Page 1

GETINGE A.B.

Technical Information Data Sheet

Specification for

Getinge cGMP

Equipment Features

Page 2

cGMP EQUIPMENT FEATURES

TECHNICAL INFORMATION DATA SHEET

Specification for

Getinge cGMP Equipment Features

Getinge A.B.

Head Office

P.O. Box 69

S-310 44 Getinge

Sweden

Phone +46 35 15 55 00 • Fax +46 35 54952

1

Page 3

The Getinge Group

Disinfection and Sterilization Business

Getinge is a world leading company in the field of medical

technology, specializing in the development and manufacture of

equipment for the HealthCare and Pharmaceutical industries.

With over sixty years of experience, and manufacturing plants in

Sweden, United Kingdom, United States, France and Australia, we

are the World's leading supplier of disinfection and sterilization

equipment, serving customers in more than 100 countries on all 5

continents.

Getinge manufactures a full range of steam and gas sterilizers. We

produce a wide range of "industry standard" models and offer a

custom design and build service for special products and

applications.

Always at the forefront of sterilization technology, we are constantly

developing new features and techniques to satisfy the demands of

our customers and regulatory bodies.

We pride ourselves in our world - class, market leading technology,

employing every aspect of our exhaustive experience and 'knowhow' to solve our clients' problems in the sterilization of the new

delivery and packaging systems for pharmaceuticals and medical

devices.

© Getinge 1997

Page 4

Introduction

As the World’s leading manufacturer of sterilization equipment for

the Pharmaceutical Industry, Getinge A.B. accepts a responsibility to

promote the ‘state-of-the-art’ in sterilization technology.

There are few rules and regulations that define ‘cGMP’ in terms of

technical specification. Indeed most sterilizers produced by Getinge

will satisfy those regulations that do exist and in this respect, most

Getinge sterilizers comply with ‘GMP’ requirements.

However, for those customers who require an additional assurance

to be at the ‘leading edge’ in terms of cGMP compliance, Getinge

offers an additional, optional, package of equipment features that

address all current concerns in the industry.

Working from experience gained over many years, we have

developed this set of equipment features designed to satisfy the

known cGMP requirements of the Pharmaceutical Industry including those of Europe, U.S. and Japan.

Scope

This document refers specifically to steam sterilizers (Getinge

reference ‘GE’, steam and air mixture sterilizers (Getinge reference

‘GEV’) and circulating water sterilizers (Getinge reference ‘GEC’).

As required, comments are added to distinguish between features

specific to each model.

2

01/05/99 GMP_.doc Issue 1 - Jan-97

© Getinge 1997

Page 5

Definitions

The 'Product' is defined as the item or items being processed in the

sterilizer.

The 'Process System' is defined as any part of the chamber or

piping system that is in contact with the product, or in contact with

media that is subsequently in contact with the product during a

sterilization process.

Generally, this includes all pipework connected to the sterilizing

chamber, up to and including the first isolation valve and all lines

carrying process media (steam, water or filtered air) to the chamber.

'Control sensor' is defined for the purpose of this document as the

sensor that activates the timer for Exposure Period.

'Exposure period' is defined as the holding period after the Control

Sensor has achieved sterilization temperature.

Comments in parentheses [ ] are specifically for customer

consideration.

'Dead-leg' is defined as any pipe or connection in the Process

System in which there is no flow, that is greater than six (6) times

the internal diameter of the pipe.

3

01/05/99 GMP_.doc Issue 1 - Jan-97

© Getinge 1997

Page 6

Chamber and Piping System

Materials - Chamber

The chamber shall be manufactured from Stainless Steel type 3161.

All components, fittings & fixings used within the chamber shall be

stainless steel of a grade appropriate to the product, process and

media. Generally, Stainless Steel type 304 shall be acceptable for

this application.

Materials - Piping and components

The Process System piping and components shall be fabricated

using piping of a material suitable for the application. The process

media shall not be contaminated by the materials and materials shall

not be corroded by the process media.

Generally, Stainless Steel type 3161 shall be used for applications

where Clean or Pure steam is used as the Process Media.

Drainage

The piping & components in the Process System shall be designed

to drain freely - either into the chamber (and from there to waste), or

directly to the waste system. No pipes or connections shall be

allowed, or have the ability to collect or hold water or condensate.

[Consideration shall be given to the steam supply to ensure it is

adequately drained.]

The piping system shall be designed, and equipment selected and

installed such that pipes, fittings and components do not retain

moisture

Piping shall be sloped to a minimum of 1% towards the drain

(e.g. 3 mm fall in a 300 mm length)

Backflow prevention

Means shall be provided to prevent backflow of one medium into

another at interconnections between systems, and from the drain

system to the Process System.

1

Type 316 ‘L’ or ‘Ti’ , etc according to local practice or requirements

4

01/05/99 GMP_.doc Issue 1 - Jan-97

© Getinge 1997

Page 7

Dead-Legs

There shall be no Dead Leg in the Process System

All Process System piping and components shall be designed to be

sterilized as part of each process cycle (or otherwise be sealed

during process cycles in which it is not used).

Consideration shall be given to lines and connections that are be

used infrequently or are unused during an alternate process.

(For example, steam inlet manifolds on GEC type sterilizers fitted

with a vacuum sterilizing capability, and vice-versa, water inlet

manifolds on the same equipment). In such cases, the use of

bleeders and/or maintenance sanitization cycles shall be used.

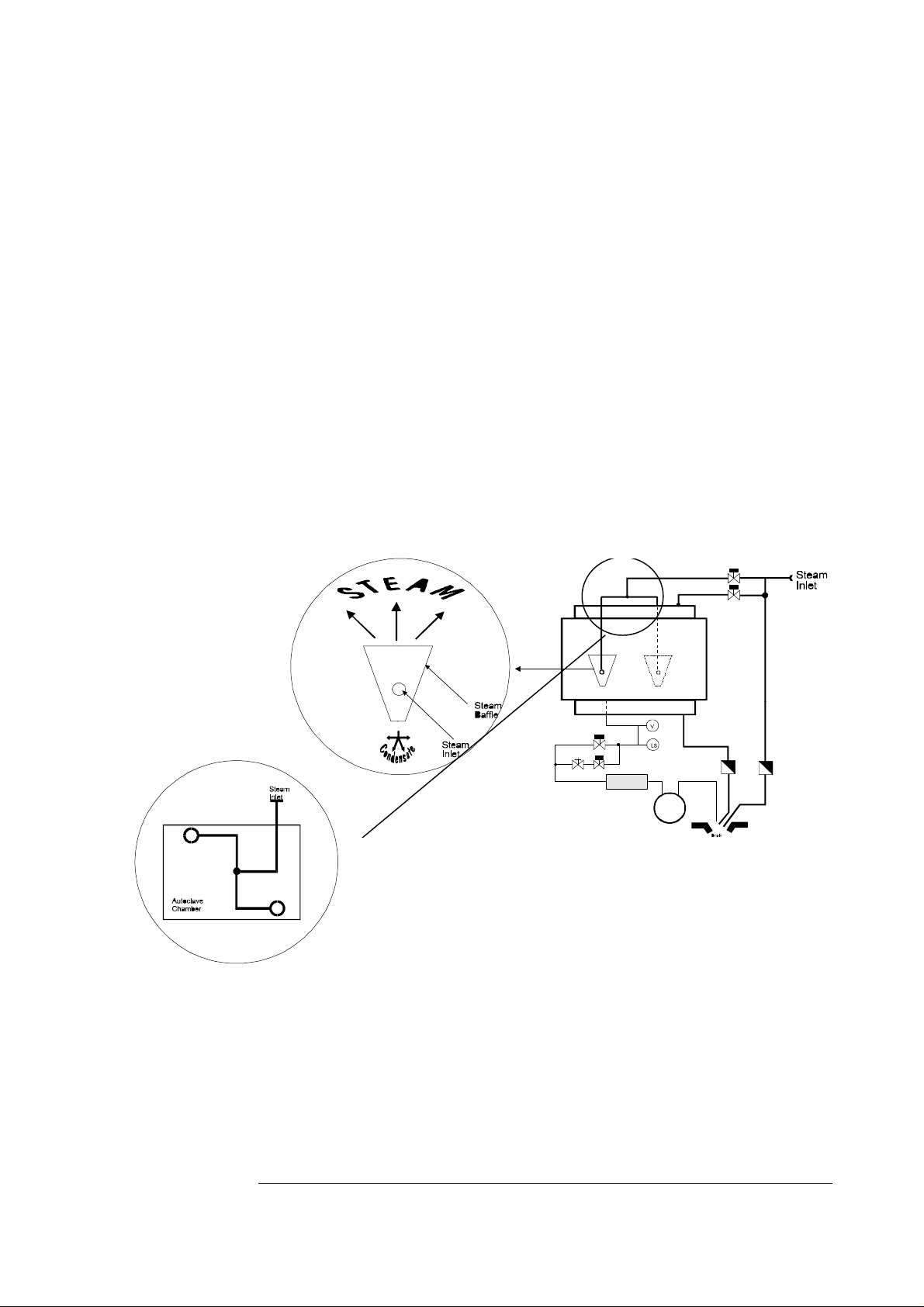

Steam Inlet

Steam inlet piping and manifolds shall be designed and constructed

to distribute steam uniformly throughout the chamber.

Air Inlet

Air entering the chamber shall be filtered if the air is subsequently in

contact with the Product.

Air inlet filters for vacuum break and admission of compressed air

shall be a microbial retentive membrane filter. The pore size of the

5

01/05/99 GMP_.doc Issue 1 - Jan-97

© Getinge 1997

Page 8

GEV

and

GEC

filter shall be according to specific regulatory and product

requirements, but shall generally be less than 0.22 µm.

Heat Exchangers

Internal Heat Exchanger - GEV

The internal heat exchangers shall be of sanitary design

and fabricated from the same material as the chamber

(usually Stainless Steel type 3161 ) and designed to negate

the possibility of leakage of coolant into the chamber or

Process System.

The heat exchanger system / control system shall

incorporate a Leak Test program to periodically check the

integrity of the Heat Exchangers.

External Heat Exchanger - GEC

The external heat exchangers shall be of sanitary design

with process contact surfaces fabricated from the same

material as the chamber (usually Stainless Steel type 316

and designed to negate the possibility of leakage of coolant

into the chamber or Process System.

Generally, where a plate heat exchanger is used, it shall

incorporate a dual gasket system.

1

1

Type 316 ‘L’ or ‘Ti’ , etc according to local practice or requirements

6

01/05/99 GMP_.doc Issue 1 - Jan-97

© Getinge 1997

Page 9

Validation Ports

A minimum of one test connection for the entry of thermocouple

temperature sensors shall be fitted in an accessible location.

As a guide, one port for each two load modules shall be provided.

Each load module is 1.0 to 1.3 m deep. This is subject to practicality

to be assessed in each case.

Connection shall be a minimum of 50 mm diameter to accept a

minimum of 12 thermocouple sensors.

Insulation

[All pipes operating above 60°C, or carrying cold water shall be

insulated. However, it may be impractical to insulate all pipes in this

definition. As a guide, pipes greater in length more than 10 times

their external diameter(10D) shall be insulated. Generally, incoming

water lines shall be insulated up to the first point of use. In most

cases, insulation is only practical after installation of the sterilizer.]

Cleaning

Internal surfaces of the chamber shall be smooth and crevice free.

The surfaces shall be polished to provide a minimum Ra value of

0.63 µm. Internal corners shall be radiused with a minimum 50 mm

radius.

The internal surface of the door shall have a surface finish similar to

the internal surface of the chamber.

The internal surface of chamber ports (nozzles) shall have a surface

finish similar to the internal surface of the chamber.

Fascia and Bioseal Panels

It shall be possible to clean the front surfaces of the fascia and

bioseal panels.

[All gaps between fixed panels and all gaps between the fascia and

the adjacent walls / floor shall be filled with suitable sealant after

installation on site.]

All areas behind fascia panels shall be accessible for cleaning.

Where required for access for cleaning, or for access for

maintenance, fascia panels shall be hinged to open.

7

01/05/99 GMP_.doc Issue 1 - Jan-97

© Getinge 1997

Page 10

GEV

and

Internal Chamber Fitments

Loading Rails and Equipment fitted to chamber

It shall be possible to remove internal loading equipment fixings

(rails, rollers) for periodic cleaning and maintenance.

Strainers

All chamber drain ports shall be fitted with a removable mesh

strainer to prevent debris from entering the chamber drain piping.

(The mesh shall be removable from inside the chamber for routine

cleaning by the machine operator.)

Internal Liner (GEV)

The internal liner of the GEV sterilizer shall be removable for

cleaning.

There shall be no ‘hidden’ areas that are inaccessible.

GEC

Internal Distribution Plate (GEC)

The internal distribution of the GEC sterilizer shall be removable for

cleaning.

8

01/05/99 GMP_.doc Issue 1 - Jan-97

© Getinge 1997

Page 11

GE

and

Control System

Temperature Control

Chamber Temperature will be controlled on a temperature or

pressure basis according to cycle and product requirements. In

either case, the Exposure Period shall be controlled according to

temperature - the lowest temperature of the chamber environment

and product.

GEV

GEC

For non-liquids cycles, this will generally be according to the

Chamber Drain temperature only (it is assumed, and verified during

qualification, that the chamber drain is the coolest part of the

chamber).

For liquids, where the liquid volume is greater then 100 ml, the

exposure period shall be controlled according to chamber drain and

load temperature.

By default, Exposure Period control shall always be by Chamber

Drain, and if fitted, Load Temperature sensors.

Temperature Control

Chamber Temperature will be controlled according to the

temperature of the circulating water. Exposure Period shall be

controlled according to temperature - the lowest temperature of the

product sensors fitted.

GE

and

GEV

Condensate Control

A bleed valve (drain valve by-pass) shall be installed in the chamber

drain line. This shall be opened during the heating and exposure

phases to eliminate condensate.

The bleed ensures a steady flow of steam across the control and

verification sensors.

Means shall be provided to detect a blockage of the bleed valve.

High condensate level shall activate an alarm within the control

system, but shall not abort the process. If the temperature at the

control sensor is depressed by the presence of condensate, the

process shall automatically abort.

9

01/05/99 GMP_.doc Issue 1 - Jan-97

© Getinge 1997

Page 12

Pressure Instruments

Pressure gauges, transducers and other capillary lines connecting

instrumentation to the chamber, shall comply with the ‘Dead Leg’

requirement above. If impractical, pressure transmitting liquid filled

diaphragm or electronic transducer systems shall be used.

In case of use of electronic systems relying on an electric power

supply, for safety, a mechanical gauge (also complying with this

specification) shall be fitted in the service area.

Process Recorder

As a minimum, temperature and pressure values shall be recorded

on a time base during each process cycle. This shall be

independent of the control system or designed to indicate

differences between the controlled and recorded values. This

recorder may be included in the optional ‘Cycle Printer’ detailed

below.

Reference Instrument

Independent reference instruments (verification sensors) shall be

fitted to monitor temperature sensors and pressure sensors

controlling the process.

The verification sensors shall be independent of the control system

in respect of the actual sensor, excitation circuits, amplifiers and

scaling and calibration.

For non-liquids cycles, the verification temperature sensor shall be a

second RTD sensor located in the chamber drain pipework (the

Chamber Drain sensor may be dual element - one element

connected to the controller and the other to the monitoring system).

For liquid cycles, a dual element load temperature sensors is

required. One element of the probe shall be connected to the

controller, and the other shall be connected to the monitoring

system.

A verification pressure sensor is required.

Temperature Sensor Accuracy

This shall be according to local codes and practices.

Generally Pt100 RTD sensors according to IEC 751, and with an

accuracy better than ± 0.2°C shall be used.

10

01/05/99 GMP_.doc Issue 1 - Jan-97

© Getinge 1997

Page 13

Alarm Systems

These shall be designed to continuously monitor conditions that are

critical to the sterilization process in order to ensure personnel

safety, equipment safety and product quality and integrity.

All alarms that occur during a process shall be recorded. The

system shall register concurrent alarms.

Alarms shall include audible and visual indicators. Means to silence

audible alarms shall be provided. Silencing the audible alarm shall

not cancel the visual alarm, until the alarm is acknowledged or

cleared. When silenced for one alarm, the audible alarm shall

remain active for other alarms.

Alarms are segregated into three types:

Fatal - those which cause the process to stop. Operator to decide

whether the cycle shall be continued or aborted. These include, but

are not limited to:

• Intentional abort by operator - operation of 'Stop' button

• Power failure for more than pre-set time

• Time-out of process or equipment critical phases - where process

efficacy would be affected or equipment damage would occur

• Failure of temperature and pressure sensors.

• Door lock failure (loss of 'closed' or 'locked' indication)

GEC

GEV

• Pump Failure (COS Ø pump monitor system error)

• Fan Failure (COS Ø fan watch system error)

Non-fatal - those which allow process to continue. These include,

but are not limited to:

• High condensate level detected

• Interlock test errors

11

01/05/99 GMP_.doc Issue 1 - Jan-97

© Getinge 1997

Page 14

Optional Items

Cycle Printer

An automatic measurement and recording system shall be provided.

The following data and parameters shall be recorded, as a minimum:

Header, including:

Date Sterilizer I.D.

Load Identification Operator I.D. & Signature

Cycle Start Time (real time) Cycle Type selected

Cycle Parameters:

Value of adjustable parameters

Set sterilizing time and temperature

Logged on adjustable time base:

Chamber pressure Load temperature(s) (note 2)

Chamber Drain Temperature (note 1) Verification sensor values (note 3)

Note 1: Applies to Non-Liquids cycles only.

Note 2: Applies to Liquids cycles only.

Note 3: See ‘Reference Instrument’ below.

The sterilizer & process I.D. shall be identified at the top of each

page of the process log such that the specific process run can be

uniquely identified. Phase changes within the process shall be

indicated.

PACS Supervisor

The PACS Supervisor is a combination Reference Instrument and

Process Recorder.

The PACS Supervisor is provided with independent sensors for

temperature and pressure. These are then the 'Verification Sensors'

mentioned above.

The verification sensors shall monitor the control sensors and may

indicate an alarm if the sensors deviate by more than a pre-set limit

during the process.

The values of the control temperature sensors, verification sensors

and pressure sensor shall be combined in a data acquisition system

(i.e. on a single data printout). All alarms shall be noted in the

documentation.

12

01/05/99 GMP_.doc Issue 1 - Jan-97

© Getinge 1997

Page 15

In-situ Air Filter Sterilization (AFS)

This applies to microbial retentive air filters in a stainless steel

housing, used for vacuum break or admission of compressed air to

the chamber. When AFS is specified:

A cycle shall be provided to automatically sterilize the filter element

within the housing. The piping system upstream of the filter, to the

first isolating valve, shall be sterilized as part of each process.

It shall be possible to record and validate each cycle. The process

record shall indicate and report its satisfactory completion.

The drain of the filter housing and/or upstream piping is equipped

with a temperature sensor (Control Sensor), and the cycle is

operated according to a sequence for a gravity displacement

sterilization cycle, with an added cooling phase. See separate sheet

for detailed description.

In-situ Air Filter Integrity Test (AFT)

This applies to microbial retentive air filters in a stainless steel

housing, used for vacuum break or admission of compressed air to

the chamber. When AFT is specified:

A cycle shall be provided to automatically test the integrity of the

filter element within the housing.

It shall be possible to record and validate each cycle. The process

record shall indicate and report its satisfactory completion.

The filter housing shall be equipped with a pressure sensor and

ancillary equipment to enable a forward flow pressure decay, water

intrusion test, or similar, to be performed.

The control system shall indicate 'Pass' or 'Fail' on termination.

The test shall be designed according to procedures and parameters

specified by the filter manufacturer. The filter manufacturer shall

provide approval in writing of the test parameters and procedure.

13

01/05/99 GMP_.doc Issue 1 - Jan-97

© Getinge 1997

Page 16

Sanitary Piping system (SAN)

When specified, this will be provided in conjunction with stainless

steel Process System piping. All piping and components in the

Process System shall be of sanitary specification.

The features of a 'sanitary' system include:

• The system shall be completely self draining, and shall not retain

moisture. The 'system' includes all components, fittings and

piping in the Process System.

• The system shall be free of crevices where dirt might accumulate.

Internal surfaces shall be cleanable. Optionally, the chamber

shall have a higher grade surface finish - E.P. or high mechanical

polish (e.g. Ra=0.2µm).

• When connections can be avoided, the components shall be

welded in place. However, consideration is given to removal of

components and assemblies for cleaning and inspection.

• Connections shall be made using approved (to 3A or IDF

standard) sanitary style fittings, such as tri-clamps. Screwed

connections shall not be used.

• Valves shall be of sanitary design, such as diaphragm type

valves. Globe valves shall not be used.

Optional items for Sanitary Specification

♦ Material specifications and mill sheet certificates may be provided

for piping and components (in Getinge’s Extended Documentation

package).

♦ Weld Records may be provided.

◊ Weld samples shall be produced before and after the

machine construction to indicate repeatable performance

of the welding equipment.

◊ Welds shall be identified by reference number (e.g.

engraving or sketch)

◊ Welds shall be inspected by video boroscope indicating

reference numbers as above.

◊ Welding equipment parameters should be printed and

included in the weld documentation.

14

01/05/99 GMP_.doc Issue 1 - Jan-97

© Getinge 1997

Loading...

Loading...