gsk GSK218MC User Manual

GSK218MC SERIES MACHINING CENTER CNC SYSTEM

Product Brief:

*GSK 218MC series is a high-level machining center system and the newest man-machine design of which its machining efficiency and cleanness can be compared favorably with the imported medium system. It is very convenient to connect the standard configuration GSK-LINK Ethernet bus and absolute motor (It is the mechanical memory encoder, regardless of that the data may lose out of battery).

Product Characteristic:

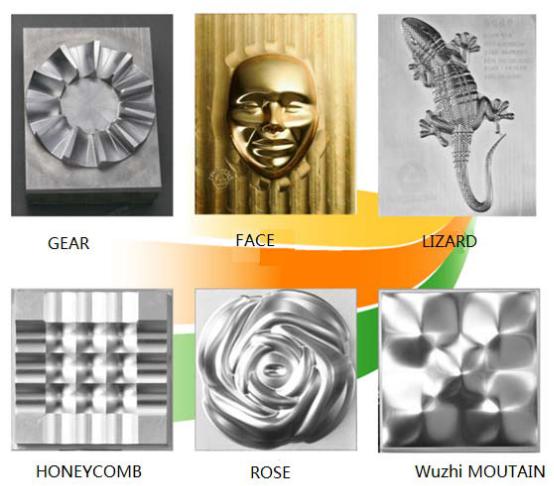

* Five-axis & Five-axis Linkage Function

It owns the five-axis control functions, such as the five-axis RTCP (Tool center control) and non-RTCP, sloping surface (3+2 positioning) (4+1 and absolute five-axis) machining. The five-axis linkage high-speed and high-accuracy interpolation function can be carried out the complicated curved surface high speed and accuracy machining to guarantee the quality of the machining precision and surface, simultaneously, improve the machining efficiency. And therefore, the surface of the machining workpiece is with clear veins, and stable at the corner of the transition, clear and activate pointedness characteristic, as well without overcutting and undercutting.

1

* High-Speed & High-accuracy Function

It adopts the high-speed interpolation technology; the complicated curved surface machining efficiency velocity is 8m/min; the optimal machining velocity is 4m/min. Up to 1000 of the pre-treatment sections; it also owns the prospective function, rapid, high-precision and perfect cleanness.

2

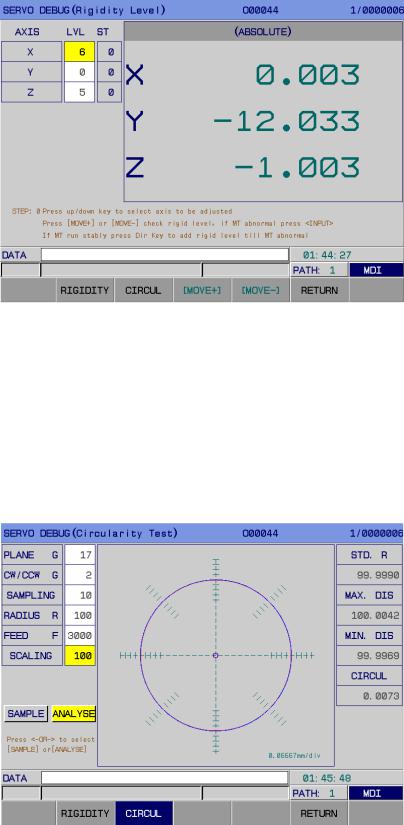

* Convenient Debugging Method

The on-line rigidity level debugging function of the bus configuration can further enhanced the machine tool rigidity adjustment and parameter optimization for the machine machining performance, instead of debugging the drive’s parameter one by one, it is simplified accordingly. Also, it has the majorization function of which the system can be optimized a group of parameter by itself to reserve the high-rigidity of the machine.

3

The on-line circular-degree testing analysis function of the bus configuration in which the circular-degree testing can be judged the responsive synchronism and its velocity of each servo axis for the machine tool by imitating the circle to cut a movement round and then collect the motor’s encoder position information based upon it.

* Convenient Extension Function

I/O board —— extend the I/O point

Spindle board —— Multi-spindle extension, 4-circuit analogy voltage, 4-circuit rigidity tapping4

Servo board —— Multi-feed-axis extension, pulse conversion from pulse Acquisition board —— Connect the grating etc. measurement feedback

equipment

Analogy board —— It can be accepted the multi-circuit analogy input/output voltage.

5

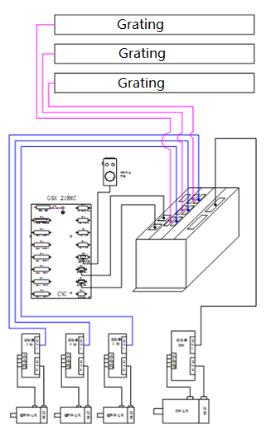

* Dual-Drive Calibration, Grating Detection Function

It has the grating read function: grating bar detects and then adjusts the levelness of the cross beam to guarantee the level accuracy during machining.

It has precision stop interpolation and corner smooth treatment function to prevent the corner from overcutting.

It has the automatic calibration dual-driving function: The synchronism error between 2 motors can be detected out by the feedback of each motor, and perform the synchronism error compensation. The alarm generates when the synchronism error exceeds the setting value to stop the axis movement and then inspect the synchronism error value.

6

Loading...

Loading...