gsk GSK980TDc User Manual

This user manual describes all items concerning the operation of

the system in detail as much as possible. However, it is impractical to give

particular descriptions of all unnecessary and/or unavailable operations of

the system due to the manual content limit, product specific operations and

other causes. Therefore, the operations not specified herein shall be

considered impossible or unallowable.

This user manual is the property of GSK CNC Equipment Co.,

Ltd. All rights are reserved. It is against the law for any organization or

individual to publish or reprint this manual without the express written

permission of GSK and the latter reserves the right to ascertain their legal

liability.

GSK980TDc Turning CNC System User Manual

FOREWORD

Dear user,

We are really grateful for your patronage and purchase of this GSK980TDc Turning

CNC system made by GSK CNC Equipment Co., Ltd.

The user manual describes the programming, operation, installation and connection

of this GSK980TDc Turning CNC system. Please read it carefully before operation in

order to get the safe and effective working.

Warning

This system can only be operated by authorized and qualified personnel as

improper operations may cause accidents.

Please carefully read this user manual before use!

Note: The power supply installed on (in) the cabinet is exclusive to GSK’S CNC

systems.

The power supply form is forbidden to be used for other purposes.

Otherwise, there may be extreme danger!

This user manual shall be kept by final user.

II

Notes

■ Delivery and storage

z Packing box over 6 layers in pile is unallowed.

z Never climb the packing box, neither stand on it, nor place heavy objects on it.

z Do not move or drag the product by the cables connected with it.

z Forbid collision or scratch to the panel and displayer.

z Packing box should be protected from damping, insolation and raining.

■ Open packing box to check

z Ensure things in packing box are the required ones.

z Ensure the product is not damaged in delivery.

z Ensure the parts in packing box are in accordance to the order.

z Contact us in time if the product type is inconsistent with the order, there is short of

Notes

accessories, or product damage in delivery.

■ Connection

z Only qualified persons can connect the system or check the connection.

z The system must be earthed, its resistance must be less than 4 Ω and the ground wire

cannot be replaced by zero wire.

z Connection must be correct and firm to avoid the product to be damaged or other

unexpected result.

z Connect with surge diode in the specified direction to avoid the damage to the system.

z Switch off power supply before pulling out plug or opening electric cabinet.

■ Troubleshooting

z Switch off power supply before troubleshooting or changing components.

z Troubleshoot and then startup the system when there is short circuit or overload.

z Do not switch on or off it frequently and an interval is 1 minute at least after the system is

powered on again.

III

GSK980TDc Turning CNC System User Manual

z This manual describes various items as much as possible. However,

operations allowable or unallowable can not be explained one by one due to

so many possibilities that may involve with, so the contents that are not

specially stated in this manual shall be considered to be unavailable.

z Please read this user manual and a manual from machine builder completely

before installation, programming and operation; do operate the system and

machine according to user manuals, otherwise it may damage the system,

machine, workpiece and even injure the operator.

z Functions, technical indexes described in this user manual are only for the

system. Actual functions and technical performance of machine tool with this

CNC system are determined by machine builder’s design, so refer to its user

manual.

z The system is employed with integrated machine control panel and the keys

on machine control panel are defined by PLC program. Functions of keys in

this user manual are for standard PLC program. Please notice it!

z Refer to user manual from machine manufacturer about functions and

meanings of keys on machine control panel.

Announcement!

Warning!

Cautions!

All specification and designs are subject to change without further notice.

IV

Summary

Ⅰ Programming

GSK980TDc CNC Technical Specification, Product

Type, Command and Program Format

Ⅱ Operation

GSK980TDc CNC Operation Use

Ⅲ Installation and Connection

GSK980TDc CNC Installation, Connection and Setting

Appendix

CNC Ladder Function Allocation, Alarm Message Table

V

GSK980TDc Turning CNC System User Manual

Safety Responsibility

Manufacturer’s safety responsibility

——The manufacturer should be responsible for the cleared or the controlled safety in the design

and the structure of the CNC system and the accessories.

——The manufacturer should be responsible for the CNC system and the accessories.

——The manufacturer should be responsible for the message and the suggestion for the user.

User’s safety responsibility

——The user should study and train the system safety operation, master the safety operation

content.

——The user should be responsible for the danger caused by increasing, changing or modifying

the CNC system, the accessories by itself.

——The user should be responsible for the danger because of the mistaken operation, regulation,

maintenance, installation and storage.

VI

CONTENTS

Contents

Ⅰ Programming

CHAPTER 1 PROGRAMMING .......................................................................................................... 1

1.1 GSK980TDc Introduction ....................................................................................................... 1

1.1.1 Product introduction ..................................................................................................... 1

1.1.2 Technical specification ................................................................................................. 2

1.1.3 Environment and conditions ......................................................................................... 4

1.1.4 Power supply ................................................................................................................ 5

1.1.5 Guard ........................................................................................................................... 5

1.2 CNC System of Machine Tools and CNC Machine Tools ...................................................... 5

1.3 Programming Fundamentals .................................................................................................. 7

1.3.1 Coordinates definition .................................................................................................. 7

1.3.2 Machine coordinate system, Machine Zero and machine reference point .................. 7

1.3.3 Workpiece coordinate system and Program Zero ....................................................... 8

1.3.4 Interpolation function .................................................................................................... 9

1.3.5 Absolute programming and incremental programming ............................................. 10

1.3.6 Diameter programming and radius programming ...................................................... 10

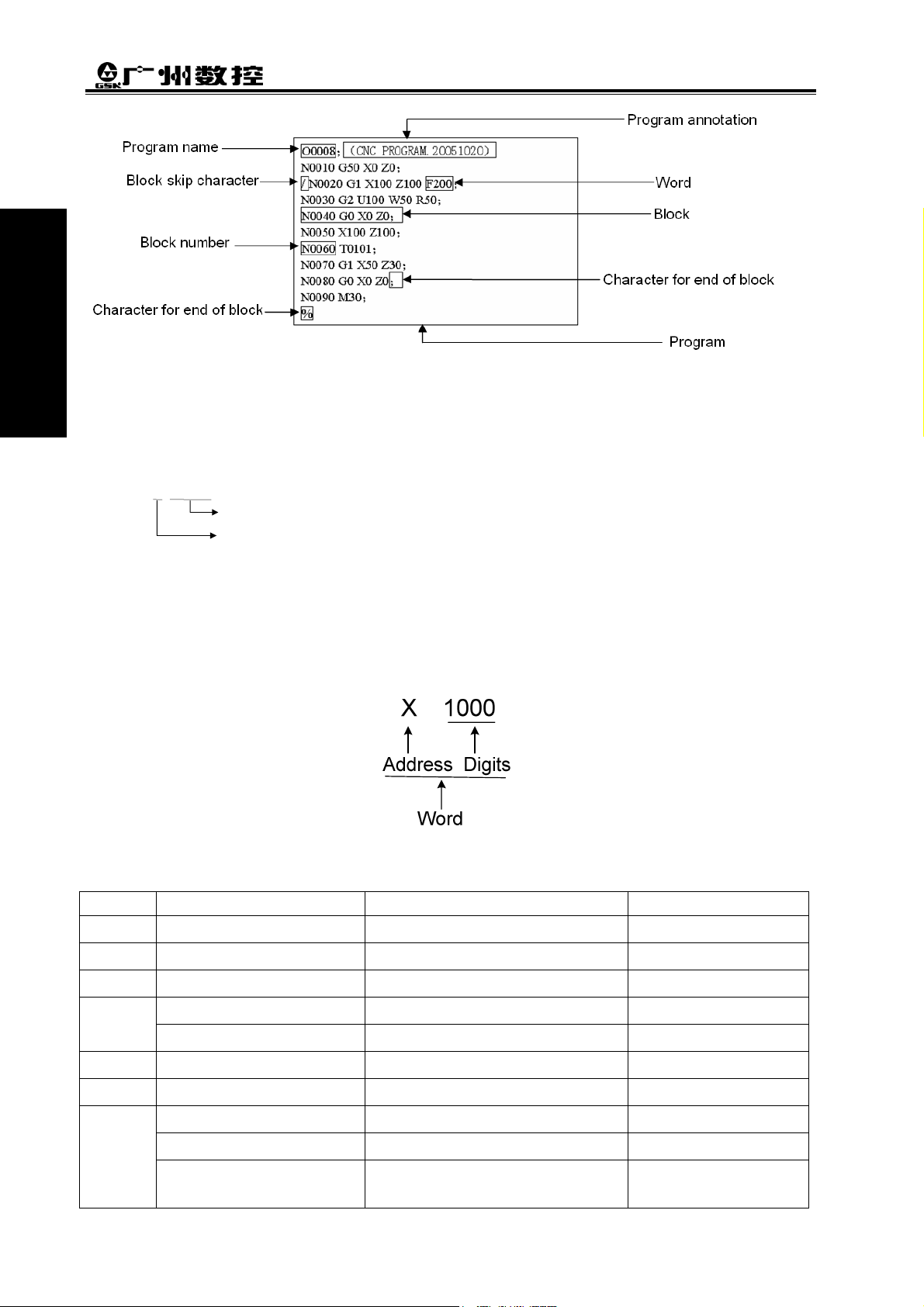

1.4 Structure of an NC Program ................................................................................................. 11

1.4.1 General structure of a program .................................................................................. 11

1.4.2 Main program and subprogram ................................................................................. 15

1.5 Program Run ........................................................................................................................ 15

1.5.1 Sequence of program run .......................................................................................... 15

1.5.2 Execution sequence of word ...................................................................................... 16

1.6 Basic Axis Incremental System ............................................................................................ 17

1.6.1 Incremental system speed of basic axis .................................................................... 17

1.6.2 Incremental system unit of basic axis ........................................................................ 17

1.6.3 Incremental system data range of basic axis............................................................. 18

1.6.4 Incremental system data range and unit of basic axis............................................... 18

1.6.5 Program address value unit and range of incremental system of basic axis ............ 20

1.7 Additional Axis Incremental System ..................................................................................... 21

1.7.1 Additional axis being the current incremental system ............................................... 21

1.7.2 Additional axis being IS-A incremental system .......................................................... 21

CHAPTER 2 MSTF COMMAND ....................................................................................................... 22

2.1 M (Miscellaneous Function) ................................................................................................. 22

End of program M02 ........................................................................................................... 22

End of program run M30 ..................................................................................................... 22

Subprogram call M98 .......................................................................................................... 23

Return from subprogram M99 ............................................................................................. 23

Macro program call M9000~M9999................................................................................... 24

M commands defined by standard PLC ladder diagram ....................................................... 24

Program stop M00 ............................................................................................................... 25

Program optional stop M01.................................................................................................... 25

Spindle CW, CCW and stop control M03, M04, M05 ............................................................ 26

Cooling control M08, M09 ................................................................................................... 26

Tailstock control M10, M11 .................................................................................................. 26

I

GSK980TDc Turning CNC System User Manual

Chuck control M12, M13 ..................................................................................................... 26

Spindle position/speed control switch M14, M15 .................................................................. 26

Spindle clamped/released M20, M21 .................................................................................... 27

The 2nd spindle position/speed switch M24, M25 ................................................................ 27

Lubricating control M32, M33 ................................................................................................ 27

Spindle automatic gear change M41, M42, M43, M44 .......................................................... 27

Spindle 8-point orientation M50~M58 .................................................................................. 27

The 2nd spindle rotation CCW, rotation CW , stop M63, M64, M65 ..................................... 27

2.2 Spindle Function ................................................................................................................... 28

2.2.1 Spindle speed switching value control ....................................................................... 28

2.2.2 Spindle speed analog voltage control ........................................................................ 28

2.2.3 Constant surface speed control G96, constant rotational speed control G97 ........... 29

2.2.4 Spindle override ......................................................................................................... 31

2.2.5 Multiple spindle control function ................................................................................. 32

2.2.6 Cs contour control funciton ........................................................................................ 33

2.3 Tool Function ........................................................................................................................ 33

2.3.1 Tool control ................................................................................................................. 33

2.3.2 Tool life management ................................................................................................. 37

CHAPTER 3 G COMMANDS ........................................................................................................... 46

3.1 Commands ........................................................................................................................... 46

3.1.1 Modal, non-modal and initial mode ............................................................................ 47

3.1.2 Omitting words ........................................................................................................... 48

3.1.3 Related definitions...................................................................................................... 49

3.2 Rapid Traverse Movement G00 ......................................................................................... 49

3.3 Linear Interpolation G01 .................................................................................................... 50

3.4 Circular Interpolation G02, G03 ......................................................................................... 51

3.5 Three-point Circular Interpolation G05 .............................................................................. 54

3.6 Ellipse Interpolation G6.2, G6.3 ........................................................................................... 56

3.7 Parabola Interpolation G7.2, G7.3 ..................................................................................... 59

3.8 Plane Selection G17~G19 .................................................................................................. 61

3.9 Polar Coordinate Interpolation G12.1, G13.1....................................................................... 62

3.10 Cylindrical Interpolation G7.1 ............................................................................................. 65

3.11 Chamfering Function .......................................................................................................... 68

3.11.1 Linear chamfering ..................................................................................................... 68

3.11.2 Circular chamfering .................................................................................................. 70

3.11.3 Special cases ........................................................................................................... 72

3.12 Dwell G04 ........................................................................................................................ 74

3.13 Machine Zero Function....................................................................................................... 74

3.13.1 Machine 1st reference point G28 .......................................................................... 74

3.13.2 Machine 2nd, 3rd, 4th reference point G30 .......................................................... 75

3.14 Skip Interpolation G31 ..................................................................................................... 77

3.15 Automatic Tool Offset G36, G37 ...................................................................................... 79

3.16 Workpiece Coordinate System G50 ................................................................................ 81

3.17 Local Coordinate System ................................................................................................... 82

3.18 Workpiece Coordinate System G54~

G59 ........................................................................ 84

3.19 Fixed Cycle Command ....................................................................................................... 87

3.19.1 Axial cutting cycle G90 .......................................................................................... 87

3.19.2 Radial cutting cycle G94........................................................................................ 90

II

Contents

3.19.3 Caution of fixed cycle commands ............................................................................ 92

3.20 Multiple Cycle Commands ................................................................................................. 93

3.20.1 Axial roughing cycle G71 ......................................................................................... 93

3.20.2 Radial roughing cycle G72 ....................................................................................... 99

3.20.3 Closed cutting cycle G73 ..................................................................................... 10 3

3.20.4 Finishing cycle G70 ................................................................................................ 107

3.20.5 Axial grooving multiple cycle G74 ....................................................................... 108

3.20.6 Radial grooving multiple cycle G75 ....................................................................... 111

3.21 Thread Cutting Commands .............................................................................................. 114

3.21.1 Thread cutting with constant lead G32 .................................................................. 115

3.21.2 Rigid thread cutting G32.1 ..................................................................................... 117

3.21.3 Thread cutting with variable lead G34................................................................. 119

3.21.4 Z thread cutting G33 ............................................................................................ 121

3.21.5 Rigid tapping G84, G88 ......................................................................................... 122

3.21.6 Thread cutting cycle G92 ....................................................................................... 125

3.21.7 Multiple thread cutting cycle G76 ........................................................................... 128

3.22 Constant Surface Speed Control G96, Constant Rotational Speed Control G97 ...... 132

3.23 Feedrate per Minute G98, Feedrate per Rev G99 ........................................................... 133

3.24. Additional Axis Function .................................................................................................. 135

3.24.1 Additional axis start ................................................................................................ 135

3.24.2 Motion of additional axis ........................................................................................ 135

3.24.3 Additional axis coordinates display ........................................................................ 135

3.25 Macro Commands ............................................................................................................ 135

3.25.1 MACRO variables .................................................................................................. 136

3.25.2 Operation and jump command G65 .................................................................... 140

3.25.3 Program example with macro command ............................................................... 143

3.26 Statement Macro Command............................................................................................. 146

3.26.1 Arithmetic and logic operation ............................................................................... 146

3.26.2 Transfer and cycle .................................................................................................. 147

3.27 Metric/Inch Switch ............................................................................................................ 150

CHAPTER 4 TOOL NOSE RADIUS COMPENSATION (G41, G42) ............................................. 152

4.1 Application .......................................................................................................................... 152

4.1.1 Overview .................................................................................................................. 152

4.1.2 Imaginary tool nose direction ................................................................................... 152

4.1.3 Compensation value setting ..................................................................................... 156

4.1.4 Command format ..................................................................................................... 157

4.1.5 Compensation direction ........................................................................................... 157

4.1.6 Notes ........................................................................................................................ 159

4.1.7 Application ................................................................................................................ 160

4.2 Tool Nose Radius Compensation Offset Path .................................................................... 16 1

4.2.1 Inner and outer side ................................................................................................. 161

4.2.2 Tool traversing when starting tool ............................................................................ 162

4.2.3 Tool traversing in Offset mode ................................................................................. 163

4.2.4 Tool traversing in Offset canceling mode ................................................................. 167

4.2.5 Tool interference check ............................................................................................ 168

4.2.6 Commands for canceling compensation vector temporarily.................................... 170

III

GSK980TDc Turning CNC System User Manual

Ⅱ Operation

CHAPTER 1 OPERATION MODE AND DISPLAY INTERFACE .................................................... 173

1.1 Panel Divi sion .................................................................................................................... 173

1.1.1 State indication ........................................................................................................ 174

1.1.2 Edit keypad.............................................................................................................. 174

1.1.3 Menu display ........................................................................................................... 175

1.1.4 Machine panel ......................................................................................................... 176

1.2 Summary of Operation Mode ............................................................................................ 179

1.3 Display Interface ................................................................................................................ 179

1.3.1 POS interface .......................................................................................................... 179

1.3.2 PRG interface .......................................................................................................... 184

1.3.3 TOOL OFFSET Interface ........................................................................................ 189

1.3.4 ALARM interface ..................................................................................................... 193

1.3.5 Setting interface ...................................................................................................... 194

1.3.6 PARAMETER Interfaces ......................................................................................... 196

1.3.7 Diagnosis Interface ................................................................................................. 198

1.3.8 Graph Interface ....................................................................................................... 199

1.3.9 Ladder Interface ...................................................................................................... 200

CHAPTER 2 POWER ON/OFF AND PROTECTION ..................................................................... 205

2.1 System Power-on .............................................................................................................. 205

2.2 System Power-off .............................................................................................................. 205

2.3 Overtravel Protection ......................................................................................................... 206

2.3.1 Hardware overtravel protection ............................................................................... 206

2.3.2 Software Overtravel Protection ............................................................................... 206

2.4 Emergency Operation ....................................................................................................... 207

2.4.1 Reset ....................................................................................................................... 207

2.4.2 Emergency stop ...................................................................................................... 207

2.4.3 Feed hold ................................................................................................................ 207

2.4.4 Power-off ................................................................................................................. 207

CHAPTER 3 MANUAL OPERATION ............................................................................................. 209

3.1 Coordinate Axis Move ....................................................................................................... 209

3.1.1 Manual feed ............................................................................................................ 209

3.1.2 Manual rapid traverse ............................................................................................. 209

3.1.3 Speed tune .............................................................................................................. 210

3.2 Other Manual Operations ................................................................................................... 211

3.2.1 Spindle CCW, CW, stop control ............................................................................... 211

3.2.2 Spindle jog ................................................................................................................ 211

3.2.3 Cooling control ........................................................................................................ 212

3.2.4 Lubricating control ................................................................................................... 212

3.2.5 Chuck control .......................................................................................................... 212

3.2.6 Tailstock control ....................................................................................................... 213

3.2.7 Hydraulic control ..................................................................................................... 213

3.2.8 Manual tool change ................................................................................................. 213

3.2.9 Spindle override ...................................................................................................... 214

CHAPTER 4 MPG/STEP OPERATION .......................................................................................... 215

4.1 Step Feed .......................................................................................................................... 215

IV

Contents

4.1.1 Increment selection ................................................................................................. 215

4.1.2 Moving direction selection ....................................................................................... 216

4.2 MPG(handwheel) Feed ..................................................................................................... 216

4.2.1 Increment selection ................................................................................................. 217

4.2.2 Moving axis and direction selection ........................................................................ 217

4.2.3 Other operations ..................................................................................................... 218

4.2.4 Explanation items .................................................................................................... 219

CHAPTER 5 MDI OPERATION ...................................................................................................... 220

5.1 Block Input ......................................................................................................................... 220

5.2 Block Execution ................................................................................................................. 221

5.3 Parameter Setting.............................................................................................................. 221

5.4 Data Alteration ................................................................................................................... 222

5.5 Other Operations ............................................................................................................... 222

CHAPTER 6 PROGRAM EDIT AND MANAGEMENT ................................................................... 223

6.1 Program Creation .............................................................................................................. 223

6.1.1 Creating a block number ......................................................................................... 223

6.1.2 Inputting a program ................................................................................................. 223

6.1.3 Searching a character ............................................................................................. 226

6.1.4 Inserting a character ............................................................................................... 229

6.1.5 Deleting a character ................................................................................................ 230

6.1.6 Altering a character ................................................................................................. 230

6.1.7 Deleting a single block ............................................................................................ 231

6.1.8 Copying and pasting a block ................................................................................... 232

6.1.9 Canceling and recovering a program ...................................................................... 233

6.1.10 Program save ........................................................................................................ 233

6.1.11 Macro program edit ............................................................................................... 234

6.1.12 Creating and modifying a program annotation ..................................................... 234

6.2 Deleting Programs ............................................................................................................. 235

6.2.1 Deleting a program .................................................................................................. 235

6.2.2 Deleting all programs .............................................................................................. 237

6.3 Selecting a Program .......................................................................................................... 238

6.3.1 Searching ................................................................................................................ 238

6.3.2 Scanning ................................................................................................................. 239

6.3.3 Direct confirmation .................................................................................................. 239

6.4 Executing a Program ......................................................................................................... 240

6.5 Renaming a Program ........................................................................................................ 241

6.6 Copying a Program ........................................................................................................... 242

6.7 Program Management ....................................................................................................... 244

6.7.1 Program list ................................................................................................................ 244

6.8 Other Operations Available in Edit Mode .......................................................................... 244

CHAPTER 7 TOOL OFFSET AND SETTING ................................................................................ 246

7.1 Tool Positioning Setting ..................................................................................................... 246

7.2 Trial Toolsetting .................................................................................................................. 247

7.3 Toolsetting by Machine Zero Return ................................................................................. 248

7.4 Coordinates Record .......................................................................................................... 251

7.5 Setting and Altering the Offset Value ................................................................................ 252

7.5.1 Offset setting ........................................................................................................... 252

V

GSK980TDc Turning CNC System User Manual

7.5.2 Offset alteration ....................................................................................................... 252

7.5.3 Offset alteration in communication mode ............................................................... 253

7.5.4 Clearing the offset values ....................................................................................... 253

7.5.5 Setting and altering the tool wear ........................................................................... 253

7.5.6 Locking and unlocking the offset value ................................................................... 254

7.5.7 No.0 tool offset moving workpiece coordinate system ........................................... 254

CHAPTER 8 AUTO OPERATION .................................................................................................. 256

8.1 Automatic Run ................................................................................................................... 256

8.1.1 Selection of a program running ............................................................................... 256

8.1.2 Start of automatic run .............................................................................................. 256

8.1.3 Stop of automatic run .............................................................................................. 256

8.1.4 Automatic run from an arbitrary block ..................................................................... 257

8.1.5 Adjustment of the feedrate, rapid rate .................................................................... 258

8.1.6 Spindle speed adjustment ....................................................................................... 258

8.2 Running State .................................................................................................................... 259

8.2.1 Single block execution ............................................................................................ 259

8.2.2 Dry run ..................................................................................................................... 259

8.2.3 Machine lock ........................................................................................................... 259

8.2.4 MST lock ................................................................................................................. 260

8.2.5 Block skip ................................................................................................................ 260

8.3 MPG Trial-cut ..................................................................................................................... 260

8.3.1 Switching MPG trial-cut mode................................................................................. 260

8.3.2 Command speed in MPG trial-cut mode ................................................................ 261

8.3.3 Notes in MPG trial-cut mode ................................................................................... 262

8.3.4 Temporarily invalid in MPG trial-cut mode .............................................................. 262

8.4 Other Operations ............................................................................................................... 263

CHAPTER 9 ZERO RETURN OPERATION .................................................................................. 264

9.1 Program Zero Return ........................................................................................................ 264

9.1.1 Program Zero .......................................................................................................... 264

9.1.2 Program zero return steps ...................................................................................... 264

9.2 Machine Zero Return ......................................................................................................... 265

9.2.1 Machine Zero .......................................................................................................... 265

9.2.2 Machine Zero return steps ...................................................................................... 265

9.3 Other Operations in Zero Return ....................................................................................... 266

CHAPTER 10 DATA SETTING ....................................................................................................... 267

10.1 Data Setting ..................................................................................................................... 267

10.1.1 Switch setting ........................................................................................................ 267

10.1.2 Level setting .......................................................................................................... 267

10.1.3 Parameter operation ............................................................................................. 270

10.2 Clock Setting ................................................................................................................... 271

10.3 Graphic Display ............................................................................................................... 272

10.4 Parameter Setting ........................................................................................................... 275

10.4.1 State parameter ..................................................................................................... 275

10.4.2 Data parameter, pitch compensation .................................................................... 278

10.4.3 Often used parameters ......................................................................................... 280

CHAPTER 11 U OPERATION FUNCTION .................................................................................... 283

11.1 File Management Function Introduction .......................................................................... 283

VI

Contents

11.2 Often Used File Operation Function Introduction ............................................................ 283

11.2.1 File extension and return ....................................................................................... 283

11.2.2 File selection and cancellation of file selection ..................................................... 284

11.2.3 File copy ................................................................................................................ 286

11.3 Data Copy and Resume .................................................................................................. 286

11.3.1 Entering backup/resume page .............................................................................. 286

11.3.2 Backup/resume operation ..................................................................................... 287

11.3.3 Operation path selection ....................................................................................... 287

11.3.4 Format of data backup/resume file........................................................................ 288

11.3.5 Level explanation of data backup/resume operation ............................................ 289

11.4 Notes ................................................................................................................................ 289

CHAPTER 12 COMMUNICATION ................................................................................................. 290

12.1 GSK980TDc Communication Software GSKComm ....................................................... 290

12.1.1 GSKComm’s system (PC) requirements .............................................................. 290

12.1.2 Software interface ................................................................................................. 290

12.1.3 Receiving files (CNC→PC) ................................................................................... 291

12.1.4 Sending files (CNC→PC) ...................................................................................... 293

12.1.5 Part program management ................................................................................... 295

12.2 Preparatory before Communication ................................................................................ 296

12.2.1 Communication cable connection ......................................................................... 296

12.2.2 Communication setting baud rate ......................................................................... 296

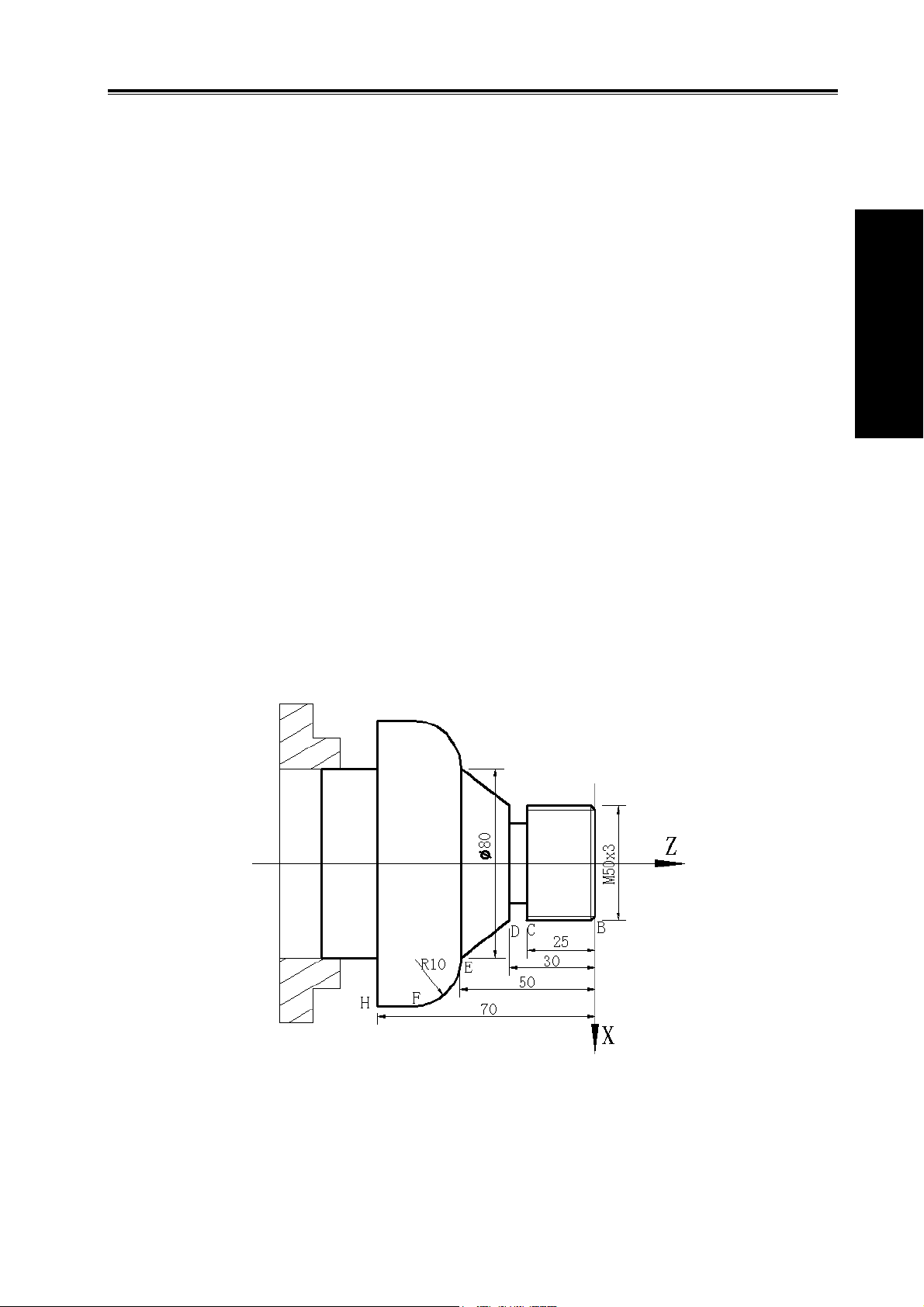

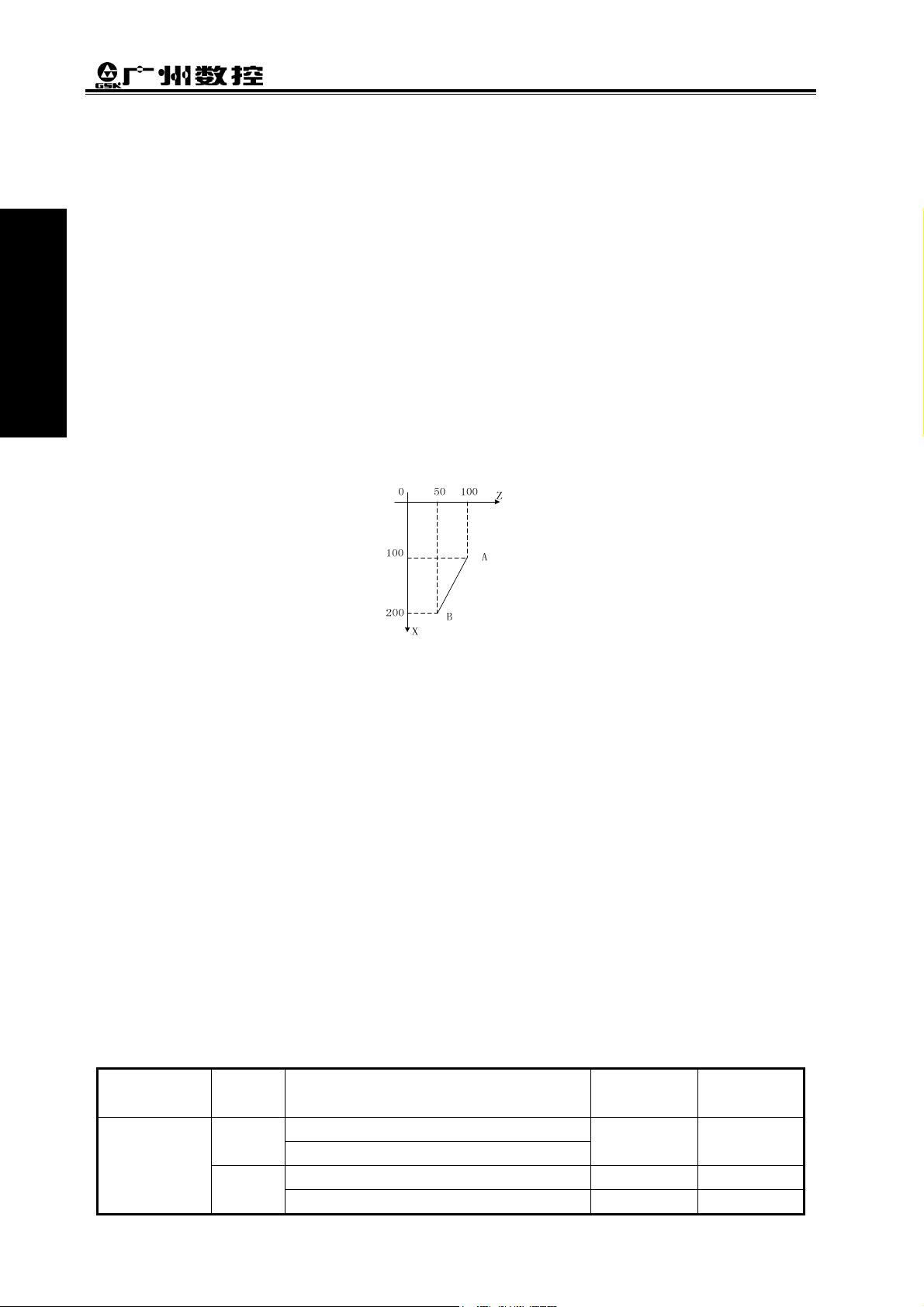

CHAPTER 13 MACHINING EXAMPLES ....................................................................................... 298

13.1 Programming ................................................................................................................... 299

13.2 Program Input .................................................................................................................. 301

13.2.1 View a saved program .......................................................................................... 301

13.2.2 Creating a new program ....................................................................................... 301

13.3 Checkout a Program .......................................................................................................... 302

13.3.1 Graphic setting ......................................................................................................... 302

13.3.2 Program check ...................................................................................................... 302

13.4 Toolsetting and Running .................................................................................................. 303

III Connection

CHAPTER 1 NSTALLATION LAYOUT ........................................................................................... 307

1.1 GK980TDc System Connection ........................................................................................ 307

1.1.1 GK980TDc, GSK980TDc-V rear cover interface layout .......................................... 308

1.1.2 Interface explanation ................................................................................................ 308

1.2 GSK980TDc Installation .................................................................................................... 308

1.2.1 GSK980TDc external dimensions ............................................................................ 308

1.2.2 Preconditions of the cabinet installation .................................................................. 308

1.2.3 Measures against interference ................................................................................ 308

CHAPTER 2 DEFINITION & CONNECTION OF INTERFACE SIGNALS ..................................... 310

2.1 Connection to Drive Unit ................................................................................................... 310

2.1.1 Drive interface definition .......................................................................................... 310

2.1.2 Code pulse and direction signals ............................................................................. 310

2.1.3 Drive unit alarm signal nALM ................................................................................... 310

VII

GSK980TDc Turning CNC System User Manual

2.1.4 Axis enable signal nEN ............................................................................................ 311

2.1.5 Pulse disable signal nSET ....................................................................................... 311

2.1.6 Zero signal nPC ....................................................................................................... 311

2.1.7 Connection to a drive unit ........................................................................................ 313

2.2 Being Connected with Spindle Encoder ............................................................................ 314

2.2.1 Spindle encoder interface definition ......................................................................... 314

2.2.2 Signal explanation .................................................................................................... 314

2.2.3 Being connected with spindle encoder interface ..................................................... 314

2.3 Being Connected with MPG (Manual Pulse Generator) ................................................... 315

2.3.1 MPG interface definition ........................................................................................... 315

2.3.2 Signal explanation .................................................................................................... 315

2.4 Spindle Interface ................................................................................................................ 316

2.4.1 Spindle interface definition ....................................................................................... 316

2.4.2 Connection to inverter .............................................................................................. 317

2.5 GSK980TDc/GSK980TDc-V being Connected with PC ................................................ 317

2.5.1 Communication interface definition ............................................................................ 317

2.5.2 Communication interface connection....................................................................... 317

2.6 Power Interface Connection .............................................................................................. 318

2.7 I/O Interface Definition ....................................................................................................... 318

2.7.1 Input signal ............................................................................................................... 320

2.7.2 Output signal ............................................................................................................ 321

2.8 I/O Function and Connection ............................................................................................ 323

2.8.1 Stroke limit and emergency stop .............................................................................. 3 23

2.8.2 Tool change control .................................................................................................. 325

2.8.3 Machine zero return ................................................................................................. 331

2.8.4 Spindle control .......................................................................................................... 337

2.8.5 Spindle switching volume control ............................................................................. 340

2.8.6 Spindle automatic gearing control ............................................................................ 341

2.8.7 Spindle eight-point orientation function .................................................................... 343

2.8.8 Spindle Cs axis control function ............................................................................... 346

2.8.9 Multiple spindle function ........................................................................................... 349

2.8.10 Rigid tapping function ............................................................................................ 353

2.8.11 External cycle start and feed hold .......................................................................... 354

2.8.12 Cooling control ....................................................................................................... 355

2.8.13 Lubricating control .................................................................................................. 356

2.8.14 Chuck control ......................................................................................................... 357

2.8.15 Tailstock control ...................................................................................................... 360

2.8.16 Low pressure detection .......................................................................................... 361

2.8.17 Hydraulic control (only applied to 980TDc-V) ........................................................ 362

2.8.18 Safety door detection ............................................................................................. 362

2.8.19 CNC macro variables ............................................................................................. 363

2.8.20 External override .................................................................................................... 363

2.8.21 External MPG ......................................................................................................... 364

2.8.22 Tri-color Lamp ........................................................................................................ 365

2.8.23 Gear/tool number display (only applied to 980TDc-V) .......................................... 365

2.9 Commonly Use Symbol of Electricity Drawing .................................................................. 366

CHAPTER 3 PARAMETERS............................................................................................................. 367

3.1 Parameter Description (by sequence) .............................................................................. 367

3.1.1 Bit parameter ..........................................................................................................

VIII

.. 376

Contents

3.1.2 Data parameter ........................................................................................................ 390

3.1.3 PLC parameters(standard PLC definition) .......................................................... 390

3.2 Parameter Description (by function sequence) ................................................................. 394

3.2.1 X, Z, Y, 4

3.2.2 Acceleration & deceleration control ......................................................................... 396

3.2.3 Precision compensation ........................................................................................... 397

3.2.4 Machine protection ................................................................................................... 399

3.2.5 Machine zero return ................................................................................................. 400

3.2.6 Threading function ................................................................................................... 403

3.2.7 Spindle control .......................................................................................................... 40 4

3.2.8 Tool compensation ................................................................................................... 406

3.2.9 Tool life management function ................................................................................. 406

3.2.10 Tool wear parameter .............................................................................................. 407

3.2.11 Edit and display ...................................................................................................... 407

3.2.12 Communication setting .......................................................................................... 408

3.2.13 MPG Parameters ................................................................................................... 408

3.2.14 PLC axis control function ....................................................................................... 408

3.2.15 Skip function ........................................................................................................... 409

3.2.16 Automatic tool setting function ............................................................................... 409

3.2.17 Input and output function in metric and inch system ............................................. 410

3.2.18 Parameters related to arc turning .......................................................................... 410

3.2.19 Parameters related to the additional ...................................................................... 410

th,5th

axis control logic ................................................................................ 394

CHAPTER 4 MACHINE DEBUGGING METHODS AND MODES ................................................. 412

4.1 Emergency Stop and Limit ................................................................................................ 412

4.2 Drive Unit Configuration .................................................................................................... 412

4.3 Gear Ratio Adjustment ...................................................................................................... 412

4.4 ACC&DEC Characteristic Adjustment ............................................................................... 413

4.5 Mechanical (Machine) Zero Adjustment ............................................................................ 414

4.6 Spindle Adjustment ............................................................................................................ 416

4.6.1 Spindle encoder ....................................................................................................... 416

4.6.2 Spindle brake ........................................................................................................... 416

4.6.3 Switch volume control of spindle speed................................................................... 417

4.6.4 Analog voltage control of spindle speed .................................................................. 418

4.7 Backlash Offset ................................................................................................................. 417

4.8 Tool Post Debugging ......................................................................................................... 418

4.9 Step/MPG Adjustment ....................................................................................................... 418

CHAPTER 5 DIAGNOSIS MESSAGE............................................................................................ 420

5.1 CNC Diagnosis .................................................................................................................. 420

5.1.1 I/O status and data diagnosis message ................................................................... 420

5.1.2 CNC motion state and data diagnosis message ..................................................... 420

5.1.3 Diagnosis keys ......................................................................................................... 421

5.1.4 Others ....................................................................................................................... 422

5.2 PLC State .......................................................................................................................... 422

5.2.1 X address (machine→PLC , defined by standard PLC ladders) ............................. 422

5.2.2 Y address (PLC→machine, defined by standard PLC ladders) .............................. 424

5.2.3 Machine panel .......................................................................................................... 426

5.2.4 F address(CNC→PLC) ............................................................................................ 428

5.2.5 G address (PLC→CNC) ........................................................................................... 432

IX

GSK980TDc Turning CNC System User Manual

5.2.6 Address A (message display requiery signal, defined by standard PLC ladders) ... 437

5.2.7 K address(K parameter, standard PLC definition) .............................................. 438

5.3 PLC Data ........................................................................................................................... 440

5.3.1 Timer address T(defined by standard PLC ladders) ................................................ 440

5.3.2 Counter address C(Defined by standard PLC Ladders) .......................................... 44 1

5.3.3 Timer presetting address DT(Defined by standard PLC ladders) ........................... 441

5.3.4 Counter presetting address DC ............................................................................... 442

CHAPTER 6 MEMORIZING PITCH ERROR COMPENSATION ................................................... 443

6.1 Function Description .......................................................................................................... 443

6.2 Specification ...................................................................................................................... 443

6.3 Parameter Setting ............................................................................................................. 443

6.3.1 Pitch compensation .................................................................................................. 443

6.3.2 Pitch error compensation number ............................................................................ 443

6.3.3 Pitch error compensation interval ............................................................................ 444

6.3.4 Offset value .............................................................................................................. 444

6.4 Notes of Offset Setting ...................................................................................................... 444

6.5 Setting Examples of Offset Parameters ............................................................................ 444

X

I Programming

GSK980TDc Turning CNC System User Manual

CHAPTER 1 PROGRAMMING

1.1 GSK980TDc Introduction

Chapter 1 Programming

1.1.1 Product introduction

GSK980TDc is a new upgraded software, its software, hardware based on GSK980TDb, its

structure horizontal and vertical, matched with 8.4 inch color LCD, with 5 feed axes (including C axis),

2 analog spindles, least input increment 0.1μm. It uses the graphic interface, friendly human-machine

operation window. It can realize the PLC on-line display, real-time monitoring and MPG trial-cut

function.

Being upgraded product of GSK980TDb, GSK980TDc CNC turning is the better choice.

Ⅰ Programming

.

GSK980TDc GSK980TDc-V

X, Z, Y, 4

2ms interpolation period, control precision 1μm, 0.1μm

Max. speed 60m/min(up to 24m/min in 0.1μm)

Adapting to the servo spindle to realize the spindle continuously positioning, rigid tapping, and

the rigid thread machining

Built-in multi PLC programs, and the PLC program currently running can be selected

G71 supporting flute contour cycle cutting

Statement macro command programming, macro program call with parameter

Metric/inch programming, automatic toolsetting, automatic chamfer, tool life management

function

Chinese, English, Spanish, Russian display can be selected by parameters.

USB interface, U disc file operation, system configuration and software

th

, 5th ; axis name and axis type of Y, 4th, 5th can be defined

1

2-channel 0V~10V analog voltage output, two-spindle control

1-channel MPG input, MPG function

41 input signals and 36 output signals

Appearance installation dimension and command system are compatible with those of

GSK980TDb, GSK980TDa

Ⅰ Programming

1.1.2 Technical specification

Controllable axes

Controllable axes: 5(X, Z, Y , 4

Link axes:3

PLC controllable axes:3(X, Z, Y, 4

Feed axis function

Least input increment: 0.001mm(0.0001inch)and 0.0001mm(0.00001inch)

Least command increment:0.001mm(0.0001inch)and 0.0001mm(0.00001inch)

Position command range: ±99999999× least command unit

Rapid traverse speed:max. speed 60m/min in 0.001mm command unit, max. speed

24m/min in 0.0001mm command unit

Rapid override: F0, 25%, 50%, 100%

Feedrate override: 0~150% 16 grades to tune

Interpolation mode: linear interpolation, arc interpolation(three-point arc interpolation),

thread interpolation, ellipse interpolation, parabola interpolation and rigid tapping

Automatic chamfer function

GSK980TDc Turning CNC System User Manual

th,5th

)

th,5th

)

Thread function

General thread(following spindle)/rigid thread

Single/multi metric, inch straight thread, taper thread, end face thread, constant pitch

thread and variable pitch thread

Thread run-out length, angle, speed characteristics can be set

Thread pitch: 0.01mm~500mm or 0.06 tooth/inch~2540 tooth/inch

Acceleration/deceleration function

Cutting feed: linear

Rapid traverse: linear, S

Thread cutting: linear, exponential

Initial speed, termination speed, time of acceleration/deceleration can be set by

parameters

Spindle function

2-channel 0V~10V analog voltage output, two-spindle control

1-channel spindle encoder feedback, spindle encoder line can be set(100p/r~5000p/r)

Transmission ratio between encoder and spindle:(1~255):(1~255)

Spindle speed: it is set by S or PLC, and speed range: 0r/min~9999r/min

Spindle override: 50%~120% 8 grades tune

Spindle constant surface speed control

Rigid tapping

Tool function

2

Chapter 1 Programming

Tool length compensation

Tool nose radius compensation(C)

Tool wear compensation

Tool life management

Toolsetting mode: fixed-point toolsetting, trial-cut toolsetting, reference point return

toolsetting, automatic toolsetting

Tool offset execution mode: modifying coordinate mode, tool traverse mode

Precision compensation

Backlash compensation

Memory pitch error compensation

PLC function

Two-level PLC program,up to 5000 steps,the 1st program refresh period 8ms

PLC program communication download

PLC warning and PLC alarm

Many PLC programs(up to 16PCS), the PLC program currently running can be

selected

Basic I/O:41 input signals /36 output signals

Ⅰ Programming

Man-machine interface

8.4″ wide screen LCD,resolution: 640×480

Chinese, English, Spanish, Russian display

Planar tool path display

Real-time clock

Operation management

Operation mode: edit, auto, MDI, machine zero return, MPG/single, manual, program

zero return

Multi-level operation privilege management

Alarm record

Program edit

Program capacity: 40MB,384 programs(including subprograms and macro programs)

Edit function: program/block word search, modification, deletion

Program format: ISO command, statement macro command programming, relative

coordinate, absolute coordinate and compound coordinate programming

Program call: macro program call with parameter, 4-level program built-in

Communication function

RS232:two-way transmitting part programs and parameters, PLC program, system

software serial upgrade

USB:U file operation, U file directly machining, PLC program, system software U

upgrade

Safety function

Emergency stop

Hardware travel limit

Software travel check

Data backup and recovery

3

GSK980TDc Turning CNC System User Manual

d

d

A

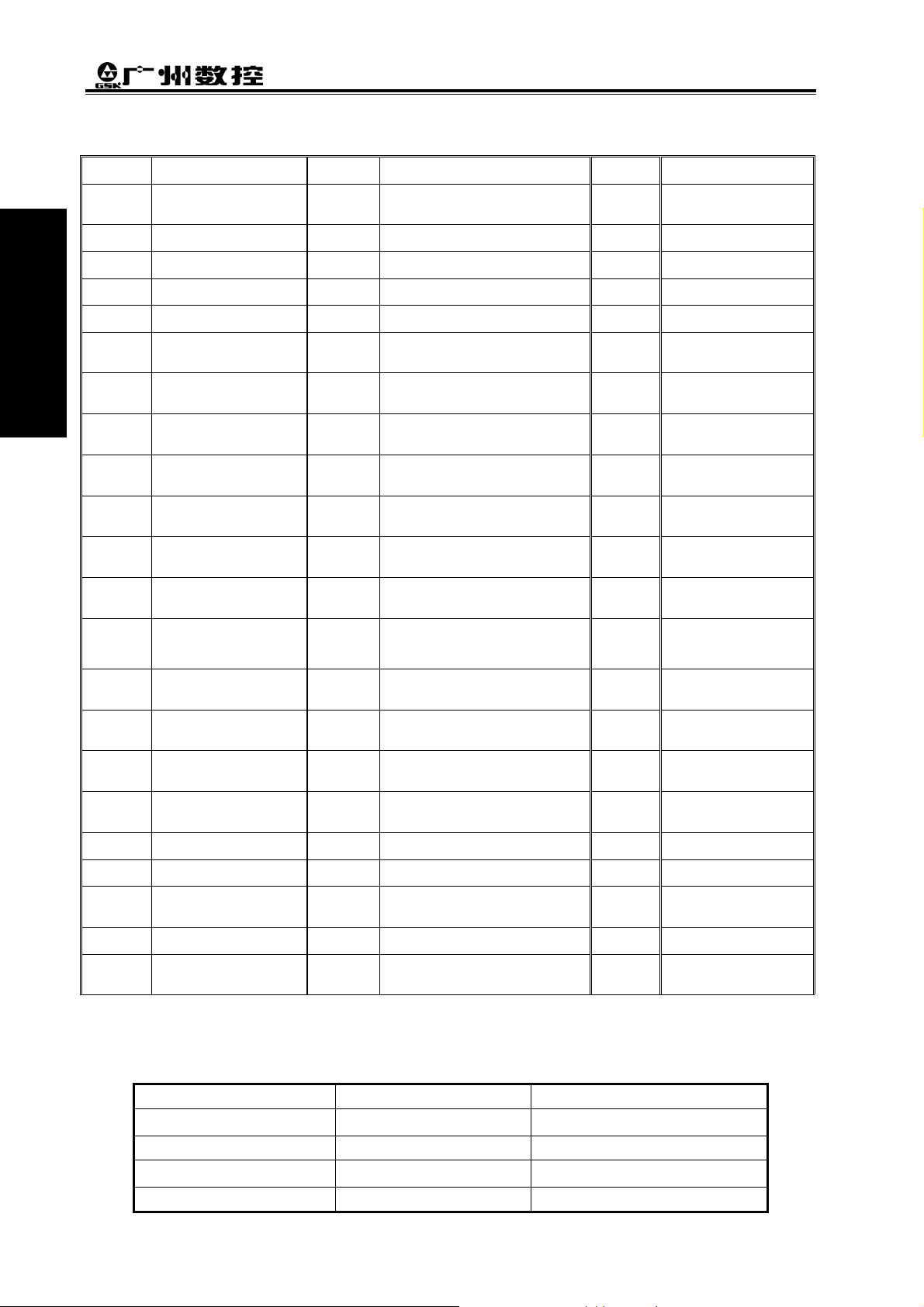

G command table

Command Function Command Function Command Function

n

G00 Rapid traverse

(positioning)

Ⅰ Programming

G01

G02

G03

G04

G05

G6.2

G6.3

G7.2

G7.3

G12.1

G7.1

G15

G16

G17

G18

G19

G10

G11

G20

G21

G28

Linear interpolation

CW arc interpolation

CCW arc interpolation

Dwell, exact stop

Three-point arc

interpolation

Ellipse interpolation

(CW)

Ellipse interpolation

(CCW)

Parabola interpolation

(CW)

Parabola interpolation

(CCW)

Polar coordinate

interpolation

Cylinder interpolation

Polar coordinate

command cancel

Polar coordinate

command

Plane selection

command

Plane selection

command

Plane selection

command

Data input ON

Data input OFF

Input in inch

Input in metric

Reference point return

G30

G31

G32

G32.1

G33

G34 Thread cutting with variable

G36

G37

G40 Tool nose radius compensation

G41 Tool nose radius compensation

G42 Tool nose radius compensation

G50 Workpiece coordinate system

G52 Local workpiece coordinate

G54

G55

G56 Workpiece coordinate system 3

G57 Workpiece coordinate system 4

G58 Workpiece coordinate system 5

G59 Workpiece coordinate system 6

G65 Macro command non-modal

G66 Macro program modal call

G67 Macro program modal call

Automatic tool compensation X

Automatic tool compensation Z

r

2

, 3

, 4th reference point

return

Skip function

Constant pitch thread cutting

Rigid thread cutting

Z tapping cycle

lead

cancel

left

right

setting

system

Workpiece coordinate system 1

Workpiece coordinate system 2

call

cancel

G71

G72

G73

G70

G74

G75

G76

G80

G84

G88

G90

G92

G94

G96

G97

G98

G99

xial roughing cycle

(flute cycle)

Radial roughing cycle

Closed cutting cycle

Finishing cycle

Axial grooving cycle

Radial grooving cycle

Multiple thread cutting

cycle

Rigid tapping state

cancel

Axial rigid tapping

Radial rigid tapping

Axial cutting cycle

Thread cutting cycle

Radial cutting cycle

Constant surface speed

control

Constant surface speed

control cancel

Feed per minute

Feed per revolution

1.1.3 Environment and conditions

GSK980TDc storage delivery, working environment as follows:

Item Working conditions Storage delivery conditions

Ambient temperature

Ambient humidity ≤90%(no freezing) ≤95%(40 )℃

Atmosphere pressure

Altitude ≤1000m ≤1000m

4

0℃~45℃ -40℃~+70℃

86 kPa~106 kPa 86 kPa~106 kPa

1.1.4 Power supply

GSK980TDc can normally run in the following AC input power supply.

Voltage: within(0.85~1.1)×200V (rated AC input voltage);

Frequency: 49Hz~51Hz continuously changing

Chapter 1 Programming

1.1.5 Guard

GSK980TDc guard level is not less than IP20.

1.2 CNC System of Machine Tools and CNC Machine Tools

CNC machine tool is an electro-mechanical integrated product, composed of Numerical Control

Systems of Machine Tools, machines, electric control components, hydraulic components, pneumatic

components, lubricant, cooling and other subsystems (components), and CNC systems of machine

tools are control cores of CNC machine tools. CNC systems of machine tools are made up of

computerized numerical control(CNC), servo (stepper) motor drive devices, servo (or stepper) motor

etc.

Operational principles of CNC machine tools: according to requirements of machining

technology, edit user programs and input them to CNC, then CNC outputs motion control commands

to the servo (stepper) motor drive devices, and last the servo (or stepper) motor completes the cutting

feed of machine tool by mechanical driving device; logic control commands in user programs to

control spindle start/stop, tool selections, cooling ON/OFF, lubricant ON/OFF are output to electric

control systems of machine tools from CNC, and then the electric control systems control output

components including buttons, switches, indicators, relays, contactors and so on. Presently, the

electric control systems are employed with Programmable Logic Controller (PLC) with characteristics

of compact, convenience and high reliance. Thereof, the motion control systems and logic control

systems are the main of CNC machine tools.

GSK980TDc Turning Machine CNC system has simultaneously motion control and logic control

function to control two axes of CNC machine tool to move, and has nested PLC function. Edit PLC

programs (ladder diagram) according to requirements of input and output control of machine tool and

then download them to GSK980TDc Turning Machine CNC system, which realizes the required

electric control requirements of machine tool, is convenient to electric design of machine tool and

reduces cost of CNC machine tool.

Software used to control GSK980TDc Turning Machine CNC system is divided into system

software (NC for short) and PLC software (PLC for short). NC system is used to control the display,

communication, edit, decoding, interpolation and acceleration/deceleration, and PLC system for

controlling explanations, executions, inputs and outputs of ladder diagrams.

Standard PLC programs are loaded (except for the special order) when GSK980TDc Turning

Machine CNC System is delivered, concerned PLC control functions in following functions and

operations are described according to control logics of standard PLC programs, marking with

“Standard PLC functions” in GSK980TDc Turning CNC System User Manual. Refer to Operation

Manual of machine manufacturer about functions and operations of PLC control because the

machine manufacturer may modify or edit PLC programs again.

Ⅰ Programming

5

GSK980TDc Turning CNC System User Manual

Ⅰ Programming

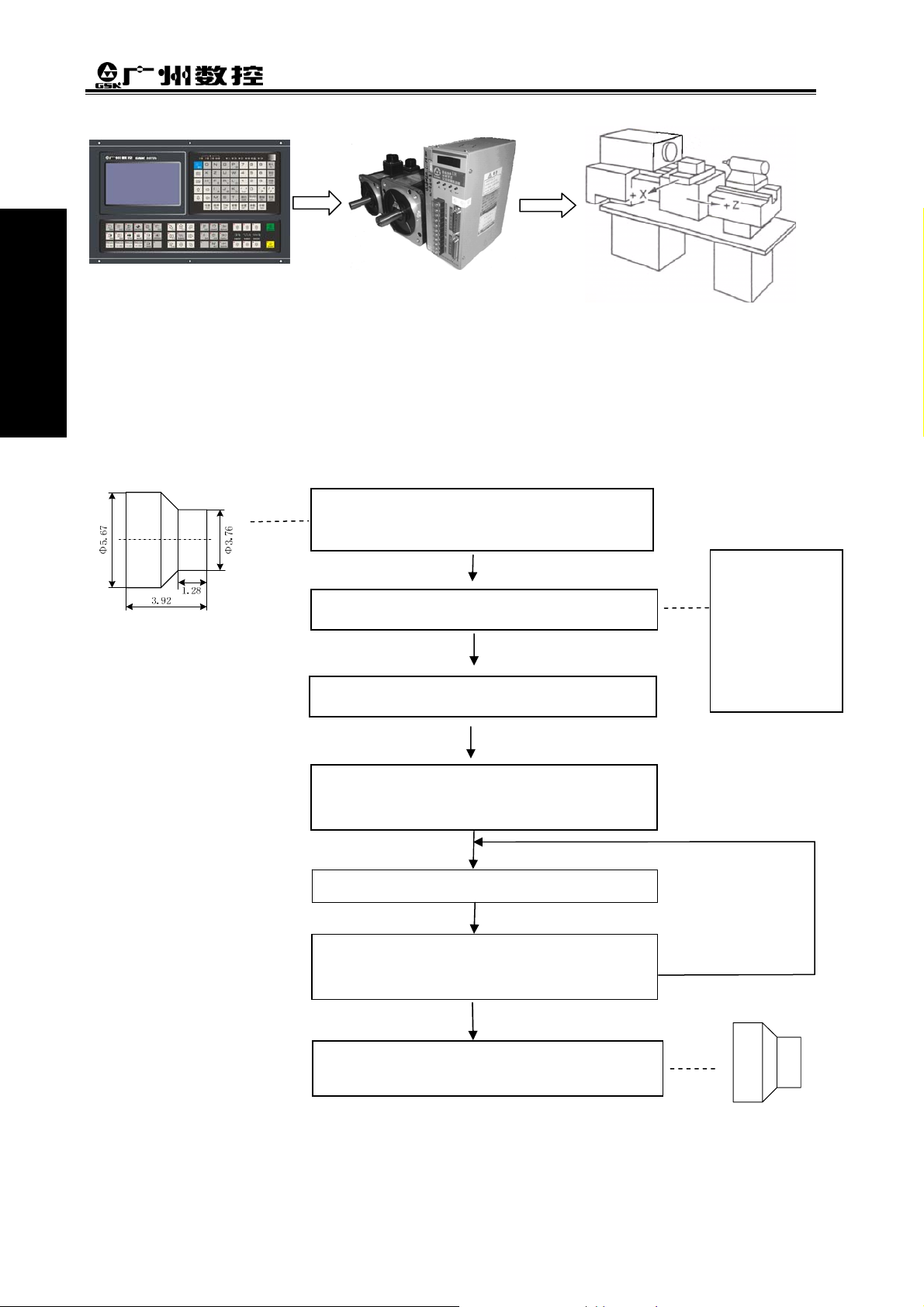

Fig. 1-1

Programming is a course of workpiece contours, machining technologies, technology

parameters and tool parameters being edit into part programs according to special CNC

programming G codes. CNC machining is a course of CNC controlling a machine tool to complete

machining of workpiece according requirements of part programs.

Technical flow of CNC machining is as following Fig. 1-2.

Analyse workpiece drawings and confirm

machining processing

O0001;

G00 X3.76 Z0;

Edit part programs and record into CNC

Test part programs and execute trial run

G01 Z-1.28 F50;

…

M30;

%

Execute toolsetting and set tool offsets and

coordinates

Run part programs and machine workpiece

Check part dimension and modify part

programs and compensations

The machining ends and the workpiece is

formed

Fig. 1-2

6

Chapter 1 Programming

1.3 Programming Fundamentals

1.3.1 Coordinates definition

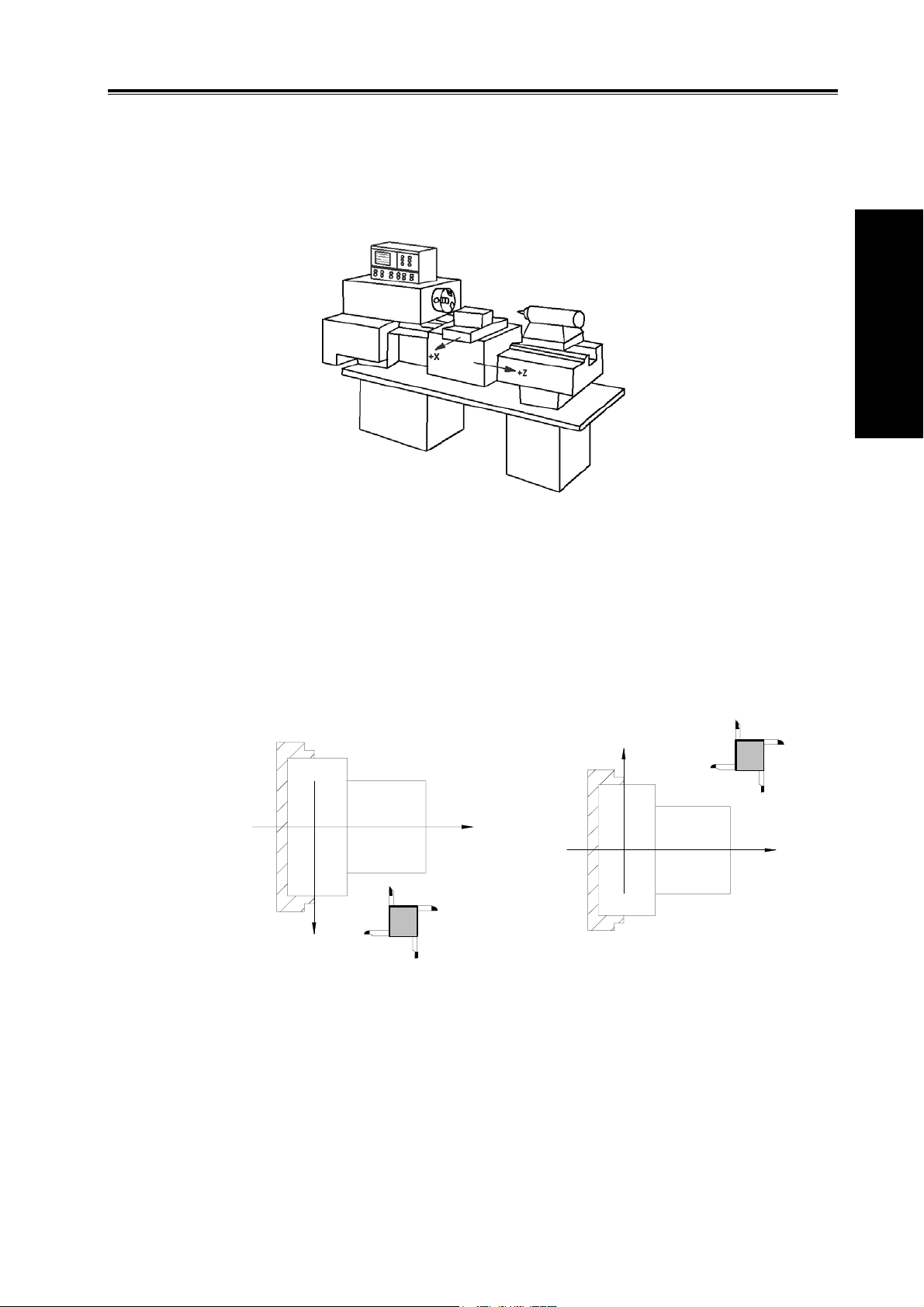

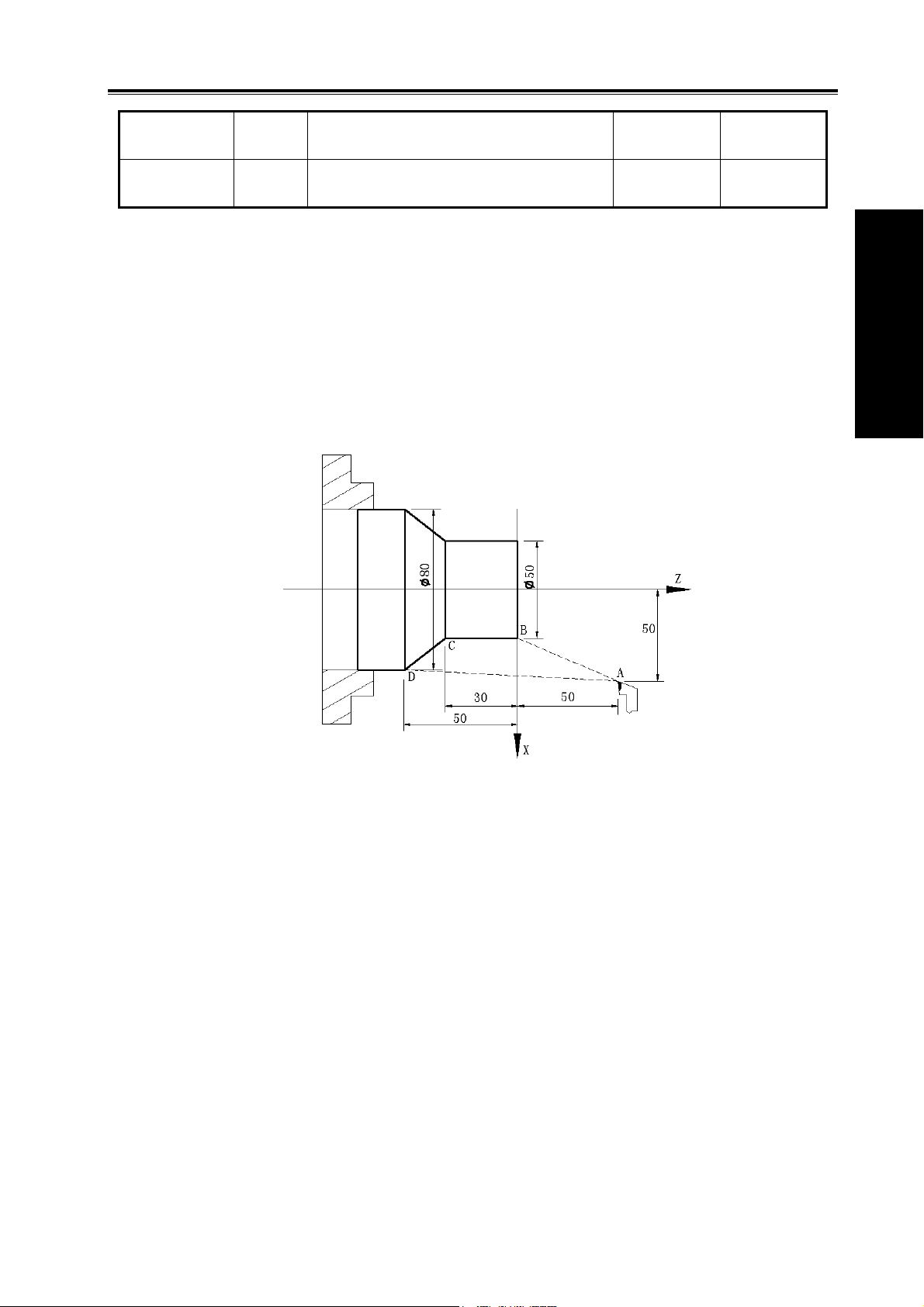

Sketch map of CNC turning machine is as follows:

Fig. 1-3

GSK980TDc uses a rectangular coordinate system composed of X, Z axis. X axis is

perpendicular with axes of spindle and Z axis is parallel with axes of spindle; negative directions of

them approach to the workpiece and positive ones are away from it.

There is a front tool post and a rear tool post of NC turning machine according to their relative

position between the tool post and the spindle, Fig. 1-4 is a coordinate system of the front tool post

and Fig. 1-5 is a rear tool post one. It shows exactly the opposite of X axes, but the same of Z axes

from figures. In the manual, it will introduce programming application with the front tool post

coordinate system in the following figures and examples.

Ⅰ Programming

X

Z

Z

X

Fig.1-4 Front tool post coordinate system Fig.1-5 Rear tool post coordinate system

1.3.2 Machine coordinate system, Machine Zero and machine reference point

Machine tool coordinate system is a benchmark one used for CNC counting coordinates and a

fixed one on the machine tool. Machine tool zero is a fixed point which position is specified by zero

switch or zero return switch on the machine tool. Usually, the zero return switch is installed on max.

stroke in X, Z positive direction. Machine reference point is located at the position at which the

machine zero value adding the data parameter No.114/No.115 value. When No.114/No.115 value is 0,

the machine reference point coincides with the machine zero. The coordinates of machine reference

7

GSK980TDc Turning CNC System User Manual

point is the No.120/No.121 value. Machine zero return/G28 zero return is to execute the machine

reference point return. After the machine zero return/machine reference point return is completed,

GSK980TDc machine coordinate system which takes No.120 value as the reference point, which is

referred to I Programming, Section 3.13.

Note: Do not execute the machine reference point return without the reference point switch installed on the

machine tool, otherwise, the motion exceeds the travel limit and the machine to be damaged.

Ⅰ Programming

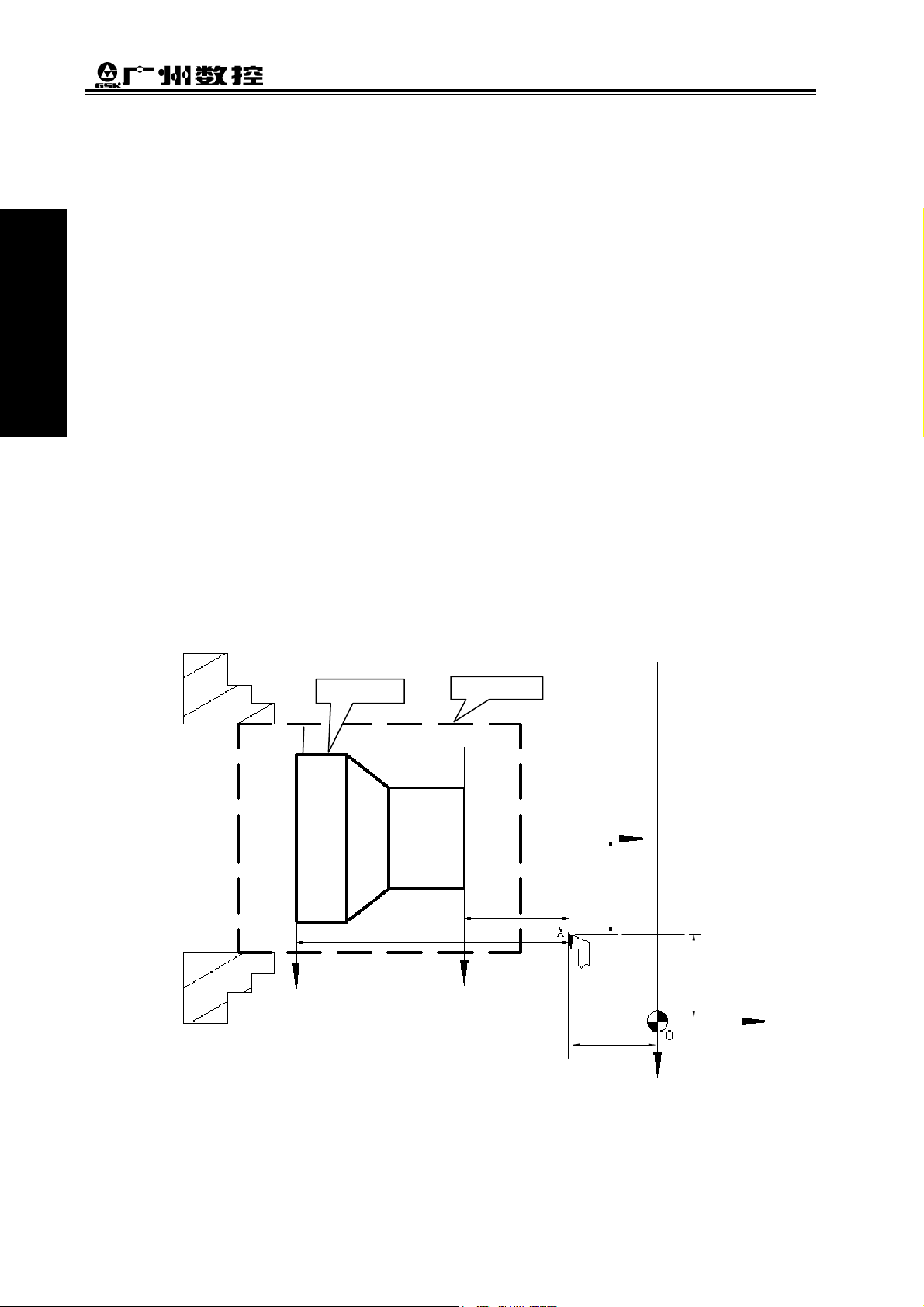

1.3.3 Workpiece coordinate system and Program Zero

The workpiece coordinate system is a rectangular coordinate system based on the part drawing,

also called floating coordinate system. After the workpiece is installed on the machine, the absolute

coordinates of tool’s current position is set by G50 according to the workpiece’s measure, and so the

workpiece coordinate system is established in CNC. Generally, Z axis of the workpiece coordinate

system coincides with the spindle axis. The established workpiece is valid till it is replaced by a new

one. The system can set 6 workpiece coordinate systems G54~G59 in advance. Refer to I

Programming, Section 3.18 about the details of workpiece coordinate system.

A sub workpiece coordinate system is created in a workpiece coordinate system, which is called