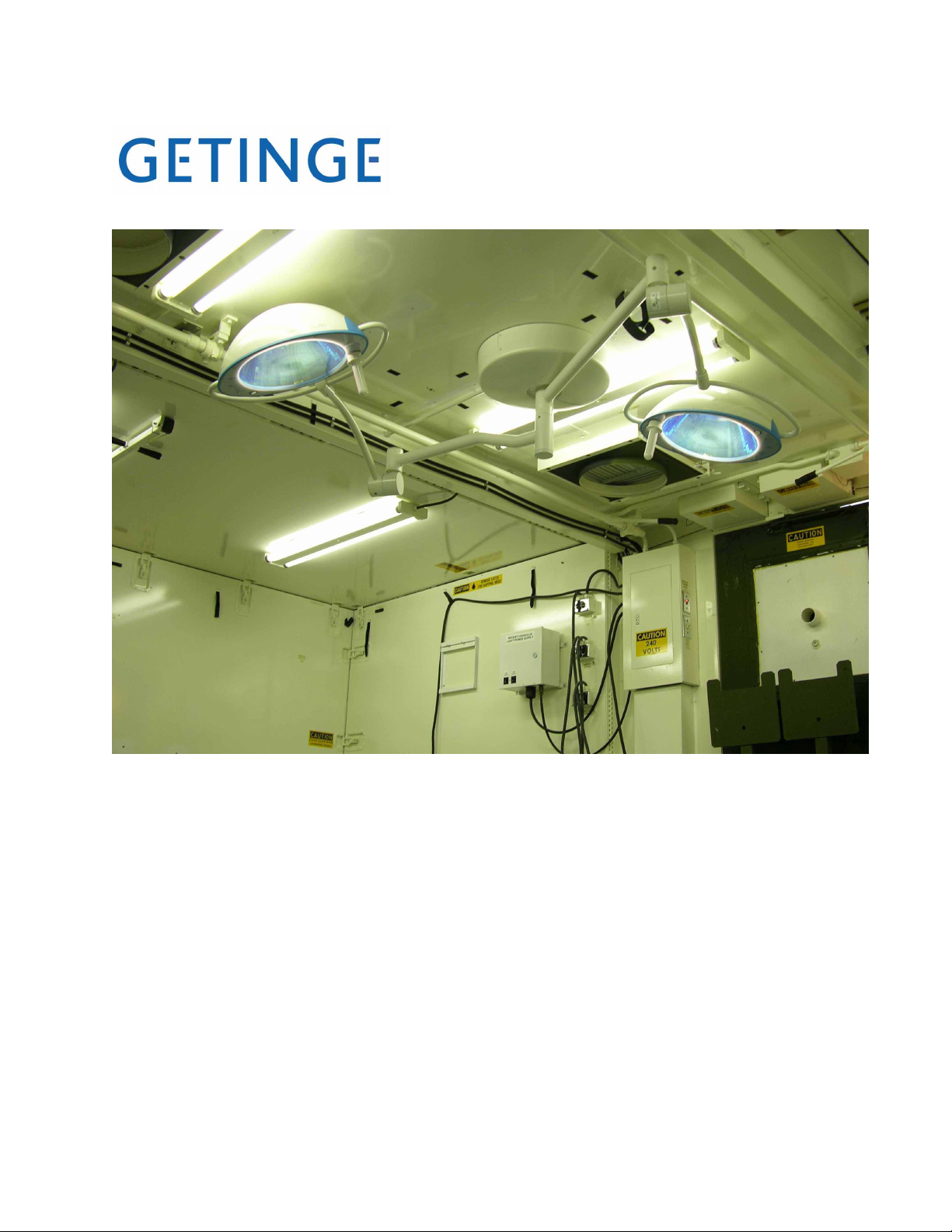

Blue 80/80 Field Light, Installation,

Operators, Service and Parts Manual.

HAN40527, Rev A

Getinge USA, Inc.

1777 East Henrietta Road

Rochester, NY 14623-3133 USA

Phone: (800) 950-991

BLUE 80/80 FIELD LIGHT, INSTALLATION, OPERATORS, SERVICE AND PARTS MANUAL

HAN40527, Rev A, 21 April, 2006

Related Publications: 56351056/B Hanaulux Blue 30/80 Operating Instructions

56321004A Hanaulux Blue 30/80 Spare Parts Lists

DESCRIPTION OF SYMBOLS & NOTES IN MANUAL

DANGER

“Danger” notes alert the user to the possibility of serious injury or death.

“Warning” notes alert the user to the possibility of personal injury.

“Caution” notes alert the user to the possibility of damage to the equipment.

“Notes” alert the user to pertinent facts and conditions.

This manual contains proprietary information of Getinge USA, Inc. It shall not be reproduced

in whole or in part without the written permission of Getinge USA, Inc.

is a registered trademark. Copyright 2006

by Getinge USA, Inc.

i

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Table of Contents

SECTION 1: GENERAL DESCRIPTION: .........................................................................................................2

1.1

BLUE 80 LAMPHEAD ....................................................................................................................................2

1.2 BLUE 80/80 POWER SUPPLY .......................................................................................................................2

1.3 BLUE 80/80 SUSPENSION SYSTEM............................................................................................................... 3

SECTION 2: REMOVAL OF EXISTING CASTLE 2420 LIGHT SYSTEM FROM ISO SHELTER...................4

2.1

DISCONNECT POWER AT MAIN BREAKER PANEL ............................................................................................. 4

2.2 REMOVE JUNCTION BOX, CONDUIT AND WIRING .............................................................................................4

2.3

REMOVE EXISTING LIGHT SYSTEM ................................................................................................................ 5

2.4 REMOVE WIRES FROM LIGHT SYSTEM ...........................................................................................................6

2.5 REMOVE TRANSPORTATION CEILING PADS ....................................................................................................6

2.6

REMOVE DIMMER SWITCH ............................................................................................................................7

SECTION 3: INSTALLATION OF LIGHT SUSPENSION, WIRING AND BRACKETS ...................................8

3.1

INSTALLATION OF CEILING MOUNTED TRANSPORTATION PLATES AND STRAPS ...............................................8

3.2.

POWER SUPPLY BRACKET .......................................................................................................................... 9

3.3 CEILING PLATE AND FLANGE...................................................................................................................... 11

3.4 CEILING FLANGE TO MAIN ARM INSTALLATION ............................................................................................12

3.5

MAIN ARM INSTALLATION...........................................................................................................................13

3.6 MAIN ARM WIRING AND CONDUIT INSTALLATION .........................................................................................14

3.7 CEILING COVER INSTALLATION................................................................................................................... 15

3.8

LOW VOLTAGE AC WIRE RUN FROM POWER SUPPLY TO LIGHT CONNECTION..............................................16

3.9 HIGH VOLTAGE AC WIRE FROM POWER SOURCE TO POWER SUPPLY .........................................................17

3.10

SPRING ARM TO MAIN ARM INSTALLATION ................................................................................................18

SECTION 4.0: INSTALLATION OF LAMPHEADS AND POWER SUPPLY: ................................................ 20

4.1

REMOVING COMPONENTS FROM SHIPPING CASE.........................................................................................20

4.2

LAMPHEAD INSTALLATION ..........................................................................................................................22

4.3 POWER SUPPLY INSTALLATION AND CONNECTION ......................................................................................25

4.4 SETTING POWER SUPPLY TAPS .................................................................................................................26

4.5

INITIAL SETTING OF POWER SUPPLY VOLTAGES ......................................................................................... 27

SECTION 5: SECURING BLUE 80 MAIN ARMS ...........................................................................................29

REMOVAL OF BLUE 80 LAMPHEADS AND MAQUET POWER SUPPLY ...............................................................29

5.1

5.2

SECURING MAIN ARM AND SPRING ARMS ..................................................................................................... 29

SECTION 6.0: OPERATION OF THE BLUE 80/80 LIGHT SYSTEM: ...........................................................31

6.1

SETTING UP LIGHT SOURCE .......................................................................................................................31

6.2

ENERGIZING THE POWER SUPPLY. ............................................................................................................. 32

SECTION 7.0: PREVENTIVE MAINTENANCE OF BLUE 80/80 LIGHT SYSTEM........................................33

INSPECTION BY THE OPERATOR .................................................................................................................33

7.2

7.3

CLEANING/DISINFECTION........................................................................................................................... 34

7.4 STERILIZING THE HANDLES ........................................................................................................................34

SECTION 8.0: CORRECTIVE MAINTENANCE..............................................................................................35

8.1

TROUBLESHOOTING PROCEDURES .............................................................................................................35

8.2 LIGHTHEAD REMOVAL PROCEDURES...........................................................................................................36

8.3

SPRING ARM TENSION ADJUSTMENT PROCEDURE ........................................................................................ 37

8.4

SETTING THE BRAKE PRESSURE OF THE BLUE 80 LIGHTHEAD ......................................................................37

8.5 REPLACEMENT OF BULBS...........................................................................................................................38

ii

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

SECTION 9. TROUBLESHOOTING THE POWER SUPPLY ......................................................................... 39

SECTION 10.0: PARTS LISTING ...................................................................................................................41

BLUE 80 LIGHTHEAD PARTS ....................................................................................................................42

10.2

10.3 ISO SHELTER MOUNTING KIT ..................................................................................................................43

10.4

POWER SUPPLY......................................................................................................................................56

10.5 REUSABLE SHIPPING CONTAINER. ...........................................................................................................62

F

IGURES

F

IGURE 1: POWER BREAKER.................................................................................................................................4

F

IGURE 2: JUNCTION BOX .....................................................................................................................................4

FIGURE 3: EXISTING LIGHT SYSTEM ...................................................................................................................... 5

FIGURE 4: REMOVING WIRES FROM LIGHT SYSTEM ................................................................................................ 6

F

IGURE 5: REMOVING TRANSPORTATION CEILING PADS .........................................................................................7

F

IGURE 6: REMOVE DIMMER SWITCH.....................................................................................................................7

FIGURE 7: INSTALLATION OF VELCRO STRAPS........................................................................................................ 8

F

IGURE 8: POWER SUPPLY BRACKET INSTALLATION............................................................................................... 9

FIGURE 9: DRILLING TEMPLATE ...........................................................................................................................10

FIGURE 10: POWER SUPPLY MOUNTING BRACKET ...............................................................................................10

F

IGURE 11: BOLT/BRACKET POSITIONING ............................................................................................................ 10

FIGURE 12: CEILING FLANGE AND PLATE .............................................................................................................11

F

IGURE 13: CEILING FLANGE AND PLATE .............................................................................................................12

FIGURE 14: MAIN ARM INSTALLATION ..................................................................................................................13

FIGURE 15: CONDUIT INSTALLATION ....................................................................................................................14

F

IGURE 16: RETAINING RING ASSEMBLY..............................................................................................................15

FIGURE 17: RETAINING CLAMPS, HOOD ASSEMBLY .............................................................................................. 15

FIGURE 18: ASSEMBLED HOOD ASSEMBLY ..........................................................................................................15

F

IGURE 19: LOW VOLTAGE AC CONNECTIONS ..................................................................................................... 16

FIGURE 20: AC OUT CABLE ROUTE.................................................................................................................... 16

FIGURE 21: HIGH VOLTAGE AC WIRE/PLUG ........................................................................................................ 17

F

IGURE 22: SPRING ARM TO MAIN ARM INSTALL ..................................................................................................18

FIGURE 23: INSERTING MALE LIGHT PLUG ...........................................................................................................19

FIGURE 24: BLUEMMSA CONTAINER LABEL ...................................................................................................... 20

F

IGURE 25: BLUE 80 LIGHT CONTAINER INVENTORY ............................................................................................ 21

FIGURE 26: LAMPHEAD INSTALLATION ................................................................................................................. 22

F

IGURE 27: SPRING ARM CONNECTION ...............................................................................................................23

F

IGURE 28: SECURING LAMPHEAD ...................................................................................................................... 23

F

IGURE 29: RETAINING RING/PROTECTIVE COVER...............................................................................................24

IGURE 30: MILITARY POWER SUPPLY ................................................................................................................25

F

F

IGURE 31: PRIMARY/SECONDARY TAPS .............................................................................................................26

F

IGURE 32: BLUE 80 BULB ACCESS PANEL..........................................................................................................27

FIGURE 33: BLUE 80 VOLTAGE MEASUREMENT....................................................................................................28

F

IGURE 34: VELCRO STRAP, P/N HAN40475...................................................................................................... 29

F

IGURE 35: SPRING ARM STRAPPING POSITION .................................................................................................... 30

F

IGURE 36: CEILING MOUNTED VELCRO STRAP, P/N HAN40468......................................................................... 30

FIGURE 37: BLUE 80 LAMPHEAD .........................................................................................................................31

F

IGURE 38: LAMPHEAD ALIGNMENT ..................................................................................................................... 31

F

IGURE 39: BLUE 80/80 POWER SUPPLY ............................................................................................................ 32

IGURE 40: WEIGHT BALANCER ..........................................................................................................................36

F

F

IGURE 41: BLUE 80 LIGHTHEAD BRAKE SCREW...................................................................................................36

F

IGURE 42: SPRING ARM BRAKE ADJUSTMENT...................................................................................................... 37

IGURE 43: BLUE 80 LIGHTHEAD BRAKE ADJUST .................................................................................................. 37

F

F

IGURE 44: LIGHT BULB REPLACEMENT PROCEDURE ............................................................................................38

iii

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

IGURE 45: SCHEMATIC, WIRING, POWER SUPPLY, MILITARY ............................................................................... 40

F

F

IGURE 46: FLANGE AND SUSPENSION ................................................................................................................41

FIGURE 47: SPRING ARMS AND LIGHTHEADS ....................................................................................................... 41

FIGURE 48: BLUE 80 LIGHT COMPONENTS........................................................................................................... 42

F

IGURE 49: HAN40457 ASSEMBLY, CONDUIT, ½” EMT, 28.5” LONG ...................................................................44

F

IGURE 50: HAN40460 ASSY, RING, ANCHOR PLATE,.........................................................................................45

FIGURE 51: HAN40464 TOGGLE, SPRING WING..................................................................................................46

F

IGURE 52: HAN40465 ROUND HEAD SCREW, ZP.............................................................................................. 47

FIGURE 53: HAN40466 PLATE, HOLDING, VELCRO ............................................................................................. 48

FIGURE 54: HAN40467 TEMPLATE, MOUNTING, TRANSFORMER BOX, ARMY ........................................................49

F

IGURE 55: HAN40468 STRAP, VELCRO, 2” .......................................................................................................50

FIGURE 56: HAN40475 COVER, TRANSPORT, ARM .............................................................................................51

FIGURE 57: HAN40482 CONNECTOR, TURN LOCK, FEMALE, 20 AMP .................................................................. 52

F

IGURE 58: HAN40487 ASSEMBLY, CABLE, AC OUT, EXTERNAL, ARMY ..............................................................53

FIGURE 59: HAN40541 BRACKET, MOUNTING, ELECTRICAL BOX, ARMY ..............................................................54

FIGURE 60: HAN40551 NUT, WIRE, TWIST LOCK, YELLOW..................................................................................55

F

IGURE 61: HAN40489 ASSEMBLY, POWER SUPPLY, ARMY, SHEET 1 OF 6..........................................................56

F

IGURE 62: HAN40489 ASSEMBLY, POWER SUPPLY, ARMY, SHEET 2 OF 6..........................................................57

FIGURE 63: HAN40489 ASSEMBLY, POWER SUPPLY, ARMY, SHEET 3 OF 6..........................................................58

F

IGURE 64: HAN40489 ASSEMBLY, POWER SUPPLY, ARMY, SHEET 4 OF 6..........................................................59

FIGURE 65: HAN40489 ASSEMBLY, POWER SUPPLY, ARMY, SHEET 5 OF 6..........................................................60

F

IGURE 67: BLUEMMSA REUSABLE SHIPPING CONTAINER.................................................................................. 62

Tables

Table 1: Parts Inventory Checklist……………………………………………………………………………………1

Table 2: Blue 80/80 System Technical Data……………………….………………………….…………………….2

Table 3: Transformer Secondary Tap Voltages…………………………..…………………………….……….…26

Table 4: Preventive Maintenance Recommendation…………………………………………………………..…..32

Table 5: Mechanical/Optical Troubleshooting…………….……………………………….……………………..…34

Table 6: Power Supply Troubleshooting………………………………………………….……………….………...36

Table 7: Upper Level System Part numbers/components…………………………….……………….………..…40

Table 8: Blue 80 Part numbers/description…………………………………………….……………….…………...41

Table 9: ISO Mounting kit……………………………………………….……………….……………….…………...42

iv

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

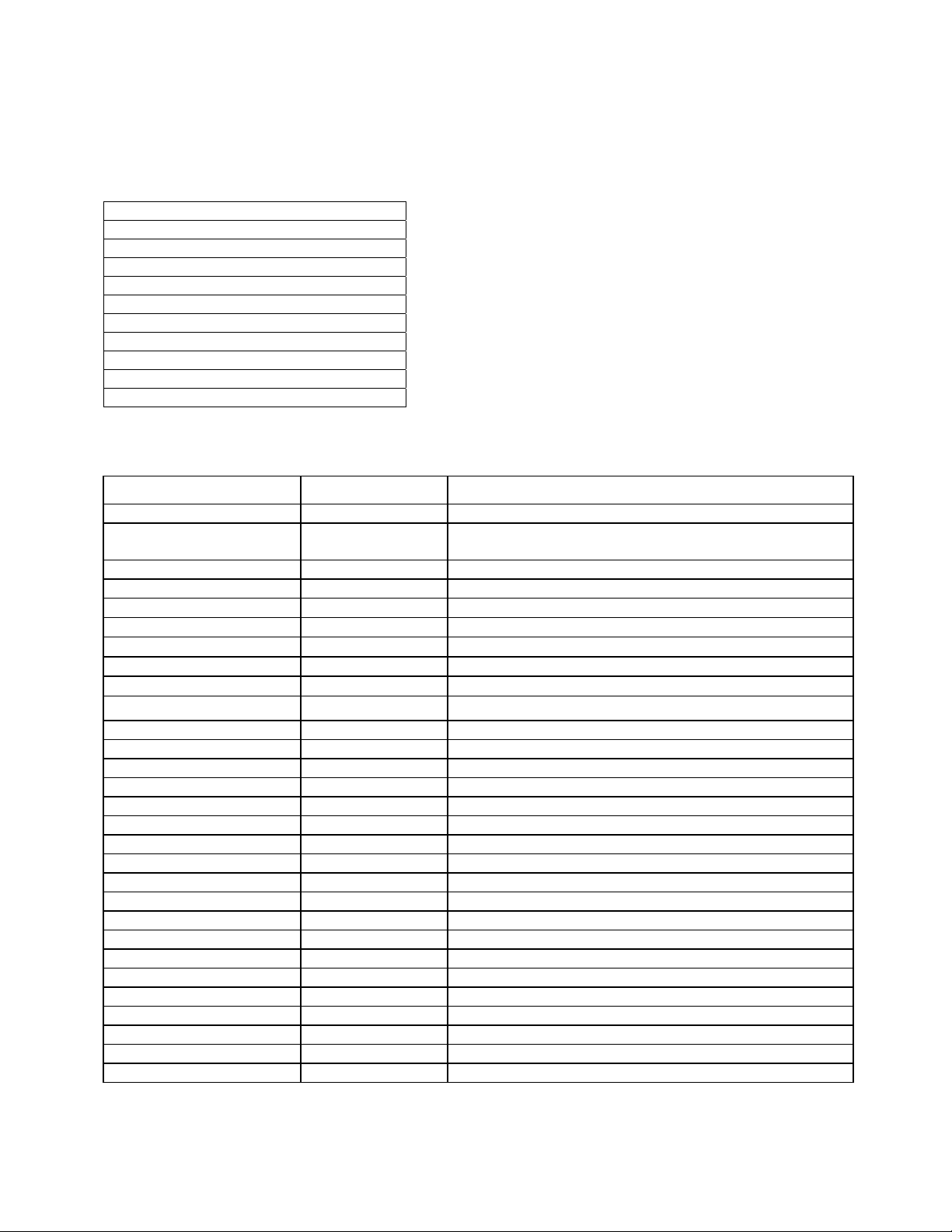

The following is the suggested tool list for proper installation.

Tools Required for Installation of the Blue 80/80 Field Light

Item

Socket Set up to 1" socket

Flatblade Screwdriver #1 and #2

Phillips Screwdriver #2 and #3

Wire Cutters

Tape Measure

Open/Closed End Wrench set to 1"

Metric Allen Set

Electric Drill

9/16" Drill Bit

Digital Multimeter

The following is an inventory checklist of items for Blue80/80 Field Light System

Received Part Number Item Name

BLUE80/80CASE

SHIPPING CONTAINER

Yes No BLUE80/80 CASE Container, Reusable Shipping (1)

Yes No 5607-7852 Blue 80 Lightheads (2)

Yes No

Yes No

Yes No

Yes No

Yes No

ISO Mounting Kit

Yes No HAN40457 Assy, conduit, 1/2" emt (1)

Yes No HAN40460 Assy, ring, anchor plate (1)

Yes No HAN40464 Toggle, spring wing (4)

Yes No HAN40465 Screw, rh, .250-20, UNC-3A (4)

Yes No HAN40466 Plate, holding, velcro (2)

Yes No HAN40467 Template, mtg, xfmr box, army (1)

Yes No HAN40468-24 Strap, velcro, 2" x 24" (1)

Yes No HAN40468-40 Strap, velcro, 2" x 40" (1)

Yes No HAN40475 Cover, transport, arm (2)

Yes No HAN40482 Conn., Turn lock, female 20amp (1)

Yes No HAN40487 Assy, cable, ac out, external (1)

Yes No HAN40541 Brkt, mtg, elect box, army (2)

Yes No HAN40551 Nut, wire, twist, yellow (6)

Yes No X0216 Tape, electrical, black (1)

Yes No HAN40580 Bubble Level(1)

Suspension System

Yes No 569004905 Ceiling Flange (1)

Yes No 569004990 Suspension, Duo, Blue 80 (1)

Yes No 569004991 Spring Arm (2)

HAN40489 Assembly, Power supply, Army (1)

5605-3036 Bulb: B80 21.5v 130w (2)

5605-0756 Handle: Plastic, 200 series (3)

5605-0756 Handle: Plastic, 200 series (3)

HAN40457 Blue 80/80 Field Light, Installation/Operators Manual (1)

Table 1: Part Inventory Checklist

1

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Section 1: General Description:

The dual Blue 80 light system is designed for installation into a military ISO Shelter. It is a

light system that can be disassembled and assembled for rapid deployment of the shelter.

The main and spring arms are permanently secured to the shelter, and the lampheads and

power supply are removable for shipment.

1.1 Blue 80 Lamphead

• Multifunctional filter and reflector system with 1,500 facets and specially coated reflector

provides high precision, true-to color and neutral white light

• Illuminance at 80,000 lux

• Equipped with a two-stage interference filter for additional infra-red filtering

• Automatic back-up system from primary to secondary light source

• Integrated ON/OFF switch, easily accessible on the light head

• Sterilizable Handle

• Full rotation around the central axis with accurate positioning where required

Table 1 provides technical data on the Blue 80 lamphead and power supply.

1.2 Blue 80/80 Power Supply

The power supply was designed for installation into a portable military ISO shelter. Mobility of

this system was a major consideration, thus the Blue 80/80 power supply was designed to be

hung via a wall mounted bracket assembly, and electrically connected with simple quick

disconnects on both the AC input and the AC output lines.

The Blue 80/80-power supply has a matched pair of transformers. Each transformer supplies

power to one lamphead. The transformers step-down the incoming voltage (110VAC to 120VAC)

into multiple secondary voltages, ranging from 24.5VAC to 27.5VAC, to accommodate for

tolerances with incoming voltages and wiring resistance.

Power resistors are placed in series with both outputs to reduce the voltage sent to enable the

bulb to operate at its specified 21.4VAC.

An inline fuse assembly is mounted on the output of the transformer to protect both lightheads.

The fuse is rated at 9 amps, 32 volts. The circuit is protected on the primary side by SPDT 20amp breaker switches installed on the front panel. Both switches are labeled and switch the

incoming AC power to each light. The breakers have visible light indication, showing the

ON/OFF switch position.

The input AC voltage is fed into the housing with a female connector. It is mated with a turn lock

style, male connector. This turn style connector is embedded within the housing enclosure and

will mate up to the input connector. These connectors are a quarter locking twist design thus

ensuring positive connection when mated together.

The output AC low voltage connection utilizes a female plug connector. This, in turn, will mate

up to a matched male connector and will be terminated at a junction box for the cable run to the

ceiling mounted light system.

2

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

1.3 Blue 80/80 Suspension System

The Blue 80/80-suspension system is made up of (3) section. The upper section is a (2) plate

system; a mounting plate that attaches directly to the ceiling of the shelter, and a suspension

plate that attaches to the mounting plate. The dual extension arm is secured to the suspension

plate, and the spring arms are secured to the main arm. Table 1 provides technical data on the

Blue 80-suspension system.

Lighting Data Blue 80 Lamphead

Illumination Ec at 39.5 in(1m) distance 80,000 lux

Light field diameter at 39.5 in (1M) distance 7 in (18cm)

Working distance 27.5 - 51 in (70-130cm)

Depth of working area with homogenous light field 23.75 in (60cm)

Depth of light exit 13.75 in (35cm)

Color temperature 4,300 Kelvin

Color rendering index Ra 93

Max. temperature increase in operation field 13 Degree C

Temperature increase at surgeon’s head 2 Degree C

Luminous efficiency 250lm/W

Total irradiance 320 W/m2

Power consumption Max 150W

Dimension of lighthead 19.5 x 14.5 z 8in (500x370x200mm)

Weight of lighthead 12lb (5.5kg

Electrical Data Blue 80/80 Power Supply

Weight of Box 61.5 lbs. (135.3 kg)

Input Voltage 110-120VAC, 60 Hz, 1 phase

Input Current Per Transformer 4.35 - 6.16 amps

Output Voltage

Output Current Per Transformer 5.5 amps at 21.4VAC

Suspension System Blue 80/80 Suspension

Main Arm lengths

Weight of main arm system

Spring Arms 25.4” (619.8mm)

Weight of spring arms 9 lbs. (4.1kg).

Ceiling plate dimensions 15.54” OD

Ceiling plate weights 32 lbs. (70.4kg)

Environmental storage

To meet the environmental conditions for storage and transportation specified in MIL-STD810, environmental test methods and engineering guidelines, the Blue 80/80 Power supply,

and Lamp heads must be packaged in the Getinge supplied shipping case, Pt#

Blu8080case, Hardigg Pt # dsi-80205-1100.

NOTE: Power supply model HAN40489 is only to be used in ISO shelter with Dual 80/80

systems, Part Number

Table 2: Blue 80/80 System Technical Data

Multiple taps, 19.5 volts to 27.5 volts

with 120 VAC input.

39” (1000mm) upper arm, (33”)

850mm lower arm

40 lbs.

3

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Section 2: Removal of existing Castle 2420 Light System from ISO Shelter

This section covers the removal of the existing Castle 2420 light systems from the ISO Shelter.

2.1 Disconnect power at main breaker panel

2.1.1 Turn off all power to the lights by turning off the appropriate breaker switches. The breaker

numbers to the lights are listed on the door, inside the breaker panel. See Figure 1.

Figure 1: Power Breaker

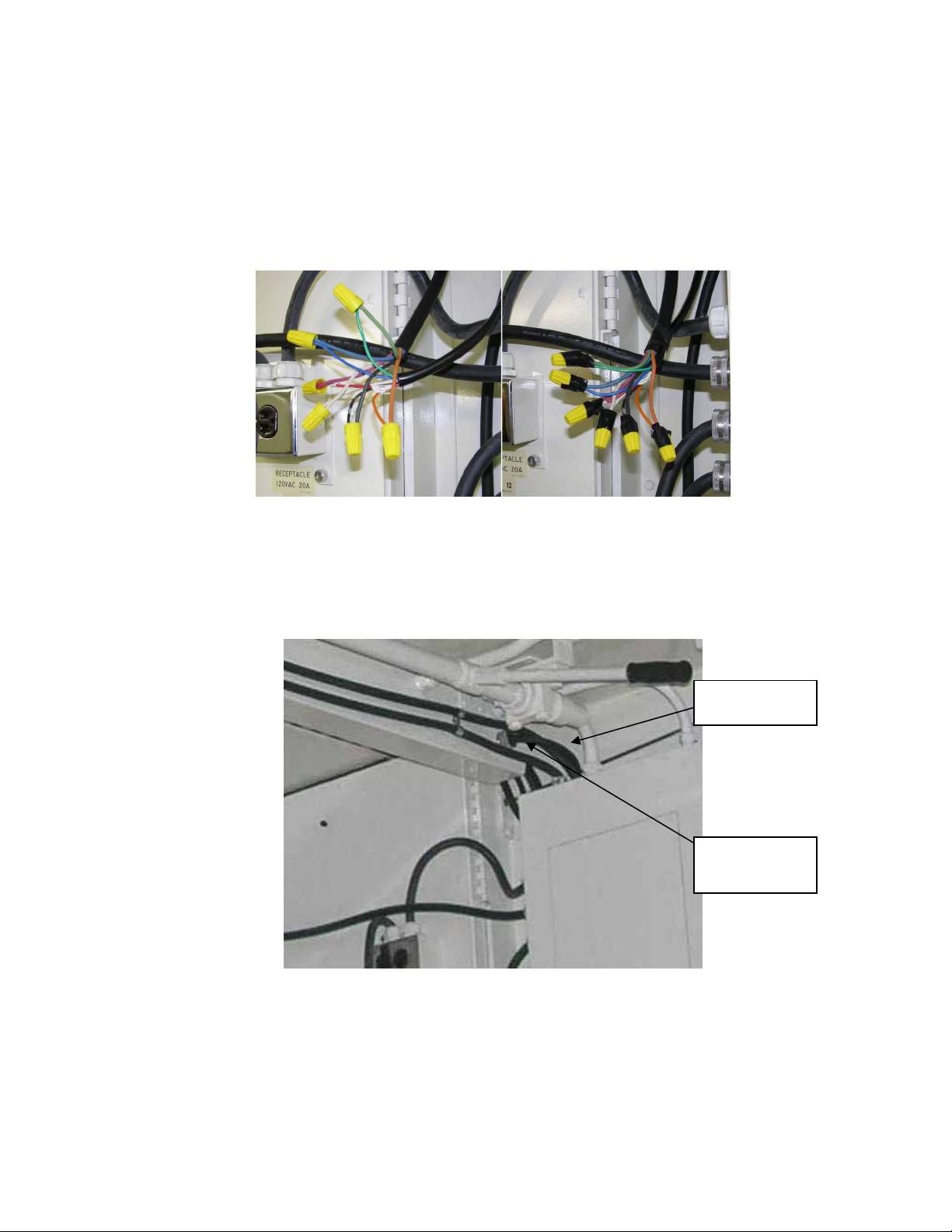

2.2 Remove junction box, conduit and wiring

Remove the junction box cover to access the wires and junction box mounting screws.

Depending on the method used to secure the wires, either twist the wire nuts off, or if

compression wire nuts were used, cut the wires from the wire nuts. After separating the wires,

remove the screws holding the junction box to the ceiling. Next, remove the screws securing

the junction box and conduit from the ceiling channel. Pull the wires through the conduit, but

do not remove them from the ceiling channel at this time. See Figure 2.

Figure 2: Junction Box

4

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

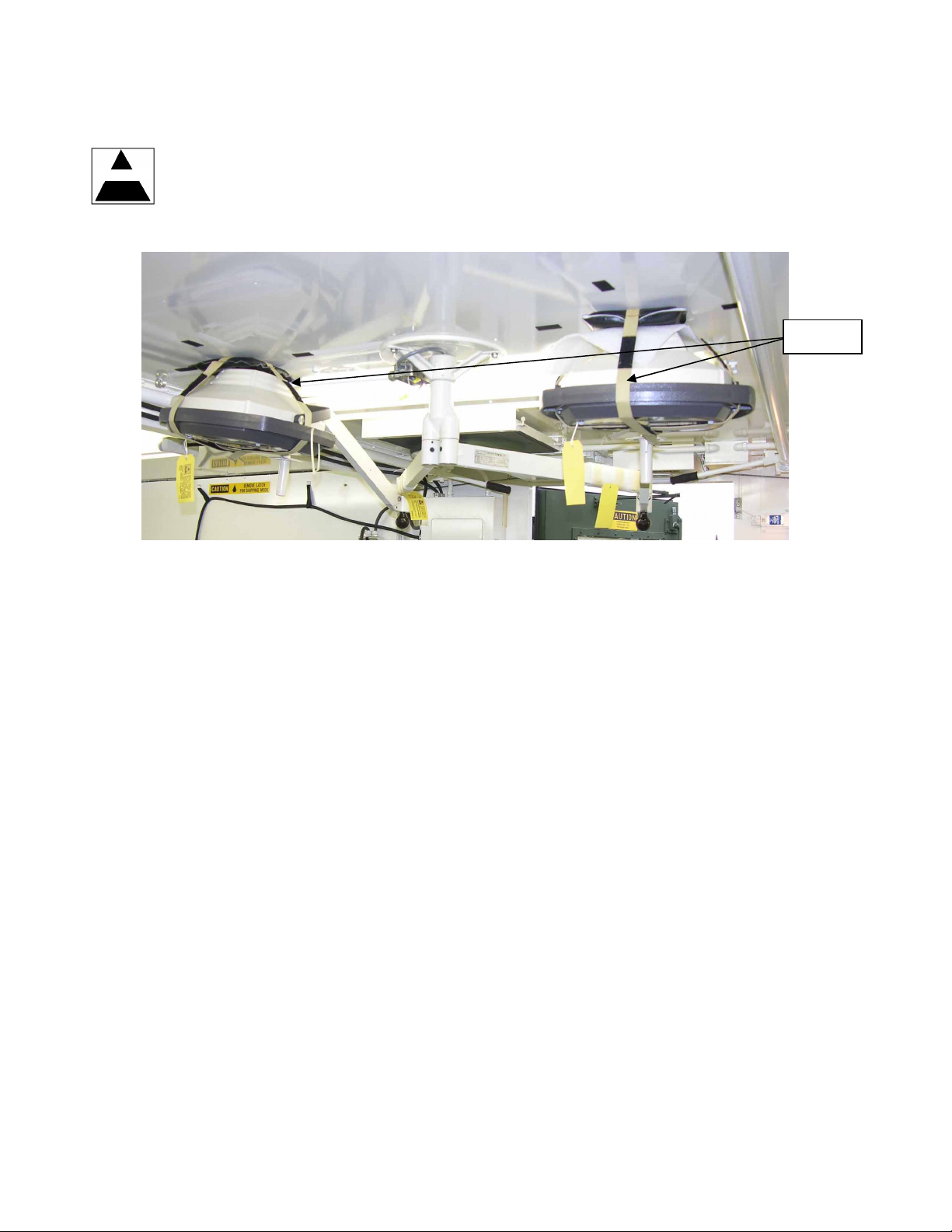

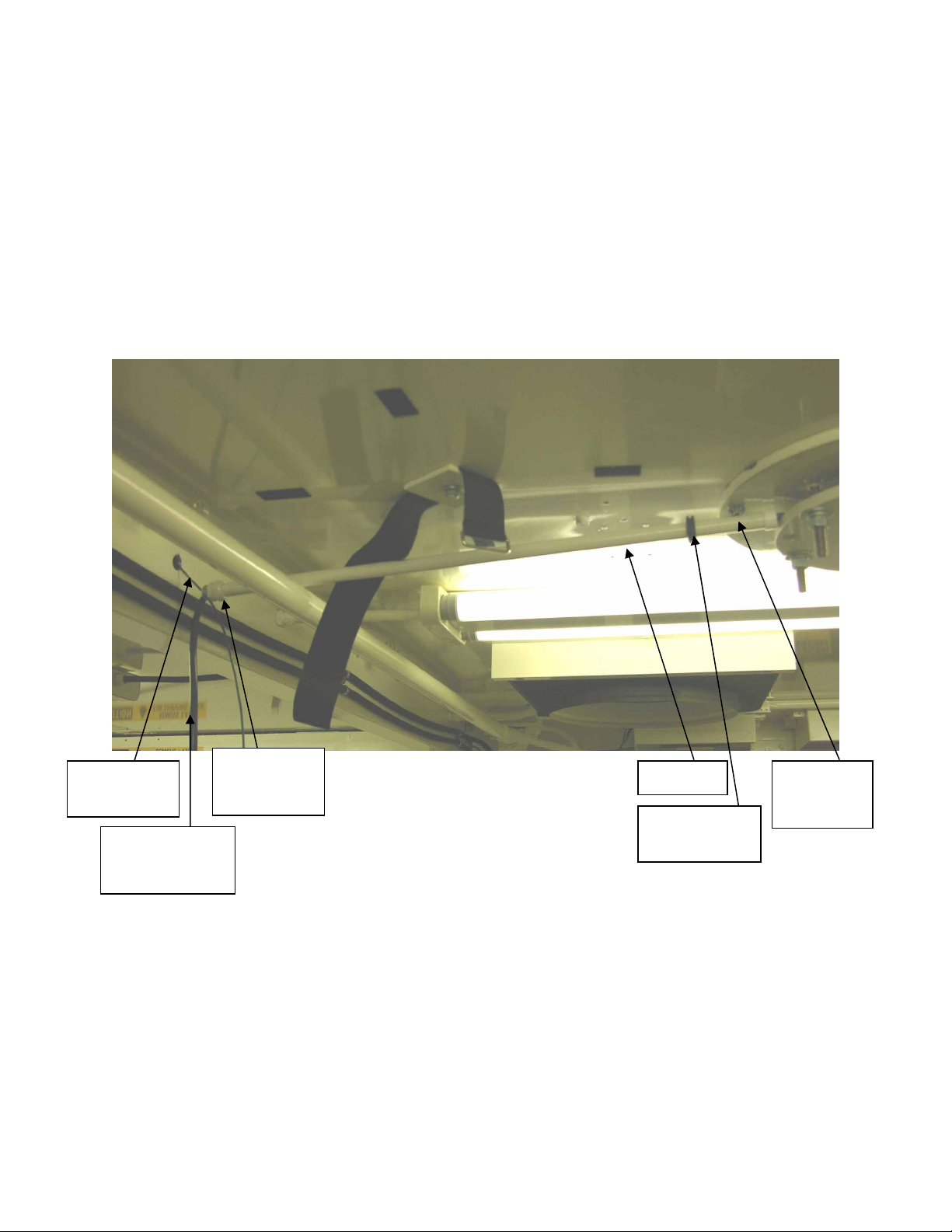

2.3 Remove existing light system

Remove the light heads from the ceiling straps and lower the light heads as far as possible

DANGER

before removing the light system from the ceiling. While one person holds the light system, a

second person shall remove the three bolts securing the lights to the ceiling. Safely lower the

light system to the ground. This is a two-person procedure, and extreme caution should be

used to avoid having the light system drop or fall on someone. See Figure 3.

Straps

Figure 3: Existing Light System

5

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

2.4 Remove wires from light system

Remove the strain relief on the far end of the ceiling wire channel located along the middle of

the ISO Shelter ceiling. Pull the cable out approximately 6 inches and cut the Green, White

and Black wires above the black cable insulation. It may be necessary to reach into the end of

the wire channel, and pull the wires out from the end of the wire channel in order to get them

to move freely. At this point do NOT remove the Green ground wire, as it will be used as a pull

wire to run the new wiring through the channel.

Remove the White and Black power wires by pulling one at a time through the opening in the

middle of the channel, or by pulling them out the open end of the channel. It may be necessary

to use needle nose pliers to remove the wires through the strain relief in the middle of the

channel, to get the wire connector through the strain relief, if this option is used. See Figure 4.

Cut wires

here after

removing

cable from

strain relief

Figure 4: Removing Wires from Light System

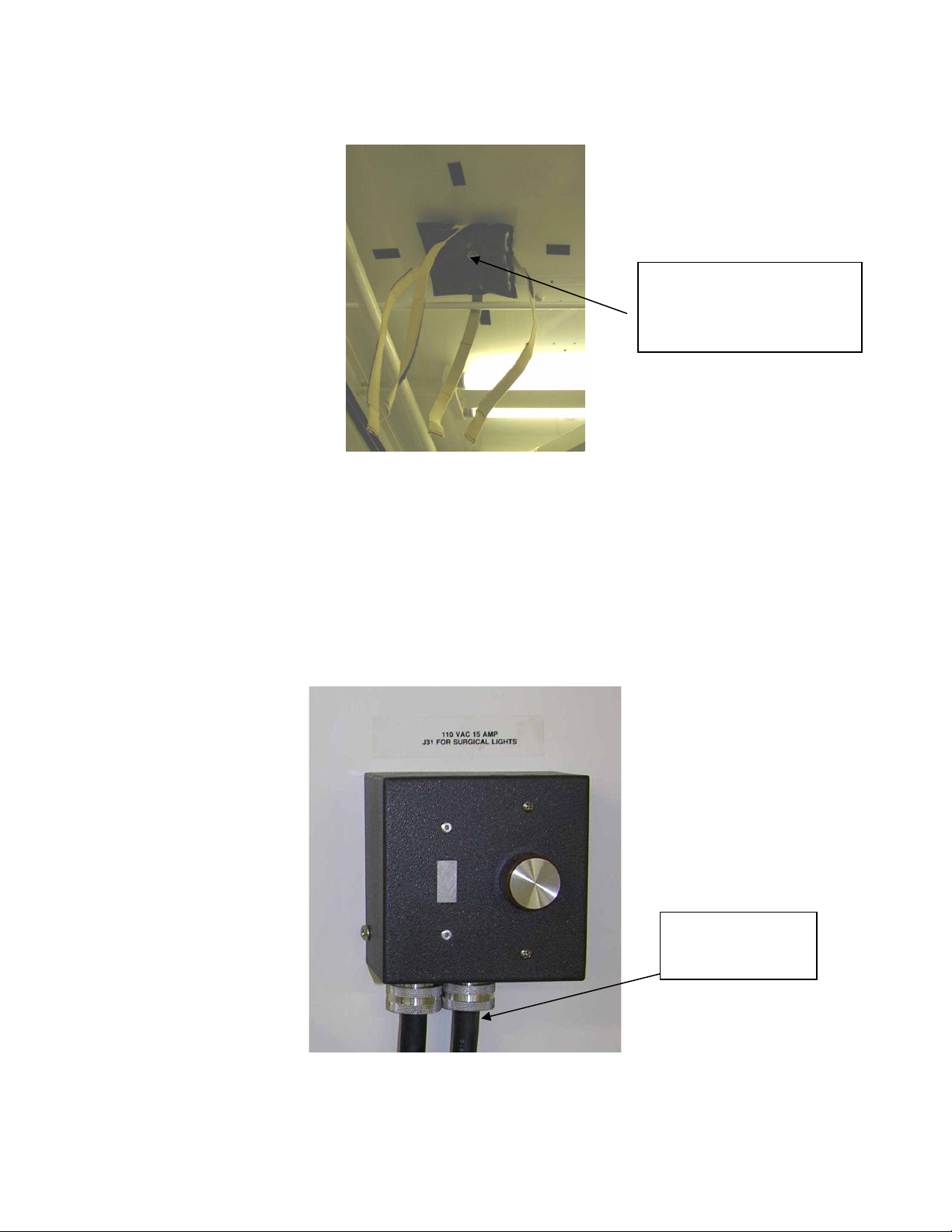

2.5 Remove transportation ceiling pads

Remove the two transportation-ceiling pads with straps that secure the light heads to the

ceiling. Replace the bolt and washer back into the ceiling after removing the straps, as they

will be used later to secure the new arm system transportation straps.

See Figure 5.

6

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 5: Removing Transportation Ceiling Pads

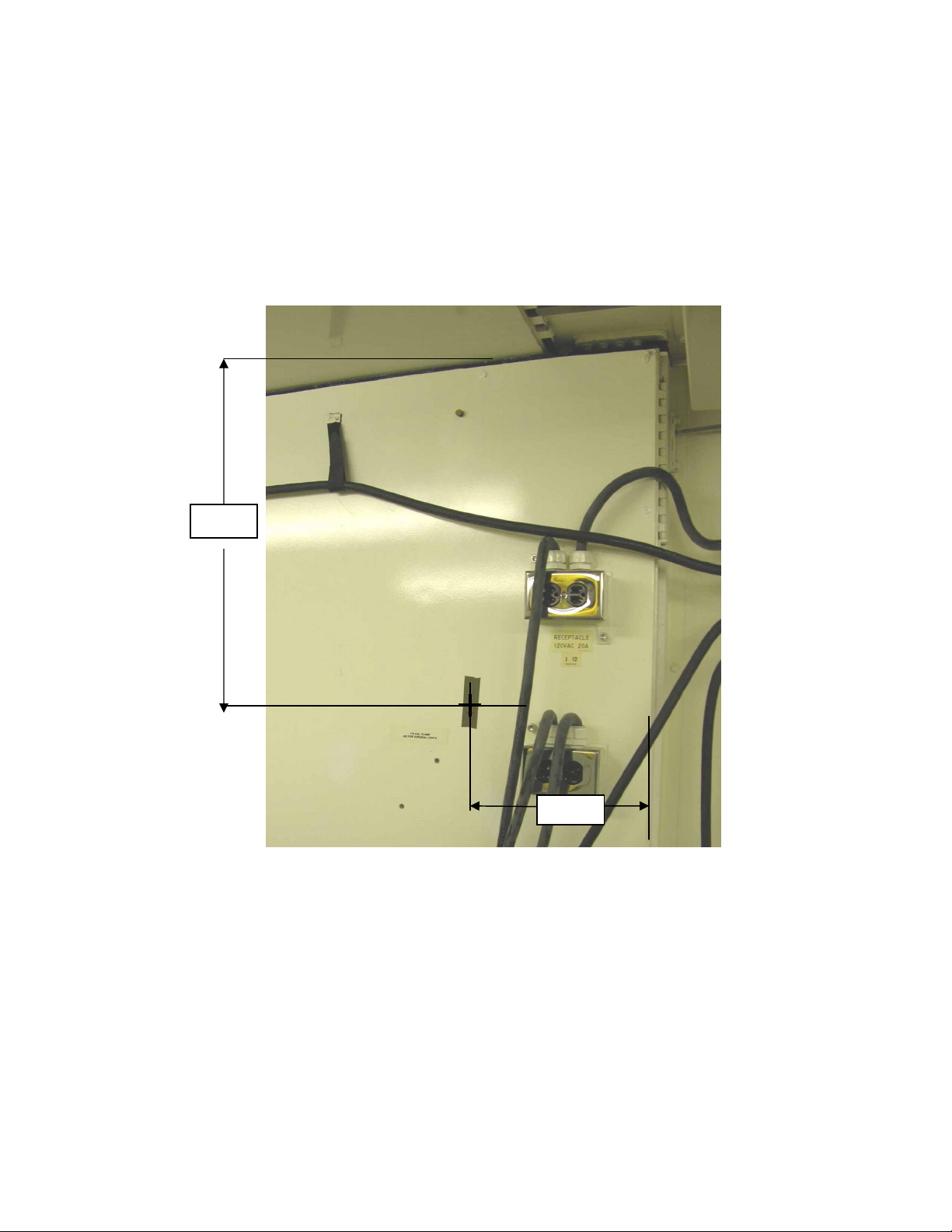

2.6 Remove dimmer switch

Unscrew the front cover on the dimmer switch, and cut the three power wires to the cable on

the right hand side. Disconnect the strain relief from the main power feed cable, and pull the

cable out of the box. The strain relief will not be used, and can be discarded. The existing

cable will be used on the new light system. After removing the cable, unscrew the backing

plate from the wall. Remove the strain relief at the ceiling wire channel, and pull the cable and

wires out. The strain relief at the ceiling wire channel will be used later in Step 3.8. See

Figure 6.

After removing the ceiling

pad, reinstall the bolt and

washer into the existing

threaded hole in the ceiling.

The power cable

will be used with

the new light

Figure 6: Remove Dimmer Switch

7

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Section 3: Installation of Light Suspension, Wiring and Brackets

This section covers the installation of the Blue 80/80 light system transport system, the main

suspension, wiring, and power supply brackets into the ISO Shelter. This step is performed once

during initial installation of a system.

Before starting the installation, make sure the ISO Shelter is completely level, using the

leveling devices associated with the shelter. If the ISO shelter is not level prior to installation,

the light systems will not hang properly.

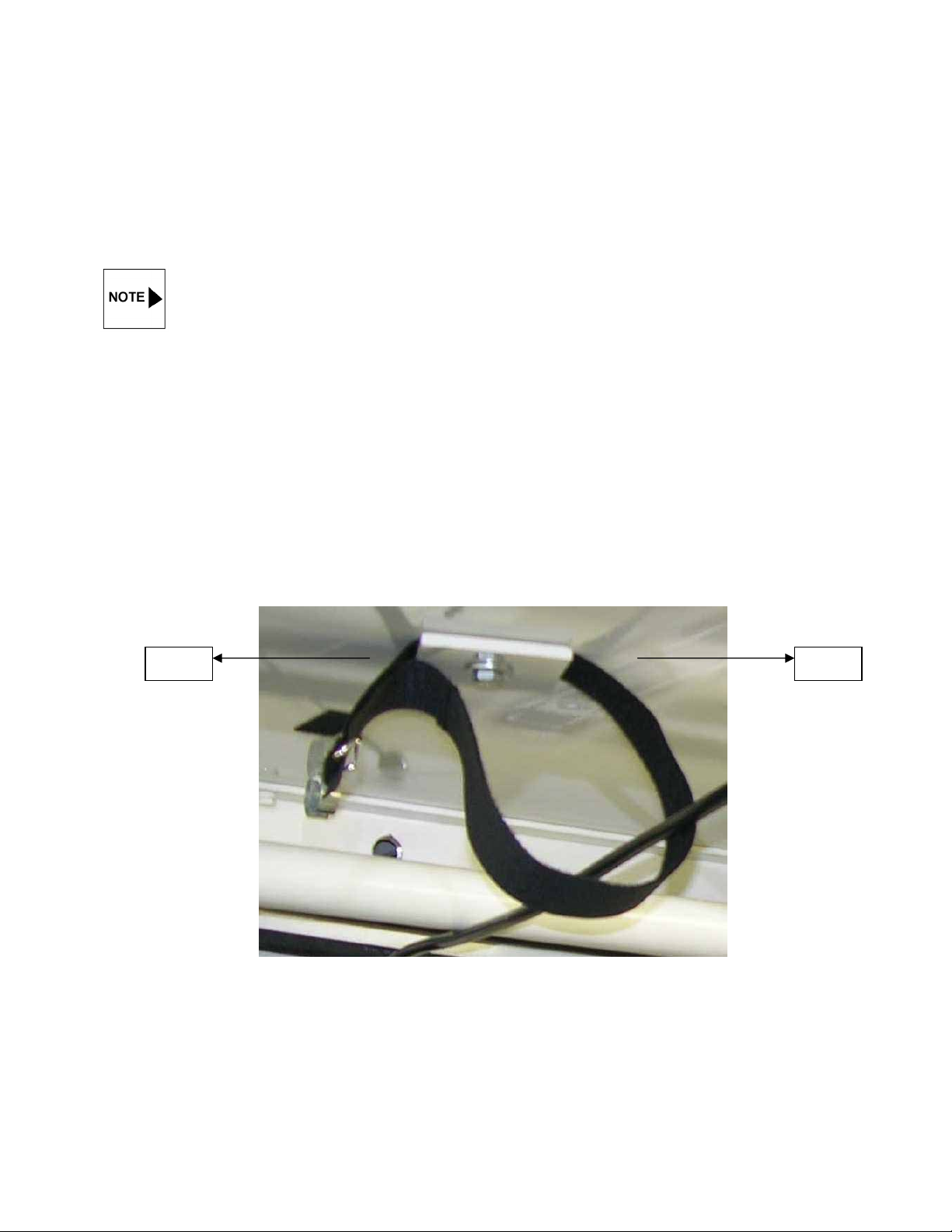

3.1 Installation of Ceiling Mounted Transportation Plates and Straps

Unscrew the bolts and washers from the ceiling that were used to secure the ceiling pads in

step 2.3. There are two different length straps, 24" and 40". Mount the 24" closest to the main

cable channel, and the 40" on the other side. If they are mounted with the 40" nearest the

main cable channel, it will have no effect on the operation of the tie down system. Take the

bolt and washer, and slide it through the bottom of the ceiling plate, which is the side without

the groove in it. There is a small hole in the Velcro, approximately 6" from the buckle. Slide the

Velcro strap onto the bolt, with the "fuzzy" loop side facing up, or away from the ceiling plate

surface. The strap will sit in the groove machined into the ceiling plate, and the "fuzzy" loop will

make contact with the ceiling. Secure the ceiling plate to the top of the shelter and tighten, with

the strap running parallel to the ISO shelter (door to door). There are (2) plates per light

system, (4) total. See Figure 7.

Door Door

Figure 7: Installation of Velcro Straps

8

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

3.2. Power Supply Bracket

3.2.1 Taking a tape measures and a piece of tape, measure down from the ceiling 22 inches,

and from the end of the side wall 11 inches, and place the tape in this area. Go back

and mark and exact centerline location of 22 inches down and 11 inches across onto the

tape. This measurement will be either the top right or top left-hand hole for the drilling

template, depending on which light system is being installed. (right hand shown). See

Figure 8.

22"

11"

Figure 8: Power Supply Bracket Installation

3.2.2 Take the drill template and line up with the marked centerline on the top right or left

hand hole, (depending on which of the two light systems is being installed). Using tape

and a level, line up the template parallel to the floor, and tape the template to the wall.

After the template is installed, mark the four holes onto the wall, and remove the

template. Drill (4) small pilot holes approximately 1/8" to 1/4" in diameter, then finish

using a 5/8" drill bit. See Figure 9.

9

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 9: Drilling Template

3.2.3 Take (2) .250-20 x 1 1/2" long threaded bolts, and insert through the Power Supply

Mounting Brackets, and screw on the spring nuts. See Figure 10.

Figure 10: Power Supply Mounting Bracket

3.2.4 It is necessary to leave a very minimum amount of threads securing the spring nut to

the bolt. Push the spring nuts into the holes, and push the bolt and bracket securely

against the wall to enable the spring clip to open. It may be necessary to tighten and

loosen the bolts a few times in order to get the spring clips to engage correctly. If a

spring clip comes loose from the bolt, the spring clip can be removed from the wall

with a pair of needle nose pliers or a similar tool. See Figure 11.

4 Bolts and

Spring Clips

Figure 11: Bolt/Bracket Positioning

10

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

acket

and Washers

HAN40527, Rev A, 21 April, 2006

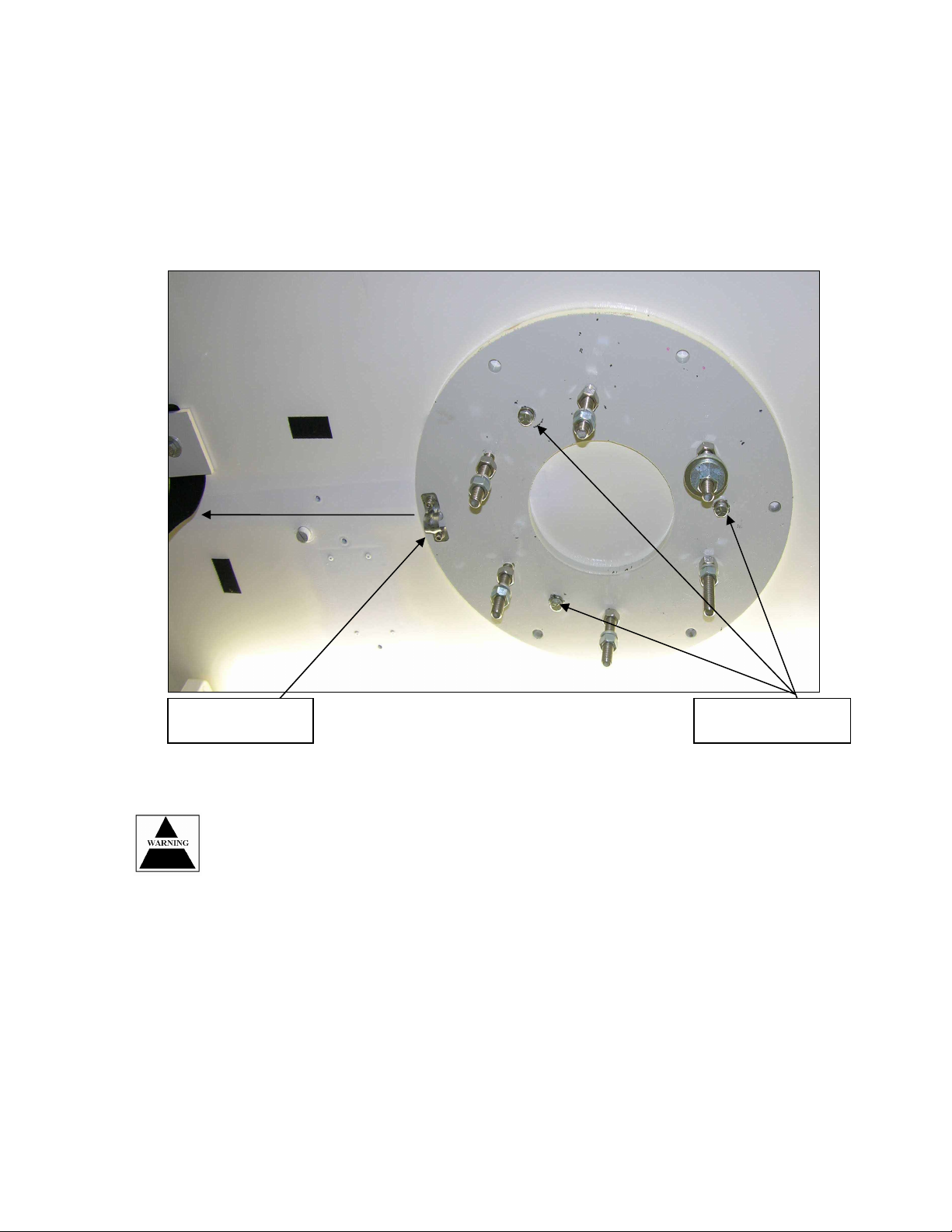

3.3 Ceiling Plate and Flange

Mount the ceiling plate to the ceiling of the ISO shelter using the mounting hardware provided.

The ceiling plate must be aligned so the conduit-mounting bracket is facing the wiring channel.

It will line up directly to the threaded hole in the wiring channel from where the previous

conduit was removed in step 2.2. This is a two-person installation. See Figure 12.

Conduit Mounting

Br

Ceiling plate is heavy, and caution should be taken when installing. Two people

should install this plate, one securing it in position, while the other installs the

hardware.

Figure 12: Ceiling Flange and Plate

(3) Mounting Bolts

11

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

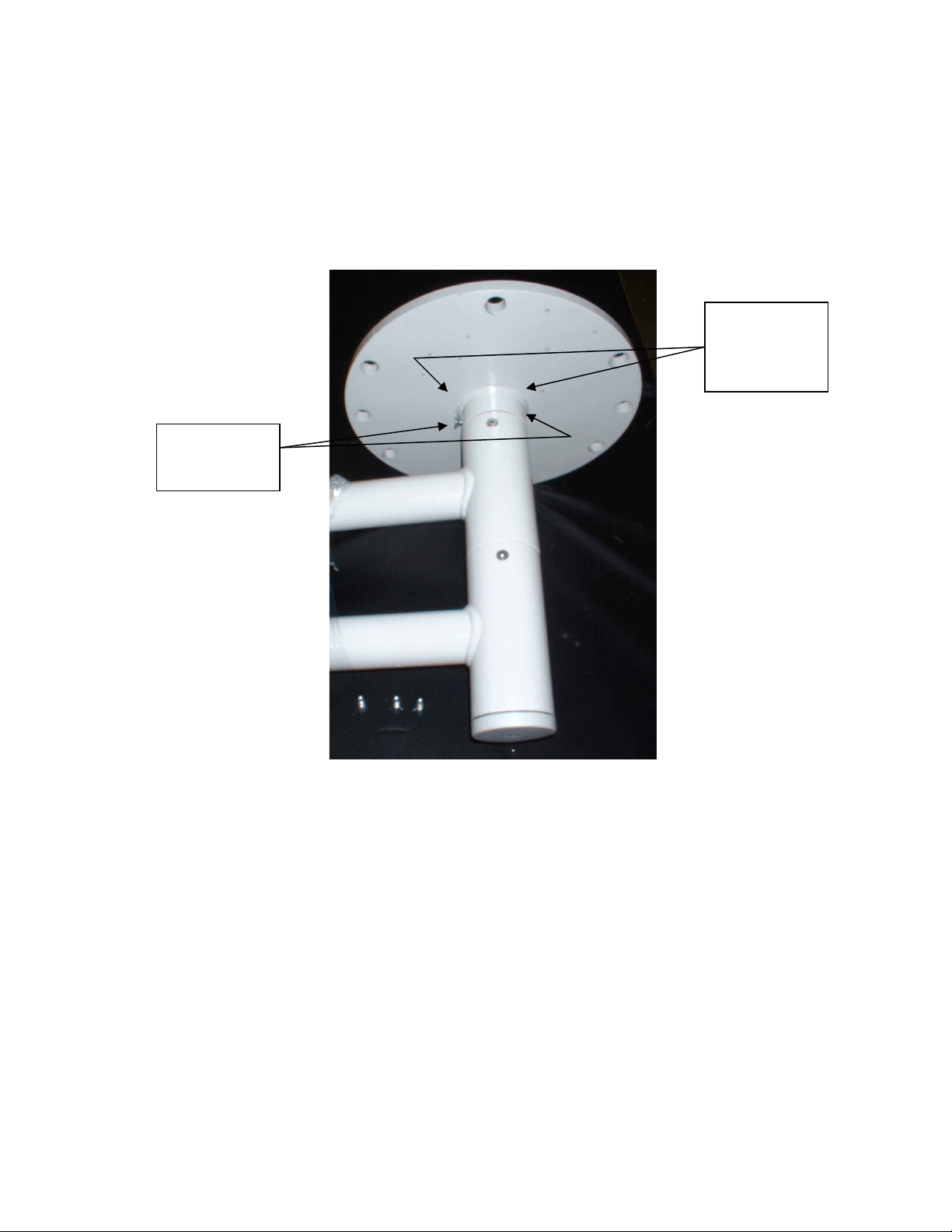

3.4 Ceiling Flange to Main Arm Installation

Slide cable from Main Arm through the throat of the Ceiling Flange. Align the (4) holes, (2)

above and (2) below the circular plate of the ceiling flange, and slide over main arm tube.

Secure to the Main Arm tube with the (4) countersunk screws provided.

See Figure 13.

(2) Screws

below circular

plate

(2) Screws

above circular

plate, (not

shown)

Figure 13: Ceiling Flange and Plate

12

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

g

HAN40527, Rev A, 21 April, 2006

3.5 Main Arm Installation

Before installing the Main Arm, The majority of the hardware on the ceiling plate must be

removed. All that should remain on the (6) studs of the ceiling plate, is (1) hex nut per stud, (6)

total. Screw these (6) nuts all the way flush to the plate. To aid in the installation of the Main

Arm, place (1) flat washer on each stud, and tape it to the ceiling plate. This will allow easier

installation of the Main Arm to the ceiling plate. The Main arm installation is a two person

operation, and the Main Arm must be aligned correctly before attaching any further mounting

hardware. There is a small notch machined out of the top of the Main Arm tube that must run

parallel to the conduit-mounting bracket. This notch is for the cable to sit in when the Main Arm

is tightened to the ceiling plate. Once the Main Arm is aligned with the notch, secure the Main

arm to the (6) studs using a flat washer, a lock washer and a hex nut on each stud. Slowly

tighten the lower nuts, but do not tighten them completely. Make sure the cable is still sitting in

the notched cutout while tightening the nuts. Once the upper tube of the Ceiling Flange is

almost touching the Ceiling Plate, take the small bubble level supplied with the installation kit,

and adjust the lower nuts until the Ceiling flange is sitting level on the studs. At this time,

tighten the upper nuts down onto the Ceiling Flange, checking afterwards to make sure the

Flange is still level.

NOTE: If Spring Arms are to be installed on Main Arm before mounting Main Arm to

ceiling flange, follow Steps 3.10.1 and 3.10.2 first, then install unit as shown above.

See Figure 14.

(1) Nut

(1) flat washer

per stud above

ceiling flange

Figure 14: Main Arm Installation

(1) Nut

(1) lock washer

(1) flat washer

per stud below

ceilin

flange

13

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

3.6 Main Arm Wiring and Conduit Installation

Take the small black grommet from the ceiling cover, and slide it over the conduit. Next, take

the power cable from the Main Arm and slide it through the cut end of the conduit, exiting the

end with the compression fitting. Take the end of the cable and tape it to the existing green

lead wire exiting the middle of the ceiling wiring channel from the old light system. Slowly pull

the green wire through the wiring channel at the far end of the channel. After the wire has

successfully been pulled through the end of the wiring channel, screw the conduit into the

existing threaded hole in the wiring channel and tighten. Next, secure the opposite end of the

conduit under the conduit-mounting flange located on the Ceiling Plate and tighten. See Figure

15.

Existing

green wire

Main arm cable

taped to green

wire

Conduit

compression

fitting

Figure 15: Conduit Installation

Conduit

Ceiling cover

grommet

Conduit

mounting

flange

14

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

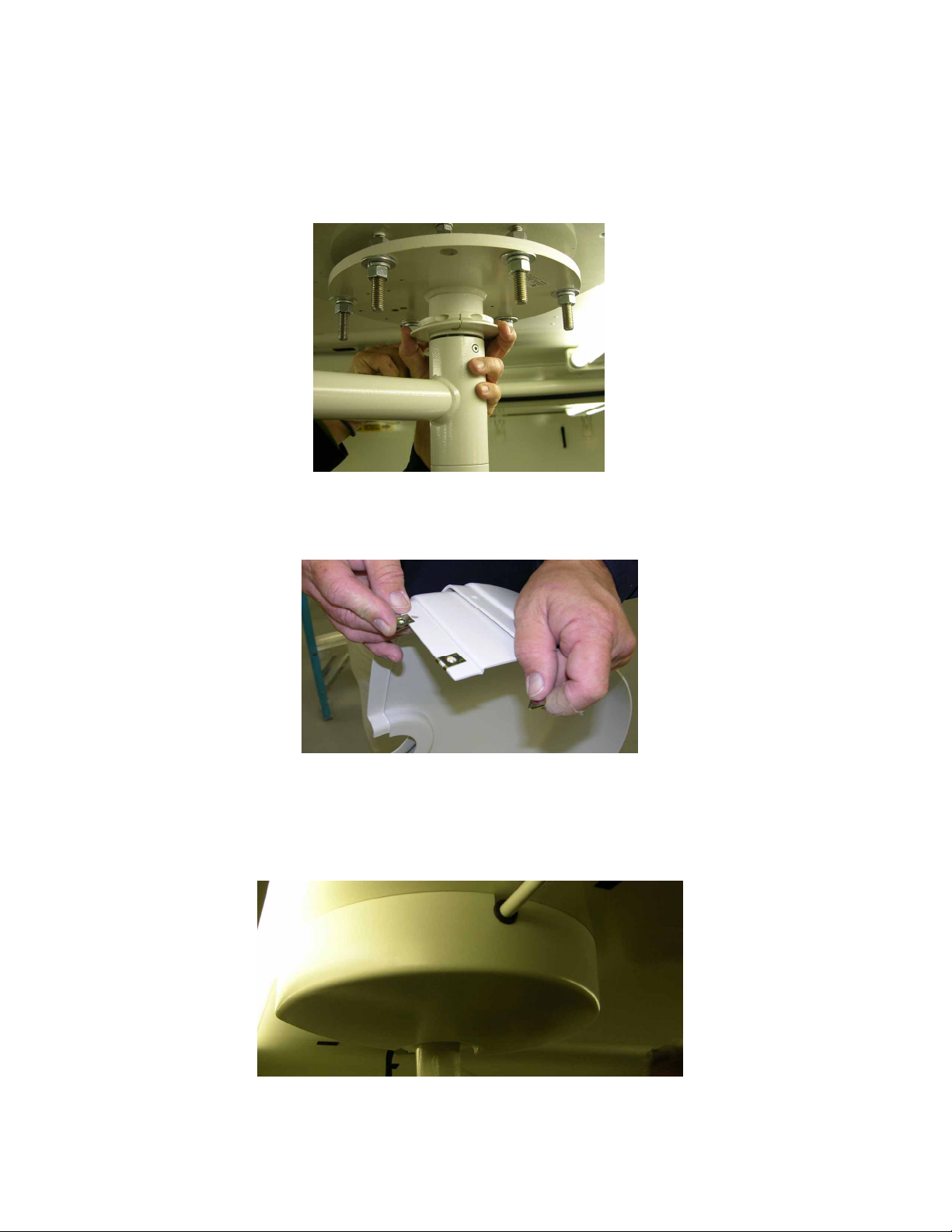

3.7 Ceiling Cover Installation

3.7.1 Around the main axle, you must now mount the retaining brackets. This is done by

clamping the two brackets around the axle, screw side out. Tighten Screws. See Figure

16.

Figure 16: Retaining Ring Assembly

3.7.2 Place the clamps onto the hood assembly as shown in Figure 17.

3.7.3 Place both hood pieces around the main shaft, inserting the bottom of hood into the

groove from the small retaining ring. Ensure that rubber grommet around conduit fits

snugly inside of hood. Screw hood assembly to plate assembly. See Figure 18.

Figure 17: Retaining Clamps, Hood Assembly

Figure 18: Assembled Hood Assembly

15

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

cable

HAN40527, Rev A, 21 April, 2006

3.8 Low Voltage AC Wire Run from Power Supply to Light Connection

3.8.1 Place the existing strain relief black rubber grommet (from Step 2.6) and nut over the 6

wire, 5 foot long, "AC out" cable end, leaving approximately 12" to 16" of cable. Place the

cable through the side of the wiring channel and pull the wires through the open end of the

channel. Take the 6-wire cable from the light system, and match the 6 wires from the AC

out cable, and secure together using the wire twist nuts provided. After securing the wires

together with the wire nuts, take the black electrical tape supplied and wrap the wire nuts

and wires securely together. See Figure 19.

Figure 19: Low Voltage AC Connections

3.8.2 Push the taped wire/cable bundle into the open end of the wiring channel, slowly pulling

the "AC out" cable through the strain relief in the wire channel. After successfully placing

the taped ends of the cables back into the open end of the wiring channel, secure the

"AC out cable to the wiring channel with the strain relief grommet and nut. See Figure 20.

5' "AC OUT"

Compression

fitting

Figure 20: AC OUT Cable Route

16

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

3.9 High Voltage AC Wire from Power Source to Power Supply

Take the female 20-amp connector and remove the rubber back, which will expose the two

cable clamping screws. Slide the rubber backing over the existing power cable that was cut

from the dimmer switch box. Slide the connector body over the cable. Splice the (3) wires from

the cable approximately 1 1/2" to 2 1/2" long, and strip the ends of the wires approximately

1/4" to 1/2" long. Secure the Green wire to the position marked "W", The Black wire to the

position marked "X" and the White wire to the position marked "Y". After securing the wires to

the connector, push the cable into it's housing, and secure the two-connector pieces together

with the (3) screws on the top of the connector. Next, pull the cable tight and secure the cable

to the connector by tightening the two sides screws. Slide the rubber back piece onto the back

of the connector, until it snaps into place. See Figure 21.

Figure 21: High Voltage AC Wire/Plug

17

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

connecto

ole

HAN40527, Rev A, 21 April, 2006

3.10 Spring Arm to Main Arm Installation

3.10.1 Unscrew the (2) screws securing the cover to the top of the Main Arm, and pull the

connector out of the Main Arm before proceeding. The Spring Arm must first be locked into

a downward position before installing. Slide the Spring Arm into the Main Arm and align

and insert the retaining pin provided with the arm, into the retaining pin hole as shown,

while holding the spring arm in the down position. This is a two-person installation. One

person should hold the Spring Arm firmly in place, while the other inserts the pin, to avoid

any injury.

Use caution when installing the Spring Arm. It is under extreme spring tension,

and can cause serious injury if it slips out of your hand and springs upward. Avoid

leaning your head over the Spring Arm during installation, and have someone help

hold the Spring Arm in position while inserting the retaining pin. See Figure 22.

Retaining pin

Retaining pin

h

Figure 22: Spring Arm to Main Arm Install

Male

r

18

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

3.10.2

Insert the Spring Arm into the Main Arm and install the two screws provided with the arm,

and gently tighten in place. Push the Male connector at the top of the Main Arm into the

Female connector of the Spring Arm and reinstall the (2) screws securing the cover and

connector into place in the Main Arm. Do not remove retaining pin in Spring Arm at this

point. It will be removed after the light head has been installed. See Figure 23.

Figure 23: Inserting Male Light Plug

19

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Section 4.0: Installation of Lampheads and Power Supply:

This section covers the repeated installation of the lampheads and power supply into the ISO

shelter.

Section 4.0 of this manual will be repeated every time the ISO shelter is assembled.

4.1 Removing Components from shipping case.

4.1.1 Verify correct shipping container by referring to label on side of container. See Figure 24

Figure 24: BLUEMMSA Container Label

4.1.2 Unfasten the 16 quick twist connect fasteners from around the shipping container.

20

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

4.1.3 Open container and verify that the following items shown in Figure 25 are present.

• (1) HAN40489 Maquet Power Supply(s)

• (2) 5607-7852 Blue 80 Lampheads

• (2) 5605-3026 Spare Light Bulbs

• (3) 5606-0756 Sterile Handles

• (1) HAN40580 Bubble Level

• (1) HAN40527 Manual, Blue 8080 Field Light Rev A

Figure 25: Blue 80 Light Container Inventory

4.1.4 All parts shall be stored as shown in Figure 25 above, when system is packed for

shipment.

21

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

4.2 Lamphead Installation

Use care when pulling the connector out using needle nose pliers. This can damage

the connector if squeezed too much via the pliers, or deformed by using too much

force. If any resistance is encountered when pulling the connector out, stop pulling

and check for obstructions.

4.2.1 If the mating connector is located inside the tube of the Spring Arm end, carefully pull

it out using a pair of needle nose pliers. If the connector is outside the arm, bypass

this step. See Figure 26.

Figure 26: Lamphead Installation

22

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

4.2.2 Remove the Blue 80 Lamphead from its protective shipping container. Connect the

mating connectors from the Spring Arm and Blue 80 Lamphead together. Make sure

the connectors are securely fastened before proceeding.

See Figure 27.

Figure 27: Spring Arm Connection

4.2.3 Slide the Blue 80 Lamphead into the Spring Arm, aligning the mounting hole. Secure

the Lamphead onto the spring arm using the socket head cap screw provided and

tighten. See Figure 28.

Figure 28: Securing Lamphead

23

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

4.2.4 Remove the retaining pin from the side of the Spring Arm and snap the protective

cover onto the end of the spring arm. Place the retaining pin in the lamphead

transportation box for future use. See Figure 29.

Remove

retaining pin

Figure 29: Retaining Ring/Protective Cover

Install protective

end cover

24

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

4.3 Power Supply Installation and Connection

Remove the Power Supply from its shipping container. Lift the Power supply onto the wall

brackets next to the breaker panel. Connect the AC power to the "AC IN" connector located on

the bottom right hand side of the Power supply. Connect the Lamphead power supply cable to

the "AC OUT" connector located on the bottom middle section of the power supply. Both

connections are labeled accordingly on the front of the Power Supply enclosure. See Figure 30.

The Power Supply is extremely heavy, and care should be taken to avoid dropping it.

It is highly recommended to have two persons lift the Power Supply into place.

Power

supply

"AC IN"

power cable

"AC OUT"

cable to

lamphead

Figure 30: Military Power Supply

Mounting

brackets

25

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

4.4 Setting Power Supply Taps

The taps to select are dependent upon the incoming voltage at the primary winding. Both the

primary and secondary taps may need to be changed to obtain the optimal voltage across the

bulb at the lamphead. See Figure 31 for Tap locations.

Primary tap

locations on

transformers

Secondary tap

H4

DONGA

CATALOG NSC-29H9PRI.

SEC.

PHASE

HERTZ

KVA

SERIAL

locations on

transformers

LOW ER

LIGHT

TRANSFORMER

H3

IN DU ST RIA L

TRANSFORM

110/115/12

24....2

SINGL

60

.500

P0312

X6X8 X7 X5 X4 X3 X1

H2 H1

ENCL

INS .

INS .

TEM P.

Figure 31: Primary/Secondary Taps

U

L

LISTED

SA

C

LR56

416180

55 C

TRANSFORMER

H4

DONGA

CATALOG NSC-29H9PRI.

SEC.

PHASE

HERTZ

KVA

SERIAL

H3

INDUSTRIAL

TRA NS FOR M

110/115/12

24....2

SINGL

60

.500

P0312

X6X8 X7 X5 X4 X3 X1

UPPER

LIGHT

ENCL

IN S.

IN S.

TEM P.

H2 H1

U

L

LISTED

SA

C

LR56

416180

55 C

26

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

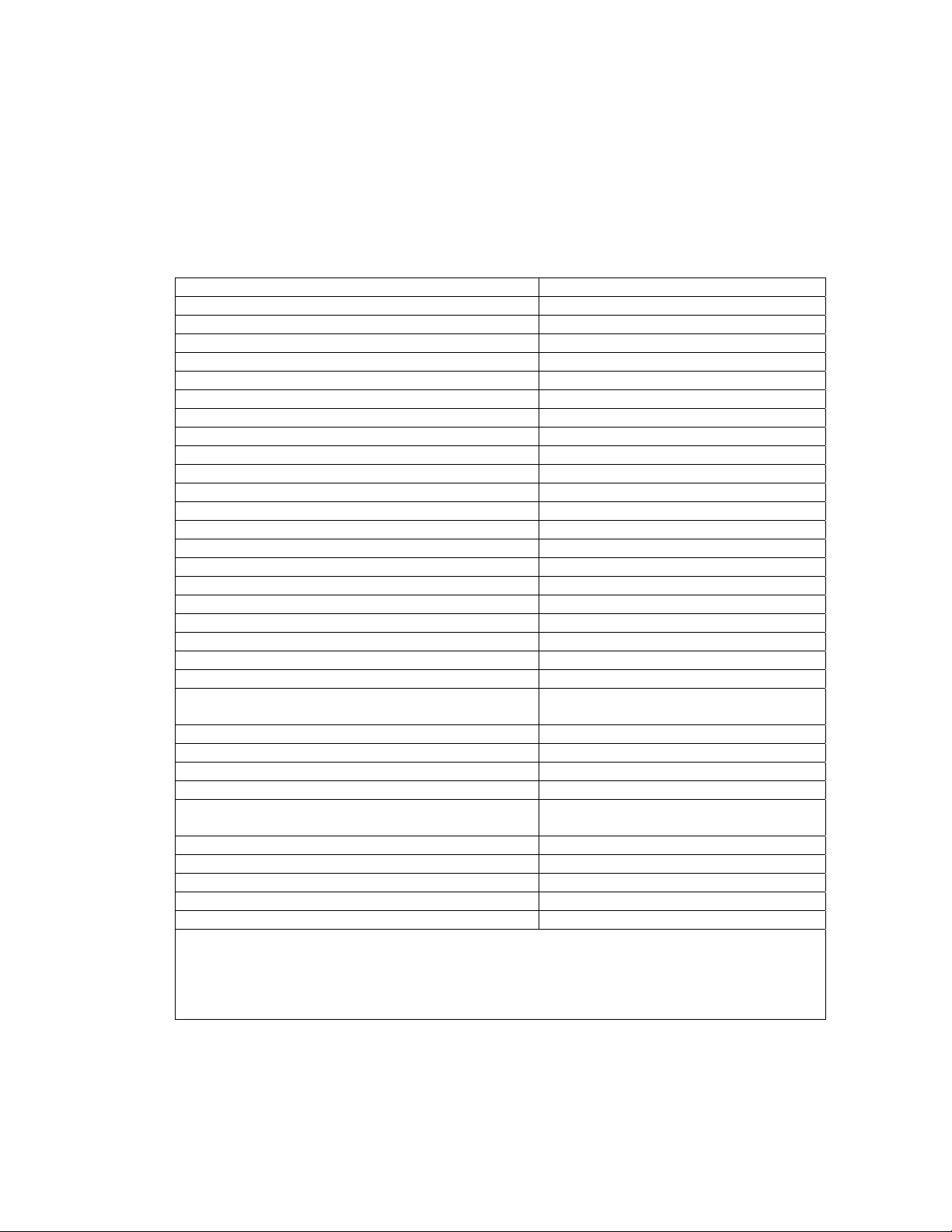

4.5 Initial Setting of Power Supply Voltages

4.5.1. Table 2 provides recommended secondary tap positions based upon using input taps

H1-H4. The secondary voltages are set to achieve the approximate 21.4vac across the

lampheads bulb.

Primary

Voltage

Primary AC

Input Tap

Recommended

Output Tap

Approximate

Voltage at Light

110vac H1 and H4 X1 and X8 21.32vac

111vac H1 and H4 X1 and X8 21.50vac

112vac H1 and H4 X1 and X7 21.31vac

113vac H1 and H4 X1 and X7 21.55vac

114vac H1 and H4 X1 and X6 21.38vac

115vac H1 and H4 X1 and X6 21.55vac

116vac H1 and H4 X1 and X5 21.28vac

117vac H1 and H4 X1 and X5 21.50vac

118vac H1 and H4 X1 and X4 21.35vac

119vac H1 and H4 X1 and X4 21.48vac

120vac H1 and H4 X1 and X3 21.20vac

121vac H1 and H4 X1 and X3 21.40vac

122vac H1 and H4 X1 and X3 21.58vac

123vac H1 and H4 X1 and X2 21.31vac

124vac H1 and H4 X1 and X2 21.46vac

125vac H1 and H4 X1 and X2 21.66vac

Table 3: Transformer Tap Voltages

4.5.2. To measure the voltage across the bulb, you must use a standard multimeter

set at VAC. Access the light panel on rear of Blue 80 light head. See Figure 32

Figure 32: Blue 80 Bulb Access Panel

27

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Precaution will be taken while measuring voltage in rear of light panel. Possibility

of shock and/or burns could occur while performing this procedure.

4.5.3 Insert multimeter leads as shown into rear of bulb that is designated by the

letter “R”. This is the main bulb; the other bulb is backup and only illuminates

when the main bulb is burnt out. See Figure 33

Figure 33: Blue 80 Voltage Measurement

4.5.4 Adjust the secondary taps shown in Chapter 5.3, Figure 28, to achieve 21.5 VAC,

+ - ½ volt across the bulb.

4.5.5 After properly checking and setting the voltage at both lampheads and transformers, the

system can be placed into operation.

28

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Section 5: Securing Blue 80 Main Arms

5.1 Removal of Blue 80 lampheads and Maquet power supply

5.1.1 Secure all power to Blue 80 Lamp System by disconnecting main power from the

Maquet power supply.

5.1.2 Remove the lampheads from main arm. NOTE: Ensure the stop pin is in main

arm as described in step 3.10.1.

5.1.3 Place lamphead(s) within shipping container as shown in Figure 25.

5.1.4 Remove all cabling (2) from Maquet power supply. Remove power supply from wall

mount and store in shipping container as shown in Figure 25.

5.2 Securing main arm and spring arms

5.2.1 Place Velcro Strap P/N HAN40475 on main arm as shown in Figure 34.

Figure 34: Velcro Strap, P/N HAN40475

29

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

5.2.2 Rotate spring arm towards main axle and place both Velcro straps around arm as

shown in Figure 35.

Figure 35: Spring Arm strapping position

5.2.3 The final strap will be placed around the main arm as shown in shown in Figure 36.

Figure 36: Ceiling Mounted Velcro Strap, P/N HAN40468

5.2.4 Repeat procedure for the second main arm unit. When complete, system is ready

for shipment.

30

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Section 6.0: Operation of the Blue 80/80 Light System:

6.1 Setting up Light source

6.1.1 The Blue 80 Light head is designed to operate in the ranges of 27.5 – 51 inches. This will

allow the light to apply the 80,000-lux over the operation field in an even field of light. To

view the light wave pattern, refer to the below picture. See Figure 37.

Figure 37: Blue 80 Lamphead

6.1.2 The dual Blue 80 light sources allows a total of 160,000 lux (80,000 lux each lamp head) to

be used on the patch area from a wide variety of angles. This light arm was designed with

the ergonomics of the ISO shelter in mind and is small and compact in nature. To move

the light heads where needed, simply place a sterilizable Handle onto light attachment and

adjust according to doctor’s field of view needs. See Figure 38.

Figure 38: Lamphead Alignment

31

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

6.2 Energizing the Power Supply.

6.2.1 The power supply has two front panel mounted breaker switches, each controlling the

voltage for the upper or lower light assembly. Once the power supply is attached via its

main AC IN and AC out power cables, the unit is ready for operation. The breakers are

individually labeled and by depressing the rocker switches, a green light will illuminate

showing the transformers inside the power supply are connected to 120VAC power. See

Figure 39.

Figure 39: Blue 80/80 Power Supply

32

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Section 7.0: Preventive Maintenance of Blue 80/80 Light System

DANGER OF BURNS

before starting any PMs

DANGER

DANGER OF INJURY:

head, Arm is under great pressure and severe injuries will

occur.

DANGER OF BODILY HARM:

7.1 Preventative maintenance is recommended to keep the lights operational when required.

Maintenance Task When Performed Details

Power Supply Mounting

Bracket Check

Illumination (Lux) Verification Every 6 months

: The lighthead heats up during operation. Allow cooling off

ENSURE Spring Arms are restrained when removing light

Disconnect the Power supply from the mains and make it

voltage-free before starting any repair work

Check fasteners to ensure that the

Prior to every installation

brackets are tight and secured to the

wall.

Using a lux meter, check for proper

output = 80,000 Lux measured at 39

inches from lamphead, with 7.1-inch

circular pattern.

Lamphead inspection Every 6 months Replace according to Chapter 8.5

Spring Arm Tension Adjustment

Every 3 months or as

necessary

Adjust according to Chapter 8.3

Table 4: Preventative Maintenance Recommendations

7.2 Inspection by the Operator

The Blue 80/80 light heads and supporting structure is to be inspected by the operator every six

months, with particular attention to the following points:

• Defects in point work

• Cracks in plastic parts

• Deformation in the supporting system

33

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

7.3 Cleaning/Disinfection

To avoid damage to plastic and glass parts, do not use any scouring agent, or

any cleaning agent which is alkaline, acidic or contains alcohol (e.g. ethanol,

propanal or aldehyde).

• Only disinfect the apparatus when it is cold

• We recommend our tested cleaning/disinfection agent HANAU-clean

• Because there are a great number of cleaning/disinfecting agents on the market, and we do

not know their interactions with plastic used, damage cannot be ruled out if other agents

are used.

• For cleaning, use a soft, lint-free cloth

7.4 Sterilizing the handles

Please immediately replace all damaged Handles showing cracks or

deformations because these could fall down into the wound.

• Push in the spherical catch of the Handle and pull Handle off downwards

• Push the Handle back on until you hear the catch click, check for proper seat.

• Place the Handles standing upright and with the open side facing down

• Do not exceed a sterilization temperature of 134 degrees Celsius

• Avoid letting the Handles come into contact with other objects while they are being

sterilized.

34

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Section 8.0: Corrective Maintenance

DANGER OF BURNS: The lighthead heats up during operation. Allow cooling off

DANGER

8.1 Troubleshooting procedures

Table 5 provides a quick reference for troubleshooting the Blue 80/80 system.

before starting any repair work

DANGER OF INJURY:

DANGER OF BODILY HARM:

ENSURE Spring Arms are retrained when removing light head,

Arm is under great pressure and severe injuries will occur.

Disconnect the Power supply from the mains and make

it voltage-free before starting any repair work

Table 5: Mechanical/Optical Troubleshooting

35

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

8.2 Lighthead removal procedures

8.2.1 Remove lid (1) from the movable side of the weight balancer (2). See Figure 40.

8.2.2 Swing the weight balancer towards the floor and insert retaining pin (3) into drill hole (4).

See Figure 40.

Figure 40: Weight Balancer

Failure to insert the retaining pin far enough into the drill hole may cause the

weight balancer to bounce up and cause injuries. Check that the weight balancer

is firmly locked into position before you let go.

8.2.3 Unscrew hexagon socket screw (1). Unscrew brake screw (2). See Figure 41.

8.2.4 Pull off Handle (3) off weight balancer and disconnect the plug connection (4). See

Figure 41.

Figure 41: Blue 80 lighthead brake screw

36

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

8.3 Spring arm tension adjustment procedure

8.3.1 Remove the lid of moveable weight balancer arm (1) and also, on the Blue 80-weight

balancer, the lid of fixed weight balancer arm (2). See Figure 42

8.3.2 Turn adjustment nut (3) by half a turn maximum: make sure to hold the hexagon socket

screw on the other side of the Blue 80-weight balancer. See Figure 42.

Figure 42: Spring arm brake adjustment

8.3.3. Turn clockwise if the light head sinks down or turn counter clockwise if the light head moves

up.

8.3.4 Check whether the light balancer stops moving in every position. Continue adjusting until

arm no longer moves from desired position.

8.3.5 Put the lid back on weight balancer.

8.4 Setting the brake pressure of the Blue 80 lighthead

CAUTION HIGH TEMPERTURE: The light heads heat up during operation. Make sure

to let the light head cool off before you set the brake pressure.

8.4.1 Let the light head cool off. Set the brake pressure of the light head by tightening or

loosening brake pressure adjustment screw (1) underneath light head Handle (2). See

Figure 43.

Figure 43: Blue 80 Lighthead brake adjust

37

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

8.5 Replacement of bulbs

Please note to use replacement bulbs supplied by Getinge to reach the safe function and

the technical lighting data. DO NOT touch the glass body of the halogen bulb with bare

fingers. When the yellow signal lights up at the lower side of lighthead, this indicates

that the reserve bulb has taken over operation. To avoid a complete failure of the

lighting system, please replace the main bulb as soon as possible. The position of the

main lamp is indicated by a dot on the reflector shield.

8.5.1 Slightly push in lid (1) on the hood (2) and push to one side. See Figure 44

8.5.2 Take out socket (5) towards to the top.

Figure 44: Light bulb replacement procedure

8.5.3 Remove broken halogen bulb (3) from the side of the connection lead.

8.5.4 Remove spare lamp (4) marked with “R” and put into the socket of the main lamp.

8.5.5 Put in new bulb into the socket of the spare lamp.

8.5.6 Put both lamps back into the reflector in a way that the marked position “R” on the

reflector and the socket is opposite. Put lid back on and check the lid for safe seating.

38

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Section 9. Troubleshooting the Power Supply

The following is a list of probable faults and their associated corrective action. Observe all

safety precautions when working on this unit. See Table 6 for Troubleshooting Guide and

Figure 45: Schematic, Wiring, Power Supply, Military.

Failure Probable Cause Corrective Action

- Reset main breaker

Unit does not

energize

• Main Breaker

• Main AC IN Connector

• H1 or H4 Terminals (Primary)

• AC wires loose (inside)

- Disconnect and reset AC IN Connector

- Check voltage at H1/H4, Possible bad

Primary Transformer. Order and replace.

- Check for loose wires, retighten as

necessary

Upper and/or Lower

Light will not

energize

Breaker indicator on,

but light not working

Light bulbs burning

out too quickly

Front panel ON light

indicators not

working

• Front panel breaker(s)

• Light bulb(s)

• Loose wire on front breakers

• Transformer secondary fuse

• Light bulb(s)

• AC OUT Connector

• AC OUT Connections

• Incorrect secondary voltage

settings

• Bad ground on breaker

• Blown LED indicator

Table 6: Power Supply Troubleshooting

- See if light indicator is on. If not, reset

breaker

- Replace bulb(s)

- Reterminate wires on breaker assembly

- Replace 9 amp secondary fuse(s)

- Replace light bulb(s)

- Reset AC Out Connector

- Check for broken wires on AC OUT

Connector

- Adjust secondary voltages by moving X2-X8

to set voltage to 21.4vac as read at light

head

- Check Red and Black 28 AWG wires on

secondary of breaker. Reterminate wires.

- Replace 20 Amp breaker assembly

39

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 45: Schematic, Wiring, Power Supply, Military

40

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Section 10.0: Parts Listing

10.1 Table 7 provides upper level part numbers for Blue 80 system components.

Ceiling Flange

1

Item PART NUMBER PART NAME FIGURE

1 569004905 Ceiling Flange Figure 46

2 569004990 Suspension, Duo, Blue 80 Figure 46

3 569004991 Spring Arms Figure 47

4 5607-7852 Blue 80 Lightheads Figure 47

5 BLUE80/80CASE Blue 80 Shipping Container Figure 24

Table 7, Upper level system part numbers/components

Duo 80 Suspension

2

Spring Arm (2)

3

Blue 80 Lampheads

4

Figure 46: Flange and Suspension

Figure 47: Spring Arms and Lightheads

41

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

10.2 Blue 80 Lighthead Parts

10.2.1 Figure 48 below, designates part numbers for Blue 80 lighthead, Part number

5607-7852. For individual component breakdown, refer to Table 7.

1

6

7

8

9

2

10

3

11

4

5

12

13

14

Figure 48: Blue 80 Light Components

Item Part number Part description

1 5605-3016 Blue switch 1 pole 250 v 10 a

2 5605-3083 Blue80, Handle-adapter

3 5605-0756 Handle; plastic ;2000 series; pkg. (3)

4 5605-3071 Assy PCB. b80 light head

5 5605-3067 Blue 80 disc, glass

6 5605-3069 Blue 80 with leaf spring

7 5605-3026 Bulb; B80 21.5v; 130 w

8 5605-3073 Blue 80 bulb sockets

9 5605-3256 Blue 80 bulb wire

10 5605-3070 Cover

11 5605-3154 Assy, dome cap cover lighthead

12 5605-3074 Blue 80 wiring complete

13 5605-3068 Blue 80 reflector

14 5605-3271 Blue 80 reflector f.

Table 8: Blue 80 Part Number/Descriptions

42

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

10.3 ISO Shelter Mounting Kit

10.3.1 Table 9 provides the parts contained in the ISO Mounting Kit, Part Number

HAN40525. The individual part drawings follow.

Figure Part number Part description

49 HAN40457 Assy, conduit, 1/2" emt

50 HAN40460 Assy, ring, anchor plate

51 HAN40464 Toggle, spring wing

52 HAN40465 Screw, rh, ph,.250-20, unc3a,

53 HAN40466 Plate, holding, velcro

54 HAN40467 Template, mtg, xfmr box, army

55 HAN40468-24 Strap, velcro, 2" x 24"

55 HAN40468-40 Strap, velcro, 2" x 40"

56 HAN40475 Cover, transport, arm

57 HAN40482 Conn., Turn lock, female 20 a

58 HAN40487 Assy, cable, ac out, external

59 HAN40541 Brkt, mtg, elect box, army

60 HAN40551 Nut, wire, twist, yellow

Table 9: ISO Mounting Kit

43

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 49: HAN40457 Assembly, Conduit, ½” EMT, 28.5” Long

44

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 50: HAN40460 Assy, Ring, Anchor Plate,

45

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 51: HAN40464 Toggle, Spring Wing

46

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 52: HAN40465 Round Head Screw, ZP

47

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 53: HAN40466 Plate, Holding, Velcro

48

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 54: HAN40467 Template, Mounting, Transformer Box, Military

49

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 55: HAN40468 Strap, Velcro, 2”

50

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 56: HAN40475 Cover, Transport, Arm

51

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 57: HAN40482 Connector, Turn Lock, Female, 20 AMP

52

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

A

B

F

E

C

D

Figure 58: HAN40487 Assembly, Cable, AC Out, External, Military

53

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 59: HAN40541 Bracket, Mounting, Electrical Box, Military

54

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Figure 60: HAN40551 Nut, Wire, Twist Lock, Yellow

55

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

10.4 Power Supply

10.4.1 The following drawings provide the power supply part numbers. See Figures 61-66.

Figure 61: HAN40489 Assembly, Power Supply, Military, Sheet 1 of 6

56

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

MAQUET HANAULUX

LIGHT POWER SUPPLY

FOR USE ONLY WITH

THE DUO BLUE 80

MILITARY LIGHT SYSTEM

LOWER

LIGHT

BREAKER

ON

I

O

OFF

UPPER

LIGHT

BREAKER

ON

I

O

OFF

The grounding reliability can only be achieved

when connected to the main power cord.

AC IN

AC IN

AC OUT

Figure 62: HAN40489 Assembly, Power Supply, Military, Sheet 2 of 6

57

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

R

UPPER

LIGHT

BREAKER

OUTPUT VOLTAGE

SELECTION

32V~

LOWER

LIGHT

BREAKER

F1 F2

LOWER LIGHT UPPER LIGHT

MDL 9A 32V~ MDL 9A 32V~

HAN40586 Rev. A

TRANSFORMER

H4

H3

INDUSTRIAL CONTROL

110/115/120

24....27

SINGLE

60

.500

P03129

X6X8 X7 X5 X4 X3 X1

WHITE

UPPER

LIGHT

TRANSFORMER

ENCL RTG:

INS. SYST:

INS. CLASS:

TEMP. RISE:

H2H1

U

L

LISTED 215H

SA

C

LR560

416-105

180 C

55 C

BLUE

BLACK

GREEN

ORANGE

WHITE

GREEN

LOWER

LIGHT

TRANSFORMER

H4

H3

DONGAN

CATALOG NO: NSC-29H9-1853

PRI. VOLTS:

110/115/120

SEC. VOLTS:

24....27

PHASE:

SINGLE

60

HERTZ:

.500

KVA

SERIAL NO:

P03129

Fuse ID

Protects

H2H1

INDUSTRIAL CONTROL

TRANSFORMER

X6X8 X7 X5 X 4 X3 X1

U

LISTED 215H

C

LR560

ENCL RTG:

INS. SYST:

416-105

INS. CLASS:

180 C

TEMP. RISE:

55 C

F1 F2

L

SA

DONGAN

CATALOG NO: NSC-29H9-1853

PRI. VOLTS:

SEC. VOLTS:

PHASE:

HERTZ:

KVA

SERIAL NO:

GREEN

BLACK

AC IN

AC OUT

Figure 63: HAN40489 Assembly, Power Supply, Military, Sheet 3 of 6

58

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

AC IN

AC OUT

Figure 64: HAN40489 Assembly, Power Supply, Military, Sheet 4 of 6

59

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

MAQUET

LIGHT POW

FOR USE

THE DUO

MILITARY LIG

LOWER

LIGHT

BREAKER

ON

I

O

OFF

UPPER

LIGHT

BREAKER

ON

I

O

OFF

Figure 65: HAN40489 Assembly, Power Supply, Military, Sheet 5 of 6

60

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

Getinge USA Inc.

7371 Spartan Blvd East

North Charleston, SC 29418

Ref #___________________________

BLU80/2006/2/001

Serial #_________________________

HAN40489

ID #____________________________

Military Power Supply Assy

Model #_________________________

Supply Input: 60HZ, 1 Phase, 110-120VAC

Power Input: 350 Watts

Power Output: 21.4VAC @ 6.5Amps

To safely store or transport this

power supply in accordance with

Mil-Std-810, place in Getinge

supplied case, pt # Blu8080ca se,

Hardigg pt # DSI-80205-100.

Figure 66: HAN40489 Assembly, Power Supply, Military, Sheet 6 of 6

61

Blue 80/80 Field Light, Installation, Operators, Service and Parts Manual

HAN40527, Rev A, 21 April, 2006

10.5 Reusable Shipping Container.

10.5.1 The drawings shown are information on the reusable shipping containers.

Figure 67: BLUEMMSA Reusable shipping container

62

Telephone (800-950-9912)

Getinge USA, Inc.

1777 East Henrietta Road

Rochester, NY 14623-3133 USA

Fax (800)-950-2570

Loading...

Loading...