Graco X5, X7, ProX7, ProX9 User Manual

Operation

™ |

™ |

™ |

™ |

X5, |

X7, |

ProX7 |

& ProX9 |

Airless Sprayers

US Patent 6,752,067 European Patent 1 208 287 Korean Patent 10-0668583

Taiwan Patent No. D124860 for "Pro X7 Airless Paint Sprayer (Design)" Chinese Patent ZL200730154436.7 for Pro X7

- For portable spray applications of architectural paints and coatings -

(Specifications, page 2.)

The manual provided with this sprayer contains English and Español.

Visit our website; http://MAGNUM.Graco.com

312001G

IMPORTANT SAFETY INSTRUCTIONS.

Read all warnings and instructions in this manual. Save these instructions. See page 2 for model and series information including dispense rate, recommended hose length, guns, and maximum working pressure.

Read all warnings and instructions in this manual. Save these instructions. See page 2 for model and series information including dispense rate, recommended hose length, guns, and maximum working pressure.

MAGNUM X5

Model: 262800

X5 & X7 Models ONLY: Use water-based or mineral spirit-type materials only. Do not use materials having flash points lower than 70° F

(21° C). For more information about your material, request MSDS from distributor or retailer.

ti11304a

MAGNUM X7 |

MAGNUM ProX7 |

MAGNUM ProX9 |

Model: 262805 |

Model: 261815 |

Model: 261820 |

ti11305a |

ti9369a |

ti9368a |

|

||

|

|

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2007, Graco Inc. is registered to I.S. EN ISO 9001

Specifications

Specifications

This equipment is not intended for use with flammable or combustible materials used in places such as cabinet shops or other “factory”, or fixed locations. If you intend to use this equipment in this type of application, you must comply with NFPA 33 and OSHA requirements for the use of flammable and combustible materials.

|

|

Dispense |

Hose Length and |

Gun |

Maximum Working |

||||

|

|

|

Pressure |

|

|||||

Model Name |

Series |

Rate gpm |

|

|

|||||

Diameter |

Model |

|

|

|

|

|

|||

|

|

(lpm) |

PSI |

|

MPa |

|

bar |

||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

MAGNUM X5 |

A |

0.24 gpm |

1/4 in. x 25 ft |

SG10 |

2800 |

|

19 |

|

193 |

(0.91 lpm) |

(6.4 mm x 7.5 m) |

|

|

||||||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

MAGNUM X7 |

A |

0.31 gpm |

1/4 in. x 25 ft |

SG10 |

3000 |

|

21 |

|

207 |

(1.17 lpm) |

(6.4 mm x 7.5 m) |

|

|

||||||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

MAGNUM ProX7 |

A |

0.34 gpm |

1/4 in. X 50 ft |

SG20 |

3000 |

|

21 |

|

207 |

(1.29 lpm) |

(6.4 mm x 15 m) |

|

|

||||||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

MAGNUM ProX9 |

A |

0.38 gpm |

1/4 in. X 50 ft |

SG20 |

3000 |

|

21 |

|

207 |

(1.44 lpm) |

(6.4 mm x 15 m) |

|

|

||||||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Getting Started

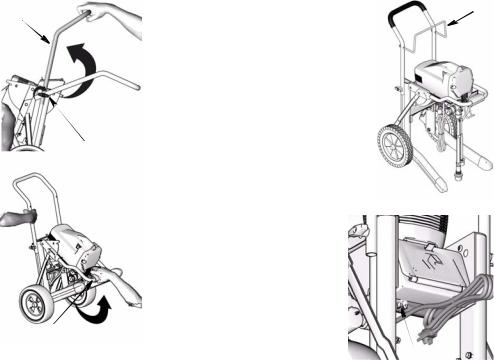

Fold-n-Store Cart (ProX Sprayers Only)

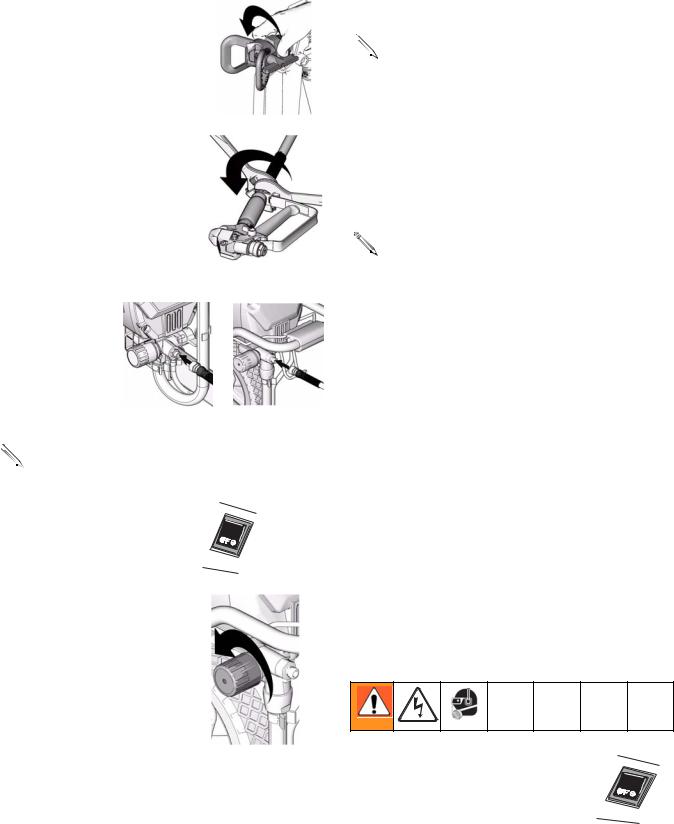

1. Unfold handle (a) and |

a |

d |

|

align as shown. |

4. Install hose rack (d) to frame |

||

|

|||

|

|

handle. Install lock nuts. |

|

|

|

Tighten securely. |

2. Tighten wingnuts (b).

b ti9675a

b ti9675a

3. Grasp cart handle securely with one hand. With the other hand lift

and pull Fold-n-Store™ handle (a) located in front of sprayer frame, toward you. Lift up front of sprayer until you hear a click and the cart is

locked in place. |

c |

ti9679a |

|

|

5.Secure power cord in clip (e) located beneath storage compartment.

e

ti9369a

ti9719a

2 |

312001G |

Warnings

Warnings

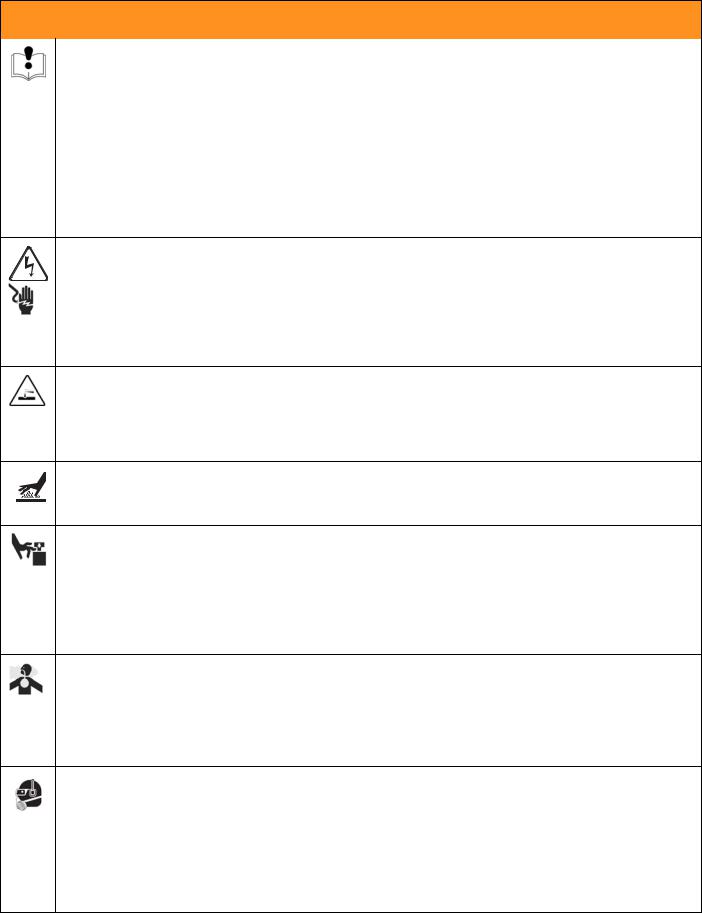

The following warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-spe- cific risks. Refer back to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable.

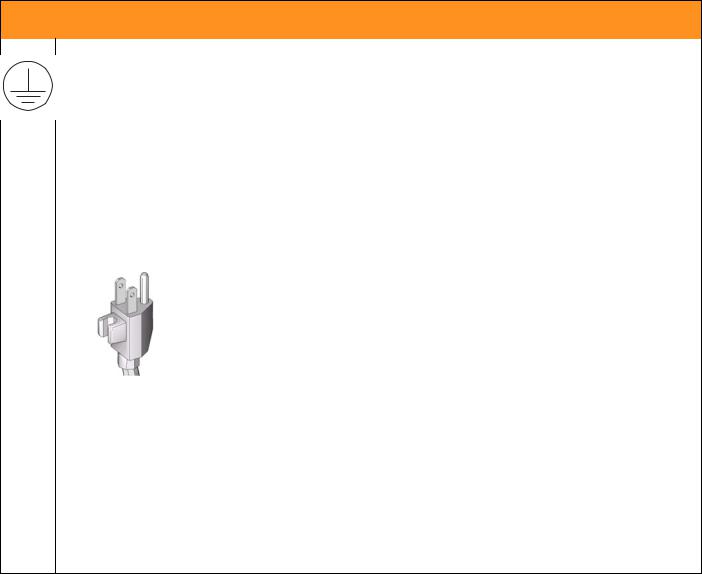

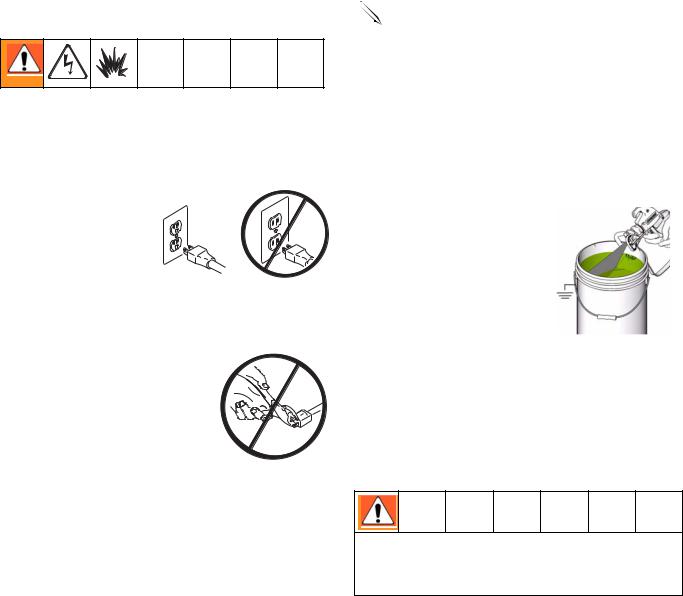

Grounding Instructions

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current. This product is equipped with a cord having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING

WARNING

GROUNDING

•Improper installation of the grounding plug is able to result in a risk of electric shock.

•When repair or replacement of the cord or plug is required, do not connect the grounding wire to either flat blade terminal.

•The wire with insulation having an outer surface that is green with or without yellow stripes is the grounding wire.

•Check with a qualified electrician or serviceman when the grounding instructions are not completely understood, or when in doubt as to whether the product is properly grounded.

•Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a qualified electrician.

•This product is for use on a nominal 120V circuit and has a grounding plug similar to the plug illustrated in the figure below.

ti9164a

•Only connect the product to an outlet having the same configuration as the plug.

•Do not use an adapter with this product.

Extension Cords:

•Use only a 3-wire extension cord that has a 3-blade grounding plug and a 3-slot receptacle that accepts the plug on the product.

•Make sure your extension cord is not damaged. If an extension cord is necessary, use 12 AWG

(2.5 mm2) minimum to carry the current that the product draws.

An undersized cord results in a drop in line voltage and loss of power and overheating.

312001G |

3 |

Warnings

WARNING

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion:

•Do not spray flammable or combustible materials near an open flame or sources of ignition such as cigarettes, motors, and electrical equipment. For X5 and X7 models: only use water-based or mineral spirit-type materials with a flash point greater than 70° F (21° C).

•Paint or solvent flowing through the equipment is able to result in static electricity. Static electricity creates a risk of fire or explosion in the presence of paint or solvent fumes. All parts of the spray system, including the pump, hose assembly, spray gun, and objects in and around the spray area shall be properly grounded to protect against static discharge and sparks. Use Graco conductive or grounded high-pressure airless paint sprayer hoses.

•Verify that all containers and collection systems are grounded to prevent static discharge.

•Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2 adapter.

•Do not use a paint or a solvent containing halogenated hydrocarbons.

•Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area. Keep pump assembly in a well ventilated area. Do not spray pump assembly.

•Do not smoke in the spray area.

•Do not operate light switches, engines, or similar spark producing products in the spray area.

•Keep area clean and free of paint or solvent containers, rags, and other flammable materials.

•Know the contents of the paints and solvents being sprayed. Read all Material Safety Data Sheets (MSDS) and container labels provided with the paints and solvents. Follow the paint and solvents manufacturer’s safety instructions.

•Fire extinguisher equipment shall be present and working.

•Sprayer generates sparks. When flammable liquid is used in or near the sprayer or for flushing or cleaning, keep sprayer at least 20 feet (6 m) away from explosive vapors.

SKIN INJECTION HAZARD

•Do not aim the gun at, or spray any person or animal.

•Keep hands and other body parts away from the discharge. For example, do not try to stop

leaks with any part of the body.

•Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

•Use Graco nozzle tips.

•Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while spraying, follow the Pressure Relief Procedure for turning off the unit and relieving the pressure before removing the nozzle tip to clean.

•Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn off the unit and follow the Pressure Relief Procedure for turning off the unit.

•High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that injection occurs, get immediate surgical treatment.

•Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

•This system is capable of producing 3000 psi. Use Graco replacement parts or accessories that are rated a minimum of 3000 psi.

•Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

•Verify that all connections are secure before operating the unit.

•Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

4 |

312001G |

Warnings

WARNING

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

•Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

•Do not operate or spray near children. Keep children away from equipment at all times.

•Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

•Stay alert and watch what you are doing.

•Do not operate the unit when fatigued or under the influence of drugs or alcohol.

•Do not kink or over-bend the hose.

•Do not expose the hose to temperatures or to pressures in excess of those specified by Graco.

•Do not use the hose as a strength member to pull or lift the equipment.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

•Turn off and disconnect power cord before servicing equipment.

•Use only grounded electrical outlets.

•Use only 3-wire extension cords.

•Ensure ground prongs are intact on sprayer and extension cords.

•Do not expose to rain. Store indoors.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1, 1, 1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical reaction and equipment rupture, and result in death, serious injury, and property damage.

BURN HAZARD

Equipment surfaces can become very hot during operation. To avoid severe burns, do not touch hot equipment. Wait until equipment has cooled completely.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

•Keep clear of moving parts.

•Do not operate equipment with protective guards or covers removed.

•Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

•Read MSDS’s to know the specific hazards of the fluids you are using.

•Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic fumes, burns, and hearing loss. This equipment includes but is not limited to:

•Protective eye wear

•Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

•Hearing protection

312001G |

5 |

Installation

Installation

Grounding and Electric

Requirements

Sprayer must be grounded. Grounding reduces the risk of static and electric shock by providing an escape wire for electrical current due to static build up or in the event of a short circuit.

•The 120 Vac sprayers require a 120 Vac, 60 Hz, 15A circuit with a grounding receptacle.

• Never use an outlet |

ti5573a |

that is not grounded or an adapter.

•Do not use the sprayer if the electrical cord has a damaged ground prong.

• Only use an extension cord with an undamaged 3-prong

plug. |

ti5572a |

Recommended extension cords for use with this sprayer:

•50 ft (15.0 m) 14 AWG (2.1 mm2)

•100 ft (30.0 m) 12 AWG (3.3 mm2)

Spray gun: ground through connection to a properly grounded fluid hose and pump.

Smaller gauge or longer extension cords may

Smaller gauge or longer extension cords may

reduce sprayer performance.

reduce sprayer performance.

Fluid supply container: follow local code. Solvent pails used when flushing: follow local code. Use only conductive metal pails, placed on a grounded surface such as concrete. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts grounding continuity.

Grounding the metal pail: connect a ground wire to the pail by clamping one end to pail and other end to ground such as a water pipe.

Maintaining grounding continuity when flushing or relieving pressure: hold metal part of the spray gun firmly to the side of a grounded metal pail, then

trigger the gun.

ti9207a

Thermal Overload

Motor has a thermal overload switch to shut itself down if overheated. If unit overheats, allow approximately 45 minutes for unit to cool. Once cool, switch will close and unit will restart.

To reduce risk of injury from motor starting unexpectedly when it cools, always turn power switch OFF if motor shuts down.

6 |

312001G |

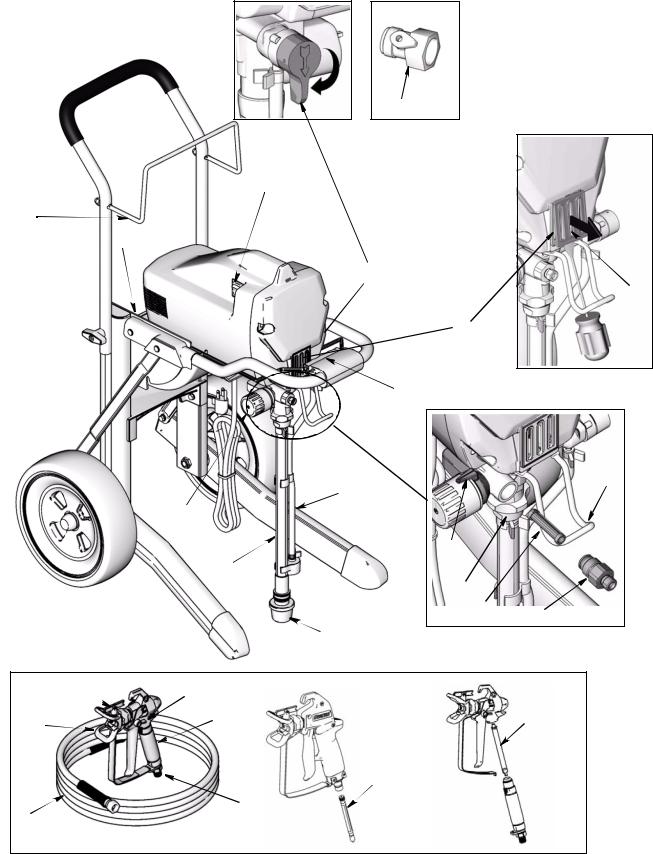

Component Identification

Component Identification

A |

Airless spray gun |

Dispenses fluid. |

|

|

|

|

|

B |

Power switch |

Turns sprayer ON and OFF. |

|

|

|

|

|

C |

Pressure control knob |

Increases (clockwise) and decreases (counter-clockwise) fluid pressure |

|

in pump, hose, and spray gun. |

|||

|

|

||

|

|

|

|

C1 |

Setting Indicator |

To select function, align symbol on pressure control knob with setting |

|

indicator, page 9. |

|||

|

|

||

|

|

|

|

D |

Pump fluid outlet fitting |

Threaded connection for paint hose. |

|

|

|

|

|

|

InstaClean™ fluid filter |

• Filters fluid coming out of pump to reduce tip plugging and improve |

|

E |

finish. |

||

(ProX Sprayers Only) |

|||

|

• Self cleans only during pressure relief. |

||

|

|

||

|

|

|

|

|

ProX Power-Piston™ |

|

|

F |

Pump (behind Easy |

Pumps and pressurizes fluid and delivers it to paint hose. |

|

Access door, not shown) |

|||

|

|

||

|

(ProX Sprayers Only) |

|

|

|

|

|

|

|

Easy Access door |

Easy Access door permits quick access to outlet valve. To remove door, |

|

F1 |

insert flat blade of screwdriver into slot on the bottom of the door (as |

||

(ProX Sprayers Only) |

|||

|

shown on page, 7). |

||

|

|

||

|

|

|

|

G |

Suction tube |

Draws fluid from paint pail into pump. |

|

|

|

|

|

H |

Prime tube (with diffuser) |

Drains fluid in system during priming and pressure relief. |

|

|

|

|

|

|

|

• In PRIME position (pointing down) directs fluid to prime tube. |

|

J |

Prime/Spray valve |

• In SPRAY position (pointing forward) directs pressurized fluid to |

|

paint hose. |

|||

|

|

||

|

|

• Automatically relieves system pressure in overpressure situations. |

|

|

|

|

|

K |

Storage compartment |

Provides onboard storage for spray tips and/or tools. |

|

(ProX Sprayers Only) |

|||

|

|

||

|

|

|

|

L |

Inlet screen |

Prevents debris from entering pump. |

|

|

|

|

|

M |

Paint hose |

Transports high-pressure fluid from pump to spray gun. |

|

|

|

|

|

N |

Fold-n-Store™ Handle |

Used to fold cart frame for hanging on wall. |

|

(ProX Sprayers Only) |

|||

|

|

||

|

|

|

|

Q |

Tip guard |

Reduces risk of fluid injection injury. |

|

|

|

|

|

|

|

• Atomizes fluid being sprayed, forms spray pattern and controls fluid |

|

R |

Reversible spray tip |

flow according to hole size. |

|

|

|

• Reverse unclogs plugged tips without disassembly. |

|

|

|

|

|

S |

Gun trigger safety lever |

Prevents accidental triggering of spray gun. |

|

(page 9) |

|||

|

|

||

|

|

|

|

T |

Gun fluid inlet fitting |

Threaded connection for paint hose. |

|

|

|

|

|

U |

Power Flush attachment |

Connects garden hose to suction tube for power flushing water-base |

|

fluids. |

|||

|

|

||

|

|

|

|

V |

Gun fluid filter |

Filters fluid entering spray gun to reduce tip clogs. |

|

|

|

|

|

W |

Hose wrap Rack |

Stows paint hose. (X7, ProX7, and ProX9 only) |

|

|

|

|

|

X |

Pail hanger |

For transporting pail by its handle. |

|

(X7, Prox7, and ProX9) |

|||

|

|

||

|

|

|

|

AA |

QuickAccess™ Inlet |

Permits quick access to inlet valve to clear debris (ProX9 only). |

312001G |

7 |

Component Identification

ti9724a

ti9346a U

|

|

|

B |

|

W |

|

|

|

|

|

|

K |

|

|

|

|

|

J |

|

|

|

|

|

F1 |

|

|

|

F |

|

|

|

|

|

ti9670a |

|

|

|

N |

|

|

|

|

H |

X |

|

|

|

|

|

|

|

C |

|

|

|

|

|

C1 |

|

|

|

G |

|

|

ti9368a |

|

|

AA |

|

|

|

|

ti9669a |

E |

|

|

|

D |

|

|

|

|

L |

|

|

R |

S |

|

|

|

|

|

|

|

Q |

|

A |

|

V (SG20) |

|

|

|

|

V (SG10)

ti9668a

T

T

ti11455a

M

ti9667a

8 |

312001G |

Operation

Operation

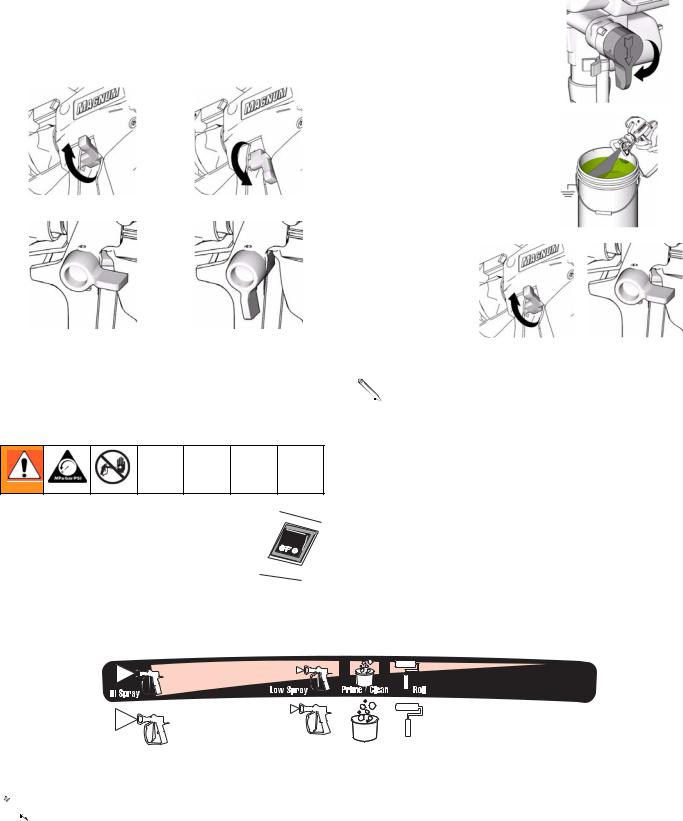

Trigger Lock

Always engage the trigger lock when you stop spraying to prevent the gun from being triggered accidentally by hand or if dropped or bumped.

ti8923a ti8922a

Trigger Locked (SG10) Trigger Unlocked (SG10)

ti8908a |

ti8909a |

Trigger Locked (SG20) |

Trigger Unlocked (SG20) |

Pressure Relief Procedure

Follow this Pressure Relief Procedure whenever you stop spraying and before cleaning, checking, servicing, or transporting equipment.

1. Turn power switch OFF and unplug power cord.

ti2810a

2.Turn Prime/Spray valve to PRIME to relieve pressure.

ti9346a

3.Hold gun firmly to side of pail. Trigger the gun to relieve pressure.

ti9207a

4.Engage trigger lock.

ti8923a |

|

|

ti8908a |

(SG10) |

(SG20) |

Leave Prime/Spray valve in the PRIME

position until you are ready to spray again.

position until you are ready to spray again.

If you suspect the spray tip or hose is clogged or that pressure has not been fully relieved after following the steps above, VERY SLOWLY loosen tip guard retaining nut or hose end coupling to relieve pressure gradually, then loosen completely. Clear hose or tip obstruction. Read Unclogging Spray Tip, page 13.

Pressure Control Knob Settings

ti5597a

High Pressure |

Low Pressure |

Prime/ Rolling |

Spray |

Spray |

Clean |

To select function, align symbol on pressure control knob with setting indicator on sprayer.

To select function, align symbol on pressure control knob with setting indicator on sprayer.

312001G |

9 |

Setup

1.Unscrew tip and guard assembly from gun.

ti9714a

2.Uncoil hose and connect one end to gun. Use two wrenches to tighten securely

3.Connect other end of hose to sprayer.

ti11456a

(X5 & X7)

ti9681a

ti9674a

(ProX7 & ProX9)

If hose is already connected, make sure

If hose is already connected, make sure

connections are tight.

connections are tight.

4. Turn OFF power switch.

ti2810a

5.Turn Pressure Control Knob all the way left (counter-clockwise) to minimum pressure.

ti9344a

Setup

Prime and Flush Storage Fluid

To spray lacquers with the ProX7 or ProX9,

To spray lacquers with the ProX7 or ProX9,

you must purchase lacquer conversion kit 256212, and follow priming procedure for oil-based materials. The X5 and X7 units are not intended for lacquers.

you must purchase lacquer conversion kit 256212, and follow priming procedure for oil-based materials. The X5 and X7 units are not intended for lacquers.

Before you use your sprayer for the first time or begin a new spraying project, you need to prime the sprayer and flush the storage fluid out of the sprayer.

Oilor Water-based Materials

•When spraying water-based materials,

flush the system thoroughly with water.

•When spraying oil-based materials, flush the system thoroughly with mineral spirits or compatible, oil-based flushing solvent.

•To spray water-based materials after spraying oil-based materials, flush the system thoroughly with water first. The water flowing out of prime tube should be clear and solvent-free before you begin spraying the water-based material.

•To spray oil-based materials after spraying water-based materials, flush the system thoroughly with mineral spirits or a compatible oil-based flushing solvent first. The solvent flowing out of the prime tube should not contain any water.

•When flushing with solvents, ground pail and gun. Read Grounding and Electric Requirements, page 6.

•To avoid fluid splashing back on your skin or into your eyes, always aim gun at inside wall of pail.

1.Make sure the power switch is OFF and the sprayer is

unplugged.

ti2810a

10 |

312001G |

Setup

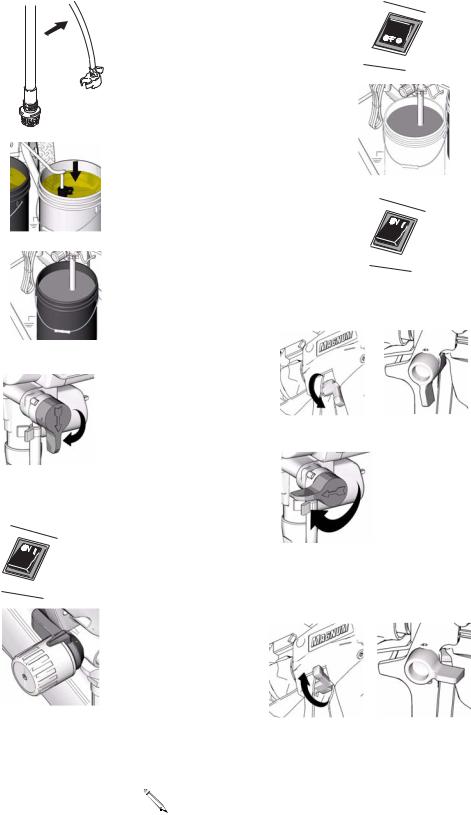

2. Separate prime tube (smaller) from suction tube (larger).

ti2039a

3.Place prime tube in waste pail.

ti9652a

4.Submerge suction tube in water or flushing solvent.

ti9651a

5.Turn Prime/Spray Valve to PRIME.

ti9346a

6. Plug sprayer in a grounded outlet.

7. Turn power switch ON.

ti5580a

8.Align setting indicator with Prime/Clean setting on Pressure Control knob until pump starts, page 9.

ti9718a

9.When sprayer starts pumping, flushing solvent and air bubbles will be purged from system. Allow fluid to flow out of prime tube, into waste pail, for 30 to 60 seconds.

10. Turn power switch OFF.

ti2810a

11.Transfer suction tube to paint pail and submerge suction tube in paint.

ti9653a

12. Turn power switch ON.

13.When you see paint coming out of prime tube:

a.Point gun into waste pail.

b.Unlock gun trigger lock.

c.Pull and hold gun trigger.

d.Turn Prime/Spray valve to SPRAY.

ti5580a

ti8922a

ti8909a

(SG10) (SG20)

ti9345a

14.Continue to trigger gun into waste pail until you see only paint coming out of gun.

15.Release trigger. Engage trigger lock.

16. Transfer prime |

ti8923a |

|

|

|

ti8908a |

||

tube to paint |

|

||

(SG10) |

(SG20) |

||

pail and clip |

|||

prime tube to |

|

|

|

suction tube. |

|

|

•Motor stopping indicates pump and hose

are primed with paint.

•If motor continues to run the sprayer is not properly primed. To reprime repeat step 8.

312001G |

11 |

Loading...

Loading...