GETINGE 88-SERIES

TECHNICAL MANUAL

502406700

SEV0647139-

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 2 of 148

Contents

FOREWORD ____________________________________________6

SAFETY REGULATIONS _________________________________7

Important _________________________________________________ 7

In an emergency ___________________________________________ 7

Product liability ____________________________________________ 7

Isolating device ____________________________________________ 7

INTRODUCTION ________________________________________8

Intended use of the machine _________________________________ 8

Attention symbols __________________________________________ 8

Residual current device (RCD) _______________________________ 8

Description _____________________________________________9

General ___________________________________________________ 9

Control system _____________________________________________9

Aborting program start ______________________________________ 10

Aborting a running program _________________________________ 10

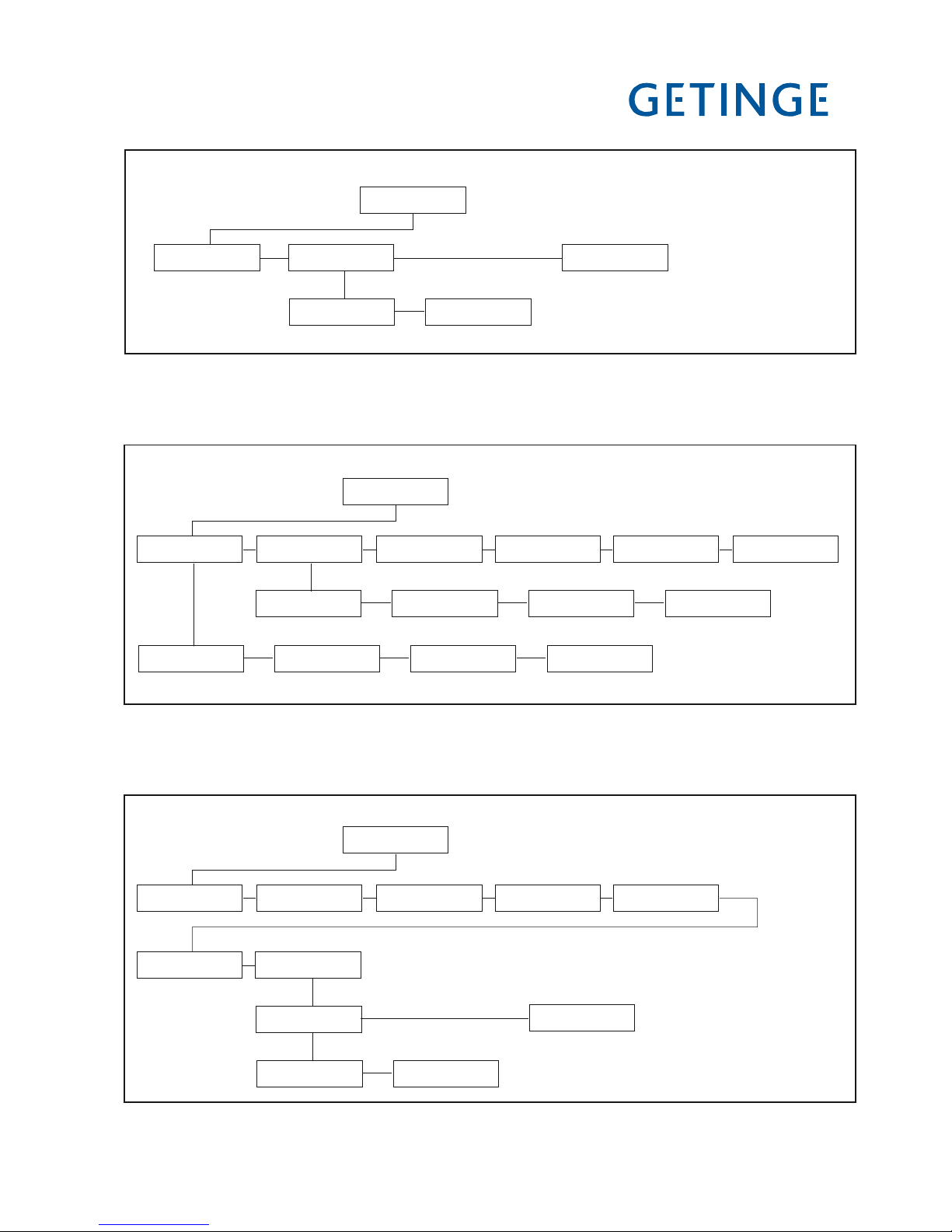

Schematic diagram _____________________________________11

Electric heating ____________________________________________ 11

Steam heating _____________________________________________ 12

Software description and settings ________________________13

Description _______________________________________________ 13

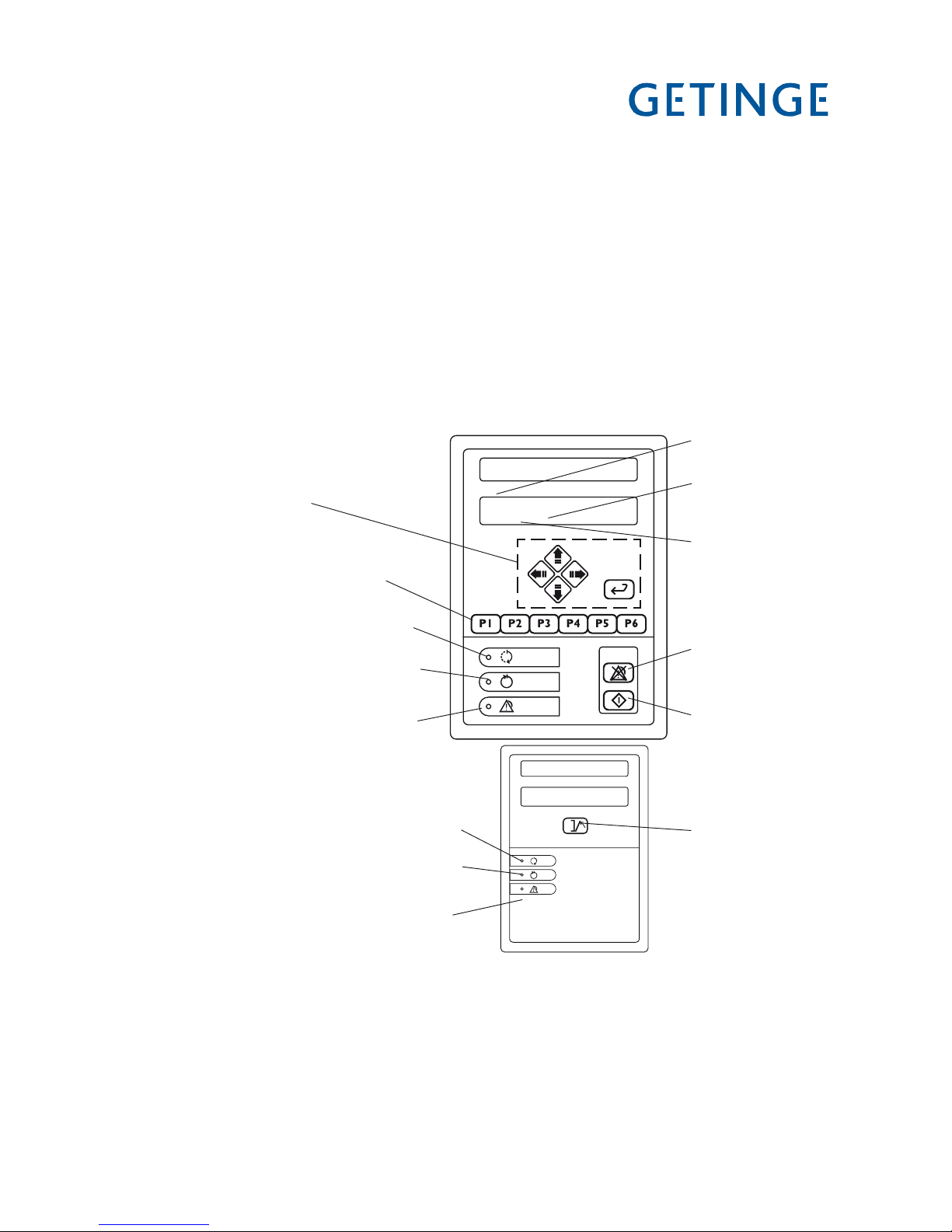

Control panel ___________________________________________14

Display ____________________________________________________14

Program selection buttons ___________________________________ 14

Menu selection buttons _____________________________________ 15

Scrolling in menus and lists __________________________________ 16

Field editing _______________________________________________16

Passwords ________________________________________________17

Menu tree ______________________________________________19

PREVENTIVE MAINTENANCE ____________________________58

General ___________________________________________________ 58

Periodic maintenance _______________________________________ 58

Function check _________________________________________59

Instruction manual, cable, switch _____________________________ 59

Filters and valves ___________________________________________ 59

Strainer ___________________________________________________ 59

Controls ___________________________________________________ 59

Insert for goods ____________________________________________59

Door ______________________________________________________ 60

Detergent dosing ___________________________________________ 60

Washing system ___________________________________________ 60

Temperature check _________________________________________60

Dryer _____________________________________________________ 60

Hoses ____________________________________________________ 60

Page 3 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Printer ____________________________________________________ 60

Cooling fans in electrical cabinets ____________________________ 60

Fault indications ________________________________________61

Handling alarms ____________________________________________ 61

Alarms ____________________________________________________ 62

Acknowledging a fault code ____________________________________62

Troubleshooting ________________________________________ 63

Repair and adjustment __________________________________70

Connecting a PC ___________________________________________ 70

Connections ____________________________________________ 71

Fixed scanner ______________________________________________ 71

Printers ___________________________________________________72

Custom FH190SP-24S3-0005 ___________________________________ 72

Printer configuration ___________________________________________73

Lexmark C524 ________________________________________________74

NetCom ___________________________________________________ 75

Connection AGS ___________________________________________ 76

Connection loader/unloader _________________________________ 77

Termination central dosing ___________________________________ 79

Potential free contacts ______________________________________ 80

Loading programs to flash memory ______________________81

Loading system programs ___________________________________ 81

Load language files _________________________________________ 84

Loading a new application into PACS _________________________ 85

With CS1000__________________________________________________85

Reloading the backup from “flash prom” to PACS ______________ 86

Without CS1000 _______________________________________________86

Cold start _________________________________________________ 87

Changing user language ____________________________________ 88

With user panel _______________________________________________88

With CS1000__________________________________________________88

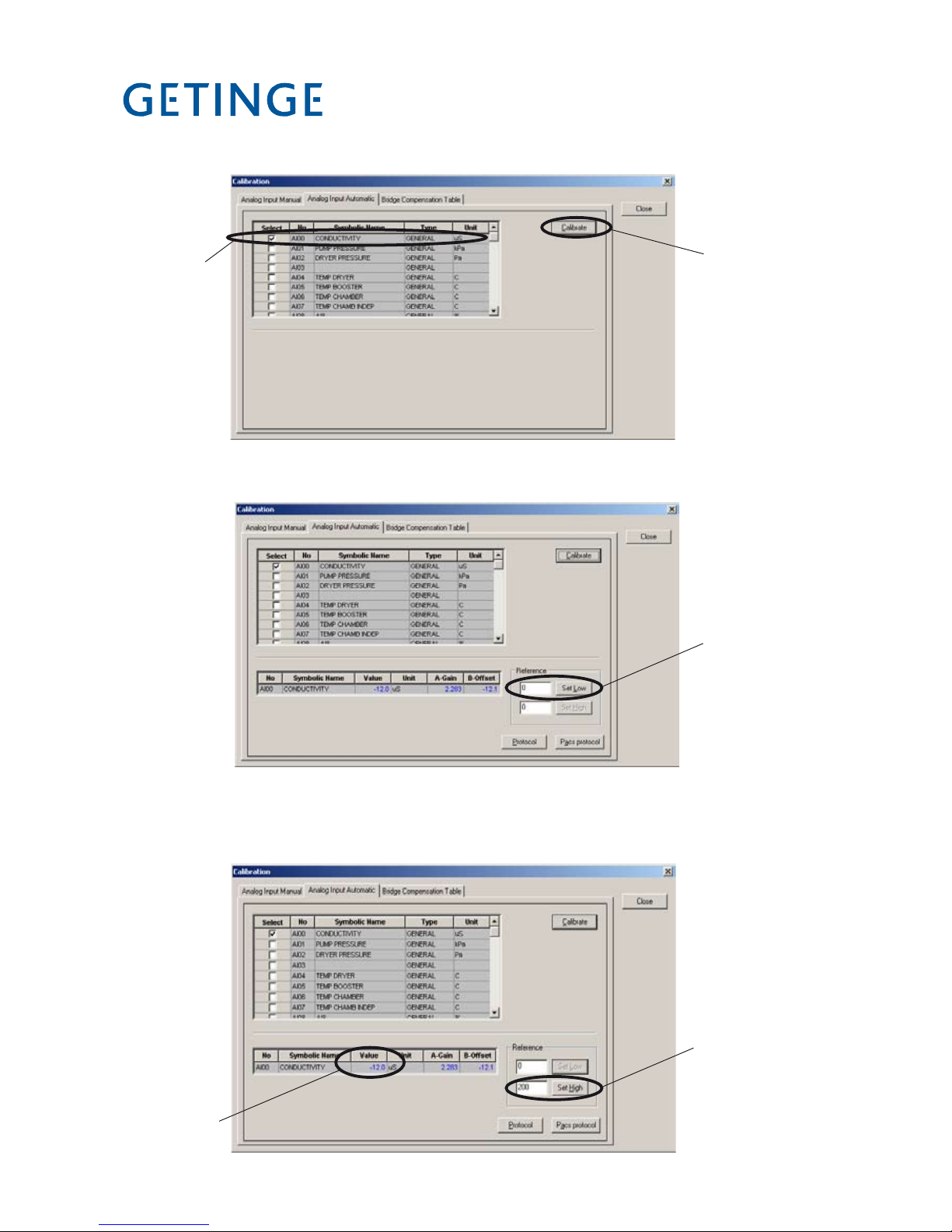

Calibration _____________________________________________89

Calibrating PACS conductivity __________________________________89

Pressure sensor for circulation pump _________________________ 92

Temperature sensors - with resistor ___________________________ 94

Temperature sensor - with ice bath and oil bath ________________96

Differential pressure gauge for dryer __________________________ 98

Dosing pumps and flow transmitters _____________________ 101

Calibration of flow transmitters _______________________________ 101

Trim panels _____________________________________________103

Clean side and soiled side ___________________________________ 103

Side panels ________________________________________________ 103

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 4 of 148

Replacing a temperature sensor _________________________104

In wash chamber and dryer __________________________________ 104

In a booster tank __________________________________________ 104

Door ___________________________________________________ 105

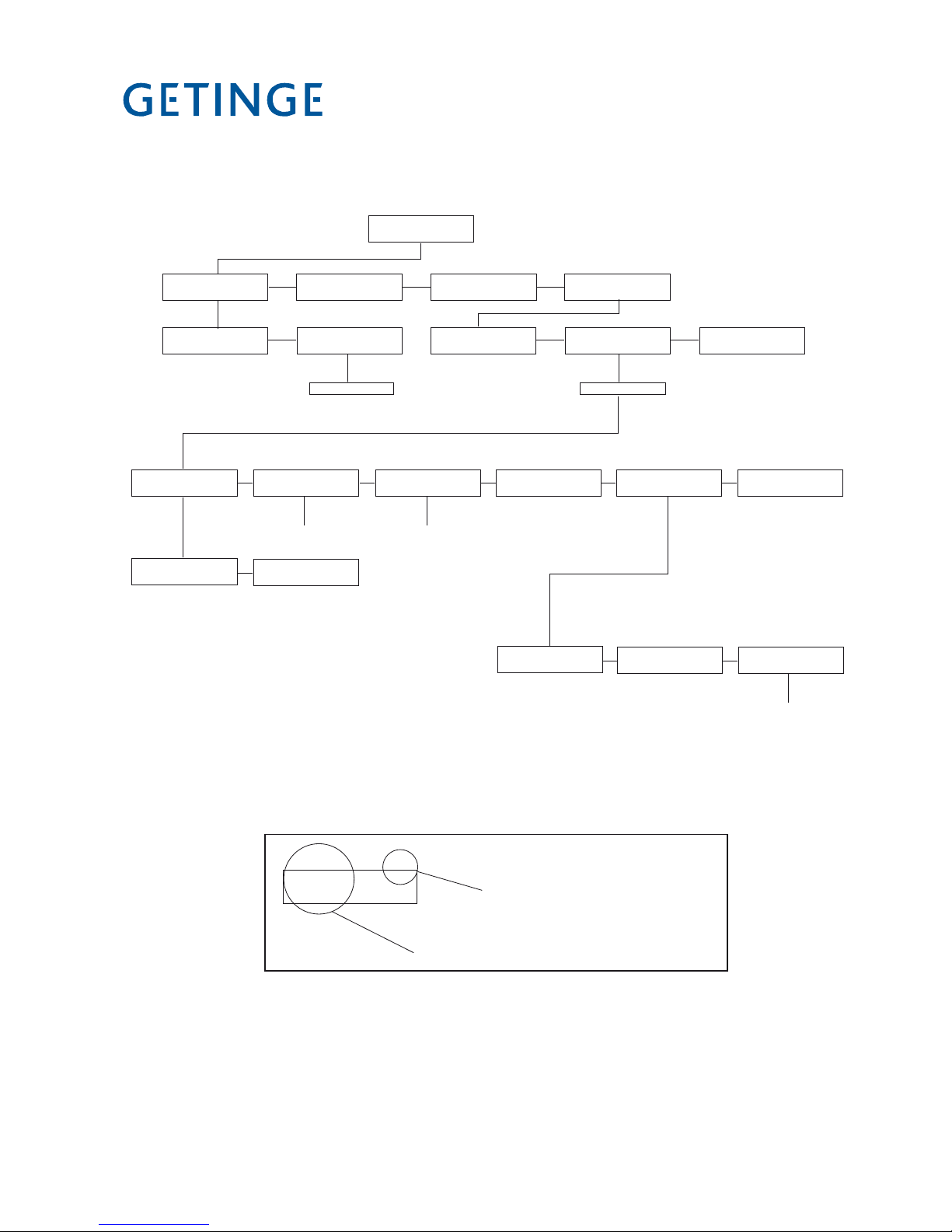

Position and operation, door switches ________________________ 105

Adjusting door switches _____________________________________ 106

Adjusting DOOR UP safety switch ____________________________ 107

Replacing the door seal _____________________________________108

Removing the door _________________________________________ 109

Adjusting the door closing force ______________________________ 110

Adjusting the door frame ____________________________________ 110

Overheat protection _____________________________________111

Replacing the overheat protection in the booster tank ______________111

Replacing overheat protection in the main pipe ____________________ 111

Cleaning the water and steam valve ______________________112

Water valve ___________________________________________________112

Steam valve __________________________________________________112

Dryer ___________________________________________________ 113

Changing the filter __________________________________________ 113

Fan replacement and checking _______________________________ 113

Check valves to main pipe ___________________________________ 113

Conductivity measurement (extra equipment) _____________114

Function in washing process _________________________________ 114

Measuring range ___________________________________________ 114

Check the output signal from conductivity meter __________________114

Setting the cell constant ________________________________________114

To set the cell constant, proceed as follows: ______________________114

Replacing the main board _______________________________115

Replacing the expansion board __________________________116

Replacing fuses _________________________________________ 117

Electrically heated _____________________________________________117

Steam heated _________________________________________________118

Replacing a hose to a hose pump ________________________119

Setting detergent and rinse-aid quantities ________________120

Servicing the booster tank _______________________________121

Booster tank with drain tap __________________________________ 121

Overheat protection ________________________________________ 121

Process valve and diaphragm ____________________________122

Checking __________________________________________________ 122

Adjusting (adjustment allowances) ____________________________ 122

Repair ____________________________________________________ 122

Replacing the diaphragm ____________________________________ 122

Page 5 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Booster pump __________________________________________123

Process tank ___________________________________________124

Draining the process tank ___________________________________124

Replacing a sensor _________________________________________ 124

Cleaning __________________________________________________ 124

Disinfecting the process tank ________________________________ 124

Volume calibration __________________________________________ 124

Hose routing for process tank with top connection _________________125

Hose routing for process tank with floor connection________________126

Drain valve _____________________________________________127

Checking __________________________________________________ 127

Adjusting (adjustment allowances) ____________________________ 127

Repair ____________________________________________________ 127

Replacing the diaphragm ____________________________________ 127

Waste tank _____________________________________________ 128

Replacing and adjusting sensors _____________________________ 128

Manual cleaning ____________________________________________ 128

Drain pump _____________________________________________129

Checking _________________________________________________ 129

Replacement ______________________________________________ 129

Water valves ____________________________________________130

Replacing a filter ___________________________________________ 130

Replacing the valve _________________________________________ 130

Steam valves and condensation traps ____________________131

Replacing and cleaning filters ________________________________ 131

Replacing a steam hose ____________________________________ 131

Detergent cabinet _______________________________________132

Dosing pump and flow transmitter ____________________________ 133

Replacing a dosing pump ___________________________________133

Replacing a flow transmitter _________________________________ 133

Replacing a pressure sensor _____________________________ 134

Replacing the differential pressure sensor ________________135

Frequency converter ____________________________________136

Replacement ______________________________________________ 136

Configuration ______________________________________________ 137

Electrical diagrams _____________________________________143

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 6 of 148

© Copyright

The content of this manual must not be copied, in

whole or in part, without the written consent of Getinge.

FOREWORD

This service manual is intended for maintenance and service personnel working with

Getinge 88-series washer disinfectors.

The service manual is divided into the following sections:

Safety regulations•

Introduction to the machine•

Software description and menu tree•

Preventive maintenance•

Fault indications and troubleshooting•

Repair and adjustments•

Electrical diagram of the washer disinfector•

Monitoring system (Option)•

Electrical diagram of the monitoring system•

The purpose of the service manual is to provide information for the maintenance and

servicepersonnelwhosejobitistoensuresafeoperationwithoptimumefciency.

See under Intended use on page 8.

Before starting work on the machine, the maintenance and service personnel must have

read the safety instructions in this manual and familiarized themselves with the operation

of the machine and its safety instructions. They must also have done a service training

course at Getinge Academy

Read the safety instructions in the service manual before starting work on

the machine.

The information in this manual describes the machine as dispatched from Getinge.

There may be differences due to customization.

The machine is accompanied by the following documentation:

User manual•

Installation manual•

Technical manual (this book)•

Spare parts list•

Goods positioning instructions•

The goods positioning instructions supplied must be put up in a clearly visible position

at the time of installation.

Getingereservestherighttochangethespecicationanddesignwithoutpriornotice.

The information in this manual was up to date on the date of issue of the manual.

Page 7 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

SAFETY REGULATIONS

This machine has been designed with a number of built-in safety devices. To avoid injury, it

is highly important not to bypass or disable these safety devices. If the equipment is used in a

mannernotspeciedbythemanufacturerthiscanimpairthesafetyequipmentonthemachine.

NOTE:

Before starting any servicing or maintenance work on the machine, isolate it from the

incoming electrical supply, shut off water and steam supplies and drain the process,

booster and waste tanks.

Important

Take care when handling the chemical agent used in the machine. Read the details •

on the container or contact the manufacturer:

- if the agent comes into contact with the operator’s eyes or skin or if the vapors are

breathed in, etc.

- about storing the agent and disposing of empty containers.

The machine must be connected in accordance with the installation instructions. •

(Check against the rating plate)

The machine may only be operated by adults.•

Installation and service work must be done by personnel trained in the use of this machine.•

Never bypass the door switch of the machine.•

Leakage in the system, due to a worn door seal for example, must be repaired without delay.•

Before repair or service work is done, the personnel concerned must study the rel-•

evant handbooks and service manuals.

Before welding begins on or close to the machine, all wiring connected by plugs •

and sockets must be disconnected from all circuit boards in the machine.

The machine must not be hosed down with water.•

Take care when using corrosive detergents.•

Precautions must be taken with hot water and steam.•

Run a program with disinfection before starting servicing work. If this is not pos-•

sible, disinfect the machine with disinfectant before starting servicing work.

Before starting servicing work on the machine, make sure that the tanks (booster •

tank, process tank, chamber and waste tank) do not contain any water.

Before starting any servicing or maintenance work on the machine, isolate it from •

the incoming electrical supply, shut off water and steam supplies and drain the

process, booster and waste tanks.

Spare parts may only be obtained from Getinge EDC.•

In an emergency

Switch off the main switch•

Close stopcocks in the water and (where present) steam supply lines.•

Product liability

AnymodicationorincorrectuseoftheequipmentwithouttheapprovalofGetingeDisinfection AB invalidates Getinge Disinfection AB’s product liability.

This product was manufactured by:

GETINGE DISINFECTION AB

Ljungadalsgatan 11, Box 1505

351 15 Växjö, Sweden

Isolating device

Themachinemustbettedwithaseparate,lockableisolatingdeviceintheelectricpower supply. The isolating device must be easily accessible on a wall close to the machine.

The installation must conform to and be marked in accordance with local provisions.

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 8 of 148

INTRODUCTION

Intended use of the machine

Getinge S-88 series machines are washer disinfectors intended for cleaning, disinfection

anddrying.Intendedeldsofapplicationaresurgicalinstruments(solidandtubular),

dishes,handbowls,glassgoods,suctionasks,babybottles,anaesthesiaequipmentand

OP shoes. Depending on program design.

Validation of goods according to intended use is done with Getinge Disinfection AB’s

standard loads.

AnInstallationQualication,anOperatingQualicationandaPerformance

QualicationaccordingtoISO15883mustbecarriedoutbeforeputtingthemachine

into service.

Incorrect use can result in damage to objects and personal injuries

Attention symbols

Some of the warnings, instructions and advice in this manual are so important that we

use the following special symbols to draw attention to them. The symbols used are as

follows:

This symbol indicates a warning in the service manual. It warns of a hazard that

may lead to more or less severe injury and in certain cases mortal danger.

It also highlights warnings to avoid damage to equipment.

This symbol highlights a warning in the text of the service manual dealing

with the handling of components sensitive to ESD. The hazard that it warns

about may result in damage to hardware and/or circuit boards.

This symbol highlights the risk of injury by burning.

The part or the surface may be very hot.

This symbol shows that voltage is or may be present in the machine or parts

of the machine.

Residual current device (RCD)

If it is intended to use a residual-current device (RCD)(30 mA personal protection) with

the machine, the RCD must be of class 4P B.

Page 9 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Description

General

A description of the mechanical design and general functions of the machine is

given the instruction manual. This section contains a general description of the

control system. For detailed information about the software and its settings, see the

chapter entitled Software description and settings.

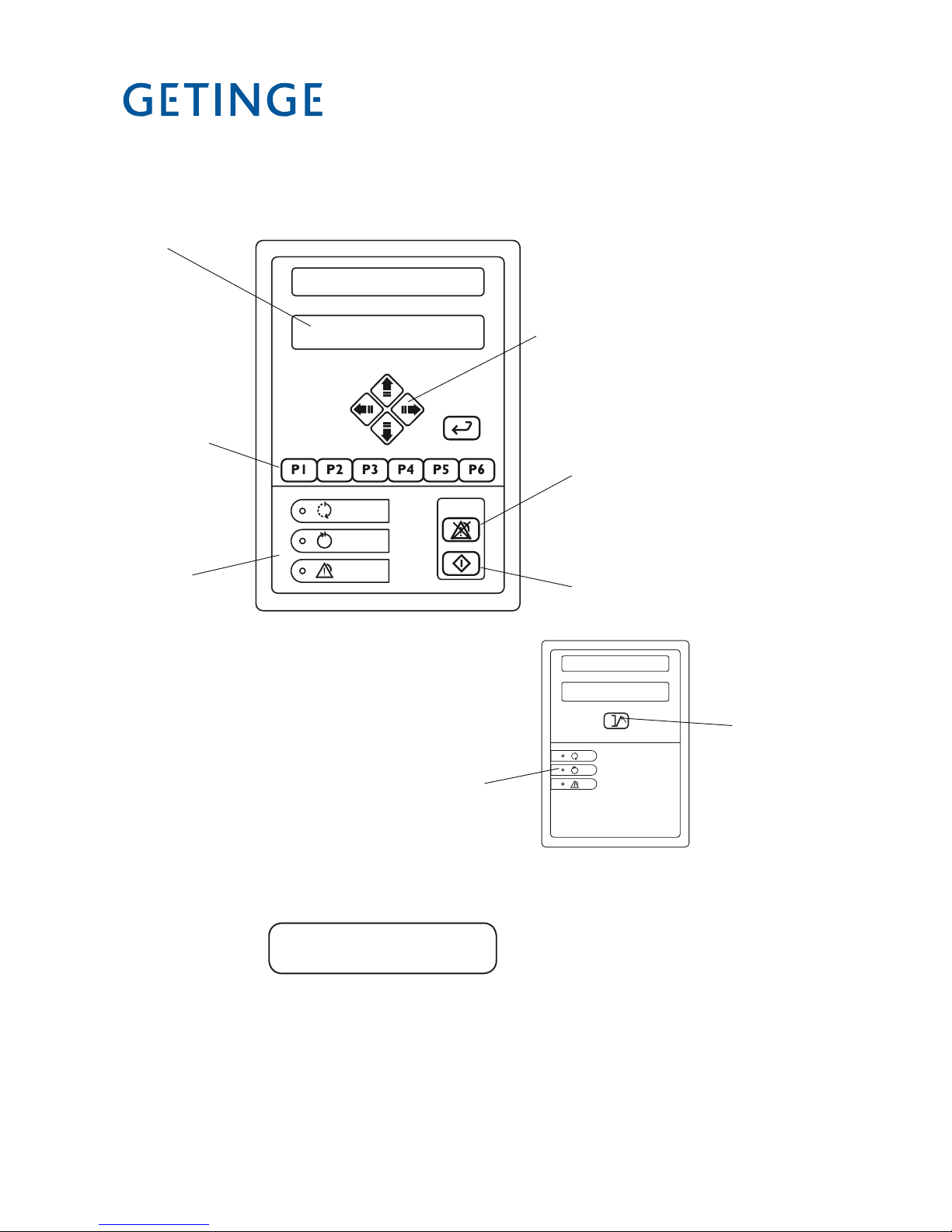

Control system

The machine has an electronically programmable control system which can hold 12 programs. The control system is operated from the control panels of the machine, to the left

of the door on the soiled side.

Six of these programs can be started with the program selection buttons. With 1-6

you can choose up to six programs. If the control system has more programs, the subsequent ones are chosen from a scrollable list. You can reach the list of available programs

(from standby mode), by pressing S twice and choosing a program with J or H.

ConrmthechosenprogramwithS .

The machine comes with a number of standard programs in the programmer (see the

appendixforStandardprograms).Parametersintheseprogramscanbemodiedtosuit

the needs of individual users. Individual programs can be created with a PC. An entire

standard program or parts of one can be used as a starting point for programming.

Programming may only be done by an authorized service technician.

P01 OP-D

60.0C 3

Menu selection buttons

(see Software description

and settings)

Start button for

wash program

Program selection buttons

V1363

Alarm reset button

Green lamp: Program complete

Yellow lamp: Program running

Red lamp: Fault code indication

Actual temperature

in the chamber

Phase of the process

Program number

Panel, clean side

P01 OP-D

60.0C 3

Green lamp: Program complete

Yellow lamp: Program running

Red lamp: Fault code indication

Open/close the

door.

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 10 of 148

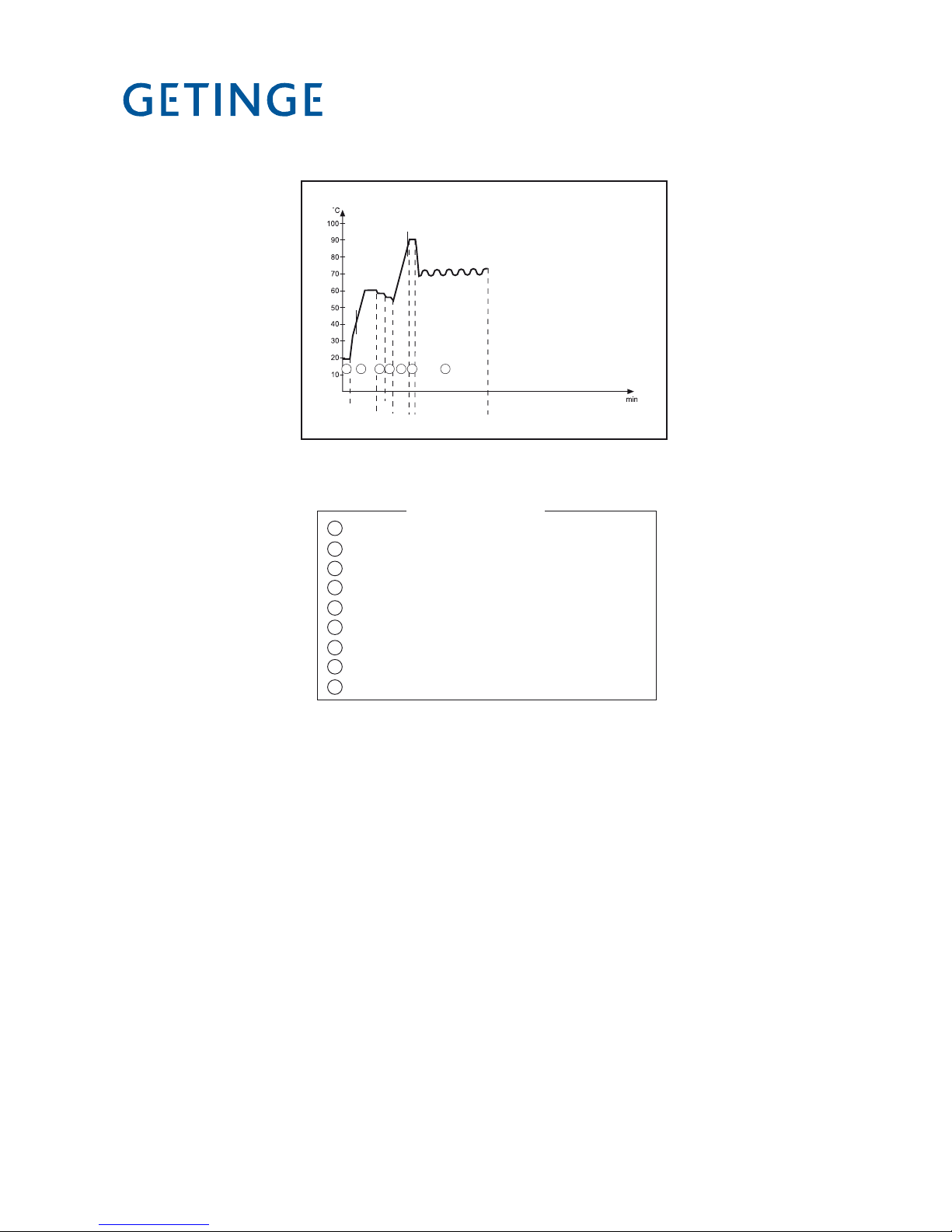

P02

1 Pre-rinse 1

2 Pre-rinse 2

3 Wash

4 Neutralization

5 Post-rinse 1

6 Post-rinse 2

7 Final rinse

8 Disinfection

9 Drying

Program cycles

A Alkaline detergent

B Neutralization

C Instrument milk

(extra equipment)

If instrument milk is

dosed, neutralization

is not dosed.

D Chemical disinfection

Programs are chosen with the program selection buttons and the program is started with

V (starting of a program is indicated by the yellow lamp at Mashingfor5secondsand

then going out). When the program is complete, a green lamp lights up at N and the clean-

side door opens automatically. (The door can stay closed after completion of the process by

a setting in the program. In this case the door is opened via the OP panel on the clean side).

The illustration at the top of the page shows the program sequence in the OP-D program.

Aborting program start

A started program can be aborted within 5 seconds of the machine starting to close the

door on the soiled side. To abort a started program, press V again. During the period

whentheprogramcanbeaborted,ayellowlampashesatM. The door is unlocked and

opened automatically and the machine can be restarted in the usual way.

Aborting a running program

While a program is running, the machine can be stopped with the main switch. This

cuts off the power supply and fault code F00 POWER FAIL is displayed. The alarm is

acknowledged by normal acknowledgement (see the user manual).

CW

+HW

CW HW HW HW

3 5 6 79

A

B

1 8

*The times may vary because of different media.

*

Page 11 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

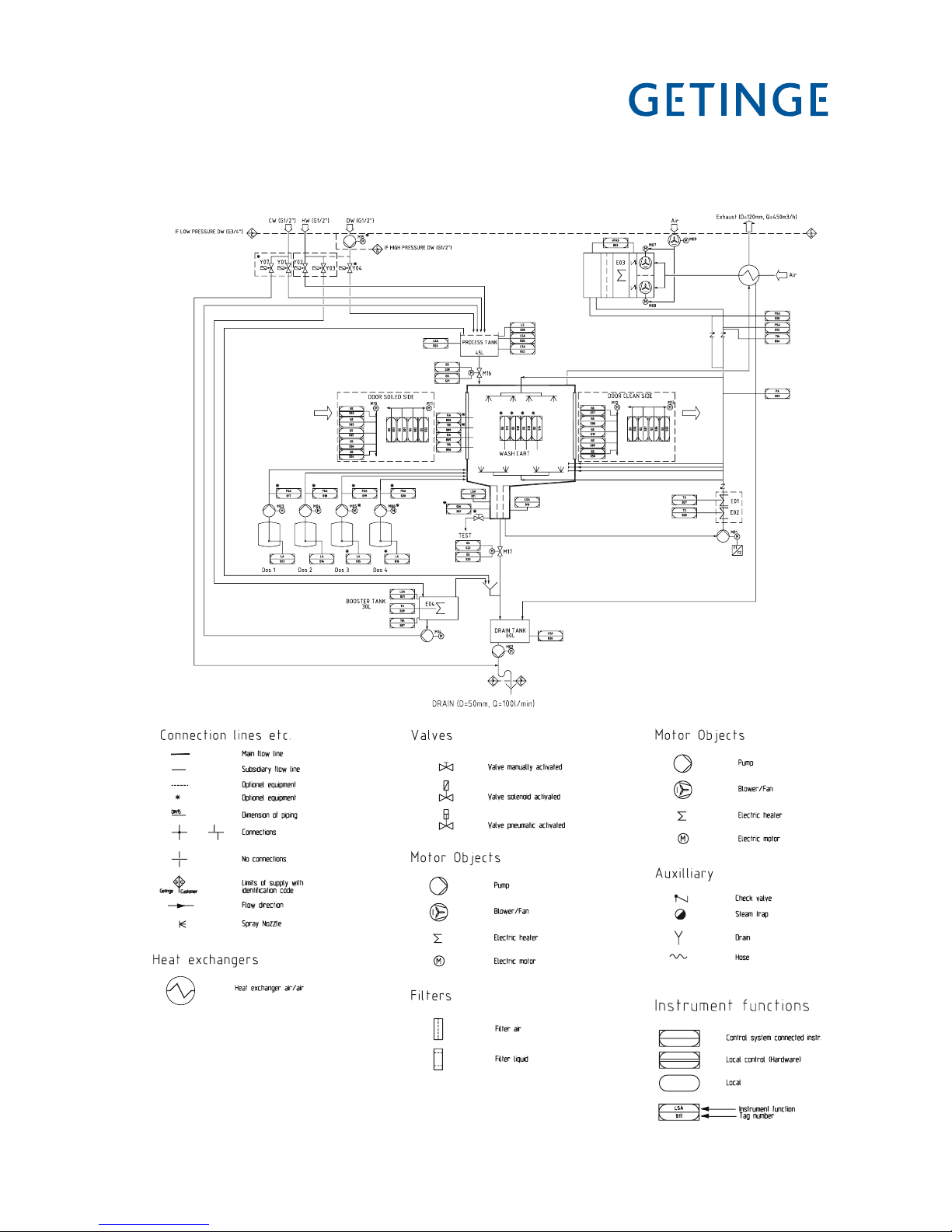

Schematic diagram

Electric heating

Explanation of symbols

V1560

J001

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 12 of 148

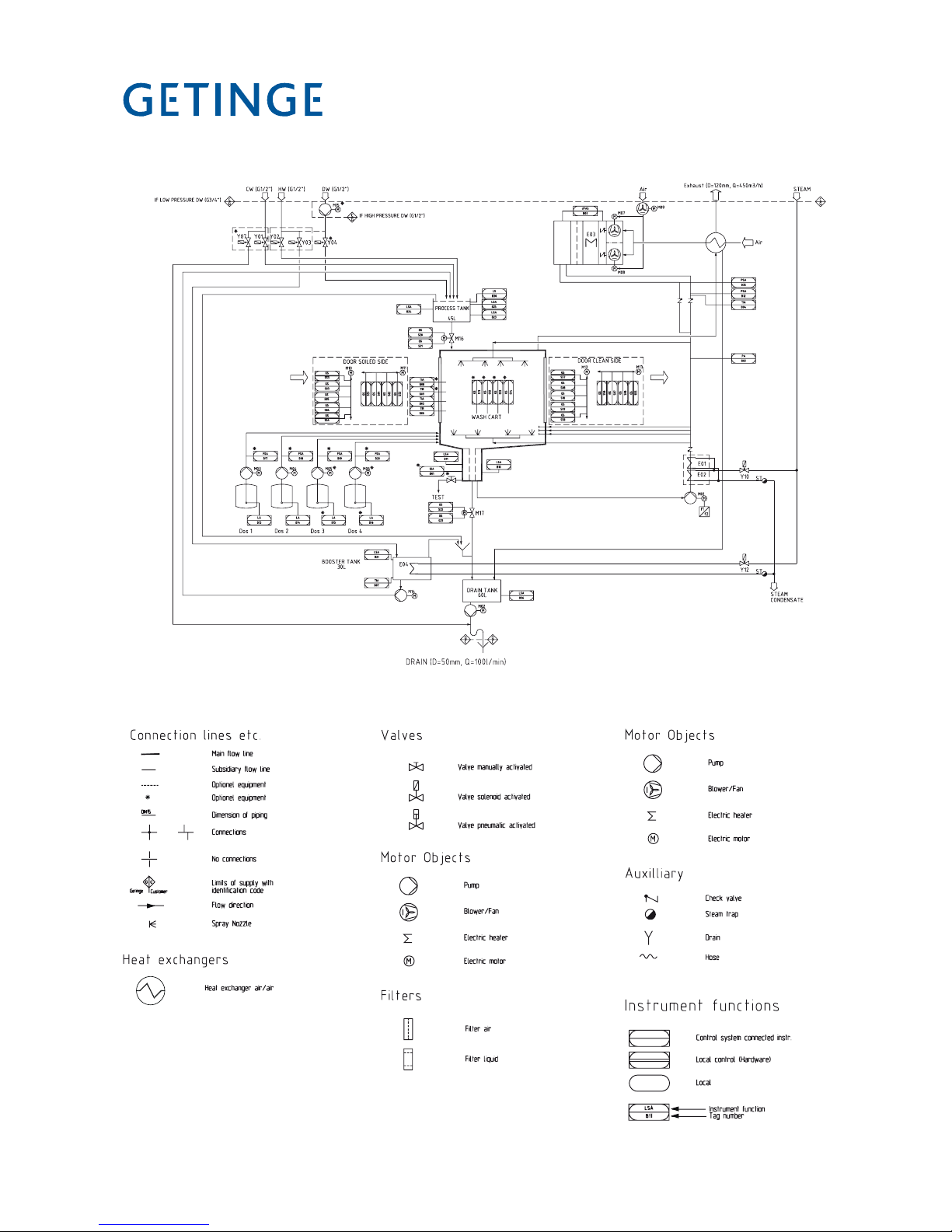

Steam heating

Explanation of symbols

V1560

J002

Page 13 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Software description and settings

Description

This section describes the PACS 350 control and monitoring system. The purpose of the

control system is to monitor safety and gather information and send it to the executive

components of the washer-disinfector so that a number of disinfection processes can be

performed in accordance with a predetermined template. The order signals are worked

out by the computer program of the control unit in conjunction with measurements of

actual parameter values for the current program. These are usually times, temperatures

and pressures.

Process selection

Several different pieces of equipment can be connected to the control unit for programming, monitoring and documenting the disinfection processes.

The operator communicates with the control unit via a control panel or an ordinary PC.

All operator panels can be used to monitor the processes, since they display all the set

parameter values as well as actual values on request.

Programs,systemdenitionsandprocessdatacanbedocumentedbyconnectinga

printer to the unit. A host computer can also be connected directly to the CPU of the

control system.

When the need arises, a measuring and monitoring system entirely independent of the

control system can be set up by connecting a PACS MONITORING SYSTEM, consisting of CPU, operator panel and connections to the control unit CPU.

The computer contains programs for calibration of the temperature and pressure sensors.

Where alternative correction constants are known, they can be entered manually. The

testing functions include means of activating analog and digital outputs and for reading

analog and digital inputs.

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 14 of 148

Control panel

The buttons on the control panel are used to choose programs, navigate the menu tree,

acknowledge fault codes, etc.

Menu selection buttons

Program selection

buttons

V1363

Button to acknowledge

an error message

Button to start

wash programs

Display

Display

The display has two lines, each with a capacity of 20 characters.

P01 OP-SHORT-D

47.0 °C 126

Information or error messages appear on the bottom line and replace the text that would

otherwise appear here.

Program selection buttons

With 1-6 you can choose up to six programs. If the control system has more pro-

grams, the subsequent ones are chosen from a scrollable list. You can reach the list of

available programs (from standby mode), by pressing S twice and choosing a program with J or H.ConrmthechosenprogramwithS .

Indicator lamps

Panel, clean side

P01 OPD

Open the

door.

Indicator

lamps

Panel, soiled side

J018

Page 15 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Menu selection buttons

Therearevebuttonsfornavigatingthepanel.Thesexedbuttonsarefourarrowbut-

tons that control the cursor (I,K, J and H) and S.

I•• Used to go back one step (up one level) in menus.

If the button is held down for a little longer, you are returned to

the main menu. It also moves the cursor.

K•• Moves the cursor. Not used in menus and lists.

J•• Shows the next object in the list.

H•• Shows the previous object in the list.

S•• Goestothechosenobjectinthelistoropensaeldforediting

ifthereisaneditableeld.

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 16 of 148

Scrolling in menus and lists

You can use I, K, J and H to scroll through menus and lists.

You can scroll either line by line or two lines at a time, depending on what is displayed.

The top line of the list may look like the example below.

The angle bracket “>” to the left of the top line shows which object will be chosen if you

press S. Bottom right there is a ”

^

” indicating that there are more objects in the list

which are displayed if you press J.

This is what you see if you are in a list. The “arrows” to the right show that there are

objects both above and below the displayed line.

When you reach the end of the object list, only one up-arrow appears at the right edge of

the display. Menus and lists are “endless”; you can reach the top of the list by pressing

J at the end of the list.

Field editing

Sopensthechoseneldforediting.ThecontentoftheeldischangedwithH

or J.Thesearrowkeysscrollinanendlesslistcontainingnumbers.Whenaeldis

openedforediting,therstcharacterishighlighted.TomovethecursoruseIor K.

Entered values are saved when you press S. On saving, the system checks that the

value is in the permitted range.

>PRINT LAST PRG.

SYSTEM

>SYSTEM ^

APPLIANCE INFO

SYSTEM ^

>APPLIANCE INFO

^

^

Page 17 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Passwords

There are four passwords with different levels of authorization in the system program.

The operator password has the lowest authority; the programming password has full

authority.

The following password levels are as follows:

Operator - code 558387.•

Supervisor - contact service for code.•

Service - contact service for code.•

Programming - contact service for code.•

Note: In the menu tree, where a password must be entered, there is a letter code (between PW: A-K) which indicates which function the respective password level gives

authorization for.

When a password is being entered, the top line shows “ENTER PASSWORD”. Press

Stoopentheentryeldforediting.EachdigitcanbechangedwithJ and H.

I and K toggle between the digits. Press Stoconrmtheenteredpassword.

Ifthewrongpasswordisentered,“WRONGPASSWORD”appearsontherstline.

Press S to return to the display that shows “ENTER PASSWORD”

Note: The password cannot be changed.

Operator

Supervisor

Code in menu tree Authority to change

A Parameters of type A and to see parameters of type I.

D Acknowledge alarms

Code in menu tree Authority to change

A Parameters

B Calendar (time and date)

C Sensor calibration

D Acknowledge alarms

H Process-criticalcongurations,parametersoftypeP.

J Passwordconguration

K Documentation

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 18 of 148

Service

Programming

Code in menu tree Authority to change

A Parameters.

B Calendar (time and date)

C Sensor calibration

D Acknowledge alarms

E Service messages

F DIP switches

G Non-process-criticalsystemcongurations

H Process-criticalcongurations,parametersoftypeP.

J Passwordconguration

K Documentation

Code in menu tree Authority to change

A Parameters.

B Calendar (time and date)

C Sensor calibration

D Acknowledge alarms

E Service messages

F DIP switches

G Non-process-criticalsystemcongurations

H Process-criticalcongurations,parametersoftypeP.

I Programming (phases and programs)

J Passwordconguration

K Documentation

Page 19 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

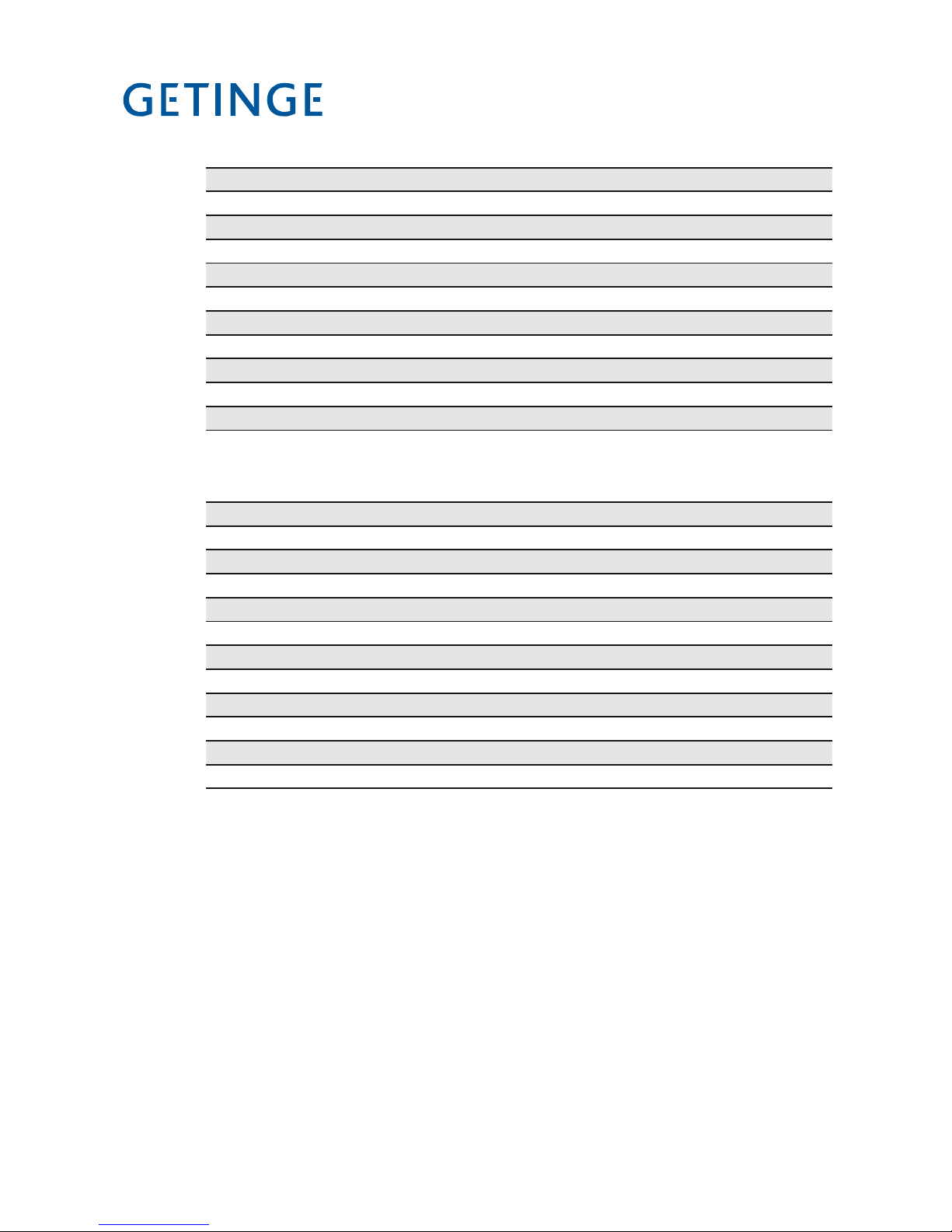

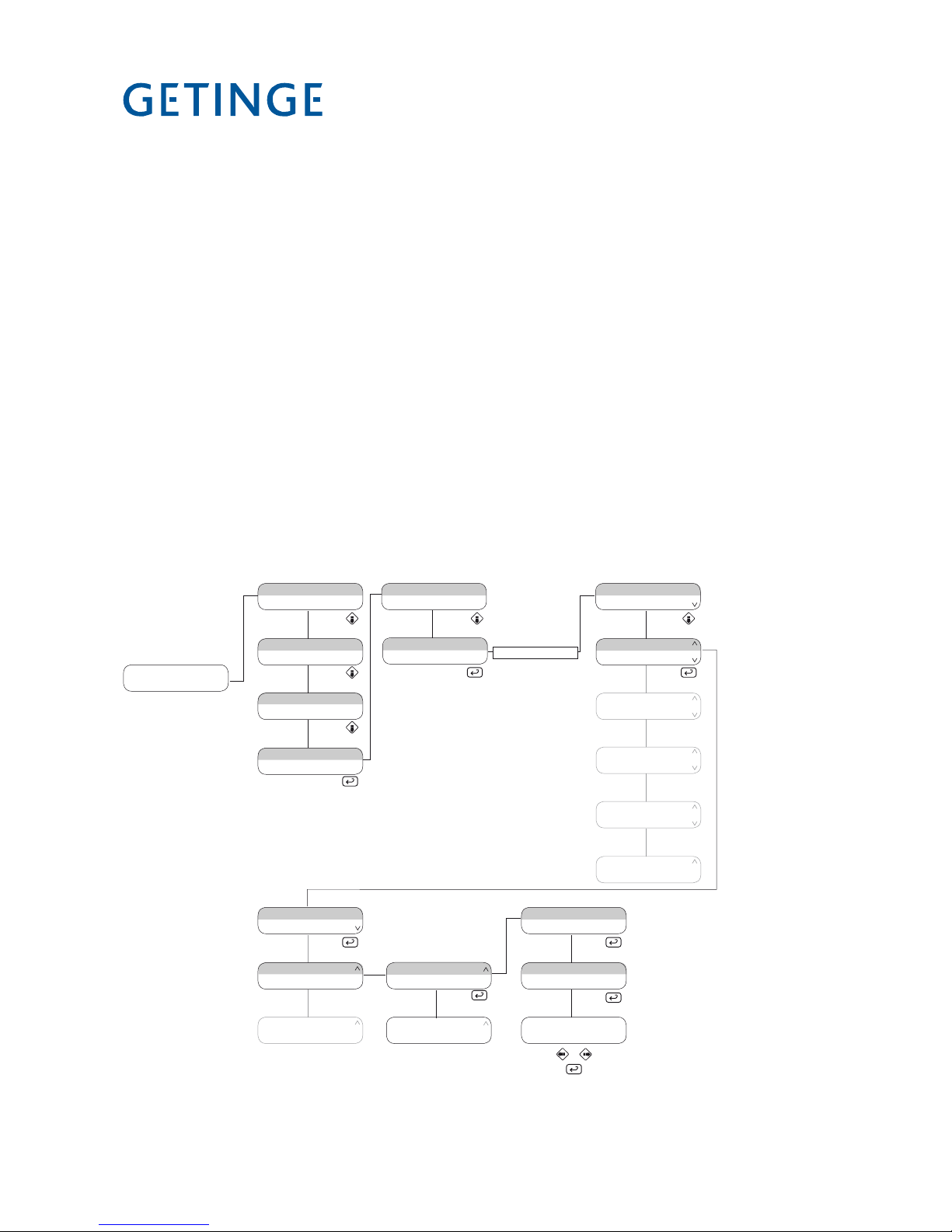

Menu tree

Menu tree _________________________________________________ 20

Main menu 1, Program name (1.1) _______________________________22

Choose a program _____________________________________________22

Change parameters (1.1.2) ______________________________________23

Main menu 2, Machine name (1.2) _______________________________23

Machine information (1.2) _______________________________________23

Main menu 3, Cycle counter (1.3) ________________________________24

Variable list (1.3.1…) ___________________________________________24

Main menu 4, Settings (1.4) ____________________________________25

Print parameters of the chosen cycle (1.4.1) ______________________25

System menu (1.4.2) ___________________________________________25

Calendar menu (1.4.2.1) ________________________________________25

Time menu (1.4.2.1.1) __________________________________________26

Date menu (1.4.2.1.2) __________________________________________ 26

Calibration menu (1.4.2.2) ______________________________________27

Manual calibration menu (1.4.2.2.1) ______________________________27

Automatic calibration menu (1.4.2.2.2) ___________________________28

Calibrate the chosen sensor (1.4.2.2.2.1) _________________________ 28

Choose a sensor (1.4.2.2.2.2) ___________________________________29

Compensation table menu (1.4.2.2.3) ____________________________30

Configuration menu (1.4.2.3) ____________________________________30

Language menu (1.4.2.3.1) _____________________________________30

Date format menu (1.4.2.3.2) ____________________________________31

Unit of pressure menu (1.4.2.3.1.3)_______________________________32

Temperature unit menu (1.4.2.3.1.4) ______________________________33

Printer menu (1.4.2.3.2) ________________________________________ 34

Print mode menu (1.4.2.3.2.1) ___________________________________34

Slow interval menu (1.4.2.3.2.2) _________________________________ 35

Fast interval menu (1.4.2.3.2.3) _________________________________36

Transfer speed menu (1.4.2.3.2.4) _______________________________37

Alarm clock menu (1.4.2.3.3) ____________________________________37

PACS address menu (1.4.2.3.4) _________________________________38

Communication settings COM0 (1.4.2.3.5.1) ______________________39

Communication settings COM1 (1.4.2.3.5.2) ______________________40

Communication mode COM2 (1.4.2.3.5.3) ________________________41

Change cycles (1.4.2.3.6.1) _____________________________________42

DIP switch menu (1.4.2.4) ______________________________________43

Service menu (1.4.2.5) _________________________________________44

Fault log menu (1.4.2.5.1) _______________________________________44

Service message menu (1.4.2.5) _________________________________ 45

Diagnostics menu (1.4.2.5.3) ____________________________________45

Test analog in menu (1.4.2.5.3.1) ________________________________46

Test analog out menu (1.4.2.5.3.2) _______________________________47

Test digital in menu (1.4.2.5.3.3) _________________________________48

Test digital out menu (1.4.2.5.3.4) ________________________________49

Test user flag menu (1.4.2.5.3.5) _________________________________50

Test printer (1.4.2.5.3.7) ________________________________________51

Test LED/buzzer display (1.4.2.5.3.8) _____________________________ 52

Save RAM in flash menu (1.4.2.6) ________________________________ 53

Appliance info (1.4.3)___________________________________________53

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 20 of 148

Menu tree

P01 PROGRAM NAME

60.0 C 0

01 MACHINE NAME

02 PHASE NAME

CYCLE COUNTER

00000

SETTINGS

GETINGE PACS 350

VERSION 3.51 (0283)

1.1 1.2 1.3 1.4

SELECT PROGRAM. CHANGE PARAMETERS

ENTER PASSWORD *

SYSTEM APPLIANCE INFO

ENTER PASSWORD *

PRINT LAST PRG

CALENDAR CALIBRATION CONFIGURATION DIP SWITCHES

1.4.2.1 1.4.2.2 1.4.2.3 1.4.2.4

1.1.1 1.1.2 1.4.1 1.4.2 1.4.3

SERVICE

1.4.2.6

SAVE RAM IN FLASH

TIME HH:MM:SS

1.4.2.1.1

DATE YYYY/MM/DD

1.4.2.1.2

See 1.4.2.2

Calibration

See 1.4.2.3

Configuration

SERVICE MESSAGES

1.4.2.5.2

ERROR LOG

1.4.2.5.1

DIAGNOSTICS

1.4.2.5.2

See 1.4.2.5.3

Diagnostics

Shows which menu group the menu belongs to

ERROR LOG

1.4.2.5.1

Shows which process the choice relates to

* Operator password required

** Service personnel password required

Page 21 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

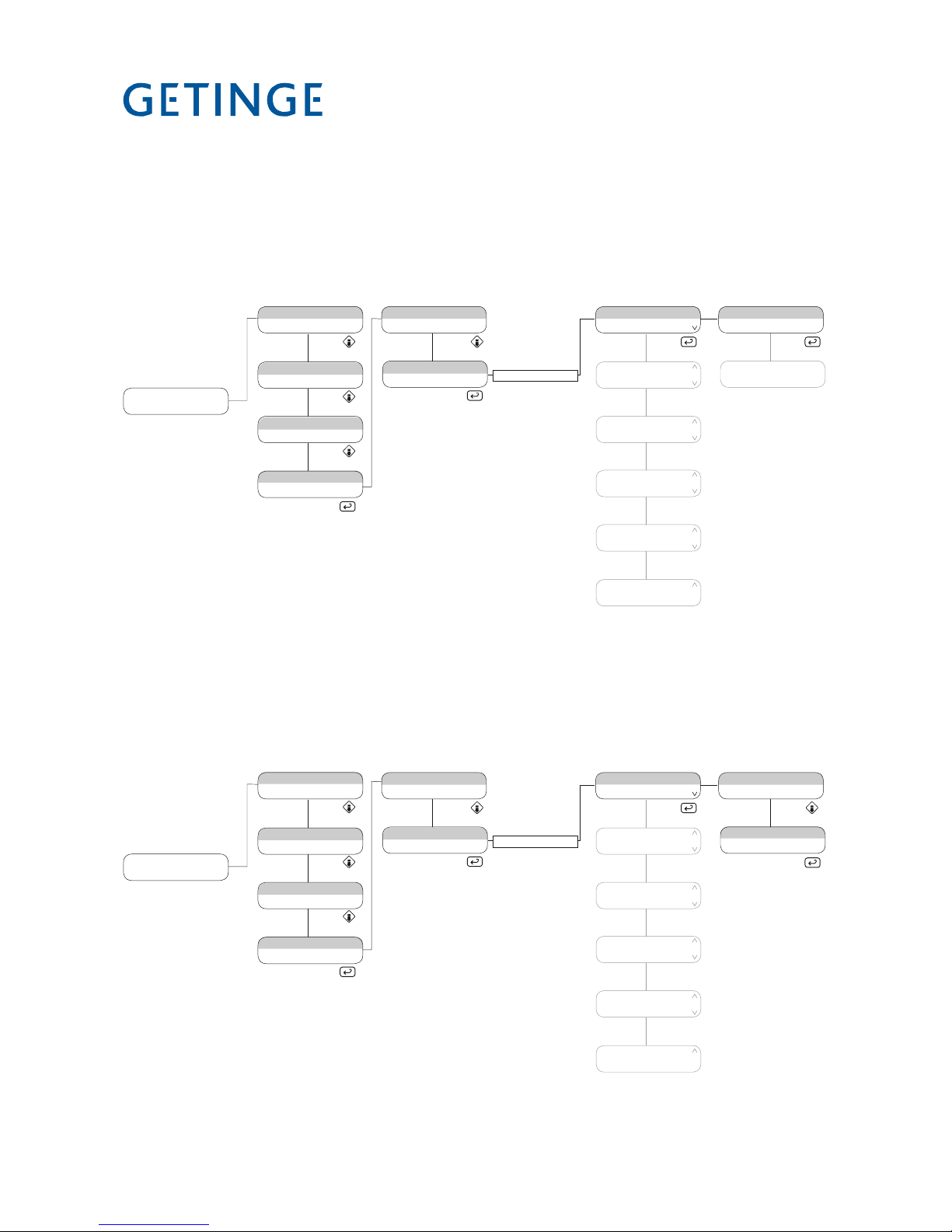

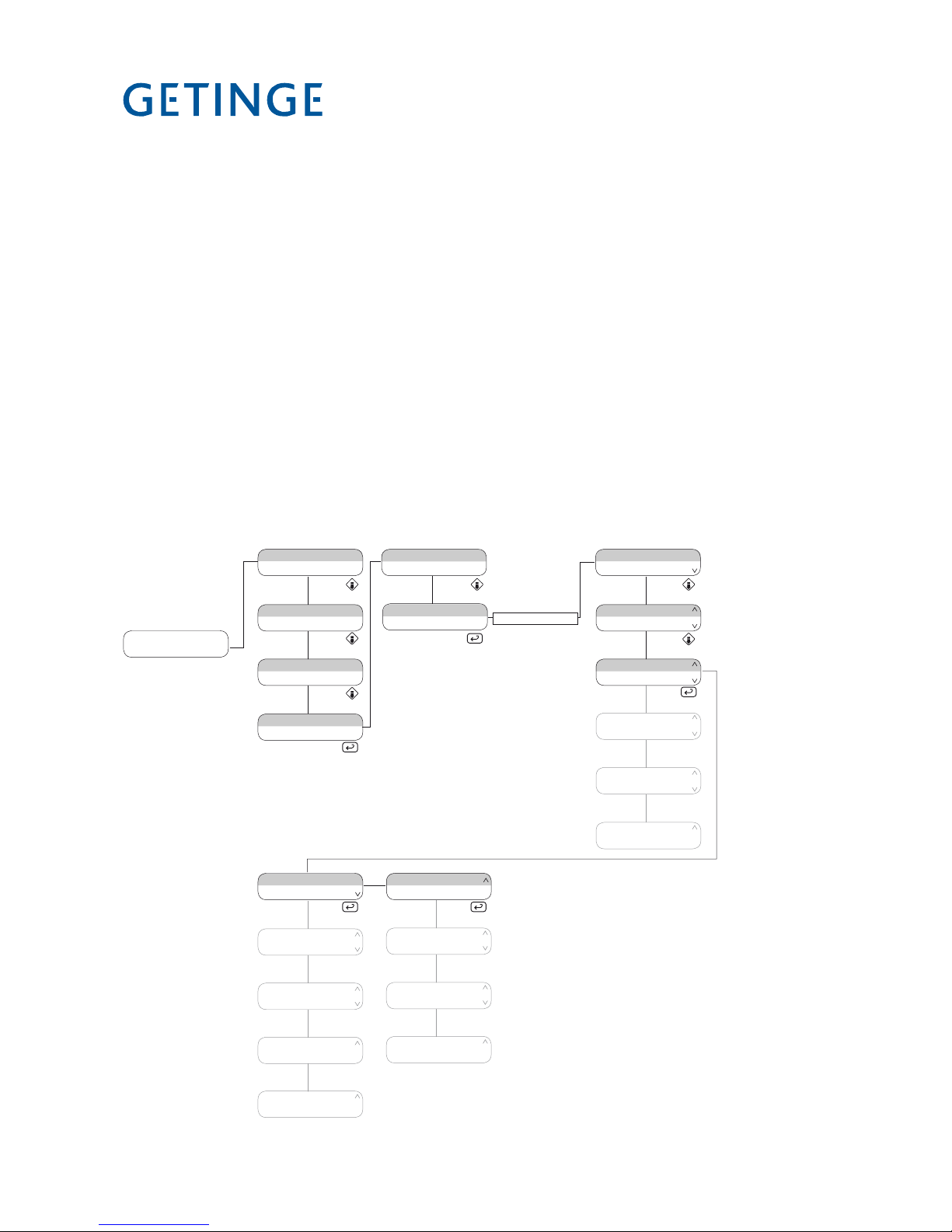

MANUAL CALIBRATION AUTO CALIBRATION COMPENSATION TABLE

CALIBRATION

1.4.2.2.1 1.4.2.2.2 1.4.2.2.3

CONTINUE 1 (32) CHOOSE SENSOR

1.4.2.2.2.1

1.4.2.2

1.4.2.2.2.2

1.4.2.2 CALIBRATION

1.4.2.3 CONFIGURATION

LANGUAGE & DATE UNIT PRINTER ALARM CLOCK

CONFIGURATION

1.4.2.3.1 1.4.2.3.2 1.4.2.3.3

PRINTER MODE SLOW INTERVAL

1.4.2.3.2.1

1.4.2.3

1.4.2.3.2.2

PACS ADDRESS

1.4.2.3.4

COMMUNICATION

1.4.2.3.5

CHANGE CYCLES

1.4.2.3.6

FAST INTERVAL

1.4.2.3.2.3

PRINTER & SPEED

1.4.2.3.2.4

LANGUAGE DATE FORMAT

1.4.2.3.1.1 1.4.2.3.1.2

UNIT OF PRESSURE

1.4.2.3.1.3

UNIT OF TEMPERATURE

1.4.2.3.1.4

1.4.2.5.3 DIAGNOSTICS

ANALOG IN ANALOG OUT DIGITAL IN

DIAGNOSTICS

1.4.2.5.3.1

1.4.2.5.3

DIGITAL OUT USER FLAG

PRINTERSYSTEM FLAG

AUTO CALIBRATION

CONTINUE 1 (32) CHOOSE SENSOR

1.4.2.5.3.2 1.4.2.5.3.3 1.4.2.5.3.4 1.4.2.5.3.5

1.4.2.5.3.6 1.4.2.5.3.7

1.4.2.2.2

1.4.2.2.2.1 1.4.2.2.2.2

COMPENSATION TABLE

1.4.2.2.3

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 22 of 148

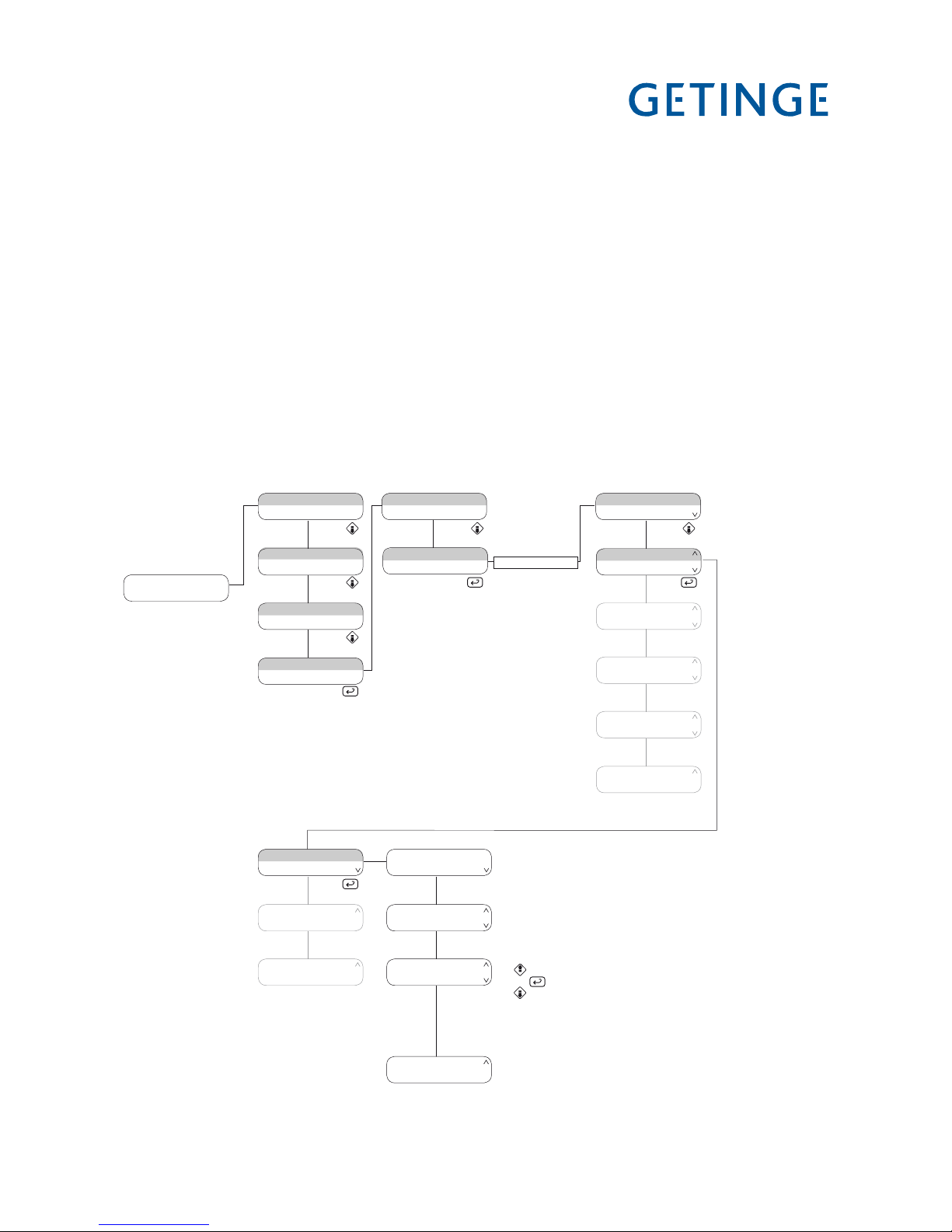

Main menu 1, Program name (1.1)

In standby mode the top line of the display shows the name of the last cycle

chosen. The second row shows two preselected values, normally this is the

temperature in the machine and the cycle counter. The main purpose of this

menu is to choose a wash cycle and to be able to change parameters.

This menu has two submenus.

SELECT PROGRAM (1.1.1)

CHANGE PARAMETERS (1.1.2)

Select the program.

In the main menu 1 press S to move to the SELECT PROGRAM menu then

press enter again to reach the various programs. Use the

J and H buttons to

highlight the program you want to use. To select a program press S. The cycles

are pre-configured in the program and cannot be changed by the operator.

1.1

1.2

1.1.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

SELECT PROGRAM.

1.1.1.1

01 PROGRAM #01

02 PROGRAM #02

1.1.1.2

1.1.1.3

02 PROGRAM #02

03 PROGRAM #03

03 PROGRAM #03

04 PROGRAM #04

1.1.1.9

1.1.1.10

1.1.1.11

09 PROGRAM #09

10 PROGRAM #10

10 PROGRAM #10

11 PROGRAM #11

11 PROGRAM #11

12 PROGRAM #12

1.1.2

CHANGE PARAMETERS

Page 23 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

1.1

1.2

1.1.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

SELECT PROGRAM.

1.1.2.1

WASH DOS TEMP

035.0C

1.1.2.2

1.1.2.3

PARAMETER #02

PARAMETER #03

PARAMETER #03

PARAMETER #04

1.1.2.57

1.1.2.58

1.1.2.59

PARAMETER #56

PARAMETER #57

PARAMETER #57

PARAMETER #58

PARAMETER #58

PARAMETER #59

1.1.2

CHANGE PARAMETERS

Change parameters (1.1.2)

In main menu 1, press S to go to the SELECT PROGRAM menu. Then press

J to activate “CHANGE PARAMETERS”. To select a program, press S again.

Every cycle has a set of preset parameters. When a cycle has been chosen as

explained in the previous section, the parameters appear on the display. The

number of the parameter depends on how the cycle was configured when it was

created in the program.

The parameters that have an “A” indication in the bottom right corner are

adjustable. With a class A password, the value can be changed by pressing

S.

If an“I” is displayed in the same position then the parameters are only

information.

P parameters can only be changed with class A + H passwords.

ENTER PASSWORD *

* Operator password required

Main menu 2, Machine name (1.2)

Main menu 2 shows information about the machine and the current phase. The

information cannot be changed.

Machine information (1.2)

The top line shows name/ID of the disinfection program and the bottom line

shows the current phase.

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 24 of 148

Main menu 3, Cycle counter (1.3)

In this menu, a selectable variable can be displayed. The top line shows the

name of the variable and the bottom line shows the value of the variable.

Variable list (1.3.1…)

There is a configured number of variables for every cycle. This list is only for

information about the variables. To choose the variable you want to see, press

J or H, then press S to display the chosen variable.

1.1

1.2

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

1.3.1

CYCLE COUNTER

00000

1.3.2

1.3.3

VARIABLE

VALUE #02

VARIABLE

VALUE #02

1.3.42

1.3.43

1.3.44

VARIABLE

VALUE #42

VARIABLE

VALUE #43

NO VARIABLE

>

Page 25 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Main menu 4, Settings (1.4)

Main menu 4 is the settings menu for the machine. The settings menu has three

submenus.

Print the parameters of the chosen cycle (1.4.1)

System setting menus. (1.4.2)

Appliance information. (1.4.3)

Print parameters of the chosen cycle (1.4.1)

When a cycle has been chosen in main menu 1, the parameters of that cycle can

be printed out.

Press

J three times to reach the settings menu, then press S to choose

settings. Pressing

S once more brings up the printing screen. Use I or K

to choose “YES” to start printing or “NO” if you do not want to print the chosen

cycle.

System menu (1.4.2)

The system settings menu has six submenus.

A calendar where you can enter the date and time. (1.4.2.1)

Calibration of analog entry values. (1.4.2.2)

Configuration of devices such as printer, alarms,

alarm clocks and node addresses. (1.4.2.3)

DIP switches. (1.4.2.4)

Service menu with fault message, service message

and diagnostics. (1.4.2.5)

Save RAM in flash. (1.4.2.6)

Calendar menu (1.4.2.1)

The time and date can be set in this menu.

There is a submenu for each function.

Set time. (1.4.2.1.1)

Set date. (1.4.2.1.2)

1.1

1.2

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

1.3.1

PRINT LAST CYCLE

SYSTEM

1.3.2

1.3.3

SYSTEM

ABOUT

SYSTEM

ABOUT

1.3.3

PRINT LAST CYCLE

YES NO

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 26 of 148

Time menu (1.4.2.1.1)

To set the time, follow the instructions in the menu tree below. Enter password

and press S when the calendar menu has been chosen. To set the time, press

S. To change the time press H and J until the desired time is displayed.

Then use

I or K to change field. When the value is correctly set, press S to

confirm the change.

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

* Service personnel password required

1.4.2.1.1

TIME HH:MM:SS

15:45:50

1.4.2.1.2

DATE YYYY/MM/DD

2006/08/23

Date menu (1.4.2.1.2)

To set the date, follow the instructions in the menu tree below. Enter password

and press S when the calendar menu has been chosen. To set the date, press

S. To change the time press H and J until the desired date is displayed.

Then use

I or K to change field. When the value is correctly set, press S to

confirm the change.

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.1.1

TIME HH:MM:SS

15:45:50

1.4.2.1.2

DATE YYYY/MM/DD

2006/08/23

* Service personnel password required

Page 27 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Calibration menu (1.4.2.2)

The calibration menu is used to calibrate analog entry values. There are three

submenus for calibration.

Manual calibration. (1.4.2.2.1)

Automatic calibration. (1.4.2.2.2)

Adjusting the compensation table. (1.4.2.2.3)

Manual calibration menu (1.4.2.2.1)

In manual calibration, two values for A-Gain and B-offset can be entered

manually. To access manual calibration, follow the instructions in the menu tree

below. To change values, press

H and J. Then use I or K to change field.

When the value is correctly set, press S to confirm the change.

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.2.1

1.4.2.2.2

1.4.2.2.3

MANUAL CALIBRATION

AUTO CALIBRATION

AUTO CALIBRATION

COMPENSATION TABLE

AUTO CALIBRATION

COMPENSATION TABLE

1.4.2.2.1.1

1.4.2.2.1.2

1.4.2.2.1.3

00 CALIBRATION TYPE

OFFSET SPAN

01 CALIBRATION TYPE

OFFSET SPAN

02 CALIBRATION TYPE

OFFSET SPAN

1.4.2.2.1.32

31 CALIBRATION TYPE

OFFSET SPAN

* Service personnel password required

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 28 of 148

Automatic calibration menu (1.4.2.2.2)

This menu has two submenus.

Continue. (1.4.2.2.2.1)

Choose a sensor. (1.4.2.2.2.2)

With automatic calibration, you must choose a sensor for calibration. Do this in

the Choose a sensor menu. When one or more sensors have been chosen for

calibration, the Continue menu shows how many sensors have been chosen and

an arrow appears on the right of the display. When you quit the calibration menu,

all chosen sensors are deselected.

Calibrate the chosen sensor (1.4.2.2.2.1)

When one or more similar sensors have been chosen (see 1.4.2.2.2.2), this

is shown by an arrow at the right-hand edge of the display, beside the word

“Continue” on the first line. Pressing S displays the low reference value. When

the value is stable, press S to confirm it. Now the high reference value is

displayed. When the value is stable, press S to confirm it. Now you have the

option of printing out the calibration value by highlighting “YES” for printout or

“NO” for no printout.

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.2.1

1.4.2.2.2

1.4.2.2.3

MANUAL CALIBRATION

AUTO CALIBRATION

AUTO CALIBRATION

COMPENSATION TABLE

AUTO CALIBRATION

COMPENSATION TABLE

1.4.2.2.2.1

1.4.2.2.1.3

CONTINUE 1 (32)

CHOOSE SENSOR

CONTINUE 1 (32)

CHOOSE SENSOR

1.4.2.2.2.1.1

1.4.2.2.2.1.2

1.4.2.2.2.1.3

LOW REFERENCE

VALUE %

HIGH REFERENCE

VALUE %

PRINT CALIBRATION

YES NO

>

>

* Service personnel password required

Page 29 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Choose a sensor (1.4.2.2.2.2)

Press S when Choose sensor is highlighted under automatic calibration.

Confirm the choice by placing the cursor on “YES” and pressing S again. The

sensor has now been chosen. Note that more than one sensor can be chosen at

the same time. If more than one sensor is chosen at the same time, they must be

of a similar type.

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.2.1

1.4.2.2.2

1.4.2.2.3

MANUAL CALIBRATION

AUTO CALIBRATION

AUTO CALIBRATION

COMPENSATION TABLE

AUTO CALIBRATION

COMPENSATION TABLE

1.4.2.2.2.1

1.4.2.2.2.2

CONTINUE 1 (32)

CHOOSE SENSOR

1.4.2.2.2.2.1

1.4.2.2.2.2.2

1.4.2.2.2.2.3

00 CALIBRATION TYPE

VALUE % CAL NO

01 CALIBRATION TYPE

VALUE % CAL NO

02 CALIBRATION TYPE

VALUE % CAL NO

>

CONTINUE 1 (32)

CHOOSE SENSOR

>

1.4.2.2.2.2.31

31 CALIBRATION TYPE

VALUE % CAL NO

* Service personnel password required

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 30 of 148

Compensation table menu (1.4.2.2.3)

This menu is not applicable on this machine.

Configuration menu (1.4.2.3)

The configuration display is used to set language, and units. The printer is also

set here. The alarm clock and PACS addresses are also set here. There are four

submenus.

Language. (1.4.2.3.1)

Date format. (1.4.2.3.2)

Unit of pressure. (1.4.2.3.3)

Unit of temperature (1.4.2.3.4)

Language menu (1.4.2.3.1)

Language settings for the various displays can be accessed in this menu. Press

S and choose the required language. To confirm, press S.

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.3.1

1.4.2.3.2

1.4.2.3.3

LANGUAGE DATE UNIT

PRINTER

ALARM CLOCK

PACS ADDRESS

1.4.2.3.1.1

LANGUAGE

SWEDISH

1.4.2.3.4

PACS ADDRESS

COMMUNICATION

1.4.2.3.5

PACS ADDRESS

COMMUNICATION

1.4.2.3.1.2

DATE FORMAT

YYYY/MM/DD

1.4.2.3.1.3

UNIT OF PRESSURE

KPA

1.4.2.3.1.4

UNIT OF TEMPERATURE

C

PRINTER

ALARM CLOCK

* Service personnel password required

Page 31 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Date format menu (1.4.2.3.2)

The date format is chosen from this menu. There are three date formats: Press

S to see the different formats. Then choose the date format you want. To

confirm, press S.

YYYY/MM/DD (1.4.2.3.2.1)

MM/DD/YYYY (1.4.2.3.2.2)

DD/MM/YYYY. (1.4.2.3.2.3)

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.3.1

1.4.2.3.2

1.4.2.3.3

LANGUAGE DATE UNIT

PRINTER

ALARM CLOCK

PACS ADDRESS

1.4.2.3.1.1

LANGUAGE

SWEDISH

1.4.2.3.4

PACS ADDRESS

COMMUNICATION

1.4.2.3.5

PACS ADDRESS

COMMUNICATION

1.4.2.3.1.2

DATE FORMAT

YYYY/MM/DD

1.4.2.3.1.3

UNIT OF PRESSURE

KPA

1.4.2.3.1.4

UNIT OF TEMPERATURE

C

PRINTER

ALARM CLOCK

1.4.2.3.1.2.1

DATE FORMAT

YYYY/MM/DD

1.4.2.3.1.2.2

DATE FORMAT

MM/DD/YYYY

1.4.2.3.1.2.3

DATE FORMAT

DD/MM/YYYY

* Service personnel password required

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 32 of 148

Unit of pressure menu (1.4.2.3.1.3)

Three units of pressure are available: Press S to access the menu with the

various units, then choose the unit you want. To confirm, press S. Note: This

only shows the available units. The value of these units is not converted.

BAR (1.4.2.3.1.3.1)

KPA (1.4.2.3.1.3.2)

PSI (1.4.2.3.1.3.3)

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.3.1

1.4.2.3.2

1.4.2.3.3

LANGUAGE DATE UNIT

PRINTER

ALARM CLOCK

PACS ADDRESS

1.4.2.3.1.1

LANGUAGE

SWEDISH

1.4.2.3.4

PACS ADDRESS

COMMUNICATION

1.4.2.3.5

PACS ADDRESS

COMMUNICATION

1.4.2.3.1.2

DATE FORMAT

YYYY/MM/DD

1.4.2.3.1.3

UNIT OF PRESSURE

KPA

1.4.2.3.1.4

UNIT OF TEMPERATURE

C

PRINTER

ALARM CLOCK

1.4.2.3.1.3.1

UNIT OF PRESSURE

BAR

1.4.2.3.1.3.2

UNIT OF PRESSURE

PSI

1.4.2.3.1.3.3

UNIT OF PRESSURE

PSI

* Service personnel password required

Page 33 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Unit of temp menu (1.4.2.3.1.4)

There is a choice of two units of temperature. Press S to see the two units.

Choose the unit you want to use and press S to confirm.

Note: This only shows the available units. The value of these units is not

converted.

Celsius. (1.4.2.3.1.4.1)

Fahrenheit. (1.4.2.3.1.4.2)

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.3.1

1.4.2.3.2

1.4.2.3.3

LANGUAGE DATE UNIT

PRINTER

ALARM CLOCK

PACS ADDRESS

1.4.2.3.1.1

LANGUAGE

SWEDISH

1.4.2.3.4

PACS ADDRESS

COMMUNICATION

1.4.2.3.5

COMMUNICATION

CHANGE CYCLES

1.4.2.3.1.2

DATE FORMAT

YYYY/MM/DD

1.4.2.3.1.3

UNIT OF PRESSURE

KPA

1.4.2.3.1.4

UNIT OF TEMPERATURE

C

PRINTER

ALARM CLOCK

1.4.2.3.1.4.1

UNIT OF TEMPERATURE

C

1.4.2.3.1.4.2

UNIT OF TEMPERATURE

F

* Service personnel password required

1.4.2.3.6

COMMUNICATION

CHANGE CYCLES

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 34 of 148

Printer menu (1.4.2.3.2)

All settings for printer and logs are made in this section. There are four

submenus:

Printer mode. (1.4.2.3.2.1)

Slow interval (1.4.2.3.2.2)

Fast interval (1.4.2.3.2.3)

Printer transfer speed. (1.4.2.3.2.4)

Print mode menu (1.4.2.3.2.1)

This menu has only one option. Only process values are printed out.

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.3.1

1.4.2.3.2

1.4.2.3.3

LANGUAGE DATE UNIT

PRINTER

ALARM CLOCK

PACS ADDRESS

1.4.2.3.2.1

PRINT MODE

1.4.2.3.4

PACS ADDRESS

COMMUNICATION

1.4.2.3.2.2

SLOW INTERVAL

01:00

1.4.2.3.2.3

FAST INTERVAL

20:00

1.4.2.3.2.4

PRINTER TRANSF. SP.

9600

PRINTER

ALARM CLOCK

* Service personnel password required

1.4.2.3.5

COMMUNICATION

CHANGE CYCLES

1.4.2.3.6

COMMUNICATION

CHANGE CYCLES

Page 35 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.3.1

1.4.2.3.2

1.4.2.3.3

LANGUAGE DATE UNIT

PRINTER

ALARM CLOCK

PACS ADDRESS

1.4.2.3.2.1

PRINT MODE

1.4.2.3.4

PACS ADDRESS

COMMUNICATION

1.4.2.3.2.2

SLOW INTERVAL

01:00

1.4.2.3.2.3

FAST INTERVAL

20:00

1.4.2.3.2.4

PRINTER TRANSF. SP.

9600

PRINTER

ALARM CLOCK

Slow interval menu(1.4.2.3.2.2)

The speed of the slow interval log times is shown here. The phases that use this

time speed are pre-configured in the program for each phase.

* Service personnel password required

1.4.2.3.5

COMMUNICATION

CHANGE CYCLES

1.4.2.3.6

COMMUNICATION

CHANGE CYCLES

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 36 of 148

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.3.1

1.4.2.3.2

1.4.2.3.3

LANGUAGE DATE UNIT

PRINTER

ALARM CLOCK

PACS ADDRESS

1.4.2.3.2.1

PRINT MODE

1.4.2.3.4

PACS ADDRESS

COMMUNICATION

1.4.2.3.2.2

SLOW INTERVAL

01:00

1.4.2.3.2.3

FAST INTERVAL

20:00

1.4.2.3.2.4

PRINTER TRANSF. SP.

9600

PRINTER

ALARM CLOCK

Fast interval menu(1.4.2.3.2.3)

The speed of the fast interval log times is shown here. The phases that use this

time speed are pre-configured in the program for each phase.

* Service personnel password required

1.4.2.3.5

COMMUNICATION

CHANGE CYCLES

1.4.2.3.6

COMMUNICATION

CHANGE CYCLES

Page 37 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.3.1

1.4.2.3.2

1.4.2.3.3

LANGUAGE DATE UNIT

PRINTER

ALARM CLOCK

PACS ADDRESS

1.4.2.3.2.1

PRINT MODE

1.4.2.3.4

PACS ADDRESS

COMMUNICATION

1.4.2.3.2.2

SLOW INTERVAL

01:00

1.4.2.3.2.3

FAST INTERVAL

20:00

1.4.2.3.2.4

PRINTER TRANSF. SP.

9600

PRINTER

ALARM CLOCK

Transfer speed menu (1.4.2.3.2.4)

You can choose the transfer speed for the printer in this menu. There are four

transfer speeds:

1200. (1.4.2.3.2.4.1)

2400. (1.4.2.3.2.4.2)

4800. (1.4.2.3.2.4.3)

9600. (1.4.2.3.2.4.4)

1.4.2.3.2.4.1

PRINTER TRANSF. SP.

1200

1.4.2.3.2.4.2

PRINTER TRANSF. SP.

2400

1.4.2.3.2.4.3

PRINTER TRANSF. SP.

4800

1.4.2.3.2.4.4

PRINTER TRANSF. SP.

9600

Alarm clock menu (1.4.2.3.3)

This function is not used on this machine.

* Service personnel password required

1.4.2.3.5

COMMUNICATION

CHANGE CYCLES

1.4.2.3.6

COMMUNICATION

CHANGE CYCLES

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 38 of 148

PACS address menu (1.4.2.3.4)

The node address for PACS is entered in this menu.

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.3.1

1.4.2.3.2

1.4.2.3.3

LANGUAGE DATE UNIT

PRINTER

ALARM CLOCK

PACS ADDRESS

1.4.2.3.4.1

ENTER PACS ID

01

1.4.2.3.4

PACS ADDRESS

COMMUNICATION

PRINTER

ALARM CLOCK

* Service personnel password required

1.4.2.3.5

COMMUNICATION

CHANGE CYCLES

1.4.2.3.6

COMMUNICATION

CHANGE CYCLES

Page 39 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Communication settings COM0 (1.4.2.3.5.1)

Protocol type and communication mode are entered in this menu.

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.3.1

1.4.2.3.2

LANGUAGE DATE UNIT

PRINTER

1.4.2.3.5.1

COM0 PROTOCOL

COMLI

1.4.2.3.5.2

1.4.2.3.5.3

PRINTER

ALARM CLOCK

1.4.2.3.5.1.1

COM0 PROTOCOL

COMLI

1.4.2.3.5.1.2

COM1 PROTOCOL

PRINTER

1.4.2.3.5.1.3

COM1 POSITION

RS232

1.4.2.3.3

ALARM CLOCK

PACS ADDRESS

1.4.2.3.4

PACS ADDRESS

COMMUNICATION

COM0 PROTOCOL

PRINTER

COM0 PROTOCOL

SCANNER 1

1.4.2.3.5.1.4

COM0 PROTOCOL

SCANNER 2

Table

Com 1 protocol For PC connection and T-Doc

Printer For printer connection

Scanner 1 Handheld scanner connected

Scanner 2 Fixed scanner connected

* Service personnel password required

1.4.2.3.5

COMMUNICATION

CHANGE CYCLES

1.4.2.3.6

COMMUNICATION

CHANGE CYCLES

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 40 of 148

Table

Com 1 protocol For PC connection and T-Doc

Printer For printer connection

Scanner 1 Handheld scanner connected

Scanner 2 Fixed scanner connected

Communication settings COM1 (1.4.2.3.5.2)

Protocol type is entered in this menu.

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.3.1

1.4.2.3.2

LANGUAGE DATE UNIT

PRINTER

1.4.2.3.5.1

COM0 PROTOCOL

COMLI

1.4.2.3.5.2

1.4.2.3.5.3

PRINTER

ALARM CLOCK

1.4.2.3.5.2.1

COM0 PROTOCOL

COMLI

1.4.2.3.5.2.2

COM1 PROTOCOL

PRINTER

1.4.2.3.5.2.3

COM1 POSITION

RS232

1.4.2.3.3

ALARM CLOCK

PACS ADDRESS

1.4.2.3.4

PACS ADDRESS

COMMUNICATION

COM0 PROTOCOL

PRINTER

COM0 PROTOCOL

SCANNER 1

1.4.2.3.5.2.4

COM0 PROTOCOL

SCANNER 2

* Service personnel password required

1.4.2.3.5

COMMUNICATION

CHANGE CYCLES

1.4.2.3.6

COMMUNICATION

CHANGE CYCLES

Page 41 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Communication mode COM2 (1.4.2.3.5.3)

Protocol type is entered in this menu.

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.3.1

1.4.2.3.2

LANGUAGE DATE UNIT

PRINTER

1.4.2.3.5.1

COM0 PROTOCOL

COMLI

1.4.2.3.5.2

1.4.2.3.5.3

PRINTER

ALARM CLOCK

1.4.2.3.5.3.1

COM1 POSITION

RS232

1.4.2.3.5.3.2

COM1 PROTOCOL

PRINTER

COM1 POSITION

RS232

1.4.2.3.3

ALARM CLOCK

PACS ADDRESS

1.4.2.3.4

PACS ADDRESS

COMMUNICATION

COM1 POSITION

RS485

Table

RS232 PC connected

RS485 T-Doc connected

* Service personnel password required

1.4.2.3.5

COMMUNICATION

CHANGE CYCLES

1.4.2.3.6

COMMUNICATION

CHANGE CYCLES

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 42 of 148

Change cycles (1.4.2.3.6.1)

Protocol type is entered in this menu.

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.3.1

1.4.2.3.2

LANGUAGE DATE UNIT

PRINTER

1.4.2.3.6.1

xxxxxxxxxxx

xxxxxxxxxxxxx

PRINTER

ALARM CLOCK

1.4.2.3.3

ALARM CLOCK

PACS ADDRESS

1.4.2.3.4

PACS ADDRESS

COMMUNICATION

* Service personnel password required

1.4.2.3.5

COMMUNICATION

CHANGE CYCLES

1.4.2.3.6

COMMUNICATION

CHANGE CYCLES

Page 43 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.4.1

1.4.2.4.2

DS00 XXXXXXXXXX

STATUS 0

DS01 XXXXXXXXXX

STATUS 0

1.4.2.4.3

DS02 XXXXXXXXXX

STATUS 0

1.4.2.4.4

DS03 XXXXXXXXXX

STATUS 0

1.4.2.4.5

DS04 XXXXXXXXXX

STATUS 0

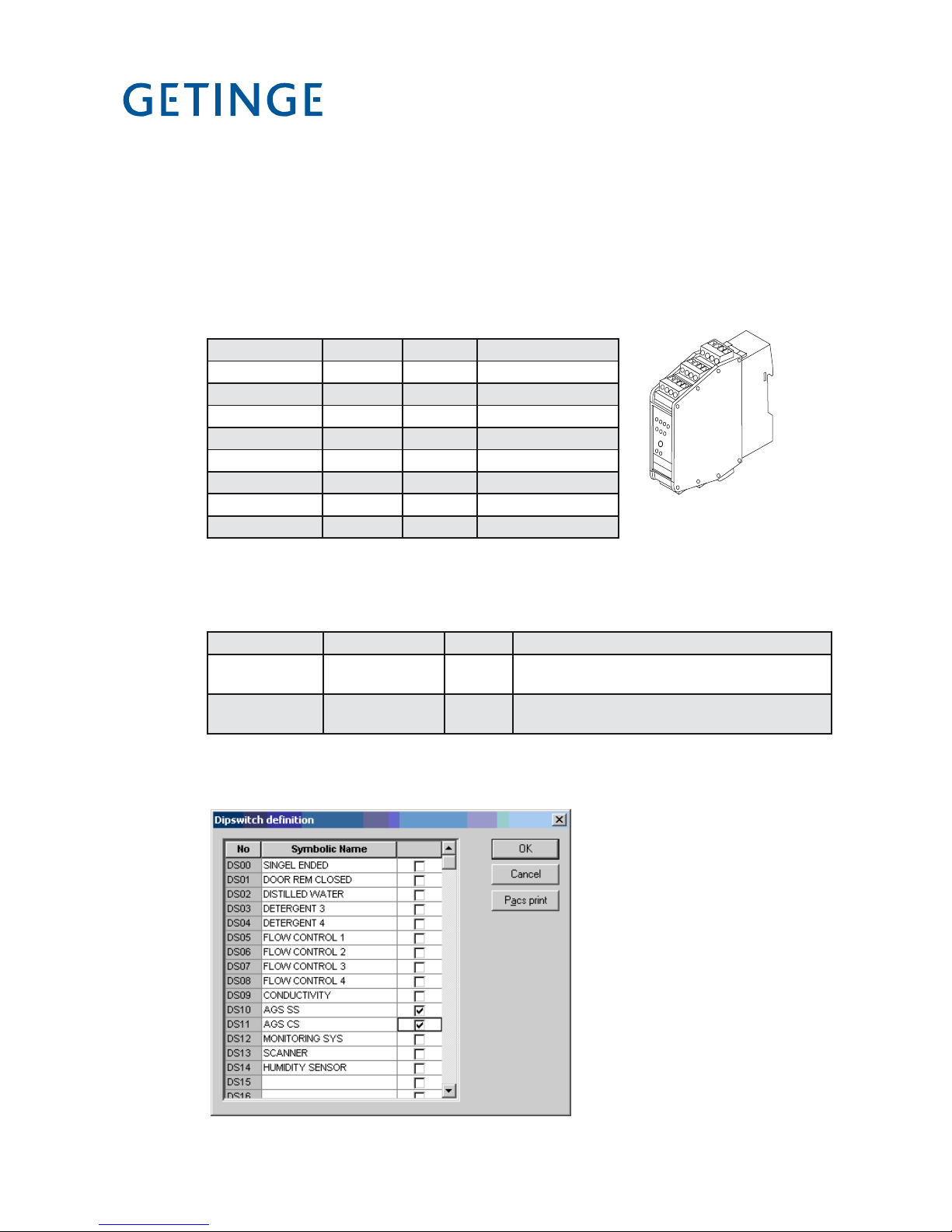

DIP switch menu (1.4.2.4)

The DIP switches are used to switch various options on and off. The various

options are pre-configured in the program. There are 16 DIP switches in all. See

Section 2.3.1

1.4.2.4.6

DS05 XXXXXXXXXX

STATUS 0

1.4.2.4.7

DS06 XXXXXXXXXX

STATUS 0

1.4.2.4.8

DS07 XXXXXXXXXX

STATUS 0

1.4.2.4.9

1.4.2.4.10

DS08 XXXXXXXXXX

STATUS 0

DS09 XXXXXXXXXX

STATUS 0

1.4.2.4.11

DS10 XXXXXXXXXX

STATUS 0

1.4.2.4.12

DS11 XXXXXXXXXX

STATUS 0

1.4.2.4.13

DS12 XXXXXXXXXX

STATUS 0

1.4.2.4.14

DS13 XXXXXXXXXX

STATUS 0

1.4.2.4.15

DS14 XXXXXXXXXX

STATUS 0

1.4.2.4.16

DS15 XXXXXXXXXX

STATUS 0

1.4.2.4.17

1.4.2.4.18

DS16 XXXXXXXXXX

STATUS 0

DS17 XXXXXXXXXX

STATUS 0

1.4.2.4.19

DS18 XXXXXXXXXX

STATUS 0

1.4.2.4.20

DS19 XXXXXXXXXX

STATUS 0

1.4.2.4.21

DS20 XXXXXXXXXX

STATUS 0

1.4.2.4.22

DS21 XXXXXXXXXX

STATUS 0

1.4.2.4.23

DS22 XXXXXXXXXX

STATUS 0

1.4.2.4.24

DS23 XXXXXXXXXX

STATUS 0

1.4.2.4.25

1.4.2.4.26

DS24 XXXXXXXXXX

STATUS 0

DS25 XXXXXXXXXX

STATUS 0

1.4.2.4.27

DS26 XXXXXXXXXX

STATUS 0

1.4.2.4.28

DS27 XXXXXXXXXX

STATUS 0

1.4.2.4.29

DS28 XXXXXXXXXX

STATUS 0

1.4.2.4.30

DS29 XXXXXXXXXX

STATUS 0

1.4.2.4.31

DS30 XXXXXXXXXX

STATUS 0

1.4.2.4.32

DS31 XXXXXXXXXX

STATUS 0

Table

DS00 Machine with only one door. DS08 Flow metering #4 DS16 XXXXXXXXXX DS24 XXXXXXXXXX

DS01 Opens the door when the cycle is complete. DS09 Conductivity measurement DS17 XXXXXXXXXX DS25 XXXXXXXXXX

DS02 Distilled water DS10 AGS loader, soiled side DS18 XXXXXXXXXX DS26 XXXXXXXXXX

DS03 Dosing pump #3 DS11 AGS unloader, clean side DS19 XXXXXXXXXX DS27 XXXXXXXXXX

DS04 Dosing pump #4 DS12 Monitoring system DS20 XXXXXXXXXX DS28 Service messages

DS05 Flow metering #1 DS13 Scanner DS21 XXXXXXXXXX DS29 A

0

-Value

DS06 Flow metering #2 DS14 XXXXXXXXXX DS22 XXXXXXXXXX DS30 PC washing log

DS07 Flow metering #3 DS15 XXXXXXXXXX DS23 XXXXXXXXXX DS31 Loop running

* Service personnel password required

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 44 of 148

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.5.1

1.4.2.5.2

FAULT LOG

SERVICE MESSAGE

1.4.2.5.1.1

01 FXX XXXXXXXXXX

02 FXX XXXXXXXXXX

1.4.2.5.1.2

1.4.2.5.1.20

SERVICE MESSAGE

DIAGNOSTICS

19 FXX XXXXXXXXXX

20 FXX XXXXXXXXXX

1.4.2.5.3

SERVICE MESSAGE

DIAGNOSTICS

02 FXX XXXXXXXXXX

03 FXX XXXXXXXXXX

Service menu (1.4.2.5)

The service menu shows the various fault messages, service messages and

diagnostics.

Fault log. (1.4.2.5.1)

Service messages. (1.4.2.5.2)

Diagnostics. (1.4.2.5.3)

Fault log menu (1.4.2.5.1)

The last 20 fault messages are displayed. The faults are confirmed with the Enter

button on the PACS. You can find the fault messages in Section 3.

* Service personnel password required

Page 45 of 148

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

1.1

1.2

1.4.1

1.3

1.4

GETINGE PACS 350

VERSION 3.51 (0283)

P01 PROGRAM NAME

PARAM1 PARAM2

MACHINE NAME

PHASE NAME

CYCLE COUNTER

00000

SETTINGS

PRINT LAST CYCLE

SYSTEM

1.4.2.1

CALENDAR

CALIBRATION

1.4.2.2

1.4.2.3

CALIBRATION

CONFIGURATION

CONFIGURATION

DIP SWITCHES

1.4.2.4

1.4.2.5

1.4.2.6

DIP SWITCHES

SERVICE

SERVICE

SAVE RAM IN FLASH

SERVICE

SAVE RAM IN FLASH

1.4.2

SYSTEM

ABOUT

ENTER PASSWORD *

1.4.2.5.1

1.4.2.5.2

FAULT LOG

SERVICE MESSAGE

1.4.2.5.2.1

RESET SERV. MESSAGE

YES NO

SERVICE MESSAGE

DIAGNOSTICS

1.4.2.5.3

SERVICE MESSAGE

DIAGNOSTICS

Service message menu (1.4.2.5)

Service messages attract the operator’s attention if something needs to be done.

You can find service messages in Section 3.

Diagnostics menu (1.4.2.5.3)

The diagnostics menu is used to test input and output data and flags. There are

eight submenus:

Test analog in. (1.4.2.5.3.1)

Test analog out. (1.4.2.5.3.2)

Test digital in. (1.4.2.5.3.3)

Test digital out. (1.4.2.5.3.4)

Test user flag (1.4.2.5.3.5)

Test system flag (1.4.2.5.3.6)

Test printer. (1.4.2.5.3.7)

Test LED and buzzer. (1.4.2.5.3.8)

* Service personnel password required

<Doc_TEC><Doc_502406700><Rel_B><Lang_GB>

Page 46 of 148

Test analog in menu (1.4.2.5.3.1)

These values are read-only. The status of various input data is displayed. The