STERILIZER

GE224c VAC

Citomat 164 Vac

Manual

1

1

2 2

Contents

DECLARATION OF CONFORMITY 1 3

INTRODUCTION 5

W

ARNING

INSTALLATION 6

STERILIZER CONTROLS 8

DISPLAY 10

DESCRIPTION OF THE PROCESS 11

THE STERILIZATION CYCLE 12

OPERATING INSTRUCTIONS 13

S

TERILIZATION

B

ETWEEN STERILIZATIONS

C

LOSING DOWN FOR THE DAY

MALFUNCTIONS 15

F

AULT CODES

PROCESS INTERRUPTED 16

5

13

14

14

15

SAFETY DEVICES 17

S

AFETY CHECKING

17

MAINTENANCE 18

YEARLY MAINTENANCE SERVICE 19

DESIGN OF THE STERILIZER 20

C

OMPONENTS

S

EARCHING FOR LEAKS

20

26

SERVICE PROGRAM 27

S

ERVICE PROGRAMME SCHEDULE

30

TECHNICAL DATA 31

TROUBLESHOOTING 32

G

ETINGE SKÄRHAMN’S POLICY

F

LOW CHART

D

OOR CHART

E

LECTRICAL DRAWING

C

IRCUIT BOARD

35

36

36

37

: 34

SPARE PARTS LIST 38

C

OMPONENTS

40

7817Mannual Eng D Fr o m ser no: 981412040 980401

3

3

5

DECLARATION OF CONFORMITY

Manufacturer

Name

3

Adresse

Telefon

4

5

Product 6

Machine reference 7

Sterilizer: GE 224c Vac / Citomat 164 Vac

Type number

978046101, 978046106, 978046103, 978046105

We declare under our sole responsibility that this product is

in conformity with the following standards or standardization

documents: 8

SS-EN50081-1, SS-EN50081-2

SS-EN50082-1, SS-EN50082-2

SS-EN61010-1, SS-EN61010-2-041

SS-EN60204-1

According to the provisions of the regulations: 9

89 / 336 / EEC

AFS 1994:39

LVD 73 / 23 EEC

MDD 93 /42 EEC (class IIa)

Place, date of issue

Skärhamn 980714

Position of issuer

Managing director

Signatur of issuer 12

2

Getinge Skärhamn AB

Box19 S-47121 Skärhamn

+46 0304 671020

13

10

11

1

4

4

Translation of ”DECLARATION OF CONFORMITY”

D

1. KONFORMITÄTSERKLÄRUNG

2. Hersteller

3. Name

4. Anschrift

5. Telefon

6. Erzeugnis

7. Beschreibung der Machine

8. Wir erklären in alleiniger

Verantwortung, dass dieses

Produkt mit den folgenden

Normen oder normativen

Dokumenten übereinstimmt

9. Gemass den Bestimmungen der

Richtlinien

10. Datum

11. Titel des Ausstellers

12. Unterschrift

NL-B

1. VERKLARING VAN

OVEREENKOMST

2. Fabricant

3. Naam

4. Adres

5. Telf.nr.

6. Produkt

7. Machine type

8. Wij verklaren dat dit produkt

voldoet aan de volgende

normen of normatieve

dokumenten

9. Volgens de bepalingen van de

richtlijnen

10. Datum van afgifte

11. Functie

12. Handteckning

FIN

1. YHDENMUKAISUUSILMOI

TUS

2. Valmistaja

3. Nimi

4. Osoite

5. Puh

6. Tuote

7. Viite

8. Todistamme täten ja

vastaamme yksin siitä, että

tämä tuote en

allalueltujenstandardien ja

standardoimisasiakirjojenvaati

musten mukainen.

9. Seuraavien ohjeiden

määraysten mukaisesti

10. Päivämäärä

11. Toimi yrityksesså

12. Allerkirjoitus

1. ERKLÆRING VEDR.

ENHETLIGHET

2. Produsent

3. Navn

4. Adresse

5. Telefon

6. Produkt

7. Type nummer

8. Vi overtar ansvaret for at

dette produkt er i

overensstemmelse med

følgende standarder eller

standard-dokumenter

9. I samsvar med

bestemmelsene i direktivene

10. Dato

11. Titel

12. Signatur

1. ÖVERENSKOMMELSED

EKLARATION

2. Tillverkare

3. Namn

4. Adress

5. Telefon

6. Produkt

7. Typbeteckning

8. Vi intygar och ansvarar för

att denna produkt

överensstämmer med

följande normer och

dokument.

9. Enligt bestämmelserna i

direktiven

10. Datum

11. Titel

12. Signatur

1. DICHIARAZIONE DI

CONFORMITA

2. Produttore

3. Nome

4. Indirizzo

5. Telefono

6. Prodotto

7. Riterimento maccina

8. Assumendone la piena

responsabilità, dichiariamo

che il prodotto é conforme

alle sequenti normative ed

al relativi documenti.

9. In base alle prescrizioni

delle directtive.

10. Data di emissione

11. Qualifica del dichiarante

12. Firma del dicharante

N

S

DK

1. ERKLÆRING VEDR.

ENSARTETHED

2. Producent

3. Navn

4. Adresse

5. Telefon

6. Produkt

7. Maskine ref.

8. Vi erklaerer undere

almindeligt ansvar at dette

produkt er i

ovensstemmelse med

følgende normer eller

normative dokumenter

9. I henhold til

bestemmelserne i

direktiverne

10. Dato

11. Titel

12. Signatur

F

1. DÉCLARATION DE

CONFORMITÉ

2. Fabricant

3. Nom

4. Adresse

5. Telephone

6. Produit

7. Ref de la machina

8. Nous déclarons sous notre

propre responsabilité que ce

produit est en conformité

avec les normes ou

documents normalisés

9. Conformément aux termes

des réglementations

10. Date

11. Fonction

12. Cachet et signature

I

1. DECLARACIÓN DE

CONFORMIDAD

2. fabricante

3. Nombre

4. Direccion

5. Telefono

6. Producto

7. Referncia de la machina

8. Declaramos bajo nuestra

sola responsabilidad que este

producto está en conformidad

con las normas o documentos

normalizados siguientes

9. De acuerdo con las

regulaciones

10. Fecha

11. Cargo

12. Firma

E

P

1. DECLARAÇÂ DE

CONFORMIDADE

2. Fabricante

3. Nome

4. Mozada

5. Telefone

6. Producto

7. No. artigo

8. Declararnos sob nossa

exclusiva

responsabilidade que este

producto cumpre as

sequintas normas ou

documentos normativos

9. De acordo com as

disposiçoes das directivas

10. Data

11. Cargo

12.

Assinatura

5

5

I

NTRODUCTION

Variants

These sterilizers are marketed under two brands which, apart from the names, are identical: Citomat is

aimed primarily at the dental market and the GE versions primarily at the medical sector.

Sterilizers GE224c/Citomat 164 and GE224c VAC/Citomat 164 VAC are bench sterilizers which

perform pre-programmed sterilization processes fully automatically.

Two versions of the sterilizer are available: the GE224c/Citomat 164 and the GE224c VAC/Citomat 164

VAC. The GE224c/Citomat 164 incorporates pulsed air removal and radiant post-drying, and is suitable

for sterilization of thermally stable items such as those made of metal, glass, plastic and rubber.

The GE224c VAC/Citomat 164 VAC has, in addition, air removal and drying with vacuum, which

means that it can also be used for sterilizing textiles, hollow instruments and packaged items.

General

Sterilizers GE224c/Citomat 164 and GE224c VAC/Citomat 164 VAC are bench sterilizers which

perform pre-programmed sterilization processes fully automatically. The sterilizers use steam which is

produced by a separate steam generator inside the unit. The steam generator is supplied with distilled or

de-ionised water from an integral tank.

Warning

Very important text and warnings are marked with a double border like this.

• The sterilizer operates with pressurised steam, so parts of the sterilizer may become hot.

Always take great care when working with the sterilizer.

• Only clean the sterilizer when it is cold.

• The tank cover can become very hot during certain parts of the process.

• Never lift the tank cover when the safety valve is operated.

• Take care when emptying the tank; the water may be very hot.

• The items in the sterilizer will be hot after the sterilization process.

• When the door is opened, hot steam may flow out of the chamber.

• When handling and loading items, remember that the chamber and the door are very hot.

Warranty

A one-year warranty is given on components, but not on components regarded as consumables, e.g. door

packings. For servicing work, reference should be made to agreements with the supplier.

IMPORTANT: The warranty on the delivered product is invalidated by faulty installation.

The legal rules relating to manufacturer's liability only apply if the instructions in this manual have been

followed

6

6

I

NSTALLATION

Internal transport

The simplest way of moving the sterilizer is to use a pallet truck or trolley, capable of carrying at least

110 kg.

Unpacking

Check that the product is undamaged. Notify any damage caused during transport immediately to the

transport company. Check that the items received are in accordance with the order.

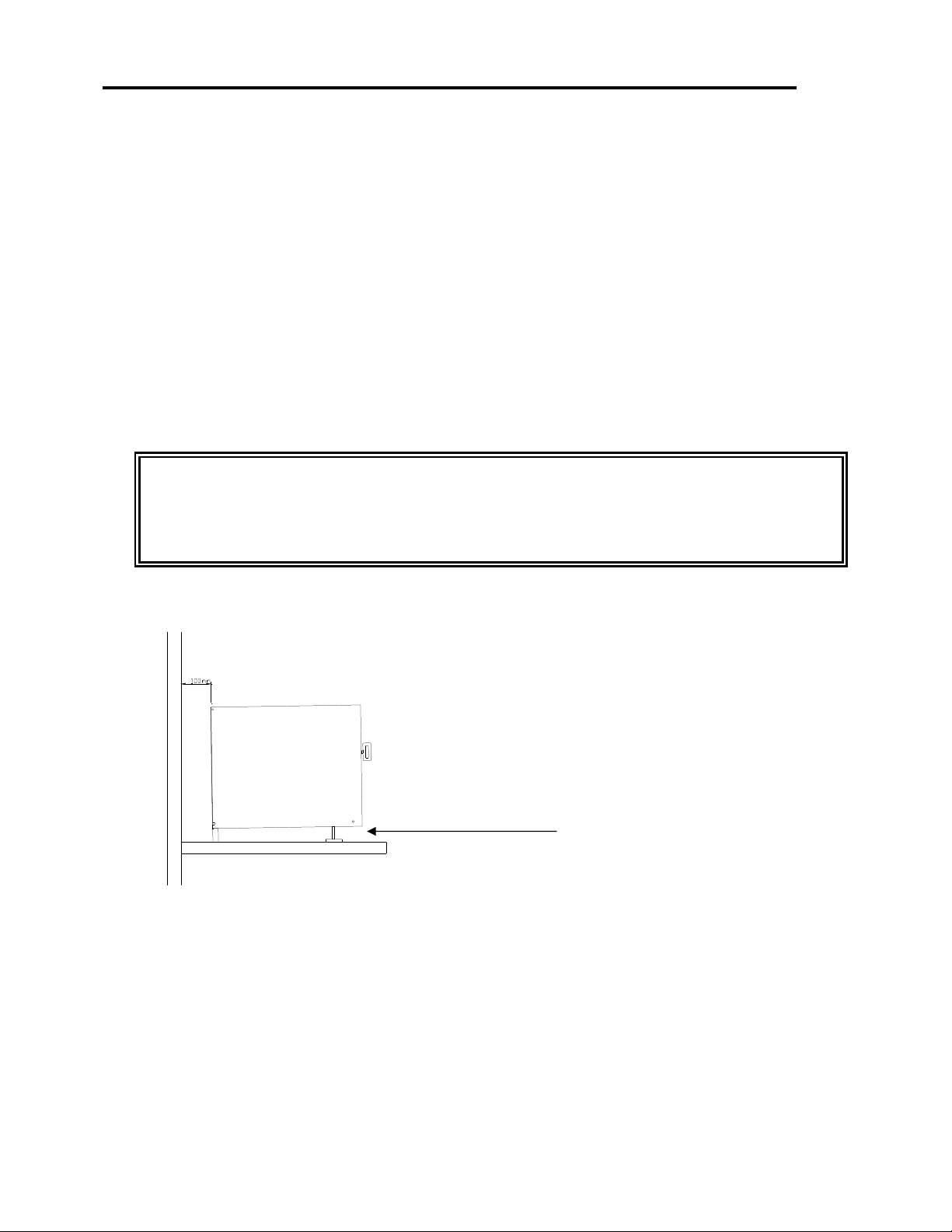

Setting up

Store the sterilizer indoors at a temperature between +2 °C and 40 °C and at a relative humidity not

exceeding 95%, non-condensing.

The sterilizer should preferably be installed by an authorised technician. There should not be a cupboard

or shelf immediately above the sterilizer: it must be possible to fill and clean the water tank from the top

of the unit without difficulty.

Position the sterilizer so that there is at least 10 cm free space all round it, in order to ensure

the necessary air circulation.

The ambient temperature around the sterilizer should not exceed 35 °C.

It is most important for correct performance that the chamber should slope backwards.

• Place the sterilizer on a firm base, that will not be damaged by any unintentional water spills. The

external dimensions of the unit are intended to fit on a normal worktop with a width of 600 mm.

Min.distance to wall :

100mm

Free space above sterilizer

min.: 200mm

The sterilizer must lean

backwards

Adjustable feet

• Make sure that the support surface can carry a load of at least 120 kg.

• Fit the door handle.

• Make sure that the sterilizer chamber slopes slightly backwards: adjust it using the front feet of the unit.

If the surface of the water is parallel with the line in the tank, the slope is satisfactory.

• Set up the Care Instructions and Description of Operation near the sterilizer.

• Make sure that the operator has access to, and has read, the Description of Operation.

• Collect all other documentation supplied with the sterilizer, and ensure that it is available throughout

the life of the sterilizer.

• Make sure that the technical documentation is available to the service technician.

7

7

holders for bags (to improve

• Check that there is a suitable power outlet in the vicinity of the sterilizer, and check that its voltage

agrees with that shown on the sterilizer rating plate. The outlet must be earthed (grounded) and

protected by a 10 A fuse.

Warning: Connection to an incorrect power supply may have lethal results.

• If the sterilizer has been transported at temperatures below -5 °C, it may be necessary to reset the

overheat protection device. (See the section entitled Controls for the position of the reset pushbutton.)

If the indicator lamp and display panel do not light up when the sterilizer is connected to the power

supply, this may have happened.

• Fill the water tank with distilled water or de-ionised water (maximum 30 µS/cm) to the maximum mark

(about 5 litres), from the de-ionisation equipment recommended by the sterilizer manufacture.

Warning: Putting the wrong liquids in the water tank can result in injury or other danger.

• Make sure that all operational and safety features have been checked by an authorised technician before

the sterilizer is used.

• If the sterilizer has been unused for a long time, the tank may need to be filled with water the day before

starting, to allow any air bubbles to disperse.

Commissioning / Validation

A document entitled “Points to be checked on installation” accompanies every sterilizer. Check each

point and return the document to the supplier or dealer.

If the sterilizer is used for the re-sterilization of medical instruments, the sterilizer must be validated

before being put to use. We recommend EN-554 as a model.

If a sterilized product is to be labeled with a CE-mark, the medical directive must be followed.

Indicators

If indicators are used to verify the process, we recommend those made by certified companies and

fulfilling applicable standards.

The following are used in the factory test runs.

Browne, Euro TST B & D type test pack 134° C / 3.5 min, for vacuum/steam

and the biological indicators used are of the following make:

Boule Nordic AB: Type B stearothermophilus art. no. 3014-s.

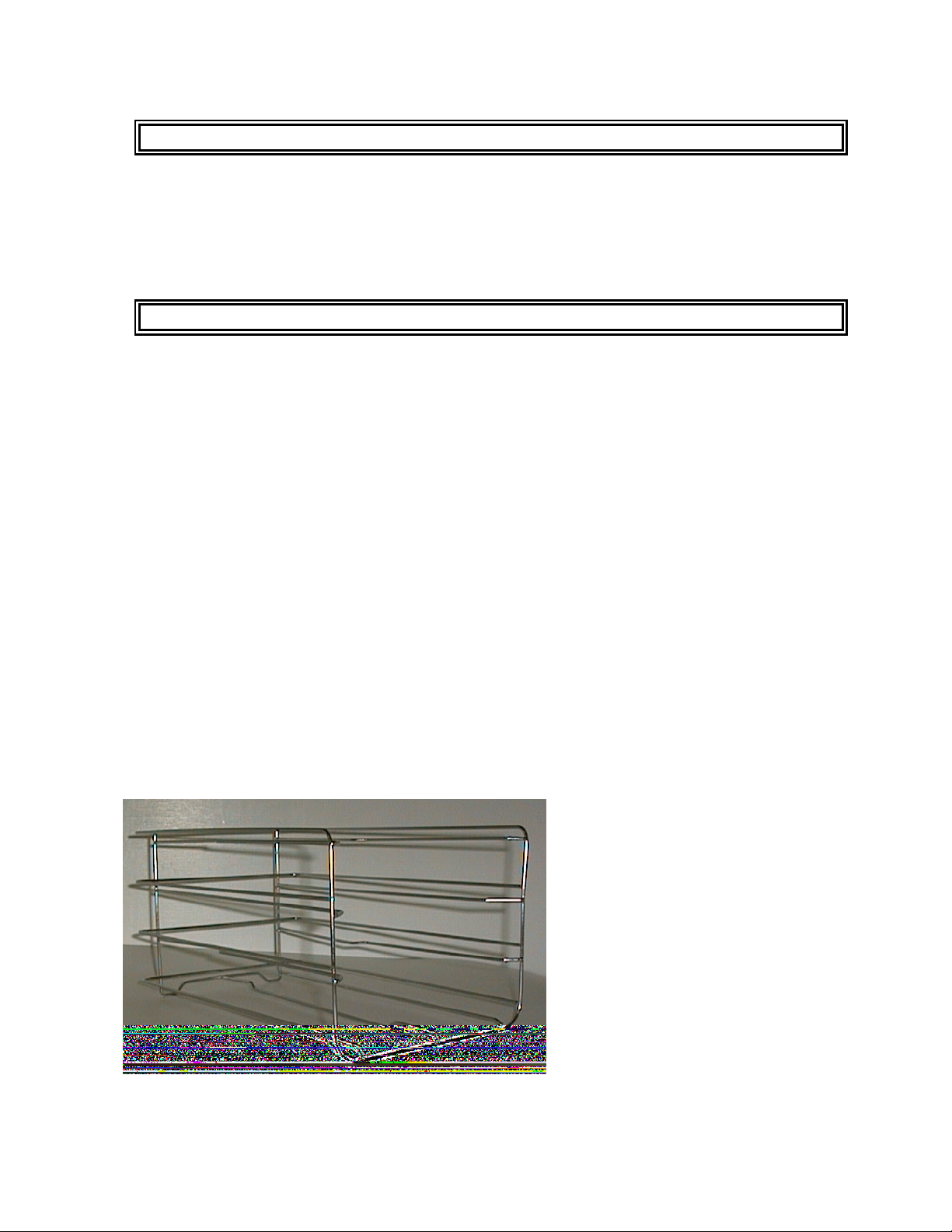

Racks

Do not use the sterilizer without the racks as illustrated below ’

Nor with any accessories

other than those supplied by

Getinge Skärhamn AB.

Examples include:

Trays - instrument baskets tray handles - special

drying results) - deionisation equipment recorder / printer.

Contact your dealer for

information.

8

5

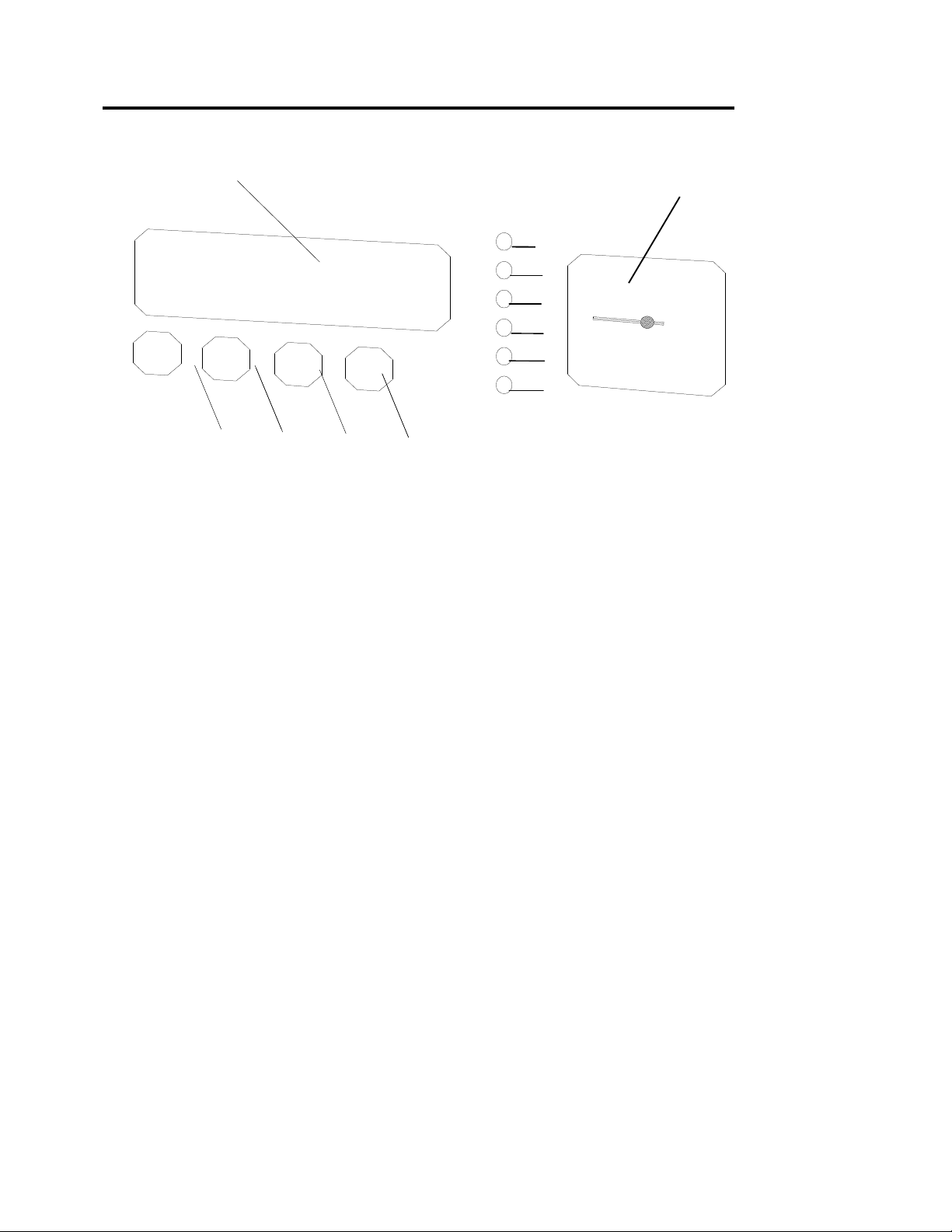

2 3 4 1

8

S

TERILIZER CONTROLS

8

12

6

7

9

10

1 Membrane key

• Program selection

2 Membrane key

• Start

3 Membrane key

• Reset (to reset faults)

4 Membrane key

• Stop

5 Display unit

• See section headed “Display unit”

6-9 Indicator lamps - yellow

• Program indication

11

10 Indicating lamp - Green

• Indicates ”Processs Finished”

11 Indicating lamp - Red

• Indicates “Error”

12 Pressure gauge

• Shows the chamber pressure

9

9

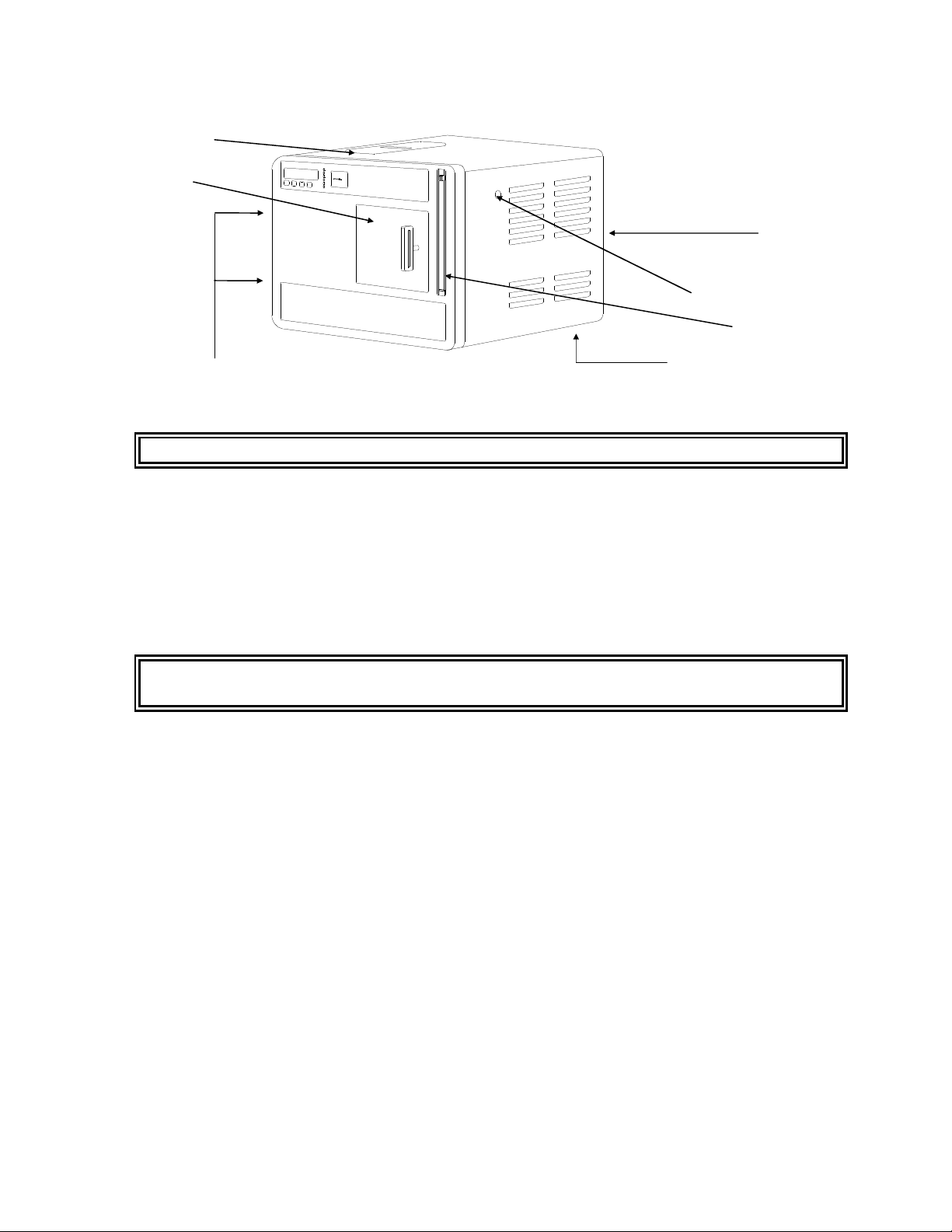

15

18

13

16

13 Front panel retaining screws

• The panel opens to the right. Unscrew the fixing screws first.

External panels must not be removed by anyone other than an authorised technician.

19

14

17

14 Manual safety valve operator (easing gear)

• Operating this during sterilization phase opens the safety valve.

15 Tank cover

• Covers the water tank.

16 Reset pushbutton, overheat protection (underneath the unit, left-hand side)

• See under ‘Installation/Setup’.

Never reset the overheating protection device without first removing the power plug from

the electrical supply socket.

17 Level tube

• Shows the water level in the water tank.

• The level tube can be disconnected at the top and hinged forwards and downwards to empty the water

tank.

18 Door handle

• For closing and locking the sliding door.

• Closing - using the handle, slide the door carefully to its right-hand end position.

• Locking - turn the handle 90° clockwise.

19 Main on/off switch, fuses and connector

• On the rear left side of the unit.

• Fuses 2 x 10A (anti-surge).

10

10

D

ISPLAY

The sterilizer has a display which provides the user with information in the form of text.

The following information is shown on the display:

Text on display Explanation

1. Heating up The sterilizer is heating up

C<70oC SG<140oC Chamber temp.Current temp. Steam generator.

2. Select 0103 Select program with “PROGR” Number of cycles run

134 oC Textile Current program. (Starting position between

sterilization cycles)

3. Close the door. Prompt to close and lock the door

(Operator has pressed start with door open)

During the process

4. 2,1 134 13 Current pressure - Current temp.- Minutes after start

Sterilization Current sequence

After completion of the process

5. 0,0 100 15 Current pressure - Current temp. Process time, min.

Finished Process is complete but door has not been opened.

6. Fault codes See “Malfunctions”

Incidental note concerning the indicated pressure after completion of the process:

As the pressure is measured by an absolute pressure sensor, the indicated pressure (when the door is closed and locked) is the

current atmospheric pressure (ie a barometer). It is displayed until the door is opened.

11

11

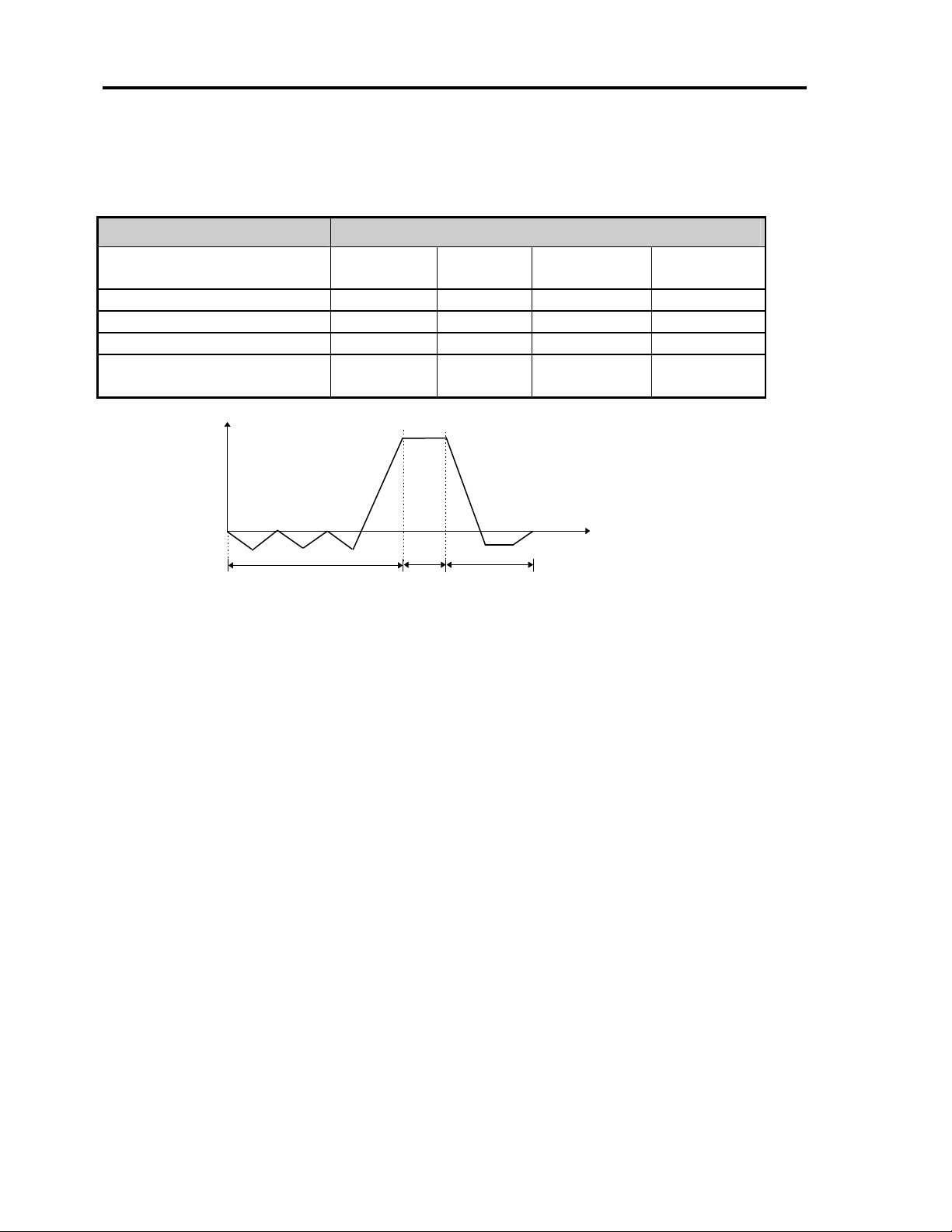

Pressure

pressure

D

ESCRIPTION OF THE PROCESS

The use of a microprocessor in the sterilizer means that it can offer a large number of program

variations. The programs shown below are supplied as standard.

Parameter

Temperature min oC 121 134 134 134

Pressure min kPa 104 203 203 203

Sterilizing time minutes 20 3.5 5 5

Total time empty chamber

(approx) minutes

Atmospheric

The sterilizer may include further programs or modified programs, as described in its test records.

NB: The program times shown above are approximate, and may be altered if standards or other factors

result in modified program sequences.

121Wrapped 134Flash 134 Wrapped 134 Textiles

33 7 18 23

Pre-treatment

Schematic pressure/time diagram for sterilizer with vacuum

Sterilizing

Post-treatment

Process

Time

Flash program

The flash program must only be used for solid unwrapped instruments.

Note: Non wrapped sterilized instruments are either intended for immediate use in the same room where

the sterilizer is placed, or for non sterile storage, transport and application (eg. to prevent cross infection)

Bowie & Dick Helix

In addition to the previous standard programs, the sterilizer is equipped with test programs for "Bowie &

Dick" and the Helix test. This is indicated on the display when the program is selected. A flash program

shall be run immidiate before a B&D helix program.

12

12

T

HE STERILIZATION CYCLE

Type of material

The sterilizer has programmes for treating heat-stable materials such as metal, glass, plastic and rubber,

unpacked or packed in paper or paper/plastic bags. The packaging material must comply with EN-868.

Heating

An unheated appliance is required. Turn on the power.

Technical: The element that preheats the steam generator and chamber is connected to the power

supply. The display shows ”Heating”. The temperature of the heater can be followed on the display as

soon as the temperature exceeds 150° on the heater. When the temperature reaches 240°, ”Select” is

shown on the display and the sterilizer is ready to start.

Pre-treatment

The pre-treatment part of the cycle purges the air from the sterilization chamber and the items in it. The

air obstructs the necessary contact between the steam and the micro-organisms to be killed.

The moistening that is crucial for eliminating the micro-organisms also takes place during the pretreatment phase.

There may also be a preheating phase, the purpose of which is to raise the temperature of the items to be

sterilized to a higher temperature before the real start of the pre-treatment phase. This reduces the

quantity of condensate resulting from the subsequent admission of steam and thus, finally, drier items.

Technical: The pre-treatment consists of a) blowing-through when pump 1 and MV-1 are opened

alternately for a particular time, b) pressure reductions when MV-1, fan and pump 2 are connected to the

power supply to a pre-programmed value (e.g.–0.6 bar), c) pressure rise when pump 1 starts and runs to

a pre-programmed value. The sterilization pressure must be reached in the last rise in pressure. When

sterilization pressure and sterilization temperature have been achieved for temperature sensor T0,

”sterilization” appears on the display.

Sterilization

It is during the sterilization phase that the micro-organisms are actually killed.

The sterilization phase lasts for a preset number of minutes at the preset temperature and pressure.

Technical: The sterilization phase continues for a pre-set number of minutes at pre-set

temperature/pressure. The pressure is regulated using pump 1, which is started as required.

Post-treatment

The purpose of post-treatment is to reduce the moisture content of the items being sterilized.

During post-treatment, the pressure falls to atmospheric pressure or lower, depending on which program

was selected.

Most programs in sterilizers with vacuum function have a “vacuum phase", in order to reduce the

boiling point of the residual condensate, thus leaving the items drier.

At the end of the vacuum phase, air is drawn in through a sterile filter until the chamber reaches

atmospheric pressure.

Technical:

pre-programmed value, a clock is started. When the time has elapsed, MV-1 closes and MV-2 opens, air

being drawn in via the air filter and the pressure rising towards atmospheric pressure.

MV-1, fan and pump 2 are connected to the power supply. When the pressure reaches the

13

13

O

PERATING INSTRUCTIONS

Preparations from cold (all lamps unlit)

• Check that the tank is filled with water to the maximum level. When filling, use only distilled water or

de-ionised water (maximum 30 µS/cm).

• Start pre-heating the sterilizer by connecting it to the mains power supply in accordance with the

Installation instructions. The following indications appear:

• “Heating up” on the display.

• After about 45 minutes, when the sterilizer has reached operating temperature the word 'Select' will

appear on the display.

• If the sterilizer has been turned off, start a flash-program without material.

Sterilization

Carefully follow suppliers' instructions for all items to be sterilized.

Sterilize only items that are intended to be steam-sterilized, and so can withstand at least

125 C.

• Check of the level tube, that the water level in the tank is not below the minimum level.

• The goods must be completely dry when loaded into the chamber.

• When closing the door, make sure that nothing (e.g. bags etc.) is caught between the door and the

chamber. If this is the case, operational problems will occur.

• Items to be sterilized must be freely exposed; in other words, instruments and packages must not be

piled on top of each other.

• If a particularly heavy load is being run, the textile programme is recommended

• When sterilizing lubricated dental hand pieces, wrap them in a paper towel which will absorb any

excess oil.

1. Place moisture-sensitive items and low-mass items at the top of the chamber.

2. Place heavy items at the bottom of the chamber.

3. Place bowl-shaped items so that the hollow part is facing downwards.

4. Place empty containers (bottles, test tubes etc.) with their opening downwards.

5. Position bags vertically, to assist run-off of condensate. This makes it more likely that the items will be

dry on conclusion of the process.

6. Choose the required sterilization program with the membrane key “PROGR”. The display shows text to

indicate the program that has been selected.

7. Close the door and turn the handle 90° clockwise to the locked position, i.e. horizontal.

8. Let the items rest in the chamber for a few minutes before starting the process. This warms them up, so

that less condensate is formed, and the items are drier at the end of the process.

• Press the membrane key “START” to start, the yellow indicator lamp for required program lights up

and the sterilization process will then proceed fully automatically.

• The process is complete when the display shows 'Finished', the green indicator lamp lights up and the

pressure gauge shows zero.

14

14

The display never shows “Finished” if the process has been interrupted.

If the display is not showing “Finished”, items in the chamber may have been put there by

someone else, and not yet been sterilized.

• The goods will get drier if they are left in the sterilizer chamber for a few minutes with the door slightly

open.

• As soon as the door is opened, the 'Finished' message disappears from the display.

• If the red indicator lamp is lit after a sterilization process, the items must be regarded as non-sterile and

must be re-sterilized.

• Opening the door causes 'Finished' to disappear from the display and be replaced by 'Heating' or '

Select', depending on the temperature of the steam generator and the chamber

• If you need to stop the process , press the membrane key “STOP” . The red indictor lamp lights up and

the display shows fault code 030 “Process stopped”; see under “Process interrupted.”

• Then press the membrane key ”RESET” and wait for the pressure gauge to show zero.

Between sterilizations

• Close the sterilizer door, but do not turn the handle.

Be sure to remove all items from the sterilizer chamber as soon as the sterilization process is

finished.

Never leave items in the sterilizer chamber.

• The sterilizer works best when the water tank is filled to the max mark with distilled or de-ionised

water.

• When using the 121°-program after a 134° program has been running. Choose 121°-program and wait

at least 15 min before start.

Closing down for the day

Unless local routines state otherwise.

• Close the sterilizer door, but do not lock it.

• Leave the sterilizer connected to the electric power supply.

At least six hours before “periodic maintenance”:

• Leave the sterilizer door fully open, ie as far to the left as possible.

• Shut down the sterilizer by unplugging the mains plug from the socket; the indicator lamps go out and

the sterilizer cools down. (See also under “Maintenance”)

15

15

M

ALFUNCTIONS

• Start by checking that the sterilizer is connected to the mains power supply.

• Check the main fuses. Shut down the sterilizer. The fuses are in a red box in the same unit as the main

switch. Fuse rating: 10 A anti-surge.

• Check that the red indicator lamp is not lit.

• Check that the tank contains distilled or de-ionised water.

• Check that nothing is between the chamber and the door.

• Check that the display reads”Select”.

• If the display is not lit, one of the overheating protection devices may have operated. Contact an

authorised technician.

Fault codes

The display may show any of several fault codes. If a fault code appears, the red indicator lamp lights up

as well. Items in the chamber must be regarded as non-sterile and must therefore be re-sterilized.

Never attempt to open the door until the pressure gauge has returned completely to zero.

Fault code 040 Pressure error

Pressure outside pressure band during sterilisation time

Fault code 041 Temp. Error

Temperature outside temperature band during sterilisation time

Fault code 050 Program missing

Type of sterilizer does not correspond to the type of sterilizer programmed in the service program

Fault code 017 Time out

Max. temperature was not reached within time limit

Fault code 018 Time out

Min. pressure was not reached within time limit

Fault code 019 Time out

Max. pressure was not reached within time limit

Fault code 043 “Door open”

The safety switch for the door was operated during process.

Fault code 014 “Proc. interrupted”

A power failure interrupted the process.

Fault code 042 “Steam generator cold”

The sterilizer has been overloaded or left with the door open between sterilization operations.

Fault code 030 “Process stopped”

The process has been stopped with the membrane key “STOP” .

Fault code 070-074 “PT-100 error”

One of the temperature sensors is open circuit.

Contact an authorised technician.

Service / Spare parts

For service or spare parts, contact your dealer.

16

16

P

ROCESS INTERRUPTED

If the sterilizer stops during the programme, check the following:

That no material has become caught between the door and chamber.

That the water level in the tank is not too low.

That the sterilizer slopes to the rear in accordance with the installation instructions.

That the strainer in the bottom of the tank is not obstructed.

That the strainer nside the chamber is not obstructed.

That the sterilizer is set up so that there is at least 10 cm space all round it.

If a process in progress has to be interrupted

Press the membrane key ”STOP”, whereupon the message ”Post-treatment” will appear on the display

and a red lamp will light up.

Wait until the pressure gauge shows zero and the message ”Process interrupted” appears on the display.

Press the membrane key ”RESET”, whereupon the red lamp will go out.

Open the door by turning the handle anticlockwise a quarter turn, but do not slide the door sideways

until about a minute has passed.

N.B. There is a risk in connection with an interrupted process of steam streaming out of the

chamber when the door is opened.

Stop / Alarm

If the sterilizer has stopped or if a red indicator lamp lights up while a process is progress, follow the

procedure below in the sequence indicated:

Alt.1 Press the membrane key “RESET” . The red indicator lamp goes out.

Operate the door switch by turning the handle anticlockwise. The display should show 'Heating

up' or 'Select'. Turn the handle clockwise to the closed position. The sterilizer is now in its

starting state.

Alt.2 Disconnect the sterilizer from the electric power supply and reconnect it after about 20 seconds.

The red lamp lights up and the display shows fault code 014 'Process interrupted'.

Press the membrane key “RESET” The red indicator lamp goes out.

When the pressure gauge shows zero, open the door by turning the handle anticlockwise. Wait

at least ten seconds before opening the door fully. The display shows 'Heating up' or 'Select'.

The sterilizer is now in its starting state.

Alt. 3 Disconnect the sterilizer from the electric power supply and reconnect it after about 20 seconds.

Manually operate the safety valve release to return the pressure in the chamber to atmospheric

pressure.

When the pressure gauge shows zero, open the door by turning the handle anticlockwise. Wait

at least 10 seconds before fully opening the door.

Close the door, but do not turn the handle.

Reconnect the electric power supply. The red indicator lamp lights up and the display shows

fault code 014 “Process interrupted”.

Press the membrane key “RESET” . The red indicator lamp goes out. The display shows

'Heating up' or 'Select'. The sterilizer is now in its starting state.

Follow the instructions in the section entitled “Operating Instructions”.

If the fault persist, call a technician.

17

17

SAFETY DEVICES

Each sterilizer incorporates components intended to ensure safety of operation and maintenance. These

components have been specially selected, and therefore must not be replaced by other makes or types of

devices unless approved by the manufacturer.

Door

The door is designed so that it cannot be opened without force if the pressure in the chamber exceeds

+0.2 bar. If force is applied to open the door at this pressure, a reed relay will be operated to open the

exhaust valve to discharge the steam in the chamber. If, despite this, the door is opened with force so

quickly that steam escapes via the door opening, it will nevertheless be directed to the sides, behind the

external cladding of the sterilizer and not scalding the operator.

Safety switch - door

This prevents the sterilizer from being started unless the door is correctly closed and secured.

Pressure vessel

The sterilizer chamber is a pressure vessel, designed and manufactured in accordance with pressure

vessel standards and requirements, as issued by the competent authorities for this area. Compliance with

the standards is checked and tested by the Swedish Pressure vessel authorities(SAQ).

Safety valve

The chamber is fitted with a safety valve, set at an appropriate opening pressure, and which also

incorporates a manual device for operating the valve to check its performance and for use during

maintenance.

Overheating protection

The steam generator and chamber are fitted with overheating protection devices.

Safety checking

• During the sterilization process, check that the door is sealing against the steam pressure.

• Check that the sterilizer cannot be started until the door is correctly closed

• Make sure that all personnel are aware of current pressure vessel standards, together with the associated

obligations

• Make sure that all personnel understand all the warning notices.

• Check that the safety valve operates at a pressure of 2.7 bar.

18

18

M

AINTENANCE

Maintenance requirements depend primarily on how heavily the sterilizer is used. This means that the

frequency of maintenance operations may vary from case to case. The manufacturer recommends that,

when the sterilizer is being used to full capacity, at least the following maintenance operations should be

performed at the specified intervals:

Periodic cleaning every 50 cycles or at least once a month

Unplug the electric plug from the socket before cleaning the unit.

The equipment must only be cleaned when it is cold.

External covers must never be removed by anyone other than an authorised service

technician..

• Drain the water from the tank by releasing the level tube at the top and tilting it forwards and

downwards.

• Clean the strainer at the bottom of the tank.

• Fill the tank with distilled or de-ionised water to its maximum level.

• Remove the chamber insert. Clean the chamber internally using a damp cotton rag. Never use steel

wool. Make sure that the strainer at the far end of the chamber, on the bottom at the right, is clean.

• Wipe down the outside of the sterilizer using a chlorine-free domestic cleaner.

• If the sterilizer is used for sterilizing lubricated dental hand pieces, the water in the tank must be

changed every 20 cycles.

Monthly

To ensure that the safety valve is working properly, it must be regularly operated as follows:

• Start a sterilizing cycle and wait for the sterilization phase

• Operate the easing gear at the “Safety valve” sign, which is accessible from the outside.

Quarterly

• Check the sterilization performance of the sterilizer, using special bacteria samples under normal

operating conditions..

Yearly

• The sterilizer must be serviced by an authorised technician.

19

19

YEARLY MAINTENANCE SERVICE

Serial no:......................................Address:................................................................

Replace the door gasket.

Lubricate the moving parts of the door with a heat-resistant grease.

Clean the rails on which the ball-bearings run.

Fit a calibrated inspection pressure gauge, for measurement of absolute pressure, to the flange

intended for it and check, when the sterilizer is in use, that the sterilizer's own pressure gauge is

maintaining the required accuracy class.

Using a calibrated thermo-instrument, check that the pre-heating temperature of the chamber is

correct.

Using a calibrated thermo-instrument, check that the steam generator is maintaining the correct

operating temperature.

While the external covering has been removed, inspect the unit for any leaks in pipe joints or

instrument connections, and correct them if found.

If necessary, perform any maintenance to be carried out by the operating personnel

Check the performance of electrical components by using the Component Test feature in the

service program.

Run all programs.

Replace the air filter, at least every 1500 cycles or once a year

Check all safety features following point 1-6.

1. During the sterilization process, check that the door is sealing against the steam pressure.

2. Check that the sterilizer cannot be started until the door is correctly closed

3. Make sure that all personnel understand all the warning notices.

4. Check that the safety valve operates at a pressure of 2.7 bar.

5. If the sterilizer includes programs for the sterilization of liquids, make sure that personnel

understand the risks associated with such applications.

Miscellaneous

Changed details:

Date: Sign:

To forfill the medical device a service according to above specification has to be

made and signed by an authorized technician The document has to be archived at

the users site until the sterilizer is taken out of use.

20

20

D

ESIGN OF THE STERILIZER

General

For flowchart, see Appendix 1

The sterilizer has a closed steam generating system; this means that evaporated water is condensed and

returned to the water tank.

Pump P1 is a vibration-type pump which pumps the water from the tank to the steam generator, which

turns the water into steam. The steam generator is supplied with distilled or de-ionised water from an

integral tank. The temperature of the steam generator is proportionally controlled to 250 °C in service,

by means of temperature sensor T4.

The temperature of the chamber walls is proportionally controlled to the set value by means of T1.

The pressure in the chamber rises when steam is supplied to it. The pressure is monitored by a pressure

sensor which, via a PID regulator, controls the frequency of pump P1. The steam temperature is

monitored by temperature sensor T0.

Solenoid valve MV1 is used to empty the chamber. The steam flows to the condenser where it is

condensed with the aid of a cooler and a fan. The resulting water is returned to the water tank.

Pump P2 powers an ejector that creates a vacuum to reduce the pressure in the chamber below

atmospheric pressure.

Solenoid valve MV2 admits air, filtered through the air filter, to the chamber.

Reference: (see X/Y) = Annex X / position Y

Components

Use only insulated tools when doing any work that requires the equipment to be energised.

Remove the power supply plug from the socket when doing any other work.

Solenoid valves

Noisy solenoid valves are trying to tell you something! The humming noise may be a warning of

incipient overheating of the coil, due to an air gap in the magnetic circuit. This is often caused by dirt on

the moving core, preventing it from closing properly when energised by the magnetic field from the

winding. This creates a small air gap in the magnetic circuit, reducing the inductance of the coil and thus

increasing the current through it.

• Deal with a humming solenoid valve by cleaning both the plunger and the cavity in which it runs.

• Always replace the O-ring between the coil and the casing after removing the coil.

Solenoid valve MV-1

This valve is fitted at the back of the sterilizer (see 6/1), and controls the evacuation of air and steam. It

opens when it is energised, and is open when the sterilizer is in the standby state. The valve closes if the

door is opened.

Solenoid valve MV-2

(see 6/24), This valve controls pressure equalisation after the post-vacuum phase. It is energised and

open when the sterilizer is in the standby state. The valve closes if the door is opened.

21

21

Inlet nozzle to steam generator

This is fitted at the back of the steam generator. Inside the nozzle (see 6/4) there is a swirl outlet (see

6/2) and a strainer (see 6/3). The strainer and the hole at the front of the nozzle can easily become

blocked if the sterilizer is not cleaned or is operated with water that is not de-ionised /distilled.

Checking:

This is done in the service program; see the relevant section. Select “Component test”, and activate

“steam pump”. The pressure should rise to 2.7 bar, at which the safety valve should open.

Steam generator overheat protection, Öv300

The steam generator is protected against harmful temperatures above 300 °C by the Öv300 thermal

cutout (see 6/5) which must be manually reset after it has operated. The reset pushbutton is accessible

from outside the unit, and is fitted beneath the left-hand corner of the sterilizer. If the thermal cutout has

operated, current to all components is cut off.

Chamber overheat protection, Ök200

This thermal overload cutout has a fixed operating temperature of 200 °C, and is fitted slightly above the

centre of the left-hand side of the chamber (see 6/7). Its purpose is to prevent the overheating of the

chamber heater or chamber. If it operates, it cuts off the electric power to all components.

General, regarding the overheat protectors

The chamber overheat cutout may operate because:

• the sterilizer has been transported at temperatures below freezing.

• of a fault in the temperature control of the steam generator / chamber preheating system.

• If the thermal cutout has operated as a result of excessive temperature, the sterilizer must be allowed to

cool down for a while before the reset pushbutton will stay in.

When resetting the cutout, always pull out the plug from the supply socket.

Check:

Because of the undue thermal stress on the equipment, it is advisable to refrain from realistic checking

of the operation of the chamber overheat protection.

Chamber pre-heating element

This element preheats the chamber to about 125 °C in 134 °C programs and 115 °C in 121°C programs.

The element is rated at 900 W, so its resistance is about 60 Ω. (see 6/32)

ip-on ampmeter to check that the heaters are drawing current.

Steam generator elements

These preheat the steam generator to about 250 °C.

The element is rated at 900 W, so its resistance is about 60 Ω. (see 6/46)

Checking the elements:

These checks are part of the service program; see the relevant section. The check involves a “component

test”, in which “chamber heat” or “heat 1” and then “heat 2” are activated. Use a clip-on ampmeter to

check that the heaters are drawing current.

NOTE: The heaters deactivates after 20 seconds in the “component test”.

22

22

Pump 1

This pump supplies the steam generator with water from the tank via check valve (non-return valve)

BV-1 and a spray nozzle fitted into the back of the steam generator heating block. The pump is a

vibration pump (see 6/35) The frequency of its power supply is controlled by the control system.

Checking is done in the service program; see the relevant section. Select “Component test” and activate

“steam pump”. The pressure in the chamber must rise to 2.7 bar, at which pressure the safety valve must

open. The flow rate is 100-200 ml/min.

Warning: Risk of scalding from discharged steam when the safety valve operates.

The cover of the water tank becomes hot when the safety valve operates or is operated.

Pump 2

The purpose of this pump is to pump water from the tank through the ejector and then back to the tank,

to produce a vacuum in the sterilizer. Pump 2 is a centrifugal pump (see 6/34).

Check the pump as part of the service program; see the relevant section. Select “Component test”, and

activate “Ejector on” and “Valve 1”. If there is nothing wrong with BV1, the pressure should fall to at

least -0.8 bar after about 15 minutes.

Check valve BV1

This check valve (non-return valve) is fitted immediately after the vibration pump (see 4/6) and prevents

steam being forced backwards through Pump 1 to the water tank.

Check valve BV-2

This check valve (non-return valve) is fitted between the air filter and solenoid valve MV-2 (see 6/25)

and prevents steam flowing through the filter in the event of a fault in solenoid valve MV-2.

Check valve BV-3

This valve is fitted between the cooler and the ejector (see 6/39) and prevents pressure equalisation after

the post-vacuum phase by any route except through the filter at solenoid valve MV-2.

Air filter

The purpose of the air filter is to supply the sterilizer with sterile filtered air after the post-vacuum phase.

The filter must be replaced after 1500 cycles or annually. (see 6/44)

Pressure gauge

This indicates the pressure in the chamber, even if the power supply is turned off (see 6/43)

Checking: Use an independent calibrated pressure gauge (see 6/47) and compare its readings with those

on the sterilizer pressure gauge.

Absolute pressure sensor

Monitors and controls the sterilizer process (see 6/30).

Checking:

Use an independent, calibrated absolute pressure gauge (see 6/47) and compare its readings with those

on the display. Range: 0-4 bar absolute corresponds to 0-5 V DC. Output signal at atmospheric pressure

about 1.25 V. See also the Service Program section.

Adjustment:

Follow the instructions under “Service program”, but before doing so, check the “Range” and “Offset”

values set during pre-delivery inspection.

23

23

Temperature sensors

The sterilizer has Pt-100 sensors to monitor:

a) Steam generator (T4) (see 6/31)

b) Chamber preheating(T1) (see 6/21)

c) Sterilizing process (T0) (see 6/41)

Note:

If the sterilizer includes programs for sterilization of liquids, there may be additional Pt-100 sensors.

Checking:

Disconnect the sensor from the control system and check it with an ohmmeter. Its resistance should be

about 100 ohm; the higher the temperature the higher the resistance. See also the Service program

section.

T4. The temperature sensor for the steam generator is fitted at the front of the steam generator. It

controls the steam generator temperature (about 250 °C), and also interrupts a process if the steam

generator temperature falls below the pre-programmed value of about 150 °C while a sterilization

process is running.

Checking:

This requires the sterilizer to have been turned on for at least an hour. Insert an independently calibrated

measuring instrument, capable of measuring to at least 300 °C, in the measurement hole at the front of

the steam generator (see 6/61) and wait for the temperature reading to stabilise. It should now show a

temperature of between 240 °C and 255 °C. Also compare the temperature during the heating phase,

when the steam generator temperature is below 160 °C, comparing the value on the sterilizer display

panel with that shown on the instrument.

T1.. The chamber sensor is mounted on top of the chamber, and controls the chamber temperature to the

programmed value of about 120 °C.

Checking:

This requires an independently calibrated temperature instrument inserted about 150 mm between the

thermal insulation and the chamber on the right-hand side of the sterilizer. Make sure that there is good

thermal contact between the thermometer and the wall of the chamber. When the sterilizer is ready for

use, this independent instrument should show a temperature of about 120 °C.

Note: If the temperature is to be checked soon after a sterilization program has been run, the chamber

must be allowed to cool down, for example by turning the sterilizer off and leaving the door open for

about 15 minutes.

Note: The chamber temperature shown on the display during the heating phase may not agree with the

value shown by the independent calibrated thermometer. This is because the measurement points are

relatively far apart.

T0. The sensor that monitors the sterilization process, and which provides the signal to the display of

chamber steam temperature, is fitted in a manifold on the left of the sterilizer.

Checking:

Use an independent calibrated temperature measuring instrument, inserted in the chamber through the

connection on the left-hand side of the chamber near the safety valve. Check that its reading with that

shown on the display. Alternatively the temperature can be calculated from the pressure reading of a

separately connected absolute pressure sensor. (104 kPa ≈ 121 °C, 203 kPa ≈ 134°C.

Ejector

The ejector is fitted in the pipe from pump 2 to the water tank (see 6/23), with its suction line connected

to check valve BV3.

The ejector is in the form of a T-piece, containing two ejector nozzles. Note that these nozzles are not

identical. The smaller holes in each of the nozzles must face each other, and the nozzle with the largest

hole must be fitted in the outlet of the T-piece towards the tank.

24

24

Safety valve

Opening pressure 2.7 ± 0.14 bar

Blow-off pressure max 2.97 bar

The function of the safety the valve is to relieve the pressure in the chamber if it rises out of control (see

6/22). Check the safety valve with the sterilizer running normally.

• Check that the safety valve is not leaking water or steam.

• Check that the lead seal of the safety valve is intact.

Checking the blow-off pressure of the safety valve:

This is done in the service program; see the relevant section. Select “Component test” and activate

“Steam pump”. The safety valve must blow off when the pressure reaches 2.7 ± 0.14 bar. Use an

independent pressure gauge for this check.

Adjustments or modifications that change the blowoff pressure of the safety valve may be

performed only by an authorised person.The safety valve should be operated regularly, at

least four times a year. See heading“Maintenance”. The lead seal must not be broken by

anyone other than an authorised person.

Circuit board (see Appendix 3) (see 6/28)

The display unit and the circuit board unit must always be stored in their conductive bags

until they are to be fitted to the sterilizer.

Before handling any of the electronic spare parts, make sure that you are not

electrostatically charged, by touching earthed radiator, for instance.

• Each output is controlled by a triac, so that there is electrical isolation between the electronics and the

control voltage to the components.

To check the operation of a triac, activate the relevant output in “component test” and connect a

voltmeter between pin 1 (Line N) and the relevant output pin.

the voltmeter shall read ≈230V

• A LED is connected to each output. It is lit when the output is active, ie when it is supplying current to

its component (valve, pump, element etc.).

Another LED (H1) is lit when the door is locked

• Programs are stored in a PROM. Markings on the PROM show the program version.

This is how to change the PROM:

1. Note the calibration settings of the pressure and temperature sensors, the cycle counter and which

inputs are activated on sensor open-circuit detection (see Appendix 5), as well as the date of the

software. This date is in the service program menu; go to the service program and press the PROGR

button. (see 6/45)

2. Switch off the electric power supply to the sterilizer.

3. Change the PROM.

4. Switch on the power.

5. Note the old cycle counter value on the inside of the circuit-board cover.

6. Check the calibration settings and sensor activation.

• When changing circuit boards, move the old processor and the PROM to the new board.

25

Door

25

Changing the door seal

Unplug the electric power lead when changing the door seal.

• Unscrew the screws and swing out the front.

• Loosen the left-hand side panel fixing screws near the Display and push the side panel back a few

centimetres.

• Open the door, move away the stop which limits lateral movement and lift off the door.

• Remove the old seal and clean the seal groove, taking care not to damage it.

• Place the new seal on the door and position it so that it covers the groove. Note: The seal is rectangular.

• Note: The seal is a parallel trapezoid in cross-section. Position the seal to that the right angles of the

cross-section are down in the groove.

• Start by pressing down the corners, then the middle, and finally the entire seal.

• Refit in reverse order.

Adjusting the door

After adjusting the door, check that all nuts and screws are tight.

Take care: some parts may be hot if the sterilizer has recently been used.

The door adjustment procedure described here may only be needed in exceptional cases, eg if the door is

too stiff to lock or if there is leakage that cannot be traced to any other part of the sterilizer.

It is advisable to replace the door seal before the door is adjusted.

Before the door is adjusted, chamber preheating must be checked. The procedure for this is described

under a separate heading.

• Check that the seal groove and the front of the chamber are undamaged and free from deposits.

• Do the adjustments with the sterilizer heated up.

VERTICAL ADJUSTMENT

The door moves a short distance vertically on interlocking. To allow for this movement, the vertical

adjustment of the upper bar (see 2/7) must be correct.

• With the door open and about 15 mm from its right-hand end position, check that there is a depth

clearance of about 1 mm at both upper ends of the door.

Adjustment:

• Slacken the nuts (see 2/6) so that the bracket (see 2/5) can change its position.

• Adjust the position of bracket (see 2/5) with screws (see 2/1) . Use the middle screw to pull the bar up

and the outer screws to push it down.

• Tighten the nuts (see 2/6).

DEPTH

• Remove the cover plate on which the door switch is mounted, to the right of the door opening.

• Check that the door seal reaches the chamber equaly both on top, bottom and left and right side when

the handle is turned.

Adjusting for minor errors

• Slacken the affected M10 Allen screws (see 2/3)

• Tighten or slacken the outer M16 nuts (see 2/2) where the error was observed. Do not turn the nuts

more than one-sixth of a turn.

• Tighten the M10 screws (see 2/3)

(see Appendix 2)

(See Appendix 2)

Adjusting for a larger error:

26

26

• Slacken the affected inner M16 nut (see 2/4) and the nearest M10 Allen screw (see2/3). If you need to

get to the lower nuts, remove the lower cover plate in front of the steam generator.

• Do not turn the inner M16 nuts (see 2/4) more than half a turn at each adjustment.

• Firmly tighten the M10 screws (see 2/3).

• Tighten the outer M16 nuts (see2/2).

• Check that the torque required to operate the door handle with a new door seal after a 135° process is

between 6,5 and 7,5 Nm (normal hand force.)

Cooler - condenser

Condenses steam to water on pressure reduction (see 6/42)

On condensing the steam, the condenser creates a vacuum in the sterilizer during the pre-vacuum and

post-vacuum phases.

Note that the sterilizer is not designed to be built in.

For best performance, the fan (see 6/40) connected to the condenser must be running. In addition, there

must be space around the sterilizer in accordance with the installation instructions as set out in the

Description of Operation.

Searching for leaks

Alternative 1: Run a leak test programme

If a green ”ready” lamp lights up, the sterilizer is leaktight. If a red lamp lights up, there is a leak.

Alternative 2: Bubble test.

Run the sterilizer down to a negative pressure using component test. When the pressure has levelled out,

check whether any bubbles appear in the transparent hose joining pump 2 and the tank. If bubbles occur,

it is a sign of leakage.

Alternative 3: Leakage test in accordance with EN-285

Perform with a cold sterilizer. The sterilizer should have been switched off overnight.

Disconnect the cables to the element from the circuit board (pins 2, 4, 6 on circuit board, see Appendix

3).

Run the sterilizer down to 70 mbar using component test. Press ”Everything off”. Wait 5 min., note the

pressure, wait a further 10 min. After this time the pressure must not have risen more than 13 mbar.

27

27

S

ERVICE PROGRAM

The sterilizer incorporates a service program comprising:

1. Choice of sterilizer type

2. Choice of language

3. Correction of pressure values

4. Correction of temperature values

5. Reset cycle counter

6. Component test

7 Setting sensor open-circuit detection

8 Erasing EEPROM

Generally there should be no need to calibrate Pt 100 sensors and pressure sensors unless a sensor has been

replaced. Language, pressures and temperatures are set at the factory. The cycle counter should only be

reset under exceptional circumstances, since doing so means that you lose track of how many cycles the

sterilizer has done. The component test can be run during servicing as an easy way of checking the

operation of components.

Appendix 5 contains a flowchart of the service program. This is how to access the service program:

• Open the front panel

• Press and hold the switch on the circuit board housing. (see 6/45)

Switch the sterilizer off and on again with the main switch at the back.

Now release the switch on the circuit board housing.

• The service program can now be followed. See Service programme schedule.

1. Sterilizer type

At present there are four types:

• VACUUM: 16-litre sterilizer with vacuum function. (Citomat 164 V, GE 224cV, 203cV):

• THREE-PHASE: 60 litre sterilizer (Citomat 564c, GE 336c)

• TEMP-CONTROLLED: Temperature-controlled (GE 203c)

• NORMAL: 16-litre sterilizer without vacuum function (Citomat 164, GE 224c)

2. Choice of language

Press until the required language appears. (The service program is in English only.)

28

28

3. Correcting pressure readings

The measurement range of the pressure sensors is -1 to 3 bar (0 to 4 bar abs).

The pressure can be adjusted and displayed from -1 to 2.5 bar.

The pressure is adjusted by changing the index for “offset” and “range”. The default setting is index 100.

Each step corresponds to 0.02 bar.

Calibration: Connect a calibrated absolute pressure sensor. Close the door. Go to the “Component test”

menu (see section 6) and activate: cooling fan, MV1 and P2. Wait until the pressure reads about -0.8 bar.

Press “everything off”. Note the pressure on the display and compare with the external sensor. If you

want a lower value on the display, adjust the offset index to a lower value, and vice versa. For range, go

to the “component test menu” and activate P1. Wait until the external pressure gauge reads about 2.1

bar. Press “everything off”. Note the pressure on the display and compare with the external sensor. If

you want a lower value on the display, adjust the range index to a higher value, and vice versa.

Hint: Read the actual temperature (T0) and pressure during a component test

Summary: RANGE: Higher index gives a lower pressure on the display.

OFFSET: Higher index gives a higher pressure on the display.

4. Correcting temperature readings

The sterilizer has two Pt 100 sensors for regulation and one Pt 100 sensor for measurement. The

measuring range of the steam generator sensor (T4) is 150 °C to 300 °C; the range of the chamber

preheating sensor (T1) and the steam temperature sensor (T0) is 50 °C to 150 °C.

To adjust the temperature reading, change the index for offset high or low as appropriate. The default

setting is index 100. Each step corresponds to 0.5 C for the chamber preheating sensor and 0.3 C for the

steam temperature sensor. The index can be set between 75 and 114.

Calibration: (NOTE: Calibrate the pressure sensor first; see above).

T0: (Input 0 Steam) Start a high-pressure program. Wait for the sterile phase, note the temperature

reading on the display. If the display reads too high, adjust T0 offset high to a lower value. After

adjustment run the high-pressure program and control the temperature. The procedure is the same for T0

offset low, but a with a low-pressure ie121°C program.

Example: At sterilization 2.1 bar, the display reads 140 °C. Reduce the index for T0 offset high by about

18 steps.(18 X 0,3= 5,4°C)

Summary: T0 HIGH and LOW: A higher index gives a higher temperature reading on the display.

T1: (Input 1 Chamber) (NOTE: The sterilizer must have been preheated at least one hour. Place a

calibrated temperature sensor between the chamber wall and the insulation. If the external sensor reading

is higher than 125 °C ±5 degC, adjust the index for T1 offset high to a higher value. NOTE: If a lowpressure program was chosen, the chamber preheating is regulated to 115 °C ± 5 degC. In this case,

adjust T1 offset low in the same way.

T4: (Input 4 Heat acc.) Push a calibrated temperature sensor into the steam generator. There is a hole for

this in the plate below the door. Check that the sensor is put into the hole in the steamgenerator. If the

external sensor reads above 250 °C ±5 degC, adjust the index for T4 offset high to a higher value.

Summary: T1, T4 HIGH and LOW: A higher index gives a lower temperature at the external sensor and

vice versa.

5. Reset cycle counter

Do not do this unless it is absolutely unavoidable.

29

29

6. Component tests

Every component that is connected to an output can be tested for correct operation. Actual temperature

and pressure are continuously shown on the display during the component test. Note that you must

choose “everything off” before individual components can be activated. To deactivate a component,

choose “Everything off”. NOTE: When the elements are activated, they are deactivated after 20 seconds.

Temperature regulation of chamber and steam generator overrides “Everything off”. Do not activate all

three elements at the same time.

General: Check whether the relevant LED lights up on the circuit board on activation.

7. Setting sensor open-circuit detection

When this function is activated, the temperature sensors are monitored for open circuit.

After an open-circuit condition has existed for 20 seconds, the process is aborted and the following error

message appears on the display. Fault code 070-074 “PT-100 sensor faulty”, where 070 stands for sensor

T0, 071 for T1 and 074 for T4. To remove the error message after taking the appropriate action, switch

the power to the sterilizer off and on again.

On setting set 1=active 0=inactive for each input.

The display shows a digit combination made up of five ones or zeros. The first digit stands for sensor

T0, the second for T1 and the fifth for T4. So on a 16-litre sterilizer with vacuum function the display

should read 11001.

8. Erasing the EEPROM

Do not do this unless it is unavoidable.

NOTE: This deletes all sensor settings and the cycle counter.

Note all settings before erasing the EEPROM (pressures, temperature calibration, sensor open-circuit

activation and cycle counter)

After erasing the EEPROM, switch off the power to the sterilizer for a few seconds.

30

30

Service programme schedule

Step through using the membrane keys ”PROGR”, ”START”, ”RESET”, ”STOP” on the front panel.

ACTION

Sterilizer

type

Languages START

Pressure

calibration

Temperature

calibration

Reset

cycle counter

Component

test

Sensor

detection

Erase

EEPROM

STEP

START

2 times

START

3 times

START

4 times

START

5

times

START

6 times

START

7

times

START

8

times

STEP WITH CALIBRATION ENTER RETURN

PROGR START PROGR

PROGR START PROGR

PROGR START

PROGR START

PROGR START PROGR

2timesr

PROGR

Choose type

Choose

language

PROGR

range/offs

Choose

sensor

PROGR

Yes

PROGR

Everything

PROGR

Choose input

START STOP

START STOP

START

Adjust

Prog=Lower

Reset=Higher

START START

Prog=Lower

Reset=Higher

START STOP

START PROGR

RESET

1=Aktiv

0=Inaktiv

START STOP

START STOP

START STOP

Adjust high

Prog=Lower

Reset=Higher

START

Choose comp.

START

Activate

Activate

2 times

STOP

2 times

STOP

FLOW

31

31

TECHNICAL DATA

Width 590 mm

Depth 565 mm

Height 473 mm

Height with feet 493 mm

Weight without vacuum function 84 kg

Weight with vacuum function 90 kg

Chamber width 200 mm

Chamber height 210 mm

Chamber depth 400 mm

Chamber corner radii 20 mm

Chamber volume 16 l

Chamber design pressure 2.7 bar

Chamber regulations AFS 1994:39

Chamber/door material Aluminium DIN 1725/1748 equivalent

to SIS 4120-02

Max. load textile 2.0 kg

Max. load instrument 4.0 kg

Feed water quality distilled or de-ionised, max 30 µS/m

Tank water content, max. 5 litres

Water consumption per process 30 - 100 grams (depends on load)

Electrical supply as per type plate

Control voltage as per type plate

Total rating without vacuum function 1800 W

Total rating with vacuum function 2000 W

Rating of steam generator elements 2 x 900 W

Rating of chamber element 900 W

Heat dissipation, closed door, approx 200 W

Heat dissipation, open door, approx 600 W

Sound level ≤55 dB

Air filter EN 143 / P3, 0,4 µm

32

32

T

ROUBLESHOOTING

Fault Cause Action

• General. Always begin by checking that the sterilizer has been properly installed, that the

tank contains water up to the max mark and that strainers in the tank and chamber are not

clogged.

• Sterilizer does

not build up

pressure after

lengthy use.

• Pressure isnot

build up.

• Stop in pre-

treatment during

the Pressure

reduction phase

• Stops in pre-

treatment during

the Pressure

increase phase

• Completely dark • Overheat cutout tripped

• Stops in post-

treatment

• Poor vacuum • Hot water. • Check fan and cooling

• Slow • Leakage • Make a leakage test

• Chamber filled

with water

• Door fails to go

up

•Pressure stops at

vacuum

• Pump 1, its hose and

check valve BV1 have

dried out.

• Nozzle in steam generator

blocked.

• Leakage in safety valve.

• MV1 or BV3 clogged or

faulty.

• Pump P2 performance

poor.

• Pressure sensor

miscalibrated or faulty.

• Air leakage

BV1 leaky.

• Pump P1 faulty

• Nozzle blocked.

• P1 not getting water

• Pressure sensor faulty

• Temperature sensor T0

faulty

• Door seal leaky

• Hot water.

• MV-1 leakage

• Blown fuse at switch or on

circuit board.

• See section pre-treatment,

pressure reduction above

• BV2 or MV2 faulty

• Steam generator not hot

enough

Air filter obstructed

MV-2 or BV-2 fails to open.

Air filter obstructed.

• Remove BV1; check that the ball is

not stuck. Connect BV1 to the pump.

Fill water, start pump, (component

test), check that water flows through

the pump / check valve.

• Clean nozzle and check flow (com-

ponent test). Flow must be 100200 ml/min

• Replace safety valve

• Check with component test in service

program.

• Checkwith component test, replace

pump if necessary

• Check calibration or replace sensor.

• Check for air bubbles in hose to tank.

Clean BV1.

• Check in component test

• Clean nozzle

• Squeeze hose before P1.

• Check calibration with external

sensor. Replace if necessary.

• Check calibration, replace sensor if

necessary.

• Replace door seal

• Check fan and cooling.

• Change MV-1

• Reset. Check relevant component.

• Replace fuse.

•

• Clean or replace.

• Check sensor T4

• Check the elements.

•Change filter

Check MV-2

•Replace MV-2 or its triac.

•Replace BV-2

•Replace filter

33

Fault Cause Action

•Hot water

•Long cycles

•High water

consumption

Fault in fan or its triac

Restricting washer in cooling

obstructed

Filter obstructed.

33

•Replace fan

•Check + clean restricting washer

•Check + clean filter.

Leakage test

The sterilizer is equipped with a leakage test programme as standard. A flash program shall be run

immediate before a leakage-test program.

Select leakage test on the display. Start the program. If the sterilizer is sealed, the program indicates

“klar”("Ready") on the display and the green lamp flashes.

If there is a leak, the red and yellow lamps flash and the “Läckage”("Leakage") text is indicated on the

display. Call a service technician if there is a leak.

34

34

Getinge Skärhamn’s policy:

Constant improvement

It helps us greatly to achieve this if we receive comments on our products from users and service personnel.

A fee will be paid for suggestions that are incorporated in series production.

We would also appreciate being informed of events in which a sterilizer has caused injury.

Write a few lines below and fax or post them to us.

Fax: +46 304 670924.

Address:

Getinge Skärhamn AB

Industrivägen 5

S-47131 Skärhamn

Sweden

Thank you in advance.

Type Serial

no.

Comments

Comments submitted by:

Name:..................................................Phone.............................................

Address......................................................................................................

35

35

2

Flow chart

Appendix 1

36

36

switch

protection

Door chart

Appendix 2

Electrical drawing

Supply voltage

Plug

circuit board

Main

Overheat

37

37

Circuit board

Appendix 3

38

S

7831P

PARE PARTS LIST

38

Appendix 4

Pos Antal Art nr Benämning Description

Ref Qty Part No

1 1 4832675 Dörr komplett Door complete

2 1 4832578 Täckplåt Cover plate

3 1 4832640 Vred svart Handle black

3 1 4832640/05 Vred vit Handle white

4 4 4834607/05 Låsbricka Lock washer

5 1 4832528 Dörrblad Door

6 1 4832645 Plåt dörr Sheet door

7 1 4832502 Dörrpackning Sealing

8 4 4834933 Kullager Ball bearing

9 1 4832731 Kil nedre Locking device bottom

10 1 4832703 Kil övre Locking device top

11 2 4832667 Länk Link

12 1 4834936 Magnet dörrbrytare Magnet door contact

13 4 4832514 Skruv Screw

14 1 4833284 Plåt dörr Sheet door

15 1 4832572 Skena nedre Rail bottom

16 1 4832575 Skena övre Rail top

17 1 4835417 Dörrbrytare Door switch

18 1 4837511 Kammare Chamber

19 1 4832650/70 Insats tråd Rack

20 1 4832527 Vev Crank

21 1 4834607/12 Låsbricka Lock washer

22 1 4832534 Linjal Ruler

23 1 4832537 Takplåt Sheet

24 1 4832562 Sidoplåt Sheet chamber

7831

39

39

Appendix 5

Pos Antal Art nr Benämning Description

Ref Qty Part No

1 1 4837559/72 Frontkåpa rostfri Front cover stainless

1 1 4837559/73 Frontkåpa vitlackad Front cover white painted

2 1 4837561/70 Sidokåpa höger rostf. Right side cover stainless

2 1 4837561/71 Sidokåpa höger vitl. Right side white painted

3 1 4837554/72 Sidokåpa vänst. rostf. Left side cover stainless

3 1 4837554/73 Sidokåpa vänst. vitl. Left side cover white painted

4 1 4832615/70 Överkåpa rostfri Top cover stainless

4 1 4832615/71 Överkåpa vitlackad Top cover white painted

5 1 4837546/70 Bakstycke rostfri Rear cover stainless

5 1 4837546/71 Bakstycke vitlackad Rear cover white painted

6 1 4832624/70 Lock rostfri Lid stainless

6 1 4832624/71 Lock vitlackad Lid white painted

7 1 4832629 Packning tank Sealing tank

8 4 4835331 Fot Leg

9 1 4837105 Nivårör komplett Level tube complete

10 1 4832519 Profil nivårör Profile level tube

11 2 4832678 Gångjärn Hinges

12 1 4837481 Dekal Decal

13 1 4837551 Dekal Decal GE 224cVac

13 1 4837626 Dekal Decal Citomat 164

14 1 4834997 Nummerskylt Number plat

7832p5a

40

40

Components

Appendix 6

Pos Antal Art nr Benämning Description

Ref Qty Part No

1 1 4834100 Magnetventil Solenoid valve

2 1 4835010 Filter Filter

3 1 4835387 Virvelbildare Turbulence producer

4 1 4837949 Hus munstycke Nozzle housing

5 1 4835419 Överhettningsskydd Overheating protection

6 1 4835388 Kopplingsplint Terminal board

41

41

Pos Antal Art nr Benämning Description

Ref Qty Part No

7 1 4834939 Överhettningsskydd Overheating protection

8 1 4837694 Tank Tank

9 1 4834066 Genomföring Joint

10 1 4834353/08 Bricka Washer

11 1 4834607/10 Låsbricka Lock washer

12 2 4837627 Dysa ejektor Receiving nozzle, ejector

13 1 4837365 Rörkrök Elbow pipe

14 1 4837368 Slang Hose

15 1 4835223 Rörnit Distance

16 1 4835066 O-ring O-ring

17 1 4835427 Sil Strainer

18 1 4835423 Nippel Nipple

19 1 4837526 Rör Tube

20 1 4835479 T-koppling T junction

21 1 4835390 Temp. givare Pt-100 Temp. transmitter Pt-100

22 1 4834152 Säkerhetsventil Safety valve

23 1 4837628 Munstycke ejektor Jet needle, ejector

24 2 4834100 Magnetventil Solenoid valve

25 1 4834687 Backventil Non return valve

26 1 483553201 Nätsladd Cable

27 1 4837495 Plåtlåda kretskort Box control unit

28 1 4837422 Kretskort Control unit

29 1 4835565 Strömbrytare /säkr.hållare Breaker/fuseholder

30 1 483548501 tryckgivare Pressure transmitter

31 1 483539001 Temp. givare Pt-100 Temp. transmitter Pt-100

32 1 4833215 Element 900W Element 900W

33 1 4831621 Elementkonsol Element bracket

34 1 4835580 Pump Pump

35 1 4835224 Pump Pump

36 1 4835226 Nippel Nipple

37 1 4835628 Filter hus Filter house

38 1 4839171 Strypbricka Restrictor

39 1 4834687 Backventil Non return valve

40 1 4835614 Fläkt Fan

41 1 483539003 Temp. givare Pt-100 Temp. transmitter Pt-100

42 1 4839226 Kyl Cooler

43 1 4837031 Manometer Manometer

44 1 4835626 Filter Filter

45 1 4835253 Brytare Breaker

46 1 4833215 Element 900W Element 900W

47 1 4839255 Konsol tryckgivare Bracket pressure transmitter

48 1 4839232 Fördelarstycke Distriibution pipe

49 1 4839251 Rör Tube

50 1 4839261 Nippel Nipple

51 1 4835059/03 Fjäder Spring

52 1 4837521 Rör Tube

53 1 4839114 Rör Tube

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68 1 4835599 Plast koppling Plastic junction

1 483 V-koppling Angular junction

1 4837705 Rör Tube

1 4837480 Display Display

1 4835393 Insats Restrictor

1 4835495 V-koppling Angular junction

1 4835059/05 Kula Ball

1 4835059/04 Fjäder Spring

1 4837727 Värmekropp Steam generator

1 4839248 Rör Tube

1 4839303 V-koppling Angular junction

1 4834207 T-koppling T-junction

1 4835428 Packning Washer

1 4835428 Slangnippel Niple Hose

1 4835423 Nippel Nipple

42

42

..

Loading...

Loading...