Page 1

USER INSTRUCTIONS

MX/QX HART Field Unit

FCD LMENIM2340-00 – 1/14

Installation

Operation

Maintenance

Experience In Motion

Page 2

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Contents

1 Introduction 6

1.1 Purpose 6

1.2 How to Use This Manual 6

1.3 User Safety 7

1.4 User Knowledge 7

1.5 MX/QX HART System Capabilities and Features 7

1.5.1 General Network Specification 8

2 System Components and Installation 9

2.1 Introduction 9

2.2 Hardware 9

2.2.1 MX/QX Electronic Actuators 9

2.2.2 MX/QX HART Interface Board 11

2.2.3 Network Host 11

2.2.4 Network Cable 11

2.2.5 Typical HART Network Configuration 11

2.3 Network Cabling Topologies 12

2.4 Site and Network Cable Preparation 13

2.4.1 Site Preparation 13

2.4.2 Network Cable Preparation 13

2.4.2.1 Network Cable Connection to the MX/QX HART Unit 13

2.5 MX/QX HART Device Installation and Setup 14

2.5.1 MX/QX HART Device Installation 14

2.5.2 MX/QX HART Device Setup 14

2.6 Installation Verification 16

2.6.1 Network Cabling Installation Verification 16

2.6.2 MX/QX HART Device Installation Verification 16

2.7 Configuration Confirmation 17

2.7.1 Checking Connections 17

2.7.2 View Settings 17

2.7.3 Checking the Normal Display 18

2.8 MX/QX HART Device Description and Device Type Manager Files 18

3 Software 19

3.1 HART Protocol 19

3.2 HART Parameters 19

3.2.1 Analog Input Ratings 19

3.2.2 Field Device Status 20

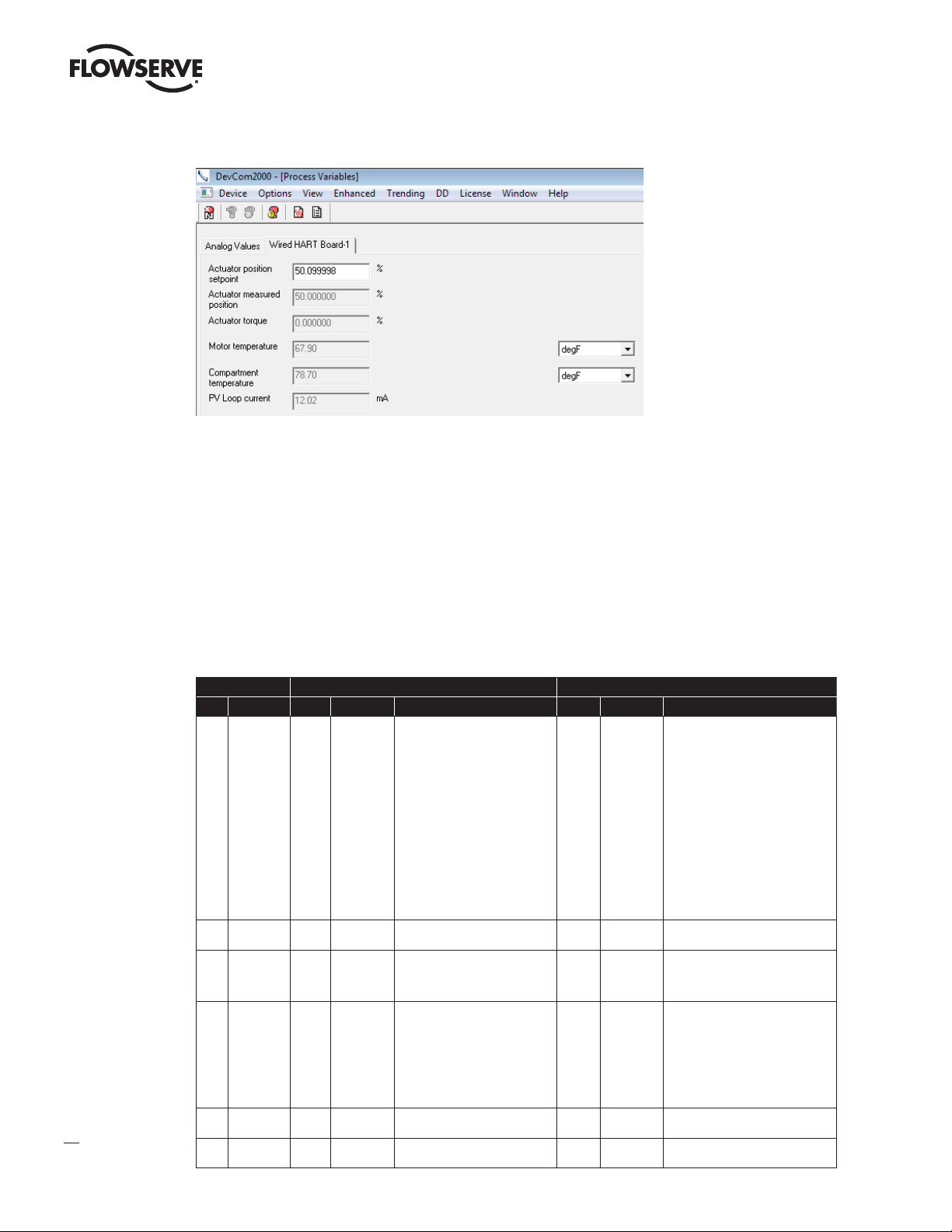

3.3 Dynamic Variables 20

3.4 Device Variables 20

3.4.1 Supported Device Variables 20

3.4.2 Device Variable Mapping 21

3.4.3 Device Variable Units 21

3.5 Supported HART Commands 22

3.5.1 Universal Commands 22

3.5.1.1 Command 48 Data 24

3.5.2 Common Commands 29

3.5.3 Burst Messages 33

3.5.3.1 Update Periods 33

3.5.3.2 Commands Supported for Burst Message 34

2

3.5.3.3 Configuring a Device for Burst Mode Operation 34

3.5.3.4 Burst Message Trigger Mode 35

3.5.3.5 Burst Trigger Mode 35

Page 3

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Contents (Continued)

3.5.4 Event Notification 35

3.5.4.1 Configuring Event Notification 36

3.5.4.2 Handling of Event Notifications 37

3.5.4.3 Update Periods 37

3.6 Device-Specific Commands 37

3.6.1 Remote Configuration Mode 37

3.6.2 Partial Stroke Test 39

3.6.3 Actuator Commands 41

3.7 Calibration 42

3.7.1 Loop Current Trim Procedure 42

3.7.2 Re-range Procedure 45

3.7.3 Analog Signal to Primary Variable Process Flow 47

4 Associated Documents 49

5 How to Order Parts 50

Appendix A – Wiring Diagrams 51

Appendix B – HART Data Formats 52

Appendix C – Enumeration and Bit Field Tables 52-55

Appendix D – Setting Data and Time 56

Appendix E – Command Response Codes 56-67

flowserve.com

3

Page 4

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Figures

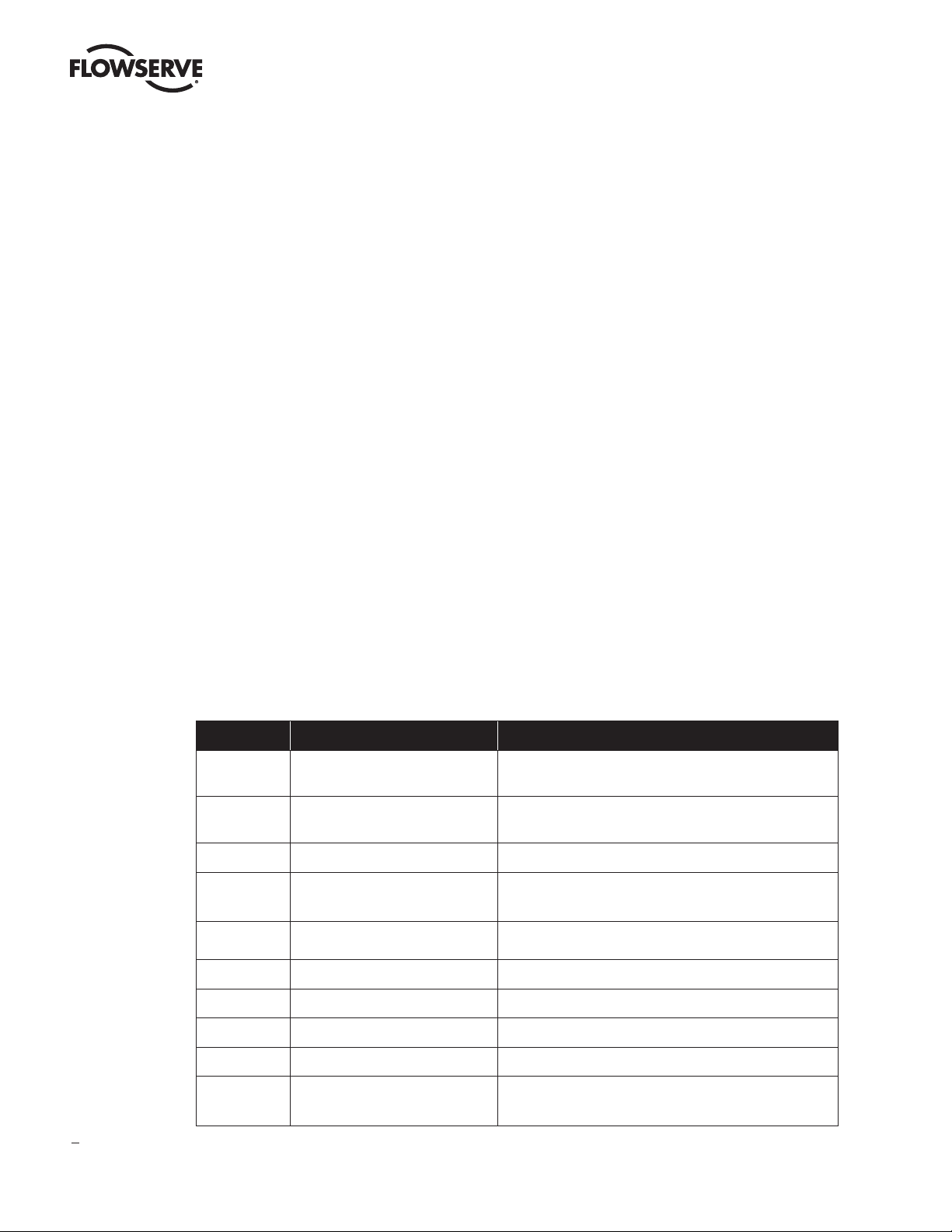

Figure 2.1a – MX-05 Actuator and Figure 2.1b – QX-05 Actuator 10

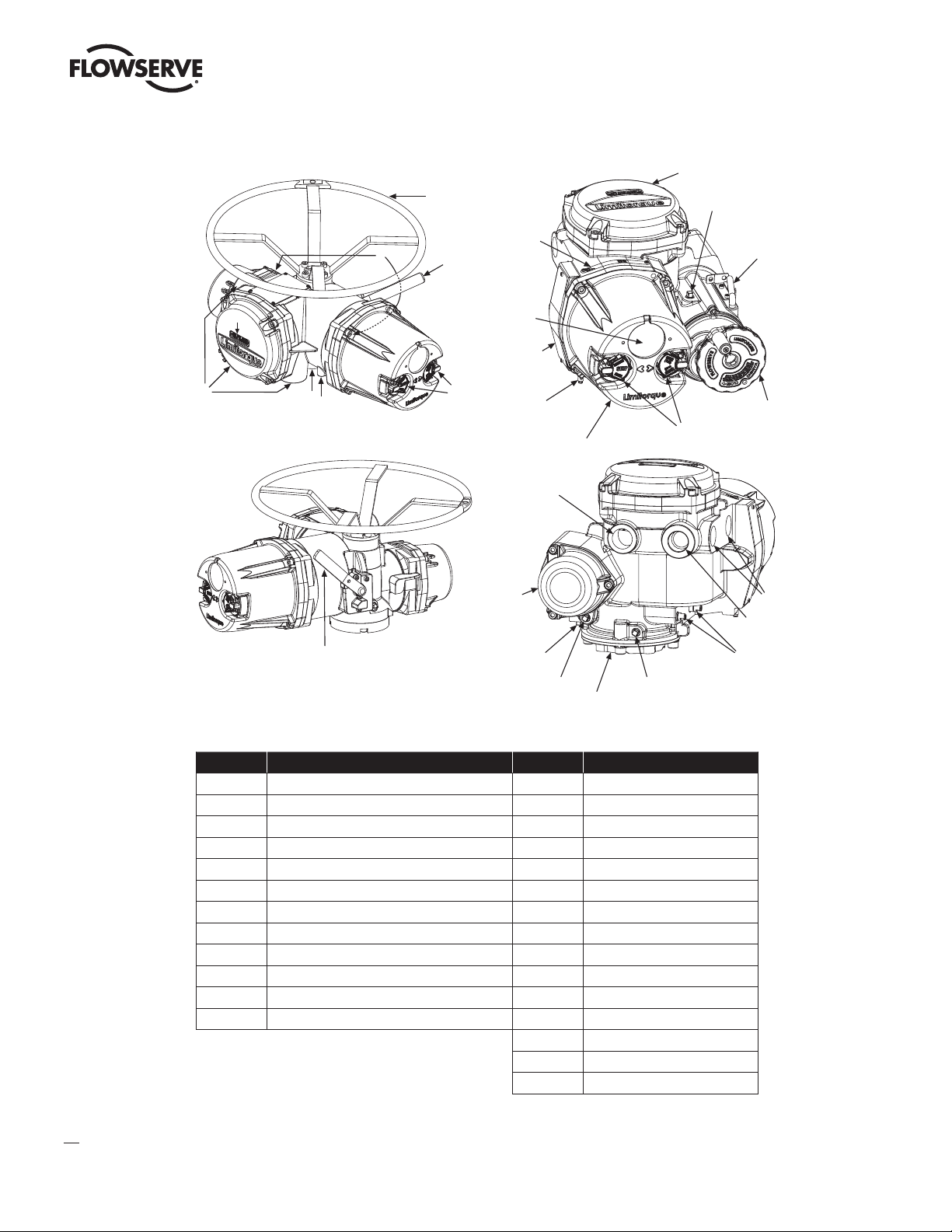

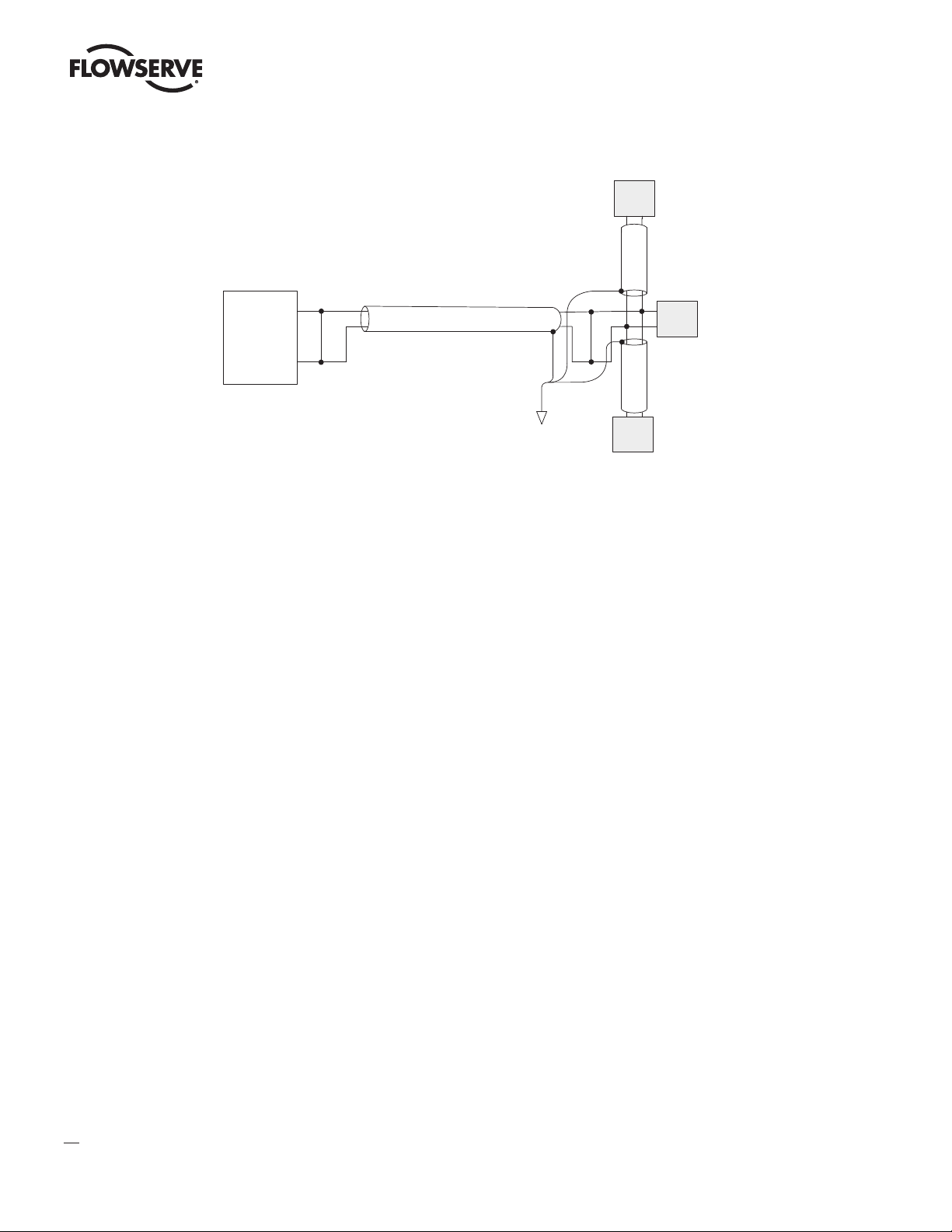

Figure 2.2 – Typical HART System With a DCS Host 11

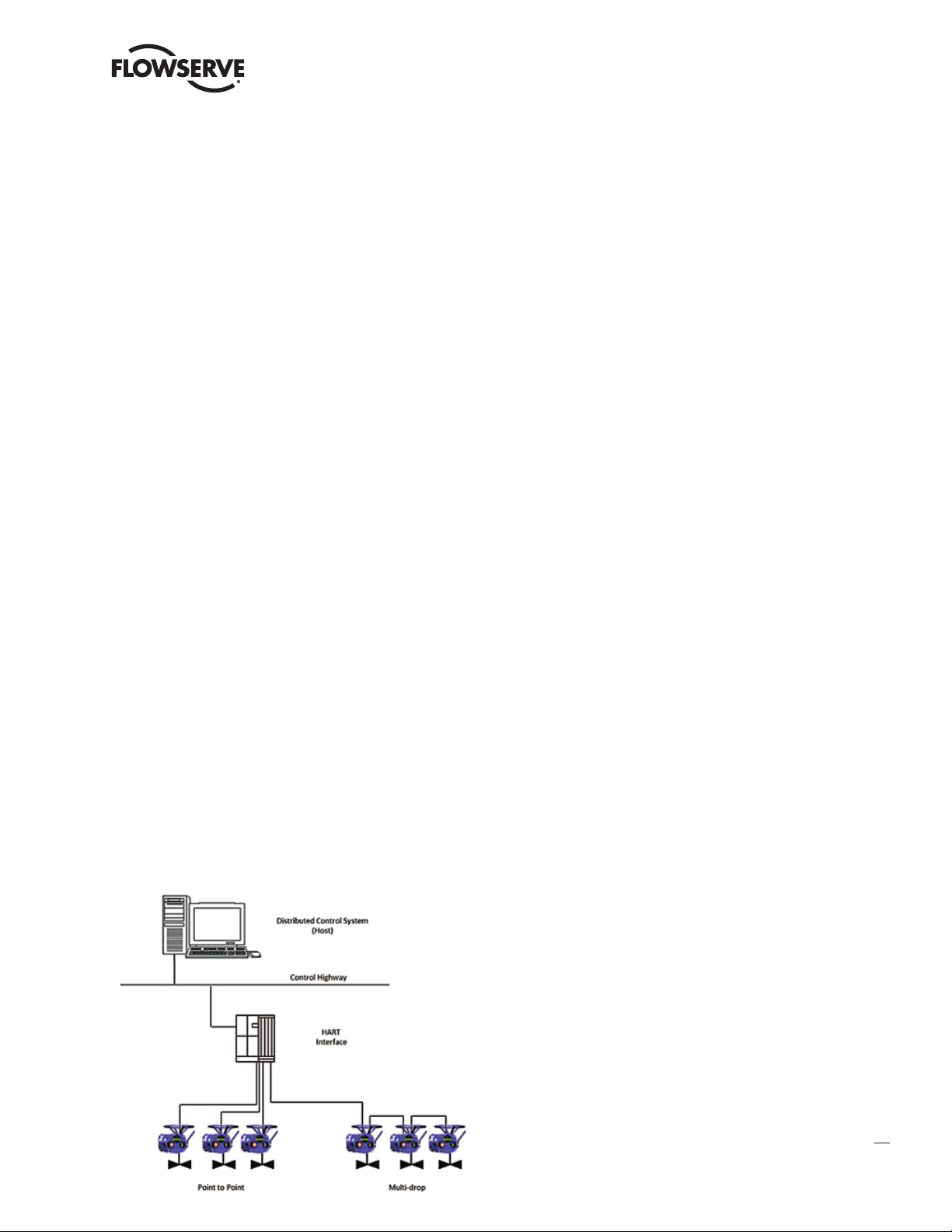

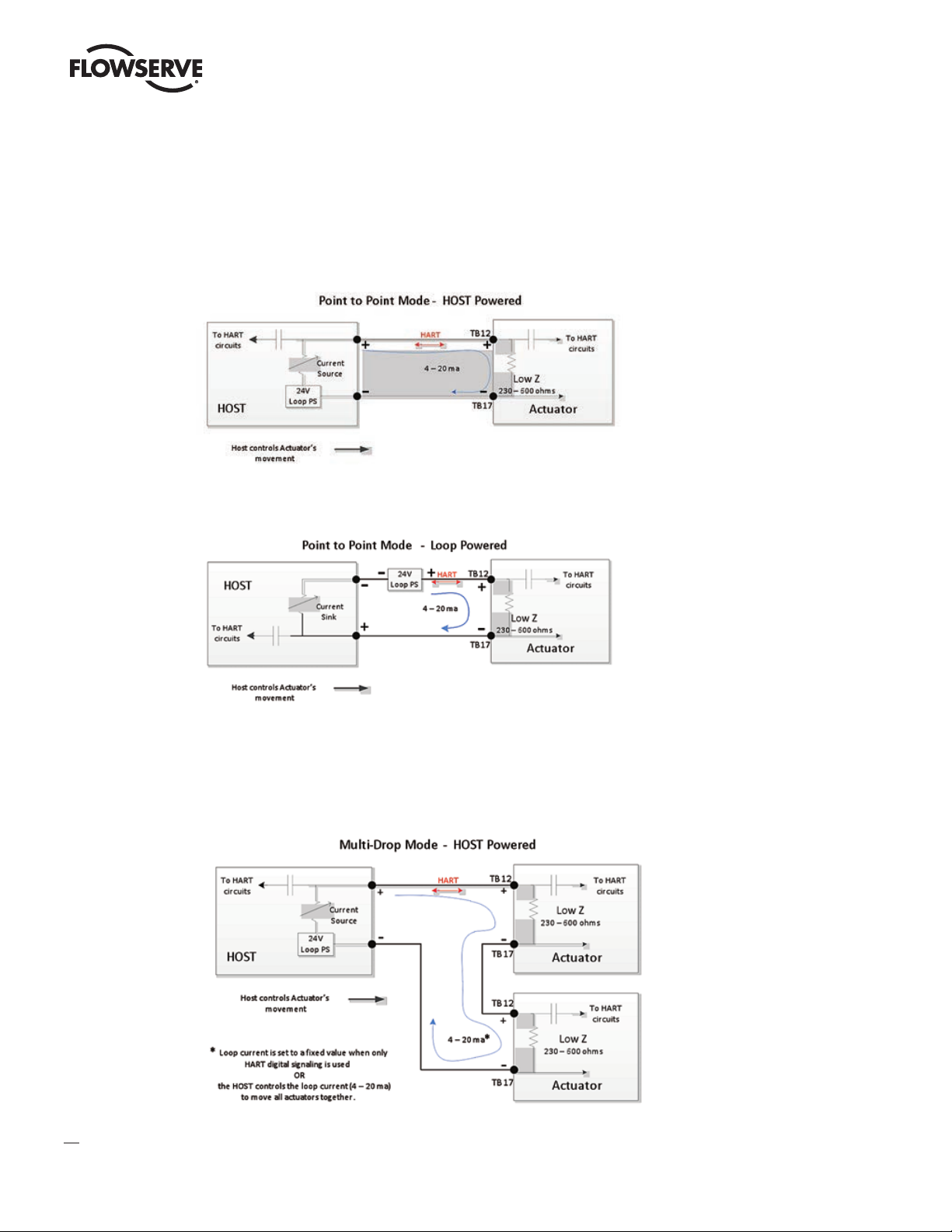

Figure 2.3 – Point-to-Point Topology (Host Powered) 12

Figure 2.4 – Point-to-Point Topology (Loop Powered) 12

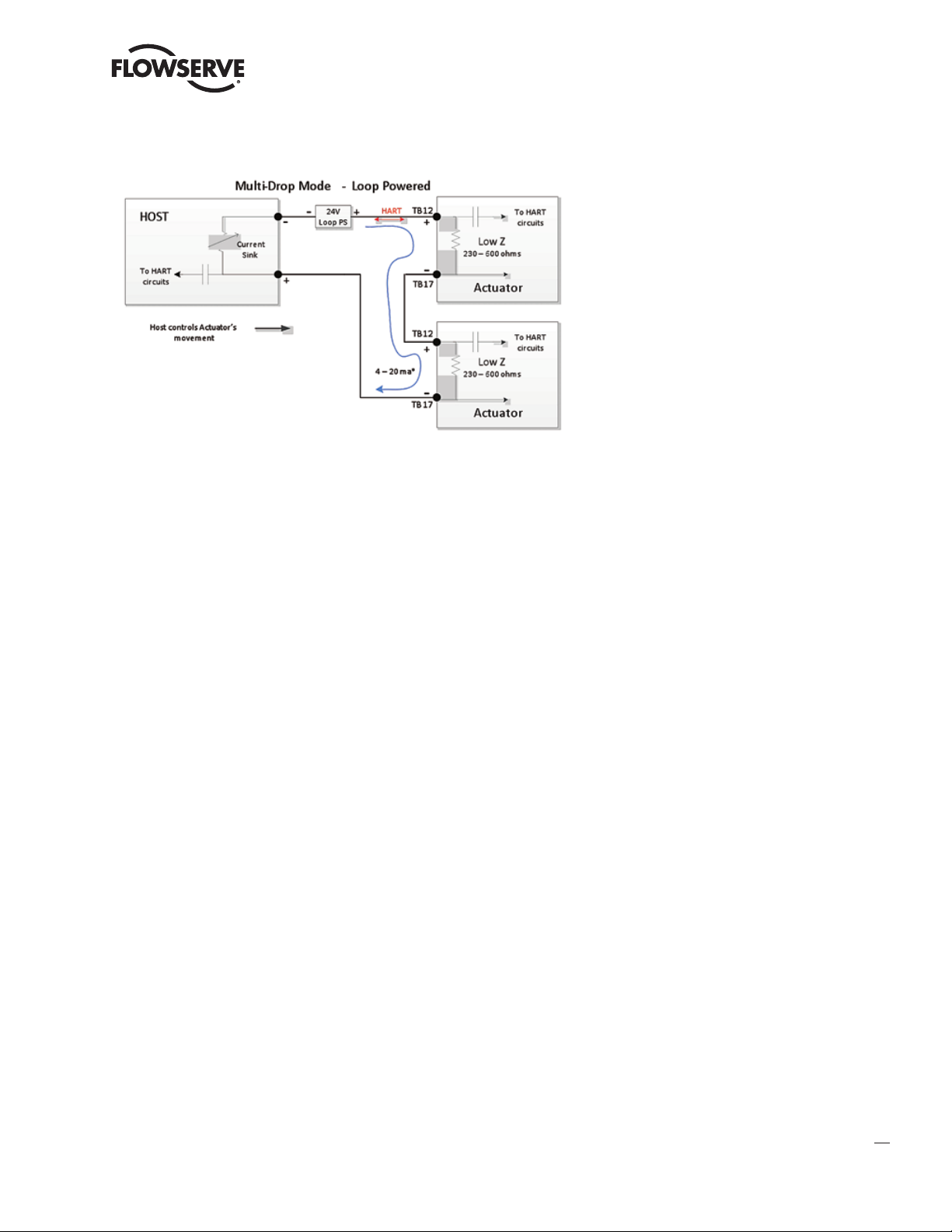

Figure 2.5 – Multi-drop Topology (Host Powered) 12

Figure 2.6 – Multi-drop Topology (Loop Powered) 13

Figure 2.7 – Connecting Network Cable to MX/QX Terminal Block 14

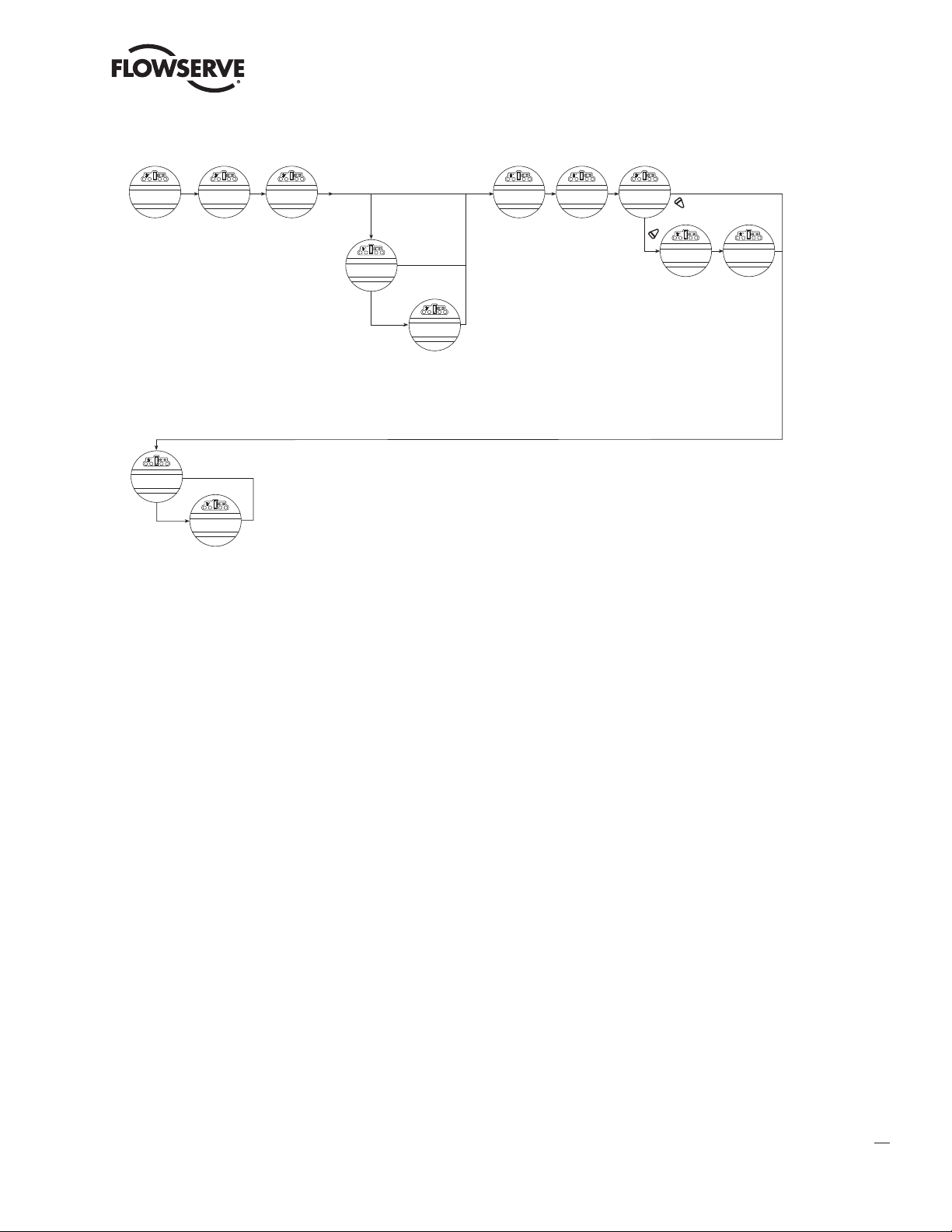

Figure 2.8 – MX/QX HART Setup Sequence 15

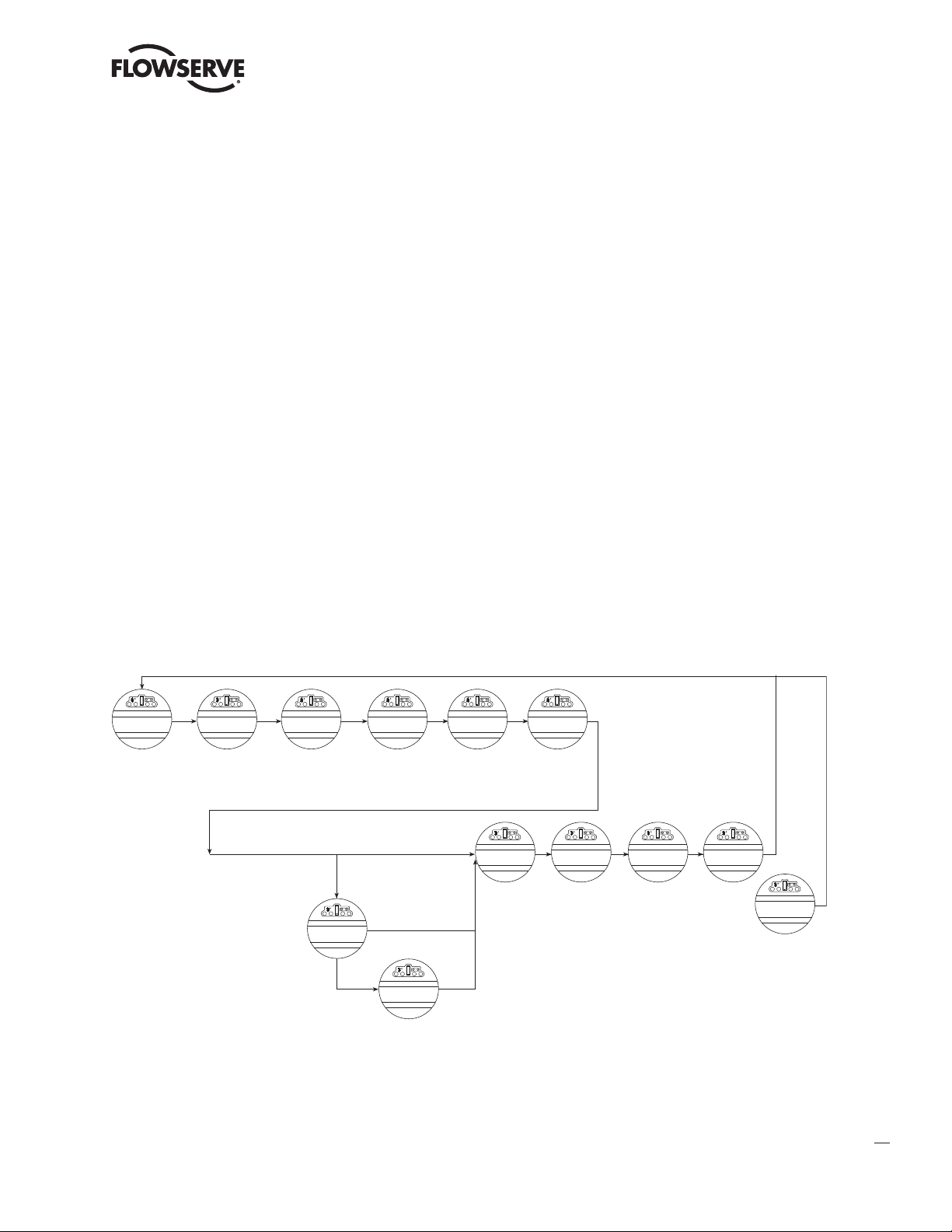

Figure 2.9 – MX/QX HART View Settings Sequence 17

Figure 2.10 – Normal Display 18

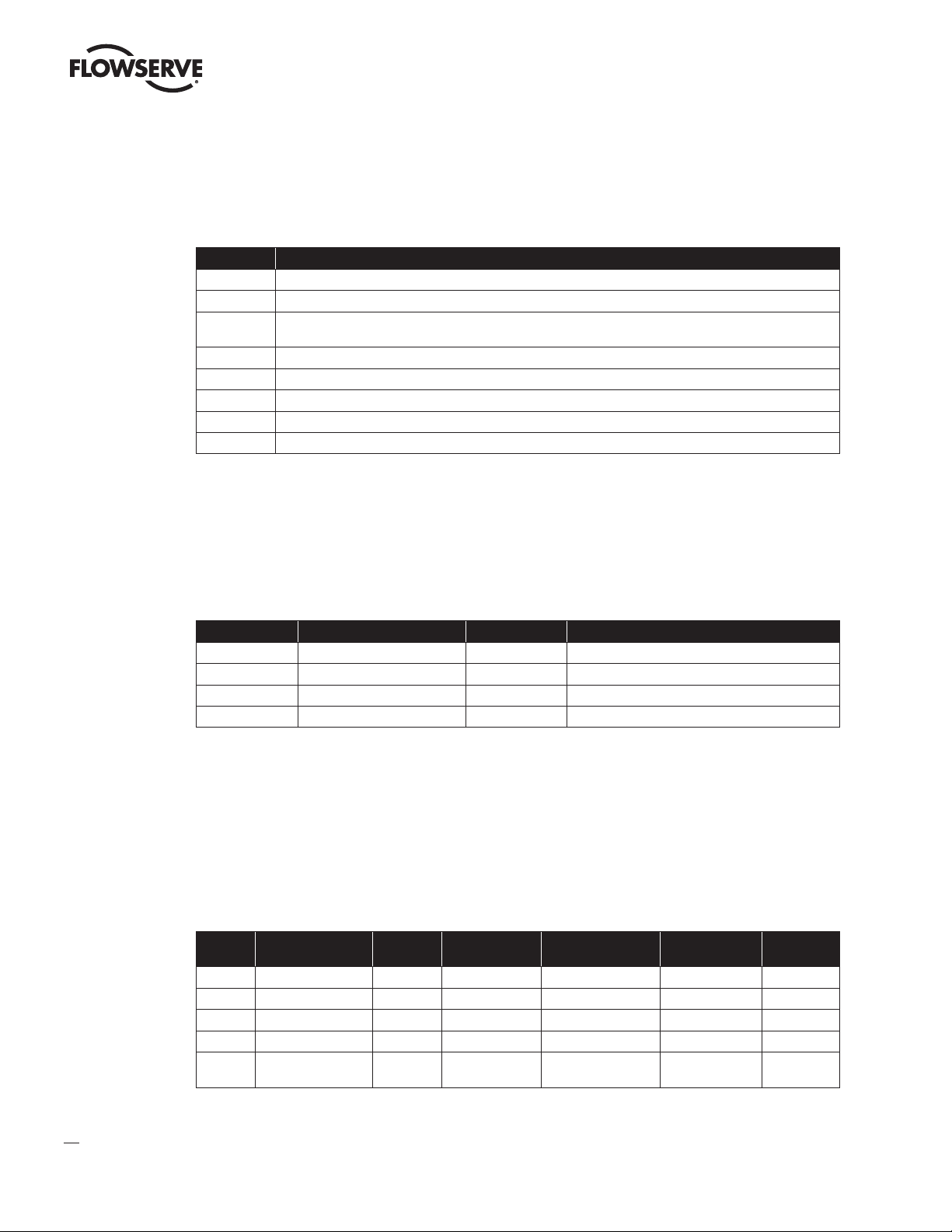

Figure 3.1 – Device Variable Mapping Setup 21

Figure 3.2 – Device Variable Units 22

Figure 3.3 – HART Diagnostics Data 28

Figure 3.4 – Burst Messages 34

Figure 3.5 – Trigger Mode 1 “Windowed” 35

Figure 3.6 – Event Notification 36

Figure 3.7 – Event Mask 36

Figure 3.8 – Remote Configuration Mode 37

Figure 3.9 – Analog Signal to Primary Variable Process Flow 48

Figure 5.1 – Device Variable Status Byte Format 53

4

Page 5

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Tables

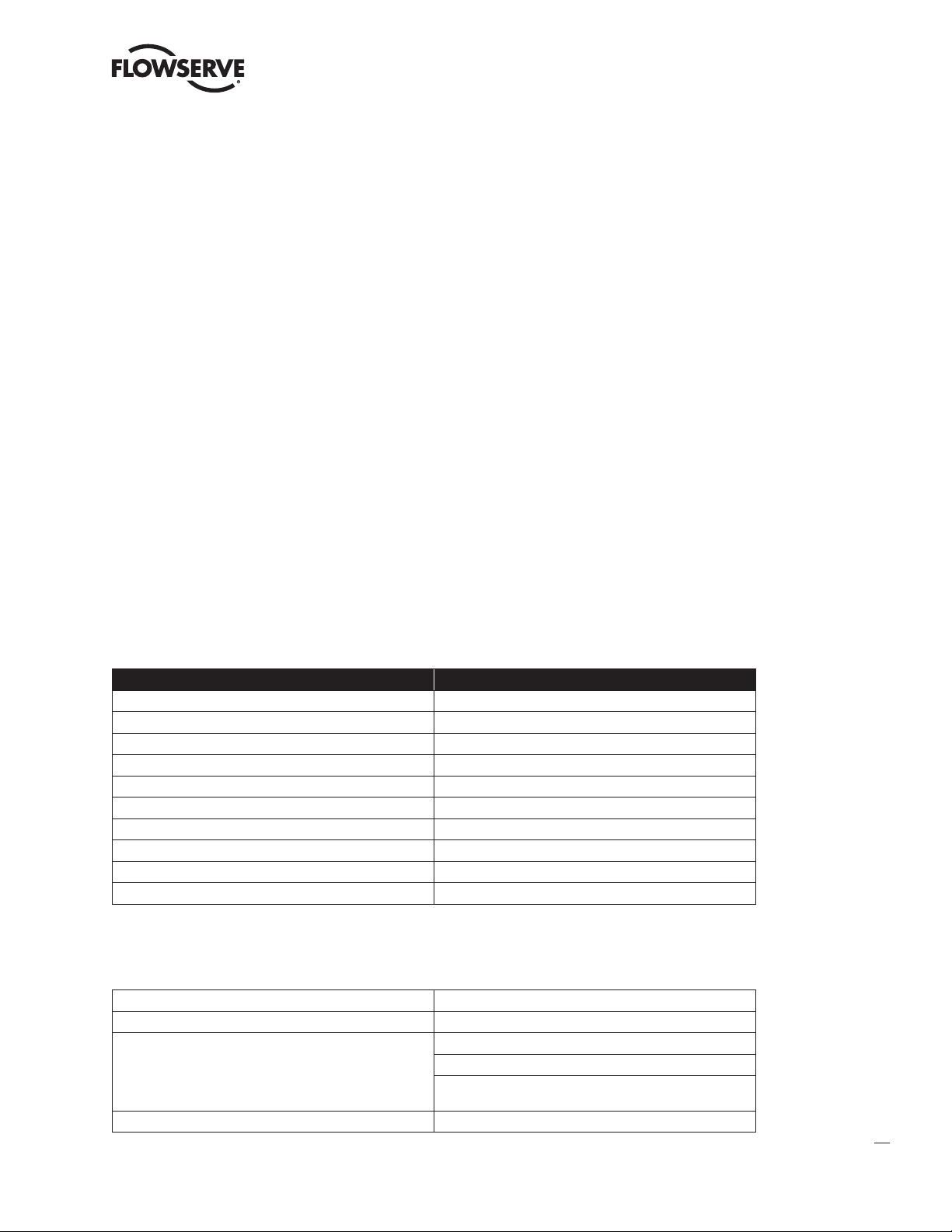

Table 2.1a – MX Actuator Components and Table 2.1b – QX Actuator Components 10

Table 3.1 – HART Parameters 19

Table 3.2 – Analog Input Ratings 19

Table 3.3 – Field Device Status 20

Table 3.4 – Supported Dynamic Variables 20

Table 3.5 – Supported Device Variables 20

Table 3.6 – Mapping of Device Variables to Dynamic Variables 21

Table 3.7 – HART Universal Commands 22

Table 3.8 – HART Defined Status Bits 25

Table 3.9 – MX/QX Defined Status Bits 26

Table 3.10 – Common Commands 29

Table 3.11 – Trigger Source for Burst Message Commands 35

flowserve.com

5

Page 6

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Introduction

1

1.1 Purpose

This manual explains how to install and operate the MX/QX HART field unit. Actuators containing the HART field unit

may be connected by a standard instrumentation twisted-pair cable to form a HART communication system network.

The HART network employs a bi-directional communication protocol, operating at 1200 bits/sec, that provides data

access between intelligent actuators and host control/monitoring systems. In addition to a digital signal, the network

simultaneously provides a 4-20 mA analog signal that is proportional to the field unit’s primary measured value. This

system allows a host system such as a distributed control system (DCS) to control and monitor the actuators, including

the acquisition of status and alarm data from each MX/QX.

1.2 How to Use This Manual

Each section provides the MX/QX HART user with information on installing and operating the MX/QX HART field unit.

Section Title Description

1 Introduction

2 System Components

3 Installation and Configuration Provides details for installing and configuring a field unit.

4 Associated Documents

5 How to Order Parts

Appendix A Wiring Diagram Detail wiring connections to the MX/QX field unit.

Appendix B HART Data Formats Listing of HART parameters and descriptions.

Appendix C Enumeration and Bit Field Tables Explains field device bit masking information.

Appendix D Setting Date and Time Defines real-time clock configuration settings.

Appendix E Command Response Codes

Details user safety and knowledge requirements, system

capabilities and features.

Focuses on the description of the HART system hardware

and software components.

Provides a list of documents on related subjects for

additional MX/QX and HART system information.

This section provides part numbers and ordering contact

information.

Listing of response codes for all universal and common

HART commands.

6

Page 7

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

1.3 User Safety

Safety notices in this manual detail precautions the user must take to reduce the risk of personal injury and damage

to the equipment. The user must read and be familiar with these instructions before attempting installation, operation,

or maintenance. Failure to observe these precautions could result in serious bodily injury, damage to the equipment,

warranty void, or operational difficulty. User must follow local and state safety regulations.

Safety notices are presented in this manual in three forms:

c WARNING: Refers to personal safety. Alerts the user to potential danger. Failure to follow warning notices could

result in personal injury or death.

a CAUTION: Directs the user’s attention to general precautions that, if not followed, could result in personal injury

and/or equipment damage.

NOTE: Highlights information critical to the user’s understanding of the operator’s installation and operation.

1.4 User Knowledge

It is recommended that the user read this manual in its entirety before the MX/QX HART equipped actuator is installed

and operated.

The user needs to have a fundamental knowledge of electronics and microprocessor concepts. An understanding of

valve actuators and digital control systems is beneficial to the field unit user. Refer to the Glossary for terms used

throughout this manual.

The following websites have documents on HART and electric actuators: www.hartcomm.org and www.flowserve.com

For HART technology and cabling information, refer to the following documents:

HART Communication Protocol Specification: HCF_SPEC-13

HART Communication FSK Physical Layer Specification: HCF_SPEC-54

HART Communication Command Summary Specification: HCF_SPEC-99

HART Communication Universal Command Specification: HCF_SPEC-127

HART Communication Common Practice Command Specification: HCF_SPEC-151

HART Communication Common Tables: HCF_SPEC-183

1.5 MX/QX HART System Capabilities and Features

Limitorque’s HART field unit conforms to the HART Communication Protocol Specification (Document HCF_SPEC-

13). The device is suitable for use on point-to-point and multi-drop network topologies. The communication system

theoretically supports up to 26 actuators connected in a multi-drop network.

The MX/QX HART field unit fits in the actuator in the sealed electrical housing. Adjustments to the MX/QX HART

settings must be made from the configuration SETUP menu.

The MX/QX HART field unit may command its actuator to:

Open

Stop

Close

Move to a set position

Perform an emergency shutdown operation

Read and control relays

Perform partial stroke test

Monitor analog inputs and position

Monitor modes and alarms

7

flowserve.com

Page 8

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Commands to the unit come over the network from the host system, which may be:

• Personal Computer (PC)

• Distributed Control System (DCS)

• Programmable Logic Controller (PLC)

• Field Device Tool (FDT) w/Device Type Manager (DTM)

• Some other microprocessor-based device

A HART field device is an intelligent device within the actuator that can send multiple digital device variables to the

control system over a 4-20 mADC analog signal loop. The device provides control and self-test capabilities, which allow

abnormal conditions to be easily and immediately identified before an unplanned shutdown occurs.

Additional features and capabilities are:

• The system reduces the cost of wiring and installation – existing wiring and multi-drop connections can be used.

• The devices are interoperable – devices from different suppliers can communicate with one another on the same

network.

1.5.1 General Network Specification

System Specifications:

Communications using the HART Communication Foundation Protocol

Network Specificationss:

• Point-to-point and multi-drop topologies

• Master/slave communication

• Simultaneous 1200 bps digital communication without 4-20 mADC signal interruption

• Up to two masters per network (primary and secondary)

• Burst mode for continuous message broadcasting

MX/QX HART Unit Specification:

The field unit mounts in the actuator and is software-controlled in order to allow functionality of:

• Dynamic Variables PV, SV, QV and TV

• Device Variables: Position Setpoint, Measured Position, Torque, Motor Temperature and Compartment Temperature

• Network Communication

• Device-Specific Commands

System Host Specifications:

The HART master is the network system host, and can be a personal computer (PC), distributed control system (DCS),

programmable logic controller (PLC), or another microprocessor-based device. The HART protocol allows for up to

two masters (primary and secondary) per network loop. Secondary masters, such as handheld communicators, can be

used without interrupting communications between the primary master and field devices.

8

Page 9

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

System Components

2

and Installation

2.1 Introduction

This section is an overview of the components used in the HART system and their installation. The MX/QX HART unit is

installed in the MX or QX actuator, as shown in Figures 2.1 and 2.2. The network cable connects to the HART unit at the

actuator terminal block. The network cable connects to the distributed control system, which usually acts as the host.

2.2 Hardware

2.2.1 MX/QX Electronic Actuators

The MX/QX actuators control the opening and closing of valves. The MX is a multi-turn valve, while the QX is a quarterturn valve actuator. Both actuators are designed for operation of ON-OFF and modulating valve applications.

The MX/QX features include the following:

• Non-intrusive setup

• Separately sealed terminal compartment

• Patented absolute encoder for valve position sensing (no battery required)

• Graphical LCD for indication and calibration

• Sophisticated electronic control, monitoring, and diagnostic capabilities with patented LimiGard™ technology

NOTE: Recommended storage procedures for the MX are detailed in Bulletin LMENIM2306, MX Maintenance and

Spare Parts Manual. QX procedures are detailed in Bulletin LMENIM3306, QX Maintenance and Spare Parts Manual.

Failure to comply with recommended procedures will void the warranty. For longer-term storage, contact Limitorque for

procedure and recommendations.

flowserve.com

9

Page 10

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Figure 2.1a – MX-05 Actuator Figure 2.1b – QX-05 Actuator

1

10

3

11

13

5

12

2

9

OPTIONAL

15

1

9

7

4

9

3

14

8

6

3

3

11

10

9

12

4

8

7

2

2

5

6

10

Table 2.1a – MX Actuator Components Table 2.1b – QX Actuator Components

Item Description Item Description

1 Handwheel 1 Handwheel

2 Declutch lever 2 Declutch lever (QX-05)

3 Oil fills (dotted arrow depicts fill on declutch side) 3 Oil fill

4 Controls compartment (field unit location) 4 Controls cover

5 LCD display 5 LCD display

6 Control knobs 6 Control knob

7 Ground lug 7 Ground lug

8 Thrust/torque base 8 Baseplate

9 Conduit entries 9 Conduit entry

10 Terminal compartment 10 Terminal compartment

11 Electric motor 11 Motor

12 Nameplate 12 Certification nameplate

13 Tag nameplate

14 Oil plug

15 Stem nut stops

Page 11

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

2.2.2 MX/QX HART Interface Board

The MX/QX HART field unit interface board is installed in the actuator controls compartment (Figures 2.1 & 2.2 and

Tables 2.1 & 2.2). This unit permits the actuator to be controlled by a DCS or other network host over the HART

network.

The following commands and feedback information are transmitted through this unit:

• OPEN, CLOSE and STOP commands

• ESD (Emergency Shutdown) commands

• Partial Stroke Test commands

• Unit output torque (0-100% rating)

• Go-to-position commands

• Actuator status, alarm and diagnostic messages

• User analog input feedback

2.2.3 Network Host

The HART network is a master/slave communication protocol. Communication to each slave (MX/QX field device) is

initiated by a master (system host device). Two masters can connect to each HART loop. Normally, the primary master

is a DCS, PLC, or PC. If desired, a handheld communicator or PC can serve as the secondary master.

2.2.4 Network Cable

Network cabling should be in accordance with the HART Communication Foundation guidelines. In general, wiring for

HART devices is the same as for conventional 4-20 mA instrumentation. It is recommended to use individually shielded

twisted pair cable. The minimum conductor size is 0.51mm diameter (#24 AWG) for cable runs less than 1500 meters

(5000 ft.), and 0.81mm diameter (#20 AWG) for distances up to the 3000 meter (10 000 ft.) theoretical limit for HART

communication. Please note that the electrical characteristics of the cable, especially capacitance, and the number of

network field devices can affect the maximum allowable cable length.

To prevent signal loop interference, tie all cable shields together and ground at only one point.

2.2.5 Typical HART Network Configuration

A typical MX/QX HART system is shown below:

Figure 2.2 – Typical HART System With a DCS Host

flowserve.com

11

Page 12

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

2.3 Network Cabling Topologies

There are two main topologies for MX/QX HART networks:

Point-to-point One field device connected to the bus (network)

Figure 2.3 – Point-to-Point Topology (Host Powered)

Figure 2.4 – Point-to-Point Topology (Loop Powered)

12

Multi-drop Multiple field devices connected to the bus (network)

Figure 2.5 – Multi-drop Topology (Host Powered)

Page 13

Figure 2.6 – Multi-drop Topology (Loop Powered)

2.4 Site and Network Cable Preparation

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

2.4.1 Site Preparation

Prepare the site and associated equipment for operation of the MX/QX HART actuators as follows:

1. Prepare a detailed site plan consisting of the following:

• Actuator locations and tag numbers

• Junction boxes, terminal strip locations and tag numbers

• Power supplies/conditioners

• Provide free access to the MX/QX control panel and terminal block for setup, configuration and troubleshooting.

2. Prepare the cable and label all wires.

3. Install power and control wires in separate conduits.

4. Install and verify earth grounds. The cable shields should be tied together and grounded at only one point. The

single ground point is typically located at or near the system host device.

2.4.2 Network Cable Preparation

Care must be taken during cable preparation:

• When stripping the insulation, use wire strippers that do not nick the wire.

• Use crimp ferrules to prevent stranded wires from getting loose and shorting to other wires.

• Use vibration-resistant wiring terminals that hold the ferrule securely.

2.4.2.1 Network Cable Connection to the MX/QX HART Unit

The field device is connected to the network through the MX/QX terminal block. The network cable is connected to the

terminal block shown in Figure 2.7.

13

flowserve.com

Page 14

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Figure 2.7 – Connecting Network Cable to MX/QX Terminal Block

Shielded Wire Pair

HART

Interface

Field

Device

Field

Device

Connect Shield

to Ground at one

place only

Field

Device

Connect the network cables to the MX/QX terminal block as shown in Figures 2.3 – 2.6. Refer to Appendix A for unit

wiring diagram.

Connect the cable shields to each other inside the unit. Do not connect them to the unit in any way. The network shield

should be grounded at only one place in the network. If it is desired to ground the entire network shield at the actuator,

then install a jumper cable from terminal 3 to earth ground or ground lug.

NOTE: The MX/QX HART device is sensitive to polarity. The cables should be labeled to indicate polarity, and polarity

should be maintained through all connection points.

2.5 MX/QX HART Device Installation and Setup

2.5.1 MX/QX HART Device Installation

The MX/QX HART field unit is located in the controls compartment. It has four standoffs and mounts on top of the

main processor board. Multiple Input/Output (I/O) option boards may also be present. If present, the I/O board will be

on top of the MX/QX HART unit. For installation instructions, refer to the MX Maintenance and Spare Parts Manual,

LMENIM2314 or the QX Maintenance and Spare Parts Manual, LMENIM3314.

14

2.5.2 MX/QX HART Device Setup

The MX/QX HART option enables the actuator to be controlled by a HART communications signal. If the option has

been purchased, it is automatically enabled.

NOTE: If the HART option has not been purchased, the screens for changing HART will not be available. To add the

HART option, please consult Limitorque service at (434) 528-4400.

Figure 2.8 illustrates the setup sequence. For proper operation, the correct mode must be selected.

To set up the MX or QX HART device, enter the Setup mode as detailed in Installation and Operation Manual Bulletins

LMENIM2306 for the MX and LMENIM3306 for the QX;

Page 15

Figure 2.8 – MX/QX HART Setup Sequence

ESD ACTION

(IGNORE)-OK?

(CLOSE)- OK?

(STOP)- OK?

(OPEN)- OK?

(POSITION)- OK?

CHANGE

HART

STATUS

(ON)-OK?

(OFF)-OK? (ENABLED)-OK?

MOVE TO

XXX% OPEN

MULTI-DROP

(DISABLED)-OK?

If Hart Actuator

& not Multidrop

FAIL POSITION

(CLOSED)-OK?

If fail position is

“position”

If fail position is

not “position”

(OPEN)- OK?

(STOP)- OK?

(POSITION)- OK?

XXX%-OPEN

MOVE TO

If Hart Actuator

& Multidrop

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

POLLING ADDRESS

(0)-OK?

Address default is zero

Range is 0-63

SAVE

SETTINGS-OK?

CHANGE PROP/

DEADBAND?

YES

NO

PROP BAND

(5%)-OK?

DEADBAND

(2%)-OK?

NOTE: This menu is displayed after the actuator and HART board have been powered up together at least one time.

1. Proceed through Setup to the CHANGE HART? display. Select YES to get to the STATUS display.

2. STATUS enables the user to change from the default condition to turn on and off the network control capability of

the actuator. Select NO to change the setting or YES to get to the next display. (Default = ON)

3. MULTI-DROP (ENABLED) or (DISABLED) allows the user to select the desired network topology. To change the

setting, select NO until the required option is displayed. Select YES if the setting is correct to go to the next display.

NOTE: Changing the topology also requires that the network be wired correctly for the selected topology.

NOTE: If MULTI-DROP ENABLED was chosen, skip to step 5. Otherwise, FAIL POSITION display is shown. In multi-drop

mode the input is digital only (write PV over network), so there is no analog fail action.

4. FAIL POSITION allows the user to configure the action desired upon loss of the analog input signal. The selections

are CLOSE, OPEN, STOP and POSITION. Select the desired setting and proceed to the next display.

NOTE: If POSITION is chosen as the action, a MOVE TO display will be shown where the user can select the desired

position between 0 and 100% open, in one percent increments, by selecting NO until the desired position is selected.

Select YES once the setting is correct to go to the next display.

5. POLLING ADDRESS allows the user to set the HART polling address of the unit. Point-to-Point units are typically

set to address 0, and Multi-drop units are typically set from 1-63. HART 5 masters will always set Point-to-Point

units to address 0.

6. SAVE SETTINGS allows the user to save the settings and make them active. This can result in a change in the

hardware configuration on the HART board to support the change in configuration. Select NO to return to STATUS

(step 2) and change settings. Select YES to save the HART configuration settings and go to additional network

settings.

NOTE: The configuration set in steps 1-6 will not be saved if the user does not select YES for SAVE SETTINGS.

flowserve.com

15

Page 16

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

7. CHANGE PROP/DEADBAND allows for the setting of proportional band and deadband. Proportional band is the

range of errors between the position and demand signal that will produce reduced speed (pulsing). The default

value is 5%. To change from default, select NO until the required value is displayed. The value is adjustable between

1% and 100%, in 1% increments. The default deadband value is 2%. For error signals less than this, no motion

occurs. The deadband should be wide enough to prevent “hunting” of the actuator but as low as possible to give

adequate response to changes in the error signal. To change from the default, select NO to adjust the value between

1% and 50%, in 1% increments to suit the application.

8. ESD ACTION allows a network ESD function to be enabled after the ESD configuration has been established for the

unit. This network ESD can be selected to do one of the following: ignore the command (NONE), CLOSE, OPEN,

STOP or POSITION the actuator. To change from the default setting, select NO until the required option is displayed.

Select YES if the setting is correct to go to the next display.

NOTE: If POSITION is chosen as the action, a MOVE TO display will be shown where the user can select the desired

position between 0 and 100% open, in one percent increments, by selecting NO until the desired position is selected.

Select YES once the setting is correct to go to the next display.

.2.6 Installation Verification

2.6.1 Network Cabling Installation Verification

After installation is complete and prior to operation, inspect the network cable and its connection to each field device.

NOTE: Units should be disconnected from power. The network should be disconnected from the host device.

Check for the following:

1. There should not be:

• Nicks in the insulation - this can cause a short to the grounded shield.

• Cut strands in a stranded conductor - this can cause a poor connection and eventually an open circuit.

2. The shield/drain wire should only be grounded at one point in the segment to avoid ground loop problems.

3. The ground/earth connection should be at true ground potential and effective at all times. See step No. 5 in Section

2.4.1, Site Preparation.

2.6.2 MX/QX HART Device Installation Verification

Verify the field device is installed as follows:

1. Enter the Setup mode as detailed in Installation and Operation Manual Bulletins LMENIM2306 for the MX or

LMENIM3306 for the QX.

2. In the Setup mode, use the black control knob to select YES to the main menu selection. VIEW DIAGNOSTICS?

3. Select YES to the display VIEW HARDWARE STATUS?

4. Select YES to scroll through the menu selections. The LCD will read HART BOARD 1 (OK) - NEXT? if installed.

NOTE: If the HART BOARD 1 (OK)? does not appear, contact Limitorque for assistance.

5. To return to the normal display, use the black knob to select either LOCAL or REMOTE.

16

Page 17

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

2.7 Configuration Confirmation

Field device operation cannot be verified until the complete HART system is operational. However, routine checks can

be performed to verify many functions.

2.7.1 Checking Connections

Verify that all connections, including data wires, shield ground, digital inputs (optional), digital outputs (optional), and

analog inputs are in accordance with MX/QX wiring diagrams and MX/QX HART device diagrams in Appendix A.

2.7.2 View Settings

Refer to Installation and Operation Manual Bulletins LMENIM2306 for the MX and LMENIM3306 for the QX to access

the view settings menu. Verify the settings as follows:

1. From the VIEW SETTINGS display, scan to the VIEW HART? display

2. From VIEW HART? display, select YES and check that the HART status is ON. This confirms that HART is enabled.

3. From HART STATUS display, select YES to go to next display, which is DEVICE ID. This is the Unique Device ID of

the HART device.

4. If the MX/QX contacts are to be controlled via the network to control external equipment, from the VIEW HART?

display, select NO and obtain the VIEW STATUS AND ALARM CONTROL? display. Verify that the digital outputs,

S1a, S1b, S2a, S2b are set for “Network” controlled.

Figure 2.9 – MX/QX HART View Settings Sequence

VIEW

HART?

STATUS

(ON)-OK?

DEVICE ID

3295509-OK?

If Hart Actuator

& not Multidrop

FAIL POSITION

(CLOSE)-OK?

If fail position is

“position”

HART-1 FIRMWARE

REV 25-OK?

MOVE TO

XXX% OPEN

If Hart Actuator

& Multidrop

If fail position is

not “position”

HART-1 HARDWARE

REV 25-OK?

POLLING ADDRESS

(0)-OK?

MULTI-DROP

(DISABLED)-OK?

PROP BAND

(5%)-OK?

DEADBAND

(2%)-OK?

ESD ACTION

(IGNORE)-OK?

MOVE TO

XXX% OPEN

flowserve.com

17

Page 18

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

2.7.3 Checking the Normal Display

Place the selector switch in LOCAL or REMOTE position. The valve position will be indicated at the top of the LCD.

STATUS OK or HARDWARE FAILURE should be indicated at the bottom of the LCD display.

• If STATUS OK is displayed, then the HART board hardware is OK.

• If HARDWARE FAILURE and HART-1 FAILED or HART-1 NOT PRESENT is displayed, no communication is occurring.

This could be due to a number of factors. Check all local connections and configurations. If these are correct and the

HARDWARE FAILURE is still displayed, then the solution to this problem must await full system commissioning.

Figure 2.10 – Normal Display

Remot e

or

Local

100% OPEN

STATUS OK

2.8 MX/QX HART Device Description and Device

Type Manager Files

In the Host system, the configuration device can use Device Description (DD) files to configure a HART system without

having the devices online. Please refer to your host system documentation for the files that are needed. The Device

Type Manager (DTM) file provides an interface between the actuator’s specific application software and a Network

Host Station’s Field Device Tool (FDT) frame. The DTM can be integrated into FDT frame applications to allow users

to perform offline and online parameterization, configuration, and status and diagnostic retrieval. The DD files are

downloaded from the HART Communication Foundation website (www.hcfcomm.org) into the DCS workstation or

host device.

In addition, the DD and DTM files can be downloaded from the Flowserve Limitorque website: www.flowserve.com

18

Page 19

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Software

3

3.1 HART Protocol

The system uses the HART protocol to communicate over the HART network with other HART devices. The HART

protocol is a master/slave communication service for process control devices. HART digital signaling is an extension of

conventional analog signaling allowing the network signal to ride on the 4-20 mADC analog process signal. It uses

1200 bps binary phase-continuous Frequency-Shift-Keying (FSK), where a high frequency current is superimposed on

a low-frequency (typically 4-20 mADC) analog current.

3.2 HART Parameters

Table 3.1 – HART Parameters

Parameter Value

HART Version 7.3

Expanded Device Type = Manufactuer ID + Device Type 0x3008

Physical Layer Supported FSK

Physical Device Catagory Actuator

Maximum Number of Burst Messages 3

Maximum Number of Event Messages 1

Size of the Event Queue 6

Maximum Number of Trends 2

Size of the Trend Buffer 12

Default Number of Preambles1 5

3.2.1 Analog Input Ratings

Table 3.2 – Analog Input Ratings

Maximum current2 30.0 mA

Maximum voltage 50 V

Current over-range

(Primary Variable Out of Limits)

Multi-drop current draw Approximately 2 mA

1. Field Device must have minimum 5 preambles, and maximum 20 preambles.

2. The analog input is automatically bypassed, if the maximum loop current is reached. The field device will continue to check the circuit for overload on a periodic basis,

and will restore the connection if the overload clears.

Analog Input > 21 mA

Analog Input < 3 mA

(HART communication may fail, if Analog Input <2 mA.)

19

flowserve.com

Page 20

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

3.2.2 Field Device Status

The Field Device Status is contained in the second data byte in a Slave-to-Master frame as a bit field table. It indicates

the current operating status of the field device as a whole and is not associated with the completion of any command.

Table 3.3 – Field Device Status

Bit Mask Description

0x01 Primary Variable Out of Limits – The PV is beyond its operating limit.

0x02 Non-Primary Variable Out of Limits – A device variable not mapped to PV is beyond its operating limits.

0x04

0x08 Loop Current Fixed – The loop current is being held at a fixed value and is not responding to process variations.

0x10 More Status Available – More status information is available via Command 48, Read Additional Status Information.

0x20 Cold Start – A power failure or Device Reset has occurred.

0x40 Configuration Changed – An operation was performed that changed the device’s configuration.

0x80 Device Malfunction – The device detected a serious error or a failure that compromises device operation.

Loop Current Saturated – The loop current has reached its upper (or lower) endpoint limit and cannot increase (or

decrease) any further.

3.3 Dynamic Variables

The Limitorque HART actuator device supports the following Dynamic Variables:

Table 3.4 – Supported Dynamic Variables

Variable Code Variable Direction Physical Interface

0 PV (Primary Variable) input Analog current input – Analog Channel 0

1 SV (Secondary Variable) output None

2 TV (Tertiary Variable) output None

4 QV (Quaternary Variable) output None

3.4 Device Variables

3.4.1 Supported Device Variables

The Limitorque HART actuator device supports the following Device Variables:

Table 3.5 – Supported Device Variables

Variable

Code

Variable Direction Unit Code

0 Position setpoint input % (57) Not Classified (0) Valve/Actuator (6) 0-100

1 Current position output % (57) Not Classified (0) Not Used (250) 0-100

2 Torque output % (57) Not Classified (0) Not Used (250) 0-100

3 Motor temperature output °C (32), °F (33) Temperature (64) Not Used (250) Not Limited

Compartment

4

temperature

output °C (32), °F (33) Temperature (64) Not Used (250) Not Limited

Device Variable

Classification

Device Variable

Family

Range

20

Page 21

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

3.4.2 Device Variable Mapping

Device Variables may be mapped to the Dynamic Variables according to the following table:

Table 3.6 – Mapping of Device Variables to Dynamic Variables

Variable

Code

0 PV input Position Setpoint Position Setpoint

1 SV output Current Position Current Position or Torque

2 TV output Motor Temperature

3 QV output Compartment Temperature

No single Device Variable may be mapped to more than one Dynamic Variable.

For Example:

Valid Mapping: Invalid Mapping:

PV = DV0 PV = DV0

SV = DV1 SV = DV1

TV = DV3 TV = DV1

QV = DV4 QV = DV4

Dynamic

Variable

Direction Default Device Variable

Device Variables which may be mapped to the

Dynamic Variable

Current Position, Torque, Motor Temperature or

Compartment temperature

Current Position, Torque, Motor Temperature or

Compartment temperature

If you try to map two Dynamic Variables to the same Device Variable, the command will return response code 2 “invalid

selection”. The Device Variables may be mapped from the DD menu Device Setup->Wired HART Board->Configuration->

Device Variable Mapping as follows:

Figure 3.1 – Device Variable Mapping Setup

3.4.3 Device Variable Units

Device Variables 0, 1, and 2 have fixed units that may not be changed. Device Variables 3 and 4 have units that may be

interchanged between °C and °F the default is °F. For Device Variables 3 and 4, the units may be changed from the DD menu

Process Variables->Wired HART Board as follows:

flowserve.com

21

Page 22

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Figure 3.2 – Device Variable Units

3.5 Supported HART Commands

The following Universal and Common HART commands are supported by the Limitorque MX/QX HART device. See

Appendix B for more information on HART data formats such as: Packed, Latin-1, Date and Time. See Appendix C for

more information on “Enum” or “Bits” formats. See Appendix E for more information on valid Response Codes for each

command.

22

3.5.1 Universal Commands

Table 3.7 – HART Universal Commands

Command Request Data Bytes Response Data Bytes

No. Description Byte Format Description Byte Format Description

0 Read Unique

Identifier

1 Read Primary

Variable

2 Read Loop

Current And

Percent Of

Range

3 Read Dynamic

Variables And

Loop Current

6 Write Polling

Address

7 Read Loop

Configuration

0

Unsigned-8

1

Enum

Polling Address of Device

Loop Current Mode

0

1-2

3

4

5

6

7

7

8

9-11

12

13

14-15

16

17-18

19-20

21

0

1-4

0-3

4-7

0-3

4

5-8

9

10-13

14

15-18

19

20-23

0

1

0

1

Unsigned-8

Enum

Unsigned-8

Unsigned-8

Unsigned-8

Unsigned-8

Unsigned-5

Enum

Bits

Unsigned-24

Unsigned-8

Unsigned-8

Unsigned-16

Bits

Enum

Enum

Enum

Enum

Float

Float

Float

Float

Enum

Float

Enum

Float

Enum

Float

Enum

Float

Unsigned-8

Enum

Unsigned-8

Enum

254”

Expanded Device Type = 0x3008

Min. number of request preambles = 5

HART Protocol Major Rev. = 7

Device Rev. Level

Software Rev. Level

(5 MSB) Hardware Rev. Level

(3 LSB) Physical Signaling Code=0

Device Flag Assignment = 1

Device ID (unique for given device type)

Min. number of response preambles=5

Max. number of device variables = 5

Configuration Change Counter

Extended Field Device Status: 0=OK,

1=Maintenance req’d, 2=Device Alert

Manufacturer Identification Code = 0x0030

Private Label Distributor Code = 0x0030

Device Profile = 1

Primary Variable Units = 57 (%)

Primary Variable

Primary Variable Loop Current (mA)

Primary Variable % Of Range

Primary Variable Loop Current (mA)

Primary Variable Unit Code

Primary Variable

Secondary Variable Unit Code

Secondary Variable

Tertiary Variable Units Code

Tertiary Variable

Quaternary Variable Unit Code

Quaternary Variable

Polling Address of Device (0-63)

Loop Current Mode

Polling Address of Device (0-63)

Loop Current Mode

Page 23

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Command Request Data Bytes Response Data Bytes

No. Description Byte Format Description Byte Format Description

8 Read Dynamic

Variable Class

9 Read Device

Variables with

Status

11 Read Unique

Identifier

Associated

With Tag

12 Read Message 0-23 Packed Message

13 Read Tag,

Descriptor,

Date

14 Read Primary

Variable

Transducer

Information

15 Read Device

Information

Read Dynamic

Variable Class

0

Unsigned-8

1

Unsigned-8

2

Unsigned-8

3

Unsigned-8

4

Unsigned-8

5

Unsigned-8

6

Unsigned-8

7

Unsigned-8

0-5 Packed Tag 0

Slot 0: Device Variable Code

Slot 1: Device Variable Code

Slot 2: Device Variable Code

Slot 3: Device Variable Code

Slot 4: Device Variable Code

Slot 5: Device Variable Code

Slot 6: Device Variable Code

Slot 7: Device Variable Code

0

1

2

3

0

1

2

3

4-7

8

9

10

11

12-15

16

17

18

19

20-23

24

25

26

27

28-31

32

33

34

35

36-39

40

41

42

43

44-47

48

49

50

51

52-55

56

57

58

59

60-63

64

65-68

1-2

3

4

5

6

7

7

8

9-11

12

13

14-15

16

17-18

19-20

21

0-5

6-17

18-20

0-2

3

4-7

8-11

12-15

0

1

2

3-6

7-10

11-14

15

16

17

Enum

Enum

Enum

Enum

Bits

Unsigned-8

Enum

Enum

Float

Bits

Unsigned-8

Enum

Enum

Float

Bits

Unsigned-8

Enum

Enum

Float

Bits

Unsigned-8

Enum

Enum

Float

Bits

Unsigned-8

Enum

Enum

Float

Bits

Unsigned-8

Enum

Enum

Float

Bits

Unsigned-8

Enum

Enum

Float

Bits

Unsigned-8

Enum

Enum

Float

Bits

Time

Unsigned-8

Enum

Unsigned-8

Unsigned-8

Unsigned-8

Unsigned-8

Unsigned-5

Enum

Bits

Unsigned-24

Unsigned-8

Unsigned-8

Unsigned-16

Bits

Enum

Enum

Enum

Packed

Packed

Date

Unsigned-24

Enum

Float

Float

Float

Enum

Enum

Enum

Float

Float

Float

Enum

Enum

Bits

Primary Variable Class

Secondary Variable Class

Tertiary Variable Class

Quaternary Variable Class

Extended Field Device Status: 0=OK,

1=Maintenance req’d, 2=Device Alert

Slot 0: Device Variable Code

Slot 0: Device Variable Classification

Slot 0: Units Code

Slot 0: Device Variable Value

Slot 0: Device Variable Status

Slot 1: Device Variable Code

Slot 1: Device Variable Classification

Slot 1: Units Code

Slot 1: Device Variable Value

Slot 1: Device Variable Status

Slot 2: Device Variable Code

Slot 2: Device Variable Classification

Slot 2: Units Code

Slot 2: Device Variable Value

Slot 2: Device Variable Status

Slot 3: Device Variable Code

Slot 3: Device Variable Classification

Slot 3: Units Code

Slot 3: Device Variable Value

Slot 3: Device Variable Status

Slot 4: Device Variable Code

Slot 4: Device Variable Classification

Slot 4: Units Code

Slot 4: Device Variable Value

Slot 4: Device Variable Status

Slot 5: Device Variable Code

Slot 5: Device Variable Classification

Slot 5: Units Code

Slot 5: Device Variable Value

Slot 5: Device Variable Status

Slot 6: Device Variable Code

Slot 6: Device Variable Classification

Slot 6: Units Code

Slot 6: Device Variable Value

Slot 6: Device Variable Status

Slot 7: Device Variable Code

Slot 7: Device Variable Classification

Slot 7: Units Code

Slot 7: Device Variable Value

Slot 7: Device Variable Status

Slot 7 data time stamp

“254”

Expanded Device Type = 0x3008

Min. number of request preambles = 5

HART Protocol Major Rev. = 7

Device Rev. Level

Software Rev. Level

(5 MSB) Hardware Rev. Level

(3 LSB) Physical Signaling Code=0

Device Flag Assignment = 0

Device ID (unique for given device type)

Min. number of response preambles=5

Max. number of device variables = 5

Configuration Change Counter

Extended Field Device Status: 0=OK,

1=Maintenance req’d, 2=Device Alert

Manufacturer Identification Code = 0x0030

Private Label Distributor Code = 0x0030

Device Profile = 1

Tag

Descriptor

Date Code

Transducer Serial Number

Transducer Limits and Minimum Span Units

Code = 57 (%)

Upper Transducer Limit

Lower Transducer Limit

Minimum Span

PV Alarm Selection Code = 250 (not used)

PV Transfer Function Code = 0 (Linear)

PV Upper and Lower Range Values Units

Code

PV Upper Range Value

PV Lower Range Value

PV Damping Value (seconds)

Write Protect Code = 251 (none)

Reserved = 250 (not used)

PV Analog Channel Flags = 0x01

23

flowserve.com

Page 24

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Command Request Data Bytes Response Data Bytes

No. Description Byte Format Description Byte Format Description

16 Read Final

Assembly

Number

17 Write Message 0-5

18 Write Tag,

Descriptor,

Date

19 Write Final

Assembly

Number

20 Read Long Tag 0-31 Latin-1 Long Tag

21 Read Unique

Identifier

Associated

With Long Tag

22 Write Long Tag 0-31 Latin-1 Long Tag 0-31 Latin-1 Long Tag

38 Reset

Configuration

Changed Flag

48 Read

Additional

Device Status

Packed

6-17

Packed

18-20

Date

0-5

Packed

6-17

Packed

18-20

Date

0-2 Usigned-24 Final Assembly Number 0-2 Usigned-24 Final Assembly Number

0-31 Latin-1 Long Tag 0

0-1 Usigned-16 Configuration Changed Counter

0-5

Bits

6

Bits

7

Bits

8

Bits

9

Bits

10

Bits

11

Bits

12

Bits

13

Bits

4

14-21

Bits

Tag

Descriptor used by the master for record

keeping

A date code used by the master for record

keeping (E.G. Last or Next Calibration Date)

Tag

Descriptor used by the master for record

keeping

A date code used by the master for record

keeping (E.G. Last or Next Calibration Date)

3

Device-Specific Status 0

Extended Device Status

Device Operating Mode

Standardized Status 0

Standardized Status 1

Analog Channel Saturated

Standardized Status 2

Standardizes Status 3

Analog Channel Fixed

Device-Specific Status 1

0-2 Unsigned-24 Final Assembly Number

0-23 Packed Message String

0-5

Packed

6-17

Packed

18-20

Date

Unsigned-8

1-2

Enum

3

Unsigned-8

4

Unsigned-8

5

Unsigned-8

6

Unsigned-8

7

Unsigned-5

7

Enum

8

Bits

9-11

Unsigned-24

12

Unsigned-8

13

Unsigned-8

14-15

Unsigned-16

16

Bits

17-18

Enum

19-20

Enum

21

Enum

0-1 Usigned-16 Configuration Changed Counter

0-5

Bits

6

Bits

7

Bits

8

Bits

9

Bits

10

Bits

11

Bits

12

Bits

13

Bits

14-21

Bits

Tag

Descriptor

Date Code

“254”

Expanded Device Type = 0x3008

Min. number of request preambles = 5

HART Protocol Major Rev. = 7

Device Rev. Level

Software Rev. Level

(5 MSB) Hardware Rev. Level

(3 LSB) Physical Signaling Code=0

Device Flag Assignment = 0

Device ID (unique for given device type)

Min. number of response preambles=5

Max. number of device variables = 5

Configuration Change Counter

Extended Field Device Status: 0=OK,

1=Maintenance req’d, 2=Device Alert

Manufacturer Identification Code = 0x0030

Private Label Distributor Code = 0x0030

Device Profile = 1

Device-Specific Status 0

Hardware Faults bytes 0-3

Main Board Status bytes 4-5

Extended Device Status

Device Operating Mode

Standardized Status 0

Standardized Status 1

Analog Channel Saturated

Standardized Status 2

Standardizes Status 3

Analog Channel Fixed

Device-Specific Status 1

Hardware Warnings bytes 14-17

Device Status bytes 18-21

Not Used bytes 22-24)

3

4

24

3.5.1.1 Command 48 Data

The “More Status Available” bit in Device Status will be set if any bit in the following command 48 data is set, which

previously was not set:

• DeviceSpecificStatus_0 (bytes 0-3 only – hardware faults)

• ExtendedDeviceStatus

• StandardizedStatus

• AnalogChannelSaturated

• AnalogChannelFixed

• DeviceSpecificStatus_1 (bytes 14-17 – hardware warnings)

NOTE: DeviceSpecificStatus_0, bytes 4-5 (main board status information) is provided only for additional

information but these bits will not trigger More Status Available, as these are not considered faults or warnings.

DeviceSpecificStatus_1, bytes 18-21 (device status information) is provided only for additional information but these

bits will not trigger More Status Available, as these are not considered faults or warnings.

3. Upon receiving this command the device shall compare the counter value received in this command with the device’s current value. If they do not match then the device

will return Response Code 9 “configuration change counter mismatch” and not reset the configuration change counter.

4. HART specification allows up to 25 bytes for this command. However, it also states that “the response data bytes returned are truncated after the last status byte

supported by the Field Device”. Therefore we only return 22 bytes of data in our response. If the master sends a request with more than 22 bytes of data, our device will

still respond, but the extra bytes beyond those supported will be ignored

Page 25

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Command 48 can also be used to clear the “More Status Available”. When the device receives command 48 it

compares the Request Data Bytes to the current value; if there is an exact match it clears the “More Status Available

bit corresponding to the requesting device (Primary Master, Secondary Master, Gateway, etc.). If there is not an exact

match or too few bytes are received then the More Status Available bit remains unchanged. Extra Bytes beyond those

supported by the device are ignored.

Table 3.8 HART Defined Status Bits

Extended Device Status (Common Table 17) Supported

Bit Description

0 Maintenance Required Yes

1 Device Variable Alert No

2 Critical Power Failure No

3 Failure No

4 Out of Specification No

5 Function Check No

6 -

7 -

Standardized Status 0 (Common Table 29) Supported

Bit Description

0 Device Variable Simulation Active No

1 Non-Volatile Memory Defect Yes

2 Volatile Memory Defect No

3 Watchdog Reset Executed Yes

4 Power Supply Conditions Out of Range No

5 Environmental Conditions Out of Range No

6 Electronic Defect No

7 Device Configuration Locked Yes

Analog Channel Saturated (Common Table 27) Supported

Bit Description

0 Analog Channel 1 Yes

1 Analog Channel 2 No

2 Analog Channel 3 No

3 Analog Channel 4 No

4 5 6 -

7 -

Analog Channel Fixed (Common Table 28) Supported

Bit Description

0 Analog Channel 1 Yes

1 Analog Channel 2 No

2 Analog Channel 3 No

3 Analog Channel 4 No

4 5 6 7 -

25

flowserve.com

Page 26

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Table 3.9 MX/QX Defined Status Bits

Device-Specific Status 0 – CMD 48 Bytes 0-3 : Hardware Faults

Bit Description

Hardware Faults – these bits will trigger More Status Available bit

0 Main board to HART board communication loss

1 Reserved

2 Valve Jam

3 Over Torque in Close direction

4 Over Torque in Open direction

5 Phase Lost

6 Motor Temperature

7 Encoder Fault

8 Main board RAM error

9 Main board FLASH error

10 Main board EEPROM error

11 Reserved

12 Knob Failure

13 Limigard Fault

14 Contactor Fault

15 Power Board

16 Digital Out Board 1 (R1-R4 & RM) board fault

17 Digital Out Board 2 (R5-R8) board fault

18 Reserved

19 Analog Board 2 Fault

20 Reserved

21 Reserved

22 Motor Controller Fault

23 Reserved

24 Oil Over Temperature (arctic units)

25 Close Torque Timer Expired

26 Open Torque Timer Expired

27 HART Board 1 Fault

28 Reserved

29 HART Board 1 memory fault

30 Reserved

31 Future

26

Device-Specific Status 0 – CMD 48 Bytes 4-5 : Main Board Status

Main Board Status – these bits will not trigger More Status Available bit

0 Main board Self-test Ongoing (1=ongoing, 0=finished)

1 Main board Self-test Ok (1=succeeded, 0=failed; only valid if “Self-test ongoing = 0”

2 Future

3 Future

4 Future

5 Future

6 Future

7 Future

8 Future

9 Future

10 Future

11 Future

12 Future

Page 27

13 Future

14 Future

15 Future

Device-Specific Status 1 – CMD 48 Bytes 14-17 : Hardware Warnings

Bit Description

Hardware Warnings – these bits will trigger More Status Available bit

0 Phase Sequence Reversed

1 Encoder Warning

2 Motor Temperature Warning

3 Analog Input 1 Lost (main board mA input)

4 Analog Input 2 lost (Hart board 1 mA input)

5 Reserved

6 Maintenance Required

7 Modulating Position Control (MPC) Halted

8 Future

9 Future

10 Future

11 Future

12 Future

13 Future

14 Future

15 Future

16 Future

17 Future

18 Future

19 Future

20 Future

21 Future

22 Future

23 Future

24 Future

25 Future

26 Future

27 Future

28 Future

29 Future

30 Future

31 Future

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Device-Specific Status 1 – CMD 48 Bytes 18-21 : Device Status

Bit Description

Device Status – these bits will not trigger More Status Available bit

0 Valve Fully Open

1 Valve Fully Closed

2 Stopped in Mid-Travel

3 Opening Remotely

4 Closing Remotely

5 Local Knob in REMOTE

6 Local Knob in LOCAL

7 Local Knob in STOP

8 Opening in Local mode

9 Closing in Local mode

27

flowserve.com

Page 28

10 Open Inhibit Active

11 Close Inhibit Active

12 ESD Conflict

13 Inhibit Conflict

14 CSE is in Local/Stop

15 Network ESD Active

16 Local ESD Active

17 Valve Manually Moved

18 Open Torque Switch

19 Open Limit Switch

20 Close Torque Switch

21 Close Limit Switch

22 Reserved

23 In Remote Configuration Mode

24 Future

25 Future

26 Future

27 Future

28 Future

29 Future

30 Future

31 Future

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

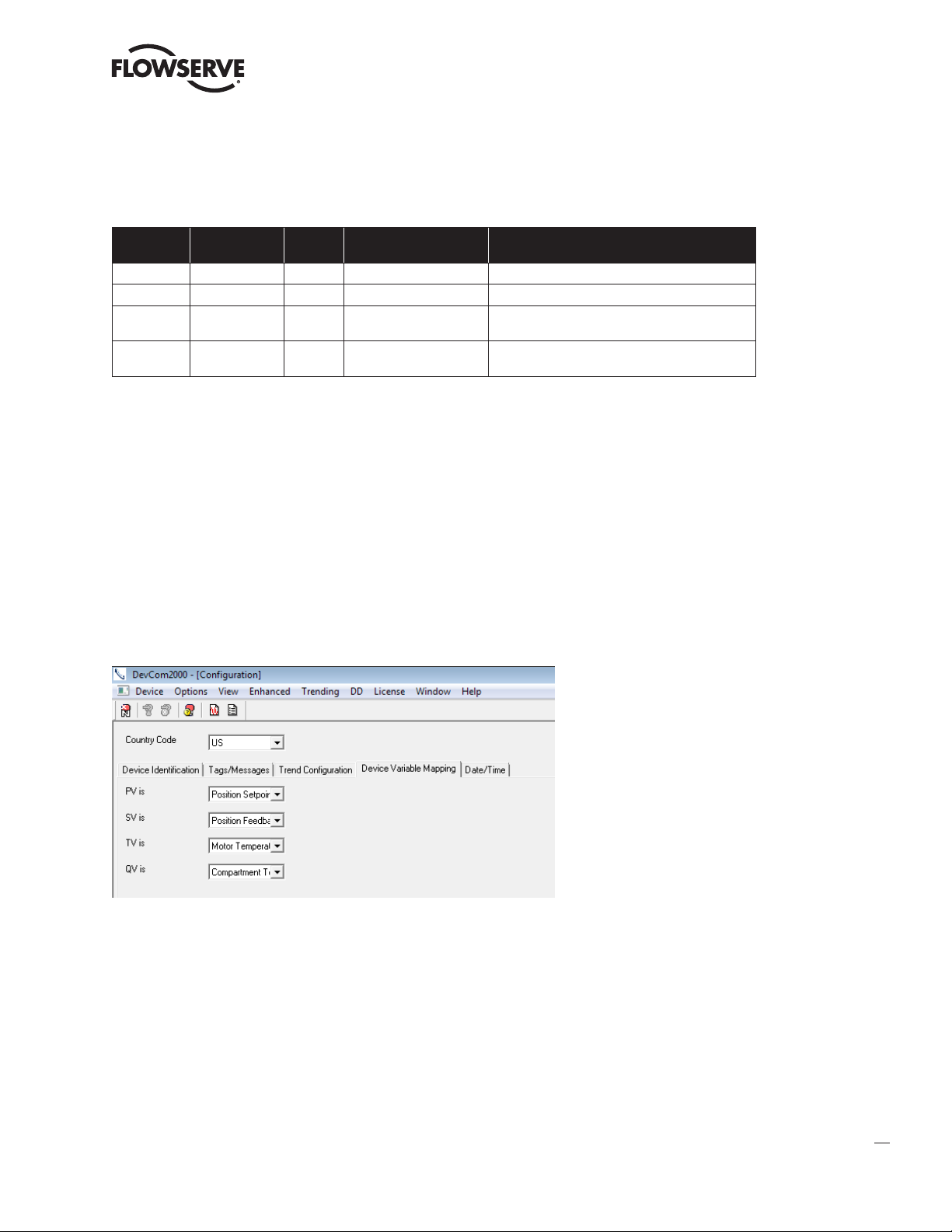

The command 48 diagnostic data can be viewed from the DD menu Diagnostics->Information->Device Status as

follows:

28

Page 29

Figure 3.3 – HART Diagnostics Data

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

3.5.2 Common Commands

Table 3.10 Common Commands

Command Request Data Bytes Response Data Bytes

No. Description Byte Format Description Byte Format Description

33 Read Device

Variables

35 Write Primary

Variable Range

Values

36 Set Primary

Variable Upper

Range Value

37 Set Primary

Variable Lower

Range Value

40 Enter/Exit Fixed

Current Mode

41 Perform Self

8

Test

42 Perform Device

9

Reset

45 Trim Loop

Current Zero

0

Unsigned-8

1

Unsigned-8

2

Unsigned-8

3

Unsigned-8

0

Unsigned-8

5

1-4

Float

5-8

Float

6

7

0-3 Float Fixed Current Level (units of milliamperes) 0-3 Float Fixed Current Level (units of milliamperes)

0-3 Float Externally Measured Loop Current Level

10

Slot 0: Device Variable Code

Slot 1: Device Variable Code

Slot 2: Device Variable Code

Slot 4: Device Variable Code

Upper and Lower Range Values Units Code

Upper Range Value

Lower Range Value

(units of milliamperes)

0

Unsigned-8

1

Enum

2-5

Float

6

Unsigned-8

7

Enum

8-11

Float

12

Unsigned-8

13

Enum

14-17

Float

18

Unsigned-8

19

Enum

20-23

Float

0-3

Float

4-7

Float

0-3 Float Actual Measured Loop Current Level (units of

Slot 0: Device Variable Code

Slot 0: Units Code

Slot 0: Device Variable Value

Slot 1: Device Variable Code

Slot 1: Units Code

Slot 1: Device Variable Value

Slot 2: Device Variable Code

Slot 2: Units Code

Slot 2: Device Variable Value

Slot 3: Device Variable Code

Slot 3: Units Code

Slot 3: Device Variable Value

Primary Variable Loop Current (mA)

Primary Variable % Of Range

milliamperes)

29

11

flowserve.com

Page 30

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Command Request Data Bytes Response Data Bytes

No. Description Byte Format Description Byte Format Description

46 Trim Loop

Current Gain

49 Write Primary

Variable

Transducer

Serial Number

50 Read Dynamic

Variable

Assignments

51 Write Dynamic

Variable

Assignments

53 Write Device

Variable Units

54 Read Device

Variable

Information

56 Write Device

Variable

Transducer

Serial No.

59 Write Number

of Response

Preambles

60 Read Analog

Channel and

Percent of

Range

63 Read Analog

Channel

Information

65 Write Analog

Channel Range

Values

0-3 Float Externally Measured Loop Current Level

12

(units of milliamperes)

0-3 Float Actual Measured Loop Current Level (units of

milliamperes)

0-2 Unsigned-24 Primary Variable Transducer Serial Number 0-2 Unsigned-24 Primary Variable Transducer Serial Number

14

0

15

0

Unsigned-8

1

Unsigned-8

2

Unsigned-8

3

Unsigned-8

0

16

Unsigned-8

1

Enum

Device Variable Assigned to the Primary Variable

Device Variable Assigned to the Secondary Variable

Device Variable Assigned to the Tertiary Variable

Device Variable Assigned to the Quaternary

Variable

Device Variable Code

Device Variable Units Code

0 Unsigned-8 Device Variable Code 0

0

Unsigned-8

1-3

Unsigned-24

Device Variable Code

Device Variable Transducer Serial Number01-3

1

2

3

0

1

2

3

0

1

1-3

4

5-8

9-12

13-16

17-20

21

22

23-26

Unsigned-8

Unsigned-8

Unsigned-8

Unsigned-8

Unsigned-8

Unsigned-8

Unsigned-8

Unsigned-8

Unsigned-8

Enum

Unsigned-8

Unsigned-24

Enum

Float

Float

Float

Float

Enum

Enum

Time

Unsigned-8

Unsigned-24

Device Variable Assigned to the Primary Variable

Device Variable Assigned to the Secondary Variable

Device Variable Assigned to the Tertiary Variable

Device Variable Assigned to the Quaternary Variable

Device Variable Assigned to the Primary Variable

Device Variable Assigned to the Secondary Variable

Device Variable Assigned to the Tertiary Variable

Device Variable Assigned to the Quaternary Variable

Device Variable Code

Device Variable Units Cod

Device Variable Code

Device Variable Transducer Serial Number

Device Variable Limits/Minimum Span Units

Code

Device Variable Upper Transducer Limit

Device Variable Lower Transducer Limit

Device Variable Damping Value

Device Variable Minimum Span

Device Variable Classification

Device Variable Family

Update Time Period

Device Variable Code

Device Variable Transducer Serial Number

0 Unsigned-8 Number of preambles 0 Unsigned-8 Number of preambles

18

0 Unsigned-8 Analog Channel Number Code 0

0 Unsigned-8 Analog Channel Number Code 0

0

Unsigned-8

1

21

Enum

2-5

Float

6-9

Float

Analog Channel Number Code

Analog Channel Upper/ Lower Range Values

Units Code

Analog Channel Upper Range Value

Analog Channel Lower Range Value

1

2-5

6-9

1

2

3

4-7

8-11

12-15

16

0

1

2-5

6-9

Unsigned-8

Enum

Float

Float

Unsigned-8

Enum

Enum

Enum

Float

Float

Float

Bits

Unsigned-8

Enum

Float

Float

Analog Channel Number Code

Analog Channel Units Code = 39 (mA)

Analog Channel Level

Analog Channel Percent of Range

Analog Channel Number Code

Analog Channel Alarm Selection Code = 250

(not used)

Analog Channel Transfer Function Code = 0

(linear)

Analog Channel Upper/Lower Range Values Units

Code = 57 (%)

Analog Channel Upper Range Value

Analog Channel Lower Range Value

Analog Channel Damping Value (seconds)

Analog Channel Flags

Analog Channel Number Code

Analog Channel Upper/ Lower Range Values

Units Code = 57 (%)

Analog Channel Upper Range Value

Analog Channel Lower Range Value

13

17

19

20

30

66 Enter/Exit Fixed

Analog Channel

Mode

67 Trim Analog

Channel Zero01

68 Trim Analog

Channel Gain01

0

Unsigned-8

1

Enum

2-5

Float

Unsigned-8

Enum

2-5

Float

Unsigned-8

Enum

2-5

Float

Analog Channel Number Code

Analog Channel Units Code

Fixed Analog Channel Level22

Analog Channel Number Code

Analog Channel Units Code

Externally Measured Analog Channel Level

Analog Channel Number Code

Analog Channel Units Code

Externally Measured Analog Channel Level

0

Unsigned-8

1

Enum

2-5

Float

0

Unsigned-8

1

Enum

2-5

Float

0

Unsigned-8

1

Enum

2-5

Float

Analog Channel Number Code

Analog Channel Units Code = 39 (mA)

Fixed Analog Channel Level

Analog Channel Number Code

Analog Channel Units Code = 39 (mA)

Fixed Analog Channel Level

Analog Channel Number Code

Analog Channel Units Code = 39 (mA)

Fixed Analog Channel Level

71 Lock Device 0 Enum Lock Code 0 Enum Lock Code

76 Read Lock

Device State

0 Enum Lock Status

23

23

23

Page 31

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Command Request Data Bytes Response Data Bytes

No. Description Byte Format Description Byte Format Description

78 Read

Aggregated

Commands

79 Write Device

Variable

89 Set Real Time

25

Clock

90 Read Real Time

28

Clock

0

Unsigned-8

24

1-2

Unsigned-16

3

Unsigned-8

4-i

Unsigned-8[]

……..

Unsigned-16

……..

Unsigned-8

……..

Unsigned-8[]

……..

Unsigned-16

……..

Unsigned-8

……..

Unsigned-8[]

0

Unsigned-8

1

Enum

2

Enum

3-6

Float

7

Bits

0

Unsigned-8

1-3

Date

4-7

Time

8-9

Unsigned-16

Number of commands requested

Cmd A

Byte count for Cmd A

Data bytes for Cmd A

Cmd B

Byte count for Cmd B

Data bytes for Cmd B

……

Cmd N

Byte count for Cmd N

Data bytes for Cmd N

Device Variable Code

Write Device Variable Command Code

Units Code

Device Variable Value

Device Variable Status

26

Time set code

Date Code

Time of Day

0x000027

0

1

2-3

4

5-A

……..

……..

……..

……..

……..

……..

……..

……..

0

1

2

3-6

7

0

1-3

4-7

0-2

3-6

7-9

10-13

14

Bits

Unsigned-8

Unsigned-16

Unsigned-8

Unsigned-8[]

Unsigned-8

Unsigned-16

Unsigned-8

Unsigned-8[]

Unsigned-8

Unsigned-16

Unsigned-8

Unsigned-8[]

Unsigned-8

Enum

Enum

Float

Bits

Unsigned-8

Date

Time

Date

Time

Date

Time

Bits

Extended Field Device Status: 0=OK,

1=Maintenance req’d, 2=Device Alert

Number of Commands Requested

Cmd A

Byte count for Cmd A

Data bytes for Cmd A (including commands

response code)

Cmd B

Byte count for Cmd B

Data bytes for Cmd B (including commands

response code)

……………………

Cmd N

Byte count for Cmd N

Data bytes for Cmd N (including commands

response code)

Device Variable Code

Write Device Variable Command Code

Units Code

Device Variable Value

Device Variable Status

Time set code

Date Code

Time of Day

Current Date

Current Time of Day

Date Clock last set

Time Clock last set

RTC Flags

91 Read Trend

Configuration

92 Write Trend

Configuration

0 Usigned-8 Trend Number 0

29

0

31

Unsigned-8

1

Enum

2

Unsigned-8

3-6

Time

Trend Number

Trend Control Code

Device Variable Code

Trend sample interval

30

93 Read Trend320 Usigned-8 Trend Number 0

Read Device

95

Communications

33

Statistics

103 Write Burst

Period

104 Write Burst

Trigger

0

34

34

Unsigned-8

1-4

Time

5-8

Time

0

Unsigned-8

1

Enum-8

2

Enum-8

3

Enum-8

4-7

Float

Burst Message

Update Period

Maximum Update Period

Burst Message

Burt Trigger Mode Selection Code

Device Variable Classification for Trigger Level

Units Code

Trigger Level

35

36

38

1

2

3

4-7

0

1

2

3-6

1

2

3

4-6

7-10

11-14

15-18

19

20-23

24

25-28

29

30-33

34

35-38

39

40-43

44

45-48

49

50-53

54

55-58

59

60-63

64

65-68

69

70-73

74

0-1

2-3

4-5

0

1-4

5-8

0

1

2

3

4-7

Unsigned-8

Unsigned-8

Enum

Unsigned-8

Time

Unsigned-8

Enum

Unsigned-8

Time

Unsigned-8

Unsigned-8

Enum

Enum

Date

Time

Time

Float

Bits

Float

Bits

Float

Bits

Float

Bits

Float

Bits

Float

Bits

Float

Bits

Float

Bits

Float

Bits

Float

Bits

Float

Bits

Float

Bits

Unsigned-16

Unsigned-16

Unsigned-16

Unsigned-8

Time

Time

Unsigned-8

Enum-8

Enum-8

Enum-8

Float

Trend Number

Total number of Trends supported

Trend Control Code

Device Variable Code

Trend sample interval

Trend Number

Trend Control Code

Device Variable Code

Trend sample interval

Trend Number

Device Variable Code

Device Variable Classification

Device Variable Unit Code

Date Stamp Of Trend Value 0

Time Stamp of Trend Value 0

Sample Interval

Trend Value 0 (newest value)

Trend Value 0 Status

Trend Value 1

Trend Value 1 Status

Trend Value 2

Trend Value 2 Status

Trend Value 3

Trend Value 3 Status

Trend Value 4

Trend Value 4 Status

Trend Value 5

Trend Value 5 Status

Trend Value 6

Trend Value 6 Status

Trend Value 7

Trend Value 7 Status

Trend Value 8

Trend Value 8 Status

Trend Value 9

Trend Value 9 Status

Trend Value 10

Trend Value 10 Status

Trend Value 11

Trend Value 11 Status

Count of STX messages received by this device

Count of ACK messages received by this device

Count of BACK messages received by this device.

Burst Message

Update Period37

Maximum Update Period

Burst Message

Burt Trigger Mode Selection Code

Device Variable Classification for Trigger Level

Units Code

Trigger Level

30

37

31

flowserve.com

Page 32

MX/QX HART Field Unit FCD LMENIM2340-00 – 1/14

Command Request Data Bytes Response Data Bytes

No. Description Byte Format Description Byte Format Description

105 Read Burst

Mode

Configuration

106 Flush Delayed

Responses

107 Write Burst

Device

Variables

108 Write Burst

Mode

Command

Number

109 Burst Mode

Control

115 Read Event

Notification

Summary

116 Write Event

Notification Bit

43

Mask

117 Write Event

Notification

Timing

118 Event

Notification

Control

119 Acknowledge

Event

Notification

0 Unsigned-8 Burst Message 0

34

34

0

Unsigned-8

1

34

Unsigned-8

2

Unsigned-8

3

Unsigned-8

4

Unsigned-8

5

Unsigned-8

6

Unsigned-8

7

Unsigned-8

8

Unsigned-8

0-12Unsigned-16

34

42

Unsigned-8

0

Unsigned-8

1

Unsigned-8

0 Unsigned-8 Event number = 0

43

0

Unsigned-8

1-27

Bits

0

Unsigned-8

1-4

5-8

9-12

0

1

0

1-4

5-6

7

8-32

Time

Time

Time

Unsigned-8

Unsigned-8

Unsigned-8

Time

Unsigned-16

Bits

Bits

43

43

43

Device Variable Code Slot 0

Device Variable Code Slot 1

Device Variable Code Slot 2

Device Variable Code Slot 2

Device Variable Code Slot 4

Device Variable Code Slot 5

Device Variable Code Slot 6

Device Variable Code Slot 7

Burst Message

Command Number of the response message

to be transmitted

Burst Message

Burst Mode Control Code

Burst Message

Event Number = 0

Event Mask

Event Number = 0

Event Notification Retry Time

Maximum Update Time

Event De-bounce Time

Event Number = 0

Event Notification Control Code

Event Number = 0

Time when first unacknowledged event was

triggered

Configuration Changed Counter

Device Status

Command 48 Data

41

44

44

47

44

44

44

Unsigned-8

1

Unsigned-8

2

Unsigned-8

3

Unsigned-8

4

Unsigned-8

5

Unsigned-8

6

Unsigned-8

7

Unsigned-8

8

Unsigned-8

9

Unsigned-8

10

Unsigned-8

11

Unsigned-8

12-13

Unsigned-16

14-17

Time

18-21

Time

22

Enum-8

23

Enum-8

24

Enum-8

25-28

Float

0

Unsigned-8

1

Unsigned-8

2

Unsigned-8

3

Unsigned-8

4

Unsigned-8

5

Unsigned-8

6

Unsigned-8

7

Unsigned-8

8

Unsigned-8

0-12Unsigned-16

Unsigned-8

0

Unsigned-8

1

Unsigned-8

0

Unsigned-8

1

Unsigned-8

2.7-2.4

Bits-4

2.3-2.0

3-6

Enum

7-10

Time

11-14

15-18

Time

19-44

Time

Time

Bits

0

Unsigned-8

1-27

Bits

0

Unsigned-8

1-4

48

5-8

9-12

0

1

0

1-4

5-6

7

8-32

Time

Time

Time

Unsigned-8

Unsigned-8

Unsigned-8

Time

Unsigned-16

Bits

Bits

Burst Mode Control Code

31 (0x1F) Command Number Extension Flag39

Device Variable Code Slot 040

Device Variable Code Slot 1

Device Variable Code Slot 2

Device Variable Code Slot 3

Device Variable Code Slot 4

Device Variable Code Slot 5

Device Variable Code Slot 6

Device Variable Code Slot 7

Burst Message

Maximum Number of Burst Messages

Extended Command Number

Update Time (1/32 of a millisecond)

Maximum Update Time (1/32 of a millisecond)

Burst Trigger Mode Code

Device Variable Classification for Trigger Value

Units Code

Trigger Value

Device Variable Code Slot 0

Device Variable Code Slot 1

Device Variable Code Slot 2

Device Variable Code Slot 2

Device Variable Code Slot 4

Device Variable Code Slot 5

Device Variable Code Slot 6

Device Variable Code Slot 7

Burst Message

Command Number of the response message to

be transmitted

Burst Message

Burst Mode Control Code

Burst Message

Event Number

Number of events supported

MS 4 Bits of Event Status

LS 4 Bits of Event Notification Control Code

Time when first unacknowledged event was

45

triggered

Event Notification Retry Time

Maximum Update Time

Event De-bounce Interval

Event Mask

Event Number = 0

Event Mask

Event Number = 0

Event Notification Retry Time

Maximum Update Time

Event De-bounce Time

Event Number = 0

Event Notification Control Code

Event Number = 0

Time when first unacknowledged event was

49

triggered

Configuration Changed Counter

Device Status

Command 48 Data

40

46

32

512 Read Country

Code

513 Write Country

Code

1-23Unsigned-8

Enum-8

Country Code

SI Units Only

50

1-23Unsigned-8

Enum-8

1-23Unsigned-8

Enum-8

Country Code50

SI Units Only

Country Code

SI Units Only

50

5. The Range Values allow the Loop Current to be converted to a percent for use by the actuator (e.g. to use as the actuator setpoint).

6. Issuing this command will write the current Primary Variable value to the Upper Range Value.

7. Issuing this command will write the current Primary Variable value to the Lower Range Value.

8. The Loop Current may not reflect the process while the Self test is executing. A master must not generate spurious error messages or disconnect form the Field Device

while the Self test is in progress.