HS 6613 ER-2

UNITED DOCTORS HOSPITAL

2530290-090-01

Original User Manual

TABLE OF CONTENTS

PREFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Attention symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Reporting an accident or incident . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

HS 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Overview of safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Built-in electrical steam generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

THE PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

The steam sterilizing process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Documentation of the process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Documentation of the process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Program start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Alarms - Avanti. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Error codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

General advice when using the sterilizer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Weekly cleaning - Avanti. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Approved consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

OPERATION INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Daily preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

CONTROL UNIT PACS 3500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Control panel type Avanti . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Operator menu Avanti. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

PROGRAM COMBINATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

PREFACE

This USER MANUAL, contains all the information you need in order

to safely operate your GETINGE STERILIZATION AB equipment.

Please read and follow the entire manual carefully, and please pay

special attention to the framed warnings and caution remarks. See

“Attention symbols” under SAFETY

In the event of an accident or incident you are obliged to report this. See

“Reporting an accident or incident” under SAFETY

GETINGE STERILIZATION AB shall not be liable for any damages,

directly or indirectly, due to actions, which are not in accordance with

this manual.

By following this manual you are ensured quality equipment for many

years ahead. Should any unforeseen problems occu r, you are of cour se

welcome to contact our local representative.

Manufacturer address:

Getinge Sterilization AB

Ekebergsvägen 26

305 75 Getinge

Sweden

Fax +46(0) 35 54952

1

2

SAFETY

Attention symbols

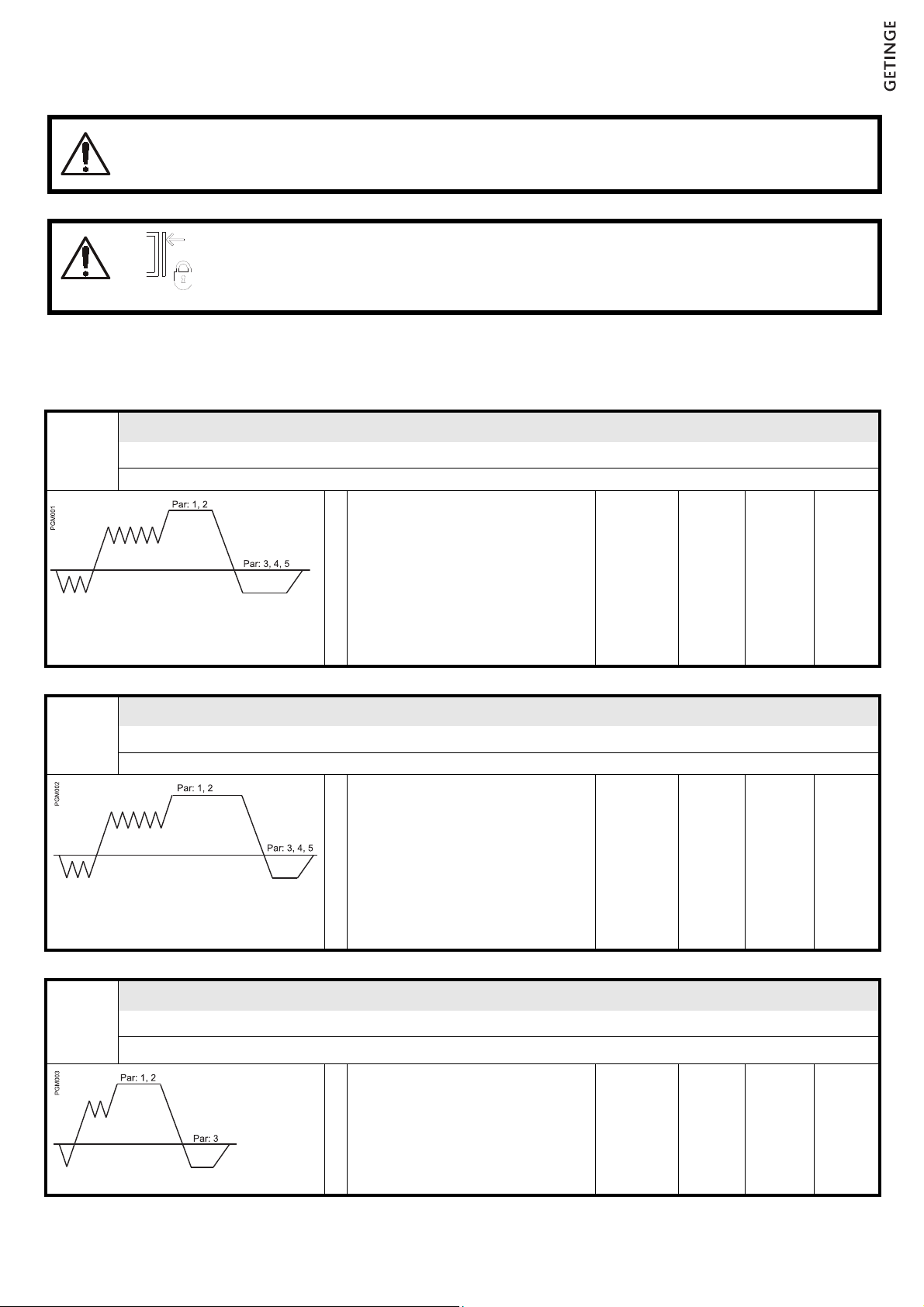

Some of the warnings, instructions and advice in this manual are so

important that we use the following special symbols to draw attention

to them. The designs and symbols used are:

Warnings

This symbol indicates a warning in the text of the manual.

It warns of a hazard that may lead to more or less severe

injury and in certain cases mortal danger.

The symbol is also used to highlight safety components,

etc. See “Safety devi ces - an ove rview” i n the Introduction

chapter in the USER MANUAL or in the Maintenance

chapter in the TECHNICAL MANUAL.

Instructions

Advice

This symbol highlights instructions that are important for

avoiding damage to the unit and/or load, among other

things.

This symbol indicates important advice and hints that

make it easier to work with the unit.

SAFETY -

3

Symbols on the unit

Hot surface

This symbol warns of a hot surface.

Electrical danger

This symbol warns of an electrical danger.

Other dangers

This symbol warns of other dangers.

4 -

SAFETY

Reporting an accident or incident

Use this information when reporting incidents and accidents involving the unit.

If an accident or an inci dent associated with the ster ilizers occurs, t his

must be reported immediately in writing to the address below. The

report must be used to identify the cause of the accident or incident and

to what extent the occurrence was due to the unit

The unit is a product in the GETINGE range.

The unit may also be a sterilizer that is a medical engineering product

and which conforms to the EU medical devices dire ctive, or which is

constructed in a similar way to a medical device. Under the medical

devices directive, the manufacturer must investigat e the cause of accidents/incidents that occur and report them to the authorities concerned.

The investigation may lead to changes in new or already delivered

devices or in instructions and guidance.

The following circumstances must be reported:

1. Circumstances that caused the death of a patient, user or someone

else, or that caused serious deterioration in the health of a patient,

user or someone else.

2. Circumstances that might have caused, the death of a patient, user

or someone else, or that might have caused serious deterioration in

the health of a patient, user or someone else.

The following infor mation is required :

The manufacturing number of the unit (on a label in the electrical cabinet), Date/time of event, Description of event, Consequences of event.

Contact: Name, Phone number, Address:, E-mail:

The information must be sent by letter or fax to:

GETINGE STERILIZATION AB

For the attention of: Quality Manager

Box 69

305 05 GETINGE

Sweden

Fax: +46 (0)35 549 52

SAFETY -

5

6 -

SAFETY

INTRODUCTION

HS 66

HS 66 is the designation of a series of GETINGE high-pressure autoclaves with vertically sliding automatic doors, all with the door opening

660 x 660 mm

There are both stand-alone and built-in versions.

The autoclaves are intended for sterilization of materials in the health

service as well as in industry. They are adapted to their particular functions by the choice of control equipment. This is built up around a

microprocessor and therefore provides a very large number of process

types, all characterized by exceptional accuracy in controlling the process parameters. The operator can call up on a display information on the

current process, current pro cess phase and the actual values of the

parameters while the process is in progress.

The dominant sterilizing agent is steam at a temperature of 121 -134 °C.

Material that is damaged by this temperature may be sterilized in some

autoclave models in formalin vapour at 55 - 80°C.

Most types of items can be treated in the HS 66-autoclaves, using

adapted programs:

Instruments, machine parts, glass, plastic, leather, textiles, hot or cold

liquids in open or vented containers and small rigid pressure-tight containers filled with liquids.

INTRODUCTION -

7

European standard EN 285 (Australia/New Zeeland, Standard AS 1410)

specifies the use of fixed programs only. However, the control equipment of HS 66-autoclaves allows the programs to be made variable during the time testing is in progress.

As not only the processes but door operation too are controlled automatically, the step to full automation of the handling of sterile items is not

a long one. The control unit is therefore prepared for controlling an

autoclave having a GETINGE ASF automatic loading and unloading

unit.

As with other GETINGE double-jacketed autoclaves, the external surface of the cham ber is more than half c overed by all-welded U-sections.. These stiffen the fla t walls of t he pressure vessel, and at the same

time accommodate the stea m which keeps the cham ber walls warm in

order to minimize condensation in the chamb er. The design principle

makes all welds accessible for visual i nspec tion aft er t he th ermal insulation has been removed.

A vacuum pump of the water-ring type removes air, steam and condensation from the chamber and door-gasket groove. The sealing water of

the pump is taken from an open tank which in some cases also supplies

the feedwater pump, on autoclaves with a steam generator, with water.

The condenser between the chamber and vacuum pump converts waste

steam to water. This reduction of the pump handling volume contributes

greatly to improving pump efficiency and protecting the pump and

waste pipes against high temperatures.

A well-damped discharge system after the vacuum pump and welldimensioned thermal insulation around the chamber mean that the autoclave affects the surroundings to an insignificant extent and is therefore

easy to position.

HS 66-autoclaves have to be supplied with electricity, cold water, compressed air and steam. When steam is supplied from a central steam-producing plant, its distribution system is required to be correctly pressurereduced, protected by a safety valve and produce a quality of steam

which is suitable in the context of sterilization. (For some versions the

pressure reducer is already fitted)

If the steam is not suitable in the context of sterilization, a steam generator can be installed inside the trim plates on all models. The task of the

8 -

INTRODUCTION

steam generator is to generate pure steam using the centrally produced

steam.

If there is no steam network or there are reasons for not using the steam

network, an electric steam generator may be installed inside the trim

plates on all models.

Overview of safety de vi ce s

Cladding and front panels must prevent access to the parts

of the installation that are normally accessible only to

trained personnel.

General access to an installation supplied without cladding, which should normally only be maintained by trained

personnel must be prevented. A convenient way of preventing access is to install the equipment in a lockable

area.

Additional information about the above safety components are given in

the “Safety checks”, “Utility data” a nd “Periodic maintenance” sec tions

of the TECHNICAL MANUAL.

Safety components

Every unit is equipped with a number of components with the specific

purpose of ensuring the safety of personnel. These items are marked

with a warning triangle below in the following documents:

•

•

•

These components have undergone special tests before being accepted

as safety components. For this reason, they must not be replaced with

components of any make or design that has not been appr oved by

GETINGE.

It is of the highest importance that the operational reliability of these

components is continuously upheld during their entire service life.

electrical diagrams

pipework diagrams

spare parts lists

The signs are used not only to indicate important components, but also

to draw attention to other safety factors that call for special attention,

such as dimensions, tolerances, materials, etc.

INTRODUCTION -

9

Doors

Emergency stop

The doors are closed and locked while the process is running and remain

locked in the event of media loss. The doors cannot be opened until the

pressure in the chamber has been equalized with the ambient pressure,

not even if fault management gives an opening command. The sliding

doors are operated by a compressed air cylinder which has a severe ly

throttled inlet. A drain valve with a considerably greater flow capaci ty

than the inlet is located in the bottom of the cylinder, which is pointing

upwards. Objects that obstruct the upward motion of the door pr ess

down a metal plate which op ens the drain valve, causing the do or

motion to stop. This prevents operator injuries and material damage. A

support latch holds the door so that it does not open if the pneumatic

operating cylinder loses pressure. When the pressure of the compressed

air is so low that the door cylinder cannot support the weight of the door,

the air is not capable of pulling away the support latch.

In the front panel, at the side of the door, there is a pushbutton with these

functions:

A On door operation.

B When the door is closed

Door interlock key

The front panel contains a key switch, intended for use whe n cleaning

the sterilizer or when it is necessary to reach into the chamber for any

reason.

With the key removed, the door cannot be closed. See also under

"Cleaning the chamber" in the Operation chapter.

Trim plates

Panels are possible to dismount by means of tools or keys. The panels

form a barrier for ope rators, but not for specially tra ined technicians.

Stainless steel surfaces within reach of the operating personnel are insulated and cooled to a harmless temperature.

to stop the door motion immediately during door operation. Pressing the button triggers an alarm. This alarm stops the door immediately:

The current process is aborted and all valves for media to the chamber are closed. This also triggers an alarm.

Valves

10 -

INTRODUCTION

If the equipment has electrically and/or pneumatically actuated valves

they are normally made to close by means of spring force. This prevents

Pressure vessels

Safety valves

undesired flow through the valves in case of power failure. A f ail safe

function is achieved.

The sterilizer chamber jacket and steam generator are pressure vessels,

designed and built in accordance with standards laid down by official

bodies charged with monitoring this area of safety.

The internal steam supply to the sterilizer is protected against excessive

supply pressure by a safety on the steam generator, the sterilizer or both.

The connected supply lines from external steam, water or compressed

air networks must be protected against exce ssive pressure by safety

valves. The sterilizer supplier is not responsible for these valves. Permitted supply media pressures are stated in “Utility data”.

Safety valves limit the system pressure, providing the last line of protection to prevent the design pressure of the vessel from being exceeded.

Safety valves are required to be inspected at prescribed intervals.

Monitoring the pressure behind the door seal

All valves admitting any medium to the chamber are kept closed until

the pressure behind the door seal is high enough to guarantee the tightness of the chamber.

Built-in electrical stea m generator

The sterilizer also has a fully-automatic built-in steam generator, with

tubular electric elements as the heat source.

Operation

The heating power is divided among a number of groups of elements.

The elements are controlled by a pressure switch with double changeover contacts, one for each heater element circuit. One group of contacts

limits the operating pressure of the steam generator. The other controls

reconnection of the power when the minimum pressure is reached.

Pressures higher than those stated on the electrical diagra m should not

be set, since the steam will be superheated when admitted to the sterilizer chamber. On the other hand, if the operating pressure is allowed to

fall too far, the steam tends to become wet, which is undesirable for sterilisation purposes.

INTRODUCTION -

11

A feedwater pump supplies the steam generator with water from a n integral water tank with air trap. The water level of the steam generator is

sensed by a device which controls the operation of the pump so that the

level is kept almost constant. Boil-dry protection cuts off the supply of

electric power to the elements when the water level is low.

See also “Steam generator settings and controls” under Advice and

instructions in the TECHNICAL MANUAL.

Control switch

The steam generator and sterilizer are controlled by the same switch. On

sterilizers with med double steam systems there is an extra shutoff button marked Steam generator.

Pressure regulation in power stages

The system prevents wear of the element contacts by switching the

power in and out in two stages at d ifferent pressure levels and with a

time offset between switch-on and switch-off for the first stage.

Spark-reduction connection

As well as shortening the life of electrical contacts, sparking at the contacts may also cause interference with nearby electronic equipment.

The anti-spark protection is based on fast-act ing a uxiliary rela ys t aking

over the load from the slow-breaking contacts of the pressure switch for

operating pressure, so largely eliminated sparking.

Safety valve, steam generator

The mandatory periodic check of the operation of the steam generator

safety valve can be done simply by means of the keyswitch described

below. See also the Maintenance chapter in the TECHNICAL MANUAL.

Keyswitch “Test pressure limiter”

When the key is in the safety valve check position, steam is produced

continuously and regardless of the setting of the operatin g pressure

switch.

Water level regulation

Version with conductive measurement

The Getinge conductive level system is designed for water with a conductivity above 2 μS/cm.

12 -

INTRODUCTION

The task of the level device is to sense and control the water level of the

steam generator. The main components are a sensitive relay and two

electrodes, the ends of which touch the water surface at the upper and

lower fill levels. Contact of the upper electrode with the water stops the

feedwater pump, whilst absence of contac t at th e low er elec trode st arts

the pump. A third, lowest, electrode cuts off the electric powe r supply

to the heating elements when the electrode loses contact with water; see

boil-dry protection below.

The type and sensitivity of the level relays can be adapted to varying

water conductivity. If the f eedwater is de-ionised, a high-sensitivity

level relay is required and the sensitiv ity setting must be increased as the

conductivity of the water decreases.

The sensitivity of the level relay is automatically adjusted at power up

to match varying conductivity.

The distance between the electrodes is another factor that affects the

overall sensitivity of the level control system.

Version with float

The GETINGE f loat-based level cont rol system is intended for water

with a conductivity of 0 to 2 μS/cm, but it can also be used for higher

conductivity.

The task of the level device is to sense and control the water level in th e

steam generator. The main components are a float with two level contacts and two relays. The level contacts change over at the upper and

lower fill levels. The upper contact stops and starts the feedwater pump,

whilst the lower contact cuts off the electric power supply to the heating

elements; see boil-dry protection below. The purpose of the relays is to

protect the float contacts from harmful currents.

Water-level monitoring

A lamp in the “reset level” button on the steam generator control panel

is lit when the water level is correct. On some models, the water level

can also be read off on a sight glass. The sight glass has two valves

which can be closed to prevent loss of water and steam in the event of

breakage of the sight glass.

Boil-dry protection

If the water filling fails, the boil-dry protection cuts of f the electric

power supply after a certain time, when the water level has fallen below

a minimum limit.

Overheat protection

This protection prevents the steam generator from overheating if the

boil-dry protection should fail to operate.

INTRODUCTION -

13

Overfilling protection

The timer relay prevents the steam generator over-filling with feedwater

if the level control system stops working.

“Reset level” button

If a fault occurs on any of the safety components of the steam generator,

it must be reset manually in accordance with applicable boiler regulations.

The button is also used when filling an empty steam generator with

water. See the Function check chapter in the INSTALLATION MANUAL.

“Test level limiter” button

This button is provides a quick test of the operation of the boil-dry protection. The test interrupts the level circuit without the need to reduce

the water level.

RCD

Safety switch

Some types of steam generator must be connected to the electric power

supply via a residual current device (RCD). See the Installation instruc-

tions chapter in the INSTALLATION MANUAL.

It must be possible to isolate all electric power supplies to the steam

generator with a safety switch. The safety switch must be locka ble in the

OFF position. See also chapter Installation in the INSTALLATION

MANUAL.

14 -

INTRODUCTION

THE PROCESS

A

B

C

The steam sterilizing process

The universal steam autoclaving process can be divided into three main

phases:

APre-treatment

B Sterilizing

C Post-treatment

Pre-treatment

Sterilizing

It has been found that moisture is an essential element in achieving sterility with steam. It is therefore important that the steam comes into

close contact with the micro-organisms to be killed.

A pre-treatment phase consisting of a number of pressure variations following a certain pattern effectively removes air from various types of

goods and produces the moisture required in the subsequent sterilizing

phase. Depending on the equipment of the sterilizer, steam may pass

through before the evacuations.

Air removal when autoclaving liquids in open containers is by applying

a vacuum or by flowing steam, to ensure that the liquid does not boil

during the decompression periods in a pulsating procedure.

For sterilizers equipped with a computerized cont rol unit, the sterilizing

time starts at the instant in the pre-treatment phase of the process when

the chamber temperature sensor signals a temperature equal to or higher

than the sterilizing temperature specified for the current program. An

alarm sounds if the temperature sensor registers a value outside the temperature band, or if the temperature differs by more than the permitted

amount from the chosen sterilizing temperature.

THE PROCESS -

15

Post-treatment

When sterilizing liquids, the te mperature is measured with a temperature sensor in the load. The condition for countdown of sterilizing time

is that both temperature sensors in the chamber and the sensor in the

load indicate the programmed sterilizing temperature.

The purpose of the post-treatment is to normalize the temperature and

moisture content of the goo ds. All goods except liquids are therefore

exposed for a certain time to a vacuum below 70 mbar (a). After suc h

post-treatment. textiles may appear to increase in weight by about 1%.

This represents the normal addition of water that occurs during steam

autoclaving process.

Post-treatment of liquids that have been sterilized in open or half-closed

containers consists of a self-cooling period. During this period the pressure and temperature are lowered very slowly until the temperature is

well below the boiling point of the liquid. This process is speeded up by

applying a slight vacuum to the chamber when its pressure appr oaches

atmospheric.

NOTE: Liquids must only be processed in sterilizers which

have a program for this type of load.

Pressure equalization from vacuum takes place by admitting atmospheric air into t he cham ber via a f ilter tha t preve nts bact eria from entering the chamber. The efficiency of the filter is 99.998% for particles of

the order of 0.3 micron (0.0003 mm) in size.

The sterilizer door is kept closed by the door gasket until the pressure in

the chamber is equal to atmospheric pressure.

Process adaptation

A large number of factors such as type of goods, goods carrier, packaging material, etc. affect the result of the process. The control equipment

offers a number of features that can be used to optimize the processes to

suit the requirements of different customers. For further information,

see "User-programmable functions" in the TECHNICAL MANUAL.

16 -

THE PROCESS

Maintenance program

Leak test

Fully automatic process for steam autoclaves

With autoclaves equipped with an analogue pressure transducer the leak

test can easily be automatically performed. The leak test is to be performed with an empty chamber. The chamber additionally has to have

been warm, for example as a result of a heating program having been

run beforehand.

The checking process has its own program button (see program list)

which starts with the vacuum system evacuating the chamber. Depending on the equipment of the sterilizer, steam may pass through before

the evacuation. The pump in the vacuum system stops when a deep vacuum has been created. For a short period of time after this evacuation a

slight rise in the chamber pressure takes place which is not due to leakage but results from evaporation of condensate and temperature-volume

changes in the recently rarefied residual steam.

It is therefore not possible to establish that an increase in pressure in the

chamber is caused by leakage until conditions in the chamber have stabilized. It is not until about 10 minutes after the pump has stopped that

the pressure and time start to be measured.

A satisfactory leak test allows for a maximum permissible pressure rise

of 13 mbar / 10 minutes.

With double-ended autoclaves, the loading door opens after a completed leak test either automatically or manually, depending on how it

has been programmed.

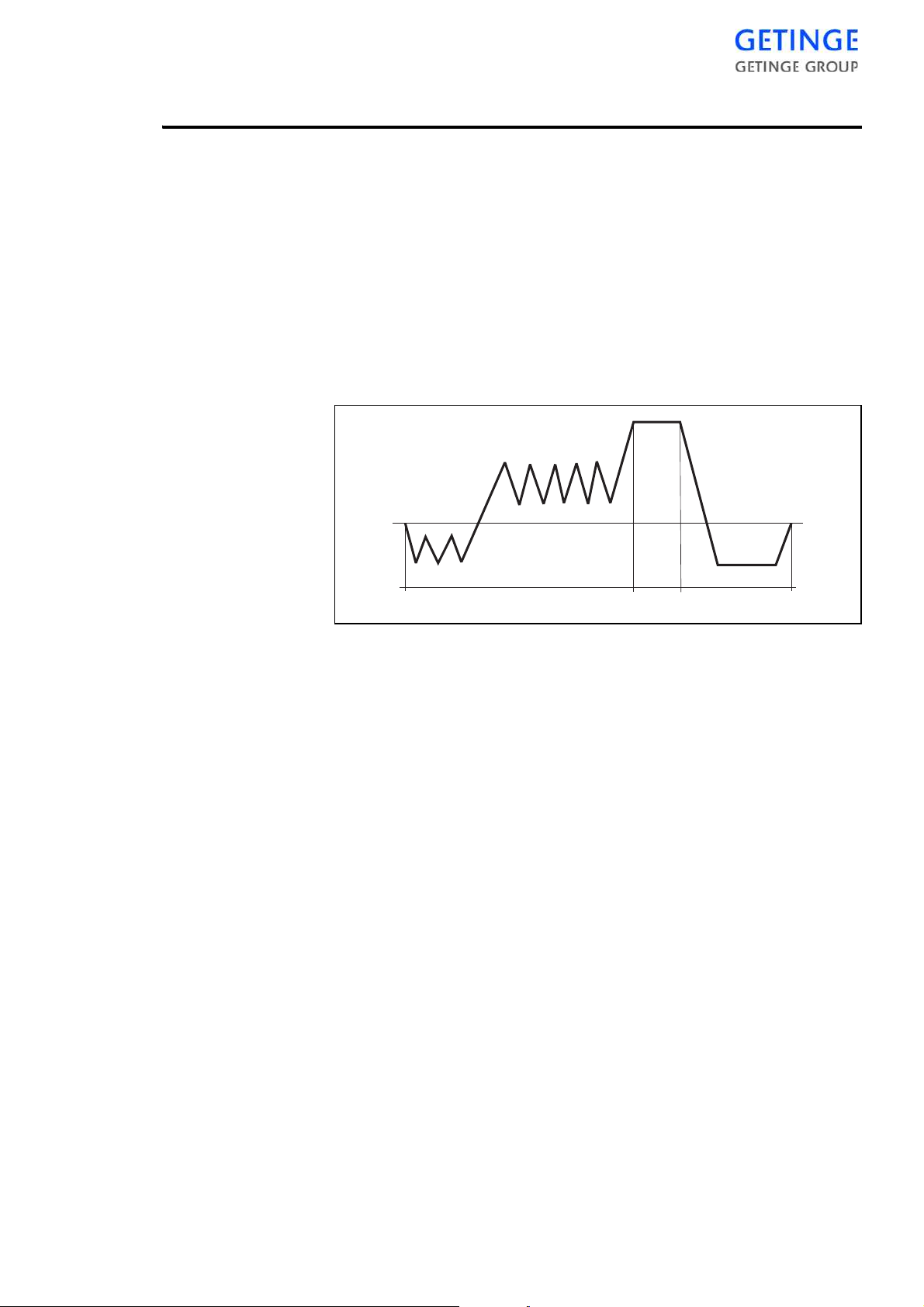

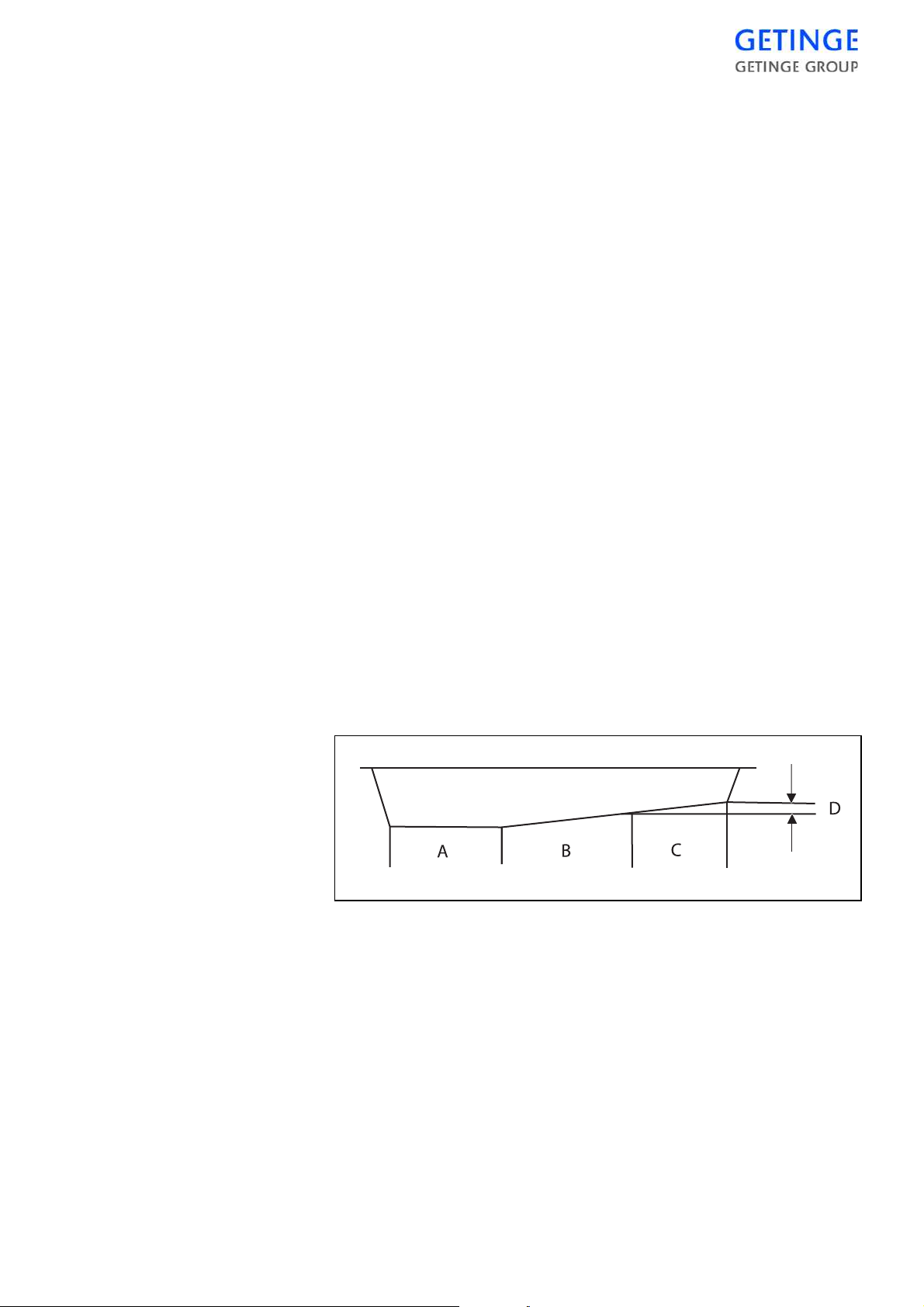

A Normal vacuum 5 min.

B Stabilization of chamber atmosphere 10 min.

C Check time 10 min.

D Pressure stepping max. 13 mbar.

Documentation of the process

A panel printer prints out data logged during the process.

THE PROCESS -

17

See Components in the TECHNICAL MANUAL for printer settings

and maintenance.

The system stores the last process so that an “emergency printout” can

be produced afterwards if there is a problem with transmission of the

printout or with the printer itself.

If the system is fitted with a SUPERVISOR, the printer is connected to

that. Otherwise it is normally connected to the control system. SUPERVISOR is an inde pendent measu ring system that records the process

data of the sterilizer. See a lso Control unit in the TECHNICAL MANUAL for further information.

The illustration below is schematic and must not be used

as a template for evaluating individual process results.

13:47 29 06 04

SIGNATURE ………

..

PROCESS OK

00:24:58 71.2 132.5 85.2 0.995

PROCESS COMPLETE

00:23:39 75.5 132.5 85.2 0.039

EQUALIZATION

00:18:35 51.1 132.2 88.6 0.096

00:16:14 134.9 135.4 134.8 3.076

DRYING

HIGHEST TEMP 135.2C

LOWEST TEMP 134.9C

5

134.9C

6

18 -

THE PROCESS

00:16:08 135.0 135.5 134.9 3.094

POST-TREATMENT

00:12:07 134.1 134.3 134.0 3.039

STERILIZING

00:09:10 106.5 132.6 103.6 1.088

4

HEATING

00:08:50 115.8 132.5 115.6 1.880

00:08:33 107.8 132.6 104.3 1.107

POS PULSING

00:08:14 115.9 132.5 115.7 1.876

00:07:57 107.2 132.6 103.1 1.103

POS PULSING

00:07:38 116.0 132.6 115.7 1.880

00:07:21 106.0 132.6 100.1 1.119

POS PULSING

00:07:02 116.1 132.2 114.9 1.877

00:06:44 104.5 132.4 77.2 1.090

POS PULSING

00:06:24 116.6 132.3 87.4 1.875

00:05:52 92.0 132.5 34.0 0.835

POS PULSING

00:05:32 78.4 132.7 33.7 0.065

00:04:22 91.3 132.5 33.9 0.836

NEG PULSING

00:04:01 75.1 132.5 33.4 0.066

00:02:54 81.4 132.5 33.7 0.849

NEG PULSING

00:02:37 81.9 132.6 33.4 0.099

00:00:15 46.6 132.6 33.4 0.997

NEG PULSING

00:00:00 46.5 132.5 33.4 0.997

START

4

PROG. TIME AI00 AI01 AI02 AI03

PROGRAM: P1 POROUS LOAD 134

AI03 CHAMBER PRESSURE

AI02 AIR DETECTOR

THE PROCESS -

19

AI01 JACKET TEMP

A100 DRAIN TEMP

SIGNALS

DRYING AIR PULSE 00:00:00

DRYING STEAM PULSE 00:00:00

DRYING TIME 00:05:00

STERILIZING TIME 00:04:00

3

STER. TEMP.

POS. PULSE 5

NEG. PULSE 3

PARAMETER SET-

TINGS

CYCLE COUNTER :16

MACHINE NAME :HS55

PROCESS START 13:20:45

DATE 29/06/2004

1. The lower part shows the date and time when the process was

started and the type designation, number and cycle counter of the

sterilizer.

2. Above the heading “Parameter settings” there is a list of the parameters of the current program that can be changed with a parameter

code. In this example, sterilizing temperature in °C and times for

various sub-processes in hours, minutes and seconds.

134.0 C

2

1

3. Above the heading “Signals” there is a list of the parameters chosen

for printing.

4. Information about which program has been started, followed by

process logging.

5. Printed out if an error occurs during the process.

6. Signature line

Documentation of the process

An A4 printer prints out data logged during the process.

20 -

THE PROCESS

See Components in the TECHNICAL MANUAL for printer settings

and maintenance.

Printout is possible in four modes. The mode shown below is preset

before delivery and is recommended by GETINGE.

The system stores the last process so that an “emergency printout” can

be produced afterwards if there is a problem with transmission of the

printout or with the printer itself.

If the system is fitted with a PACS SUPERVISOR, the printer is connected to that. Otherwise it is normally connected to the control system.

PACS SUPERVISOR is an independent measuring system that records

the process data of the sterilizer. See also Control unit in the TECHNI-

CAL MANUAL for further information.

The illustration below is schematic and must not be used

as a template for evaluating individual process results.

DATE 16/05/2001 SIGNALS Page: 1

PROCESS START 08:01:36 AI00 DRAIN TEMP

AUTOCLAVE NAME HS6613-2 AI24 S DRAIN TEMP

AUTOCLAVE NUMBER 1

CYCLE COUNTER 5 AI27 S CHAMBER PRESS.

PARAMETERS

NEG. PULSE 3

POS. PULSE 5

STERILIZING TEMP134.0 C

STERLIZING TIME 00:07:00

DRYING TIME 00:05:00

DRYING STEAMPULSE 00:00:00

DRYING AIRPULSE00:00:00

PROGRAM: P1 POROUS LOAD 13 4

--------------------------------------------------------------------------------------------------------------------------------------------------PROGTIME AI00 AI24 AI03 AI27 AI04 AI05

START

00:00:01 83,1 82,7 1.000 1.021 89.2 89.1

NEG. PULSE

00:00:23 82.3 82.3 0.955 0.960 101.4 101.0

00:02:53 67.4 67.4 0.100 0.097 105.6 104.1

POS. PULSE

00:00:03 93.4 93.3 0.822 0.822 120.6 120.8

00:00:58 117.5 117.5 1.865 1.865 129.9 129.9

HEAT UP

00:00:49 104.5 104.5 1.245 1.251 113.5 113.7

STERILIZING

00:01:14 134.4 134.3 3.052 3.065 134.1 133.9

00:03:14 135.0 135.0 3.116 3.120 135.3 135.4

IDENTIFICATION: HS6613-2 1 CYCLE COUNTER: 5 Page: 2

--------------------------------------------------------------------------------------------------------------------------------------------------PROGTIME AI00 AI24 AI03 AI27 AI04 AI05

00:00:14 135.0 135.0 3.116 3.116 135.2 135.3

LOWEST TEMP 134.9

DRYING

00:00:18 135.0 135.0 3.110 3.113 135.2 135.3

HIGHEST TEMP 135.2

00:02:12 60.1 59.9 0.130 0.124 105.2 105.4

EQUALIZATION

00:03:16 89.9 89.8 0.055 0.052 119.6 119.2

PROCESS COMPLETE

00:33:27 93.7 93.6 0.987 0.987 130.3 130.1

PROCESS FAILURE

---------------------------------------------------------------------------------------------------------------------------------------------------

1

2

5

AI03 CHAMBER PRESS.

AI04 T1

AI05 TI2

3

4

4

SIGNATURE:__________________________________

DATE : 16/05/2001 PARAMETERS

6

Page: 3

THE PROCESS -

21

PROCESS START : 08:01:36 NEG. PULSE 3

0 . 0

AUTOCLAVE NAME : HS6613-2 POS. PULSE 5

AUTOCLAVE NUMBER : 1 STERILIZING TEMP134.0 C

CYCLE COUNTER : 5 STERLIZING TIME 00:07:00

PROGRAM: P1 POR O U S LOA D 13 4

----------------------------------------------------------------------------------------------------------------------------------------CHAMBER PRESS DRAIN TEMP

DRYING TIME 00:05:00

DRYING STEAMPULSE 00:00 :00

DRYING AIRPULSE00:00:00

7

1 In the top part, the date and time when the process was

started and the type designation, number and cycle counter of the sterilizer are shown.

2 Parameters of the current program that can be changed

with a parameter code are listed under PARAMETERS.

In this example, sterilizing temperature in °C and times

for various sub-processes in hours, minutes and seconds.

3 The parameters chosen for printing are listed under

SIGNALS.

4 Information about which program has been started, fol-

lowed by process logging.

5 Printed out if an error occurs during the process.

6 These lines are printed out after a faulty process. Identi-

fication code of the person who entered the password and

a line for a signature.

7 Graphical representation of the process

22 -

THE PROCESS

INSTRUMENTS

2

3

5

1

4

7

6

Loading side

1. Steam supply pressure gauge. 5. Control switch.

2. Pressure gauge chamber pressure. 6. Door interlock key

3. Operator's control panel 7. Emergency stop.

4. Panel lock.

Operator's control panel

Learn the function of the control panel by studying

chapter Control unit PACS 3500.

Door-blocking key

See chapter Introduction, “Safety devices, an overview”.

Emergency stop

See chapter Introduction, “Safety devices, an overview”.

INSTRUMENTS -

23

Unloading side

2

3

1

4

1. Recorder for temperature and

pressure.

2. Pressure gauge chamber pressure. 4. Emergency stop.

3. Operator’s control panel

Recorder

See recorder operating instructions in the TECHNICAL MANUAL

chapter Components.

Operator.s control panel

Learn the function of the control panel by studying chapter Control unit

PACS 3500.

Emergency stop

See chapter Introduction, “Safety devices, an overview”.

24 -

INSTRUMENTS

OPERATION

Program start

Where applicable, the operator m ust s tate process parameters and other

information requested by the contr ol system. On equipment where an

authorisation code for programs not intended for routine sterilization is

activated, the operator must also enter an authorisation code immediately after startup.

Via operator panel Avanti

To start a cycle:

•

Select the desired cycle.

•

Load goods and close the door.

•

Wait until the Door closed indicator lights

up and the

Now the machine is ready to start.

•

Start the cycle.

Process startup is prevented if:

•

there is an unacknowledged alarm

•

the door is not closed and interlocked in accordance with the conditions

•

the control system has detected an interlocking error (affects door

safety)

•

the keyswitch for manual stepping is activated

•

the keyswitch for door blocking has been activated (only if there is a

keyswitch)

•

media supply, eg steam or cooling water, is not available (only if the

sterilizer is equipped with sensors for this).

Start

button becomes visible.

•

the jacket temperature has not been reached or is too high (only if the

process includes jacket heating)

OPERATION -

25

Authorization protected programs only:

Message

After the start button is pressed, the operator is

requested to enter the authorization code.

If the operator chooses to attempt to start the sterilizer, even though

starting is blocked, the operator panel display shows a message referring to an essential condition that is not met.

•

JACKET TEMP HIGH - Indicates that lowering of jacket temperature is in progress.

•

JACKET TEMP LOW - Indicates that raising of jacket temperature

is in progress.

•

STEPPING KEY ON - Indicates that key switch for stepping is on.

•

PRINTING ACTIVE - Indicates that printing from the printer is

blocking the start of a new program.

•

UNACKNOWLEDGED ALARM – Indicates that a previous alarm

has not been acknowledged and blocks the start of a new program.

•

SEAL PRESSURE – Indicates that the door seal is pressurised.

[START]

•

•

•

•

•

•

Alarms - Avanti

If a fault occurs, in standby or during a cycle, the system goes to an

alarm phase. This is an exceptional situation, but it is normally not

dangerous. The current cycle is stopped and output signals from the

control system go to settings that maintain the safety of personnel, the

unit, and the load.

DOOR KEYSWITCH - Indicates that the keyswitch for cleaning is

on.

DOOR NOT CLOSED - Indicates that a sterilizer door is not properly closed.

LOW WATER LEVEL – Indicates that the water le vel in the ta nk is

low.

COMPRESSED AIR – Indicates that the pressure of the air supply is

low.

DEGASSING TANK – Indicates that the temperature in the degassing tank is low.

START CONDITION - Indicates that a starting condition specific to

the type of unit is not met.

(Steam, cooling water, formalin bottle or vent ilation at formalin sterilizers)

26 -

OPERATION

•

An alarm signal goes off and the relevant fault code is

displayed on the cycle screen, while the cycle screen’s

background turns red.

•

After the alarm signal goes silent, the

Alarm indicator in the status field blinks.

•

If the unit is equipped with a printer, the alarm text is

also printed out as part of the cycle log.

In case of alarm:

Read the error message and correct the fault.

The fault codes are explained later in this chapter.

In case of an error concerning a temperature sensor, a

pressure transducer or the Back-up battery a service technician is to be called for.

Blowing safety valve

If a safety valve blows off:

•

Press the EMERGENCY STOP button.

•

If this has no effect, cut off the electric power supply with the control

switch on the front of the unit.

•

In an emergency, the power supply can be cut off with the working

switch.

Send for a service technician without delay.

On power failure or if the control switch or working switch

of the sterilizer had to be turned off during a process, there

is a risk of leakage a t the door. Safe ty measure when there

is positive pressure in the chamber:

KEEP WELL AWAY FROM THE DOOR AND CALL A TECHNICIAN!

OPERATION -

27

Alarms in standby mode

An alarm from an idle sterilizer prevents it being started.

•

Call a technician.

If the load contains liquids, choosing the wrong program

may endanger personnel and equipment.

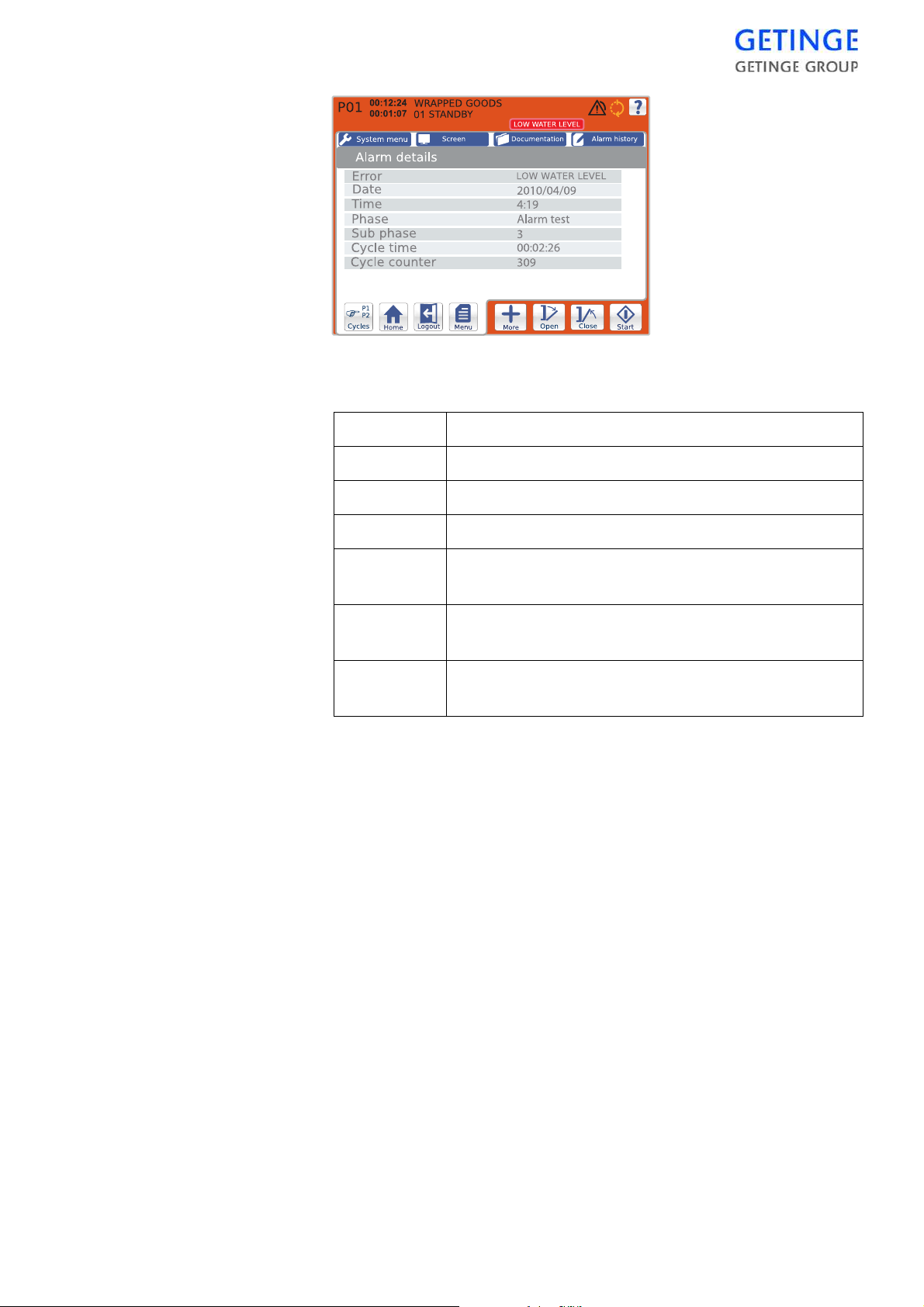

Alarms during a cycle / Avanti

A fault occurring during a cycle stops the cycl e. All valves close in

order to stabilize the conditions in the chamber.

An alarm signal sounds and the relevant error code is

displayed on the cycle screen. The cycle screen’s

background turns red and the Alarm indicator is shown.

•

Press

Silent alarm signal

•

To show detailed alarm information press

The most recent alarm is displayed at the top of the list.

Press the desired alarm to get detailed information

about the alarm.

•

After acknowledging the alarm, the following

alternatives are available:

·

Automatic quick stop of the cycle

·

Call a technician.

Automatic quick stop of the cycle

To quick stop:

•

Depending on how the cycle is set, the cycle stops

automatically or the cycle stops until the user presses

Start

.

to turn off the alarm signal.

Alarm

.

28 -

OPERATION

•

The Finished Cycle indicator lights up red after the

cycle is finished.

•

Acknowledge the alarm by pressing

More

and then

Ack.

•

If the unit is equipped with a printer, the alarm text is

also printed out as part of the cycle log.

Call a technician.

In case of a serious fault, always call a technician.

After the technician activates the key switch to the Stepping/Authorized

user setting, the technician has the following alternatives:

•

Restart the cycle where it stopped.

•

Move the cycle to another phase and start the cycle from there or

move it to the end.

To restart:

•

Press

Start

.

To move to a different step:

•

Press

More

and then repeatedly press

Step

.

After the cycle ends:

•

The Finished Cycle indicator lights up red after the

cycle is finished.

•

Acknowledge the alarm by pressing

•

If the unit is equipped with a printer, the alarm text is

also printed out as part of the cycle log.

For safety reasons, it is not possible to step past a pressure equalisation phase or a cooling phase.

Shutting off the alarm indicator - Avanti.

More

and then

Ack.

•

Finish the current cycle.

OPERATION -

29

Repeated alarms

•

Press

More

.

•

Press

Ack.

to acknowledge the alarm, by which the

Alarm indicator goes out and the red background

disappears.

To reset certain types of faults, a technicia n must first activat e the key

switch for Stepping / Authorized users.

If the process repeatedly hangs at the same alarm point, call a technician

to step the process to the end. If several faults occur, only the last one is

displayed.

In certain phases, sensor faults prevent stepping of the

program.

Stepping may only be done by trained personnel.

Alarm printout in process documentation

Where a main fault causes one or more secondary faults, the operator

panel shows on the most recent fault. If the unit has a printer or similar,

all faults are printed out, together with the time when they occurred.

Doors

When a fault has occurred, the unloading door of a double-ended sterilizer will not open. Exceptions are errors that occur so late in the process

that unlocking of the door has begun.

The door can only b e opened when the corr ect password has been

entered. For further information, see the menu description in the Con-

trol unit chapter.

Steam generator alarms

Alarms from the steam generator may be due to the operating pr essure

being exceeded or the water level in the steam generator falling below

the minimum. Low water level may also indicate that the boiler water

quality is beginning to be very poor and that the water should therefore

be emptied.

Call a service tech nician to analyse and correct the fault, with the aid of

the description in the Advice and instructions chapter in the TECHNICAL MANUAL.

30 -

OPERATION

Error codes

NOTE!

Important where a steam generator safety valve has been

blowing off for a long time and the chamber is under pressure at the same time.

Only switch off the sterilizer control switch as a last re sort,

because doing so disables certain safety functions.

Instead, call a service technician who can trip the steam

generator circuit-breakers.

The error messages listed below are defined in the control system. If

more than one error occurs consecutively, only the error code for the

last error is displayed.

If the sterilizer is equipped with a printer, the error message is printed

out. For secondary errors, all error messages are printed out.

Information about the last twenty faults is saved in the control system

and is accessible in the service menu. If the sterilizer has a printer, this

information can be printed out.

Service codes

When the word “S E RV ICE ” app e ars o n th e d is pla y , se rv ice is re q uire d

and must be carried out by a service technician. See below for explanations of the codes.

NOTE!

No error has occurred.

The sterilizer can still be used.

Error code/

Message

BATTERY

ERROR

AI FAILCHAMBER

Explanation

The backup battery of the control system is

flat. Programs and stored parameters may

have been lost.

Chamber temperature sensor defective.

OPERATION -

31

Error code/

Message

Explanation

AI FAIL-

Jacket temperature sensor defective.

JACKET

AI FAIL-

Pressure transducer defective.

PRESSURE

AI FAIL-LOAD Load temperature sensor defective.

NOTE: Not present on all sterilizers.

AI FAILDEGASS.

De-aeration temperature sensor defective.

NOTE: Not present on all sterilizers.

Mistakes when correcting the above ty pes of fa ult s may

lead to situations where there is a risk of injury.

Always call a trained service technician.

Error code Explanation

High pressure The chamber pressure has been too high dur-

ing the sterile phase. This may indicate the

presence of air or non-condensable gases. The

actual pressure in the chamber is compared to

a theoretical saturation pressure calculated

from the sterile temperature + 3°C. A message

is printed in the alarm log when the error

occurs.

32 -

OPERATION

Low pressure The chamber pressure has been too low during

the sterile phase. This may indicate a faulty or

improperly calibrated sensor. The actual pressure in the chamber is compared with a theoretical saturation pressure calculated from the

sterile temperature. A message is printed in

the alarm log when the error occurs.

HIGH JACKET

TEMP

GASKET

The jacket temperature has been too high during part of the process.

Door gasket pressure too low.

FAILURE

DOOR FAILURE Door(s) not closed and interlocked.

PUMP FAILURE Vacuum pump has stopped.

HIGH TEMPER-

ATURE

The chamber temperature has been above the

permitted limit during the sterilization phase.

Error code Explanation

LOW TEMPER-

ATURE

PHASE TIME-

OUT

The chamber temperature has been below the

permitted limit during the sterilization phase.

The phase named on the display exceeded the

time limits for completion. Chec k whether the

cause is a component fault or media fault.

POST. TIMEOUT The post-treatment exceeded the times limits

for completion. Check whether the cause is a

component fault or media fault.

MAINTENANCE This message appears when the programmed

service interval has elapsed and the current

process is complete. The message continues to

be displayed until it is de-activated by the

service technician.

The autoclave can still be used.

Call a service engineer immediately.

MANUAL OUTPUTS

A digital output has been manually switched

off or on. Call a service technician to re set the

output to auto mode.

LEAK RATE

FAIL

SUPERVISOR

ERROR

POWER

FAILURE

EMERGENCY

STOP

STEAM GENERATOR

DOOR INTERLOCK

GASKET INTERLOCK

An automatic leak test has failed.

The Supervisor’s independent monitoring of

process time and temperature conditions has

indicated that these have not been fulfilled and

have triggered an alarm.

There has been a power failure longer than 10

seconds.

The program has been stopped with the emergency stop button.

The supply of feedwater to the steam generator has stopped working.

The independent safety interlocking of media

admission to th e chamber, as co ntrolled by the

door switch, is faulty.

The independent safety interlocking of media

admission to th e chamber, as co ntrolled by the

gasket pressure switch, is faulty.

PRESS. INTERLOCK

The independent safety interlocking of the

door function, as controlled by the chamber

pressure switch,pressure monitor or the

Supervisor, is faulty.

OPERATION -

33

Error code Explanation

TEMP. INTER-

LOCK

I/O FAULT The control system has lost communication

WATER

SUPPLY

COMPR.AIR

SUPPLY

DEGAS. TANK

FAIL

The independent safety interlocking of the

door function, as controlled by the load temperature switch, or the Supervisor, is faulty.

NOTE: Not present on all sterilizers.

with the input or output cards.

Call a service engineer immediately.

The water level in the tank is too low.

Pressure of incoming compressed air is too

low.

The temperature in the degassing tank has

fallen below the permitted value.

NOTE: Not present on all sterilizers.

General advice when using the sterilizer

•

Keep the sterilizer door closed when the unit is not in use.

•

Read the section “General advice on packaging material” in the

guide below.

•

If it is difficult to get items dry, the post -treatment stage can be modified. See the guide “Cycle modification according to the type of

load” further down.

•

Read the manual for the medical device to be sterilized before starting the process.

•

Be alert to everything that appears unusual such as leaks, humming

solenoid valves, stickily mechanical devices etc. Remedy the situation before it becomes a malfunction.

Heating of load

Heating of items to be processed may jeopardie sterilization result due

to poor humidification. Make sure appropriate process has been chosen

before loading the sterilizer.

34 -

OPERATION

Fire hazard

There have been reports of textile loads catching fire in the sterilizer

chamber. In all cases this has been due to the load becoming excessively

dry and hot. This can happen in two ways:

•

The load has been placed in a heated chamber and left for a long time

without the process being started. Ignition is believed to take place

when the load is moistened again on the admission of steam to the

chamber.

•

The load is left in the chamber for a long time without the process

being completed. This probably happens when the process has been

interrupted because of a fault and the load has not been taken out of

the chamber.

Ignition takes place when the process is completed and the load is

exposed to air.

Users should be aware of the risks and establish procedures to ensure

that loads are not left in a heated chamber for longer than necessary.

Weekly cleaning - Avanti

External cleaning.

Clean stainless steel surfaces on the outside of the sterilizer with a

standard household cleaner that does not contain abrasives. Take care

when cleaning painted surfaces, texts, and plastic parts.

Cleaning the chamber

When cleaning inside the chamber, a key switch on the front can be used

to block the door open, and shut off chamber preheating at the same

time.

On double-ended steriliz ers, the same key switch can also be use d to

open and block the unloading door for better access; see below.

•

With the sterilizer is in standby mode, turn the key

switch to the locked position and remove the key. The

text “DOOR KEY SWITCH” appears on the operator

panel display.

•

Open the door by pressing the

sterilizer cool down before starting work.

Open

button. Let the

OPERATION -

35

The sterilizer should have cooled down before cleaning.

When the key switch cannot be constantly observed, the

person doing the cleaning must always take the key with

them. This is to ensure that no-one mistakenly resets the

key switch.

•

Clean the strainer in the chamber floor drain.

•

Remove any shelves, guides, and bottom plates and

clean the inside of the sterilizer chamber.

Use a general-purpose chlorine-free cleaner. Scouring

powder may be used occasionally on stubborn stains.

Never use steel wool.

Sterilizers that are often used to sterilize products

containing salt require especially thorough cleaning,

since residual deposits may even have a corrosive

affect on stainless steel. An acidic cleaning agent

followed by careful rinsing is most suitable for the

purpose.

•

After cleaning, insert the key in the key switch and turn

it to the initial position.

•

•

•

Bowie Dick testing

The purpose of the Bowie Dick test is to reve al deficie ncie s in the abi lity of the sterilizer to expel air and reveal leaks or an excessive content

of non-condensable gases in the steam. In testing in accordance with EN

285, (or applicable national standard) an indicator paper is placed in the

centre of a test pack. The pack, which must be 220 - 300 mm square and

approx. 250 mm high, must consist of folded cloths of 100% cotton. The

pre-treatment of the te st programme must be identical to t he pre-treatment for the processes used for routine sterilization, while the steriliza -

Then close the door by pressing the

On double-ended sterilizers, the unloading door can be

opened for cleaning by repeating steps in the points

above.

Note! Note that there may be restrictions on door

opening on SPF sterilizers and sterilizers with

controlled work flow.

When cleaning is complete, both doors must be closed

and the key must be left in the key switch.

Close

button.

36 -

OPERATION

tion time may be adapted to the performance of the sterilizer but must

not exceed 3.5 minutes.

When the indicator paper has be en sufficiently exposed to steam at a

particular temperature, further exposure tends to hide the indication of

any deficiencies. GETINGE’s Bowie Dick programme is there fore

tested with the shortest possible sterilization time so that any deficiencies are not concealed by overexposure.

In day-to-day work, the above, standardised test packs for the sake of

convenience are sometimes replaced by various types of disposable

packs which are manufactured by a large number of manufacturers. As

these packs are generally even more sensitive to overexposure than the

standardised test pack, it is extremely important to c hoose the correct

make. Test packs in accordance with BS 7720 :1995 must be used for

GETINGE’s Bowie Dick programme.

Approved consu m ables

Consumables are used for different purposes as packaging for goods to

be sterilized, for testing, for replacement of sterilizer parts with limited

life or a sterilization media for low-temperat ure sterilizing. The list of

consumables below is intended as a guide to be used with GETINGE’s

CE-marked sterilizers.

Always check whether consumables have a use-by date

before using them.

Articles for packing items to be sterilized

Packaging materials must be matched to the method of sterilizing, the

load carrier and the goods to be sterilized. To guarantee compatibility

with GETINGE sterilizers, it is the responsibility of the user to ensure

that packaging material and methods used conform to European standard EN868-1, the other parts of which also specify particular requirements for different types of packaging material.

Packaging material for steam sterili zation

Getinge AB recommends warping in paper for textile packages and for

instrument grilles in baskets and containers.

Getinge AB recommends paper/plastic bags for separately packed articles.

OPERATION -

37

Packaging material for formaldehyde

For formaldehyde sterilizing, we recommend pape r/plastic bags

intended for steam sterilizing.

Articles for test purposes

The user is responsible for maintaining a routine check of the operation

of the sterilizer in accordance with European standard EN17665. There

are various types of test articles on the market to assist the user.

Chemical indicators

Chemical indicators used when testing various types of sterilizer must

conform to European standard EN867-1, the other parts of which also

specify particular requirements for different types of indicator.

Getinge AB recommends using chemical indicators in steam sterilization processes. For other types of processes it the user’s responsibility

to evaluate whether individual makes are applicable to the GETINGE

sterilizer process.

An established test method in which chemical indicators are used is the

Bowie-Dick test, with test packages or its equivalent with a disposable

package. For information see also under “Bowie-Dick testing”.

Biological indicators

Biological indicators used when testing various types of sterilizer must

conform to European standard EN866-1, the other parts of which also

specify particular requirements for different types of indicator.

Getinge AB recommends using biological indicators in steam sterilization processes. For other types of processes it the user’s responsibility

to evaluate whether individual makes are applicable to the GETINGE

sterilizer process.

Sterilizer parts for periodic replacement

Spare parts

So that correct operation and product safety can be guaranteed, parts for

recorders, printers or periodic maintenance must be genuine GETINGE

spare parts or parts approved by Getinge Infection Control. Article

numbers of genuine parts are stated in the relevant sections of the service manual.

Sterilization media for low-temperature sterilising with

formaldehyde sterilizers

Low-temperature sterilizing can only be done with special sterilizers

intended for the purpose. During sterilizing with formal dehyde, the

medium is added from containers attached to the sterilizer.

38 -

OPERATION

Formaldehyde solution

Containers holding formald ehyde solution are brought to the site an d

attached to the sterilizer by the operator.

Accessories

Where relevant, details of concentration, volume, packaging, handling

and properties are described under Operating instructions and under

“General advice on formaldehyde sterilizers”.

The sterilizer's CE label makes the manufacturer responsible for

ensuring that its product safety and function satisfies the strict

requirements laid out in the relevant EC directive. Accessories that are

mechanically, electrically or otherwise connected to the ster ilizer must

be compatible with this. As a result, only equipment that has been

evaluated by Getinge AB and registered as approved equipment may be

used together with the sterilizer.

Should non-approved equipment be used, Getinge AB

exempts itself of all product liability for the sterili zer and its

CE label.

Approved accessories

The accessories listed below are compatible with the sterilizer once the

sterilizer has been configured to function with the a ccessory in question.

Such configuration shall be performed by a professional authorized by

Getinge Sterilization AB.

Accessories for extended

documentation, etc.

1 A4-Printer EPSON LX-300 X X X X X

2A4-Printer LEXMARK XXXX X

Loading equipment

accessories

3 Shelf Rack (Light load) X X X

HS44 HS55 HS66 HS69 HS

Floor

Loaded

4 Shelf (light load) X X

5 Shelf Rack (heavy load) X X X

6 Shelf (heavy load) X X

7 Rails for Shelf Rack X X

8 Rails for Baskets X X

OPERATION -

39

9 Rails for AGS X X

10 Support bar (Rails for basket X X

11 Loading Platform X X

12 Loading Module X X

13 L-Rails (Extendable Shelves) X X

14 Extendable Shelves (perfo) X X

15 Extendable Shelves (Wire) X X

16 Sterilizer Basket (DIN)

X X

(600*300*150/290)

17 600*400*115/150/290) X X

18 Sterilizer Basket (ISO)

X X

(100) / (200)

19 Sterilizer Basket (SPRI)

XX

(100) / (200)

20 Sterilizer Basket (SPRI-

X X

Swedish) (100) / (200)

21 Automatic Loader (Basket) X X

22 Automatic Unloader

X X

(Basket)

23 Automatic Loader (Racks) X X

24 Automatic Unloader (Racks) X X

25 Basket Feeder (Manual) X X

40 -

OPERATION

26 Loading Trolley Fix Height X X X

27 Loading Trolley Height Adj.

X

(Racks)

28 LT FIXED 6606/6613HL/

X

633-07

29 LT FIXED 6610/6620HL/

X

633-10

30 LT FIXED FOR 6613/633-

X

13

31 LT FIXED FOR 6617 X

32 LT FIXED SAL FOR 6610/

X

633-10

33 LT FIXED SAL FOR 6613/

X

633-13

34 LT FIXED SAL PD 6610/

633-10

X

35 LT FIXED SAL PD 6613/

X

633-13

36 LT H/A 6610/6620HL/6910/

X X

633-10

37 LT H/A FOR 6613/6913/

XX

633-13

38 LT H/A FOR 6617 X

39 LT H/A SAL 6x10/633-10 X

40 LT H/A SAL 6613/6913/

X X

633-13

41 LT H/A SAL PD 6x10/633-

X

10

42 LT H/A SAL PD 6x13/633-

X

13

Other accessories.

43 Air Compressor 175 EO-24 X X

44 Air Compressor 55E-24 X X

45 Water Treatment System

X X

"RO 51"

46 Water Softener Princess

XX

MIDI

47 Water Softener Princess

X X

TURBO

48 Water Chiller MINI X X X

49 Water Chiller MIDI X X X

50 Water Chiller MAXI X X X

51 AGS X X

52NetCOM XXXX X

53 Free standing steam

X X X

generator

OPERATION -

41

42 -

OPERATION

OPERATION INSTRUCTIONS

The following operating instruction deals with the day-today use of the sterilizer.

A further copy of this operating instruction, together with

the program combination, is packaged with the sterilizer

when it is dispatched from the factory.

These documents must be displayed so that the personnel

can read them when working at the operator panel.

Use

This sterilizer must not be used for processing other m aterial than stated in the program combination list.

Pathogenic material must not be sterilized in this sterilizer.

Warning! Fire hazard!

Do not leave goods in a heated chamber. See chapter Oper-

ation.

Beware of hot surfaces inside the st erilizer chambe r when

the door is open!

Keep the sterilizer doors closed as much as possible to

reduce energy loss and minimise temperature rise in the

room.

OPERATION INSTRUCTIONS -

43

Daily prepara t ion s

•

Learn the functions of the control buttons and signal lamps by studying the Instruments and Control unit chapters. Find out how the

user-programmable parameters are set on this unit.

•

Open valves for water, air and, where applicable, steam.

•

Switch on the mains switch of the unit.

•

Check that recording instruments and printers have sufficient paper.

The paper of recording instrument shows a red line when it is nearly

finished.

•

Run the first steam sterilization process of the day with t he chamber

empty. This heats up and drains the system pipework.

Running a process

Select the desired program. The selected program is indicated on the

•

control panel.

Parameter password

•

Before a selectable parameter can be changed, a parameter password

must be entered, after which all parameters (see Program combination) can be changed.

Password-protected programs

•

Programs that are not intended to be used routinely are protected

with a password. Some degree of consideration is called for before a

password-protected programs is chosen. Examples include test programs, programs for emergency situations, programs with selectable

parameters or programs using some sterilization medium other than

steam.

•

Load the sterilizer.

Start via operator panel Avanti

•

Make sure that cycle media are available.

•

Close the door by pressing

Close

.

44 -

OPERATION INSTRUCTIONS

•

If the “Door locked” indicator is lit and

the

Start

button can be selected, the

machine is ready to start.

If the lamp does not light up, start is prevented for some

reason (also see chapter Operation and Control unit).

•

Choose the cycle by pressing the

button in the button field.

In order to run the latest cycle, this step

can be skipped.

•

Press

Start

to start the cycle.

After completion of the process

Beware of hot surfa ces ins ide the sterili zer chamber when do or is

open!

Cycles

The control panel displays progress of the process.

Operating from the operator panel Avanti

•

The “Finished cycle” indicator lights up green after an

error-free cycle is completed.

•

The panel lights up green and an acknowledgement

key

lights up on the completion of an error-free process.

(Does not apply to automatic loaders)

•

Press

Open

if the door on the discharge side does not

open automatically.

Process check

Check that the completed process has been carried out correctly by

comparing the process printout with a corresponding type load printout

from the sterilizer validation.

OPERATION INSTRUCTIONS -

45

Goods handling

Remember that the goods may contain a c onsiderable amount of heat

when unloaded. Position them with regard to a good working environment.

Note that the goods may be very hot immediately after

unloading.

Let the goods cool down or wear safety gloves to handle

them.

Long sterilizers can take two load carriers in a row. Use a

hook (ordered separately) to reach into the chamber and

extract the inner load carrier.

Things to do when the work is finished

Unless otherwise prescribed by local rules:

•

Turn off the control power supply by the switch on the front.

•

Inspect the strainer in the bottom of the chamber and clean it if necessary.

•

Close valves for air, water and, if used, steam and gas.

If necessary:

•

Shut down the sterilizer for long enough to let it cool down, eg overnight.

•

Clean the inside of the chamber. Use a chlorine-free cleaner if necessary.

The sterilizer must always be cold when cleaned. To prevent injury, switch off the power to the control system.

The cleaning instruction is given in the section “General advice on

using the sterilizer” in the Operation chapter.

46 -

OPERATION INSTRUCTIONS

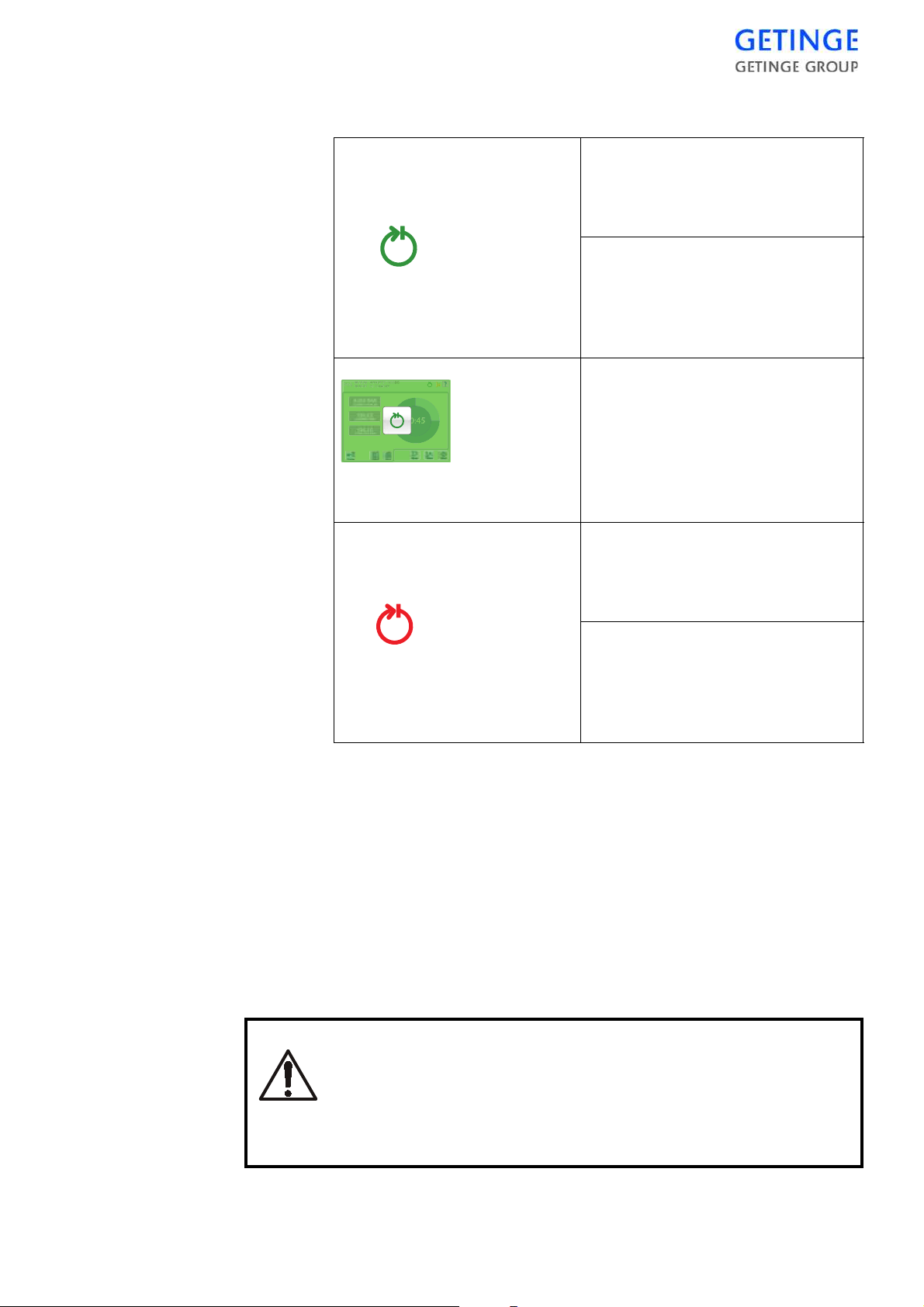

To interpret the “Finished cycle” indicator

Normal routine cycle:

After completion of fault-free normal routine cycle, the indicator

shows a steady green light.

Maintenance cycles:

After a completed, fault-free automatic leakage test or filte r sterilization, for example, the indicator

shows a flashing green light.

Normal routine program:

On the completion of an error-free

routine process, the panel lights up

green and an acknowledgement

key lights up.

(Does not apply to automatic loaders)

Normal routine cycle with fault:

After completion of stepped or

alarmed normal routine cycle, the

indicator shows a steady red light.

Maintenance cycles with fault:

After completion of a stepped or

alarmed maintenance cycle the

indicator shows a flashing red

light.

Stopping the program or a blowing safety valve

In an emergency, the program can be stopped or a safety valve that is

blowing off can be made to close, by means of the EMERGENCY

STOP button on the front panel, without disabling the safety systems of

the unit. An alarm is triggered when the program is stopped.

•

Press the EMERGENCY STOP button.

•

Follow the instructions under “What to do if there is an alarm”

below.

Only switch off the control unit power switch as a last

resort, since this affects t he safe ty sys tems of th e installation.

The main power supply switch or disc onnector to the st erilizer may be turned off only in an emergency.

OPERATION INSTRUCTIONS -

47

On power failure or if the control switch or working switch

of the sterilizer had to be turned off during a process, there

is a risk of leakage at the door. Safety measur e when there

is positive pressure in the chamber:

KEEP WELL AWAY FROM THE DOOR AND CALL A TECHNICIAN!

ALWAYS LEAVE THE PREMISES and call a technician if

the chamber pressure is in the RED area of the pressure

gauge.

Measures in case of alarm

Programs that are installed to be ended automatically

•

The program ends automatically.

An emergency stopped process or program that did not finish automatically.

•

Note the process phase during which the fault occurred.

•

Silence the alarm signal by pressing

signal

.

Options for alterative actions are described in the chapter “Alarm” in

chapter Operation.

After a fault in a process, the pas sword must be entered be fore the loading side door can be opened.

Silence alarm

48 -

OPERATION INSTRUCTIONS

CONTROL UNIT PACS 3500

The letters PACS stand for Programmable Autoclave Control System.

The purpose of the control system is to issue orders and send them to

the executive components of the unit so that a number of process steps

are performed in accordance with a pred eterm ined tem plat e. The orde r

signals are worked out by the computer program of the control unit in

conjunction with measurements of actual parameter values for the current program. These are usually times, temperatures and pressures.

Several different pieces of equipment can be connecte d to the control

unit for programming, monitoring and documenting the processes.

The operator communicates with the control unit via a control panel or

an ordinary PC. There are several versions of the operator-machine

interface, from the simplest, which consists of two pushbuttons and

eight LEDs to show that certain statuses have been reached, to the most

advanced, which allows complete programming of the control system,

among other things.

All operator panels are manufactured to monitor the processes by

displaying all the set parameter values as well as actual values on

request. All relevant data associated with a given process, such as cycle

number, operator number, date, etc., can be entered by the operator.

Programs, system definitions and process data can be documented by

connecting a printer to the unit. A host computer can also be connected

directly to the CPU of the control system.

If necessary, a measurement and monitoring system which is completely independent of the control system, can be set up by providing the

equipment with a SUPERVISOR. This contains a separate CPU and its

own measurement and control boards. The SUPERVISOR performs its

measurements by means of separate temperature and pressure sensors

alongside those of the control unit. The system has links to the control

unit CPU and can therefore use the shared operator panel, as well as

adding the c ontrol unit readi ngs to the process documentation. The

SUPERVISOR can also be involved in independent interlocking of

door opening, for example.

The computer contains programs for automatic calibration of the temperature and pressure sensors. Where alternative correction constants

are known, they can be entered manually. The testing functions include

means of activating analog and digital outputs and for monitoring analog and digital inputs.

The control unit hardware is divided, so that the operator panels can

form small separate units that are easy to position at the most suitable

location. CPU, measurement and control boards and the power supply

are installed in separate electrical enclosures which are connected to the

operator panels by shielded cables.

CONTROL UNIT -

49

A number of special terms

STERILIZATION refers to the entire series of treatments that make up

a process aimed at achieving the total killing of all living organisms.

This applies to sterilizers and usually includes air removal, heat treatment and a drying phase.

STERILIZING refers to the actual killing part of the process, the heat

treatment.

On the same basis as the two terms above, STERIL IZATION TIME

refers to the duration of the entire process from the start until the obje cts

can be taken out of the sterilizer. The PROCESS TIME is the same as

the sterilization time.

The STERILIZING TIME is only that part of the process for which the

programmed STERILIZING TEMPERATURE exists in the chamber.

In this context, PARAMETERS means FACTORS THAT I NFLUENCE THE sterili zatio n pro cess . Ex amples of p aram eters in th e ster ilization process are temperature, pressure, time, humidity, gas

concentration, etc.

PARAMETER VALUES may be permanen tly set in the program, be

adjusted by the operator, be included in selectable recipes or downloaded from a higher-level system.

50 -

CONTROL UNIT

Control panel type Avanti

General description

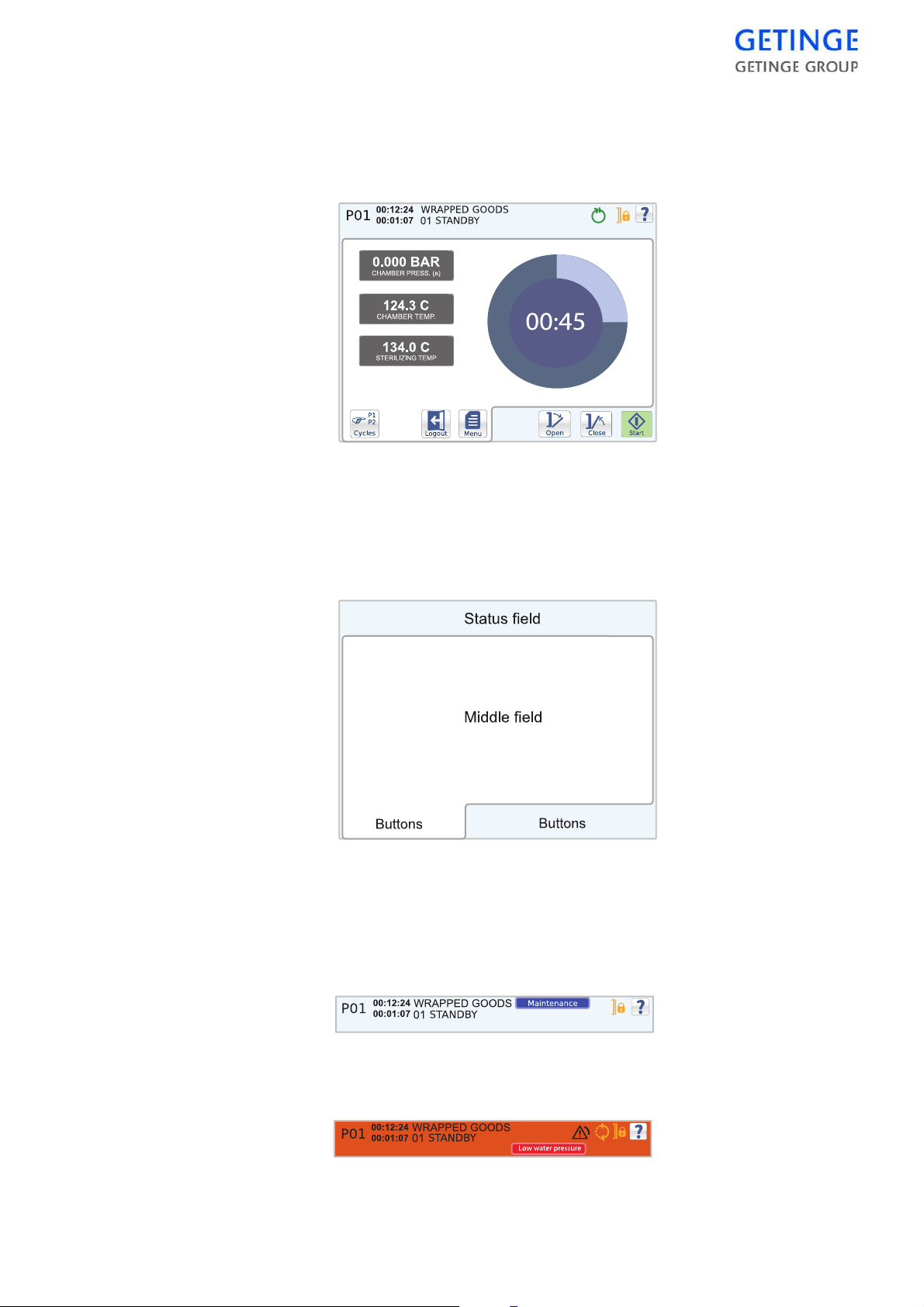

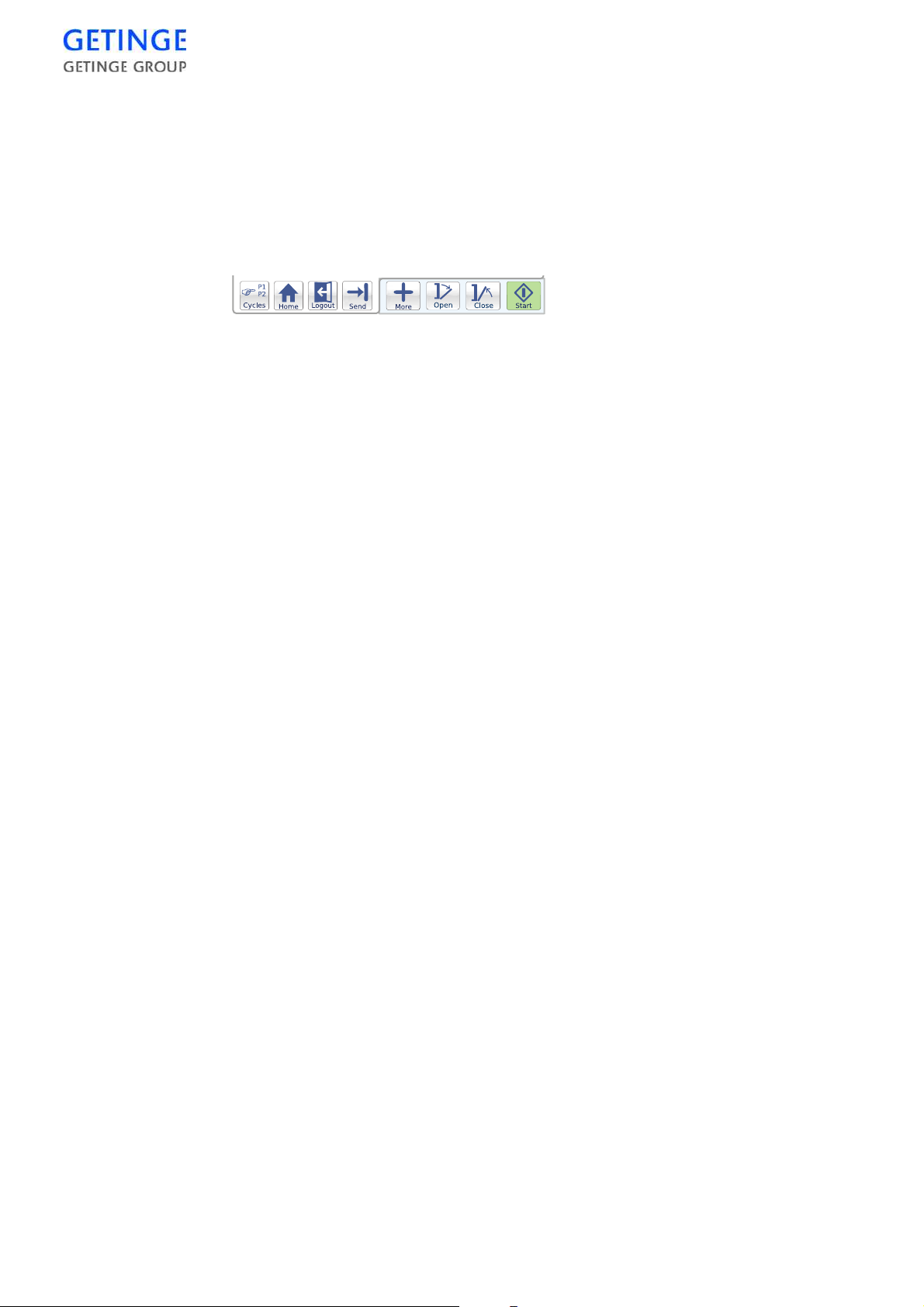

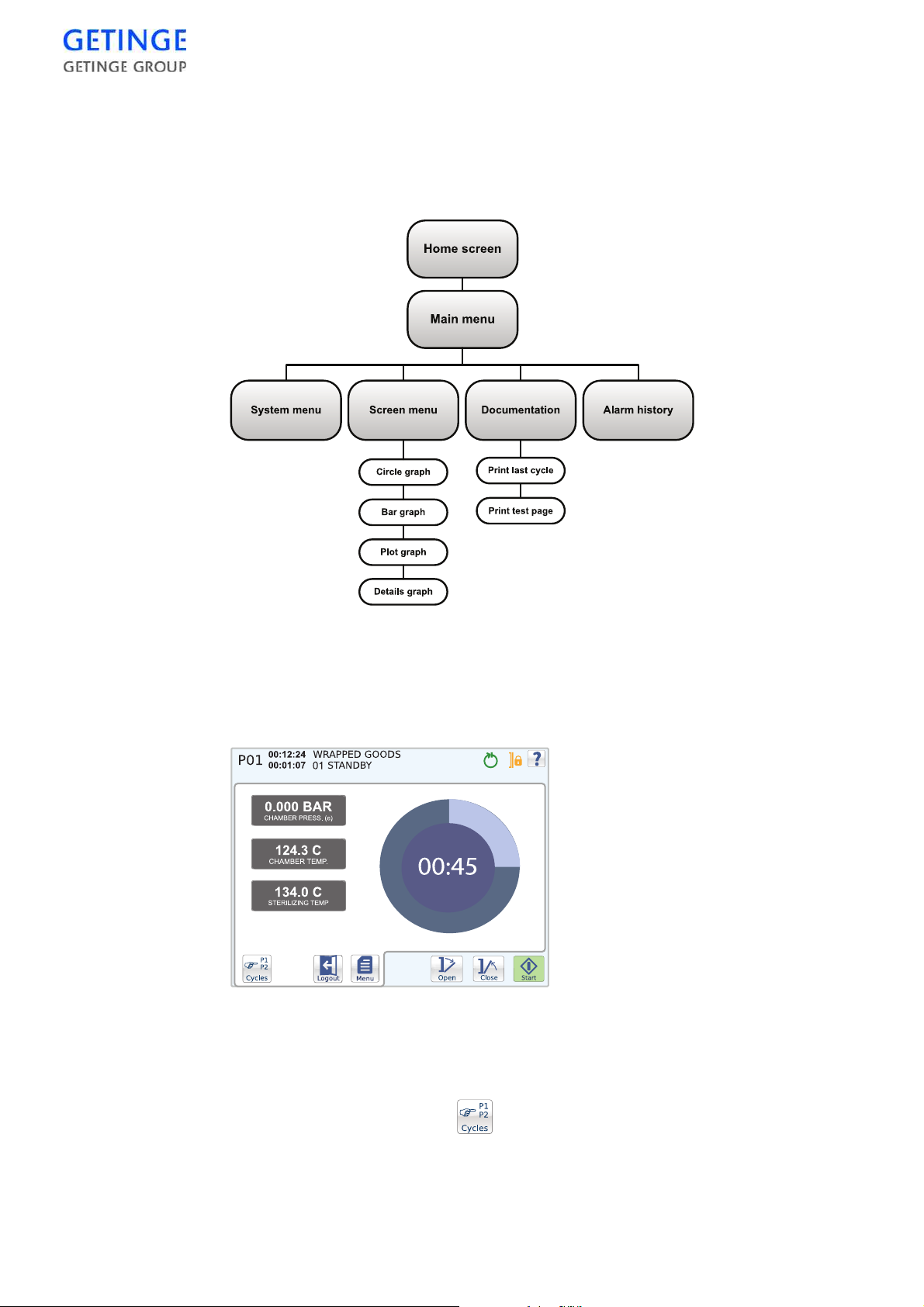

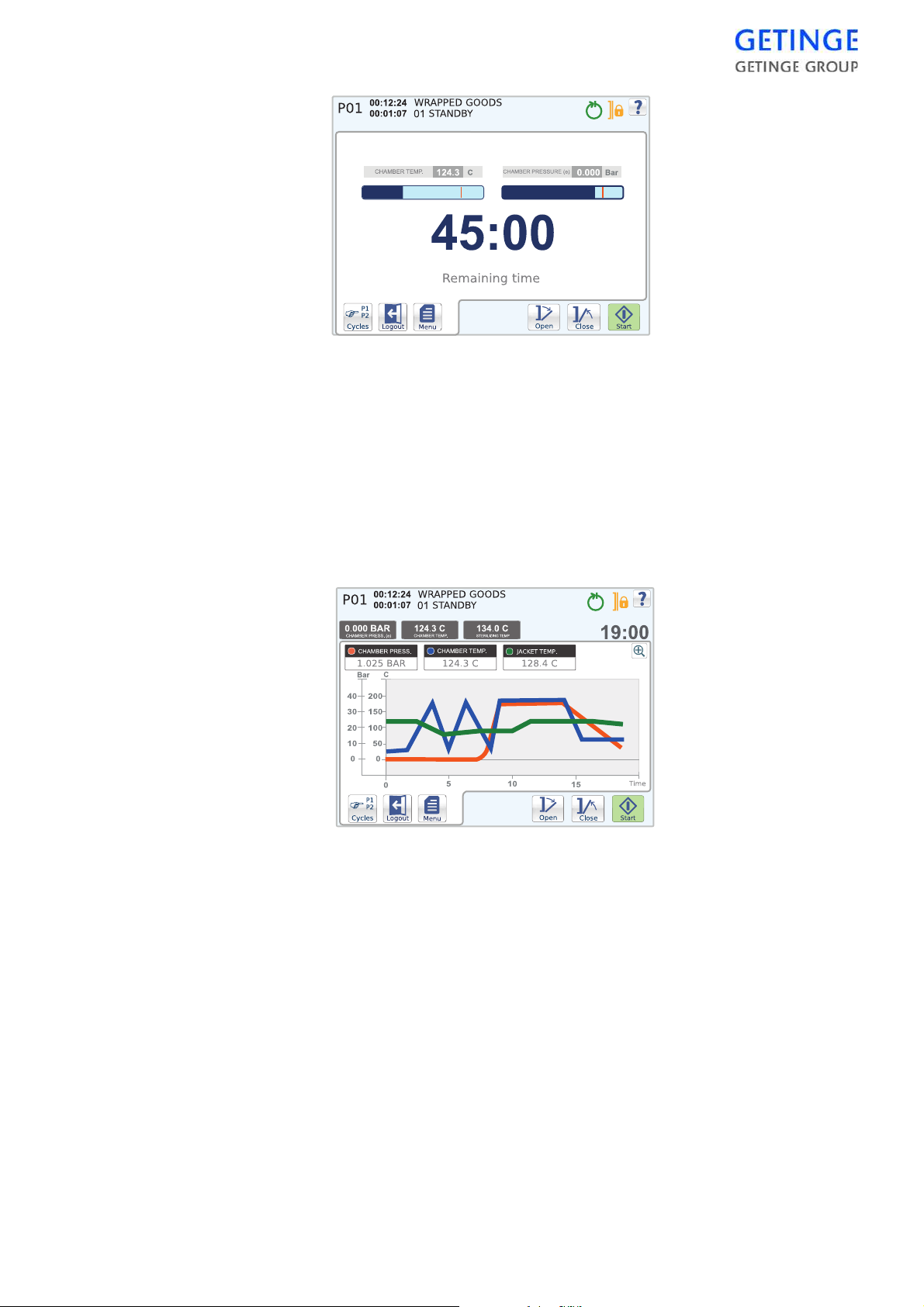

Screen

The screen can be divided into three areas: status field, middle field and

button field.

Status field

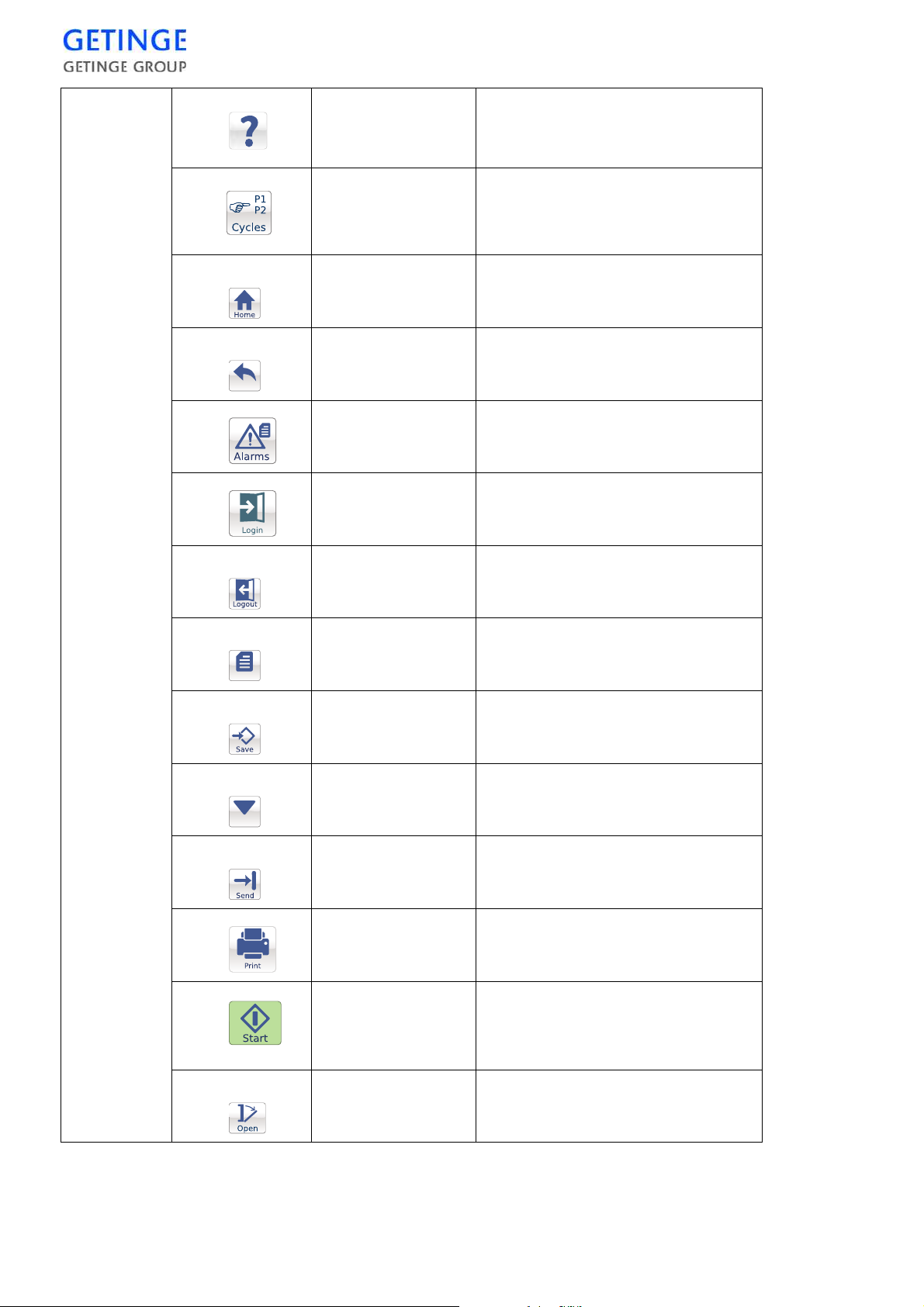

The status field is displayed in all cycle images. The field contains