Service ma

nual

Getinge

ProSeal

V1.9

GETINGE

V1.9

ProSeal

Classic/Plus/

Premium

SERVICE

MANUAL

EN

P/N: V1.9

SERVICE MANUAL ProSeal Classic/Plus/Premium

Name

Version

Date

Comment

Coen van de Laar

1.8

26-02-2014

Manual adjusted after first review by

GvR

Coen van de Laar

1.9

26-02-2014

Manual adjusted after second review

by GvR

History

Contents

1 General notes ...................................................................................................... 4

1.1 Prerequisites ................................................................................................ 5

1.2 Danger of injury ............................................................................................ 5

1.2.1 Risk of electric shock ................................................................ ................ 5

1.2.2 Risk of burning .......................................................................................... 6

1.2.3 Risk of Entrapment ................................................................................... 6

1.2.4 Tools ......................................................................................................... 6

2 Preventive maintenance plan .............................................................................. 6

2.1 Opening the unit ........................................................................................... 7

2.2 Removing the base frame from the housing ................................................. 8

2.3 Replacing the PTFE material ....................................................................... 9

2.3.1 The belt guides ......................................................................................... 9

2.3.2 The heating elements ............................................................................. 10

2.4 Transport belts ........................................................................................... 12

2.5 Printer (only ProSeal Premium) .................................................................. 13

2.6 Upper pressing wheel. ................................................................................ 14

2.7 Lower pressing wheel ................................................................................. 15

3 Trouble shooting ................................................................................................ 15

3.1 Error codes ................................................................................................. 15

3.2 Print head (ProSeal Premium) ................................................................... 19

4 Repair ................................................................................................................ 20

4.1 Repair printer (ProSeal Premium) .............................................................. 20

4.2 Control board ............................................................................................. 21

4.3 Assembling ................................................................................................. 22

4.3.1 Heating elements .................................................................................... 22

4.3.2 Transport belts ........................................................................................ 24

4.3.3 Belt guides .............................................................................................. 25

4.3.4 Upper pressure roller ................................................................ .............. 26

4.3.5 Mounting the base frame in the bottom housing ..................................... 26

5 Validation ........................................................................................................... 27

5.1 Validation Kit .............................................................................................. 27

5.2 Classic ........................................................................................................ 28

5.2.1 Logging in ............................................................................................... 28

5.2.2 Pressure ................................................................ ................................. 28

5.2.3 Speed ..................................................................................................... 28

5.2.4 Temperature ........................................................................................... 28

5.3 Plus and Premium ...................................................................................... 28

5.3.1 Logging in ............................................................................................... 29

2

SERVICE MANUAL ProSeal Classic/Plus/Premium

5.3.2 Pressure ................................................................ ................................. 29

5.3.3 Speed ..................................................................................................... 30

5.3.4 Temperature ........................................................................................... 31

6 Spare parts ........................................................................................................ 31

3

SERVICE MANUAL ProSeal Classic/Plus/Premium

1 General notes

This manual provides the user with the appropriate instructions for safe and proper

maintenance and repair of the sealing unit. Each person involved in maintenance or

repair of the sealing unit must be familiar with these instructions or the safety

regulations respectively. In order to avoid operating errors and to ensure trouble-free

operation of the sealing unit these instructions must always be accessible for the

personnel. By receiving this document you do not automatically participate in an

updating service.

Copyright

This maintenance instruction manual must only be handed over to third parties with

the written consent of GETINGE. All documents are protected by copyright law.

Disclosure as well as reproduction of documents, even in form of excerpts, utilization

and announcement of its content is prohibited, if not explicitly admitted. Violations are

liable to prosecution and oblige to compensation. We reserve the right for the

exercise of industrial property rights.

Warranty and liability

We assume liability for possible faults or omissions within the framework of the

specified warranty obligations, under exclusion of further claims.

In the course of further development we reserve the right for technical modifications

to the sealing unit, which is subject of these maintenance instructions.

We will not assume liability for any damage or malfunction caused by operating

errors, negligence of these maintenance instructions or inappropriate repairs. We

would like to point out that only genuine spare parts and accessories from GETINGE

which have been approved by us should be used.

The installation or use of spare parts or accessories which have not been approved,

will lead to the exclusion of any liability of GETINGE for damage resulting from this.

Technicians preferably should be trained by Getinge Academy.

Drawings and graphical presentations are not to scale.

For maintenance work it is necessary to open the housing.

During maintenance and repair work the unit must be disconnected from the power

supply!

4

SERVICE MANUAL ProSeal Classic/Plus/Premium

1.1 Prerequisites

Getinge has ESD protection integrated into the production and testing of electronic

equipment, and also requires ESD protection to be used after delivery for the

warranty to apply.

It is important to reduce the likelihood of ESD to avoid damage to sensitive electronic

components. As a basic precaution, it is recommended to wear ESD wrist strap, sole

grounders or conductive shoes when preforming maintenance on the unit. Keep

electronic components in the anti-static bag until you are ready to install them in

order to prevent charge from building up.

Requirements when performing maintenance to avoid ESD:

Use ESD pads connected to the earth in accordance with the manufacturer’s

instructions to hold disassembled or new electronic boards during assembly

work.

Do not touch electronic boards with tools that may be charged, like

screwdrivers with a plastic or wooden handle.

Use grounded tools, if necessary.

Always use an ESD wrist strap connected to the earth in accordance with the

manufacturer’s instructions when working in the electronic enclosure or when

handling boards.

Do not keep any foreign objects, such as drawings or plastic pockets, inside

the electronic box.

Test the ESD protective equipment on a regular basis.

To start with the maintenance/repair inspection the following steps should always be

followed first:

Check whether the mains plug of the unit has been pulled out.

Attention! To avoid damage caused by electrostatic charging.

1.2 Danger of injury

During troubleshooting, calibrating or validation of the unit it may be necessary

to turn on the unit with an open housing. You should do this with extreme care

1.2.1 Risk of electric shock

Operating a running unit with open housing can result in an electric shock.

The areas marked in Pic 1 use mains voltage.

5

SERVICE MANUAL ProSeal Classic/Plus/Premium

Daily or after 400 seals

Yearly or after 100,000 seals

whichever occurs first

Visual seal seam check

Preventive maintenance

Check printed text on seal bag

Touching these areas can cause lethal injury!

Pic 1

1.2.2 Risk of burning

During operation, the heat elements can reach temperatures to 200°C.

Touching these parts or parts around them can result in severe burning.

1.2.3 Risk of Entrapment

In standby mode, the sealer transport belt can start to move to avoid radiant

heat on the transport belt.

1.2.4 Tools

Tools needed to service and repair the unit are:

Allen key

Circlip pliers

ESD protection

Knife

Non aggressive solvent and degreasing agent

Pinch pliers

3M VHB cleaner

, 4, 5 and 8

2 Preventive maintenance plan

In order to avoid damage or a failure of the unit as a result of insufficient

maintenance we recommend servicing the unit at least once every year or after

100,000 seals. During maintenance the above-mentioned precautions should be

followed. The sealing result should be checked after each maintenance.

6

SERVICE MANUAL ProSeal Classic/Plus/Premium

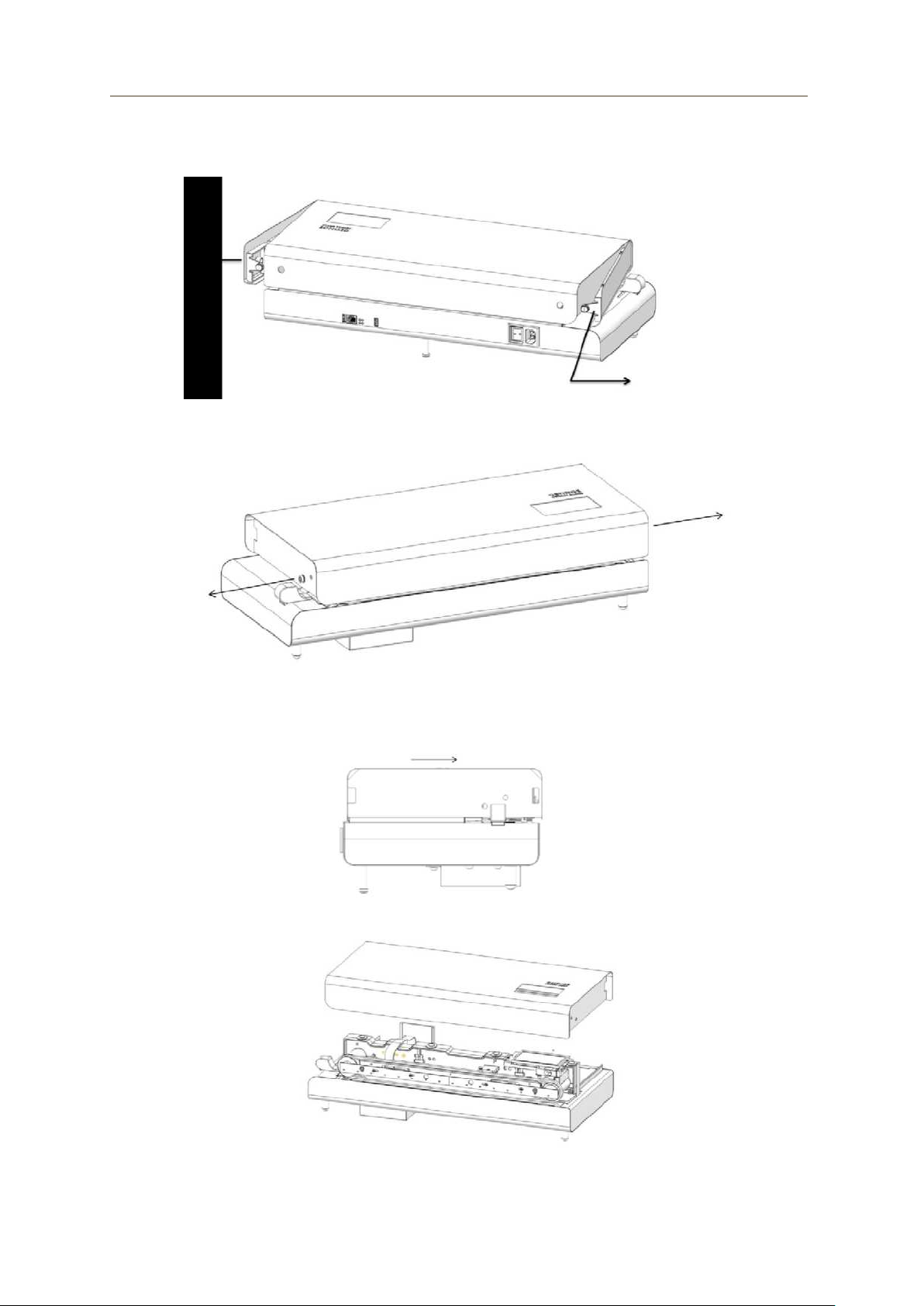

2.1 Opening the unit

Open the housing; remove the side covers (Pic 2)

Pic 2

Remove the screws on both sides of the top cover(Pic 3)

Pic 3

Lift the top cover somewhat on the front and pull it forward so you can remove

it (Pic 4 + Pic 5)

Pic 4

Pic 5

7

SERVICE MANUAL ProSeal Classic/Plus/Premium

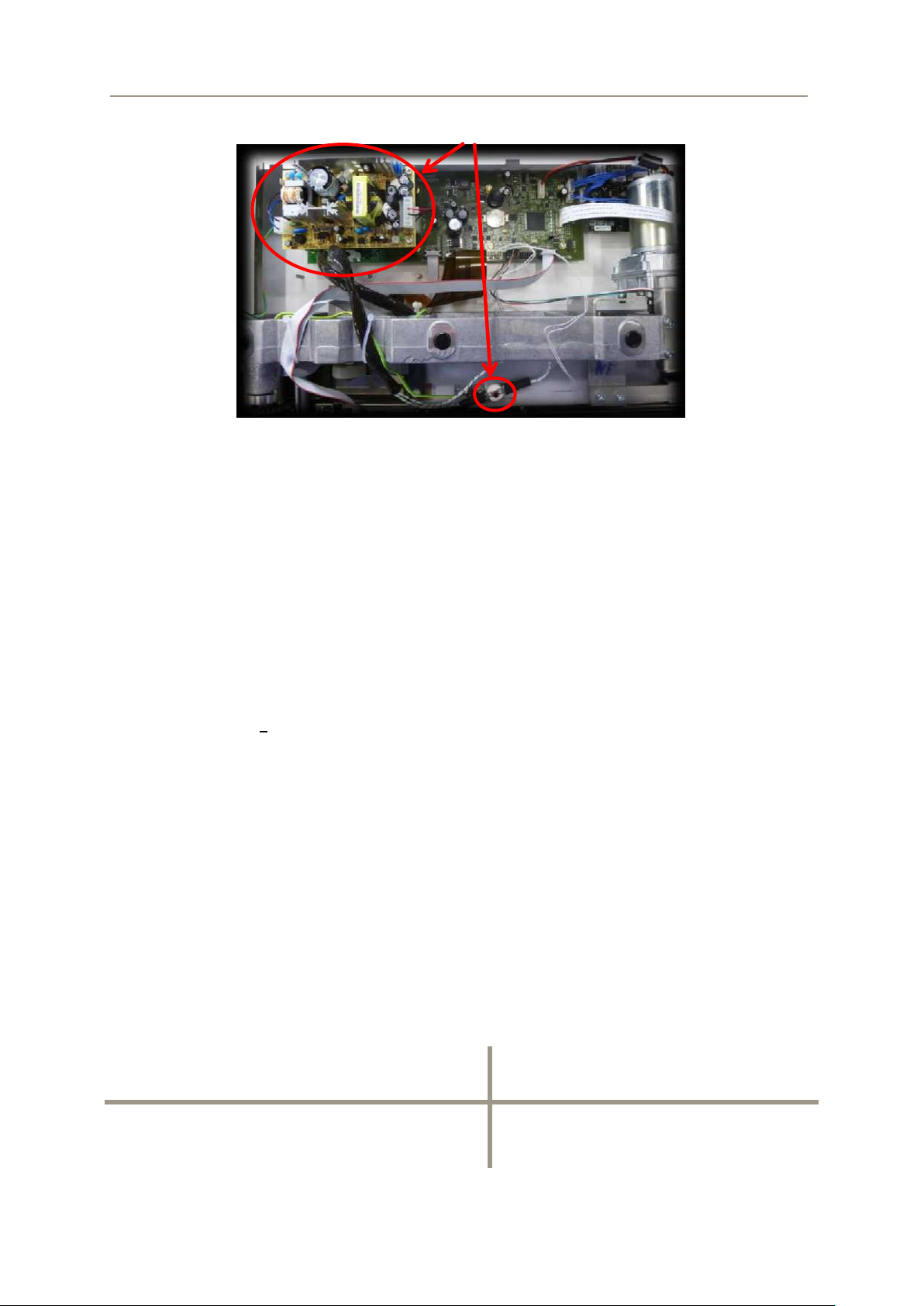

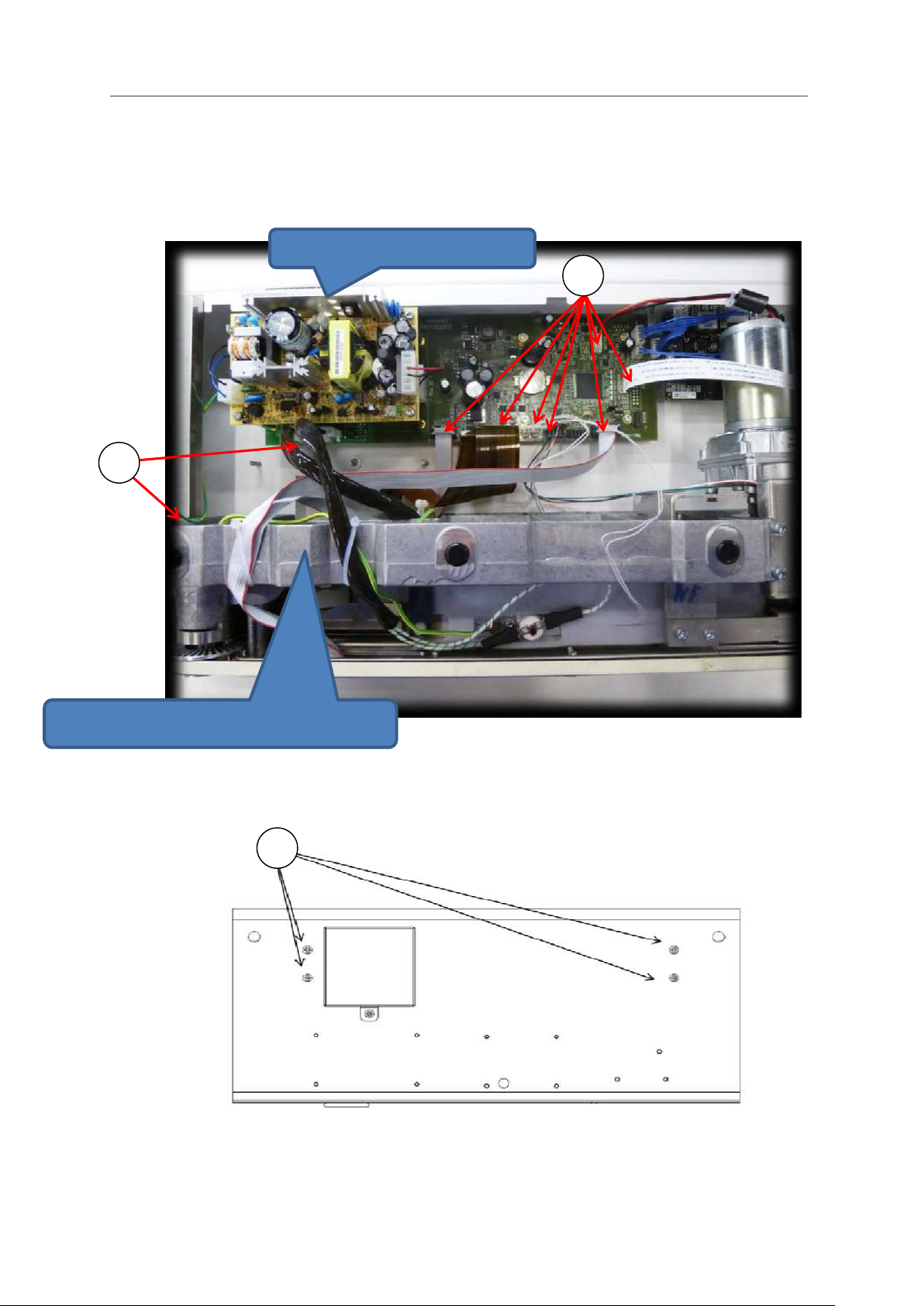

Control board

Base frame

2.2 Removing the base frame from the housing

Disconnect the wiring from the base frame and the control board (Pic 6). Use

special care with the flat cable coming of the display. This cable is easily

damaged.

Pic 6

Turn the unit on the front side, be careful with the touchscreen! Remove

screws (1) to separate the base frame from the housing (Pic 7). After

removing the screws, turn the sealer back.

Pic 7

8

SERVICE MANUAL ProSeal Classic/Plus/Premium

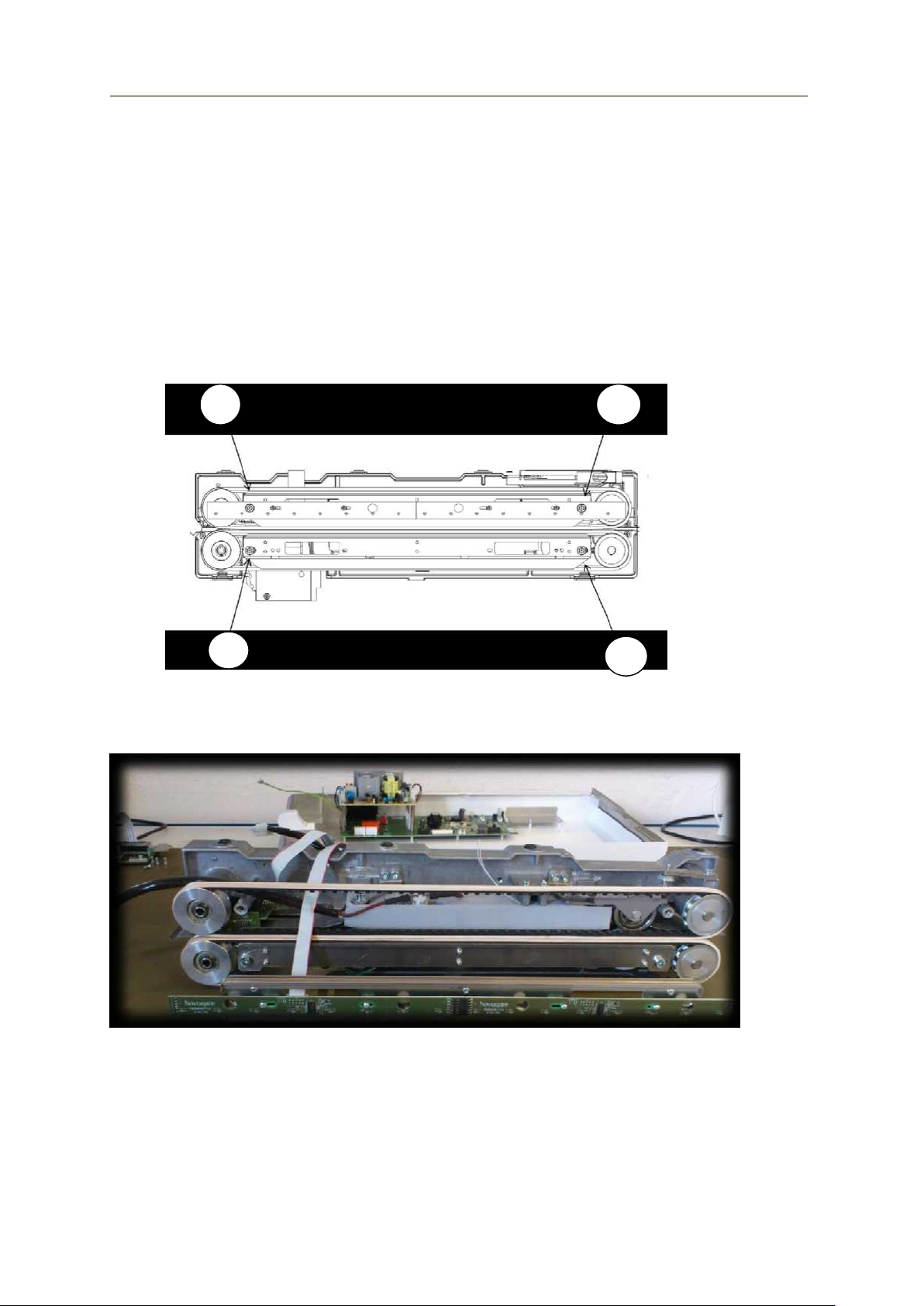

2

2

2

2.3 Replacing the PTFE material

The belt guides and the heating rails are lined with a non-stick strip (PTFE tape). It is

non-stick so your pouches will not stick on the heating rails. It is also on the belt

guides which expands the life of the transportation belts.

For preventive maintenance the PTFE material on the heating rails and belt guides

must be replaced.

2.3.1 The belt guides

The base frame has been removed from the housing.

Unscrew the belt guides (Pic 8)

Pic 8

Press the upper belt guide down. The top of the upper belt guide can now

move forward and the whole upper belt guide can be removed.(Pic 9)

Pic 9

When the upper belt guide is loose, the lower belt guide can be pulled out.

9

SERVICE MANUAL ProSeal Classic/Plus/Premium

Remove the press plate and the guide plate of the upper belt guide assembly

(Pic 10)

Pic 10

Remove the worn PTFE strips on the guide plate and press plates.

Clean off the bonding agent residues with a solvent and degrease the bonding

surface with a non-aggressive degreasing agent.

Stick the new PTFE tape on the guide plate and press plate; do not touch the

cleaned bonding surface and press the tape over the complete area

thoroughly.

Reinstall the belt guide assembly. Make sure that the press plate moves

freely.

See paragraph 4.3.2 for the mounting instruction of the belt guide assembly to

the base frame; for preventive maintenance, see paragraph 2.3.2.

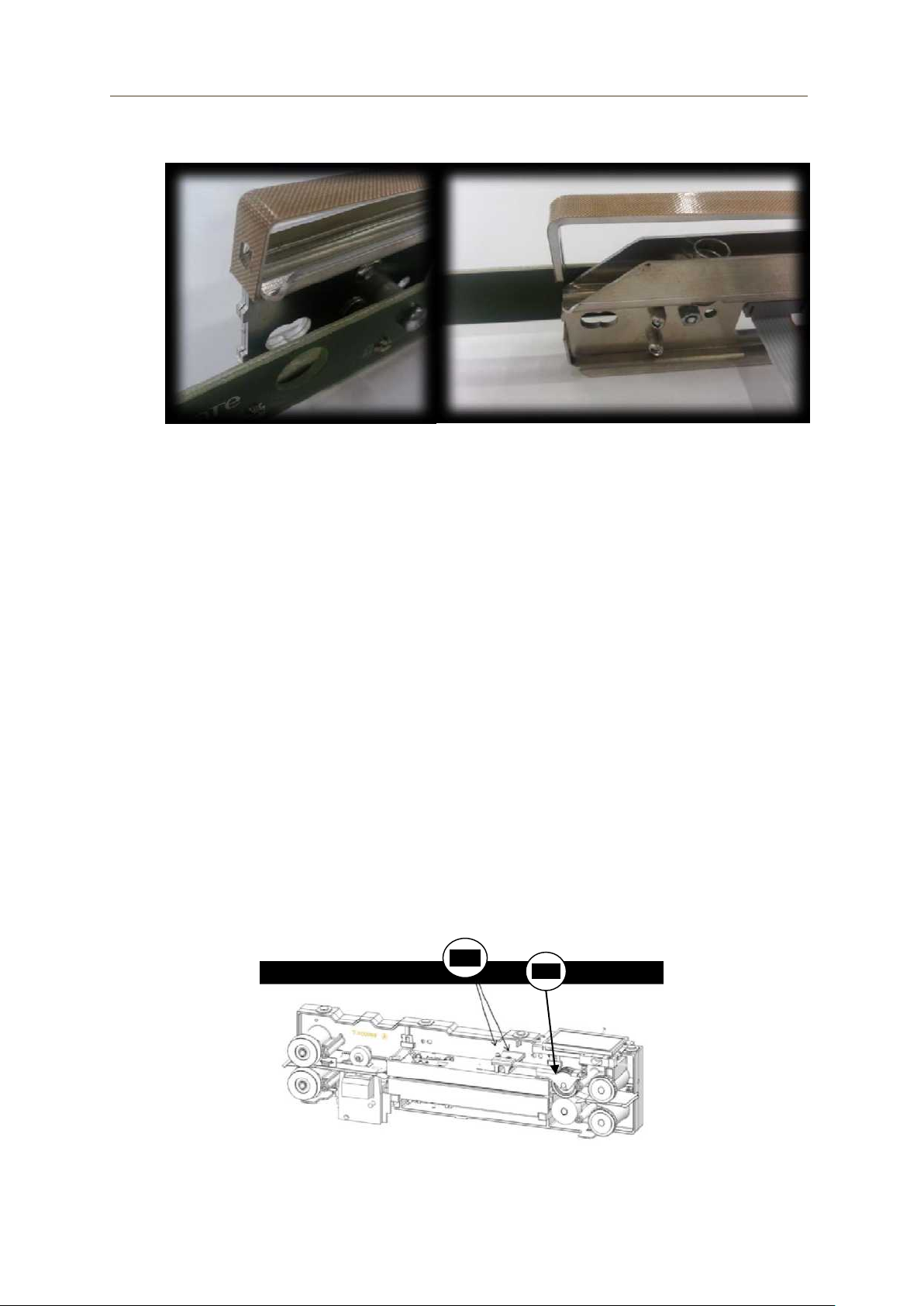

2.3.2 The heating elements

Disconnect the ground wire of the upper and lower heating element with a

plier.

Attention! Do not pull the cables; this could damage the heating

elements! Use a plier on the connector.

Remove the upper pressure roller (Pic 11) by releasing the pressure with

screw (1).

After releasing the pressure remove the screws (2) to dismount the

suspension of the upper pressure roller.

Pic 11

10

SERVICE MANUAL ProSeal Classic/Plus/Premium

Unscrew the two screws on top of the heating elements to release the upper

heating element with isolation from the frame (Pic 12).

Pic 12

When the upper element is removed it is easy to remove the lower element

and insulation (Pic 13).

Pic 13

Remove the insulation foam from the heating rails (Pic 14).

Pic 14

Remove the worn PTFE strip. Clean off the bonding agent residues with a

solvent and degrease the bonding surface with a non-aggressive degreasing

agent. Stick the new PTFE strip on the element. Cut the PTFE strip to fold the

11

SERVICE MANUAL ProSeal Classic/Plus/Premium

1

strip around the heating cables. Do not touch the cleaned bonding surface and

press the strip thoroughly over the complete area.

Cut a notch into the PTFE strip (1) (Pic 15).

Pic 15

See paragraph 4.3.1 for the mounting instruction of the heating elements to

the base frame.

2.4 Transport belts

During use, the transport belts in the ProSeal will start to get worn out. It is therefore

important to replace the transport belt during preventive maintenance.

Remove the belt guides (paragraph 2.3.1). It is not necessary to remove the

heating elements.

Remove the clamp with a circlip plier holding the smooth wheel in place

(Pic 16). Do this with the upper and lower wheel.

Pic 16

Remove the upper and lower smooth wheel (Pic 17) and replace the transport

belt. Make sure that the arrows on the belt are pointing in the movement

direction of the belt.

Pic 17

12

SERVICE MANUAL ProSeal Classic/Plus/Premium

2

1

1

Tension the belt by hand and fasten the belt pulley. (Pic 18)Make sure that the

belt is not sag down.

Pic 18

2.5 Printer (only ProSeal Premium)

We recommend to exchange the printer ribbon each time during maintenance.

Remove screw (1) and remove lid (2). (Pic 19).

Pic 19

Unscrew the fastening screws a couple mm to release the printer module. (Pic

20)

Pic 20

Remove the printer ribbon from the printer module. Pull at the printer ribbon at

the bottom side of the printer module to remove it.(Pic 21)

Pic 21

13

SERVICE MANUAL ProSeal Classic/Plus/Premium

Turn the printer module upside down and clean the area around the printer

needles(Pic 22).

Pic 22

Switch the unit on.

Produce some seal samples with printing.

Check if the text on the seal samples is printed well.

If the text is illegible, turn the pin on the printer ribbon housing (2) (Pic 23).

Produce some seal samples again with printed parameters or text.

Check if the text on the seal samples is printed well.

If the text is illegible, check if the distance between the printer head and the

printer wheel is still 0.3-0.4 mm (depending on sealing material). Use a feeler

gauge with 0.3-0.4 mm thickness.

If the distance is not 0.3-0.4 mm, loosen the screw; see Pic 23 (1).

Pic 23

Lay a feeler gauge with a 0,3-0,4 mm thickness above the printer head.

Place the nylon printing wheel so that it is lying on top of the feeler gauge.

Fasten the screw and remove the feeler gauge.

Check the printing result.

2.6 Upper pressing wheel.

Check – at every maintenance inspection – if the surface of the upper pressing wheel

is worn out or damaged. If the upper pressing wheel is worn out or damaged, it

should be replaced.

14

SERVICE MANUAL ProSeal Classic/Plus/Premium

Nr.

Error text

Description

Possible problem / solution

1

Bag too small for

printer text

Selected printer text

doesn't fit on the

inserted pouch

Insert larger pouch or adjust printed text length

(chapter 7.9) or decrease dot spacing (printer

menu)

PCB on the inlet of the pouch mounted

incorrectly

Check “sensors active” parameter by inserting

pouch

Cable start sensors disconnected / broken

Start sensor PCB defect

Control PCB defect

The upper pressure wheel can be removed and exchanged.

See paragraph 4.3.4 for the mounting instruction of the upper pressure roller.

2.7 Lower pressing wheel

For the lower pressing wheel one should follow the same procedure as for the upper

pressing wheel. Check if the surface of the lower pressing wheel is worn out or

damaged. If the lower pressing wheel is worn out or damaged, replace the complete

part.

Remove the spur gear (1) from the shaft (Pic 24) by removing the clamping

pin Ø3x12mm (2).

Pic 24

The lower pressing wheel can be pulled out of the base frame and exchanged

with the new one.

Reassemble the unit in the opposite order; after assembly check if the

mechanism is running properly.

3 Trouble shooting

3.1 Error codes

Error codes higher than 12 are critical errors. Sealing is not possible anymore, only

after turning off and on the sealer, the error is reset. Always try first to turn the sealer

off and on to fix the problem. Also check if newer software version is available.

15

SERVICE MANUAL ProSeal Classic/Plus/Premium

2

Could not print due

to pouch depth

Not able to print due

to pouch insertion

depth

Pouch not entered deep enough into the sealer.

The pouch doesn’t run over the printer head

PCB on the inlet of the pouch mounted

incorrectly

Check “sensors active” parameter by inserting

pouch

Cable start sensors disconnected / broken

Start sensor PCB defect

Control PCB defect

3

Temperature too

low

Temperature below

set point - alarm limit

Pouch detected before temperature was

reached

Alarm limit temperature too low

Cable temperature sensor disconnected /

broken

Temperature sensor on heating element defect

Control PCB defect

4

Temperature too

high

Temperature above

set point + alarm

limit

Pouch detected before temperature was

reached

Alarm limit temperature too low

Cable temperature sensor disconnected /

broken

Temperature sensor on heating element defect

Control PCB defect

5

Pressure too low

Pressure below set

point - alarm limit

Set point pressure not correct

Alarm limit pressure too low

Pressure not correct (adjust the screw on the

pressure sensor according to paragraph 4.3.3)

Pressure wheel not clean

Pressure sensor defect

Control PCB defect

6

Pressure too high

Pressure above set

point + alarm limit

Pouch too thick

Set point pressure not correct

Alarm limit pressure too low

Pressure not correct (adjust the screw on the

pressure sensor according to paragraph 4.3.3)

Pressure wheel not clean

Pressure sensor defect

Control PCB defect

7

Speed too low

Speed below set

point - alarm limit

Pouch too heavy or thick

Alarm limit speed too low

Belt too loose or too tight

PCB on the inlet of the pouch mounted

incorrectly

Encoder sticker on the belt pulley damaged

Cable start sensors disconnected / broken

Start sensor PCB defect

Control PCB defect

16

SERVICE MANUAL ProSeal Classic/Plus/Premium

8

Speed too high

Speed above set

point + alarm limit

Pouch too heavy or thick

Alarm limit speed too low

Belt too loose or too tight

PCB on the inlet of the pouch mounted

incorrectly

Encoder sticker on the belt pulley damaged

Cable start sensors disconnected / broken

Start sensor PCB defect

Control PCB defect

9

Reverse error

Reverse button

pressed during

sealing

Reverse button pressed during sealing (only

used in log and reported to the NetCOM)

10

No seal command

received

Trying to seal when

the unit is in

NetCOM command

mode but no seal

command received

from the NetCOM

Send seal command from NetCOM and seal

again.

Use the sealer in “auto” mode instead of

“command” mode

11

NetCOM event

NetCOM sent an

error event that must

be acknowledged by

the user

Check manual NetCOM

12

NetCOM error

NetCOM

communication error

Cable(s) between control PCB and NetCOM

disconnected / broken

Wrong software version in NetCOM

No activated license for sealer in NetCOM

NetCOM defect

Control PCB defect

13

USB overcurrent

Overcurrent event

detected on (unit)

USB port

Short circuit in attached USB device

Control PCB defect

14

Printer over

temperature

Printer head over

temperature event

detected

Too much printer activity

Cable printer disconnected / broken

Printer head defect

Control PCB defect

15

Print buffer

underrun

Software error

Update firmware

16

Printer overcurrent

Ribbon motor or

needle drive circuit

detected an

overcurrent event

Too much printer activity

Printer head defect

Ribbon motor defect

Control PCB defect

17

Printer needle

stuck

Print current

measured while no

printer needle was

activated

Printer head defect

Control PCB defect

17

SERVICE MANUAL ProSeal Classic/Plus/Premium

18

Temperature

difference error

Large temperature

difference between

lower and upper

heater element

Cable heating element (power) disconnected /

broken

One of the 2 heating elements defect (check

resistance, should be almost equal)

Cable temperature sensor disconnected /

broken

Temperature sensor on heating element defect

Control PCB defect

19

Heating error

Heating elements

are on but the

temperature doesn't

rise (fast enough).

Cable heating element (power) disconnected /

broken

Thermostat upper heating element activated

Thermostat lower heating element activated

Heating element(s) defect (check resistance)

Cable temperature sensor disconnected /

broken

Temperature sensor on heating element defect

Control PCB defect

To reset thermostat:

Wait until heating elements are cooled down and

press button on thermostat to reset, use low force.

If thermostat was activated a click can be felt when

pressing the reset button

20

Temp1K8Calib

error

Temperature selftest of the control

PCB failed.

Control PCB defect

21

Temp1K2Calib

error

Temperature selftest of the control

PCB failed.

Control PCB defect

22

PressFullCalib

error

Pressure self-test of

the control PCB

failed.

Control PCB defect

23

PressNullCalib

error

Pressure self-test of

the control PCB

failed.

Control PCB defect

24

Pressure sensor 1

error

No communication

with pressure sensor

1

Cable pressure sensor disconnected / broken

Pressure sensor defect

Control PCB defect

25

Pressure sensor 2

error

No communication

with pressure sensor

2

Cable pressure sensor disconnected / broken

Pressure sensor defect

Control PCB defect

26

SPI flash error

Error while

communicating with

flash memory

Firmware update

Control PCB defect

27

Mains detection

error

Error while

measuring mains

frequency and

voltage

Mains voltage or frequency out of range for

sealer specification

Control PCB defect

28

Temperature

overheat error

Temperature of one

or two temperature

sensors above

210°C

Cable temperature sensor disconnected /

broken

Temperature sensor on heating element defect

Control PCB defect

18

SERVICE MANUAL ProSeal Classic/Plus/Premium

29

Software error

General software

error

Firmware update

Control PCB defect

30

Hardware error

General hardware

error

Firmware update

Control PCB defect

Measure the resistance between the

ground and the other contacts. If the

resistance on one of the contacts is

lower than stated, the printhead is

defective.

Attention!

A defective print head can destroy

the electronic system in the sealer.

3.2 Print head (ProSeal Premium)

Attention! A defective print head can destroy the electronic system in the

sealer.

Therefore, first check whether the print head is defective. Measure the resistance of

the individual contacts (Pic 25). If the resistance is not correct, the print head must be

replaced.

19

Pic 25

SERVICE MANUAL ProSeal Classic/Plus/Premium

1

4 Repair

4.1 Repair printer (ProSeal Premium)

The print head needs to be handled very carefully. For correct printing, the print head

needs to be replaced by following the next steps.

Attention! To avoid damage caused by electrostatic charging.

Before starting always remove the base frame from the housing

(paragraph 2.2).

Remove the printer ribbon housing (1) (Pic 26).

Pic 26

Remove the defective print head and replace it with a new one.

Place the blue lever (1) (Pic 27) on its middle position.

A space of 0.3-0.4 mm has to be applied between the print head and the nylon

printing wheel (see paragraph 2.5).

Loosen the screw (2) (Pic 16).

Lay a feeler gauge from 0.3-0.4 mm above the print head.

Place the nylon printing wheel so that it is lying on top of the feeler gauge.

Fasten the screw and remove the feeler gauge.

Place the printer ribbon housing back.

20

SERVICE MANUAL ProSeal Classic/Plus/Premium

Lift upper part connector

1 2 1

Put the blue lever (1) back on its lowest position (Pic 27).

Pic 27

Check whether the flat cable or the control board is defective. Before removing

the flat cable, the upper part of the connecter must be lifted (Pic 28).

Pic 28

4.2 Control board

Attention! Ground yourself to avoid damage caused by

electrostatic charging.

Disconnect all connectors from the control board (Pic 29) (1).

Remove the 2 connectors between the control board and the power supply,

and unscrew the power supply.

Disassemble the defective control board by loosening the socket head screws.

Dispose of the defective control board in an environment-friendly manner or

send it back to the manufacturer.

Install a new control board.

Re-assemble the complete unit in the opposite order. (Don’t forget to

reconnect the protective ground.)

21

SERVICE MANUAL ProSeal Classic/Plus/Premium

Pic 29

Check all functions. After replacing the control board, the speed, temperature and

pressure should be revalidated. For the ProSeal Classic the speed and temperature

should be validated. For instructions how to validate see section 5.

.

4.3 Assembling

Clean the parts and the lower housing of the unit with compressed air and

surface cleaner.

4.3.1 Heating elements

Turn the heat element upside down and place it in the isolation (Pic 30).

Pic 30

Place the heat element and isolation on the suspension of the base frame

(Pic 31).

22

SERVICE MANUAL ProSeal Classic/Plus/Premium

Pic 31

Align the upper heating element in line with the lower heating element, and

press the spring between the upper heating element and the clamp.(Pic 32)

Pic 32

Fasten the right side, of the upper heating element, until the heating elements

are just separated from each other(Pic 33)

Pic 33

Do the same with the left side, but the elements must barely touch each

other.(Pic 34)

Pic 34

23

SERVICE MANUAL ProSeal Classic/Plus/Premium

Upper belt wheel

Lower belt wheel

Connect the wiring of the upper and lower element. Do not forget to connect

the ground cable. Make sure that the correct cable is connected to the

corresponding control board slot.

4.3.2 Transport belts

Place the belt around the toothed wheel. (Pic 35), make sure that the arrows

on the belt are pointing in the movement direction of the belt.

Pic 35

Place the smooth wheel in the belt (Pic 37). Make sure the wheel with sticker

goes to the upper belt (Pic 36).

Pic 36

24

Pic 37

SERVICE MANUAL ProSeal Classic/Plus/Premium

Belt guide

Clamp wrong

Clamp good

Fix the smooth wheel with the original clamp and the circlip pliers. Make sure

the clamp is properly fixated. (Pic 38)

Pic 38

4.3.3 Belt guides

Mount the upper belt guide to the base frame, slide the guide over the inside

of the belt and press it down until the belt can move over the belt guide. Check

that the flat belt wheel and the toothed wheel run smoothly (Pic 39).

Pic 39

After fastening the upper belt guide, mount the lower belt guide in the same

way.

25

SERVICE MANUAL ProSeal Classic/Plus/Premium

4.3.4 Upper pressure roller

First mount the suspension and the pressure roller on the base frame (Pic 40).

Pic 40

Place the spring between the suspension and the load cell and fasten it with

the M4 screw (Pic 41).

Pic 41

4.3.5 Mounting the base frame in the bottom housing

Place the base frame upside down; be careful with the touchscreen! Place the

bottom housing over the base frame and secure it with 4 screws (Pic 42).

Pic 42

26

SERVICE MANUAL ProSeal Classic/Plus/Premium

Temperature

probe

Tachometer

Temperature

meter

Pressure

meter

•ProSeal

Pressure tool

Cable

ProSeal

Pressure

tool

Adapter

Pressure meter

After assembling the sealer, calibrate the replaced parts if possible. It is

advised to validate the pressure, speed and temperature to ensure the

ProSealer is still within specs.

5 Validation

During preventive maintenance, the ProSeal needs to be validated to ensure the

sealer is still within specifications.

5.1 Validation Kit

The ProSeal can be validated using the validation kit. This kit contains:

Tachometer

Temperature meter

Temperature probe

Heat conductive paste

Pressure meter

ProSeal Pressure tool

Adapter Pressure meter

Cable ProSeal Pressure tool

Pic 43

27

SERVICE MANUAL ProSeal Classic/Plus/Premium

Turn knob left.

Press button to select

Configuration.

Password blinking.

Turn knob to enter passcode.

To select press button. (all 4

digits need to be confirmed)

Turn knob right.

Turn knob right.

Press button.

Speed will blink.

Turn knob left or right to adjust

speed.

Confirm speed by pressing the

button.

Hold a pouch under the sensor

and validate the speed with the

tachometer.

Turn knob right .

Press button.

Put heat conducting paste on

the upper heat element.

Temperature will blink.

Validate the temperature with

the temperature meter and

probe.

Turn knob left or right to adjust

temperature.

Confirm temperature by

pressing the button.

5.2 Classic

5.2.1 Logging in

A service technician can use the service functions of the unit after logging in the

“service login”. The service password is 8729. Without this password, the

configuration settings can be viewed but cannot be changed.

5.2.2 Pressure

It is not possible to validate the pressure of the ProSeal Classic.

5.2.3 Speed

5.2.4 Temperature

5.3 Plus and Premium

The ProSeal Plus and ProSeal Premium can be validated using the validation menu.

In order to reach the validation menu, you must login as service.

28

SERVICE MANUAL ProSeal Classic/Plus/Premium

5.3.1 Logging in

A service technician can use the service functions of the unit after logging in the

“service login”. The service password is 8729. Without this password, the

configuration settings can be viewed but cannot be changed.

Press Menu Press Service login

Enter password 8729 Press Configuration

Press OK to log in

Press Service to enter service menu

After logging in, the validation menu can be reached to navigate to the service

menu. In this menu press validaton to reach the validation menu (Pic 44).

Pic 44

5.3.2 Pressure

Pic 45

In the pressure menu (Pic 45) the pressure set point and the measured pressure can

be seen. Both values should be equal(±1N). If there is a difference you can change

the measured pressure by adjusting screw (1) (Pic 46).

29

SERVICE MANUAL ProSeal Classic/Plus/Premium

Pic 46

For validation of the pressure you need the ProSeal pressure tool. Mount the

tool on the pressure load cell (Pic 47).

Pic 47

Adjust screw (1) so that the value of the measured pressure on the display of

the unit is “0”. The value of the display of the ProSeal calibration tool should

be equal to the pressure set point (±10N) (Pic 48). If the pressure exceed the

tolerance of 10N, a new load cell and load cell print needs to be installed.

.

Pic 48

Remove the ProSeal calibration tool, and check if the measured pressure of

the unit is equal to the pressure set point. If not, adjust it with screw (1)

(Pic 48).

You have validated the pressure of the unit.

5.3.3 Speed

Pic 49

Go back to the validation menu and press Speed.

In the speed settings (Pic 49) the speed settings can be changed.

By pressing on the + or – from Motor manual you can turn on or shut off the

motor manually.

30

SERVICE MANUAL ProSeal Classic/Plus/Premium

Press the + button to turn on the motor forward. On the right in the display you

can read the speed of the running motor; the value should be the same (± 10

mm/sec).

For validation adjust the speed to 120 mm/s (min. speed); check with a

tachometer if the speed of the belt is equal, check also at 170 mm/s

(max. speed).

The factory setting for speed is 160mm/s.

5.3.4 Temperature

Be aware of the tolerance of the temperature device you use.

Pic 50

Go back to the validation menu and press Temp.

In this Temperature menu (Pic 50) you see the temperature set point and the

measured temperature of the unit. There will always be a difference between

these values which is caused by the temperature control.

Place heat conduction paste on top of the heat element (Pic 51).

Pic 51

Change the set temperature to 100 °C

Place the temperature probe on top of the heat conducting paste.

Compare the temperature of the upper heat element with the temperature

meter. Be sure that the measured temperature is the same as the temperature

of the upper heat element (± 5°C).

Change the set temperature to 200 °C

Compare the temperature of the upper heat element with the temperature

meter. Be sure that the measured temperature is the same as the temperature

of the upper heat element (± 5°C).

6 Spare parts

Spare parts can be ordered by means of the enclosed drawings. Always state the

type designation and the serial number of the unit when ordering spare parts. Copy

the respective drawing and mark the required spare part.

31

SERVICE MANUAL ProSeal Classic/Plus/Premium

Part number

Description

Classic

Plus

Premium

66007025

PM kit

x

66007026

PM kit x x

The following spare parts are delivered as pre-assembled assemblies:

32

Loading...

Loading...