Page 1

GE 6610 AC-1

Page 2

Page 3

Reporting an ac cident or incident

Use this information when reporting incidents and

accidents involving the unit.

If an ac cident or an in cident ass ociated with the occu rs, this must be

reported immediately in writing to the address below. The report must

be used to identify the cause of the accident or incident and to what

extent the occurrence was due to t he unit

The unit is a product in the Getinge range.

The unit may also be a ster ilizer that is a medical engineering product

and which confo rms to the EU medic al devices direc tive, or wh ich is

constr ucted in a sim ilar way t o a medical device. U nder the m edical

devic es direc tive, the manufac turer must investi gate the cause of

accidents/incidents that occur and report them to the authorities

concerned.

The investigation may lead to changes in new or already delivered

devices or in instructions and guidance.

The following circumstances must be reported:

1. circumstances that caused the death of a patient, user or someone

else, or that caused serious deterioration in the health of a patient,

user or someone else.

2. circumstances that might have caused, the death of a patient, user or

someone else, or that might have caused serious deterioration in the

health of a patient, user or someone else.

The following info rma tio n is requ ir ed:

The manufacturing number of the unit (on a label in the electrical

cabinet), Date/time of event, Description of event, Consequences of

event.

Contact: Name, Phone number, Address:, E-mail:

The information must be sent by letter or fax to:

GETINGE STERILIZATION AB

For the attention of: Quality Manager

Box 69

31044 GETINGE

Sweden

Fax: +46 (0)35 549 52

Page 4

Attention symbols

I Some of the warnings, instructions and advice in this manual are so

important that we used the following special symbols to draw attention

to them. The symbols used are as follows:

Warnings

This symbol indicates a warning in the text of the manual.

The nature of what the warning relates to is such that it

may result in more or less severe injury and in certain

cases mortal danger.

The symbol is also used to highlight safety components,

etc. See “Safety devices - an overview” under

“Introduction” in the DESCRIPTION OF OPERATION or

under “Maintenance” in the SERVICE MANUAL.

Instructions

This symbol highlights instructions that are important for

avoiding damage to the unit and/or load, among other

things.

Advice

This symbol indicates important advice and hints that

make it easier to work with the unit.

Symbols on t he unit

Hot surface

This symbol gives warning of a hot surface.

S

SS

Page 5

SERVICEMANUAL

TABLE OF CONTENTS

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Genera l requirements to be me t b y the i n stallatio n l o c a t i o n. . . . . . . . . . . . . . . . . . . . 7

Unpac k i n g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Instal l a t i o n. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

ESD (Ele ctrosta t i c discharge ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Incoming media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connecting water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Steam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Compressed air quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Air connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Outlet fro m safety val v e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Response for pressure vessel and safety valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Functio n al check-up prio r t o us e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

FUNCTION CHECK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Before u se . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Overvi e w o f safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Maint e n an c e p l an . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Cycle counter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

The ECO wa t e r-saving sy stem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

ADVICE AND INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Manual i n t e rv entions in the process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Manual steppi n g wit h k e y sw i t c h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Faulty a n a l o g se n so r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Press u re sensor fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Manual control b y man u a l l y a c t u ating the con trol val v es. . . . . . . . . . . . . . . . . . . . . 42

Extern a l sa fety inte rl o c k fau lt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Backup battery fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Restoring softw a re from E-PROM (cold st a r t) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Manual door opening. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Power failure alarm with door open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

User-p ro gramma b l e fu n ctions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Safety v a l v e check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

THE DOOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Seal between door and chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Media to t h e c h a m b e r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Page 6

Checking the door action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Checking and adjusting the door position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Remov ing t h e d o or . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 7

The door seal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Lubrication and replacement of the door seal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Replacing the door cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Repla ci n g th e p i st o n se a l. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Door safety arran g e m e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Blocking the start and opening the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Blocking the media supply to the chamber. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Safety interlocking of the door opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

CONTROL UNIT PACS 3000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 3

Operat i n g p a n el ty p e O P 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 6

Indica t o rs and contr o l s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 6

Displ a y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Operat o r menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 1

Descr i p t ion o f operator menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Syste m m en u . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

I2C-link faults on PACS 3000 modules.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Technical data, PACS 3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Illust ration on d raw i n g s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Panel-mounted printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Vacuu m pum p LEM 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Pressure transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Single circuit pressure switch 469 56 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Soleno i d valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Pt 100 sensor (RTD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Piston v alves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Filters and strainers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Restr i c t o rs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Soldered plate-type heat exchangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

SCRAPPING INSTRUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Page 7

INSTALLATION

This pre-installation instruction covers the information needed to prepare the installation site, before delivery of the unit.

With the delivery of the machi ne a specific installation instruction will

be enclosed. A copy of the s pecific instruction is als o enclosed in the

manual.

The specific instruction may also cover details such as:

• Unpacking

• Rigging and transportation within the facility

• Reassembly of the dismounted equipment

• Functional test prior to use.

General requirements to be met by the installation

location

Use Ge tinge St eriliza tion AB’s instal lation d rawings for desig n and

building purposes when determining the necessary dimensions and

design. Experience has shown that particular attention should be paid to

the following points.

• The ceiling height in the service room must be sufficient to allow

space for all equipment according to the installation drawing.

• The service room must have good lighting and be ventilated. For

requirements regarding ventilation, see the special section on this

topic in this instruction manual.

• All dimensions relating to foundations, floor pits, wall openings, etc.

refer to finished dimensions. These dimensions must be complied

with when floor, wall and ceiling linings have been installed.

• When choosing the wall covering in the service room it should be

kept in mind that the room may be filled with steam the event of a

failure.

• The equipment must be set up so that the distance to the nearest

workplace or treatment position is more than 1.5 meters (5 foot).

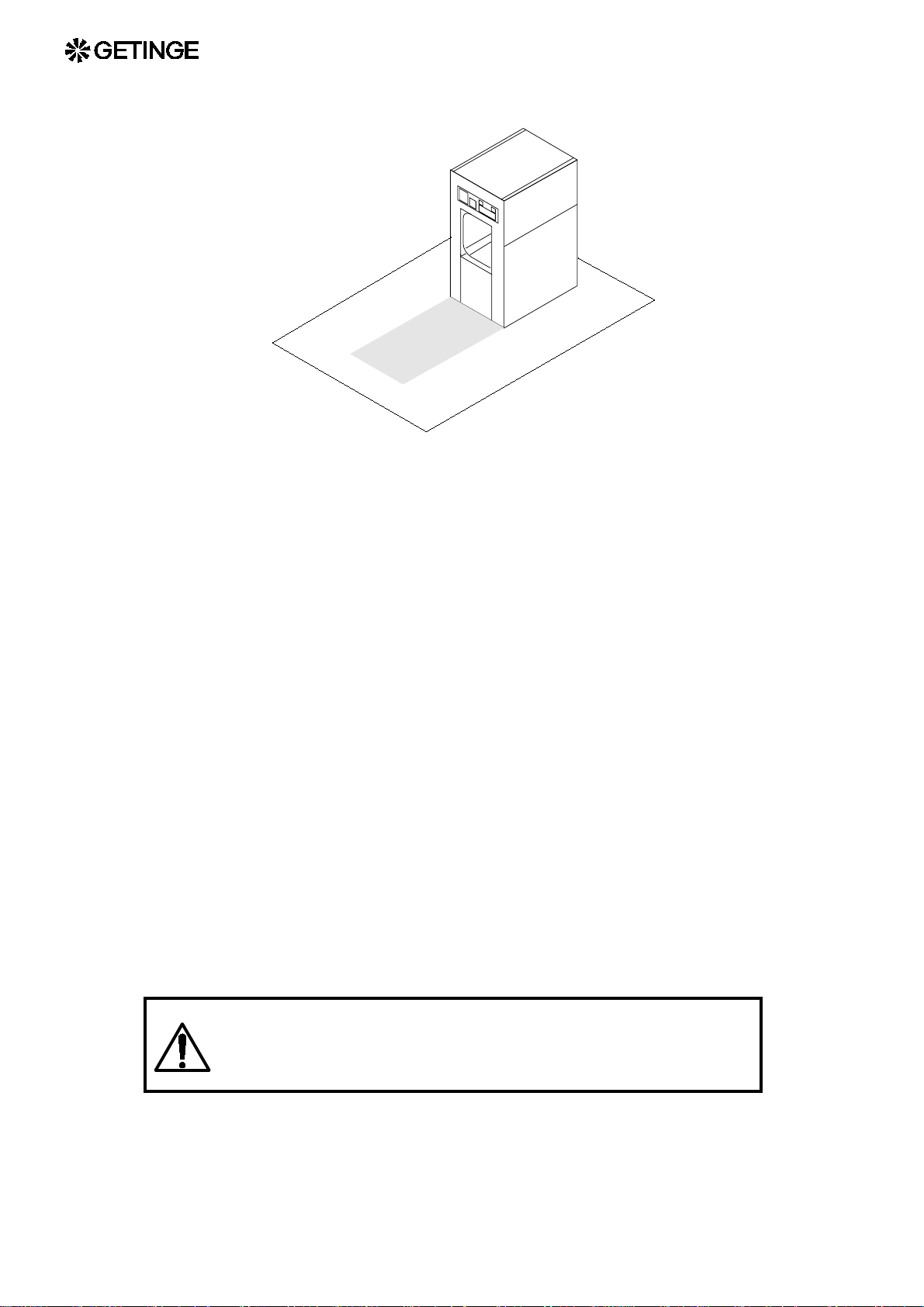

• The floor in front of the door( s) of the sterilizer must be flat and level

within in a zone as shown in the diagram below. When installing

several steriliz ers that are to be served by a common loader, the

width of this area must be the same as that of the entire installation.

7

Page 8

These requirements, and others such as those relating to floor

loading, are specified in more detail on the installation drawing.

Installing a sterilizer in a wall opening

• There must be no trim, baseboards or similar objects within

approximately 5 centimeters (2 inch) from the edge of the opening

next to the wall opening for building in the sterilizer.

• Sterilizers installed in wall openings should be sealed to the wall in

order to separate the sterile and non-sterile sides. The edges of the

wall opening and the transition between the front plates of the

sterilizer and the wall should be finished in a properly hygienic

manner.

• Sterilizers with vertically-operating doors: These models have a

generous gap between the front plates of the sterilizer and the wall

opening. The gap must be covered with suitable fitting pieces.

Getinge sells an add-on system for this purpose.

• Sterilizers with horizontally-operating doors There are two

variants: either the front plates are designed to lie outs ide and overlap

the wall, or a gap is left between the wall and the plates. The version

with the gap must be sealed with silicone compound or similar . The

outside of the front plates meets the wall in this version so that a

smooth transition is obtained. The installation drawing shows the

specific installation method for a particular sterilizer.

Find out the central point of gravity when lifting and transporting a packed or not pa cked ster ilizer th ere by avoidi ng

serious accidents.

8

Page 9

Unpacking

• Check when unpacking the equipment that the order No. of its data

plate conforms with the ordering No. of the documents.

• Check that the sterilizer is faultless. Any transportation damage

should be reported within seven days to the transport company that

was responsible for delivery.

• Do not remove the protective plastic film from stainless st eel panels

until the installation is completed.

• There is certain equipment such as expendable items, control unit,

operating instruction and list of programs by-packed the sterilizer

inside the chamber. The two latter are to be posted where easily

observed by the operator at work.

Please note that those articles are adapted for each sterilizer. When unpacking more than one sterilizer the articles

are not to be interchanged.

Storage

Installation

The unit must be stored in a temperature between 2 and 40oC (35 and

105°F) and at a maximum relative humidity 95% (non-condensing).

• Observe national and local regulations concerning service space.

• Make sure that the clearance distances required by health and safety

regulations are provided.

9

Page 10

Connection

Certain types of installation work, water and electrical, for

example, should be done by authorized technicians.

If the work is not done properly, injury and damage may

result.

Faulty installation work invalidates the warranty on the

product supplied.

Pipework and electrical wiring should be done in a professional manner

so that the service compartment looks workmanlike and provides a

practical workplace which minimizes the risk of accidents.

• Find out the connection points and connection data of the equipment

by studying the installation drawings.

• Pay attention to local regulations.

• Remove debris by flushing or blowing t hrough all pipes that will be

connected.

Electrical

• Insulate hot and very cold pipes.

• Mark pipes and electrical wiring.

Install shut-o ff devices in the media supp ly lines near ea ch

unit, so that the operator can use them without passing

through a risk area. The inner part of the service

compartment is not a suitable place for this.

Before welding on or near the sterilizer, ALL plug-in leads

must disconnected from ALL the PCBs of the control

system.

Components in the control system of the i nstallation and other electrical

components tolerate supply voltage variations of -10/+5 %. If greater

voltage variations are likely, a mains voltage stabilizer will have to be

provided between the ma ins cicuit breaker of the install ation and the

control equipment. As the equipment will present an inductive load to

the stabilizer, the stabilizer should be well oversized (at least 500 VA).

Permitted frequency deviation ±1%.

10

Page 11

• Check that all terminal screws are tight..

General:Connect the equipment through a nearby multipole lockable, safety-marked switch to a three-phase

supply with non-disconnectible protective earth

conductor.

In the planning p has e: Con cernin g voltage and frequenc y,

mains cicuit breaker ratings and wiring sizes, see the

document “Technical data”.

When conne cting the equipm ent: connect a s show n on th e

wiring diagram. The drawing number is given in the

documentation of the equipment.

• If the building where the equipment is installed has a separate

equipotential bonding system, a wire must be run from this to the

earthing (grounding) terminal of the surge protection. The surge

protection is located in the terminal box. See the wiring diagram.

• If the control system of the equipment is to be connected to a

standalone computer, the power supply to the computer should be

taken from the the same distribution board as the equipment is

connected to. Common supply is important in order to avoid

potential differences and therefore the risk of damage to the

electronic circuits of the equipment.

• A printer used to print from the equipment must be

connected in accordance with the wiring diagram. Normally

it will take its supply directly from the electrical system of

the equipment. Some equipment has sockets for a printer. If

so, these are marked with the symbol for heavy current and

the text E110 and 230 V. The signal cable is connected to a

multipole socket marked E110.

• A printer used elsewhere must be powered from the same

distribution board as the equipment. Common supply is important in

order to avoid potential differences and therefore the risk of damage

to the electronic circuits of the equipment.

• The supply cable to the sterilizer should be run so that the

temperature rise in the cable due to its insulation and ambient

temperature remains within permissible limits.

• The routing and overcurrent protection of the supply cable must be

such that the sterilizer cannot be subjected to short-circuit currents

exceeding 6 kA.

• The following requirement is applicable in countries there IEC

61000-3-3 applies: Equipment with a current less than 16 Amps on

each phase which is supplied from a public power distribution

system applies to the directive. The public power distribution system

11

Page 12

must at least be capabable to provide 100 Amps on each phase or

have a impedance of Z[ohm]=0,15+0,15*i.

• Load-breaking switches in accordance with IEC 898, with B or C

characteristic, are recommended for circuit protection. If such

switches are not available, protection can be provided by IEC 269-1

fuses, characteristics gG or gM.

• Vacuum pumps, fans, pumps and motors located in separate rooms

away from the common service area of the installation must have

their own individual multi- pole, lockable, safety-marked switches. A

switch of this description must always be installed close to the motor.

• Vacuum pumps and pumps for liquids: First make sure that the

feedwater tanks and pipework are filled with water. Th en check that

the direction of rotation of the pump is correct by briefly operating

the pump contactor by hand. Correct this as shown in the drawing

below.

Running the shaft seal dry could destroy it in just a few

seconds.

• Fans and three-phase motors: check that the direction of rotation

is correct by briefly operating the motor contactor by hand. Correct

this as shown in the drawing below.

• Correcting the direction of rotation: Swap two of the phase wires

in the supply cable between the motor and the contactor. For some

equipment the “contactor” may take form of a frequency converter

or soft-starter.

• It is recommended that the three-phase supply should be protected by

an earth leakage circuit breaker with a 300 mA trip current.

ESD (Electrostatic discharge)

ESD damage in in sta llatio n and ser vic ing may d estr oy the

electronic equipment. Read the instructions below

BEFORE starting work.

ESD damage

12

ESD is an overall term describing how electronic circuits a re damaged

by the static charging to w hich they are exposed when they come into

contact with electrically charged objects. Virtually all non-earthed

objects in the world around us have a static charge. Equipment and people are imperceptibly charged by friction in the air or between shoes and

Page 13

floor in ordinary walking. This charge is transferred to the electronic

circuits when they are touched.

Any damage that occurs to the electronics may be difficult to de tect

and trace. It varies from immediate destruction of a circuit so that it no

longer works at all to insidiously affecting operation so that performance is not maintained. The circuits may even appear to be undamaged and then later disintegrate inexplicably.

Most replacements of electronic boards where the fault cannot be

explai ned and is bla med on uneven quality are probably du e to ESD

damage.

Requirements for protection in installation and servicing

GETINGE has ESD protection integrated into the production and testing of electronic equipment and also requires ES D protection to be used

after delivery for the warranty to apply.

Damage usually occurs after delivery if electronic boards are stored in

non-ESD-approved packs, if electronic boards are placed on non-ESDprotected work surfaces or if people not wearing ESD protection touch

them. Simple equipment can be obtained for all these situations which

prevents charging and theref ore ESD damage. Contact your local distributor of ESD protective equipment or GETINGE After Sales.

Practical requirem ents

Keep electronic boards only in screened and ESD-approved

•

(marked) bags.

• Use ESD pads connected to earth in accordance with the manufac-

turer's instructions to hold disassembled or new electronic boards

during assembly work.

• Do not touch electronic boards with tools that may be charged, e.g.

screwdrivers with a plastic or wooden handle. Use earthed tools if

necessary.

• Always use an ESD wrist band connected to earth in accordance with

the manufacturer's instructions when working in the electronic

enclosure or when handling boards.

• Newer keep foreign objects such as drawings or plastic pockets

inside the electronic box.

• Test the ESD protective equipment regularly.

13

Page 14

Incoming media

General safety requirements for supply lines

The document Technical Data states permitted pressure levels for all

incoming media.

If the state d pressure of the me dium does not exce ed the design

pressure of the pressure vessel , the equipment does not normally have

protection against excessive pressure for that medium.

Where the supply medium pressure (as stated in Technical Data)

exceeds the design pressure of the pressure vessel, the equipment is

protected against exce ssive pressure for a well-define d inflow rate of

that medium. The protection takes the form of a specific safety valve

and suitable designed restrictions and valves in the internal pipework.

To ensure that the equipment is only supplied at the permitted

pressure levels, the user must accept liability for fitting the supply lines

with reducing valves and safety valves in accordance with the

regulations.

Whether or not the sterilizer is equipped with a safety

valve, the user must install correctly dimensioned safety

valves in the supply lines for incoming media.

Note that the pressure vessel safety systems cease to

operate if the pressure of any medium exceeds the range

stated in Connection data. This results in a RISK OF

BURSTING.

o

C (60°F). This temperature may be exceeded by 5°C (10°F) if reduced

depth of evacua tion and pump c apacity can b e accepted. This applies

primarily to sterilizers of the EN model, i.e. designed for the European

market.

Certain models intended primarily for tropical climates can easily be

modified for use with water temperatures up to 35oC (95°F). This topic

is covered under "Connection and pressures" in this section and in the

section headed "Customer-programmable functions" in the SERVICE

MANUAL.

HARDNESS

To minimise sterilizer service and maintenance costs, the water

hardness should not exceed 4dH / (0.7mmol/l) / (70 ppm). A water

softener is recommended where the water is harder than this.

14

Page 15

Driving liquid for the vac uum pump

TEMPERATURE

The highest water temperature for maximum pump performance is 15

o

C. This temperature may be exc eeded by 5 degC if reduced depth of

evacuation and pump capacit y can be a ccepted. This appli es primarily

to sterilizers of the EN model, i.e. designed for the European market.

Certain models intended primarily for tropical climates can easily be

modified for use with water temperatures up to 35 oC. This topic is

covere d under "C onnecti on and pr essures" in this sec tion and in the

section headed "Customer-programmable functions" in the SERVICE

MANUAL.

HARDNESS

To minimise sterilizer service and maintenance costs, the water

hardness sh ould not exceed 4d H (0.7mmol/l). A w ater softener is

recommended where the water is harder than this.

Cooling water for heat exchangers

TEMPERATURE

The highest water temperature for satisfactory performance is 15oC

(60°F) . This temper ature may be e xceeded by 5°C (10°F) if reduced

performance is acceptable.

WATER QUALITY

To minimise service and maintenance costs, the water hardness should

not exceed 4dH / (0.7mmol/l) / (70 ppm). A water softener is

recommended where the wa ter is harder than this. The cooling water

must not be corrosive, nor must it contain s ubstances that are abrasi ve

or which form deposits. The water salt content should not be so high as

to cause scaling as a result of the temperature.

Connecting water

Common water supply

Some equipment in the basic version is supplied with water from a

single common connection to the sterilizer. T his means that the water

temperature and hardness are the same for all the water-using

equipment.

The water must always be colorless, with no solid contaminants such

as sand, f lakes of rust , graphite, e tc. The conte nt of other sub stances

may vary, as previously mentioned, and the temperature should be

suited to the require ments of the vacuum pum p sealing w ater. If the

sterilizer is connected to the drinking w ater supply, requi rements for

15

Page 16

Back flow prevention must be observed; see Connecting with reverse

siphon protection.

Connection with reverse siphon protection

Any connec tions made to a dri nking water suppl y must comply with

national and local regulations. In countries where EU regulations apply,

the national requirements will gradually be complemented by

harmonis ed EN stan dards, r egulating the con nection and presc ribing

equipment for such purposes as reverse siphon protection.

Reverse siphon protection

When the equipment is instal led, an appr oved (and , in certai n cases ,

type-tested) reverse-siphon prote ction device must be fitted in the

supply line. Details of the particular types of rever se siphon protection

devices that must be used, and how they must be installed, are regulated

by the responsible authorities in each country.

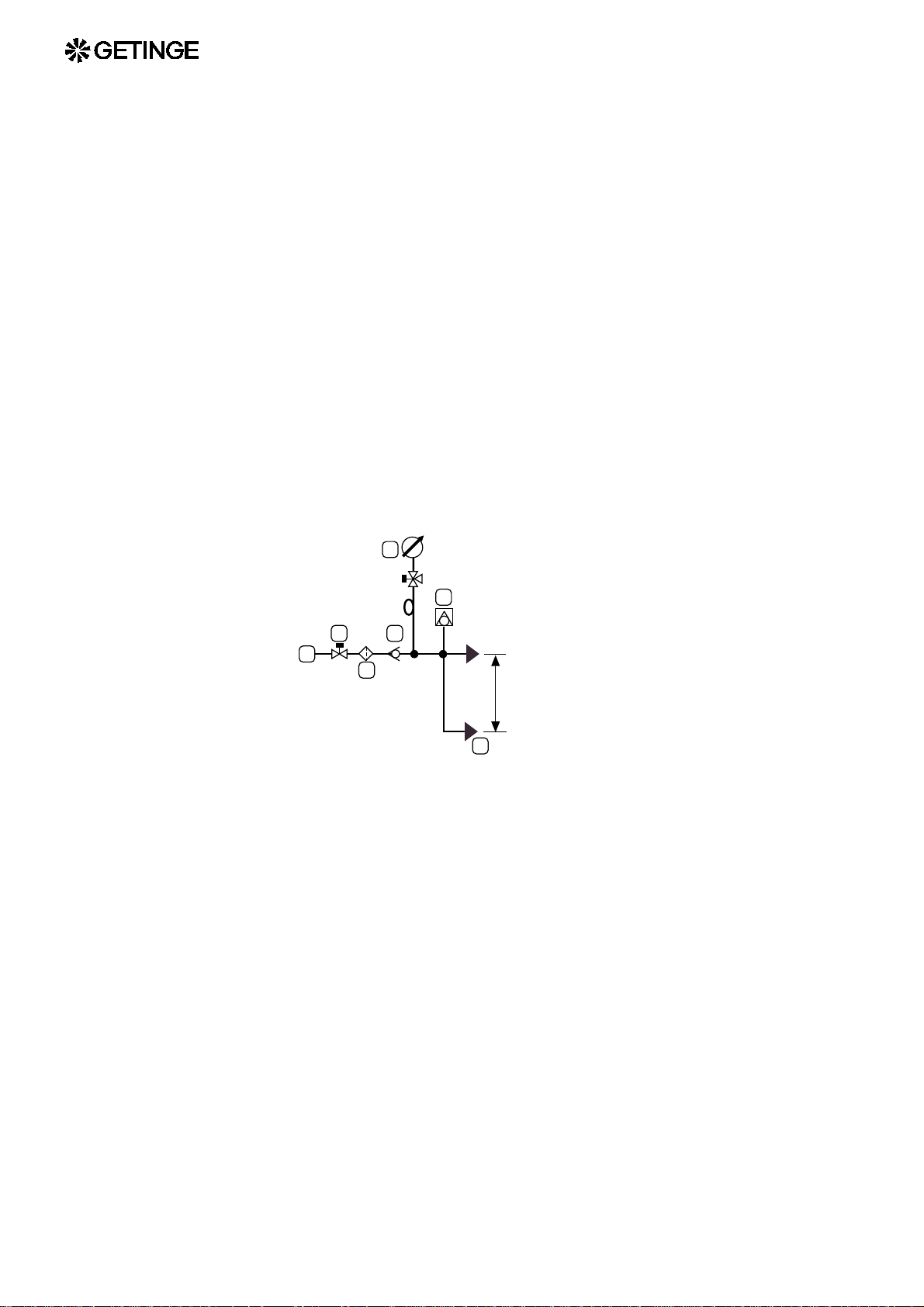

• In the absence of specific rules for connection, we recommend that a

connection to the drinking water supply should be arranged as

follows:

5

6

2

1

4

3

H > 300 mm

7

1 Main supply line 2 Shut-off valve

3 Filter 4 Non-return valve

5 Pressure gauge,

including water

pockets and

6 Reverse siphon protection

7 Connection to sterilizer

isolating valve

• The above components should be supplied by the customer unless

the contract states otherwise.

Pressure

16

For service water systems: Normally the equipment is supplied via

•

a shutoff valve to a water pipe syst em with a positive p ressure of 3.5

to 6 bar(e), equivalent to 350 to 600 kpa(e) or 50 to 90 psig. Models

for certain markets and models that can be converted for tropical

Page 17

conditions can be connected to pipe systems with a pressure as low

as 1.0 bar(e), equivalent to 100 kpa(e) or 15 psig. Precise information

about pressures, temperatures, consumption rates and connection

size for each medium is given in the Technical Data document. In

case of doubt, Technical Data always takes precedence.

• For closed systems: Normally the equipment is supplied via a

shutoff valve to a circulating system with a positive pressure of 3.5

to 6 bar(e), equivalent to 350 to 600 kpa(e) or 50 to 90 psig. Note that

the pressure in the return line must normally be at least 1.0 bar lower,

equivalent to 100 kpa lower or 15 psi lower . Precise information

about pressures, temperatures, consumption rates and connection

size for each medium is given in the Technical Data document. In

case of doubt, Technical Data always takes precedence.

The Technica l Data d ocu me nt st ate s a per mi tted pressu re

range for all incoming media. Always check that the

equipment is connected to supply lines in which the

pressure is within the correct range.

Note that the pressure vessel safety systems cease to

operate if the pressure of any medium exceeds the range

stated in Technical Data. This results in a RISK OF

BURSTING!

Steam

The result of a sterilization is very dependent on the nature of the

steam used. The steam must therefore meet certain quality

requirements.

Steam generators based upon evaporation from high pressure hot

water should not be used since the steam produced is of inferior quality

for sterilization purposes.

Minimum cleanness requirements

The following are minimum cleanness requirements, but may be

regarded as normal requirements to be met by steam for heating in heat

exchangers and jackets. It is the user’s responsibility to choose the

steam quality for sterilization, taking account of local regulations and

official require me n ts .

1. Solid particles such as welding pellets, graphite, rust flakes, sand

etc must not occur, since the steam comes into physical contact with

the goods to be sterilized. These impurities may also block steam

traps and chokes.

17

Page 18

2. For the same reason, liquids must not occur, except very small

amounts of water.

3. Gases will prevent close contact between the steam and the microorganisms to be killed. They must be kept below the proportions

below.

· Hydrazine (N2H4) max 0.11 mg/kg (ppm) steam.

· Ammonia (NH3) max 5 mg/kg (ppm) steam.

· Air and/or non-condensable gases max 7 ml (0.25 oz) per 200 ml

(6.75 oz) condensate, formed by the steam-air/gas mixture.

4. Other chemicals such as softener residue and similar substances

must not occur in sterilizing steam.

· Salt content max 1 mg/kg (ppm) steam.

Analysis of condensate

An analysis of the condensate f rom the steam gives an idea of its

cleanness as regards other substances. These substance should not occur

in concentrations exceeding the values given in mg/kg condensate in the

table below.

Evaporation residues 1.0 mg/l (ppm), of which:

Silicon in the form of SiO

Iron 0.1 mg/kg (ppm)

Cadmium 0.005 mg/kg (ppm)

Lead 0.05 mg/kg (ppm)

Other heavy metals 0.1 mg/kg (ppm)

Chlorides 0.1 mg/kg (ppm)

Phosphates 0 mg/kg (ppm)

Recommended pH = 5 - 7

Suitable conductivity < 3 µS/cm [at 20 °C (68°F)]

Suitable hardness ≤ 0.1 dH (1.8 ppm)

Steam of the quality specified below under Process steam is

recommended for the sterilization of products that come into direct or

indirect contact with the human blood circulation, where there are very

stringent requirements for cleanness.

2

0.01 mg/kg (ppm)

Process steam

18

In accordance with cGMP, the chemical content of the steam must

conform to the requirements for WFI of the European Pharmacopoeia

Page 19

Pressure

(EP) 3rd edition 1997, United States Pharmacopoeia (USP XXIII) and/

or another local pharmacopoeia.

Alternatively, st eam wi th a chemical content equivalent to clean steam

for ster ilization as p er HTM 2031 may be used if the use r’s local

regulations and official requirements allow it.

A See the document “Technical Data” for correct information about

steam p r e ssure.

If the steam supply line pressure exceeds the steam

pressure stated in Con nection d ata, th e user must in stall a

pressure reduction unit with a suitable safety valve which

has sufficient blow-off capacity for the amount of steam

supplied.

B Permitted pressure variations max ± 0.1 bar (equivalent to ±10.0

kPa or ± 1.5 psi).

Moisture content

Sterilizer s should be supplied with dry s aturated steam. The ideal

physical state “dry saturated” is difficult to maintain in a practical

application, and measurement/control of the moisture content of the

steam is tricky .

Applying the adv ice given below, which is based upon practical

experience, will generally result in steam with a satisfactory moisture

content. This means that it is not superheated either. Superheating of the

steam is highly undesirable in connection with sterilization because it

does not con tribute the humidification necessary to kill microorganisms.

Methods and values for determining the quality of the steam and the

degree of superheating are described in standard EN285, for instance.

Practical arrangements

1. Connect the equipment to a line in which steam is consumed

continuously. Long branch connections should be avoided.

2. Choose the appropriate pipe size from the table below. If more than

one piece of equipment is connected to the same line, a diversity

factor of 0.8 or higher may be applied.

Steam pressure Highest design gas velocity

19

Page 20

2.5 [bar (e)], 36 [psig] 38 [m/s], 125 [feet/s]

3 [bar (e)], 45 [psig] 35 [m/s], 115 [feet/s]

4.5 [bar (e)], 65 [psig] 30 [m/s], 100 [feet/s]

6 [bar (e)], 90 [psig] 25 [m/s], 80 [feet/s]

The specific steam pressur e of the equipment is given in the

document “Technical Data”. If the installation is to be connected to

a steam supply at a different pressure, the table can be used for

guidance. If in doubt, contact Getinge Sterilization AB.

3. The steam supply pipes should have a fa ll of at least 1:50 (1/4 inch

per foot) in the direction of flow.

4. Install reducing valve(s) in the supply line if the pressure is higher

than that specified in Technical Data. The steam pressure upstream

of the reducing valve should not fluctuate more than 10%.

Do not reduce the pressure by a factor s maller than 0. 5 in one step.

Use a second reducing valve for greater reduction ratio. Each

reducing valve must be followed by a safety valve.

If the steam in the supply line is wet, include condensate

removal as shown in Figure "A" just before the reducing

valve, as shown in the sketches below.

The drain line of safety valves should have at least the same

dimension as the valve blowoff opening and must not contain shut

off devices or chokes. Water pockets formed in the piping, must be

drained.

5. There must be no chokes or restrictions placed in horizontal pipes.

6. Fit the last reducing valve not more than 6 m (20 ft) pipe length

away from the sterilizer, but not closer than 4 m (13 ft) if the

maximum reduction ratio (2:1) is used.

If the reducing valve is positioned much more than 6

meters (20 feet) from the sterilizer, include condensate

removal as shown in Figure "A" just before the sterilizer.

20

7. The last condensate removal device (see figure below) should not

be placed more than 1 meter (3 feet) away from the sterilizer steam

connection. If this is not possible for practical reasons, a steam

dryer can be installed directly at the steam connection.

8. There should be no steam consumers other than sterilizers, steam

converters or treatment stations (WSSD) connected downstream of

the last reducing valve.

Page 21

9. Branch pipes should be connected to the top of a horizontal main

pipe.

10. A steam sampling point with shutoff valve should be provided

between the reducing valve and the sterilizer so that the quality of

the steam can be checked. The sampling point can also be used for

blow-down in preparation for work that requires the steam system

to be depressurized.

11. Because it is intended to be used daily, the shut off valve should be

easy to operate, for instance a remote controlled ball valve.

12. Insulate steam pipes up to the sterilizer steam connection.

21

Page 22

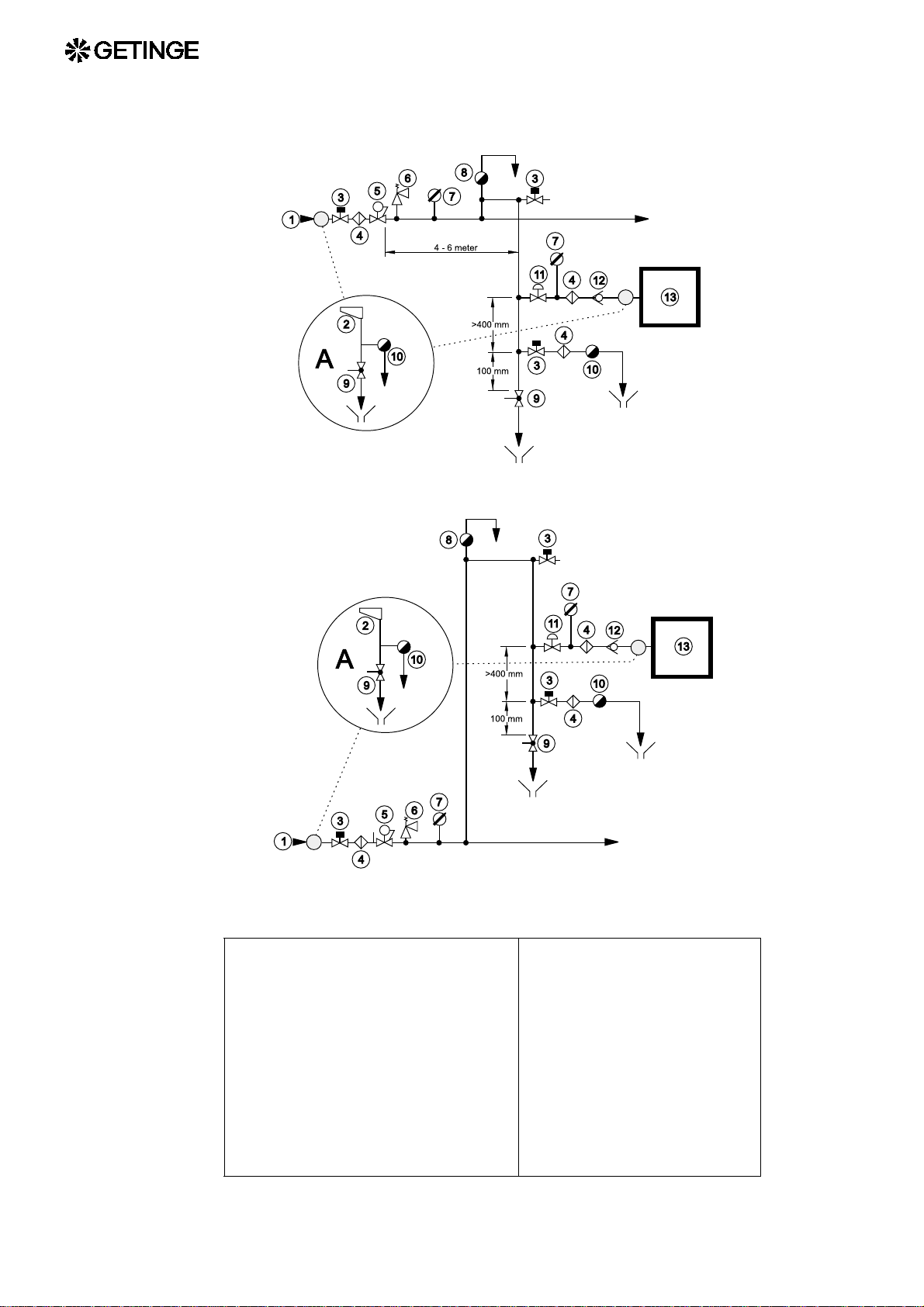

An arrangement as shown below normally satisfies the requirements for

dewateri ng, filtr ation and m onitoring faciliti es when su pplying a

sterilizer with steam from a main steam supply line.

Feed line in the ceiling (bilder skall ändras 12 t.h. om 4)

22

Supply line in floor or in the storey below (ändr)

1 High-pressure line 8 Vent

2 Labyrinth diverter / separator 9 Ball valve

3 Shut-off valve 10 Ste am trap

4 Filter 11

Remote- controlle d valve

5 Reducing valve 12 Check valve

6 Safety valve 13 Sterilizer

7 Pressure gauge

Page 23

Compressed air quality

Instrume nt air

To ensure long life and reliable operation, the pneumatic components of

the equipment must be connected to a compressed air network that

supplies dry air with a low content of particles and oil.

Modern compressed air components are lubricated for life, so there is

no need for oil to be added to the instrument air. The air must obviously

not contain any solvents or abrasive or corrosive foreign substances that

may damage the pneumatic components.

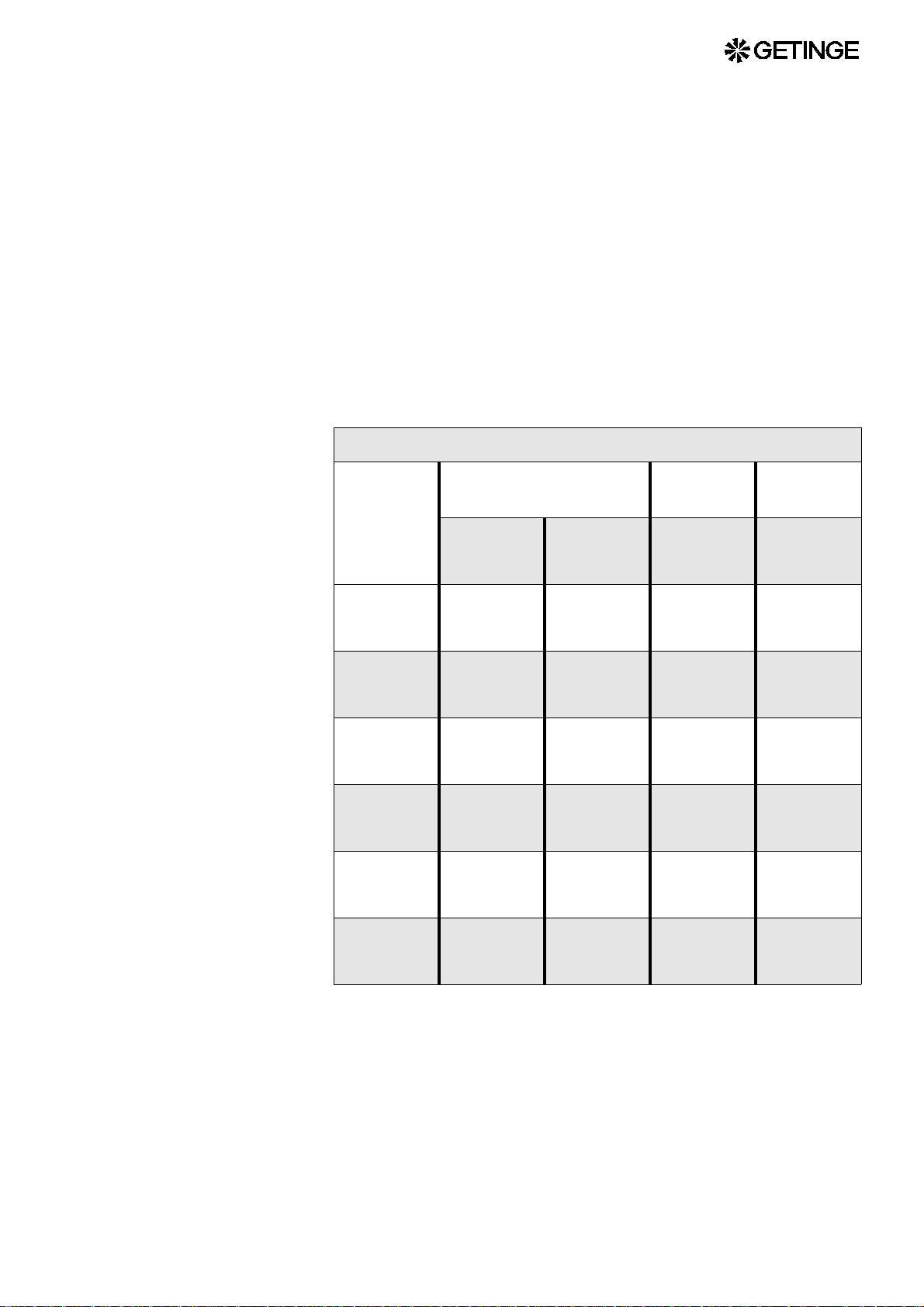

According to international standards, air quality is divided into

classes.

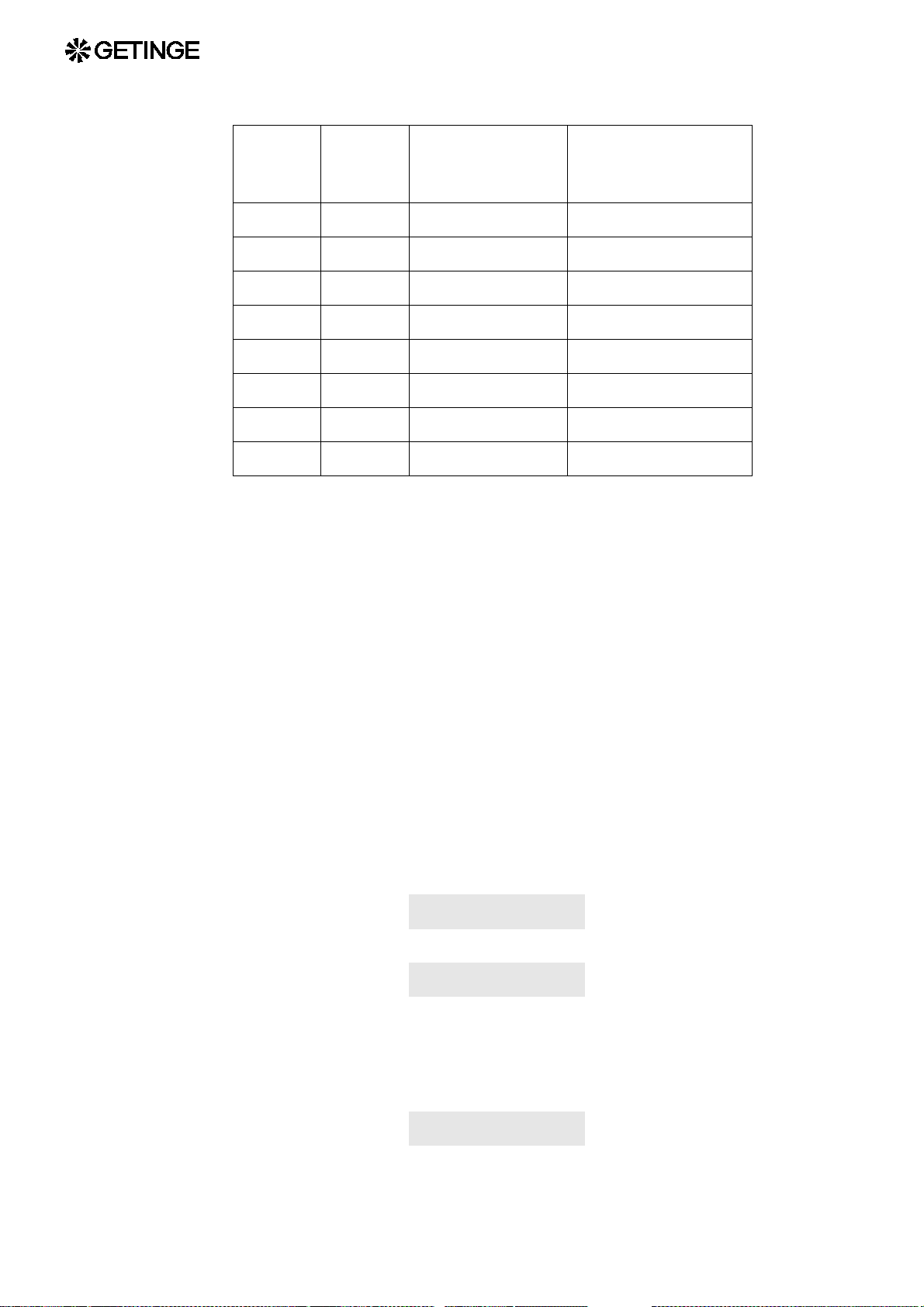

ISO 8573-1 quality classes

Quality

class

1 0,1

2 1

3 5

4 15

5 40

Content of contaminants

Size and max conc.

µm

(µInch)

(4)

(39)

(197)

(591)

(1600)

mg/m3

(ppm)

0,1

(84)

1

(838)

5

(4190)

8

(6704)

10

(8380)

Dewpoint Oil

content

°C

(°F)

-70

(-94)

-40

(-40)

-20

(-4)

+3

(+37)

+7

(+45)

mg/m3

(4190)

(20950)

(ppm)

0,01

(8,4)

0,1

(84)

1,0

(838)

5,0

25

6 - - +10

(+50)

Where the equipment is connected to a common supply of process air

and instrument air, the levels recommended below may be unacceptable

for process air from a hygienic point of view.

Getinge recommends instrument air in the following classes:

-

• Contaminants content Class 3 or better.

• Dew point Class 4 or better.

23

Page 24

• Oil content Class 3 or better.

Air connection

Instrumen t air only

Some equipment in its basic version has only instrument air. Refer to

the practica l arrangement s below. Any non-r eturn valves, filters, etc.

are supplied by the purchaser, unless the contract states otherwise.

Common supply

If the user’s r equirements for air quality and the compressed air network

can meet the peak loading of the equipment without the pressure

dropping below 6 bar(g) / 600 kPa(g) / 85 psig, process air and

instrument air can be connected to the same compressed air network. A

check valve and sterile air filter, if required, should be supplied by the

customer unless other wise stat ed in the contract . See “T echnical data”

for details of peak consumption, etc.

Separate supply

Some equipment with a high peak process air loading is intended to be

supplied separately with process air and instrument air. The equipment

may not operate properly and may be unsafe if the pressure in the

instrument air supply falls because of high process air consumption.

Any check valves, filters, etc. must be supplied by the customer unless

the contract states otherwise. See “Technical data” for details of peak

consumption, pressure, etc.

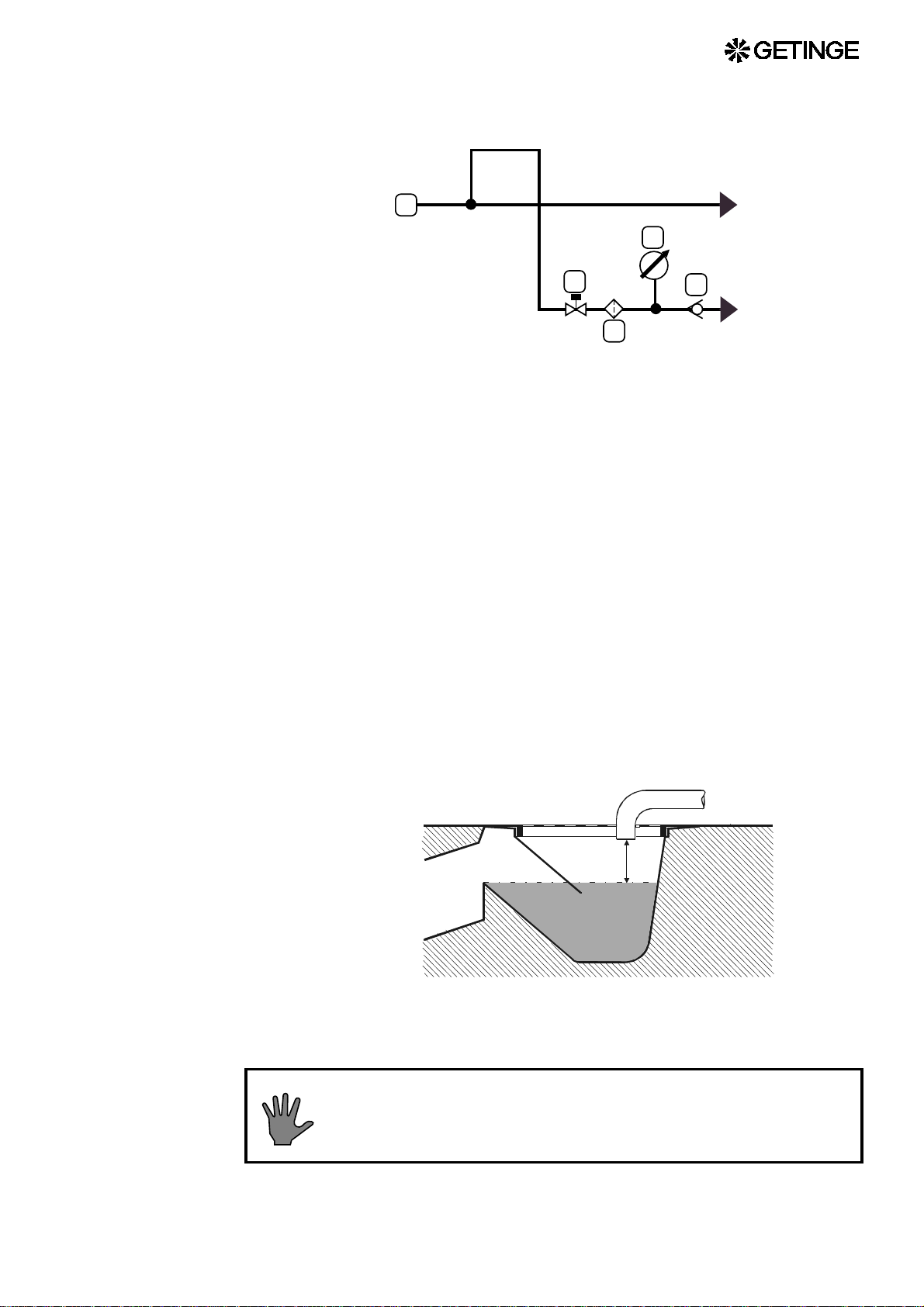

Practical arrangements

Connect the air connections of the equipment via a shutoff valve to a

compressed air network with a pressure of at least 6 bar(g) / 600 kPa(g)

/ 85 psig and no more than 8 bar(g) / 800 kPa(g) / 115 psig. See also the

24

Page 25

document “Technical data”. Where information is contradictory,

“Technical data” always takes precedence.

1

4

Drain

2

3

5

1 Main supply line 2 Shut-off valve

3 Filter 4 Pressure gauge

Waste pipes coming from different parts of the equipment must not be

combin ed. The y must be piped se parate ly to the floor dra in with out

restriction or back-pressure.

Comply with local regulations relating to waste water (addition of

formalin, temperatur e re str ic tions, etc. ).

• Run the drain pipe(s) with a f all towards the floor drain, where it/the y

must terminate at a distance of at least two pipe diameters above the

highest water level of the water trap, but at least 20 mm (1”) above

the water level (dimension A). Pipes less than 1.5 m (5 ft) long

require only a minimal fall.

A

• Design the waste pipes for short duration temperatures of about

100oC (212°F)..

Plastic waste pipes shou ld be avoid ed, as a los s of cooling

medium may result in the outlet being exposed to waste

water at 100°C (212°F) for a long time.

25

Page 26

• The capacity of the waste water system must comply with current

regulations. The technical data of the equipment states starting

values for the calculation of standard flow in hospital and industrial

environments. These calculations must be made in accordance with

national regulations. Normally, after calculation of the design flow

rate, the system capacity must be increased by an additional 50 %.

• The size and number of floor drains must match the size and number

of the connections on the equipment; see Technical data. The floor

drain opening should be at least 200 mm (8”).

Outlet from safety valve

The equipment and/or its supply lines are fitted with one or more safety

valves. Safety valves on equipment with a small opening are fitted with

outlet pipes which carry the blown-off steam or air to a safe position in

the service area.

Safety valve outlets 50 mm (2”) and large r are normally not fitt ed with

outlet pipes at the factory.

Ventilation

We always recommend, where circumstances allow, that the oulet

pipes are re-routed so they they end at a safe place outside the building.

In some countries this is a requirement of the pressure vessel authority.

The reason for this is that, in most cases, it is safer to arrange for the

steam/air to be discharged out side t he ser v ice ar ea because of the large

volume ejected. If this cannot be done, the safety valve must be fitted

with a pipe to carry the steam/air to a safe place. The responsible

authority must approve the choice of outlet location.

Pipework connected to the safety valve:

• must have at least the same size of opening as the safety valve

• must NOT contain shut-off valves or other throttling devices

• must be designed to prevent the formation of water pockets or, if this

is not possible, must be fitted with drain pipes to carry away trapped

water

26

All types of equipment

On the bas is of the va lues for h eat dissipa tion given i n the tec hnical

data, the ambient temperature around the equipment mus t be r egulated

to 15 to 35oC (60 to 95°F) by means of a suitable ventilation system. If

possible, relative humidity should not exceed 85 %.

These requirements apply not only to the service area of the equipment

but also to the operator areas.

Page 27

All sterilizers

Bear in mind the heat contribution of the load when unloading and when

storing after the process.

The load contributes a significant amount of heat to the

operator area when th e loa d is un load ed on comp letion of

the process. This heat emission is not stated in the

technical specification.

Sterilizers with a vertically-operating door:

Each sterilizer door is fitted with a ventilation stub, which must be

connected to the ventilation system. This provides an efficient barrier to

prevent excessive surplus moisture a nd heat finding their way into the

operator area.

Inspectio n by auth o rities

The user of the equipment must, upon installation of the unit, inform the

approp riate authoritie s that this ha s been done a nd also comply with

local restrictions governing the connection of water, drainage and ventilation. There are often local restrictions on connection to the drinkingwater mains, on how wastewater is to be treated and how ventilation is

to be arranged. This is particularly importa nt when installi ng steril izer s

for formalin sterilization or ethylene oxide sterilization as limit values

for emissions may have to be complied with.

The owner of the equipment must find out whether a pressure vessel authority inspection must be carried out prior

to use.

Response for pressure vessel and safety valves

Pressur e vessels s ubjected to cycl ic loads mus t accordi ng to pressure

vessel regulations be inspected periodically.

The end-user is responsable to arrange inspections of pressure vessels

and checks of safety valves in accordance with requirements f rom notified bodies in each country.

All equipment with safety valves: If the equipment is provided with

one or more safety valves, a description of a check is to be found in the

section Check of safety valve in the chapter GENERAL ADVICE.

All equipment with bursting disc: A description for assembly of

bursting discs is to be found at Assembly of bursting disc in chapter

COMPONENS.

27

Page 28

Pressure vessel with door(s): If the equipment is provided with pressure vessel doors, a description of a safety check is to be found in the

DOOR chapter.

Only for equipment according to the European pressure vessel

directive: T he first inspection must be carried out at the latest upon a

number of cycles given by the manufacturer on the pressure vessel EEC

declaration of conformity. Further inspections is stated by the notified

body, normally at the first inspection.

Functional check-up prior to use

• This function check must be carried out by a s killed te chnic ian. See

chapter FUNCTIONAL CHECK for further information.

• For sterilizers that are to be validated under European Standards, the

function check must be based on instructions according to EN554.

The user should set up a routine for continuous tests of the equipment.

28

Page 29

FUNCTION CHECK

Before use

Read all the documentation and check that all supply

media are correctly connected to the connection points.

• Check that the guidelines of the installation instructions about the

connection of supply media are followed: electric power, water,

compressed air , steam, etc.

• Check also that the guidelines for waste and ventilation have been

met.

• Check that the operating instructions are displayed at the unit.

• Carry out any customisations of the unit (where applicable). See the

section headed “Functions which can be programmed by the user” in

the chapter on ADVICE AND INSTRUCTIONS.

• Check that all the connecting screws belonging to electric cables are

sufficiently tightened. Pay particular attention to power wiring.

• Open the valves for all supply media.

• Check that the water tank level is about 13 mm (1/2”) below the spill

way. Adjust if necessary on the float valve.

• Check that the feed water enters at least 20 mm above the overflow

level.

• When the feedwater tank is full of water, check the direction of

rotation of the vacuum pump by briefly pressing the contactor. The

direction of rotation of the pump must agree with the arrow on the

pump housing. To reverse the direction of rotation, follow the

instructions under Electrical in the chapter INSTALLATION.

• If the vacuum pump does not draw sealing water immediately when

it starts, fill the feedwater tank to the brim by closing off the

overflow and holding down the float. It may also be necessary to

briefly open the pump t hrottle va lve fully, to restore it to the correct

position when the pump gas started to draw water.

Do not let the pump run dry for more than a few seconds.

29

Page 30

• If the vacuum pump has jammed, pull off the pump impeller

according to the instructions in the COMPONENTS chapter of this

manual.

• Perform all safety checks as described in the GENERAL ADVICE

and The Door chapters.

• Check and, if necessary, adjust the supply of sealing water and leak

air to the vacuum pump. See under the heading “ECO-water

conservation system” in the MAINTENANCE chapter for

adjustment of the sealing water, and under “Vacuum pump” in the

COMPONENTS chapter for adjustment of the leak air.

• Check the fans for correct direction of rotation. When seen from

inside the chamber, they should rotate anti-clockwise. To reverse the

direction of rotation, follow the instructions under Electrical in the

chapter INSTALLATION.

• Check that condensate drips down into the collecting cups at the fan

seals when the sterilizer is running. The rate should be a at least five

drops per second (200 ml/minute).

• Check that the fan seal does not leak condensate through the

overflow pipe.

• Do a leakage check on the installation and the sterilizer. Covered-in

equipment and cabinet models must be checked with the cladding

plates removed.

• Run all processes while checking pressure, temperatur e, times and

the operation of the indicator lamps. Set points will be found in the

phase list. File the test run printouts.

Note that the basic version of some equipment, and apparatus

connected to higher-level systems, may not have special provision

for process printout.

30

Page 31

MAINTENANCE

To be do ne by trained technic ians only

ESD (Electrostatic discharge)

ESD damage in installation and servicing may destroy the

electronic equipment. Read the instructions in the ESD

section in the INSTALLATION chapter BEFORE starting

work.

Overview of safety d evices

Claddi ng and front panels must pr event access to the parts

of the installation that are normally accessible only to

trained personnel.

General access to an installation supplied without

cladding, which should normally only be maintained by

trained personnel must be prevented. A convenient way of

preventing ac cess is t o in sta ll th e e qu ipment in a lo ckab le

area.

The cladding panels of the unit, or if none are fitted, the room in which

the unit is installed, must ensure that only authorised and specially

trained personnel can have access to the internal parts of the installation.

Safety components

Every unit is equipped with a number of components with the specific

purpose of ensuring the safety of personnel. These items are marked

with the a warning triangle below in the following documents:

• electrical diagrams

• pipework diagrams

• spare parts lists

31

Page 32

These comp onents have und ergone sp ecial tests befor e being

accepted as safety components. For this reason, they must not be

replaced with components of any make or design that has not been

approved by GETINGE AB. It is of the highest importance that the

operational reliability of thes e components is continuously upheld

during the entire service life of the installation. The signs [tecknen??]

are used not only to indic ate important components, but als o to draw

attention to other safety factors that call for special attention, such as

dimensions, tolerances, materials, etc .

After commissioning

When the sterilizer has been in service for one month, deposits and

particles from new pipes will have collected in filters and sensitive

components. If these deposits are not dealt with they will cause

malfunctions, leakage and reduced performance.

• Clean all dirt filters and restrictors.

• Clean all steam traps. Remove deposits on their seats and floats.

• Check that the pipework of the installation and unit is leaktight.

• Check that all the electrical connection screws on power, earth and

neutral cables are tight.

• Clean the plastic strainer in the float valve inlet.

• Perform a leaktightness test by running the Leakage test process. See

Leakage test in the OPERATOR MANUAL under The process.

After a long idle period

After the sterilizer has been idle for a long time, it is advisable to carry

out the actions below. A long idle perio d may be a shutdown or a

holiday.

During the idle period

• If possible, the unit should be started and operated once a week.

On starting after the idle period:

• Run an approved leakage test.

Maintenance plan

Replacing the air-in filter

Depending on the size of the sterilizer, the air-i n filter mus t be changed,

after a certain number of processes as stated below, or when pressure

32

Page 33

equalisation takes too long.

In any event, the filter must be changed at least once a year.

Replacing the sterile filter

Depending on use, number and size, the filter should be replaced, in the

event of a breakdown or according to local regulations, but in any event

at least once a year.

The integrity of the filter should be checked in accordance with local

regulations or every week in continuous operation.

The filter units should be replaced more often if the

environment is damp or dusty.

HS 6606 300 cycles

HS 6610 275 cycles

HS 6613 250 cycles

HS 6617 200 cycles

General gui delin es fo r peri od ic main te na nc e

In many cases, maintenance specified under weekly and monthly can be

done by an authorized user trained in perfor ming the stated tas ks. The

slightly more demanding maintenance tasks under quart erly, six-

monthly, etc. must be done by trained technical maintenance personnel.

Local and national safety regulations must always be followed.

Once a week

Check the air-in filter for a tight and rigid attachment.

•

Monthly

•

Check that the door closing motion can be stopped by gently

pushing, the squeeze protection plate in the door anti-motion

direction.

• Check the operation of printer pens, ink cartridges and/or ribbons,

for example by checking the graphical printout. Replace if

necessary.

33

Page 34

Quarterly

Every six months

Carry out the maintenance under “Monthly”.

•

• Check the door seal. If necessary, lubricate or replace the seal. See

the section on DOOR. Note that special operating conditions and/or

media quality may require shorter or longer intervals.

• Perform a leaktightness test by running the Leakage test process. See

Leakage test in the OPERATOR MANUAL.

Perform the maintenance operations as described under "Every

•

month" up to and including "Every three months".

• Clean all dirt filters and restrictors.

• Clean all steam traps. Remove deposits on their seats and floats.

• Check that the pipework of the installation and unit is leaktight. Seal

all leaks. Replace any leaking gaskets.

• Check that all the electrical connection screws on power, earth and

neutral cables are tight.

• Clean the plastic strainer in the float valve inlet.

• Perform the following maintenance operations, which are described

in more detail under DOOR.

· Check the door action.

· C heck the door position vertically, laterally and backward/

forward.

· Checking the operation of door seal and seal groove valves.

· Lubricate or replace the door seal if necessary.

· Perform safety checks as described in “Door safety devices”.

· Perform safety checks as described in “Interlocking the start

function”.

· Safety checks as described in “Blocking of chamber media

supply”.

· Safety checks as described in “Safety blocking of door opening”.

• Check the lead seals on all safety valves.

34

Page 35

• If the seal is not intact, the valve must be replaced. Alternatively, an

authorized person from the pressure vessel authority can be called to

re-inspect and re-seal the valve.

If the seal of a safety valve has been broken, the

opening pressure may have been changed.

Units with broken safety valve-seals must not be used.

• Check that none of the safety valves is leaking water or steam.

• Clean the flow restricters and adjust the flow of vacuum pump

sealing water if necessary, as described under “Maintenance” in the

“ECO water saving system” section.

• Print out the list of the twenty mos t recent faults (see the CONTRO L

UNIT chapter) and assess whether these indicate faults in

components or incorrect settings.

• Check the operation of the operator panel display, any LEDs and

printer, if any. See the CONTROL UNIT chapter.

Yearly

•

Perform the maintenance operations described under “Monthly” up

to and including “Six monthly”.

• Temperature sensors and pressure sensors connected to the control

system must be checked against an independent system with

documented accuracy, traceable to a national standard. Note that the

measurement error of the reference instrument must not exceed onethird of the measurement inaccuracy to be achieved. National

standards and local regulations must be complied with.

Temperature check: We recommend doing the check in ice water

at 0 °C (32 °F) and in an oil bath at process temperature, eg 121 °C

(250 °F). It is very important to allow the sensors to stabilise in the

baths before doing the check. An ice bath must be filled with crushed

ice and be properly stirred.

The temperature measuring error must not exceed 0.5 °C (0.9 °F).

Calibration of temperature sensors, see CONTROL UNIT.

Pressure check : A reference instrument for pressure checking is

usually combined with equipment for raising and lowering the

pressure. If this is not the case, the check can often be done by

connecting the reference instrument directly to the unit and using the

built-in features to alter the pressure. Note that the pressure

measuring system of the unit can detect pressure changes within ± 1

mbar / ±0.1 kPa / ±0.0145 psi and that the permitted measurement

error below refers to absolute levels for the entire range.

35

Page 36

The pressure measurement error must not exceed ±8 mbar / ±0.8 kPa

/ ±0.115 psi within a range 0-1 bar(a) / 0-100 kPa(a) / 0-14.5 psia.

At pressures above 1 bar(a) / 100 kPa(a) / 14.5 psia, the difference

must not be greater than 0.01 x P(a). Calibration of pressure sensors,

see CONTROL UNIT.

If the pressure sensor of the unit is removed, the gasket

must be replaced with a genuine Getinge spare part.

• Check and adjust the water level in the feedwater tank so that it is

about 12 mm below the overflow.

• Check that the feedwater inlet pipe discharges at least 20 mm above

the overflow outlet.

• Check and adjust the amount of sealwater to the vacuum pump and

where applicable its cavitation protection, according to the

instructions under “Vacuum pump...” in the COMPONENTS

chapter.

• Run all processes while checking pressure, temperatur e, times and

the operation of the indicator lamps. File the relevant process

documentation such as recorders charts, process printouts or log files

from the test runs.

Additional maintenance operations, every second year

Perform the following operations, as described in the “Heat

•

exchangers” section of the COMPONENTS chapter.

· If the water is harder than 4 dH (70 ppm), clean all plate-type heat

exchangers.

· Pressure-test al l the heat exchanger s.

• Replace the humidity protection device in the control cabinet. Write

the replacement date on a label and attach the label beside the

humidity protection device.

Cycle counter

The PACS 3000 control system is fitted with a cycle counter. The cycle

counter is p rinted o ut on each p rocess log with Sup ervisor or an A4

printer connected to PACS 3000. On cold-start or replacement of CPU,

this cycle counter will be reset to zero. The cycle counter can only be

adjusted or read off using GETINGE CS 1000.

36

Page 37

The ECO water-saving system

Patent pending PCT/SE94/00998

The autoclave is fitted with the ECO (economy-ecology) water-saving

system. This means that the wat er system s of the autocl ave are divided

up into two separate pipe networks. One system contains water that has

come into direct or indirect contact with the it ems, and has consequently

been contaminated. The other system contains water that has been used

for cooling in such a way th at it is not contaminat ed and can therefor e

be used as process water.

The contaminated water is mainly us ed as sealing water to the vacuum

pump and is circulated in a system where it is cooled and diluted with

approximately 1/6 fresh water from a water tank with air disconnection

to increase pump capacity.

ECO-system reduces the water requirement by approximately 40 % if

the pure process water is not re-used and approximately 75 % if this is

re-used.

E

4

3

A

1

2

A Cold water

B Clean process water inlet

C Clean process water outlet

D Contaminated process water outlet

4

4

B

C

D

E Ventilation

37

Page 38

Recovery of cooling water

Connections A and B are normally linked, but if the water in the cooling

water circuit is to be re-used as process water, th en A and B will be

separated. Water via connection A will be used exclusively for sealing

water for the vacuum pump and, in certain cases, also as feed water for

the steam generator.

Connections B and C will have been connected on installation to the

special cooling water circuit for re-use, for which the following

requirements apply.

• Incoming water pressure (B) must not be higher than 10 bar(e).

• The pressure in the incoming supply main (B) must be at least 3 bar

higher than in the return main (C).

• The temperature in the incoming main should not be higher than 20

°C, and the water hardness should not exceed 4 °dH (0.7 mmol/l).

Maintenance

Restrictions

Fixed restrictions 1 and 2 and ball valve 3 must be cleaned at least every

six months. Note or preferably mark the setting of the ball valve before

it is removed.

Take care to set the ball valve opening angle after reassembly as it was

prior to disassembly.

Settings and inspection

• Adjustment of settings/inspection can most suitably be performed

during a process incorporating post-vacuum, as the vacuum pump is

then working under stable pressure conditions.

· 5. 5 cm height in the tank is equivalent to approximately 1 litre.

· C a refully ke ep ing the float valve in its closed position, use a

stopwatch to measure the time for the water level to drop by an

amount equivalent to one litre.

Note: The water level must drop in the tank a s a whole. If the tank

is divided, it may be necessary to remove the divider in order to

ensure this.

· Calculate the flow capacity through the restriction 1 and 2 using

the formula given below. The capacity must be within the range

of the value shown above.

(measured volume in litres / measured time in seconds) x 60 =

litres/min.

· If necessary, adjust ball valve 3 if the capacity in the fixed

restriction is not within the specified range.

Reducing the flow through the ball valve automatically increases

the capacity through restriction 1, while increasing the flow

through the valve produces an opposite effect.

38

· Return the equipment to its normal operating state.

Page 39

Heat exchangers

The plate heat exchangers must be cleaned at least once every two

years. Clogging depends very much on the water quality, and

particularly on the water hardness. The part of the system that is most

inclined to clog is the final heat exchanger before outlet C. Clogging

causes a reduction in cooling capacity and longer process times.

When the h eat exchanger s are cleaned , they should als o be pressur etested in order to check that no cracking has occurred.

Cleaning, pressure testing and capacity testing are described in the

"Heat exchangers" section of the COMPONENTS chapter.

Recycling of cooling water

Connections 1) and 2) are normally connected together, but when the

water in the cooling circuit is to be recycled, 1) and 2) are separated.

Connection 1) is then used exclusively for sealing liquid for the vacuum

pump.

2) and 3) are connected during installation to the special cooling water

circuit for recycling. This is subject to the requirements of the document

“Technical Data” and the INSTALLATION chapter.

Warranty

Service

Spare parts

Warranty conditions and warranty period are described in the

commercial documentation. See the order confirmation that governs the

terms of delivery for this unit.

Contact your local GETINGE representative

or

GETINGE Service Team

International dept.

Phone: +46 35-15 56 36

Fax: +46 35-583 08

Contact your local GETINGE representative

or

GETINGE

Spare parts dept.

Phone: +46 35-15 56 37

Fax: +46 35-15 56 60

39

Page 40

40

Page 41

ADVICE AND INSTRUCTIONS

Manual interventions in the process

When faults occur during a process because of interruptions in the

supply of media or compone nt faults, the process may, after an alarm

has been triggered, get stuck in a phase from which the control

equipment cannot proceed.

Various options are then open to the user. Options that do not involve

a hazard to the user are described in the “Alarms” section of the

OPERATOR MANUAL. If the operator’s options for action are not

possible or do not solve the problem, a trained technician must be called

to advance the program manually.

With the stepping option, a technician can under certain

circumstan ces m anu ally b ypas s bu ilt- in saf ety co nd itio ns.

Manual stepping with keyswitch

On manual stepping of a program with the button or the “STEP”

button after the keyswitch has been set to Stepping/Authorized us er, all

parameters are controlled by the automatic control equipment, so that

hazardous situations cannot normally occ ur. With manual control, the

program is stepped from one process phase to another without

temperature, time or pressure conditions being met.

For safety reasons, the ability to step past critical process conditions

is blocked. This applies to certain pres sure, temperature and leve l

conditions, except where there is a fault in an anal og sensor. Stepping

should be while the unit is still in the alarm phase.

When using this method, the blocks that prevent

hazardous situations from arising are removed. The

technician himself has to decide which operations are

permitted.

The above method may only be used by technicians who

are thorou ghl y familiar with the proc ess, th e proper tie s of

the goods and the functioning of th e individual

components.

41

Page 42

Faulty analog sensor

If an analog pressure sensor or temperature senso r becomes faulty

during a pro cess, the process st ops. The ty pe of fault does not all ow

restarting of the process, since the sensor fault persists after

acknowledgement, even if it is not indicated again. Another

consequence of a faulty analog sensor is that no pressure or temperature

controller becomes operative. This in turn means that neither

temperature, pressure nor ramped temperature changes can be

controlled.

With a pressure sensor fault, the operator must also step past the

pressure conditions on post-vacuum, evacuation, emptying, selfcooling and pressure equalisation. With a temper atur e s ensor fault, the

operator must step past the corresponding temperature conditions.

Sensor fault, independent system

In case the process is stopped in a cooling- or door opening phase, due

to failure of the independent sensors, the safety system can be by-passed

by manual operation of the safety relays.

See the electric wiring diagram.

Pressure sensor fault

Temperature sensor fault

Manual control by manually actuating the control

valves

The above method can be used to check the operation of individual

components, for troubleshooting and with system faults that keep the

process in the same phase.

When operating from menus on the operator panel or via a program

tool, there ar e no software interlocks to prevent haza rdous situations

arising. See the CONTROL SYST EM chapter for precise info rmation

about which menus are used at each interface.

When control valve s are operated directly t here are no interlocks at

all. We advise against this form of control.

42

Note that when operating via the operator panel or programming tool,

it is extremely important that all output s are reset to auto mode when the

work is complete. If this is not done, the safety and operation of the unit

will be at risk during the remainder of the process.

Page 43

Normally the operator is informed at the start of the next process if an

output is set to manual mode. Despite this, the status must always be

reset to auto mode immediately on completion of work.

When using this method, the blocks that prevent

hazardous situations from arising are removed. The

technician himself has to decide which operations are

permitted.

External safety interlock fault

The sterilizer is equipped with an aut omatic monitoring system for

those external components that serve as safety interlocks independently

of the control system.

If the external components changed the ir position, or got stuck a nd ar e

constantly indicating “safe position”, this would not normally have

been noticed in service. It would only have been discovered when it was

too late and the control system ha also failed, ie when the external

components were needed for safety purposes.

The purpose of the monitoring system is to ensure the operation of both

the safety systems that allow media, among other things, to be admitted

to the chamber or the door to be opened.

Monitoring is done by a system of relays which is in contact with the

external components and the control s ystem. At certain predeter mined

places before and during the process, t he control system checks by

means of the relay monitoring that the respective external component

has opened or closed its contacts as expected.

If the relay information does not agree with the contr ol system’s own

information, the control system stores the discrepancy until the process

has ended.

After the process, an alarm is activated and a message indicated what

type of interlocking is present (see also “Fault codes” in the operation

chapter of the OPERATION manual).

The alarm cannot be reset in the normal way, and as long as the alarm

is activated, a new process cannot be started.

INTERLOCK FAULTS

1. Shut off the audible signal by pressing the button or the

[ALARM OK] button.

2. Rectify the faulty component.

3. Activate the stepping key and reset the alarm with the button

or the [ALARM OK] button.

4. Set up the component and do a safety check. The procedure is

described in the DOOR chapter.

43

Page 44

5. Check that interlock faults have not been activated after completion

of a process.

Backup battery fault

If there is a f ault in the control sy stem backup battery, an al arm is

triggered when the current process has ended and the control system has