Fujitsu fi-6140, fi-6240, fi-6130, fi-6230 Maintenance Manual

fi-6140/fi-6240 fi-6130/fi-6230 Image Scanner fi-614PR, Imprinter Maintenance Manual

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design |

July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

|

|

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

1 /257 |

|

Revision Record |

|

||

Edition |

Date published |

Revised contents |

|

01 |

July 27, 2007 |

First version released |

|

02 |

August 31, 2007 |

47, 48: Error Recovery Guide messages added. |

|

77, 106-107, 114: Replacement procedure changed. |

|||

|

|

||

03 |

September 20, 2007 |

78, 122, 128, 171: Photos changed. |

|

93: Reference step changed. |

|||

|

|

||

04 |

November 14, 2007 |

fi-6130/fi-6230/fi-614PR added. |

|

P30, 44: Maintenance parts numbers revised. |

|||

|

|

||

|

|

P12, 13: Specification revised. |

|

|

|

Chapter 5 and Section 8-6: Screw classification added. |

|

05 |

December 18, 2007 |

P110: Tension when the spring balance touches the rib revised. |

|

P226: Tips for removing the inner cover added. |

|||

|

|

||

|

|

P233-234: LF Motor belt tension adjustment procedure revised. |

|

|

|

P253-254: Screw specifications added. |

|

06 |

March 10, 2008 |

P49, 68: “J0” error added. |

|

|

|

Section 1-1-2: Minimum document (A8) size changed. |

|

07 |

November 12, 2008 |

Section 4-3-11: Procedures on “Vertical straight streaks appear in scanned image” added. |

|

Section 5-3-4: Procedure for cleaning “Glass inside of Flatbed” changed. |

|||

|

|

||

|

|

Appendix 2: Emulation mode” added. |

|

|

|

Section 4-3-23 (P61): Troubleshooting for “F4: Background changeover unit alarm” revised. |

|

08 |

July 27, 2009 |

Section 5-9-5 (P95): Notes on US Sensor FX installation added. |

|

|

|

Section 6-1, 6-1-5 (P156, 167): Notes on Maintenance mode (white level adjustment) added. |

|

The contents of this manual are subject to change without prior notice.

All rights reserved. Copyright© PFU LIMITED 2007-2009

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

|

|

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

2 / 257 |

|

This manual provides the technical information such as maintenance, troubleshooting procedure and parts replacement procedure for field Engineers on fi-6140/fi-6240/fi-6130/fi-6230 image scanner.

This manual is for use as a maintenance tool only.

For information that is not contained in this manual, refer to the following manuals:

Item |

Manuals |

P/N * |

Remarks |

1 |

fi-6140/fi-6240 Image Scanner Operator’s Guide |

P3PC-2062-xxEN |

Attached to fi-6140/fi-6240 (CD-ROM) |

2 |

fi-6140/fi-6240 Image Scanner Getting Started |

P3PC-2052-xxEN |

Attached to fi-6140/fi-6240 (booklet) |

3 |

fi-6130/fi-6230 Image Scanner Operator’s Guide |

P3PC-2162-xxEN |

Attached to fi-6130/fi-6230 (CD-ROM) |

4 |

fi-6130/fi-6230 Image Scanner Getting Started |

P3PC-2152-xxEN |

Attached to fi-6130/fi-6230 (booklet) |

5 |

fi-614PR Imprinter Operator’s Guide |

P3PC-2112-xxEN |

Attached to fi-614PR (CD-ROM) |

6 |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

P4PA03540-B0XX/6 |

|

|

Illustrated Parts Catalog |

|

|

|

* xx represents revision number of the manuals. |

|

|

Special information, such as warnings, cautions, is indicated as follows:

WARNING

WARNING

This indication alerts operators to an operation that, if not strictly observed, may result in severe injury or death.

This indication alerts operators to an operation that, if not strictly observed, may result in safety hazards to personnel or damage to equipment.

NOTICE provides 'how-to" tips or suggestions to help you perform a procedure correctly.

Be careful not to power off the scanner while communicating with the host computer. In case that the scanner is accidentally powered off during communication with the host, follow the procedure below:

1.Power off the host computer

2.Power on the scanner.

3.Power on the host computer.

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

|

|

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

3 / 257 |

|

Microsoft, Windows, and Windows NT are registered trademarks of Microsoft Corporation in the United States and/or other countries.

ISIS, QuickScan and their respective logos are trademarks or registered trademarks of Pixel Translations, a division of Captiva Software Corporation in the United States.

Adobe, the Adobe logo, and Acrobat are either registered trademarks of Adobe Systems Incorporated in the United States and/or other countries.

Other product names are the trademarks or registered trademarks of the respective companies.

References to operating systems (OS) and applications are indicated as follows:

Windows 2000: Microsoft® Windows® 2000 Professional operating system.

Windows XP: Microsoft® Windows® XP Professional operating system (32-bit/64-bit)

Microsoft® Windows® XP Home Edition operating system.

Windows Server2003: Microsoft® Windows ServerTM 2003 Standard Edition operating system (32-bit/64-bit)

Windows Vista: Microsoft® Windows VistaTM Home Basic operating system (32-bit/64-bit)

Microsoft® Windows VistaTM Home Premium operating system (32-bit/64-bit)

Microsoft® Windows VistaTM Business operating system (32-bit/64-bit)

Microsoft® Windows VistaTM Enterprise operating system (32-bit/64-bit)

Microsoft® Windows VistaTM Ultimate operating system (32-bit/64-bit)

Where there is no distinction between the different versions of the above operating system, the general term “Windows” is used.

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

|

|

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

4 / 257 |

|

|

|

|

Contents |

|

Chapter 1 |

Overview ................................................................................................................ |

10 |

||

1-1 |

Specification.......................................................................................................................................... |

10 |

||

1-1-1 Features ..................................................................................................................................................................... |

10 |

|||

1-1-2 |

Scanner Specifications............................................................................................................................................... |

11 |

||

1-1-3 |

Environmental Specifications.................................................................................................................................... |

12 |

||

1-1-4 Appearance................................................................................................................................................................ |

13 |

|||

1-1-5 |

Outer Dimensions ...................................................................................................................................................... |

16 |

||

1-1-6 |

Document Specifications........................................................................................................................................... |

17 |

||

1-1-7 Multi feed Detection Condition ................................................................................................................................. |

18 |

|||

1-2 |

Scanner Configuration .......................................................................................................................... |

19 |

||

1-2-1 |

ADF Unit................................................................................................................................................................... |

19 |

||

1-2-2 |

Reading Station ......................................................................................................................................................... |

20 |

||

1-2-3 Controller .................................................................................................................................................................. |

22 |

|||

1-2-4 Electric Component Block Diagram.......................................................................................................................... |

24 |

|||

Chapter 2 Description of Scanner Operation ....................................................................... |

25 |

|||

2-1 |

Unpacking the scanner.......................................................................................................................... |

25 |

||

2-2 |

Installing the scanner ............................................................................................................................ |

27 |

||

2-2-1 |

For safety installation ................................................................................................................................................ |

27 |

||

2-2-2 Installation................................................................................................................................................................. |

27 |

|||

Chapter 3 |

Maintenance Parts ................................................................................................ |

29 |

||

3-1 |

BASE UNIT.......................................................................................................................................... |

31 |

||

3-2 |

BASE ASSY ......................................................................................................................................... |

31 |

||

3-3 |

INVERTER........................................................................................................................................... |

32 |

||

3-4 |

LAMP |

................................................................................................................................................... |

32 |

|

3-5 US SENSOR FX (Multifeed detection) ................................................................................................ |

33 |

|||

3-6 |

OPT UNIT ............................................................................................................................................ |

33 |

||

3-7 |

BW MOTOR......................................................................................................................................... |

34 |

||

3-8 GUIDE P ASSY (Sheet Guide) ............................................................................................................ |

34 |

|||

3-9 |

PICK MOTOR ASSY........................................................................................................................... |

35 |

||

3-10 |

|

PICK MOTOR .................................................................................................................................... |

35 |

|

3-11 |

|

PICK SHAFT ASSY........................................................................................................................... |

36 |

|

3-12 SWITCH (ADF open detection) ......................................................................................................... |

36 |

|||

3-13 |

|

UPPER UNIT...................................................................................................................................... |

37 |

|

3-14 |

|

UPPER ASSY..................................................................................................................................... |

37 |

|

3-15 |

|

ADF MOTOR ..................................................................................................................................... |

38 |

|

3-16 |

|

(Reserved)........................................................................................................................................... |

38 |

|

3-17 |

|

(Reserved)........................................................................................................................................... |

38 |

|

3-18 |

|

(Reserved)........................................................................................................................................... |

38 |

|

3-19 US SENSOR RV (Multifeed detection).............................................................................................. |

38 |

|||

3-20 SENSOR EMP (Paper empty detection)............................................................................................. |

39 |

|||

3-21 |

|

PANEL PCA....................................................................................................................................... |

39 |

|

3-22 |

|

BR SHAFT ASSY .............................................................................................................................. |

39 |

|

3-23 |

|

CONTROL PCA................................................................................................................................. |

40 |

|

3-24 |

|

(Reserved)........................................................................................................................................... |

41 |

|

3-25 |

|

STACKER UNIT................................................................................................................................ |

41 |

|

3-26 CHUTER UNIT (ADF paper chute)................................................................................................... |

41 |

|||

3-27 |

|

AC ADAPTER.................................................................................................................................... |

42 |

|

3-28 |

|

AC CORDSETS.................................................................................................................................. |

42 |

|

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

|

|

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

5 / 257 |

|

3-29 |

USB CABLE....................................................................................................................................... |

|

42 |

|

3-30 |

FB TOP COVER................................................................................................................................. |

|

43 |

|

3-31 FB MOTOR UNIT.............................................................................................................................. |

|

43 |

||

3-32 |

FB MOTOR ........................................................................................................................................ |

|

44 |

|

3-33 |

OPT BOX UNIT ................................................................................................................................. |

|

44 |

|

3-34 |

(Reserved)........................................................................................................................................... |

|

44 |

|

3-35 |

(Reserved)........................................................................................................................................... |

|

44 |

|

3-36 |

(Reserved)........................................................................................................................................... |

|

44 |

|

3-37 |

CR CABLE ......................................................................................................................................... |

|

45 |

|

3-38 |

DOC COVER ASSY .......................................................................................................................... |

|

45 |

|

3-39 |

JOINT PCA......................................................................................................................................... |

|

46 |

|

6-40 |

(Reserved)........................................................................................................................................... |

|

46 |

|

Chapter 4 Troubleshooting..................................................................................................... |

|

47 |

||

4-1 Operation Panel Sequence at Power-on ................................................................................................ |

|

47 |

||

4-2 Temporary errors and Alarm detection algorithm................................................................................. |

|

48 |

||

4-2-1 |

Temporary errors....................................................................................................................................................... |

|

48 |

|

4-2-2 Alarms....................................................................................................................................................................... |

|

48 |

||

4-2-3 |

Error Recovery Guide ............................................................................................................................................... |

|

48 |

|

4-3 |

Troubleshooting .................................................................................................................................... |

|

49 |

|

4-3-1 Scanner is not turned ON (Display of the operator panel goes out)........................................................................... |

51 |

|||

4-3-2 |

Scanning does not start.............................................................................................................................................. |

|

51 |

|

4-3-3 Scanned image is distorted ........................................................................................................................................ |

|

51 |

||

4-3-4 Resolution is not satisfactory or tone error is too large ............................................................................................. |

|

52 |

||

4-3-5 |

Too much jitter on scanned image with FB scanning |

fi-6240/fi-6230.................................................................... |

52 |

|

4-3-6 |

Scanned image is misaligned with FB scanning fi-6240/fi-6230............................................................................ |

53 |

||

4-3-7 |

Scan magnification factor abnormal with FB scanning |

fi-6240/fi-6230 ................................................................. |

53 |

|

4-3-8 Too much jitter on scanned image with ADF scanning............................................................................................. |

|

54 |

||

4-3-9 Scanned image is misaligned with ADF scanning..................................................................................................... |

|

55 |

||

4-3-10 Scan magnification factor abnormal with ADF scanning ........................................................................................ |

55 |

|||

4-3-11 Vertical streaks appear in scanned image ................................................................................................................ |

|

56 |

||

4-3-12 When calibrating white of scanned image............................................................................................................... |

|

56 |

||

4-3-13 Frequent “J1: paper jam” error at scanner section ................................................................................................... |

|

57 |

||

4-3-14 Frequent “J2: multi feed error”................................................................................................................................ |

|

58 |

||

4-3-15 Error detection of “U4: Scanner Cover open” ......................................................................................................... |

|

58 |

||

4-3-16 Error detection of “No paper on the ADF paper chute (Chuter Unit)” .................................................................... |

58 |

|||

4-3-17 Frequent “U0: Shipping lock error” or “E0: Carrier drive alarm” ........................................................................... |

59 |

|||

4-3-18 |

“E1/E2/E3: Optical alarm” ...................................................................................................................................... |

|

59 |

|

4-3-19 “E6: Operator panel alarm” ..................................................................................................................................... |

|

60 |

||

4-3-20 |

“E7: EEPROM alarm”............................................................................................................................................. |

|

60 |

|

4-3-21 |

“E8: SCSI alarm” .................................................................................................................................................... |

|

60 |

|

4-3-22 “E9: Image memory alarm”..................................................................................................................................... |

|

60 |

||

4-3-23 “F4: Background changeover unit alarm” ............................................................................................................... |

|

61 |

||

4-3-24 |

“C0: LSI alarm” ...................................................................................................................................................... |

|

61 |

|

4-3-25 |

“H0/H8: Motor alarm” ............................................................................................................................................ |

|

62 |

|

4-3-26 |

“Lamp alarm”.......................................................................................................................................................... |

|

63 |

|

4-3-27 “L6: US sensor alarm”............................................................................................................................................. |

|

63 |

||

4-3-28 “F: ROM sum check alarm” .................................................................................................................................... |

|

63 |

||

4-3-29 |

Driver error.............................................................................................................................................................. |

|

63 |

|

4-3-30 |

“Abnormal command”............................................................................................................................................. |

|

64 |

|

4-3-31 |

“Interface alarm” ..................................................................................................................................................... |

|

64 |

|

4-3-32 |

Frequent “J1: paper jam” error at Imprinter (with Imprinter installed) fi-6140/fi-6130 ......................................... |

64 |

||

4-3-33 |

Error detection of “U5:Imprinter cover open” (with Imprinter installed) fi-6140/fi-6130 ..................................... |

64 |

||

4-3-34 |

Imprinter does not initially operate (with Imprinter installed) fi-6140/fi-6130 ...................................................... |

65 |

||

4-3-35 |

“U6: No print cartridge” (with Imprinter installed) fi-6140/fi-6130 ...................................................................... |

65 |

||

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

|

|

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

6 / 257 |

|

4-3-36 “H6: Imprinter fuse blown” (with Imprinter installed) fi-6140/fi-6130.................................................................... |

66 |

|||

4-3-37 |

“A0: Imprinter control board alarm” (with Imprinter installed) fi-6140/fi-6130 ................................................... |

66 |

||

“A1: Imprinter communication timeout” (with Imprinter installed) fi-6140/fi-6130 ........................................................... |

66 |

|||

“A2: Ink head alarm” (with Imprinter installed) fi-6140/fi-6130......................................................................................... |

66 |

|||

“A3: Imprinter EEPROM alarm” (with Imprinter installed) fi-6140/fi-6130....................................................................... |

66 |

|||

“A4: Imprinter ROM alarm” (with Imprinter installed) fi-6140/fi-6130.............................................................................. |

66 |

|||

4-3-38 No printing / Printed letters are distorted (with Imprinter installed) fi-6140/fi-6130 ............................................. |

67 |

|||

4-3-39 |

Print form is dirty (with Imprinter installed) fi-6140/fi-6130 ................................................................................ |

67 |

||

4-3-40 |

Printing is interrupted in process (with Imprinter installed) fi-6140/fi-6130 ......................................................... |

67 |

||

4-3-41 |

Frequent “J0: paper jam” (paper protection function) fi-6140/fi-6240 .................................................................. |

68 |

||

Chapter 5 |

Disassembly/Assembly.......................................................................................... |

69 |

||

5-1 For the safety operation ........................................................................................................................ |

69 |

|||

5-2 |

Periodic Maintenance ........................................................................................................................... |

70 |

||

5-3 |

Cleaning................................................................................................................................................ |

71 |

||

5-3-1 OPT Unit (common to ADF front/backside and Flatbed) ......................................................................................... |

71 |

|||

5-3-2 Glass inside of Base Unit .......................................................................................................................................... |

71 |

|||

5-3-3 Glass inside of Upper Unit ........................................................................................................................................ |

71 |

|||

5-3-4 |

Glass inside of Flatbed fi-6240/fi-6230 .................................................................................................................. |

72 |

||

5-3-5 White reference inside of Base Unit.......................................................................................................................... |

72 |

|||

5-3-6 White reference inside of Upper Unit ....................................................................................................................... |

72 |

|||

5-4 |

Maintenance tool .................................................................................................................................. |

73 |

||

5-5 Parts that should not be Disassembled.................................................................................................. |

74 |

|||

5-6 (Reserved) ............................................................................................................................................... |

74 |

|||

5-7 |

Removing Flatbed fi-6240/fi-6230 .................................................................................................... |

75 |

||

5-8 Chuter Unit (ADF Paper Chute), Stacker Unit ..................................................................................... |

77 |

|||

5-8-1 Chuter Unit (ADF Paper Chute)................................................................................................................................ |

77 |

|||

5-8-2 |

Stacker Unit fi-6140/fi-6130..................................................................................................................................... |

78 |

||

5-9 |

Base Unit .............................................................................................................................................. |

79 |

||

5-9-1 |

Base Unit................................................................................................................................................................... |

79 |

||

5-9-2 |

Base ASSY................................................................................................................................................................ |

84 |

||

5-9-3 Inverter (for front side scanning)............................................................................................................................... |

85 |

|||

5-9-4 Lamp (for front side scanning).................................................................................................................................. |

87 |

|||

5-9-5 US Sensor FX (Multifeed detection)......................................................................................................................... |

93 |

|||

5-9-6 OPT Unit (for front side scanning)............................................................................................................................ |

96 |

|||

5-9-7 |

BW Motor ................................................................................................................................................................. |

98 |

||

5-9-8 Guide P ASSY (Sheet Guide) ................................................................................................................................. |

100 |

|||

5-9-9 |

PICK Motor ASSY ................................................................................................................................................. |

101 |

||

5-9-10 |

PICK Motor........................................................................................................................................................... |

103 |

||

5-9-11 |

PICK Shaft ASSY ................................................................................................................................................. |

105 |

||

5-9-12 Switch (ADF open detection)................................................................................................................................ |

106 |

|||

5-10 |

Upper Unit ........................................................................................................................................ |

107 |

||

5-10-1 |

Upper Unit ............................................................................................................................................................ |

107 |

||

5-10-2 |

Upper ASSY ......................................................................................................................................................... |

108 |

||

5-10-3 |

ADF Motor............................................................................................................................................................ |

109 |

||

5-10-4 OPT Unit (for backside scanning)......................................................................................................................... |

112 |

|||

5-10-5 |

Inverter (for backside scanning)............................................................................................................................ |

114 |

||

5-10-6 Lamp (for backside scanning) ............................................................................................................................... |

116 |

|||

5-10-7 US Sensor RV (Multifeed detection) .................................................................................................................... |

123 |

|||

5-10-8 Sensor EMP (Paper empty detection).................................................................................................................... |

124 |

|||

5-10-9 |

Panel PCA............................................................................................................................................................. |

125 |

||

5-10-10 |

BR Shaft ASSY................................................................................................................................................... |

127 |

||

5-10-11 |

Top Cover ........................................................................................................................................................... |

128 |

||

5-11 |

Control PCA ..................................................................................................................................... |

130 |

||

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

|

|

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

7 / 257 |

|

5-12 |

Flatbed .............................................................................................................................................. |

|

|

133 |

||

5-12-1 |

FB Top Cover |

fi-6240/fi-6230 ........................................................................................................................... |

133 |

|||

5-12-2 |

FB Motor Unit |

fi-6240/fi-6230 .......................................................................................................................... |

134 |

|||

5-12-3 |

FB Motor |

fi-6240/fi-6230 .................................................................................................................................. |

138 |

|||

5-12-4 |

OPT Box Unit |

fi-6240/fi-6230 ........................................................................................................................... |

140 |

|||

5-12-5 |

OPT Unit |

fi-6240/fi-6230................................................................................................................................... |

143 |

|||

5-12-6 |

Inverter fi-6240/fi-6230...................................................................................................................................... |

145 |

||||

5-12-7 |

Lamp fi-6240/fi-6230 ......................................................................................................................................... |

147 |

||||

5-12-8 |

CR Cable |

fi-6240/fi-6230................................................................................................................................... |

150 |

|||

5-12-9 |

Document Cover fi-6240/fi-6230 ....................................................................................................................... |

153 |

||||

5-12-10 |

Joint PCA |

fi-6240/fi-6230 ................................................................................................................................ |

154 |

|||

Chapter 6 |

Adjustment/Settings............................................................................................ |

156 |

||||

6-1 |

Maintenance mode.............................................................................................................................. |

156 |

||||

6-1-1 |

Activating the Maintenance mode........................................................................................................................... |

156 |

||||

6-1-2 Maintenance mode #1: Paper feeding / Sensor / Background changeover test........................................................ |

158 |

|||||

6-1-3 Maintenance mode #2: Main scanning / Sub-scanning magnification adjustment .................................................. |

160 |

|||||

6-1-4 Maintenance mode #3: Offset adjustment............................................................................................................... |

164 |

|||||

6-1-5 Maintenance mode #4: White level adjustment....................................................................................................... |

167 |

|||||

6-1-6 Maintenance mode #5: Consumable counter display and reset ............................................................................... |

170 |

|||||

6-1-7 Maintenance mode #6: Miscellaneous information display .................................................................................... |

172 |

|||||

6-1-8 Maintenance mode #7: EEPROM data restore........................................................................................................ |

174 |

|||||

6-2 |

Saving EEPROM data ........................................................................................................................ |

175 |

||||

Chapter 7 Basic Operation and Daily Care........................................................................ |

177 |

|||||

7-1 |

Basic Operation .................................................................................................................................. |

|

177 |

|||

7-1-1 Turn ON/OFF the Scanner ...................................................................................................................................... |

177 |

|||||

7-1-2 Loading Documents on the ADF for Scanning ....................................................................................................... |

178 |

|||||

7-1-3 |

Loading Documents on the Flatbed for Scanning fi-6240/fi-6230 ....................................................................... |

181 |

||||

7-2 |

Daily Care........................................................................................................................................... |

|

|

182 |

||

7-2-1 |

Cleaning the ADF ................................................................................................................................................... |

182 |

||||

7-2-2 |

Cleaning the Flatbed fi-6240/fi-6230 ................................................................................................................... |

185 |

||||

7-3 |

Replacing the consumables................................................................................................................. |

186 |

||||

7-3-1 Consumables ........................................................................................................................................................... |

|

186 |

||||

7-3-2 Checking and Resetting the Consumables Counters ............................................................................................... |

187 |

|||||

7-3-3 |

Brake roller replacement ......................................................................................................................................... |

189 |

||||

7-3-4 |

Pick roller replacement ........................................................................................................................................... |

191 |

||||

Chapter 8 |

Imprinter (Optional)........................................................................................... |

194 |

||||

8-1 |

Imprinter Specifications...................................................................................................................... |

194 |

||||

8-1-1 |

Printing Functions ................................................................................................................................................... |

194 |

||||

8-1-2 |

Environmental Specifications.................................................................................................................................. |

195 |

||||

8-1-3 Appearance ............................................................................................................................................................. |

|

|

196 |

|||

8-1 |

Imprinter Operation ............................................................................................................................ |

198 |

||||

8-2-1 |

Imprinter Operation................................................................................................................................................. |

198 |

||||

8-2-2 |

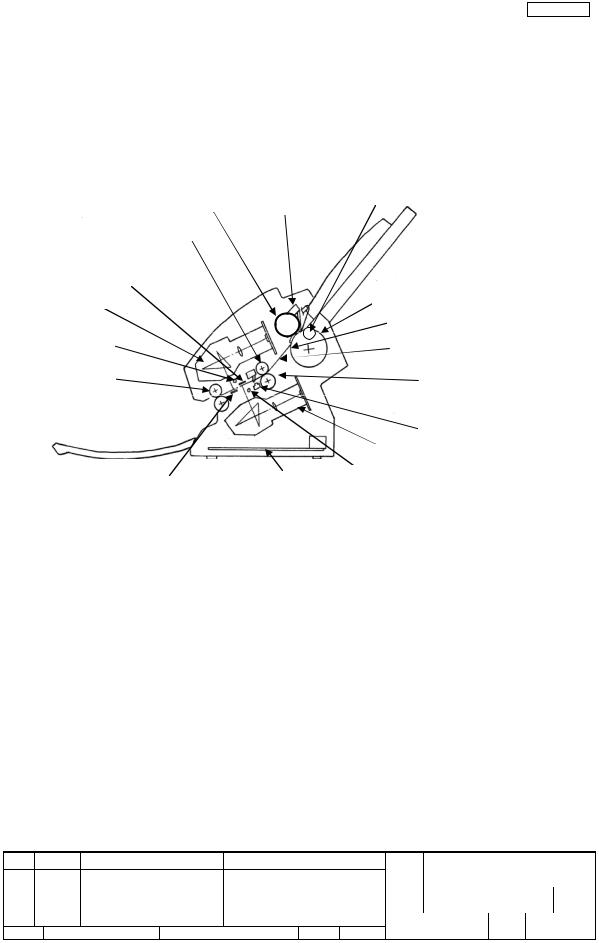

Circuit Block Diagram ............................................................................................................................................ |

199 |

||||

8-3 Unpacking and Installation of Imprinter............................................................................................. |

200 |

|||||

8-3-1 |

Unpacking the Imprinter ......................................................................................................................................... |

200 |

||||

8-3-2 |

Installing the Imprinter............................................................................................................................................ |

201 |

||||

8-3-3 Loading the Print cartridge...................................................................................................................................... |

203 |

|||||

8-3-4 |

Operation Test......................................................................................................................................................... |

|

205 |

|||

8-4 Maintenance Parts for the Imprinter ................................................................................................... |

206 |

|||||

8-4-1 SENSOR ................................................................................................................................................................. |

|

|

207 |

|||

8-4-2 |

IMP CT ................................................................................................................................................................... |

|

|

207 |

||

8-4-3 |

IMP JNT.................................................................................................................................................................. |

|

|

208 |

||

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

|

|

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

8 / 257 |

|

8-4-4 |

PR HARNESS......................................................................................................................................................... |

208 |

||

8-4-5 |

IM FELT ................................................................................................................................................................. |

209 |

||

8-4-6 |

LF MOTOR ............................................................................................................................................................ |

209 |

||

8-4-7 |

IM HOLDER ASSY3 ............................................................................................................................................. |

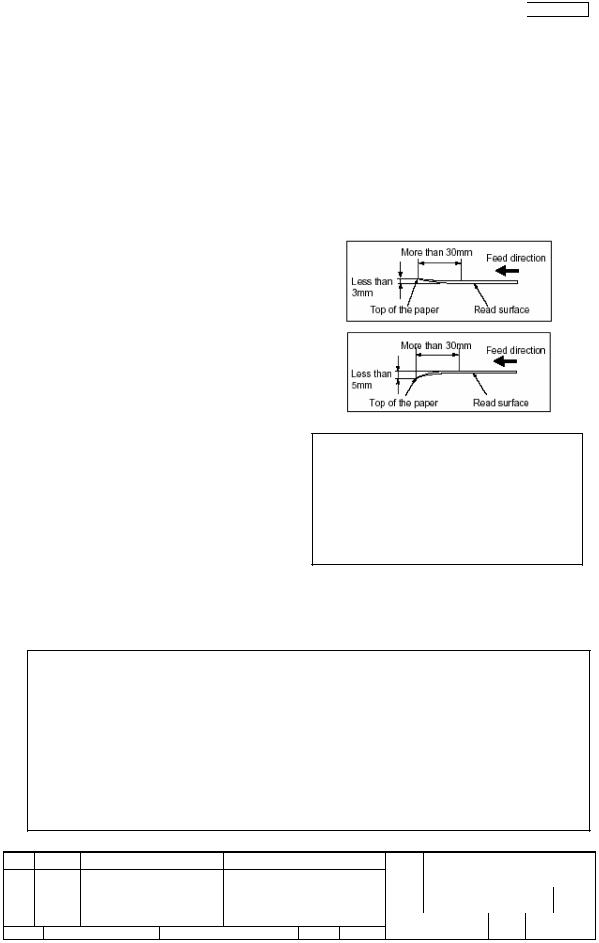

210 |

||

8-4-8 |

IM HOLD LEVER3................................................................................................................................................ |

210 |

||

8-4-9 |

FPC CABLE ........................................................................................................................................................... |

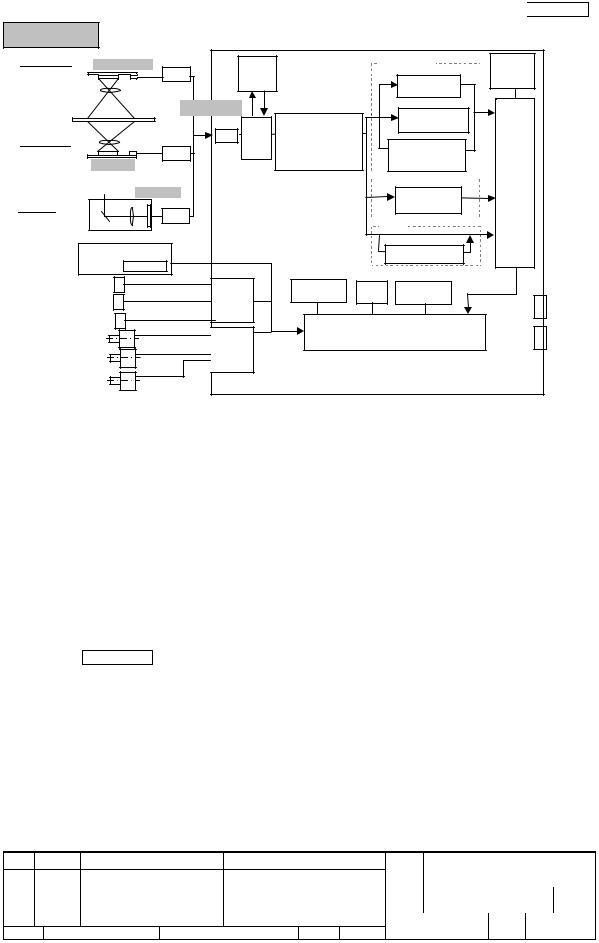

211 |

||

8-4-10 |

IM PINCH ASSY3................................................................................................................................................ |

211 |

||

8-4-11 |

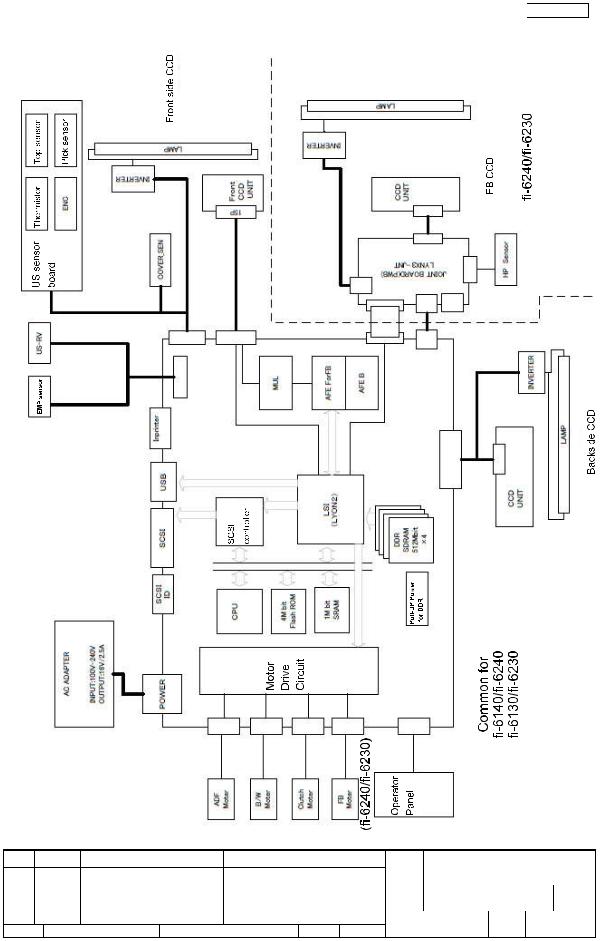

IM LOCK LEVER ................................................................................................................................................ |

212 |

||

8-4-12 SWITCH (Cover open detection).......................................................................................................................... |

212 |

|||

8-4-13 |

GUIDE SHEET..................................................................................................................................................... |

213 |

||

8-4-14 |

PAPER GUIDE3................................................................................................................................................... |

213 |

||

8-5 |

Troubleshooting.................................................................................................................................. |

214 |

||

8-6 |

Disassembly/Assembly....................................................................................................................... |

215 |

||

8-6-1 |

For Safety operation................................................................................................................................................ |

215 |

||

8-6-2 |

Maintenance tool..................................................................................................................................................... |

215 |

||

8-6-3 (Reserved) ............................................................................................................................................................... |

215 |

|||

8-6-4 |

Removing Imprinter................................................................................................................................................ |

216 |

||

8-6-5 |

IM HOLD LEVER3................................................................................................................................................ |

217 |

||

8-6-6 |

IM PINCH ASSY3.................................................................................................................................................. |

218 |

||

8-6-7 |

IMP JNT.................................................................................................................................................................. |

221 |

||

8-6-8 IM HOLDER ASSY3/FPC CABLE ....................................................................................................................... |

223 |

|||

8-6-9 |

IMP CT ................................................................................................................................................................... |

225 |

||

8-6-10 SENSOR ............................................................................................................................................................... |

227 |

|||

8-6-11 SWITCH (Cover open detection).......................................................................................................................... |

230 |

|||

8-6-12 |

LF MOTOR........................................................................................................................................................... |

232 |

||

8-6-13 |

PR HARNESS....................................................................................................................................................... |

235 |

||

8-6-14 |

IM FELT ............................................................................................................................................................... |

236 |

||

8-6-15 |

IM LOCK LEVER ................................................................................................................................................ |

238 |

||

8-6-16 |

GUIDE SHEET..................................................................................................................................................... |

239 |

||

8-7 |

Adjustment/Settings............................................................................................................................ |

240 |

||

8-8 Basic Operation and Daily Care of the Imprinter ............................................................................... |

241 |

|||

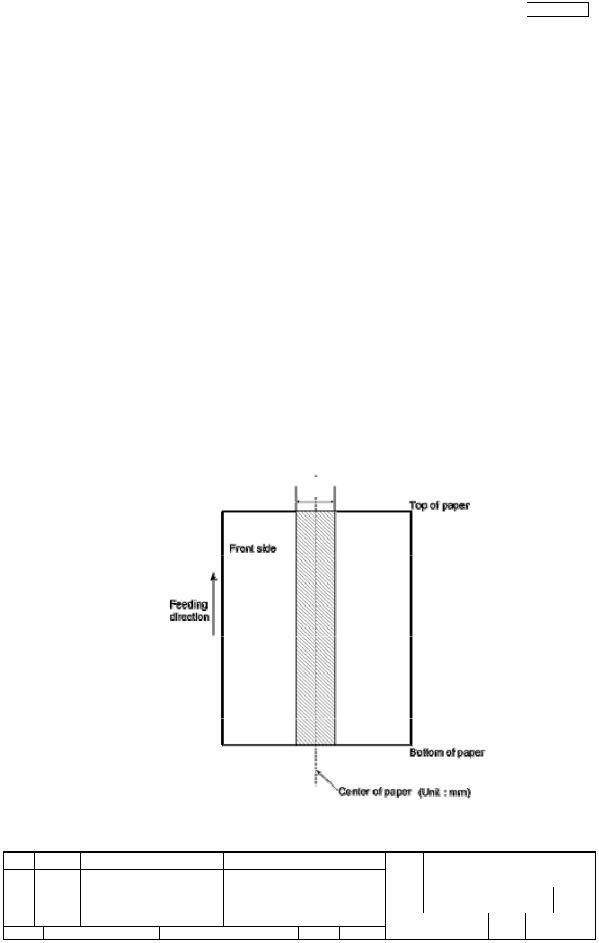

8-8-1 Setting The Print Position ....................................................................................................................................... |

241 |

|||

8-8-2 How to Use the Paper Guides.................................................................................................................................. |

242 |

|||

8-8-3 |

Print Setup............................................................................................................................................................... |

244 |

||

8-8-4 |

Removing Jammed Documents............................................................................................................................... |

247 |

||

8-9 |

Cleaning and Consumables................................................................................................................. |

248 |

||

8-9-1 Cleaning the Print Cartridge.................................................................................................................................... |

248 |

|||

8-9-2 |

Cleaning the Imprinter ............................................................................................................................................ |

249 |

||

8-9-3 |

Cleaning the Imprinter Rollers................................................................................................................................ |

250 |

||

8-9-4 |

Replacing the Print Cartridge.................................................................................................................................. |

251 |

||

Appendix 1 |

Screws ................................................................................................................ |

253 |

||

Appendix 2 |

Emulation Mode ............................................................................................... |

255 |

||

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

|

|

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

9 / 257 |

|

Section 1-1

Chapter 1 Overview

1-1 Specification

1-1-1 Features

The fi-6140/fi-6240/fi-6130/fi-6230 (hereinafter called “the scanner”) offers high-speed color/gray/monochrome scanning with 600 dpi of optical resolution, up to A4 size (Legal size for ADF). It supports two interfaces, SCSI interface and USB interface, either of which can be used at a time.

The following points have been improved for the scanner compared to the previous type (fi-5120C/fi-5220C).

(1)Improvement of color scanning speed

By changing the CCD, color scanning speed (A4 Portrait 300dpi) is improved from 30 ppm to 40 ppm.

(2)Ultrasonic multi feed sensor

As with the previous model, the scanner introduces ultrasonic sensor in order to perform very reliable multi feed detection.

(3)Prevention of image chipping at overscan

Increasing the number of CCD pixels enables to extend overscan width, so that the image will not be chipped even when the document is skewed.

(4)Thicker card transportation

Feeding thick cards up to 1.4mm thick (including emboss) is available by improving the ADF transportation path.

(5)Specified number of scanned pages ejected to the stacker

Pre-pick is operable when the number of documents to be scanned is specified.

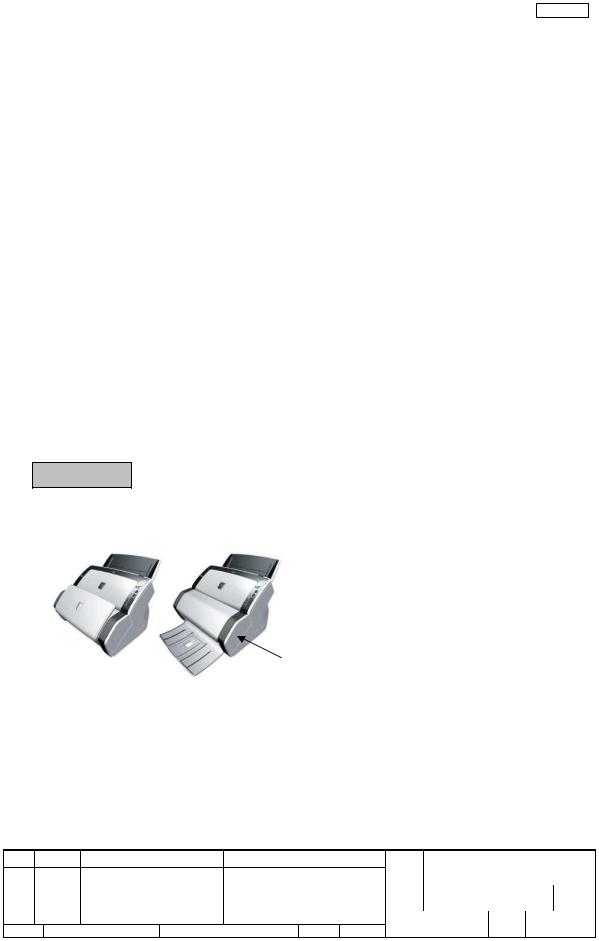

fi-6140/fi-6130

An exclusive imprinter (fi-614PR, option) can be installed under fi-6140/fi-6130 as shown in the photo below. See Chapter 8 for the details of the imprinter.

Scanner

Scanner

Imprinter

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

||

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

10 / 257 |

|

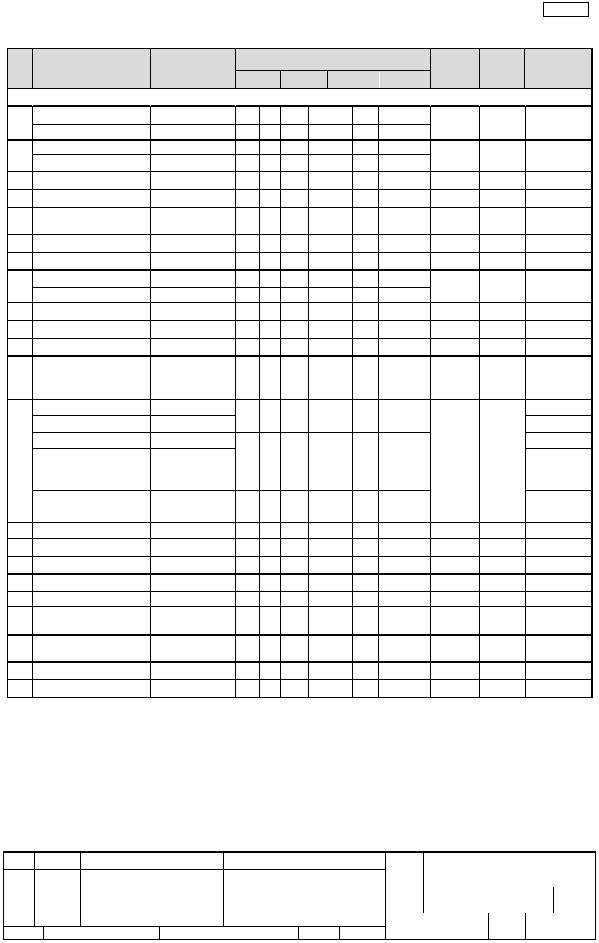

1-1-2 |

Scanner Specifications |

|

|

Section 1-1-2 |

||

Specifications |

|

|||||

No. |

Items |

|

|

|

||

|

fi-6140 |

fi-6130 |

fi-6240 |

fi-6230 |

||

|

|

|

||||

1 |

Operating method |

|

Automatic Document Feeder (ADF) |

Automatic Document |

Feeder (ADF) and |

|

|

Flatbed (FB) |

|

||||

|

|

|

|

|

|

|

2 |

Optical resolution |

|

600 dpi |

|

|

|

|

|

|

Binary: 50 – 600dpi (unit: 1dpi), 1200dpi (by driver) |

|

||

3 |

Output resolution |

|

Gray: 50 – 600 dpi (unit: 1dpi), 1200dpi (by driver) |

|

||

|

|

|

Color: 50 – 600 dpi (unit: 1dpi), 1200dpi (by driver) |

|

||

|

|

|

Color 24 bit/pixel, 8 bit/pixel (by driver), 4 bit/pixel (by driver) |

|

||

4 |

Bit depth |

|

Gray 8 bit/pixel, 4 bit/pixel (by driver) |

|

|

|

|

|

|

Binary 1 bit |

|

|

|

|

|

|

Simplex/Duplex |

Simplex/Duplex |

Simplex/Duplex |

Simplex/Duplex |

|

Scanning speed |

60 ppm / 120 ipm |

40 ppm / 80 ipm |

60 ppm / 120 ipm |

40 ppm / 80 ipm |

|

5 |

(Engine speed) |

|

05 |

|

05 |

|

|

@A4, 200dpi |

40 ppm / 80 ipm |

30 ppm / 60 ipm |

40 ppm / 80 ipm |

30 ppm / 60 ipm |

|

|

|

|

||||

|

|

|

Max: A4 (210 x 297 mm) or Legal (216 x 355.6 mm / 8.50 x 14 in.) |

|

||

6 |

Document size |

Up to 3045 3048 mm (120 in.) of long page scanning is available. |

||||

|

|

|

Min: A8 (53 52 x 74 mm) Portrait / Landscape 07 |

|

||

7 |

Paper weight |

|

0.05 ~ 0.26 mm (41 ~ 210 g/m2, 9.4 ~ 56 lbs) |

|

||

|

A8 size: 0.15 ~ 0.26 mm (127 ~ 210 g/m2) |

|

|

|||

|

|

|

Available, Portrait/Landscape feeding, |

|

|

|

|

|

|

Continuous feeding (up to 3 sheets of continuous feeding) |

|

||

8 |

Card transport |

Thickness: 1.4mm or less |

|

|

||

|

|

|

(fi-6140/fi-6240 models: Monochrome, 200dpi or smaller, Landscape, Card thickness: |

|||

|

|

|

1.25mm or smaller) |

05 |

|

|

9 |

Capacity of ADF |

50 sheets @ A4, 80g/m2 or 20lb |

|

|

||

10 |

Background |

|

Selectable (black or white) |

|

|

|

11 |

Multi |

feed |

Ultrasonic sensor and paper detection sensor |

|

|

|

detection |

|

Document overlapping and document length detection |

|

|||

|

|

|

||||

12 |

Document size |

|

--- |

Maximum: 216 x 297mm / 8.5 x 11.7 in. |

||

13 |

Scanning time |

|

--- |

Binary/Gray/Color: approx.1.7 sec. |

||

|

@A4 Portrait, 200dpi |

|

||||

|

|

|

|

|

|

|

14 |

background |

|

|

--- |

White (Option: black) |

|

15 |

Scanning sensor |

|

Color CCD x 2 |

|

Color CCD x 3 |

|

16 |

Light source |

|

White cold cathode discharge lamp x2 |

White cold cathode discharge lamp x3 |

||

17 |

Interface |

|

Ultra SCSI (x1) |

USB 2.0 (x1) |

Ultra SCSI (x1) |

USB 2.0 (x1) |

|

USB 2.0 (x1) |

USB 2.0 (x1) |

||||

|

|

|

|

|

||

18 |

Image memory |

|

256 MB |

64 MB |

256 MB |

64 MB |

19 |

Attached driver |

|

FJ TWAIN / ISIS, ScandAll PRO, Adobe Acrobat, |

|

||

|

QuickScan Pro.Demo (Trial), Image processing software option (Trial) |

|||||

|

|

|

||||

20 |

Operator panel |

|

Buttons: Function, Send to, Scan/Stop, Power |

|

||

|

Lamps: Check LED, Power LED, Scanner status (Function No. Display) |

|||||

|

|

|

||||

21 |

Supported Options |

|

fi-614PR Imprinter |

|

Black document pad |

05 |

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

||

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

11 / 257 |

|

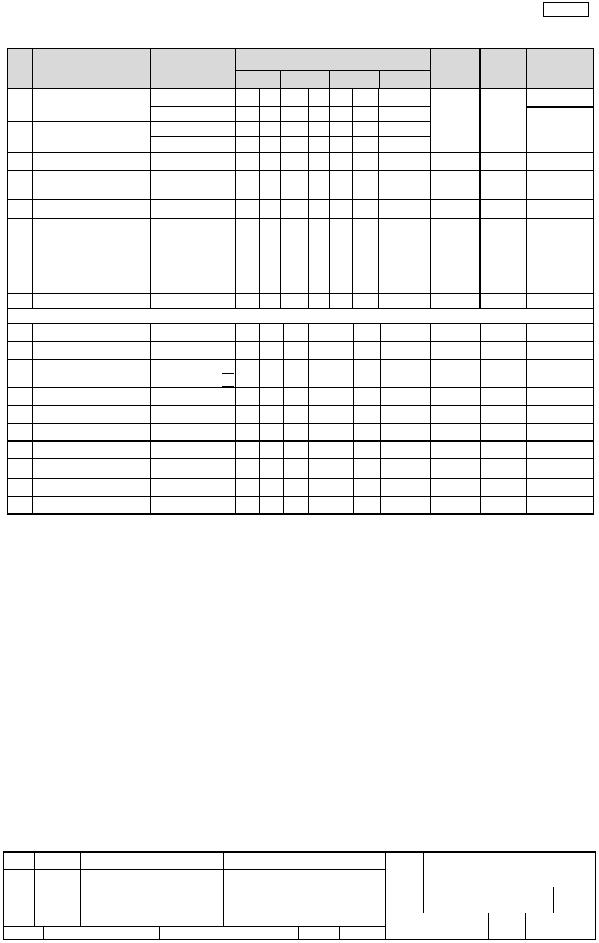

1-1-3 |

Environmental Specifications |

|

|

|

Section 1-1-3 |

||

Specifications |

|

||||||

No. |

|

Items |

|

|

|||

|

fi-6140 |

fi-6130 |

|

fi-6240 |

fi-6230 |

||

|

|

|

|

||||

1 |

Input |

Voltage |

|

|

100 to 240V |

|

|

power |

Frequency |

|

|

50/60 Hz |

|

||

|

|

|

|

||||

2 |

Power consumption |

42 W or less |

38 W or less |

|

50 W or less |

45W or less |

|

(Rated power) |

|

||||||

|

|

|

|

|

|

||

3 |

|

Noise |

|

50 dB or less (excluding operator’s area) |

|

||

|

Outer dimensions |

301 (W) x 160 (D) x 158 (H) mm |

|

301 (W) x 567 (D) x 229 (H) mm |

|||

4 |

(Without ADF paper |

|

|||||

11.8 (W) x 6.3 (D) x 6.2 (H) inch |

|

11.8 (W) x 22.3 (D) x 9.0 (H) inch |

|||||

|

Chute and Stacker Unit) |

|

|||||

|

|

|

|

|

|

||

5 |

|

Weight |

4.2kg (9.3 lb) |

|

8.8kg (19.4 lb) |

||

6 |

Ambient |

Temperature |

5 to 35 oC / 41 to 95 oF (Operating) |

-20 to 60 oC / -4 to 140 oF (Not operating) |

|||

condition |

Humidity |

|

20 to 80 % (Operating) |

8 to 95 % (Not operating) |

|

||

|

|

|

|||||

|

|

|

|

||||

7 |

Calorific value 05 |

36.2 kcal/H |

37.7 kcal/H |

|

43.0 kcal/H or |

38.7 kcal/H |

|

or less |

or less |

|

less |

or less |

|||

|

|

|

|

||||

8 |

Weight at shipping |

|

6.5 kg |

|

13.0 kg |

|

|

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

||

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

12 / 257 |

|

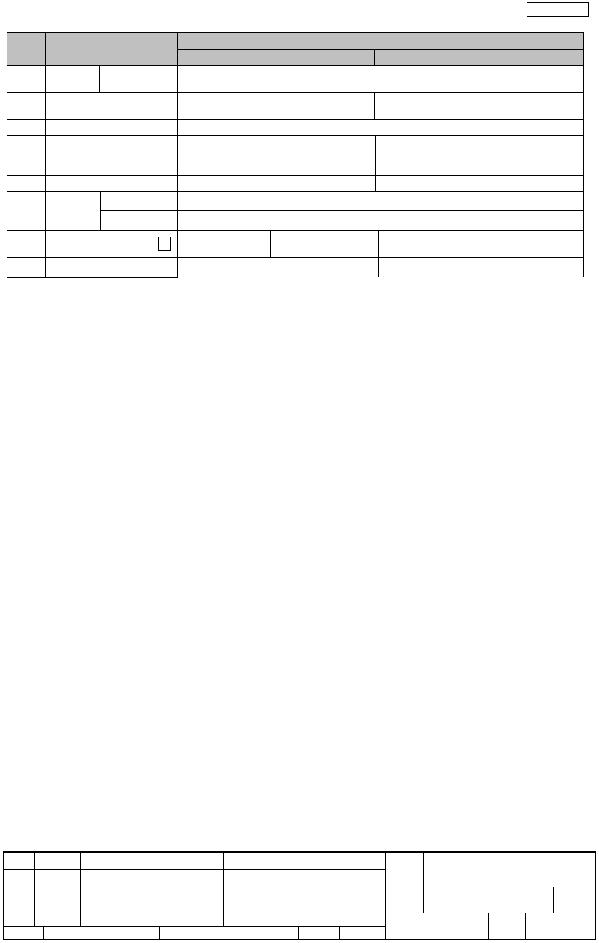

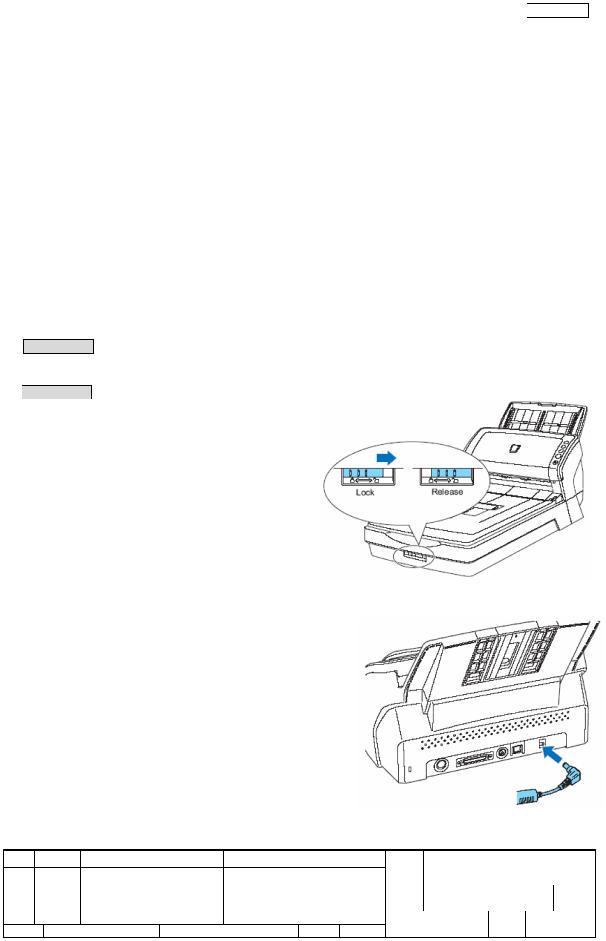

Section 1-1-4

1-1-4 Appearance

[Front]

fi-6140/fi-6130 |

fi-6240/fi-6230 |

No. |

Parts name |

Function |

|

1 |

ADF (Automatic Document Feeder) |

Transports the documents to the reading position automatically. |

|

2 |

ADF Paper Chute (Chute Unit) |

Holds in place the document pages / sheets that are fed into the ADF. |

|

3 |

Paper chute extension 1 |

||

4 |

Paper chute extension 2 |

|

|

5 |

Side Guide |

Adjusted to the width of the paper in order not to scan skewed pages. |

|

6 |

ADF open lever |

Pull this lever toward you to open the ADF. |

|

7 |

Operator Panel |

This panel consists of a Function No. Display, four operating push |

|

buttons, and a LED. |

|||

8 |

Stacker |

||

Scanned documents are ejected from the ADF onto this stacker. |

|||

9 |

Stacker extension |

||

|

|||

10 |

Flatbed (FB) [fi-6240/fi-6230 only] |

Place documents on the glass sheet by sheet for single-sheet scanning. |

|

11 |

Transport lock switch |

Used to lock the carrier unit inside the flatbed during transportation. |

|

[fi-6240/fi-6230 only] |

|||

|

|

[Inside]

fi-6240/fi-6230

No. |

Parts name |

Function |

1 |

Document bed |

Place documents on the glass when scanning through the flatbed. |

2 |

Document holding pad |

Holds documents down on the document bed. |

3 |

Document cover |

Holds the document loaded at the reading position when closed. |

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

||

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

13 / 257 |

|

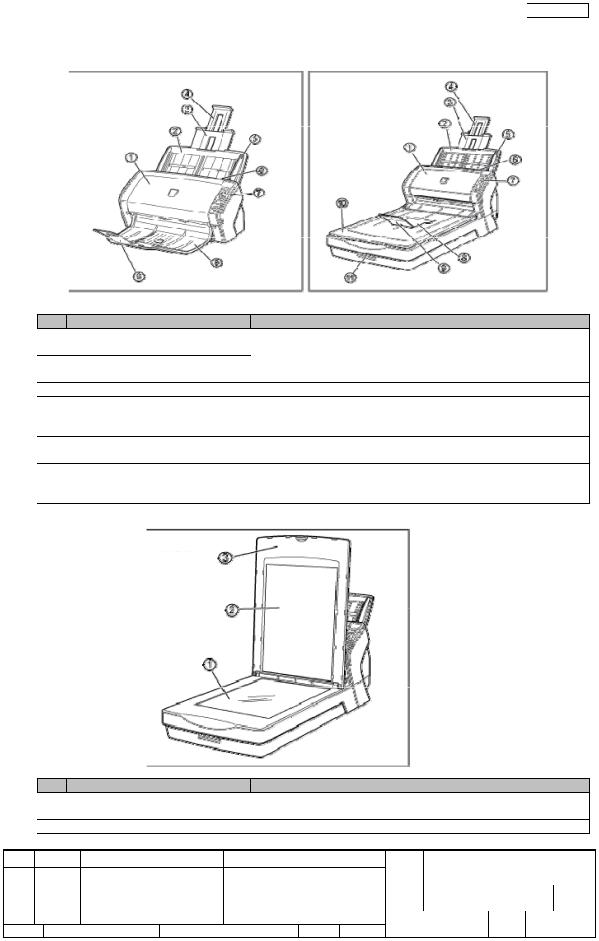

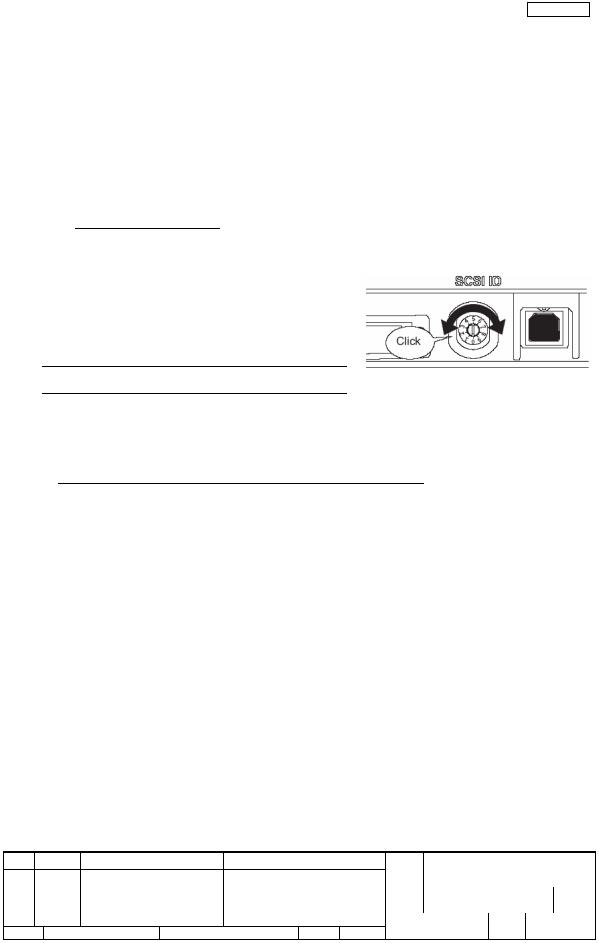

Section 1-1-4

[Rear]

fi-6140/fi-6130 |

fi-6240/fi-6230 |

No. |

Parts name |

Function |

1 |

Security sot |

Attaches the antitheft chain |

2 |

EXT connector (for imprinter) |

Connects the cable from the Imprinter. |

|

[fi-6140/fi-6130 only] |

|

3 |

SCSI connector |

Connects the SCSI interface cable from the host system. |

4 |

SCSI ID switch |

Sets the SCSI ID. (default setting: SCSI ID=5) |

5 |

USB connector |

Connects the USB cable from the host system. |

6 |

DC inlet |

Connects the AC Adapter. |

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

||

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

14 / 257 |

|

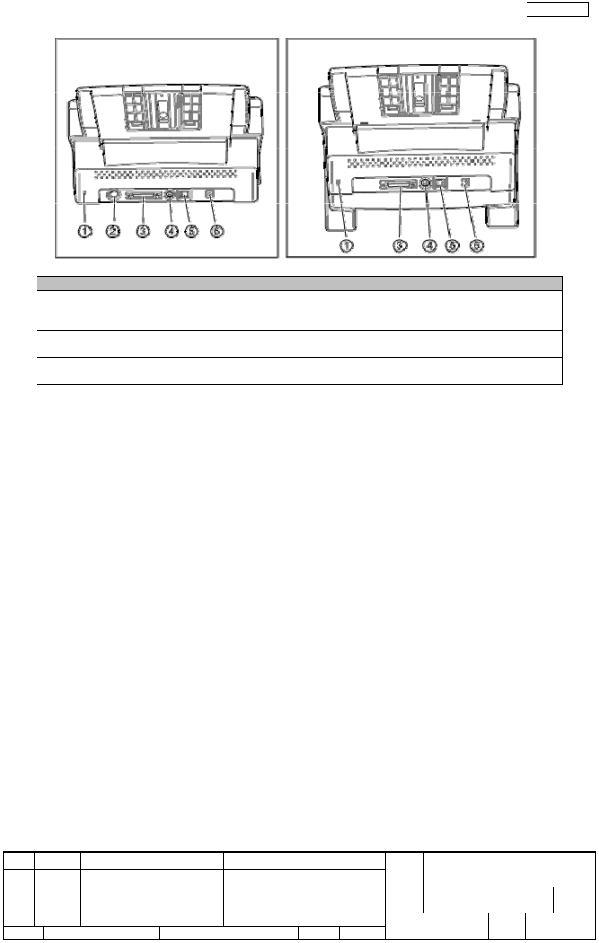

Section 1-1-4

[Operator Panel]

No. |

Name |

Function |

2 |

Check LED |

Lights when an error occurs. |

1 |

Function Number Display |

Indicates the function number and error status. |

3 |

[Function] button |

Changes the Function activated by the [Send to] button. |

4 |

[Send to] button |

Launches the linked application software. Resets an error. |

|

[Scan / Stop] button |

Launches the linked application software. |

5 |

|

Resets and error. |

|

|

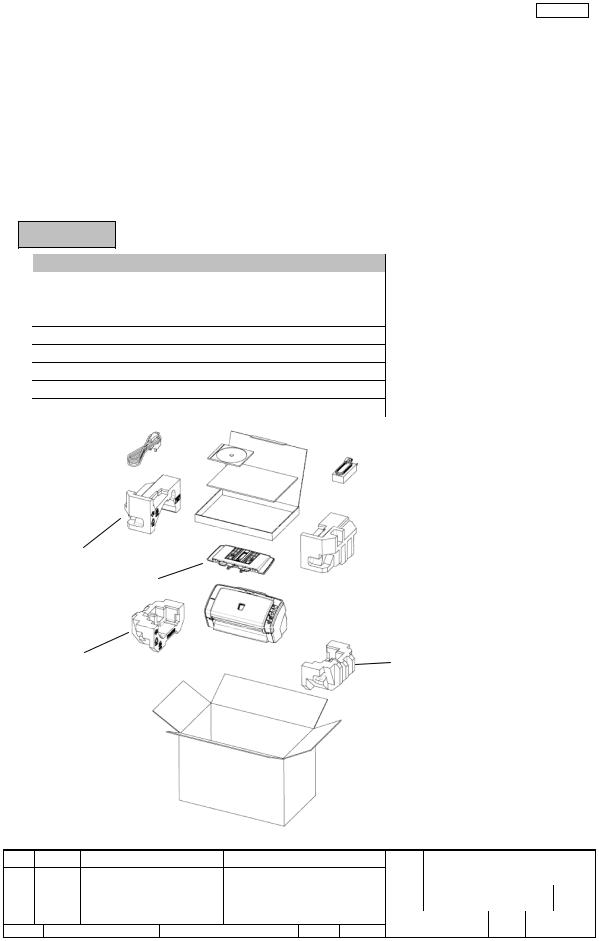

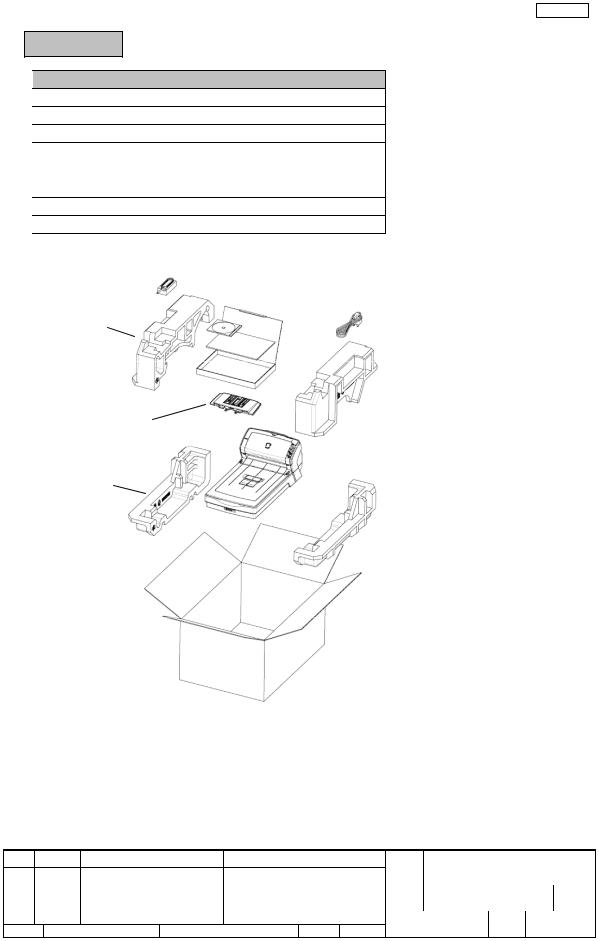

Cancels ongoing scanning. |

6 |

Power button / LED |

Turns the scanner ON and OFF. |

|

Lights when the scanner is turned ON. |

|

|

|

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

Nov.12, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

06 |

Mar.10, 08 |

K.Okada |

T.Anzai |

I.Fujioka |

Refer to Revision Record on page 2. |

|

Rev. |

DATE |

DESIGN |

CHECK |

APPR. |

DESCRIPTION |

|

Design July 27, 2007 K.Okada CHECK K.Okada |

APPR. T.Anzai |

|||||

TITLE |

fi-6140/fi-6240/fi-6130/fi-6230/fi-614PR |

|

Maintenance Manual |

||

DRAW |

P1PA03540-B0XX/6 |

CUST. |

No. |

|

|

PFU LIMITED Page |

15 / 257 |

|

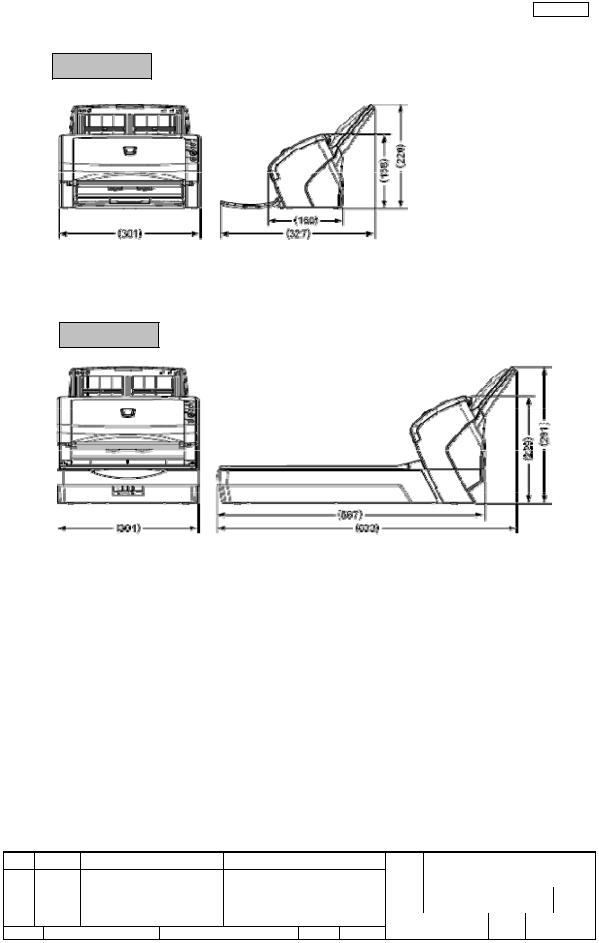

ection 1-1-5

1-1-5 Outer Dimensions

fi-6140/fi-6130

fi-6240/fi-6230

08 |

July 27, 09 |

K.Okada |

A.Miyoshi |

I.Fujioka |

Refer to Revision Record on page 2. |

|

07 |

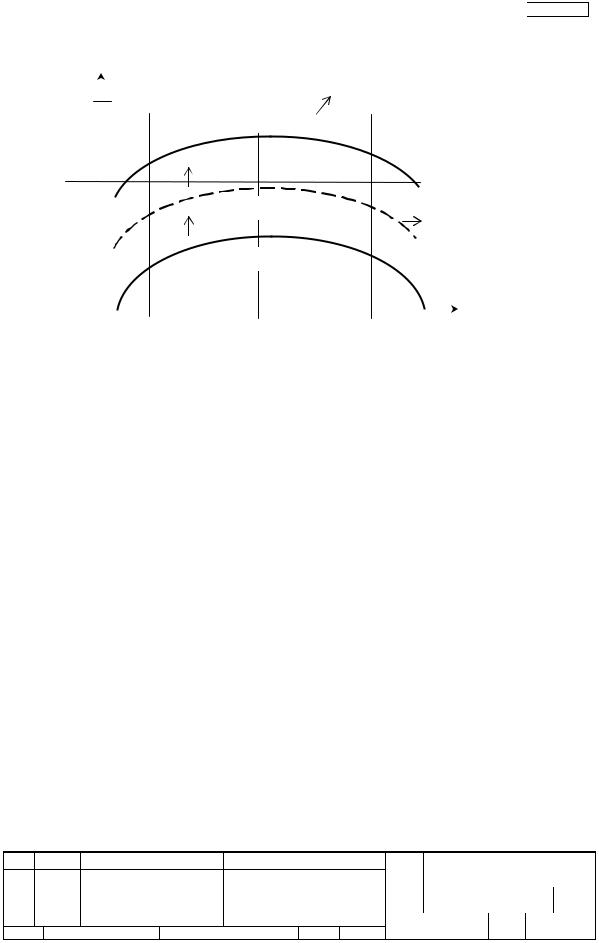

Nov.12, 08 |