mm 10.000mm

Tool compensation: 16 tool numbers, 64 groups of tool length compensations

Tool setting mode: Trial tool setting, fixed point tool setting; Tool compensation execution mode: tool compensation executed by modifying coordinates, tool compensation executed by moving tool post

M00, M02, M20, M30, M03, M04, M05, M08, M09, M10, M11, M12, M32, M33, M41, M42, M43, M44, M78, M79, M80, M81, M82, M83, M96, M97, M98, M99, M91, M92, M93, M94, M21, M22, M23, M24 user defined M codes M60 M74

Up to 16 tool numbers (T01□□ T16□□), control process of tool change is selected by setting tool post type parameters; tool post type is set to 0 when using a line-up tool.

Speed switch value control mode: The output range of S command 4-gear direct control is S01 S04; or the output range of the 16-gear BCD code is S00 S15.

Speed analog voltage control mode: S commands specify the spindle speed per minute or cutting linear speed (constant surface speed control); the CNC outputs 0V 10V voltage to the spindle frequency converter; spindle stepless speed variation; support for 4 spindle mechanical gears M41 M44

I/O function diagnosis display

I/O interface: 23 points input/18 points output

Display: 480×234 lattice true color LCD, with LED or CCFL backlight

Display mode: Chinese or English display interface set by parameters; real-time display of machining path

Program number: up to 255 programs, program storage capacity: 4400KB

Edit mode: Full-screen editing, support for incremental/absolute coordinate mixed programming, program calling, and subprogram multi-level nesting

5

OPERATION

GSK928TD Turning CNC System User Manual

Communication

With USB interface; bidirectional transmission of programs, parameters and tool compensations between CNC and USB; support for system software upgrade by USB download

Adaptive driver

GSK DA98 series digital AC servo or DY3 series step drive device, with pulse + direction signal input

GSK DA98 series digital AC servo or DY3 series step drive device, with pulse + direction signal input

OPERATION

6

Chapter Three Operation Panel

CHAPTER THREE OPERATION PANEL

This turning machine CNC system (abbreviated to system or CNC) employs an operation panel made from aluminum alloy.

3.1LCD

LCD: Human-machine interface, with resolution of 480×234, lattice true color LCD

3.2LED Status Indicator

LED indicators are used to indicate the current working states of the system. There are 15 function keys with a LED indicator. When the indicator lights up, the corresponding function of the key is enabled; when it goes out, the function is disabled.

OPERATION

3.3Keyboard

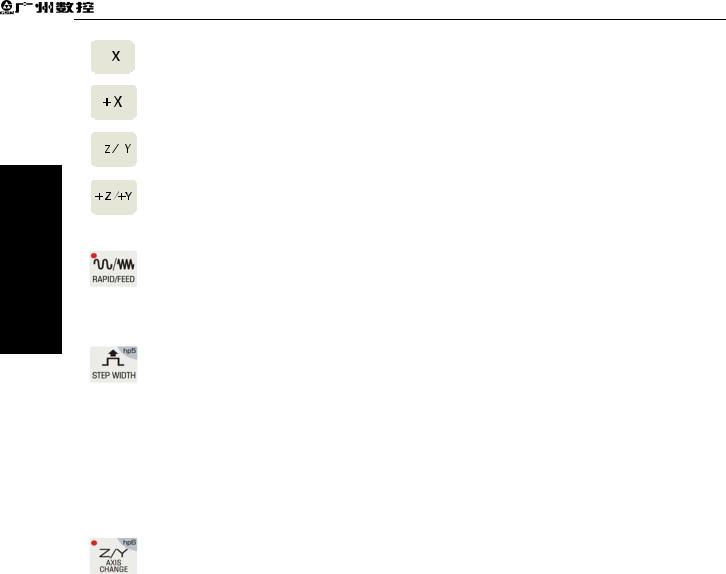

According to the standard of GSK, the function keys with the visible signs below are designed for the system. The corresponding function of a function key is enabled when it is pressed. The meaning of each key is as follows:

3.3.1Character Key

Character keys consist of numbers, letters and some signs.

In the Edit mode, each letter key can switches between two or three keycodes; in other modes, each letter key only indicates one keycode. (E.g. Though I and P are on the same key, the system will automatically identify the keycode (I or P) to be used after pressing this key.)

Numeric key: Inputs data (0 ~9) Letter key: Inputs letters

Sign key: Inputs signs such as + (plus sign), - (minus sign), * (multiplication sign), / (division sign) , + (positive sign), - (negative sign), . (decimal point), (is greater than), = (is equal to), (is less than), and, or, as well as ( ).

7

OPERATION

GSK928TD Turning CNC System User Manual

3.3.2Operation Mode Select Key

The keys are identified by a sign and letters. The user can finish the corresponding function by pressing an operation mode select key. The meaning of each key is as follows:

selects Edit operation mode

selects Edit operation mode

selects Manual operation mode

selects Manual operation mode

selects AUTO operation mode

selects AUTO operation mode

selects Parameter operation mode

selects Parameter operation mode

selects Tool Offset operation mode

selects Tool Offset operation mode  selects Diagnosis operation mode

selects Diagnosis operation mode

3.3.3Function Key

The keys are indicated by a sign and letters. With a function key pressed, its function is enabled. The meaning of each key is as follows:

Rapid override increase increases the rapid traverse override in MANUAL operation mode, and increases the speed override of G00 command in AUTO operation mode.

Rapid override increase increases the rapid traverse override in MANUAL operation mode, and increases the speed override of G00 command in AUTO operation mode.

Rapid override decrease decreases the rapid traverse override in MANUAL operation mode, and decreases the speed override of G00 command in AUTO operation mode.