Graco XM6A00, XM3A00, XM7A00, XM1B00, XM8A00 Operation Manual

...

Operation

™

XM

Plural-Component

312359J

Sprayers

For spraying two-component epoxy and urethane protective coatings in hazardous and

non-hazardous locations.

For professional use only.

EN

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

See page 7 for model information and agency approvals.

See page 84 for maximum working pressure.

ti21272a

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Isocyanate Hazard . . . . . . . . . . . . . . . . . . . . . . . 9

Material Self-Ignition . . . . . . . . . . . . . . . . . . . . . . 9

Moisture Sensitivity of Isocyanates . . . . . . . . . . . 9

Components A and B . . . . . . . . . . . . . . . . . . . . 10

Changing Materials . . . . . . . . . . . . . . . . . . . . . . 10

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Proper Lifting of Sprayer . . . . . . . . . . . . . . . . . . . 11

Initial System Setup . . . . . . . . . . . . . . . . . . . . . . . 12

Component Identification . . . . . . . . . . . . . . . . . . . 13

Typical Setup: 20 Gallon Hoppers with Recirculation

(Front View) . . . . . . . . . . . . . . . . . . . . . . . . 13

Typical Setup: 20 Gallon Hoppers with Recirculation

(Back View) . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fluid Control Assembly . . . . . . . . . . . . . . . . . . . 15

Junction Box/Heater Controls . . . . . . . . . . . . . . 16

Air Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connect Power Cord . . . . . . . . . . . . . . . . . . . . . 19

Configure to Supply Power . . . . . . . . . . . . . . . . 20

Wire Sprayers with Explosion-Proof Heaters . . 21

Connect Air Supply . . . . . . . . . . . . . . . . . . . . . . 21

Connect Fluid Hose Assembly . . . . . . . . . . . . . 22

Adjust Packing Nuts . . . . . . . . . . . . . . . . . . . . . 22

Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Power On (Alternator Power Supplied Systems) 23

Power On (Wall Power Supplied Systems) . . . . 23

Adjust Ratio and Setup . . . . . . . . . . . . . . . . . . . 23

Final Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

View Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Set System Settings (Optional) . . . . . . . . . . . . . 24

Set Maintenance Parameters (Optional) . . . . . . 25

Set Sprayer Limits (Optional) . . . . . . . . . . . . . . 26

Prime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Prime A and B Fluids . . . . . . . . . . . . . . . . . . . . 27

Prime Solvent Flush Pump . . . . . . . . . . . . . . . . 29

Recirculate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Without Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

With Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Heat Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Adjust B Machine Outlet Restriction . . . . . . . . . . 33

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 34

Flush Mixed Material . . . . . . . . . . . . . . . . . . . . . . . 36

Park Fluid Pump Rods . . . . . . . . . . . . . . . . . . . . . . 38

Shutdown Entire System . . . . . . . . . . . . . . . . . . . . 39

System Verification . . . . . . . . . . . . . . . . . . . . . . . . 40

Mix and Integration Tests . . . . . . . . . . . . . . . . . . 40

Pump and Metering Test . . . . . . . . . . . . . . . . . . 40

Batch Ratio Dispense Test . . . . . . . . . . . . . . . . 43

Down Stream Valve Leak Test . . . . . . . . . . . . . . 44

XM Setup and Troubleshooting Guide . . . . . . . . 45

Empty and Flush Entire System

(new sprayer or end of job) . . . . . . . . . . . . . . 46

Download Data from USB . . . . . . . . . . . . . . . . . . . 48

USB Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Download Setup . . . . . . . . . . . . . . . . . . . . . . . . 48

Download Procedure . . . . . . . . . . . . . . . . . . . . . 48

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . 50

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

View Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Diagnose Alarms . . . . . . . . . . . . . . . . . . . . . . . . 51

Clear Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Alarm Codes and Troubleshooting . . . . . . . . . . 52

LED Diagnostic Information . . . . . . . . . . . . . . . . 58

Accessories and Kits . . . . . . . . . . . . . . . . . . . . . . . 59

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

User Interface Display . . . . . . . . . . . . . . . . . . . . 61

Setup Mode Screens . . . . . . . . . . . . . . . . . . . . . 62

Operator Command Functions Screens . . . . . . 69

Auto Display Screens . . . . . . . . . . . . . . . . . . . . 75

Appendix B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Metering Diagrams . . . . . . . . . . . . . . . . . . . . . . 77

Appendix C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Power Cord Guidelines . . . . . . . . . . . . . . . . . . . 79

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

System Dimensions without Hoppers . . . . . . . . 80

System Dimensions with Hoppers . . . . . . . . . . . 81

System Dimensions with Hoppers . . . . . . . . . . . 82

Pump Performance Charts . . . . . . . . . . . . . . . . . . 83

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 86

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 86

2 312359J

Related Manuals

Manuals are available at www.graco.com.

Component Manuals in U.S. English:

Manual Description

313289

313292

311762

311238

312747

309524

312145

312769

312794

406699

406739 Desiccant Kit Instructions-Parts

406690 Caster Kit Instructions-Parts

XM Plural-Component Sprayers

Repair-Parts

XM Plural-Component OEM Sprayers

Instructions-Parts

®

Xtreme

Displacement Pumps

Instructions-Parts

™

NXT

Air Motor Instructions-Parts

Double Wall Hopper Kit

Instructions-Parts

®

Viscon

XTR

HP Heater Instructions-Parts

™

5 and XTR™ 7 Spray Guns

Instructions-Parts

Feed Pump and Agitator Kits

Instructions-Parts

®

Merkur

Pump Assembly

Instructions-Parts

7-Gallon Hopper Installation Kit

Instructions-Parts

Related Manuals

406691 Hose Rack Kit Instructions-Parts

313258

313259

312770

312749

313293

313342

313343

Electric Heated Hose Power Supply Kit

Instructions-Parts

Hopper or Hose Heat Circulation Kit

Instructions-Parts

Lower Strainer and Valve Kit

Instructions-Parts

XM Mix Manifold Kit

Instructions-Parts

Alternator Conversion Kits

Instructions-Parts

Dosing Valve Repair Kit

Instructions-Parts

High Flow Severe Duty Shutoff Check

Valve Repair Kit Instructions-Parts

312359J 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

• Do not connect USB device in explosive atmospheres.

SPECIAL CONDITIONS FOR SAFE USE

• To prevent the risk of electrostatic sparking, the equipment’s non-metallic parts must be cleaned with

only a damp cloth.

• Refer to the Viscon HP Heater manual for special conditions for safe use.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

4 312359J

Warnings

WARNING

INTRINSIC SAFETY

Intrinsically safe equipment that is installed improperly or connected to non-intrinsically safe equipment

will create a hazardous condition and can cause fire, explosion, or electric shock. Follow local regulations and the following safety requirements.

• Only models with model number XM_D_ _ or XM_E_ _, and packaged models with part numbers

ending in 00-13, 17-23, 27-29, 31, utilizing the air-driven alternator are approved for installation in a

Hazardous (explosive atmosphere) Location - see Approvals:, page 8. Only the models stated

above meet all local safety fire codes including NFPA 33, NEC 500 and 516, and OSHA 1910.107.

To help prevent fire and explosion:

• Do not install equipment approved only for a non-hazardous location in a hazardous location.

See model ID label for intrinsic safety rating of your model.

• Do not substitute system components as this may impair intrinsic safety.

• Equipment that comes in contact with the intrinsically safe terminals must be rated for Intrinsic

Safety. This includes DC voltage meters, ohmmeters, cables, and connections. Remove the unit

from the hazardous area when troubleshooting.

• Do not connect, download, or remove USB device unless unit is removed from the hazardous (explosive atmosphere) location.

• If explosion-proof heaters are used, ensure wiring, wiring connections, switches, and electrical distribution panel all meet flame-proof (explosion-proof) requirements.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

•Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

•Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

312359J 5

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

6 312359J

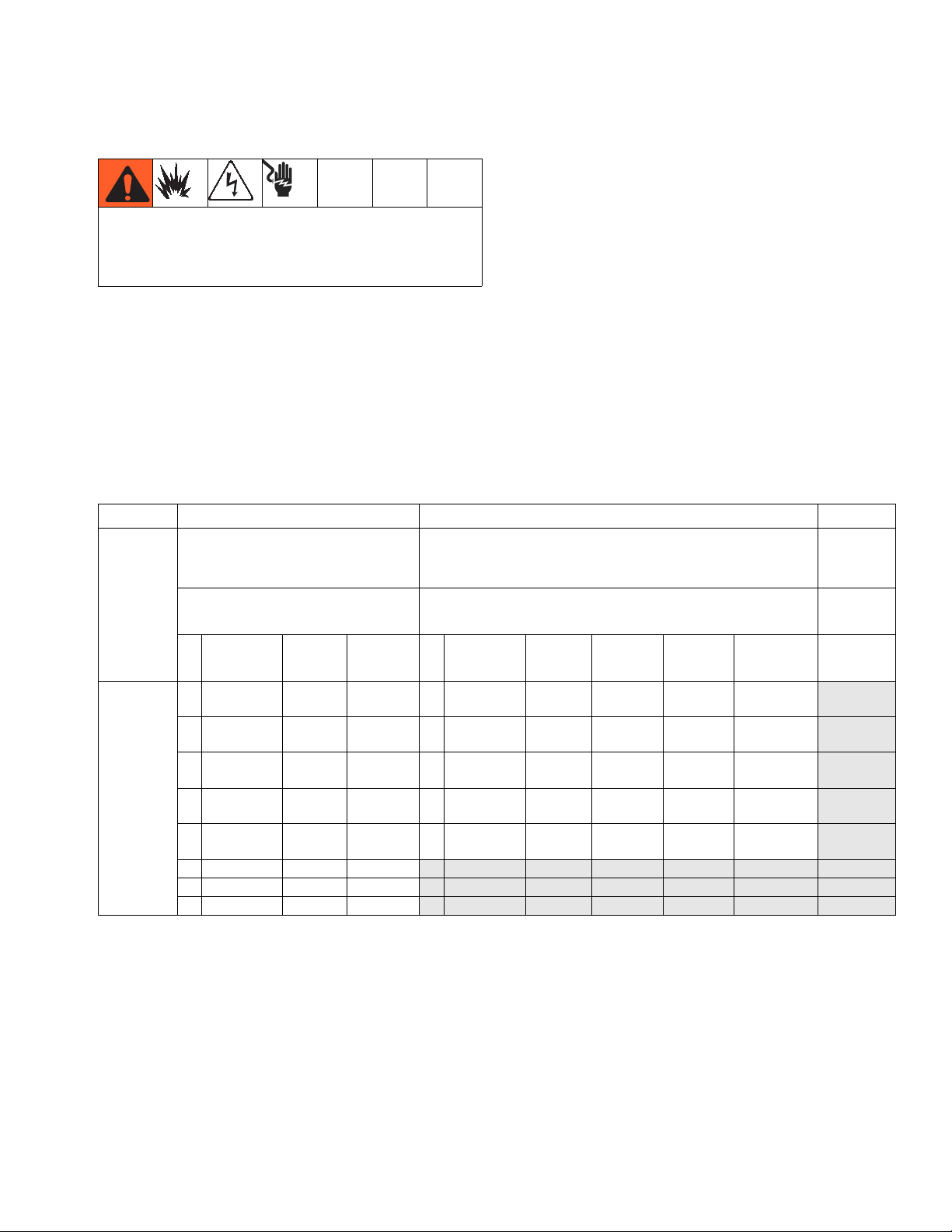

Models

Models

XM sprayers are not approved for use in hazardous

locations unless the base model, all accessories, all

kits, and all wiring meet local, state, and national

codes.

Check the identification plate (ID) for the 6-digit part number of the sprayer. Use the following matrix to define the

construction of the sprayer, based on the six digits. For example, Part XM1A00 represents an XM Plural-Component

sprayer (XM); 5200 psi pump set with pump filters (1); wall power supply, no heaters, no junction box, and is not

approved for hazardous areas (A); with no additional kits (00).

NOTE:

Some configurations in the following matrix cannot be built. Consult with distributor or Graco representative.

To order replacement parts, see Parts section the XM Plural-Component Sprayer Repair-Parts manual 313289. The

digits in the matrix do not correspond to the Ref. Nos. in the Parts drawings and lists.

XM 1 A

First and

Second

Digits

XM

(plural com-

ponent

sprayer

mounted

on a frame)

(See Table 1 for lower models) Kit Choice

Pump Set

(hose/gun)

1 5200 psi

2 5200 psi B

3 6300 psi

4 6300 psi D

5 5200 psi

6 5200 psi

7 6300 psi

8 6300 psi

Third Digit Fourth Digit

System Choice

Pump

Filters

✔

✔

✔✔

✔✔

Remote

Manifold

✔

✔

Control

Box

Wall Power

A

Supply NE

Wall Power

Supply

Wall Power

C

Supply

IS/

Alternator EH

IS/

E

Alternator

Fluid

Heaters

Location Category Key:

Junction

Box

✔✔

✔

✔

Location

Category

Approvals

(see page 8

for approvals

CE, FM,

FMc

NE CE, FM,

c

FM

NE CE, FM,

FMc

CE, FM,

FMc, Ex

EH

CE, FM,

FMc, Ex

00

Fifth and

Sixth

Digits

Additional

Kit

See Table

2 for

)

selections

NE Not for use in explosive atmospheres.

EH For use in explosive atmospheres and hazardous

locations

312359J 7

.

Models

Approvals:

See appropriate column on page 7.

XM _ A_ _

XM _ B_ _

XM _ C_ _

XM _ D_ _

XM _ E_ _

Intrinsically safe for Class I, Div 1, Group D, T2

Class I, Division 1, Group D, T2

Ta = 0°C to 54°C

See Special Conditions for Safe Use in Warnings, page 4.

FM09ATEX0015X

II 2 G

Ex d ia px IIA T2 Tamb = 0ºC to 54ºC

Table 1: Lower Models and Corresponding Identification Codes

System Pressure

Code

(MPa, bar)

1 or 5 5200 psi (35, 350)

Pump

Filters

✔

A Lower

(see manual 311762)

L250C4 L220C4

B Lower

(see manual 311762)

2 or 6 5200 psi (35, 350) L250C3 L220C3

3 or 7 6300 psi (49, 490)

✔

L180C4 L145C4

4 or 8 6300 psi (49, 490) L180C3 L145C3

Table 2: Additional Kits - Identification Code/Part No. Index

7 Gal.

Hopper

Hopper

20 Gal.

Hopper

Kit

00

11 1111 1

13 11111

14 11111 1

15 11 11 1 1

16 11 11 11

17 1111 1 1

19 11111 1

21 2222

23 2222

24 22222

25 22 22 2

26 22 22 2

27 2222 1

29 2222 1

30 2

31 2

32 11

Hopper

Heater

Kit 240V

Hopper

Fluid

Inlet Kit

Universal

Mount

Kit

Twi stork

Agitator

Kit

T2 Pump

Feed Kit

(on

hopper)

5:1 Pump

Feed Kit

(on

hopper)

(Green)

and

Bracket

Kit

7 Gal.

Hopper

(Blue)

and

Bracket

Kit

Drum

Feed Kit

(Dual T2

and

Agitator)

Drum

Feed Kit

(Dual 5:1

and

Agitator)

Heated

Hopper/

Hose

Circulation

Kit

NOTE:

See Accessories and Kits, page 59, for more information.

See Related Manuals, page 3, for kit manual numbers.

8 312359J

Overview

Overview

Usage

XM plural-component sprayers can mix and spray most

two-component epoxy and urethane protective coatings.

When using quick-setting materials (less than 10 minute

pot life) a remote mix manifold must be used.

XM plural-component sprayers are operated via the user

interface, air controls, and fluid controls.

XM sprayers are not approved for use in hazardous

locations unless the base model, all accessories, all

kits, and all wiring meet local, state, and national

codes. See Models, page 7, to determine the appropriate location for your particular sprayer model.

Isocyanate Hazard

Spraying materials containing isocyanates creates

potentially harmful mists, vapors, and atomized particulates.

Material Self-Ignition

Some materials may become self-igniting if applied

too thick. Read material manufacturer’s warnings and

material MSDS.

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

urethane coatings. ISO will react with moisture (such as

humidity) to form small, hard, abrasive crystals, which

become suspended in the fluid. Eventually a film will

form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

NOTE:

The amount of film formation and rate of crystallization

varies depending on the blend of ISO, the humidity, and

the temperature.

To prevent exposing ISO to moisture:

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always park pumps when you shutdown.

• Always lubricate threaded parts with Part 217374

ISO pump oil or grease when reassembling.

312359J 9

Overview

Components A and B

IMPORTANT!

Material suppliers can vary in how they refer to plural

component materials.

Be aware that in this manual:

Component A refers to resin or major volume.

Component B refers to the hardener or minor volume.

NOTE:

This equipment doses the B component into the A component flow. An integration hose must always be used

after the mix manifold and before the static mixer.

NOTE:

Follow these recommendations for setup:

• use at least a 3/8 in. (10 mm) x 25 ft. (7 m) hose as

the integration hose.

• install a 24-element static mix tube after the integration hose.

Changing Materials

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers and outlet filter

after flushing, Flush Mixed Material, page 36.

• Check with your material manufacturer for chemical

compatibility.

• Epoxies often have amines on the B (hardener)

side. Polyureas often have amines on the A (resin)

side.

NOTE:

If the amine will switch between the two sides, see

Flush Mixed Material, page 36.

Keep Components A and B Separate

NOTICE

To prevent cross-contamination of the equipment’s wetted parts, never interchange component A (resin) and

component B (hardener) parts.

10 312359J

Location

Location

XM sprayers are not approved for use in hazardous

locations unless the base model, all accessories, all

kits, and all wiring meet local, state, and national

codes. See ModelsModels, page 7, to determine the

appropriate location for your particular sprayer model.

Grounding

Connect the XM sprayer ground wire clamp (FG) to a

true earth ground. If wall power is used to power controls or heaters, ground electrical connection properly

according to local codes.

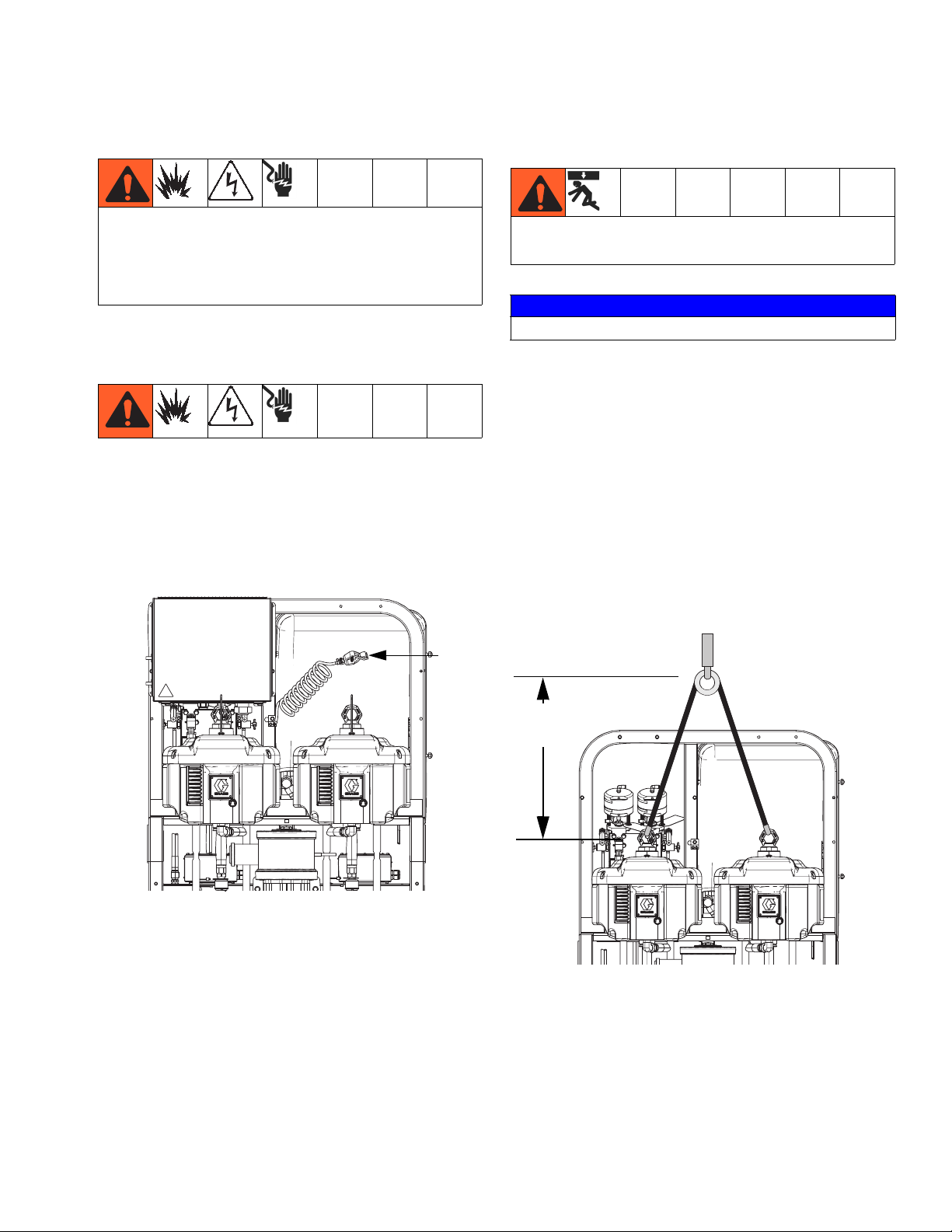

Proper Lifting of Sprayer

Follow instructions to avoid serious injury or damage

to equipment. Never lift with the hopper(s) filled.

NOTICE

Drain all fluid prior to lifting sprayer.

Lift Using a Forklift

Power must be off. Sprayer can be raised and moved

using a forklift. Carefully lift the sprayer; make sure it

balances evenly.

Lift Using a Hoist

Sprayer can also be lifted and moved using a hoist. Connect a bridle swing, hooking an end to each of the air

motor lift rings. Hook the center ring to a hoist. See the

following figure. Carefully lift the sprayer; make sure it

balances evenly.

ti21273a

FG

2.0 ft. (0.61 m)

minimum

ti21274a

312359J 11

Initial System Setup

Initial System Setup

Complete the following steps in the order they are listed,

as they apply to your specific system, for initial system

setup.

1. Check your shipment for accuracy. Ensure you have

received everything you ordered. See Component

Identification, page 13, to familiarize yourself with

typical system components.

2. Mount caster kit, if ordered. See manual 406690 for

instructions.

3. Mount hopper brackets, if ordered. See manual

312747 for instructions.

4. Loosely mount hoppers, if ordered, on brackets. See

manual 312747 for instructions.

5. Connect bottom hopper outlet if using a gravity feed

pump. See manual 312747 for instructions.

6. Tighten hopper mounting bolts. See manual 312747

for instructions.

7. Mount and connect agitator(s) and feed pump(s), if

ordered. See manual 312769 for instructions.

15. For hazardous location sprayers, connect explosion-proof heaters. See Wire Sprayers with Explo-

sion-Proof Heaters, page 21, and manual 309524

for instructions and recommendations.

16. Connect air supply line. See Connect Air Supply,

page 21, for instructions and recommendations.

17. Connect fluid hose assembly, including whip hose

and gun. See Connect Fluid Hose Assembly,

page 22, for instructions. Also connect remote mix

manifold, if ordered. See manual 312749 for instructions.

8. Mount and connect hopper immersion heater kit, if

ordered. See manual 312747 for instructions.

9. Connect recirculation hose, restrictor valve (including knob and nipple), and recirculation tube. Place

in hopper or drum. See manual 312747 for instructions.

10. Replace USB label (front of control panel) with correct language version, if needed.

11. Replace Alarms Codes label (under fluid control

valves) with correct language version, if needed.

12. Install hopper/hose heated circulation kit, if ordered.

See manual 313259 for instructions.

13. For non-hazardous location sprayers, connect

power cord (not supplied). See Connect Power

Cord, page 19, for instructions.

14. For non-hazardous location sprayers, connect junction box wiring for immersion or recirculation heaters. See manual 312747 for immersion heater

instructions. See manual 309524 for recirculation

heater instructions.

12 312359J

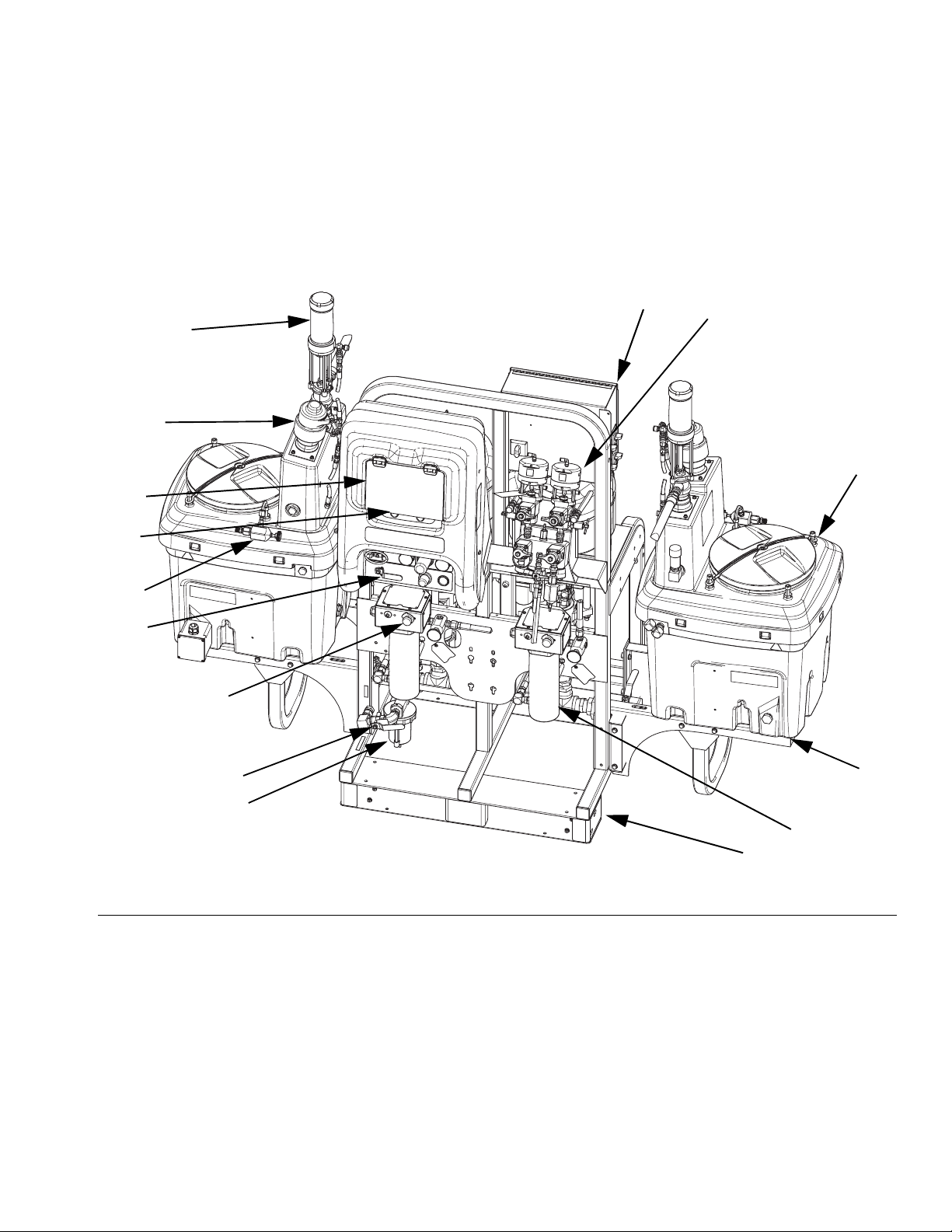

Component Identification

Component Identification

Typical Setup: 20 Gallon Hoppers with Recirculation (Front View)

L

P

N

F

G

R

J

B

C

M

E

H

K

A

D

ti21272a

FIG. 1: Typical Setup: 20 Gallon Hoppers with Recirculation (Front View)

AFrame

B Fluid Control Assembly (see Fluid Control Assembly,

page 15)

C 20 Gallon Hopper Assembly (see manual 312747)

D 20 Gallon Hopper Bracket (see manual 312747)

E Main Air Valve

F GCA Control Display (see User Interface Display, page

18)

312359J 13

G Pump Control On and Off Buttons

H Air Filter

J Air Controls

K Viscon HP Fluid Heater

L Junction Box/Heater Controls (see Junction Box/Heater

Controls, page 16)

M Inline Fluid Heater Control

N Air Powered Agitator

P Pressure Feed Pump

R Recirculation Control Valve

Component Identification

Typical Setup: 20 Gallon Hoppers with Recirculation (Back View)

S

T

FIG. 2: Typical Setup: 20 Gallon Hoppers with Recirculation (Back View)

S Air Motor

T High Pressure Fluid Pump

U Solvent Flush Pump (Merkur

V Fluid Inlet Assembly

®

Pump)

U

V

14 312359J

Fluid Control Assembly

Component Identification

AC

AL

AE

AH

AA

AB

AD

AF

AG

AM

AJ

AK

r_XM1A00_312359_313289_18A

FIG. 3: Fluid Control Assembly

AA Dosing Valve A

AB Dosing Valve B

AC Recirculation Valve A

AD Recirculation Valve B

AE Sampling Valve A

312359J 15

AF Sampling Valve B

AG Restriction Valve

AH Mix Manifold Shutoff / Check Valve A

AJ Mix Manifold Shutoff / Check Valve B

AK Solvent Shutoff Valve

AL Pressure Sensor

AM Solvent Check Valve

Component Identification

Junction Box/Heater Controls

BA

FIG. 4: Junction Box/Heater Controls

BB

BC

BE

BD

BA Main Power Disconnect Switch

BB Fluid Heater A Control

BC Fluid Heater B Control

Air Controls

CA

CB

FIG. 5: Air Controls

BD Hopper Heater A Control

BE Hopper Heater B Control

CC

CD

CE

CF

CG

r_XM1A00_312359_313289_14A

CA Main Pump and Air On/Off Control

CB Solvent Pump Air On/Off Control

CC Inlet Air Pressure Gauge

CD Main Pump Air Regulator

16 312359J

CE Main Pump Air Regulator Gauge

CF Solvent Pump Air Gauge

CG Solvent Pump Air Regulator

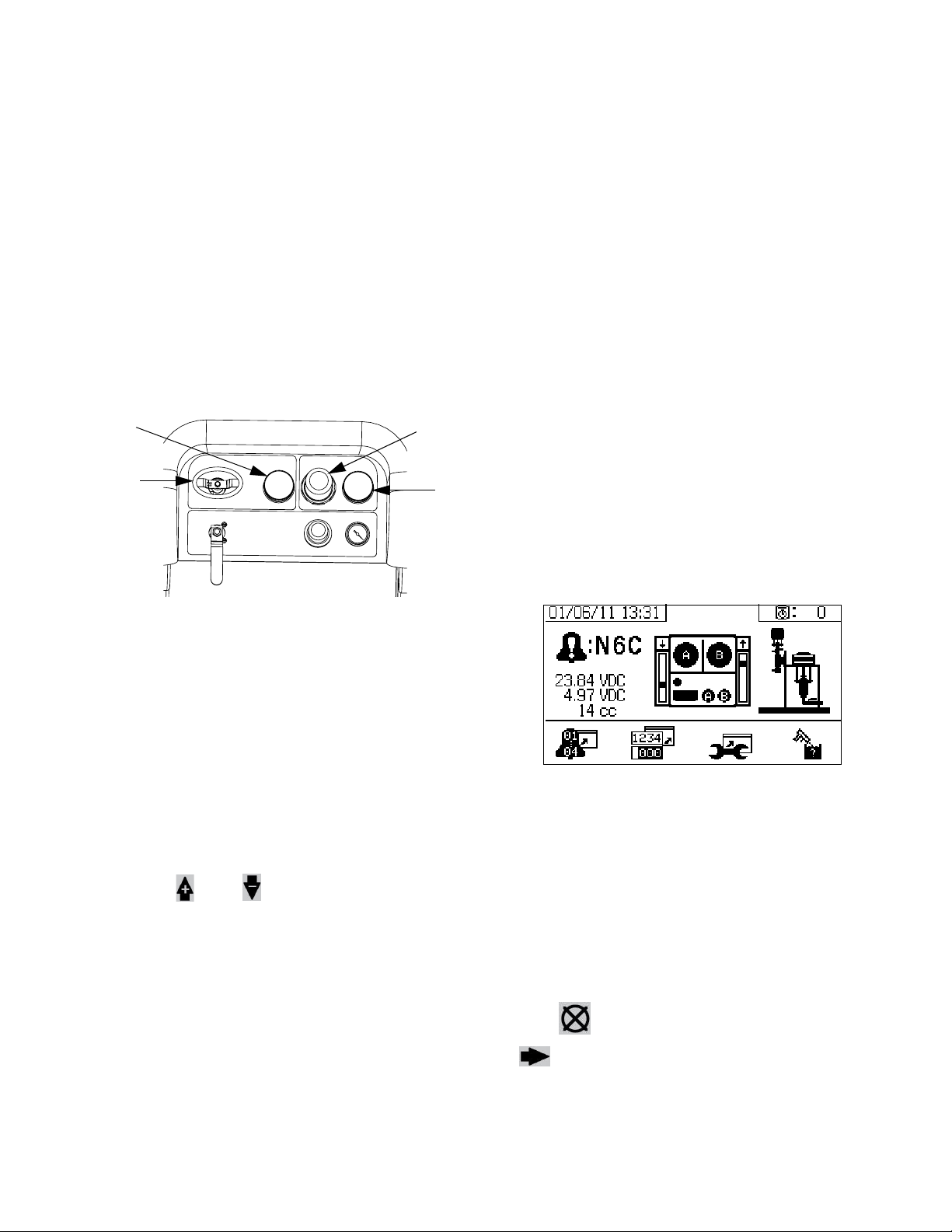

User Interface

Component Identification

DJ

IG. 6: User Interface

F

DR

DA

DG

DF

DD

DM

DB

Buttons LEDs

DK

DC

ti13365a

DN

DH

DE

DP

Call

out Button Function

DA Display

Screen

DB Start Initiates Active Run Mode function cur-

DC Stop Terminates Active Run Mode function

DD Enter Press to open drop-down fields, selection

DE Alarm

Reset

DF Left/Right Move between screens in run or setup

DG Function Activates mode or action represented by

DH Up/Down Move between selection boxes,

DJ Setup Key

Lock

DR USB Port Connection for data download. Use only

Use to view Ratio, Mode Selection, Error

Conditions, Totalizers, System Information.

rently selected in Run Screen.

currently selected.

options, and save values.

Resets alarms and advisories.

modes.

the icon above each of the four buttons in

the LCD.

drop-down fields, and selectable values

within Setup screens.

Change ratio or enter Setup mode.

in non-hazardous locations.

There are four types of LEDs on the display.

Call

out LED Function

DK Blue Dosing valve active

• on - dosing valve is active

• off - dosing valve is not active

DM Green Spray mode active

• spray mode is on (active)

• spray mode is off (inactive)

DN Red Alarm

• on - alarm is present

• off - no alarm

DP Yellow Warning

• on - is active.

• off - no warning indicated. Ratio

and setup fields are not changeable.

• flashing - key is present and

turned. Ratio and setup fields

are changeable.

312359J 17

Component Identification

User Interface Display

NOTE:

For details regarding the user interface display see User

Interface Display, page 61.

Main Display Screen Components

The following figure calls out the navigational, status, and general informational components of each display screen.

Current Date and Time

Current Status Bar

Navigate to screens

within same group

Navigational Bar

F

IG. 7: Main Display Screen Components (shown with all display features enabled)

Remaining Potlife Time

Function Display

Go back one screen

NOTICE

To prevent damage to soft key buttons, do not press

the buttons with sharp objects such as pens, plastic

cards, or fingernails.

18 312359J

Setup

Setup

Connect Power Cord

(For sprayers with heater junction boxes.

Non-hazardous location sprayers only.)

Graco does not supply heater junction box power cords.

Use the following chart to determine which power cord

your specific model requires.

Power Cord Requirements

2

Voltage Cord Specification AWG (mm

240V, 1 PH 4 (21.2) 2 wire + ground

240V, 3 PH 6 (13.3) 3 wire + ground

380V, 3 PH 6 (13.3) 4 wire + ground

NOTE:

Sprayers without heaters for non-hazardous locations

include a U.S. style NEMA 5-15 power cord and an

IEC-320 power cord. (European and Australian adapters

are also included.) These power cords are rated for

90-240 Vac, 47-63 Hz. See the XM Plural-Component

Sprayers Repair-Parts manual or the XM Plural-Component OEM Sprayers Instructions-Parts manual for part

numbers.

)

230V, 1 Phase: Use a screwdriver to connect two power

leads to the top terminals N and L2 positions. Connect

green to ground (GND).

L2

L1

7L4

L1 L2 L3N

1L1

ti8611a

123N

L1

N

PE

GRND

G

L3

L2

230V, 3 Phase Delta: Use a screwdriver to connect

three power leads to top terminals L1, L2, and L3. Connect green to ground (GND).

PE

L3

L2

L1

L1 L2 L3N

1L1

ti8612a

123N

GRND

G

L3

L1

N

L2

380V, 3 Phase WYE: Use a screwdriver to connect three

power leads to the top terminals L1, L2, and L3. Connect

neutral to N. Connect green to ground (GND).

NOTE:

Disregard terminal numbers on disconnect switch

blocks. Wire to positions shown.

1. Open junction box cover.

N

7L4

L1 L2 L3

1L1

ti8613a

L1N

123N

GRND

G

L3

L1

N

L2

PE

L3

L2

2. Connect electrical cord as follows.

312359J 19

Setup

Configure to Supply Power

(Non-hazardous location sprayers only.)

NOTE:

Disregard terminal numbers on disconnect switch

blocks. Wire to positions shown.

1. Locate power jumpers.

2. Use a flat-blade screwdriver to move red jumpers

from storage positions to positions for your power as

shown below. Push jumpers firmly into new position.

NOTE:

For 230V, 1 Phase and 230V, 3 Phase Installations,

change jumper positions as shown below. Machine is

shipped with jumpers in the fail-safe 380 3Ø position.

3. Close junction box cover.

TB2

Terminal Blocks

Position red jumpers

as shown

ti18664a

L3

L2

L1

N

380V 3ø WYE

(as shipped)

Power

Jumpers

N

L1

L2

L3

230V 3ø Delta

N

L1

L2

230V 1ø

L3

20 312359J

Setup

Wire Sprayers with Explosion-Proof Heaters

(Hazardous location sprayers only)

If your sprayer is rated for hazardous areas, and you

have explosion-proof heaters, you must have a qualified electrician connect heater wiring. Ensure wiring

and installation comply with local electrical codes for

hazardous areas.

Improperly installed or connected equipment will create

a hazardous condition and cause fire, explosion, or electric shock. Follow local regulations.

When explosion-proof heaters are used, ensure wiring,

wiring connections, switches, and electrical distribution

panel all meet flame-proof (explosion-proof) requirements.

Refer to Viscon HP heater manual 309524 for electrical

connection instructions and guidelines in hazardous

locations.

Connect Air Supply

Connect air supply line to 3/4 npt(f) air filter inlet.

NOTE:

Use a 3/4 in. (19.1 mm) ID minimum air hose.

E

NOTE:

Air supply requirement: 150 psi (1.0 MPa, 10.3 bar)

maximum; 50 psi (0.35 MPa, 3.5 bar) minimum (while

running).

Flow volume required: 70 scfm (1.96 m

250 scfm (7.0 m

sure and flow rate are directly related to available air volume. See Pump Performance Charts, page 83.

3

/min) maximum. Available fluid pres-

3

/min) minimum;

General flow volume guidelines:

• 70 scfm (1.96 m

spraying

• 10 scfm (0.28 m

• 10 scfm (0.28 m

pump

NOTE:

If your sprayer is for use in hazardous areas, the control

box is powered by an air-driven alternator.

NOTE:

Dosing valves are operated by air. The sprayer will not

operate correctly if the inlet air gauge drops below 50

psi (0.35 MPa, 3.5 bar) while spraying.

3

/min) per gpm (lpm) while

3

/min) added per agitator

3

/min) added per drum feed

312359J 21

Setup

Connect Fluid Hose Assembly

1. Connect fluid hose to fluid manifold outlet. Do not

install gun spray tip yet.

Fluid

Integrator

Hose

NOTICE

Do not assemble static mixer directly to the fluid manifold. Install static mixer after first 25 ft. (7.5 m) of integrator hose to ensure material doses are completely

integrated. Spraying poorly integrated material could

require rework of parts sprayed.

2. Tighten all fittings.

Adjust Packing Nuts

1. Fill A and B pump packing nuts with throat seal liq-

™

uid (TSL

low instructions in Xtreme Lowers manual 311762.

NOTE:

After the first day of use re-torque packing nuts.

2. Fill metering valves A and B packing nuts with throat

seal liquid (TSL) and tighten 1/4 turn after nut contacts packings; about 145-155 in-lbs (16-18 N•m).

r_XM1A00_312359_313289_20A

TSL

NOTE:

For pump and meter valves, check packing nut tightness

after first hour of operation and again after 24 hours.

Then check as needed, or when TSL discolors or seeps

over packing nut. Also check tightness whenever

sprayer is transported. Tighten packing nuts only when

all fluid pressure is relieved.

) and torque to 50 ft-lbs (67.5 N•m). Fol-

TSL

22 312359J

Basic Operation

Basic Operation

Power On (Alternator Power Supplied Systems)

1. Set main pump air regulator (CD) to minimum setting.

2. Open main air valve (E) and main pump and air

valve (CA) to start air-powered alternator.

Main air pressure is displayed on gauge (CC). Fluid

Control screen will display after five seconds.

CC

CA

CD

CE

Final Setup

Perform the following steps if shutting down during

setup.

1. Relieve system pressure. See Pressure Relief Pro-

cedure, page 34.

2. Flush and prime system. See Prime (page 27),

Flush Mixed Material (page 36) and Park Fluid

Pump Rods (page 38).

3. Check ratio accuracy. Run Pump and Metering

Test (page 40) and Batch Ratio Dispense Test

(page 43) to check ratio accuracy.

View Alarms

When an alarm occurs the alarm information screen

automatically displays. It shows the current alarm code

along with a bell icon. It also shows the alarm location

with top and side views of the sprayer

Power On (Wall Power Supplied Systems)

Turn on main power disconnect. Fluid Control screen

will display after five seconds.

Adjust Ratio and Setup

1. Turn key to right (setup position). Yellow LED will

flash and the Home Setup screen will display.

2. Press and to change ratio.

3. When desired ratio is displayed, turn key to left. Yellow LED will turn off.

4. Change optional setup selections to desired parameters, as described in Set System Settings

(Optional), page 24.

There are two levels of error codes: alarms and advisories. A bell icon indicates an alarm. A solid bell icon with

an exclamation point and three audible alerts indicate a

alarm. And an outlined hollow bell icon and a single

audible alert indicate an advisory.

Diagnose Alarms

See Alarm Codes and Troubleshooting, page 52, for

causes and solutions to each alarm code.

Clear Alarms

Press to clear alarms and advisories. Press

to return the run (fluid control) screen.

For more information on alarms and alarm codes, see

Alarms, page 51.

312359J 23

Basic Operation

Set System Settings (Optional)

NOTE:

For details regarding the user interface display screens

see User Interface Display, page 61.

To set user interface parameters and USB parameters,

press from the Home Setup screen.

Set User Interface Parameters

Press from the potlife/hose length screen to

move to the user interface parameters screen.

The following user interface parameters are configurable:

• date format

• date (factory set)

• time (factory set)

• units of measurement for:

• fluid flow rate

•pressure

• temperature

• hose length

To change the date format, press to select the field.

To change the date and time, press to select the

field. Press to make the field selectable. Press

and to scroll through each digit. Press

and to move to the next digit in the field.

Press to save the change.

Set USB Parameters

Press from the user interface parameters

screen to move to the USB parameters screen.

To set the sprayer number, configure the number of

hours downloaded to external USB flash drive, and how

Press to open the drop down field. Press

and to select the preferred format. Press

again to save that date format. Follow this procedure to

change the units of measurement formats as well.

often the data will record: press and to move

through each field. Press to make a field select-

able. Press and to scroll through each digit.

Press and to move to the next digit in

each field. Press to save the change.

24 312359J

Basic Operation

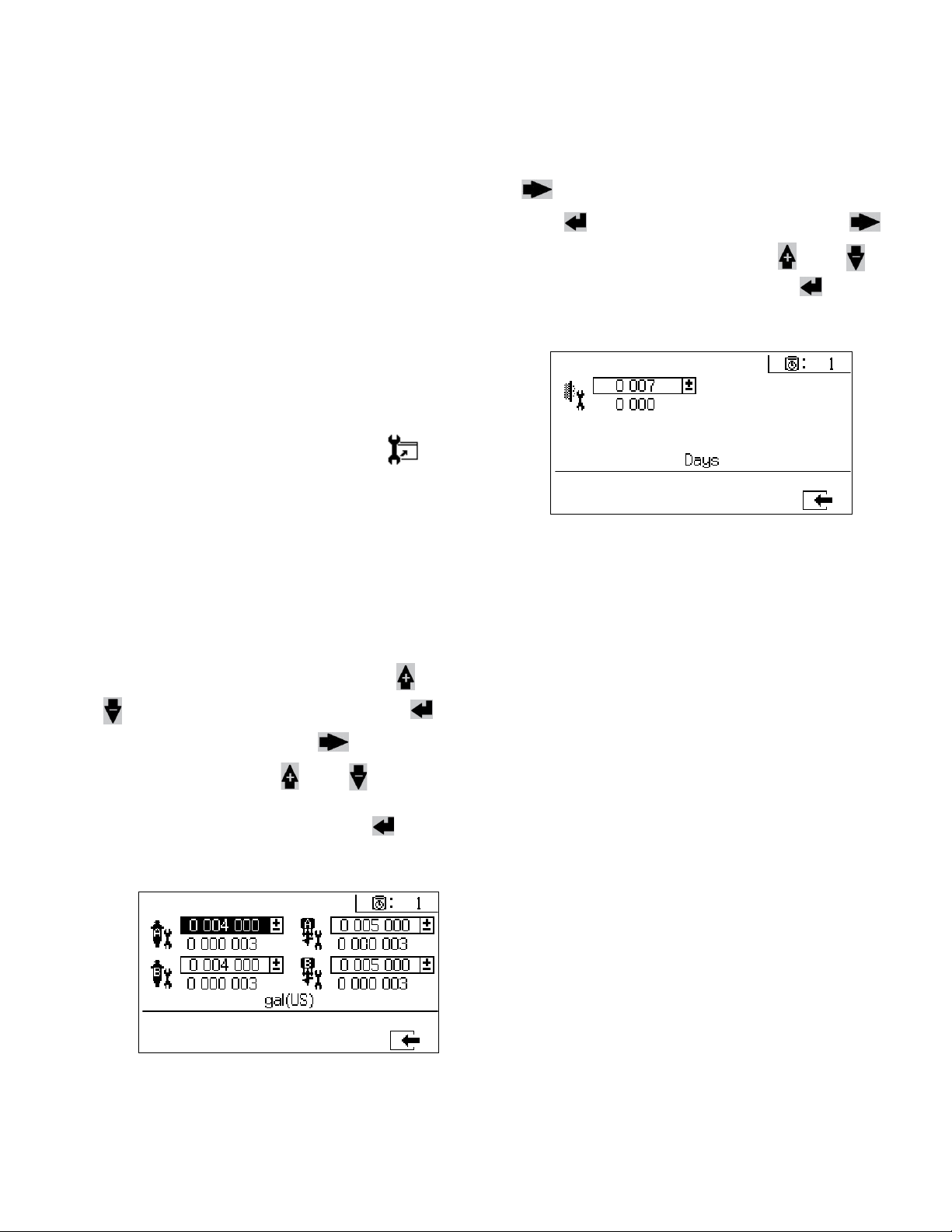

Set Maintenance Parameters (Optional)

NOTE:

Prior to configuring system settings, see Enable Setup

Screens, page 66, to ensure screens shown in this sec-

tion are viewable and configurable. If they are not, follow

instructions in Enable Setup Screens to enable them.

NOTE:

For details regarding the user interface display screens

see User Interface Display, page 61.

To set maintenance parameters for pumps and valves,

including maintenance schedules, press from

the Home Setup screen.

Use the first screen to set maintenance setpoint

amounts for pumps and dosing valves. Use the second

screen to set the maintenance schedule for changing

the incoming air filter.

Set Maintenance Schedule

To set the number of days between changing the incoming air filter that will result in a reminder advisory, press

to move to the Maintenance Setup 2 screen.

Press to make the field selectable. Press

to scroll through each digit, and press and to

scroll through the optional values. Press to save

the number of days value.

Set Maintenance Setpoints

To set maintenance setpoint values, press and

to move through each field, and press to

make a field selectable. Press to scroll through

each setpoint digit. Press and to scroll

through the optional values. Continue this process until

the desired setpoint is reached. Press to save

that setpoint.

312359J 25

Basic Operation

Set Sprayer Limits (Optional)

NOTE:

For details regarding the limits setup screens, see User

Limits Setup Screens, page 68.

To set and adjust pump pressure limits and temperature

limits:

1. Select in the Enable Setup 2 screen. See

Enable Setup Screens, page 66, for instructions.

2. From the Home Setup screen press to jump

to the limits screens.

3. Follow the instructions in Set Pressure Limits and

Set Temperature Limits.

Set Pressure Limits

Set Temperature Limits

Use the following instructions to set temperature limits

that if met will issue an advisory and/or warning.

Press to move to the temperature limits screen.

To set temperature limits, press and to move

through each field, and press to make a field

selectable. Press to scroll through each tempera-

ture digit, and press and to scroll through the

optional values. Continue this process until you reach

your desired temperature limit. Press to save the

value.

NOTE:

The allowable range for the temperature setpoint is 34° 160°F (1° - 71°C).

Use the following instructions to set pressure limits for

each pump that if met will issue an advisory and/or

warning.

To set pressure limits, press and to move

through each field, and press to make a field

selectable. Press to scroll through each pres-

sure digit, and press and to scroll through the

optional values. Continue this process until you reach

the desired pressure limit. Press to save.

NOTE:

The B pump pressure always runs 10-20% higher than

the A pump pressure.

26 312359J

Loading...

Loading...